Dodecylbenzene sulfonic acid doped PANI/MXene composite wave absorbing material and preparation method thereof

A technology of dodecylbenzene sulfonic acid and composite wave absorbing material, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limiting the application range of wave absorbing materials, heavy metal compound quality, thick matching thickness, etc. Achieve the effect of thin matching thickness, stable product quality and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Specifically, regarding the preparation method of the composite wave-absorbing material, the steps are as follows:

[0043] (1) Preparation of few-layer Ti 3 C 2 T x MXene suspension, is Suspension A; Ti 3 C 2 T x The concentration of MXene is 10-15mg / ml;

[0044](2) Add aniline monomer and dodecylbenzenesulfonic acid into deionized water, the molar ratio of aniline monomer and dodecylbenzenesulfonic acid is (1:1.5-1:2), to obtain the mixed solution B;

[0045] (3) Add ammonium persulfate to deionized water, the mass concentration of ammonium persulfate is 0.1-0.15g / ml to obtain solution C;

[0046] (4) Add the suspension A to the mixture B, and add it according to the mass ratio of MXene to aniline monomer at 1:1-3:1;

[0047] After stirring evenly, add solution C again, wherein, according to the molar ratio of aniline monomer and ammonium persulfate is 1:1-1:1.2; obtain mixed solution D;

[0048] (5) Stir the mixture D at room temperature for 6-8 hours;

[...

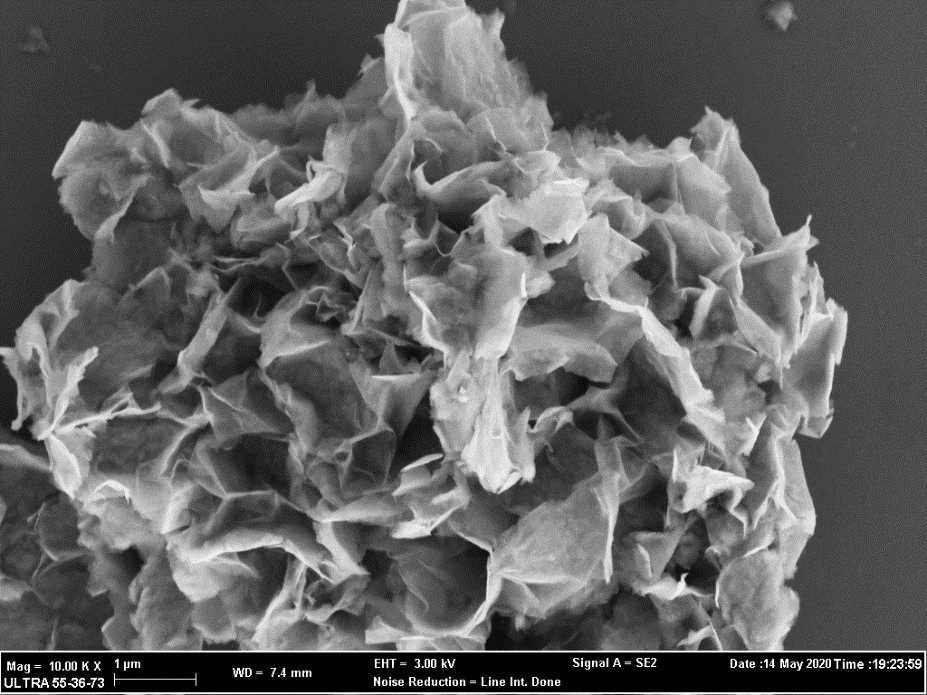

Embodiment 1

[0055] Example 1: prepare a 10mg / ml few-layer MXene aqueous solution for later use, add 30ml of deionized water and 2.9g of dodecylbenzenesulfonic acid to 490μl of aniline monomer, and stir the acidified aniline monomer solution at 0°C 3h, weigh 1.22g of ammonium persulfate (1:1 molar ratio to aniline monomer) and dissolve it in 10ml of deionized water for later use. After the acidification of aniline monomer is completed, measure 50ml of the above MXene aqueous solution and add it to the aniline monomer solution Stir evenly (the mass ratio of MXene to aniline monomer is 1:1), then add ammonium sulfate solution dropwise, stir the mixed solution at room temperature for 6h, centrifuge wash after the reaction is completed, and freeze-dry to obtain dodecylbenzene Sulfonic acid doped PANI / MXene composite absorbing material.

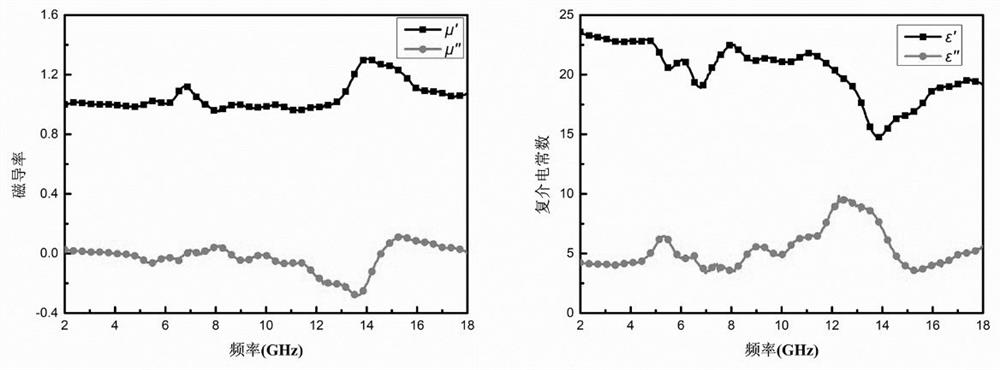

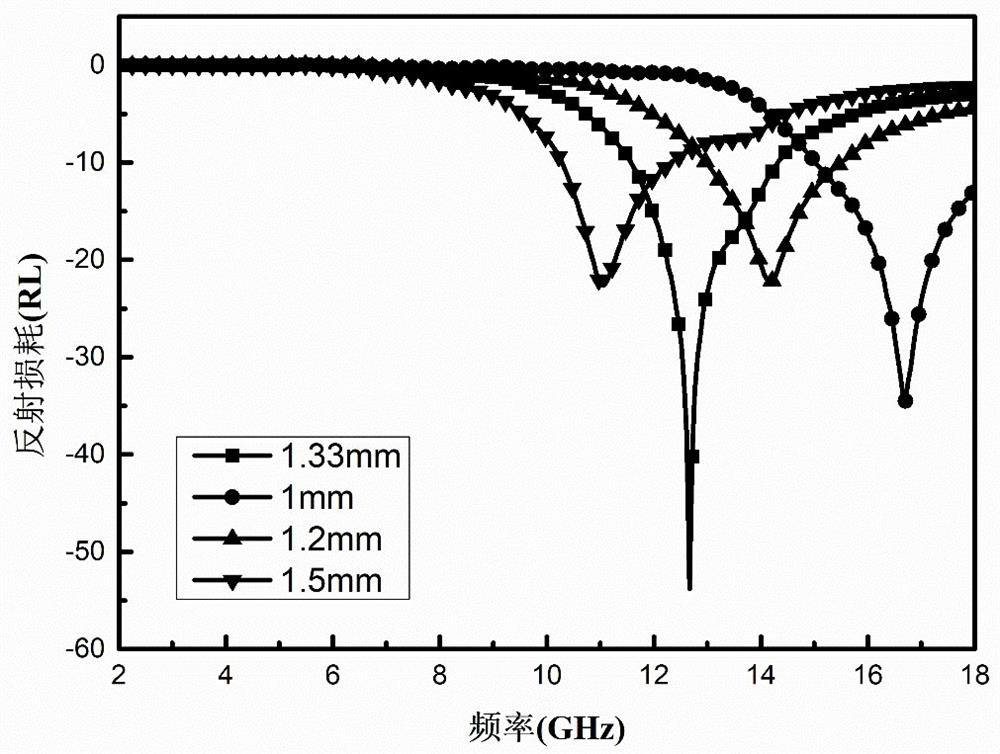

[0056] Dodecylbenzenesulfonic acid-doped PANI / MXene composite absorbing material electromagnetic parameter test sample preparation steps are as follows: dodec...

Embodiment 2

[0060] Example 2: Prepare a 10mg / ml few-layer MXene aqueous solution for later use, add 30ml of deionized water and 1.45g of dodecylbenzenesulfonic acid to 245μl of aniline monomer, and stir the acidified aniline monomer solution at 0°C 3h, weigh 0.61g of ammonium persulfate (1:1 molar ratio to aniline monomer) and dissolve it in 10ml of deionized water for later use. After the acidification of aniline monomer is completed, measure 50ml of the above MXene aqueous solution and add it to the aniline monomer solution Stir evenly (the mass ratio of MXene to aniline monomer is 2:1), then add ammonium sulfate solution dropwise, stir the mixed solution at room temperature for 6h, perform centrifugal washing after the reaction is completed, and freeze-dry to obtain dodecylbenzene Sulfonic acid doped PANI / MXene composite absorbing material.

[0061] Dodecylbenzenesulfonic acid-doped PANI / MXene composite absorbing material electromagnetic parameter test sample preparation steps are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com