Patents

Literature

335 results about "Calcium carbonate precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precipitated calcium carbonate (PCC) is an innovative product derived from lime, which has many industrial applications. PCC is made by hydrating high-calcium quicklime and then reacting the resulting slurry, or “milk-of-lime”, with carbon dioxide.

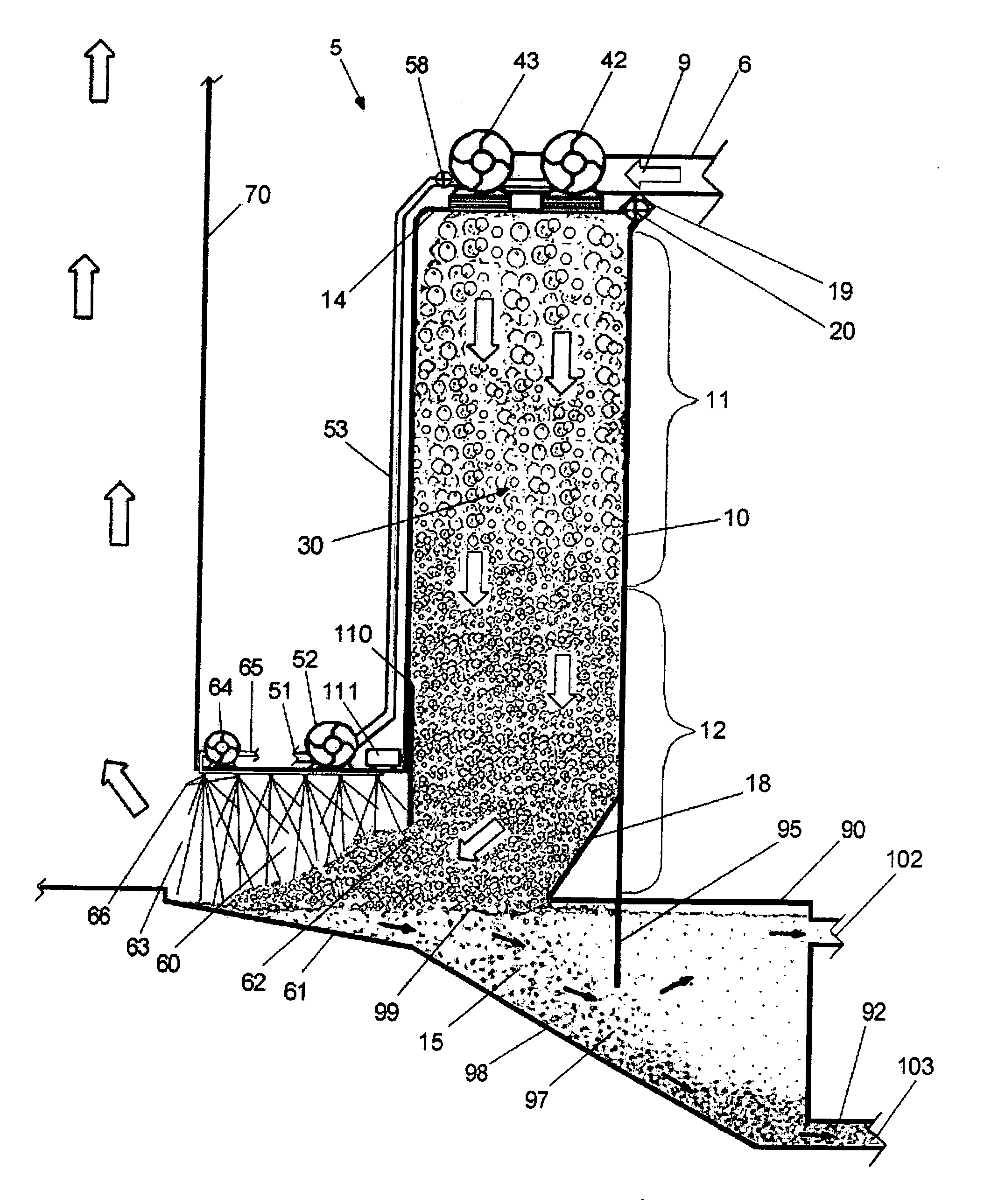

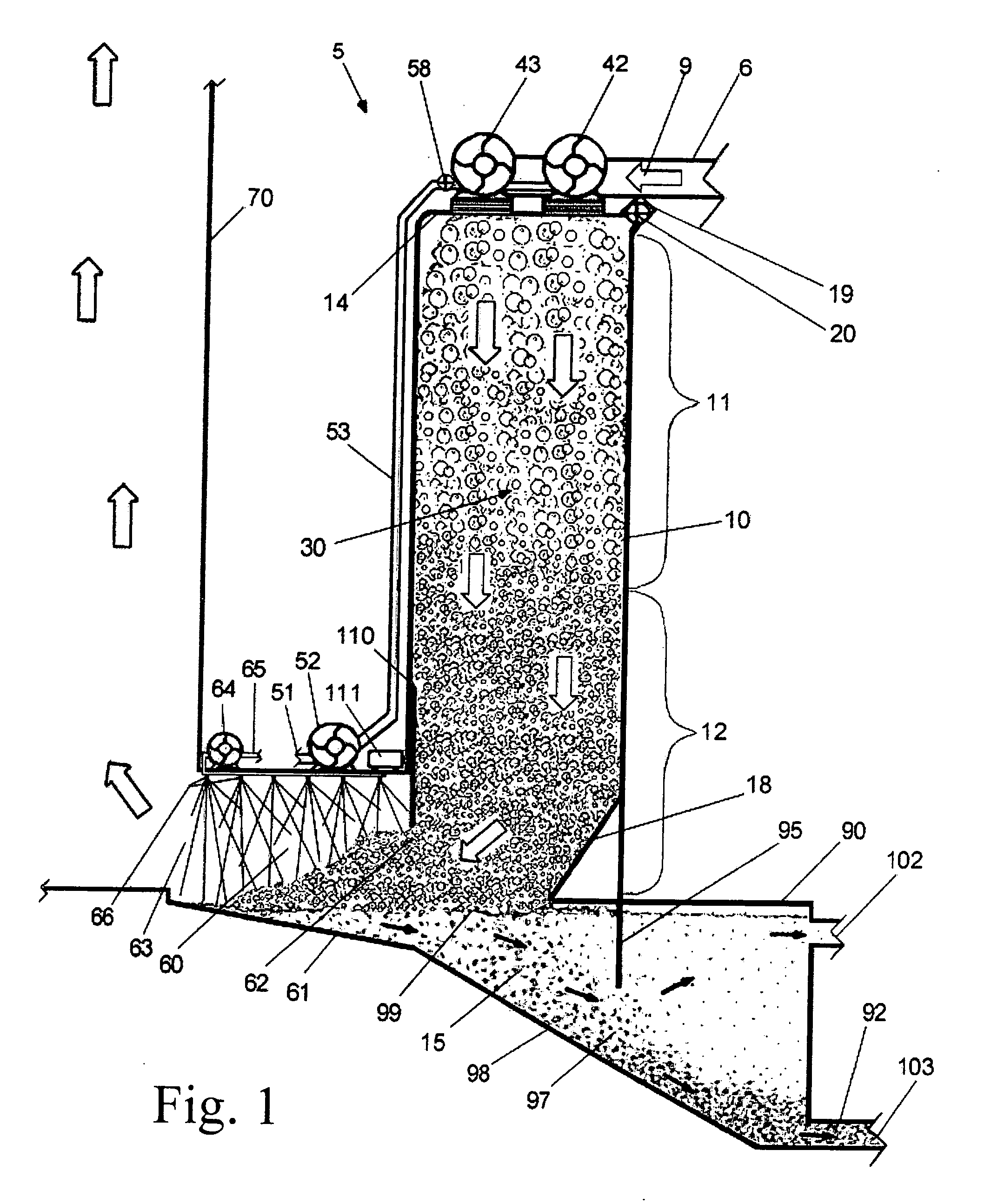

Method and means for capture and long-term sequestration of carbon dioxide

InactiveUS20090081096A1High heat of reactionHigh regeneration energyCombination devicesGas treatmentSolubilityAmbient pressure

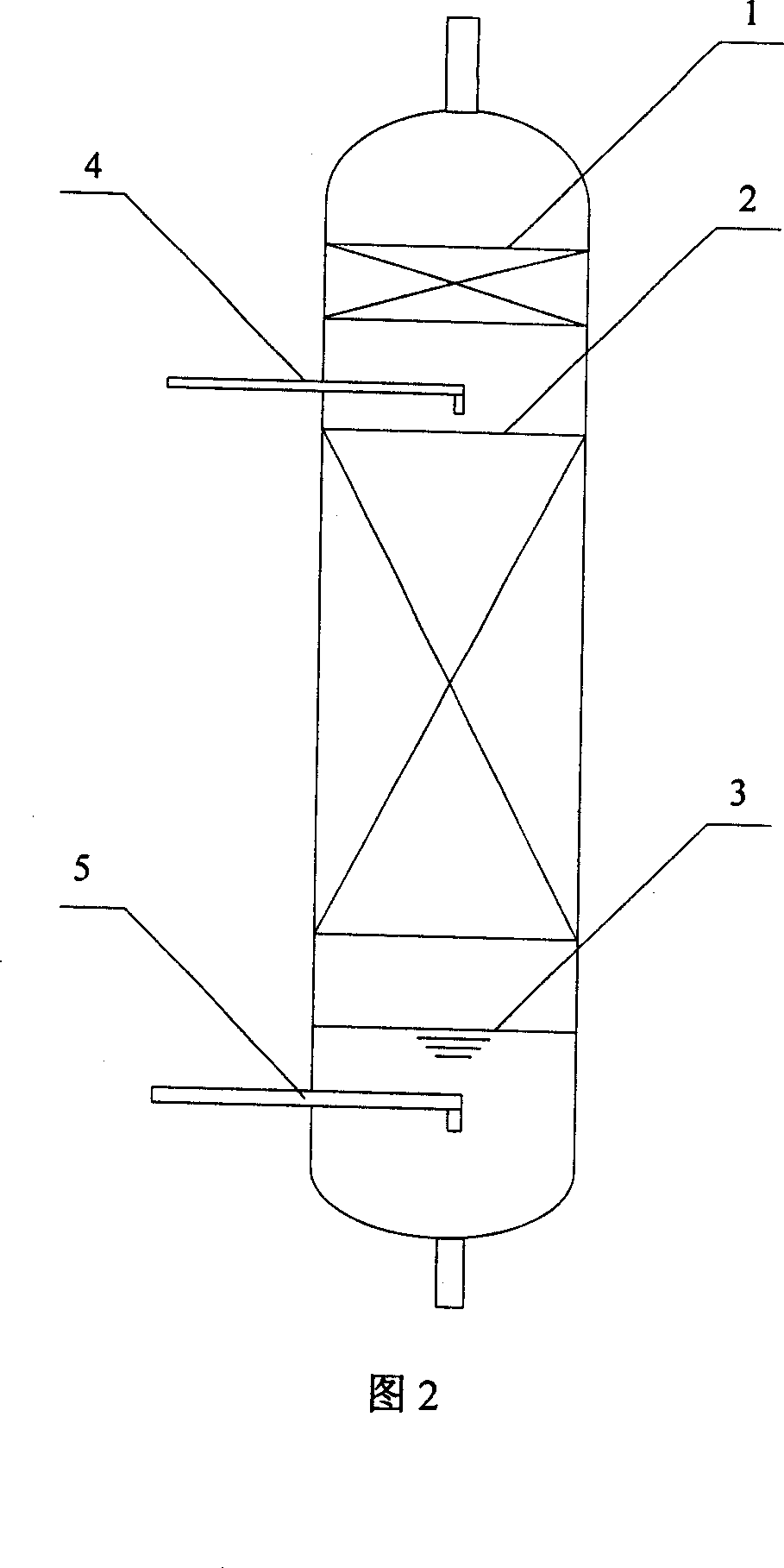

The invention teaches a practical method of recovering CO2 from a mixture of gases, and sequestering the captured CO2 from the atmosphere for geologic time as calcium carbonate and provides a CO2 scrubber for carbon capture and sequestration. CO2 from the production of calcium oxide is geologically sequestered. A calcium hydroxide solution is produced from the environmentally responsibly-produced calcium oxide. The CO2 scrubber incorporates an aqueous froth to maximize liquid-to-gas surface area and time-of-contact between gaseous CO2 and the calcium hydroxide solution. The CO2 scrubber decreases the temperature of the liquid and the mixed gases, increases ambient pressure on the bubbles and vapor pressure inside the bubbles, diffuses the gas through intercellular walls from relative smaller bubbles with relative high vapor pressure into relative larger bubbles with relative low vapor pressure, and decreases the mean-free-paths of the CO2 molecules inside the bubbles, in order to increase solubility of CO2 and the rate of dissolution of gaseous CO2 from a mixture of gases into the calcium hydroxide solution.The CO2 scrubber recovers gaseous CO2 directly from the atmosphere, from post-combustion flue gas, or from industrial processes that release CO2 as a result of process. CO2 reacts with calcium ions and hydroxide ions in solution forming insoluble calcium carbonate precipitates. The calcium carbonate precipitates are separated from solution, and sold to recover at least a portion of the cost of CCS.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

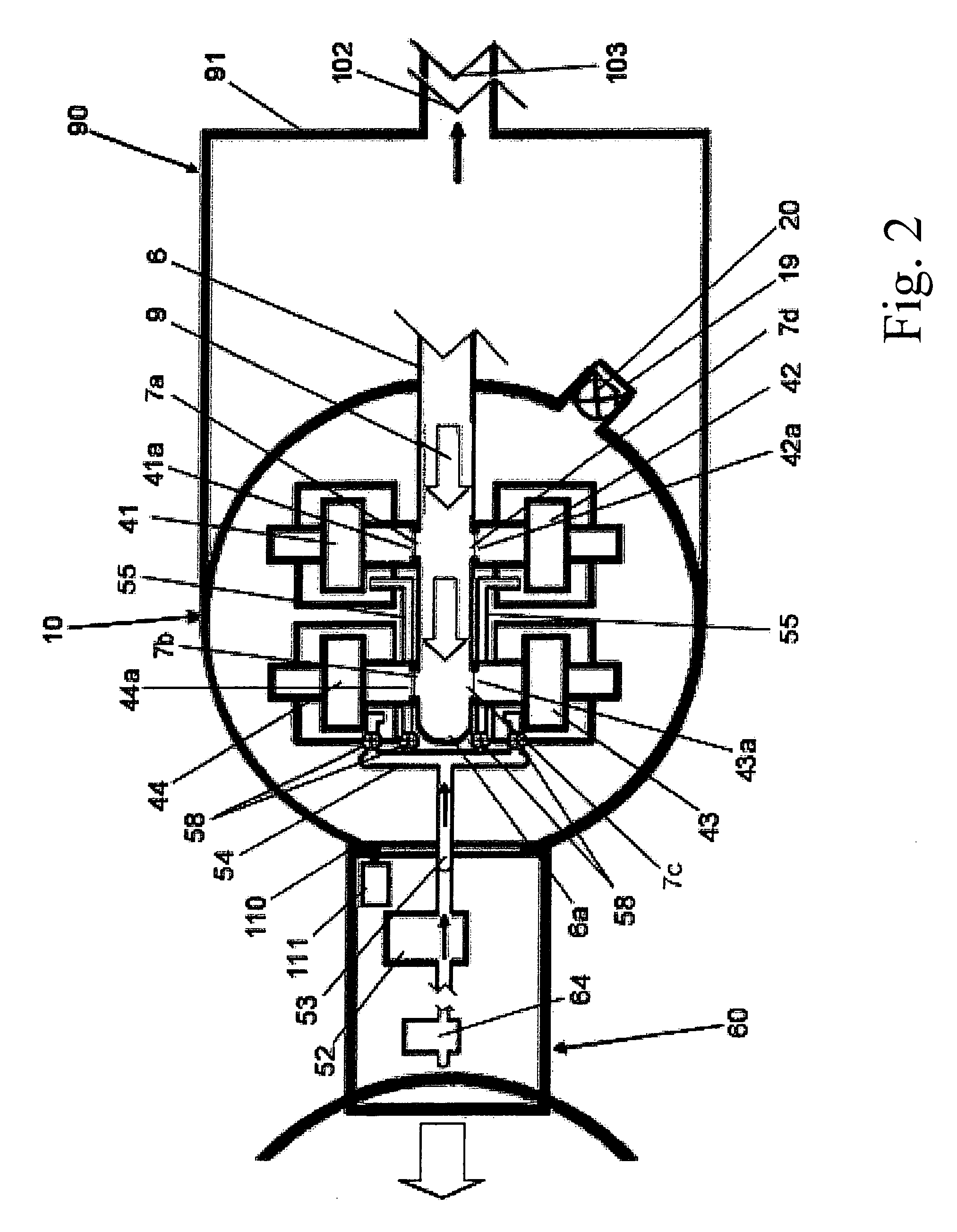

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

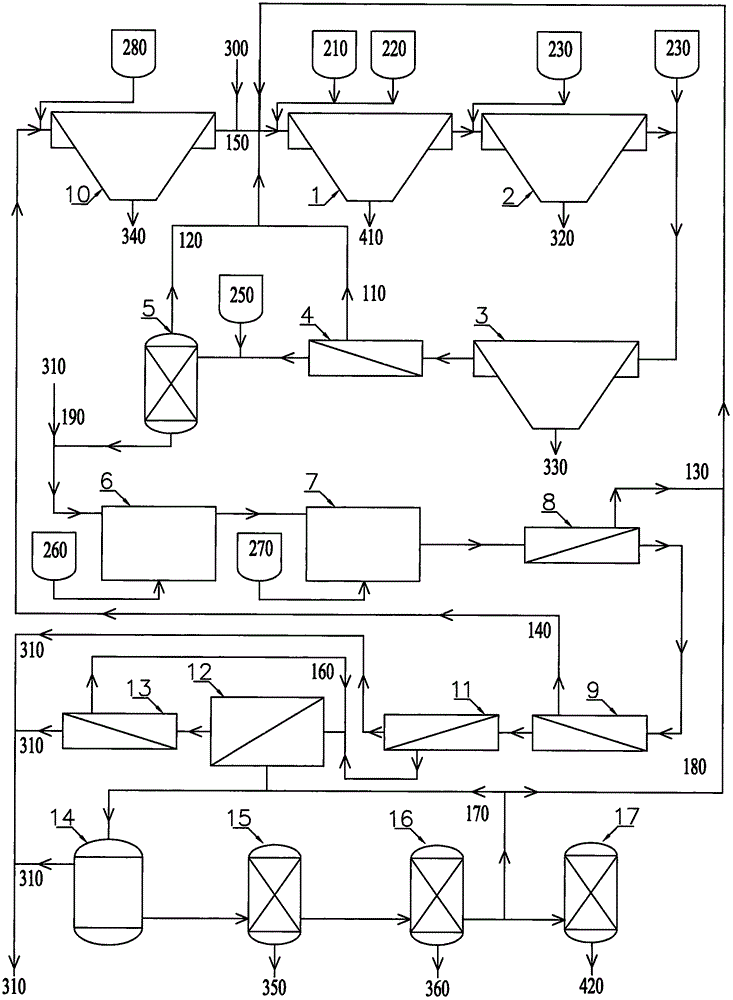

Calcium carbonate precipitation method

InactiveUS6036933ACalcium/strontium/barium carbonatesMagnesium carbonatesNitratePrecipitated calcium carbonate

PCT No. PCT / GB96 / 00488 Sec. 371 Date Oct. 22, 1997 Sec. 102(e) Date Oct. 22, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 26902 PCT Pub. Date Sep. 6, 1996A method for producing precipitated calcium carbonate by reacting an aqueous solution of calcium nitrate [Ca(NO3)2] with an aqueous solution of ammonium carbonate [(NH4)2CO3] and allowing calcium carbonate to precipitate from the resultant mixture containing nitrate [NH4NO3] in the mother liquor, the process being characterized in that: (i) the calcium nitrate [Ca(NO3)2)] solution utilized in the processes is prepared by slaking lime [CaO] in water in the presence of ammonium nitrate [NH4NO3] to form calcium nitrate [Ca(NO3)2] and ammonium hydroxide [NH4OH] in solution, filtering the solution to render it solids free, and heating the filtrate to dissociate the ammonium hydroxide [NH4OH] and to drive ammonia gas [NH3] from the solution; (ii) the ammonium carbonate (NH4)2CO3 solution utilized is prepared by absorbing ammonia gas [NH3] and carbon dioxide gas [CO2] in water, the ammonia gas preferably being derived from the step in (i) above in which the Ca(NO3)2 solution is heated; and (iii) the ammonium nitrate used is derived from the precipitation phase during which calcium carbonate is precipitated from the mother liquor containing ammonium nitrate.

Owner:PRETORIA PORTLAND CEMENT COMPANY +1

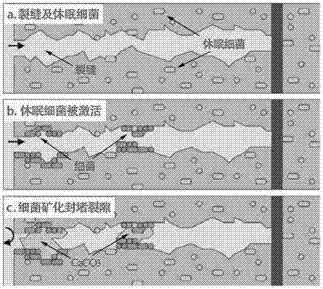

Use of bacteria to prevent gas leakage

InactiveUS20060216811A1Reduce leakageReduce penetrationCarbon-dioxide storageFermentationGas leakMicrobial Biofilms

The present invention relates to the use of microbial biofilms and microbial induction of calcium carbonate precipitation to sequester gases in underground geological formations. In one embodiment, methods of the invention can be used to prevent the leakage of supercritical CO2 in underground geological formations such as aquifers.

Owner:MONTANA STATE UNIVERSITY

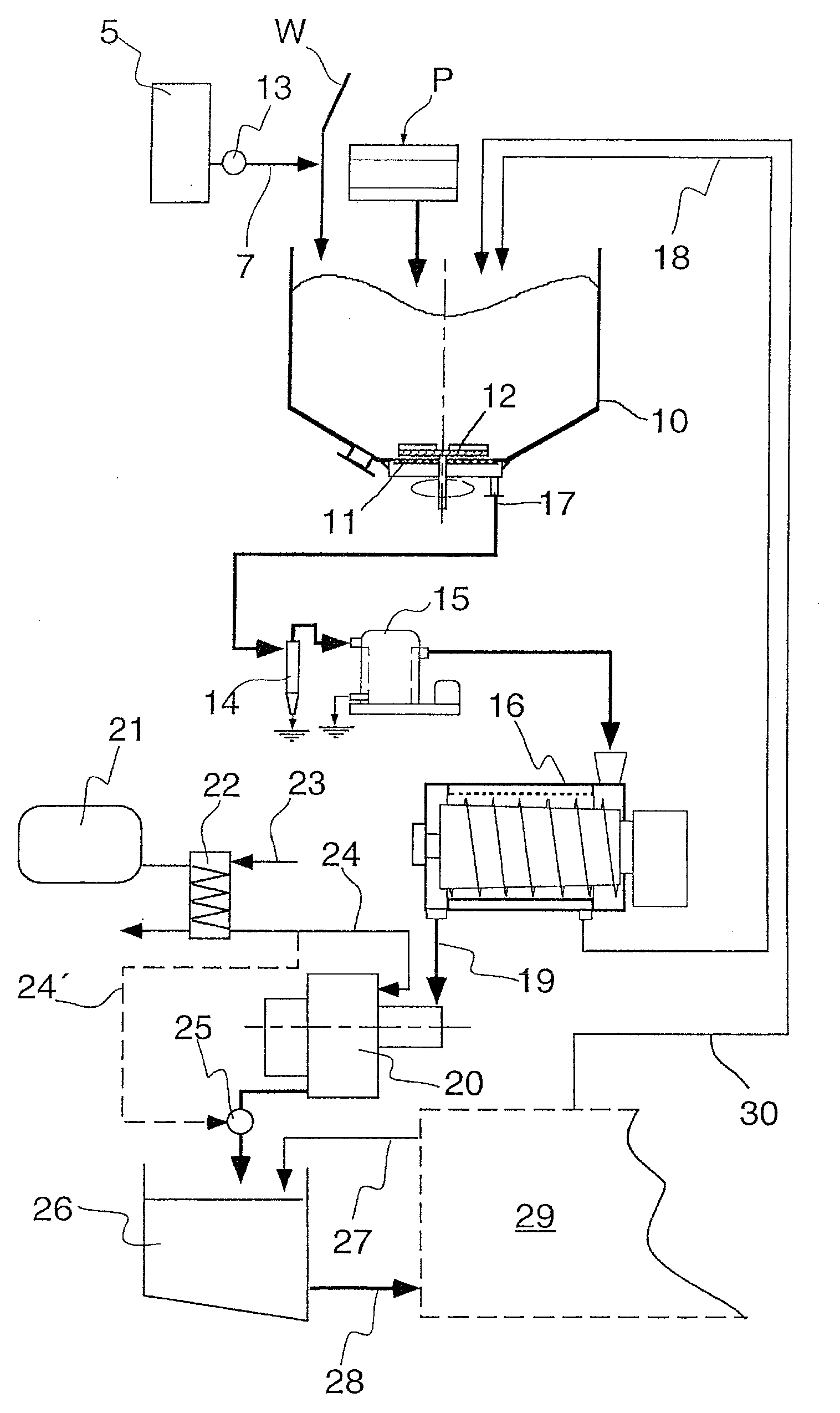

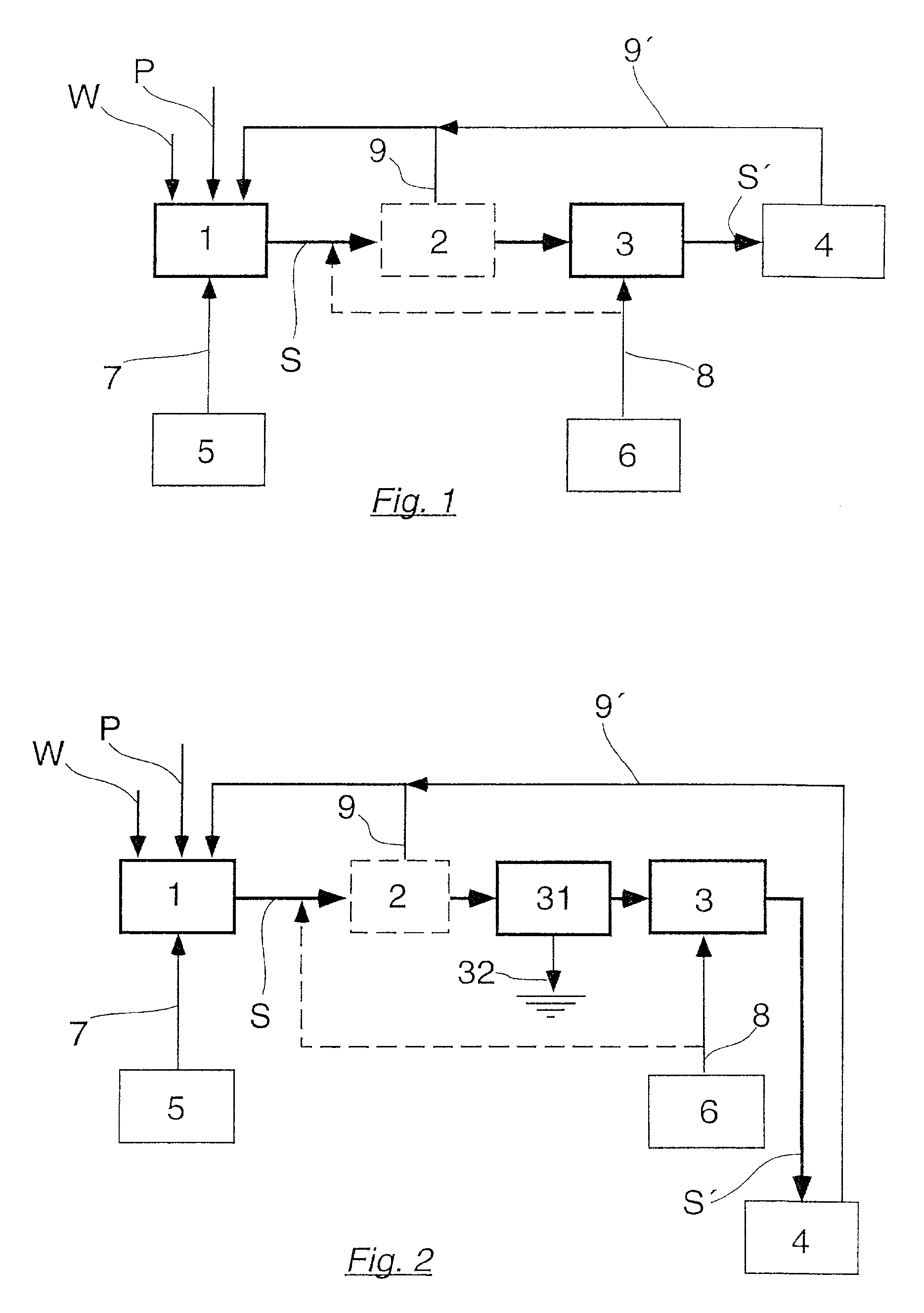

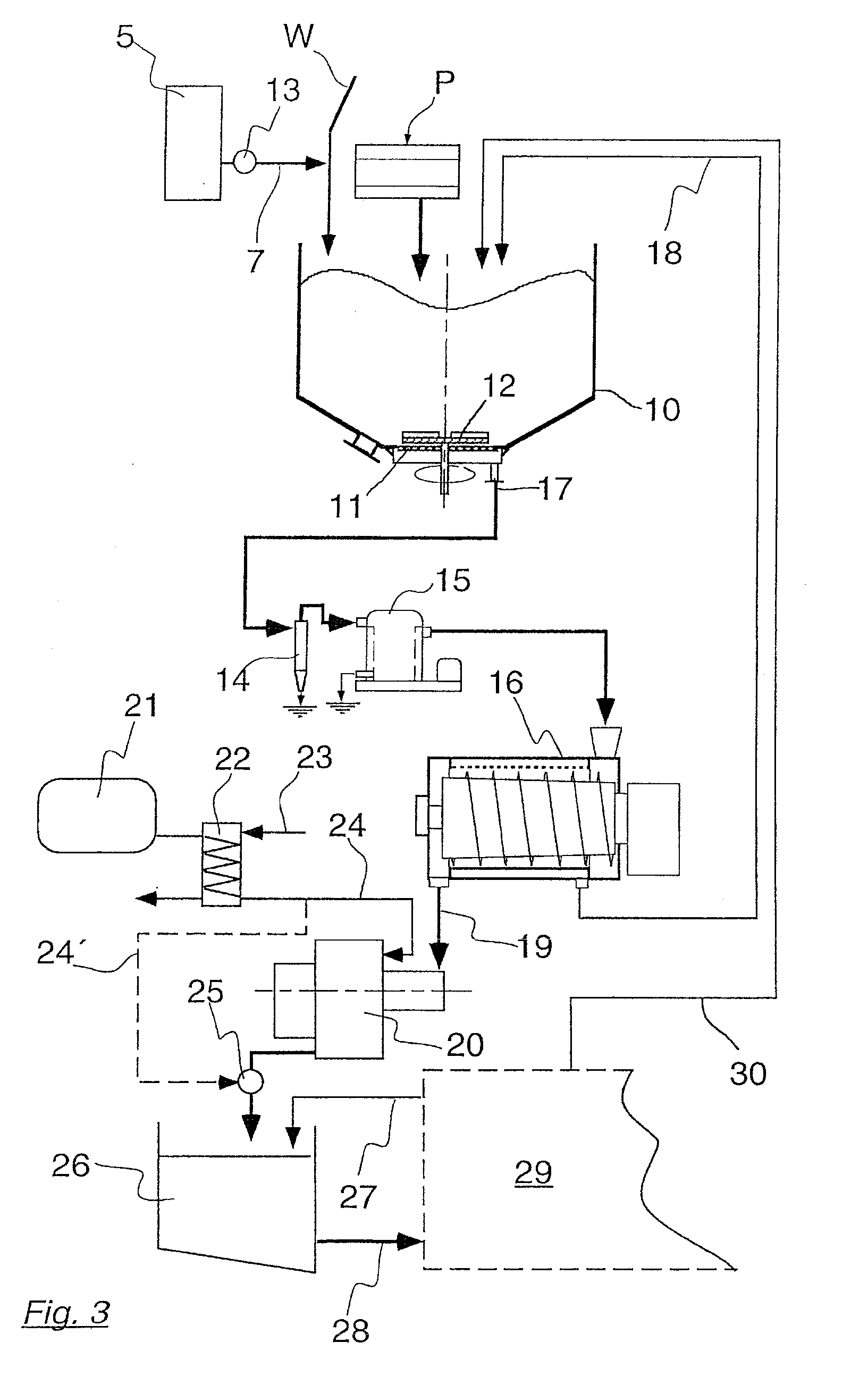

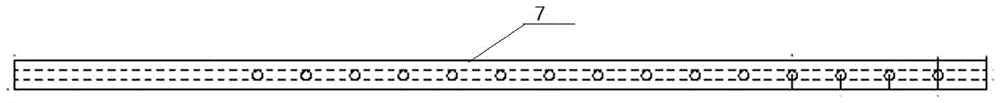

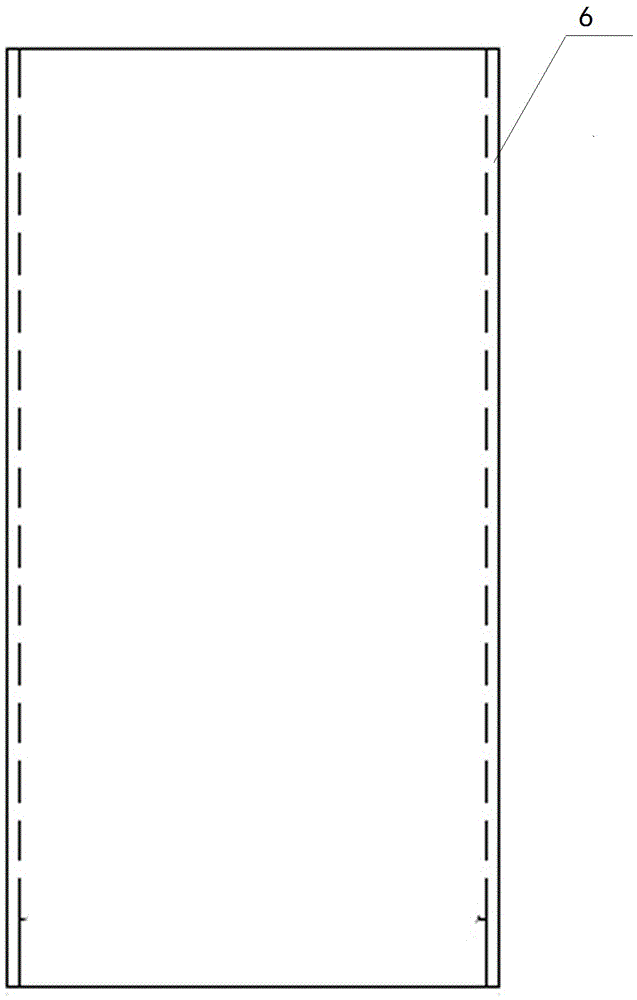

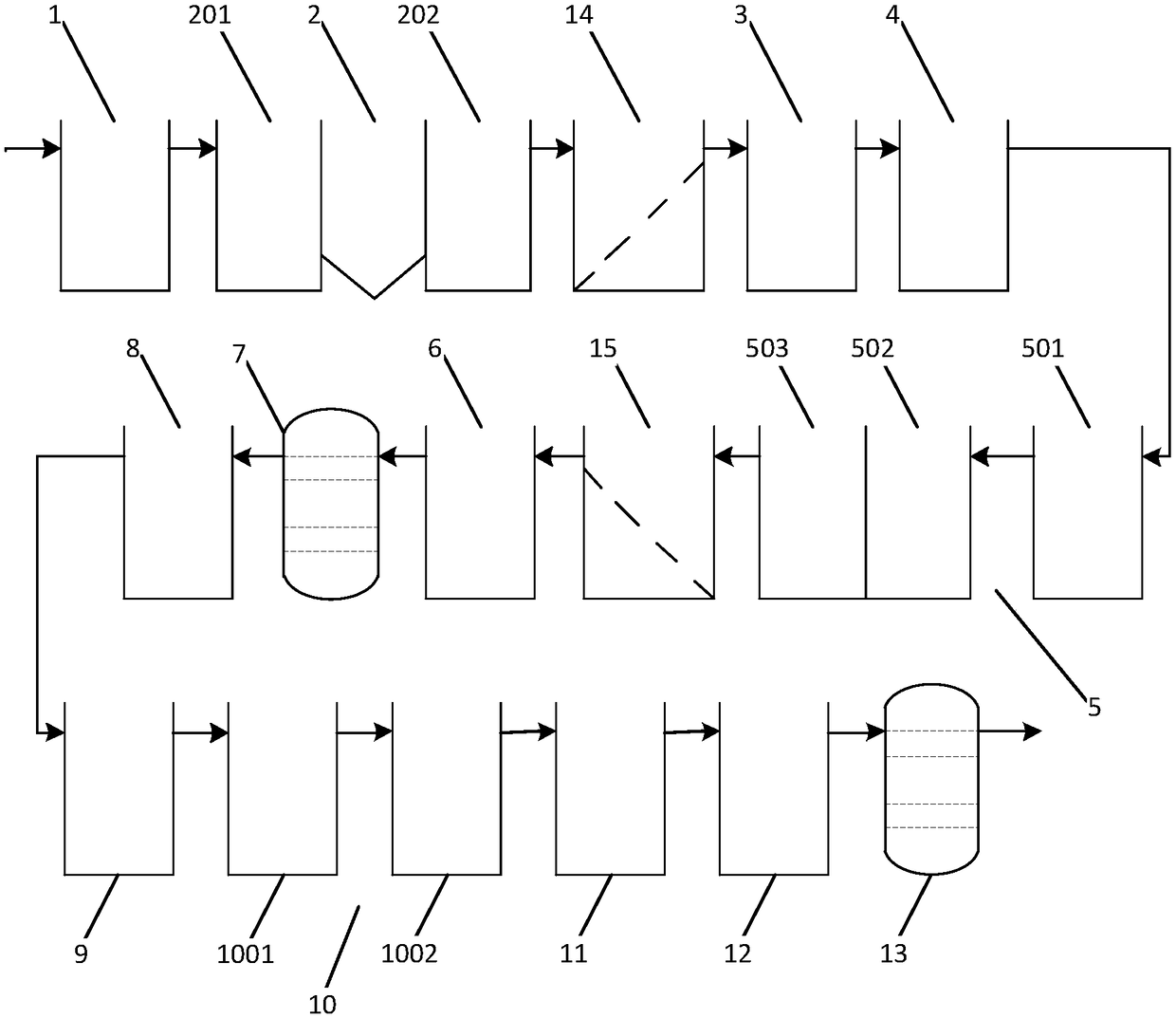

Method for loading fibers contained in a pulp suspension

InactiveUS20080210391A1Easy to usePulp properties modificationWashing/displacing pulp-treating liquorsFiberCalcium hydroxide

The present invention serves for loading a pulp suspension (S) with calcium carbonate. Liquid calcium hydroxide as milk of lime (7) is added during or before the pulp operation (1) carried out to form the pulp. By introducing gaseous carbon dioxide (8) into the pulp suspension thus treated, a chemical reaction is triggered therein, in which the finely divided calcium carbonate is precipitated. The present invention is particularly economic and effective due to the early addition of calcium oxide or calcium hydroxide.

Owner:VOITH PATENT GMBH

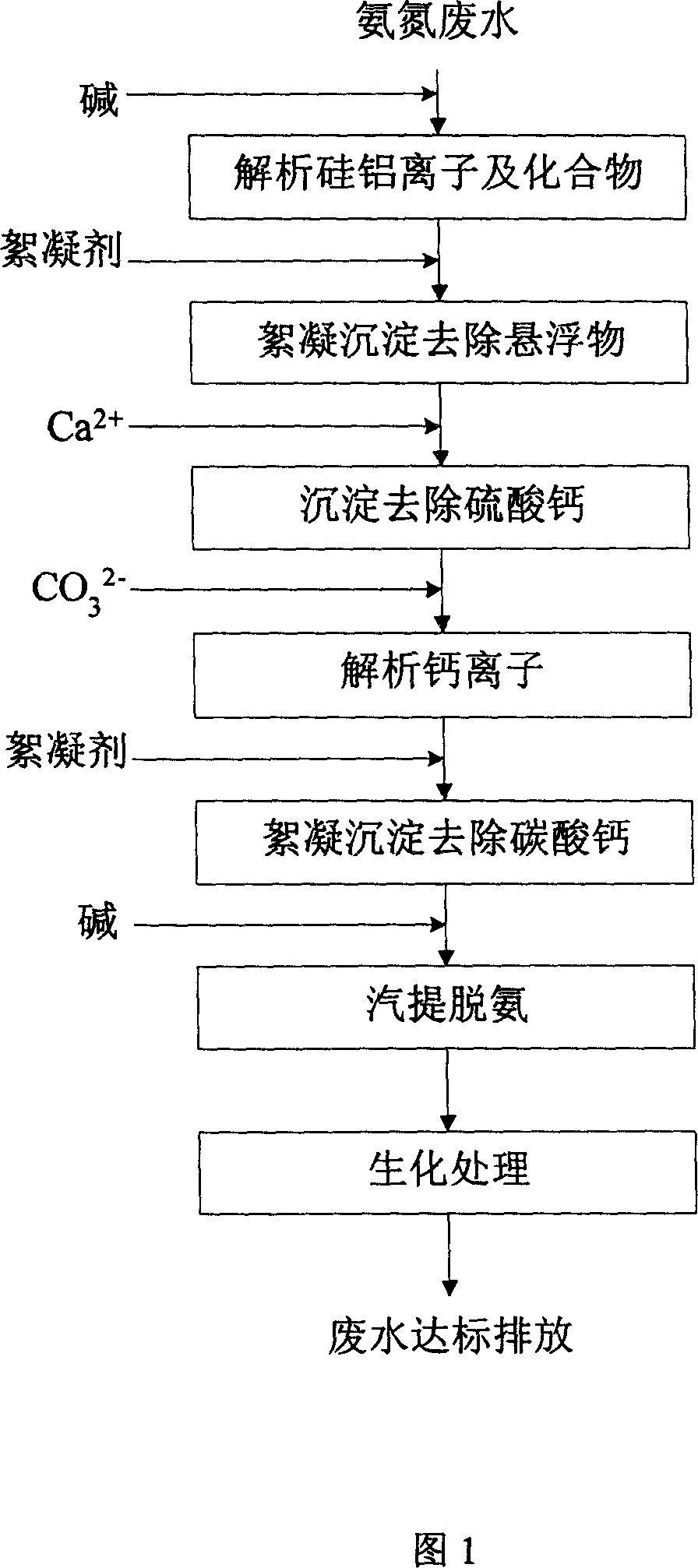

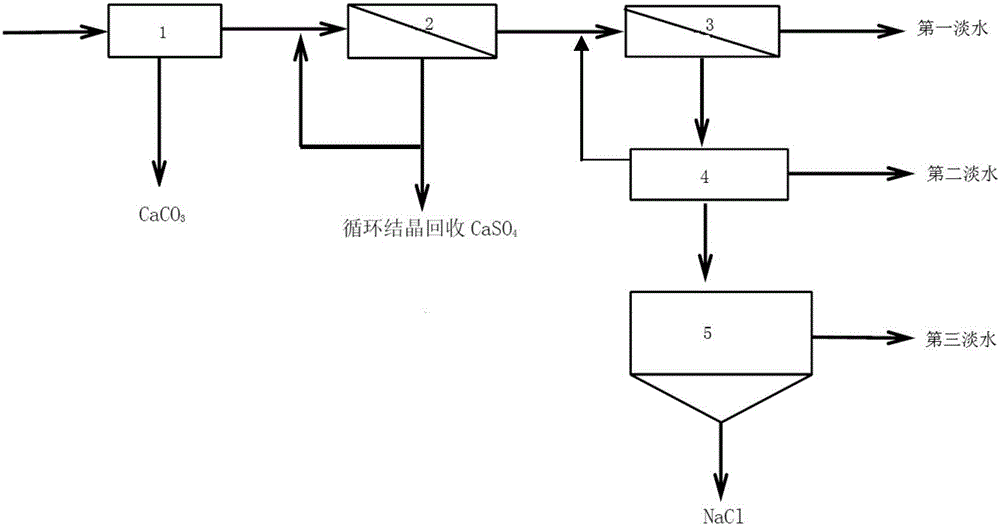

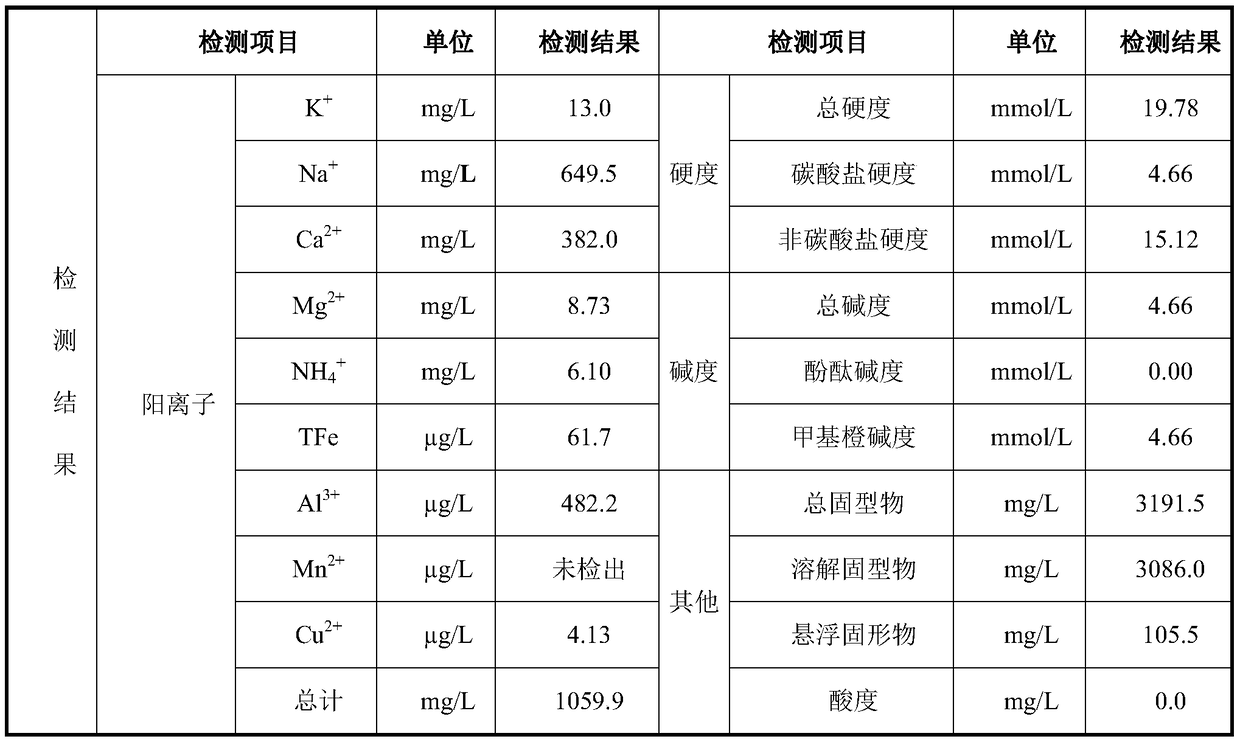

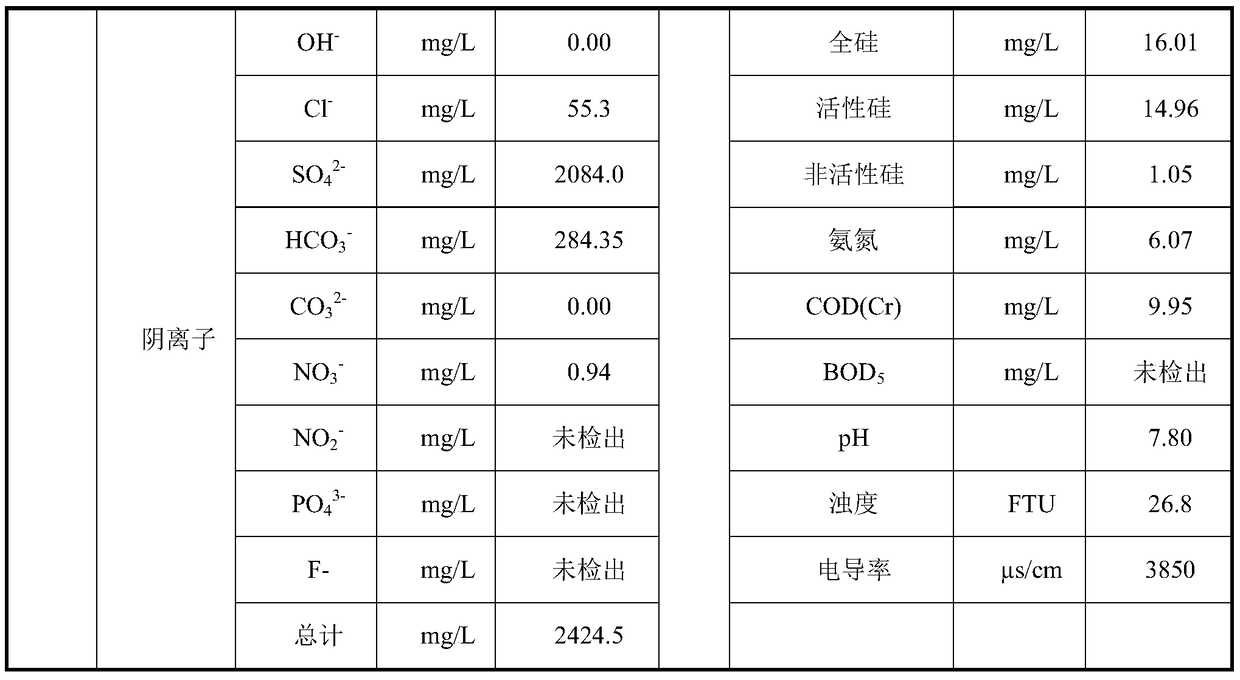

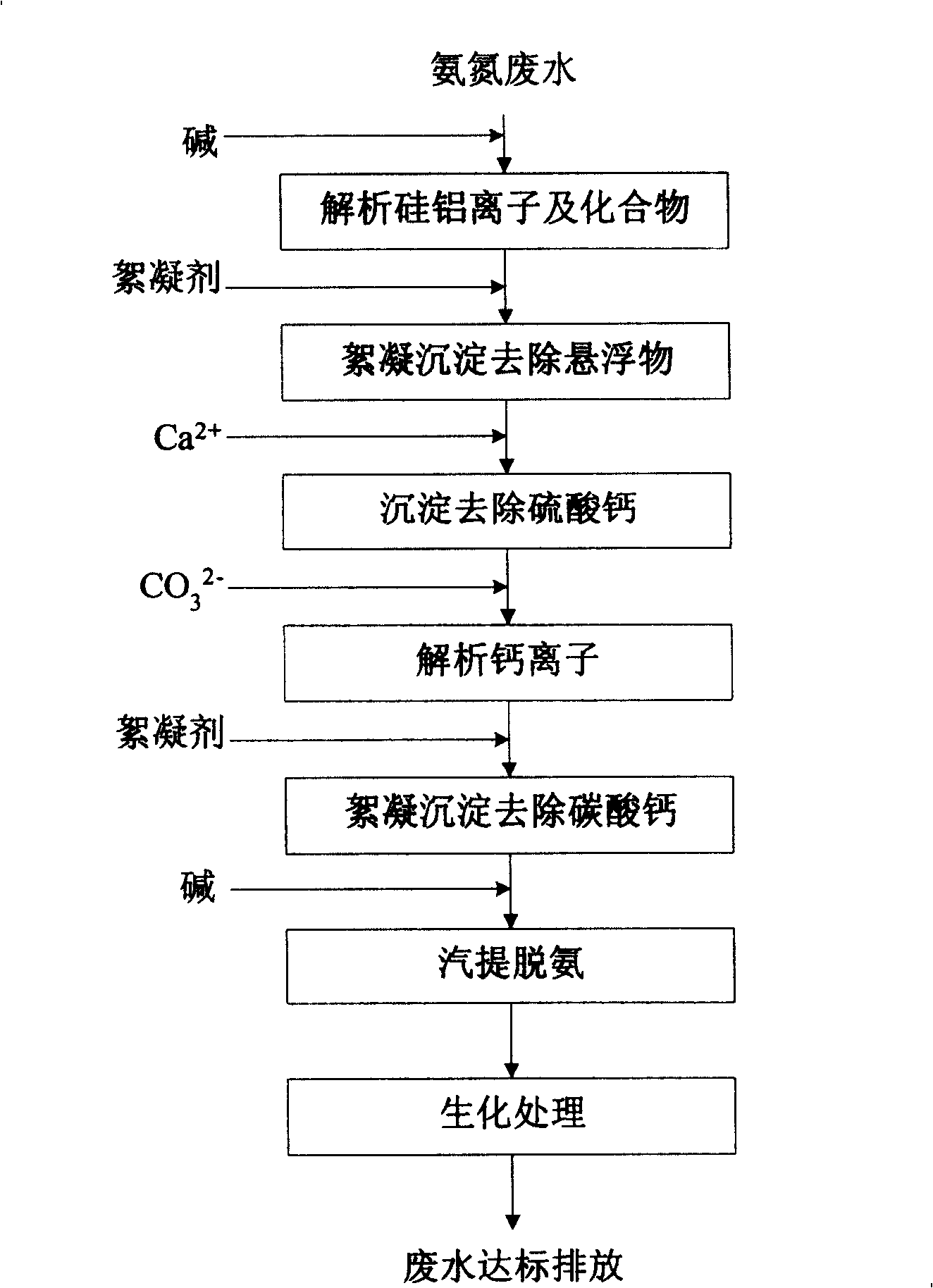

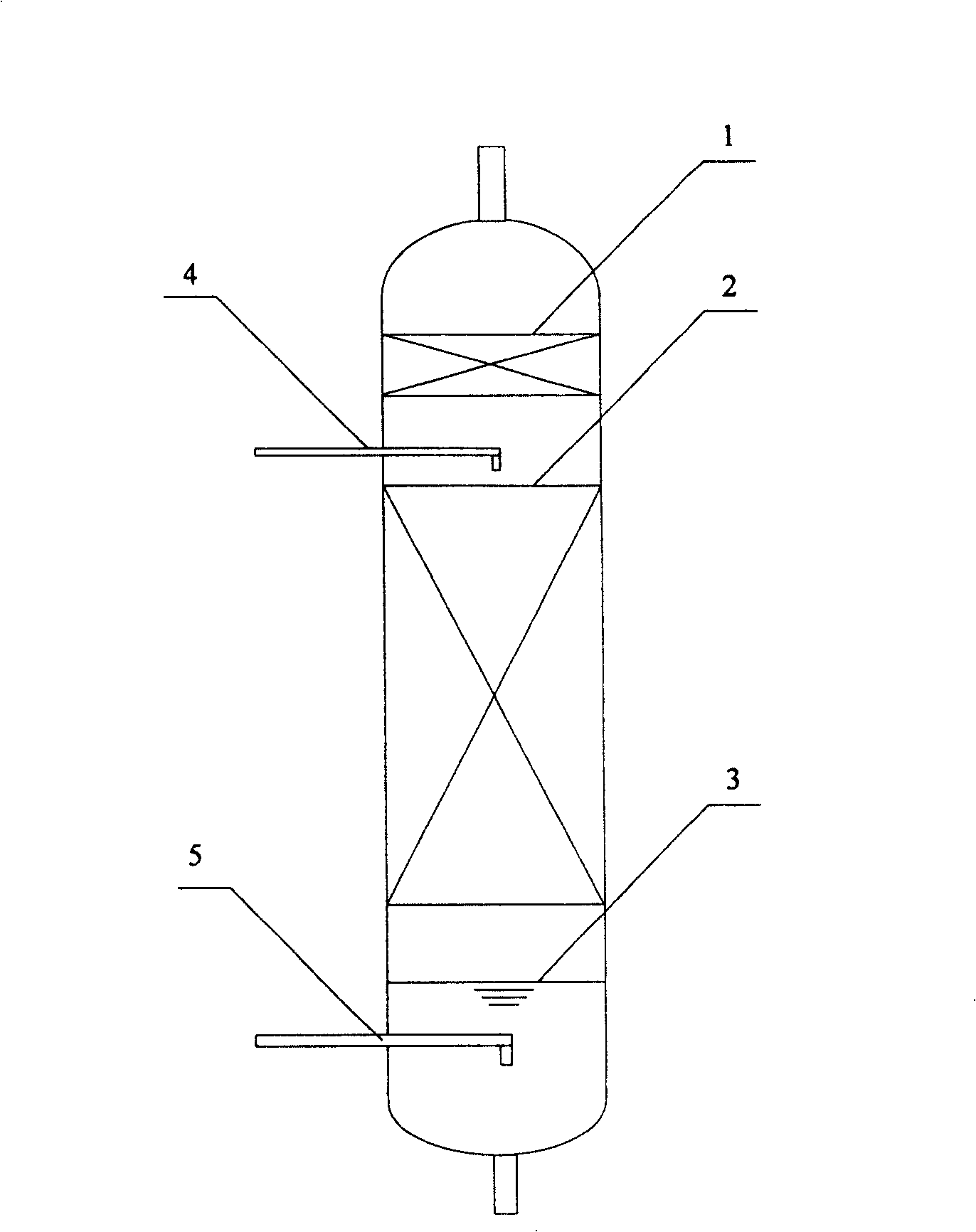

Method for treating ammonia nitrogen wastewater

ActiveCN1958471APrevent scalingAvoid problems such as tower blockageTreatment using aerobic processesMultistage water/sewage treatmentHigh concentrationTherapeutic effect

This invention relates to a method for treating ammonia nitrogen wastewater, especially high-concentration ammonia nitrogen wastewater produced during manufacture of oil-refinery catalyst. The method comprises: (1) adjusting the pH value of the wastewater, and solid-liquid separating to remove suspended matters and dissolved Si2+, Al3+ and their compounds; (2) adding Ca2+ to form CaSO4 precipitate, and solid-liquid separating to reduce acidic matters in the wastewater; (3) adding CO32- to form CaCO3 precipitate, and solid-liquid separating to remove Ca2+ in the wastewater; (4) steam-stripping for deamination, and performing biochemical treatment so that wastewater reaches state discharge standards. The method can solve the problems of low effect on removing suspended matters and dissolved Si2+, Al3+ and their compounds, scaling and column blockage during steam-stripping process, and the need for a large amount of alkali added, and can improve wastewater treatment effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

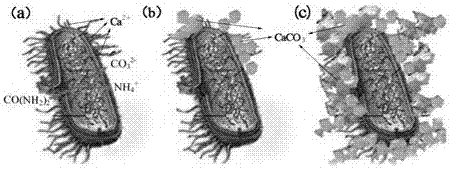

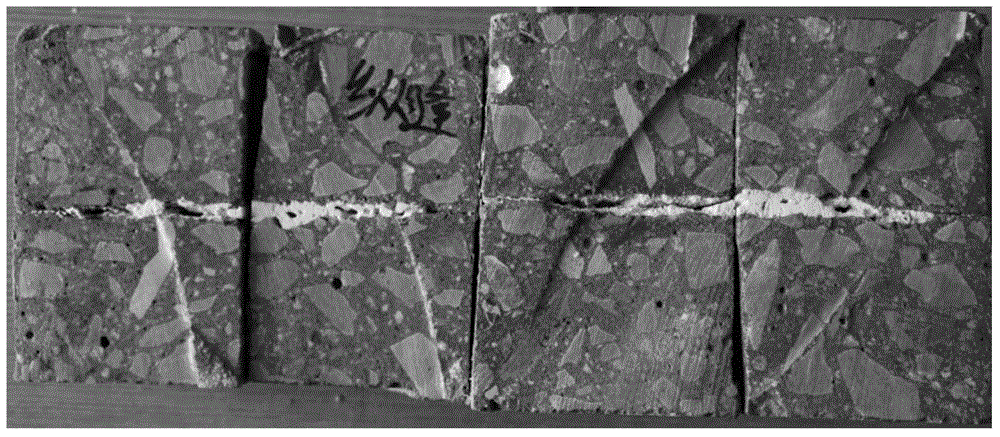

Sprayed concrete with microorganism crack self-repairing capacity and preparation method of sprayed concrete

InactiveCN108017337AStrong adaptability to high alkaline environmentIncreased durabilityPorosityShotcrete

The invention discloses sprayed concrete with microorganism crack self-repairing capacity and a preparation method of the sprayed concrete. The sprayed concrete is prepared from components as follows:self-repairing particles carrying a microorganism repair agent and nutrients, cement, pebbles, sand, silica fume, water, polypropylene fibers, a sodium aluminate liquid accelerator and a polycarboxylate superplasticizer. The microorganism with mineralization and sedimentation characteristics is taken as the crack repair agent of the sprayed concrete, and expanded perlite or flyash pottery sand with high porosity is taken as a carrier of the repair agent; the carrier is coated with the nutrients and is isolated from a cement-based material by an isolating layer. The concrete cracks are repaired by calcium carbonate precipitate produced by the microorganism repair agent in a metabolism process, and the crack self-repairing capacity of the sprayed concrete in the service is improved, so thatimpervious performance and durability of the sprayed concrete are improved. The sprayed concrete with crack self-repairing capacity as a sprayed concrete material with crack self-diagnosis and self-repairing functions has great research value and application potential.

Owner:李珠

Method for processing production waste water of propylene oxide

InactiveCN101337745ARealize environmental protection and decontaminationCalcium/strontium/barium carbonatesWater/sewage treatment bu osmosis/dialysisEpoxyCalcium bicarbonate

A method for processing industrial wastewater of epoxy propane relates to a processing method of wastewater produced by epoxy propane, in particular to the treatment and the re-utilization of calcium chloride in wastewater. The invention provides a method for processing the industrial wastewater of the epoxy propane, which is used for processing and better utilizing the calcium oxide in the industrial waste water of the epoxy propane. The method comprises the following steps: firstly, generating calcium bicarbonate and calcium chloride by utilizing the reaction of ammonium bicarbonate and ammonium chloride; secondly, generating calcium carbonate precipitate, water and carbon dioxide through thermally decomposing the calcium bicarbonate; and thirdly, generating the calcium carbonate precipitate and the water by utilizing the reaction of calcium hydroxide in the wastewater and CO2 generated by thermally decomposing the calcium bicarbonate.

Owner:LIAONING DAZE ENVIRONMENT ENG

Microbial seal-healing capsule for coal mine air leakage plugging as well as preparation method and application of microbial seal-healing capsule

InactiveCN107973542AImplement automatic detectionAchieve automatic healingMicroparticleCalcium carbonate precipitation

The invention discloses a microbial seal-healing capsule for coal mine air leakage plugging as well as a preparation method and application of the microbial seal-healing capsule. Dry powder of bacterial spores is uniformly dispersed in water, a suitable substrate is selected according to the kinds of the bacterial spores, the substrate is added into a uniformly-dispersed mixed solution according to a certain ratio of the bacterial spores to the substrate and is uniformly stirred to be agglomerated, the agglomerated mixture is slowly added into a multifunctional granulator and is extruded, a cooling system is started, the temperature of the material is maintained, and the extruded strip-shaped substance is added into a rounder for rounding and is sieved and dried to obtain microparticles; and the microbial seal-healing capsule is prepared from the microparticles and a wall material by using a vacuum impregnation method or an interfacial polymerization method, the microbial seal-healingcapsule and a main material for air leakage plugging are mixed to be used, once concrete is cracked, the spores inside the material can be activated to normally metabolize, and calcium carbonate is continuously induced to be precipitated, so that the self-repair of cracks is realized.

Owner:SHANDONG UNIV OF SCI & TECH

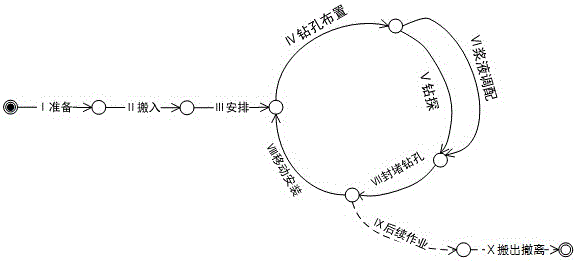

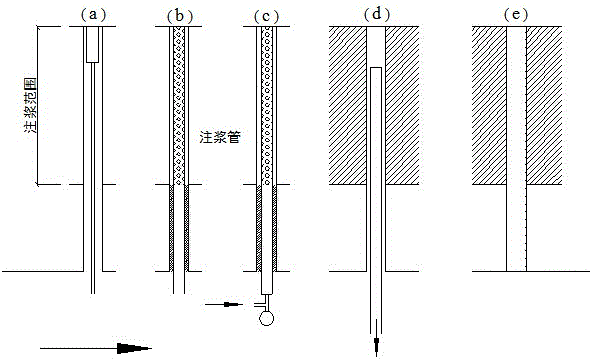

Solidification and pore forming method for coal rock stratum containing weak structural bodies

ActiveCN106837237APrevention of dynamic instabilityEfficient curingSealing/packingChemical treatmentStructure of the Earth

The invention relates to a solidification and pore forming method for a coal rock stratum containing weak structural bodies. The solidification and pore forming method comprises the following steps that 1, a plurality of solidification holes are drilled, specifically, the solidification holes are formed according to the range of the weak structural bodies of the coal rock stratum to be solidified; 2, bacterium liquid, stationary liquid and cementing liquid are sequentially injected in the holes in a pressurization mode through grouting pipes, and calcium carbonate is induced to crystallize through a MICP in-situ grouting technology; and 3, after fractures and the weak structures around the solidification holes are solidified through the microorganism slurry, production is organized in solidification positions according to the subsequent process. On the one hand, microorganisms are adsorbed on the surfaces of pores and the fractures around the drilling holes, the calcium carbonate is effectively induced to precipitate, and the inner surface of the coal (rock) stratum is bonded and cemented, and surrounding rock with the soft characteristic is solidified and cemented to form a whole with certain mechanical properties, so that the strength of hole wall surrounding rock is strengthened; and on the other hand, the microorganism slurry is a solution or suspension liquid, the viscosity of the slurry is low, fluidity is good, permeability is strong, compared with a chemical treatment method, the limit grouting pressure is small, the solidification radius is large, and the cementation strength of the drilling hole surrounding rock can be regulated and controlled.

Owner:CHONGQING JIAOTONG UNIVERSITY

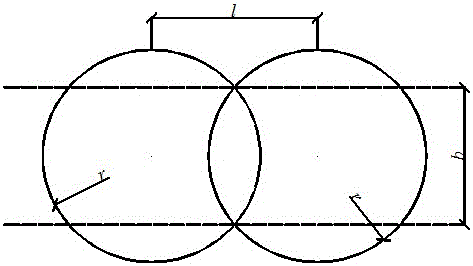

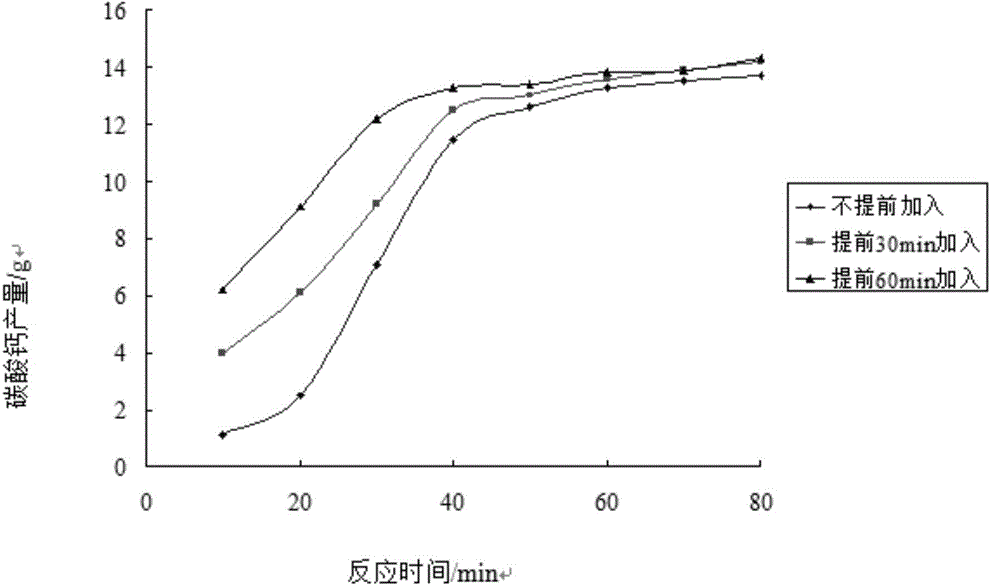

Microorganism grouting method capable of improving early-stage calcium carbonate deposit volume

ActiveCN104818719AIncrease early depositionIncrease depositionArtificial islandsUnderwater structuresMicroorganismCalcium carbonate precipitation

The invention discloses a microorganism grouting method capable of improving an early-stage calcium carbonate deposit volume, which comprises the following steps: (1) a nutritive salt solution is added into a microorganism bacterium liquid to obtain a mixed liquid of bacterium liquid and nutritive salt, and standing is carried out for 0.5-1h; and (2) during grouting, the mixed liquid of bacterium liquid and nutritive salt is blended with a calcium salt solution according to a predetermined proportion. Due to the adoption of a microorganism grouting material, not only is the total output of calcium carbonate sediment effectively improved, but also the early-stage output of the sediment is can be effectively improved, so that important significance is provided for blocking concrete cracks by utilizing a grouting method. Only a lot of calcium carbonate sediment is generated in relatively short time, the concrete cracks can be blocked in relatively short time, and thus grouting amount and times can be reduced.

Owner:SHANDONG JIANZHU UNIV

Microcapsule for continuous self-repairing of coal mine wind plugging material crack, and preparation method thereof

InactiveCN108823198AImplement automatic detectionAchieve automatic healingBacteriaOn/in inorganic carrierSporeHigh volume manufacturing

The invention provides a microcapsule for continuous self-repairing of a coal mine wind plugging material crack, and relates to the technical field of coal mine wind plugging material crack repairing.The microcapsule comprises a microcapsule core material and a microcapsule wall material, and the microcapsule core material is prepared from lyophilized bacterium powder and a substrate. Urease-producing bacteria are used to provide a method for protecting long-time survival of bacteria in a cement-based material, providing sufficient nutrients and reducing the influences of bacterium addition on the mechanical properties of the cement-based material. The microcapsule is prepared from the lyophilized bacterium powder and its substrate, and is added in the mixing process of the cement-based material, so once the concrete has a crack, the microcapsule is broken, and spores in the material are activated to perform normal metabolism and continuously induce calcium carbonate precipitation, soself-repairing of the crack in the coal mine wind plugging material is continuously achieved. The preparation method has the advantages of simplicity in operation, and realization of large-batch production.

Owner:SHANDONG UNIV OF SCI & TECH

Method for selectively removing calcium ions from concentrated water byproduct of sea water desalination process and other high-calcium-magnesium-content concentrated brines

InactiveCN102936067AHigh removal rateQuick responseGeneral water supply conservationMultistage water/sewage treatmentLoss rateWater desalination

The invention relates to a method for selectively removing calcium ions from a concentrated water byproduct of a sea water desalination process and other high-calcium-magnesium-content concentrated brines, which comprises the following steps: regulating the pH value of the concentrated water to 7.0-8.5, and then heating to a certain temperature; introducing the concentrated water into a heat-insulating apparatus capable of realizing sealed stirring, adding a sodium sulfite or sodium carbonate solution having a certain concentration while stirring, reacting for 1-40 minutes while sufficiently stirring, standing for 5-10 minutes, and then filtering to remove calcium sulfite or calcium carbonate precipitate; and adding hydrochloric acid into the filtrate to regulate the pH value back to 6. According to the invention, the problems of low calcium removal rate, high magnesium loss rate, long stirring time and the like during the concentrated water treatment based on the traditional normal-temperature sodium carbonate precipitation method are overcome, the operation is convenient, the investment is low, and the operation cost is low; and the concentrated water liquid subjected to decalcification treatment can be further deeply concentrated through a membrane method or hot method, thereby improving the fresh water recovery rate and realizing the reutilization and zero discharge of the resources. The method provided by the invention is suitable for selectively removing calcium ions from sea water, sea water or brackish water subjected to other treatment processes such as reverse osmosis or multiple-effect evaporation and concentration, underground salt brines and concentrated water of industrial waste water subjected to reverse osmosis treatment.

Owner:天津凯铂能膜工程技术有限公司

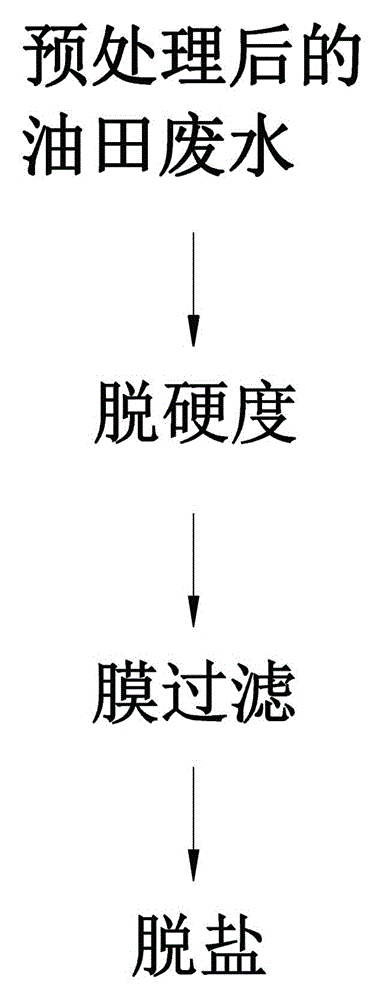

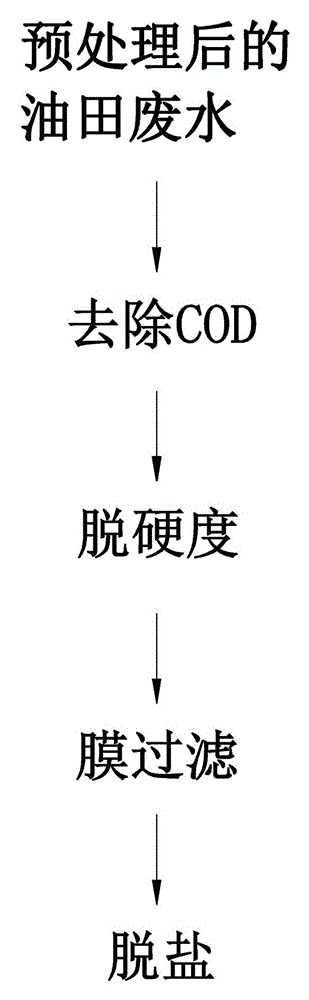

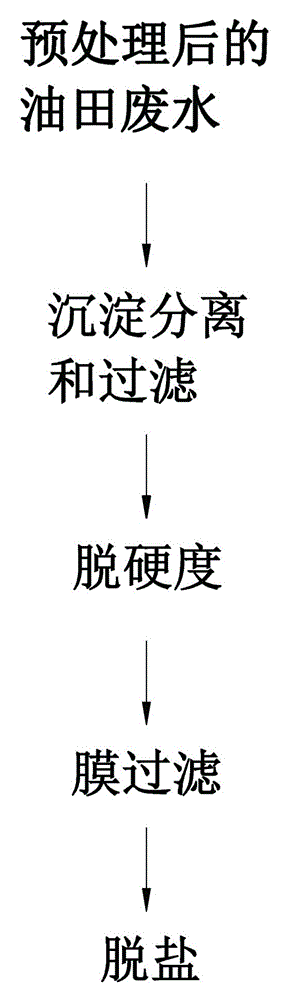

Method for treating and recycling high-salt oil-field wastewater

InactiveCN105000726AReduce osmotic pressureResolve membrane calcificationWaste water treatment from quariesGeneral water supply conservationTurbidityCalcification

A method for treating and recycling high-salt oil-field wastewater comprises the following steps: (1) adding lime milk and sodium carbonate into pre-treated oil-field wastewater to generate calcium carbonate precipitation and magnesium carbonate precipitation by cooperating with a coagulant and a flocculating agent, and removing the calcium carbonate precipitation and the magnesium carbonate precipitation through precipitation separation to eliminate the calcification of a membrane and avoid the blockage of the membrane; (2) after filtering and clarification, removing particle impurities through microfiltration, hyperfiltration or nanofiltration membrane filtering; (3) performing reverse osmosis, forward osmosis, electroosmosis and capacitive adsorption treatment to obtain recycled reused water and a concentrated solution. According to the method provided by the invention, CODcr can be effectively reduced, the indexes, such as SS and turbidity of wastewater can be reduced, the metal ions in water can be removed, the salt content can be lowered, and the recovery rate of 50 to 65 percent of oil-field wastewater is realized.

Owner:BOYING XIAMEN SCI & TECH

Penetration type microorganism uniformly-cured sandy soil sample preparation device and sample preparation method thereof

ActiveCN105424438AReduce disturbanceUniform curingPreparing sample for investigationMicroorganismTest sample

The invention discloses a penetration type microorganism uniformly-cured sandy soil sample preparation device. The penetration type microorganism uniformly-cured sandy soil sample preparation device comprises a capillary tube needle injection device, a microorganism solution pressure supplying device, a nutrient solution pressure supplying device and a liquid collection container, wherein the capillary tube needle injection device comprises a capillary tube needle and an organic glass splitting die; and the capillary tube needle is inserted into a sandy soil test sample to inject a microorganism solution. The microorganism solution pressure supplying device comprises a pressure controller and a solution isolation device, wherein the pressure controller carries out injection compression until the microorganism solution is injected into the capillary tube needle by the solution isolation device. The nutrient solution pressure supplying device comprises a water pump and a nutrient solution container; and the nutrient solution is pressurized by the water pump and then is injected to the sandy soil test sample from the bottom of the splitting die. After the microorganism solution and the nutrient solution are mixed, the mixed solution is discharged out from the top of the test sample to the liquid collection container; and meanwhile, calcium carbonate sediment generated by mixing the microorganism solution and the nutrient solution in the test sample can be used for reinforcing the sandy soil test sample. With the adoption of the penetration type microorganism uniformly-cured sandy soil sample preparation device, the calcium carbonate sediment can be relatively uniformly distributed in the sandy soil test sample.

Owner:西安银鼎科技有限公司

Method for modifying recycled aggregate based on aerobic basophilic mixed bacterium mineralization deposition

ActiveCN107226630ANo negative impact on physical and mechanical propertiesImprove surface compactnessSolid waste managementMicroorganismsScreening methodOxygen

The invention discloses a method for modifying recycled aggregate based on aerobic basophilic mixed bacterium mineralization deposition. The method comprises I, screening aerobic basophilic mixed bacteria and II, modifying recycled aggregate. Through a bacterial screening method, aerobic basophilic mixed bacteria having good practicability to the survival environment are screened. In the environment with enough calcium sources, oxygen and water, the mixed bacteria realize mineralization deposition of a large amount of calcium carbonate precipitates through metabolism. Through the excellent mineralization deposition capacity of the mixed bacteria, cracks and holes on the surface of recycled aggregate are repaired. In modification of the recycled aggregate, the desired mixed bacteria are screened and then are cultured, then the bacterium solution is adsorbed by the surface of recycled aggregate through a vacuum absorption method, and a calcium lactate solution is sprayed to the recycled aggregate to cure the recycled aggregate so that the surface defects of the recycled coarse aggregate are repaired. The method can effectively improve the physical and mechanical properties of the recycled coarse aggregate.

Owner:山西耀辉实业发展股份有限公司

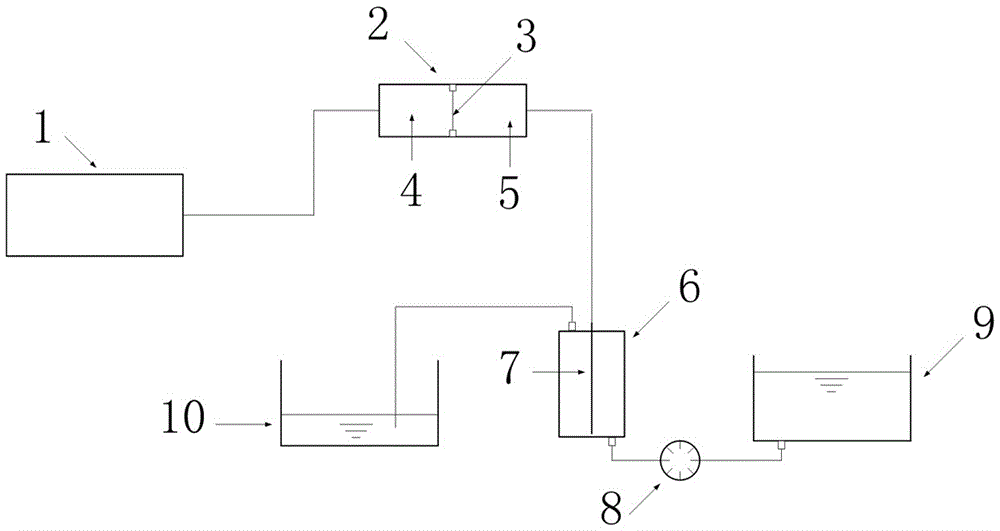

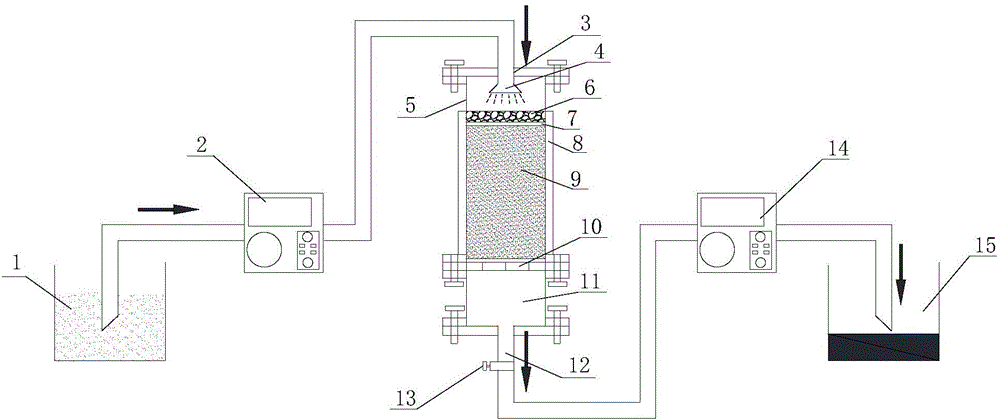

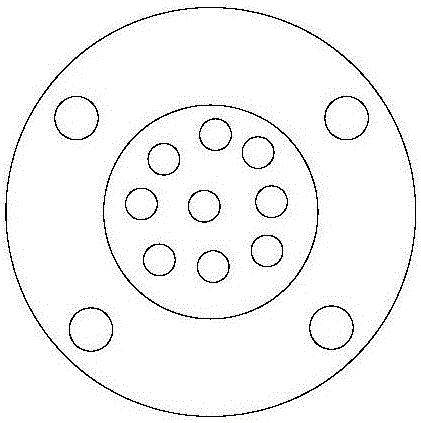

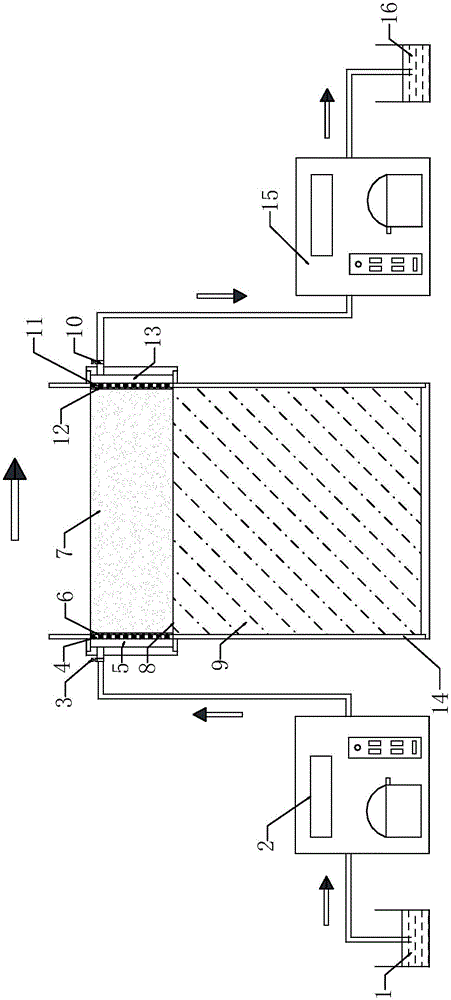

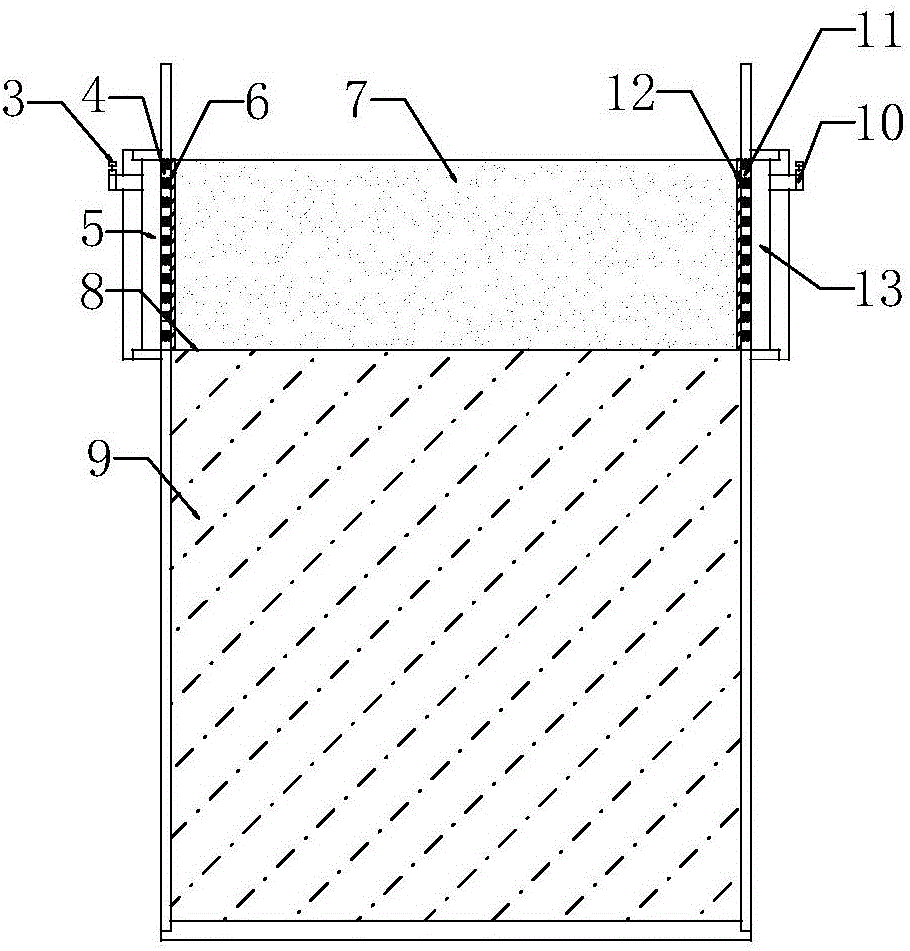

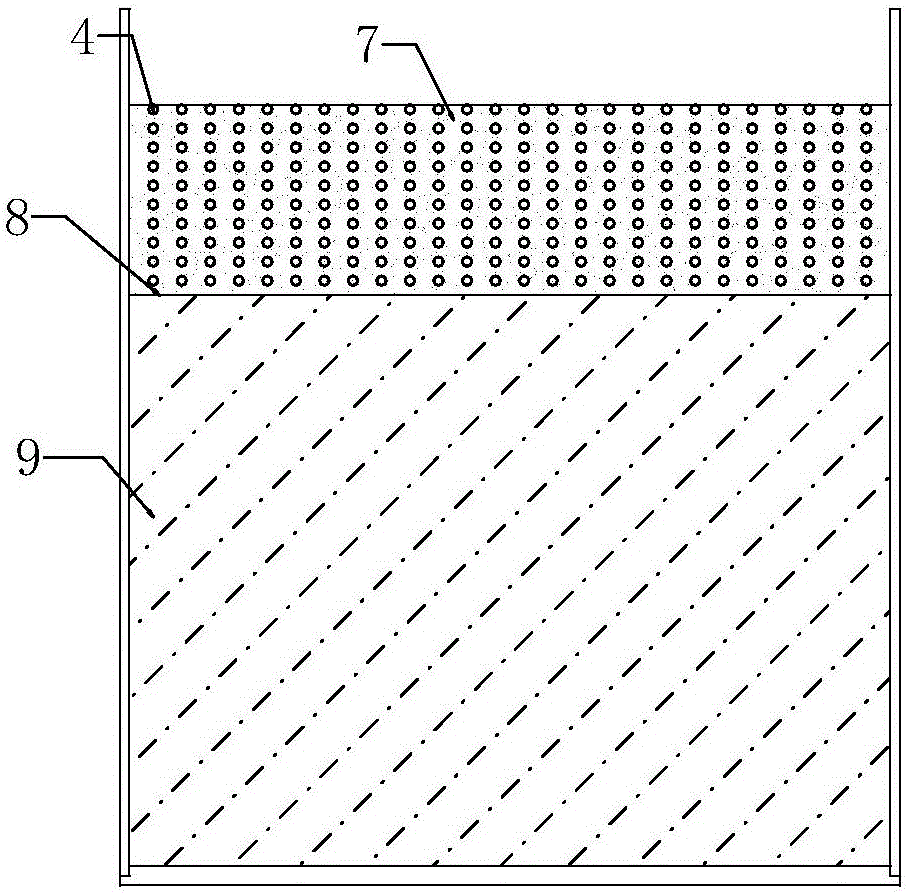

MICP (microbiologically induced calcium carbonate precipitation) cementing test device

InactiveCN105891085AUniform infiltrationImprove permeabilityEarth material testingPermeability/surface area analysisPorosityPeristaltic pump

The invention discloses an MICP (microbiologically induced calcium carbonate precipitation) cementing test device. The MICP cementing test device comprises a sand column, wherein an inlet is formed in the top center of the sand column; geotextile covering a soil mass sample is arranged in the sand column; a sand gravel layer is formed on the geotextile; a porous plate is fixedly connected to the lower end of the sand column; a middle liquid storage column fixedly connected with the porous plate is arranged below the porous plate; a liquid outlet is formed in the bottom of the middle liquid storage column and is connected with an inlet of a peristaltic pump II through a pipeline, and an outlet of the peristaltic pump II is connected with a liquid containing vessel; a valve is arranged on the pipeline connecting the liquid outlet of the middle liquid storage column and the inlet of the peristaltic pump II; the inlet of the sand column is connected with an outlet of a peristaltic pump I, and an inlet of the peristaltic pump I is connected with a microbial slurry tank. A microbial liquid can infiltrate more uniformly, uniform space-time distribution of the microbial liquid in an infiltration process can be guaranteed, and the permeability in soil mass with low porosity is good, and the cementing strength is high.

Owner:TIANJIN UNIV

Indoor test method forming artificial hard shell layer by microbial curing silty-fine sand

ActiveCN106168550AGuaranteed uniformityGuaranteed SaturationPreparing sample for investigationPeristaltic pumpCarrying capacity

The invention discloses an indoor test method forming an artificial hard shell layer by microbial curing silty-fine sand. Silty-fine sand is paved on slurry which is thick enough, the slurry is separated from the silty-fine sand by a seepage-proofing thin film, liquid is injected into the left side by a liquid injecting peristaltic pump until a sand layer is saturated, liquid on the right side is extracted by a liquid extracting peristaltic pump to form horizontal laminar flow, the flow velocity of liquid injection and extraction is controlled, so that liquid injection and extraction are balanced, and silty-fine sand layers are cemented and cured by MICP (microbial induced calcium carbonate precipitation) technology to form the hard shell layer. The hard shell layer has high rigidity and strength, the carrying capacity of a soft soil foundation can be multiply improved, sand consumption is greatly decreased, the hard shell layer is resistant to liquefaction, and the requirement of basic carrying capacity can be met.

Owner:TIANJIN UNIV

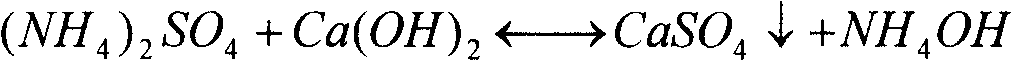

Resource utilization method of half-dry desulfurized fly ash

ActiveCN104096707AFull realization of resource valueImprove conversion rateCalcium/strontium/barium carbonatesSolid waste disposalResource utilizationSlurry

The invention discloses a resource utilization method of half-dry desulfurized fly ash. The resource utilization method comprises the following steps: (1) the half-dry desulfurized fly ash is oxidized to fully convert CaSO3 into CaSO4; (2) water is added to prepare the oxidized desulfurized fly ash to desulfurized fly ash slurry; and then, CO2 is filled in the desulfurized fly ash slurry, so that the CO2 is fully reacted with Ca(OH)2 in the desulfurized fly ash slurry to generate CaSO3, wherein the CO2 is filled by 1.2-1.5: 1 of the mol ratio of the CO2 to the Ca(OH)2; (3) NH4HCO3 is added by 1.2-1.5: 1 of the ratio of the NH4HCO3 to calcium in the obtained slurry, and the pH is adjusted within 7-9, so that sulfur-contained calcium is fully converted to calcium carbonate precipitate; and (4) the slurry obtained in the step (3) is prepared to a calcium oxide and ammonium sulfate solid. The method fully uses the characteristics of high calcium and high sulfur in the half-dry desulfurized fly ash to convert the desulfurized fly ash into ammonium sulfate and calcium carbonate, so that the conversion rates of a calcium element and a sulfur element respectively reach above 95%, and the resource value of the desulfurized fly ash is fully realized.

Owner:武汉钢铁有限公司

Method for producing magnesium hydroxide and calcium carbonate in manners of burning dolomite and dissolving into water to separate calcium and magnesium

ActiveCN103738986ASimple processLow costCalcium/strontium/barium carbonatesMagnesium hydroxideCalcium hydroxideCalcium carbonate precipitation

The invention provides a method for separating calcium and magnesium and preparing magnesium hydroxide by water dissolving and leaching of burnt dolomite. The method comprises the following operation steps: crushing the dolomite and burning into dolomite ashes; slaking the dolomite ashes by water to generate calcium hydroxide and magnesium hydroxide; filtering and separating an insoluble substance magnesium hydroxide; introducing carbon dioxide to leaching liquid to separate out calcium carbonate precipitate; separating again to obtain a calcium carbonate product, adding a purifying agent to filter residue to remove impurities such as iron, aluminum and the like, centrifuging and separating, and baking, so as to obtain the magnesium hydroxide product. The method has the characteristics of being low in cost, simple in process, and good in product quality, and a new production way is provided for preparation of magnesium hydroxide from dolomite.

Owner:贵州胜威化工新材料研究院有限公司

Composition and method for preparing modified calcium carbonate

ActiveCN101857734AImprove retentionSimple methodInorganic compound additionPigment treatment with macromolecular organic compoundsPolymer modifiedHydroxypropyltrimethyl ammonium chloride chitosan

The invention relates to a composition and a method for preparing modified calcium carbonate and belongs to the field of chemicals. The composition comprises the following components: a polymer, calcium chloride and carbonate, wherein the polymer is any one or more of cationic starch, cationic guar gum, chitosan hydrochloride and 2-hydroxypropyl trimethyl ammonium chloride chitosan; and the carbonate is any one or more of potassium carbonate, sodium carbonate, ammonium carbonate and ammonium bicarbonate. The preparation method comprises the following steps of: (1) preparing aqueous solution of the polymer; (2) adding the calcium chloride into the carbonate; (3) adding the aqueous solution of the polymer into a mixture obtained by the step (2); (4) obtaining calcium carbonate precipitate; and (5) washing and drying the calcium carbonate precipitate. The method has the advantages of simpleness, temperate reaction conditions, and capability of preparing polymer modifier-containing filler and remarkably enhancing filler retention and the like.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Desulfurization wastewater treating method and device

ActiveCN106430786AEasy to handleRemove and recycleWaste water treatment from gaseous effluentsMultistage water/sewage treatmentReverse osmosisEvaporation

The invention relates to the field of wastewater treatment, in particular to a desulfurization wastewater treating method and device. The desulfurization wastewater treating method comprises the steps that softening pretreatment is conducted on clear liquid obtained through flocculation treatment and alkali carbonate to obtain calcium carbonate precipitate and softened desulfurization wastewater; nanofiltration treatment is conducted on the softened desulfurization wastewater to obtain sulfuric-acid-rich salt water and sulfuric-acid-deficient salt water; reverse osmosis treatment is conducted the sulfuric-acid-deficient salt water to obtain first chlorine-rich concentrated water and first fresh water; electrodialysis treatment is conducted on the chlorine-rich concentrated water to obtain second chlorine-rich concentrated water and second fresh water; evaporation crystallization treatment is conducted on the second chlorine-rich concentrated water to obtain chlorine salt and third fresh water, wherein the nanofiltration treatment is cyclically conducted on the sulfuric-acid-rich salt water and the softened desulfurization wastewater. By the adoption of the method, wastewater produced after flue gas desulfurization of coal-fired power plants and the like can be effectively treated, the treated wastewater can be resourcefully utilized, the cost for removing and recovering chlorine-containing salt can be reduced, and more purified water can be obtained.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for remedying heavy metal polluted soil by inducing calcium carbonate precipitation through microorganisms

ActiveCN111672900AWide variety of sourcesTake advantage ofContaminated soil reclamationMicroorganismSoil science

The invention discloses a method for remedying heavy metal polluted soil by inducing calcium carbonate precipitation through microorganisms, and belongs to the technical field of geotechnical engineering. The method comprises the following steps: step 1, preparing a bacterial liquid and a cementing liquid; step 2, detecting the concentration of heavy metal pollutants in a suspected contaminated site; step 3, remedying the heavy metal polluted soil; and step 4, detecting the remedying effect. A slurry mixing mode is adopted, the cementing liquid, the bacterial liquid and the heavy metal pollutants can be in full contact, the operation is easy, the cost is low, the remediation uniformity is good, secondary pollution is avoided, and remedied soil can serve as a roadbed filler.

Owner:HEFEI UNIV OF TECH

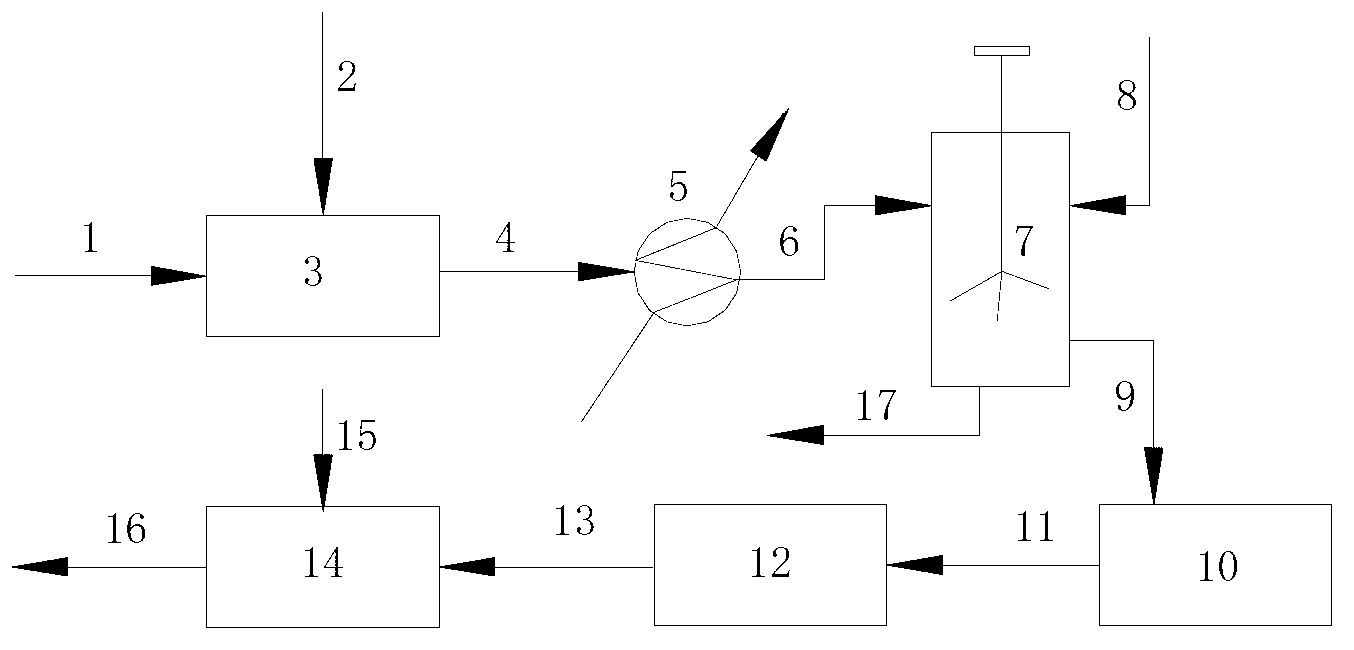

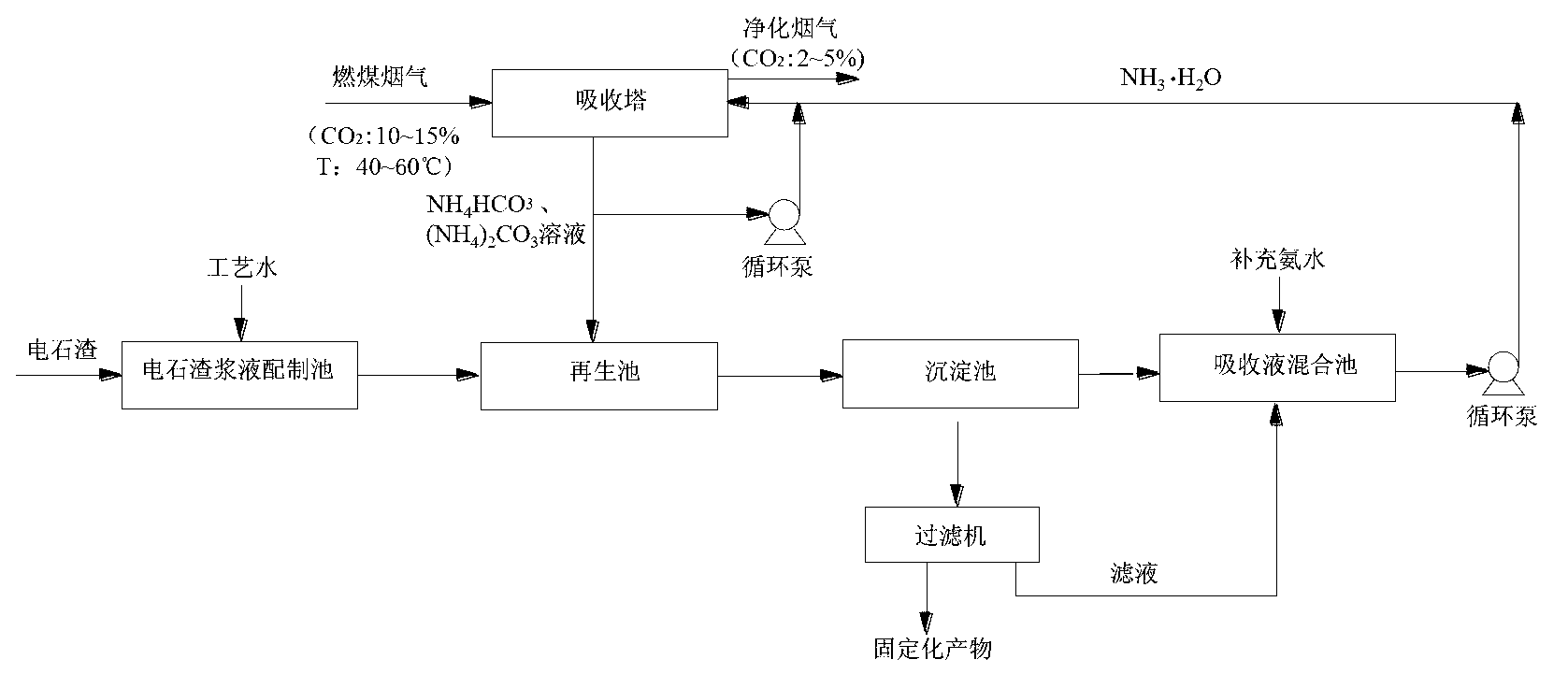

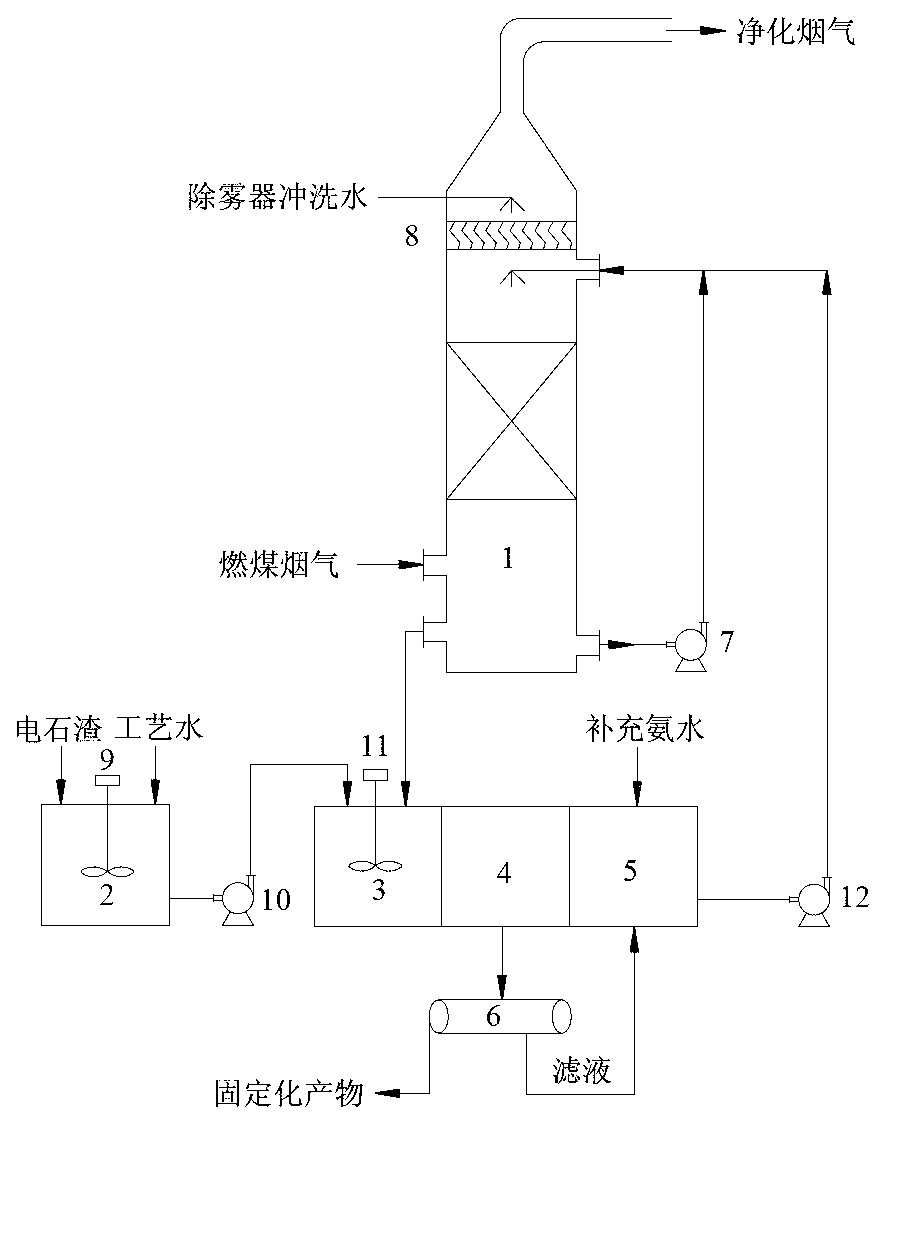

Ammonia circulation-based method and device for carbonating fixation of CO2 in coal-fired flue gas

InactiveCN103007721ARealize comprehensive utilizationFixed applicationDispersed particle separationAir quality improvementHigh concentrationSlag

The invention discloses an ammonia circulation-based method and device for carbonating fixation of CO2 in coal-fired flue gas. The method comprises the following steps that ammonia water is sprayed for absorbing CO2 in the coal-fired flue gas, part of absorption liquid generated in reaction is recycled for use, the rest of the absorption liquid flows into a regeneration pool through tower bottom so as to be reacted with added carbide slag slurry to be converted into calcium carbonate and ammonia water, after sediment through a sedimentation basin, supernatant liquor which is rich in ammonia flows into an absorption liquid mixed pool, and then a proper amount of ammonia water is added into the absorption liquid mixed pool so as to be sent to a CO2 absorption tower through a pump for reuse, after filtration of calcium carbonate sediment in the sediment pool, calcium carbonate is recycled, and the filtrate is sent to the absorption liquid mixed pool for reuse. According to the method, CO2 in the coal-fired flue gas is directly converted into calcium carbonate under normal temperature and pressure by taking ammonia water as an absorbent and taking carbide slag as a regenerant. Compared with the technology that CO2 of high concentration is obtained by ordinary ammonia water absorption and regeneration and carbonation seal is performed, the method has obvious technical economy advantages.

Owner:SOUTHEAST UNIV

Zero-emission sewage reutilization device and method

PendingCN106186550AGuaranteed uptimeReduce evaporationCalcium/strontium/barium carbonatesAlkali metal nitratesReverse osmosisSedimentation

The invention relates to the technical field of zero-emission sewage reutilization and provides a zero-emission sewage reutilization device. A zero-emission sewage reutilization method sequentially comprises steps as follows: miscellaneous salt is subjected to coagulative sedimentation, sodium carbonate is added and calcium carbonate precipitates are obtained; caustic soda is added, and magnesium hydroxide is obtained; membrane filtration is performed, the pH value is regulated, ion exchange softening, advanced oxidation, biochemical treatment with a biological membrane are performed, filtration with a membrane filter and nanofiltration are performed, lime milk is added to interception water obtained through nanofiltration, calcium sulfate is obtained, a supernatant flows back to a miscellaneous salt sedimentation basin, nanofiltration permeate water is concentrated through a reverse osmosis separator A and then is concentrated by a brine concentrator, fresh water produced by the brine concentrator is concentrated by a reverse osmosis concentrator B and flows back to the brine concentrator, concentrated water produced by the brine concentrator enters an crystallizing evaporator and is subjected to hot separation and cold separation, sodium chloride and sodium nitrate are obtained respectively, most crystallization mother liquor is subjected to refluxing treatment, and a small part of crystallization mother liquor is dried; reverse osmosis produced water and distilled water are reused. According to the invention, commercial calcium carbonate, magnesium hydroxide, calcium sulfate, sodium chloride, sodium nitrate salts and high-quality reused water are recycled, emission of solid waste is small, and the operating cost is low.

Owner:GELANTE ENVIRONMENTAL PROTECTION ENG BEIJING CO LTD

Treatment method and system for reutilization and resource utilization of high-mineralization mine water

PendingCN109231632AImprove processing efficiencyAchieving "Zero Emissions"Scale removal and water softeningWater/sewage treatment by ion-exchangeResource utilizationEvaporation

The invention provides a treatment method and system for reutilization and resource utilization of high-mineralization mine water. The treatment method comprises the following steps: firstly, pre-treating to effectively reduce the rigidity and form calcium carbonate sediment; recycling the calcium carbonate and carrying out first-time desalting; secondly, concentrating and carrying out second-timedesalting; finally, carrying out evaporation and crystallization treatment to really realize zero emission of wastewater. The treatment technology and system, provided by the invention adopt a reasonable flow design; the system is operated stably, the treatment efficiency of the wastewater is high, energy sources are saved, and the treatment cost is effectively reduced.

Owner:华电水务工程有限公司

Method for treating ammonia nitrogen wastewater

ActiveCN100429157CPrevent scalingReduce the cost of adding alkaliTreatment using aerobic processesMultistage water/sewage treatmentHigh concentrationTherapeutic effect

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing industrial ultra-fine activated calcium carbonate from carbide slag

The invention discloses a method for preparing industrial ultra-fine activated calcium carbonate from a carbide slag, and particularly relates to preparation of employing O / W-type microemulsion. The technology disclosed by the invention comprises the steps of extracting calcium in the carbide slag by saturated ammonium chloride solution, and separating undissolved impurities to filter and obtain calcium chloride solution; reacting fatty acid and alkyl alcohol with sodium hydroxide solution, and adding petroleum ether to form microemulsion; fining microemulsion particles by ultrasound, slowly dripping the obtained calcium chloride solution under an agitation condition, dripping carbonate or bicarbonate solution after dripping, thereby respectively obtaining an upper layer of oil phase, a middle layer of opaque oil phase containing calcium carbonate sediment, and a lower layer of water phase after reaction and delivery are finished; and centrifugally separating, washing and drying the middle layer to obtain industrial ultra-fine activated calcium carbonate, wherein the oil phase and the water phase can be recovered to apply mechanically. By adopting the method, the processing problem of the carbide slag can be well solved; the obtained oil phase and water phase can be recycled; the cost is saved; the prepared light calcium carbonate surface is coated with a layer of fatty acid; the dispersibility is good; the problem that the product is easily gathered is solved; and the method has economical, social and environment-friendly concepts.

Owner:ANHUI YOUSHENGMEI NEW MATERIAL TECH CO LTD

Method for curing sandy soil by using renewable calcium resource through MICP(microbially induced calcite precipitation)

InactiveCN108718586AHigh strengthGood lookingBacteriaAnimal corpse fertilisersCalciteNutrient solution

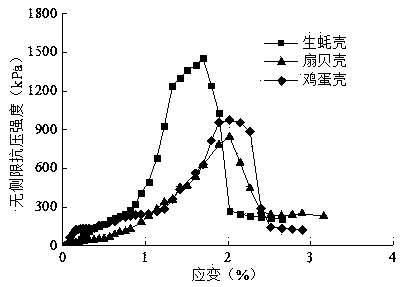

The invention provides a method for curing sandy soil by using renewable calcium resource through MICP(microbially induced calcite precipitation). The method comprises the following steps: S1, preparation of a nutrient solution; S2, preparation of a bacteria solution; S3, preparation of a renewable calcium resource nutrient solution; and S4, preparation of biological sand pulp, wherein fresh oyster shells, scallop shells and egg shell from kitchen residuals are used as a renewable calcium resource, according to the method provided by the invention, the renewable calcium resource is subject toacid pickling so as to obtain calcium ions which are applied to the sandy soil application technology, kitchen wastes are used, solidifying and curing to the sandy soil are further performed, and materials obtained are excellent in intensity and appearance. Compared with the prior art that calcium is adopted for chemical analysis, the method provided by the invention has the advantages that the cost is greatly reduced, and the economical efficiency and the environmental protection effect are relatively good.

Owner:GUANGDONG UNIV OF TECH

New process for fixing carbon dioxide

InactiveCN103170226AAchieve full absorptionSolve pollutionCalcium/strontium/barium carbonatesProductsReaction temperatureDissolution

The invention relates to a new process for fixing carbon dioxide and in particular relates to a new method for absorbing carbon dioxide with low concentration by using alkaline wastes. The new process comprises the steps of mixing the alkaline wastes with a certain weight of water, then adding ammonium chloride solution for dissolution to prepare calcium chloride solution and filling CO2 to generate calcium carbonate precipitates. CO2 in the low concentration range can be absorbed by controlling the gas flow rate and the reaction temperature, so that the limitation that CO2 with concentration being more than 30% (volume ratio) can be only absorbed by the traditional methods is overcome, thus achieving complete absorption and near-zero emission of CO2. The process avoids new waste generation when being used for fixing carbon dioxide and meets the requirements of cyclic economy and low-carbon economy.

Owner:杨晓林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com