Desulfurization wastewater treating method and device

A technology for desulfurization wastewater and treatment methods, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of difficult desalination, high cost, low water resource utilization rate, etc., and achieve reduction Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment is used to illustrate the desulfurization wastewater treatment method and its device of the present invention.

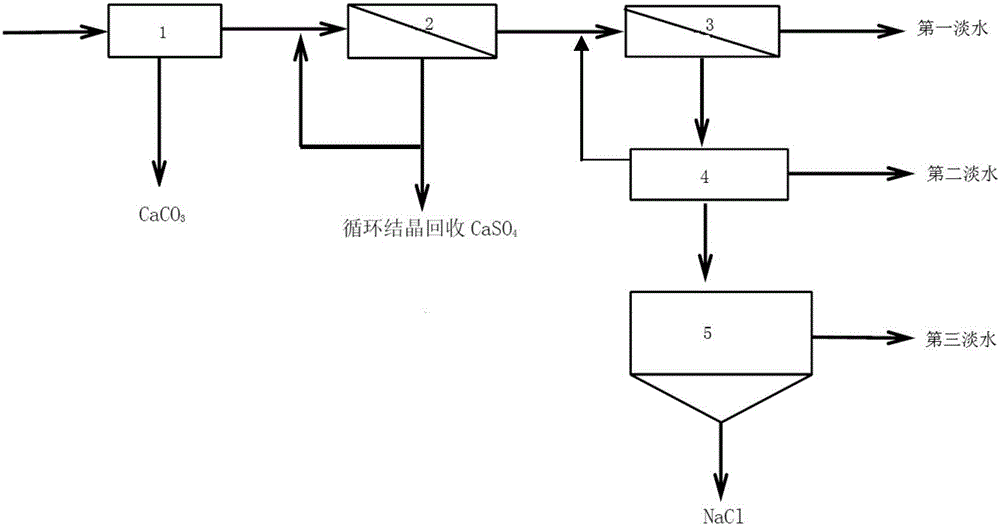

[0078] The desulfurization wastewater is sent to the triple box for neutralization treatment, sedimentation treatment and flocculation treatment in sequence, and the effluent of the flocculation box is sent to the concentration clarifier, and further concentrated and clarified under the addition of polyacrylamide to obtain the supernatant Y1 (water quality is as follows shown in Table 1), using figure 1 The device shown was used for further processing. That is, the supernatant is sent to the softening pretreatment unit 1, and sodium carbonate is added until no calcium carbonate precipitates are produced to obtain calcium carbonate precipitates and softened desulfurization wastewater Y2, and the resulting calcium carbonate precipitates are sent to the desulfurization slurry pool of the desulfurization tower Gypsum is prepared in gypsum; the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com