Microorganism grouting drainage solidification pile and construction method and application thereof

A construction method and microbial technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as the inability to meet the drainage requirements of soft soil foundations, the decline of sand pile drainage performance, and the large amount of cement slurry, and achieve good drainage performance. , small influence, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

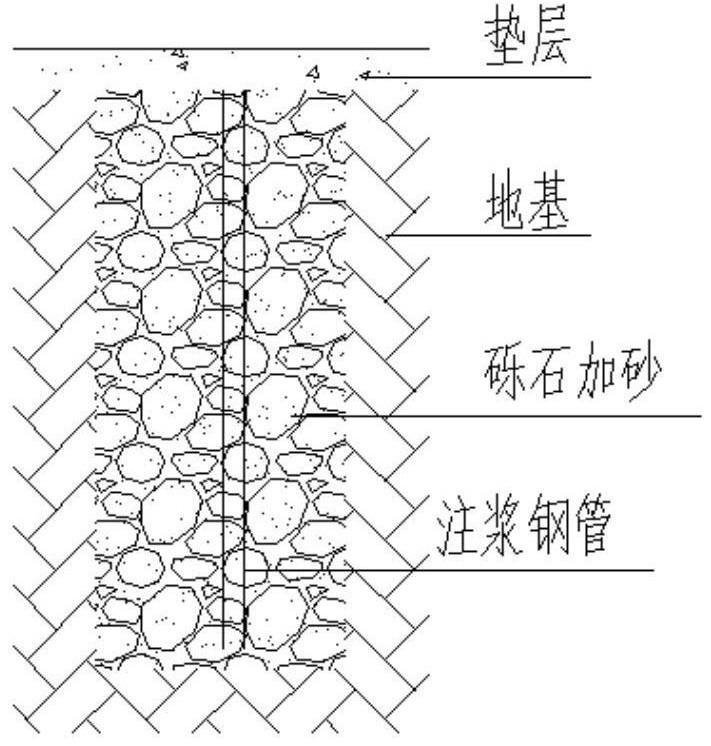

[0045] (1) Leveling the site: removing surface planting soil and obstacles;

[0046] (2) Measuring and setting out: According to the coordinates, the specific position of each pile is released and marked;

[0047] (3) The pile driver is in place: the valve-type pile tip is used, and the valve at the pile tip should be tightly closed with hemp rope or iron wire. The gap between the valves should be tight, so that the pile tip is vertically aligned with the center of the pile position;

[0048] (4) Vibration sinking pipe: drive the pile pipe into the predetermined design depth through the vibration piling method;

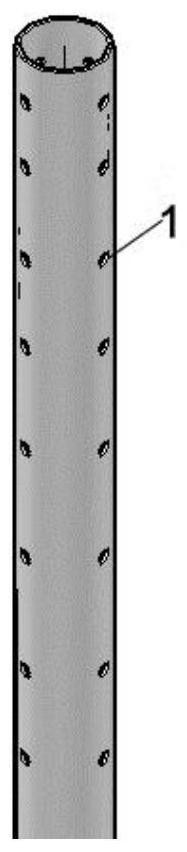

[0049] (5) Putting gravel and sand: pre-embed the grouting pipe with several holes in the pipe wall in the pile pipe in advance; then put gravel and sand with a height of not less than 2m in the pile pipe, and vibrate for 8s , pull out the pipe while vibrating, stop pulling out and vibrate for 8 seconds after every 0.8m; repeat the above operations (loading gravel and ...

Embodiment 2

[0056] (1) Leveling the site: removing surface planting soil and obstacles;

[0057] (2) Measuring and setting out: According to the coordinates, the specific position of each pile is released and marked;

[0058] (3) The pile driver is in place: the valve-type pile tip is used, and the valve at the pile tip should be tightly closed with hemp rope or iron wire. The gap between the valves should be tight, so that the pile tip is vertically aligned with the center of the pile position;

[0059] (4) Vibration sinking pipe: drive the pile pipe into the predetermined design depth through the vibration piling method;

[0060] (5) Putting gravel and sand: pre-embed the grouting pipe with several holes in the pipe wall in the pile pipe in advance; then put gravel and sand with a height of not less than 2m in the pile pipe, and vibrate for 5s , pull out the pipe while vibrating, stop pulling out and vibrate for 5 seconds after every 0.5m of pulling out; repeat the above operations (lo...

Embodiment 3

[0067] (1) Leveling the site: removing surface planting soil and obstacles;

[0068] (2) Measuring and setting out: According to the coordinates, the specific position of each pile is released and marked;

[0069] (3) The pile driver is in place: the valve-type pile tip is used, and the valve at the pile tip should be tightly closed with hemp rope or iron wire. The gap between the valves should be tight, so that the pile tip is vertically aligned with the center of the pile position;

[0070] (4) Vibration sinking pipe: drive the pile pipe into the predetermined design depth through the vibration piling method;

[0071] (5) Putting gravel and sand: pre-embed the grouting pipe with several holes in the pipe wall in the pile pipe in advance; then put gravel and sand with a height of not less than 2m in the pile pipe, and vibrate for 10s , pull out the pipe while vibrating, stop pulling out and vibrate for 10s after every 1.0m of pulling out; repeat the above operations (loading...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com