Multilayered baking oven system

A technology of oven and lifting system, which is applied in the direction of drying, drying machine, progressive drying machine, etc. It can solve the problems of affecting the speed of the assembly line, low efficiency, slow speed, etc., and achieve labor saving, good baking effect and feeding efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

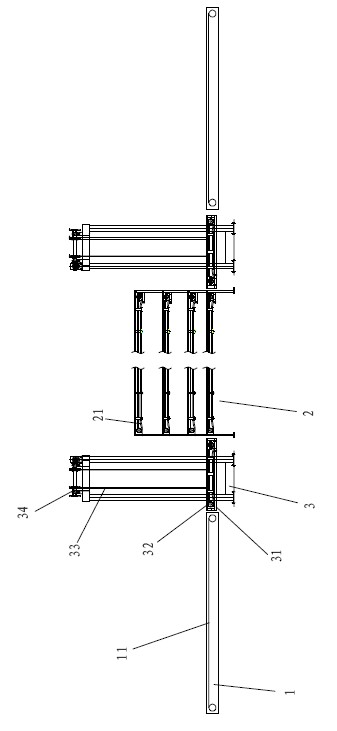

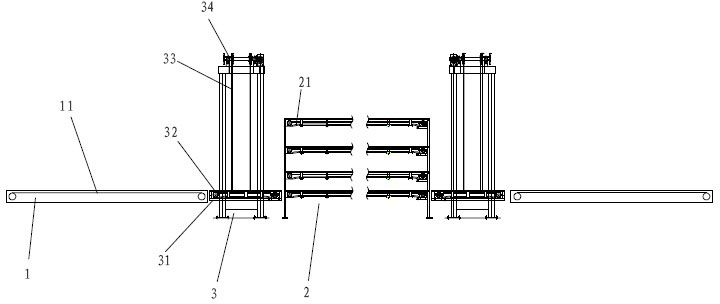

[0026] A multi-layer oven 2 system such as figure 1 As shown, it includes a conveying part 1 and an oven 2 communicating with the conveying part 1. There are three layers inside the oven 2 from top to bottom; the conveying part 1 and the oven 2 are connected by a lifting system 3, and the conveying part 1 Conveyor chain 11 is formed, and outer conveyer chain 11 is accumulation chain; In oven 2, each layer is all provided with inner conveyer chain 21, and this inner conveyer chain 21 is connected with outer conveyer chain 11 through lifting system 3, and lifting system 3 It includes a lifting controller and a lifting platform. The lifting platform 31 is provided with a transition mechanism 32 connecting the oven 2 and the conveying part 1. The lifting platform 31 is connected with a lifting chain 33 that drives the lifting platform 31. The lifting chain 33 is provided with a drive to drive the lifting. The drive motor 34 that the chain 33 runs and is connected with the controll...

Embodiment 2

[0029] The difference from Embodiment 1 is that there are five layers inside the oven 2 .

[0030] When working, the oven 2 needs to bake five different types of workpieces at the same time, then turn on the natural gas furnace, and the natural gas furnace sends high-temperature air into the oven 2 through the air outlet. When the workpiece is transported from the conveying part 1 to the lifting system 3, the transition mechanism 32 takes the workpiece from the outer conveyor chain 11 to the lifting platform 31, and at the same time the controller reads the model of the workpiece to determine which floor it should be sent to, and then controls the lifting platform 31 to lift to this floor, and the transition mechanism 32 will lift the workpiece on the lifting platform 31. The workpiece is delivered to the inner conveyor chain 21 in the oven 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com