Patents

Literature

805 results about "Clinker (waste)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clinker is a general name given to waste from industrial processes, particularly those that involve smelting metals, welding, burning fossil fuels and use of a blacksmith's forge, which commonly causes a large buildup of clinker around the tuyere. Clinker often forms a loose, dark deposit consisting of waste materials such as coke, coal, slag, charcoal, and grit. Clinker often has a glassy look to it, usually because of the formation of molten silica compounds during processing. Clinker generally is much denser than coke, and, unlike coke, generally contains too little carbon to be of any value as fuel.

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

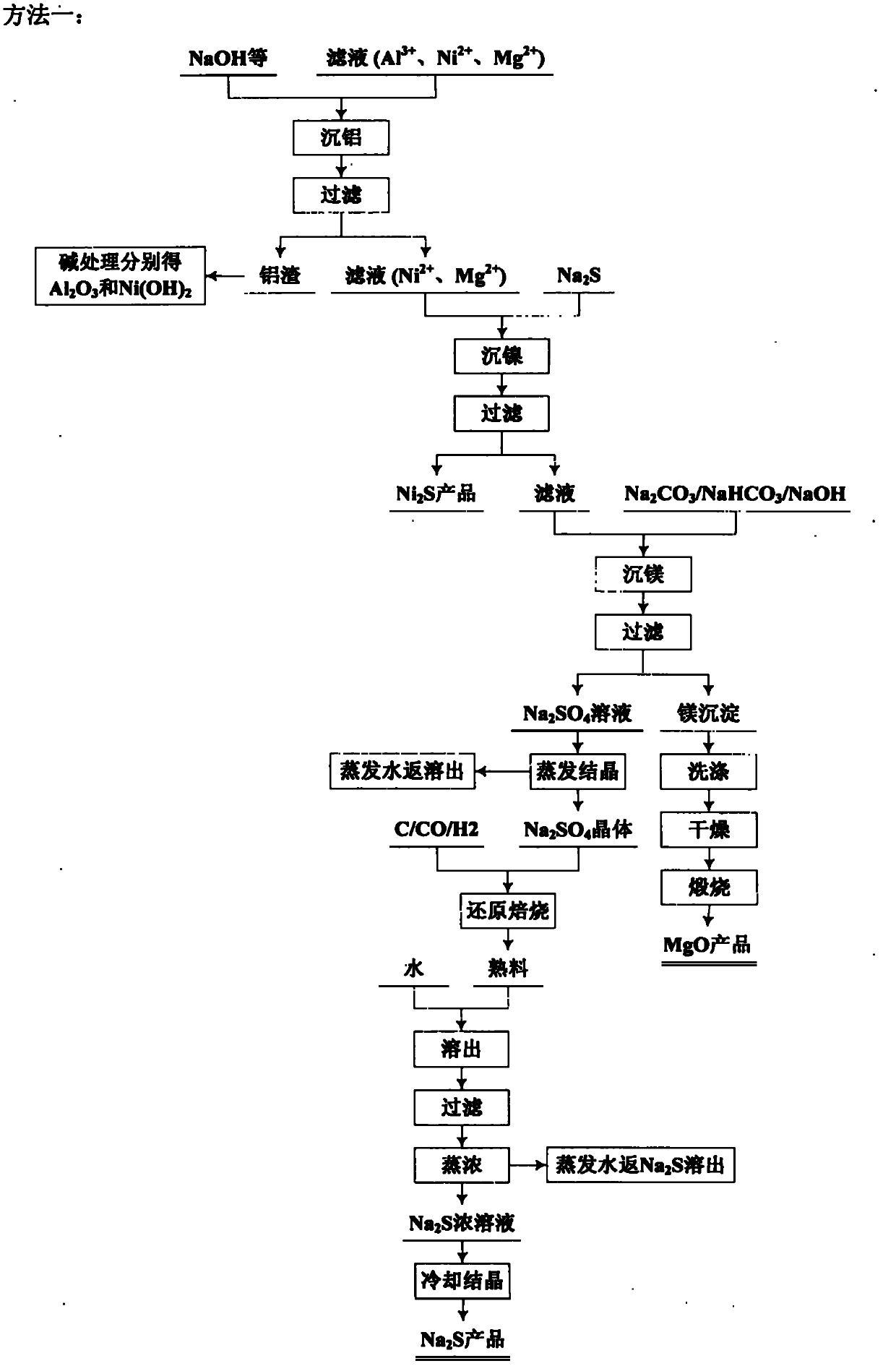

Comprehensive utilization method for laterite-nickel ore

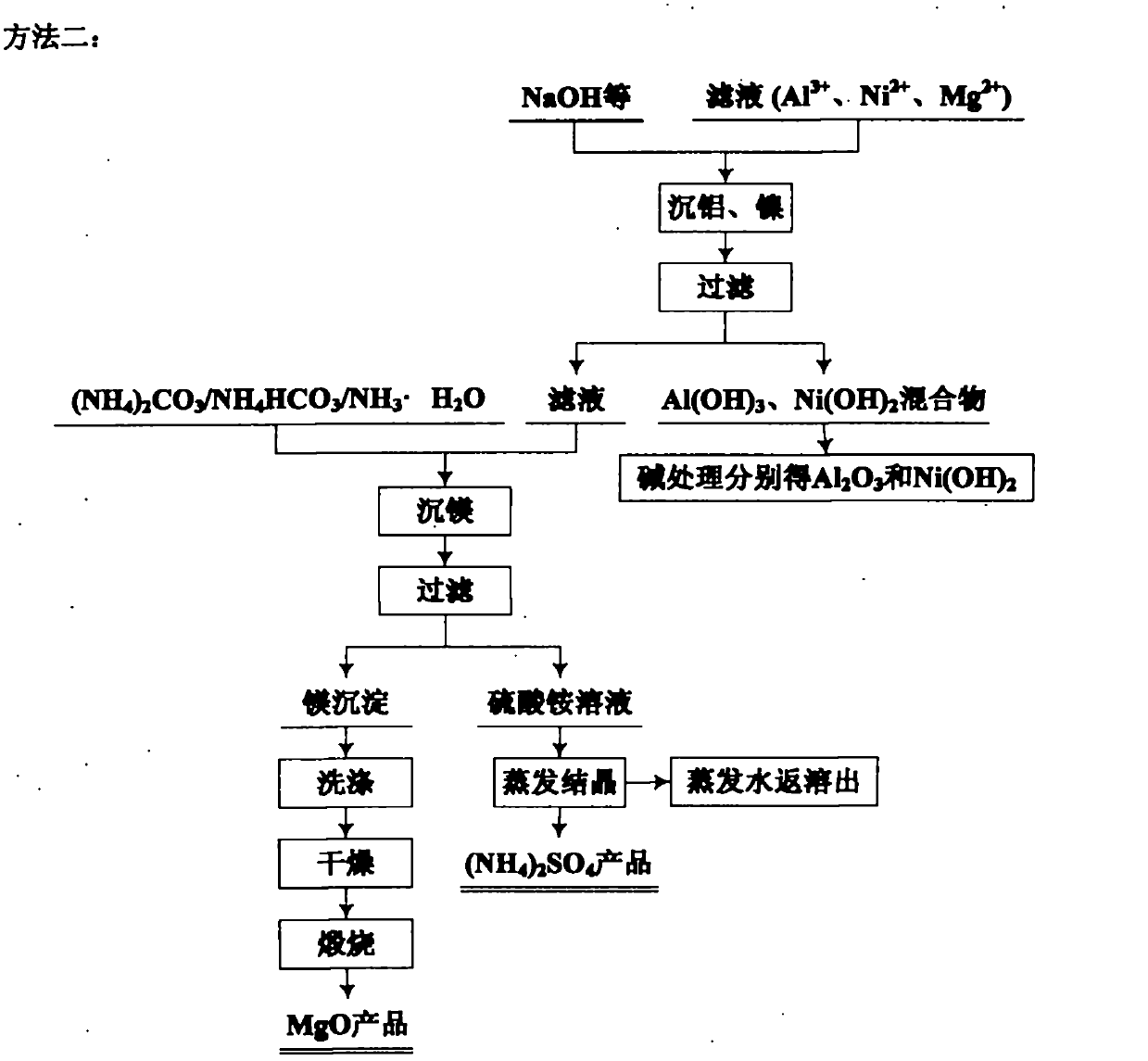

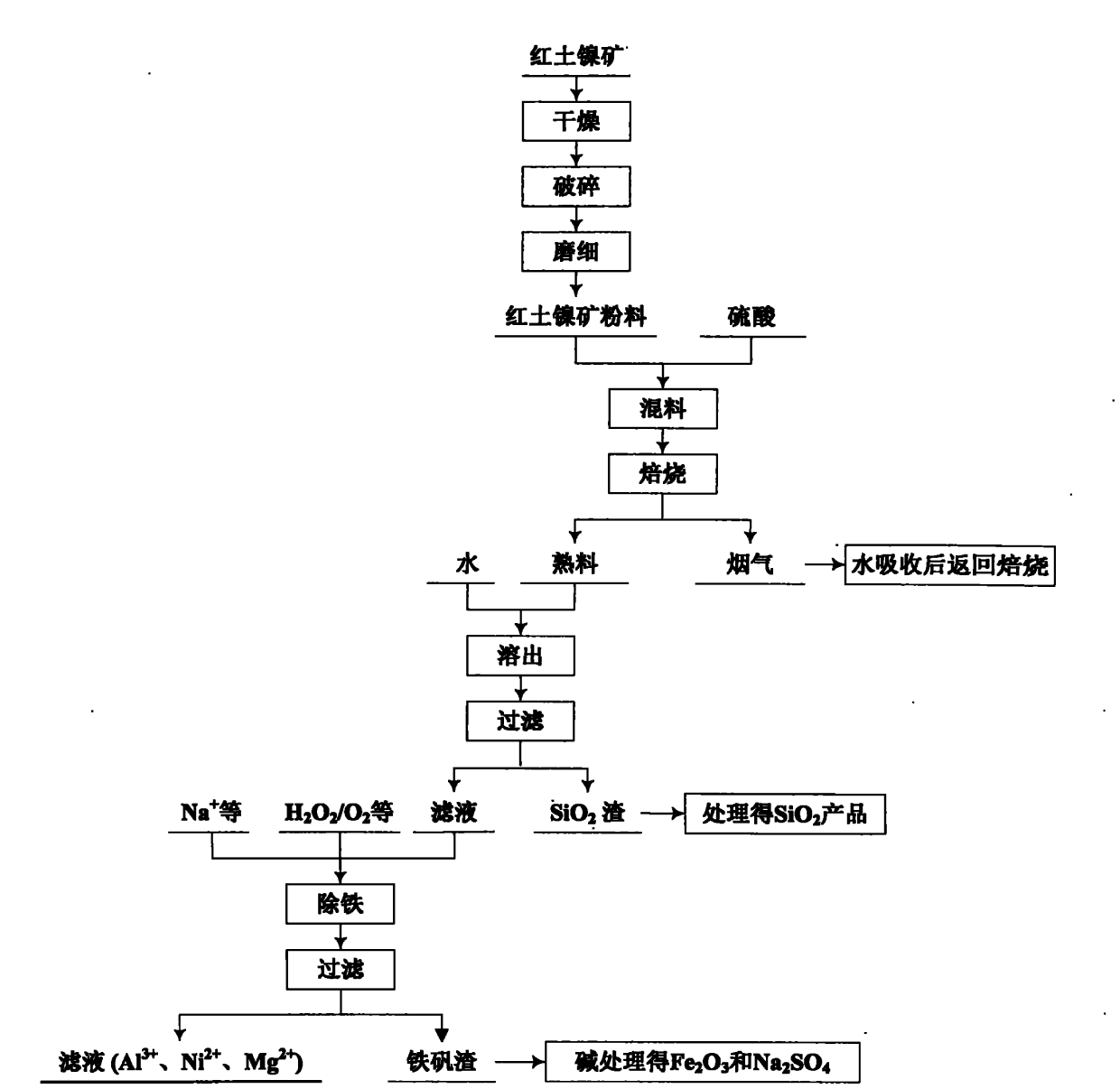

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

Building material based on interaction of alkali and CO2

ActiveCN101381217AWiden the range of process parametersReduce carbonization depth requirementsSolid waste managementSlagCarbonization

The invention discloses a building material product based on the synergic action between alkali and CO2 and a method for preparing the same, which belongs to the field of silicate building material and product thereof. In the building material product, the fly ash the fineness of which is controlled in the range of between 400 and 600m<2> / Kg and the slag form a mixed powder material, and an aggregate and water glass are added into the mixed powder material for forming so as to obtain a blank, and the blank is subjected to natural curing and carbonization to obtain the building material product. In the invention, the industrial waste slag is used as raw materials, the high-performance silicate product is prepared under the conditions of low alkali and not doping lime and cement clinker, so that the strength level is high, no scumming phenomenon occurs on the surface of the product, the release quantities of various toxic and harmful ions are far below the threshold value; moreover, the building material product has the advantages of good durability, strong freezeproof and weather resistance capabilities, and is suitable to be the building wall material. The invention has active effect on utilizing waste slag resources, saving energy and reducing emission.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

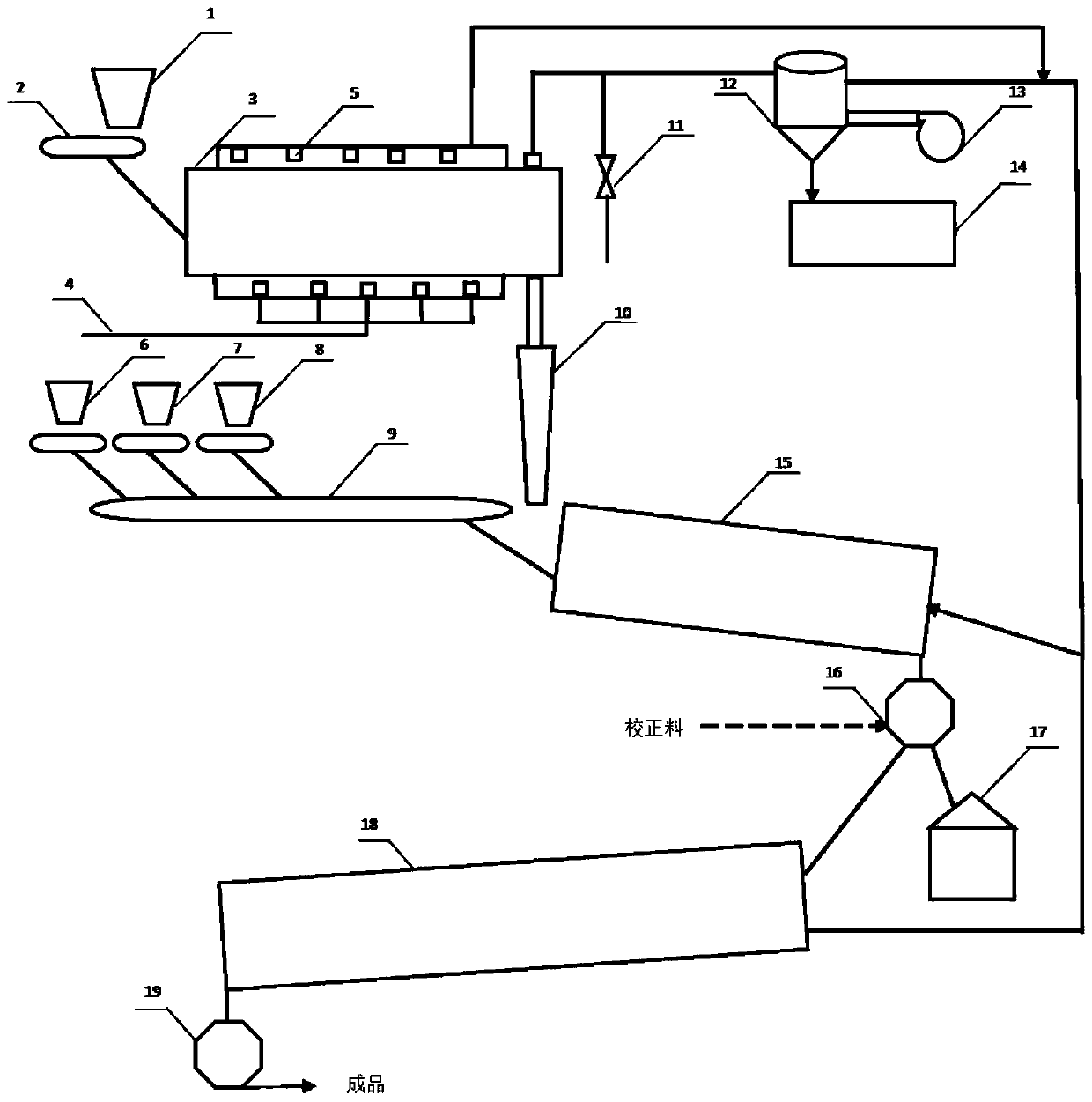

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

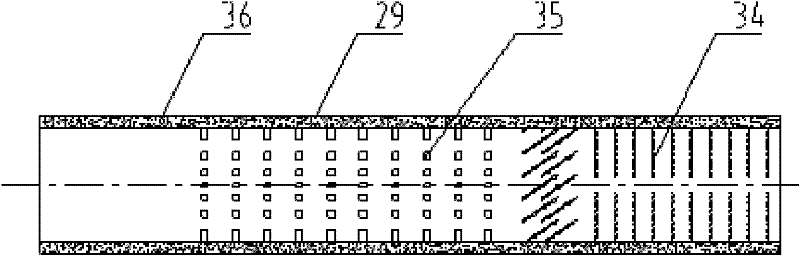

Industrial waste slag-doped composite silicate cement and production method thereof

InactiveCN102101757ABlending amount increasedImprove early strengthCement productionMetallurgical slagAlloy

The invention discloses industrial waste slag-doped composite silicate cement and a production method thereof. The industrial waste slag-doped composite silicate cement comprises the following material components: 45-58 percent of silicate cement clinker, 3-5 percent of desulfurization gypsum, 1.5-4 percent of lime stone, 0.2-0.3 percent of cement grinding additive, 10-29 percent of granulated blast furnace slag, 2-10 percent of coal slag, 4-10 percent of pulverized fuel ash, 2-10 percent of ferroalloy slag, 2-10 percent of zinc metallurgical slag and 0.2-0.25 percent of waste slag grinding aid active excitant. The production method comprises the following steps of: taking and mixing the first four materials according to the proportion and grinding into 300-350m<2> / kg of powder; taking and mixing the rest six materials according to the proportion and grinding into 420-450m<2> / kg of superfine powder; and then combining the two kinds of powder, stirring and homogenizing. By adopting respective grinding of clinker and waste slag, the waste slag fineness reaches an optical value for stimulating the activity, the hydration progress and the cement clinker reach synchronization, and the doping amount and doping category of waste slag are also improved.

Owner:王明贵

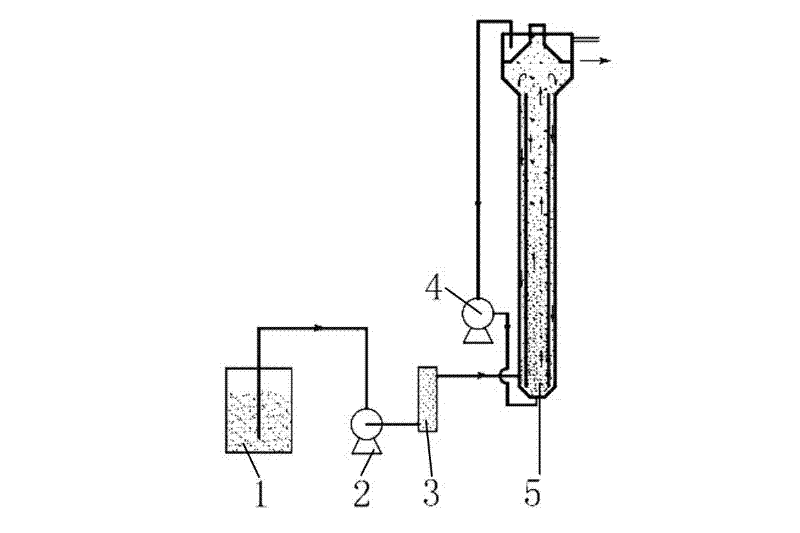

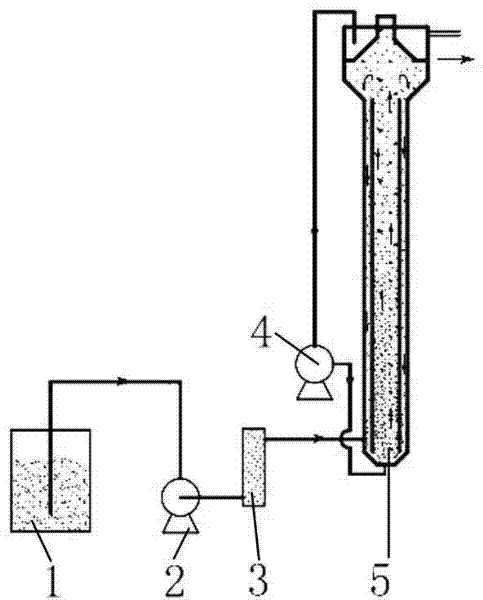

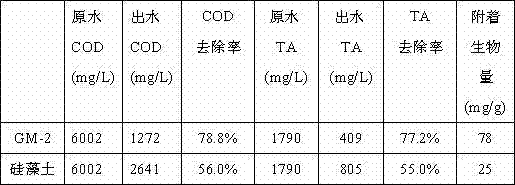

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

Method for preparing sulphoaluminate cement clinker by using red mud and phosphogypsum

The invention discloses a method for preparing a sulphoaluminate cement clinker by using red mud and phosphogypsum. According to the invention, red mud, phosphogypsum, bauxite, and limestone are adopted as production raw materials; the materials are respectively dried by baking, and are grinded, such raw materials with sizes below 180 meshes are obtained. According to the weight, 8-20 parts of the red mud raw material, 12-20 parts of the phosphogypsum raw material, 25-40 parts of the bauxite raw material, and 35-50 parts of the limestone raw material are mixed, and the mixture is placed in a rotary kiln; sintering is carried out for 30-50min under a temperature of 1250-1350 DEG C; the material is fetched rapidly, such that the sintered raw material is rapidly quenched in the air, and the sulphoaluminate cement clinker finished product is prepared. According to the invention, large amounts of industrial solid wastes such as red mud and phosphogypsum are effectively utilized as production materials. The method also has the advantages of good quality, simple preparation process, low preparation cost, and the like.

Owner:贵州省建筑材料科学研究设计院有限责任公司

Method for harmlessly treating aluminum ash and preparing sandy alumina

ActiveCN104261445ARealize recycling of resourcesHarmlessAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium electrolysisAluminium hydroxide

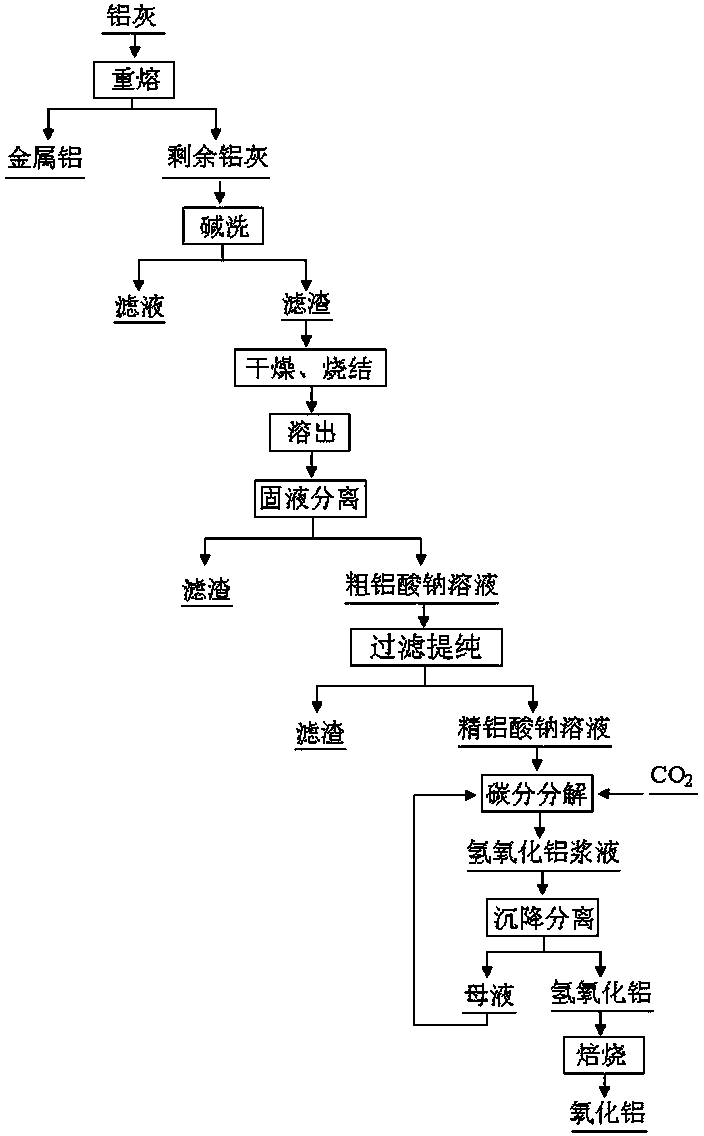

The invention discloses a method for harmlessly treating aluminum ash and preparing sandy alumina. The method disclosed by the invention mainly comprises the following main steps of remelting, alkaline washing, drying and sintering, dissolving out, filtrating and purifying, carbon component decomposition, and roasting, and is specifically implemented by taking aluminum ash produced in the processes of aluminum electrolytic smelting and coarse aluminum refining as a raw material through the process post-treatment steps of recovering metallic aluminium, carrying out alkaline wash for removing impurities, sintering sodium carbonate, dissolving out sintered clinker, carrying out deep impurities removal on a sodium aluminate solution, separating and washing carbon components and aluminum hydroxide, roasting aluminum hydroxide, evaporating carbon component mother liquor, and the like, so that a sandy alumina product is obtained. Fluorine in aluminum ash, after being discharged in silicon fluoride form, is absorbed by using an aqueous solution. The method disclosed by the invention realizes the harmless treatment of aluminum ash, the method is simple in process and low in production cost, and the environmental pollution and the resource wastes caused by the aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

Industrial residue activating grinding aid

InactiveCN101062845APromotes hydration activityAchieve clinker effectCement productionSlagActivator technique

The invention discloses a composition with catalytic activatable and grinding aid function at the same time in industrial residue utilizing new technique, which comprises the following steps: allocating mass percent as 1-8% accelerant, 30-80% activator, 0-20% regulated set agent, 3-12% grinding aid and 3-30% carrier; getting the product. This invention adopts catalytic activator technique, which overcomes the defects of harsh terms of industrial waste slag and high clinker request.

Owner:SHANGHAI GUOYE ENGINEERING TECHNOLOGY CO LTD

Method for extracting aluminium oxide from coal ash and producing cement by using waste slag

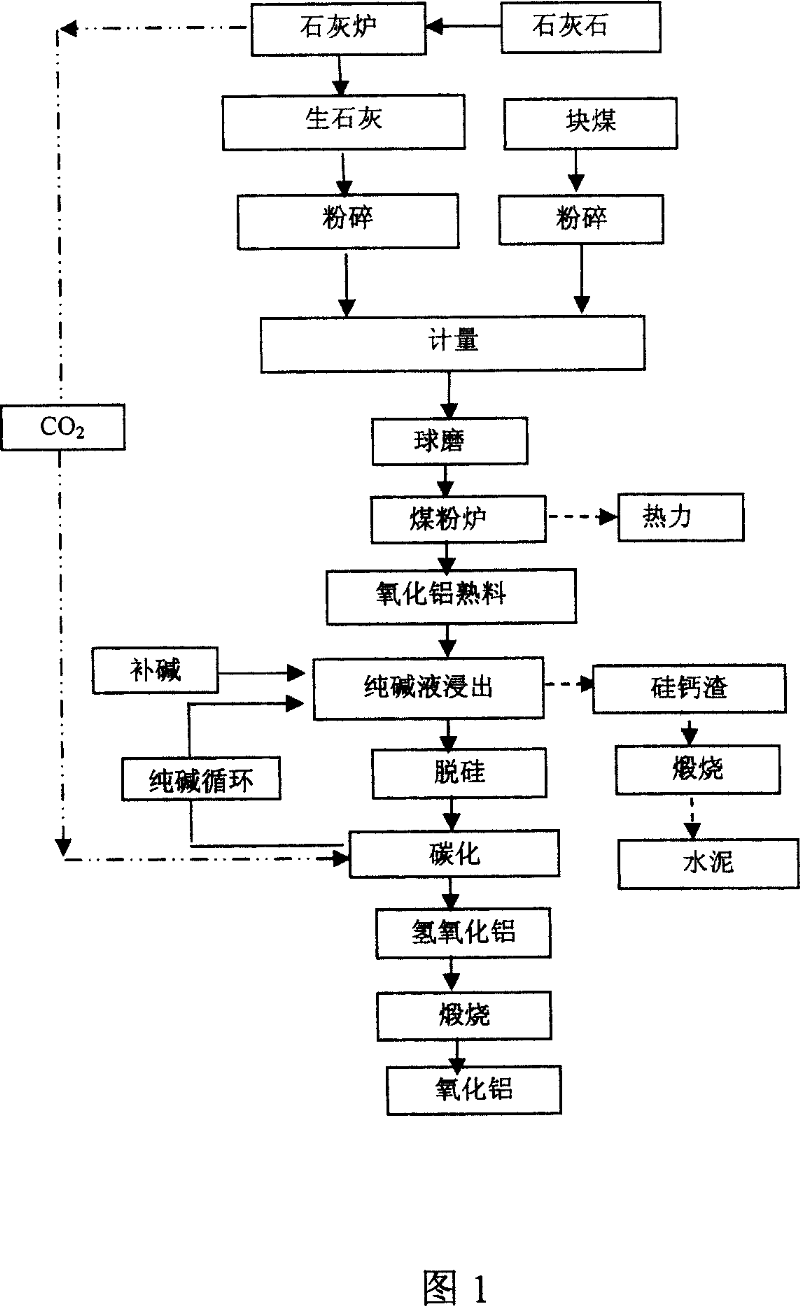

InactiveCN101041449AOvercoming qualityOvercome the problem that it is not easy to obtain high-grade cementAluminium oxide/hydroxide preparationCement productionSlagCoal dust

The invention discloses a method of extracting aluminum oxide from coal ash and preparing cement with waste slag, which comprises the following steps: adopting ''one stove two usage'' craft through coal dust stove of heat power plant; cooling and producing aluminum oxide clinker at the same time; abstracting aluminum oxide to get aluminum oxide product; using waste slag to prepare cement. This invention possesses characterize of reducing the energy consumption of aluminum oxide and cost of production.

Owner:CHANGAN UNIV

Ecological nanoparticle reinforced cement based composite material and preparation method thereof

ActiveCN103319129ASimple compositionSimple structureChemical admixtureEnvironmental resource management

The invention discloses an ecological nanoparticle reinforced cement based composite material and a preparation method thereof. High-strength and high-elastic spherical nanoparticles in industrial waste residues are adopted for largely replacing cement, and a high-performance admixture with a water-reducing rate of over 50% and high-strength superfine coppered steel fibers are used, and through the effective and efficient application of cement, the ecological nanoparticles, the chemical admixtures, the steel fibers and multi-element composite techniques thereof, the composition and structure optimization of concrete materials is greatly promoted, and an effect that the advantages of the components are superposed, and components are complementary is achieved. According to the invention, the problem that under standard curing and steam curing conditions, the compressive strength of an existing cement-based composite material can not reach over 300 Mpa and the bending strength can not reach over 60 Mpa is solved, the highly efficient regeneration and utilization rate and core technological value of the industrial waste residues are greatly enhanced, and the application amount of cement clinkers in the cement-based composite material is reduced, and therefore, the composite material is suitable for being used as a large civil engineering structure material with a designed concrete compressive strength of 300 Mpa.

Owner:河北蓝科悦拼建筑科技有限公司

Cement with high water-retaining property

ActiveCN104193202AThere is no decomposition failure problemSimple processCement productionCalcium hydroxideCement factory

The invention discloses cement with high water-retaining property. The cement with high water-retaining property consists of silicate cement clinker, a dechlorination caustic sludge mixture, a mixed material, gypsum and other auxiliaries. The water-retaining component dechlorination caustic sludge mixture of the cement is an inorganic material, so that the decomposition failure problem of organic materials is unavailable and the water-retaining rate of the cement is not lower than 90%; the cement can be produced by equipment in the existing cement plants so that the process is easy to realize; and the large solid waste such as caustic sludge and returned sand and rocks of the soda plants can be digested at the same time, and soda ash can be produced by using part of the calcium hydroxide.

Owner:SOUTH CHINA UNIV OF TECH

Blank for manufacturing bakeware ceramic products, and corresponding glaze and manufactured products thereof

InactiveCN101348362AAvoid environmental pollutionChange the phenomenon of monotonous color patternClaywaresFritCalcite

The invention discloses blank for preparing ceramic products such as baking pans, etc., relative glaze and the finished ceramic product. The blank comprises kaolin, talc, feldspar and limestone; in addition, the blank also comprises waste glass, the weight of which against the total weight of the blank is between 10 and 28 percent; the glaze comprises low-temperature clinker, feldspar, quartz and calcite; the blank is used to make the ceramic body, the surface of the ceramic body is coated with the glaze and burned at a temperature of between 1060 and 1150 DEG C, and the ceramic products such as baking pans, etc. can be obtained. The invention fully utilizes the waste glass, the burning temperature is low, the prepared ceramic product undergoes the quenching after being burned at a temperature of 280 DEG C and the quench cracking does not occur, and after the burning and the quenching, no fog dot exist on the glaze.

Owner:CHAOZHOU XIONGJIA PORCELAIN MFG

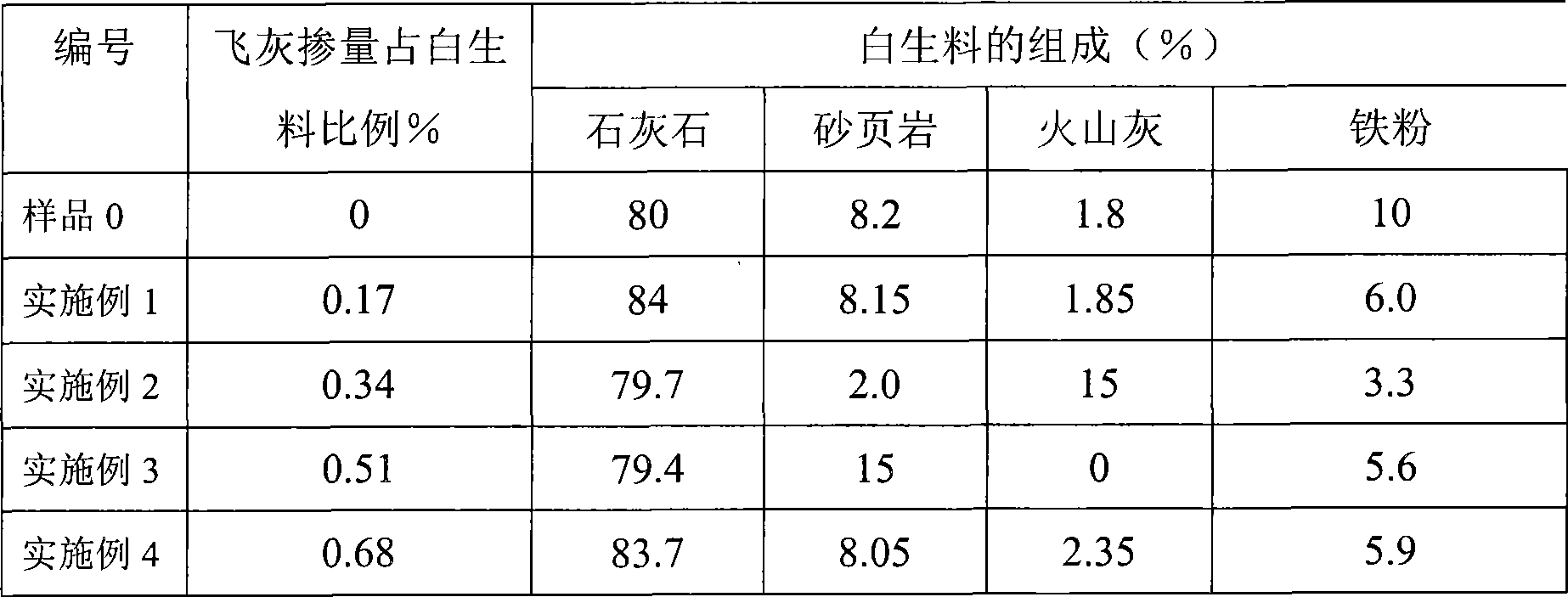

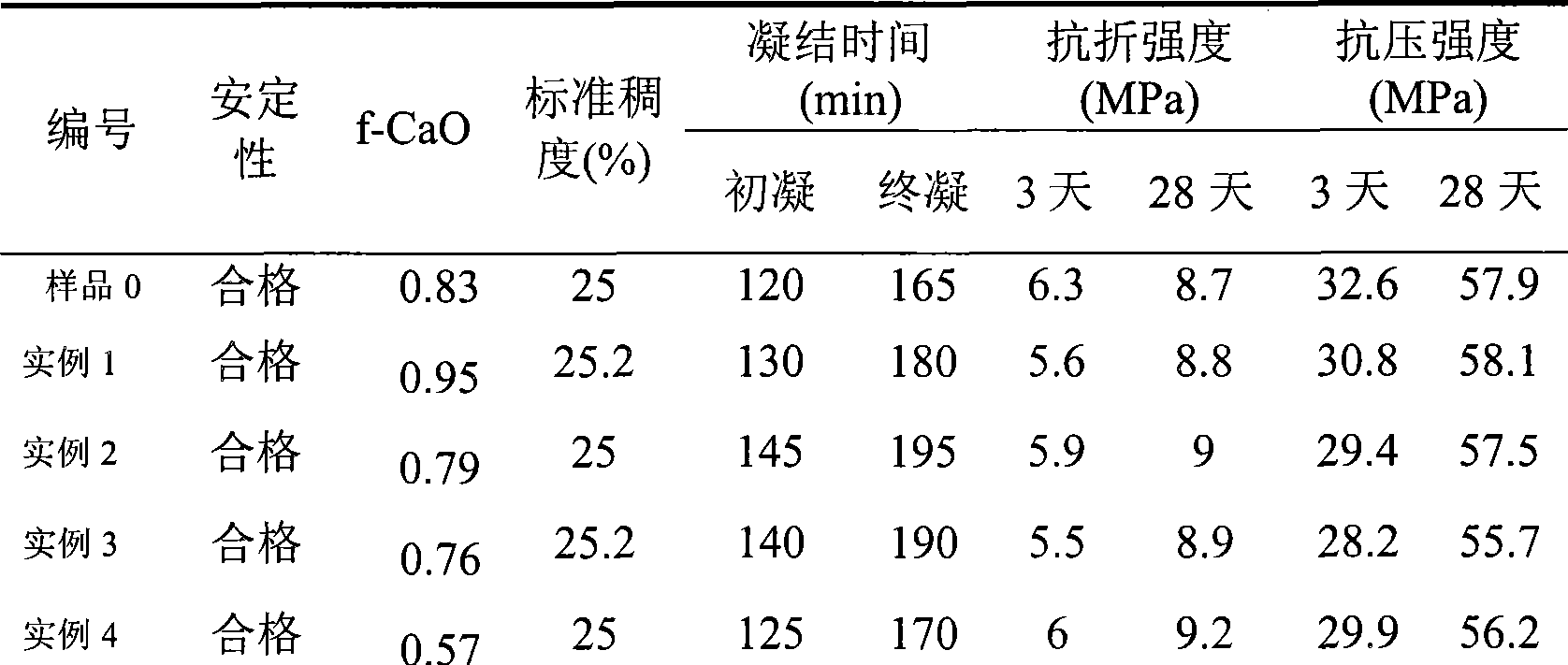

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

Pretrement of tail ore, concretion cementing material prepared therewith and their prepn

The present invention relates to pre-treatment of tail ore, concretion cementing material obtained therewith and their preparation process. Tail ore in 30-90 wt%, salts connecting K+, Na+, Ca2+, Mg2+ and / or Fe2+ ion and acid radical ions in 0.1-8 wt%, and other material containing crystal water, hydroxide radical, hydroxyl group, CO22 or other volatile components in 5-60 wt% are mixed, and the mixture is then hydrothermal alteration reacted at 200-900 deg.c. Then, the hydrothermal alteration reacted material in 50-90 wt%, cement clinker in 0.1-29 wt%, blast furnace slag or other high temperature treated waste in 0-30 wt%, gypsum in 0-8 wt% and rock forming agent in 0.1-5 wt% are mixed and ground to obtain cement powder. The cement powder has high strength and high stability.

Owner:TSINGHUA UNIV +1

Pretreatment of Yellow River silt, concretion cementing material obtained therewith and their prepn

InactiveCN1887763AAvoid damageReduce loadSolid waste managementCement productionChemistryWater of crystallization

The present invention relates to pre-treatment of Yellow River silt, concretion cementing material obtained therewith and their preparation process. Yellow River silt in 30-90 wt%, salts connecting K+, Na+, Ca2+, Mg2+ and / or Fe2+ ion and acid radical ions in 0.1-5 wt%, and other material containing crystal water, hydroxide radical, hydroxyl group, CO22 or other volatile components in 5-60 wt% are mixed, and the mixture is then hydrothermal alteration reacted at 100-900 deg.c. Then, the hydrothermal alteration reacted material in 50-90 wt%, cement clinker in 0.1-29 wt%, blast furnace slag or other high temperature treated waste in 0-30 wt%, gypsum in 0-8 wt% and rock forming agent in 0.1-5 wt% are mixed and ground to obtain cement powder. The cement powder has high strength and high stability.

Owner:TSINGHUA UNIV +1

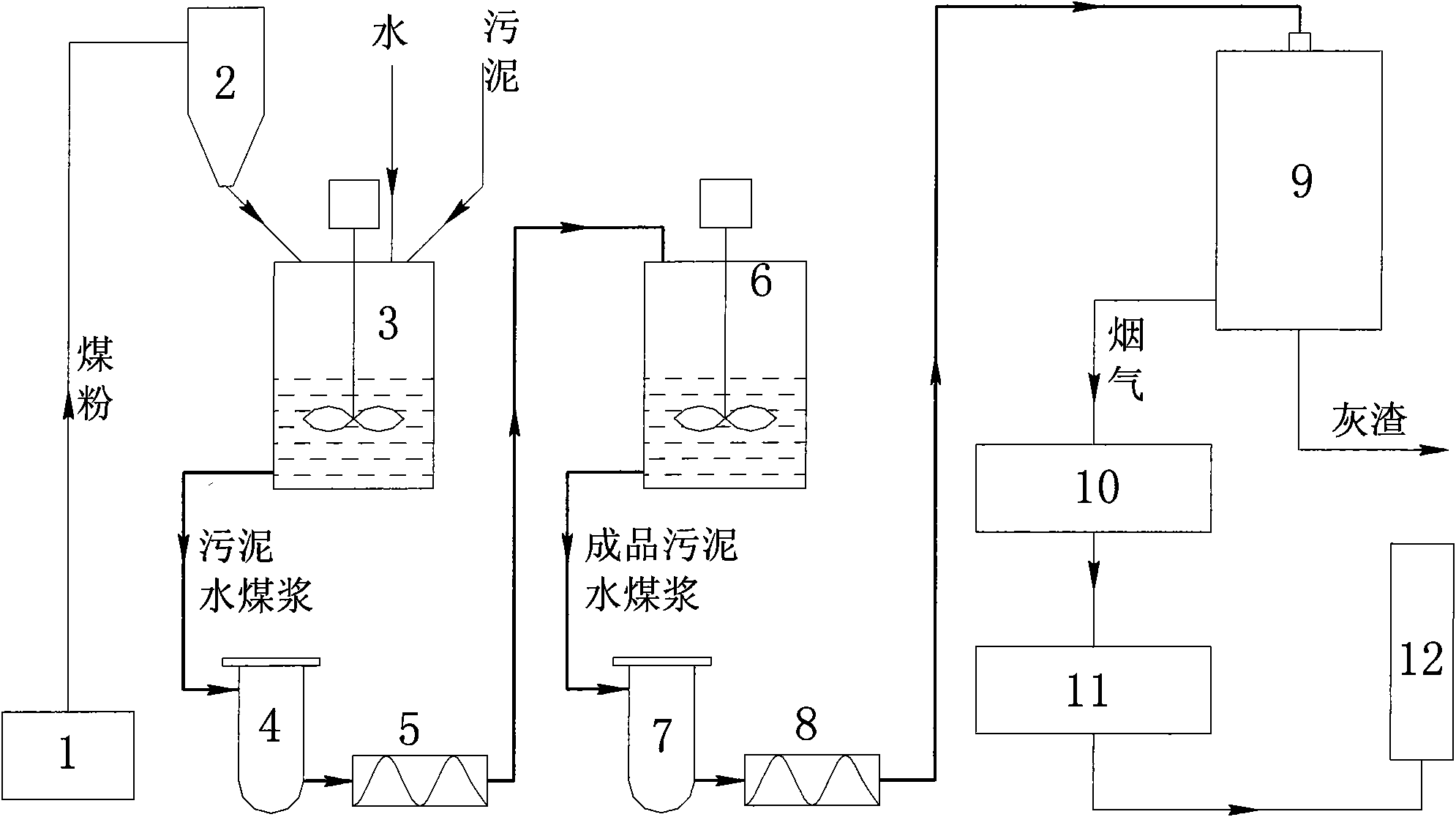

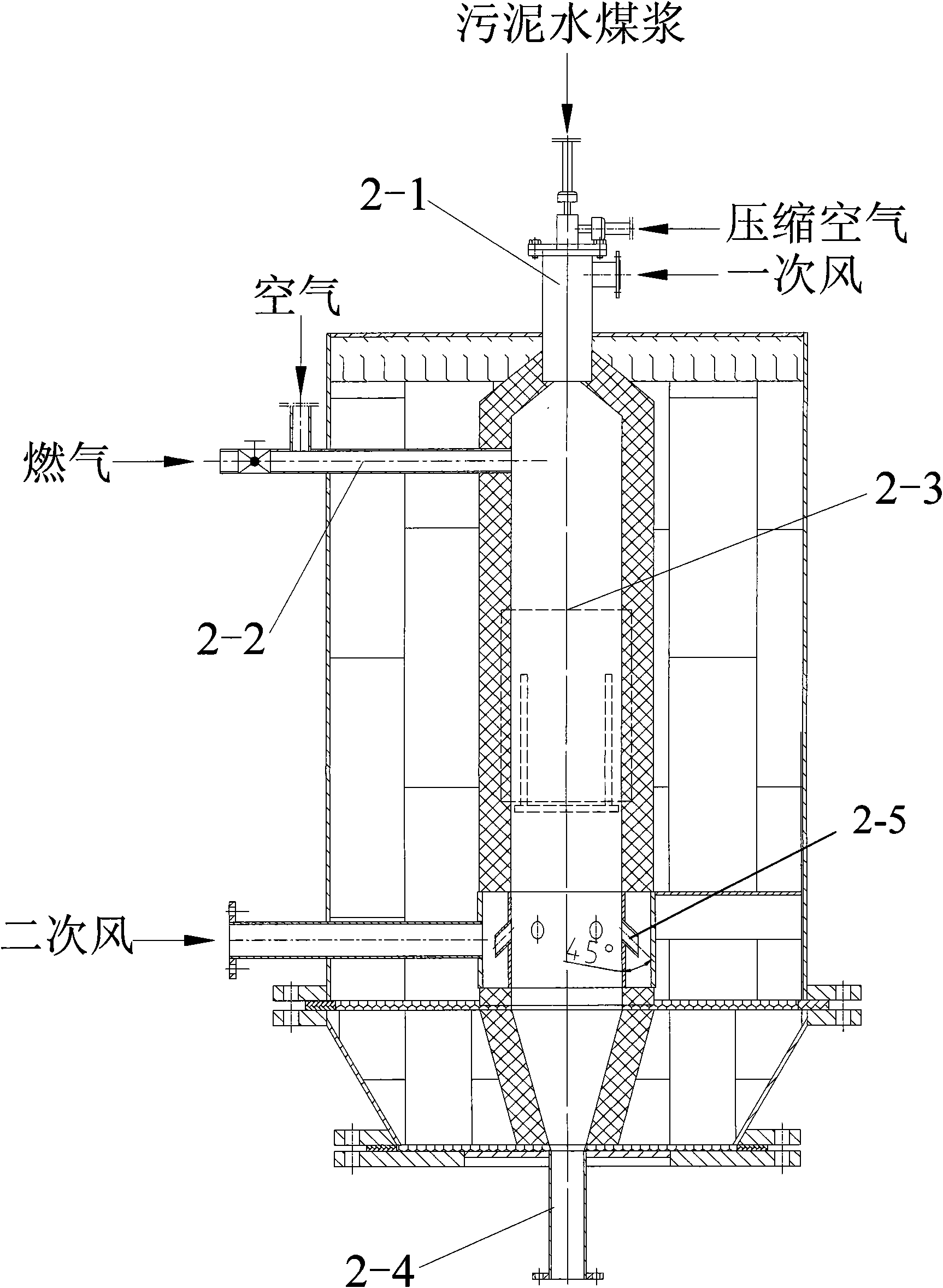

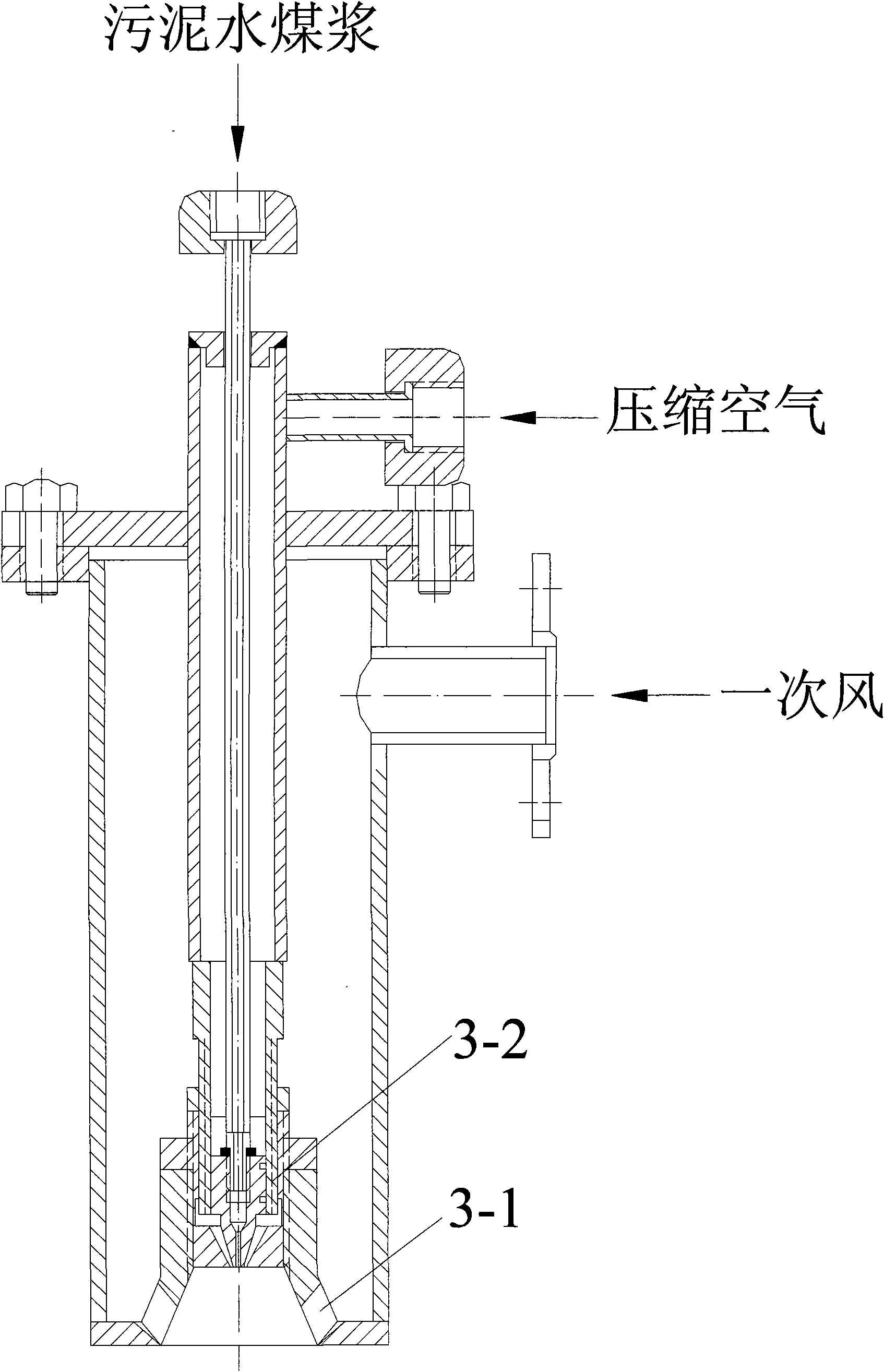

Incineration treatment method of municipal sludge and device thereof

InactiveCN101551108AReduce collectionSave storageIncinerator apparatusCombustion chamberAtmospheric air

The invention relates to an incineration treatment method of municipal sludge and a device thereof. The method comprises the steps of directly mixing powdered coal with average particle diameter of 75 to 90 micrometers, municipal sludge with water content of 95 wt percent and water according to the mass ratio of 60:25:15, then stirring for two times and filtering to manufacture finished sludge water-coal-slurry, directly adopting a screw pump for pressurizing, feeding the sludge water-coal-slurry into a sludge water-coal-slurry atomizing nozzle, and simultaneously feeding compressed air and primary air into the atomizing nozzle to ensure that the sludge water-coal-slurry is injected into a combustion chamber in a good spray pattern. Generated high-temperature flue gas is discharged into atmosphere after heat is recycled by a waste-heat boiler, and clinker is recycled. The device mainly consists of a coal grinding mill, a powder storage bin, an agitator tank, a first filter, a first screw pump, a storage tank, a second filter, a second screw pump, a combustion chamber, a waste-heat boiler and a bag-type dust collector. The disadvantages in the conventional sludge incineration method that the process is complex and the energy consumption during the sludge drying is high are overcome, and the low pollution emission of the flue gas and the comprehensive utilization of the clinker are realized.

Owner:SOUTHEAST UNIV

Concrete material for paving road surface and preparation method of concrete material

The invention relates to the field of building materials, and in particular relates to a concrete material for paving a road surface and a preparation method of the concrete material. The concrete material for paving the road surface comprises the following components, namely a gel material, aggregate and additives; the gel material consists of iron tailings, blast furnace slag, cement clinker and gypsum; the aggregate consists of waste rubber powder treated by NaOH, sand and pebbles; the additives comprise an air entraining agent, an early strength agent and a water reducing agent; and the waste rubber powder is neutral rubber powder which is a rubber powder suspension treated by using NaOH. The concrete material disclosed by the invention has the beneficial effects of achieving reasonable utilization of waste resources, effectively utilizing the iron tailing, waste rubber powder and other resources, solving the problem of treating the iron tailings, improving the performances, such as impact resistance, antifreezing property and anti-cracking property of concrete on the basis of saving the production cost, and prolonging the service life.

Owner:中光财盛实业(北京)有限公司

Steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and manufacturing method thereof

ActiveCN101994283AMitigate the heat island effectGuaranteed water circulationSolid waste managementSingle unit pavingsBrickSodium Bentonite

The invention relates to a steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: adding a lower brick material obtained by uniformly mixing waste ceramic residue powder, waste glass powder, garbage clinker powder, portland cement, calcium oxide, calcium sulfate, sodium chloride, a rosin hot polymer, calcium sulfonate, sodium aluminate and water to a double-axis mixing stirrer to stir into a wet state, and then vibrating, extruding and molding into a lower brick of the ecological water permeable environmentally friendly brick; uniformly coating a layer of fine material of an upper brick material obtained by uniformly mixing waste ceramic fragment powder, bentonite, talcum powder and water on the upper part of the lower brick by using a secondary spreader to manufacture a water permeable environmentally friendly brick blank under the pressure of 25-30Mpa; maintaining with steam; heating at constant temperature; and naturally cooling to manufacture the steamed ecological water permeable environmentally friendly brick product of the waste ceramic residues. The raw materials of the invention also can be manufactured into vegetation bricks of different specifications. The product has certain water permeability, air permeability and water retentivity, also has various functions of cooling, reducing noise, regulating the climate, eliminating the heat island effect of a city, improving the air quality, maintaining the surface water circulation, and the like and the advantages of high product strength, no pollution, low cost and good benefit and conforms to the requirements on saving energy, reducing emission, protecting environment and developing low-carbon economy.

Owner:清远绿由环保科技有限公司

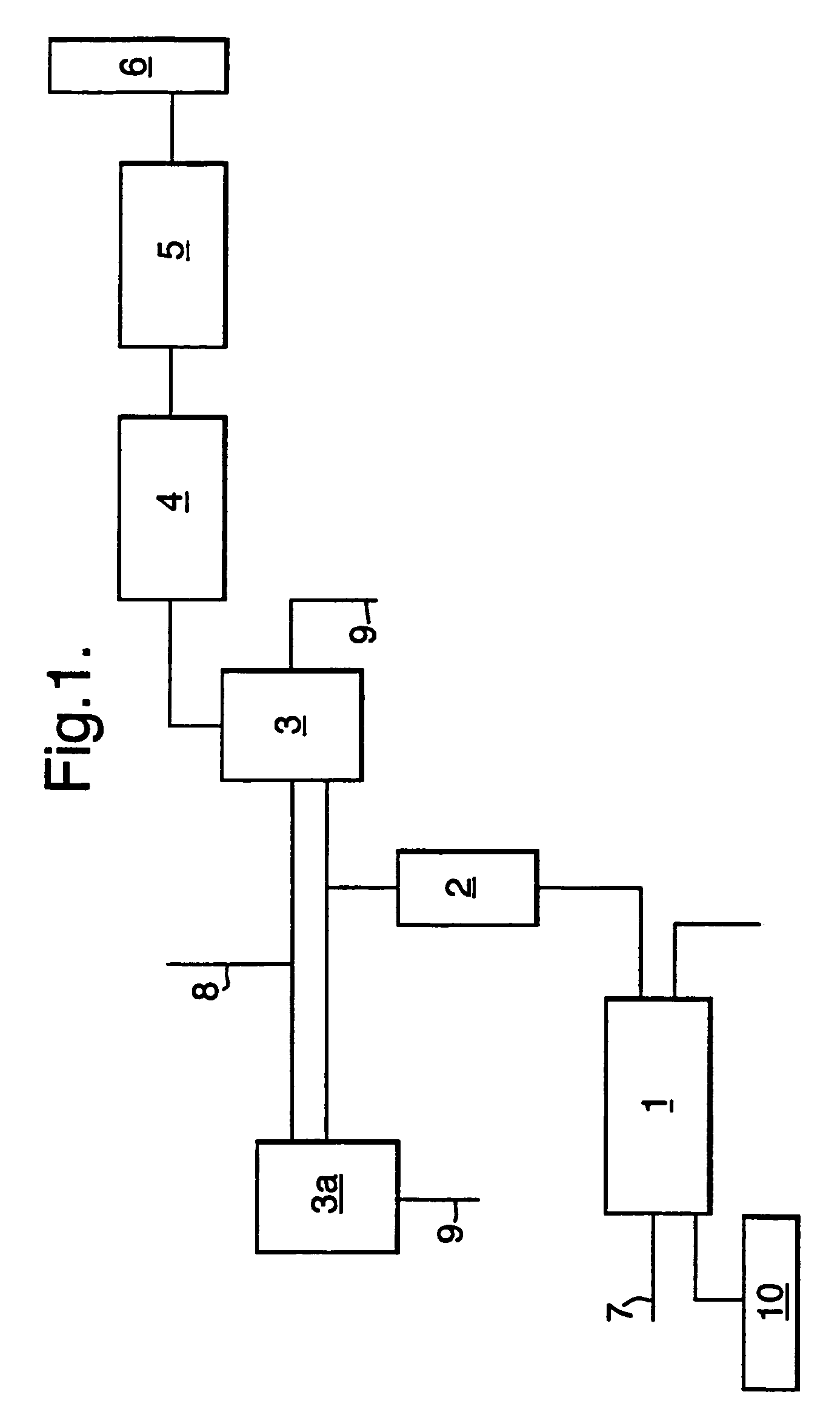

Method and process for co-combustion in a waste to-energy facility

InactiveUS7189074B2Reduce chanceImprove usabilityRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber; bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

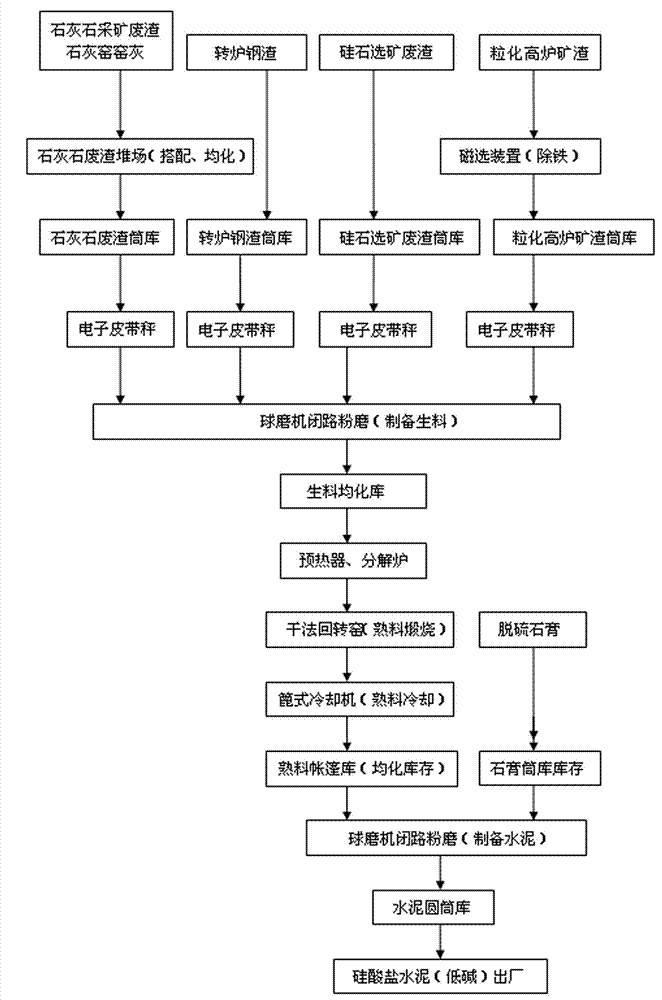

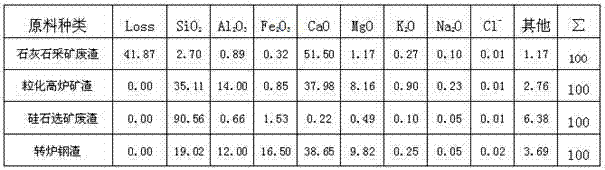

Method for producing low-alkali Portland cement by using industrial solid waste

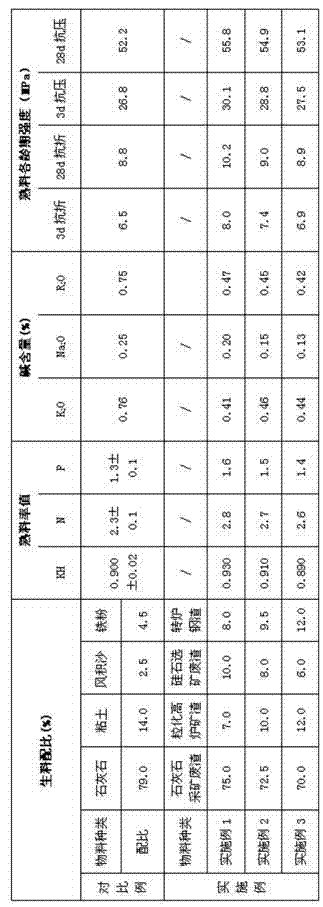

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

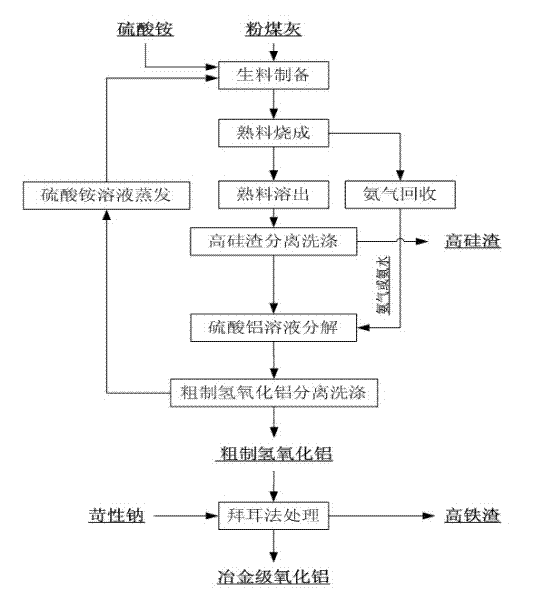

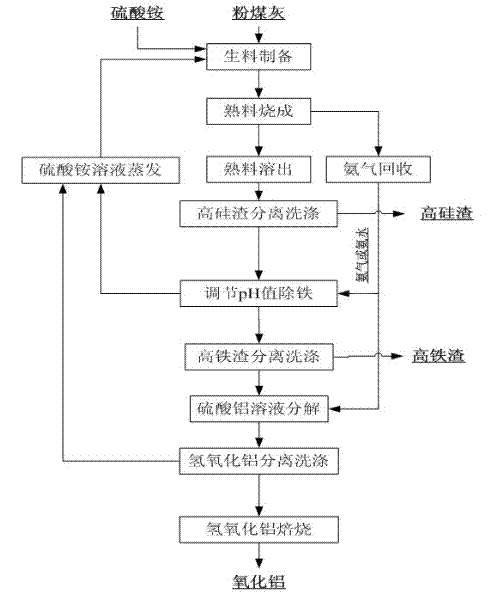

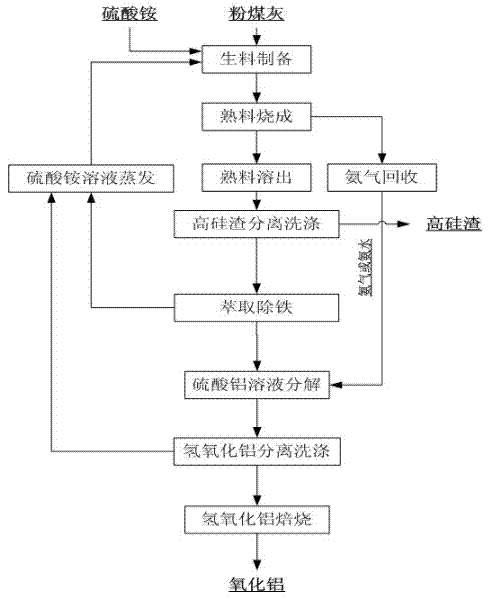

Method for producing alumina by using pulverized fuel ash

InactiveCN102502736AEfficient extractionEfficient use ofSolid waste disposalAluminium oxides/hydroxidesPulverized fuel ashSilicon dioxide

The invention relates to a method for preparing alumina by using pulverized fuel ash. The method comprises the following steps of: (1) preparing raw meal; (2) baking clinker; (3) recovering ammonia gas; (4) dissolving the clinker out; (5) separating and washing high-silicon residues; (6) preparing alumina with an obtained aluminum sulfate solution; and (7) evaporating an ammonia sulfate solution. The method has the advantages and effects that: no aid is added, so that alumina in pulverized fuel ash can be extracted effectively, and the extraction ratio of alumina can be over 85 percent. In the process flow of the method, circulation of ammonia sulfate is realized, so that alumina can be extracted from pulverized fuel ash in batches by circulating; no waste gas or waste liquid is discharged in an entire process; and a major component in residues left by extraction of alumina from pulverized fuel ash is carbon dioxide which is easy to utilize. A reaction system is a weakly acid system, equipment is easy to handle, and industrialization is facilitated.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

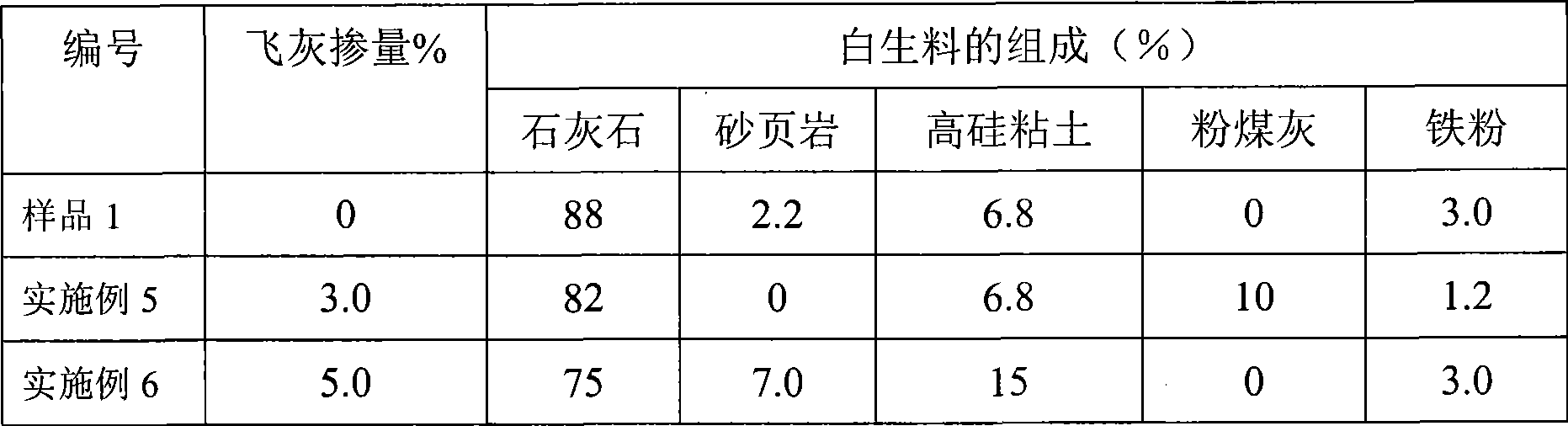

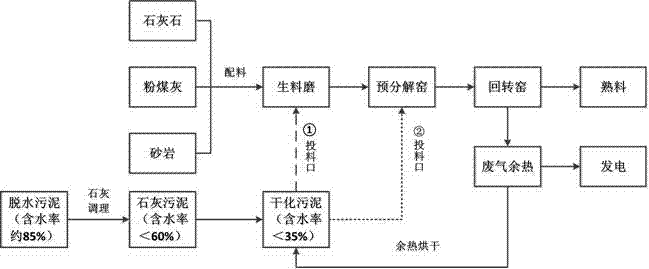

Method for adjusting and controlling feeding mode of lime-dried municipal sludge cooperatively treated with cement kiln

The invention relates to a method for adjusting and controlling a feeding mode of lime-dried municipal sludge cooperatively treated with a cement kiln. The method comprises the following steps: producing cement clinker by virtue of an existing novel dry-process cement clinker production line; recycling lime-stabilized sludge; specifically, conditioning the sludge with the water content being more than 80% by using lime, drying by virtue of residual heat of flue gas until the water content of the sludge is less than 35%, directly feeding the dried sludge to a vertical mill or a predecomposition kiln to serve as substitute raw material and fuel for cement raw materials, homogenizing, and firing in a rotary kiln to obtain the cement clinker, wherein the additive amount of the lime-dried sludge is 1wt%-21wt% of the cement raw materials; feeding from a proper feeding hole according to the components of the lime sludge, and effectively adjusting and controlling the cement raw materials to keep the cement production line stable and ensure good clinker quality. According to the method, the efficiency of cooperatively treating the lime-dried sludge with the cement kiln is improved, the sludge treatment capacity is high, the secondary pollution is alleviated, the consumption of calcium carbonate in the cement raw materials can be reduced, microelements in the sludge take the effect of a mineralizing agent, and the clinker can be conveniently fired. The method can provide a reference for study on cooperative treatment of solid wastes and the like during industrial production by the cement kiln.

Owner:TONGJI UNIV

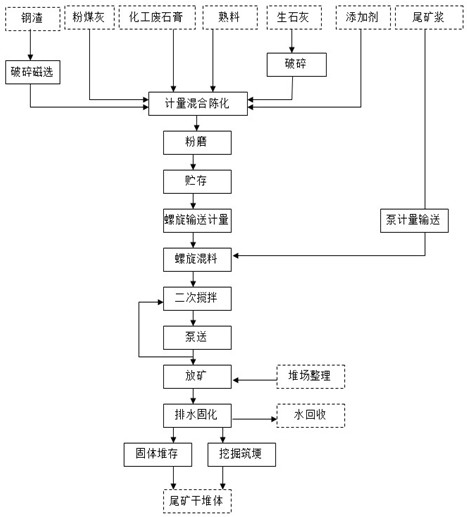

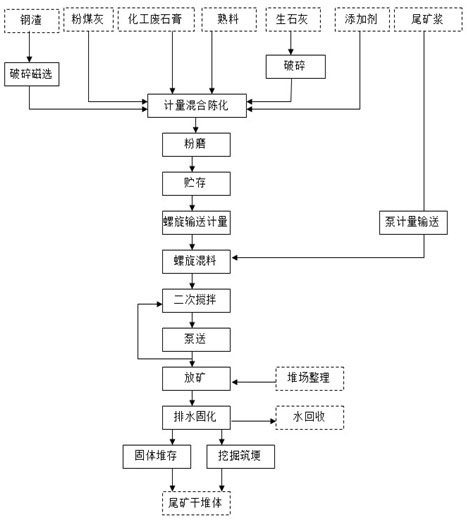

Curing and dry-piling method of iron tailings

The invention relates to a curing and dry-piling method of iron tailings, belonging to the technical field of mine safety. The curing and dry-piling method comprises the following steps of: adding a curing agent and a chemical additive produced by adopting steel slag, chemical waste gypsum, clinker, coal ash and quick lime in tailing pulp, and synchronously realizing precipitation, water drainage and curing and pile-up by secondary mixing and stirring. Compared with the prior art, the curing and dry-piling method has the advantages of simple technical process, low cost, small occupied area and high safety, and is a new method for safe pile-up of the iron tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

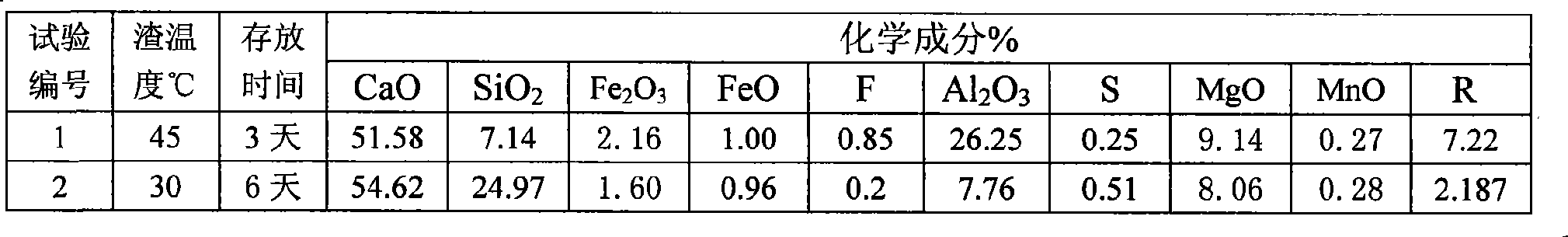

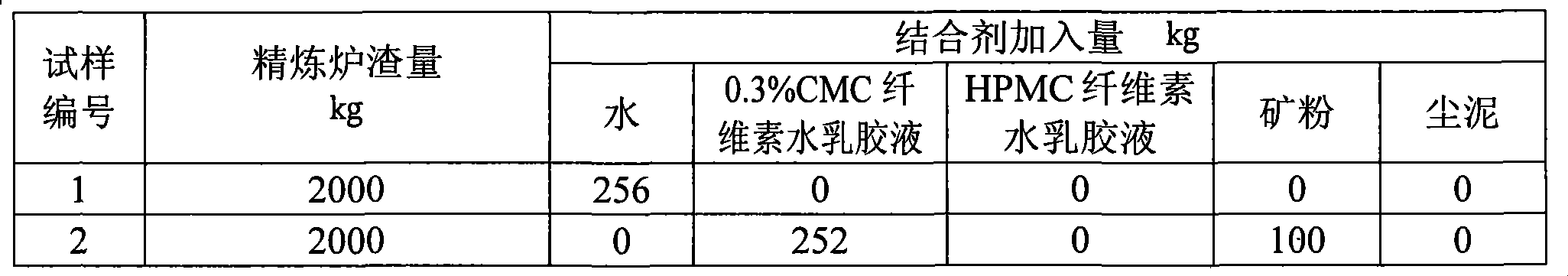

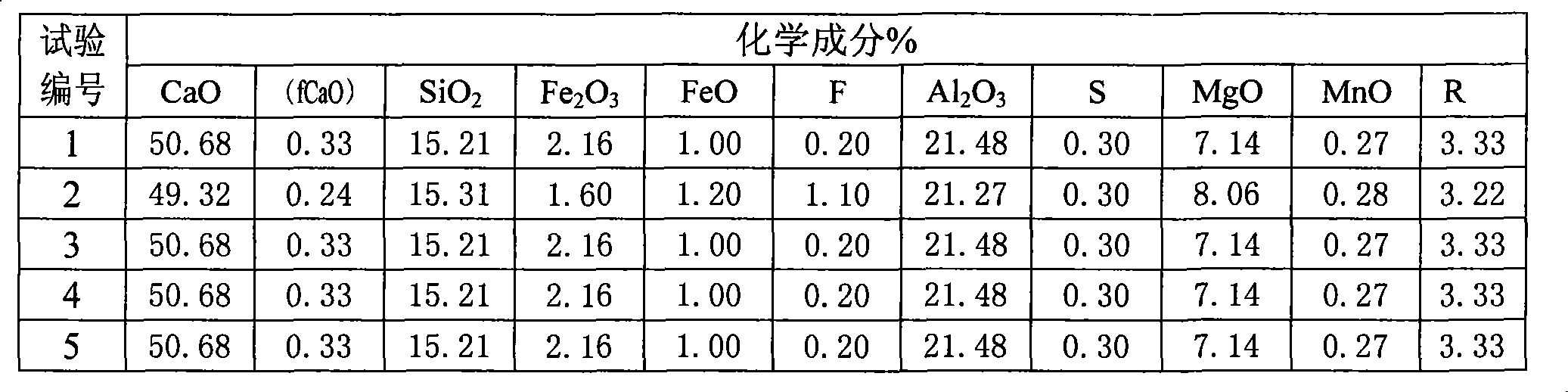

Converter fluxing medium with LF refinery cinder as raw material and production method thereof

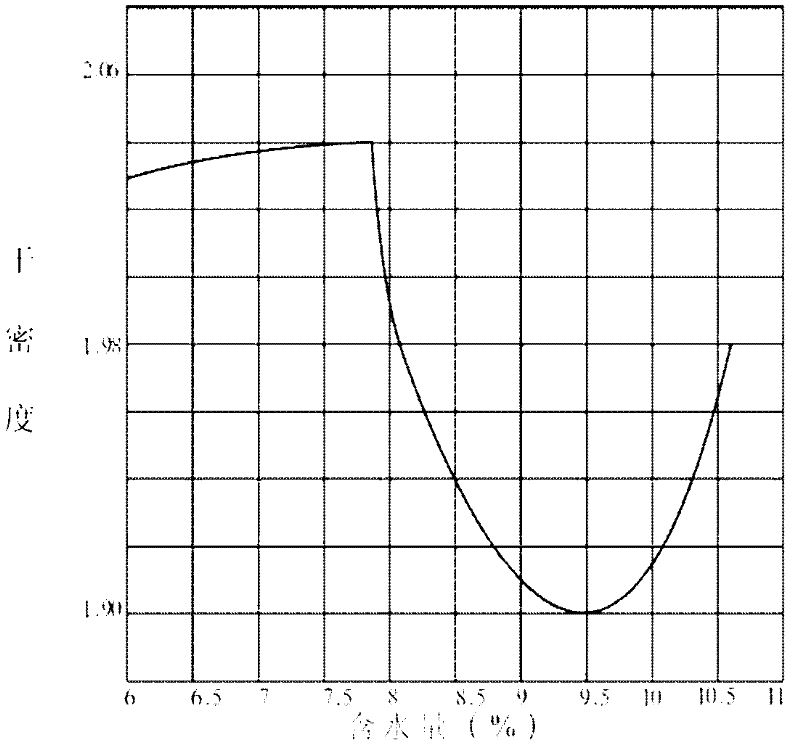

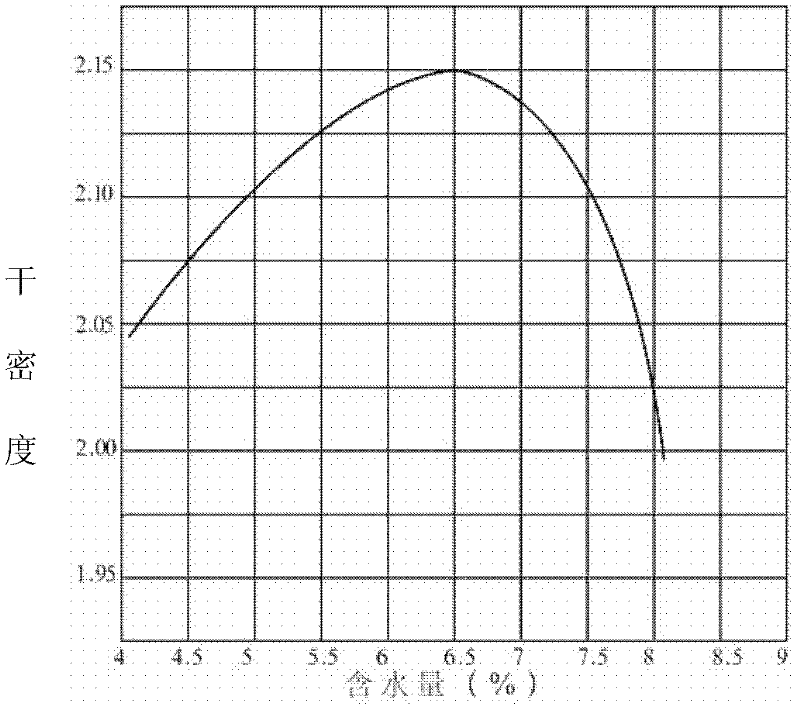

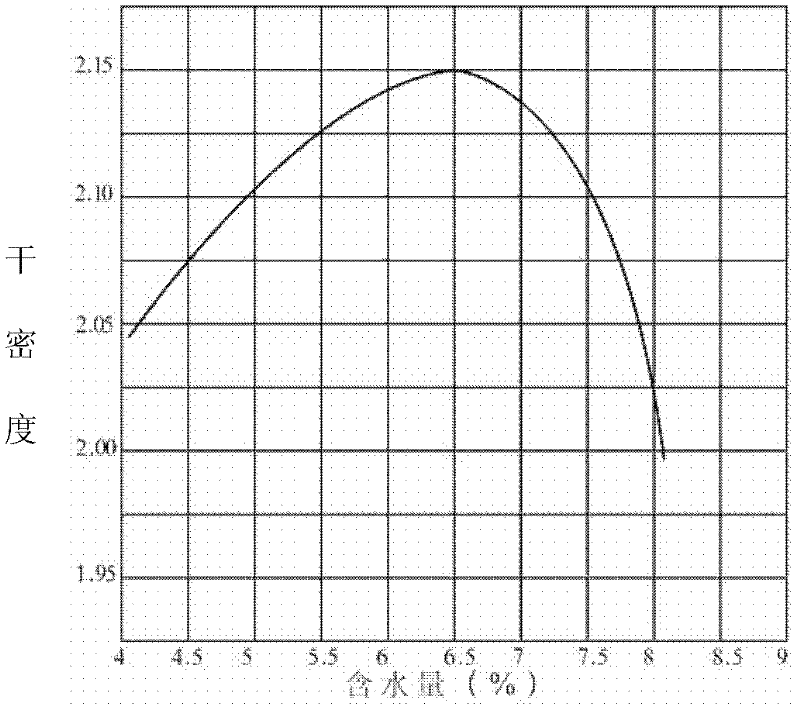

InactiveCN101463406ASolve uneven chemical compositionSolve easy pulverizationSteelmakingChemical composition

The invention discloses a converter flux agent which uses LF refining slag as raw material and a production method thereof. The LF refining slag is sieved and magnetically separated after being mixed uniformly. Partial clinkers and iron particles are removed to obtain homogeneous silt-shaped material under 10mm as the production raw material. The material is mixed with water. The adding amount of water is 10%-15% of the weight of the raw material. After the material is mixed and rolled, part of the water in the raw material evaporates to achieve the compactness requirement, and the raw material is delivered to compaction equipment to be molded into an entity. After the forced drying or the air-curing, the strength is larger than or equal to 11MPa, and the water content is less than or equal to 1 percent. With using conditions of the converter flux agent and fast slag melting speed, the converter flux agent which uses the LF refining slag as the raw material and the production method thereof solve the problems of uneven chemical components and easy pulverization of original refining slag and reduces the phenomena of dry returning and lance slag sticking and can replace bauxite, save part of limestone, fully utilize waste slag, reduce environmental pollutions and lower the steelmaking production cost.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION +2

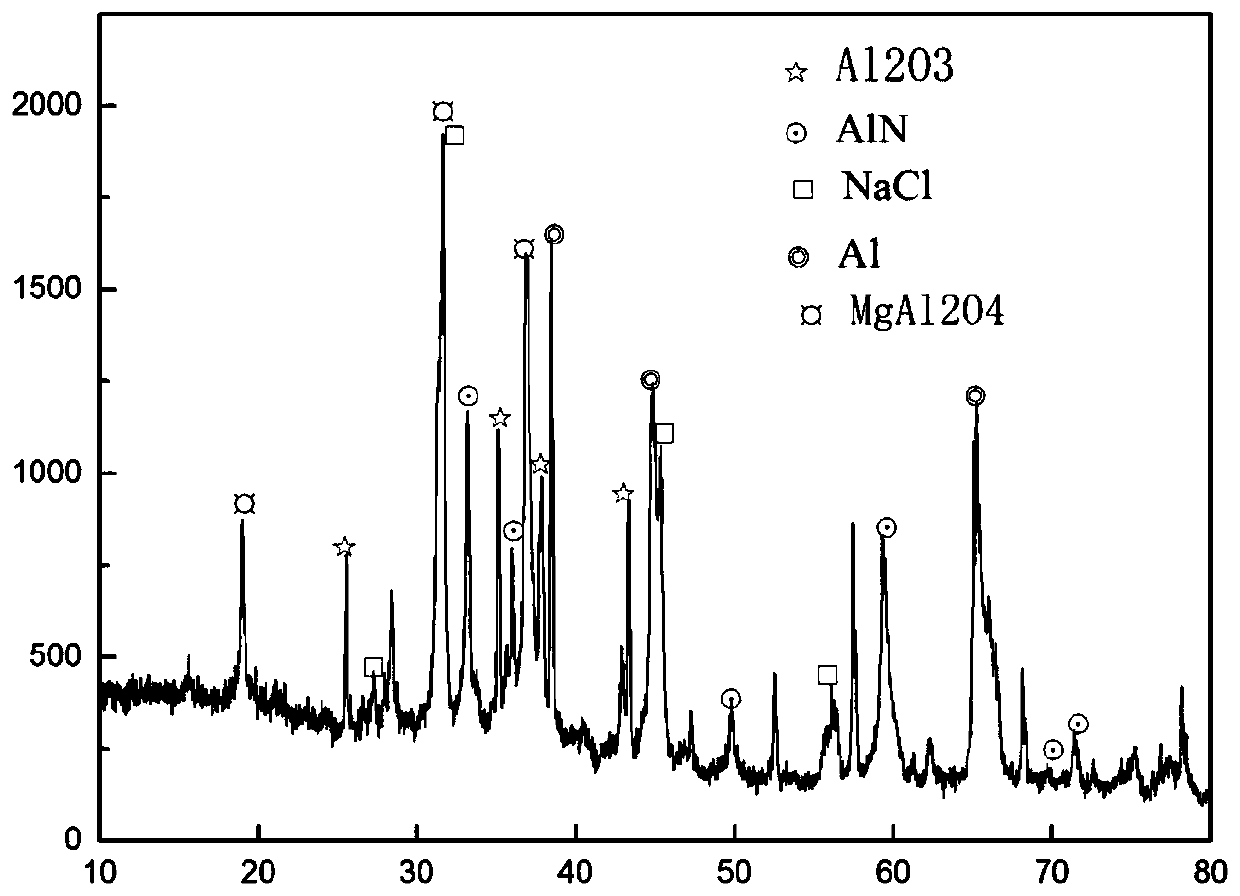

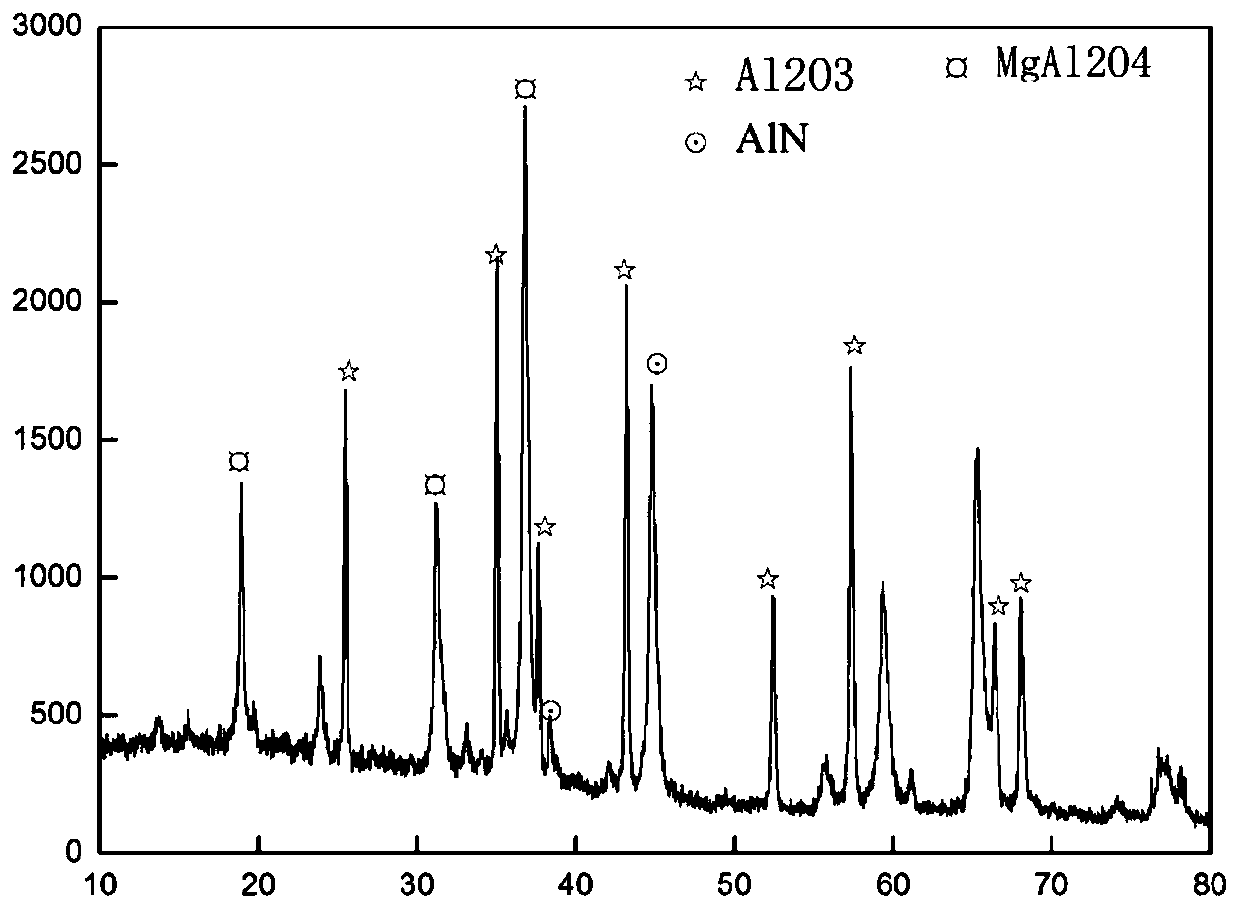

Method and system for preparing sulfoaluminate cement from all solid wastes pretreated by aluminum ash

The invention discloses a method and a system for preparing sulfoaluminate cement from all solid wastes pretreated by aluminum ash. The method comprises the following steps of: heating aluminum ash tocarry out a heat treatment on aluminum ash at a temperature of not lower than 900 DEG C; homogenizing and mixing processed aluminum ash with red mud, desulfurized gypsum and carbide slag, drying themixed materials by using hot gas generated by the heat treatment, carrying out raw powder proportioning and grinding on the dried materials, and calcining the materials after raw powder proportioningand grinding to obtain sulfoaluminate cement clinker; wherein the aluminum ash comprises secondary aluminum ash or the aluminum ash is secondary aluminum ash. The tail of the rotary kiln is not proneto ring formation, the condenser is prevented from being blocked, long-time operation is guaranteed, and bauxite can be completely replaced.

Owner:SHANDONG UNIV +2

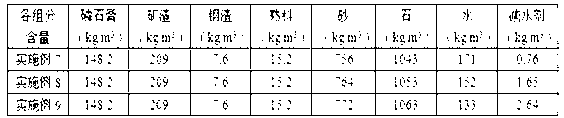

Cement concrete preventing corrosion of chlorine salt and preparation method thereof

The invention belongs to the technical field of building materials, and discloses cement concrete preventing corrosion of chlorine salt and a preparation method thereof. The concrete comprises a concrete gel material, yellow sands, stones, water and a water reducer, wherein the gel material comprises the following components in percentage by weight: 20-50% of ardealite, 30-60% of slag, 1-20% of steel slag and 1-20% of clinker. C30 mobile cement concrete, C40 mobile cement concrete and C40 hard concrete can be prepared by the method provided by the invention. The chlorine salt corrosion preventing performance of the cement concrete is remarkably superior to that of common silicate cement concrete or slag silicate cement concrete. The preparation method provided by the invention is simple. Various solid wastes can be effectively and reasonably utilized, and the condition that the cost and consumption of the existing cement concrete are high is reduced. Meanwhile, the cement concrete prepared by the invention further has excellent chlorine salt corrosion preventing performance.

Owner:广东武理湾区科技发展有限公司

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

Preparation method of active manganese residue micro powder

The invention discloses a preparation method of active manganese residue micro powder. The preparation method comprises the following steps: (1) preparing materials in percentage by weight: 70%-90% of manganese residues, 4%-16% of red mud and 5%-20% of cement clinker, wherein the red mud refers to Bayer-process red mud or sintering-process red mud with over 1% (in percent by weight) of K2O and Na2O in total; (2) respectively drying the red mud and the manganese residues in the step (1) until moisture content is smaller than 1%; (3) respectively grinding the cement clinker, the red mud in the step (2) and the manganese residues in a ball mill until specific surface area is 380 m<2> / kg-450m<2> / kg for later use; and (4), preparing the micro powder in the step (3) according to the proportion in the step (1), and uniformly mixing to obtain the active manganese residue micro powder. Based on a current situation that activity of manganese residues is low, and a comprehensive utilization problem of the red mud is to be solved, active indexes of the manganese residue micro powder are improved by adding a certain amount of red mud and cement clinker to stimulate activity of the manganese residue micro powder; and meanwhile, a certain amount of red mud is consumed, so that pollution of red mud on environment is reduced, and resource utilization of waste residues is realized.

Owner:湘潭市华昇环保科技有限公司

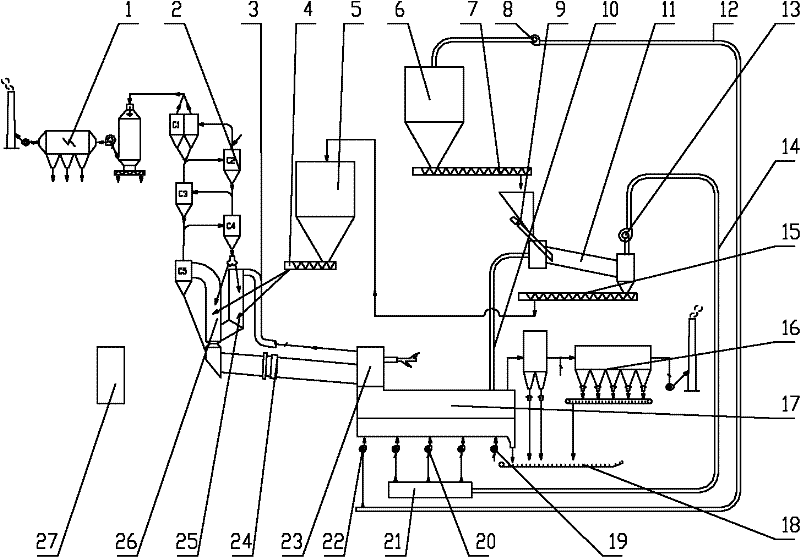

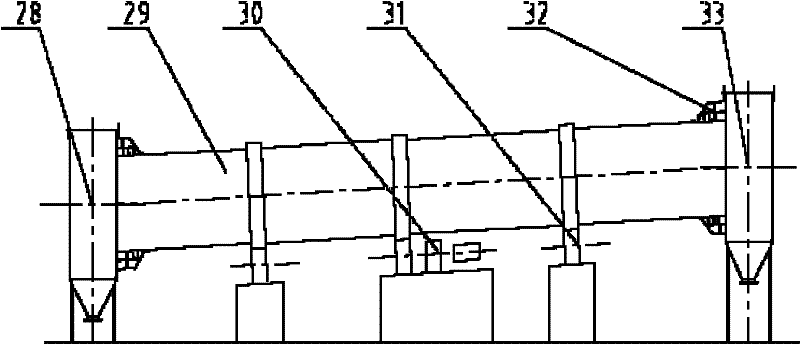

System for drying and handling sludge with waste gas from cement production

InactiveCN102173554AIncrease heat transfer areaImprove heat transfer efficiencySludge treatment by de-watering/drying/thickeningCement productionSludgeClinker (waste)

The invention discloses a system for drying and handling sludge with waste gas from cement production and is characterized in that the system comprises a novel dry-method cement clinker firing system, a wet sludge drying system, a dry sludge storage and cement kiln feeding system, an electrical dragging and automatic control system; the gas inlet pipe and the gas outlet pipe of a sludge dryer of the wet sludge drying system are both connected with a cooler of the cement clinker firing system; the dry sludge storage and cement kiln feeding system is connected with a cement kiln exhaust decomposing furnace or an uptake flue; and the sludge dryer is a rotary sludge dryer with chains. The system makes full use of the high-temperature waste gas of the cement cooler to dry the sludge, the drying waste gas returns to the cooler, the waste gas is dried by the high-temperature purified sludge, and the dried sludge is burned in the cement kiln, so that the harmful substances are decomposed, theheat energy is used for cement firing and the burning ash forms cement. Therefore, the system achieves the effect of pollution-free full-utilization disposal of sludge and is significant in environmental and economic benefits.

Owner:袁文献

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com