Ultrathin piece material microwave drying device

A technology for microwave drying and flakes, which is applied in drying, dryer, drying of solid materials, etc., can solve the problems of high energy consumption, insufficient quality and safety of heating materials, environmental impact, etc., and achieves high thermal effect, Improve the working environment and labor intensity, no thermal inertia effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

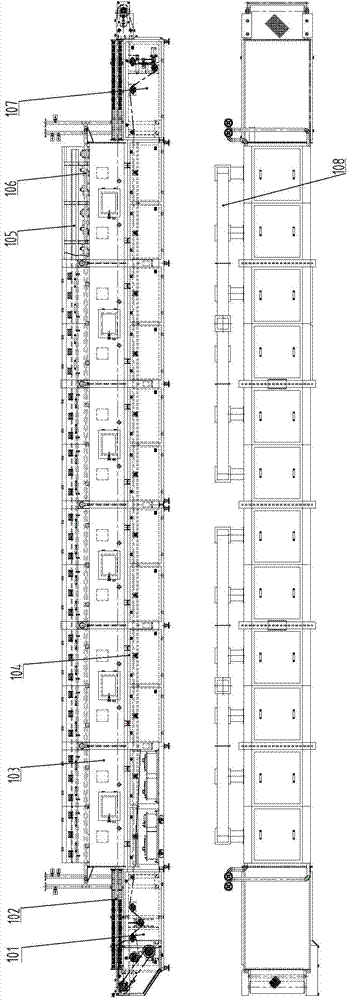

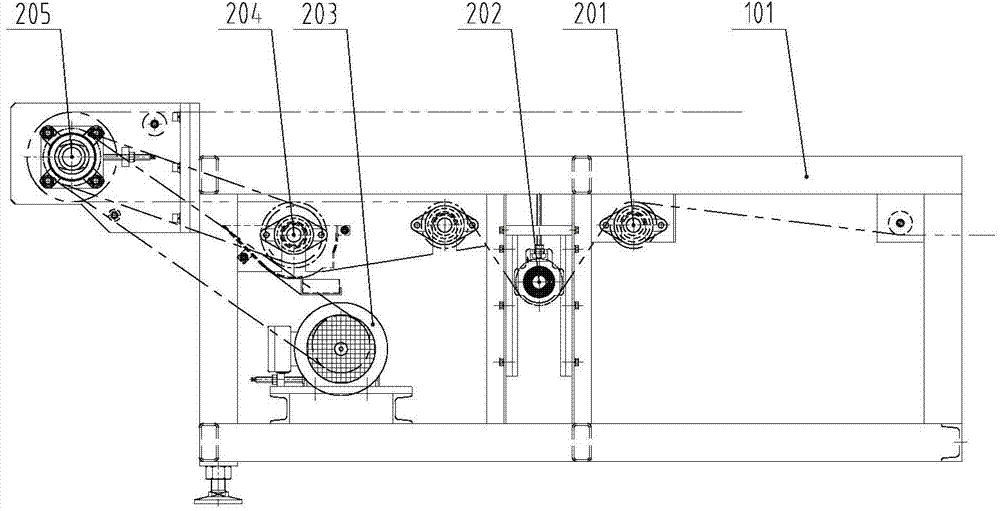

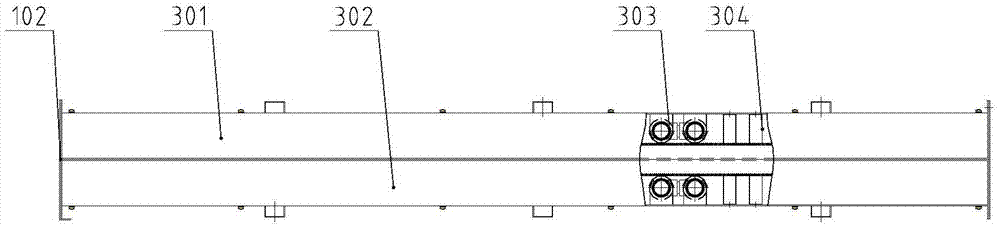

[0027] like Figure 1~Figure 8 As shown, a microwave drying device for extremely thin objects includes a frame 701 and a mesh belt. A microwave suppressor 102 and a heating device are installed on the frame 701. The microwave suppressor 102 is connected to the heating device, and the heating device is installed on the There is a waveguide 401 on which a microwave magnetron 402 is mounted.

[0028] The rack 701 includes a rear rack 101, a middle rack 104, and a front rack 107 connected in sequence. A microwave suppressor 102 is fixedly installed on each of the rear rack 101 and the front rack 107, and a microwave suppressor 102 is installed on the middle rack 104. A heating device is installed. The heating device is connected with six sections of heating boxes 103 by screws and fixedly installed on the middle frame 104 . A plurality of waveguides 401 arranged orthogonally are arranged on any section of the heating box 103 . Two microwave suppressors 102 are connected to both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com