Patents

Literature

415 results about "Alkali carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The alkali–carbonate reaction is a process suspected for the degradation of concrete containing dolomite aggregate. Alkali from the cement might react with the dolomite crystals present in the aggregate inducing the production of brucite, (MgOH) 2, and calcite (CaCO 3).

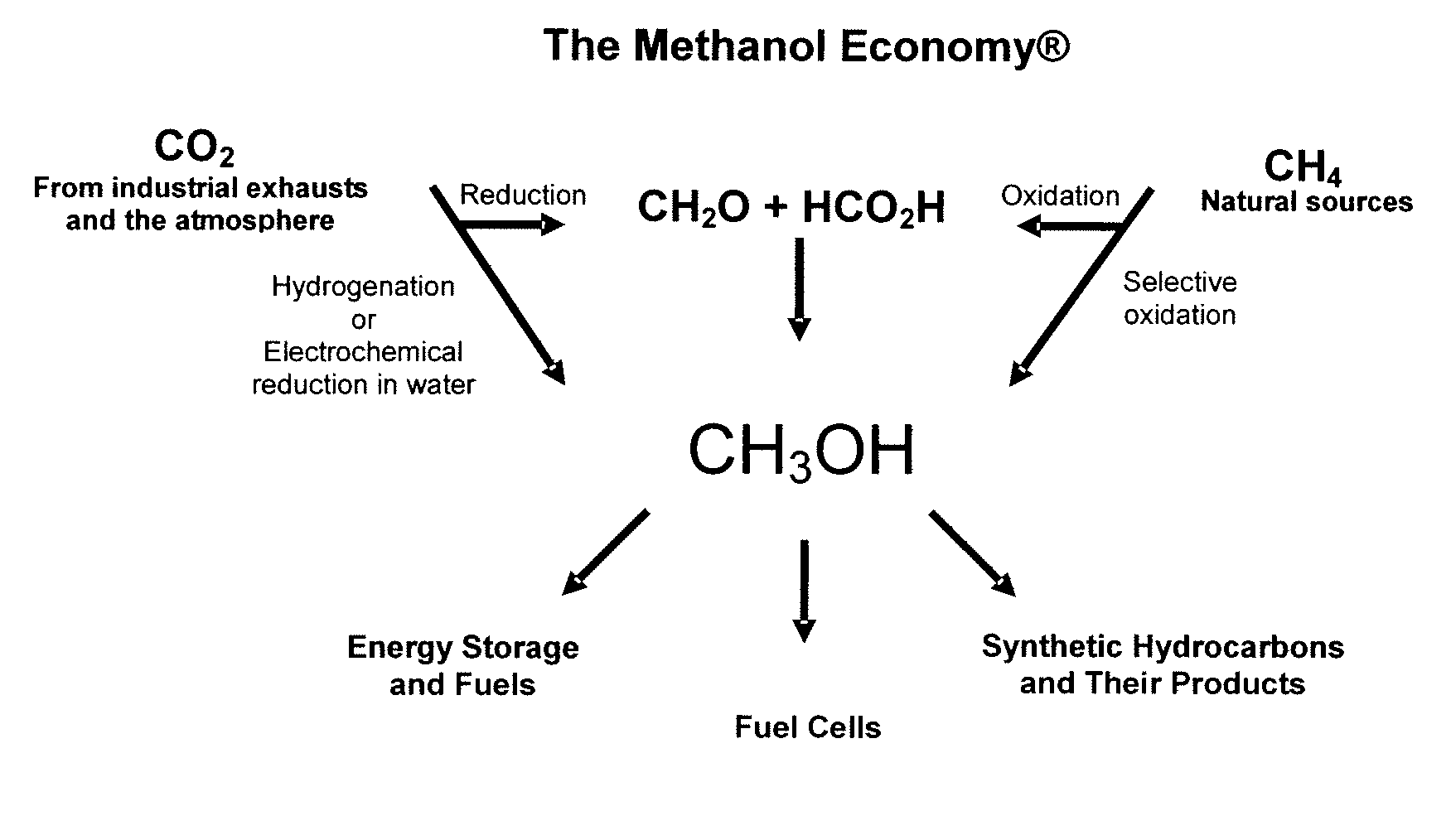

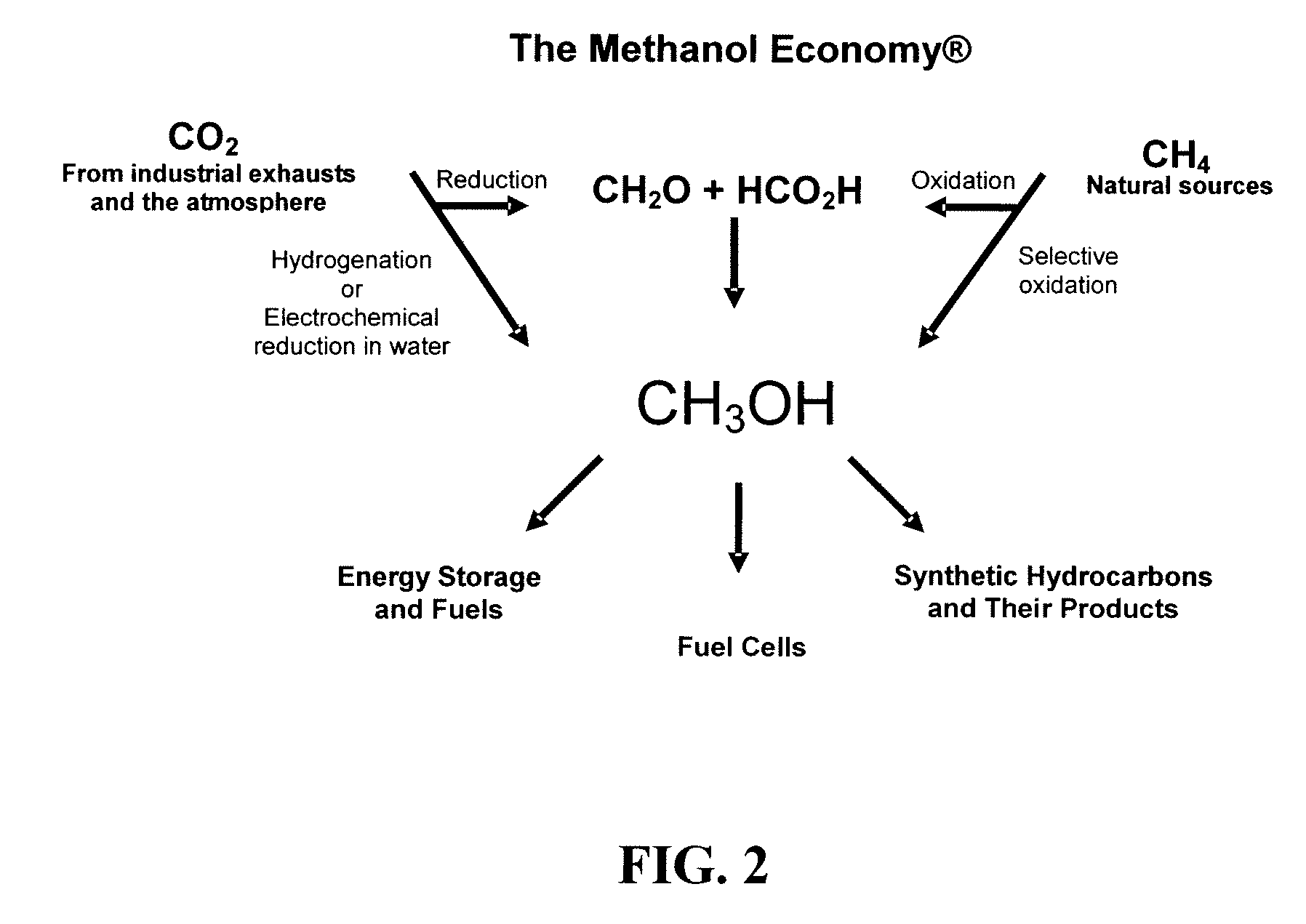

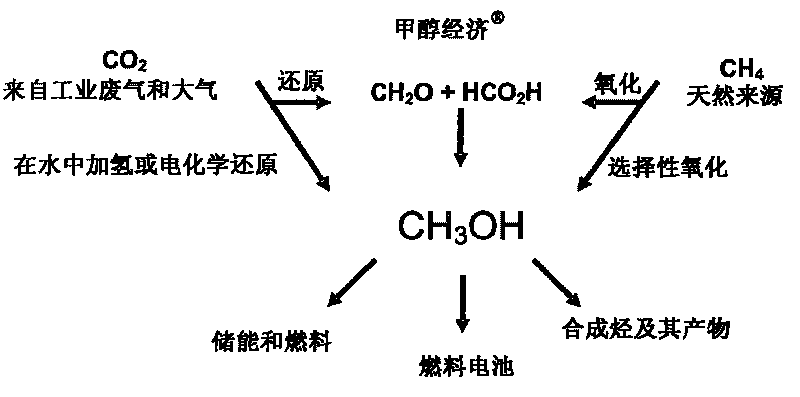

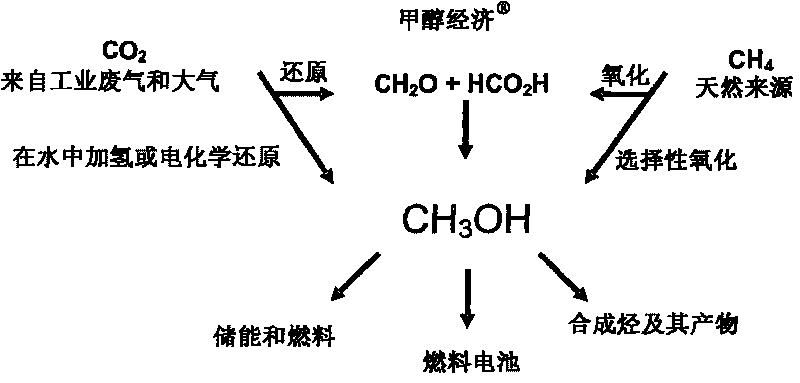

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

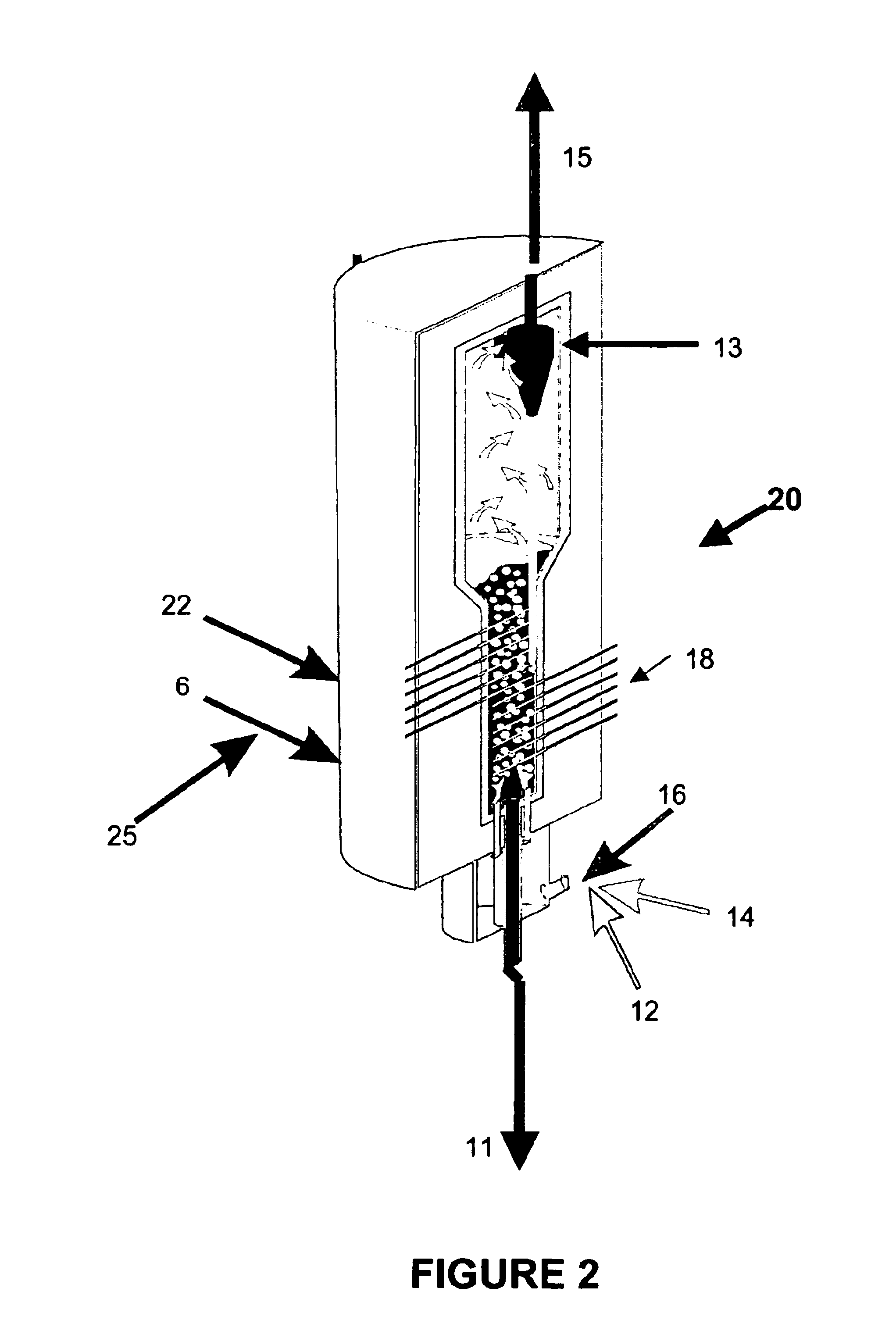

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

Composite heavy metal polluted soil in-situ fixing method

ActiveCN102303041APromote mineralization reactionQuick fixContaminated soil reclamationWater insolubleMagnesium sulfite

The invention discloses a composite heavy metal polluted soil in-situ fixing method. The method comprises the following steps of: preparing a heavy metal polluted soil restoration agent by using 80 to 90 weight parts of bentonite or kaolin serving as a filling agent, 0.5 to 15 weight parts of ferrous sulfide, 0.5 to 5 weight parts of magnesium sulfate, 1.5 to 8 weight parts of magnesium sulfite, 1 to 5 weight parts of magnesium oxide, 2 to 10 weight parts of calcium hydroxide and 1 to 5 weight parts of phosphorus-containing preparation; and mixing the components and heavy metal polluted soil according to the weight ratio of 1:(5-20), and uniformly stirring to make the humidity of the soil kept between 15 and 30 percent, wherein heavy metal ions in the polluted soil are converted into water-insoluble metal sulfides, hydroxides, multi-metal co-precipitates, basic carbonates and phosphate minerals, the biological activity of heavy metal is lost, and the heavy metal is fixed in the soil. The restored soil meets the requirement of second-level standard values of 'Environmental Quality Standard for Soil' (GB 15618-1995) in China.

Owner:刘阳生

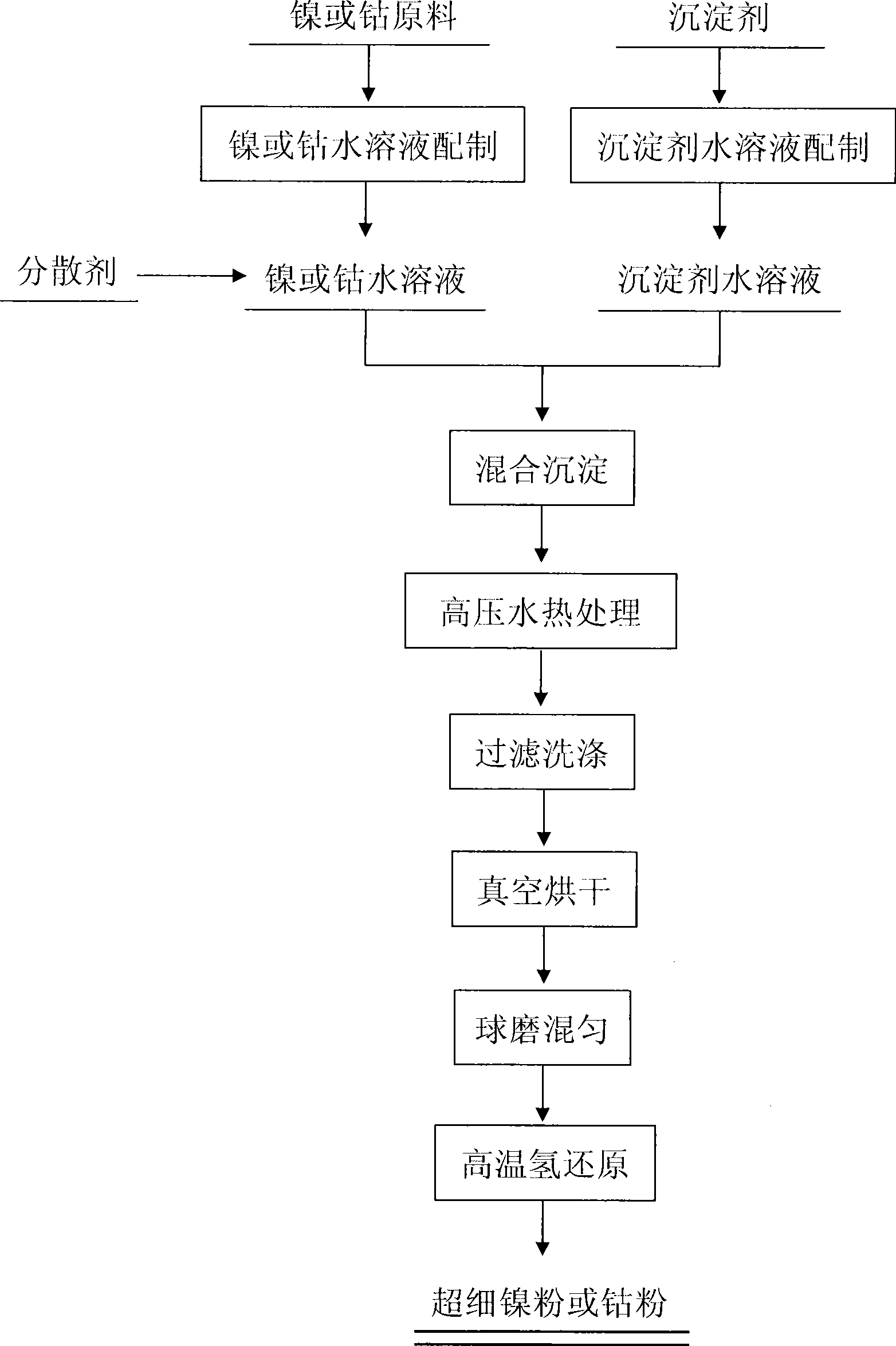

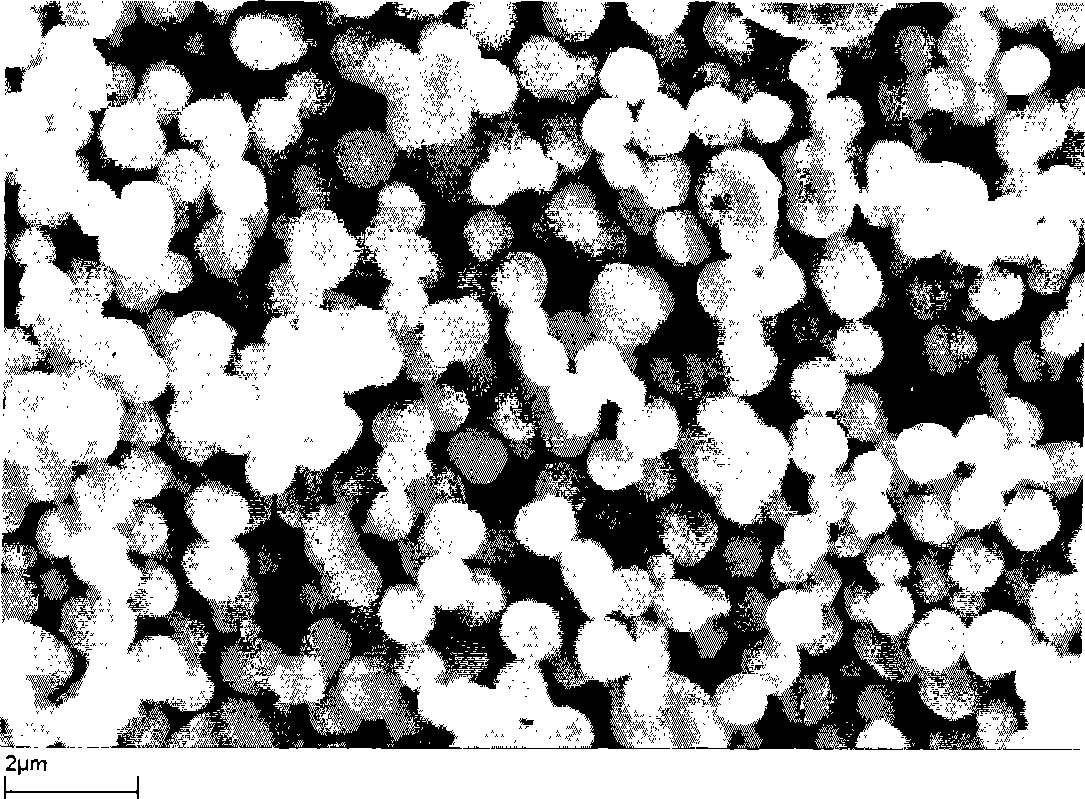

Process for producing spherical submicron metal with hydro-thermal treatment

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

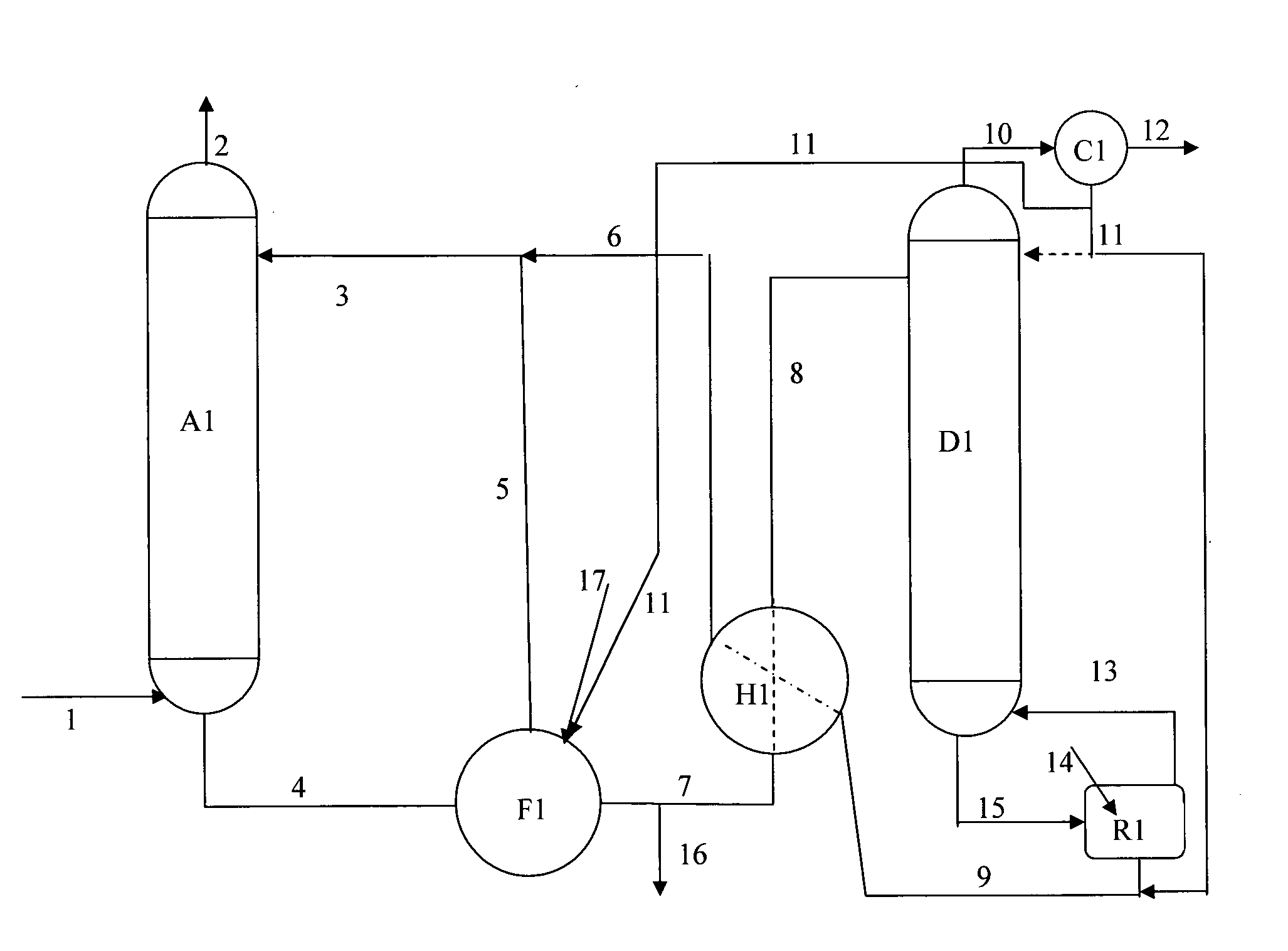

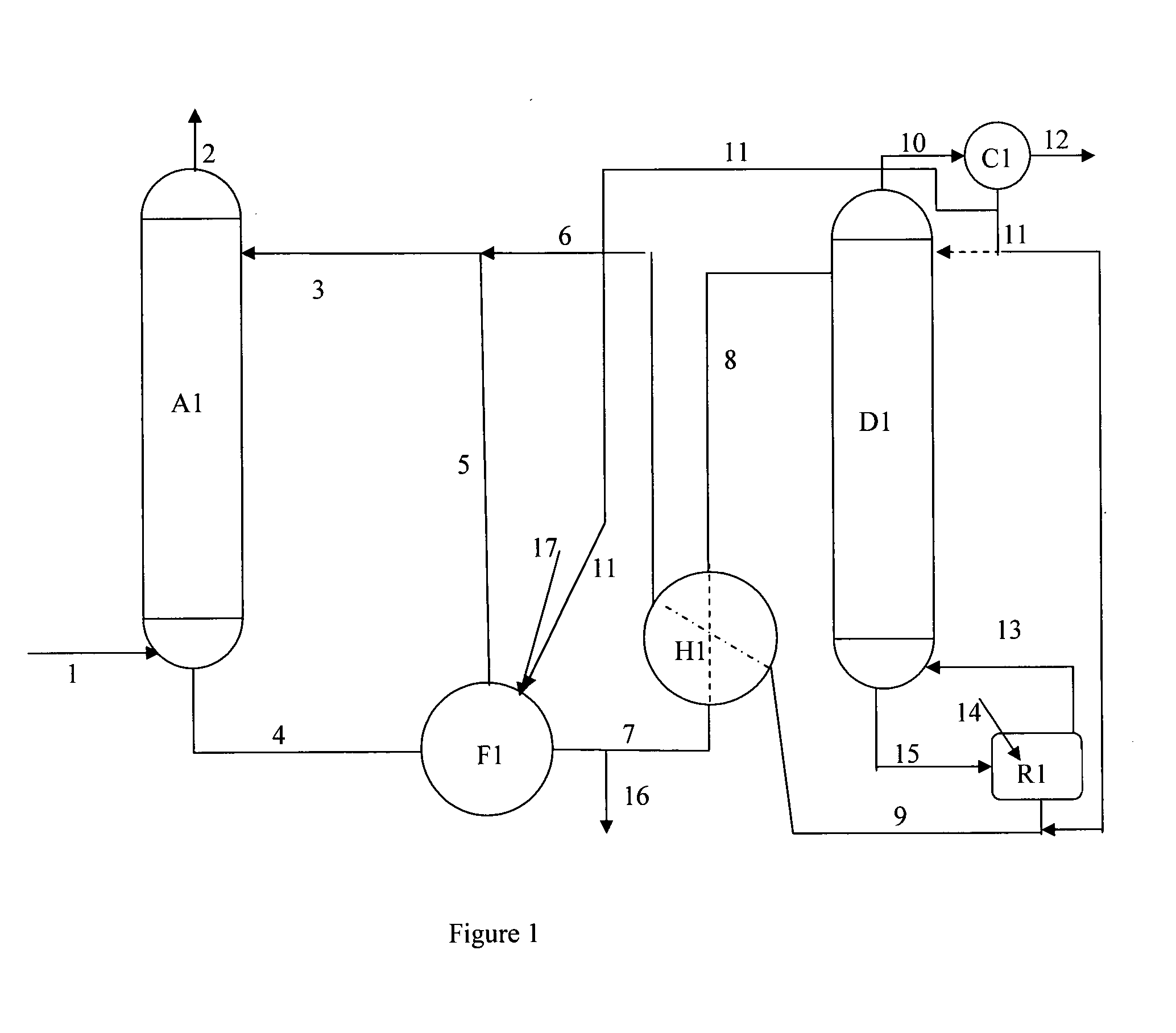

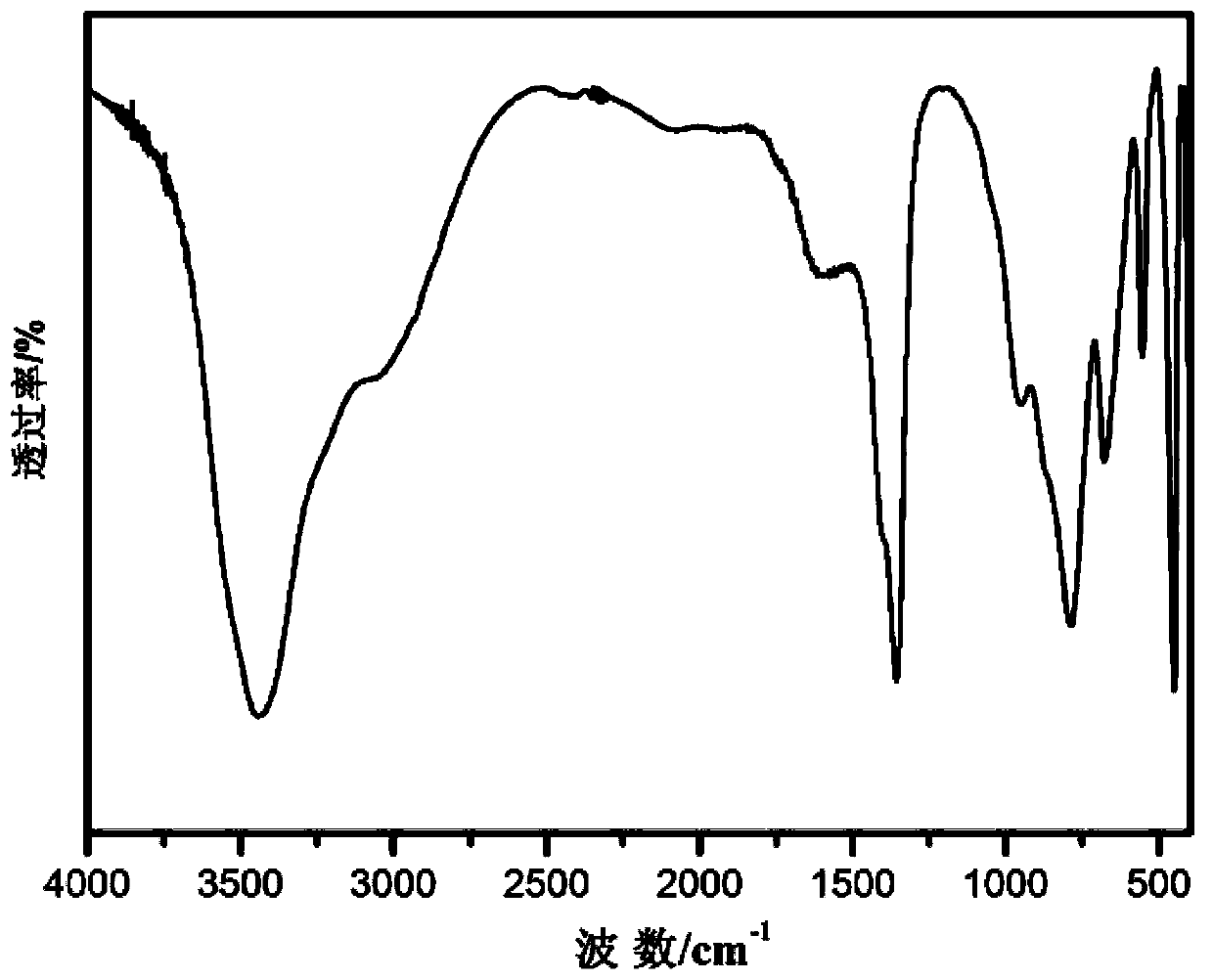

Method for capturing co2 from exhaust gas

The present invention relates to a method for capturing CO2 from exhaust gas in an absorber (A1), wherein the CO2 containing gas is passed through an aqueous absorbent slurry wherein said aqueous absorbent slurry comprises an inorganic alkali carbonate, bicarbonate and at least one of an absorption promoter and a catalyst, and wherein the CO2 is converted to solids by precipitation in the absorber, said slurry having the precipitated solids is conveyed to a separating device (F1), in which the solids are separated off, essentially all of at least one of the absorption promoter and catalyst is recycled together with the remaining aqueous phase to the absorber.

Owner:SINVENT AS

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

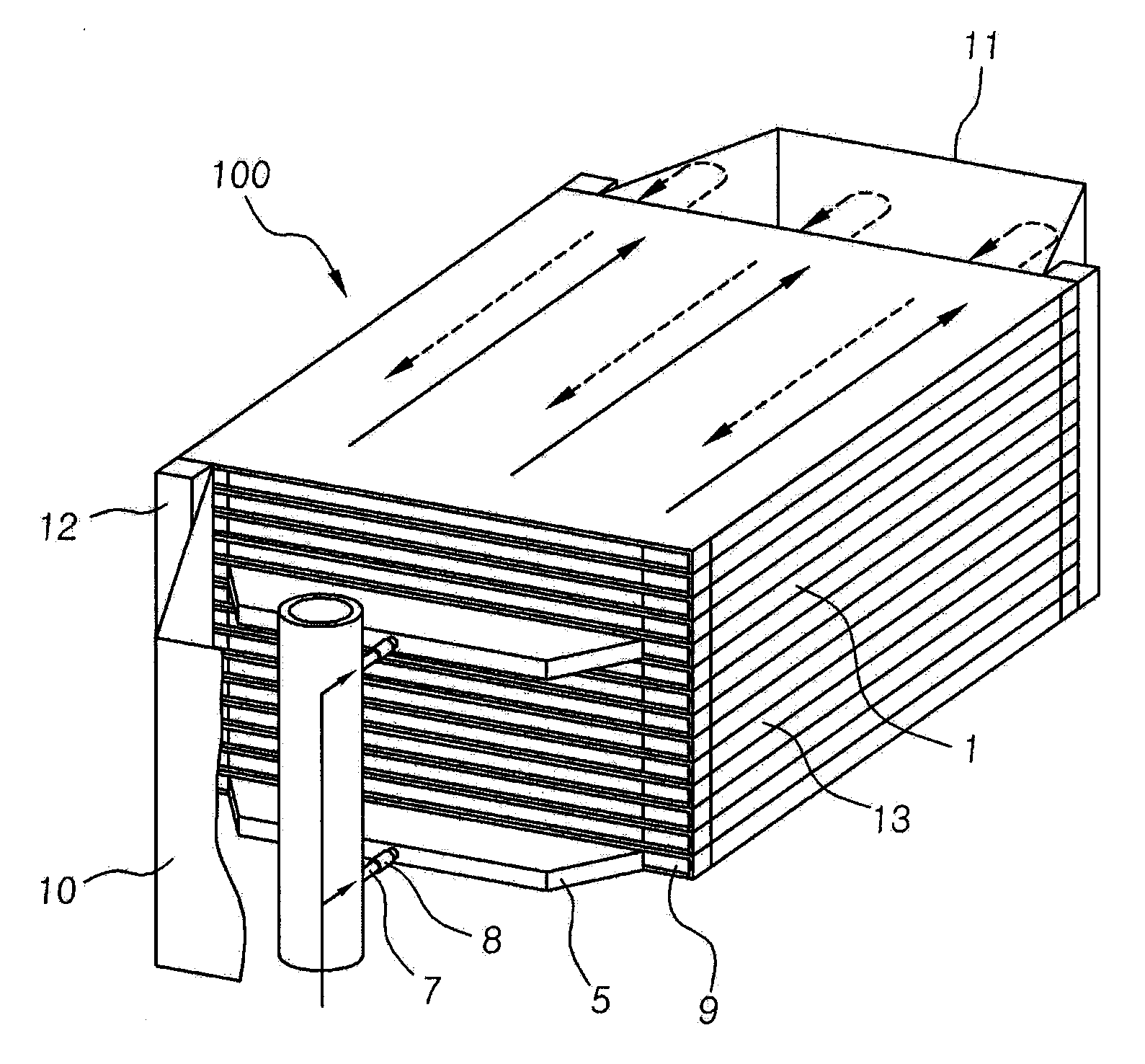

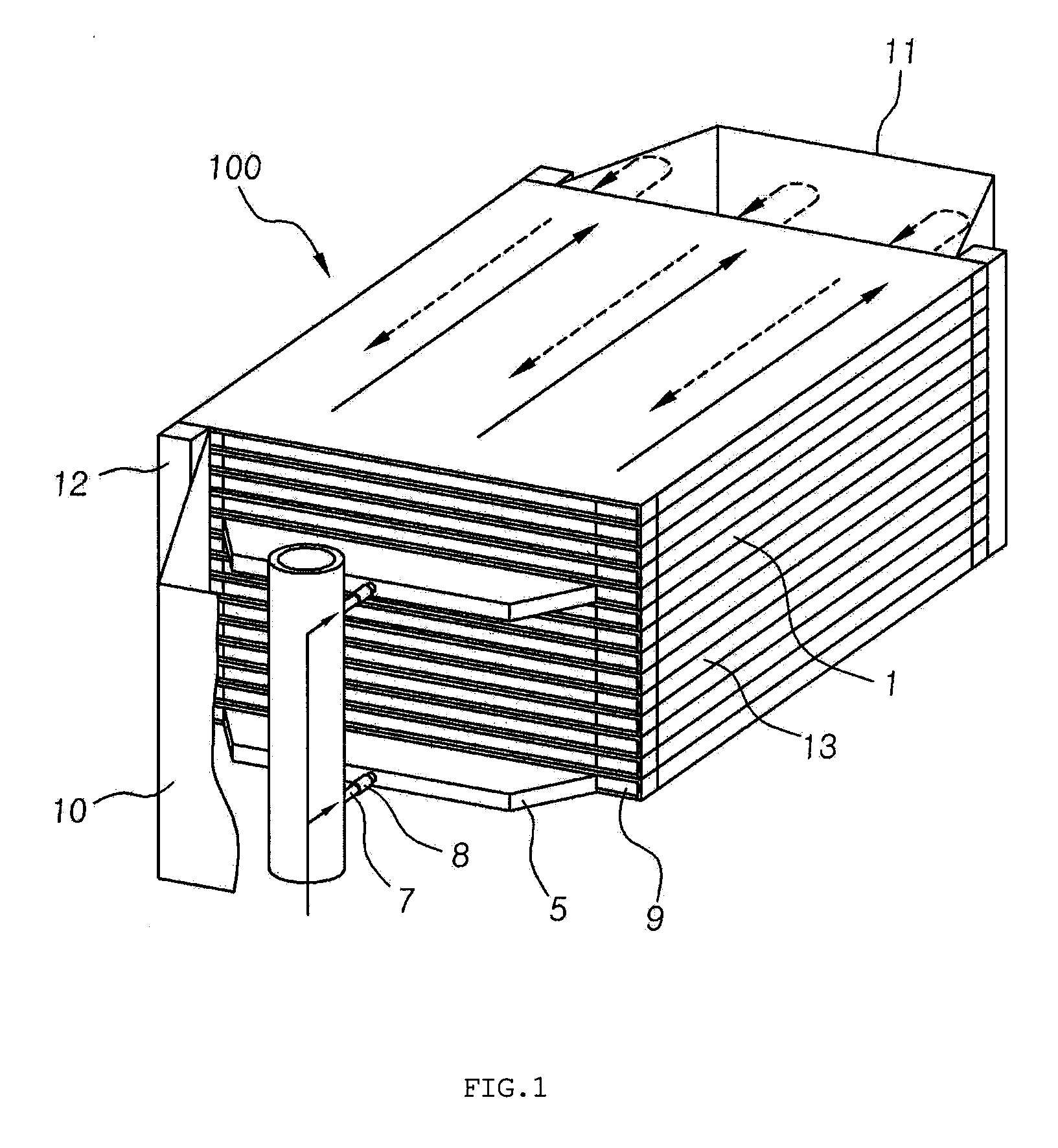

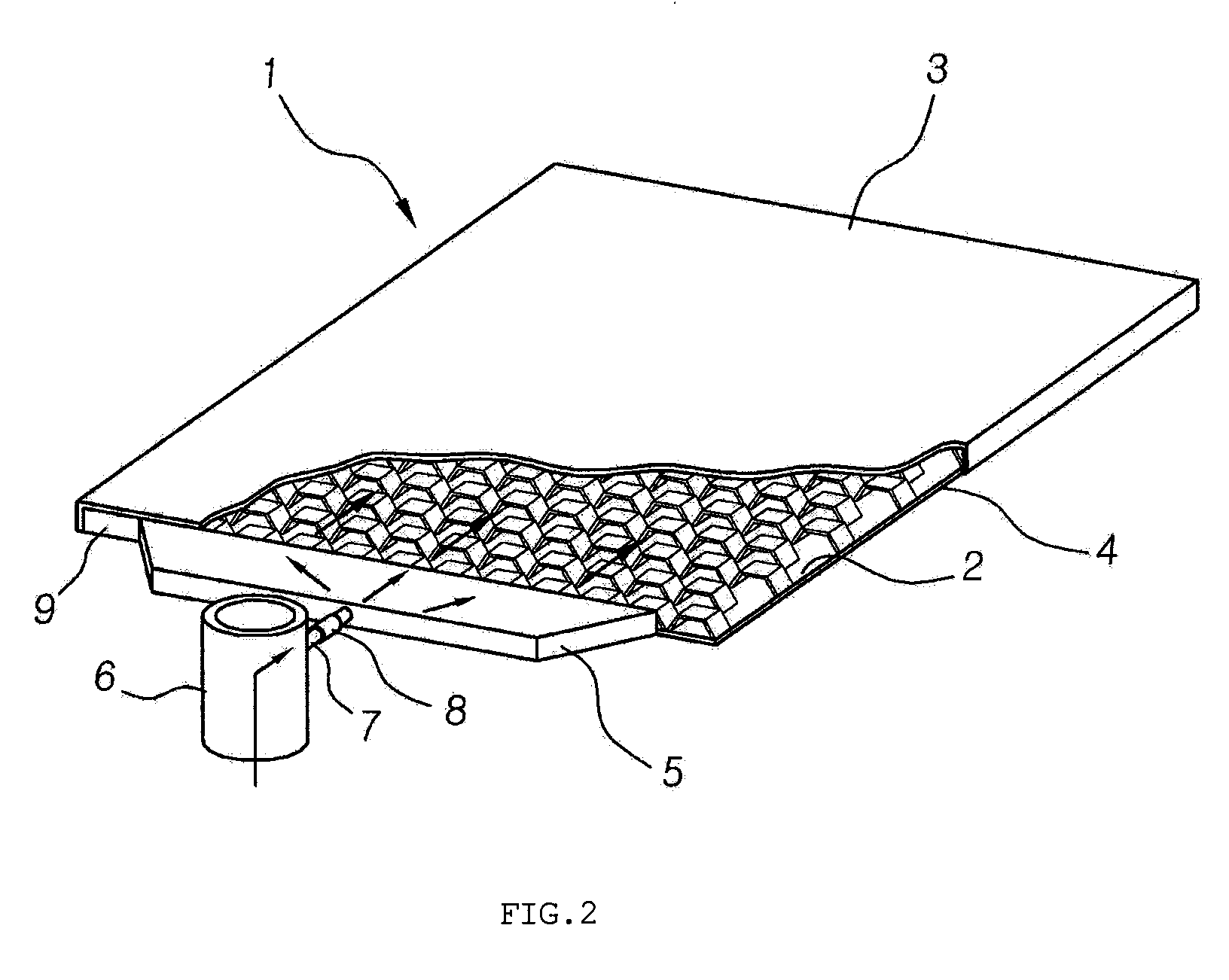

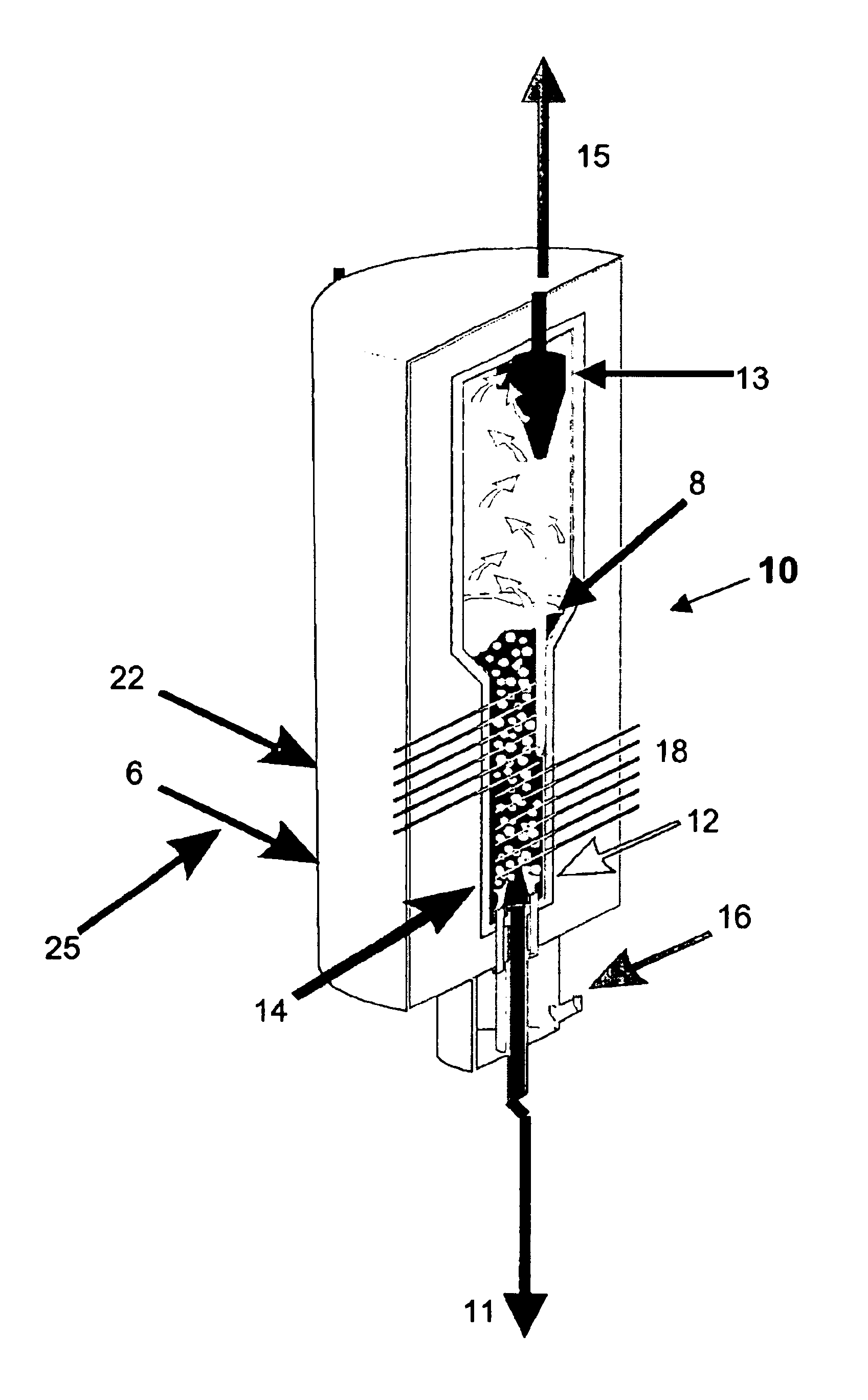

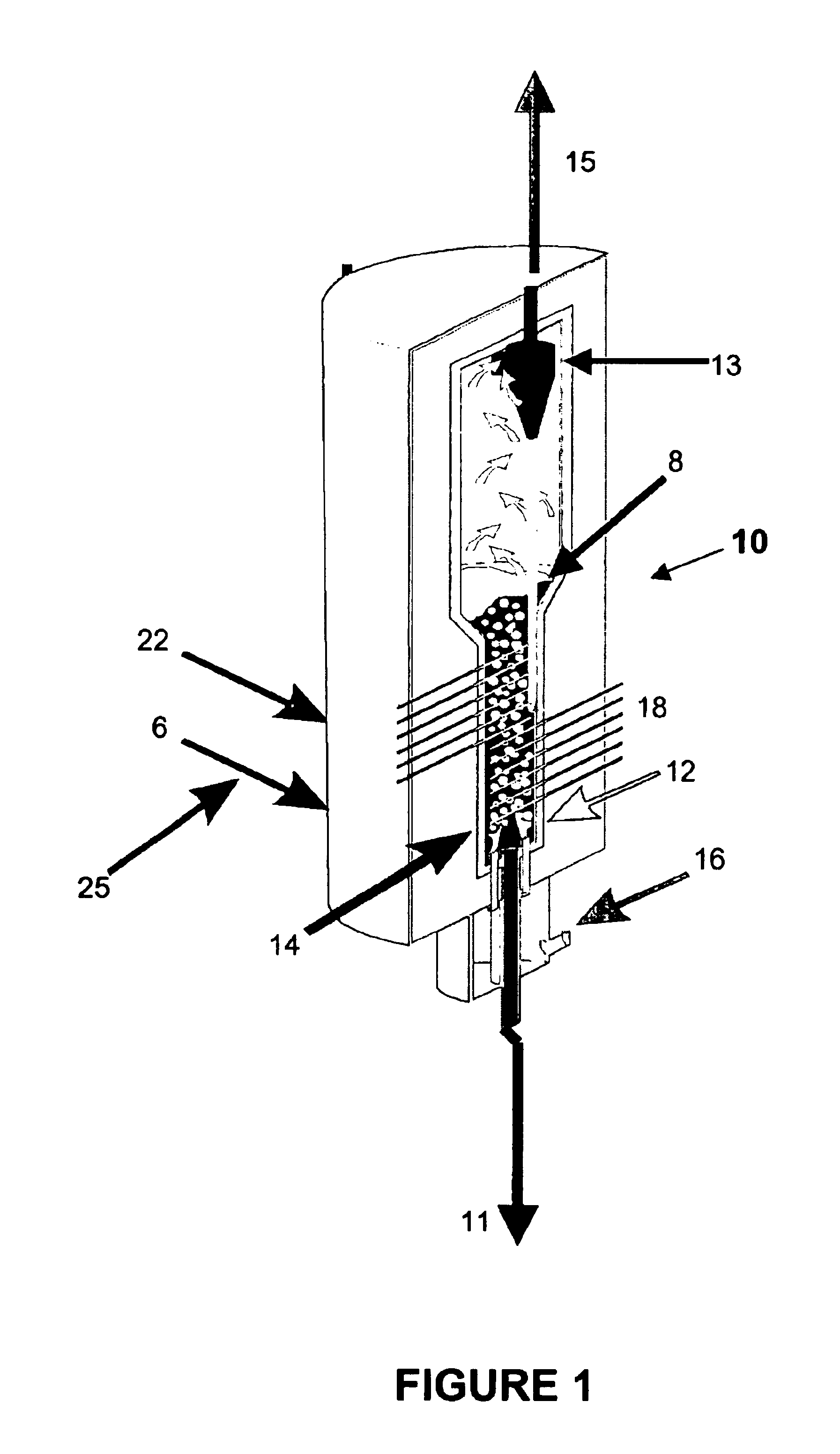

Molten Carbonate Fuel Cell Provided with Indirect Internal Steam Reformer

InactiveUS20070184310A1Controlled heatingSimple system constructionHydrogenFuel cells groupingSteam reformingOperational costs

A molten carbonate fuel cell, which is provided with an indirect internal steam reformer to efficiently control heat and simplify the system construction and has a simple structure to reduce production cost and efficiently controls heat to reduce operational cost and increase operational efficiency, is disclosed. The molten carbonate fuel cell of the present invention has a plurality of unit cells each including a porous matrix plate which is interposed between an anode plate and a cathode plate and is filled with an alkali carbonate electrolyte, the unit cells being stacked on top of another; at least one indirect internal steam reformer interposed between the stacked unit cells and reforming a fuel to hydrogen through a reforming reaction and supplying the hydrogen to the unit cells; a fuel manifold air-tightly installed at an inlet of both the indirect internal steam reformer and the unit cells and receiving a fuel supply pipe therein to supply the fuel to the indirect internal steam reformer; and a reformed fuel manifold air-tightly installed at an outlet of both the indirect internal steam reformer and the unit cells and supplying the hydrogen produced by the indirect internal steam reformer to the unit cells.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

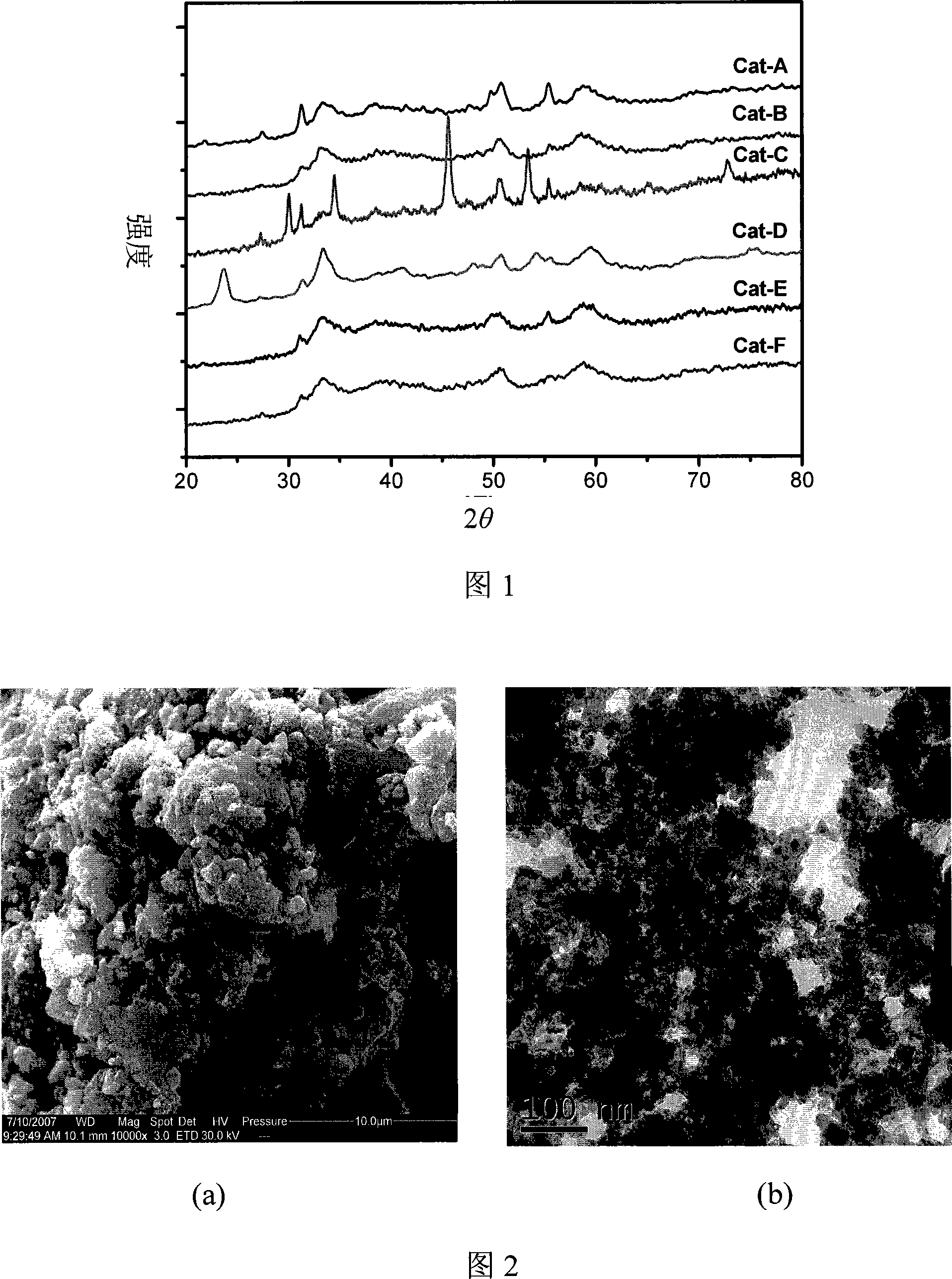

Multi-metal noumenon catalyzer for hydrodesulphurization of diesel oil, producing method and application of the same

InactiveCN101153228ARaw materials are simple and cheapEasy to operateRefining to eliminate hetero atomsHydrodesulfurizationSolvent

A polymetallic bulk catalyst for diesel oil hydrodesulfurization is provided. The particle diameter of the present invention is 10-100 nm, and the present invention consists of a species of VIII metal and two species of VIB metal, wherein, the mole ratio of the VIII metal and the VIB metal is 1:9-9:1, while the mole ratio of two species of VIB metal is 1:5-5:1. The preparation method is that: a) the basic carbonate of VIII metal is led to dissolve in solvent to form suspension liquid; b) two species of metal salts of the VIB metal are led to dissolve in the solvent, and surfactant is added into the solvent, stirred and heated to 50-250 DEG C; c) the suspension liquid in step a is added into the solvent in step b and led to react in reflux for 4-25 hours under 50-250 DEG C; d) the product obtained in step c is filtered, washed and dried to obtain target product. The catalyst of the present invention is used in the ultra-deep hydrodesulfurization of diesel oil and shows extremely high hydrodesulfurization activity. Under the same operating conditions, the activity of the present invention is 5.9 times as much as industrial reference agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

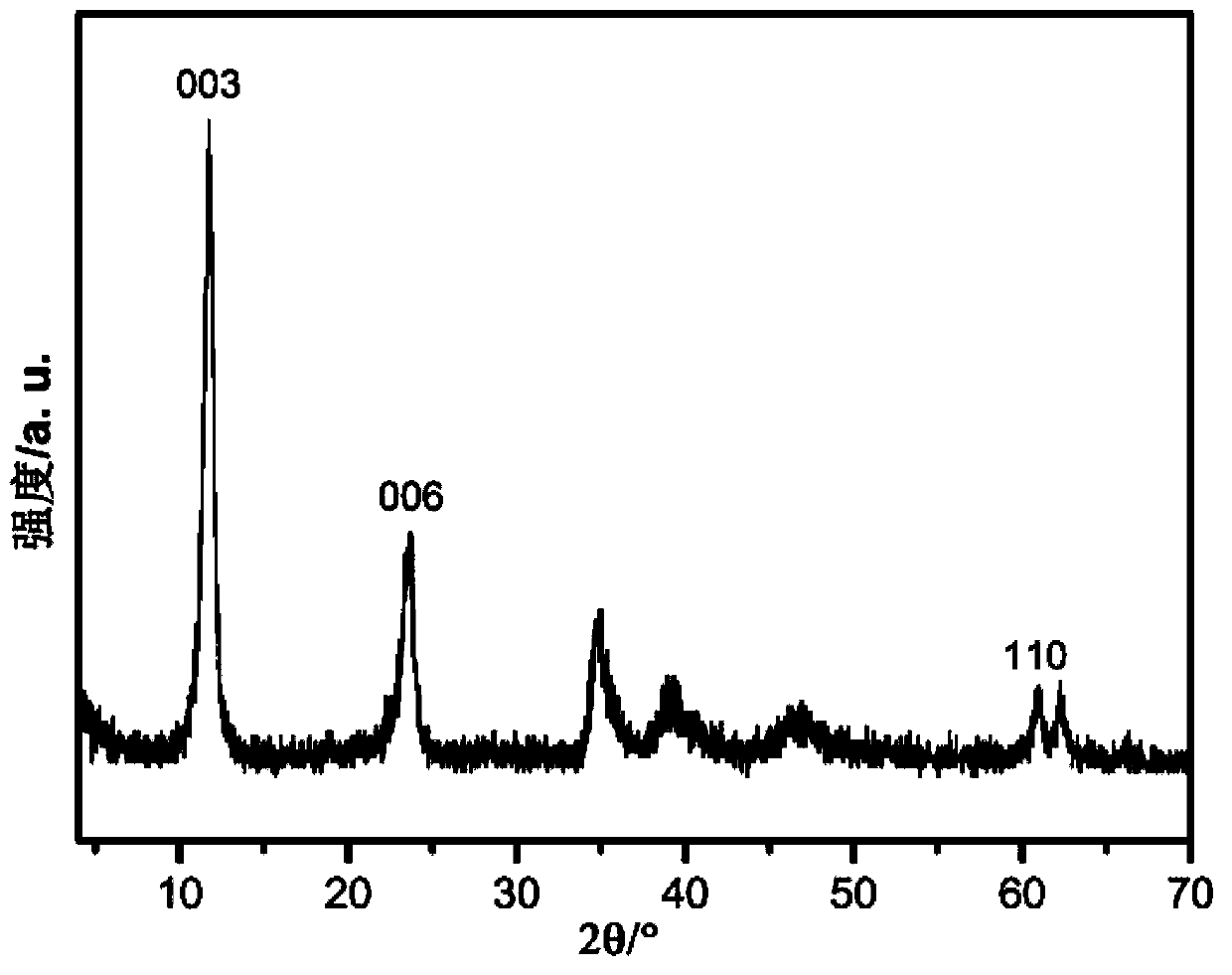

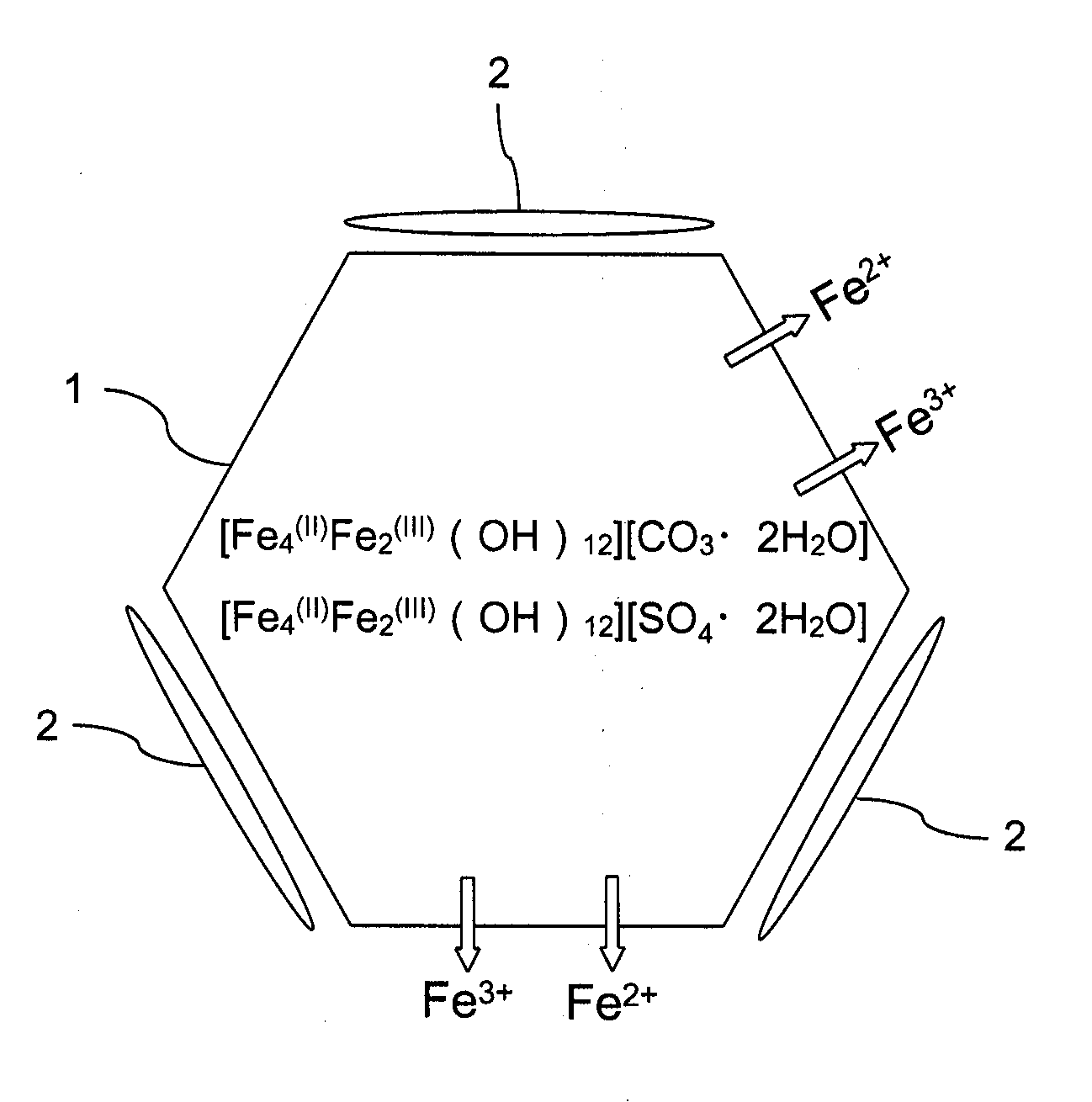

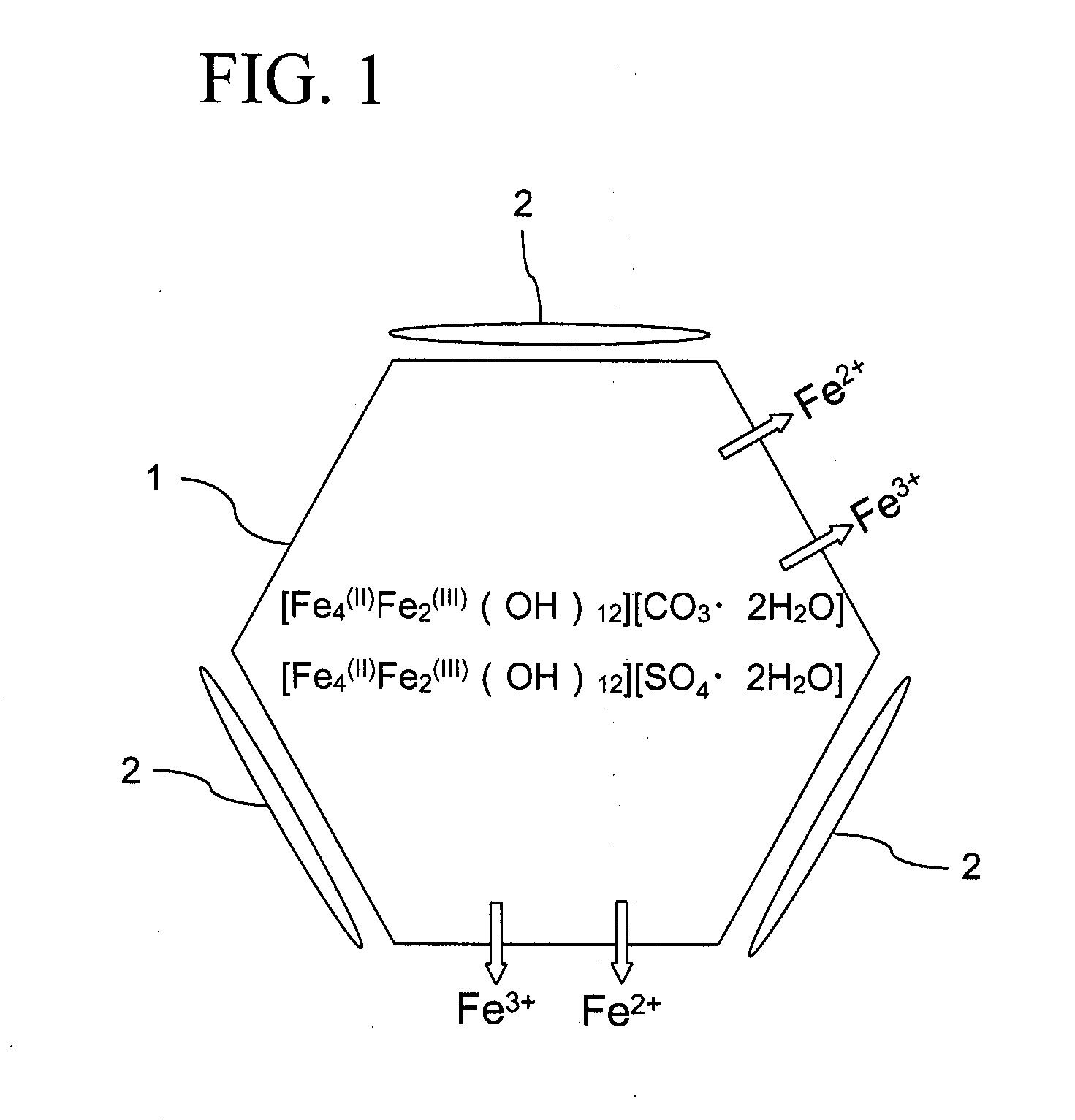

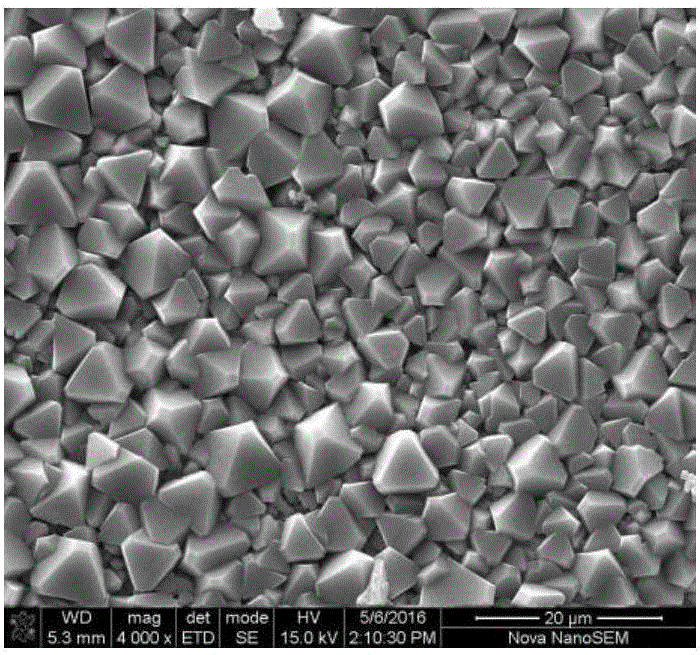

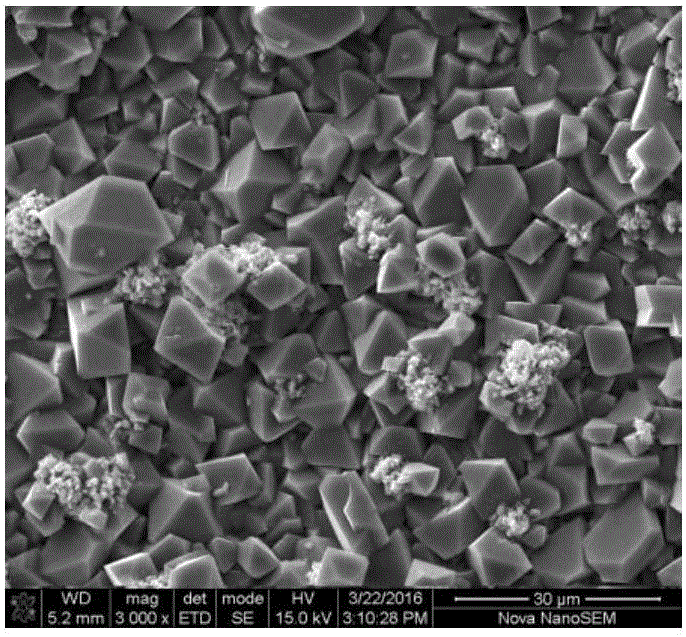

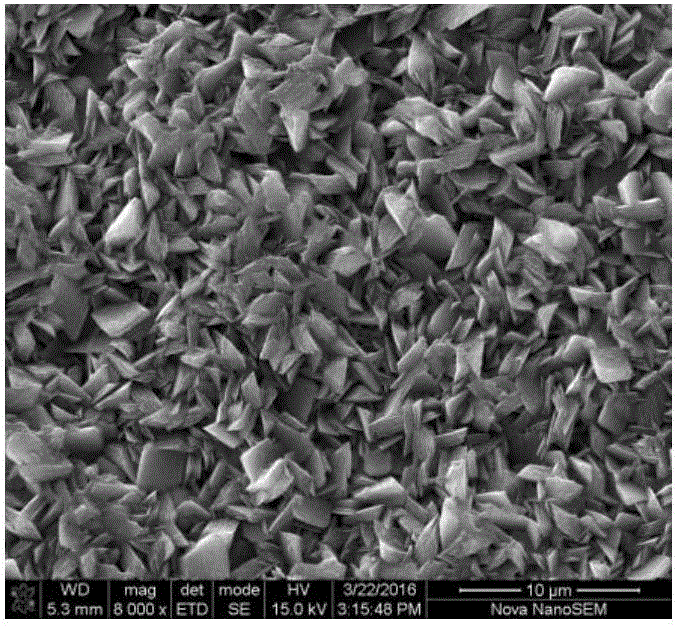

Flaky structure layered composite hydroxide and preparation method thereof

The present invention provides a flaky structure layered composite hydroxide and a preparation method thereof. According to the preparation method, a metal hydroxide, an oxide, a basic carbonate, a metal soluble salt and an alkali are adopted as raw materials, the addition speed of the alkali solution is controlled to prepare the flaky LDH, and the space confinement effect of the metal hydroxide, the oxide or the basic carbonate exists, such that the produced LDH flakes do not easily aggregate so as to finally obtain the LDH with a large specific surface, wherein the BET specific surface area is 130-200 m<2> / g and is much larger than the specific surface area of the ordinary LDH. According to the invention, the preparation method has characteristics of simpleness, no requirement of high temperature, high pressure and special equipment, rich raw material source and low cost; and the flaky structure layered composite hydroxide can be widely used in the fields of absorption separation, catalysis, polymer materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

Process for the treatment of waste streams

The present invention is directed to a process for treating, reducing, and / or stabilizing various wastes or flue gases. In one embodiment, the process is directed to treatment of alkali bearing wastes that include nitrate and / or nitrite-rich wastes. Optionally, the disclosed method can be utilized for treatment of hazardous wastes, including radioactive hazardous waste compounds. In general, the present invention includes processing a waste or gaseous stream with the addition of suitable carbon-containing additives to treat and reduce nitrogen-containing compounds in the waste. Additives may be gaseous, liquid or solid reduction-promoting agents, catalysts, and the like. The reaction products obtained from the process of the invention include mainly alkali carbonate, nitrogen, hydrogen, carbon monoxide and carbon dioxide.

Owner:MFG & TECH CONVERSION INT

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for synthesizing cobalt oxide/graphene composite wave-absorbing material

InactiveCN104263317AEasy to adjust dielectric constantImprove microwave absorption performanceOther chemical processesAlcoholSaline solutions

The invention discloses a method for synthesizing a cobalt oxide / graphene composite wave-absorbing material and relates to nanometer wave-absorbing materials. The method comprises the following steps: (1) dissolving a metal cobalt salt, ammonium fluoride and urea in water, thereby obtaining a metal saline solution; (2) adding the metal saline solution prepared in the step (1) into a hydrothermal kettle, and magnetically stirring to be uniform; (3) dispersing graphene solid powder into an absolute ethyl alcohol solution, thereby obtaining a graphene alcohol solution; (4) adding the graphene alcohol solution prepared by the step (3) into the metal saline solution prepared in the step (2), mixing, stirring, putting the hydrothermal kettle into a drying oven for reacting, thereby obtaining purple turbid liquid; and centrifuging, washing the obtained precipitate by using the ethanol solution, thereby obtaining a subcarbonate / graphene material; and (5) heating and drying the subcarbonate / graphene material obtained in the step (4), calcining, thereby obtaining the product cobalt oxide / graphene composite wave-absorbing material. The method is simple, high in operability, mild in preparation conditions, clean and pollution-free in reaction process, high in reaction efficiency and high in reproducibility.

Owner:XIAMEN UNIV

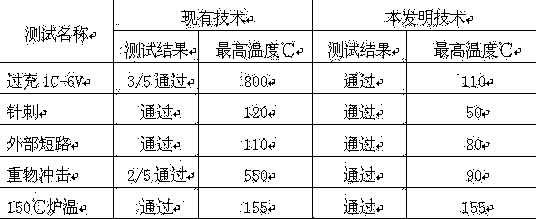

Lithium ion battery safe coating and preparation method thereof

InactiveCN103059613AImprove securitySmall currentElectrode manufacturing processesCell component detailsElectrical batteryLithium-ion battery

The invention discloses a lithium ion battery safe coating which is made of one or more of alkali hydroxide, alkali carbonate and alkali bicarbonate; and the chemical general formula of the lithium ion battery safe coating is shown as MX(OH)y, MX(CO3)y and MX(HCO3)y, wherein M refers to alkali metal. The lithium ion battery safe coating has the functions of thermal decomposition by heating and heat absorption, crystal structure change or pulverization, or release of water and carbon dioxide, can reduce the battery temperature and stop the charging / discharging under the condition that the battery is overheated, reduces the short circuit or current under the overcharge state, improves the safety of the battery, and has important practical significance.

Owner:TIANJIN ENERGIES

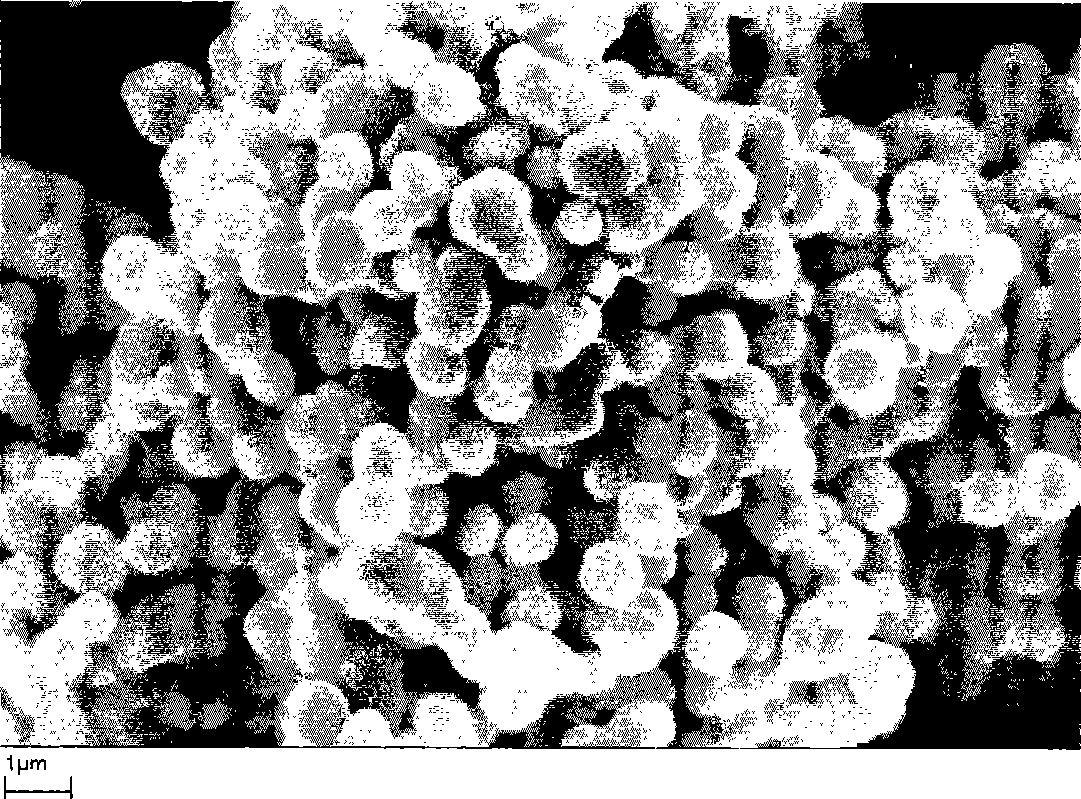

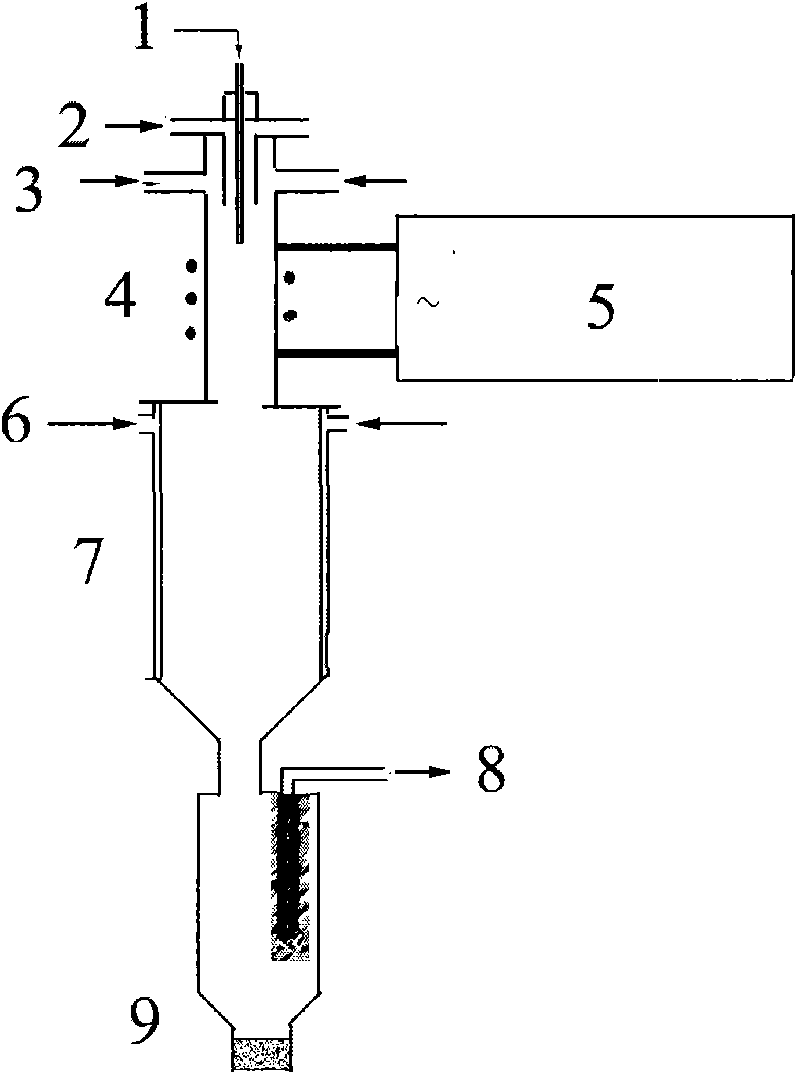

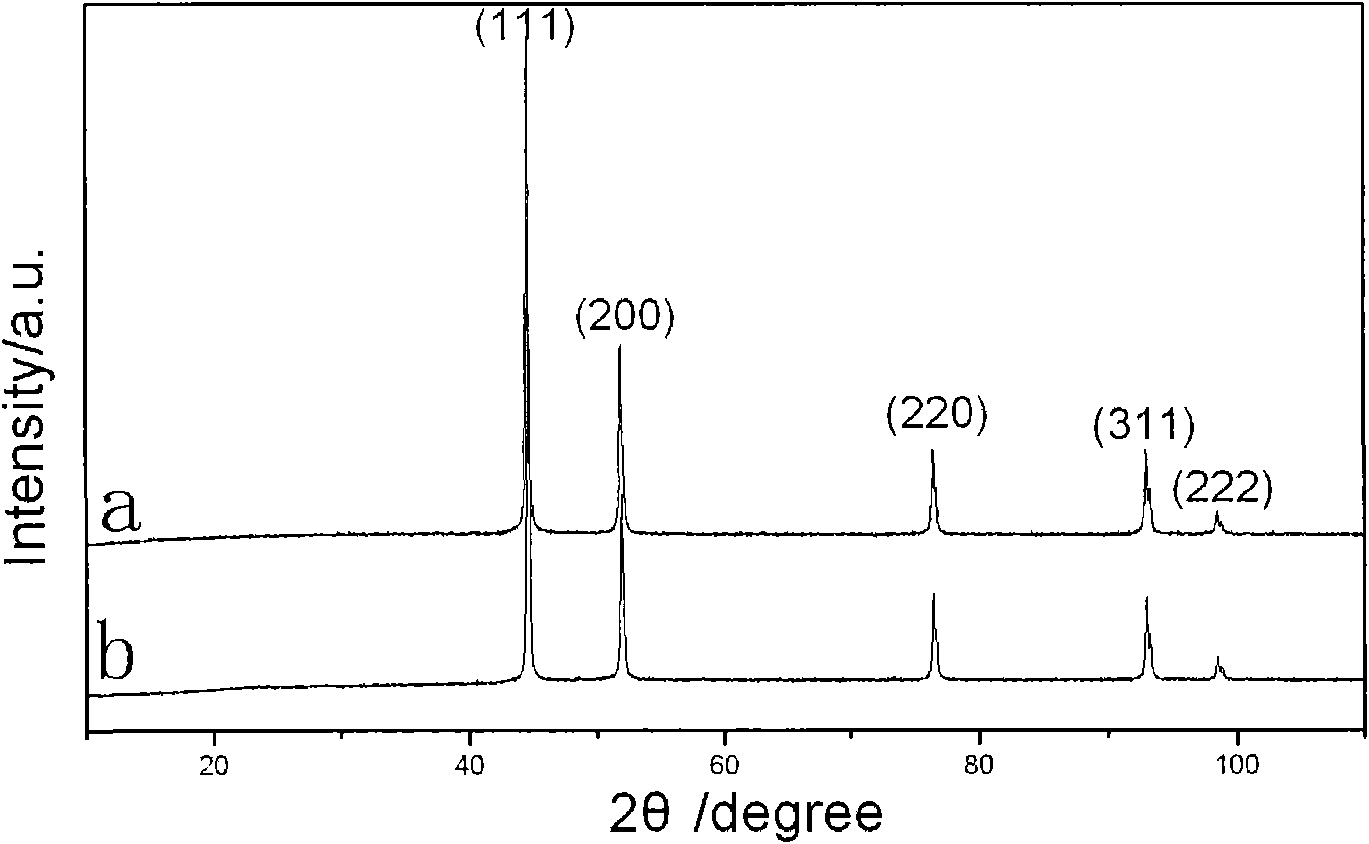

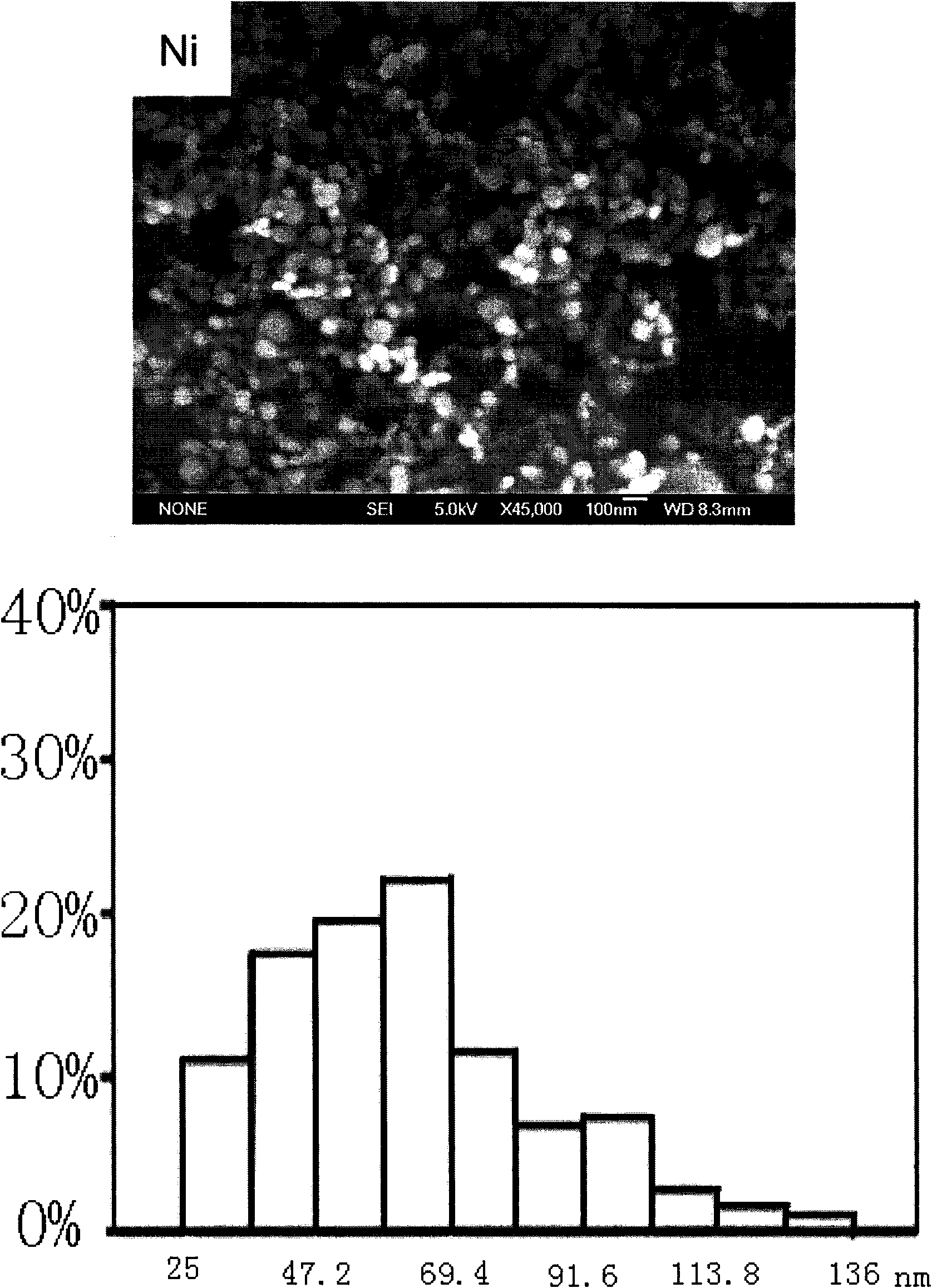

Method preparing superfine metallic nickel powder with high frequency plasma

The invention relates to a method preparing spherical metallic nickel powder with high frequency plasma. The method takes the hydrate of metallic nickel or subcarbonate as raw material and carries out hydrogen reduction through the high frequency plasma technology to prepare the superfine spherical nickel powder. Plasma arc is added to the raw material. The plasma is heated in high temperature through high frequency induction and generates reduction reaction with high-activity hydrogen plasma. The superfine spherical nickel powder can be obtained through a shape controller in the condensation process. The utility model is characterized in that the nickel hydroxide or the subcarbonate are used as the raw material, in the reduction process of the plasma, the particle size and the shape of the nickel powder can be controlled easily, the process flow is short and the production process is environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

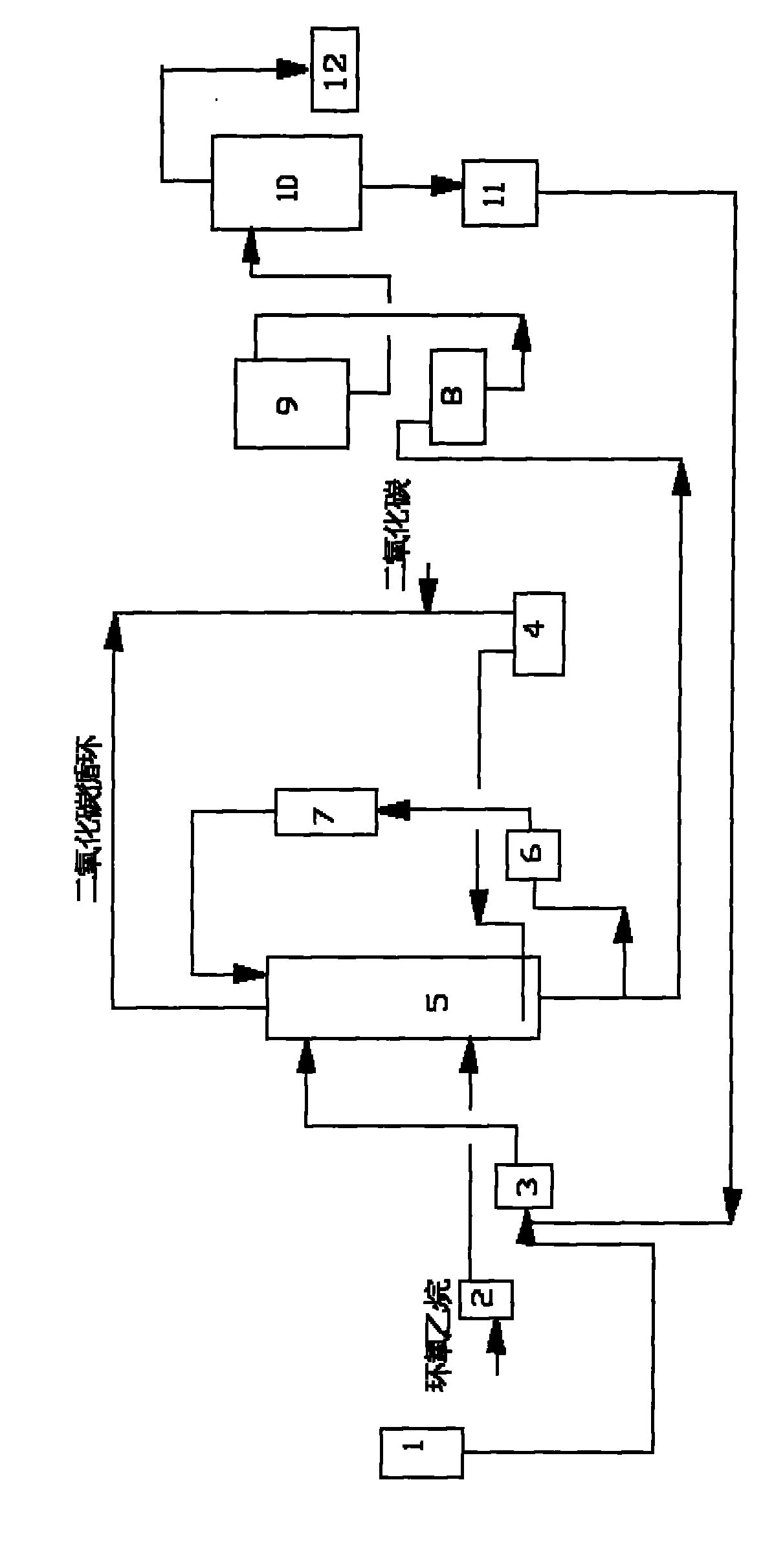

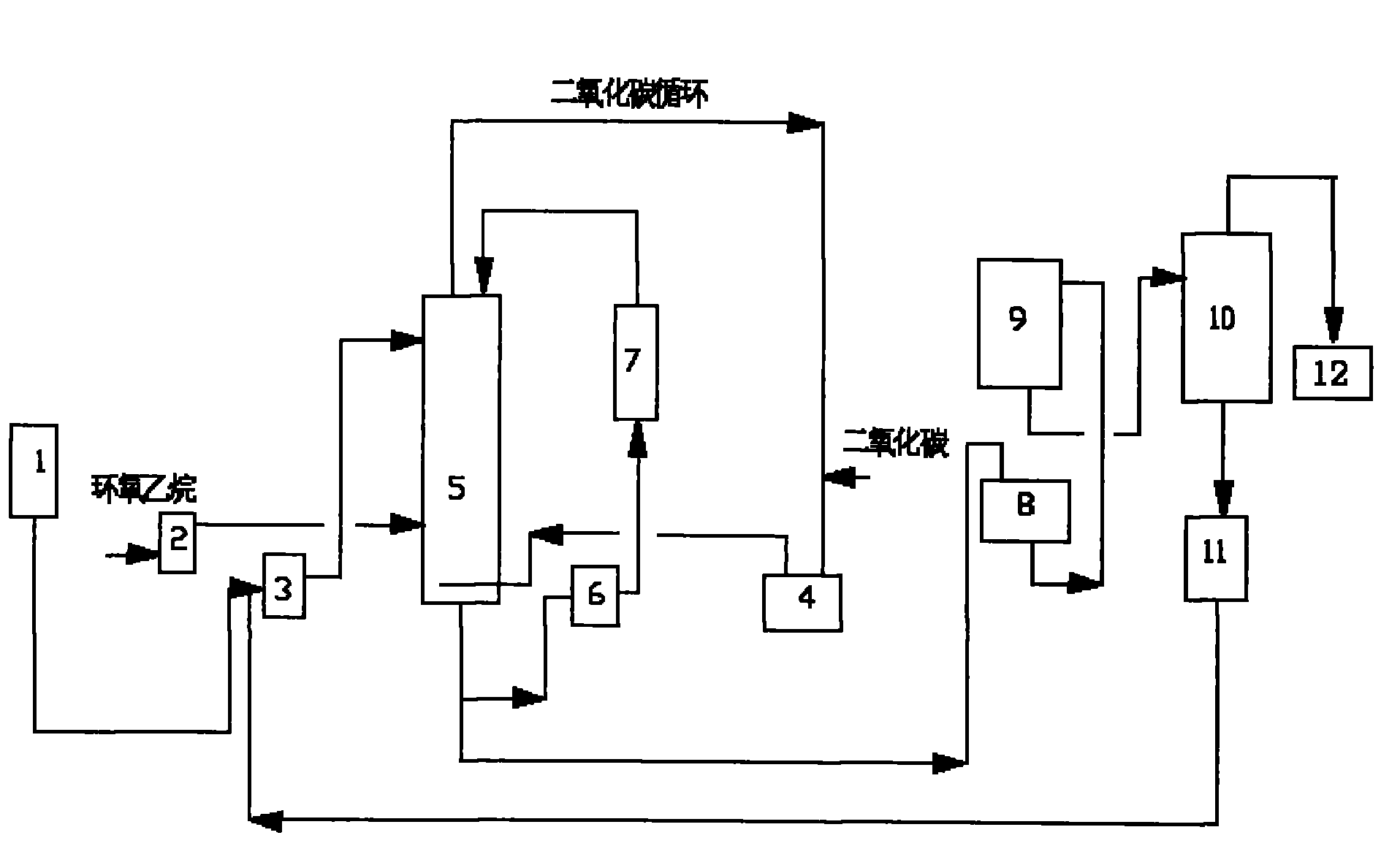

Method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide

ActiveCN101824022AHigh activityReduce lossesOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyAlkaline earth metal

The invention relates to a method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide. The method adopts continuous circulation reaction; 150g / h ethylene oxide or propylene oxide and 2-4Mpa of carbon dioxide are respectively added from the bottom of a reactor; the reaction pressure is 1.0-5.0Mpa, the reaction temperature is 100-200 DEG C, and the reaction time lasts for 1-5 hours; a catalyzer is compositive catalyzer formed by carbonate and alkyl imidazolium or fxanol ionic liquid; the catalyzer is 7.5g / h, and the weight ratio of the carbonate to the alkyl imidazolium or fxanol ionic liquid ammonia is 1: 6.5; and the carbonate is alkali carbonate or aldaline-earth metal carbonate. The invention has simple process, high activity of the catalyzer and less loss of the catalyzer, the percent conversion of epoxy ethane reaches 96-99 percent, and the selectivity is 97-99 percent.

Owner:PETROCHINA CO LTD

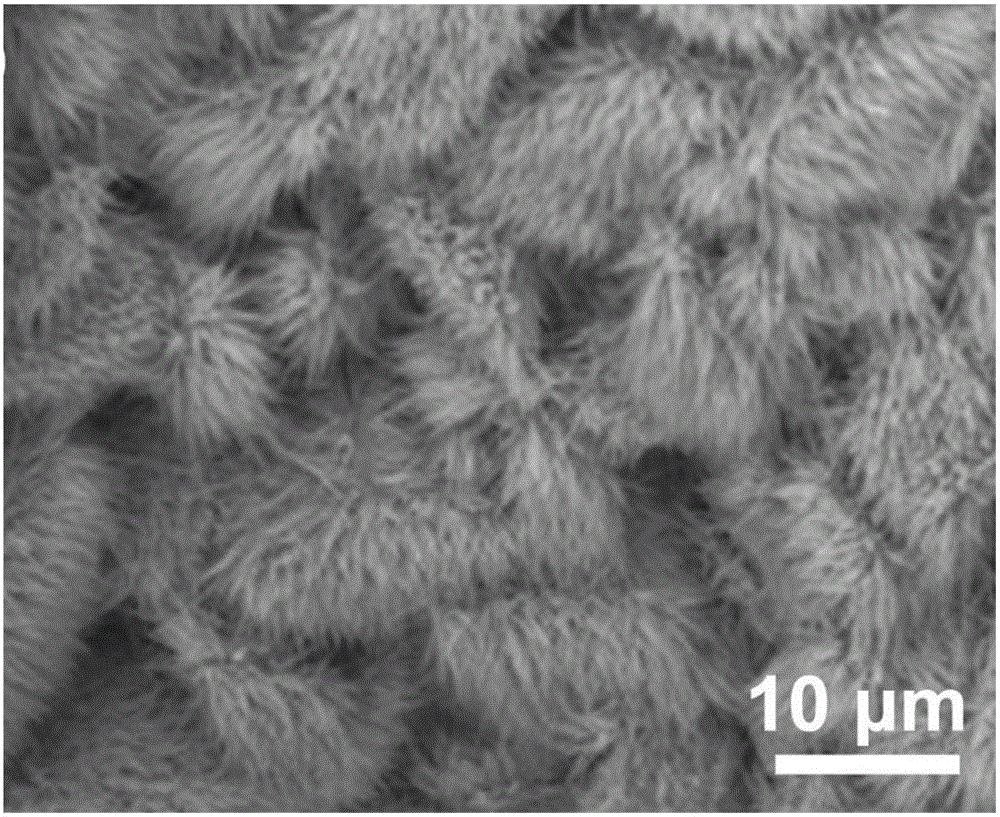

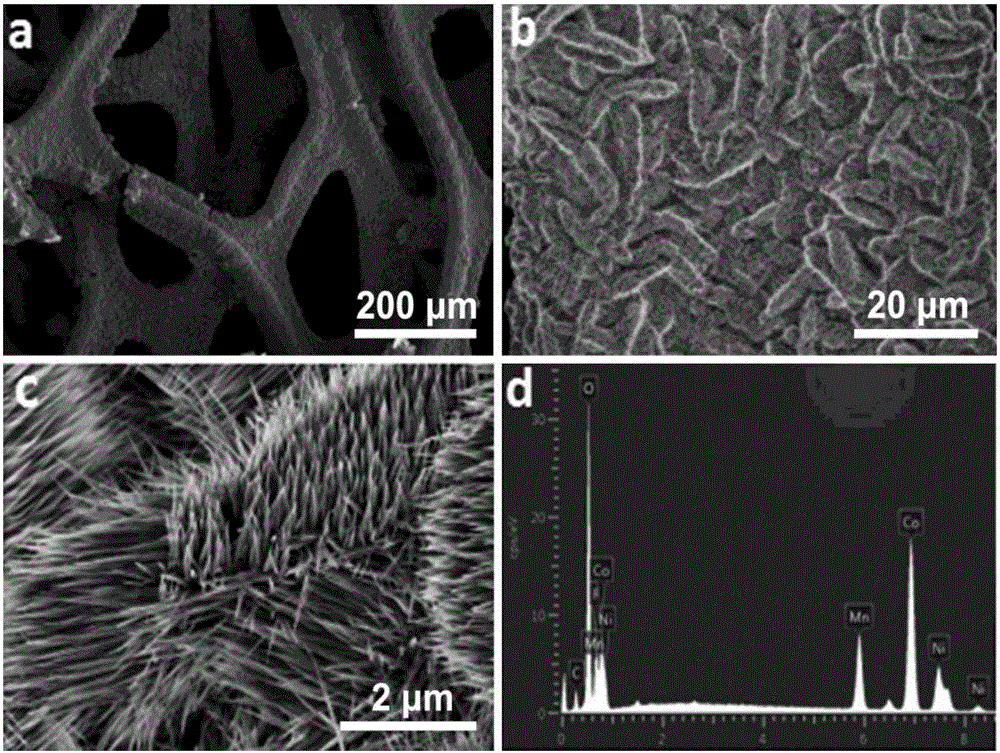

Preparation method of alkali oxygen evolution reaction electrocatalyst

InactiveCN106732649AImprove electrocatalytic performanceImprove adsorption capacityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsArgon atmosphereDecomposition

The invention discloses a preparation method of an alkali oxygen evolution reaction electrocatalyst. The preparation method comprises the following steps: firstly, carrying out ultrasonic cleaning on a conductive substrate, then preparing aqueous solution with soluble cobalt salt, soluble manganese salt, ammonium fluoride and urea, and in a reaction kettle, vertically growing a manganese cobalt subcarbonate nano array multilevel structure on the surface of the substrate; then preparing aqueous solution with soluble alkali and a reducing agent, carrying out secondary treatment, and carrying out structure and performance optimization on the manganese cobalt subcarbonate nano array multilevel structure; finally, in a tube furnace, in nitrogen or argon atmosphere, carrying out calcination at a temperature of 200 to 1,000 DEG C to prepare the alkali oxygen evolution reaction electrocatalyst with a manganese-doped cobalt oxide nano array multilevel structure. The preparation method disclosed by the invention adopts a simple hydro-thermal synthesis / calcination treatment method, is simple in process and is easy to regulate and control; the prepared product is excellent in performance and is an electrocatalyst with wide prospect in the application process of alkali water decomposition.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for producing iron oxyhydroxide particle

Owner:TDK CORPARATION

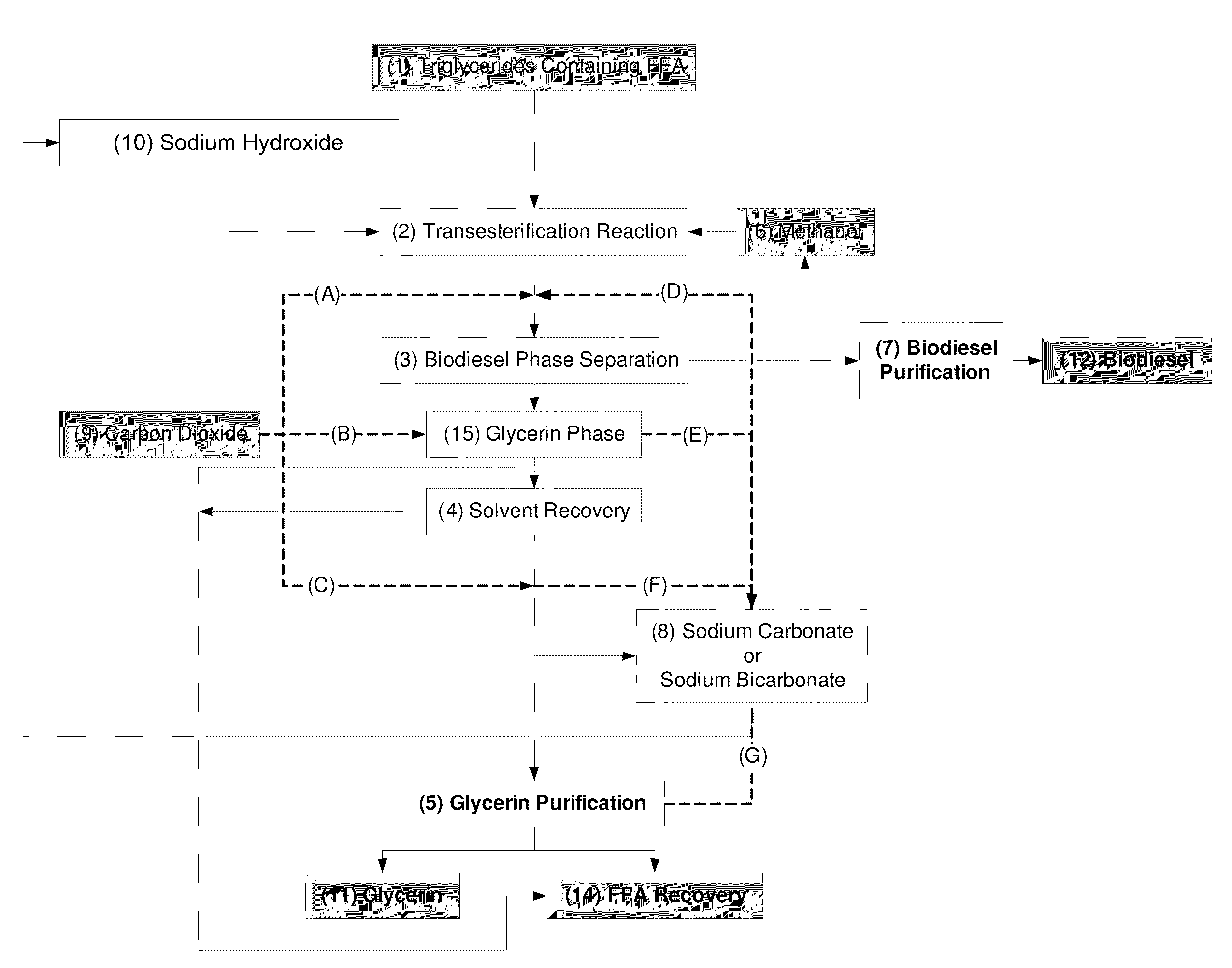

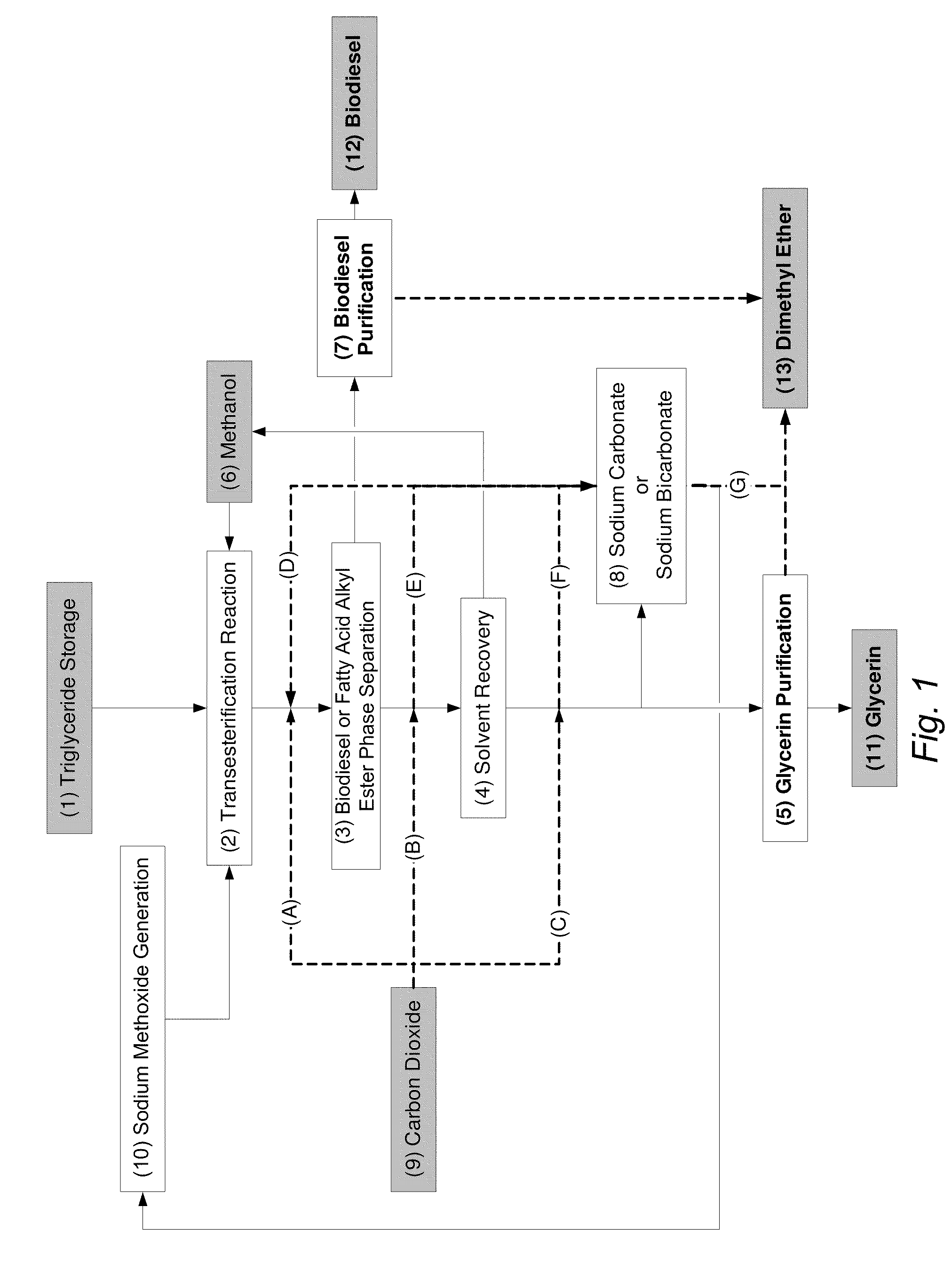

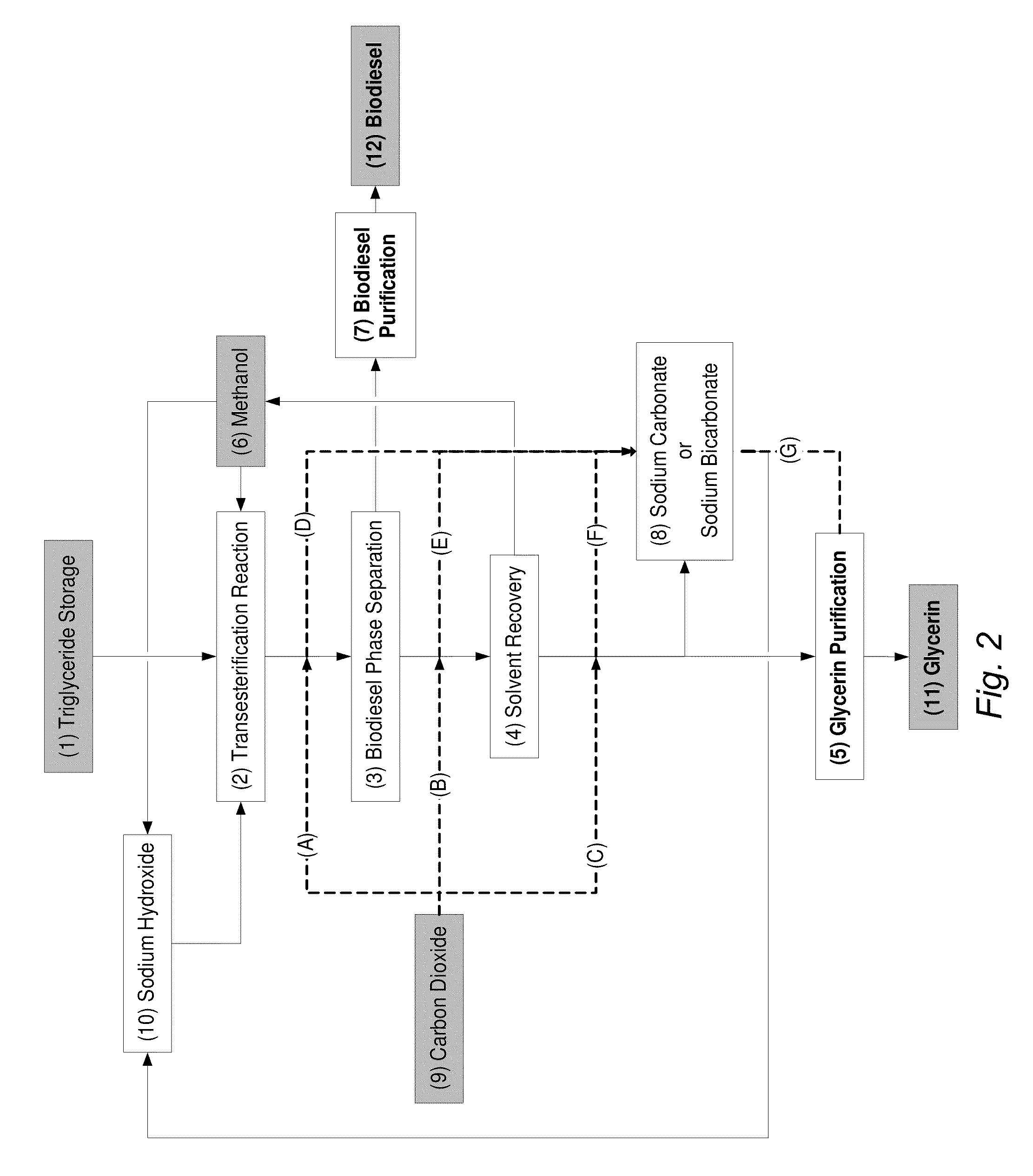

Systems and methods for removing catalyst and recovering free carboxylic acids after transesterification reaction

ActiveUS20110015419A1Low costFatty oils/acids recovery from wasteFatty acid esterificationAlcoholTransesterification

Systems and methods for using carbon dioxide to remove an alkali catalyst and to recover free carboxylic acids after a transesterification reaction are disclosed. Generally, the methods include first providing a mixture resulting from the transesterification of an ester, wherein the mixture includes substances selected from the alkali catalyst, an alcohol, and a transesterification reaction product such as biodiesel. Second, the methods generally include adding carbon dioxide to the mixture. In some cases, adding the carbon dioxide to the mixture causes the alkali catalyst to convert into an alkali carbonate and / or an alkali bicarbonate. In other cases, adding the carbon dioxide to the mixture causes the carboxylic acid alkali salt to convert into a free carboxylic acid. In either case, the alkali carbonate, the alkali bicarbonate, and / or the free carboxylic acid can be separated from the mixture in any suitable manner.

Owner:ENLIGHTEN INNOVATIONS INC

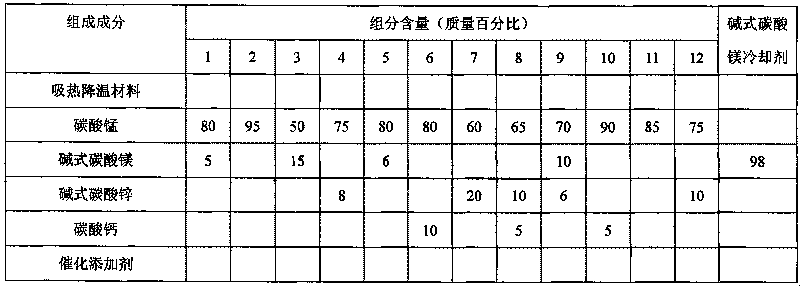

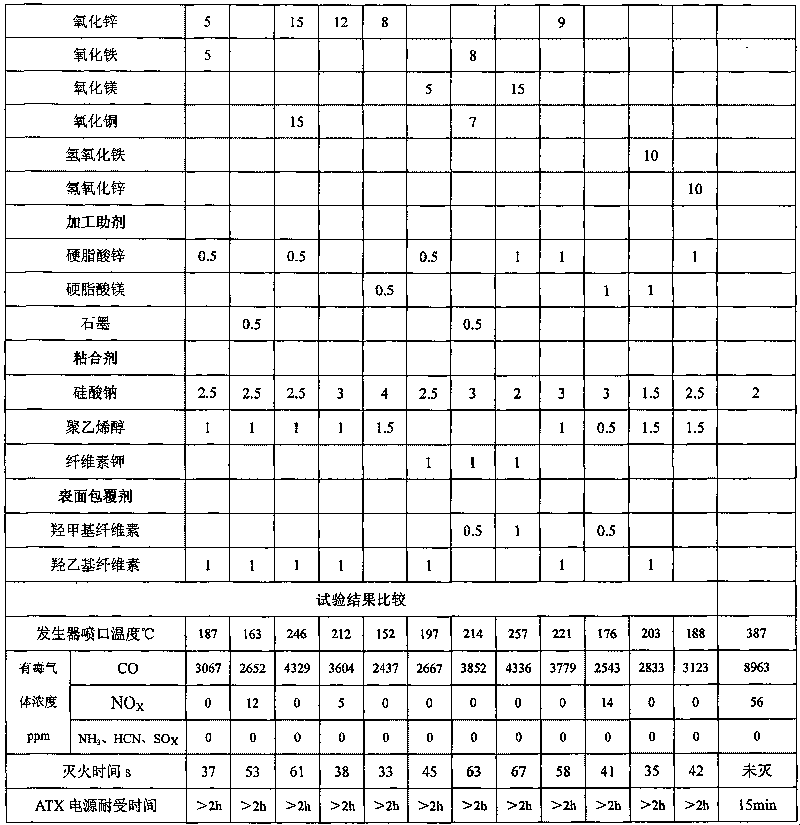

Catalytic chemical coolant for hot aerosol and preparation method thereof

InactiveCN101757760AImprove cooling efficiencyLow toxicityFire extinguisherHydroxyethyl celluloseFilm material

The invention relates to a catalytic coolant used in a hot aerosol fire extinguishing device and a processing technique of the catalytic coolant. As to the coolant, heat absorption cooling components mainly include manganese carbonate or manganese oxalate, manganese phosphate, potassium manganate, metal carbonate of a family I, a family II and a transition family, basic carbonate, oxalate and the like; a metal oxide or a hydroxide are adopted as a catalyst, an oxidant and a reinforcing filling; stearate, graphite and the like are adopted as a processing aid; composite solution of alkalis silicate and a water soluble polymer is adopted as an adhesive; and film materials such as hydroxymethyl or hydroxyethyl cellulose are adopted as a surface coating agent. The processing technique includes the steps of mould pressing, squeezing, pelletizing, coating and forming. Compared with the prior art, the catalytic coolant not only has high intensity and good cooling effect, but also can reduce secondary damage of an extinguishing agent and eliminate the content of poisonous gases in an extinguishing agent product so as to improve the environmental safety of the extinguishing agent.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Preparation method of low-molecule brown seaweed glucan

ActiveCN102153669ARealize comprehensive utilizationPlant growth regulatorsAmyrisHydrogen peroxide degradation

The invention belongs to a preparation method of low-molecule brown seaweed glucan. Alkali carbonate solution is used for breaking up seaweed tissue and cells, acid is used for adjusting a pH value to be proper, alginic acid, brown seaweed polysaccharide and brown seaweed starch are extracted from the seaweed tissue and the cells, and the starch is degraded with hydroxide to turn into the brown seaweed glucan with the average molecular weight being 800-1000 Dalton. As reported, the brown seaweed glucan with the low molecular weight can enhance the immunity of a human body and the stress resistance of plants.

Owner:北京雷力联合海洋生物科技有限公司

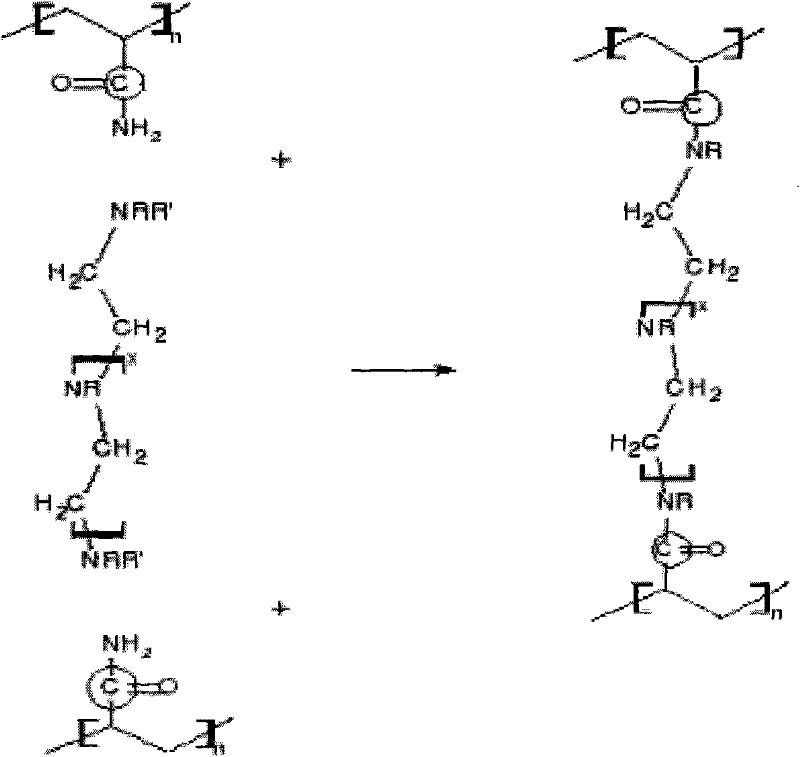

Organogel blocking agent for water blocking and profile control, and preparation method and application thereof

ActiveCN102453473AHigh strengthImprove thermal stabilityDrilling compositionWater solubleCarboxylic acid

The invention relates to an organogel blocking agent for water blocking and profile control, and a preparation method and application thereof. The blocking agent consists of the following substances: 0.2 to 1.5 weight percent of polymer thickening agent, 0.2 to 3.0 weight percent of macromolecular modified crosslinking agent, 0.2 to 1.5 weight percent of pH regulator and the balance of water. The polymer thickening agent is selected from polymers of ethylene unsaturated polar monomers and ethylene unsaturated esters, and has the molecular weight of 5.0*10<5>-1.5*10<7>; the macromolecular modified crosslinking agent is selected from carboxylic acid derivatives of water-soluble amino functional group-containing polymer, and has the molecular weight of 3.0*10<3>-8.0*10<4>; and the pH regulator is alkali carbonate. The blocking agent is suitable for construction such as oilfield water blocking and profile control, deep profile modification and the like, has selective blocking capacity and adjustable gelling time, is easy and convenient to use, and has important significance for efficiently developing oilfields of China and stabilizing oil and reducing water.

Owner:CHINA PETROLEUM & CHEM CORP +1

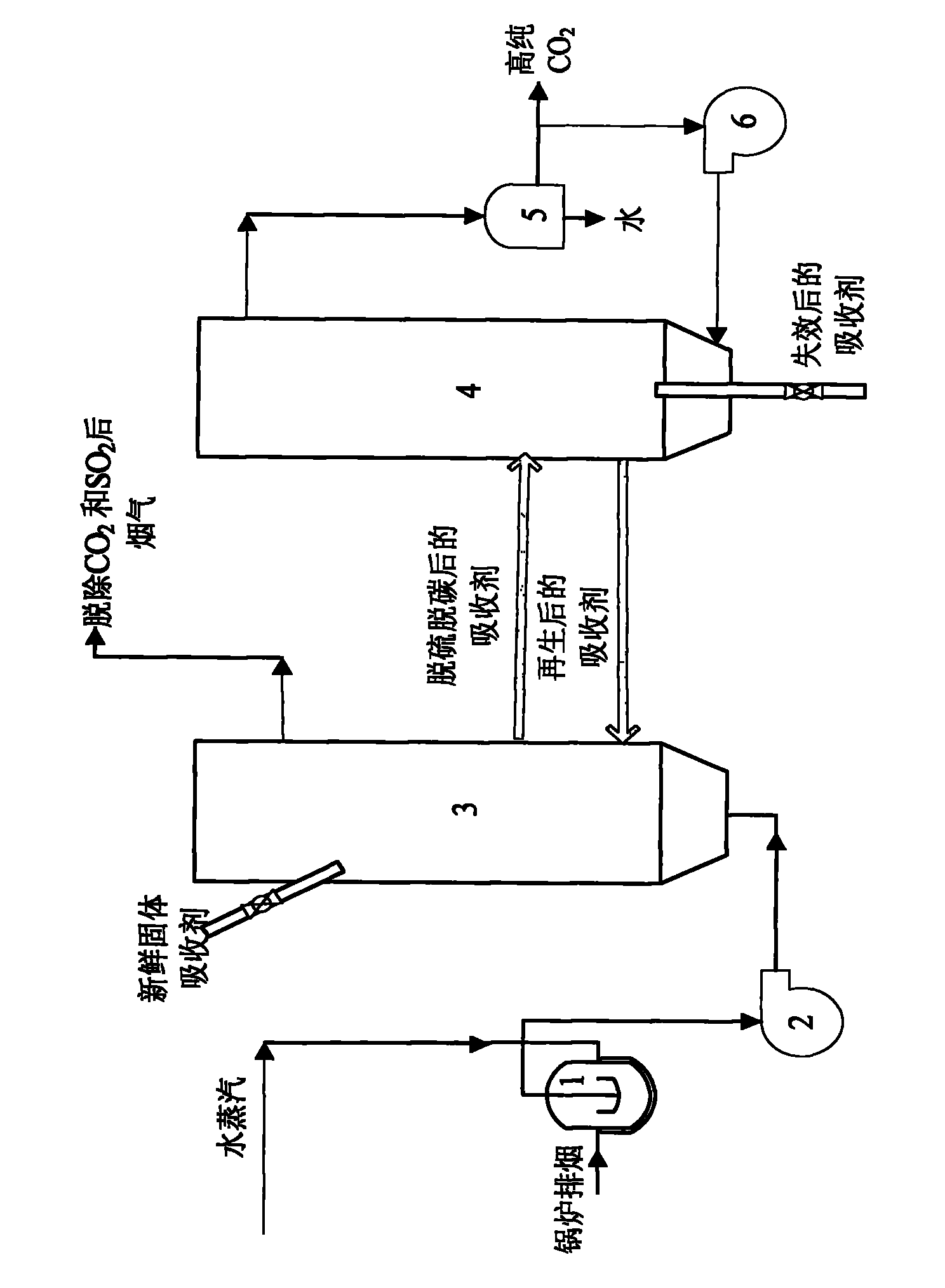

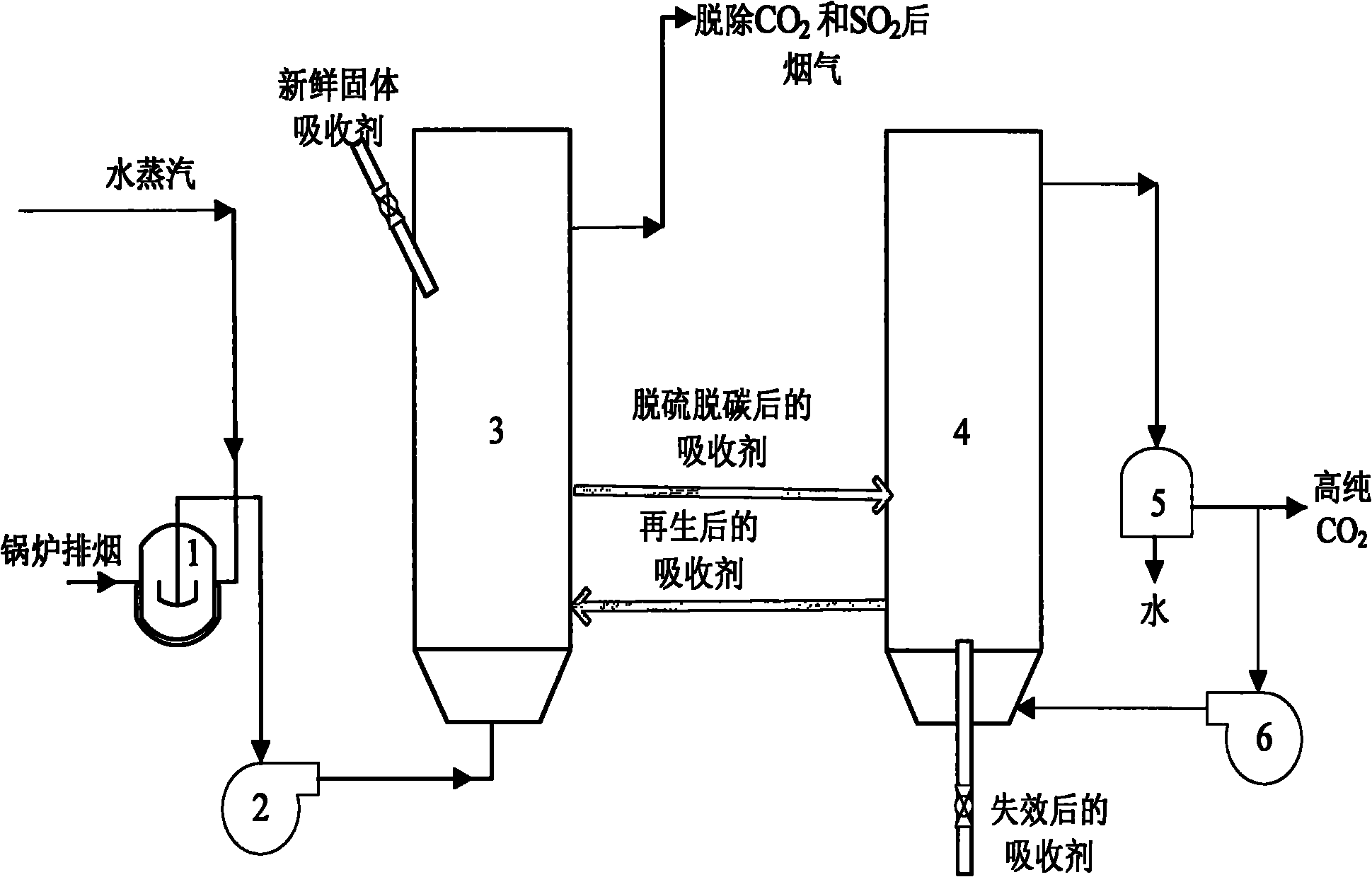

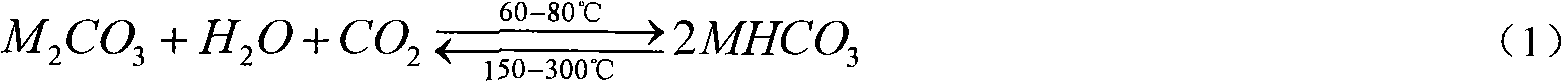

Method for jointly removing carbon dioxide and sulfur dioxide from smoke

InactiveCN101780371AHigh process removal efficiencyReduce energy consumptionDispersed particle separationBy chemical separationWater vaporFixed bed

The invention discloses a method for jointly removing carbon dioxide and sulfur dioxide from smoke, which is mainly characterized in that: alkali carbonate is supported on a carrier to serve as a solid absorbent; under the condition of low temperature (60-100DEG C), CO2 and SO2 are jointly removed by utilizing vapor in the smoke in a smoke absorption reactor to generate bicarbonate and sulphite of alkali metals; the absorbent after the reaction is subjected to temperature rise (the temperature is raised to between 150 and 300 DEG C), the sulphite is not decomposed, and the bicarbonate is decomposed to generate carbonate, CO2 and vapor; after the carbonate, the CO2 and the vapor are condensed, high-purity CO2 can be separated out; the generated carbonate serves as the absorbent for recycling, and the SO2 is fixed in the solid absorbent and is discharged along with disabled materials after multiple circulation; and the smoke absorption reactor and an absorbent regeneration reactor can adopt various operating modes such as a fixed bed, a babble fluidization bed, a circulating bed and a transport bed. The method has the advantages of high efficiency of removing CO2 / SO2, and simple equipment, and is an optimized scheme with low investment and energy consumption.

Owner:SOUTHEAST UNIV

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

High water-containing mud curing agent for mine filling and using method thereof

InactiveCN102211917AIncrease moisture contentSpeed up condensationSolid waste managementMaterial fill-upAluminateSlag

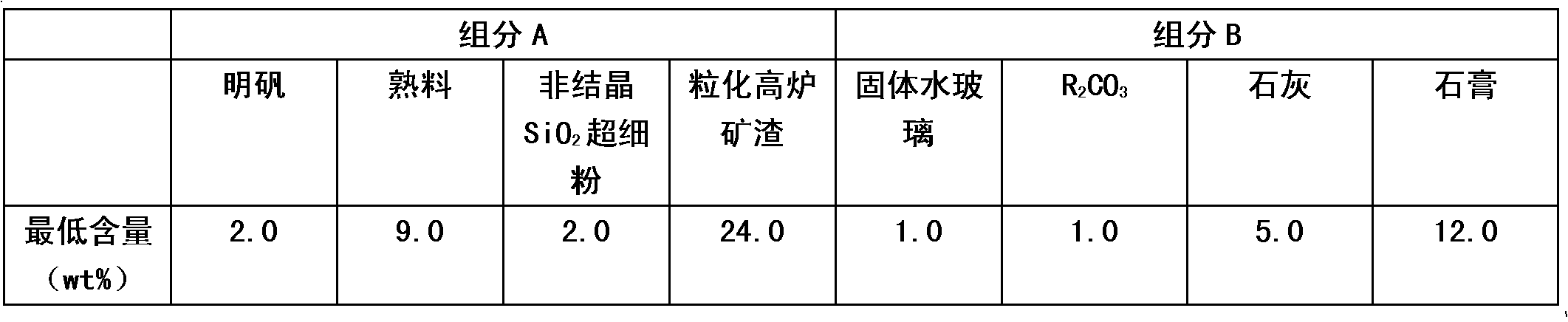

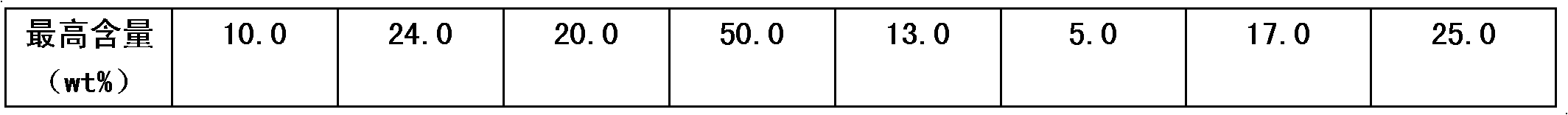

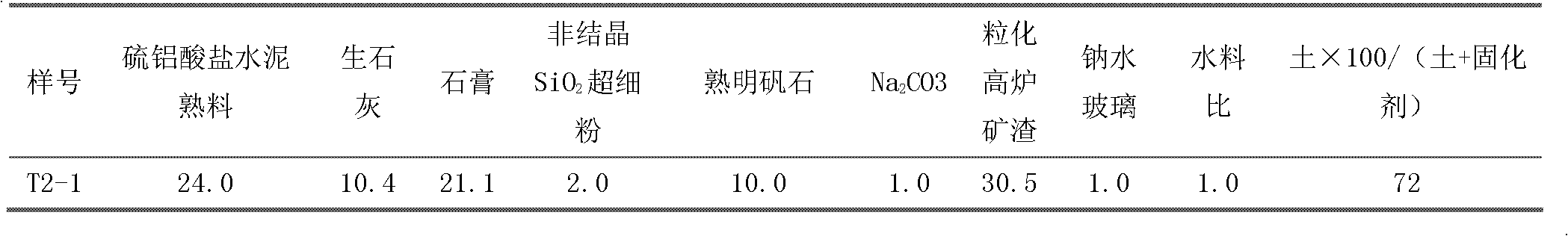

The invention discloses a high water-containing mud curing agent for mine filling and a using method thereof. The curing agent consists of a component A and a component B, wherein the component A consists of alum, sulfuric aluminate and / or ferrous aluminate and / or high-aluminum cement clinker, amorphous SiO2 superfine powder and pelletized blast furnace slag; the component B consists of solid water glass, alkali carbonate, lime and gypsum; and the components are ground into solid fine powder materials of 200 meshes with screen residue of not more than 10 percent, and the solid fine powder materials are mixed uniformly to form the component A and the component B respectively. In use, the component A and the component B are prepared into aqueous slurry respectively, the slurry B is delivered together with mud, the slurry A is separately delivered, and the slurry in double pipes is mixed and cured after the slurry is delivered to a filling field. The strength of the filled cured body in 7 days is 0.5 to 3.5MPa, and the strength of the filled cured body in 28 days is 1 to 5MPa. The high water-containing mud is cured by using a composite gel system, so that the water content and the condensation rate of the mud are improved, the early strength of the mud is increased, and the later strength of the mud is continually increased.

Owner:HUNAN UNIV OF SCI & TECH

Compound iron melt desulfurizing agent and method of preparing the same

The invention relates to a composite type molten iron desulfurizer and a preparation method thereof, which relates to a novel desulfurizer used for desulfurizing of molten iron or molten steel and a manufacturing process thereof. The components and the weight percentage ratio of the composite type molten iron desulfurizer are: 70.0 to 75.0 percent of CaO, 2.0 to 3.0 percent of TMg, 10.0 to 12.0 percent of CaC2, 8.0 to 10.0 percent of NaHCO3, 0.5 to 1.5 percent of Al, C 1.0 to 4.0 percent of C, 0 to 5.0 percent of CaF2, less than and equal to 0.18 percent of S, less than and equal to 0.10 percent of P and the rest of impurities; the finished product of the desulfurizer is powdery. The preparation method of the sulfurizer is that lime, passivated magnesium powders, calcium carbide, alkali carbonate additives, aluminum powders, graphite or charcoal, fluorite, etc. are utilized as the raw materials and are mixed evenly according to a certain weight percentage, dried and pretreated; passivated liquid is prepared; then the passivated liquid is poured into the materials to be stirred till the materials are dried, and the materials are cooled naturally and ground to make into powdery finished product. Compared with the prior art, the composite type desulfurizer and the preparation method thereof of the invention have the following advantages: short time required by the desulfurizing treatment, small quantity of slags, small temperature drop and good desulfurizing effect; low comprehensive using cost; simple production process and wide resources of the raw materials; improvement of slag forms during molten iron desulfurizing and reduction of iron loss of the molten iron. The calcium carbide, especially the magnesium powders (particles) are the products of high energy consumption, the effect of energy saving is achieved because the composite type molten iron desulfurizer of the invention correspondingly lowers the using amount of CaC2 or Mg.

Owner:PANZHIHUA DONGPAN IND & TRADE

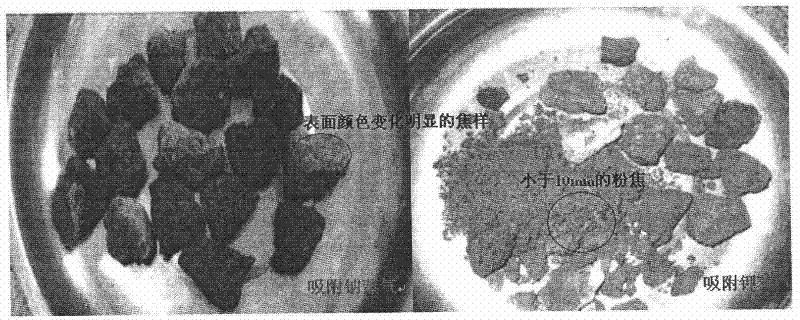

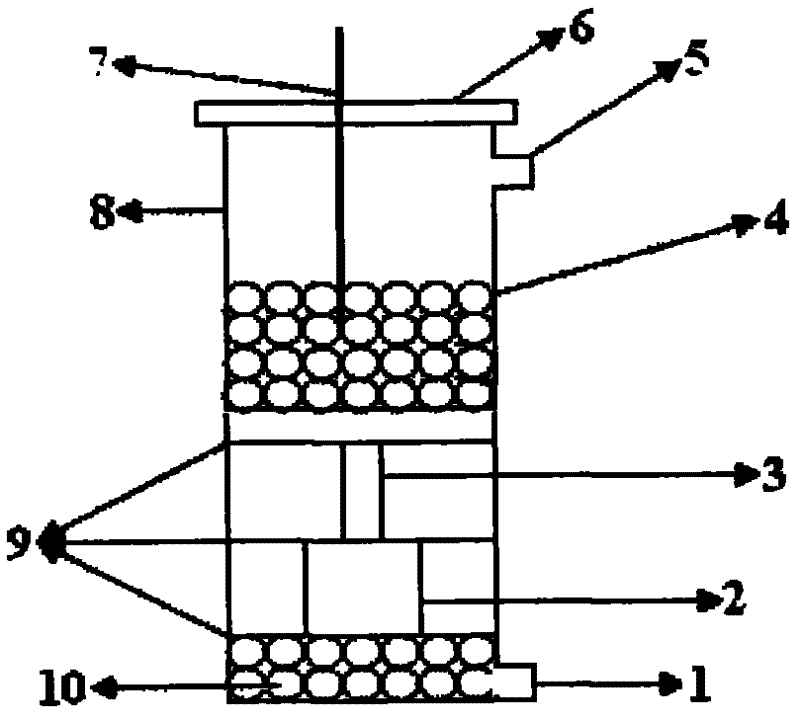

Method for simulation test of influence of alkali metal on coke degradation

ActiveCN102183477AHazard preventionBlast furnace detailsColor/spectral properties measurementsMaterials scienceCorundum

A method for a simulation test of the influence of alkali metal on coke degradation belongs to the field of blast furnace ironmaking technology. Aactive carbon powder and alkali carbonate powder are mixed and added into a corundum crucible; the crucible is placed on the upper part of a high-alumina ball at the bottom of a high temperature reaction vessel; a porous permeable corundum gasket is placed on the corundum crucible; three high temperature resistant corundum branch pipes with a height of 30-60 mm are placed on the gasket; a permeable gasket is placed above the corundum branch pipes; acoke sample is placed on the permeable gasket; after the sample is in place, the sample is heated and argon is pumped in to discharge air in the reaction vessel; when the temperature in the reaction vessel reaches 1200 DEG C, alkali metal vapor is generated; the sample is cooled to room temperature with the protection of argon, and the coke adsorbed with alkali vapor is inspected and analyzed. The advantages are that: the problem is solved that simulation tests of the adsorption of alkali metal elementary vapor on coke during the vapor rising process at 1100-1300 DEG C and the influence of CO2 on coke degradation can not be performed, and an evaluation index for evaluating the alkali metal harm resistance of coke at high temperature is provided.

Owner:BEIJING SHOUGANG CO LTD

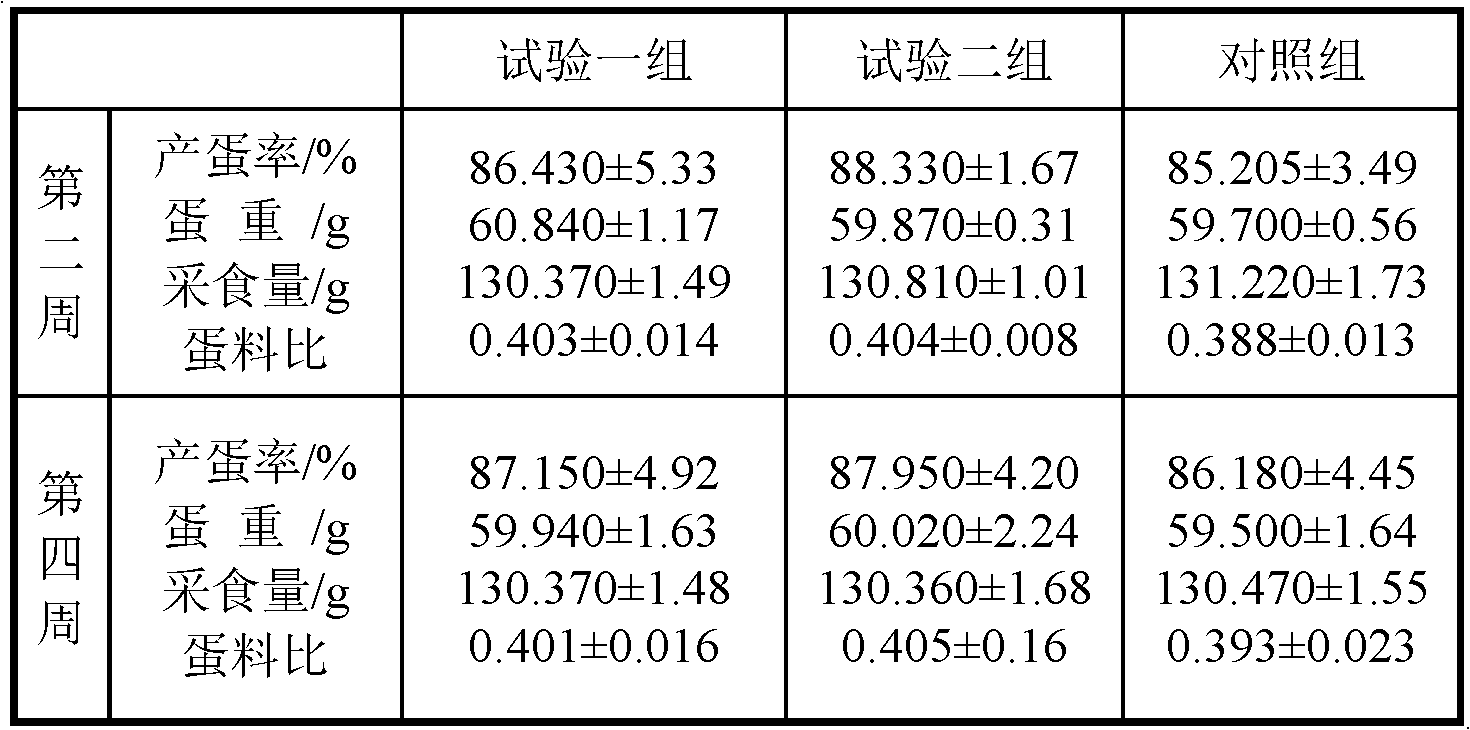

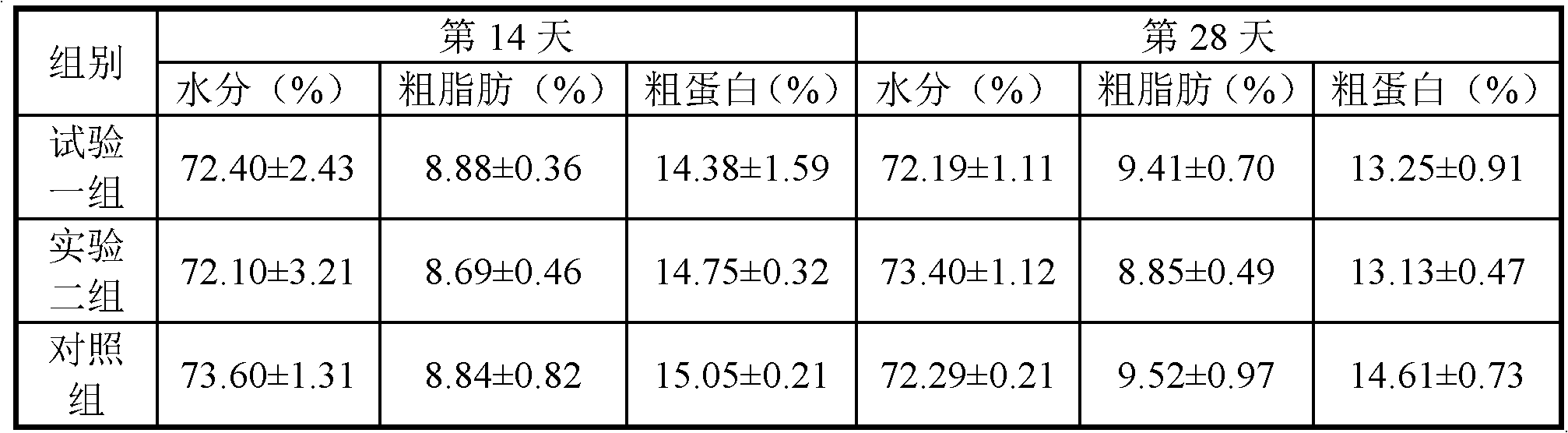

Animal nutrient additive trace element compound bag as well as preparation method and application thereof

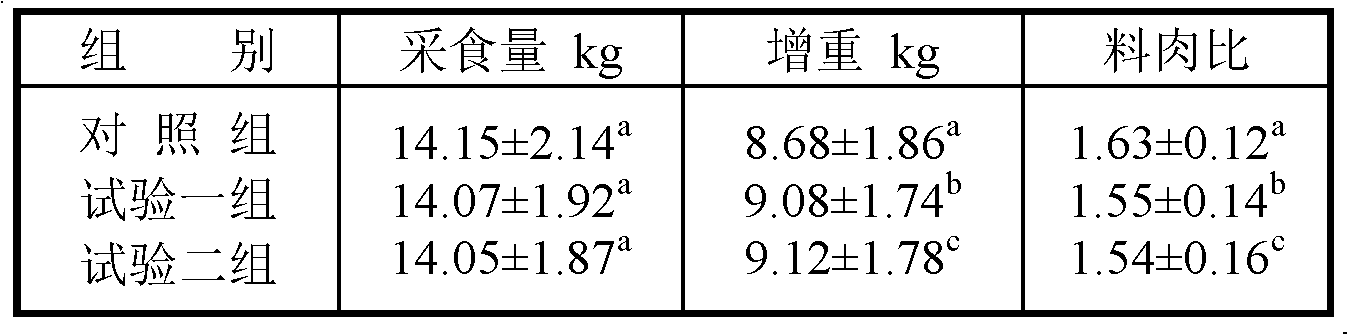

The invention discloses an animal nutrient additive trace element compound bag as well as a preparation method and an application thereof. The compound bag mainly comprises compound glycine polymineral, selenite and basic salt of a trace element, wherein the compound glycine polymineral contains copper glycinate, ferrous glycinate, zinc glycinate, manganese glycinate and the like; and the basic salt of the trace element contains at least one of basic chlorate, basic carbonate and basic sulfate corresponding to the trace elements such as copper, zinc, and manganese. The preparation method comprises the following steps of: mixing the glycine raw material and the inorganic trace element compound, adding the mixture into water, regulating the pH value, heating, fully stirring, reacting, then discharging, adding other raw materials into the reaction product to form uniformly dispersed suspension, drying, granulating, and thus obtaining the trace element compound bag. The trace element compound bag can be used as an animal feed additive, and has the advantages of simplified process, high biological value, low adding quantity, obvious growth-promoting effect, low side reaction of animals and the like.

Owner:昕嘉生物技术(长沙)有限公司

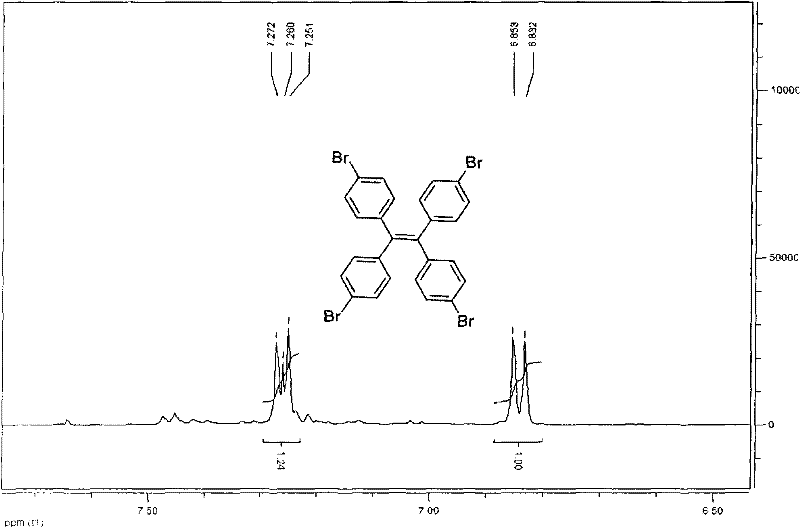

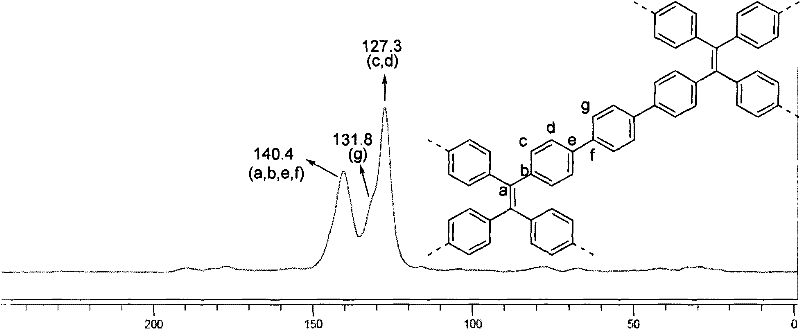

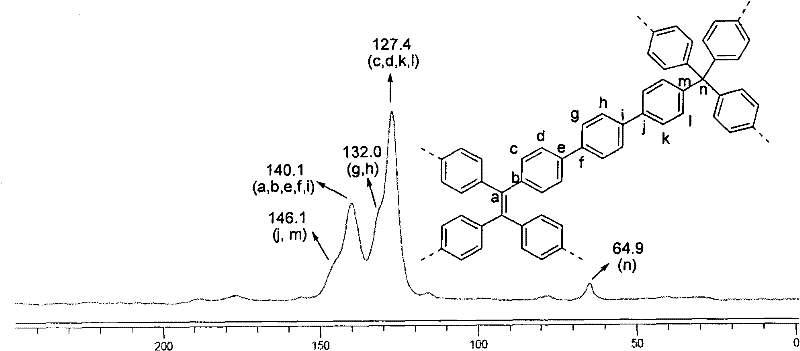

Fluorescence nanometer organic porous material as well as preparation method and application thereof

InactiveCN102442873AStable pore structureLarge π conjugated systemHydrocarbonsFluorescence/phosphorescenceFluorescencePalladium catalyst

The invention provides a preparation method of a fluorescence nanometer organic porous material, which comprises the following steps that: organic molecular building blocks are in contact with joint molecules under the Suzuki-Miyaura reaction conditions in inertia atmosphere and under the existence of catalysts containing palladium, alkali carbonate water solution and organic solvents; the organic molecular building blocks contain tetra-(4-bromobenzol) ethylene, and the joint molecules are one kind or several kinds of materials from P-boric acid, M-boric acid and phthalic boric acid. The invention also provides the fluorescence nanometer organic porous material prepared by the method. The porous material prepared by the method has certain Brunauer, Emmett and Teller (BET) specific surface area and has the fluorescence property, so the porous material can be used in aspects of catalysis, gas storage, molecular separation, organic photoelectric materials, optical control switches, fluorescence probes, chemical or biological sensors, novel optical materials and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

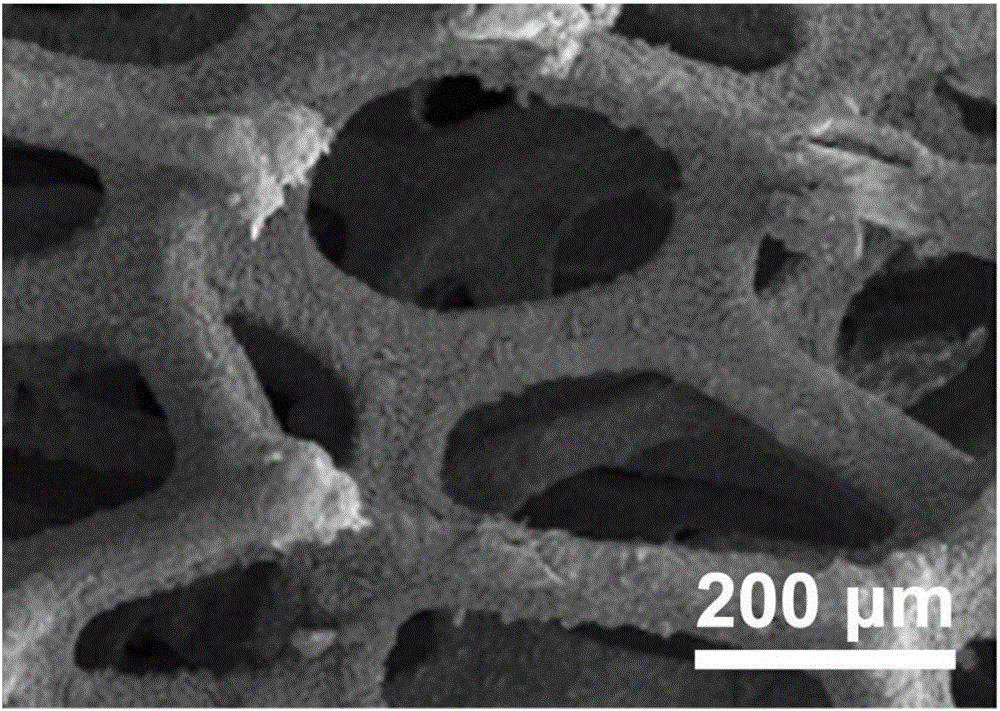

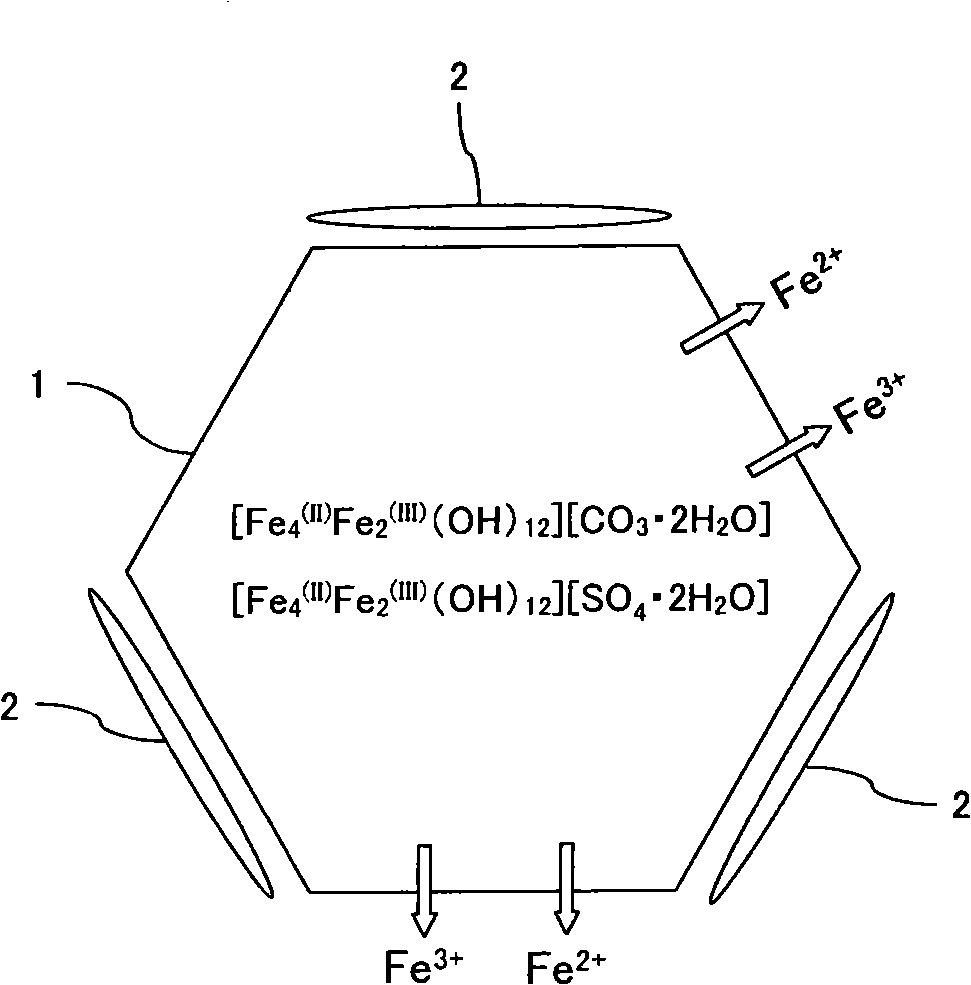

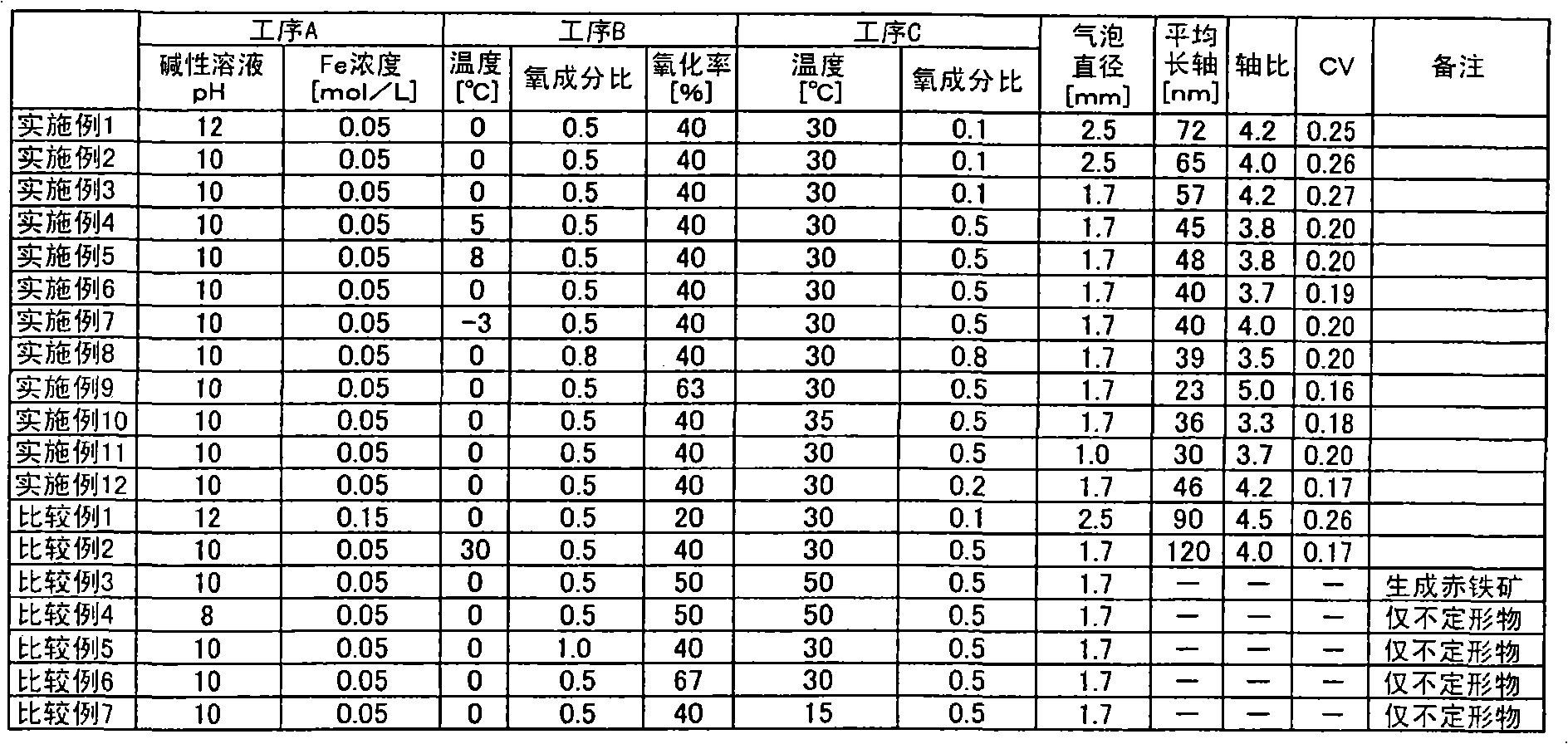

Method for producing iron oxyhydroxide particle

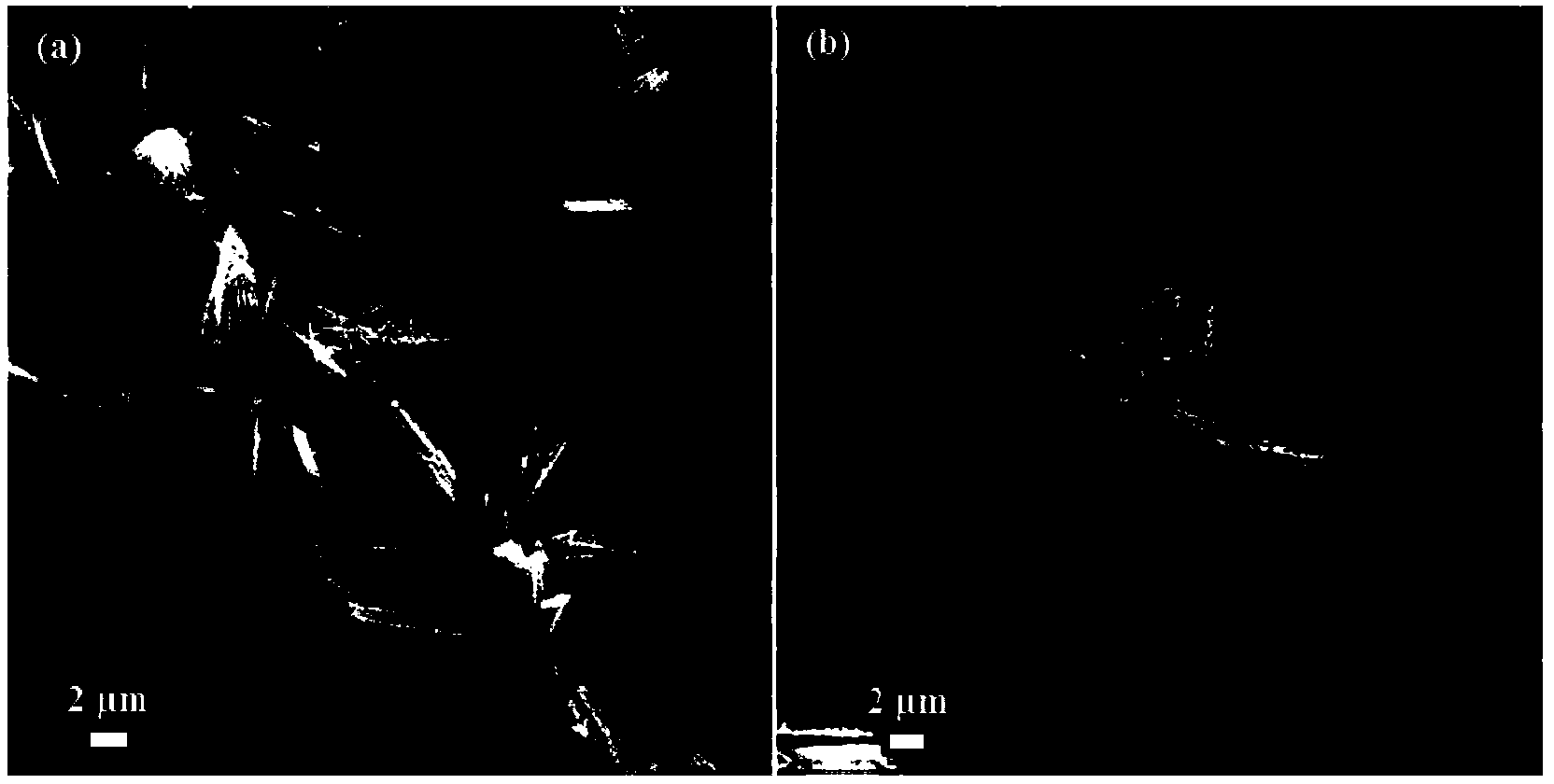

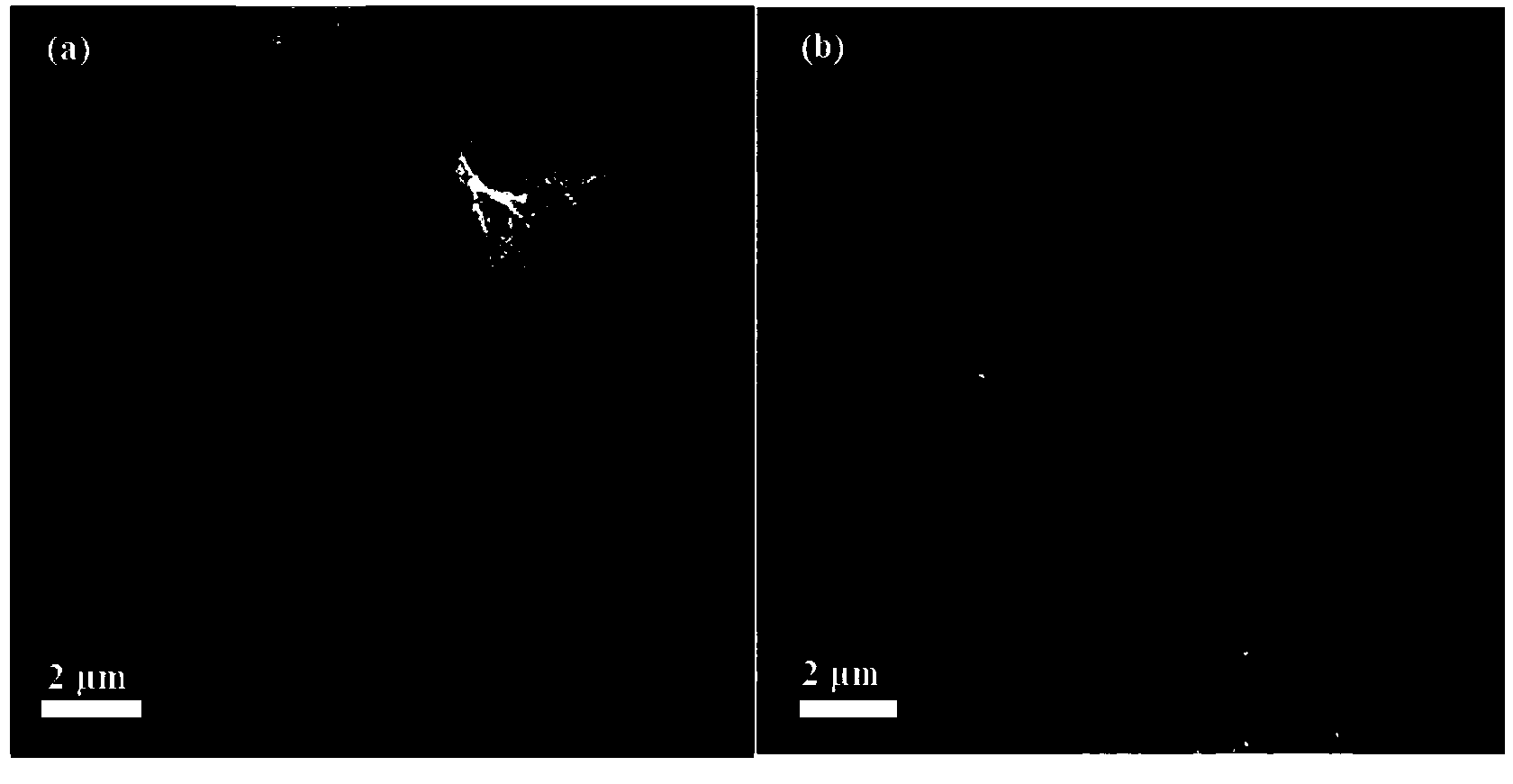

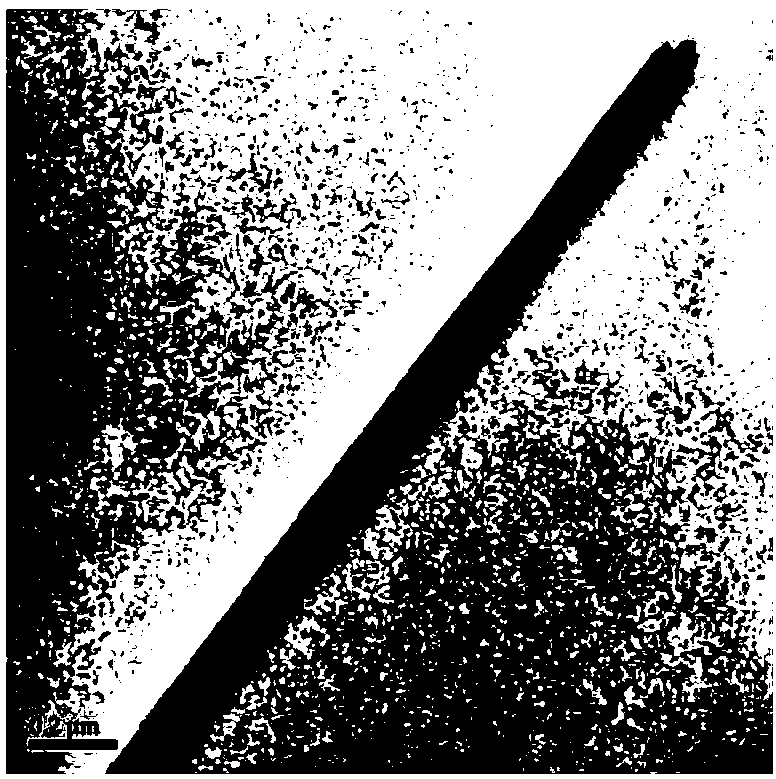

InactiveUS20080241055A1Yield can be ensuredReduce mixMaterial nanotechnologyNitrogen compoundsFerrous saltsIron oxyhydroxide

First, a ferrous iron-containing suspension solution is obtained by mixing an aqueous ferrous salt solution and an aqueous alkali solution containing one or two of an alkali carbonate and an alkali hydroxide. Then, an iron oxyhydroxide particle precursor is obtained by blowing an oxygen-containing gas having an oxygen component proportion of 0.5 to 0.8 into the suspension solution thus obtained to oxidize the ferrous iron in the suspension solution at an oxidation rate of 30 to 65% while the suspension solution is being controlled to fall in a temperature range of −5° C. or higher and lower than 10° C. Thereafter, the iron oxyhydroxide particles 2 are produced from the iron oxyhydroxide particle precursor by blowing an oxygen-containing gas into the suspension solution containing the iron oxyhydroxide particle precursor while the suspension solution is being controlled to fall in a temperature range of 20° C. or higher and lower than 45° C.

Owner:TDK CORPARATION

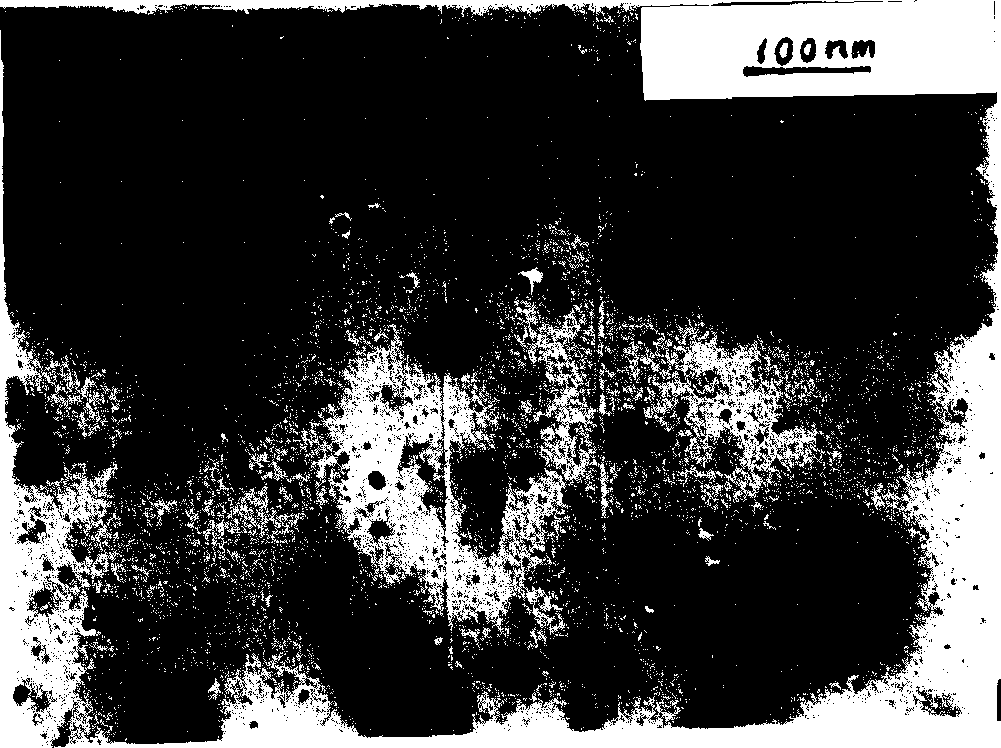

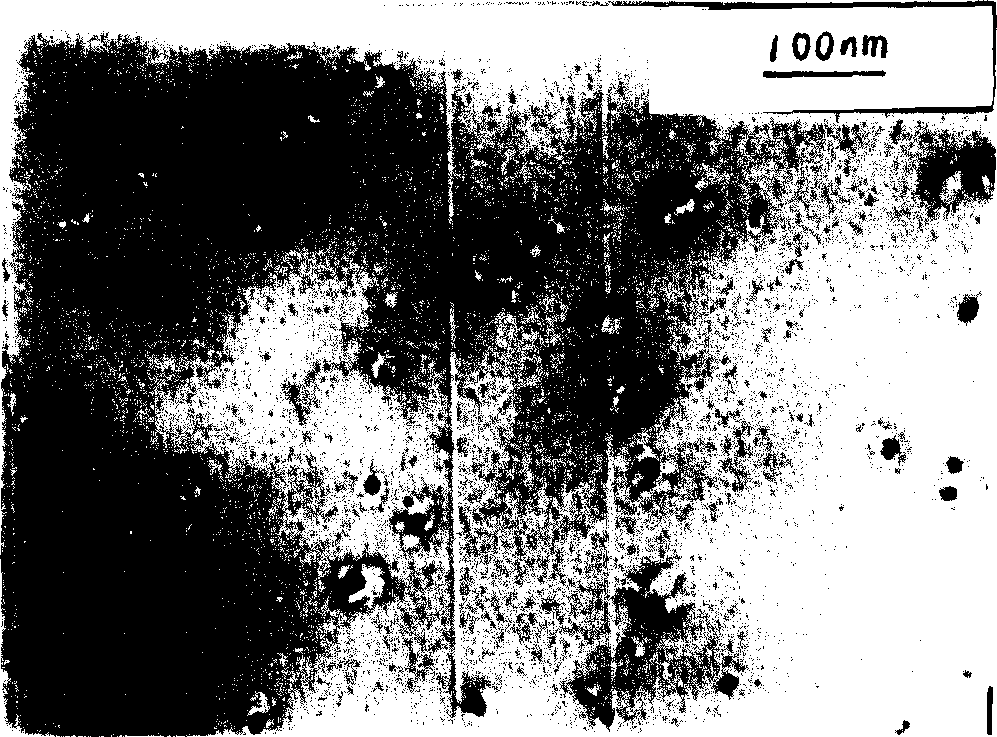

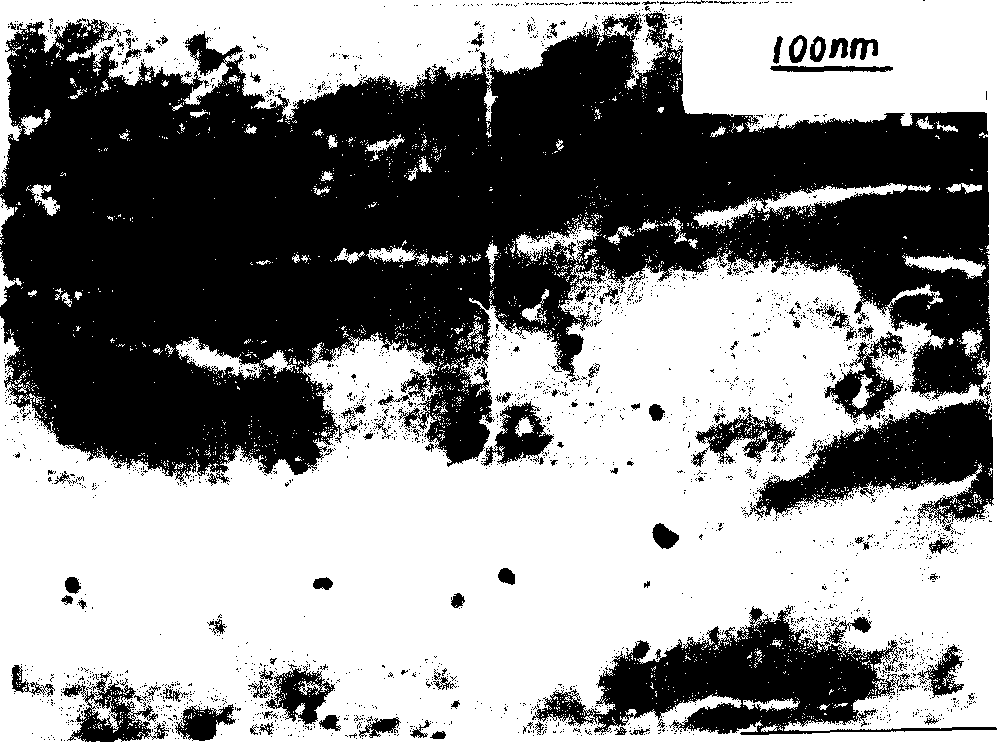

Method for preparing metal-organic framework films based on self transformation of basic carbonates

ActiveCN106178982AImprove stabilitySolve the interface binding problemSemi-permeable membranesFilm baseMetal-organic framework

The invention discloses a method for preparing metal-organic framework (MOF) films based on self transformation of basic carbonates, and belongs to the technical field of film separation. The method comprises the steps: preparing porous copper substrates, and pretreating the porous copper substrates; preparing precursor solutions with different basic carbonates; putting the treated copper substrates into the precursor solutions of the basic carbonates, and under certain conditions, generating basic carbonate nano arrays on the surfaces of the substrates in situ; putting the copper substrates modified with the basic carbonate nano arrays into different MOF ligand solutions, allowing the basic carbonates to be slowly dissolved in carboxylic acid organic ligands and releasing metal ions to generate coordination interaction with the ligands, and thus generating the continuous MOF films on the surfaces of the substrates. The invention provides the method for preparing the novel MOF films. Through basic carbonate nano array self transformation of the continuous MOF films, the adhesion between the MOF films and the substrates is effectively increased, and the method is simple in process, easy to implement, and conducive to large-scale application.

Owner:BEIJING UNIV OF TECH

Process for preparing nano rareearth oxidate powder

The preparation method of nano rare earth oxide powder includes the following steps: mixing the nitric acid or hydrochloric acid aqueuos solution of raw material rare earth and precipitant carbonate,making ignition, specially, the rare earth nitrate is Ln(NO3)3 and rare earth hydrochloride is LnCl3, in which Ln=La, Nd, Sm, Gd, Eu, Y, Ce and Dy. and the mole number of its aqueous solution is 0.1-0.6 mol / L; then mixing the aqueous solution of the precipitant NaOH or carbonate Na2CO3 whose concentration is 0.3-0.6 mol / L with the above-mentioned Ln(NO3)3 or LnCl3 aqueous solution, their volume ratio of is 1.5-3:1 pH value is 6-7, stirring for above 10 min. and drying to obtain basic carbonate or carbonate or hydroxide, stirring dispersing agent alcohol material and the above-mentioned obtained material.

Owner:ANHUI LITE ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com