Method for synthesizing cobalt oxide/graphene composite wave-absorbing material

A graphene composite and wave-absorbing material technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as single absorption frequency band, low absorption intensity, and high density, and achieve simple synthesis devices, simple methods, and high reaction efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

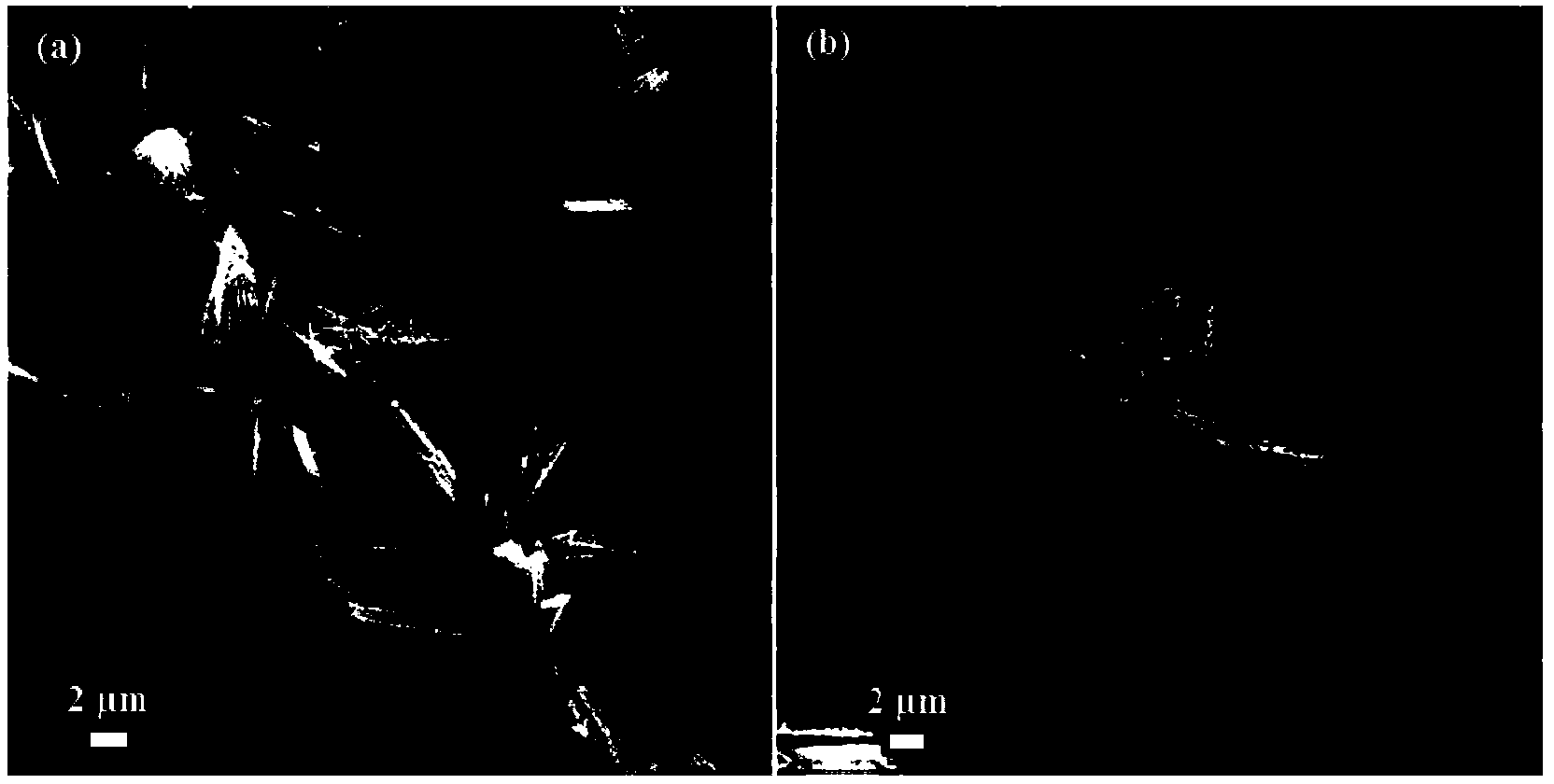

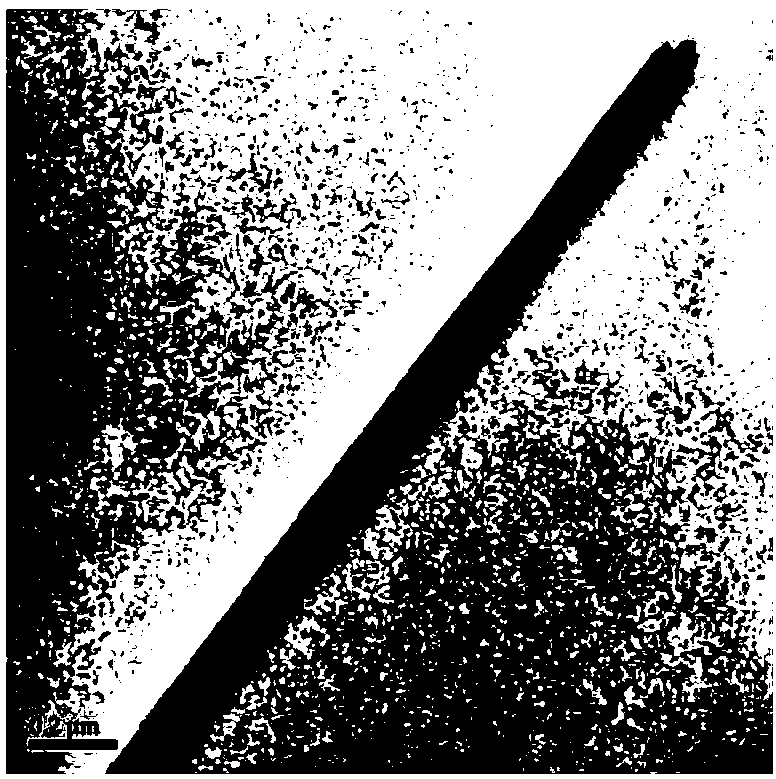

Image

Examples

Embodiment 1

[0026] 1) Prepare a solution of cobalt nitrate: weigh 1 g of cobalt nitrate hexahydrate, 0.3 g of ammonium fluoride and 1 g of urea, and dissolve it in 60 mL of distilled water to obtain an aqueous solution of cobalt nitrate (50 mM);

[0027] 2) Place the aqueous solution of cobalt nitrate prepared in step 1) in a hydrothermal kettle, and magnetically stir for 30 minutes;

[0028] 3) Put the hydrothermal kettle into an oven and keep it at 120°C for 8 hours to ensure that the reaction is complete. Finally, the pink turbid liquid was obtained, centrifuged, and the obtained precipitate was washed 3 times with ethanol solution to obtain the basic carbonate material;

[0029] 4) heating and drying the precipitate obtained in step 3), and controlling the temperature at 80°C;

[0030] 5) The dried sample obtained in step 4) was put into a tube furnace, and calcined at 300° C. for 2 hours with argon gas to obtain the product cobalt oxide material.

[0031] 6) Mix the sample prepared...

Embodiment 2

[0034] 1) Prepare a solution of cobalt nitrate: weigh 1g of cobalt nitrate hexahydrate, 0.3g of ammonium fluoride and 1g of urea, dissolve it in distilled water to obtain an aqueous solution of cobalt nitrate (50mM);

[0035] 2) Place the aqueous solution of cobalt nitrate prepared in step 1) in a hydrothermal kettle, and magnetically stir for 30 minutes;

[0036] 3) Preparation of graphene alcohol solution: Weigh 5 mg of graphene solid powder and disperse it in 5 mL of absolute ethanol solution to obtain graphene alcohol solution (concentration is 1 mg / mL);

[0037] 4) Inject the graphene alcohol solution prepared in step 3) into the cobalt nitrate aqueous solution in step 2), and mix well. Put the hydrothermal kettle into an oven and keep it at 120°C for 8 hours to ensure that the reaction is complete. Finally, the purple turbid liquid was obtained, centrifuged, and the obtained precipitate was washed 3 times with ethanol solution to obtain the basic carbonate / graphene mate...

Embodiment 3

[0043] 1) Prepare a solution of cobalt nitrate: weigh 1g of cobalt nitrate hexahydrate, 0.3g of ammonium fluoride and 1g of urea, dissolve it in distilled water to obtain an aqueous solution of cobalt nitrate (50mM);

[0044] 2) Place the aqueous solution of cobalt nitrate prepared in step 1) in a hydrothermal kettle, and magnetically stir for 30 minutes;

[0045] 3) Preparation of graphene alcohol solution: Weigh 10 mg of graphene solid powder and disperse it in 5 mL of absolute ethanol solution to obtain graphene alcohol solution (2 mg / mL);

[0046] 4) Inject the graphene alcohol solution prepared in step 3) into the cobalt nitrate aqueous solution in step 2), and mix well. Put the hydrothermal kettle into an oven and keep it at 120°C for 16 hours to ensure complete reaction. Finally, the purple turbid liquid was obtained, centrifuged, and the obtained precipitate was washed 3 times with ethanol solution to obtain the basic carbonate / graphene material;

[0047] 5) heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com