Cryogenic insulation material for low-temperature storage, transportation and application equipment, and preparation method thereof

A technology of cryogenic heat insulation and application equipment, which is applied in the field of polyurethane composite materials, can solve problems such as difficult industrial production, no need for cold insulation, and difficulty in uniform distribution of glass fiber mats, etc., and achieves simple operation, improved strength and flame retardancy, dispersion and The effect of enhanced distribution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

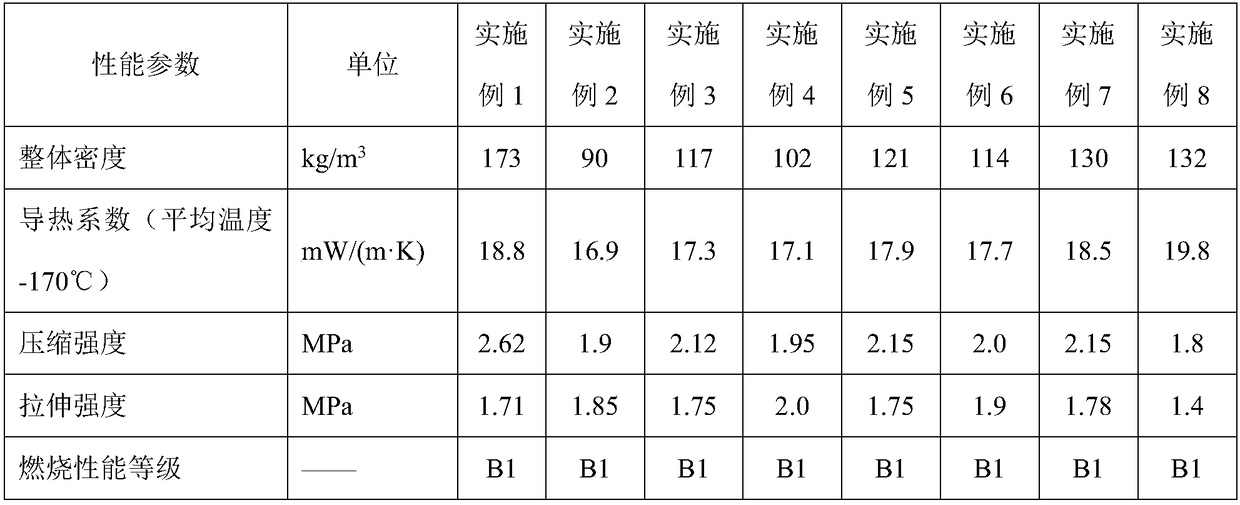

Examples

Embodiment 1

[0043] Preparation of reinforcing fibers: 50 parts by weight of glass fibers with a fiber length of 5 mm;

[0044] Filler preparation: 7 parts by weight of 100-120 mesh silica sand, 5 parts by weight of 100 mesh expandable graphite, 3 parts by weight of 100 mesh calcium hydroxide, and 5 parts by weight of 400 mesh emery;

[0045] Preparation of component A of rigid polyurethane foaming material: 60 parts by weight of polyether polyol (HP2502, Hongbaoli), 40 parts by weight of polyether polyol (H4650, Hongbaoli), 2 parts by weight of triethanolamine, 1 , 1.5 parts by weight of 3,5-tris(dimethylaminopropyl) symmetrical hexahydrotriazine, 2 parts by weight of foaming agent water, 1.5 parts by weight of water, 15 parts by weight of diphenylisooctyl phosphate, foam stabilizer AK8830 (Meister) 3 parts by weight; B component: polyphenyl polymethylene polyisocyanate M20S (Basf) 225 parts by weight;

[0046] The reinforcing fibers and fillers are formulated into a mixture in proportio...

Embodiment 2

[0048] Preparation of reinforcing fibers: 50 parts by weight of carbon fibers with a fiber length of 10 mm;

[0049] Preparation of filler: 0.1 part by weight of 800 mesh silicon powder;

[0050] The preparation of component A of polyurethane rigid foam foaming material: take 23 parts by weight of polyether polyol (H4110, Hongbaoli), 77 parts by weight of polyester polyol (PS-2502, Stepan), and 1.9 parts by weight of triethylenediamine Parts, 0.4 parts by weight of potassium isooctanoate-dipropylene glycol solution, 8 parts by weight of pentane, 7 parts by weight of HFC-245fa, CO 2 10 parts by weight, 1.6 parts by weight of water, 20 parts by weight of tris (2-chloropropyl) phosphate, 10 parts by weight of dimethyl methyl phosphate, 4 parts by weight of foam stabilizer B8460 (Degussa); Preparation: 228 parts by weight of polyphenyl polymethylene polyisocyanate M200 (Kumho Mitsui);

[0051] The reinforcing fiber and the filler are prepared into a mixture in proportion, and th...

Embodiment 3

[0053] Preparation of reinforcing fibers: 60 parts by weight of carbon fibers with a fiber length of 5 mm;

[0054] Preparation of filler: 5 parts by weight of 325 mesh titanium dioxide, 5 parts by weight of 200 mesh borax, 5 parts by weight of calcite powder of 2500 mesh, 5 parts by weight of hollow glass beads of 400 mesh;

[0055] The preparation of polyurethane rigid foam foam material A component: get 100 parts by weight of polyester polyol (PS-2852, Stepan), 4.5 parts by weight of dimethylcyclohexylamine, 0.5 part by weight of dibutyltin dilaurate, HCFC- 23 parts by weight of 141b, 2 parts by weight of water, 10 parts by weight of tris(2-chloropropyl) phosphate, 10 parts by weight of dimethyl methyl phosphate, 1.15 parts by weight of foam stabilizer AK8805 (Mester); component B Preparation: 227 parts by weight of polyphenyl polymethylene polyisocyanate M50 (Basf);

[0056] The reinforcing fiber and the filler are formulated into a mixture in proportion, and the polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com