High-transmittance microwave absorption light window with electrically controlled and adjustable reflection frequency band

A technology of electronic control adjustment and microwave absorption, applied in optics, electrical components, optical components, etc., can solve problems such as poor light transmittance, inability to adjust the frequency band of reflection, complex design and excitation control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

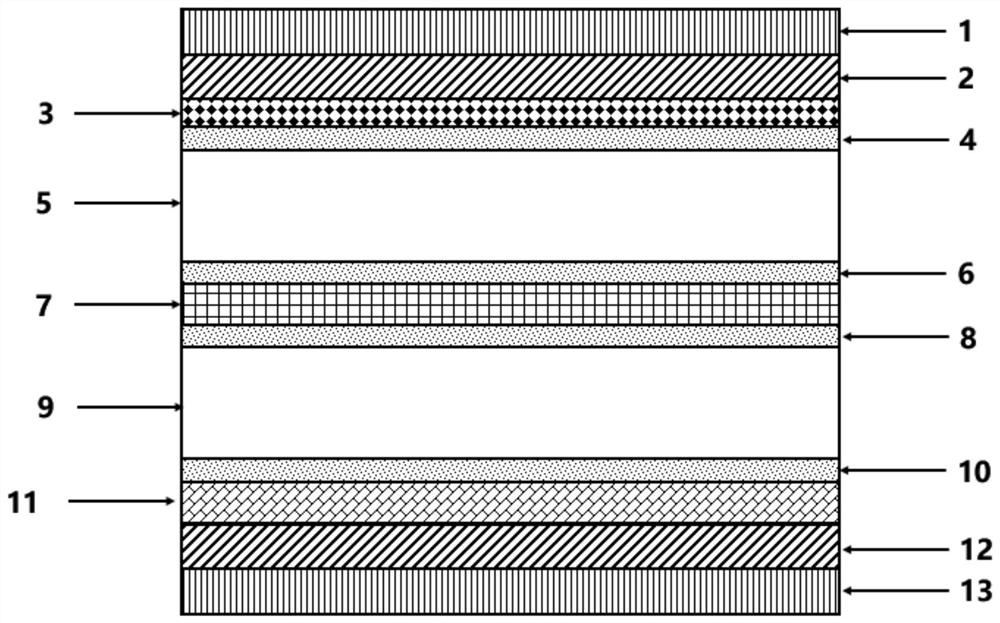

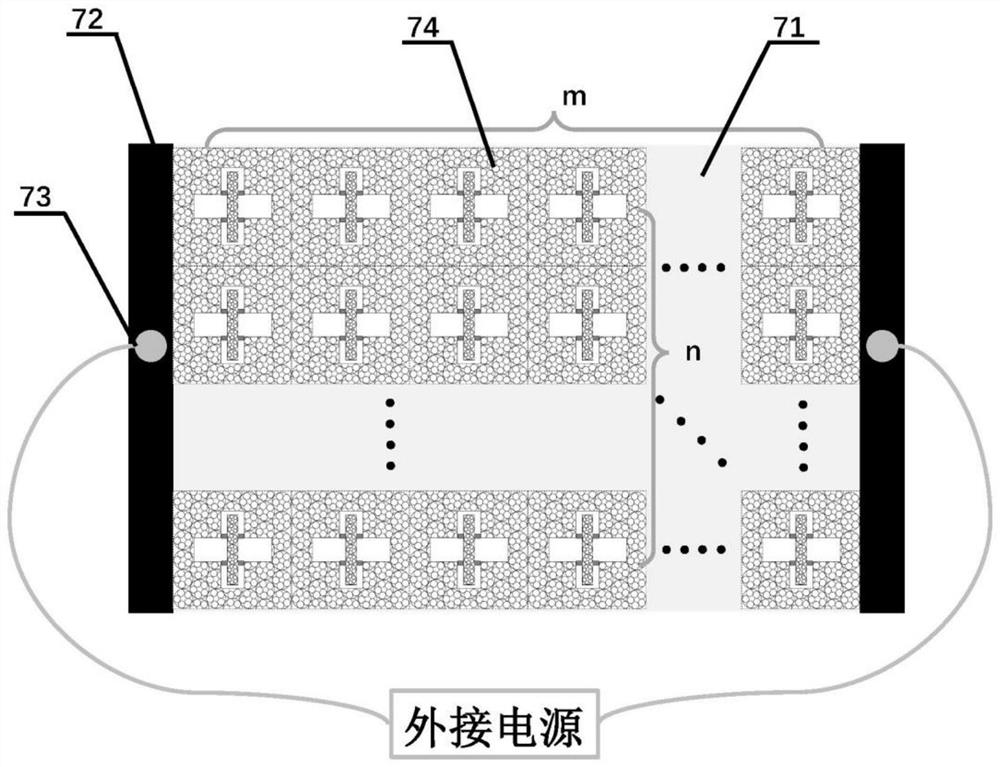

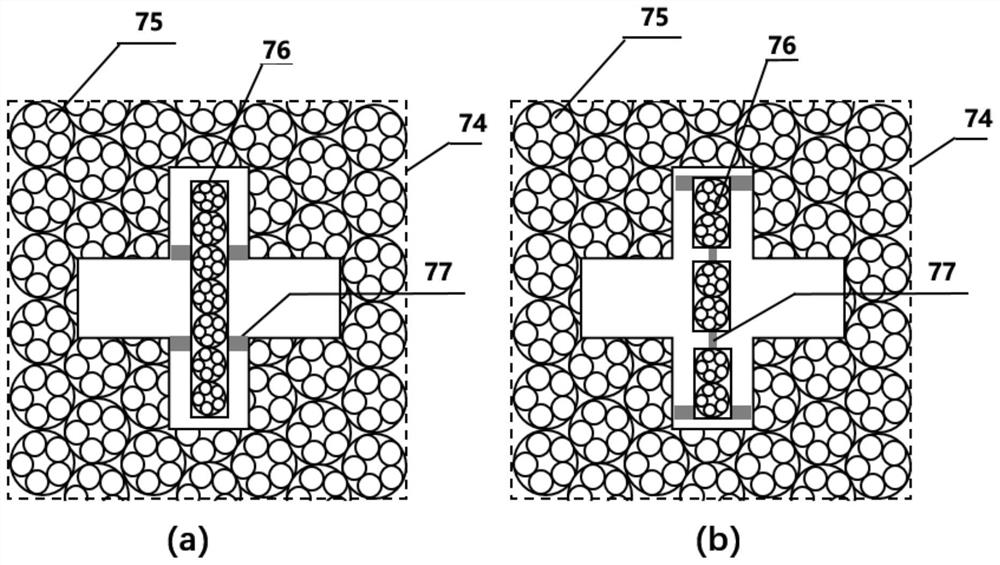

[0066] According to an embodiment of the present invention such as Figure 10 As shown, its overall structure diagram is shown in Figure 10 As shown in (a), the top layer consists of the first single-layer graphene layer, the second layer of transparent silica, the third layer of electrically controlled adjustable frequency selective surface layer integrated with phase change materials, the fourth layer of transparent silica, The fifth layer of metal mesh layer is composed of the structure diagram of the electronically controlled adjustable frequency selective surface layer integrated with phase change materials in the third layer as shown in Figure 10 (b) shown. In this example, the electronically controlled adjustable frequency selection surface layer and the metal grid layer of the integrated phase change material are used. The metal grids used are triangular distribution rings and sub-ring array grids; the stagger angle is 20°; the aperture type frequency selection Sur...

Embodiment 2

[0071] According to an embodiment of the present invention such as Figure 13 As shown, its overall structure diagram is shown in Figure 13 As shown in (a), the top layer consists of the first single-layer graphene layer, the second layer of transparent silica, the third layer of electrically controlled adjustable frequency selective surface layer integrated with phase change materials, the fourth layer of transparent silica, The fifth layer of metal mesh layer is composed of the structure diagram of the electronically controlled adjustable frequency selective surface layer integrated with phase change materials in the third layer as shown in Figure 13 (b) shown. In this embodiment, the electronically controlled adjustable frequency selection surface layer and the metal grid layer of the integrated phase change material are all made of triangular distribution rings and sub-ring array grids; the stagger angle is 20°; the aperture frequency Select the cross-aperture type fre...

Embodiment 3

[0076] According to an embodiment of the present invention such as Figure 16 As shown, its overall structure diagram is shown in Figure 16 As shown in (a), the top layer consists of the first single-layer graphene layer, the second layer of transparent silica, the third layer of electrically controlled adjustable frequency selective surface layer integrated with phase change materials, the fourth layer of transparent silica, The fifth layer of metal mesh layer is composed of the structure diagram of the electronically controlled adjustable frequency selective surface layer integrated with phase change materials in the third layer as shown in Figure 16 (b) shown. In this embodiment, the electronically controlled adjustable frequency selection surface layer and the metal grid layer of the integrated phase change material are all made of triangular distribution rings and sub-ring array grids; the stagger angle is 20°; the aperture frequency Select the cross-aperture type fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com