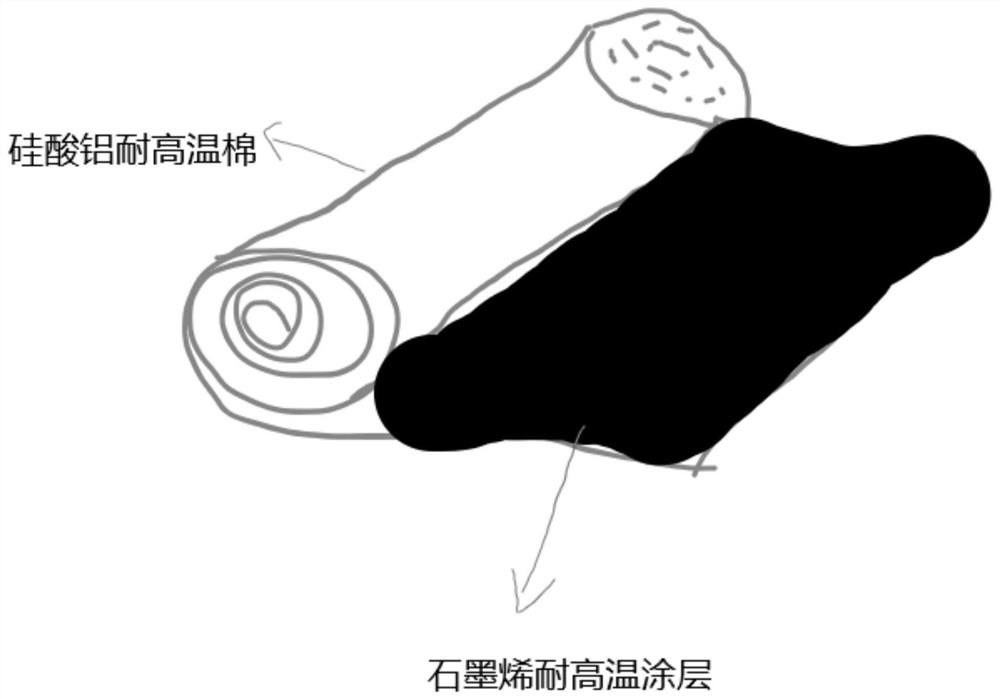

Aluminum silicate high-temperature-resistant cotton for fireproof coiled material and preparation method thereof

A technology of high temperature resistance and aluminum silicate, which is applied in the field of aluminum silicate high temperature resistant cotton for fireproof coils and its preparation, can solve the problems of insufficient flexibility of materials, and achieve excellent fire prevention effect, good flexibility and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Aluminum Silicate High Temperature Resistant Cotton for Fireproof Coil

[0028] (1) After mixing aluminum oxide, silica powder and graphene microflakes, they are melted and blown into flocculent fibers;

[0029] (2) Take the blown floc fiber, add inorganic binder water glass and superfine powder (weight ratio is 2:1), organic binder tar pitch and water reducer sodium pyrophosphate and water, and mix and make pulp. get slurry;

[0030] (3) Use mechanical kneading molding method or manual molding to produce the serving blank;

[0031] (4) Treat the garment base at 130°C until it contains no moisture, so as to obtain the above-mentioned aluminum silicate high-temperature-resistant cotton for fireproof coils;

[0032] Wherein, in step (1), the weight consumption ratio of aluminum oxide, silica powder and graphene microplate is 5:4:1; The weight consumption of described inorganic binder accounts for 7% of floc fiber; The weight consumption of organ...

Embodiment 2

[0033] Example 2 Preparation of Aluminum Silicate High Temperature Resistant Cotton for Fireproof Coil

[0034] (1) After mixing aluminum oxide, silica powder and graphene microflakes, they are melted and blown into flocculent fibers;

[0035] (2) Take the blown floc fiber, add inorganic binder water glass and ultrafine powder (1:1 by weight), organic binder tar pitch, water reducer sodium tripolyphosphate and water, and mix and make pulp , get slurry;

[0036] (3) Use mechanical kneading molding method or manual molding to produce the serving blank;

[0037] (4) Treat the garment base at 150°C until it contains no moisture, so as to obtain the above-mentioned aluminum silicate high-temperature-resistant cotton for fireproof coils;

[0038] Wherein, in step (1), the weight consumption ratio of aluminum oxide, silica powder and graphene microplate is 6:5:1; The weight consumption of described inorganic binder accounts for 6% of floc fiber; The weight consumption of organic bi...

Embodiment 3

[0039] Example 3 Preparation of Aluminum Silicate High Temperature Resistant Cotton for Fireproof Coil

[0040] (1) After mixing aluminum oxide, silica powder and graphene microflakes, they are melted and blown into flocculent fibers;

[0041] (2) Take the blown flocculent fiber, add inorganic binder water glass and superfine powder (weight ratio is 2:1), organic binder tar pitch, water reducer sodium hexametaphosphate and water, and mix and make pulp , get slurry;

[0042] (3) Use mechanical kneading molding method or manual molding to produce the serving blank;

[0043] (4) Treat the garment base at 100°C until it contains no moisture, so as to obtain the above-mentioned aluminum silicate high-temperature-resistant cotton for fireproof coils;

[0044] Wherein, in step (1), the weight consumption ratio of aluminum oxide, silica powder and graphene microplate is 4:3:1; The weight consumption of described inorganic binder accounts for 8% of floc fiber; The weight consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com