Inorganic lightweight grouting material, and manufacture method thereof

A manufacturing method and grouting material technology, applied in the field of building materials and their manufacturing, can solve the problems of pollution, affecting people's life and property safety, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to fully understand the purpose, features and effects of the present invention, the following specific embodiments are used in conjunction with the accompanying drawings to illustrate the present invention in detail. The description is as follows:

[0019] The present invention provides a new type of inorganic lightweight grouting material and its manufacturing method. The inorganic lightweight grouting material of the present invention can be stored for a long time, about six months, and when used, add a certain proportion of water and stir evenly. Chemical reaction to form a wall filled with grout.

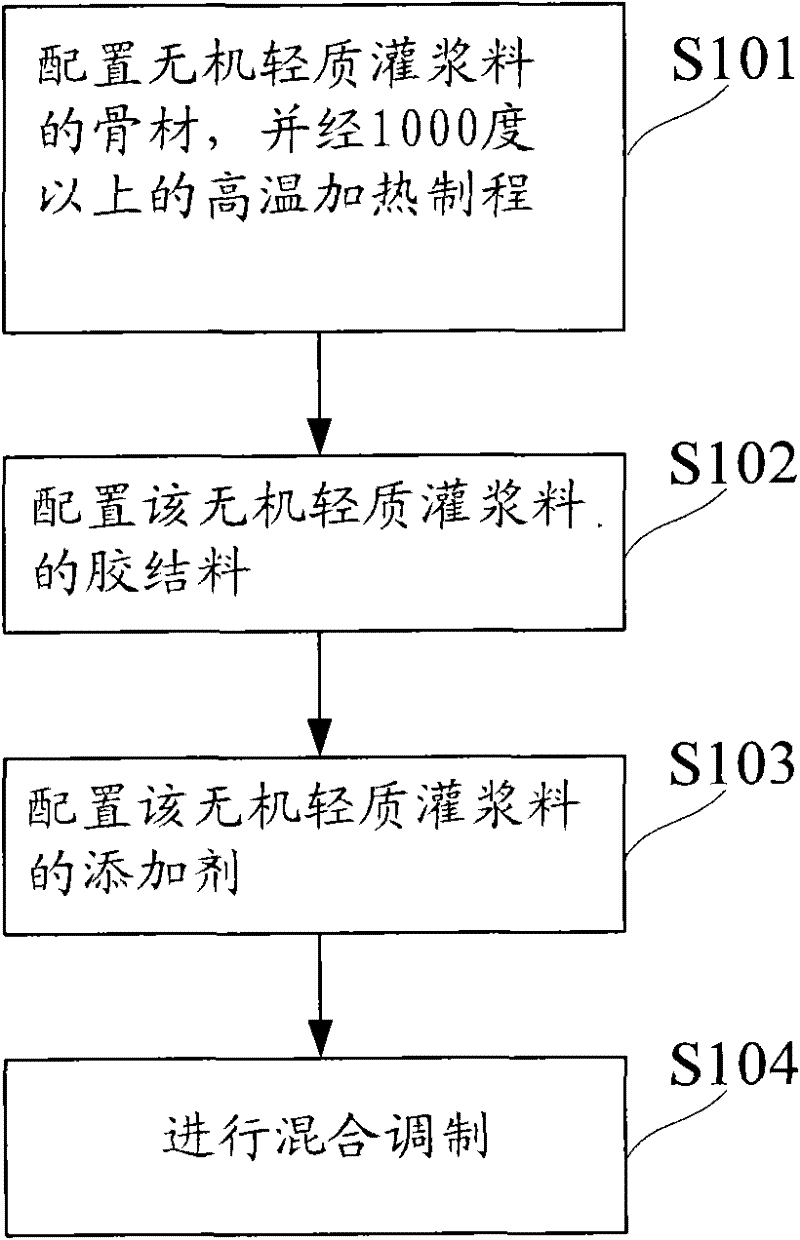

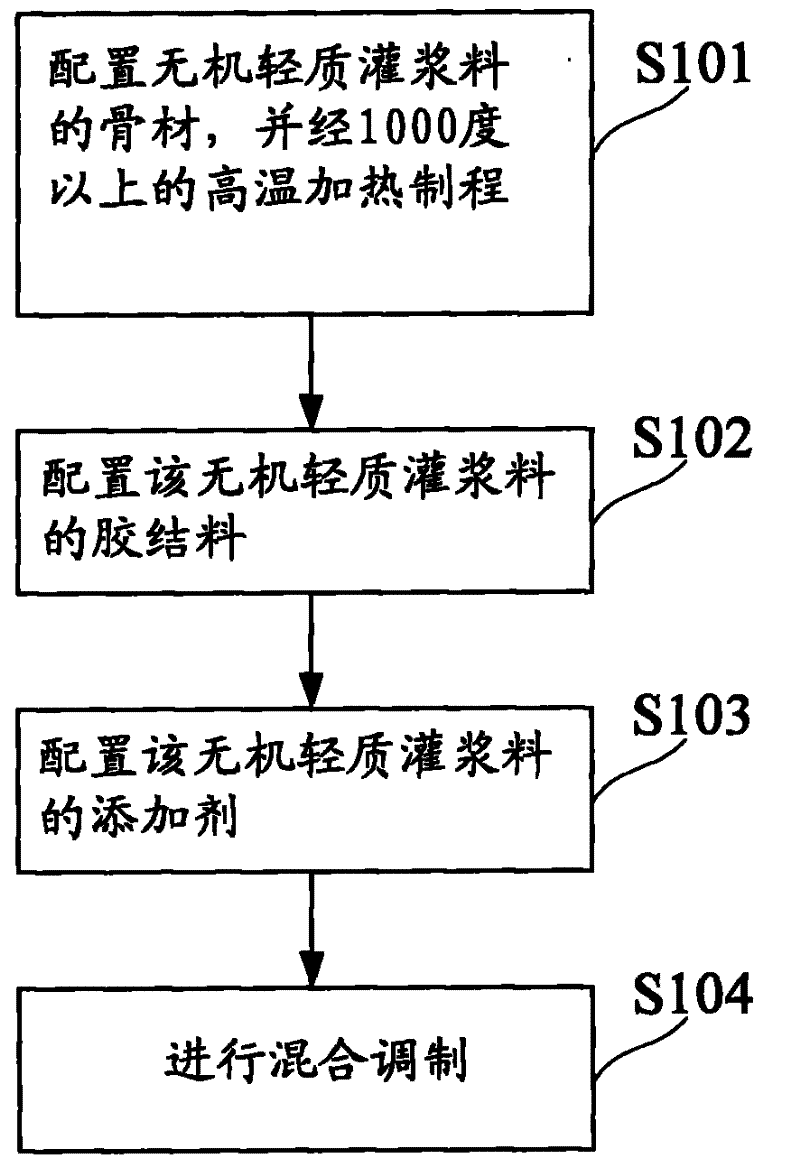

[0020] See first figure 1 , Is the flow chart of the manufacturing method of the inorganic lightweight grout of the present invention. The manufacturing method of the inorganic lightweight grouting material of the present invention includes the following steps: Step S101: preparing the aggregate of the inorganic lightweight grouting material, and subjecting it to a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com