Patents

Literature

423 results about "Sandcrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sandcrete is a yellow-white building material made from a binder (typically Portland cement), sand in a ratio of circa 1:8, and water. Sometimes other ingredients may be added to reduce the amount of expensive Portland cement such as pozzolanas and rice husk ash. Sandcrete is similar but weaker than mortar, for which the ratio is circa 1:5. Soil cement and landcrete are similar materials but use other types of soil and hydraform blocks which are compressed, stabilized, earth blocks.

Microorganism cause concrete or concrete, producing method and application thereof

InactiveCN101270369ADoes not hinder precipitationApplicable treatmentBacteriaMicroorganism based processesMicroorganismEnvironmental hazard

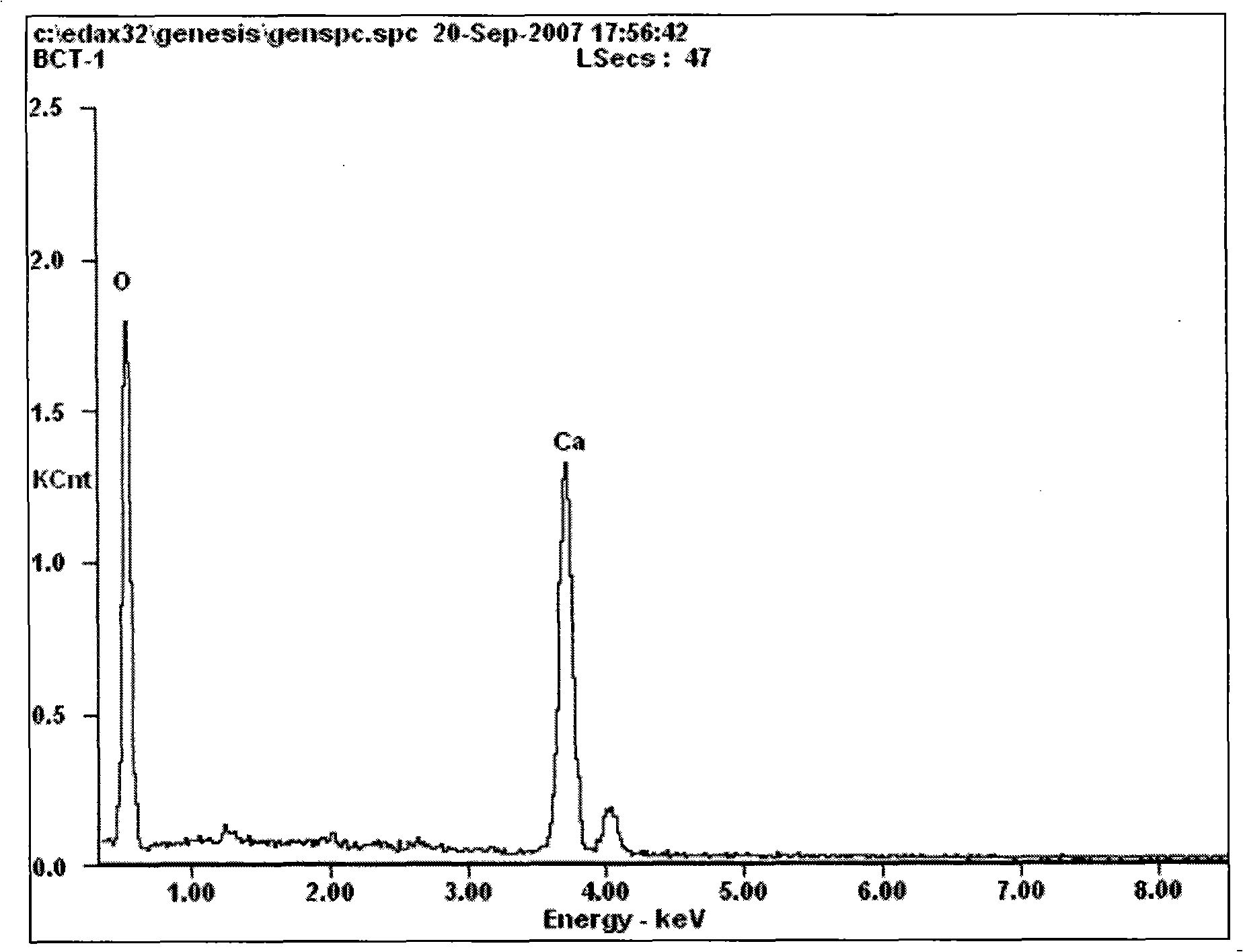

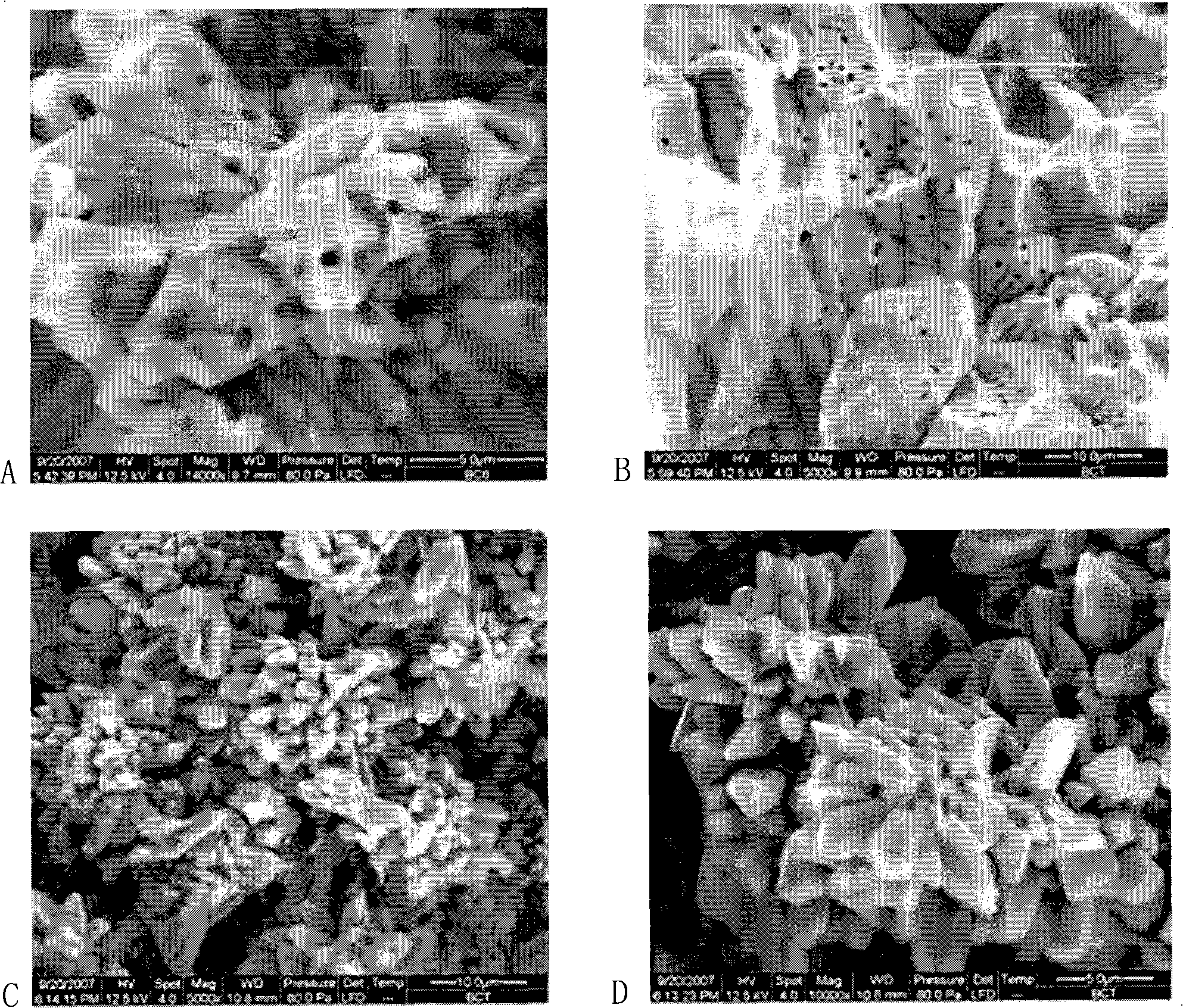

The invention discloses a microbiogenic cement and concrete and a production method thereof, which mainly mixes the Bacillus pasteurii solution for producing urease and an admixture of containing urea and mineral calcium salt and obtains the microbiogenic cement after reacting in a certain condition; adds admixture such as sand etc. into the mixture of mixing the bacterial solution and the mixture and reacts to generate the microbiogenic concrete. The microbiogenic cement or concrete of the invention can be used on protection and restoration of masonry ancient architectures and repair of cracks on concrete building or treatment of liquescent sandy soil. The invention provides a permanent method of safety, effectiveness and without environmental hazard for repair and strengthening technology of large quantity of civil architecture and structure; the invention has the advantages of the good effects, the good weatherability, the good permeability of gas and the good permeability of water and being especially suitable for treatment of the sandy soil; the invention is safe and environmental-friendly, and belongs to the environmental-friendly restoring material.

Owner:TSINGHUA UNIV

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

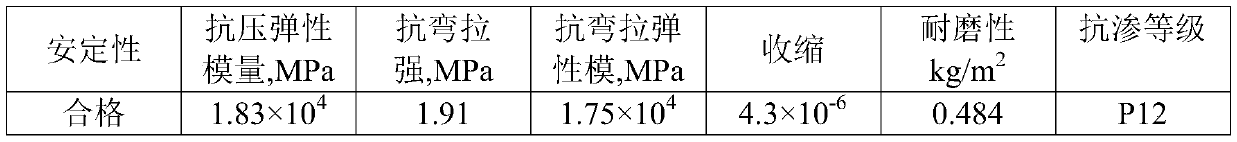

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

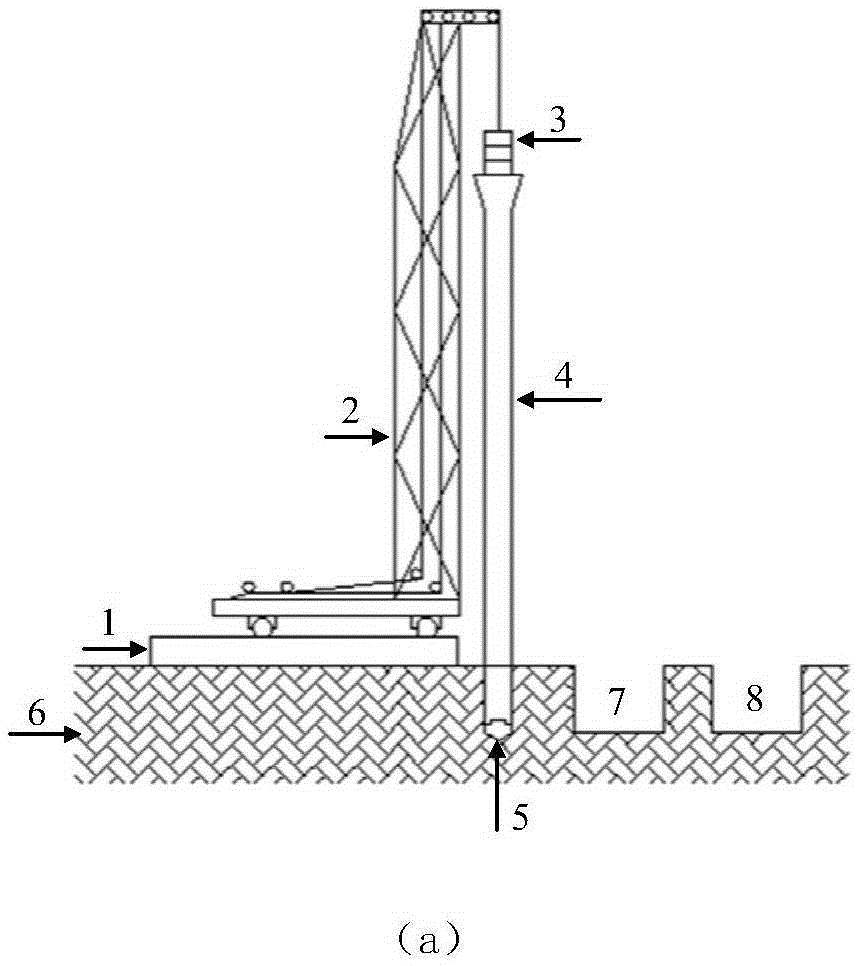

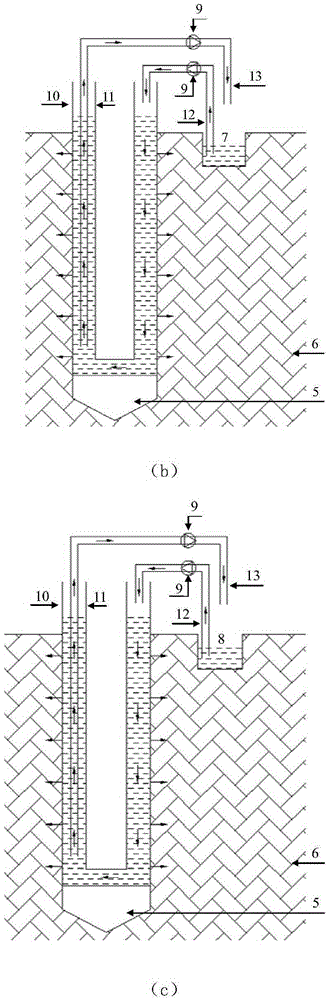

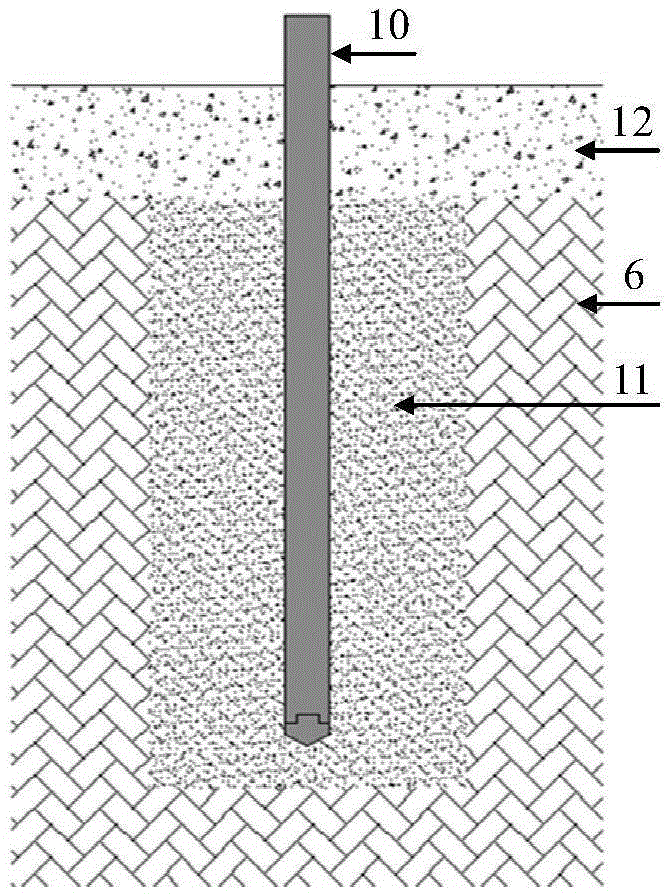

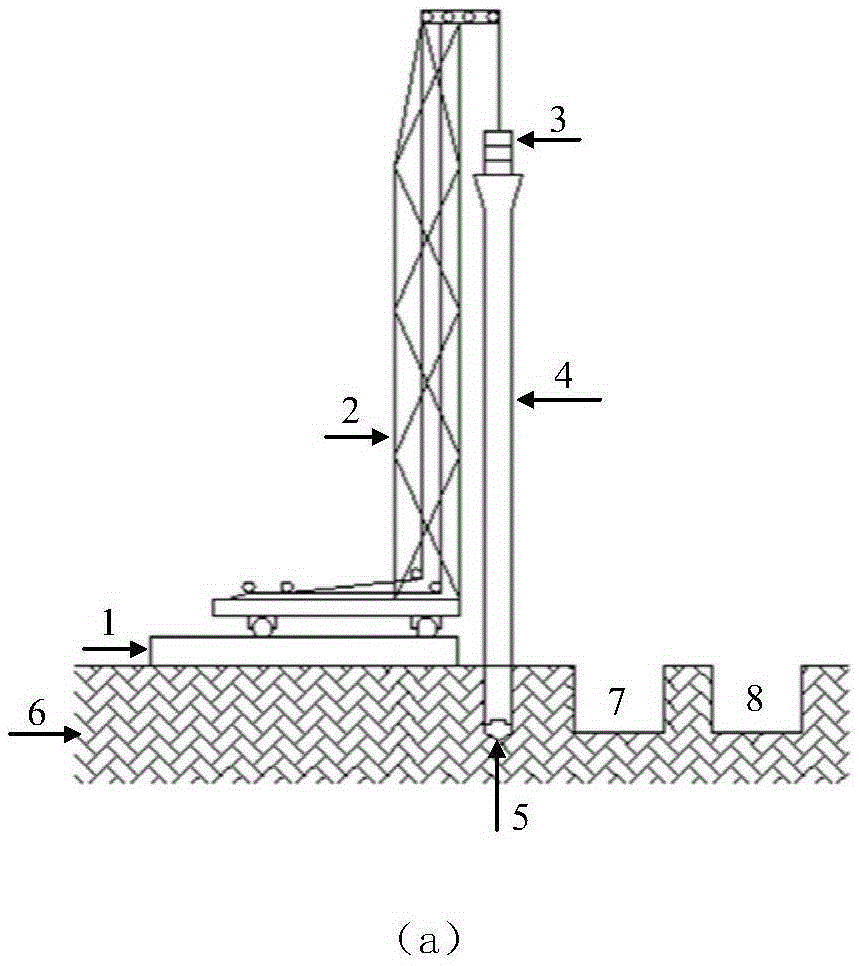

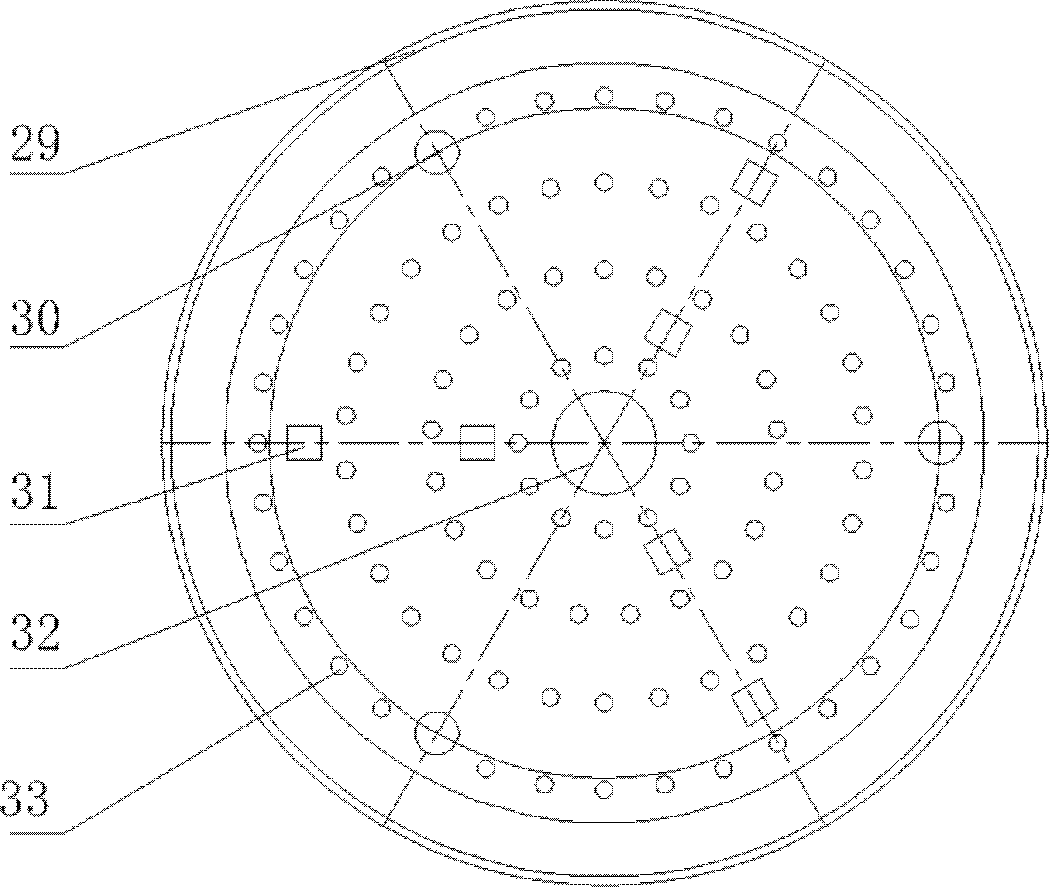

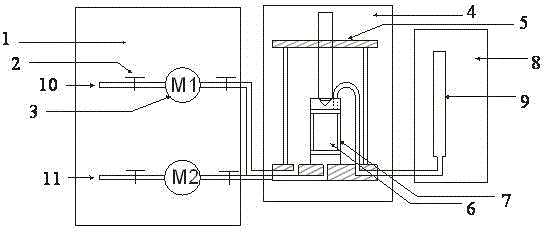

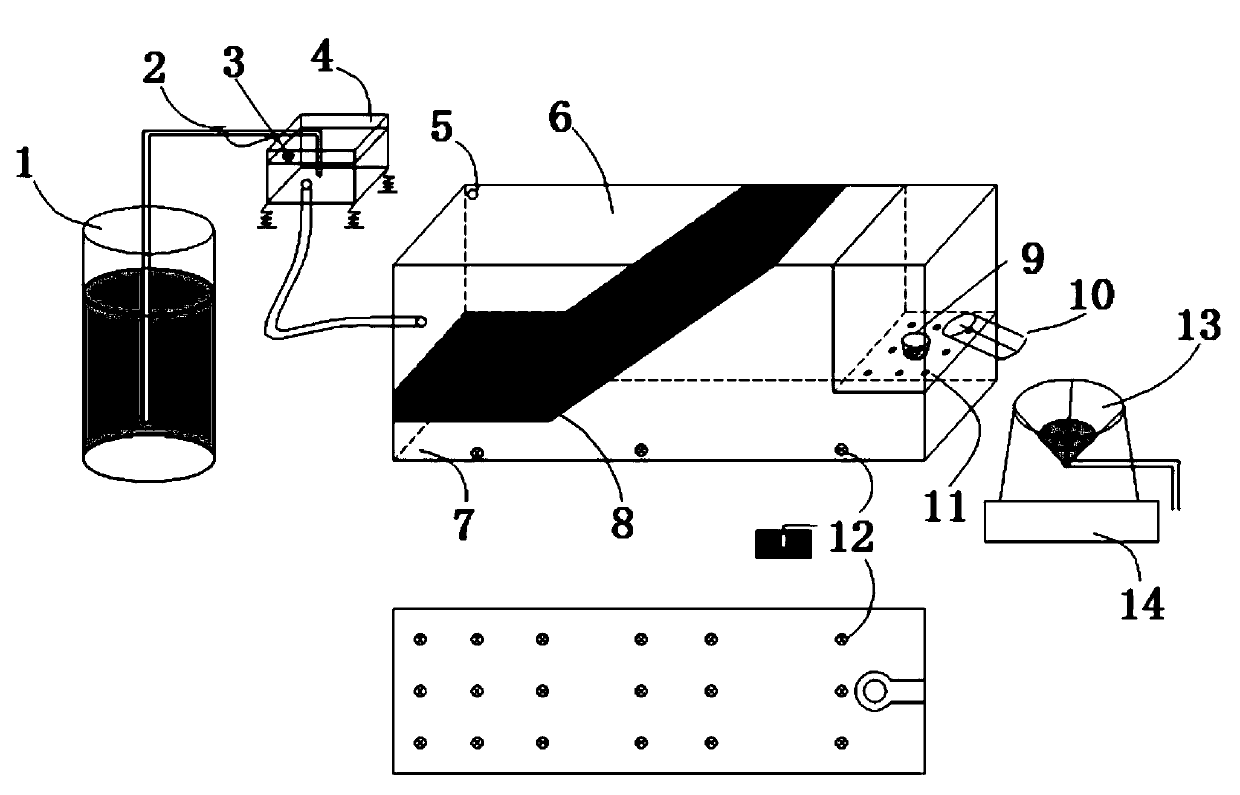

Reinforcing device for reinforcing sand foundation through combination of microorganisms with vacuum drainage and reinforcing method of reinforcing device

InactiveCN105649003AExpand the scope of processingAlleviate the plug holeSoil preservationMicroorganismStructural engineering

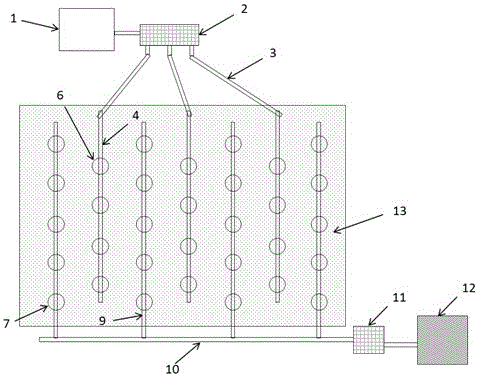

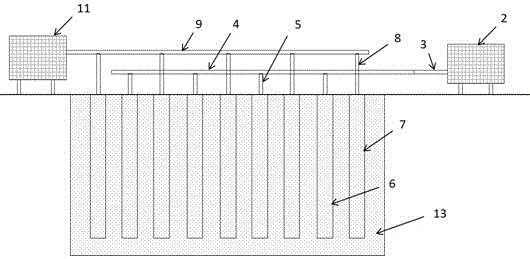

The invention provides a reinforcing device for reinforcing a sand foundation through combination of microorganisms with vacuum drainage and a reinforcing method of the reinforcing device. The device comprises grouting pipes, drainage pipes, a grouting well array, a drainage well array, vacuum water pumping equipment and slurry grouting equipment, wherein the grouting pipes and the drainage pipes are laid on a sand surface in parallel in the horizontal direction, the grouting well array and the drainage well array are located in the sand foundation below the grouting pipes and the drainage pipes respectively, the grouting well array comprises at least two grouting wells, and the drainage well array comprises at least two drainage wells. The reinforcing method comprises steps as follows: I, the reinforcing device is mounted; II, a bacterial solution and a consolidation fluid are prepared; III, the bacterial solution is injected; IV, vacuum drainage is preformed; V, the consolidation fluid is injected; the steps IV and V are repeated for 6-7 times. According to the reinforcing device and the reinforcing method, directional horizontal migration of the microorganisms in a soil body is realized through vacuum drainage, and the treatment range is enlarged; plug holes produced in the grouting process are reduced, and the reinforcement uniformity is improved.

Owner:HOHAI UNIV

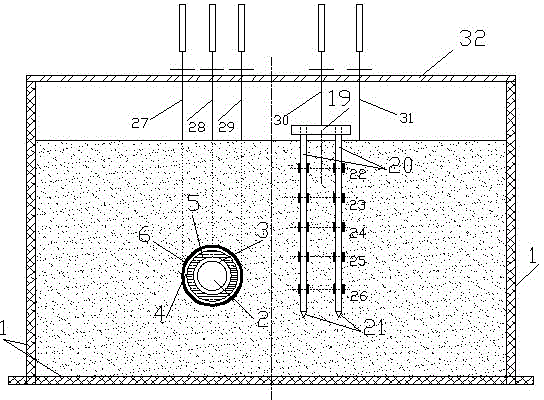

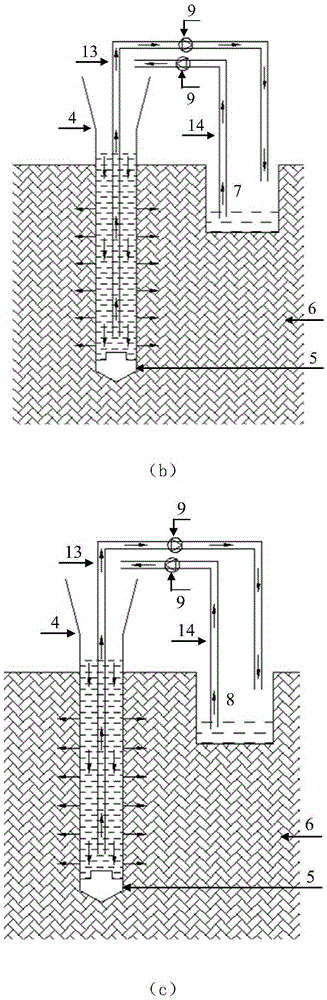

Indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations

InactiveCN103558044AImprove scalabilityAccurate measurementStructural/machines measurementSolenoid valveSlurry

The invention relates to an indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations. The indoor model testing apparatus comprises a model box, a tunnel grouting construction simulator, a tunnel lining model and a pile foundation model. The model box is filled with sandy soil mass, the tunnel lining model comprises longitudinally-segmented aluminum alloy hollow pipes and is placed in the left half part of the model box, and lining segments are separated by annular thin rubber plates; the pile foundation model is placed in the right half part of the model box and vertical to the tunnel lining model; a displacement meter support is fixed to the top surface of the model box; multiple displacement meters are respectively fixed to the corresponding sandy soil mass and the surfaces of piled raft foundations of the pile foundation model through the displacement meter support; the tunnel grouting construction simulator comprises a latex film surrounding the periphery of the tunnel lining model and an annular liquid cavity formed between the tunnel model and the latex film, the annular liquid cavity is filled with grouting liquid, one end of the annular liquid cavity is connected with a liquid injection guide pipe provided with a liquid injection solenoid valve, and a liquid discharge guide pipe provided with a liquid discharge solenoid valve is arranged at the other end of the annular liquid cavity in the horizontal direction.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

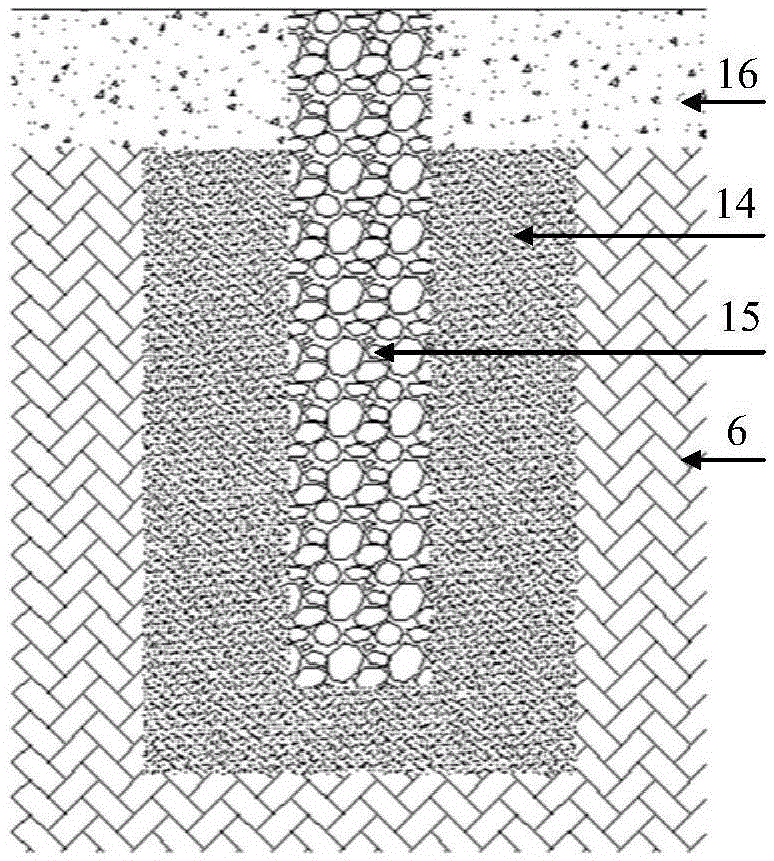

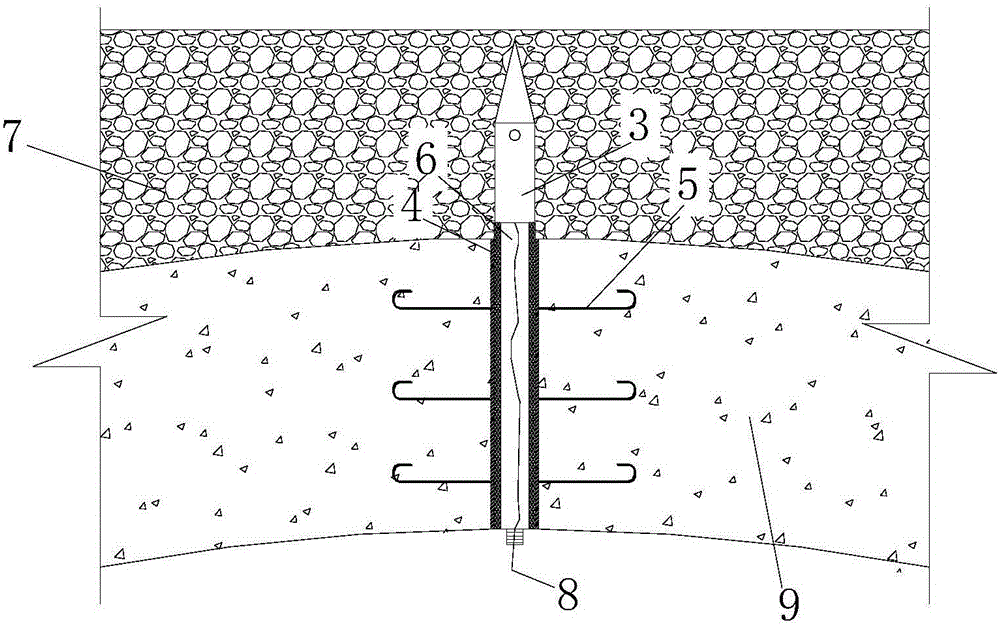

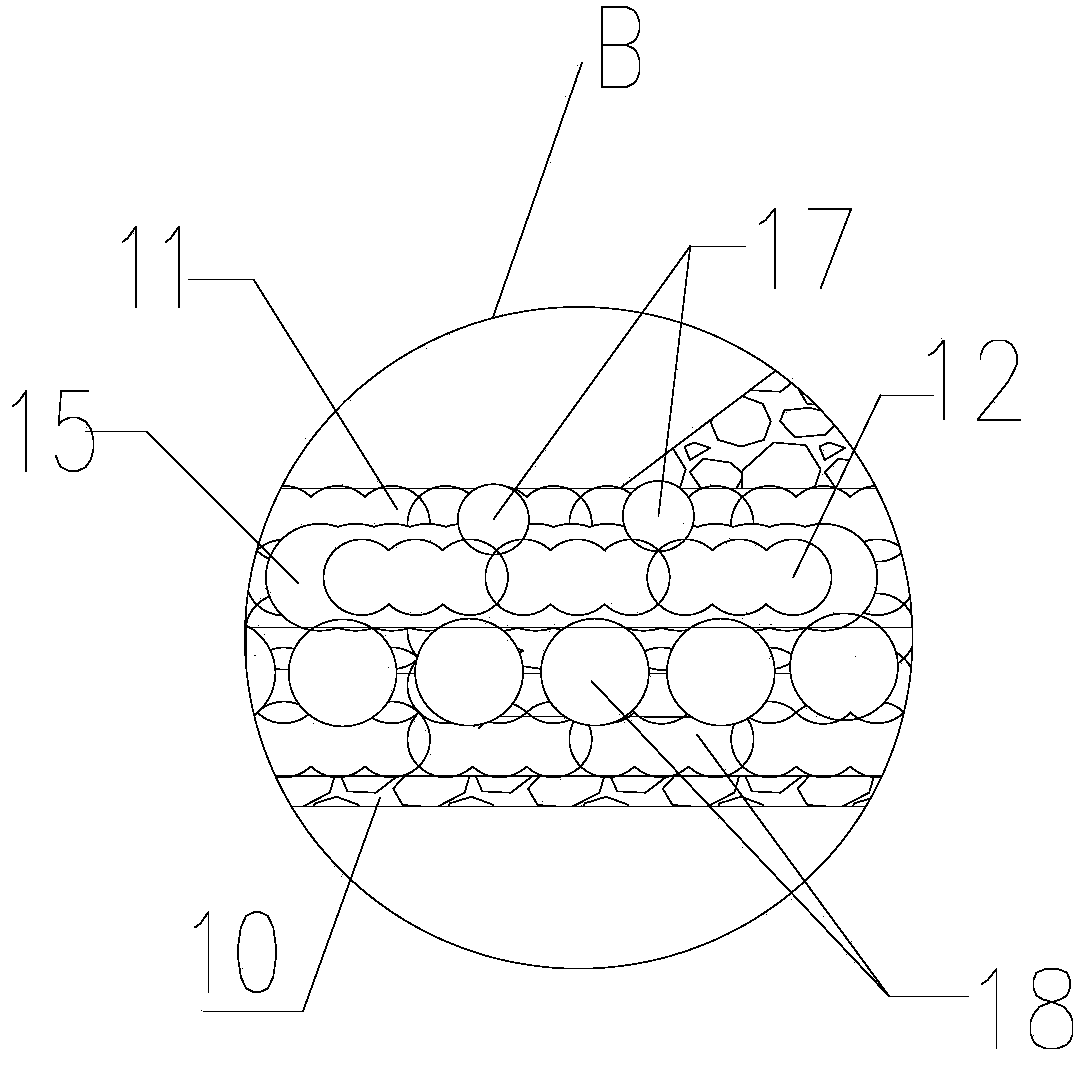

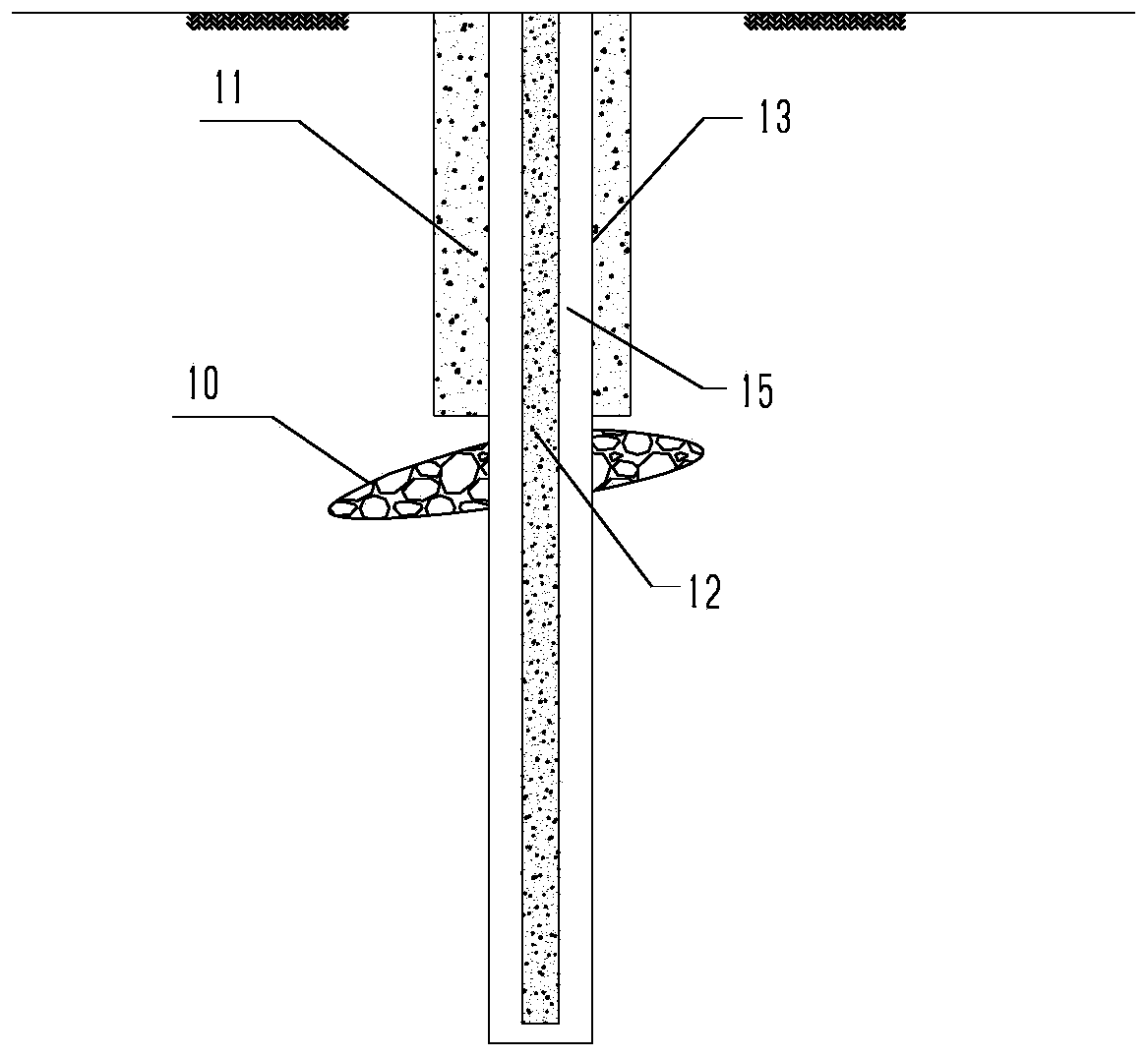

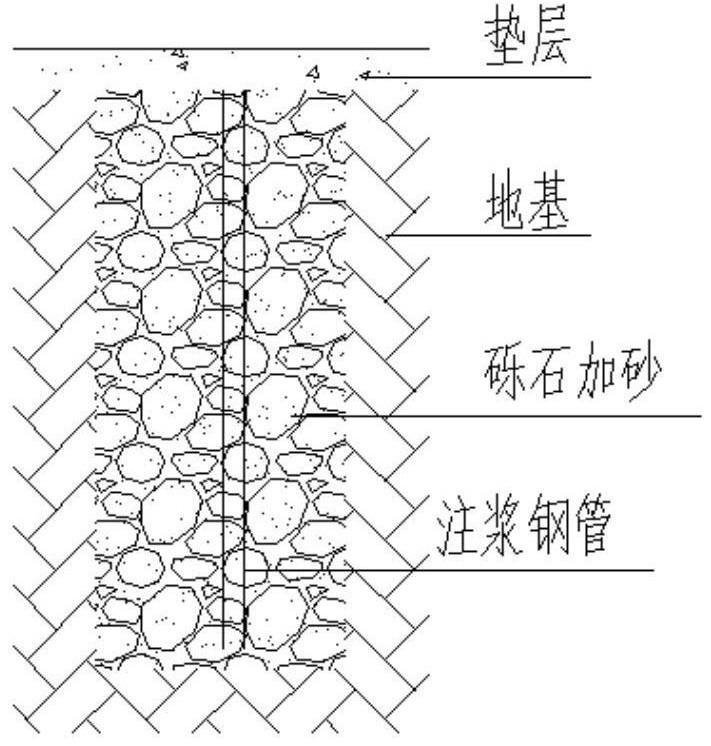

Composite foundation with discrete material pile restrained through microorganism soil solidification and construction method

ActiveCN105386436AImprove bearing capacityIncrease profitBuilding constructionsOrganic fertilisersMicroorganismSoil science

The invention relates to a composite foundation with a discrete material pile restrained through microorganism soil solidification and a construction method. The construction method includes the steps that a, a pile pipe is pressed into a foundation body; b, meanwhile, microorganism bacterium liquid is injected into a gap between an inner steel sleeve and an outer steel sleeve and diffused into the foundation body around the pile; c, the microorganism bacterium liquid is pumped out, a cementing solution is injected and diffused into the foundation body around the pile and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and loose sandy soil or floury soil is cemented; d, the step b and the step c are repeated until the soil around the pile meets reinforcement requirements; e, discrete materials are poured into a hole of the inner steel sleeve; and f, a bed course is laid, so that the composite foundation is formed. According to the composite foundation with the discrete material pile restrained through microorganism soil solidification, the microorganism bacterium liquid and the cementing solution react to generate calcium carbonate so as to solidify the soil around the pile, so that the strength of the soil around the pile is improved, and the discrete material pile is protected against the problems of different pile diameters, bulging damage, pile hole caving and the like; the microorganism solidified soil and the pile can be combined to bear loads, and thus the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

Microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and construction method

ActiveCN105386433AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationMicroorganismAggregate (composite)

The invention discloses a microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and a construction method. The construction method comprises the steps that a, a pile pipe is pressed into a foundation; b, microorganism bacterium liquid is injected into the pile pipe at the same time, and the microorganism bacterium liquid is made to diffuse towards the foundation around the pile pipe; c, the microorganism bacterium liquid is pumped out, and a cementing solution is injected into the pile pipe and made to diffuse to the foundation around the pile pipe and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and incompact sandy soil or floury soil is cemented; d, the step b and the step c are executed repeatedly till the soil around the pile pipe meets the reinforcement requirement; e, pipe-drawing pile formation is conducted while cement-ash stabilized aggregates are poured; and f, a bed course is laid, so that the CFG pile composite foundation is formed. According to the microorganism soil-reinforcement CFG pile, the soil around the pile pipe is reinforced through calcium carbonate generated through reaction between the microorganism bacterium liquid and the cementing solution, so that the strength of the soil around the pile pipe is improved, and the quality problems of necking, pile breakage, soil carrying and the like in the pile forming process are solved; in addition, a reinforced soil body can be combined with a pile for bearing, and the bearing capacity of the single pile is effectively improved.

Owner:NANJING FORESTRY UNIV

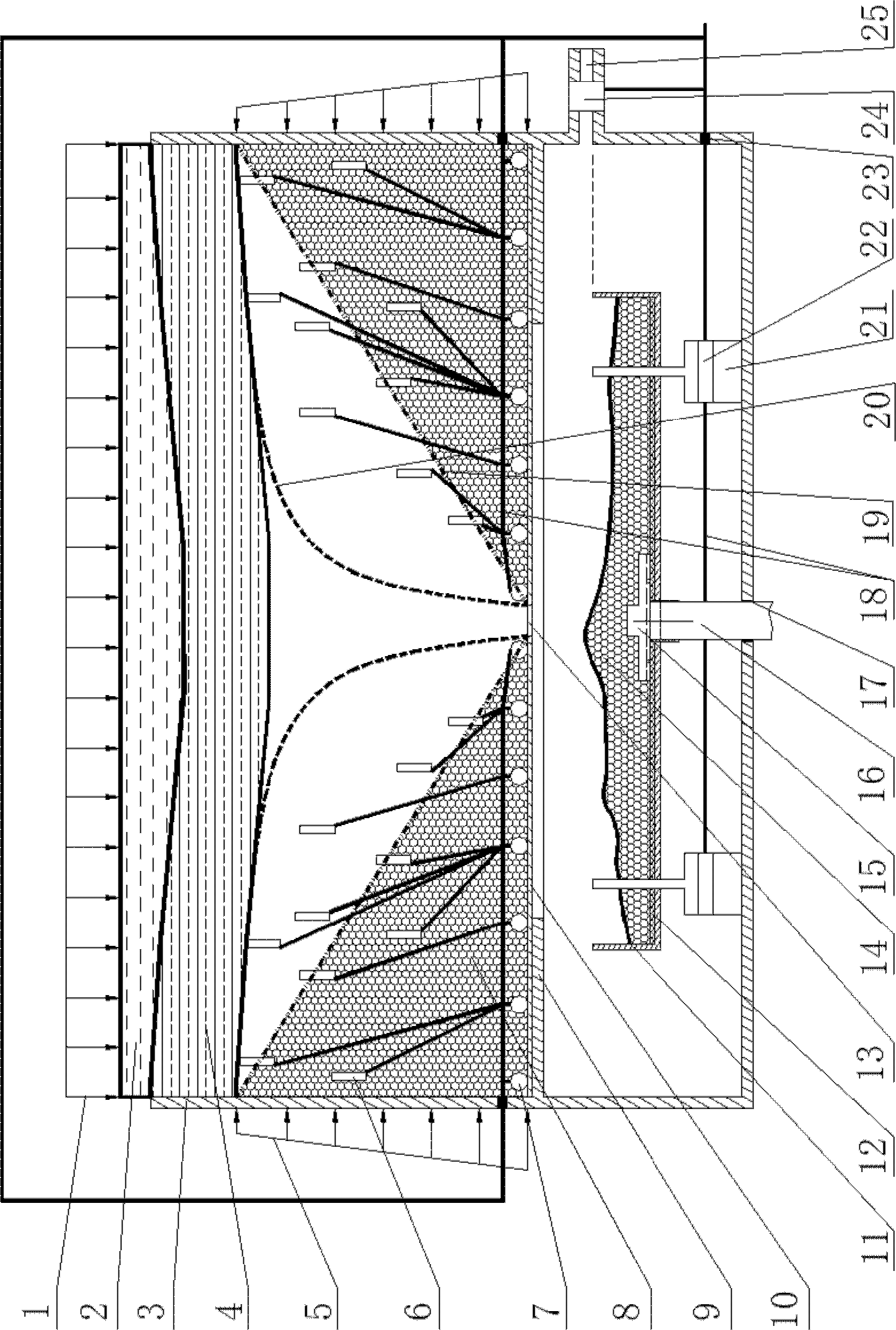

Simulation test device and test method of sand inrush

The invention relates to the technical fields of sandy soil seepage failure and mine hydrogeological test, in particular to a test device and method for monitoring of a sand inrush process induced by mining and related engineering under a simulation test condition. Based on a mine water disaster comprehensive simulation system and test method for automatic mining with high water pressure and high stress (application number: 201010285897.9), the device consists of a variable sand inrush opening and sand stop plug module, a lateral water source replenishment module, a sand inrush process monitoring module and a sand inrush collection and test module, and is characterized in that sand inrush test conditions of different vertical loads, low-seepage cover coats of different thicknesses and characteristics, different initial boundary water heads, dynamically changing cone of depression, different water-containing sand layer thicknesses and grain composition and different sand inrush fracture sizes and gradient monitoring conditions for seepage damage range, sand inrush and water inflow, water head and hydraulic power in a sand inrush process can be provided, and meanwhile sand inrush testing parameters are acquired; the test method is characterized by being an infinite boundary-based water head control and vertical load adjustment and control method, a sand inrush range recognition method and a determination method for weight and volume of the sand inrush and the actual water inflow.

Owner:CHINA UNIV OF MINING & TECH

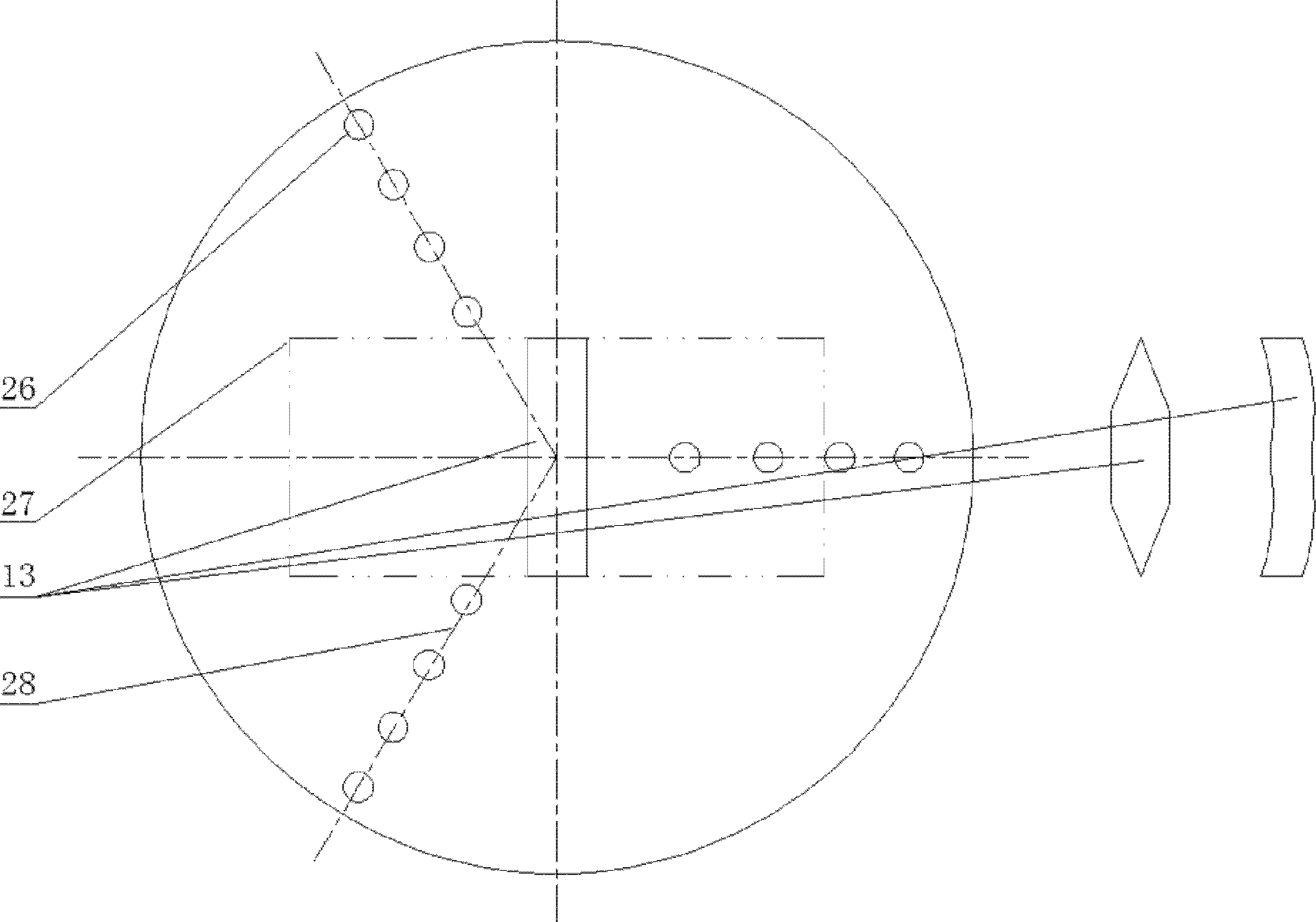

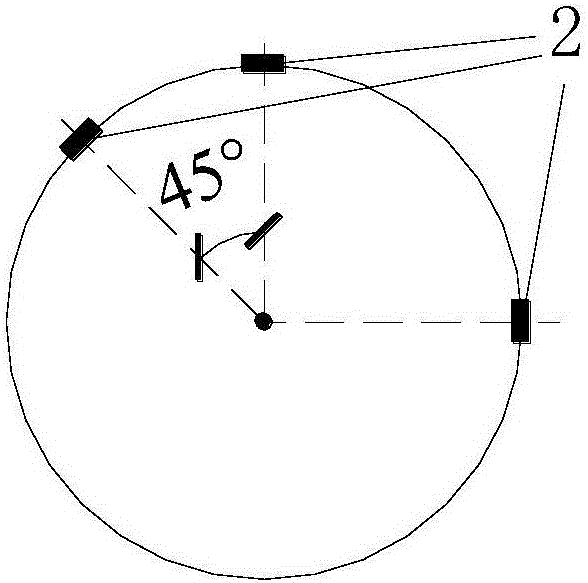

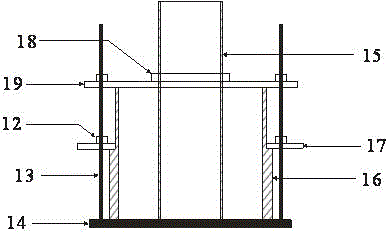

Liquefaction discriminating device and method of pipe piece surrounding saturated sand caused by shield construction

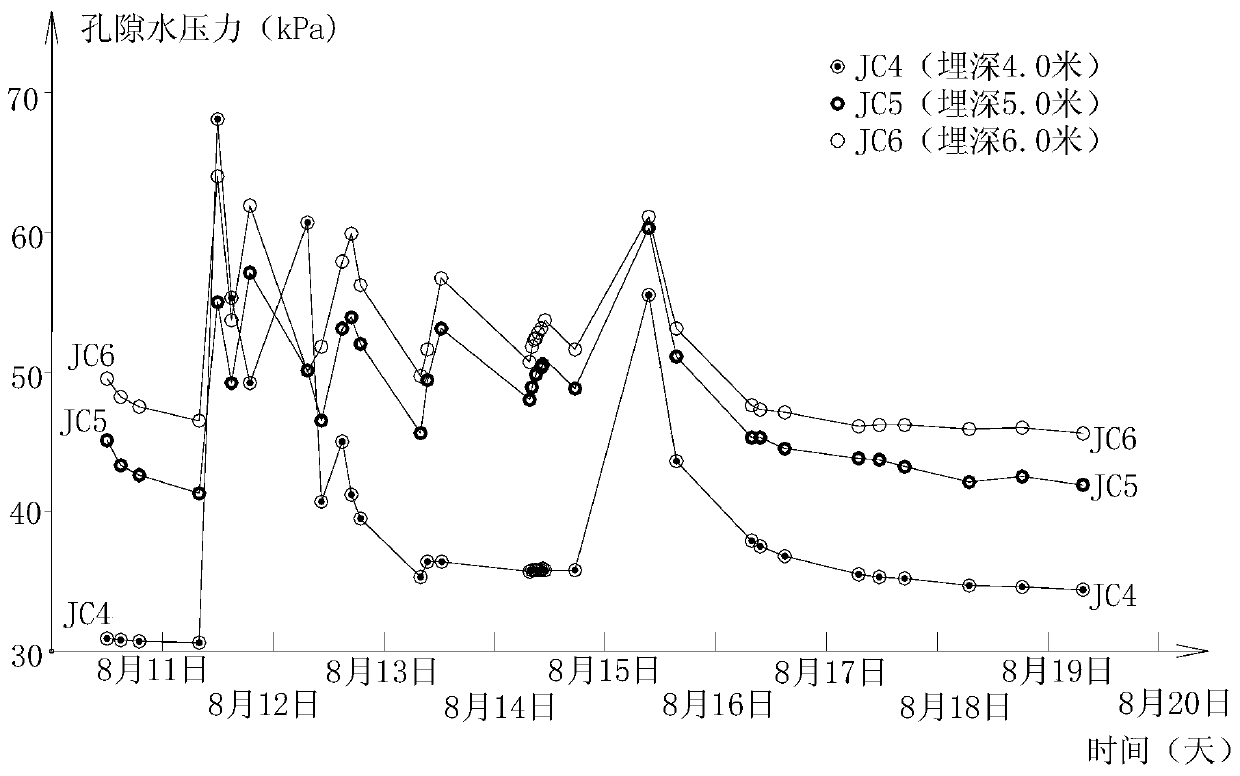

ActiveCN104989411AAdjust in timeAvoid damageUnderground chambersTunnel liningPore water pressureLiquefaction

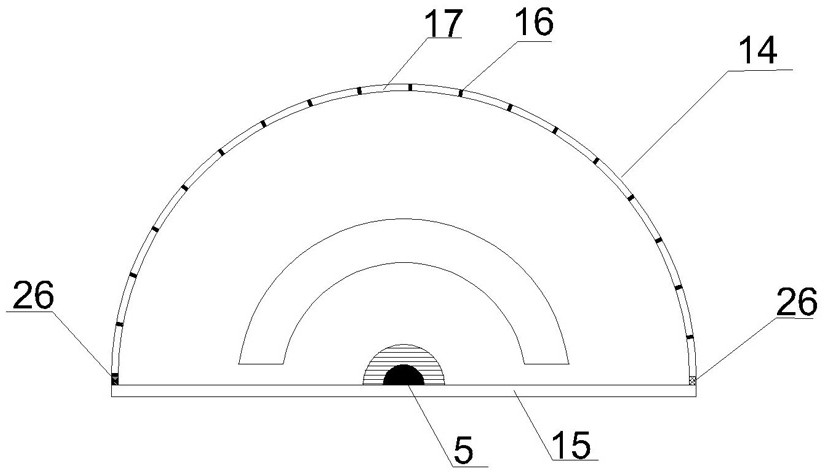

The invention discloses a liquefaction discriminating device and method of pipe piece surrounding saturated sand caused by shield construction. The device is characterized in that a seamless steel pipe embedded part (4) and a T-shaped embedded part (17) which are arranged in a pipe piece (9) in advance are included, one end of the seamless steel pipe embedded part (4) is provided with a seamless steel pipe temporary sealing cover (11) at the outer surface of the pipe piece (9), and the other end of the seamless steel pipe embedded part (4) extends to the inner surface of the pipe piece (9). According to the liquefaction discriminating device and method of pipe piece surrounding saturated sand caused by shield construction, a pore water pressure value and a soil pressure value of pipe piece surrounding sand can be measured effectively and accurately, then, whether the pipe piece surrounding sand caused by shield construction is liquefied is judged, the liquefying degree is judged, and then solutions are carried out to remove liquefying damage.

Owner:HOHAI UNIV

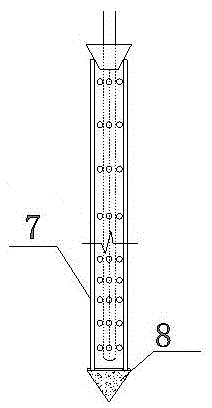

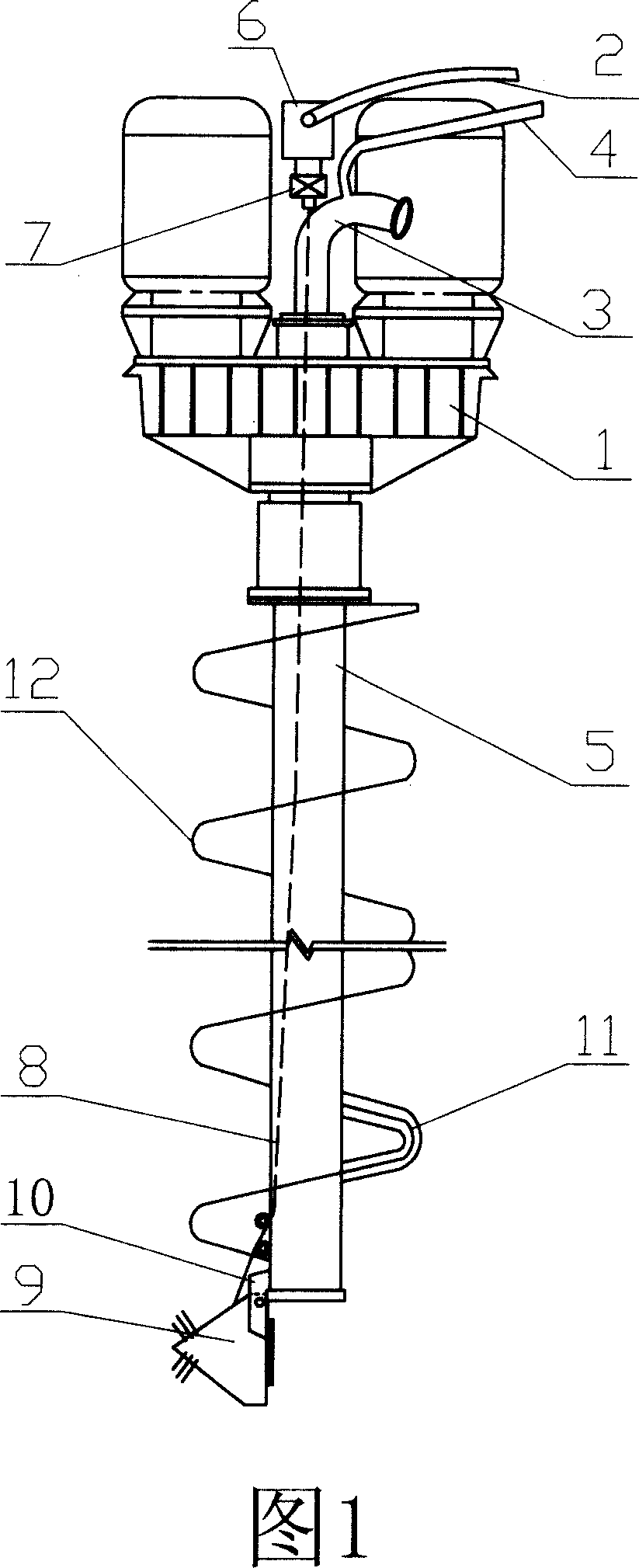

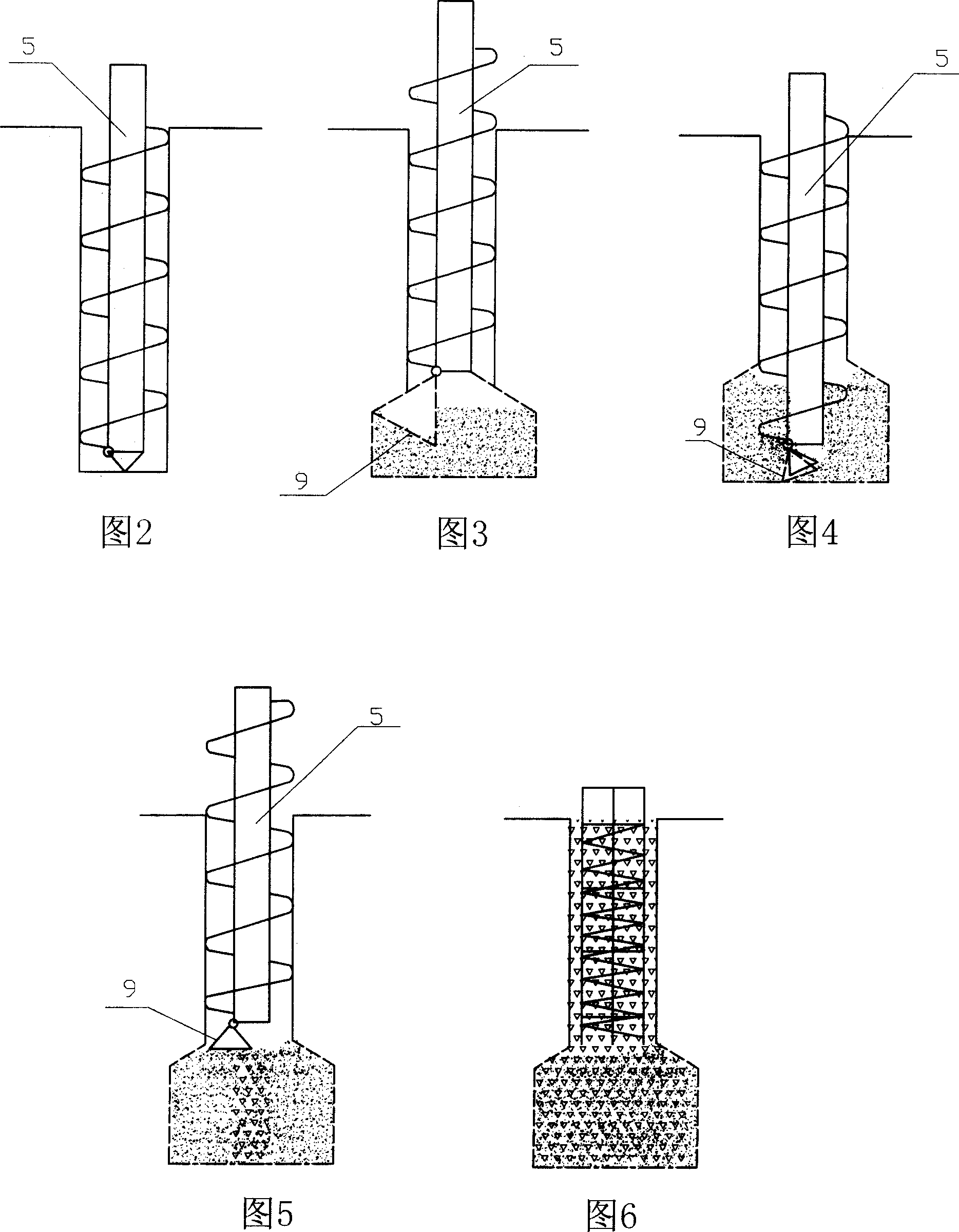

Drilling-hole press-filling-concrete-pulp agitation base-enlarging method and apparatus

ActiveCN1936194AImprove bearing capacityEnlarging the resistance areaEarth drilling toolsBulkheads/pilesHydraulic ramCement slurry

The invention relates to boring pressing filling concrete grouting whisking enlarging base method and the device. While boring, filling cement slurry into the drilling stem core pipe, once reaching the designed depth, starting hydraulic ram on the power unit, pulling steel cable by screw-proof turret head to drive reversal drilling bit, and the diameter of reversing should exceed the designing request of drilling stem diameter, rotating and lifting. When the sand soil layer and cement slurry whisking enlarging base reaches the designed height, retracting the hydraulic ram and stopping whisking, filling concrete and lifting drill in peg. The invention could be used in construction of construction peg base.

Owner:黑龙江东宇基础工程有限公司

Ultralow-density ceramisite sand proppant and preparation method thereof

InactiveCN104592970ASmall bulk densityLow densityFluid removalDrilling compositionSurface finishExpanded clay aggregate

The invention discloses an ultralow-density ceramisite sand proppant and a preparation method thereof. The ultralow-density ceramisite sand proppant is prepared from the following raw materials in percentage by weight: 15-20% of purple clay, 10-15% of silica and 65-75% of raw aluminum ores. The preparation method comprises the following steps: crushing the required raw materials at first, then performing blending and grinding, and putting obtained fine powder into a granulator for granulation; and screening obtained raw granules after granulation, then calcining in a rotary kiln, cooling, and finally screening again to obtain a product. The ceramisite sand proppant prepared by the method disclosed by the invention has the advantages of ultralow volume density, relatively low apparent density, relatively high crushing resistance and good surface finish quality. By using the ultralow-density ceramisite sand proppant disclosed by the invention, the exploitation cost of an oil field can be reduced, and the yield of the oil field can be increased.

Owner:ZHENGZHOU JUYING CERAMSITE SAND

Sample preparation device and sample preparation method for sand-soil contact surface test sample as well as osmotic coefficient determination method

InactiveCN104655468ASolving Permeability Measurement ProblemsLow costPreparing sample for investigationPermeability/surface area analysisTest sampleEngineering

The invention discloses a sample preparation device and a sample preparation method for a sand-soil contact surface test sample as well as an osmotic coefficient determination method. The sample preparation device mainly comprises an outer barrel and an inner barrel which are coaxially arranged; the part between the inner barrel and the outer barrel is filled with sand by layers and is impacted; the inner barrel is slowly upwards lifted to a certain height and then is fixed; a certain amount of clay is weighed and is poured into the inner barrel; the clay is impacted to a pre-set height and then the inner barrel is slowly upwards lifted; the clay is poured and impacted, and the step is repeated for multiple times to reach a pre-set sample height; and the sample preparation device is detached and a test sample is taken out; the sand adhered to the surface of the test sample is slightly brushed off by a soft hairbrush, namely the sand-soil contact surface cylindrical test sample which is tightly filled with the sand at the periphery can be obtained. Then the thickness and the sand content of a sand-soil contact surface are measured by adopting a parallel test. Furthermore, a flexible wall test can be utilized and water in each sand-soil contact surface test sample permeates along two paths of the middle clay and the sand-soil contact surface; and the osmotic coefficient of the sand-soil contact surface can be calculated according to a Darcy law.

Owner:HOHAI UNIV

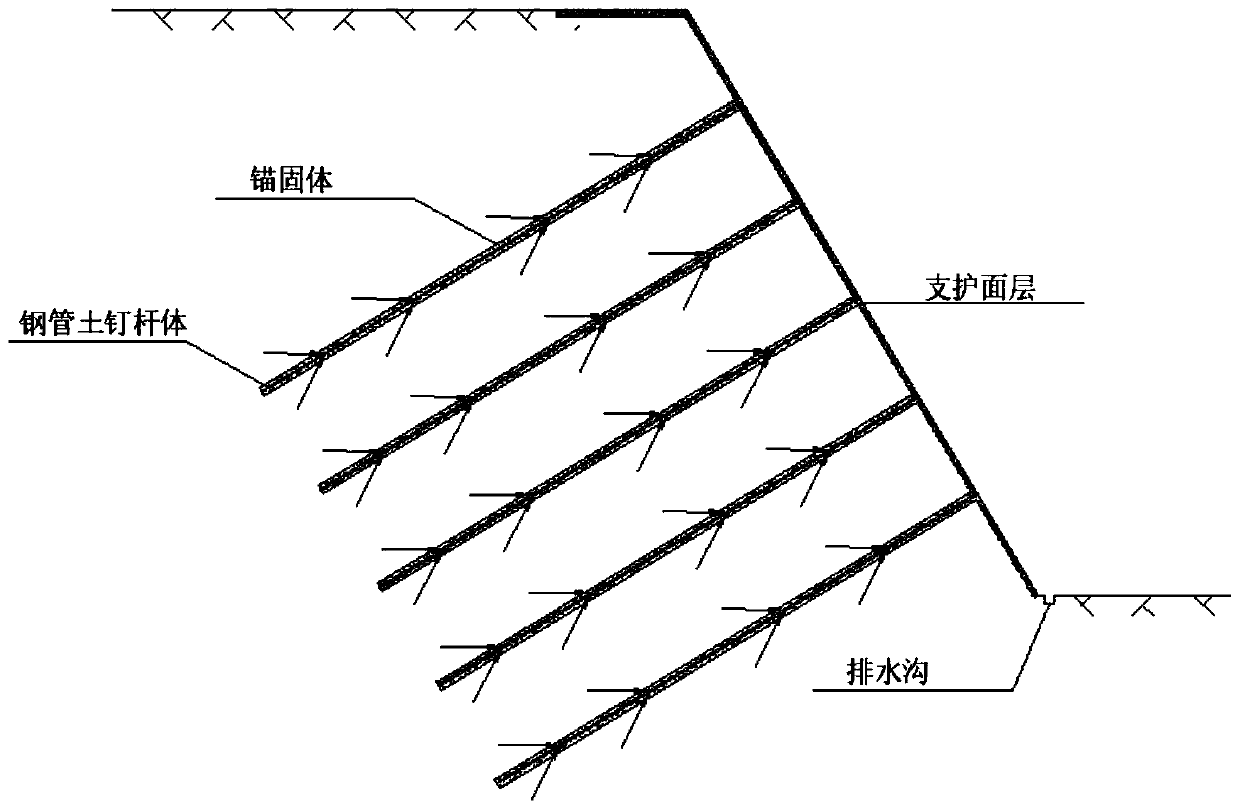

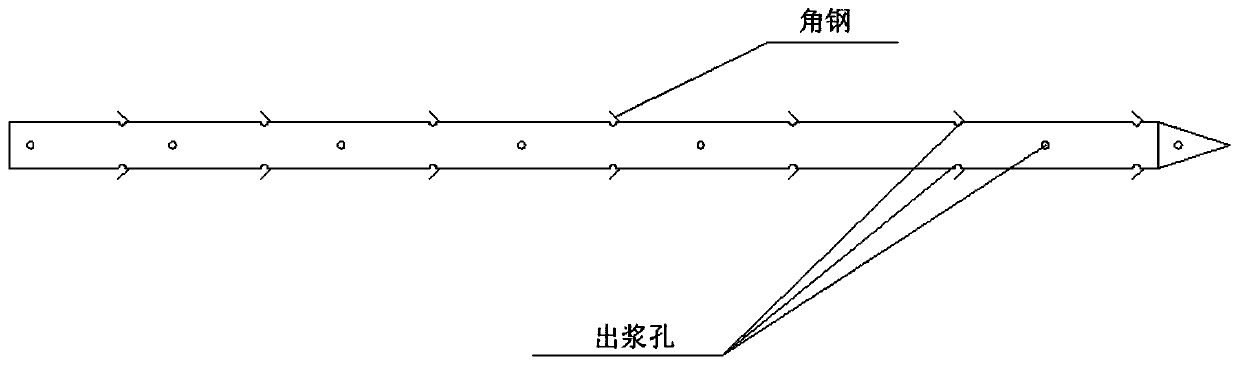

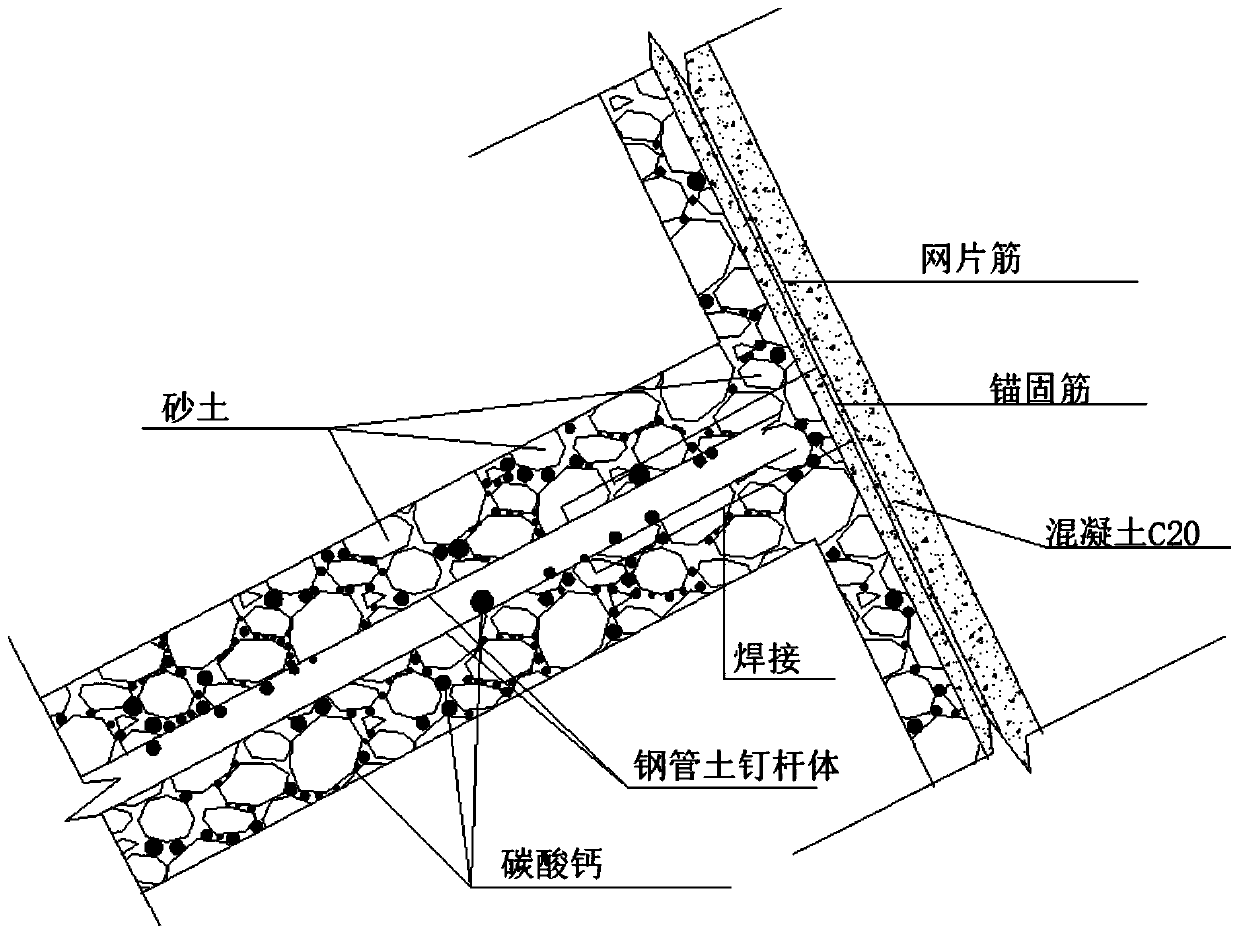

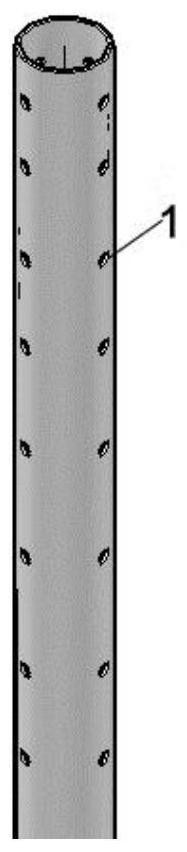

Microorganism curing striking-in type steel pipe soil nail and construction method thereof

InactiveCN110528533AImprove mechanical propertiesImprove integrityExcavationsSoil preservationSoil nailingNutrient solution

The invention discloses a microorganism curing striking-in type steel pipe soil nail and a construction method thereof. The steel pipe soil nail mainly comprises a steel pipe and angle iron. The steelpipe comprises a pipe head and a pipe body. The construction method mainly includes the steps that the steel pipe soil nail is manufactured, and the steel pipe soil nail is struck into mud through apneumatic down-the-hole hammer; sporosarcina pasteurii is activated and subjected to enlarge cultivation, and a microorganism bacterium solution is obtained; the obtained microorganism bacterium solution is injected into the soil nail through the steel pipe soil nail so that the microorganism bacterium solution can be spread in sandy soil; a composite nutrient solution is prepared and includes 0.5mol / L of urea and 0.5 mol / L of calcium salt; the composite nutrient solution is injected into the steel pipe soil nail and a slope face, and an anchoring body is formed; and the above steps are repeated till the strength of the soil nail reaches the design requirement, and the microorganism curing striking-in type steel pipe soil nail is obtained. By means of the microorganism curing striking-intype steel pipe soil nail and the construction method thereof, the sandy soil in the soil nail is cemented through a cementing effect of microorganisms, the mechanical property of a slope soil body isimproved, the integrity and self stability of the slope soil body are improved, and the slope can be more stable.

Owner:GUANGDONG UNIV OF TECH

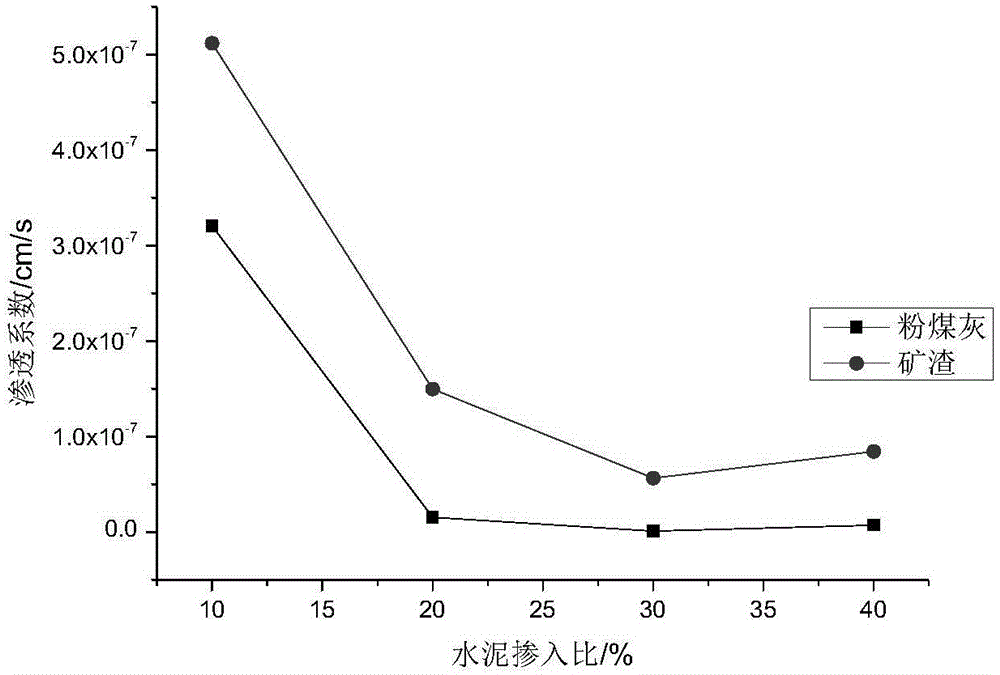

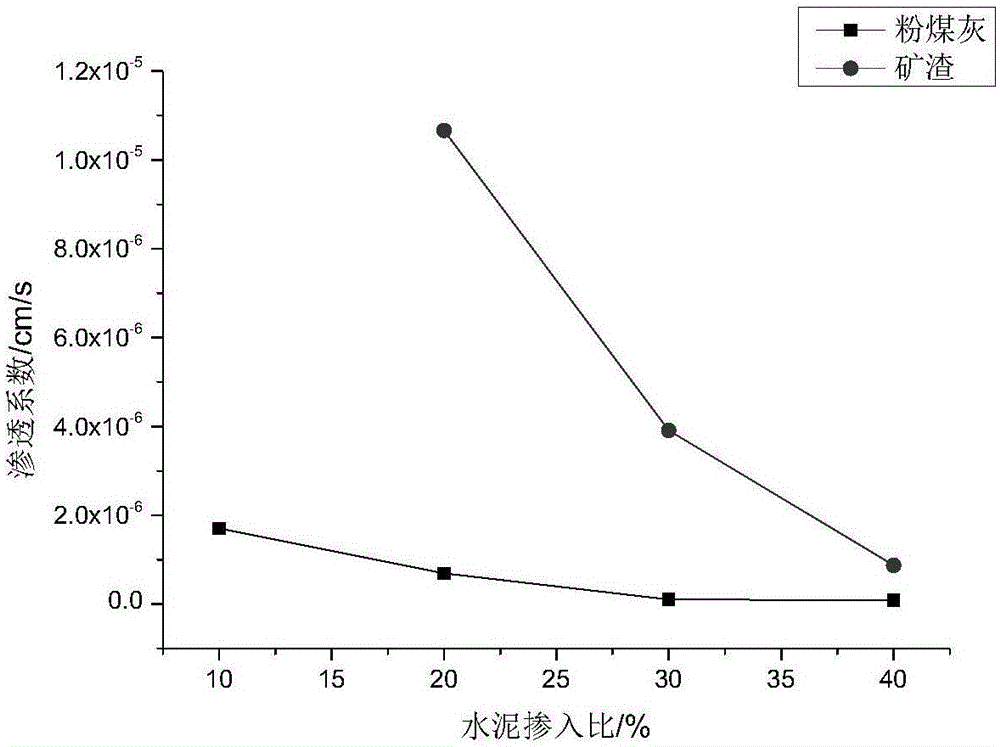

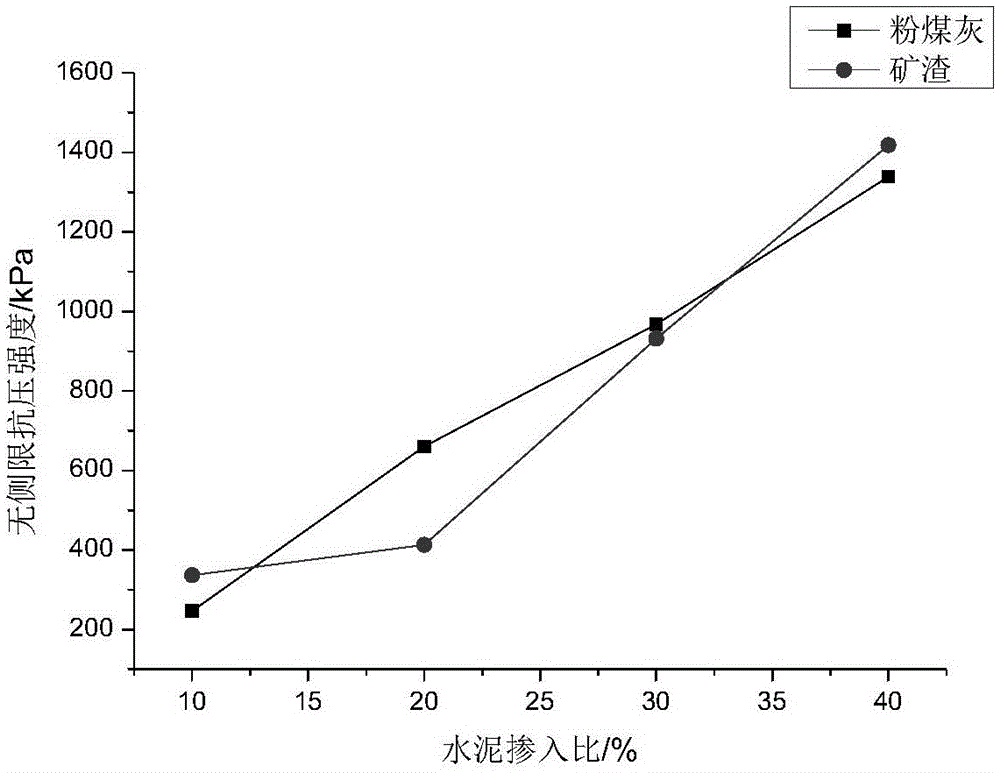

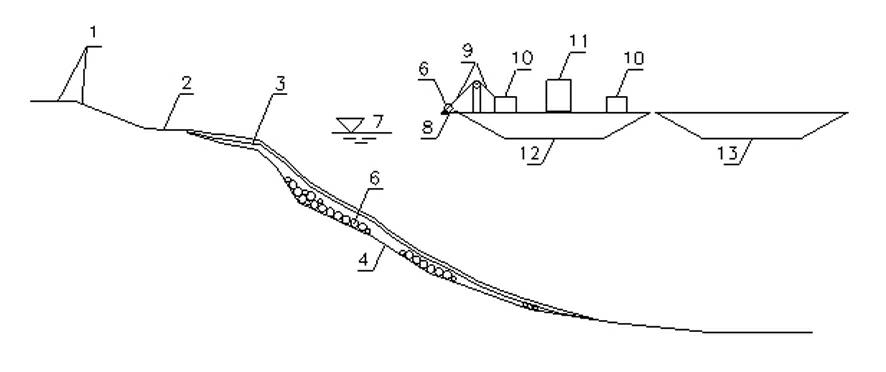

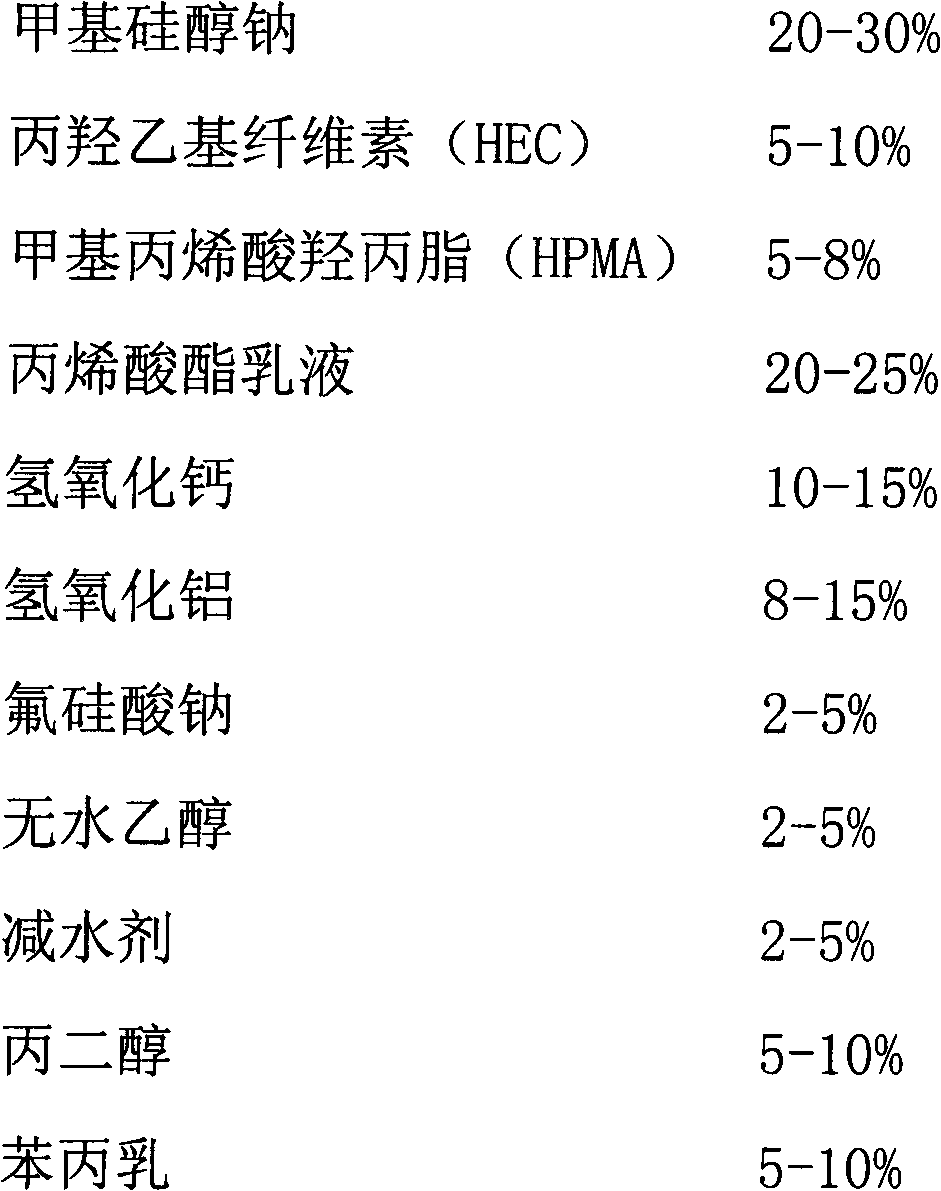

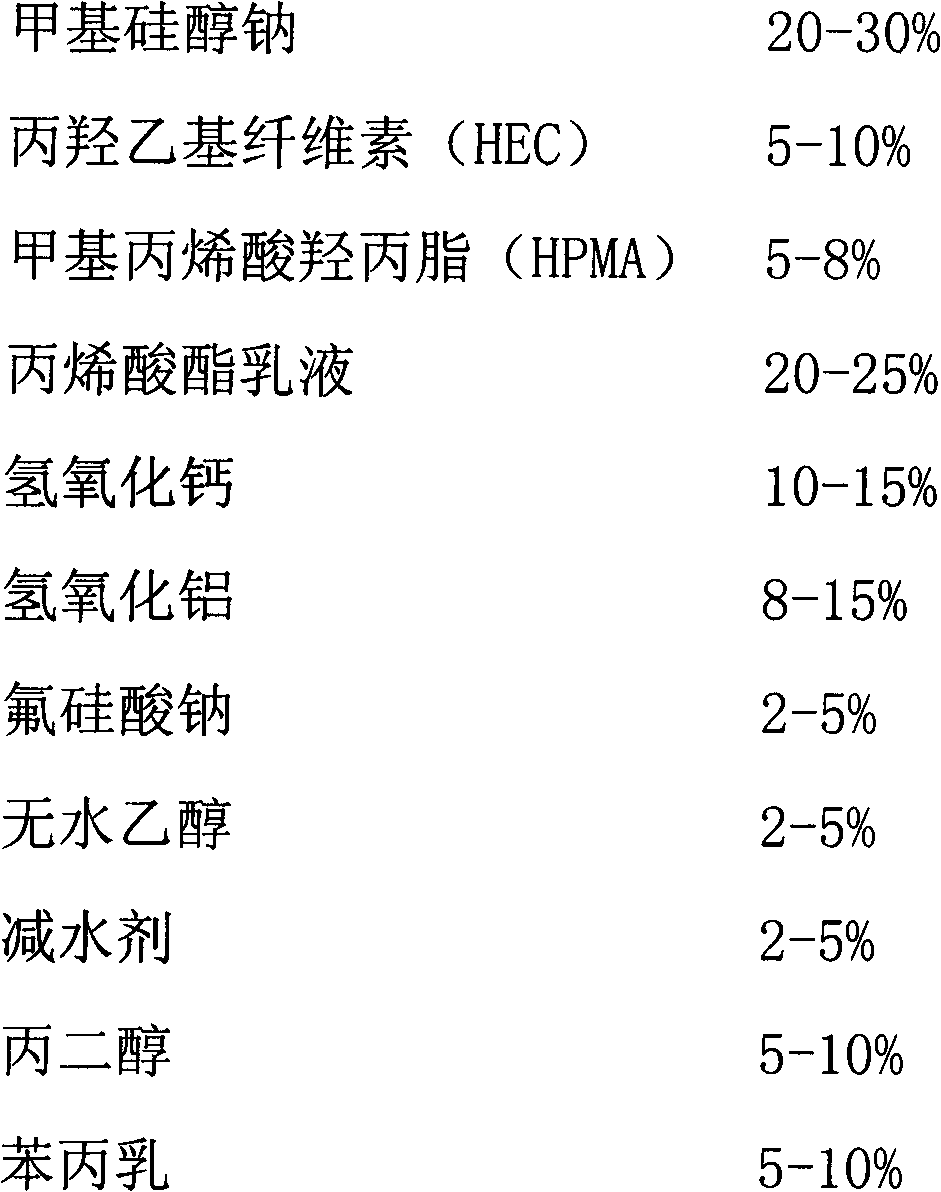

Foundation pit engineering waterproof curtain material based on industrial waste residue

ActiveCN105130349AHigh strengthImprove early strengthSolid waste managementFoundation engineeringSlagReclaimed water

The invention discloses a novel cement soil material, which is prepared with clay / sandy soil and cement as raw materials with addition of industrial waste residue / fly ash or ore slag for replacing a part of cement and can reach the requirement of foundation pit engineering waterproof curtain / equal thickness cement soil mixed continuous wall (TRD). The material includes following components, by mass, 15-25% of water, and the balanced being solids and sodium silicate, wherein the mass of the sodium silicate accounts for 3% of the mass of the solids. The solid is composed of a base material and a curing agent, wherein the base material includes clay or sandy soil and the curing agent is composed of cement, industrial waste residue and quick lime. The mass of the curing agent accounts for 25% of total mass. The industrial waste residue is fly ash or ore slag. In the curing agent, the mass percentage of cement is 10-40%. The mass percentage ratio of the quick lime to the industrial waste residue is 1:10-1:5.

Owner:SOUTHEAST UNIV

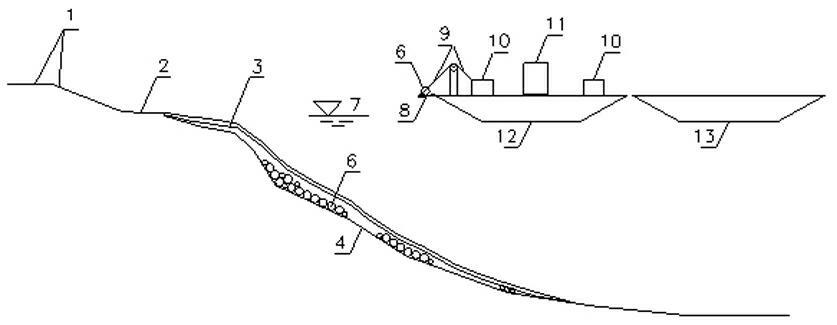

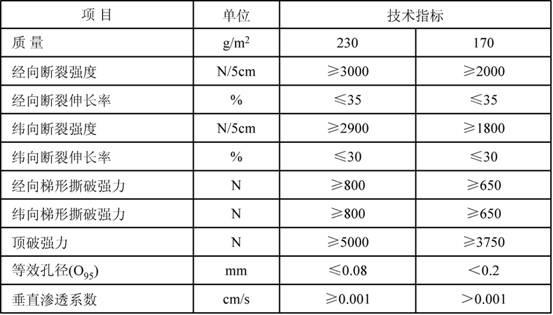

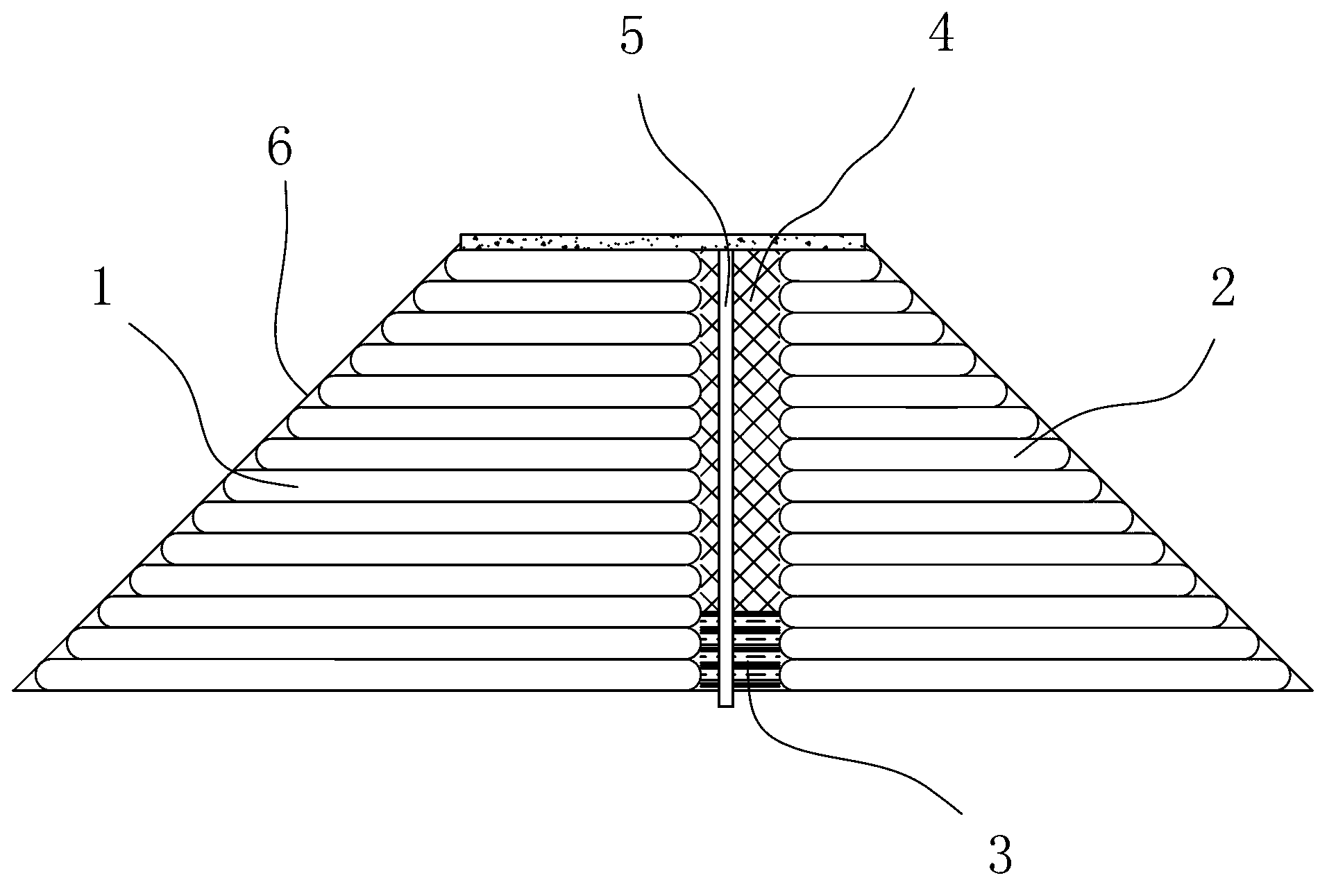

Underwater slope backing method of bulky sand filled geotechnical pillow bags

InactiveCN102162227AImprove stability and securityAvoid slope cuttingCoastlines protectionSoil characteristicsLand acquisition

The invention relates to an underwater slope backing method of bulky sand filled geotechnical pillow bags. The method comprises the following operation steps of: 1, measurement of an underwater bank slope; 2, soil characteristic investigation of the underwater bank slope; 3, technical parameter determination and preparation of the geotechnical pillow bags; and 4, sand filling and sinking of the bulky sand filled geotechnical pillow bags. By the method, slope cutting is avoided, the bank shoal of certain width is reserved, and stability and safety of a river dike can be effectively improved; land acquisition is reduced, and the project investment can be greatly reduced; and the bulky sand filled geotechnical pillow bags have good extension and deformation capacities in the longitudinal and transverse directions, are combined tightly with the underwater irregular bank slope after being laid in place, have large volume, heavy dead weight, good stability and good slope backing treatment effect, and create conditions for wide application of a new composite geotextile software row bank protection technology in river bank collapse treatment projects.

Owner:ANHUI SURVEY & DESIGN INST OF WATER CONSERVANCY & HYDROPOWER

Slurry protection wall construction method with holes formed in cast-in-situ bored pile sand soil layer

The invention discloses a slurry protection wall construction method with holes formed in a cast-in-situ bored pile sand soil layer. The slurry protection wall construction method comprises the following steps: (1) before construction, a slurry pit is dug in advance, and artificial slurry making is conducted, wherein a mortar mixing drum is used for preparing slurry with a water-cement ratio ranging from 0.55 to 0.6, hyper-viscous swelling soil is used as raw materials, industrial alum which accounts for 0.8-1.2% of the hyper-viscous swelling soil in weight is added at the same time, and the specific gravity of the prepared slurry ranges from 1.2 to 1.35; (2) drilling is conducted, and the prepared slurry is pumped by a slurry pump and injected into drilled holes to form circulation so as to protect walls when an ore layer is drilled; (3) after the sand soil layer is drilled, clear water is added to the holes to reduce the specific gravity of the slurry to be within the range of 1.1-1.25 until hole forming is completed. The slurry protection wall construction method with the holes formed in the cast-in-situ bored pile sand soil layer has the advantages that compared with the prior art, the integrality of pile foundations is improved greatly under geological conditions provided with the sand soil layer, and the situation that a drilling bucket is buried or collapse occurs in the holes and other accidents due to poor quality are avoided; the concrete filling coefficient of pile shafts is reduced, and therefore the concrete consumption is reduced.

Owner:ZHENJIANG URBAN & RURAL CONSTR FOUNDENG

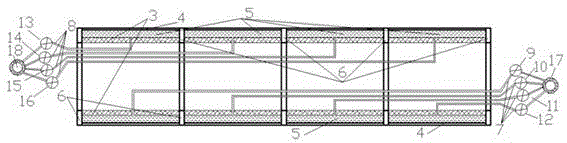

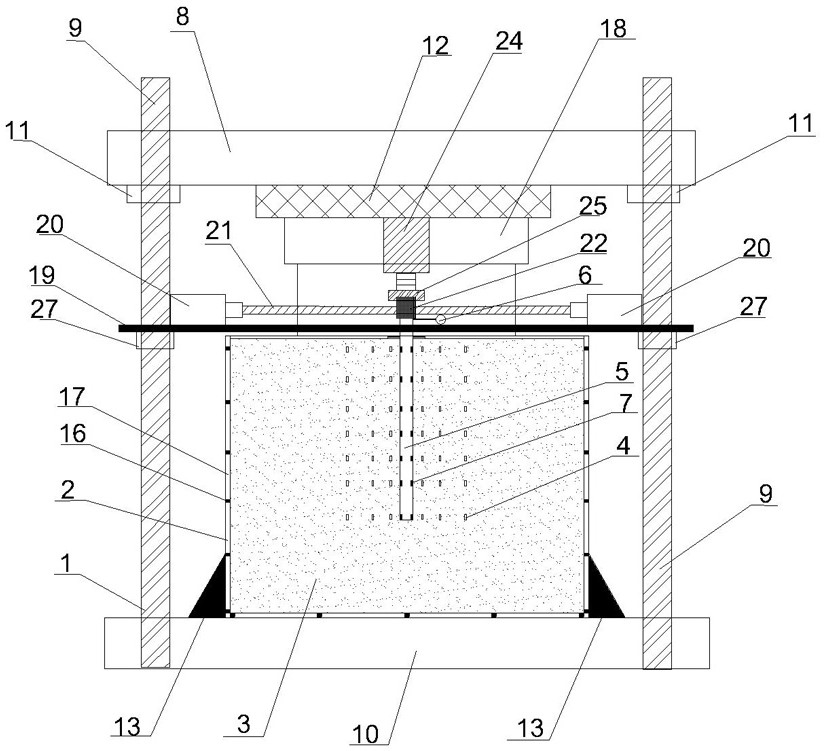

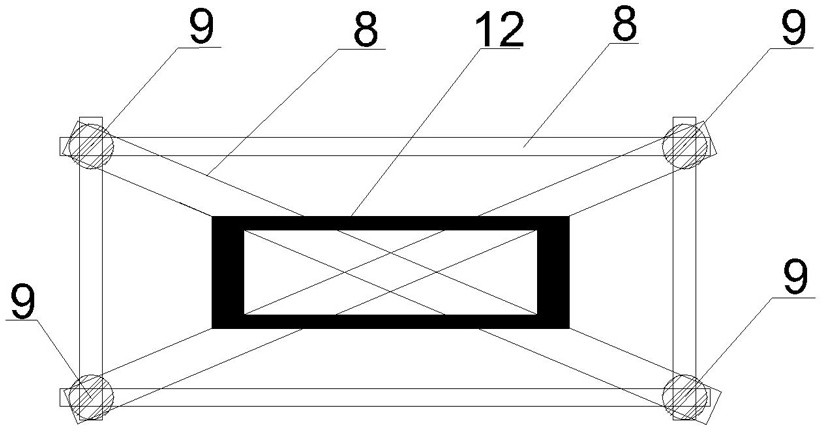

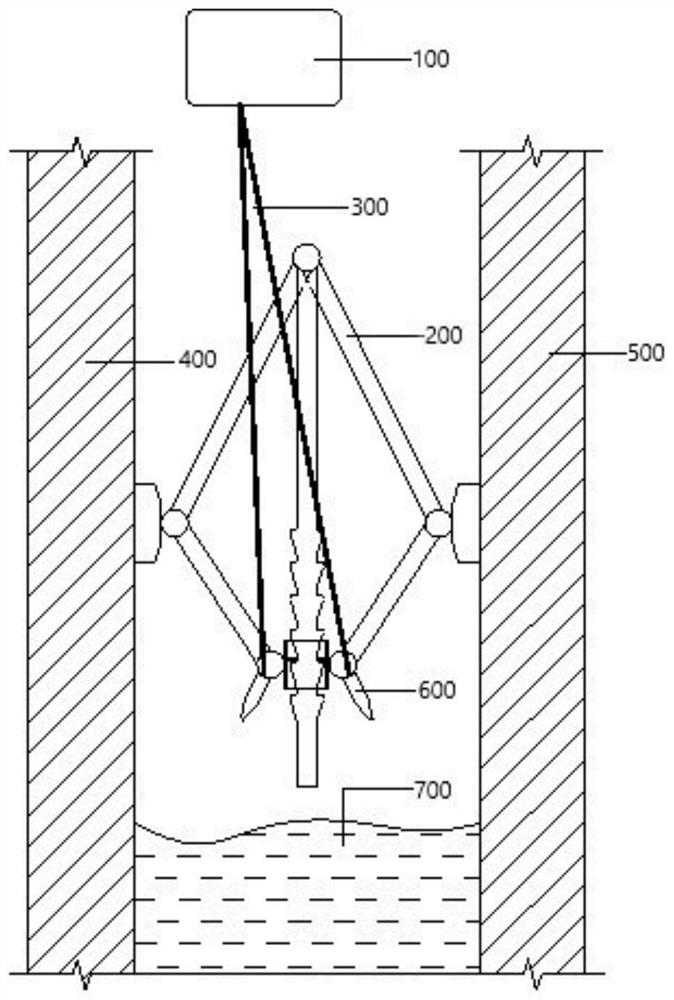

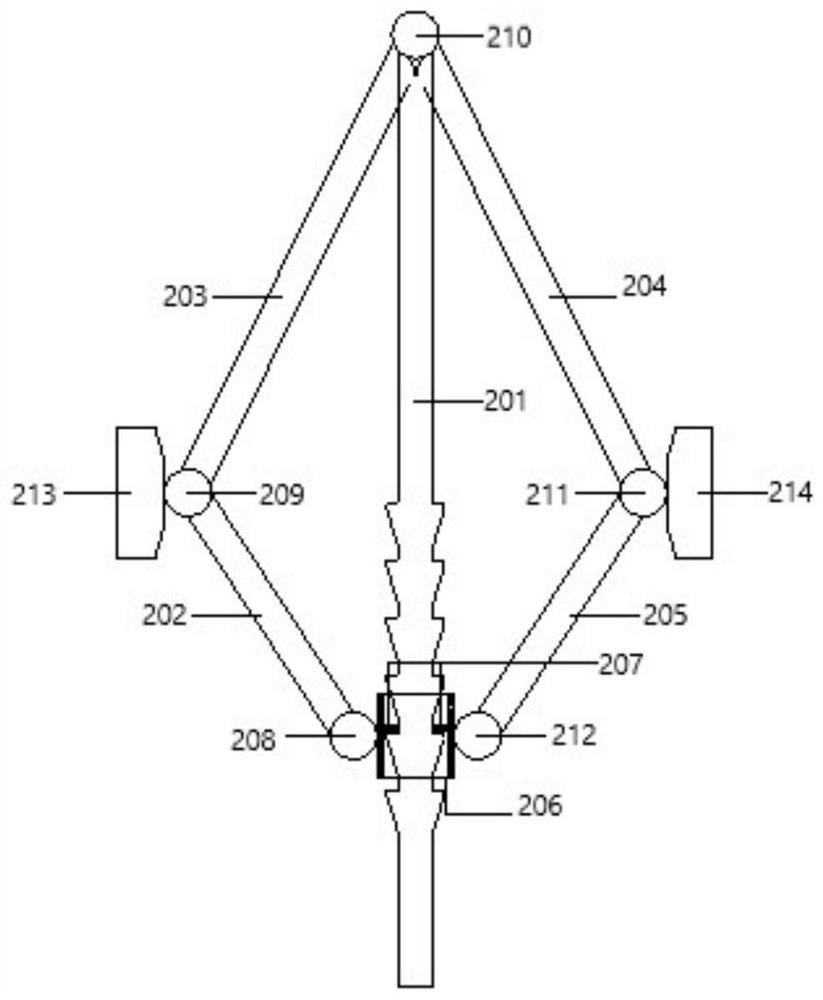

Pile-soil interaction indoor test device under action of combined cyclic load and installation method

PendingCN112160353ARecord Deformation FeaturesFoundation testingBulkheads/pilesSoil scienceSoil properties

The invention discloses a pile-soil interaction indoor test device under the action of a combined cyclic load. The device comprises a counter-force system and a model box; the model box is filled witha soil body and a soil body physical and mechanical parameter acquisition element; a loading system is arranged on the counter-force system; the loading system is located above the model box and corresponds to the model box; the end face, facing the loading system, of the model box is an open end; one end of a model pile is installed on the loading system; the model pile is inserted into the soilbody and is placed in the model box; a plurality of physical and mechanical state acquisition elements are arranged in a pile body of the model pile; a horizontal displacement meter is arranged at the top of the model pile; the loading system comprises a soil body overlying pressure loading system, a horizontal loading system and a pile vertical load loading system; the horizontal loading systemhas horizontal cyclic force loading and continuous force loading functions; and the pile vertical load loading system has a function of applying vertical load to the model pile. The test device can show the response and interaction rules of the pile and the soil body under the combined action of horizontal cyclic and vertical load, and can carry out pile-soil interaction tests of soil properties (including sandy soil and clay) in different initial stress states and different pile foundation forms under different combined loads; and therefore, the bearing performance of the pile, the response rule of the soil body and the like can be detected, and the deformation characteristics of the pile and the soil body in the test process can be visually recorded.

Owner:WENZHOU UNIVERSITY

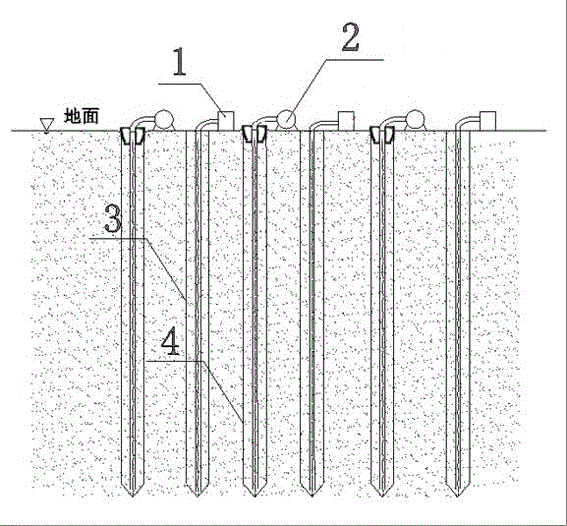

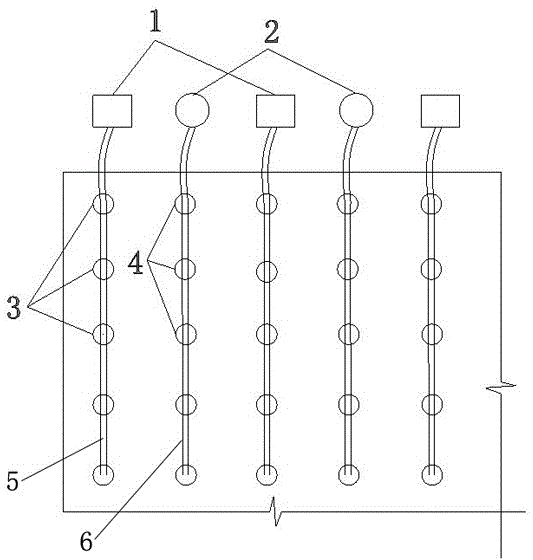

Soil body reinforcement device and reinforcement method for pipe jacking construction in sand soil foundation

InactiveCN105951708AEasy to installShort construction periodSoil preservationMicroorganismWater storage

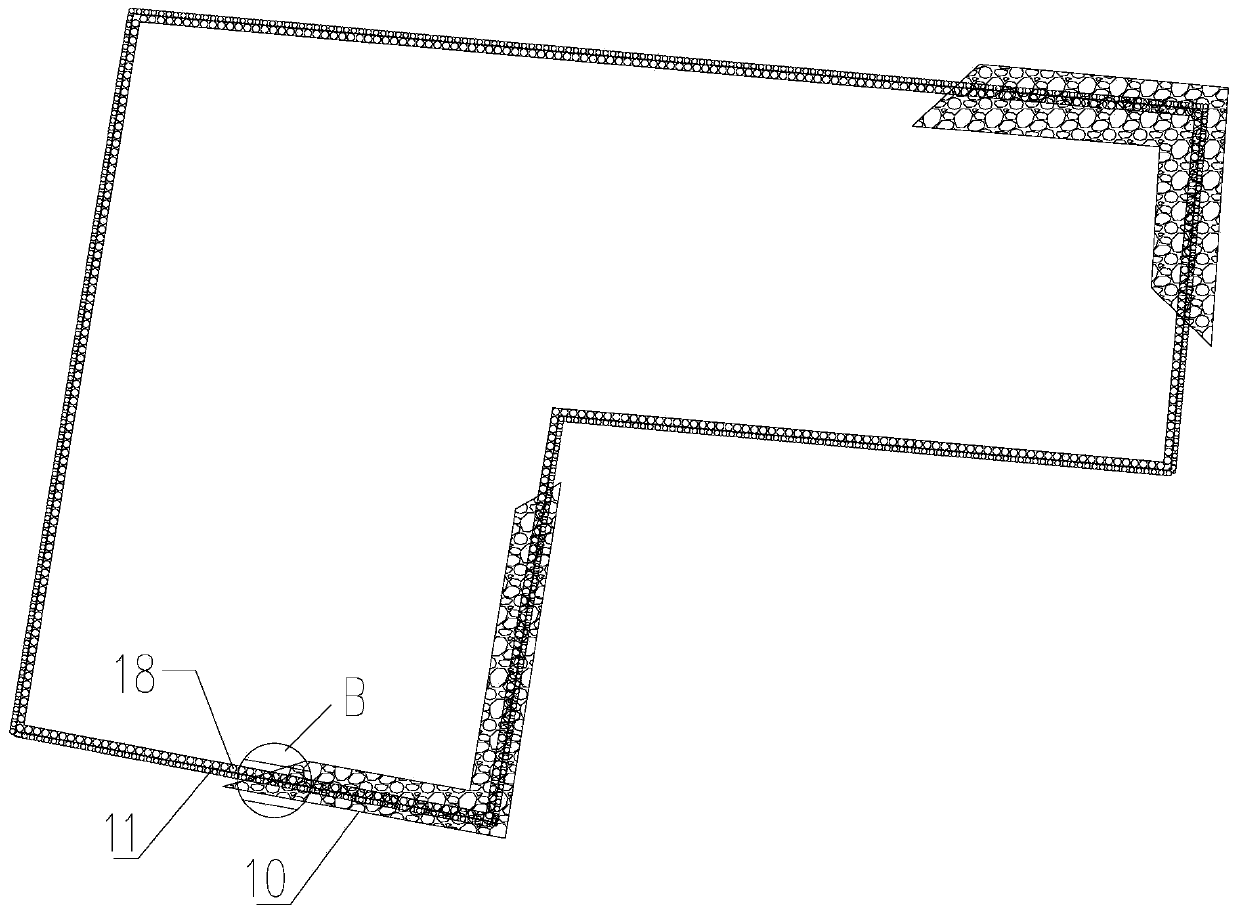

The invention discloses a soil body reinforcement device for pipe jacking construction in a sand soil foundation. The reinforcement device comprises a water injection pool, a water injection pump, a primary water injection guide pipe, water injection through pipes, secondary water injection guide pipes, water injection wells, water pumping wells, secondary water pumping and water collecting guide pipes, water pumping and water collecting through pipes, a primary water pumping and water collecting guide pipe, a water pumping pump and a water storage pool, wherein the water injection wells and the water pumping wells are positioned in the sand soil foundation; microorganism consolidation fluid is contained in the water injection pool; a water outlet of the water injection pool is connected with a water inlet of the water injection pump through a pipeline; a water outlet of the water injection pump is connected with a water inlet of each water injection well through a water injection pipeline assembly; a water outlet of each water pumping well is connected with a water inlet of the water pumping pump through a water pumping pipeline assembly; and a water outlet of the water pumping pump is connected with a water inlet of the water storage pool through a pipeline. A reinforcement method has the advantages that the strength stability of the sand soil foundation can be effectively improved; the operation is convenient; the influence on surrounding environment is small; the efficiency is high; and the reinforcement treatment cost of the sand soil foundation can be greatly reduced.

Owner:SOUTHEAST UNIV

Agitation pile water stopping curtain for reclamation deep and thick block stone area and construction method thereof

The inventio provides an agitation pile water stopping curtain for a reclamation deep and thick block stone area and a construction method thereof. The construction method of the agitation pile waterstopping curtain for the reclamation deep and thick block stone area includes following steps: (1) performing agitation pile reinforcement on a soil layer above a block stone layer in a block stone containing area in the axial direction of a foundation pit support; (2) using a rotary drilling rig for performing drilling hole leading construction on the block stone layer after completing the reinforcement; (3) performing clay backfilling on the hole leading construction area of the rotary drilling rig; and (4) performing construction of the agitation pile water stopping curtain on the block stone area after being completely treated. The agitation pile water stopping curtain for the reclamation deep and thick block stone area and the construction method thereof can complete the groove segment division drilling hole leading construction by reinforcing the soil layer above the block stone area, can backfill drill holes with clayey soil or sandy soil, and then perform the routine construction of the agitation pile water stopping curtain, and solve the problem that the agitation pile water stopping curtain cannot be constructed on the soil layer containing block stone.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

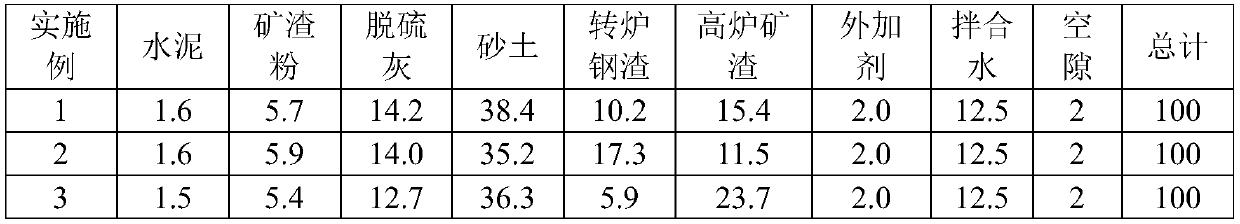

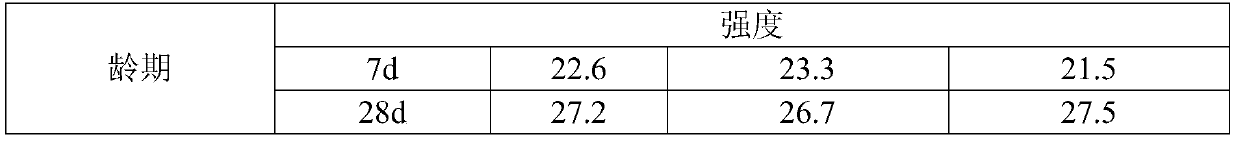

Low-clinker high-impermeability field floor hardening material based on dry process desulfurized fly ash

The invention discloses a low-clinker high-impermeability field floor hardening material based on dry process desulfurized fly ash. The material comprises, by volume, 10-40 parts of blast furnace slag, 5-45 parts of converter steel slag, 0.1-40 parts of sandy soil, 5-20 parts of sintered desulfurized ash, 5-8 parts of slag powder, 1-2 parts of cement, 0.1-2 parts of an additive and 12-13 parts ofwater. Batching, stirring, paving, rolling and curing construction are carried out in sequence on the components, thus obtaining the low-clinker high-impermeability field floor hardening material. Theinvention adopts blast furnace slag, converter steel slag, sintered desulfurized ash and sandy soil as the main raw materials, and takes an appropriate amount of slag powder and a small amount of cement as the auxiliary materials, the obtained field floor hardening material has a strength grade up to C10-C25, and can replace low-strength grade concrete for application to floors of factories and mines, storage yards and construction sites and roadbases.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Microorganism grouting drainage solidification pile and construction method and application thereof

The invention relates to the technical field of foundation reinforcement, in particular to a microorganism grouting drainage solidification pile and a construction method and application thereof. A gravel sand pile is obtained through a vibration pipe sinking pile forming method; and a microorganism bacteria solution and a nutrient solution are injected into the gravel sand pile, precipitation ofcalcium carbonate is induced through microorganisms to solidify gravel and sand into a pile, and cementing and solidifying are carried out on a foundation around the pile to obtain the microorganism grouting drainage solidification pile. According to the microorganism grouting drainage solidification pile, the microorganism induced calcium carbonate precipitation technology is utilized, and generated calcium carbonate, gravel and sand are solidified into the pile through the bonding effect of microorganisms; and on one hand, the bearing capacity of the pile is improved, on the other hand, calcium carbonate generated by microorganisms is cemented with gravel and sand, but does not fill pores among sand particles, the pile maintains excellent drainage performance, and is economical and environment-friendly, materials are convenient to take, and the manufacturing cost is low.

Owner:GUANGDONG UNIV OF TECH

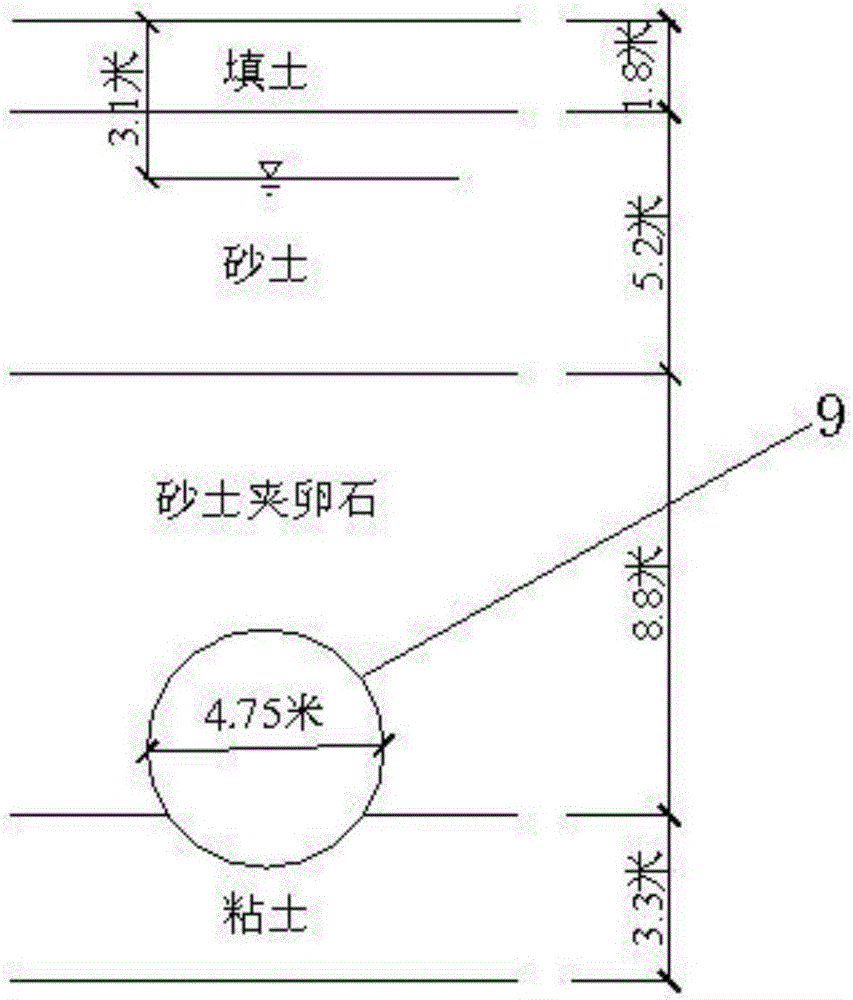

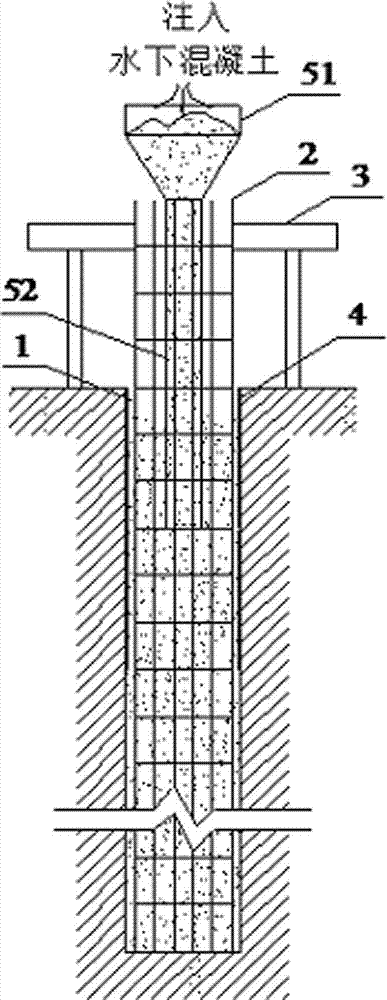

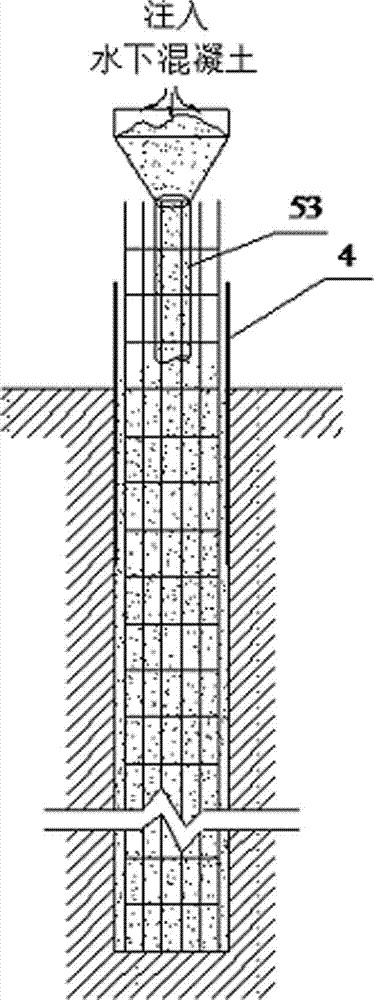

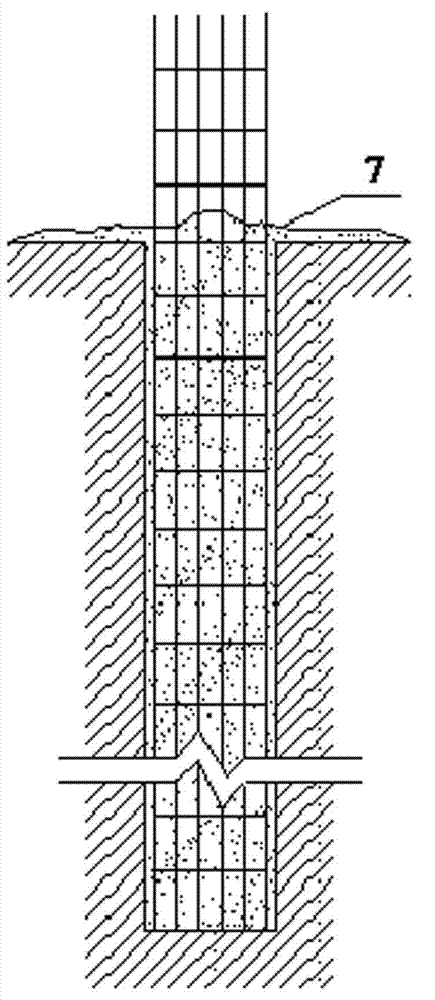

Underground and overground continuous construction method for major-diameter high flat bed pile in sandy soil stratum

ActiveCN103541352AAvoid Weak Structural SurfacesGuarantee the pile qualityBulkheads/pilesDrill holeBuilding construction

An underground and overground continuous construction method for a major-diameter high flat bed pile in a sandy soil stratum comprises the following steps: (I) a hole is drilled and cleaned, steel reinforcement cages and a grouting guide pipe are placed, and underwater concrete is poured; (II) an upper earlier stage construction platform and the grouting guide pipe are removed, a pile casing is pulled upwards slowly, and pouring is suspended when the concrete pouring height is 30-50cm above the ground; (III) the pile casing is pulled out slowly, and a grouting funnel is removed; (IV) concrete 5m below an orifice is vibrated, remaining concrete and slurry around the drilled hole are cleaned up, and sand and sand bags are piled up at the bottom of a steel formwork in a filling mode; (V) overground concrete is poured and vibrated repeatedly through a vibrating spear, and pouring of the overground concrete is stopped when the surface of the overground concrete exceeds a certain height; (VI) secondary vibrating is conducted within 30 minutes before initial setting of the overground concrete; form stripping is conducted 24 hours later, and maintenance is conducted. According to the underground and overground continuous construction method for the major-diameter high flat bed pile in the sandy soil stratum, the construction steps are reasonable in design, construction is convenient, cost is low, the construction period is short, and construction quality is controllable; the high flat bed pile after construction has the advantages that the connection position continuity of a pile body is good, so that the pile body is free of leakage, and pile quality is high.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Auxiliary pile sinking device for prefabricated hollow pile

ActiveCN112982407AFix fixAddressing Adaptive IssuesBulkheads/pilesStructural engineeringHigh pressure water

The invention discloses an auxiliary pile sinking device for a prefabricated hollow pile. The device is composed of a booster pump, a water pipe, a nozzle and a fixing frame. The fixing frame is installed on the inner wall, close to the pile bottom, of the prefabricated hollow pile. The nozzle is installed on the fixing frame. The nozzle and the booster pump are connected through the water pipe. During implementation, after water is pressurized through the booster pump, the water is connected with the nozzle fixed to the fixing frame through the water pipe and sprayed out through the nozzle to be sprayed to pile bottom soil, pile sinking resistance is reduced after the pile bottom soil is softened and liquefied by high-pressure water, and sinking of the prefabricated hollow pile can be accelerated. The problems that the prefabricated hollow pile is difficult to sink in sandy soil and hard clay soil layers, and the construction efficiency is low can be effectively solved.

Owner:江苏诚晖工程技术有限公司

Stepwise repeated destabilization and stabilization of highly collapsible soil mass by 'soil nailing technique' used for construction of railway/road underpass

ActiveUS20150197895A1Prevention of sudden collapseInexpensively and safely constructionRoadwaysProtective foundationSoil nailingInstability

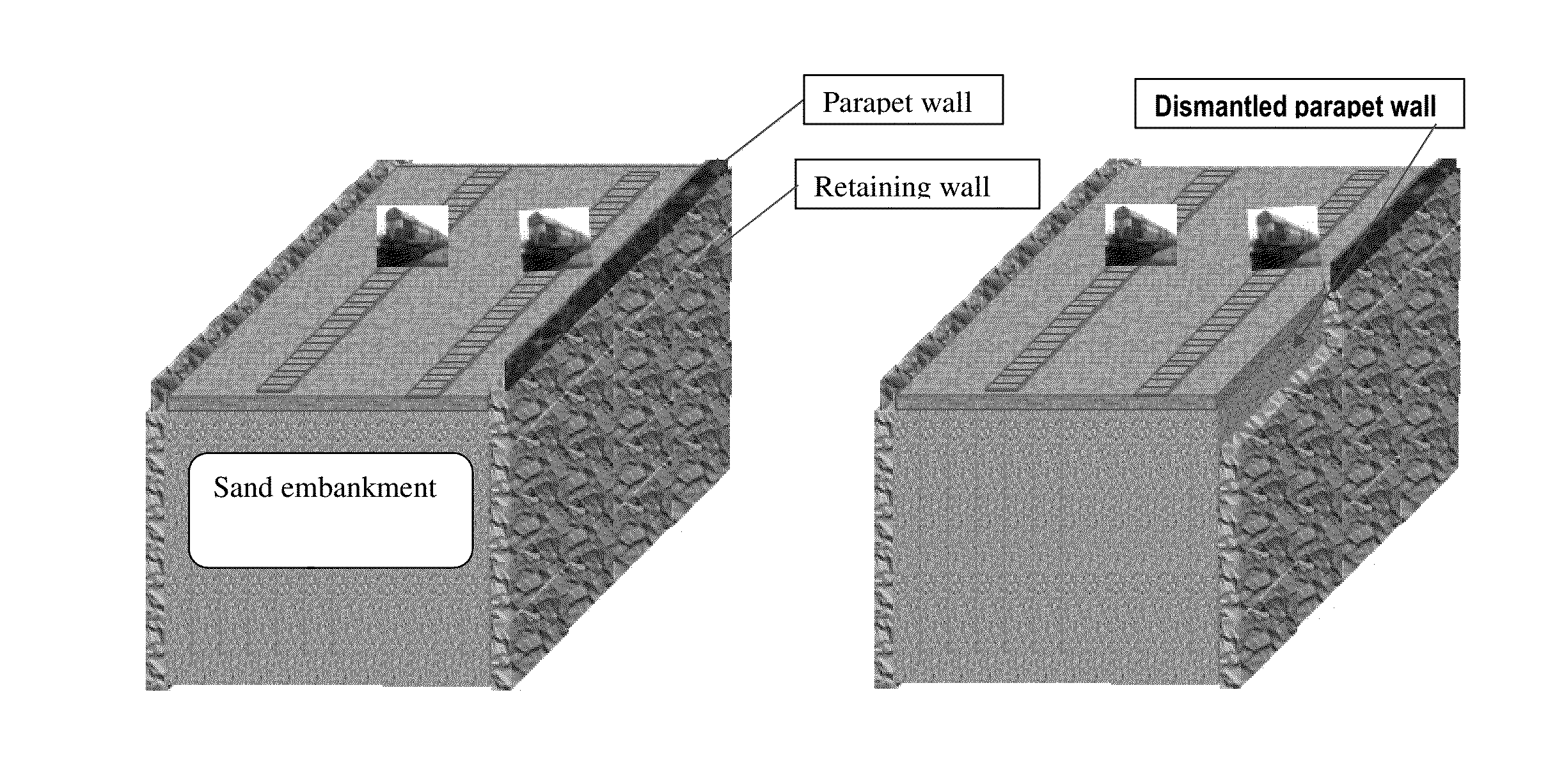

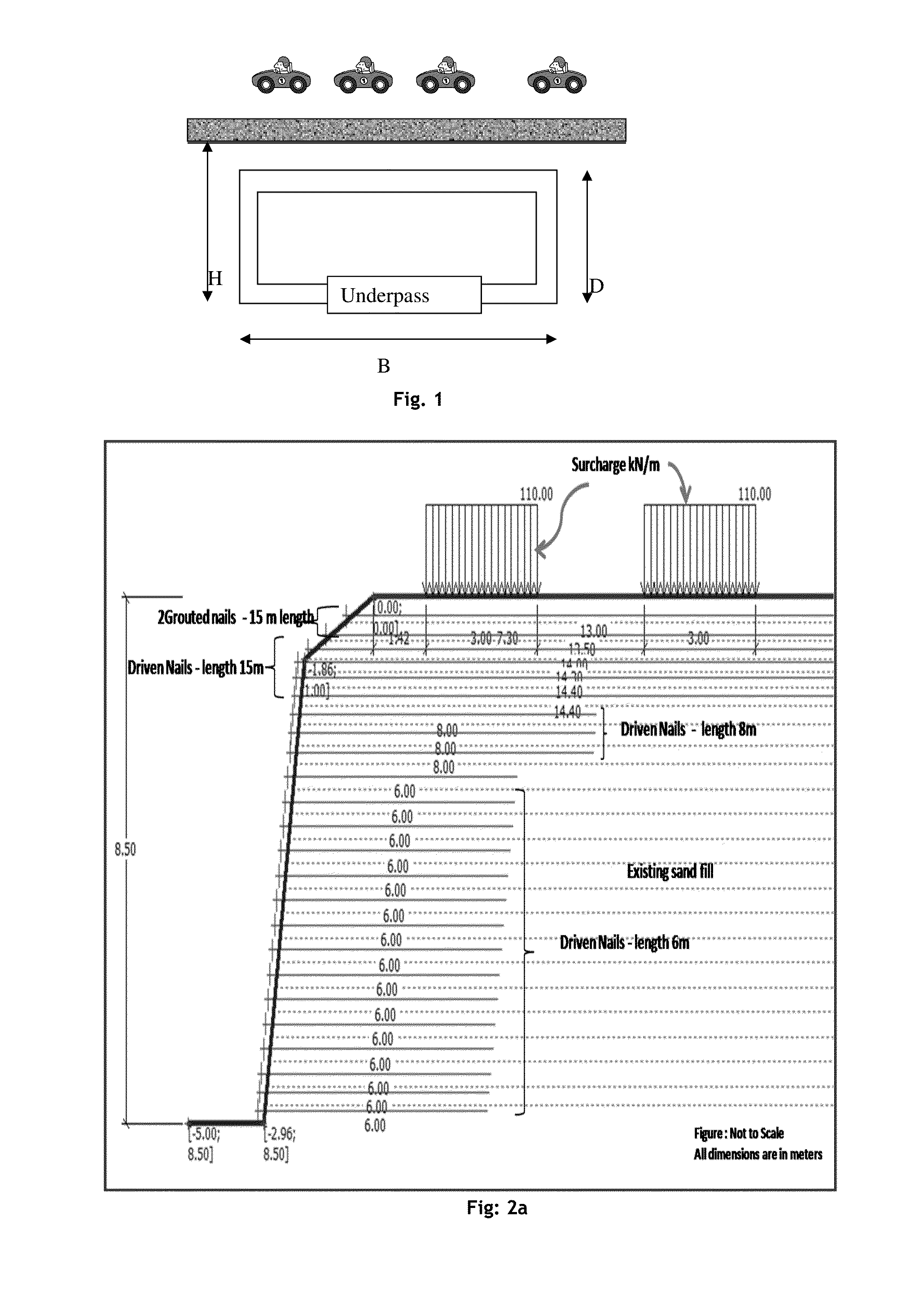

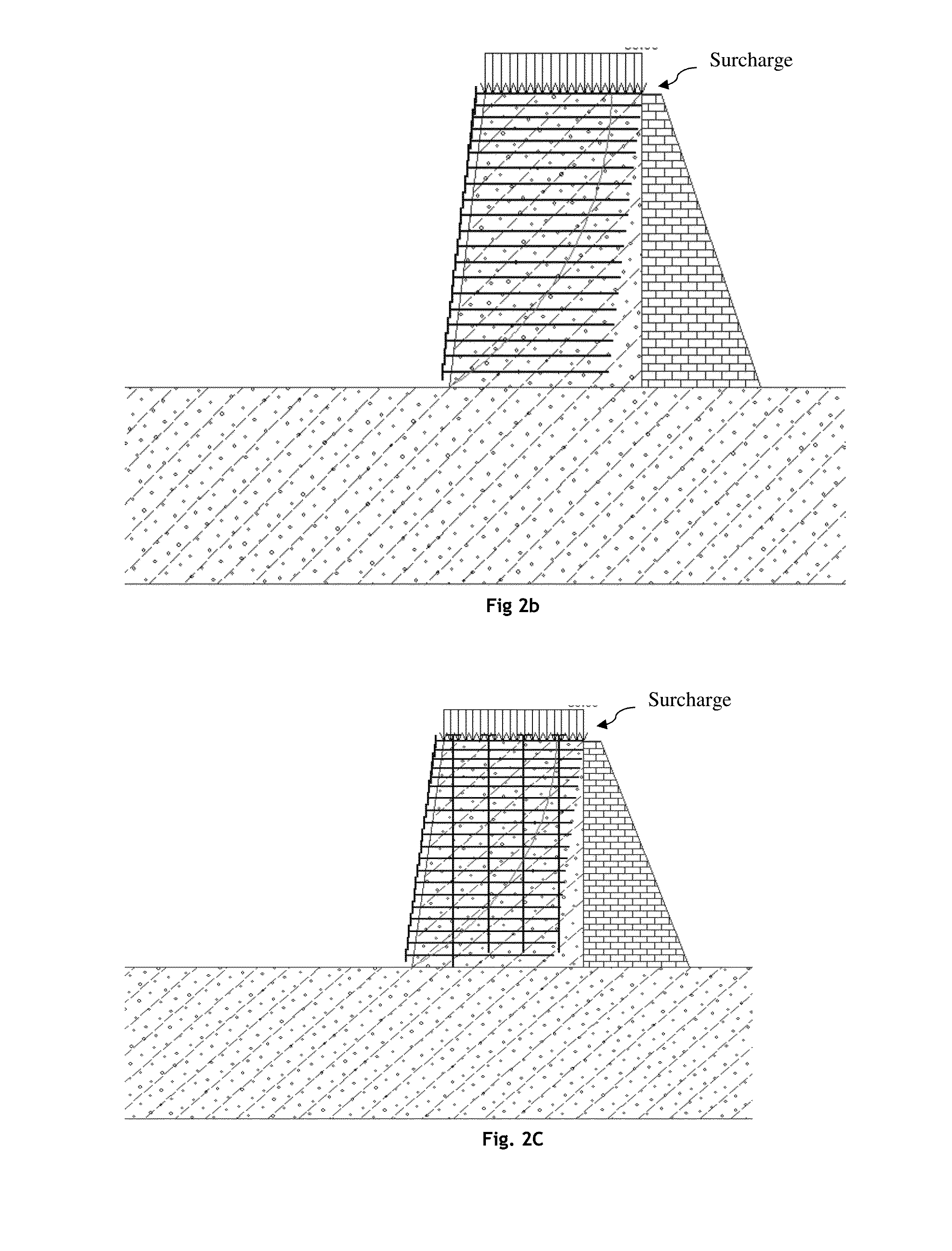

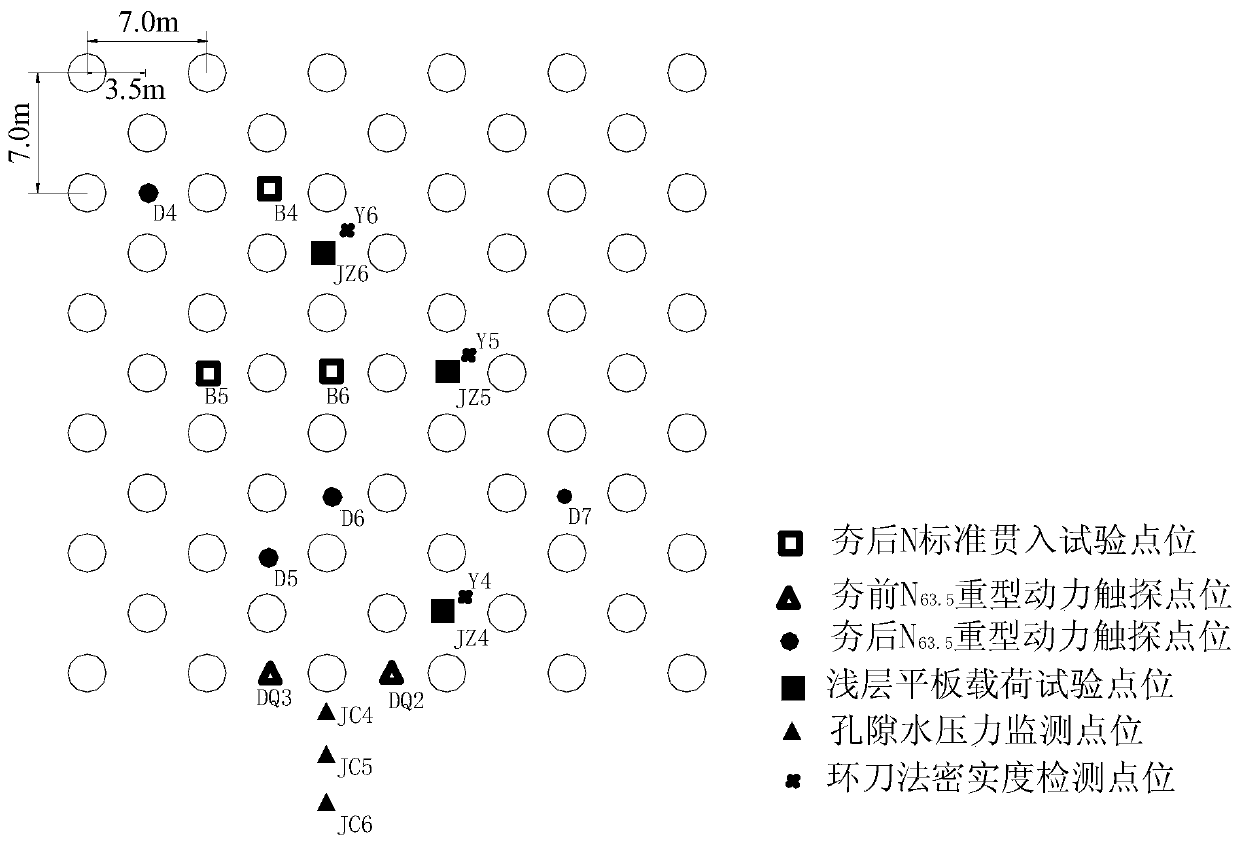

The excavations of side vertical walls for building and underpasses must be shored so that the excavations adjacent to the neighboring properties do not cave in during the constructions. A Soil Nailing system has been used for stabilization of excavations and natural slopes for the last few decades in India and Abroad. Soil Nailing Technique used steel anchor rods inserted directly into the soil mass as a driven nails and when Nails are placed in pre-drilled holes to form grouted nails. In both the cases, it restrained load and the side deformations. In the present study, an innovative technique of ‘Soil Nailing’ has been developed for stepwise vertical de-stabilization and stabilization of compacted collapsible sandy soil for the construction of railway underpasses in live railway loading conditions. This technique is successfully implemented first time in the world for controlled destabilization of vertical cut slope and again stabilization for creating a space for pushing of box for railway underpasses for the length of 22 m and 50 m at two sites, namely Yamuna Bazzar and Apsara border, respectively, in Delhi, India. This Soil Nailing Technique of controlled destabilization of soil and again stabilization in steps has proved a superficial method of stabilization with the other methods for such kind of dynamic loading situations.

Owner:COUNCIL OF SCI & IND RES

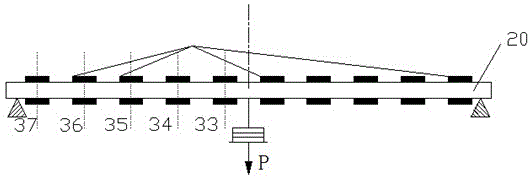

Effective reinforcing depth design method for strengthening saturated sand foundation through dynamic consolidation method

ActiveCN110344387AImprove construction efficiencyReduce engineering costsSoil preservationFoundation engineeringEngineering

The invention provides an effective reinforcing depth design method for strengthening a saturated sand foundation through a dynamic consolidation method, and relates to the technical field of soft soil foundation strengthening. According to the method, the compaction shell maximum depth z<1> and the compaction shell influence depth h<y> generated due to dynamic consolidation vibration are calculated, finally, the effective reinforcing depth Z of the dynamically-consolidated and strengthened saturated sand foundation is obtained through calculation and is the sum of the compaction shell maximumdepth z<1> and the compaction shell influence depth h<y> generated due to dynamic consolidation vibration and the consolidation pit depth h<h> generating the compaction shell maximum depth. Accordingto the provided effective reinforcing depth design method for strengthening the saturated sand foundation through dynamic consolidation, the dynamic consolidation saturated sand foundation engineering design can be objectively developed, the dynamic consolidation engineering trial consolidation and detection work is developed in a targeted manner, the engineering construction efficiency is improved, and the engineering cost is reduced.

Owner:中冶沈勘工程技术有限公司

Method of using plain soil to produce hydraulic engineering seepage-proofing brick in situ

InactiveCN102633485AImprove adsorption capacityHigh compressive strengthSolid waste managementBrickHydraulic engineering

The invention relates to the field of building materials and the field of water conservancy construction, in particular to various clay, weathered granite soil and hoggin soil. Soil at construction sites of artificial lakes, artificial canals and irrigation channels is used as main materials, special macromolecular coagulant, limestone or gravel sandy soil are mixed with Portland cement, and compression molding equipment is used for once forming of seepage-proofing bricks. The main materials include, by weight, 0.02 part of coagulant, 0.2 part of glass fiber chopped strands (biological straws), 70-80 parts of soil, 5-6 parts of cement and 10-15 parts of gravels (weathered granite soil). In terms of performance, the seepage-proofing bricks made by the method have sufficient compressive strength and shear resistance and can meet the normal artificial water conservancy seepage proofing requirements; in terms of process, operation is simple and easy and soil is taken in situ; and in terms of cost, the cost is at least 50% lower than that of cement mortar seepage proofing, soil needed to be removed at the construction sites is treated, construction cost is reduced, and construction cycle is shortened.

Owner:蒋黔湘 +3

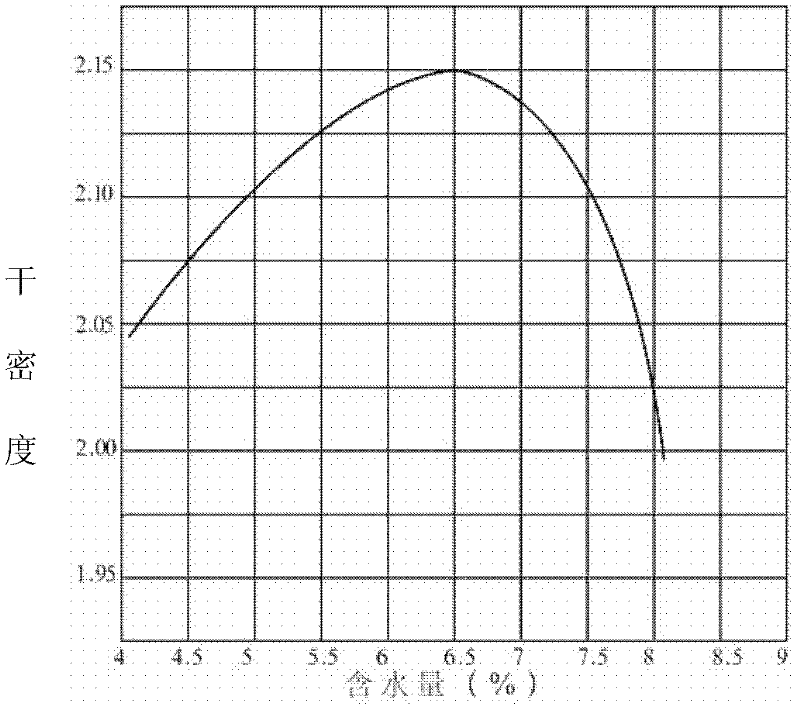

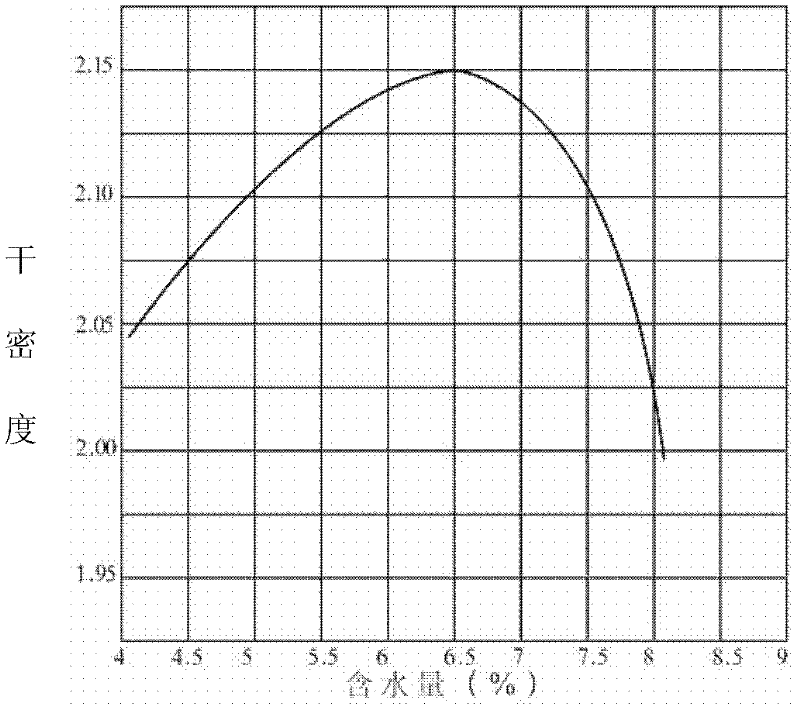

Bentonite modified sand soil material replacing clay liner of refuse landfill and preparation method of bentonite modified sand soil material

InactiveCN103723998AAvoid wastingShorten the construction periodProtective foundationClaywaresEcological environmentSoil material

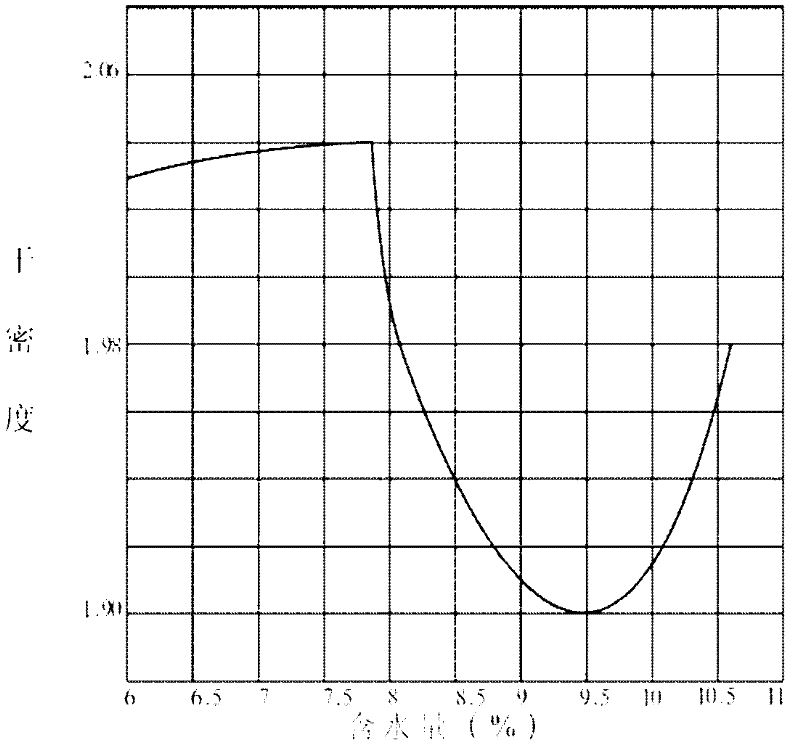

The invention relates to a bentonite modified sand soil material replacing a clay liner of a refuse landfill and a preparation method of the bentonite modified sand material, and belongs to the technical field of solid waste retreatment. The bentonite modified sand soil material comprises the following components by weight: 82.5-85.5 parts of silty sand, 2-5 parts of bentonite and 12.5 parts of water. The preparation method comprises the following steps: uniformly mixing the silty sand and the bentonite and then laying on a to-be-constructed working face, uniformly spraying water on the surface of a material, carrying out rolling-compaction to obtain the bentonite modified sand soil material replacing the clay liner of the refuse landfill. The bentonite modified sand soil material is subjected to the modification treatment through addition of bentonite and water, so that the problems of difficult clay purchasing and large transportation and construction cost due to clay resource shortage are solved, and meanwhile, soil can be used on the spot, the earthwork balance is achieved on the spot, so that the problem that an excavation party spoils soil difficultly is solved, and the ecological environment protection is facilitated. Since the technology is simple in construction, and the material source is wide, the technology applicability is relatively wide, and the implementation is easy.

Owner:WUXI MUNICIPAL DESIGN INST

Sand-bag and steel sheet pile combined cofferdam for hard formation and construction method of cofferdam

The invention discloses a sand-bag and steel sheet pile combined cofferdam for hard formation and a construction method of the cofferdam. The sand-bag and steel sheet pile combined cofferdam comprises an inner cofferdam body and an outer cofferdam body which are disposed on the hard formation. Clay is disposed in the clearance between the inner cofferdam body and the outer cofferdam body, sand is then filled, and a steel sheet pile is then driven to penetrate through the sand and clay and into the hard formation deeply. The clay is disposed at the bottom of the clearance between the inner cofferdam body and the outer cofferdam body, the sand is disposed above the clay, and the steel sheet pile penetrates through the sand and the clay into the hard formation deeply to form a water stopping core wall. Due to the fact that the clay is high in viscosity, poor in water permeability and the like, when the steel sheet pile penetrates through the clay, the clay is adhered to the bottom of steel sheet pile and penetrates into the hard formation deeply, tight combination of the clay with the hard formation is achieved, water is prevented from permeating from the bottom of the steel sheet pile, and the water stopping core wall has good water stopping performance.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

High-temperature-resistant purple sand container

ActiveCN103588465AGuaranteed high temperature performanceSpeed up the flowClaywaresThermodynamicsKaolin clay

The invention discloses a high-temperature-resistant purple sand container. The bottom of the purple sand container comprises three or more projection parts; the main body of the purple sand container comprises the following components in percentage by weight: 20-55% of purple sand soil, 40-60% of spodumene and 5-20% of kaolin. The purple sand container of the invention can be used for boiling water and tea on open fire and an electric stove, and buffer contact areas are formed between the purple sand container and the surface of the opening fire or the electric stove through the projection parts at the bottom, so that the purple sand container made of a natural material is prevented from rupture when used on the electric stove or the open fire; as a certain distance is reserved between the purple sand container and the electric stove, heated air flows upwards and evenly acts on the purple sand container, and thus the service lives of the purple sand container and the electric stove are long.

Owner:周曙时

Opencut coal mine abandoned bare land ecological remediation method

InactiveCN110754161AImprove survival rateImprove the efficiency of ecological restorationSoil-working methodsVegetationEnvironmental resource management

The invention discloses an opencut coal mine abandoned bare land ecological remediation method, comprising bare land habitat ecological remediation work, vegetation ecological restoration work and enclosure governing. The bare land habitat ecological remediation work includes arranging and classifying abandoned aggregate, cement blocks and gravel sand in a mining area according to grain size, utilizing the abandoned cement blocks and bricks to build pavement, stacking other aggregate from bottom to top from large to small, and finally filling gaps of gravel with fine gravel sand; the vegetation ecological restoration work includes performing community investigation to the surrounding of the coal mine, selecting suitable local tree species and planting the tree species, and planting vine plants at the slope toe. By means of using local materials, namely, by directly utilizing the abandoned aggregate, cement blocks and gravel sand to create a habitat environment suitable for natural survival of plants, cost for ecological remediation is reduced, and ecological remediation efficiency is increased.

Owner:LIAONING TECHNICAL UNIVERSITY

Variable water level clay dam slope seepage failure occurrence condition test device and method

PendingCN111505248AThe actual complex operation environment of the simulation project is goodEarth material testingPermeability/surface area analysisWater storageSoil science

The invention discloses a variable water level clay dam slope seepage failure occurrence condition test device and method. The device comprises a water storage tank, a water pump, a pressure regulating water tank and a test box, and the test box is divided into a closed water storage chamber and a tail observation chamber through a partition plate, the top of the observation chamber is flush withthat of the water storage chamber, and the bottom of the observation chamber is higher than that of the water storage chamber. A water inlet of the water storage chamber is communicated with a water outlet of the pressure regulating water tank through a pipeline, water is supplied and the water pressure is regulated through the pressure regulating water tank, and the height of the pressure regulating water tank is adjustable. A sandy soil layer is laid at the bottom of the water storage chamber according to the set gradient and thickness, a clay covering layer is laid at the top of the sandy soil layer, and osmometer sensors are embedded in different positions of the sandy soil layer and the clay covering layer respectively. A sand gushing outlet and a plurality of drainage holes are formed at the bottom of the observation chamber and are used for observing and judging the seepage failure conditions, and the sand gushing outlet and the drainage hole are communicated with a sand soil layer filled in the water storage chamber.

Owner:NANJING HYDRAULIC RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com