Preparation method of wave-absorbing composite material used for isolator loading

A composite material and isolator technology, which is applied in the field of preparation of wave-absorbing composite materials for isolator loads, can solve the problem that absorption performance and withstand power cannot be both at the same time, and cannot meet the development requirements of isolator miniaturization and high power. Problems such as low heat distortion temperature, to achieve the effect of good microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Main ingredients: mass ratio (carbonyl iron powder): (epoxy resin E51) = 7:1

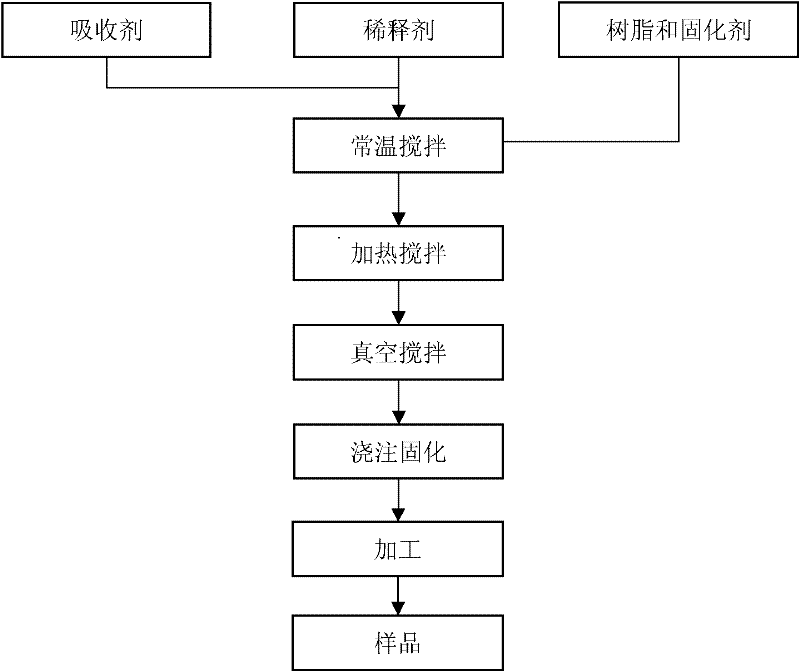

[0045] Mix 70g of carbonyl iron powder and 14g of absolute ethanol in a three-necked flask, and stir at high speed for 30 minutes. After the carbonyl iron powder was mixed and dispersed in absolute ethanol, 10 g of epoxy resin and 3 g of curing agent (4,4-diaminophenyl sulfone) were put in, and stirred and degassed at 90° C. When the viscosity of the material in the three-necked flask is relatively high, vacuum stirring and degassing is carried out, and the temperature is gradually heated from 90°C to 120°C. When no air bubbles can be observed with the naked eye at 120°C, pouring is carried out, and the mold is preheated with a release agent and 150°C in advance. The cast bodies were cured at 120°C for 3 hours and post-cured at 170°C for 2 hours. The casting body is demoulded, and finally cut and polished to be processed into samples of required specifications.

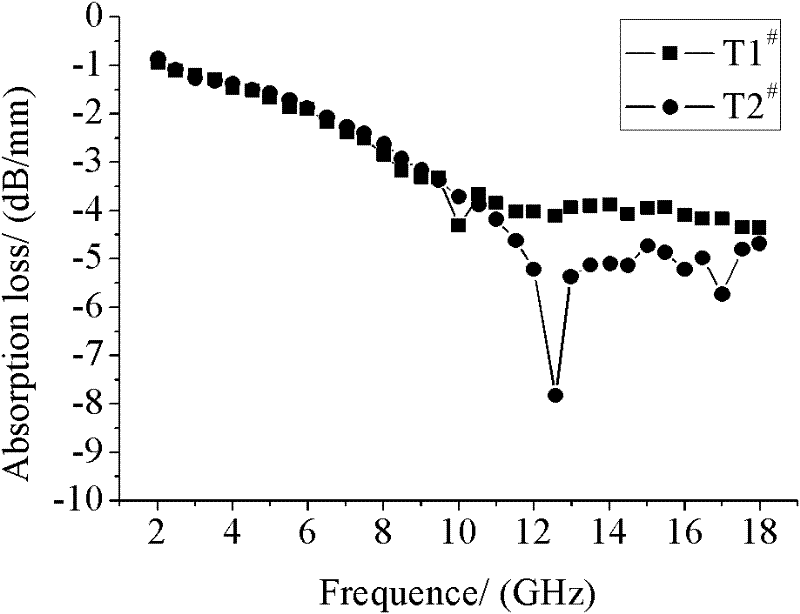

[0046] Under 10GHz, the mi...

Embodiment 2

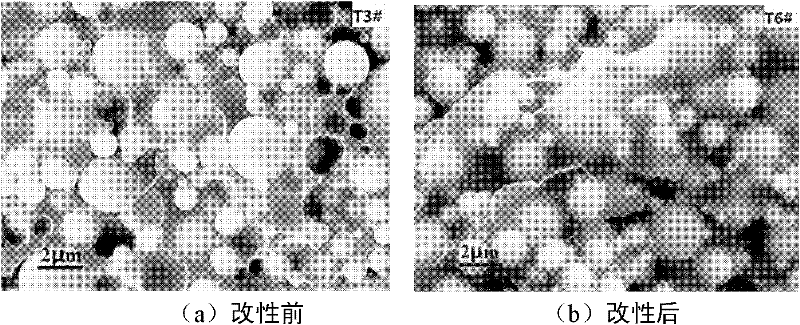

[0048] Main ingredients: mass ratio (modified carbonyl iron powder): (epoxy resin E51) = 7:1

[0049] Add 50ml of absolute ethanol, 0.69g of distilled water, and 3g of KH-560 silane coupling agent into a three-necked flask to prepare a silane coupling agent solution, adjust the pH value to 3.5-5.5 with glacial acetic acid, place it in a three-necked flask, and weigh 100g of carbonyl iron powder Put it into a three-necked flask, ultrasonically disperse the solution, and stir at the same time. After reacting for 30 minutes, let the reactant stand still, wash it with absolute ethanol until it is neutral, dry it naturally for 24 hours, and finally dry it at 110°C for 2 hours to obtain Silane modified carbonyl iron powder.

[0050] 70 g of the modified carbonyl iron powder and 14 g of absolute ethanol were mixed in a three-necked flask, and stirred at high speed for 30 minutes. After the carbonyl iron powder was mixed and dispersed in absolute ethanol, 10 g of epoxy resin and 3 g ...

Embodiment 3

[0053] Main ingredients: mass ratio (carbonyl iron powder): (carbonyl nickel powder): (epoxy resin E51) = 5:2:1

[0054]Mix 50 g of carbonyl iron powder, 20 g of carbonyl nickel powder and 14 g of absolute ethanol in a three-necked flask, and stir at high speed for 30 minutes. After the metal powder was mixed and dispersed in absolute ethanol, 10 g of epoxy resin and 3 g of curing agent (4,4-diaminophenyl sulfone) were put in, and stirred and degassed at 90° C. When the viscosity of the material in the three-necked flask is relatively high, vacuum stirring and degassing is carried out, and the temperature is gradually heated from 90°C to 120°C. When no air bubbles can be observed with the naked eye at 120°C, pouring is carried out, and the mold is preheated with a release agent and 150°C in advance. The cast bodies were cured at 150°C for 2.5 hours and post-cured at 200°C for 1.5 hours. The casting body is demoulded, and finally cut and polished to be processed into samples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com