Patents

Literature

64results about How to "No thermal inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

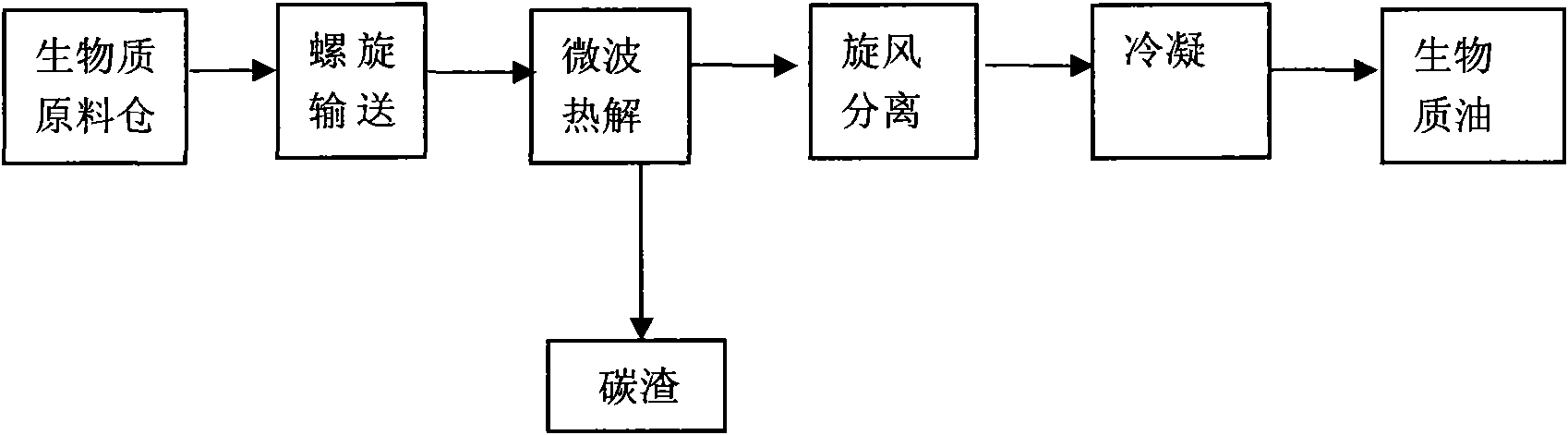

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

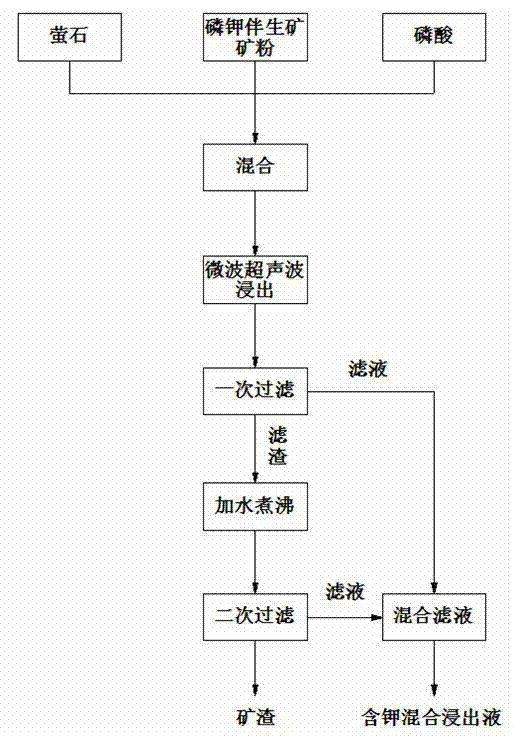

Method for leaching potassium in phosphorus potassium associated ore at low temperature by assisting with microwaves/ultrasonic waves

InactiveCN102864303AHeating fastFacilitate the transfer of substancesProcess efficiency improvementMineralogyUltrasonic assisted

The invention relates to a method for leaching potassium in phosphorus potassium associated ore at low temperature by assisting with microwaves / ultrasonic waves. The method comprises the following steps of (1) mixing materials, taking phosphorus potassium associated ore powder and assistant fluorite to be evenly mixed, and then adding phosphoric acid for soaking to obtain a mixture; (2) conducting microwave and ultrasonic wave leaching; (3) obtaining primary filter residues and primary filter liquor; (4) obtaining secondary filter residues and secondary filter liquor; and (5) mixing a leaching liquid, mixing the obtained primary filter liquor and the obtained secondary filter liquor to obtain the leaching liquid containing potassium. The method has the advantages of substantially shortening heat conduction time, avoiding shortcomings of uneven heating in a traditional heating mode, being energy-efficient due to microwave heating, and almost having no other loss except for temperature rise of materials to be heated. Cavatition of the ultrasonic waves enables liquid to cause a series of movements such as swelling, compression and sinking and the like, and produced chemical effects and mechanical effects can change reaction conditions and quicken reaction speed.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

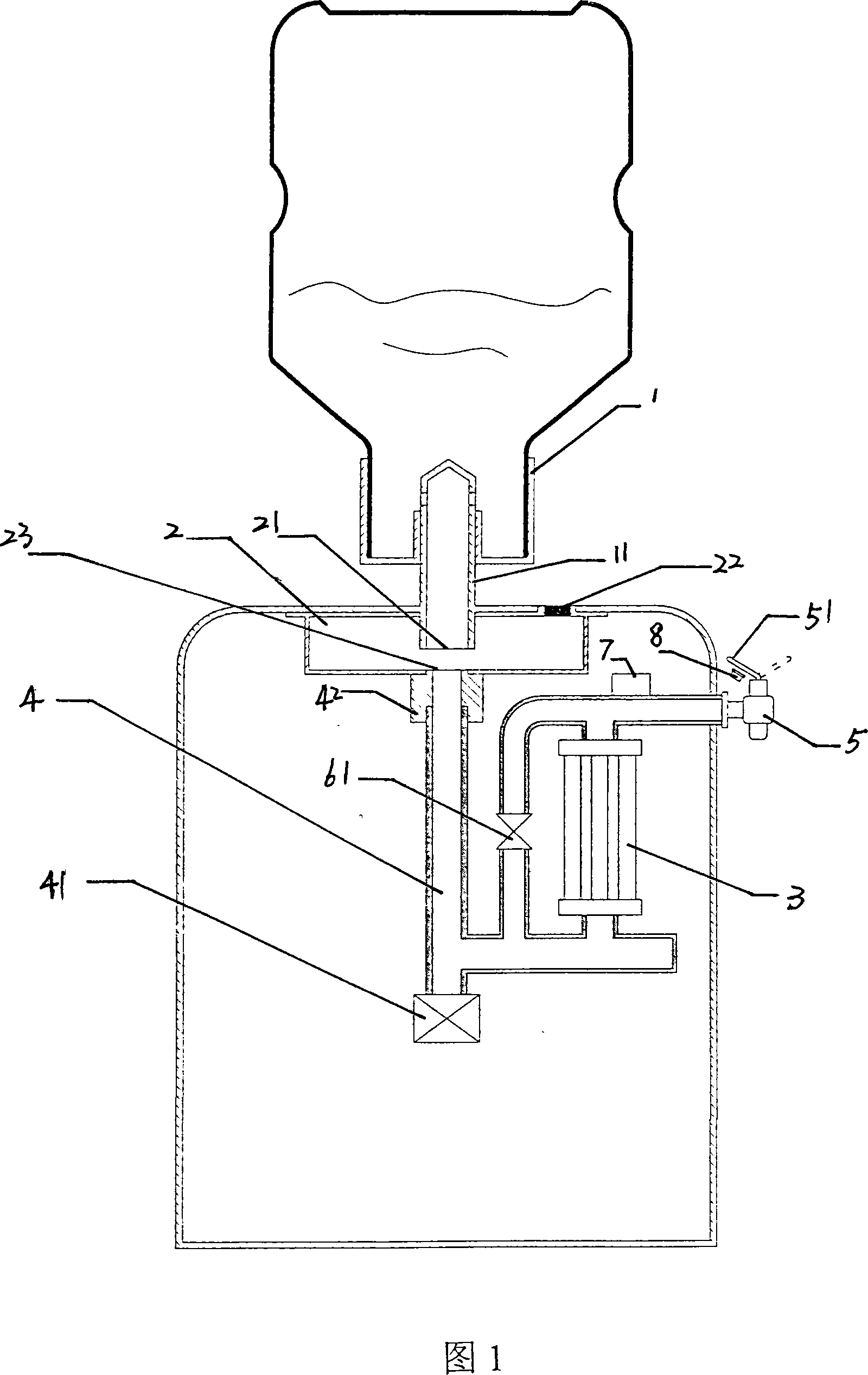

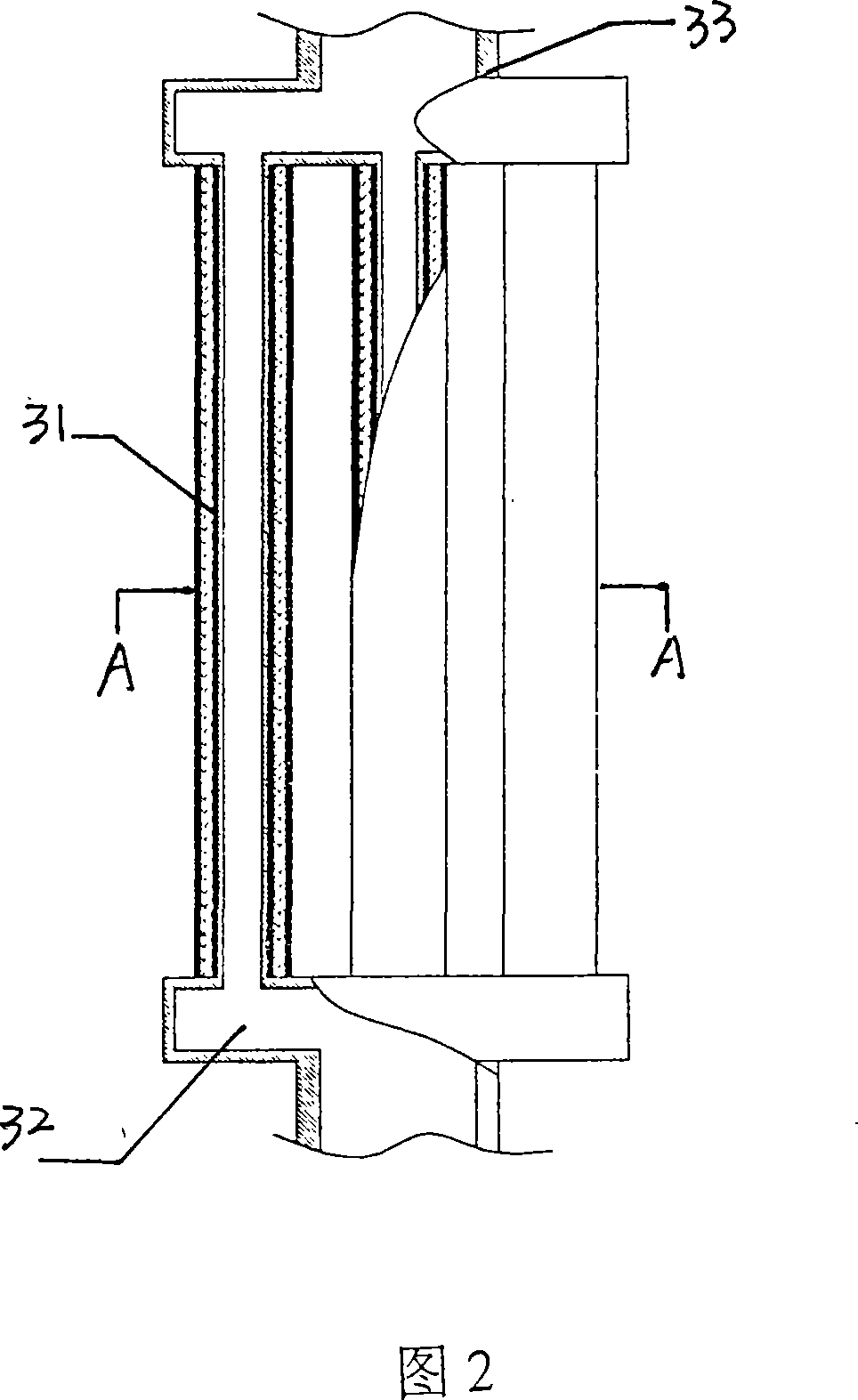

Instant-heating water drinking machine

The present invention provides an instant heating drinking machine which can provide needed drinking hot water instantly and needs not pre-store hot water in machine. The drinking machine in the invention includes shell, bottle seat, bucket, heating body, channel water pipes, water discharging valve and water outlet, the heating body consists of many electrothermal tubes which are parallel each other and can allow water flows, the electrothermal tube is flat, the width of short edge of electrothermal tube inner cavity is 1. 0-2. 0mm and the width of long edge is 5-10 mm, one end of the electrothermal tubes are fixed on the water inlet variable flow seat and another ends are fixed on the water outlet variable flow seat, the energizing and heating of heating body is controlled by the water discharging valve. The drinking machine in the invention need not preheating device, ensure the first cup of water is hot water, and the heating or not is controlled by the water discharge valve individually, it can realize the purpose of instant and continuous hot water supply and instant drinking at the time of starting the machine.

Owner:王承辉

Method for preparing paeoniflorin

InactiveCN101418025AReduce extraction timeLess solvent usageSugar derivativesChemistryChromatography column

The invention relates to a method for preparing paeoniflorin, which is simple in operation and low in equipment investment. The method comprises the following process steps: a raw material containing paeoniflorin is placed into microwave extraction equipment and added with water for microwave extraction; filtrate is collected and filtered, so that the filtrate passes through a macroporous absorbent resin column for sample loading, water is used to elute impurities first, 20 to 80 percent ethanol is used for elution, ethanol eluate is collected, and the ethanol is decompressed, reclaimed and concentrated; the concentrated liquid is added into a chromatography column filled with active carbon, and then eluted by water; and eluate is collected, concentrated by a reverse osmosis membrane and dried to obtain the paeoniflorin. The method has the advantages of lowering production cost, improving product quality and facilitating industrialized operation.

Owner:ANHUI GUANGYINTANG CHINESE MEDICINE

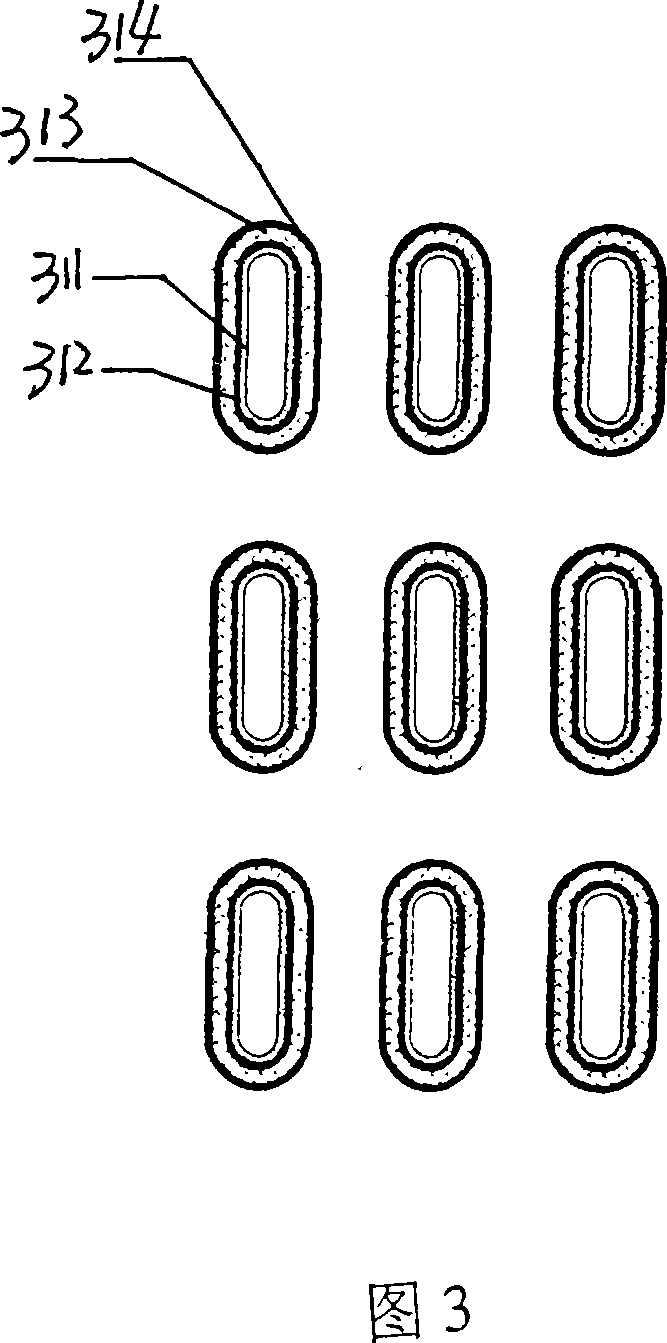

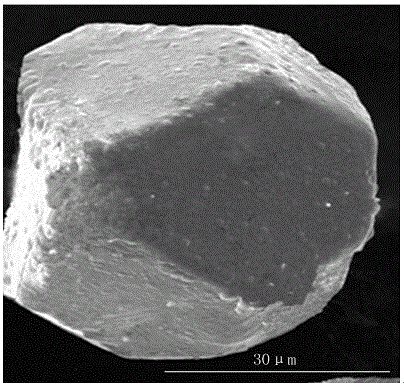

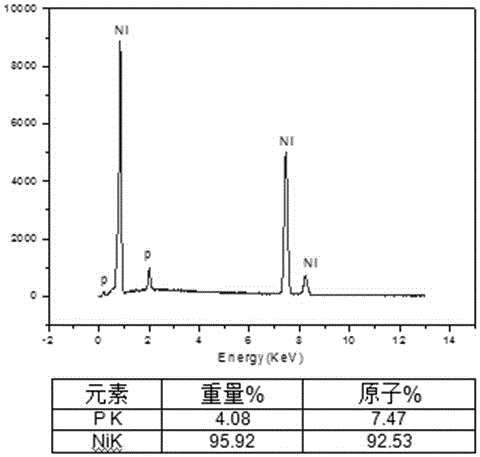

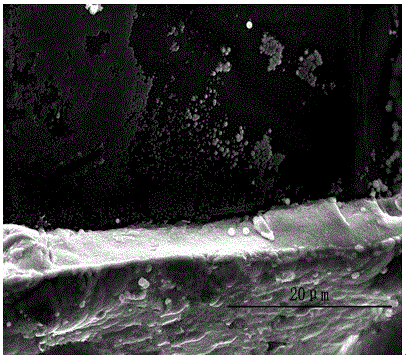

Method for chemically plating surface of diamond with Ni and P in microwave-ultrasound combined mode

InactiveCN105112891AReduce dosageLow costLiquid/solution decomposition chemical coatingChemical platingMicroparticle

The invention relates to a method for chemically plating the surface of diamond with Ni and P in a microwave-ultrasound combined mode and belongs to the technical field of diamond composites. The method includes the steps that firstly, grease and dirt of diamond particles are removed after the diamond particles are boiled in a NaOH solution, and then the surfaces of the diamond particles are roughened after the diamond particles are boiled in a dilute HNO3 solution; the diamond particles obtained after surface roughening are placed in a base colloid palladium solution for sensitization-activation; the diamond particles obtained after sensitization-activation are added into a sodium hypophosphite-water(1 / 2) solution with the concentration of 30 g / L for surface Pd2+ reduction of the diamond particles; and the diamond particles obtained after surface Pd2+ reduction are added into a chemical plating solution, are plated for 1-1.5 h under the microwave irradiation and ultrasound stirring conditions and stand still after being plated, and the diamond particles plated with Ni-P on the lower layer are washed with distilled water for vacuum drying. According to the method, the microwave irradiation heating technology and the ultrasound technology are combined to be applied to the Ni-P chemical plating process of the surface of the diamond, the quality of a coating is improved, and the coating is flat, smooth, dense, uniform and high in binding capacity and corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

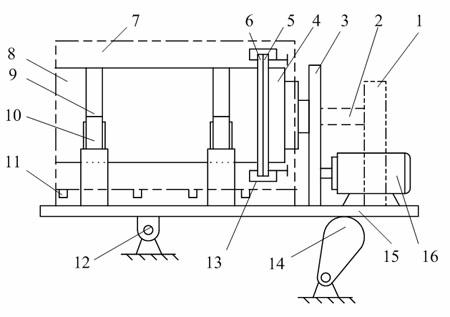

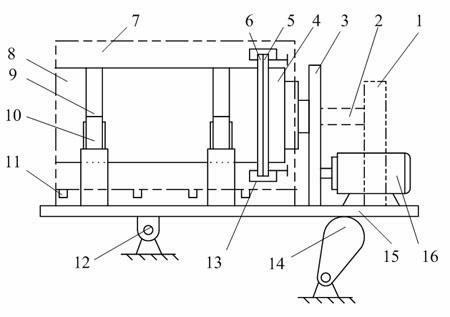

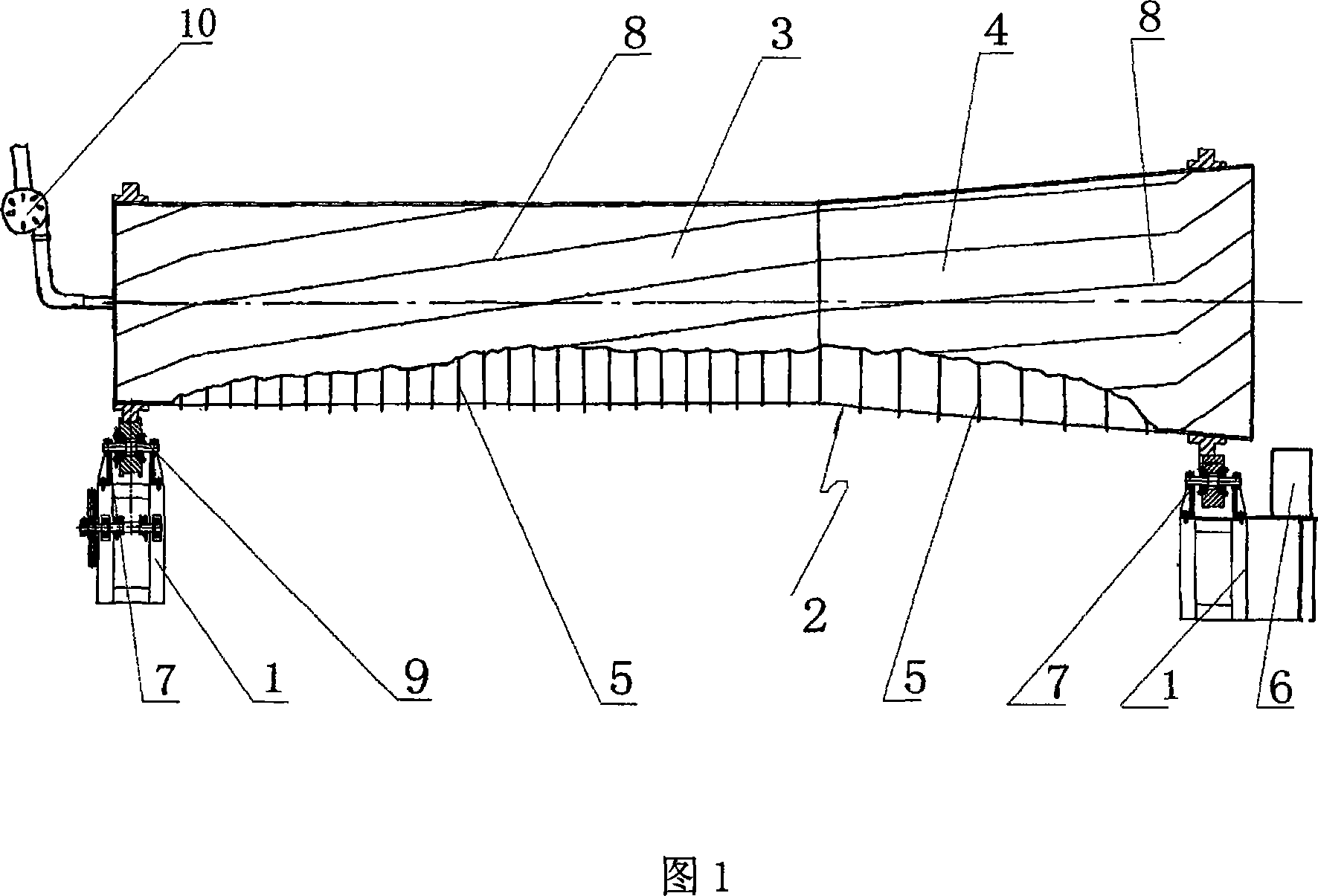

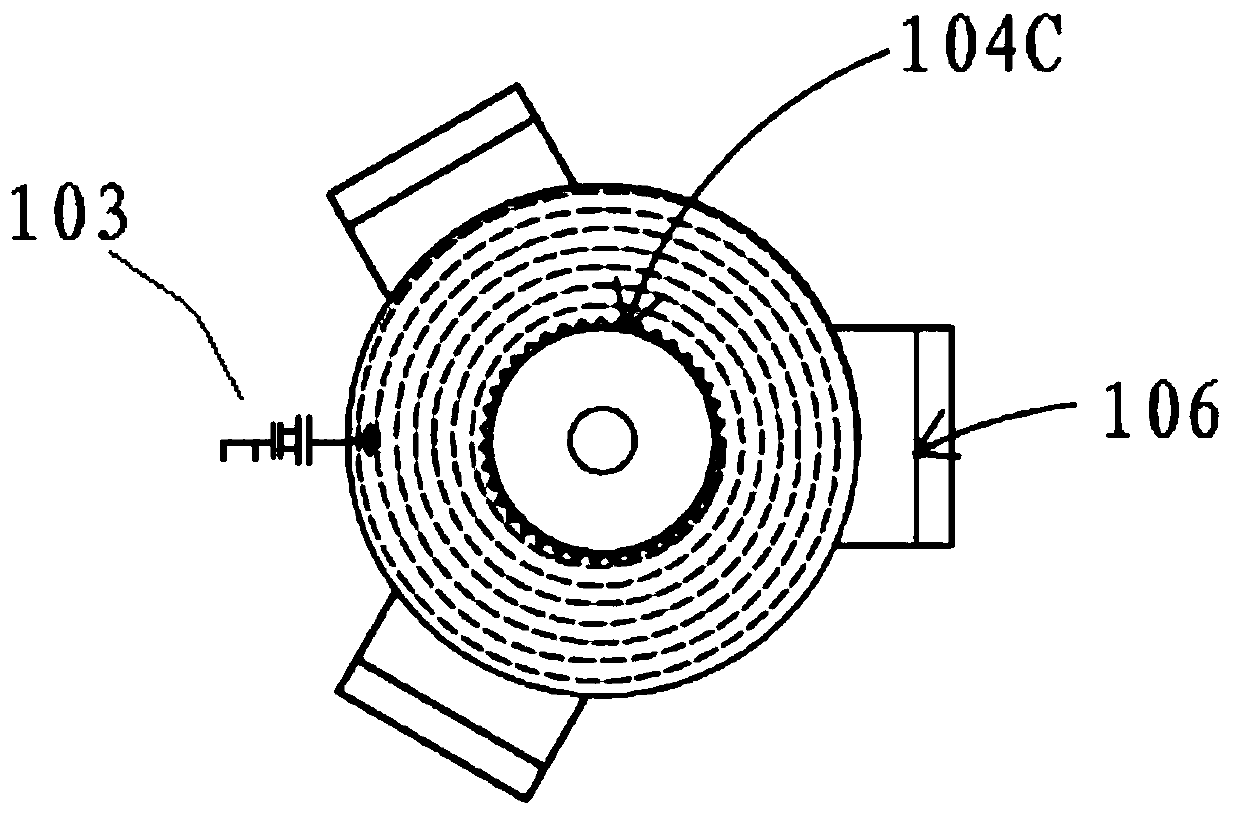

Microwave-heated rotational molding die equipment and method for manufacturing rotational molding product

InactiveCN102107479AHeating fastImprove heat transfer efficiencyChemical industryChemical industryLow noise

The invention relates to microwave-heated rotational molding die equipment, and relates to machines in chemical industry. The microwave-heated rotational molding die equipment is characterized by comprising a microwave source, a die upper die, an upper die flange, a lower die flange and a movable constant temperature heating box; a clamping groove is fixed on a die lower die; the clamping groove and a support roller are matched to support the die lower die; the upper die flange and the lower die flange on the die lower die are locked by a die clamp to form a die whole; the die upper die is connected with a motor by a transmission device to rotate axially; the microwave heating source is connected with the die upper die by a microwave transmission pipe so as to input microwave to a die cavity; the constant temperature heating box with a thermodetector is covered on the die whole formed by the die upper die and the die lower die; the components are arranged on a base integrally; and both ends of the base are respectively connected with a base hinge and a base wabble mechanism to form a wabble structure. The microwave-heated rotational molding die equipment has high heat conduction efficiency, uniform heating, low cost and low noise.

Owner:WUXI AOFUTE PRECISION RAPID PROTOTYPING TECH

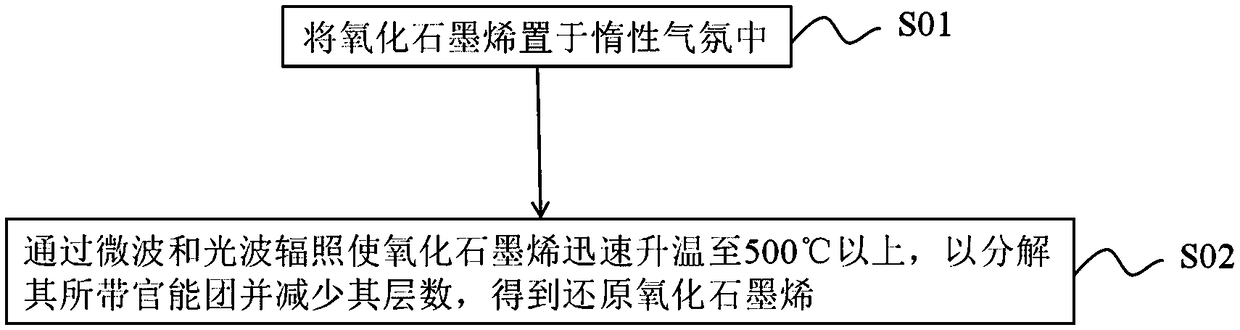

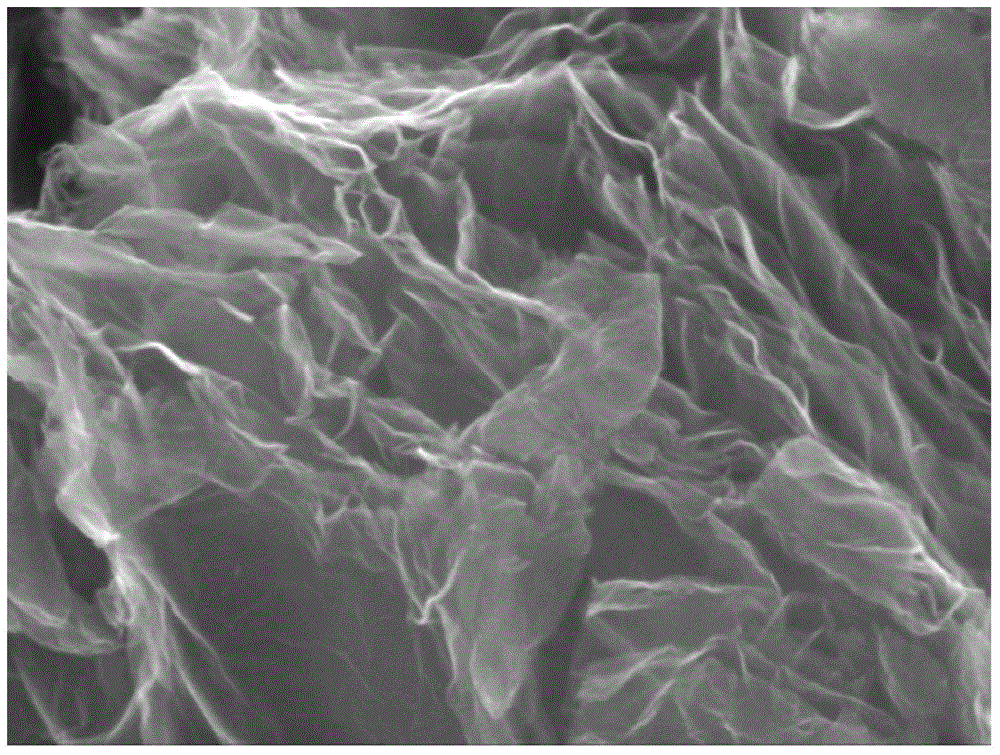

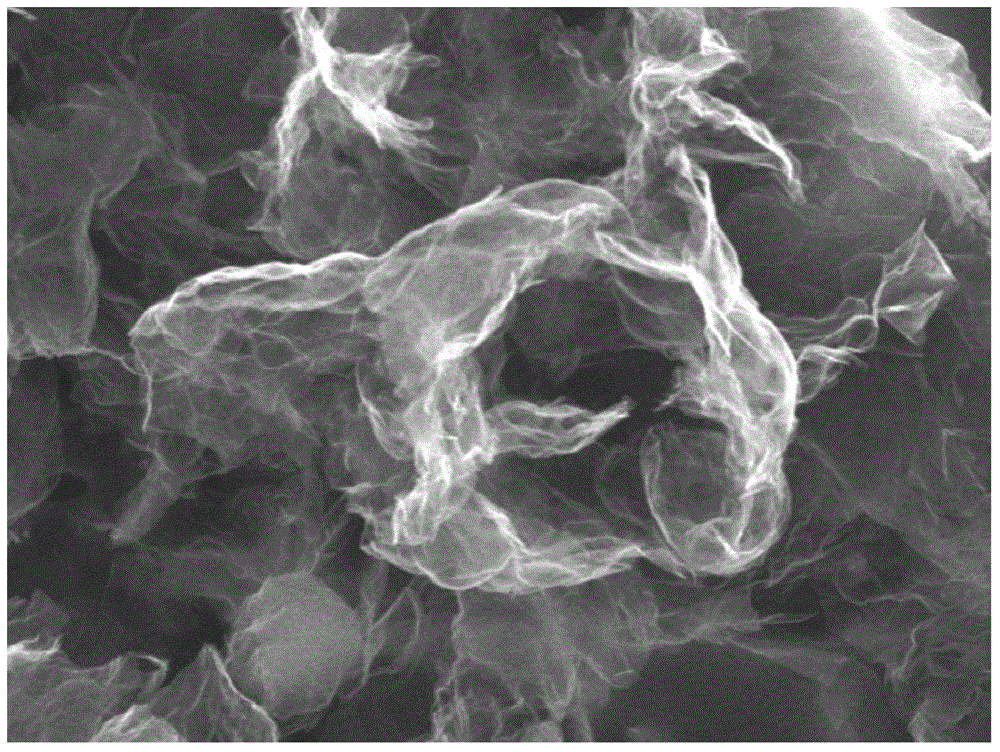

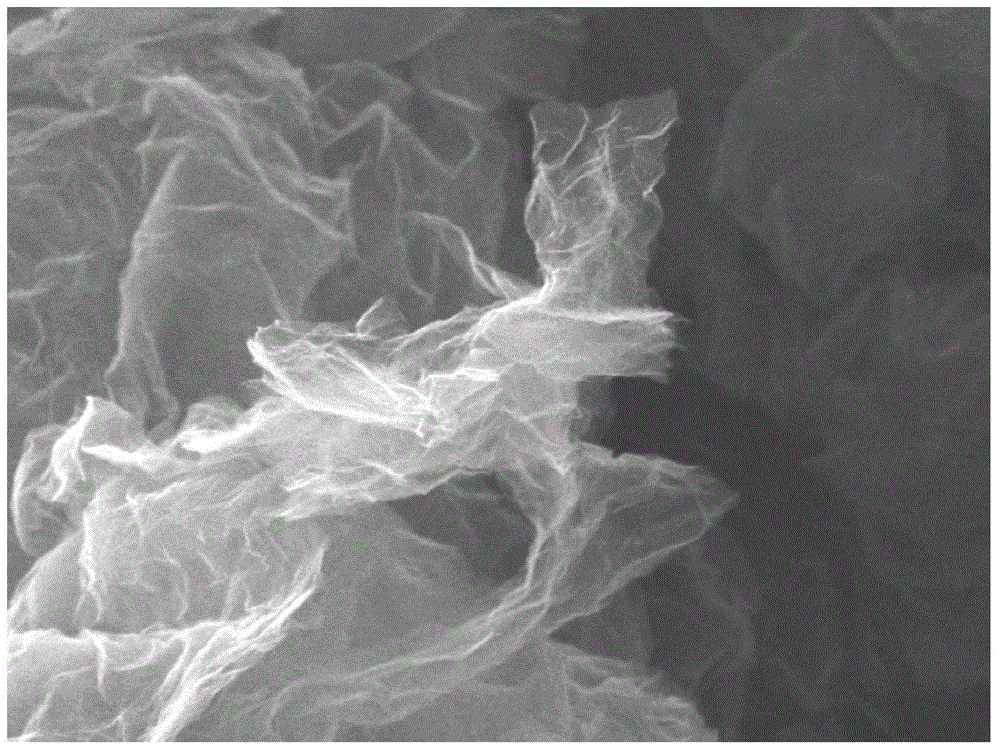

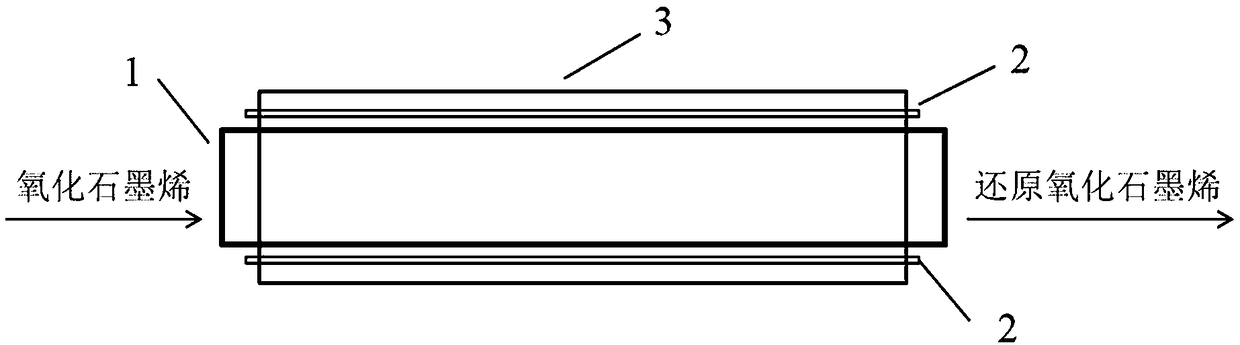

Method for reducing graphene oxide by optical microwaves

The invention provides a method for reducing graphene oxide by optical microwaves. The method can include the steps: placing graphene oxide into inert atmosphere; rapidly heating the graphene oxide toreach the temperature of 500 DEG C or more by the microwaves and optical wave irradiation, decomposing functional groups of the graphene oxide and decreasing the number of layers of the graphene oxide to obtain reduced graphene oxide. The microwaves can penetrate the graphene oxide in a traveling wave mode, the frequency of the microwaves is 300MHz-300GHz, and the frequency of optical waves is 3*1011-3.8*1014Hz. The method has the advantages that the graphene oxide is rapidly and uniformly heated by the optical microwaves, heat inertia is avoided, energy is saved, efficiency is high, reducingefficiency is high, and the graphene oxide can be selectively oxidized.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

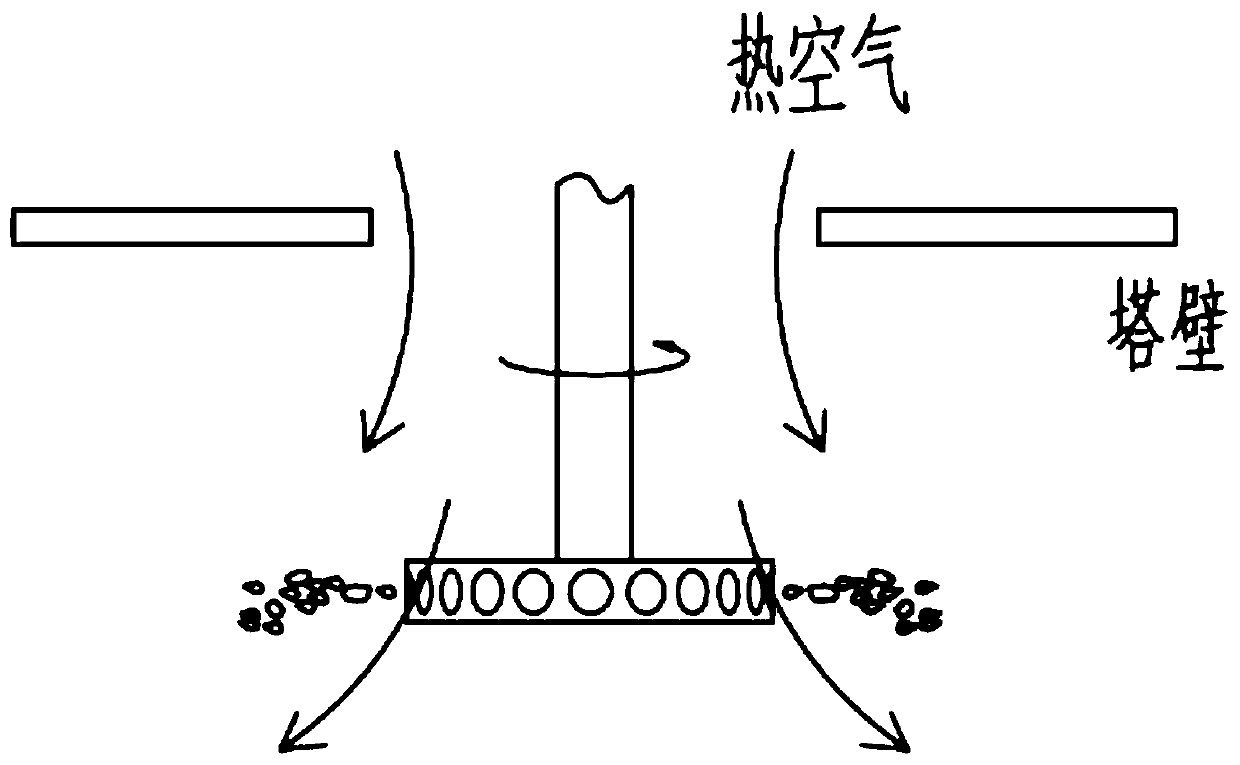

Tea-steaming machine suitable for making famous and high-grade tea

ActiveCN101084770ANo thermal inertiaCompletePre-extraction tea treatmentElectricityTemperature control

The invention discloses a tea leaf steaming machine suitable for preparing famous tea, which comprises a frame and a rotating drum. The rotating drum comprises a rotating drum cylinder section and a rotating drum conical section. Interval uniformly distributed annular electrical heating tubes are respectively arranged on the external surface of the cylinder section and conical section. The plane of the center line of each electrical heating tube is perpendicular to the axial line of the rotating drum. Each electrical heating tube is electrically connected to the temperature control unit on the top of the rotating drum. The interval between the electrical heating tubes on the external surface of the cylinder section is smaller than that between the electrical heating tubes on the external surface of the conical section. Compared with present technology, with the configuration, the invention has the advantages of no thermal inertia, uniform and fully steaming, and improved product quality.

Owner:谢裕大茶叶股份有限公司

Bio-oil preparation technology

InactiveCN103666516AImprove microwave absorption performanceLow particle size requirementBiofuelsLiquid hydrocarbon mixture productionGas solidMicrowave pyrolysis

The invention belongs to the technical field of fuel oil, particularly relates to a bio-oil preparation technology. The bio-oil preparation technology is characterized in that the technology comprises the following steps: smashing biomass materials; drying; feeding smashed biomass materials to a screw conveyer; feeding the materials into a microwave pyrolysis reactor to be pyrolyzed; performing primary cooling on pyrolyzed products; performing gas-solid separation on high-temperature organic steam produced through pyrolysis in the microwave pyrolysis reactor to remove carbon granules and sand therein; performing secondary cooling and collecting bio-oil; performing third-time cooling and collecting oil with low-boiling point; collecting non-condensed gas for recycling. According to the invention, bio-oil is prepared by adopting the technology, and the biomass materials and carbon residues have good performance on absorbing microwave, so that the microwave heating speed is fast, outside and inside heating can be realized at the same time, and heat conduction is not needed, so that the preparation technology meets the requirements for bio-oil extraction of an optimal process; the requirement of the particle size of raw materials is lowered, so that the cost of pre-treatment is reduced; the pyrolysis temperature can be precisely controlled, and the thermal-inertia is avoided.

Owner:山东易能生物能源有限公司

Microwave hot bending kiln and microwave heating hot bending glass ceramic preparing method

PendingCN108328910AReduce unit energy consumptionReduced bending process timeGlass reforming apparatusGlass productionRoom temperatureGlass-ceramic

The invention discloses a microwave heating hot bending glass ceramic preparing method. The m microwave heating hot bending glass ceramic preparing method comprises placing a polished glass ceramic plate in the center of a curved green body, pushing a drawer kiln until the drawer kiln is tightly connected with a main kiln, starting a power supply, adjusting the microwave frequency to 2450 megahertz, and controlling the power of every microwave generator to be 6 kw-8 kw; increasing the temperature of a sample for 10-15 min to 780-850 DEG C; under the power condition of 4 kw-8 kw, heat-preserving the sample at 780-850 DEG C for 30-40 min for hot bending; after hot bending is completed, cooling the sample for 10-15 min until reaching an annealing temperature of 650 DEG C, performing thermal preservation, and then rapidly cooling down the sample for 60-80 min to room temperature. The invention also discloses a microwave hot bending kiln. The microwave heating hot bending glass ceramic preparing method and the microwave hot bending kiln can greatly shorten the heat increasing time, improve the crystallization efficiency and reduce the defective percentage.

Owner:四川一名微晶科技股份有限公司

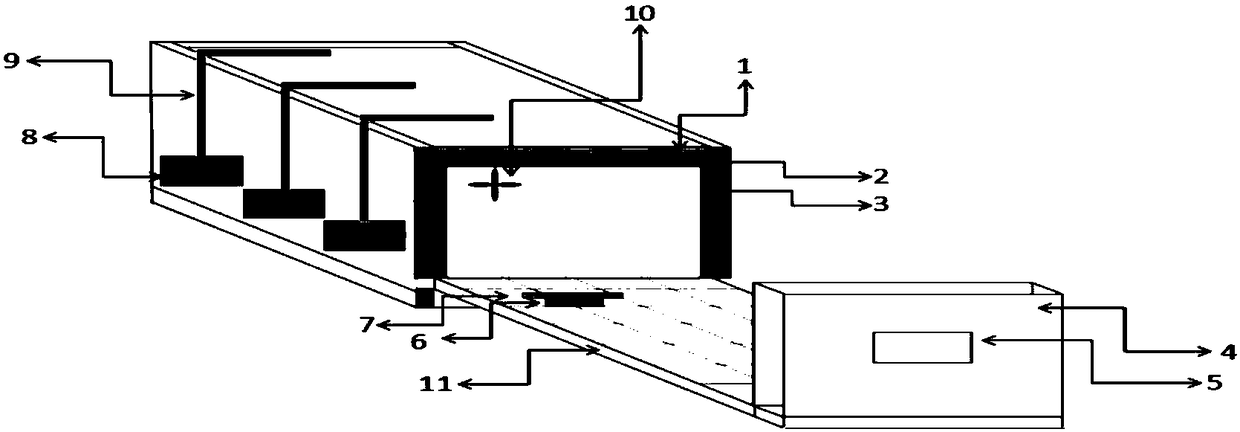

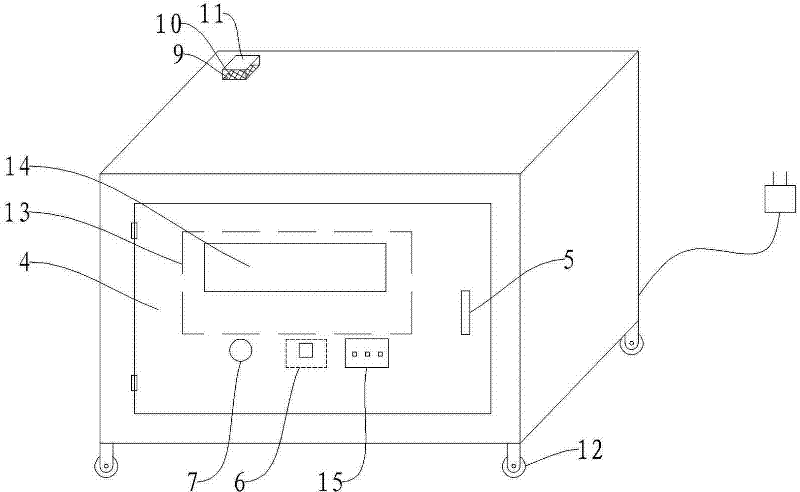

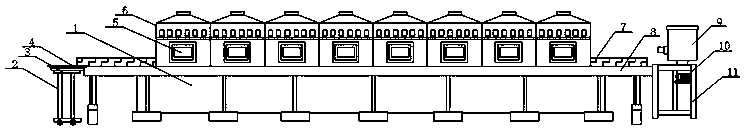

Efficient energy-saving microwave drying device of solar energy vacuum heat-collecting tubes

InactiveCN102692116AImprove heating efficiencyDry evenlyDrying chambers/containersDrying machines with local agitationElectricityHeating time

Disclosed is an efficient energy-saving microwave drying device of solar energy vacuum heat-collecting tubes, which is characterized in that: the device comprises a box body and the inner wall of the box body is provided with one microwave generator or more microwave generators; the box body is equipped with a door, wherein the door is equipped with a handle used for opening and closing the door, a power supply module, and a power adjustment switch, and the microwave generator is electrically connected to the power supply module through the power adjustment switch; a microwave shielding layer is arranged on the inner wall and / or outer wall of the box body; the top portion of the box body is provided with an air vent; and a shielding mesh for preventing microwave leaking is arranged on the air vent. The efficient energy-saving microwave drying device of the invention heats selectively, which has the advantages of reducing the heating time, improving the production efficiency, and realizing effects of high efficiency and energy saving; not producing waste water and waste gases; and heating rapidly, uniformly, and omni-directionally without a local temperature peak.

Owner:JINAN DONGFANG WEIMIN SOLAR ENERGY TECH

Anti-pilling treatment method for light and thin wool-polyester fabric

InactiveCN107938309AGood physical and mechanical propertiesImprove felting performanceWeft knittingWarp knittingPolyesterYarn

The invention relates to an anti-pilling treatment method for a light and thin wool-polyester fabric. The method comprises the following steps: weaving wool-polyester yarns, wherein the wool content of the yarns is 20-99%, and the yarns are 12.5-19.23tex; boiling the woven fabric, dehydrating, scotching, performing wool fabric scouring, washing, dehydrating, putting into microwave drying shaping-low-temperature normal-pressure plasma treatment equipment, performing microwave drying shaping firstly, and performing low-temperature normal-pressure plasma treatment secondly; finally performing softening finishing, so as to obtain the light and thin wool-polyester fabric. Microwave heating of the method has the advantages of high efficiency, energy conservation, low temperatures, uniform drying, no thermal inertia, and the like; industrial production of magnetrons is already achieved, so that the equipment is convenient to repair and replace and low in maintenance cost; by using a low-temperature normal-pressure plasma treatment technique, surface modification treatment on wool fibers in the fabric is implemented through medium baffled power discharge, so that the amounts of chemical reagents and water in the after finishing process of a woolen fabric are reduced, the energy is saved, the environment is protected, and the anti-pilling property of the fabric is improved.

Owner:DONGHUA UNIV +1

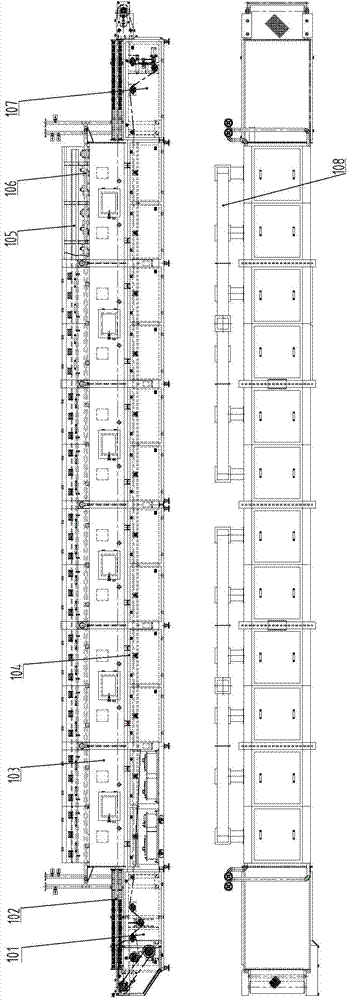

Continuous countercurrent extraction method of pectin in Chinese medicine residue by microwave

The invention discloses a continuous countercurrent extraction method of pectin in Chinese medicine residue by microwave. The method includes: adding cellulase and cellulose degrading bacteria into raw Chinese medicine residue to degrade cellulose, centrifuging, collecting centrifuged material, adding the centrifuged material into a microwave continuous countercurrent extraction tank unit, regulating pH to the acid value, and performing microwave extraction; centrifuging, micro-filtering, subjecting supernate to ultrafiltration and concentration, removing micromolecules and coloring impurities, adding ethanol into concentrated solution to keep the ethanol concentration to be 75%, performing full mixing, cleaning and centrifuging, collecting the centrifuged material, namely pectin, and drying the pectin. The method has the advantages that the production cost is lowered, product quality is increased, industrial operation is facilitated, the limits on traditional extraction and production of pectin materials in Chinese food industry can be eliminated, and production scale of pectin is enlarged.

Owner:安徽亿源生物工程有限公司

Processing method of instant dish

Disclosed is a processing method of instant dish which comprises removing roots of the vegetable and washing, cutting into small segments, charging right amount of condiments and mixing homogeneously, vacuum-packing with optical recombination packaging bag, heating rapidly with microwave oven and cooling down quickly. The obtained product contains no preservative agent, and can be made into various tastes as required.

Owner:金鑫

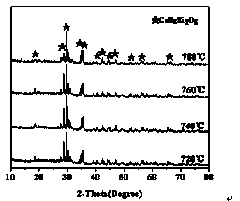

Method for quickly preparing high-performance graphene

The invention discloses a method for quickly preparing high-performance graphene. The method comprises the steps of putting graphite oxide into a reactor, vacuumizing the reactor, treating the graphite oxide by three-stage gradient microwave radiation, and peeling off the graphite oxide expanded with heat, thus obtaining high-performance graphene. The method has the advantages of high production efficiency, low production cost, high safety and reliability in the operation process and high product quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

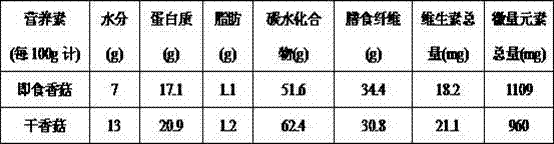

Making method of ready-to-eat shiitake mushrooms

InactiveCN107232584AFacilitated DiffusionAvoid carbonizationFood freezingFood thermal treatmentReady to eatFlavor

The invention provides a method for making ready-to-eat shiitake mushrooms. The method comprises the following steps of performing pretreatment, performing freezing, performing vacuum microwave drying, performing seasoning and performing packaging. The ready-to-eat shiitake mushrooms produced by the method have the characteristics of being rich in fragrance, crisp in mouth feel, rich in nutrition, low in calorie and the like, original flavor and the nutrient value of shiitake mushrooms are furthest maintained, and the quality and the added value of the ready-to-eat shiitake mushrooms are notably increased.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Coating containing trace photoinitiator and solidifying method thereof

InactiveCN102304318AShort curing timeImprove efficiencyPretreated surfacesPolyester coatingsAir atmospherePolyester

The invention relates to a coating containing trace photoinitiator. According to the invention, the main components of the coating are unsaturated polyester resin or acrylic acid type oligomer, acrylic acid monoester and polyester compounds as well as the photoinitiator, wherein the mass percentage of the photoinitiator is 0.1%-1%. The invention also provides a solidifying method of the coating. The solidifying method comprises the following steps: covering the coating on a substrate by using printing, spreading, roller painting and combination processes; irradiating the coating with ultraviolet light; and enabling the substrate to pass through a self-shielding electron accelerator which is located in the air atmosphere at the linear speed of 1-10 m / s, wherein the electron accelerator generates a low-energy electron beam to irradiate the coating so that the coating can be instantly solidified. The coating has the advantages that no odor emerges in the production process, trace residue of the photoinitiator in the coating can meet the requirement of food package, cost is low, and production efficiency is high; and the solidifying method is suitable for solidifying production of all-color coatings.

Owner:HUBEI ERAY NUCLEAR TECH

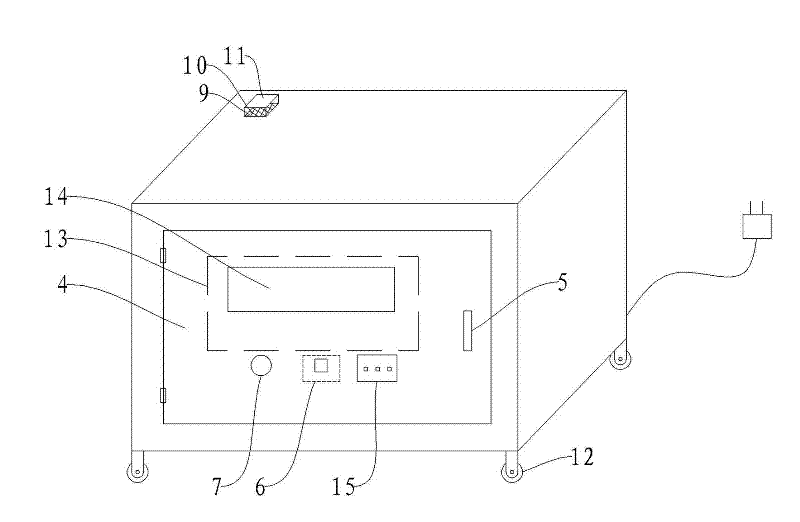

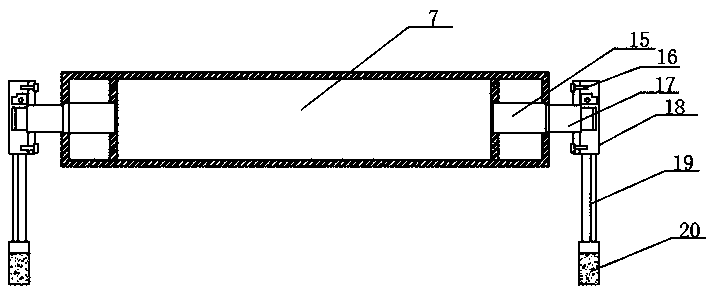

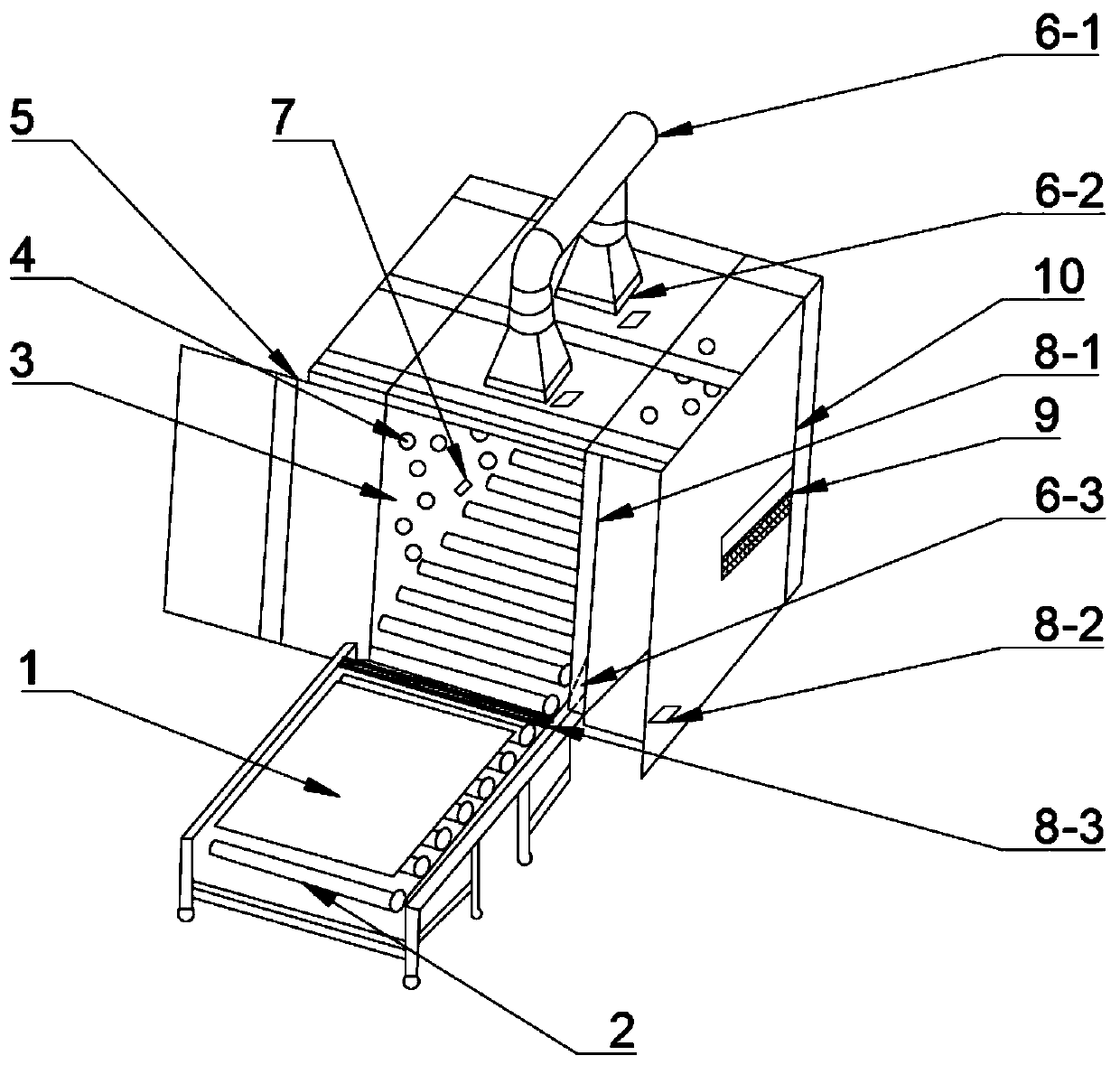

Lithium battery negative electrode material drying device based on microwave drying new technology

InactiveCN111121395AHeating fastNo heat transfer requiredDrying solid materials with heatDrying chambers/containersEngineeringStructural engineering

The invention discloses a lithium battery negative electrode material drying device based on a microwave drying new technology. The lithium battery negative electrode material drying device comprisesa housing, wherein a workbench is fixedly mounted on the upper end face of the housing, and a plurality of reinforcing bases are transversely and fixedly mounted on the lower end face of the housing at equal intervals; one end of the workbench is connected with a second supporting frame; a material barrel is arranged at the position, positioned on one side, of the upper end face of the second supporting frame; a feeding pump is arranged on the second supporting frame; and eight microwave drying boxes are arranged in the middle of the upper end face of the workbench. According to the lithium battery negative electrode material drying device based on the microwave drying new technology, the drying speed is high, and environmental protection and energy saving are achieved; a carrier roller type conveying belt is adopted, and safe and stable operation of carrier roller accessories is guaranteed through buffer rubber blocks; a detachable material collecting plate is adopted, so that disassembly and assembly are convenient, and cleaning is easy; and trapezoidal side plates and sliding plates are adopted, so that discharging is convenient, and a better application prospect is brought.

Owner:柳州四通材料科技有限公司

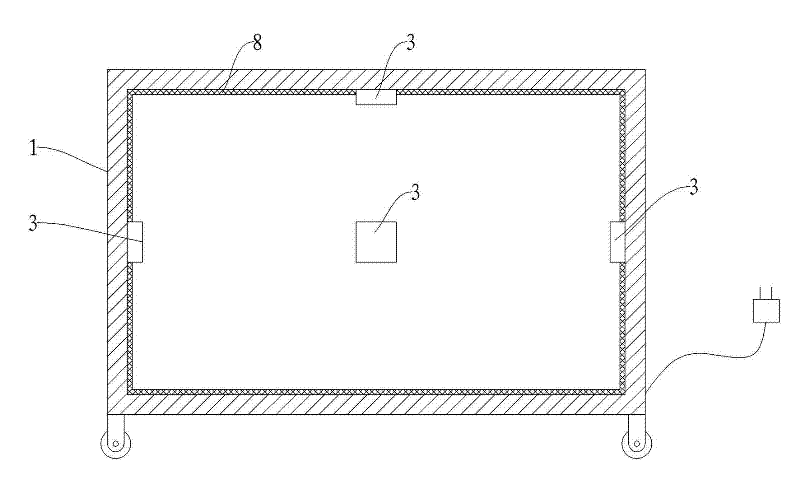

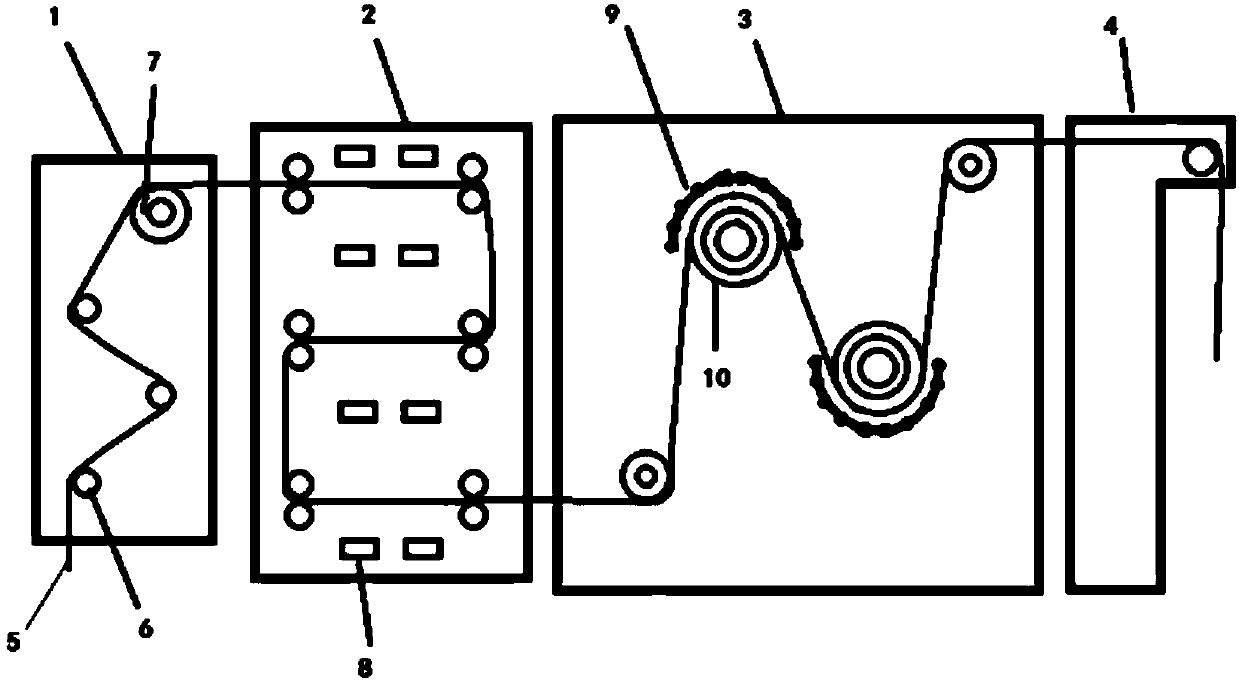

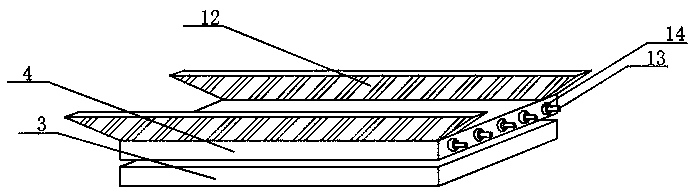

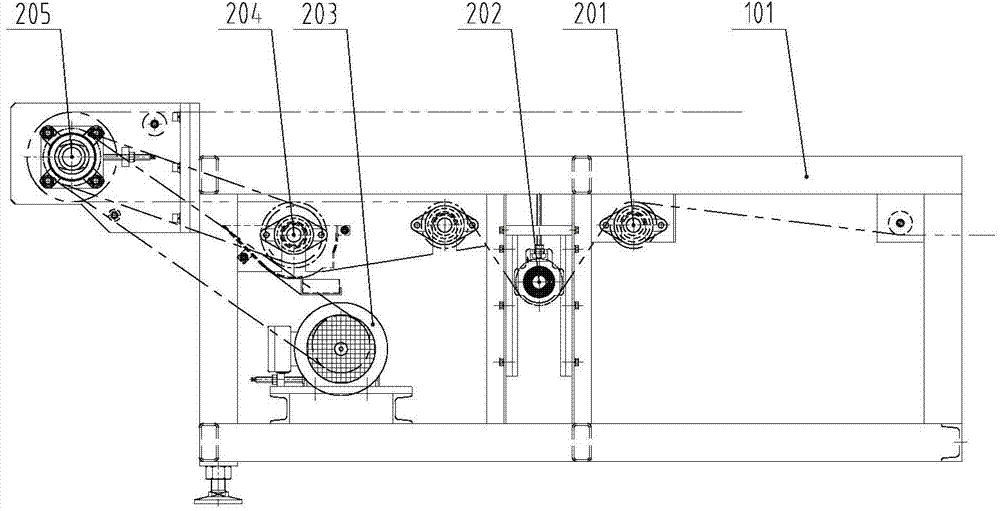

Ultrathin piece material microwave drying device

InactiveCN104748528AUniform heating temperatureNo harmDrying solid materials with heatDrying machines with progressive movementsProduction lineMicrowave

The invention discloses a ultrathin piece material microwave drying device. The ultrathin piece material microwave drying device comprises a frame, wherein a microwave inhibitor and a heating device are mounted on the frame; the microwave inhibitor is connected with the heating device; a wave guider is mounted on the heating device; and a microwave magnetron is mounted on the wave guider. The frame comprises a back frame, a middle frame and a front frame connected in sequence, wherein microwave inhibitors are respectively mounted on the back frame and the front frame; a heating device is mounted on the middle frame; and the microwave inhibitors are connected to the two ends of the heating device. The ultrathin piece material microwave drying device can be specifically applied to a rolling method slice production line to dry rolled wet slices as dry slices with stated water content, and can be applied to high-speed drying places of other ultrathin piece materials.

Owner:YICHANG BAOXING TECH IND DEVCO LTD

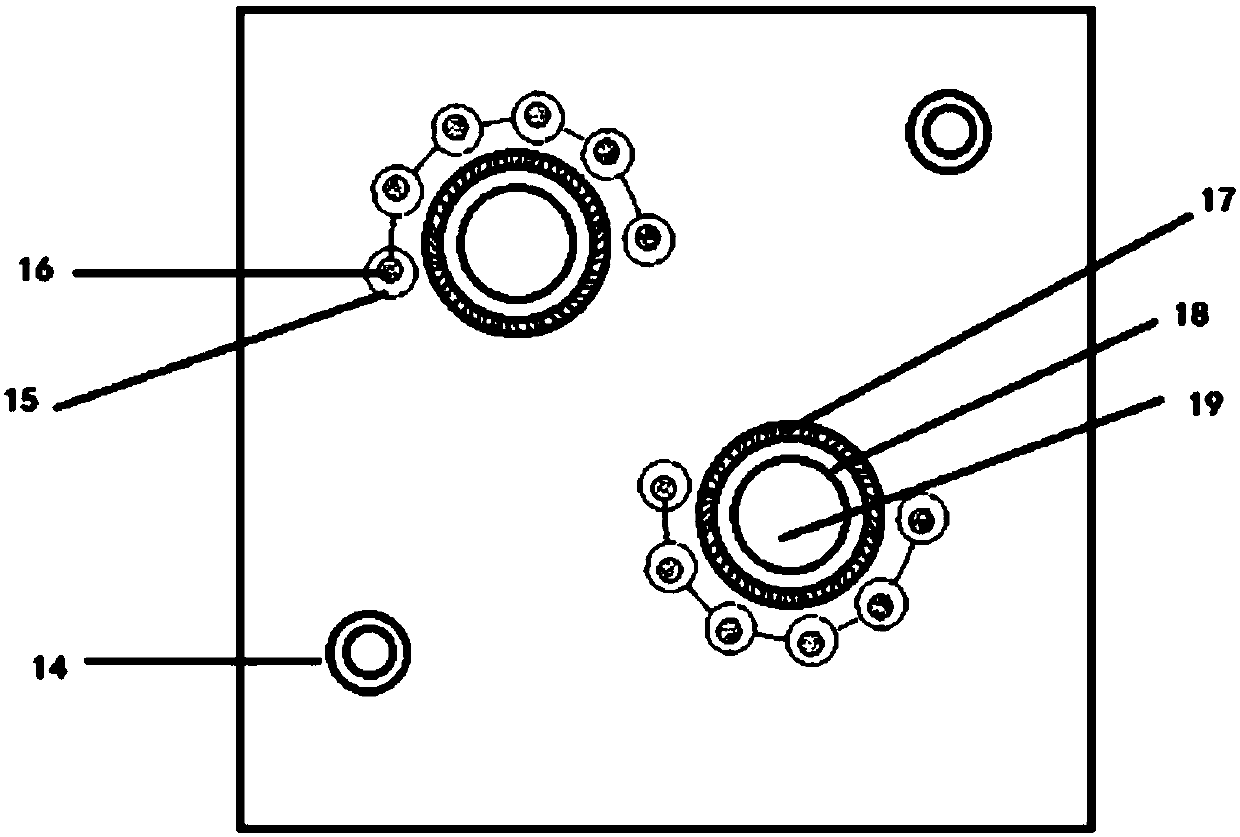

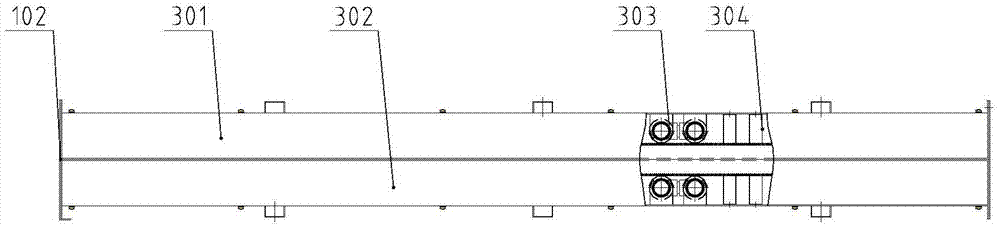

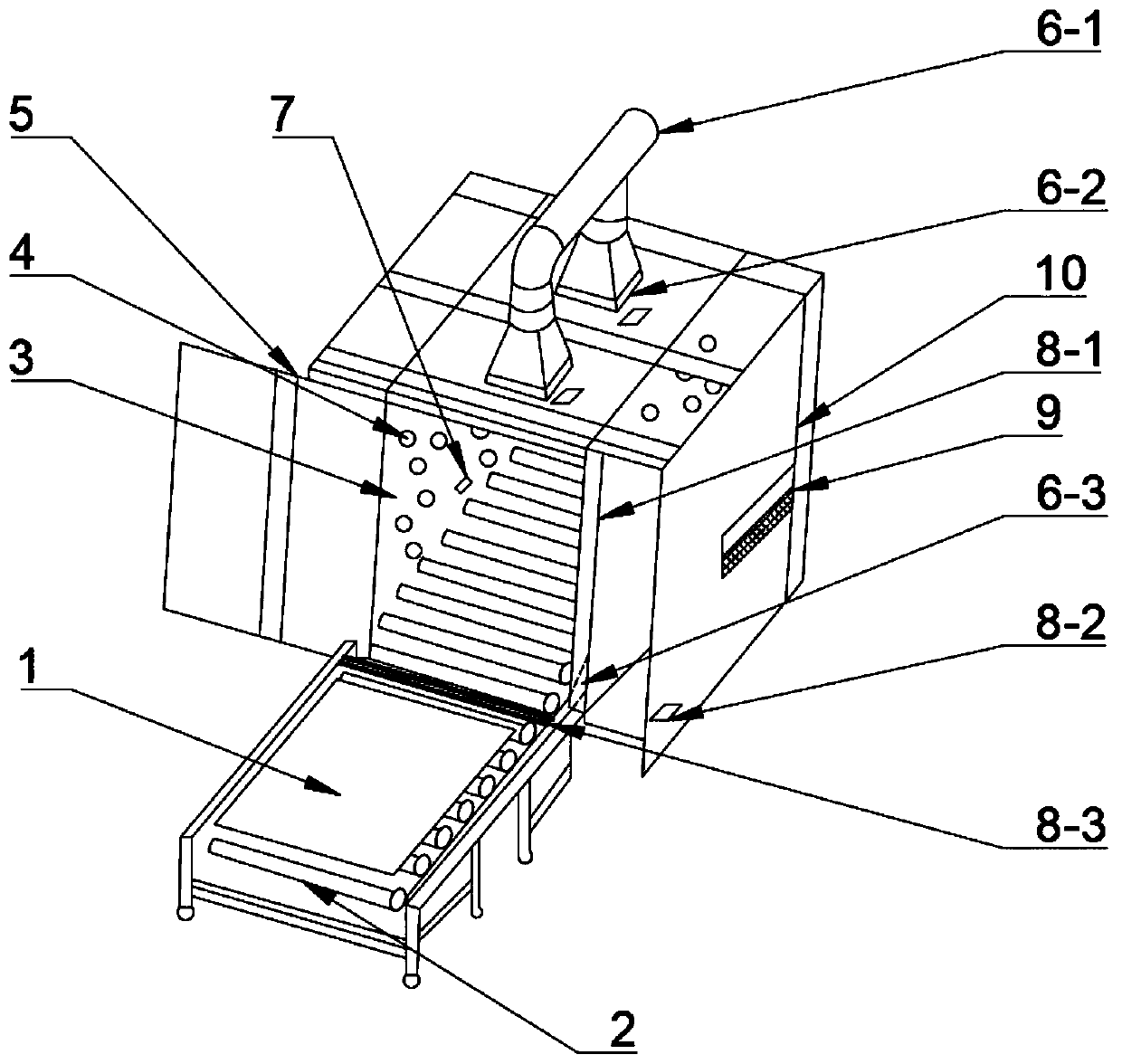

Microwave dryer for vegetable and fruit crops

PendingCN110973664AHeating evenlyNo thermal inertiaFood treatmentAgricultural cropsAgricultural engineering

The invention discloses a microwave dryer for vegetable and fruit crops. The microwave dryer comprises a tray, a roller way, a cavity, magnetrons, a door body, a moisture removal system, a temperatureand humidity sensor, a shielding protection layer, an operation panel and a control cabinet, the tray is arranged on the roller way; a plurality of antiskid patterns are arranged at the lower end ofthe tray; the cavity is formed in the bottom in a fruit and vegetable microwave dryer; a door body is arranged on one side of the cavity; pulleys and sliding rails are arranged below the door body, aplurality of magnetrons are arranged on the inner walls of the two sides of the cavity, the magnetrons are distributed in a rectangular array mode, one ends of the magnetrons are electrically connected with a control cabinet through a concentrator, the moisture removal system comprises an exhaust channel, a fan and a water guide groove, and the exhaust channel is provided with two channels and arranged at the top end of the cavity. The fruits and vegetables are uniformly heated under the direct action of the fruit and vegetable microwave dryer, heat conduction is not needed, sanitation and high efficiency are achieved, the puffing effect is better than that of a conventional wind-heat drying process, and meanwhile the sterilization effect is achieved under the dual action of the heat effect and the non-heat effect of microwaves.

Owner:江苏全链通信息科技有限公司

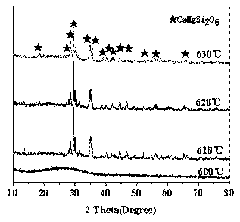

Preparation method of nano-crystal glass ceramic

The invention relates to a preparation method of nano-crystal glass ceramic. The preparation method comprises the steps of delivering a formed glass product into a microwave oven for microwave heat treatment to realize crystal nucleus formation and growth processes; finally, cooling to the room temperature. The heat treatment temperature in the crystal nucleus formation process is 610-630 DEG C; the heat treatment temperature of the crystal nucleus growth process is 640-780 DEG C. The crystal nucleus formation and growth are controlled precisely by means of microwaves, so that the nano-crystal glass ceramic with a nano-scale crystal grain size and a uniform structure can be relatively easily obtained. Due to the adoption of microwave heating, the whole material can be simultaneously heated, the heating speed is high, no thermal inertia is generated, and the temperature and time in the crystal nucleus formation and growth processes can be precisely controlled; the preparation method is simple in process, capable of effectively reducing the cost, free of pollution, capable of saving energy and environmentally friendly; in addition, the main technical indexes of the obtained nano-crystal glass ceramic product are relatively good.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Rhubarb anthraquinones component extracting and separating method

ActiveCN102188501BNo thermal inertiaEasy to controlAntibacterial agentsOrganic active ingredientsActivated carbonMicrowave

The invention relates to a rhubarb anthraquinones component extracting and separating method which is characterized by comprising the following steps of putting raw materials containing rhubarb anthraquinone into a microwave extracting device, and adding a basic solvent, extracting microwaves; collecting and filtering an extracting solution, adjusting the pH value of the extracting solution to bein acidity, sampling through a macroporous adsorbent resin column, and decompressing, recovering and concentrating ethanol; adding a concentrated solution to a chromatographic column filled with activated carbon, eluting the chromatographic column with water; and collecting an eluent, concentrating the eluent with a reverse osmosis membrane and drying the eluent to obtain the rhubarb anthraquinones component. By adopting the method, the production cost can be reduced, and the product quality can be enhanced. The method is convenient for industrialization operation.

Owner:南通东湖国际商务服务有限公司

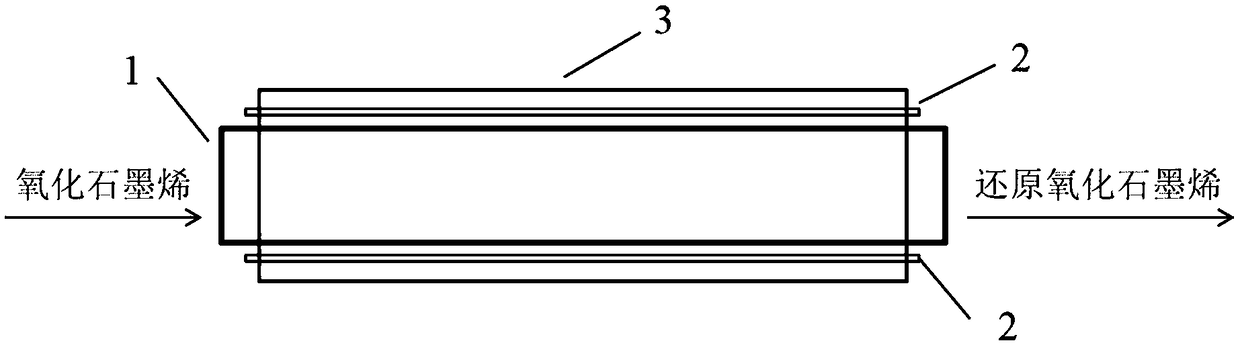

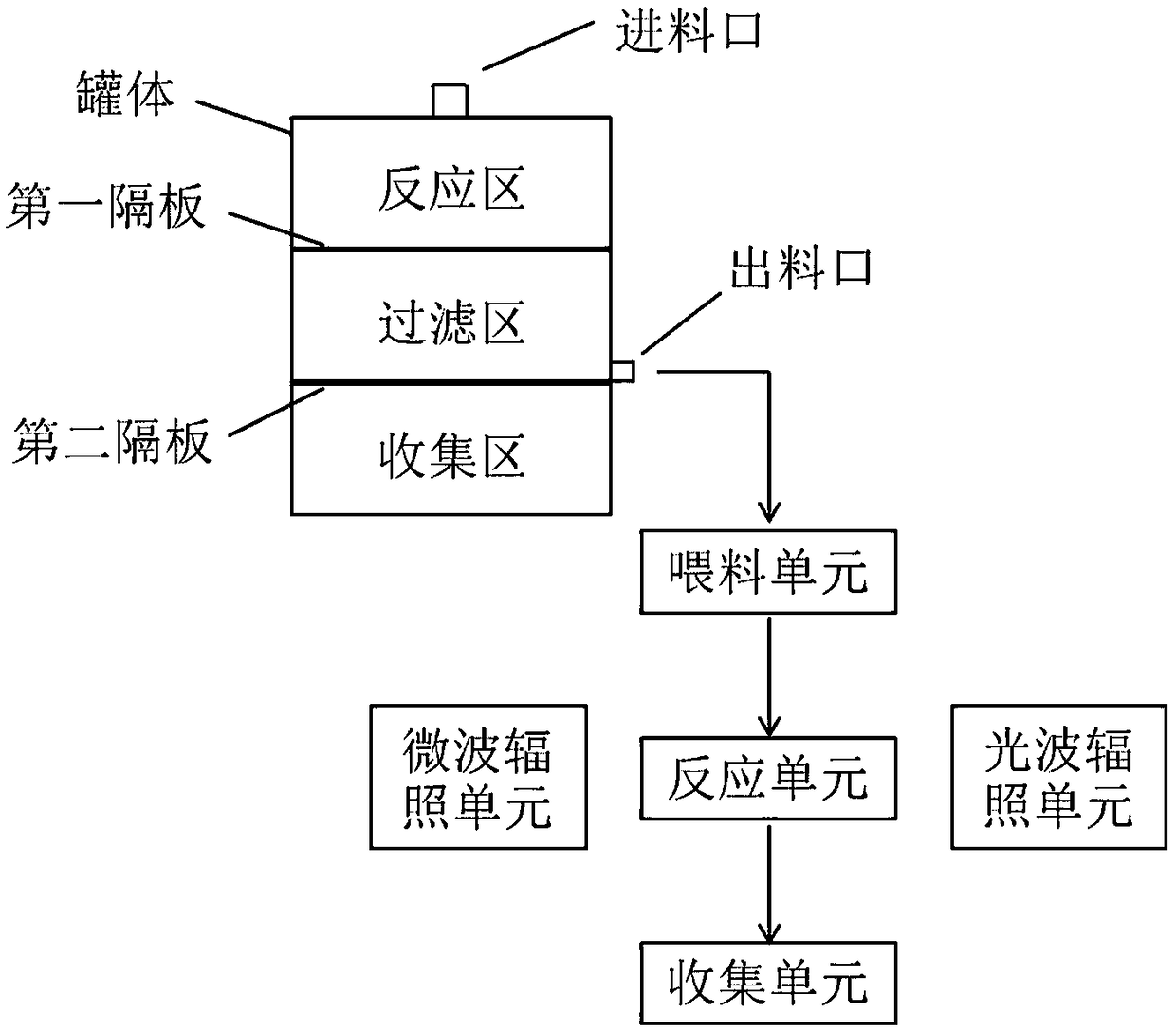

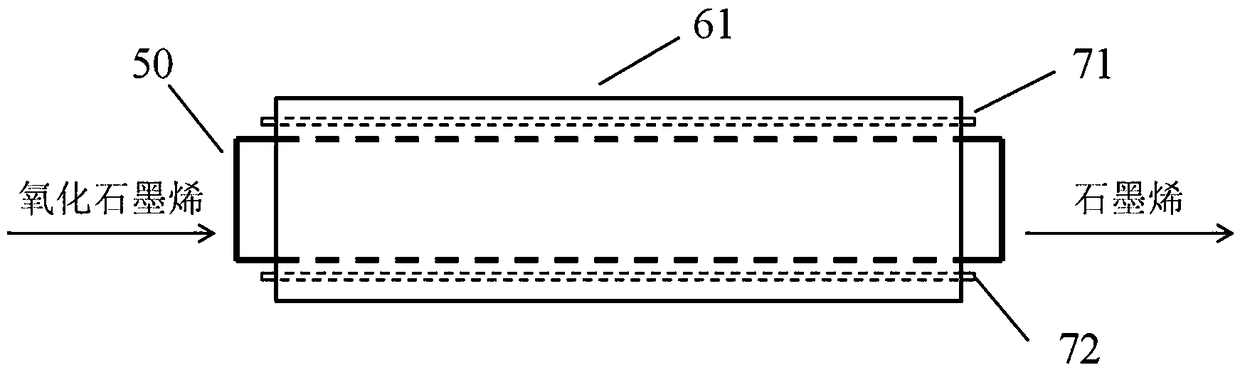

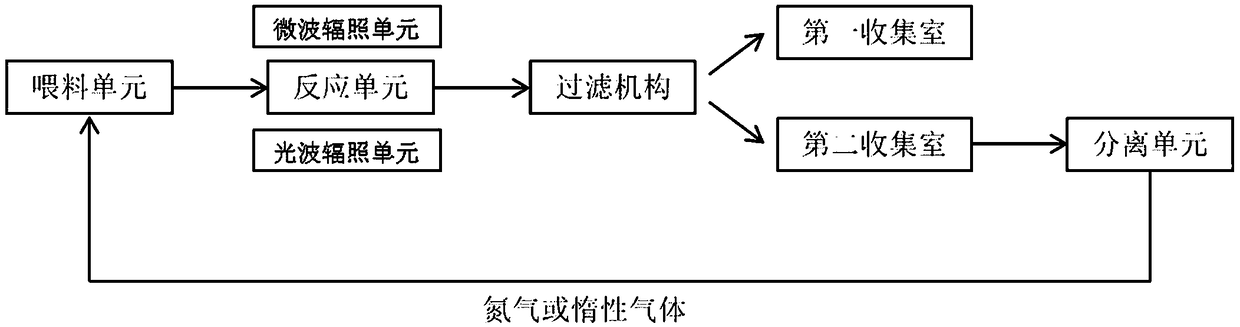

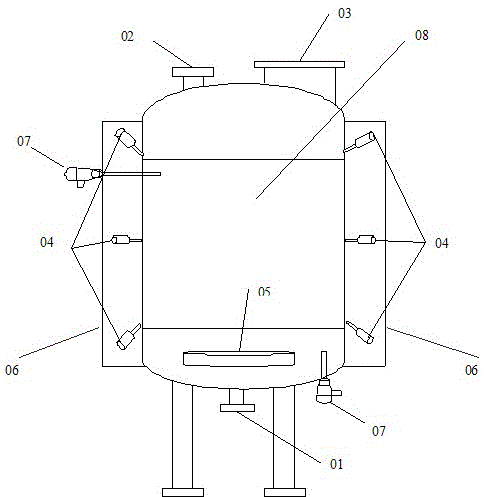

System for preparing graphene with purification and optical microwave reduction

The invention provides a system for preparing graphene with purification and optical microwave reduction. The system can comprise a purification device and an optical microwave reduction device whichare sequentially connected, wherein the purification device comprises a feeding hole, a tank body, a first partition plate, a second partition plate, an ultrasonic unit and a discharge hole; the firstpartition plate and the second partition plate are transversely arranged in the tank body and divide the tank body into a reaction region, a filtering region and a collection region; the feeding hole, the discharge hole and a liquid drainage hole are connected with the three regions respectively; the optical microwave reduction device comprises a feeding unit, a reaction unit, a collection unit,a microwave irradiation unit and an optical wave irradiation unit; and the microwave irradiation unit and the optical wave irradiation unit are arranged around the reaction unit. The system provided by the invention has the beneficial effects that the purification device can effectively separate graphene oxide from impurity ions and is high in purification efficiency and low in cost; the optical microwave reduction device is rapid in heating speed without thermal inertia, is energy-saving and efficient and is high in reduction efficiency; and the equipment is long in service life, simple in structure and convenient to use.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

Extraction method for flos lonicerae active materials

The invention relates to an extraction method for flos lonicerae active materials. The extraction method comprises the following steps: drying and crushing steams and leaves of flos lonicerae to prepare flos lonicerae particles; soaking the obtained flos lonicerae particles into an extraction solvent, and then carrying out microwave countercurrent extraction; collecting an extraction solution, heating and filtering the extraction solution by a ceramic membrane an then collecting filtrate A and retentate A; and filtering the obtained filtrate A with an ultra-filtration membrane, collecting filtrate B and concentrating, extracting and crystallizing the filtrate B to prepare flos lonicerae organic acid, flavonoid and saponin. The method is simple in process and convenient to operate; the extraction rate of the organic acid, the flavonoid and the saponin reaches 68.5%; and the purity reaches 83%.

Owner:GUIZHOU INST OF BIOLOGY

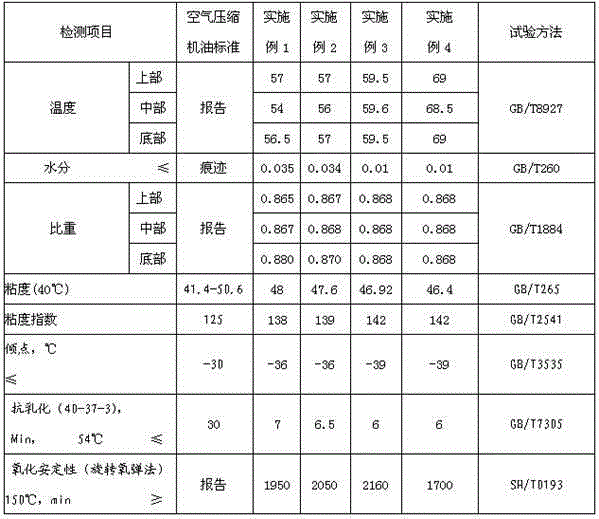

Novel boundary lubrication protective agent production device and production method of protective agent

InactiveCN105056860AImprove absorption rateIncrease temperatureEnergy based chemical/physical/physico-chemical processesLubricant compositionPulse pressureEngineering

The invention discloses a novel boundary lubrication protective agent production device and a production method of a protective agent. A microwave generator heating technique is applied in a blending kettle of the novel boundary lubrication protective agent production device; a controller controls microwave power, microwave radiation time, pulse pressure, pulse frequency and impact blending time; a PLC (programmable logic controller) panel controls the opening degree and the frequency of an electromagnetic valve to control the air pressure and the flow of a high-pressure air distribution plate at the bottom of the reaction blending kettle, so that the volume and the pressure of impact bubbles are controlled in order to achieve the purpose of blending various materials and additives by impact, and thus base oil and the additives can be sufficiently and uniformly blended. Consequently, the problem that a conventional heating method is deficient can be solved, and thereby the novel boundary lubrication protective agent production device has the characteristics of high heating speed, uniform heating, energy saving, high efficiency, easiness in control, sanitation, safety, harmlessness and the like.

Owner:LUOHE BEIJIA BILL SCI & TECH CHEM

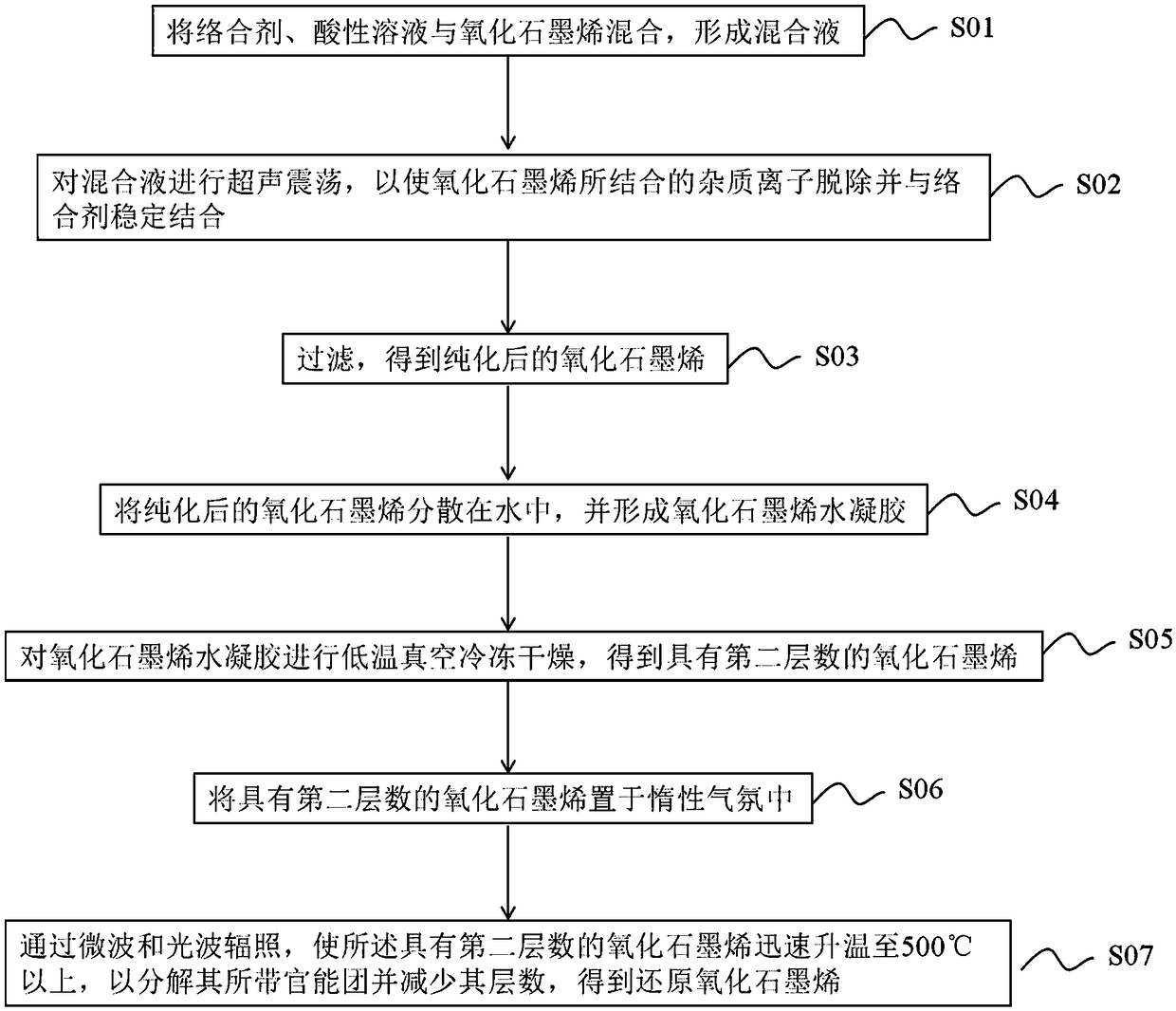

Method for producing reduced graphene oxide

The invention provides a method for producing reduced graphene oxide. The method comprises the following steps: mixing graphene oxide, a complexing agent and an acidic solution to obtain a mixed solution, wherein the graphene oxide has impurity ions combined on functional groups and has a first layer number; carrying out ultrasonic concussion to remove the impurity ions and combining the impurityions with the complexing agent; carrying out filtration to obtain purified graphene oxide; dispersing the purified graphene oxide in water to form a hydrogel; placing the hydrogel at a first temperature and a first pressure to obtain graphene oxide with a second layer number, wherein the second layer number is smaller than the first layer number; placing the obtained graphene oxide in an inert atmosphere; rapidly heating the graphene oxide to 500 DEG C or above by microwave and light wave irradiation to obtain reduced graphene oxide. The method provided by the invention has the following beneficial effects: the thoroughness of purification of graphene oxide can be effectively improved; the freeze-dried graphene oxide has a large interlayer spacing between sheet layers and few layers; in aphoto-microwave reduction process, the heating speed is high, the heating is uniform, and the reduction efficiency is high.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

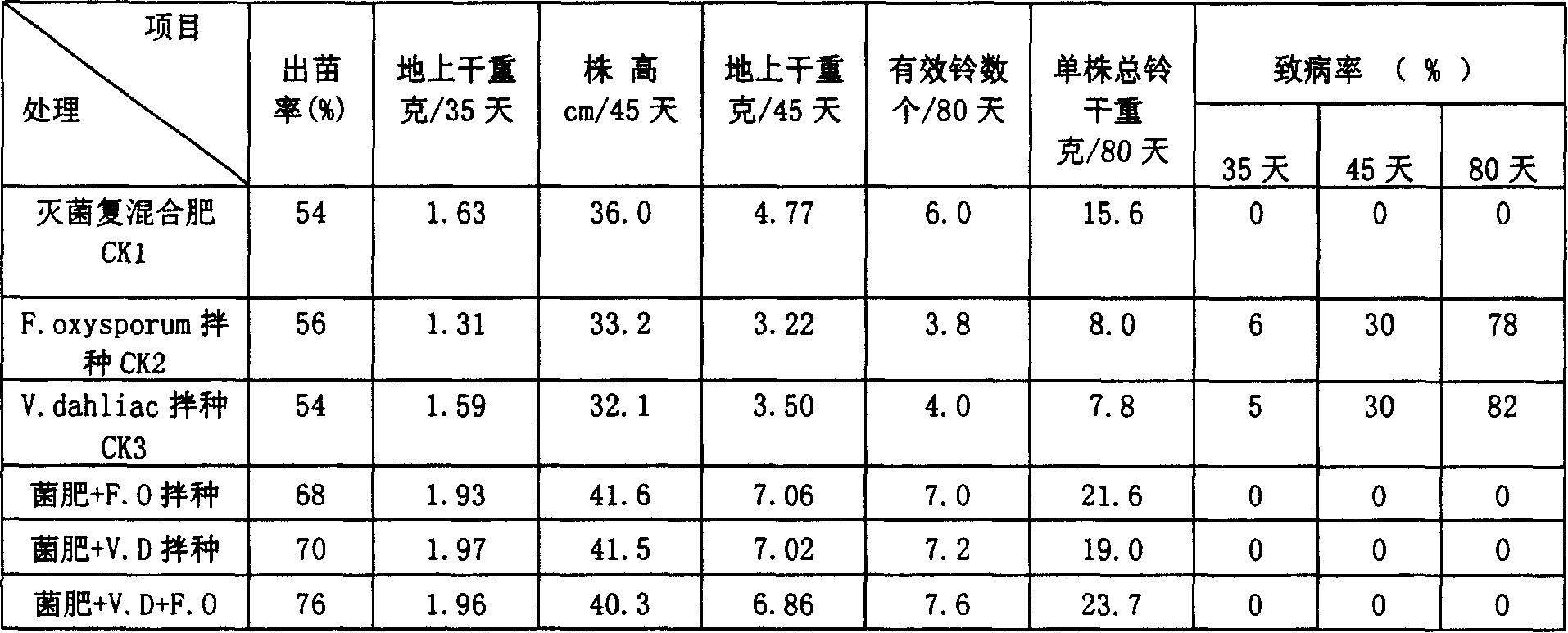

Sterilization technology for microbe fertilizer carrier and its application

InactiveCN1546436ANo heat lossImprove heating efficiencyImmobilised enzymesElectrical/wave energy microorganism treatmentDiseaseMicroorganism

The invention discloses a microbiological fertilizer carrying agent sterilization process by employing microwave technique and microwave equipment for germicidal treatment for microbiological fertilizer, which realizes stabilized number of effective bacteria, high vitality and assorted bacteria base number, and long storing period. The invention can be applied for effectively preventing diseases, hastening cotton seed germination and accelerating growth, thus increasing volume of cotton production.

Owner:SOIL & FERTILIZER INST CHINESE ACAD OF AGRI SCI

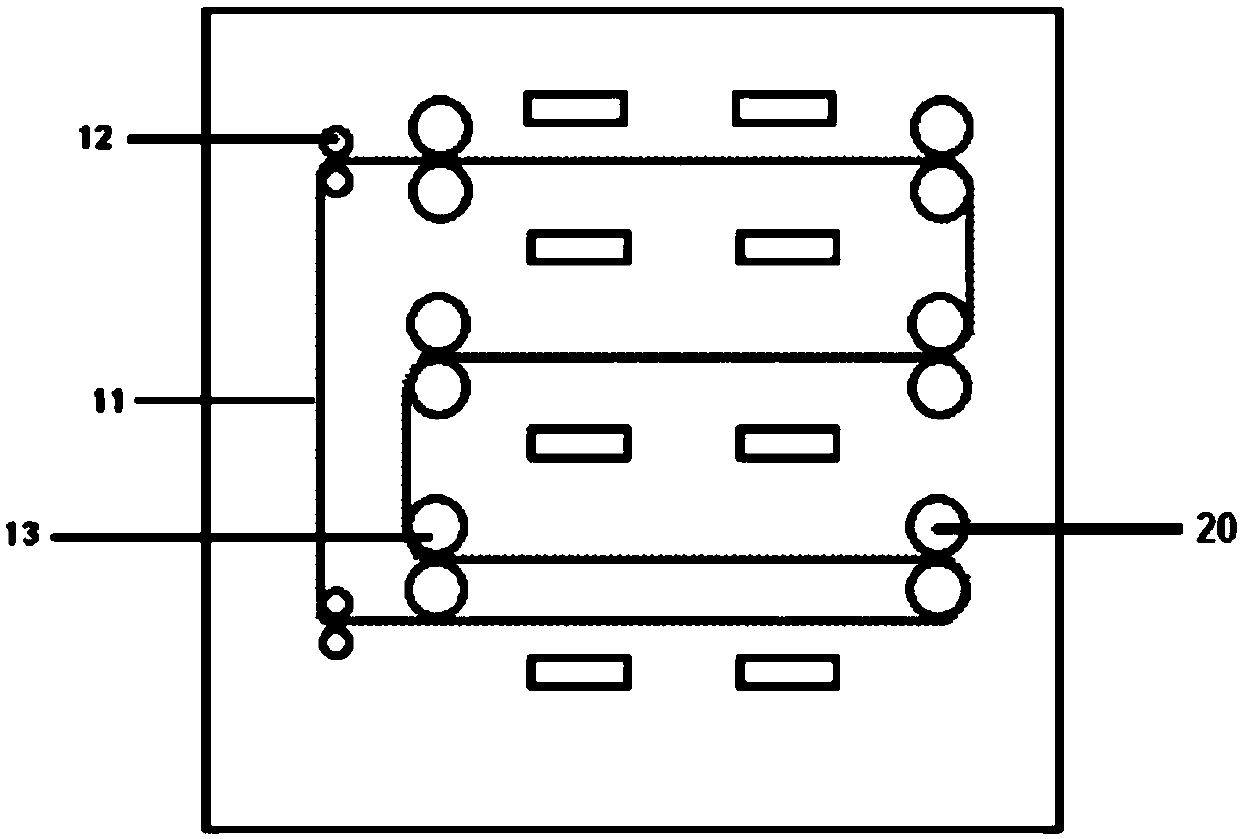

Novel walnut microwave drying machine

PendingCN110916218AHeating evenlyNo thermal inertiaSeed preservation by irradiation/electric treatmentSeed preservation by heatingEngineeringElectrical and Electronics engineering

The present invention discloses a novel walnut microwave drying machine. The novel walnut microwave drying machine comprises a tray, a roller way, a cavity, magnetrons, a door body, a moisture exhaustsystem, a temperature and humidity sensor, a shielding protective layer, an operation panel and a control cabinet, the tray is arranged on the roller way, besides, a plurality of anti-skidding patterns are arranged at a lower end of the tray, the cavity is arranged at a bottom part inside the walnut microwave drying machine, besides, the door body is arranged at one side of the cavity, pulleys and slide rails are arranged below the door body, besides, a plurality of the magnetrons are arranged on inner walls of both sides of the cavity, the magnetrons are distributed in a rectangular array, one end of each magnetron is electrically connected with the control cabinet through a concentrator, the moisture exhaust system comprises an exhaust channel, a fan and a water guide groove, and the exhaust channel is provided with two channels and arranged at a top end of the cavity. Walnuts are uniformly heated under a direct action of the walnut microwave drying machine, heat conduction is not needed, and the walnut microwave drying machine is sanitary and efficient, has a puffing effect better than that of a conventional wind-heat drying technology, and at the same time has a sterilizationeffect under double effects of a heat effect and a non-heat effect of microwaves.

Owner:徐州鼎禾农业科技有限公司

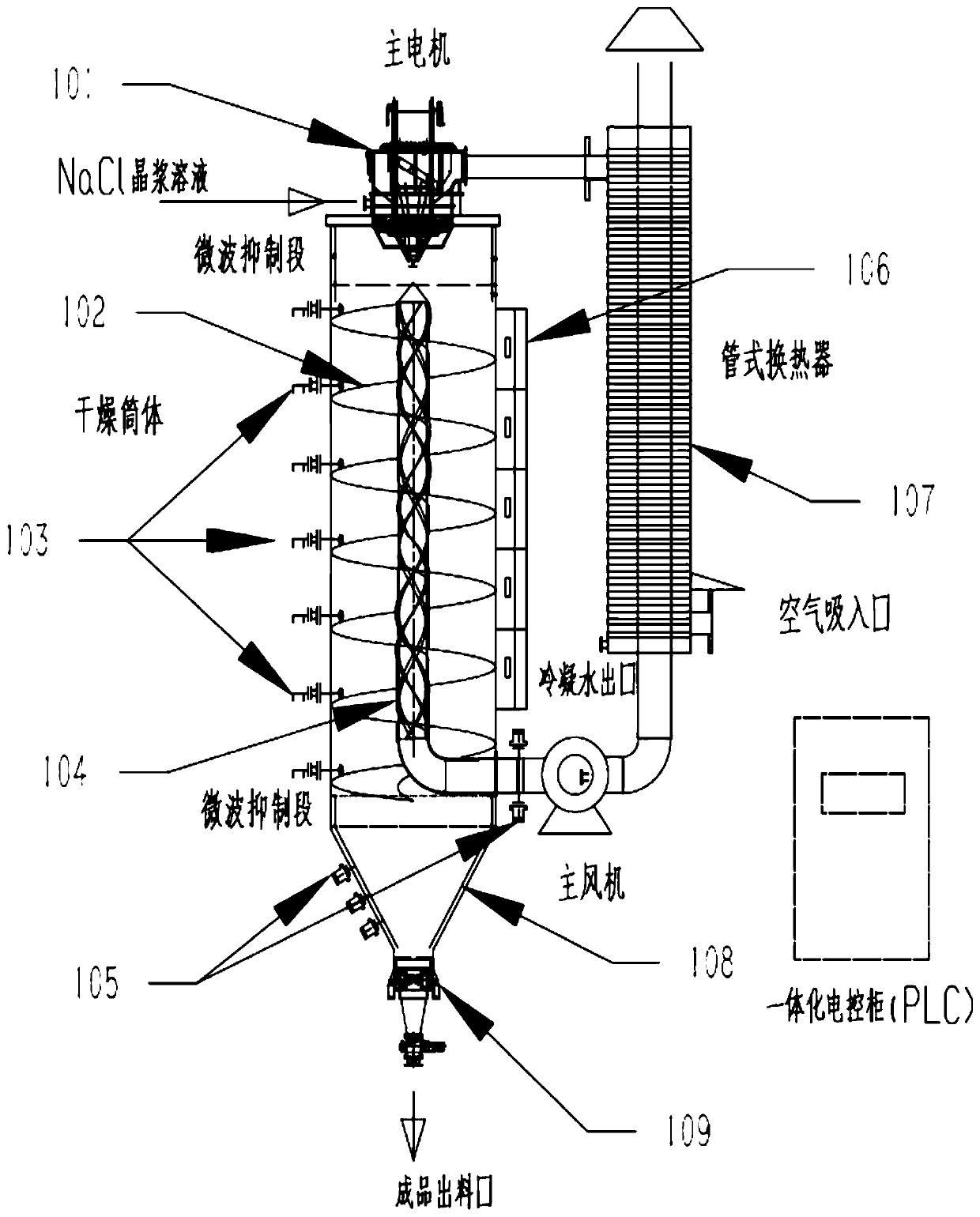

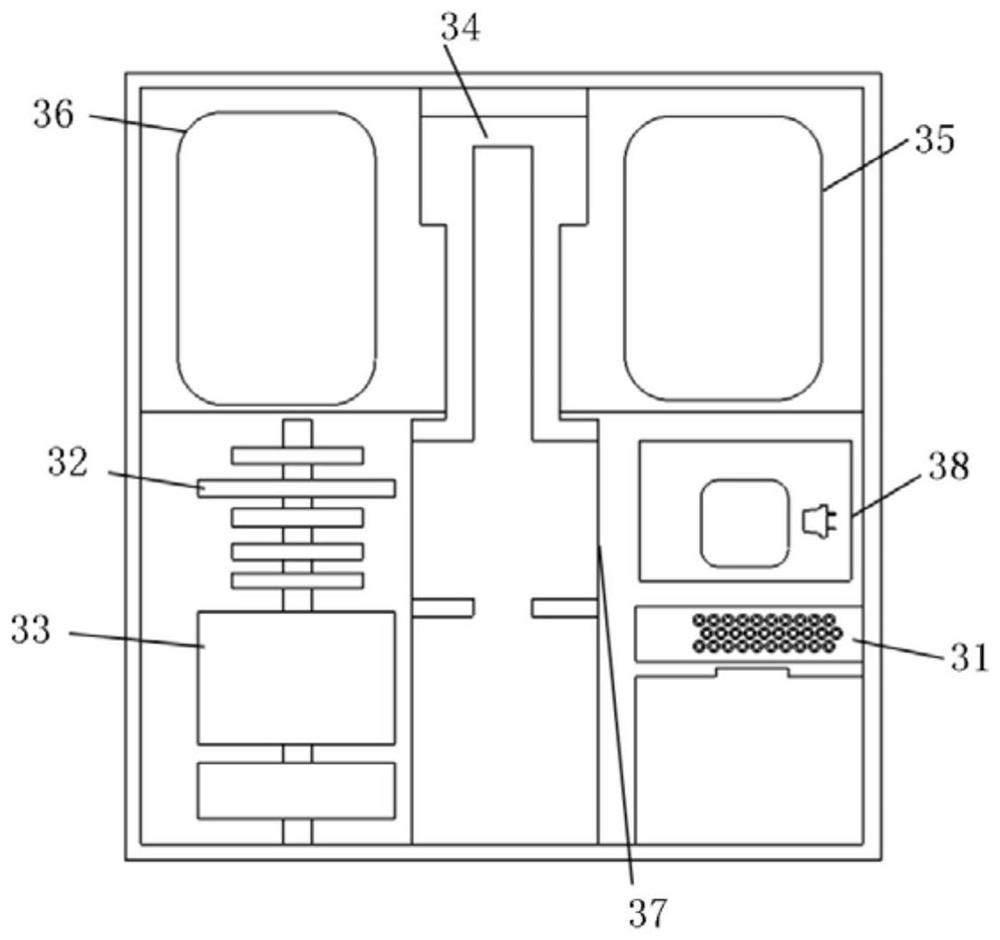

Microwave crystal oscillator drying device for zero emission of desulfurization wastewater

PendingCN110947349AThe overall structure is simple and reliableDry evenly and thoroughlyEnergy based chemical/physical/physico-chemical processesEvaporation by sprayingWastewaterSlurry

The invention relates to a microwave crystal oscillator drying device for zero emission of desulfurization wastewater. According to the microwave crystal oscillator drying device, a spray end of a rotary spray head faces downwards and extends into a drying cylinder, a liquid inlet end is communicated with a crystal slurry solution, an air inlet end is communicated with one end of a heat exchanger,and the other end of the heat exchanger is provided with an air suction inlet communicated with the heat exchanger; the drying cylinder is vertically arranged, a spiral guide groove is formed in theinner wall of the drying cylinder from top to bottom, and a finished product discharging port is formed in the bottom of the drying cylinder; a magnetron device for emitting microwaves to the center is arranged around the drying cylinder, a vertical nested vibrating screen pipe corresponding to the magnetron device is arranged in the center of the drying cylinder, the outer ring of the nested vibrating screen pipe is a microwave scattering surface with a breathable film clamped inside, the inner ring of the nested vibrating screen pipe is a crystal oscillator element, and an air interlayer isreserved between the outer ring and the inner ring; the nested vibrating screen pipe extends out of the drying cylinder and is connected with a fan, air is exhausted outwards through an air exhaust pipeline, the air exhaust pipeline penetrates through a heat exchanger, and air sucked in through an air suction inlet is heated through the heat exchanger.

Owner:SHANGHAI TIANXIAO ENVIRONMENTAL PROTECTION ENG CO LTD

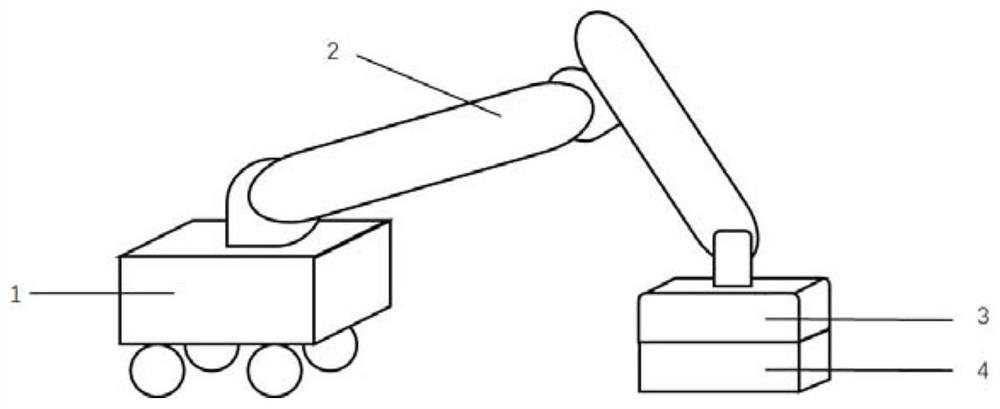

Moon-based landing platform and construction method thereof

The invention relates to a moon-based landing platform and a construction method thereof, in particular to a platform used when a spacecraft lands on the moon and a construction method of the platform, and belongs to the technical field of deep space exploration of the moon. According to the invention, the microwave sintering molding of the multi-component simulated lunar soil material with small particles, light weight and large specific surface area in the aerospace field is realized, the molding precision and density requirements of a spacecraft landing platform are met, a technical basis is provided for subsequent lunar base construction and lasting operation, and good economic benefits and social benefits are achieved.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com