Patents

Literature

239results about How to "Improve microwave absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

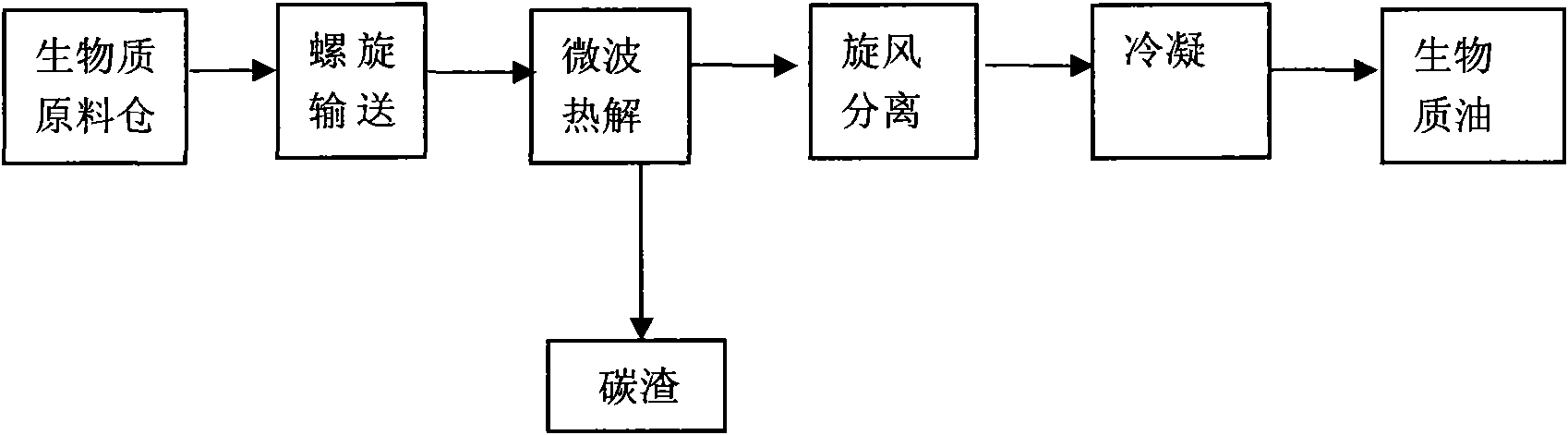

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

Method for synthesizing cobalt oxide/graphene composite wave-absorbing material

InactiveCN104263317AEasy to adjust dielectric constantImprove microwave absorption performanceOther chemical processesAlcoholSaline solutions

The invention discloses a method for synthesizing a cobalt oxide / graphene composite wave-absorbing material and relates to nanometer wave-absorbing materials. The method comprises the following steps: (1) dissolving a metal cobalt salt, ammonium fluoride and urea in water, thereby obtaining a metal saline solution; (2) adding the metal saline solution prepared in the step (1) into a hydrothermal kettle, and magnetically stirring to be uniform; (3) dispersing graphene solid powder into an absolute ethyl alcohol solution, thereby obtaining a graphene alcohol solution; (4) adding the graphene alcohol solution prepared by the step (3) into the metal saline solution prepared in the step (2), mixing, stirring, putting the hydrothermal kettle into a drying oven for reacting, thereby obtaining purple turbid liquid; and centrifuging, washing the obtained precipitate by using the ethanol solution, thereby obtaining a subcarbonate / graphene material; and (5) heating and drying the subcarbonate / graphene material obtained in the step (4), calcining, thereby obtaining the product cobalt oxide / graphene composite wave-absorbing material. The method is simple, high in operability, mild in preparation conditions, clean and pollution-free in reaction process, high in reaction efficiency and high in reproducibility.

Owner:XIAMEN UNIV

Supported metallic oxide catalyst for assisting microwave denitration and preparation method and using method thereof

ActiveCN105170150AHigh activityReduce loadDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxidesCatalytic decomposition

The invention discloses a supported metallic oxide catalyst for assisting microwave denitration and a preparation method and a using method thereof. The catalyst is the supported catalyst using carbon as a carrier and using a metallic oxide as an active ingredient. The carrier of the catalyst is carbon-based, is convenient to obtain, large in specific surface area and capable of playing a very good dispersing role on the active ingredient of the catalyst, and the phenomenon of ingredient agglomeration is not produced. The metallic oxide is high in activity, and required supporting amount is small. The carbon-supported metallic oxide has very good microwave absorbing ability, can well play the synergistic effect of microwaves and the catalyst, the catalytic decomposition efficiency of nitrogen oxide is high, the NO decomposition rate can be above 98%, and the catalytic decomposition temperature is low and the loss of the carbon carrier is low by means of the method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

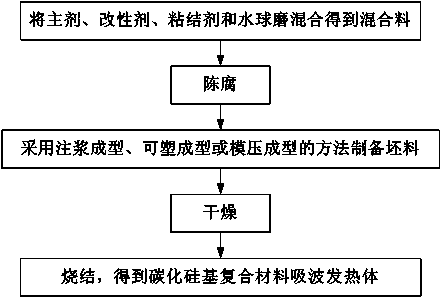

Silicon carbide based composite microwave-absorbing heating body composition and preparation method thereof

The invention discloses a silicon carbide based composite wave-absorbing heating body composition and a preparation method thereof. The heating body composition is prepared from the raw materials in parts by mass: 75-95 parts of main agent, 5-25 parts of modifier, 1-6 parts of additive binder and 5-50 parts of water; the preparation method of the silicon carbide based composite wave-absorbing heating body composition comprises the following steps: carrying out ball milling to mix the materials; ageing; molding; drying; and sintering. The silicon carbide based composite wave-absorbing heating body composition disclosed by the invention has good microwave absorbing and rapid heating performance in the civilian band (2.45GHz). The wave-absorbing heating body composition can be processed into various shapes according to the needs of sintered products, is simple in production process, low in production cost, wide in use temperature range, good in high-temperature oxidation resistance, extensive in use and easy in the forming of different atmospheres, can meet the requirements of products of different types on sintering and is extensively used as heating elements of various high-temperature furnaces.

Owner:XIAN UNIV OF SCI & TECH

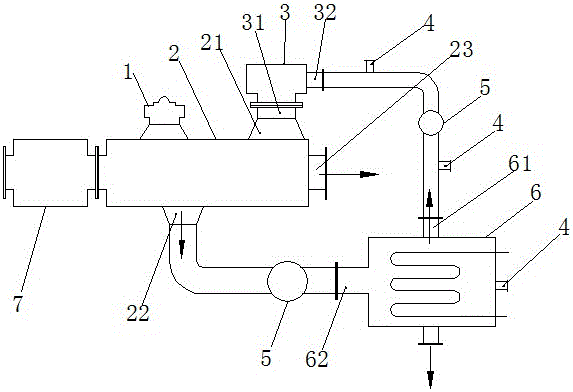

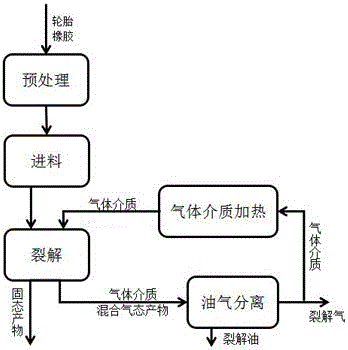

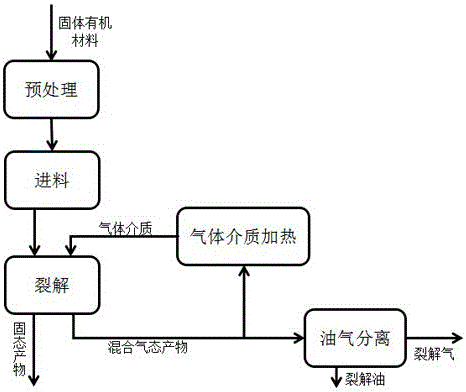

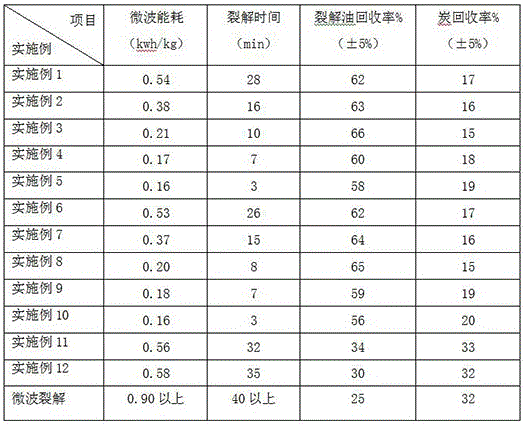

Tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves

ActiveCN105733644AStrong process controllabilityImproved microwave absorption propertiesProductsReagentsMicrowaveProduct gas

The invention provides a tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves. The method includes the steps of A, preprocessing tire rubber; B, feeding the preprocessed tire rubber into a composite pyrolysis cavity; C, using a gas heating device to heat gas media to 350-700 DEG C; D, continuously feeding the heated gas into the composite pyrolysis cavity, and allowing the heated gas and the microwaves to jointly act on the tire rubber so as to perform pyrolysis to obtain solid products and mixed gas products; E, performing oil-gas separation on the mixed gas products to remove pyrolysis oil; F, partially feeding the gas obtained after the oil-gas separation in the step E into the gas heating device of the step C, and heating the gas to 350-700 DEG C for the circulation pyrolysis of the step D. By the tire rubber pyrolysis method, pyrolysis energy consumption and pyrolysis time can be reduced and cost is saved.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

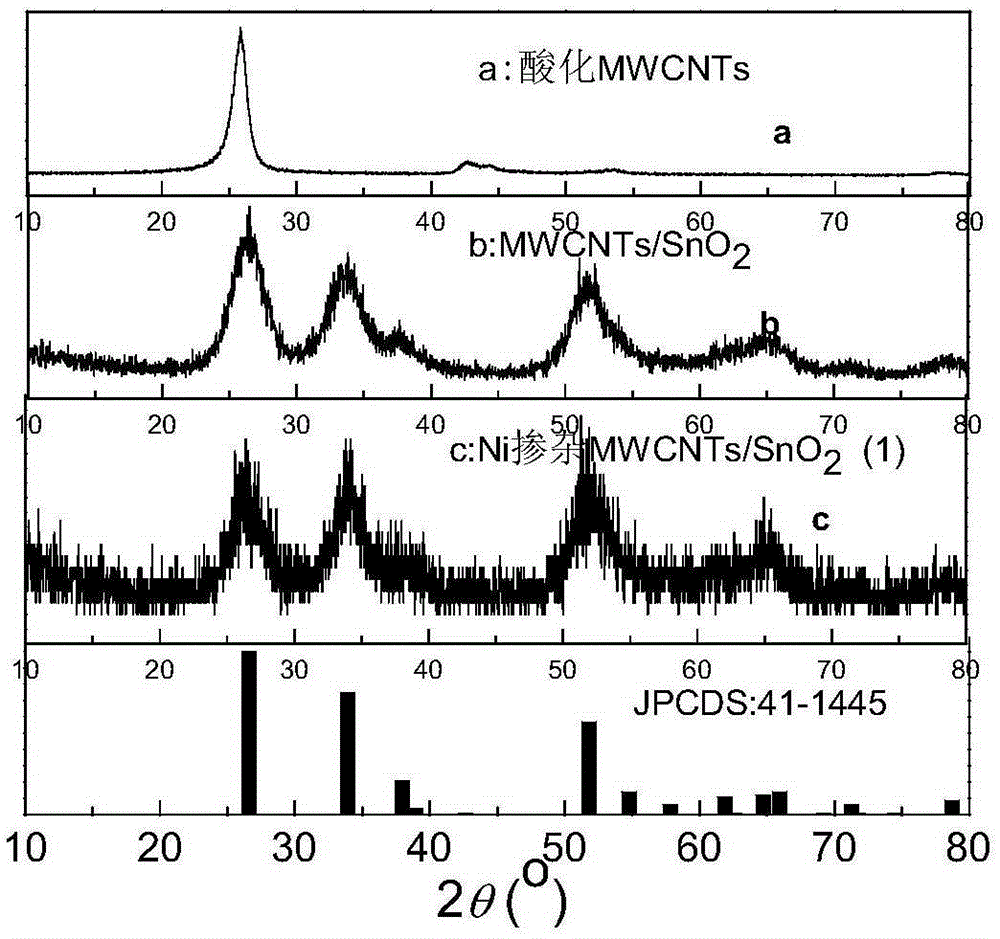

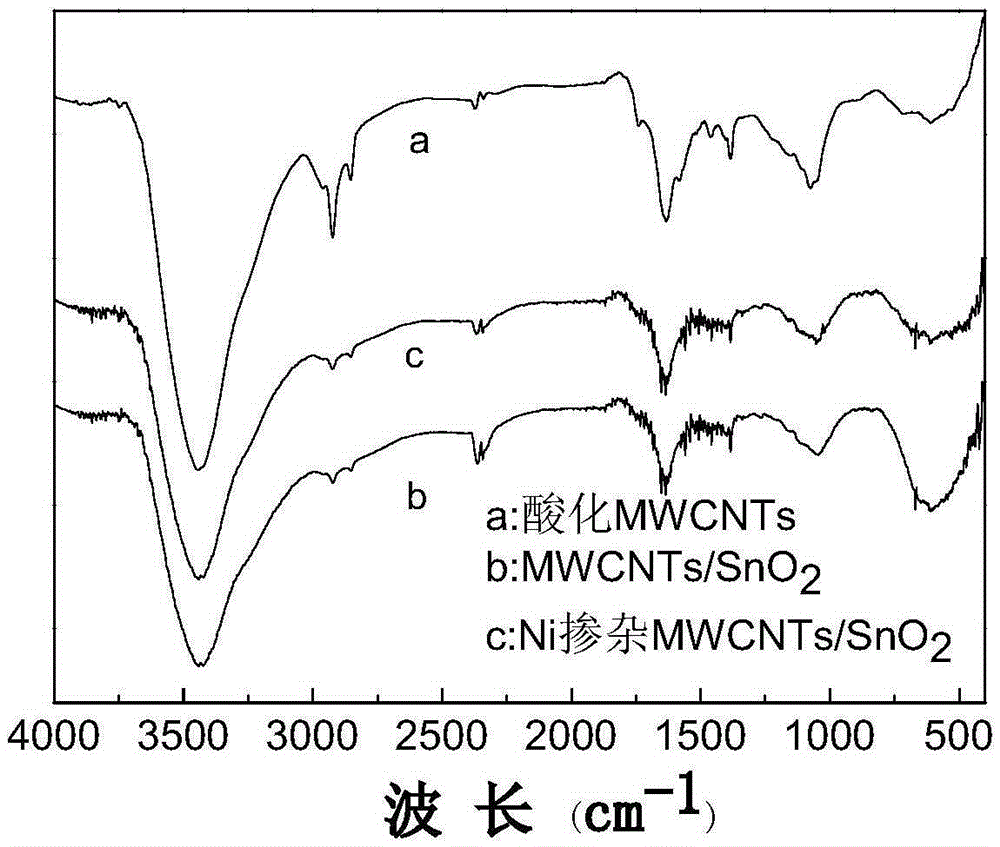

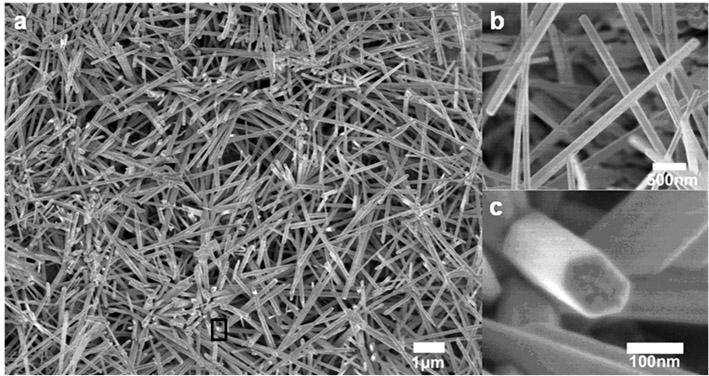

Nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes/tin dioxide

ActiveCN105338799ALight weightImprove conductivityMagnetic/electric field screeningTin dioxideNanocomposite

The invention discloses a nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes / tin dioxide, and the nanocomposite can be widely applied to the aspect of electromagnetic wave absorption. A preparation method of the nanocomposite comprises the following steps: 1, conducting acidificaiton on multiwalled carbon nanotubes; 2, dispersing the acidified multiwalled carbon nanotubes treated in step 1 into water, obtaining dispersion liquid of the multiwalled carbon nanotubes, adding tin tetrachloride pentahydrate, then adding nickel nitrate hexahydrate or ferric nitrate nonahydrate or cobalt nitrate hexahydrate, then adding acid, then slowly adding stronger ammonia water, adjusting pH to be 7-10, conducting a reaction for 8-24 hours at the temperature of 120-180 DEG C, and obtaining the nanocomposite made of the magnetic-metal (M)-doped multiwalled carbon nanotubes / tin dioxide through aftertreatment, wherein M represents Fe, Co and Ni, and the massic volume ratio of the acidified multiwalled carbon nanotubes to the tin tetrachloride pentahydrate to the nickel nitrate hexahydrate or the ferric nitrate nonahydrate or the cobalt nitrate hexahydrate to the acid is 0.04 g: 1-4 g: 0.5-3 g: 0.5-4 mL.

Owner:ANHUI UNIV OF SCI & TECH

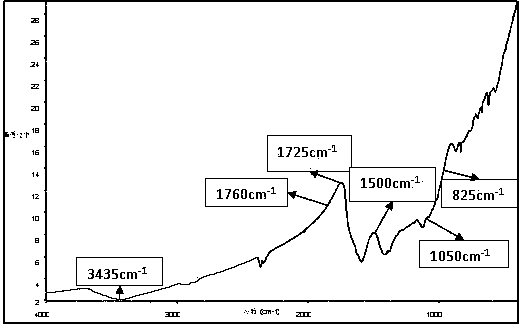

Preparation method of polyaniline/sliver-coated/cobalt ferrite composite material

ActiveCN103436013AImprove electrical performanceEasy to processOther chemical processesNitrateElectrical performance

The invention discloses a preparation method of a polyaniline / sliver-coated / cobalt ferrite composite material. The preparation method comprises the following steps: respectively weighing three substances according to a stoichiometric ratio of cobalt nitrate to ferric nitrate to citric acid of 1:2:4: preparing cobalt ferrite (CoFe2O4) by adopting a sol-gel process; carrying out chemical silver-plating onto the prepared CoFe2O4 to obtain wave-absorbing filler with excellent electromagnetic performances; and preparing PANI (Polyaniline) / Ag / CoFe2O4 composite material by using aniline monomer and Ag / CoFe2O4 as raw materials through a chemical in-situ polymerization method. The composite material is combined with the excellent electrical performance of metal single substance Ag, the good magnetic performance of CoFe2O4 as well as good processability, stability and electrical performance of the conductive high polymer polyaniline, is a good microwave-absorbing material, and has an important application value in the microwave-absorbing field. The Ag / CoFe2O4 composite filler obtained by the preparation method disclosed by the invention is combined with the excellent electrical performance of the Ag and the good magnetic performance of the CoFe2O4, and is a good electromagnetic composite material; the PANI / Ag / CoFe2O4 prepared by using the composite material as the filler has good microwave-absorbing performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

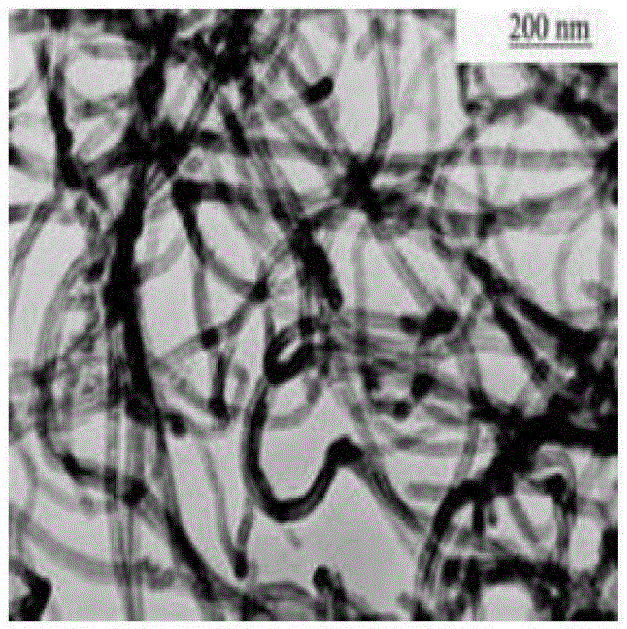

Preparation and application of Fe3O4@C@MoS2 composite material with core-shell structure

ActiveCN109825252AImprove microwave absorption performanceOther chemical processesMagnetic/electric field screeningThioureaAutoclave

The invention discloses a preparation and an application of an Fe3O4@C@MoS2 composite material with a core-shell structure. The preparation method includes the following steps: S1. adding FeCl3 and NaOH into water, uniformly mixing, loading the mixed solution into a polytetrafluoroethylene stainless steel autoclave, and reacting to obtain uniform cubic Fe2O3 particles; S2, adding the Fe2O3 particles prepared in S1 and dopamine hydrochloride into a trimethylolaminomethane buffer solution, stirring and reacting at room temperature with a magnetic stirrer, then washing the reaction product, and collecting an Fe2O3@PDA composite with a core-shell structure through a centrifugal method; S3. adding the Fe2O3@PDA prepared in S2, ammonium molybdate tetrahydrate and thiourea into water in sequenceand stirring uniformly, washing the product after the reaction is finished, and collecting Fe2O3@PDA@MoS2 composite through the centrifugal method; and S4. calcining the Fe2O3@PDA@MoS2 composite underthe flow of hydrogen and argon to finally obtain the Fe3O4@C@MoS2 composite. The Fe3O4@C@MoS2 composite material prepared by the method has excellent microwave absorption performance.

Owner:ANHUI UNIV OF SCI & TECH

Multilayer hollow composite wave-absorbing material

InactiveCN107163500ALow densityRequirements for realizing lightweightOther chemical processesFilling materialsCarbon nanotube

The application relates to a multilayer hollow composite wave-absorbing material, made by mixing magnesium phenolic resin as a substrate with TiO2 / SiO2 / hollow nickel, zeolite powder, barite powder, carbonyl iron powder and carbon nanotubes as filling materials.

Owner:陈剑桃

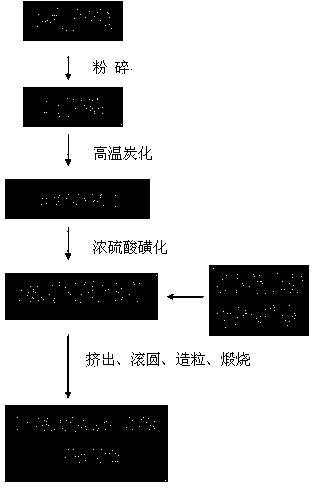

Solid acid catalyst suitable for microwave-assisted reaction and preparation method of solid acid catalyst

ActiveCN104028294AStrong microwave absorption capacityImprove distribution uniformityFatty acid esterificationMolecular sieve catalystsSulfuric acidSolid acid

The invention discloses a solid acid catalyst suitable for a microwave-assisted reaction and a preparation method of the solid acid catalyst. The preparation method comprises the following steps: with grains or beans as a raw material, crushing, high-temperature carbonizing, concentrated sulfuric acid sulfonation, wet granulation after washing, and calcining to obtain the solid acid catalyst. The solid acid catalyst provided by the invention is simple to operate, short in period and low in cost in the whole preparation process, and is a novel solid acid catalyst which resists high temperature and is suitable for a microwave environment.

Owner:JIANGNAN UNIV

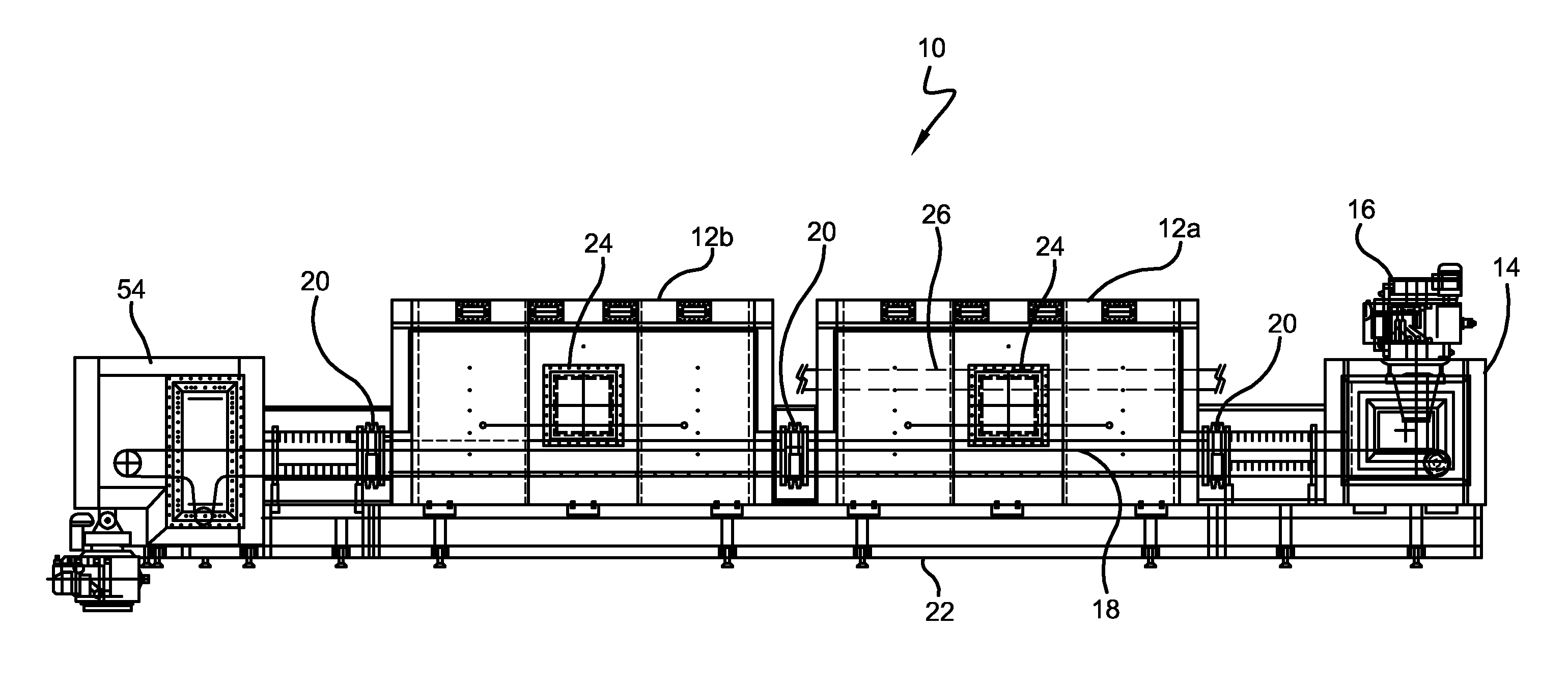

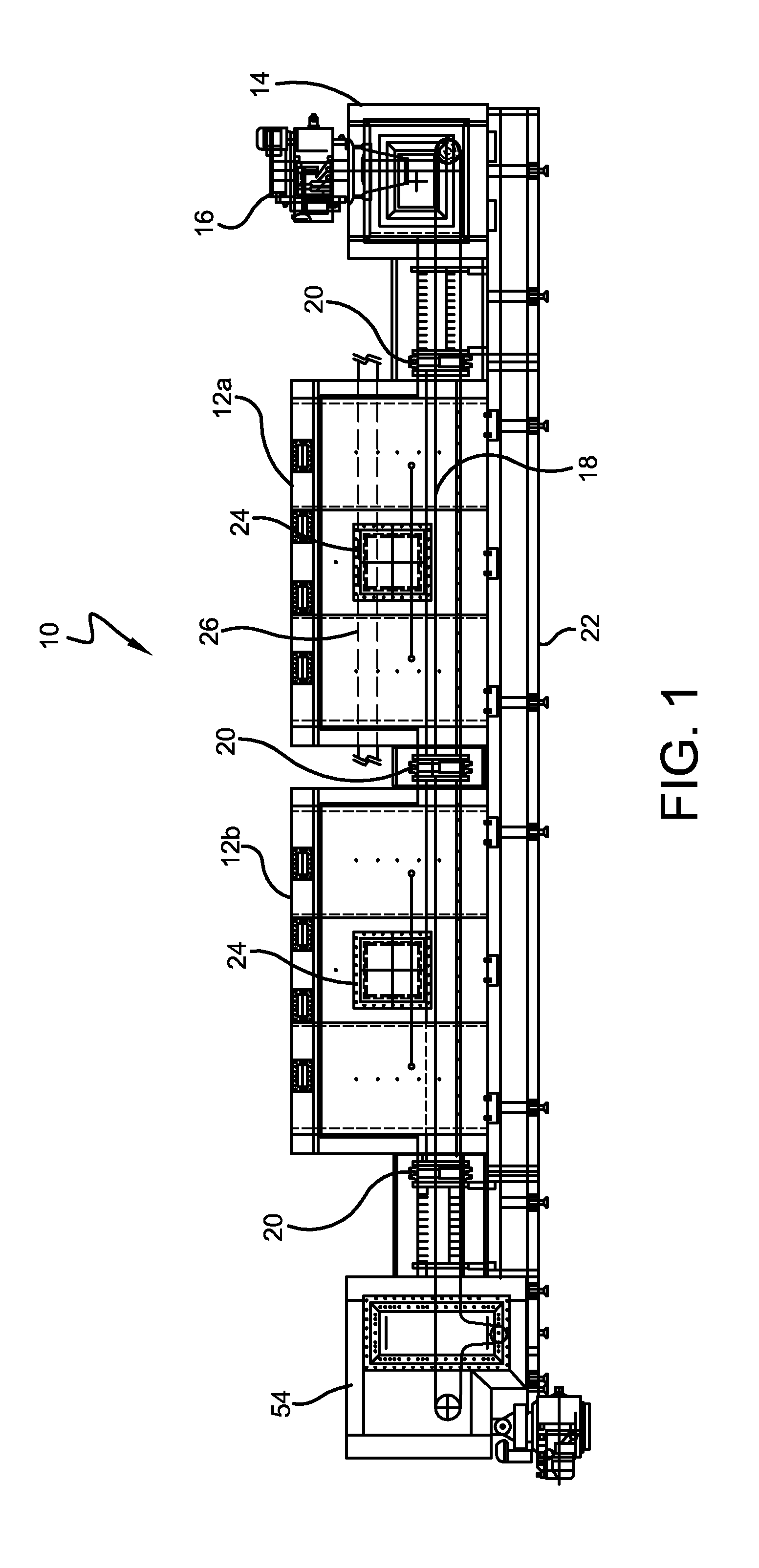

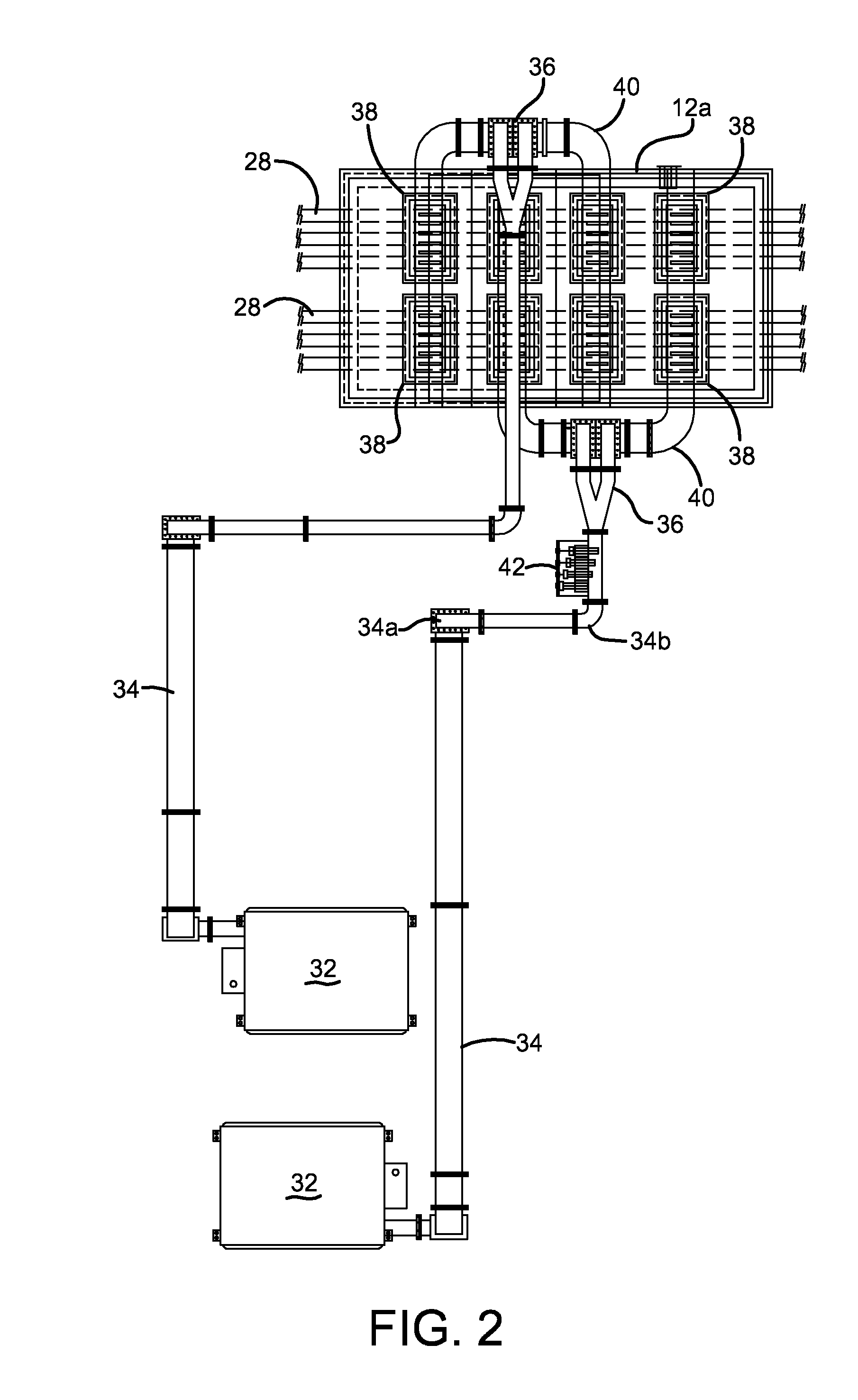

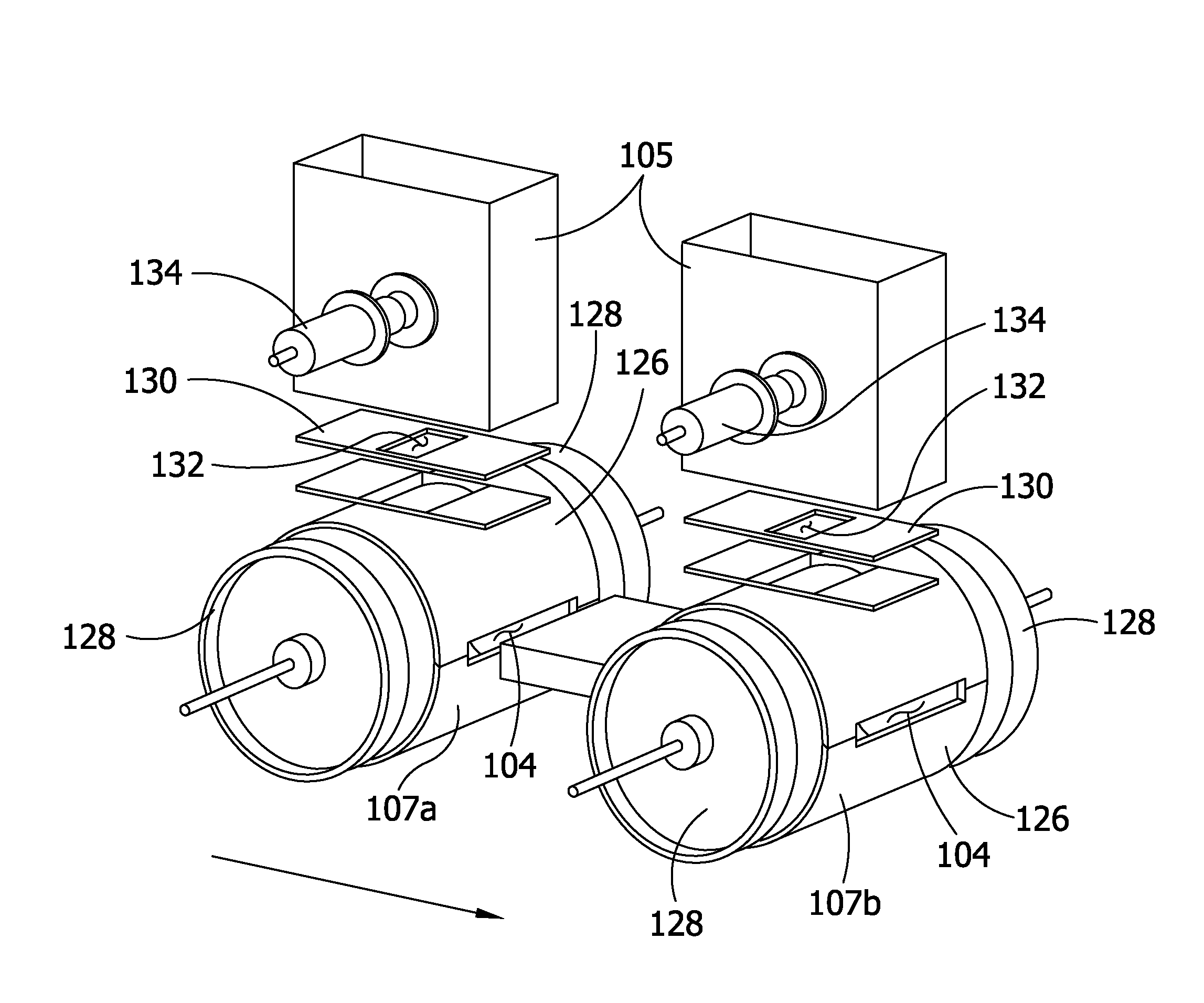

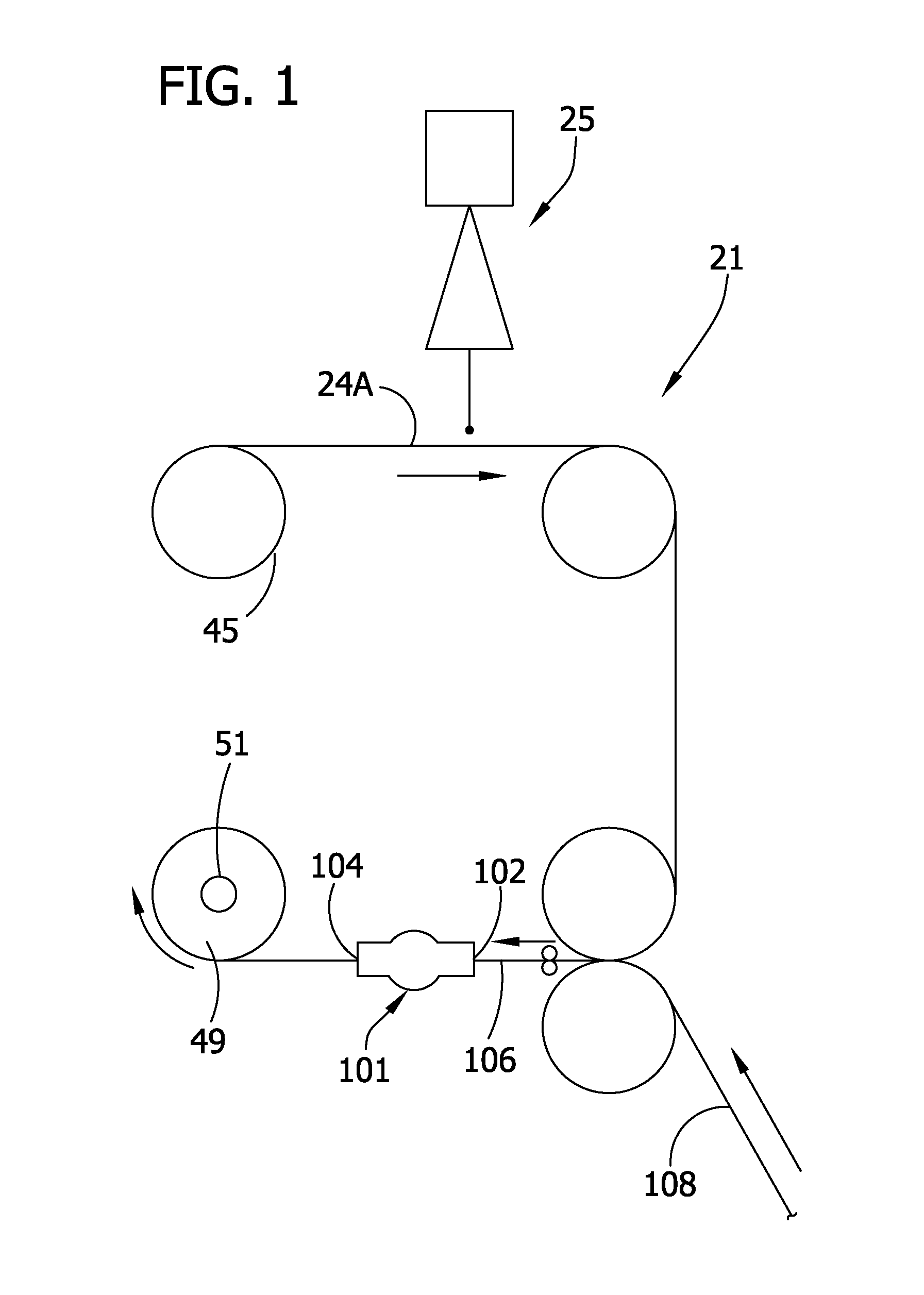

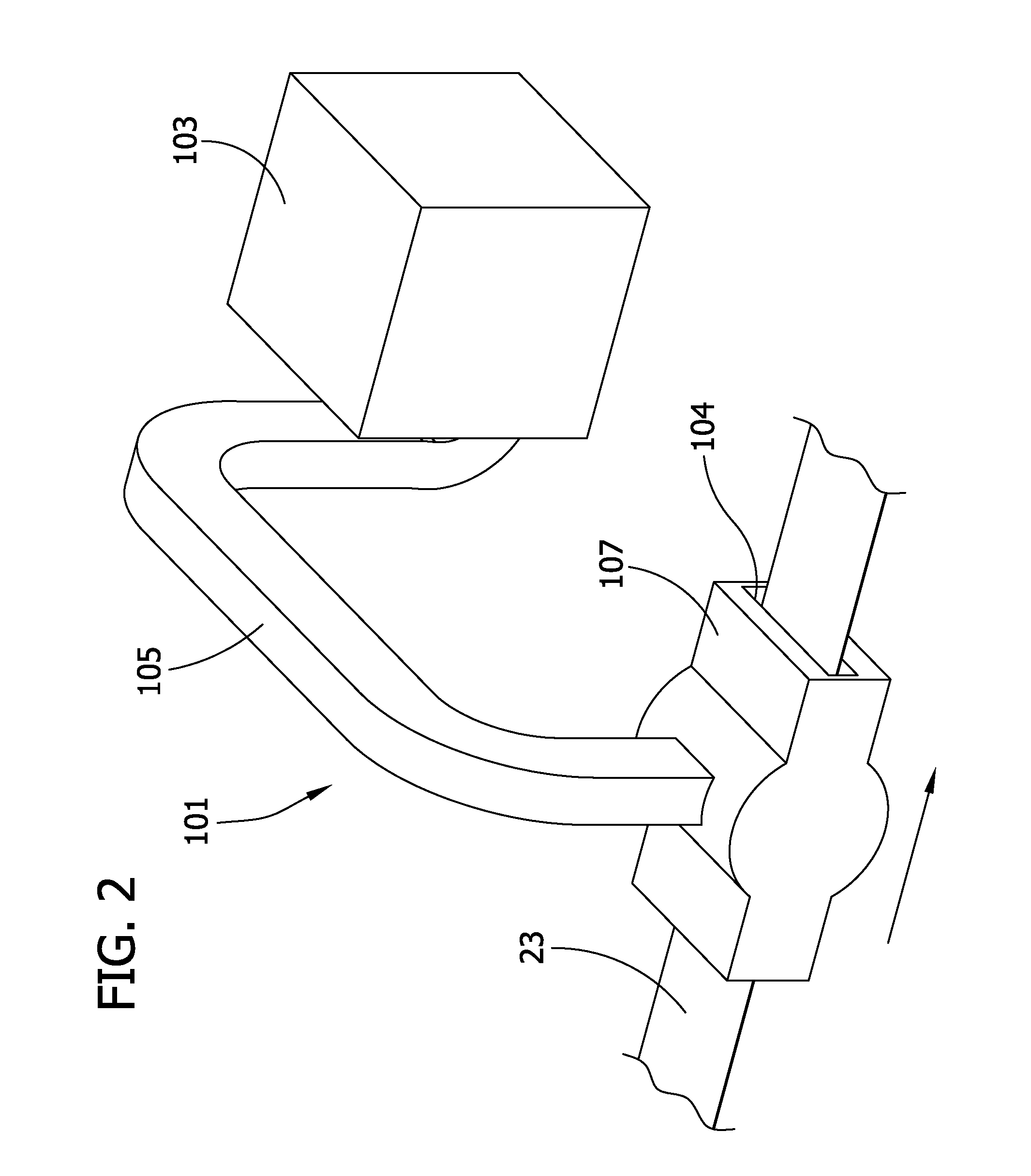

Method and apparatus for dual applicator microwave design

ActiveUS20120125920A1Improve efficiencyIncrease costThermal non-catalytic crackingInduction heatingSyngasMicrowave

The invention described herein pertains generally to a more efficient and cost-effective method and apparatus for: (1) coupling of microwave energy from a microwave generator or plurality of microwave generators into an integral set of applicators; (2) extraction and separation of organic compounds from a mixture of organic and inorganic compounds; and (3) recovery and conversion of the organic compounds to gaseous and liquid fuels. The apparatus described in this invention result in improved microwave absorption within the mixture flowing through the applicators by increasing residence time within the applicators, resulting in a higher temperature within the material. The higher temperature lowers the viscosity of the solution, but also provides a limited reduction of the combination of complex chain and aromatic organic compounds to allow recovery of syngas and fuel oil.

Owner:NOVAK JUDITH

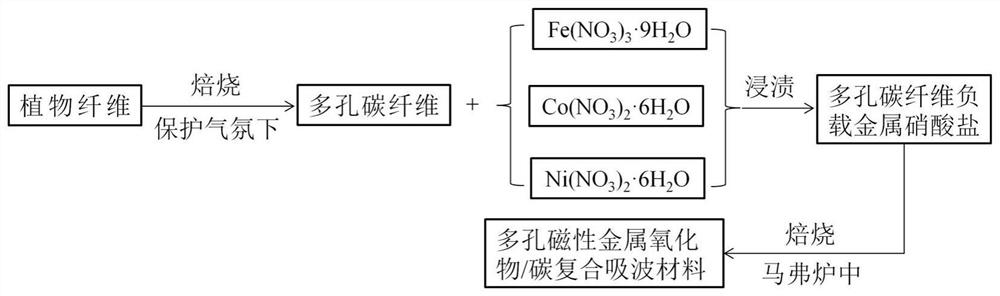

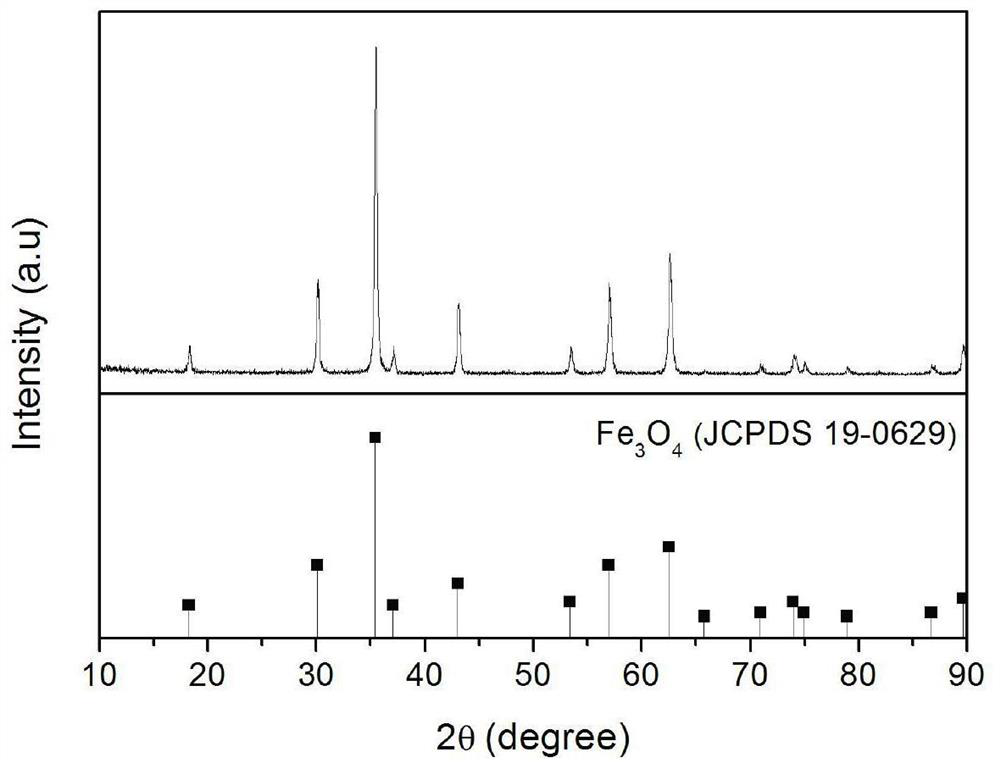

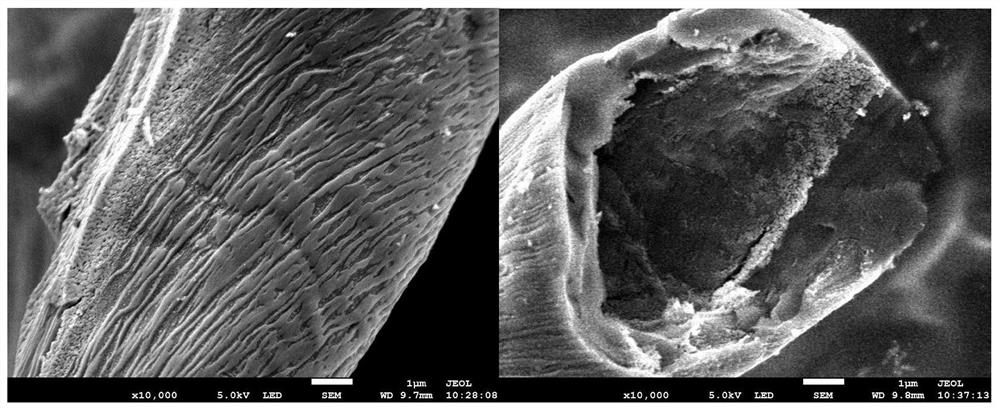

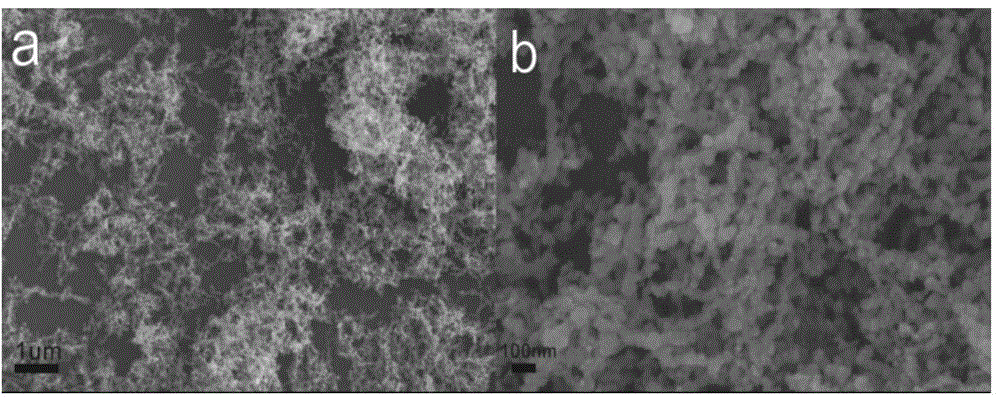

Synthesis method of porous magnetic metal oxide/carbon composite wave-absorbing material

ActiveCN112195013AWide variety of sourcesLow costOther chemical processesMagnetic/electric field screeningCarbon compositesCarbon fibers

The invention discloses a synthesis method of a porous magnetic metal oxide / carbon composite wave-absorbing material. The method comprises the following steps of: using porous carbon fibers obtained by roasting plant fibers with stable structures like cotton fibers, hemp fibers, bamboo fibers and the like in a high-temperature protective atmosphere as a carbon source and a template, impregnating nitrates of metals like Fe, Co, Ni and the like, and then performing roasting, thus obtaining the porous magnetic metal oxide / carbon composite wave-absorbing material, and further realizing regulationand control of the loading capacity of Fe3O4, Co3O4, NiO and other magnetic metal oxides in a wide range. The method disclosed by the invention has the advantages that: (1) the raw materials are widein source, renewable and low in cost; (2) the process is simple, the synthesis cost is low, complex synthesis equipment and chemical reagents are not needed, and the method is suitable for industrialproduction; (3) the magnetic components are loaded on the porous carbon, so that the material density is very low; (4) by controlling process conditions, the ratio of the magnetic components to the porous carbon can be regulated and controlled in a relatively wide range; and (5) the composite material has multiple electromagnetic loss mechanisms and is a novel light efficient microwave absorbent.

Owner:JINZHONG UNIV

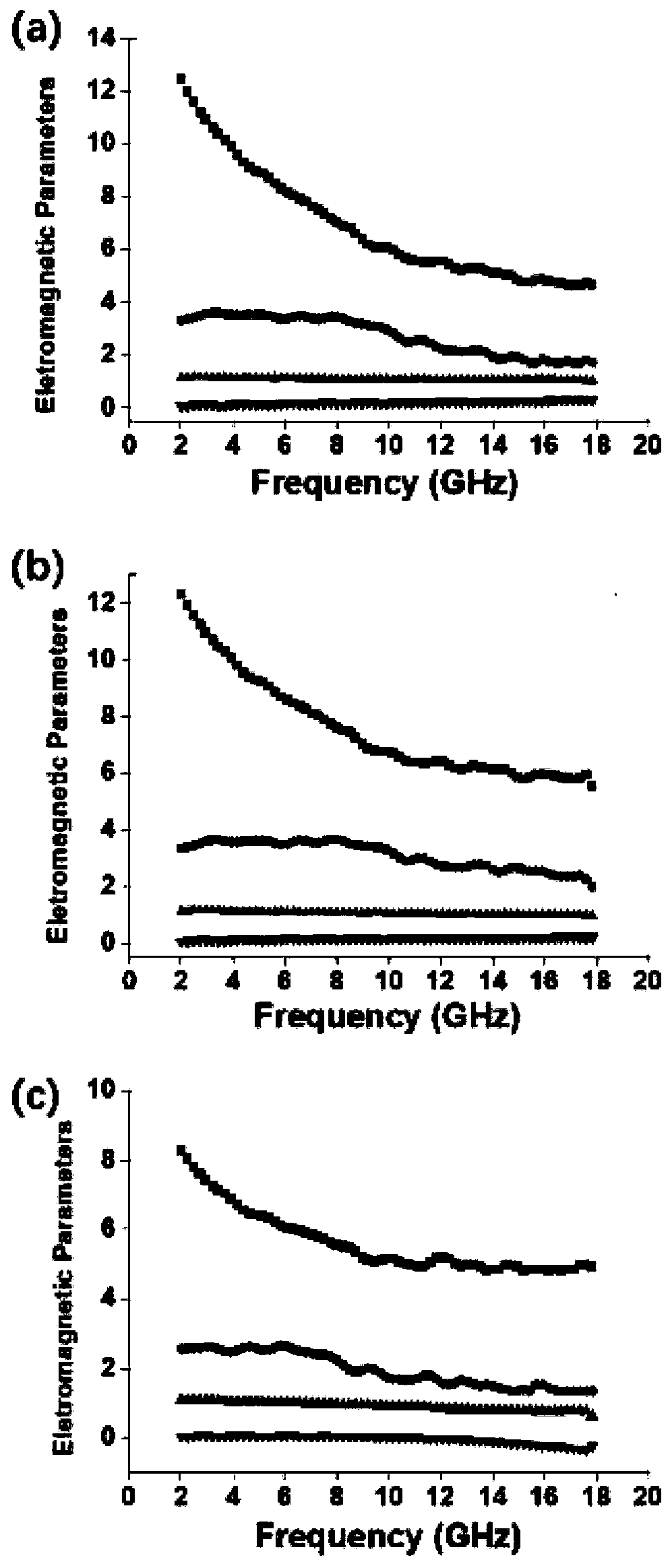

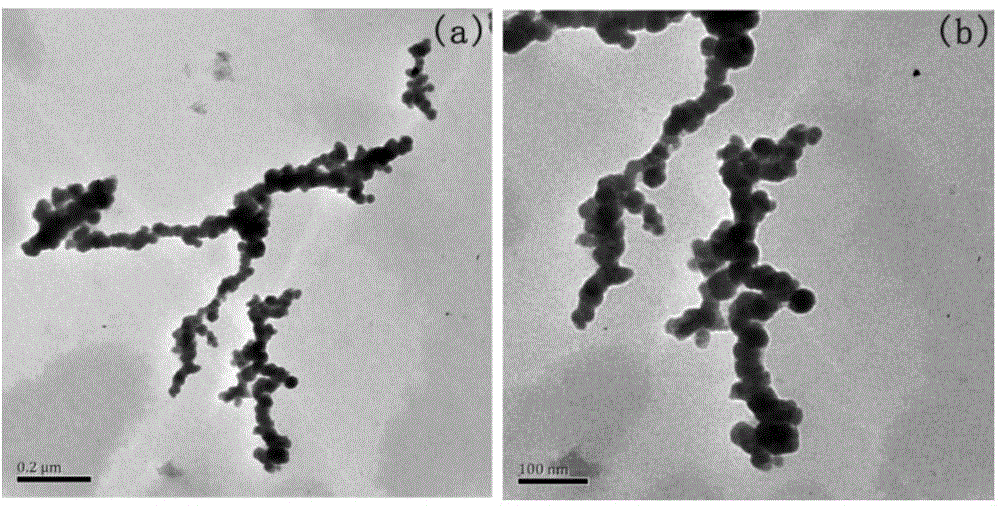

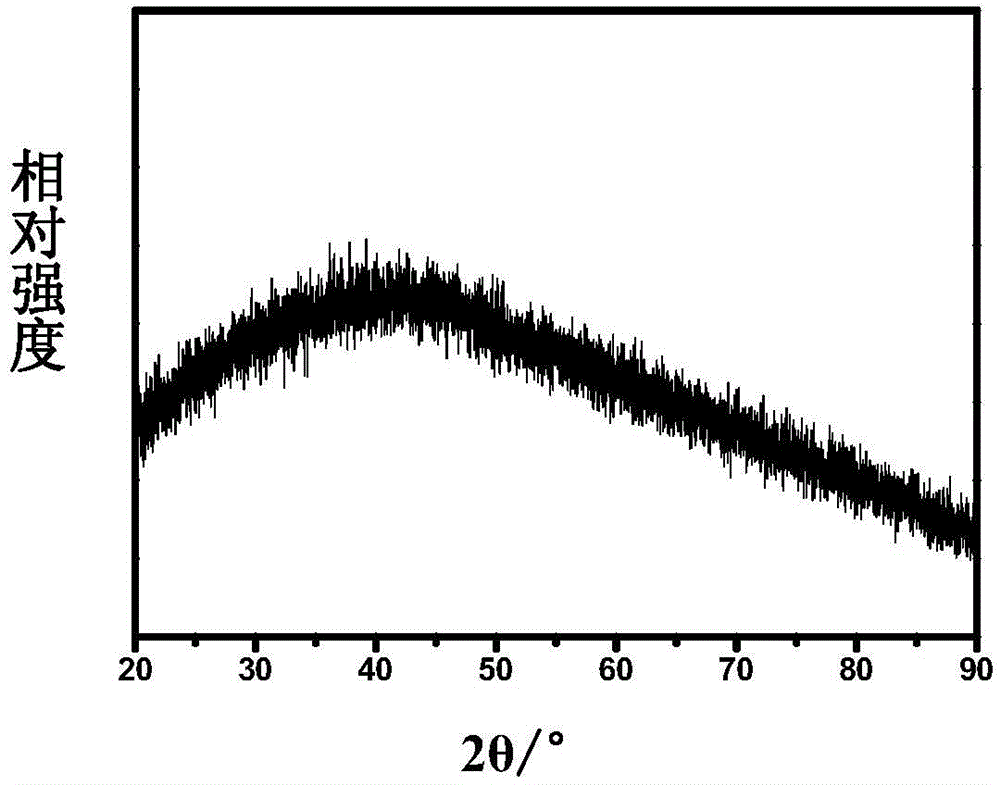

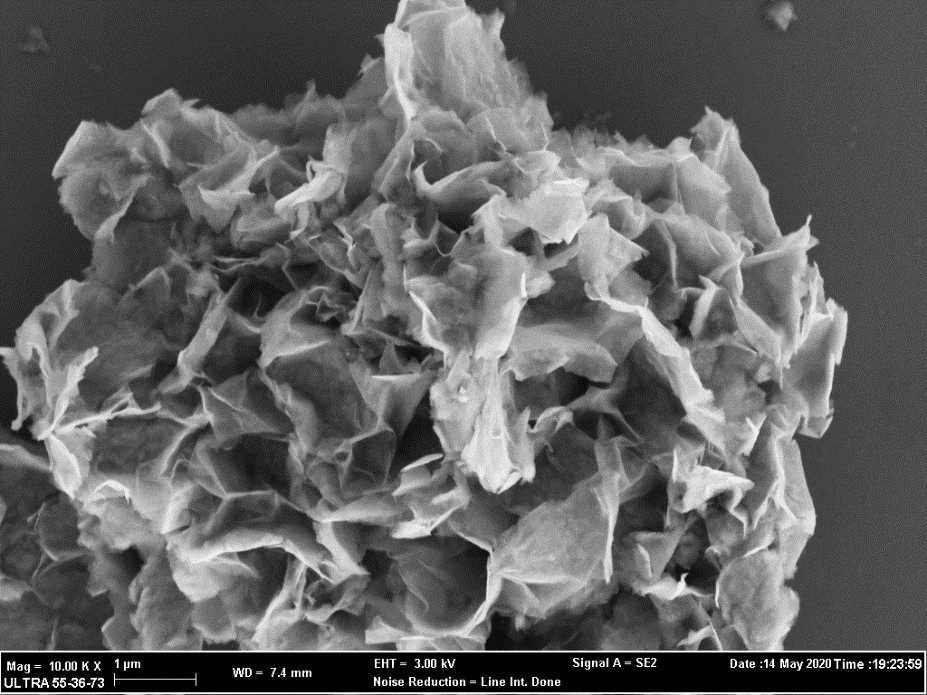

Cobalt-based amorphous nanometer wave-absorbing material and synthetic method of cobalt-based amorphous nanometer wave-absorbing material

ActiveCN104014815AImprove microwave absorption performanceImprove coercive forceMaterial nanotechnologyCentrifugationNitrogen

The invention relates to a cobalt-based amorphous nanometer wave-absorbing material and a synthetic method of the cobalt-based amorphous nanometer wave-absorbing material, and relates to amorphous nanometer wave-absorbing materials. The synthetic method includes the steps of (1) dissolving metal salt in water to obtain a metal salt water solution, (2) containing the metal salt water solution prepared in the step (1) in a reaction vessel, and leading nitrogen in the reaction vessel under the magnetic stirring conditions to remove oxygen in a system, (3) dissolving sodium borohydride solid powder in water to obtain a sodium borohydride water solution, and (4) injecting the sodium borohydride water solution prepared in the step (3) into the metal salt water solution in the step (2) to obtain black muddy liquid after a reaction is finished, conducting centrifugation to obtain cobalt-based amorphous nanocrystallines after obtained sediments are washed, then drying the cobalt-based amorphous nanocrystallines, mixing obtained dried samples and solid paraffin, heating the mixture, and then conducting resolidification to obtain the cobalt-based amorphous nanometer wave-absorbing material, wherein the cobalt-based amorphous nanometer wave-absorbing material can be pressed into annular samples. The synthetic method is simple, high in operability, soft in preparation condition, clean and free of pollution in the reaction process, high in reaction efficiency and high in reproducibility.

Owner:XIAMEN UNIV

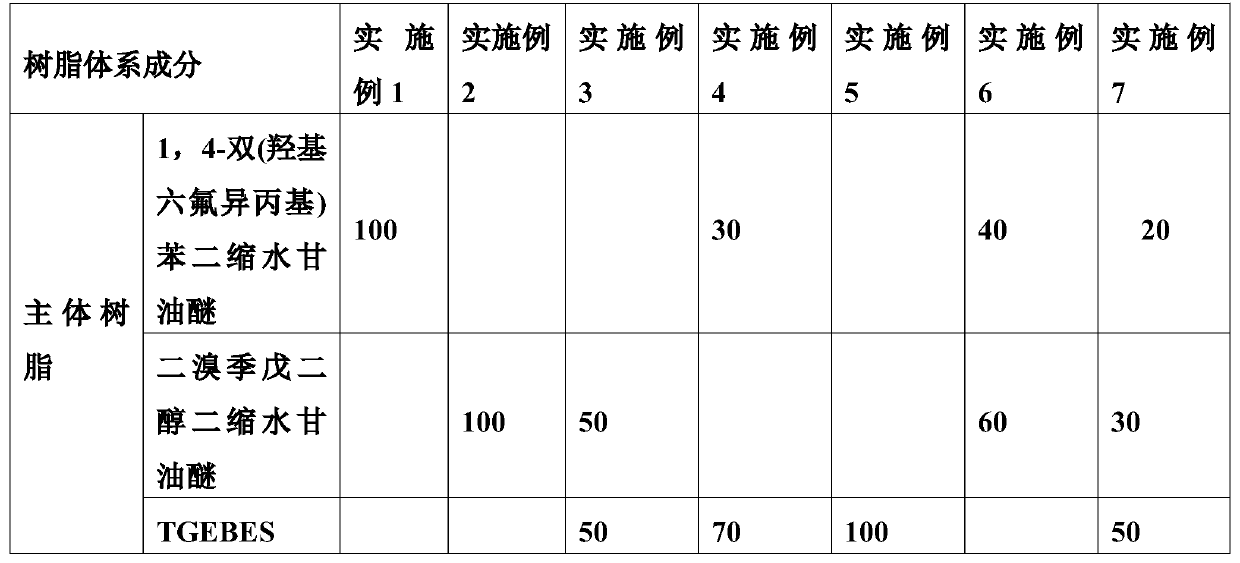

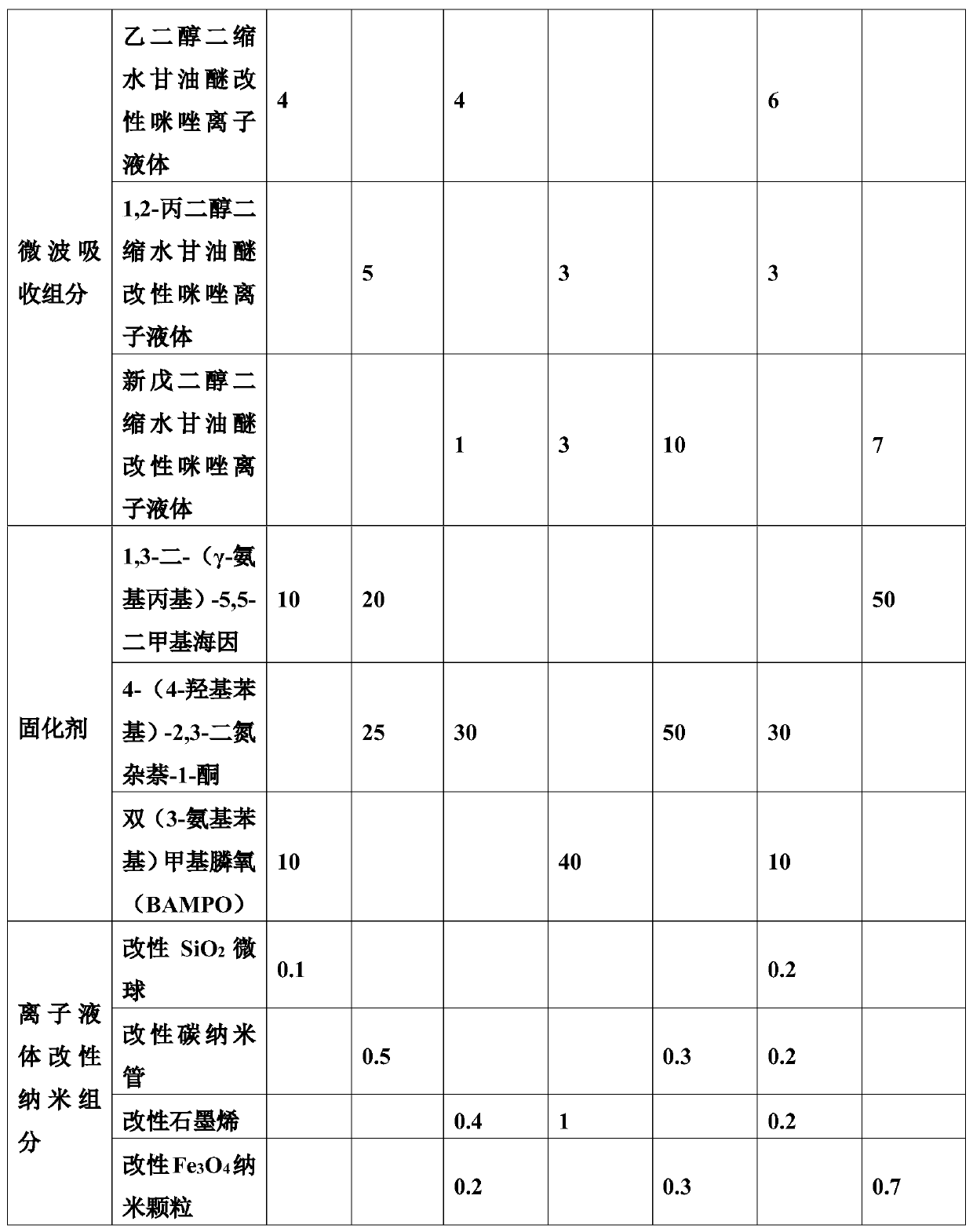

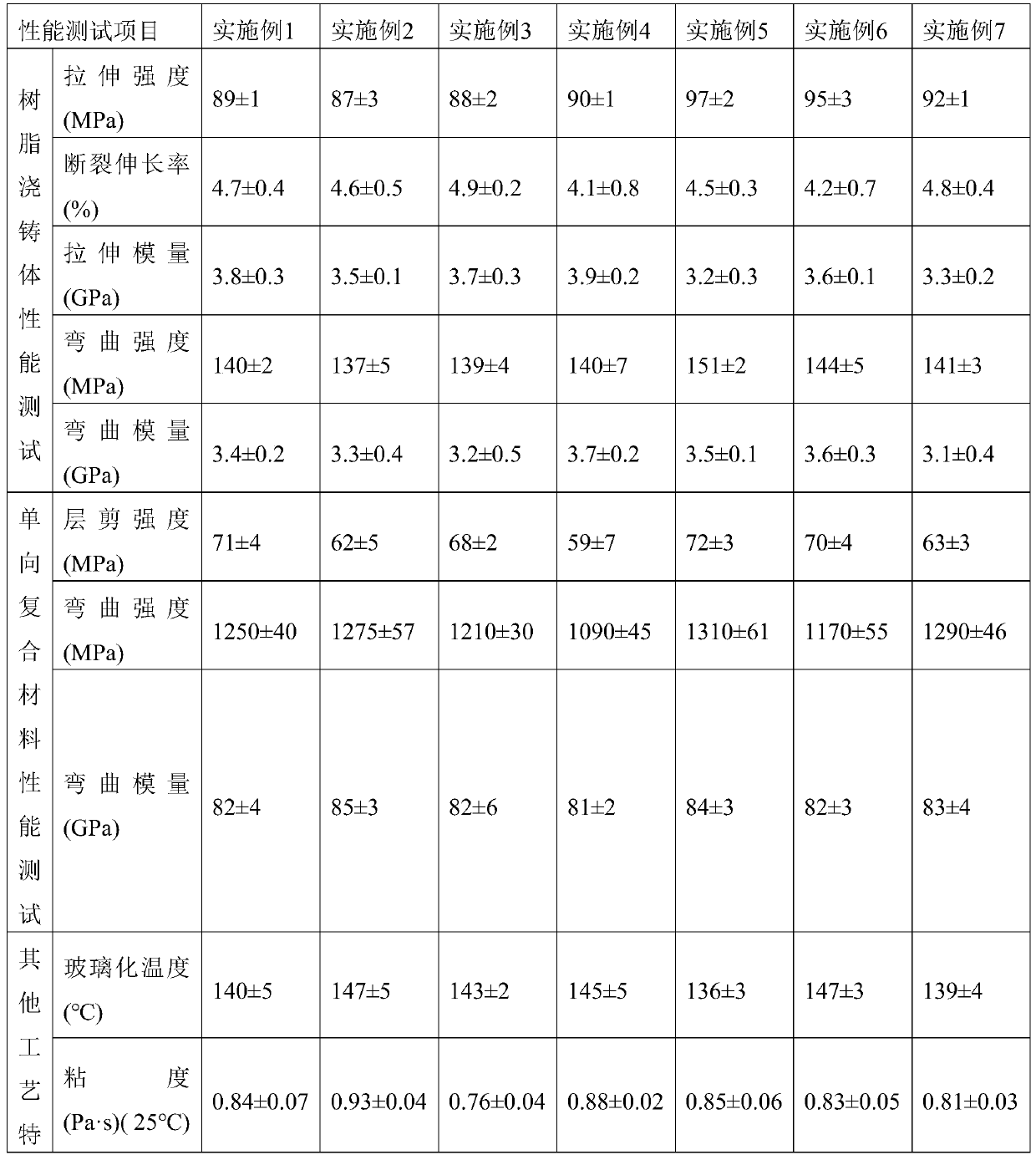

Resin matrix with strong microwave absorbability and preparation method thereof

Aresin matrix with strong microwave absorbability and a preparation method thereof belong to the field of composite materials. In the invention, high-performance epoxy resin with strong polarity is selected as matrix resin, a microwave absorptioncomponent is added for adjusting microwaveresponsiveness and viscosity of a resin system to adapt to liquid molding by winding and the like, a curing agent is selected for adjusting themicrowaveresponse activity of the resin system, and the mechanical property, the heat resistance and thedimensional stability of the resin matrix are achieved; on the basis, an ionic liquid modified nanometer component is adopted for further enhancing the microwaveresponsiveness of the resin matrix. By adjusting the component structure and thematch ratio of the matrix resin, the microwave absorption component, the curing agent,theionic liquid modified nanometer componentand the like, a microwave curing resin system with good microwave absorbability, good dispersity of the nanometer component, proper viscosity, uniform curing, excellent comprehensive mechanical property, good heat resistance and high dimensional stability is developed. The resin matrix has great guiding significance for preparation of fiber composite materials and can be widely applied to the fields of aerospace and the like.

Owner:BEIJING UNIV OF CHEM TECH

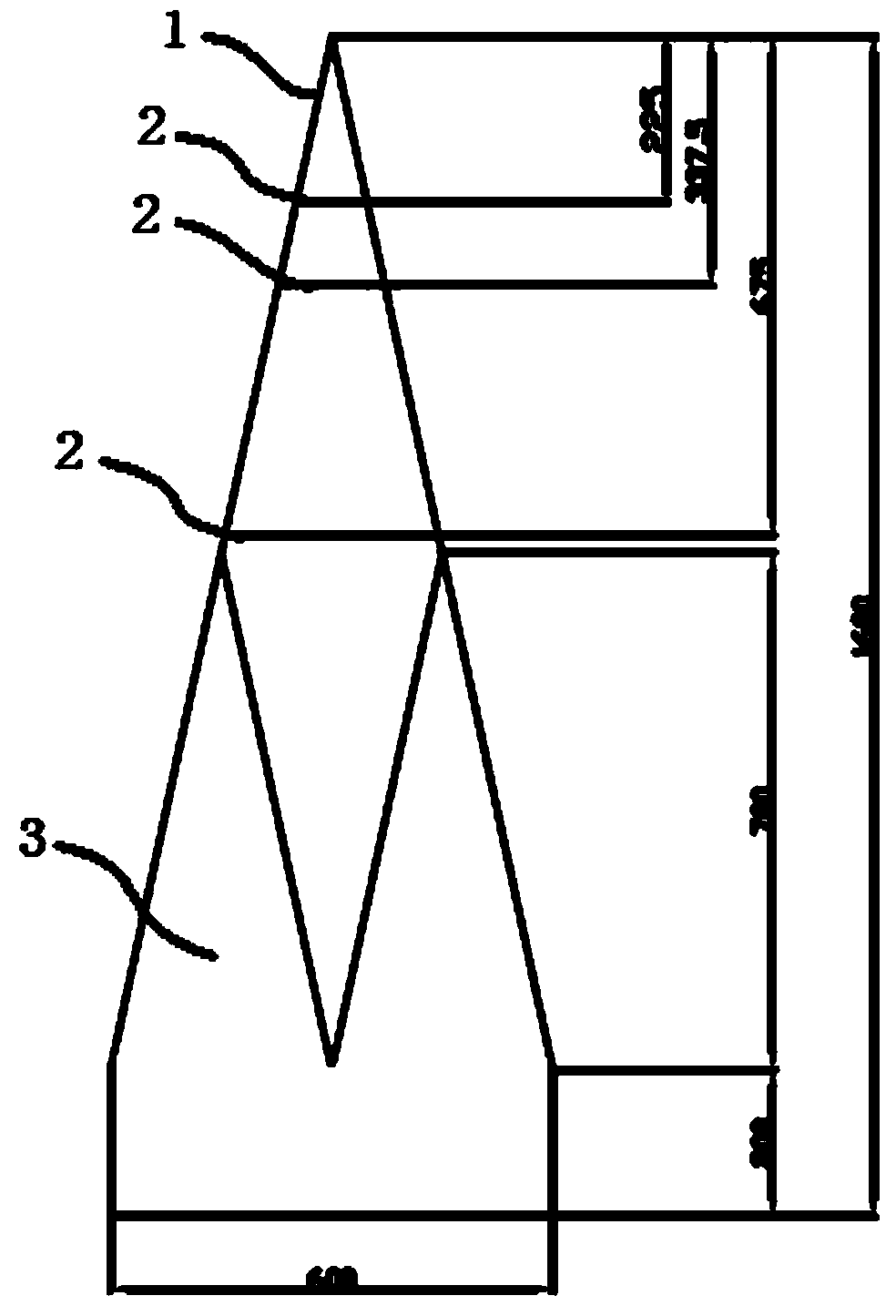

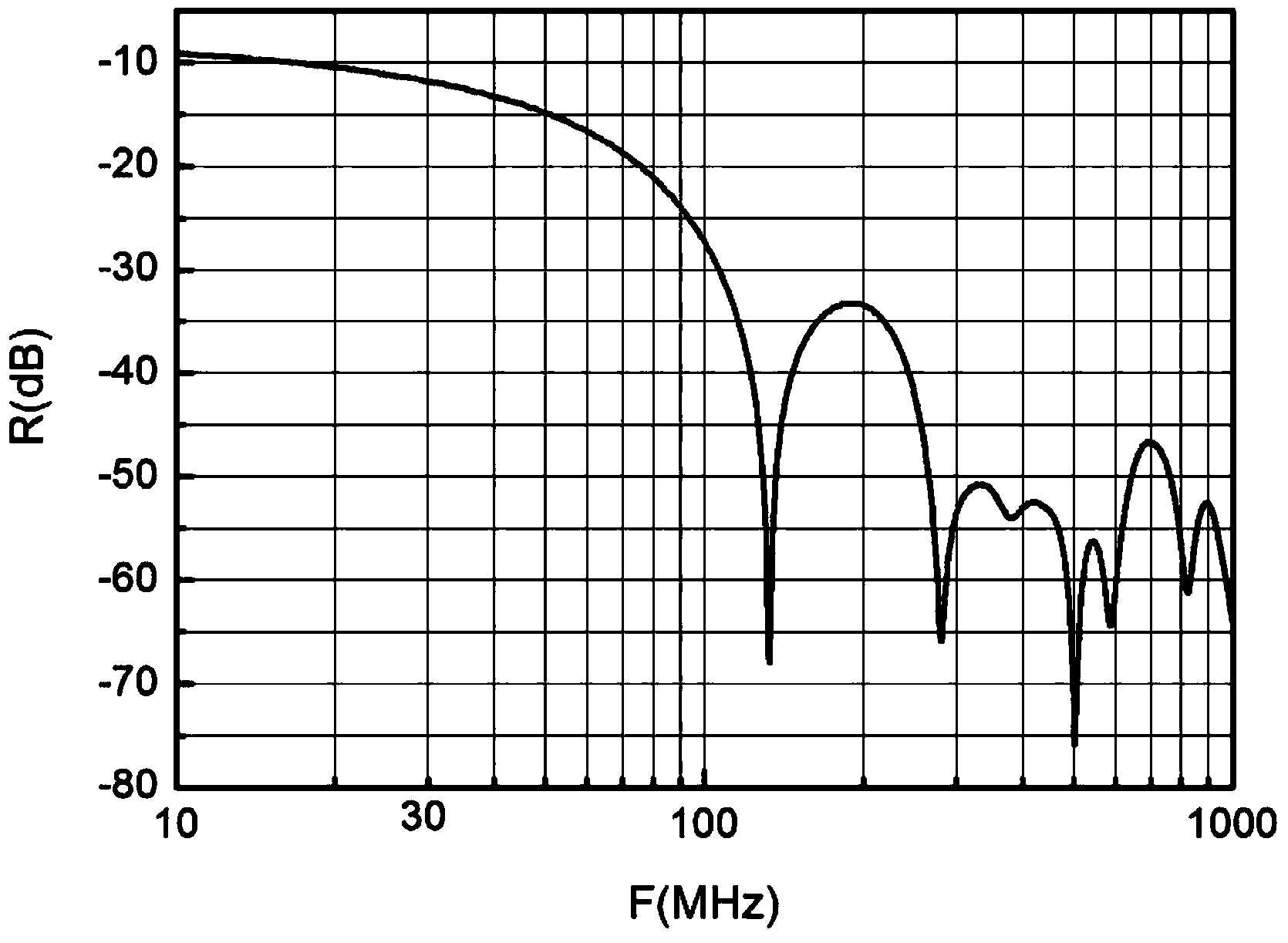

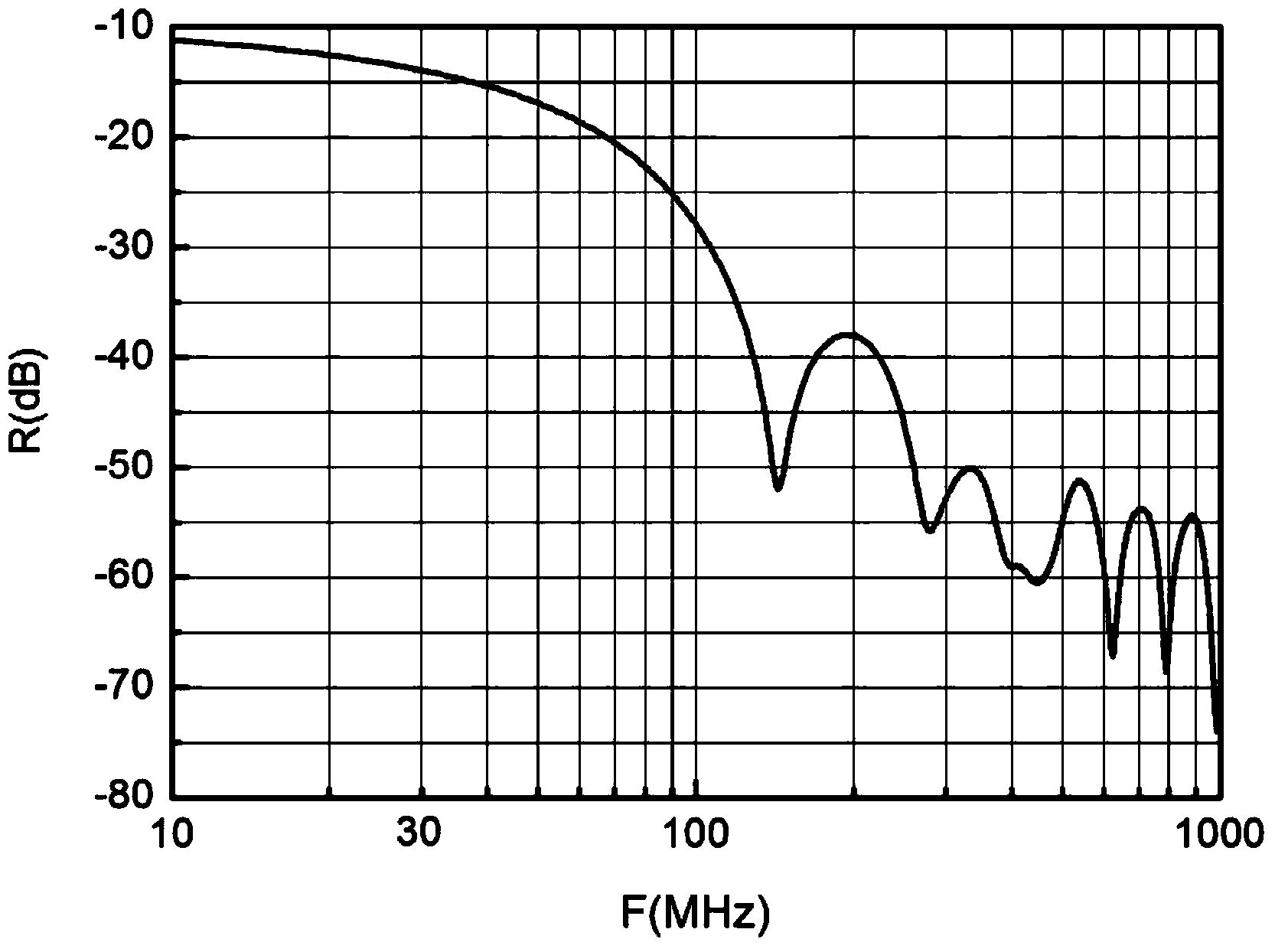

Low-frequency stage microwave absorption material

InactiveCN103436220AMeet needsImprove microwave absorption performanceOther chemical processesElectrical resistance and conductanceMicrowave

The invention relates to a low-frequency stage microwave absorption material which comprises a polyurethane pyramid and a base, wherein the polyurethane pyramid is internally provided with two same inner single cones close to the base; three-layer microwave absorption sheets with same square resistance values are arranged above the inner single cones and parallel to a cone base; the square resistance values of the microwave absorption sheets range from 350 ohm to 420 ohm, the square resistance of the polyurethane pyramid ranges from 400 ohm to 600 ohm, and the square resistances of the inner single cones range from 150 ohm to 200 ohm. According to the invention, the three-layer parallel structure approximate to an electric wave in space equivalent square resistance value (377 ohm) is arranged in a polyurethane pyramid material, so that the microwave absorption property of the polyurethane pyramid wave-absorbing material between 30 MHz and 100 MHz is improved, and the absorption value ranges from -12 dB to 20 dB. The low-frequency stage microwave absorption material disclosed by the invention meets the requirement for electromagnetic compatibility and the requirement of an antenna simulation darkroom on the material.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

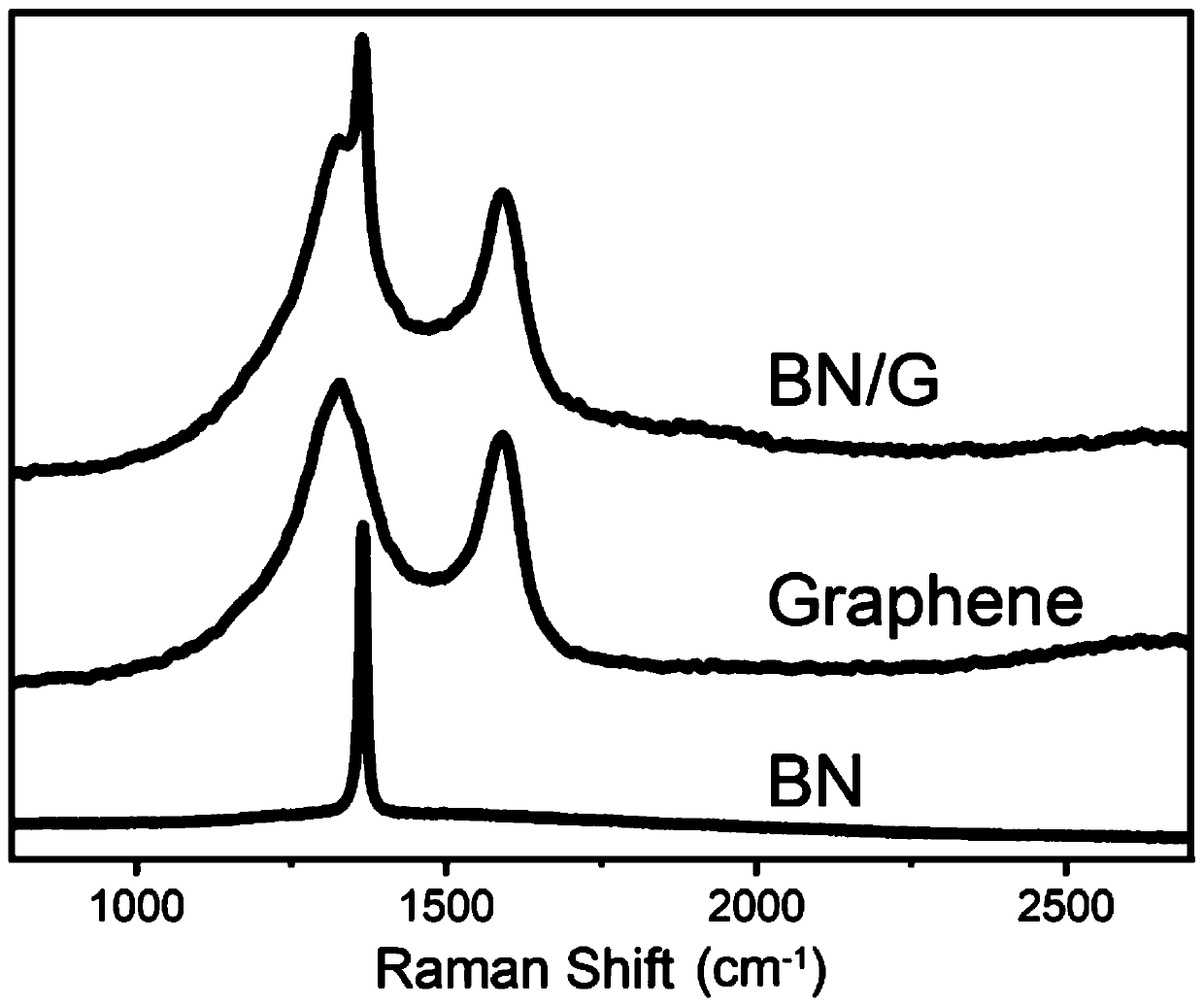

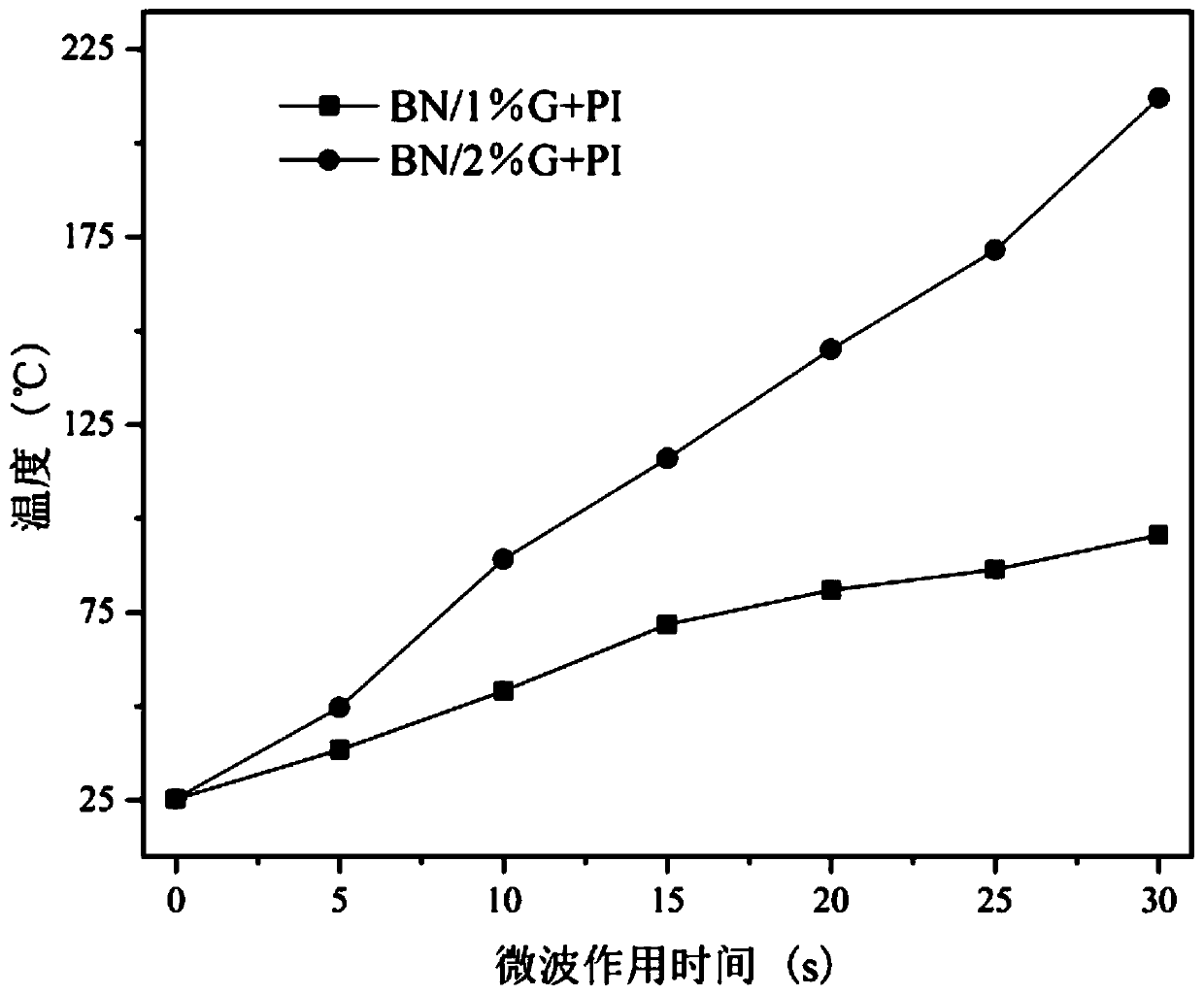

Preparation method and application of boron nitride/graphene/polyimide composite wave-absorbing and heat-conducting material

ActiveCN111171318AReduce contentReduce lossesOther chemical processesHeat-exchange elementsBoron nitrideHeating effect

The invention discloses a preparation method and application of a boron nitride / graphene / polyimide composite wave-absorbing and heat-conducting material. The preparation method comprises the followingsteps: weighing boron nitride powder and graphene powder, mixing, adding absolute ethyl alcohol, and carrying out ball-milling treatment; preparing a precursor of a polyimide material, adding diamineinto a polar solvent, magnetically stirring uniformly, and adding dianhydride; drying the prepared solution to obtain boron nitride / graphene composite powder, tabletting the boron nitride / graphene composite powder, and dropwise adding the prepared polyimide precursor solution after tabletting until the whole tablet is infiltrated; and heating and curing the obtained composite material twice to obtain the boron nitride / graphene / polyimide composite wave-absorbing and heat-conducting material. According to the invention, the integration of wave-absorbing and heat-transferring materials is achieved, the heat energy loss in the heating process is reduced, the heating effect is obvious, the mass volume is small, the cost is low and the mechanical property is improved. The invention provides a new method for microwave heating of non-wave-absorbing materials.

Owner:XI AN JIAOTONG UNIV

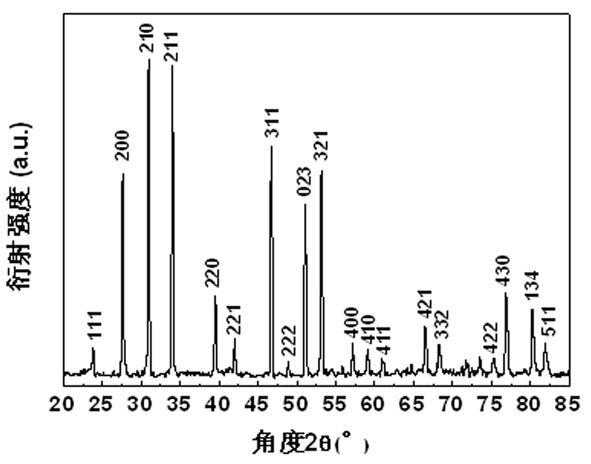

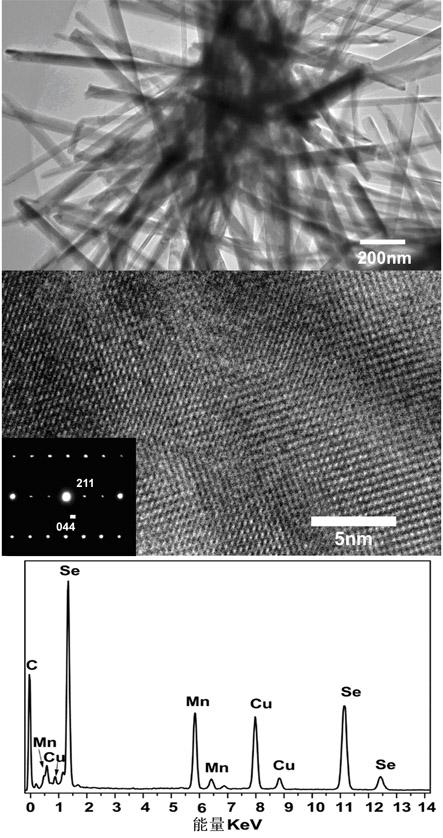

Manganese diselenide manometer bar as well as synthetic method and application thereof

InactiveCN102557059AReduce reflection lossImprove microwave absorption performanceOther chemical processesNanotechnologyPhysicsActive agent

The invention belongs to the technical field of manometer function materials and particularly relates to a manganese diselenide manometer bar as well as a synthetic method and an application of the manganese diselenide manometer bar. The manganese diselenide manometer bars with different length-diameter ratios are obtained through regulating the addition quantity of surface active agents of polyvinyl pyrrolidone (PVP), and good microwave absorption performance is shown. The length-diameter ratio of the manganese diselenide manometer bar is 15 to 70, the minimum reflection loss is reduced along with the increase of the length-diameter ratio, and the minimum reflection loss can reach -12.72 dB. In addition, the preparation cost of the manometer material is low, the efficiency is high, the industrial amplification is easier for solving the practical application problem, the manometer material is used as a novel wave absorbing material to be widely applied to electromagnetic shielding andmicrowave absorption, and wide application prospects are realized.

Owner:FUDAN UNIV

Preparation method of carbon nano tube reinforcement asphalt based composite water-proof material

InactiveCN102993758AResolving entanglements and reunionsImprove mechanical propertiesBuilding insulationsEmulsionCarbon nanotube

The invention discloses a preparation method of carbon nano tube reinforcement asphalt based composite water-proof material, comprising the following steps: (1) weighing each component of the following raw materials according to weight percentages: 0.2-5% of dispersing agent, 1-5% of carbon nano tubes, 35-60% of asphalt, 9-15% of modified rubber powder and 20-40% of stuffing; (2), dissolving the dispersing agent in mixed liquor with a weight concentration of 0.1-10% prepared from asphalt, adding the carbon nano tubes in the mixed liquor, stirring by a high-speed emulsion shearing machine so as to form carbon nano tube disperse phase mixed liquor; (3) injecting the asphalt in a reaction kettle, heating till 170-190 DEG C, throwing the modified rubber powder to maintain the temperature of reaction liquid at 170-190 DEG C, modifying at a constant temperature for 1-4 hours, adding the stuffing at 150-190 DEG C for 20-80 minutes, injecting the carbon nano tube disperse phase mixed liquor obtained in the step (2), keeping a constant temperature of 140-170 DEG C, and stirring for 1-5 hours. The mechanical property of the product prepared by the invention is obviously improved, and the functions of static electricity resistance, microwave absorption, electromagnetic shielding and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

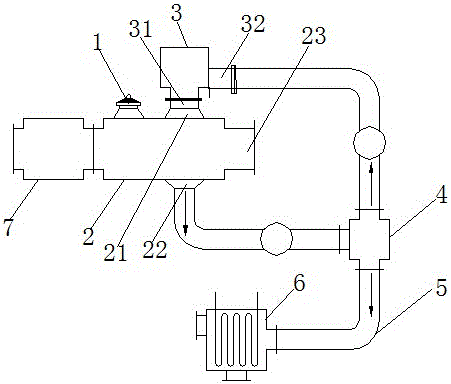

Solid organic material cracking method and system

ActiveCN106338066AImproved microwave absorption propertiesStrong process controllabilityProductsReagentsMicrowaveProduct gas

The invention provides a solid organic material cracking method and system. The method comprises the following steps of: A, pre-treating a solid organic material; B, sending the pre-treated solid organic material into a cracking device; C, heating a gas medium to 350-700 DEG C; D, continuously importing the heated gas medium into the cracking device to act on the solid organic material with microwave, so as to carry out cracking to obtain a solid product and a mixed gaseous product; and E, importing a part of the obtained mixed gaseous product into a gas heating device in the step C so as to heat the mixed gaseous product to 350-700 DEG C to be circularly used for the cracking in the step D. The process can effectively decrease the cracking energy consumption and the cracking time, and can save the cost.

Owner:成都德理克新材料科技有限公司

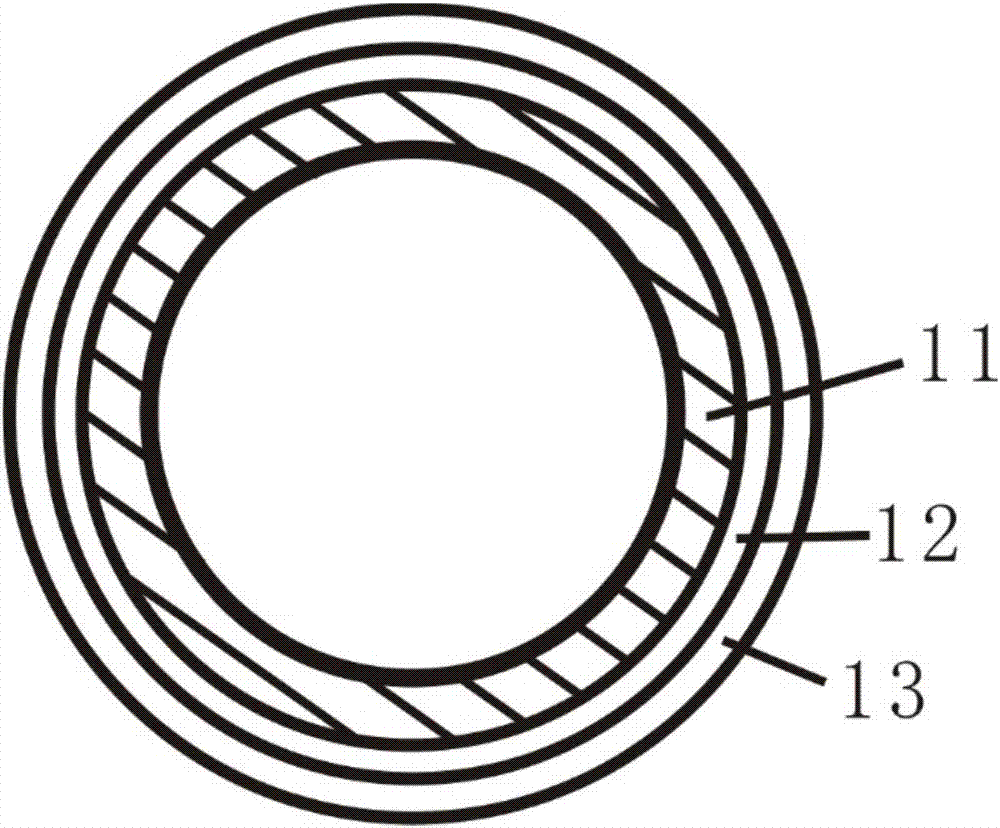

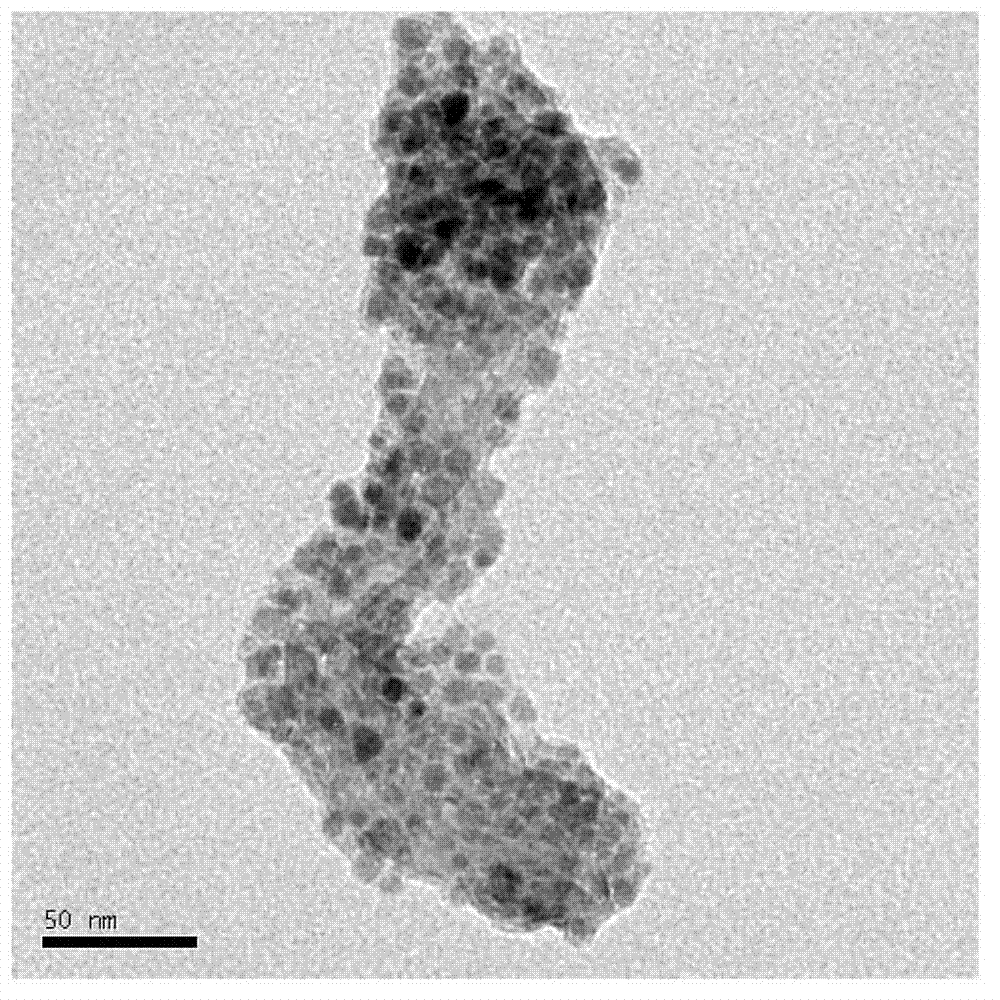

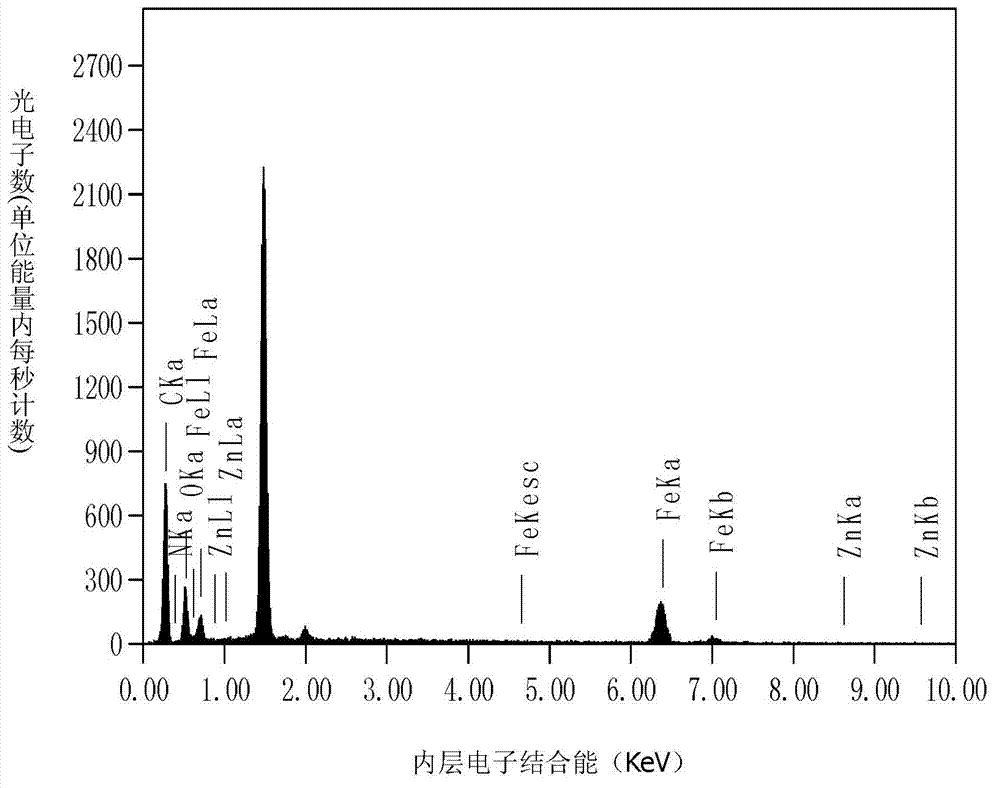

Preparation method of coaxial cable structure MWCNT/Fe3O4/ZnO/PANI microwave absorbant

ActiveCN103113580AImprove microwave absorption performanceGuaranteed mechanical propertiesOther chemical processesMicrowaveCoaxial cable

The invention provides a preparation method of a coaxial cable structure MWCNT / Fe3O4 / ZnO / PANI microwave absorbant, and relates to a preparation method of a microwave absorbent, and the method is used for solving the problems that the wave absorption material prepared by adopting the existing method is limited into binary and ternary, and is bad in binding force with matrixes to cause poor wave absorption effect. The preparation method comprises the steps: I preparing an MWCNT / Fe3O4 nanomaterial; II preparing MWCNT / Fe3O4 / ZnO composite powder; III preparing compound water solution; and IV preparing ammonium persulfate aqueous solution, then dropwise adding into the composite aqueous solution, performing constant-temperature reaction under the condition of 0-25 DEG C, then performing magnetic separation, collecting solid phase matters, and drying to obtain the coaxial cable structure MWCNT / Fe3O4 / ZnO / PANI microwave absorbant, thereby completing the preparation method. The preparation method is applied in the field of microwave absorption materials.

Owner:内蒙古海特华材科技有限公司

Dodecylbenzene sulfonic acid doped PANI/MXene composite wave absorbing material and preparation method thereof

InactiveCN111892816ALight in massMatching thickness thinOther chemical processesBenzenesulfonic acidDodecylbenzenesulfonic acid

The invention belongs to the field of electromagnetic wave absorbing materials, and particularly relates to a dodecylbenzene sulfonic acid doped PANI / MXene composite wave absorbing material and a preparation method thereof. The composite wave absorbing material is prepared by doping a polyaniline / MXene nano composite material with dodecylbenzene sulfonic acid. The method has the advantages of mildprocess conditions, low production cost, simple process and stable product quality, and is beneficial to industrial production.

Owner:ZHEJIANG SCI-TECH UNIV

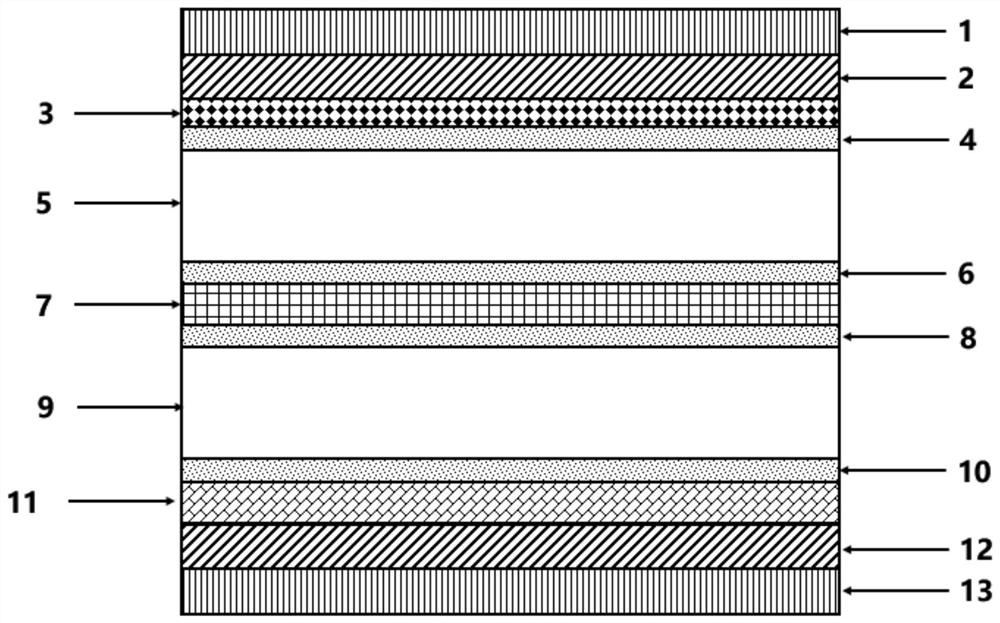

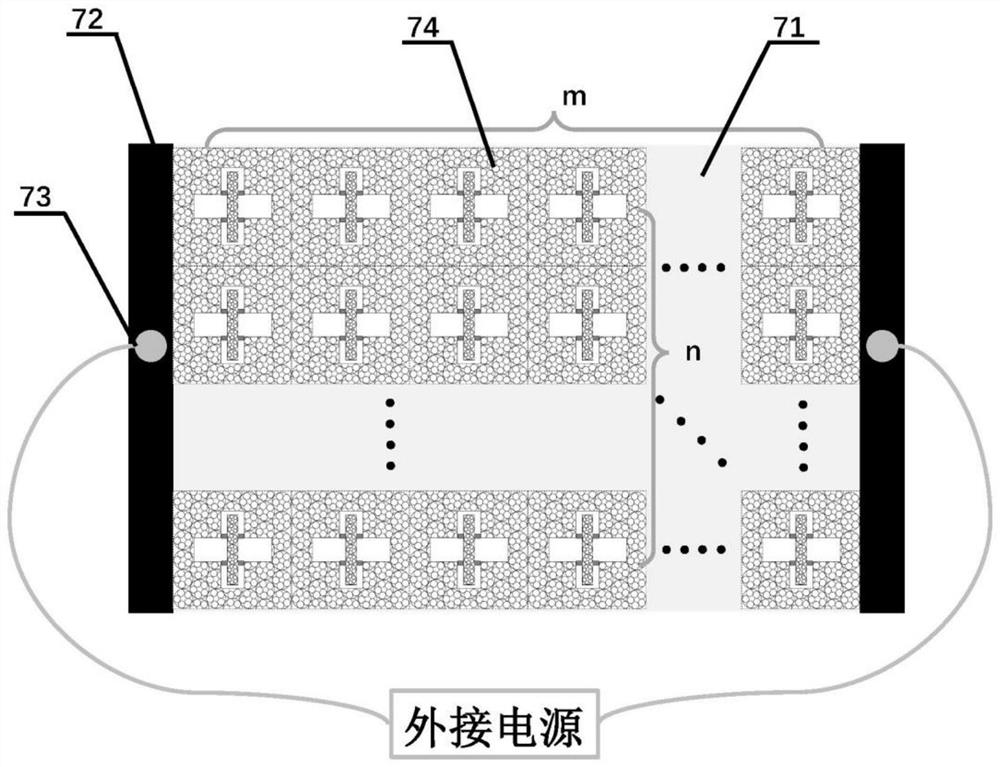

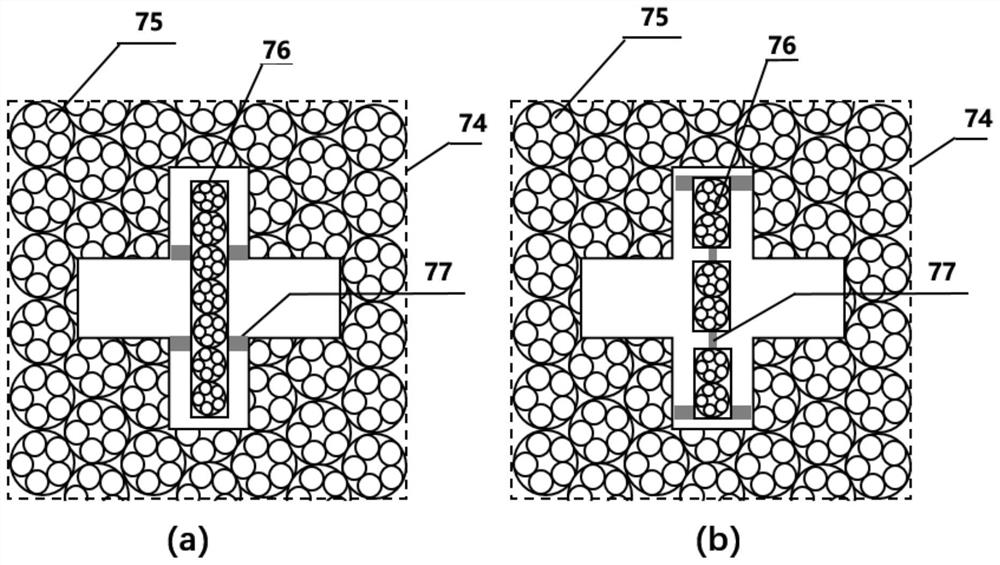

High-transmittance microwave absorption light window with electrically controlled and adjustable reflection frequency band

ActiveCN112332100AImprove microwave absorption performanceSolve the problem of poor frequency selection characteristicsAntennasOptical elementsTransmittancePhase-change material

The invention discloses a high-transmittance microwave absorption light window with an electrically controlled and adjustable reflection frequency band, and belongs to the field of optical transparentelectromagnetic shielding and microwave communication. The light window is formed by assembling a graphene layer, a transparent dielectric layer A, an electronic control adjustable frequency selective surface layer integrated with a phase change material, a transparent dielectric layer B and a metal mesh layer which are sequentially overlapped and arranged in parallel. The electronic control adjustable frequency selective surface layer of the integrated phase change material is composed of a frequency selective surface of the integrated phase change material, a metal electrode and a lead. Thefrequency selective surface of the integrated phase-change material is formed by periodically and closely connecting and arranging frequency selective surface array units of the integrated phase-change material, wherein the frequency selective surface array units are composed of a grid mesh aperture type frequency selective surface, a grid mesh patch type frequency selective surface and tiny phase-change material patches. The invention solves the problem that the existing microwave reflector is difficult to realize high optical transparency, adjustable reflection frequency band and out-of-band rejection of the reflection frequency band at the same time so as to mainly realize absorption.

Owner:HARBIN INST OF TECH

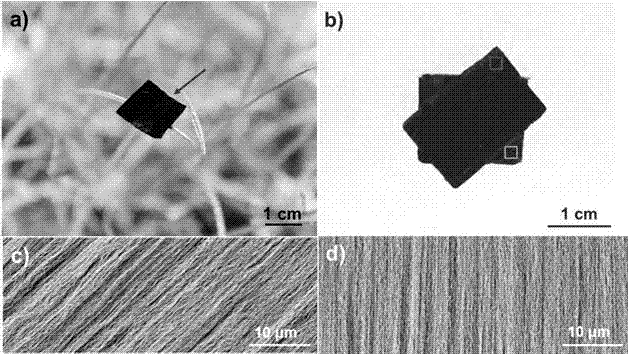

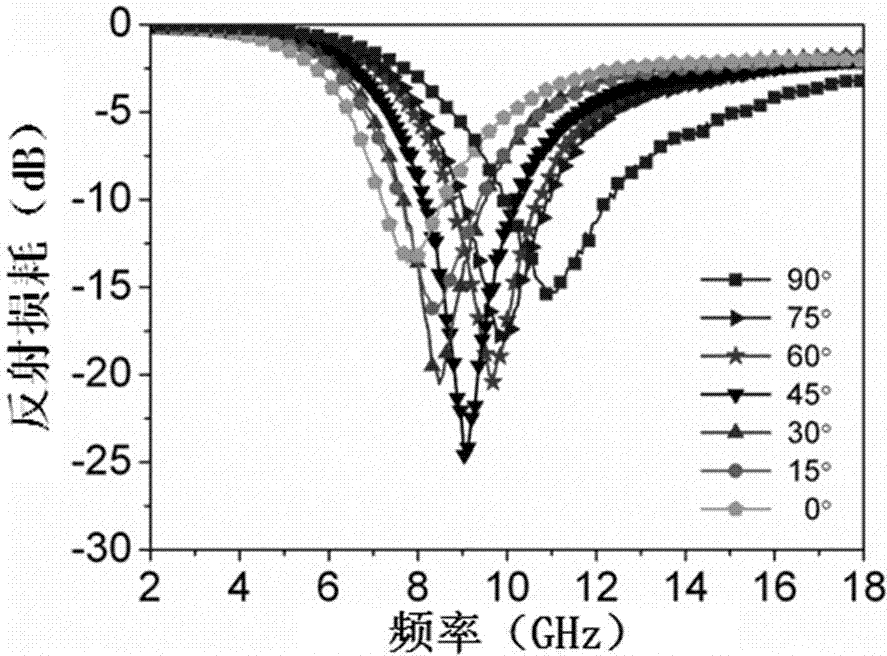

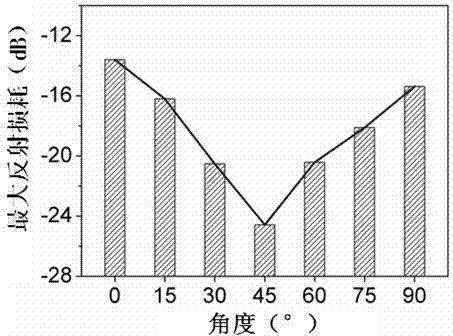

Absorption frequency adjustable microwave absorption material and preparation method thereof

ActiveCN104244689AThickness monitoringControl thicknessMagnetic/electric field screeningAntennasMicrowavePhysical chemistry

The invention belongs to the technical field of preparation of microwave absorption materials, and particularly relates to an absorption frequency adjustable microwave absorption material and a preparation method thereof. A monolayer oriented carbon nano tube film of the microwave absorption material is composed by height oriented carbon nano tubes arrayed in the same direction, and the surface density is 1.97gm<-2>. A series of absorption frequency adjustable microwave absorption materials are acquired through change of an included angle (0-90 degrees) of two oriented carbon nano tube films. Iron and polyaniline are composited on the oriented carbon nano tubes through electron beam evaporation and electrochemical polymerization to further improve microwave absorption performance of the material. Through adjustment of the included angle of the two oriented carbon nano tube films, adjustment of microwave absorption frequency is realized; through increase of the number of the oriented carbon nano tube films or composition with the iron and the polyaniline, microwave absorption performance is improved.

Owner:FUDAN UNIV

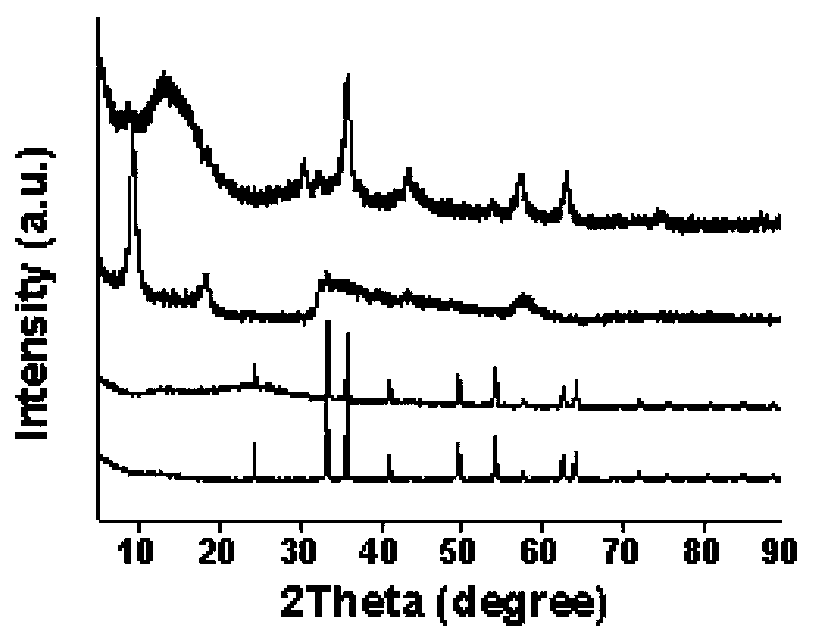

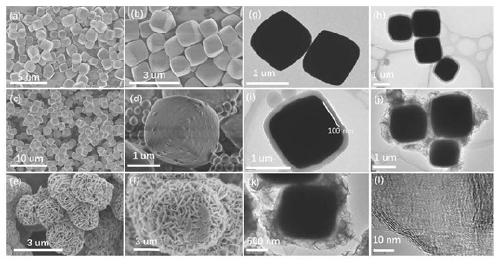

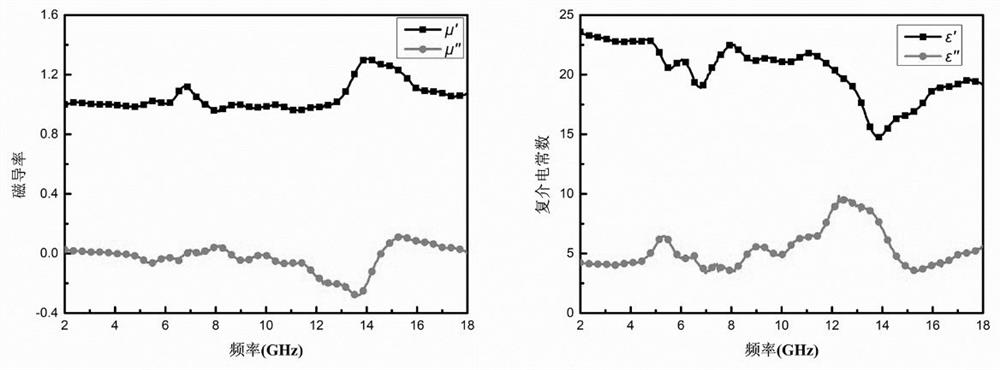

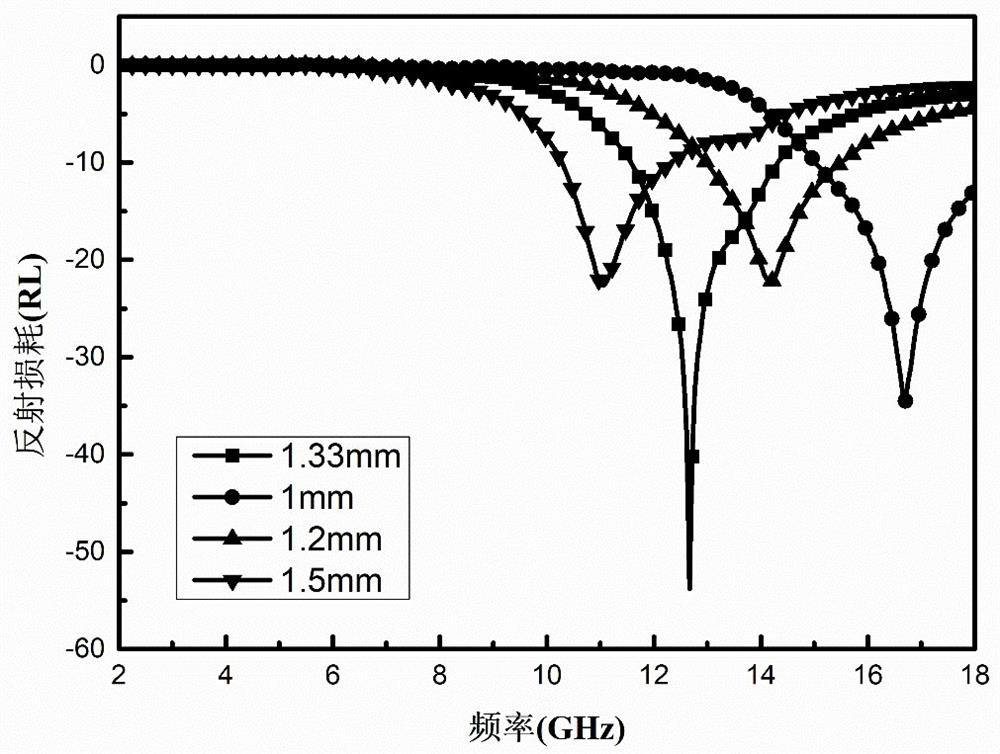

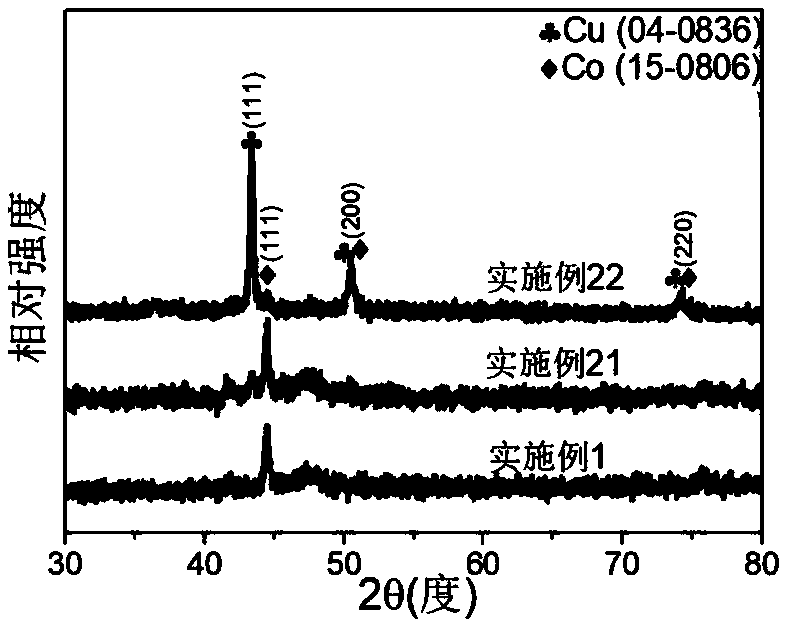

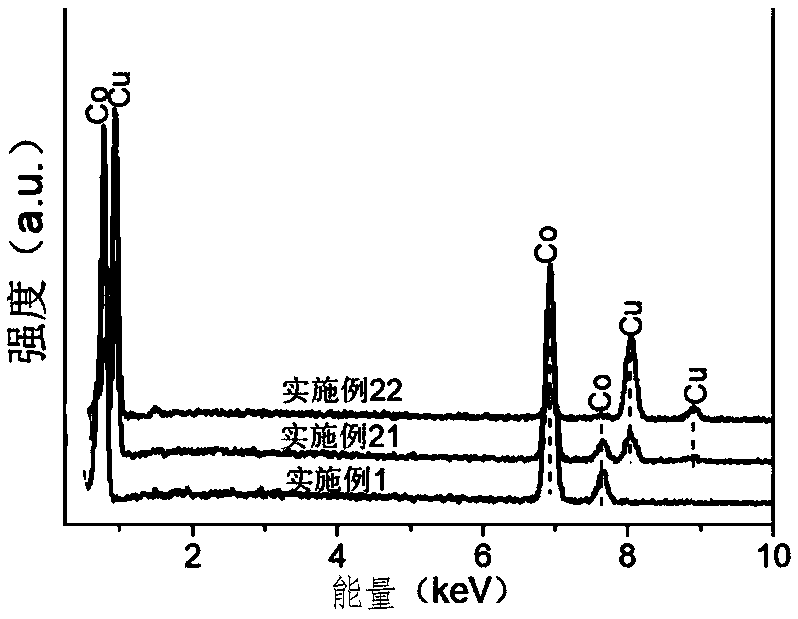

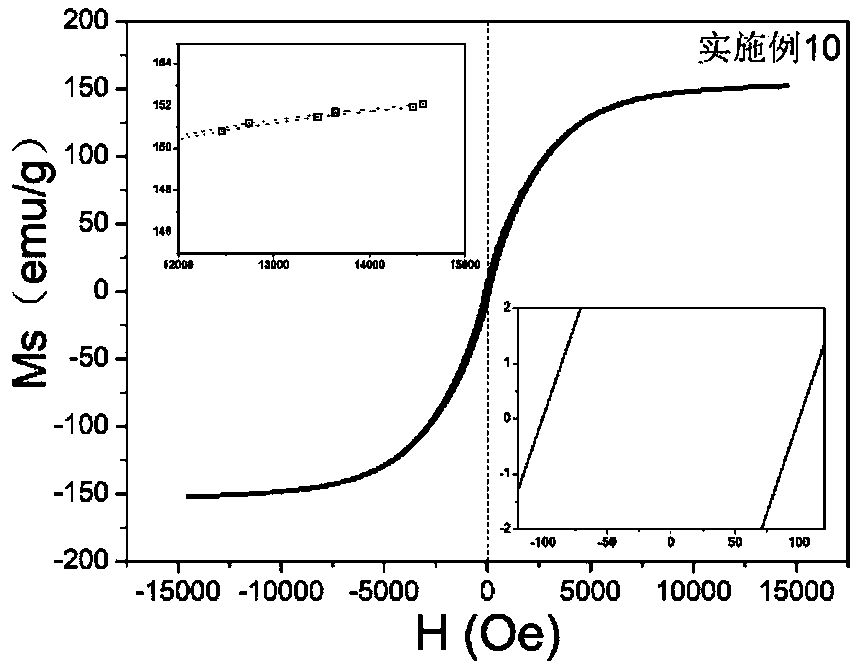

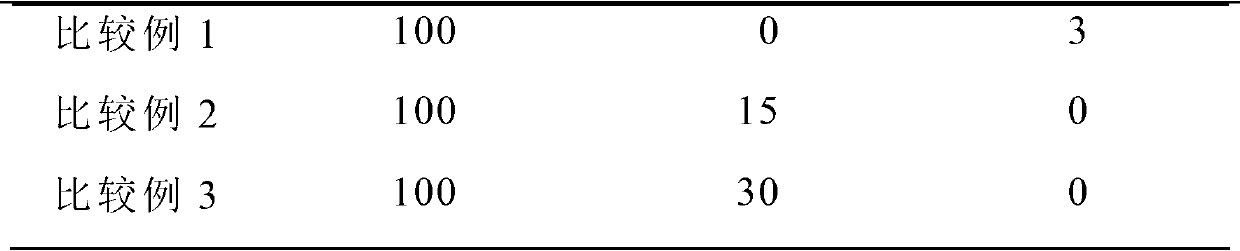

Bimetallic cobalt-based core-shell material as well as preparation method and application thereof

ActiveCN109261981AAdjustable sizeComposition adjustableTransportation and packagingMetal-working apparatusFiberHigh absorption

The invention relates to a bimetallic cobalt-based core-shell material and a preparation method and application thereof. A core of the bimetallic cobalt-based core-shell material is a magnetic metal Co, and a shell of the bimetallic cobalt-based core-shell material is a non-magnetic metal Ag or Cu; a shape of the bimetallic cobalt-based core-shell material is fibrous or spherical, a fiber diameteris 1.3 to 36 micrometer, and a spherical diameter is 1 to 7.3 micrometer; an atomic ratio of Co to Cu is 0.25 to 21.6, and the atomic ratio of Co to Ag is 59.8 to 74.8; a saturation magnetization strength ranges from 62.2 to 159.9 emu / g<-1>. The bimetallic cobalt-based core-shell material adopts an in-situ metal replacement method and has a microwave absorption characteristic of broadband and high absorption, wherein an effective frequency band width of which the reflectivity is less than or equal to -10dB is 5.1-7.76GHz; a bandwidth less than or equal to -20dB is 2.32-16.0GHz; a maximum reflection loss ranges from -52.5 dB to -19.7 dB. The bimetallic cobalt-based core-shell material has the advantages of simple process, easy industrial popularization, excellent material performance and good application prospect in the fields of catalysis, electrode materials, microwave absorption, high-density magnetic recording materials, sensors and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

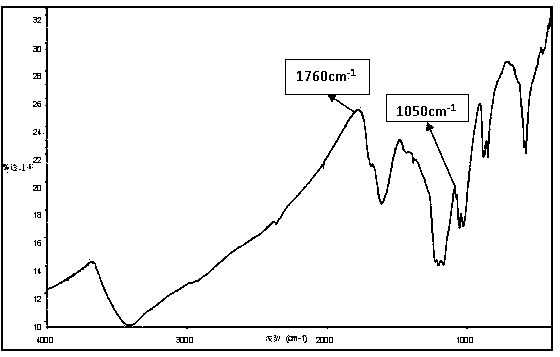

Process For Bonding Substrates With Improved Microwave Absorbing Compositions

InactiveUS20080156428A1Improve microwave absorption performanceStrong adhesive bondLamination ancillary operationsLayered product treatmentMicrowaveOrganic chemistry

The present disclosure provides for methods of using adhesive compositions having improved microwave absorbing properties to bond substrates to form laminated structures. Specifically, the adhesive compositions utilized in the methods of the present disclosure absorb the microwave energy, thereby heating and melting into the substrate materials and bonding the substrates together, providing for an improved laminated structure.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for extracting proanthocyanidin from banana peels

The invention discloses a method for extracting proanthocyanidin from banana peels. The method comprises the following steps of: banana peel extraction; color protection; quick freezing; smashing; microwave drying; ionic liquid extraction; ultracentrifugation; and spray drying to obtain a finished product of the proanthocyanidin. By utilizing quick freezing and low-temperature smashing technologies, the banana peels can be smashed uniformly and are small in particle size, low in proanthocyanidin loss and high in drying speed, and a sterilizing effect can also be realized while the banana peels are dried and dehydrated; the proanthocyanidin is prevented from being damaged by using a microwave-assisted ionic liquid extracting method; and the ionic liquid is easy to recycle. The method is simple in operation, mild in condition, high in yield and efficiency, clean and harmless in production process, low in energy consumption, high in benefit, high in yield and purity of the proanthocyanidin, suitable for large-scale production and application, and wide in prospects for comprehensive utilization of the banana peels and the commercialized market development of natural proanthocyanidin.

Owner:杨公明

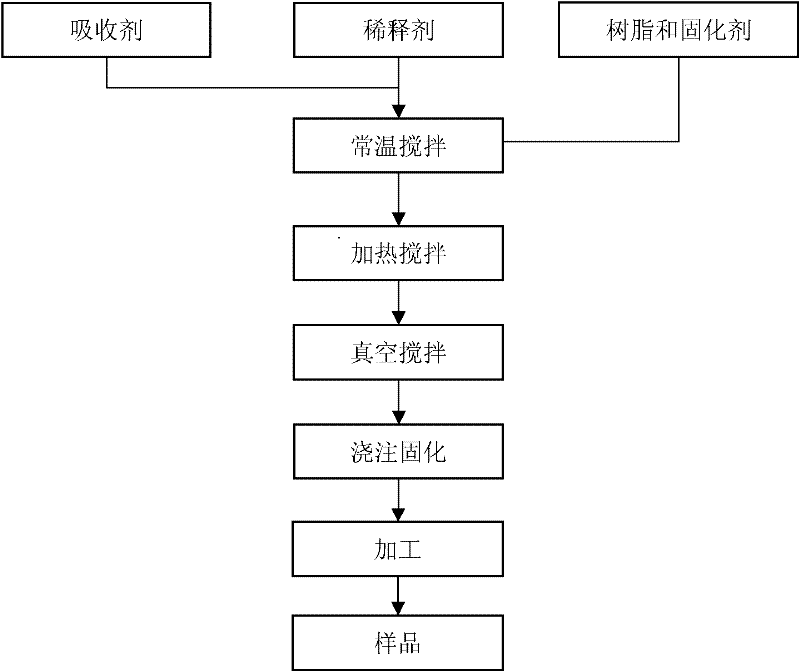

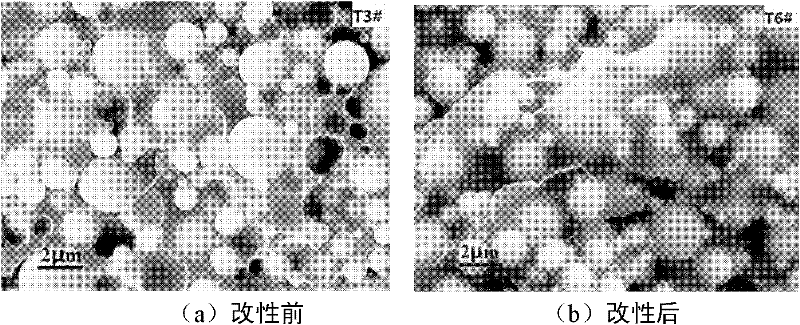

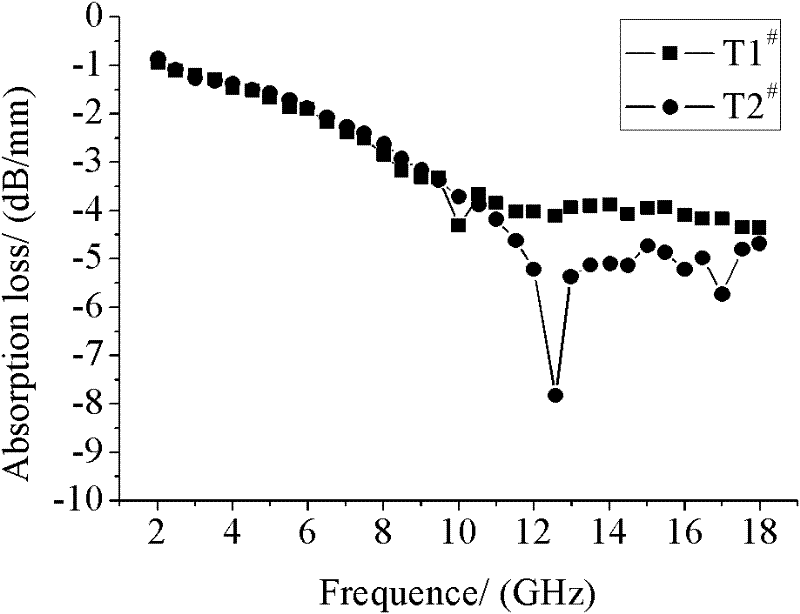

Preparation method of wave-absorbing composite material used for isolator loading

Belonging to microwave absorbing material technologies, the invention relates to a preparation method of a wave-absorbing composite material used for isolator loading. The method comprises the steps of: 1) putting powder into a diluent, stirring and dispersing the mixture; (2) adding epoxy resin and a curing agent, conducting stirring and degassing at a temperature of 70-100DEG C; 3) carrying outstirring and degassing in vacuum, with the temperature raised gradually from 90 to 120DEG C; 4) while generating no bubble, performing casting so as to obtain a casting body; 5) subjecting the casting body to curing, demoulding, and finally to cutting and polishing so as to be processed into a sample of required specifications. The microwave-absorbing composite material prepared by the method of the invention has good microwave-absorbing properties of: an adsorption loss of 4.69-6.88dB / mm under the conditions of 8-12GHz and 25DEG C, breakdown strength up to 1000V / mm, and a softening temperature of 170DEG C. The microwave-absorbing composite material provided in the invention can be used as loading elements in x-band isolators.

Owner:SOUTHWEAT UNIV OF SCI & TECH

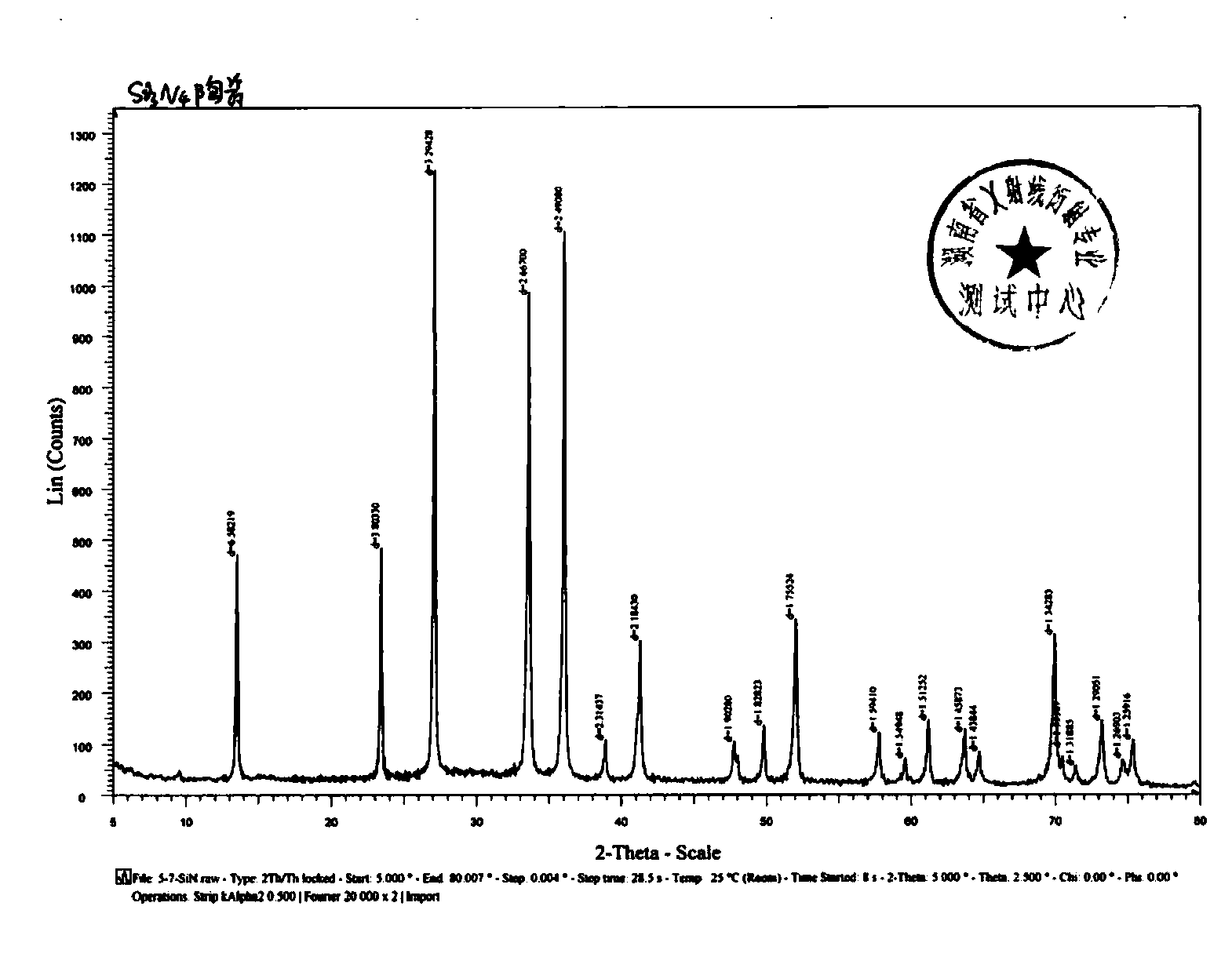

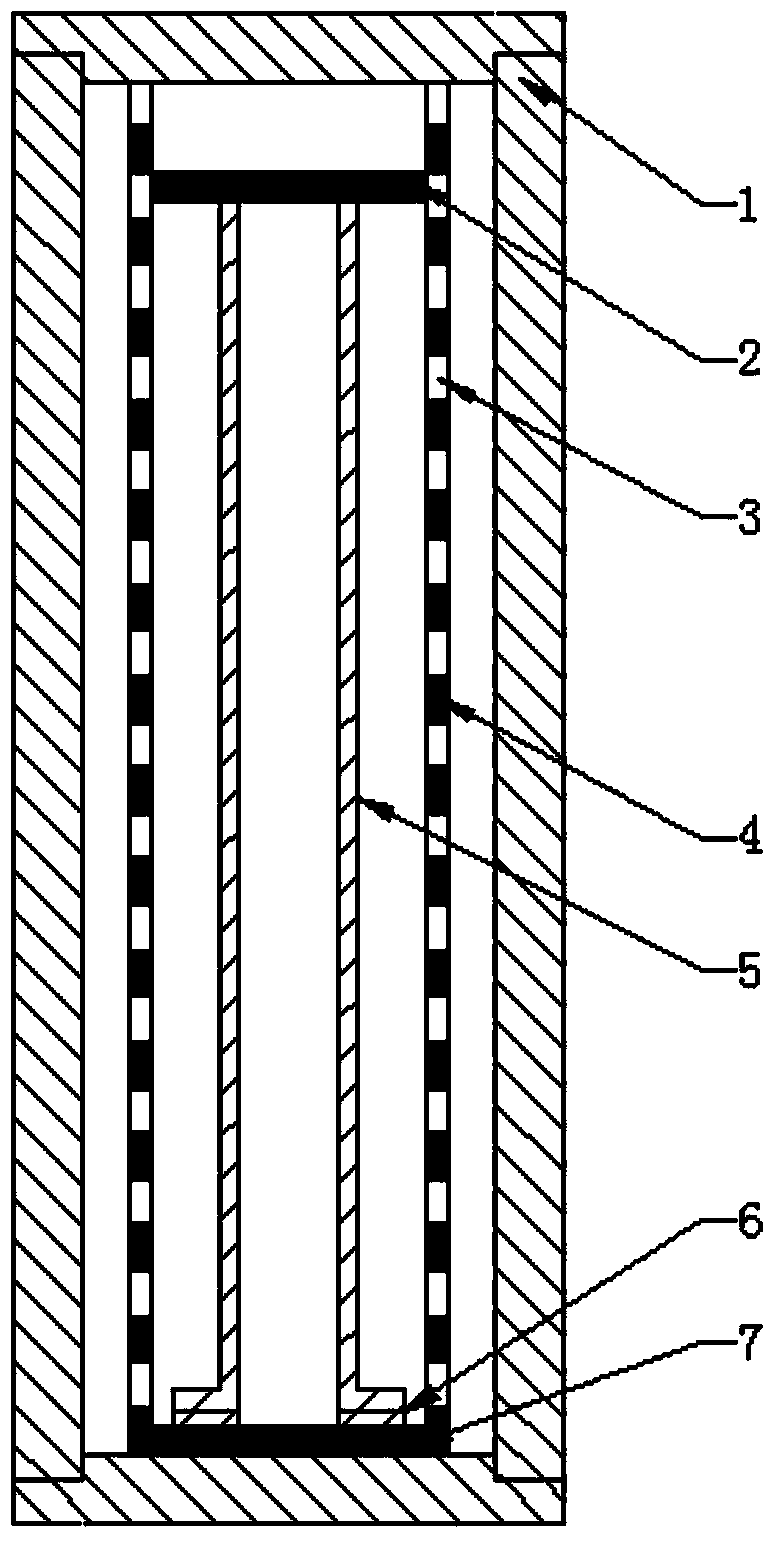

Microwave sintering preparation method of high purity silicon nitride ceramic lift tube for low-pressure casting

The invention discloses a microwave sintering preparation method of a high purity silicon nitride ceramic lift tube for low-pressure casting. The preparation method comprises the following steps: placing silicon nitride powder and an additive in a ball milling machine, carrying out wet method ball milling to obtain material slurry, drying and granulating the slurry, placing the granules into a mould, pressing, and forming so as to obtain a lift tube blank; and placing the blank into a sintering cavity to carry out microwave sintering so as to obtain the high purity silicon nitride ceramic lift tube; wherein the sintering cavity is prepared by overlapping corundum and mullite round tubes and graphite round tubes, and the upper opening and the lower opening of the sintering cavity are both provided with a graphite round plate. The preparation method utilizes the special wave bands of microwaves to couple the silicon nitride composite material to generate heats, the material is consumed to heat the composite material as a whole, the optimized microwave sintered structure is matched with the structural characteristics of high purity silicon nitride ceramic lift tube, and thus the utilization rate and efficiency of microwaves is maximized. The preparation method has the advantages of good sintering quality, high yield rate, low sintering temperature, short sintering time, and low sintering energy consumption.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

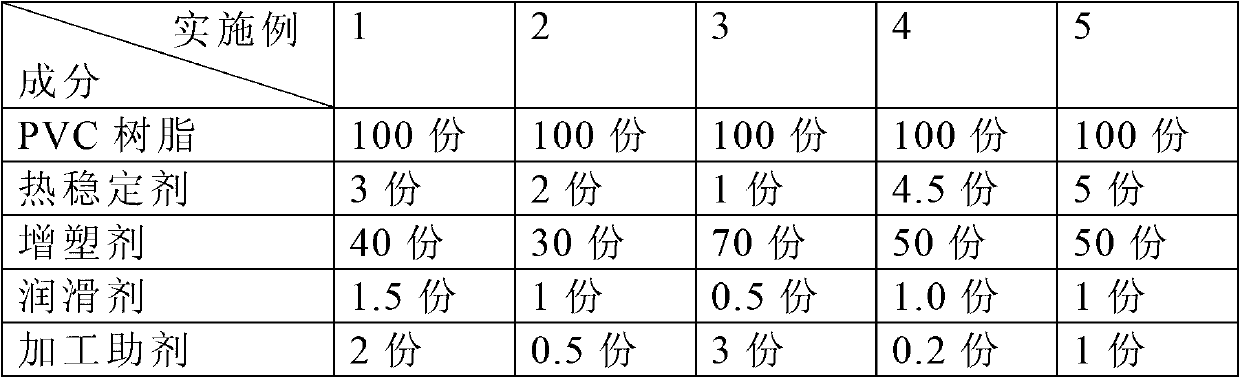

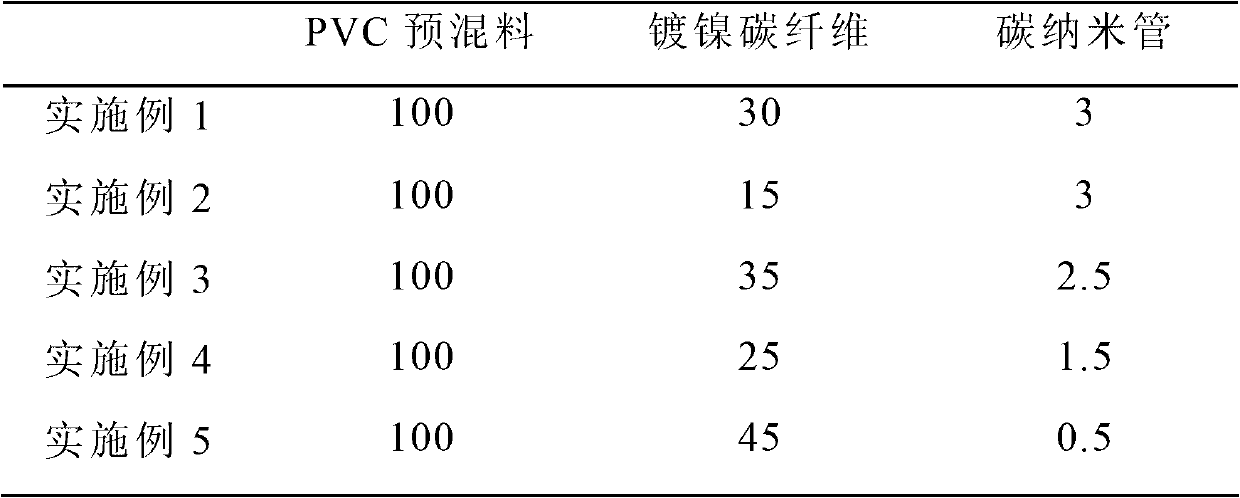

Polyvinyl chloride composite material with microwave absorption property and preparation method thereof

ActiveCN102993603ACompatibility is reasonableImprove microwave absorption performanceFiberCarbon fibers

The invention provides a polyvinyl chloride composite material with microwave absorption property and a preparation method thereof, and belongs to the technical field of novel materials. The problems of poor microwave absorption property and narrow frequency range in the prior art are solved. The polyvinyl chloride composite material with microwave absorption property consists of 100 parts of polyvinyl chloride (PVC) premix compound, 0.5-5 parts of multiwalled carbon nanotubes and 10-50 parts of nickel-plated carbon fibers, wherein the PVC premix compound consists of 100 parts of PVC resin, 1-5 parts of heat stabilizer, 30-70 parts of plasticizer, 0.5-2 parts of lubricant and 0.1-4 parts of processing addictive. The preparation method comprises the steps of premixing the PVC material and banburying. The polyvinyl chloride composite material with microwave absorption property is wide in sources of raw materials, low in cost, good in microwave absorption property, wide in absorption frequency, simple in production procedures, and suitable for industrial production.

Owner:NINGBO XIANFENG NEW MATERIAL

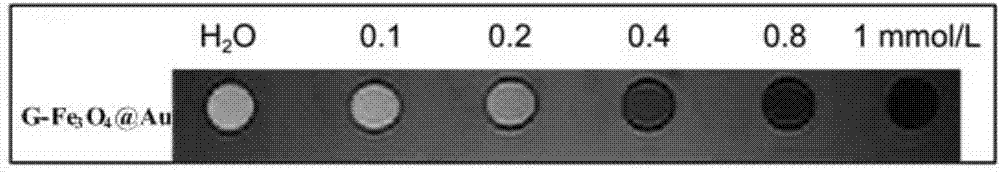

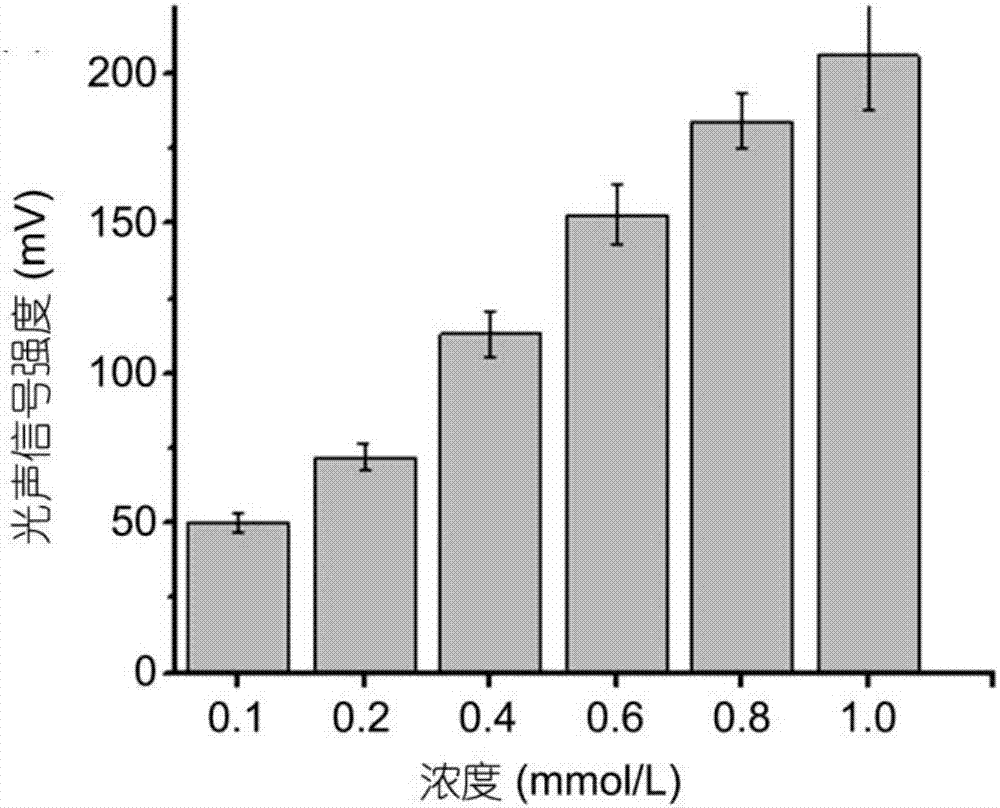

Graphene and ferroferric oxide @gold composite, and preparation method and application of graphene and ferroferric oxide @gold composite

ActiveCN107127351AFast responseImprove efficiencyTransportation and packagingMetal-working apparatusAzideNitrogen atmosphere

The invention relates to a graphene and ferroferric oxide @gold composite, and a preparation method and an application of the graphene and ferroferric oxide @gold composite. The preparation method of the graphene and ferroferric oxide @gold composite comprises the following steps: a ferroferric oxide @gold complex modified by azide mercaptan is constructed, oxidized graphene is activated by thionyl chloride and then reacts with propargyl alcohol to produce alkynylation oxidized graphene, and then the ferroferric oxide @gold complex and the alkynylation oxidized graphene are catalyzed in a nitrogen atmosphere and alkynyl groups and and azide groups undergo click reaction, thereby obtaining the graphene and ferroferric oxide @gold composite. Reaction conditions of the preparation method of the graphene and ferroferric oxide @gold composite are mild and the preparation method is simple and reliable. The graphene and ferroferric oxide @gold composite allows a system to be stable through covalent bond connection, has the characteristics of magnetism, good microwave absorption performance, good plasma resonance absorption and attenuation to X-rays, and can be applied to nuclear magnetic imaging, microwave-induced thermoacoustic tomography, photoacoustic tomography and X-ray imaging.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com