Patents

Literature

362results about How to "Uniform heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

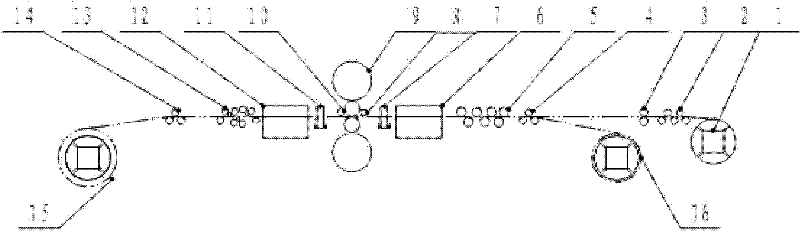

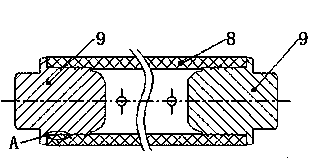

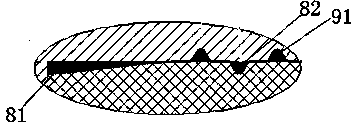

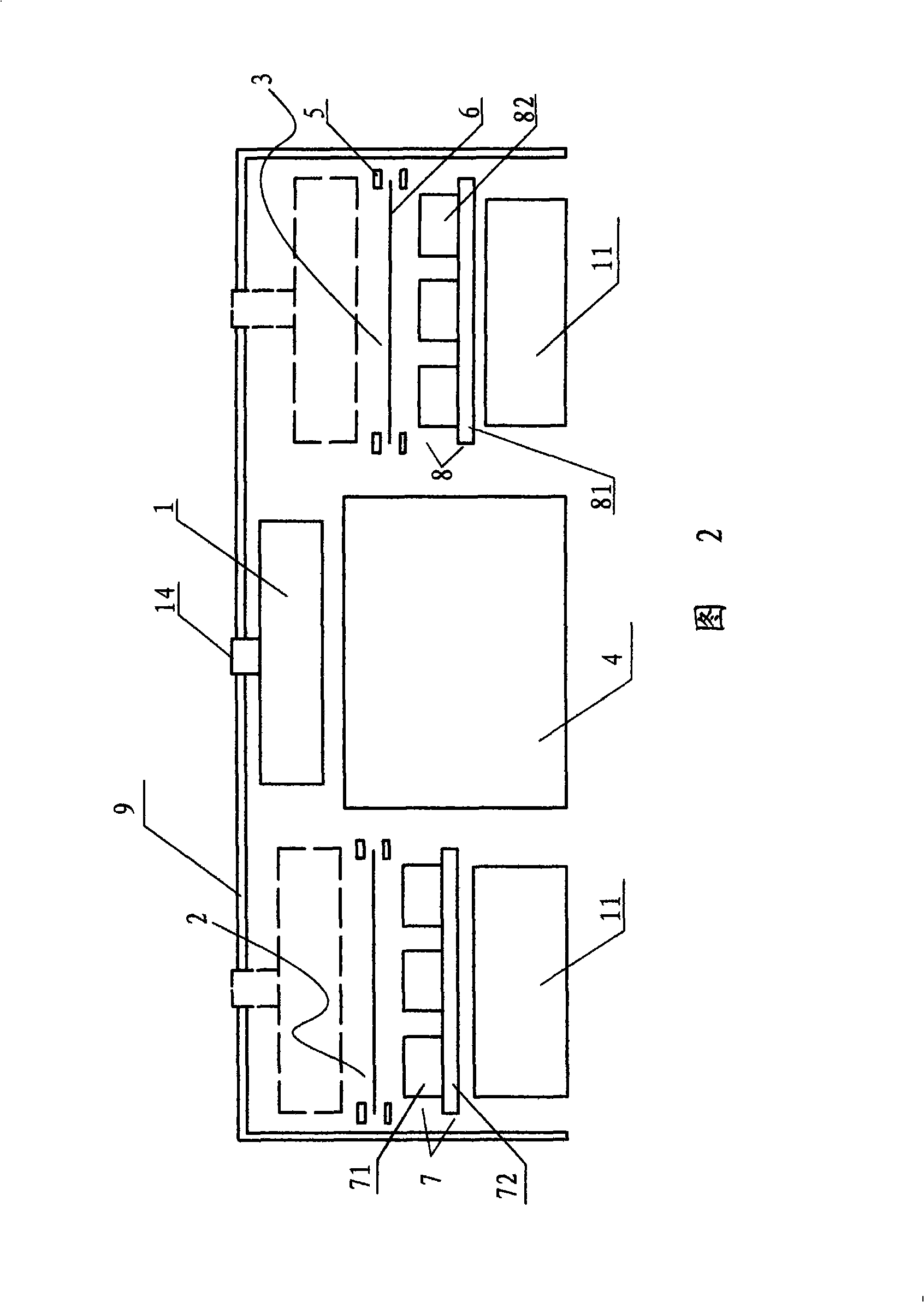

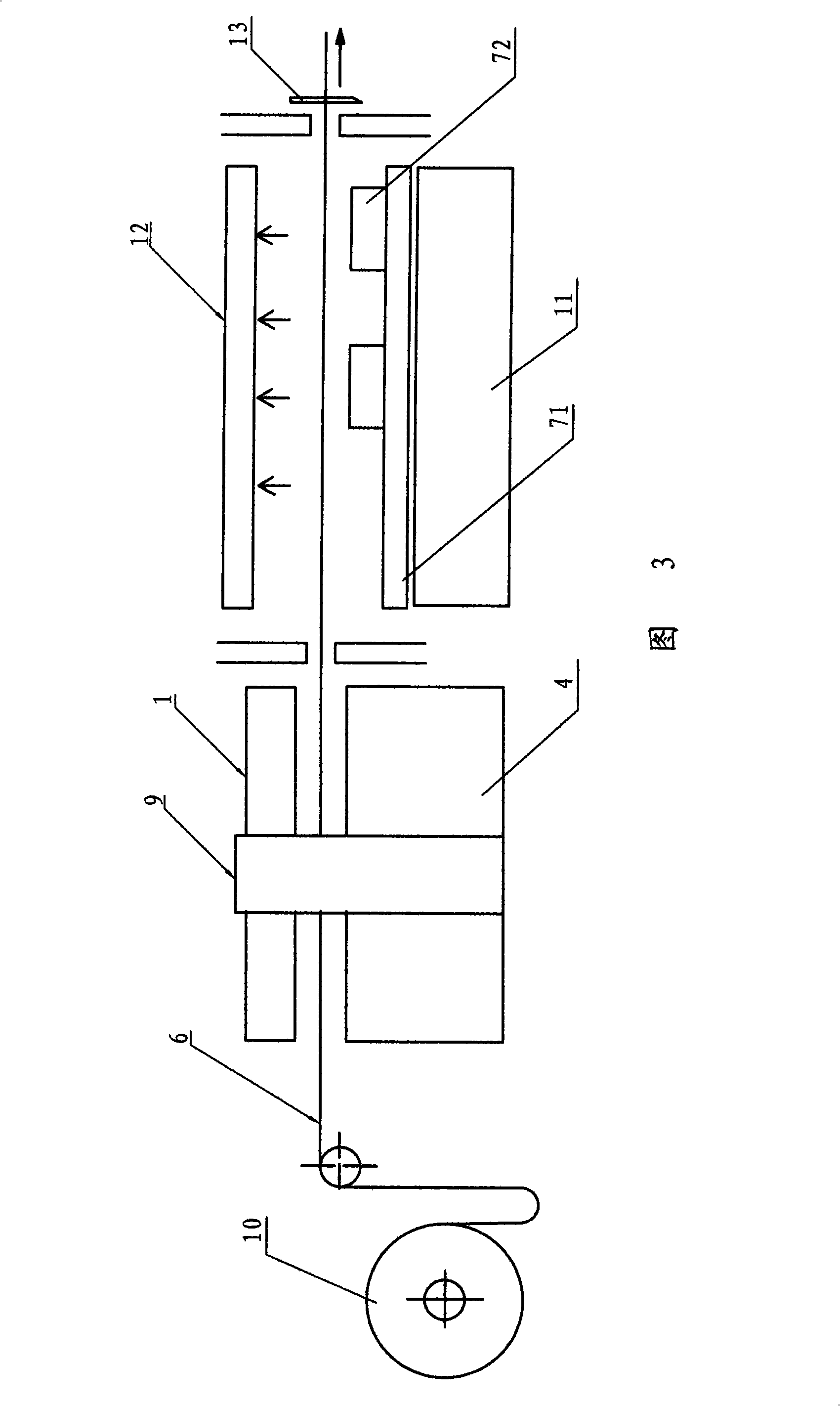

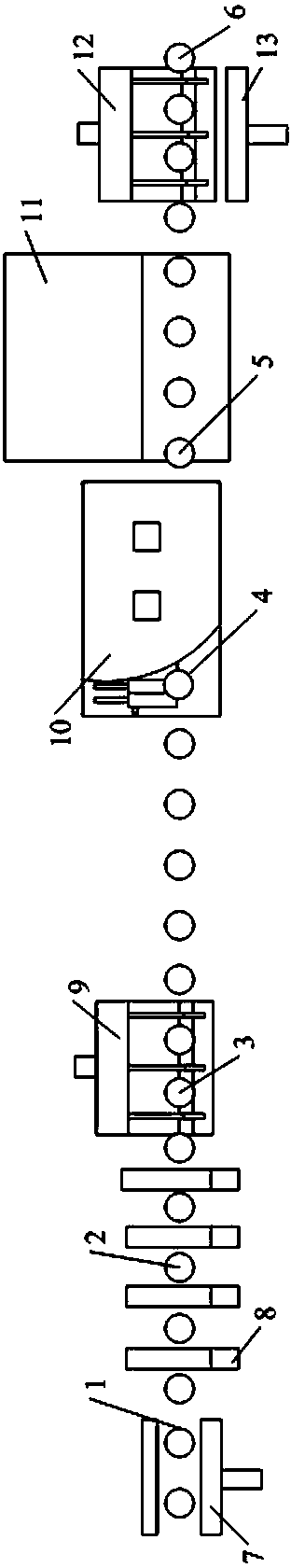

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

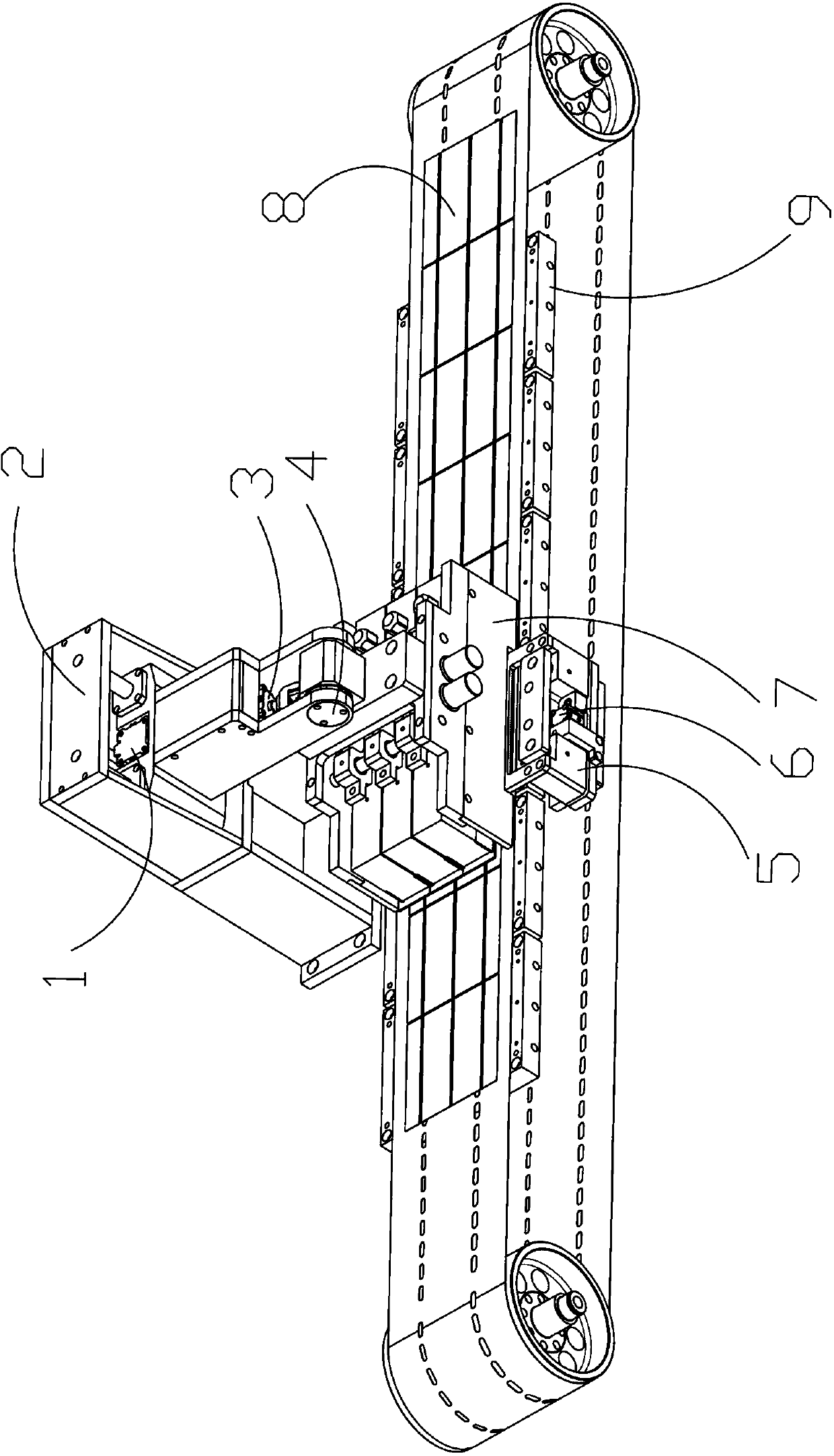

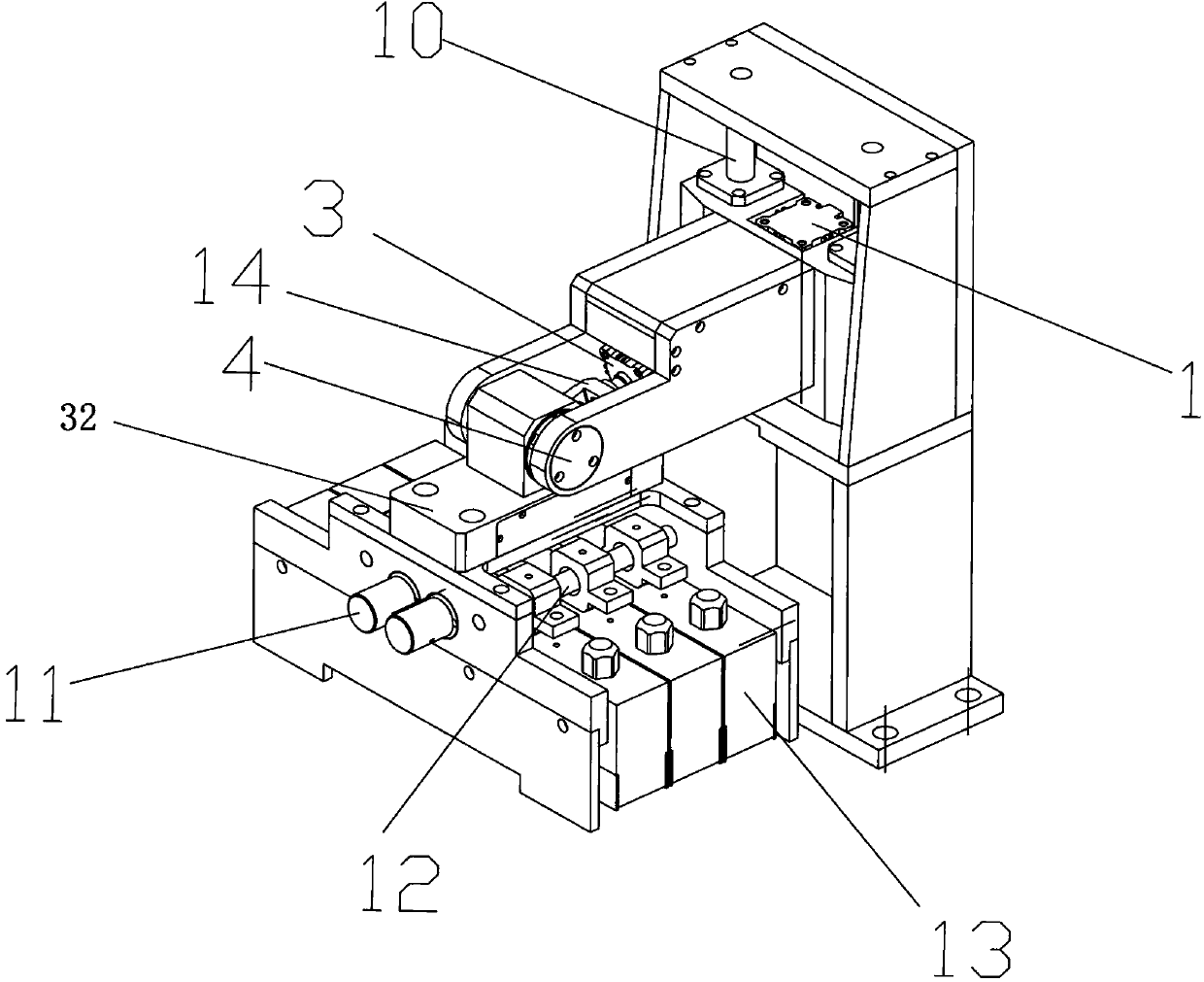

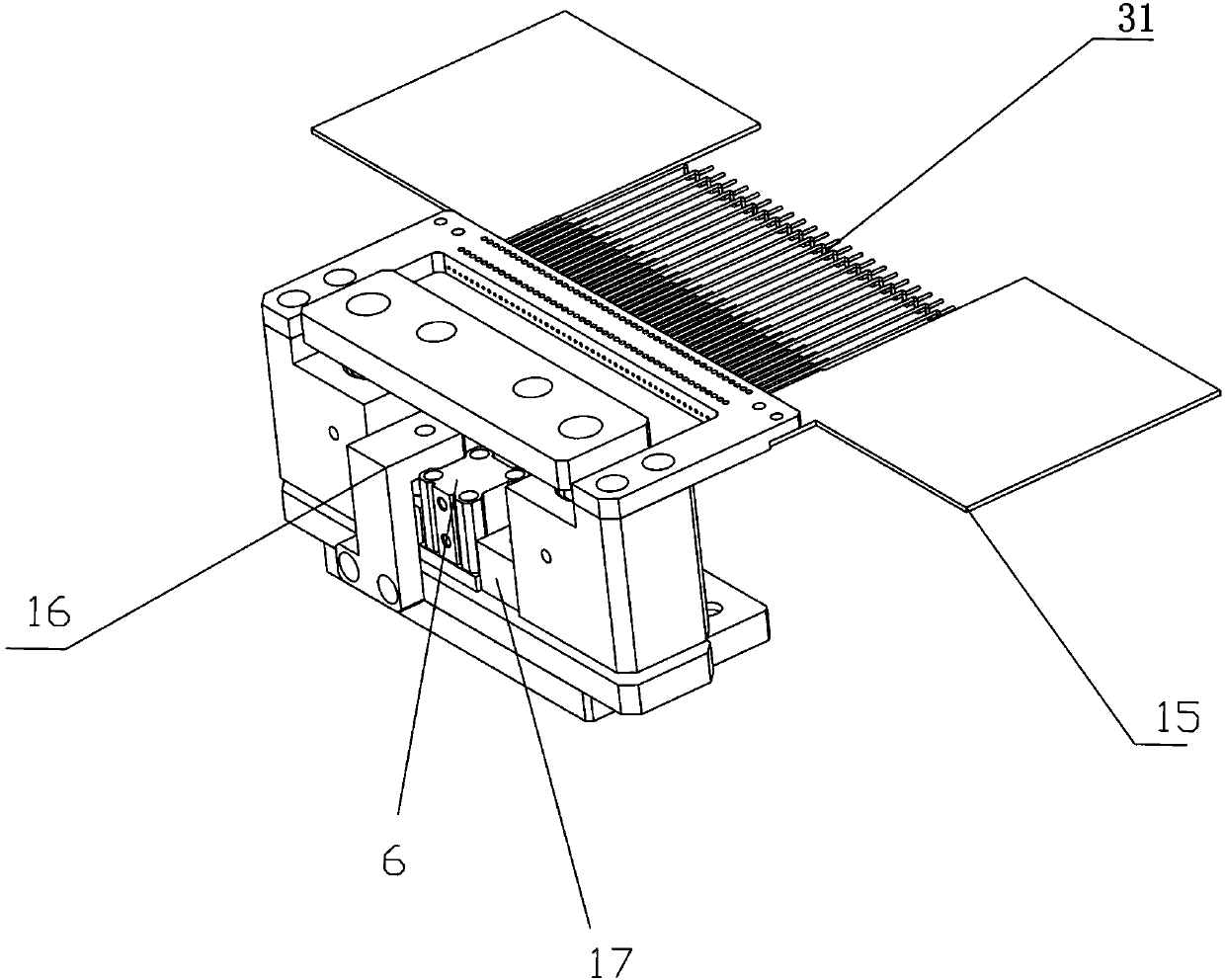

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

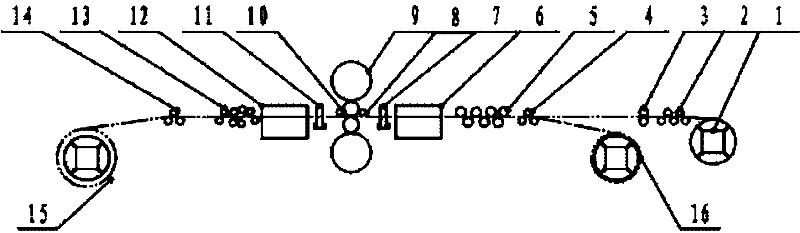

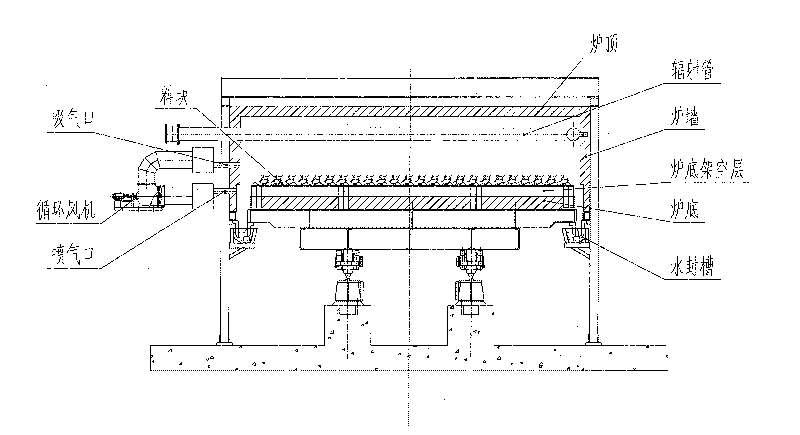

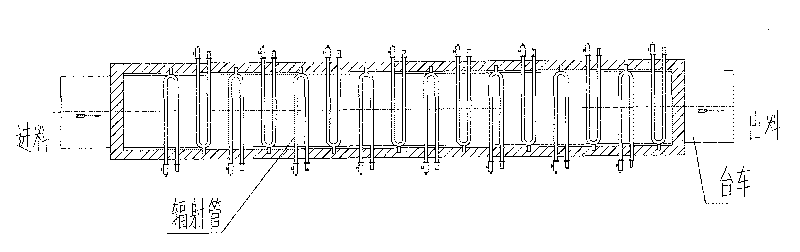

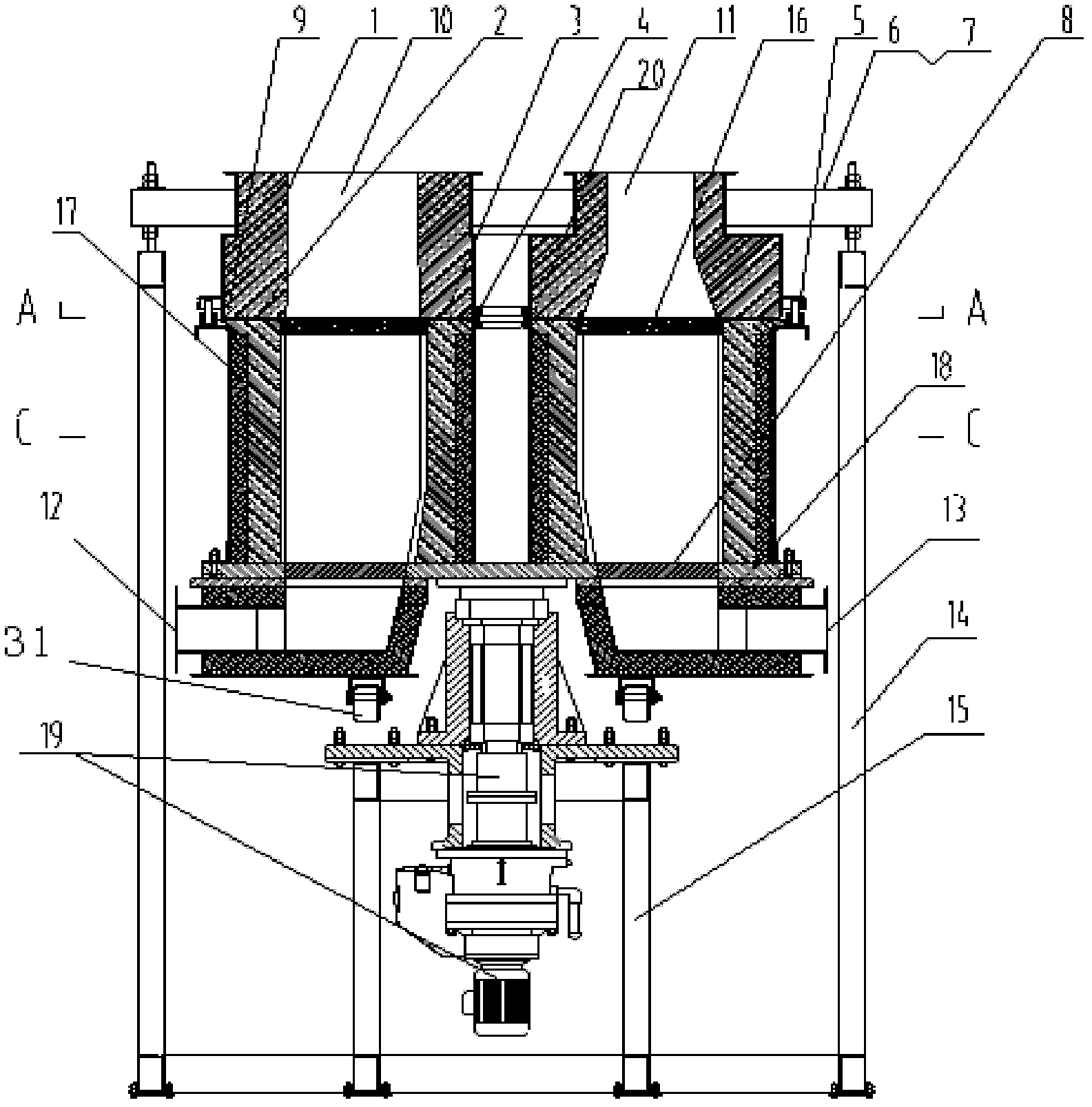

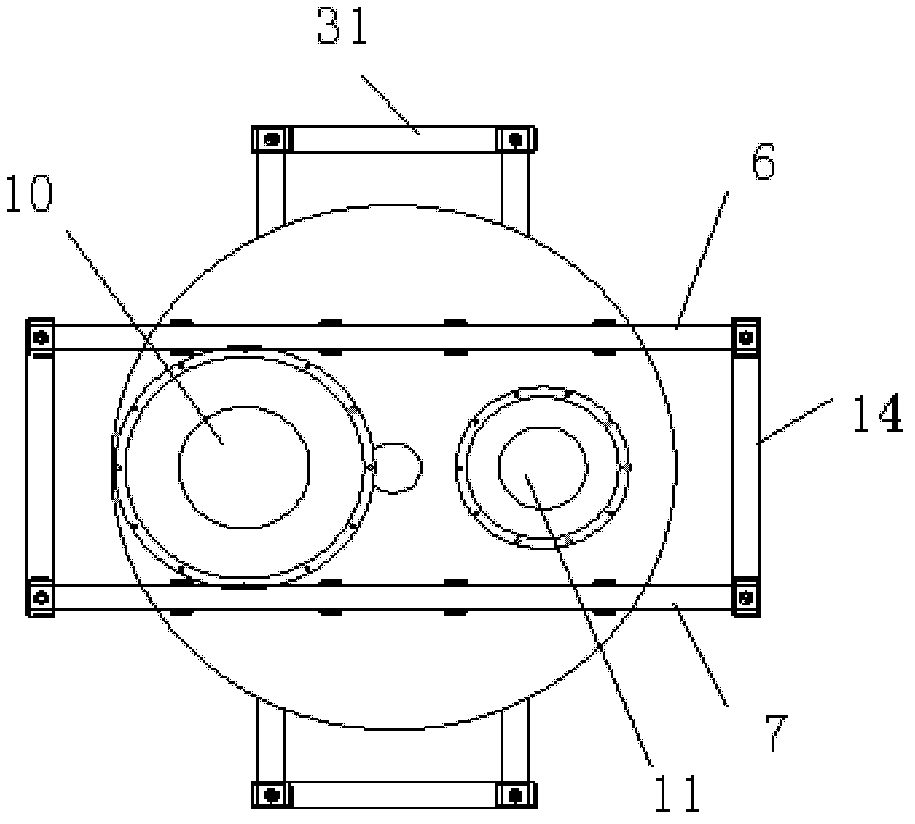

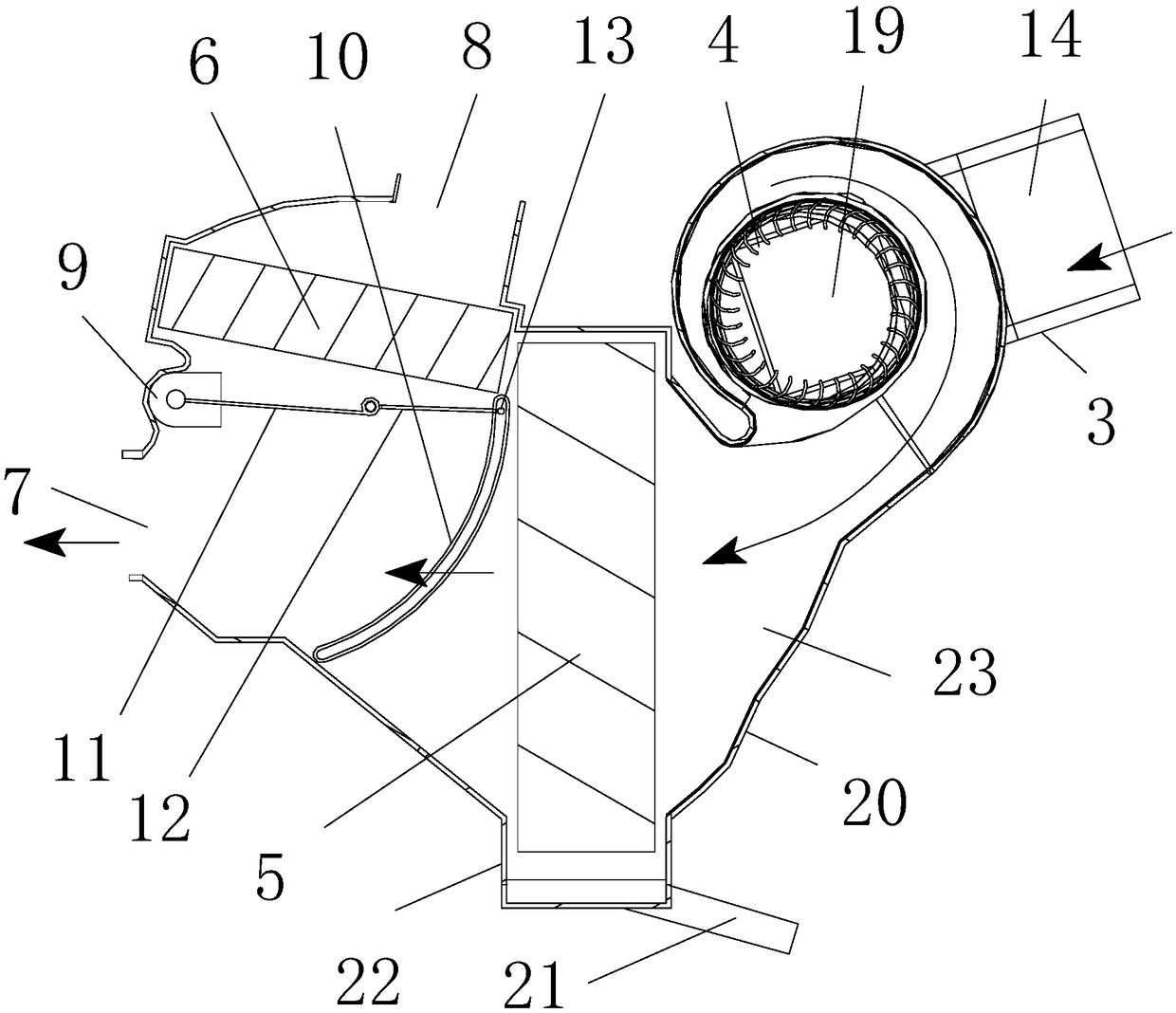

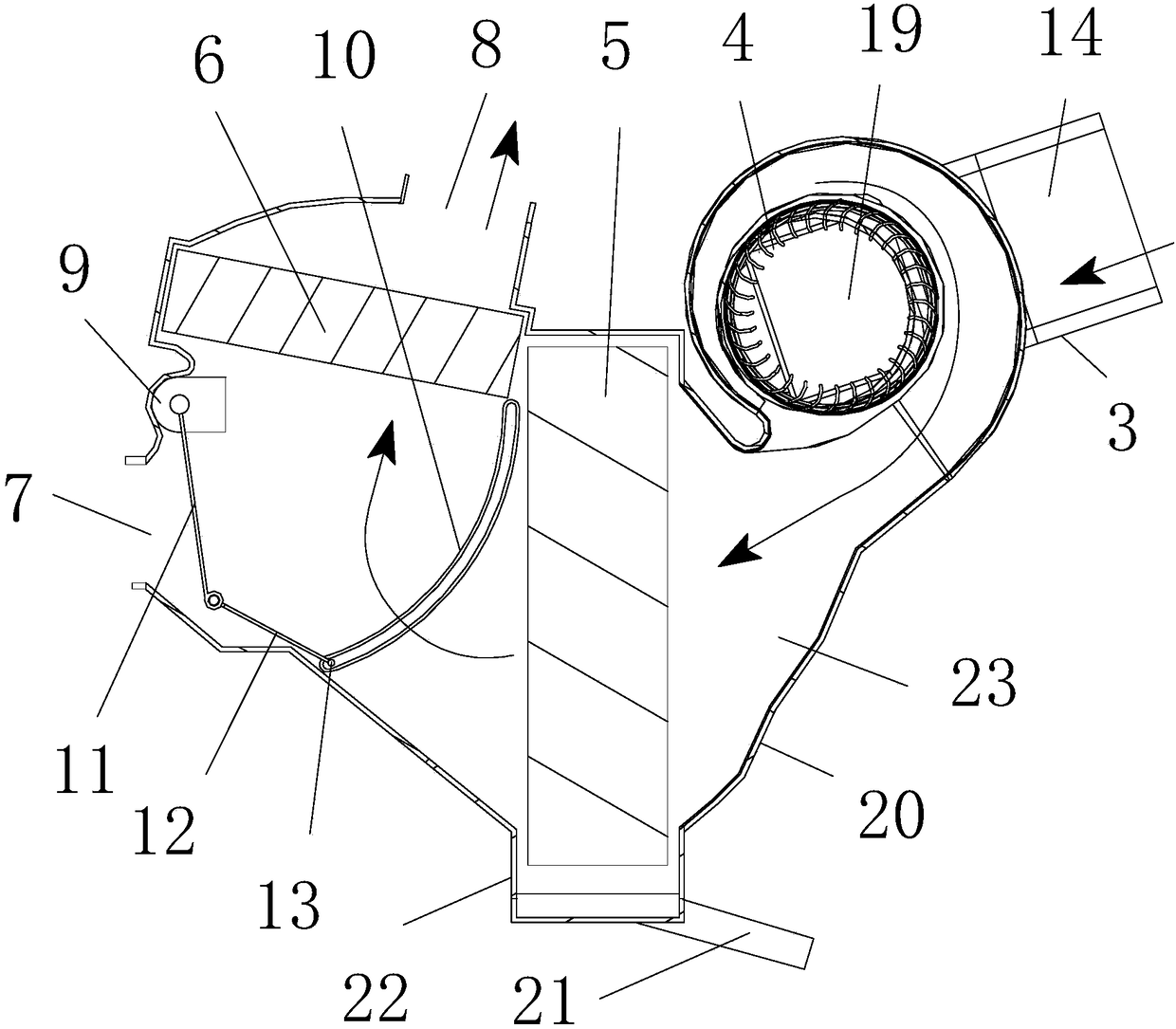

Moving-bed retorting furnace heated comprehensively by radiant tube and circulating airflow

ActiveCN101712878AUnbreakableUniform heating temperatureDirect heating destructive distillationIndirect heating destructive distillationHearthMoving bed

The invention discloses a moving-bed retorting furnace heated comprehensively by a radiant tube and a circulating airflow, comprising a hearth formed by furnace walls, a furnace top and a furnace bottom. The furnace bottom is a circular or through movable furnace bottom; and the upper space of the hearth is provided with a radiant tube heater. By adopting the radiant tube heater to heat, burning products can not be doped in retorting gas, generated retorting oil can keep inherent components, and the retorting gas has high heat value. The furnace bottom is in an overhead layer structure, and afurnace gas-circulating device is arranged between the overhead space and the hearth space above the furnace bottom. The invention has high heat-transferring rate and uniform material-heating temperature and is widely used to retort materials, such as oil shale, coal, lignite, oil sand, plants, and the like.

Owner:SHENWU TECH GRP CO LTD

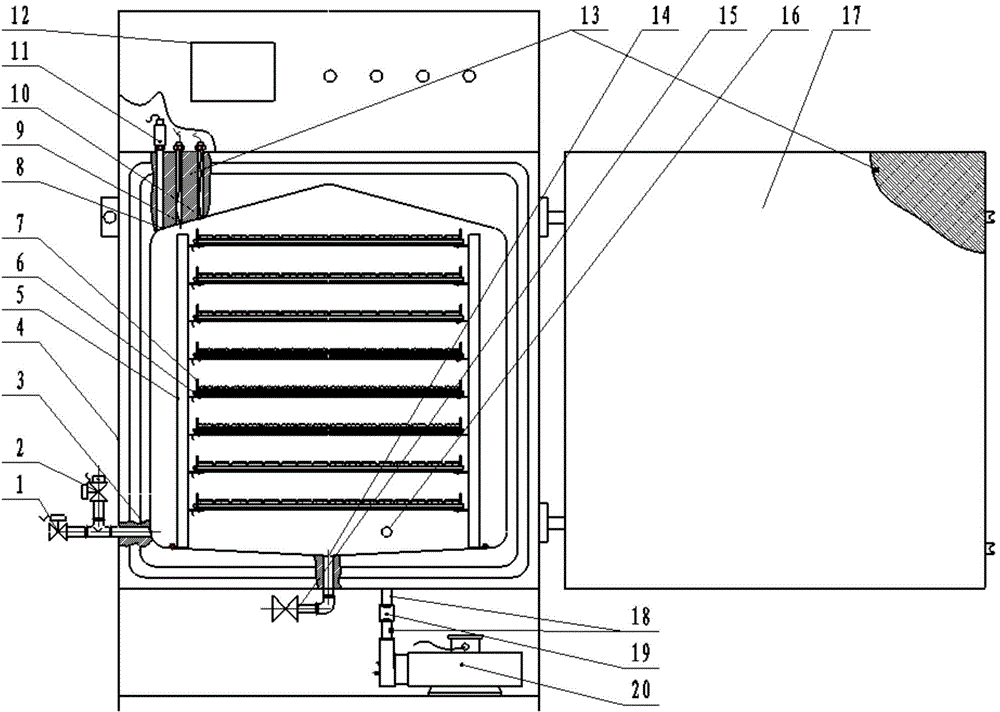

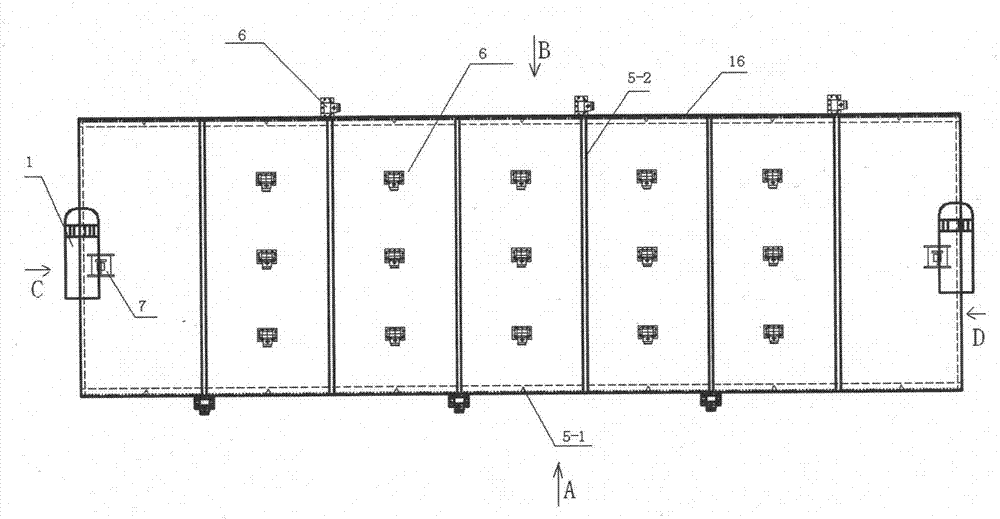

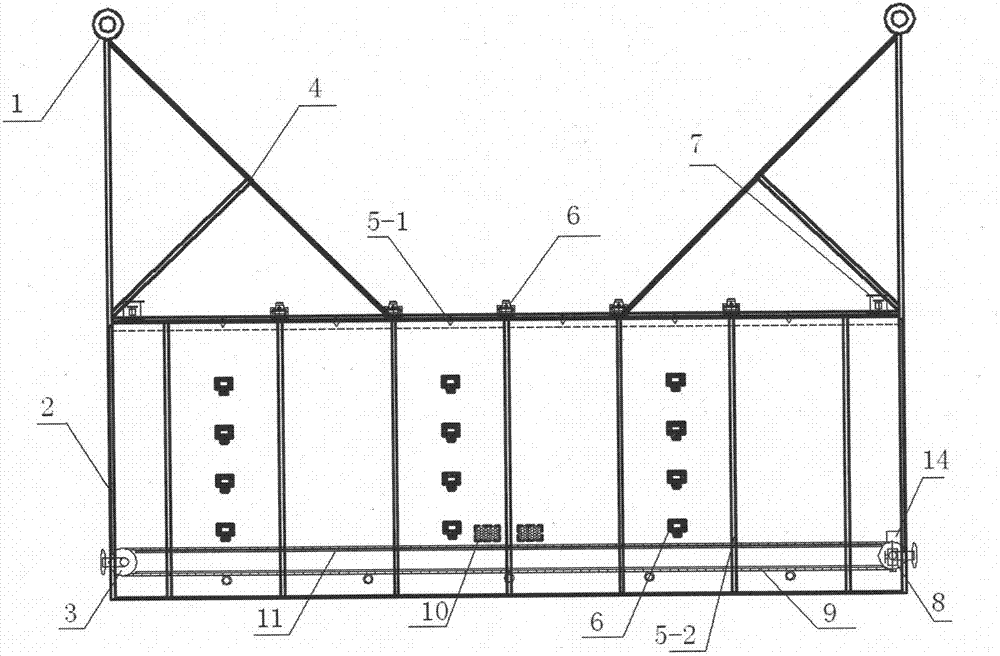

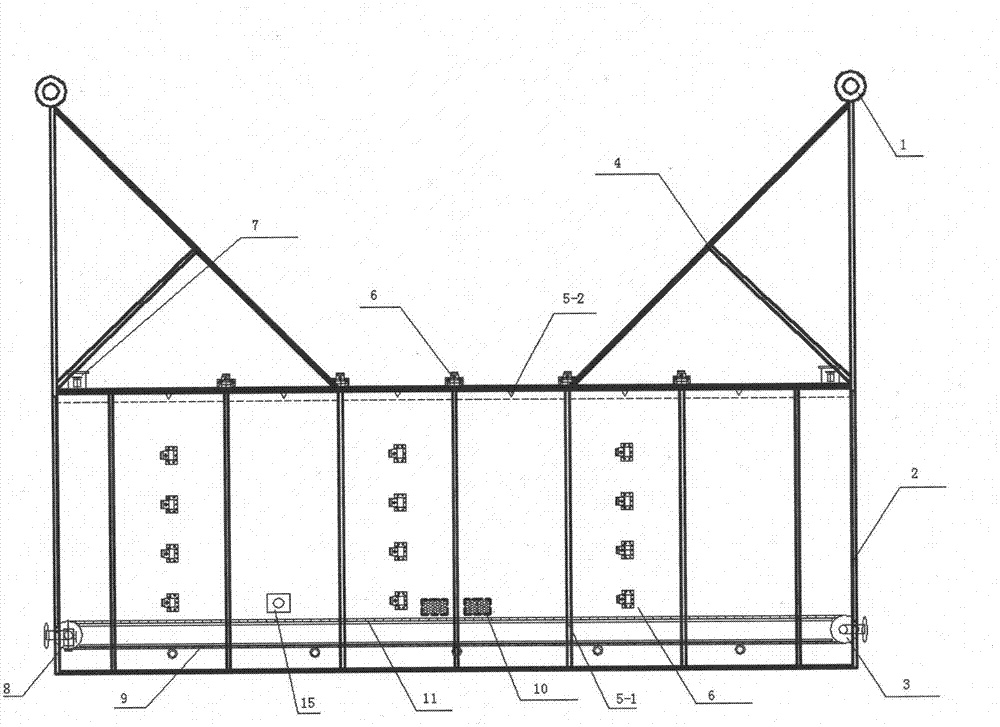

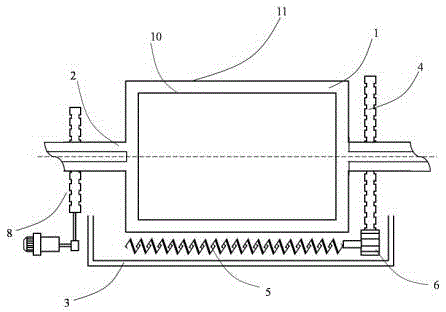

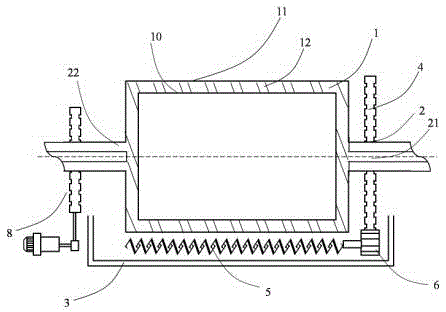

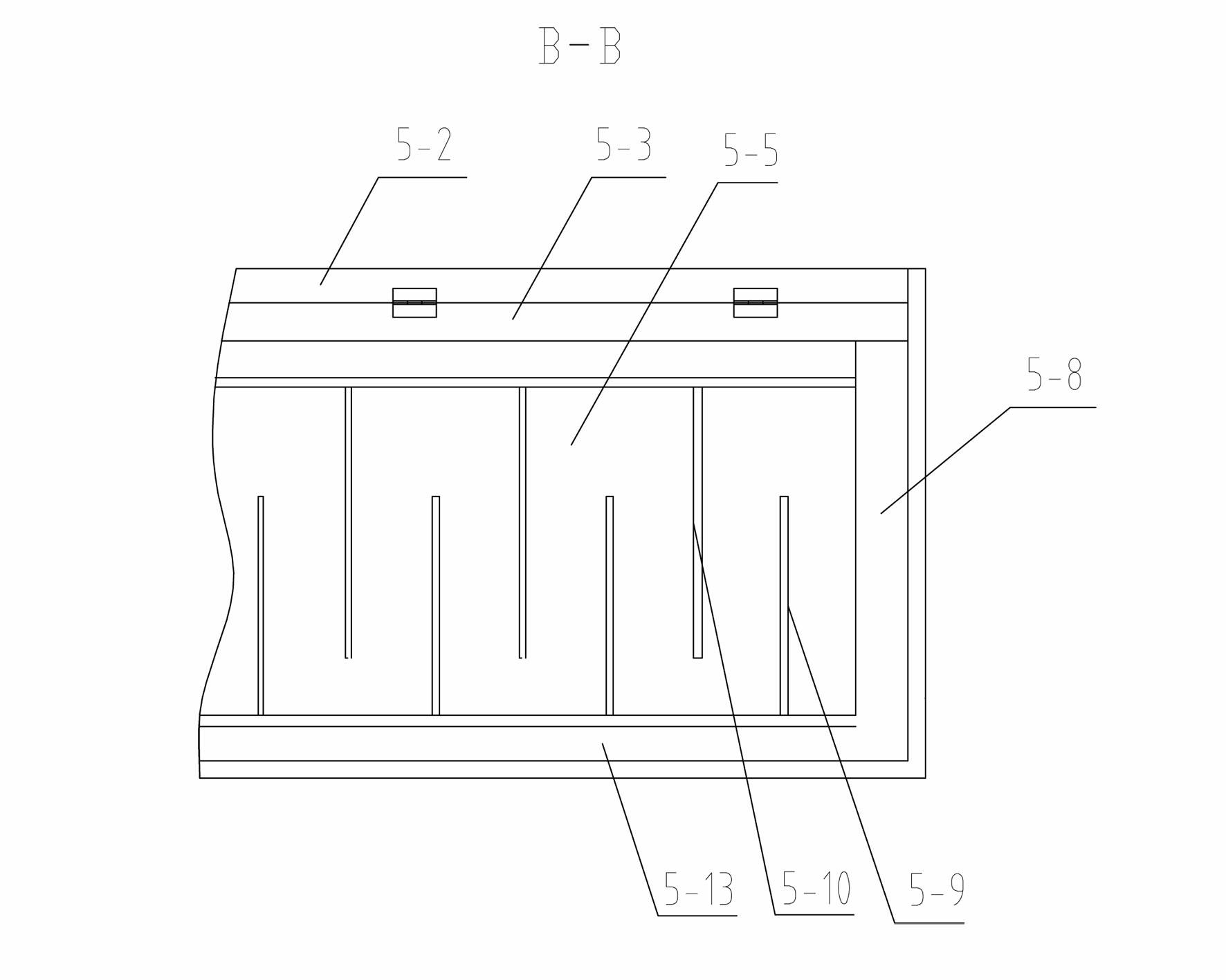

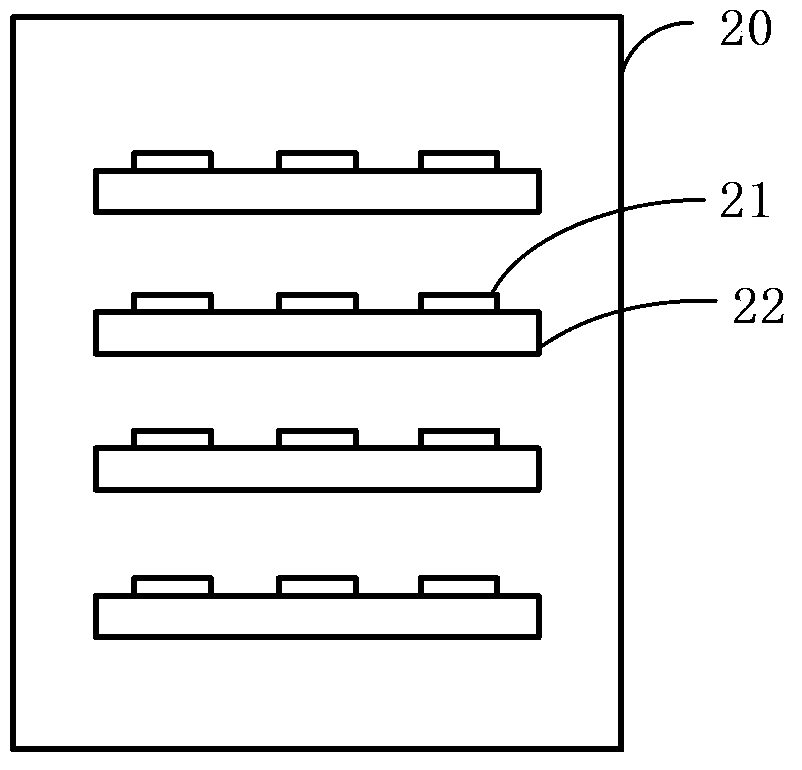

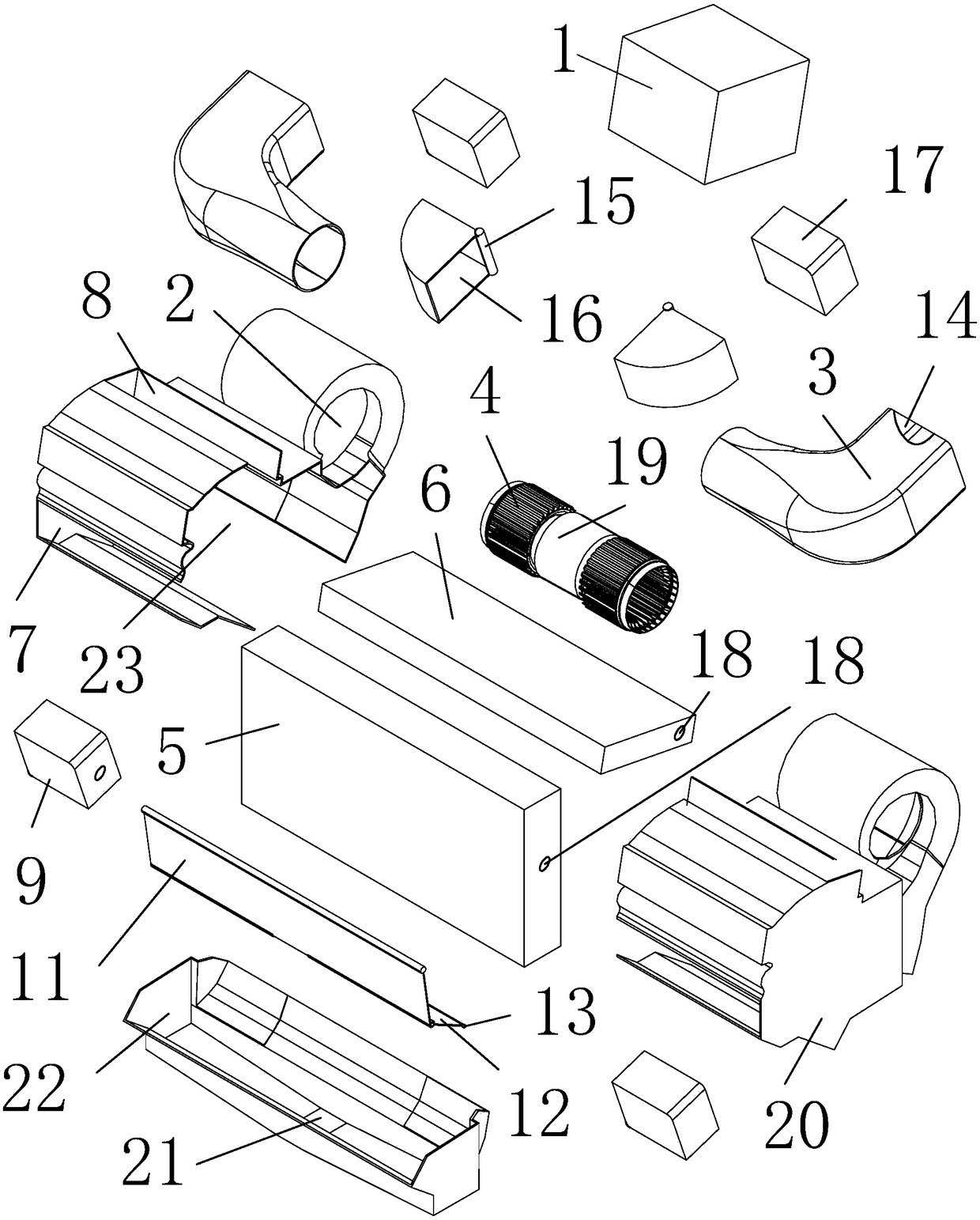

Flat plate type vacuum pulsation drying machine

ActiveCN104596207ANo damageReduce consumptionDrying using combination processesDrying machines with local agitationSoft materialsPulp and paper industry

The invention belongs to the technical field of agriculture product processing, and particularly relates to a flat plate type vacuum pulsation drying machine. The flat plate type vacuum pulsation drying machine comprises a machine body, a control unit, a material drying unit and a pulsation vacuum unit, wherein the material drying unit is provided with multiple layers of material shelves. According to the flat plate type vacuum pulsation drying machine disclosed by the invention, a heating part adopts special electric heating plates, so that the processing is simple and convenient, the cost is low, the heating temperature is uniform, and the manufacturing cost, the using cost and the maintaining cost of the drying machine are greatly reduced; through a hierarchical control mode, corresponding heating plates can be opened according to actual processing amount, so that the energy consumption is reduced; meanwhile, soft material trays are adopted, so that the contact conditions between the material trays and the heating plates are remarkably improved, the quality of dried products can be effectively ensured, and the problem that the soft material trays are inconvenient to move is overcome by using a dedicated material tray shovel to assemble and disassemble the material trays; in addition, the flat plate type vacuum pulsation drying machine belongs to static drying, the breakage of materials cannot be caused; the processing and loading capacity of equipment can be effectively increased by virtue of a multi-layer structure.

Owner:CHINA AGRI UNIV

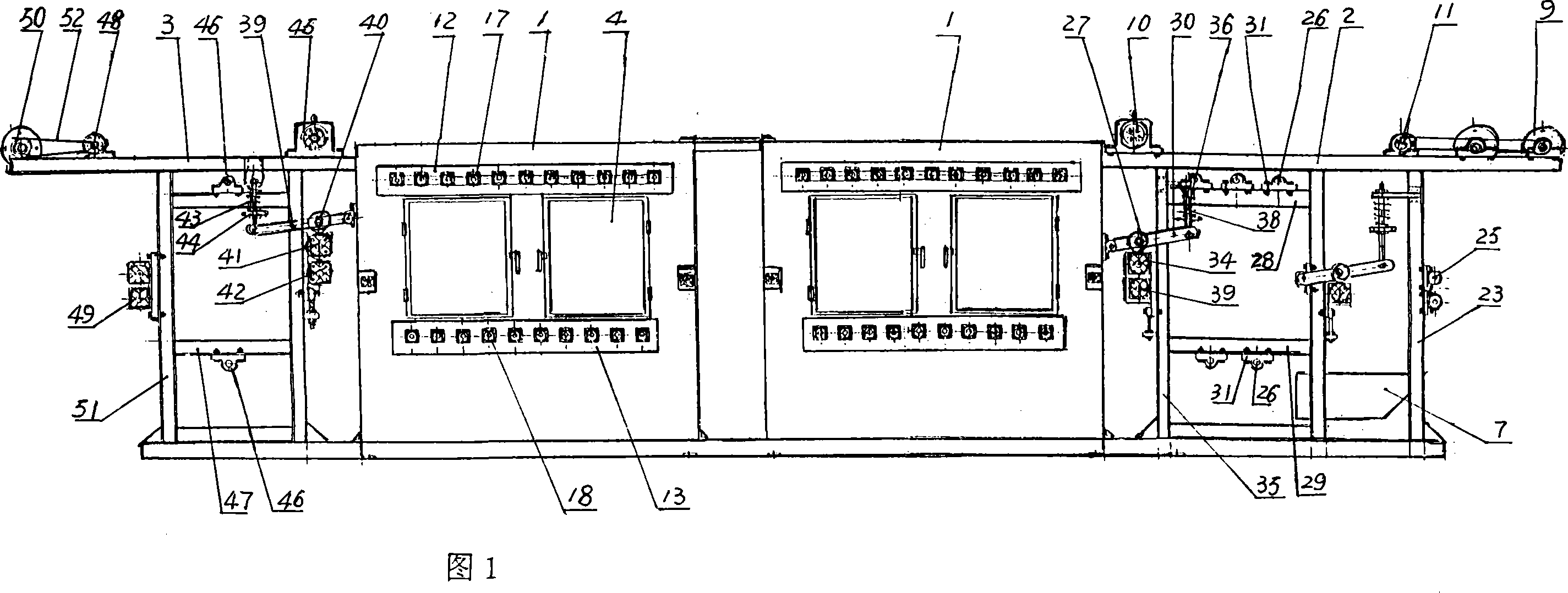

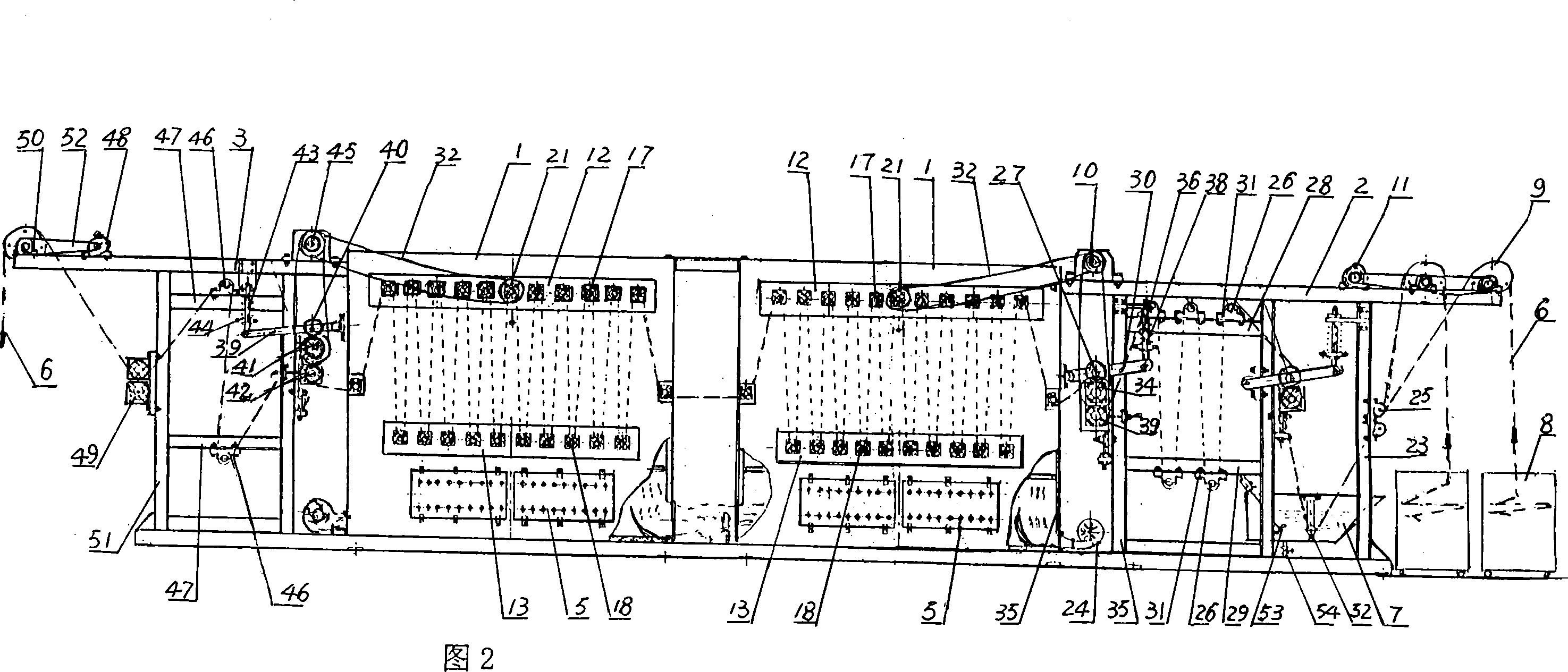

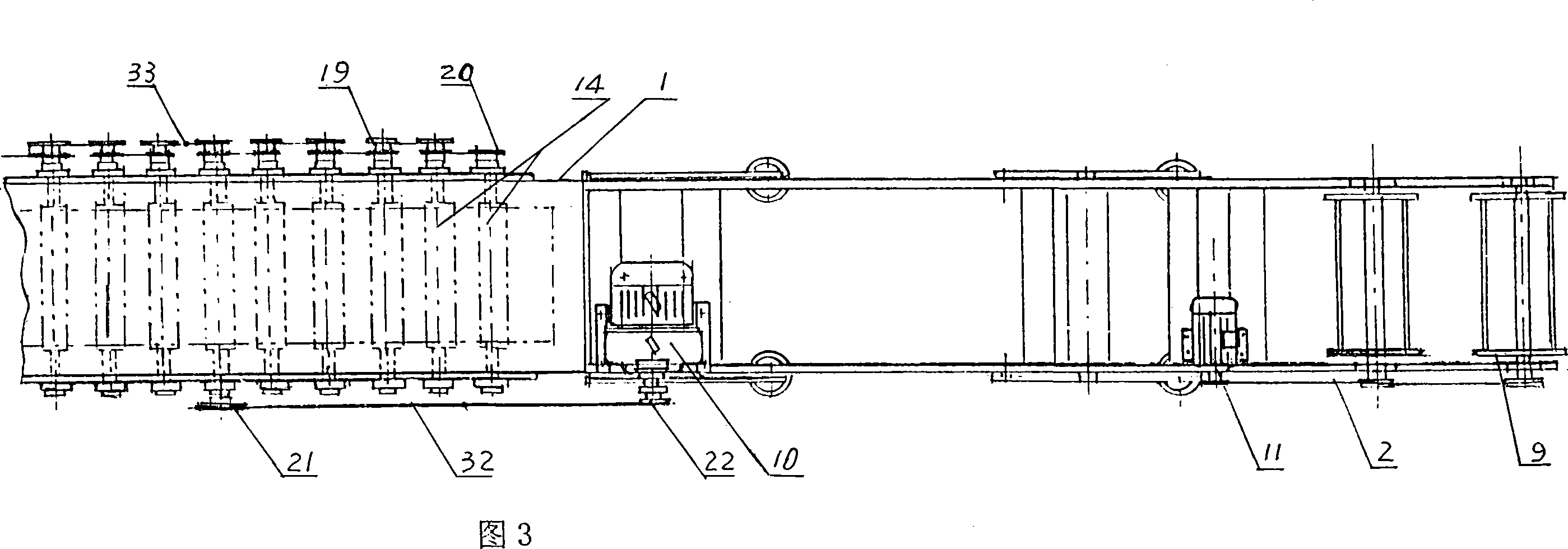

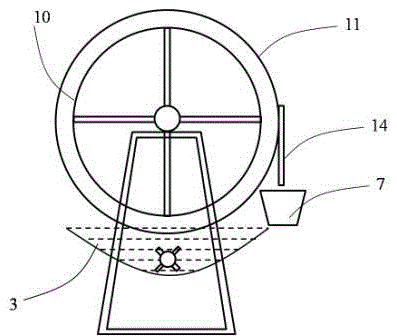

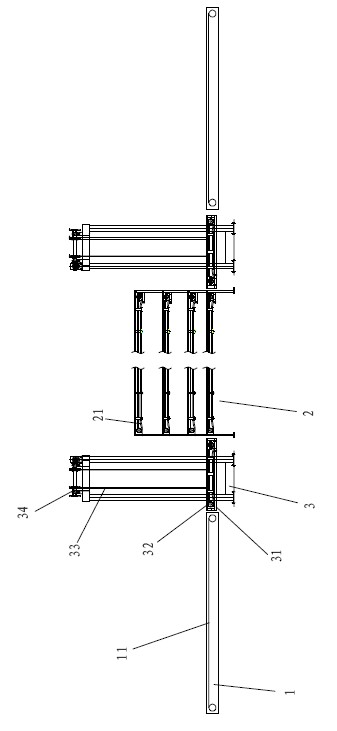

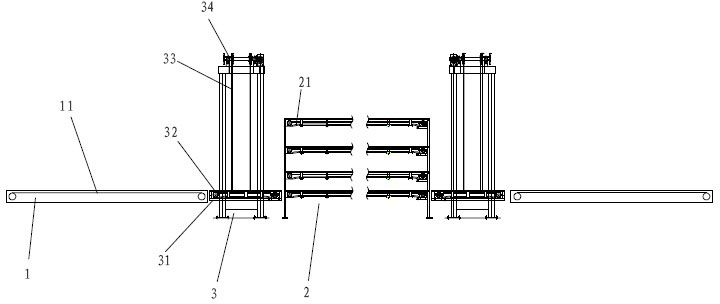

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

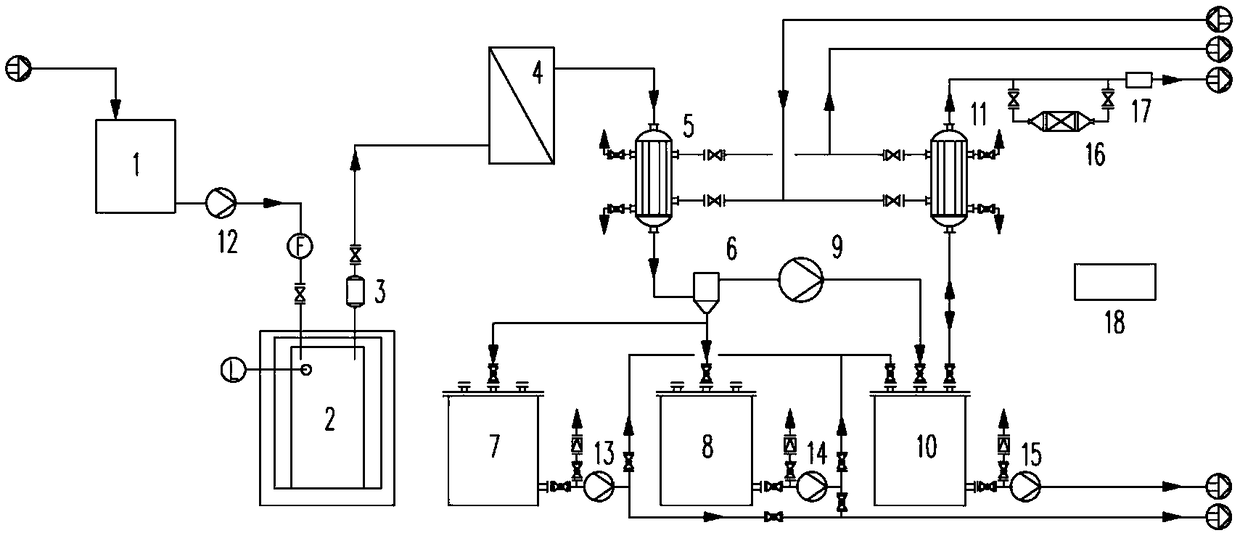

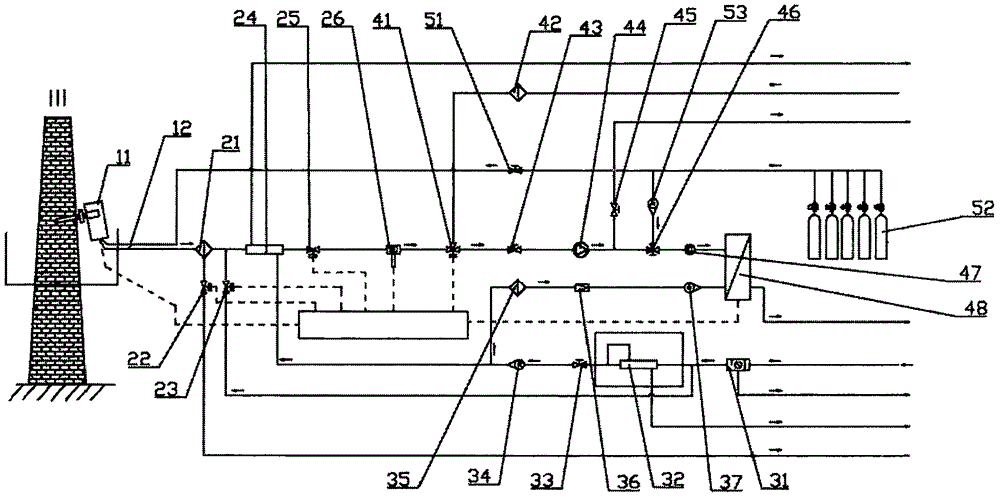

In-barrel vacuum microwave drying system and method for radioactive wet wastes

InactiveCN108630335ADry fastMeet staging criteriaDrying solid materials without heatSludge dryingMicrowaveAtmospheric air

The invention belongs to the technical field of radioactive waste treatment and relates to an in-barrel vacuum microwave drying system and method for radioactive wet wastes. The drying system comprises a drying barrel, a demister, a filter, a condenser, a steam-water separator, a vacuum pump, a tail gas continuous monitoring device and connecting pipelines; the drying barrel is used for drying thewastes by microwave heating; the demister, the filter, the condenser, the steam-water separator and the vacuum pump which are connected in sequence are respectively used for realizing demisting, filtration, condensation, steam-water separation and vacuumizing treatment of evaporated tail gases generated by drying; and the tail gas continuous monitoring device is connected with the condenser and is used for monitoring noncondensable gases in the evaporated tail gases and discharging qualified noncondensable gases into the air by the connecting pipeline connected with an outlet of the tail gascontinuous monitoring device. By using the drying system and method disclosed by the invention, the rapid drying of various radioactive wastes can be realized, new substances are not introduced in a drying process, and the tail gases discharged after being dried almost have no any harmful effects on the environment.

Owner:CHINA NUCLEAR POWER ENG CO LTD

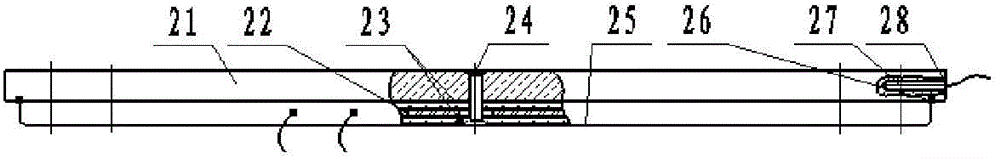

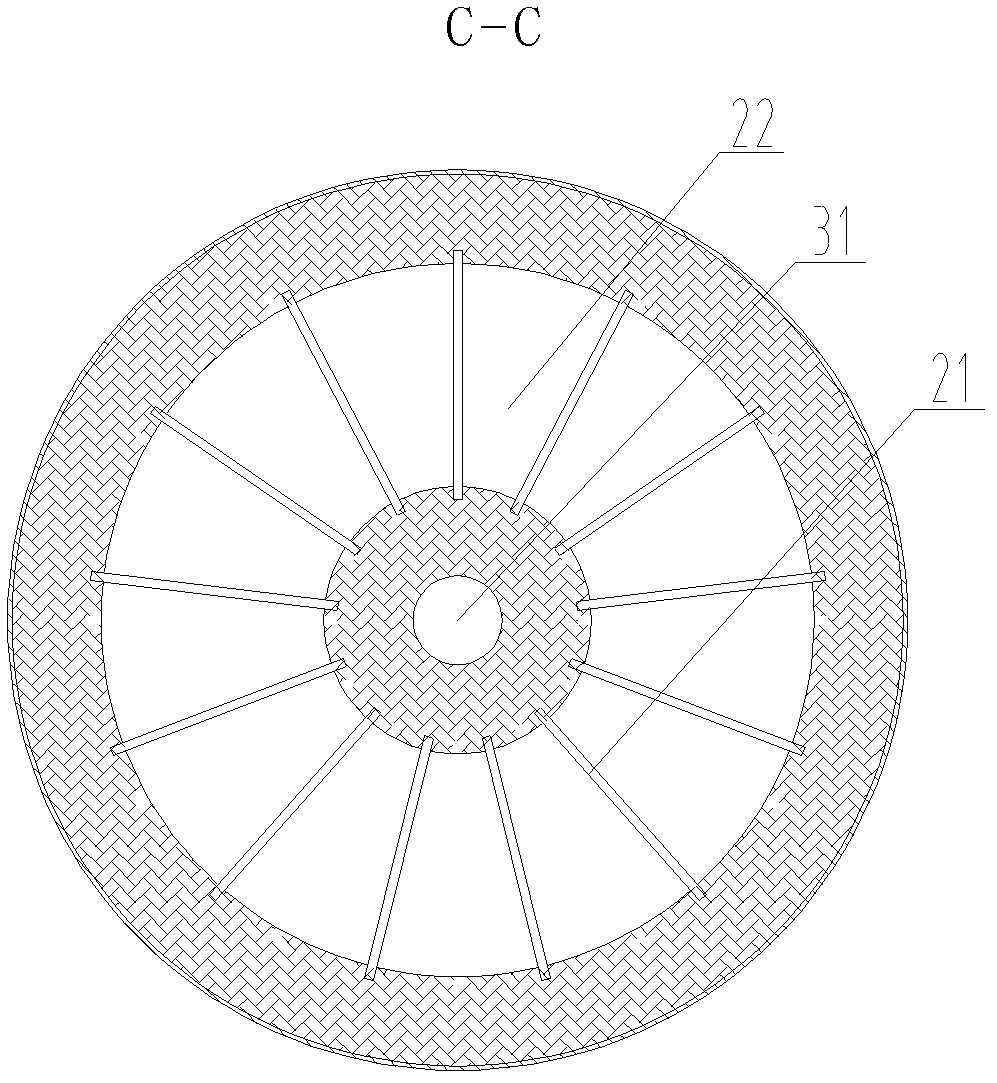

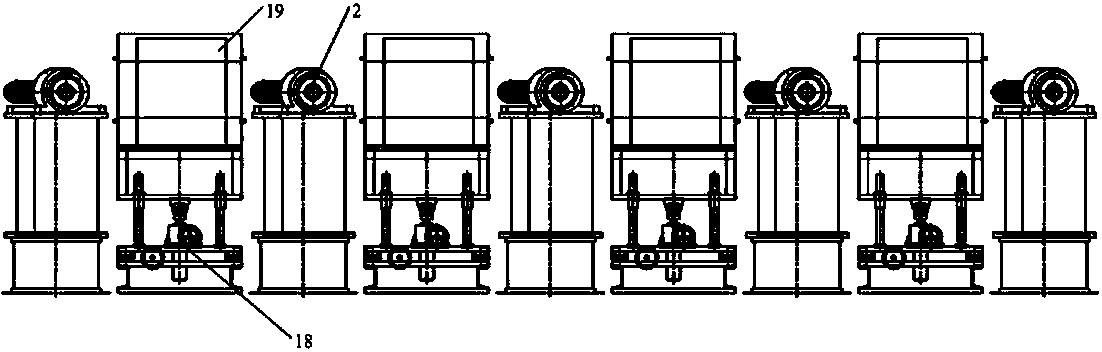

Continuous heat accumulating type heat exchanger

ActiveCN102645116AAchieve alternate flowRealize continuous hot air supplyCombustion processIndirect carbon-dioxide mitigationFurnace temperatureInsulation layer

The invention discloses a continuous heat accumulating type heat exchanger. A groove (28) and an air hole (27) are arranged on a supporting plate (8), a plurality of channels are arranged in an annular hollow device (22), and heat accumulators are filled in the plurality of channels. A ceramic covering plate (16) with holes is arranged at the upper portion of a cylinder body (17) which is installed on a power transmission device (19). A high-temperature air cap (1) is in butt-joint with the ceramic covering plate (16) with holes, a sealing device is arranged between the high-temperature air cap (1) and the ceramic covering plate (16) with holes, a low-temperature air cap (18) is in butt-joint with the supporting plate (8), and a sealing structure is arranged between the low-temperature air cap (18) and the supporting plate (8). Smoke flows in from an inlet (10), flows through the heat accumulators, and then is exhausted out from an outlet (12), and air flows in from an inlet (13), flows through the heat accumulators, and then is exhausted out from an outlet (11). The high-temperature air cap (1) and the low-temperature air cap (18) are static. A motor and a transmission device drive the cylinder body (17) to rotate at the constant speed, and insulation layers (20) are arranged both inside and outside the motor, the transmission device and the cylinder body (17). The continuous heat accumulating type heat exchanger is small in fluctuation of furnace temperature, furnace pressure and preheated air temperature.

Owner:CENT SOUTH UNIV

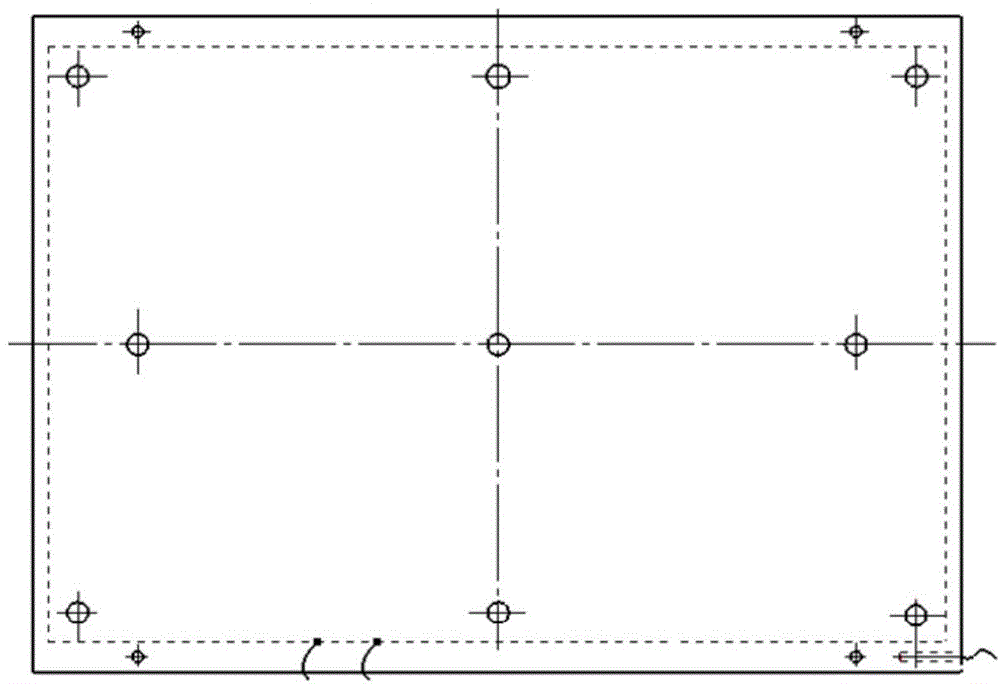

Production process of insulation pull rod

The invention discloses a production process of an insulation pull rod. The production process comprises an insulation pipe blank pipe curing and molding phase, an insulation pipe blank pipe machining phase and a connector bonding phase, wherein in the insulation pipe blank pipe curing and molding phase, fiber materials are dried in vacuum; resin is impregnated under a vacuum environment and the fiber materials are subjected to primary curing; after de-molding, the fiber materials are subjected to secondary curing to obtain an insulation pipe blank pipe; the insulation pipe blank pipe is machined; the insulation pipe blank pipe is bonded with a connector by adopting a heat-expansion and cold-contraction principle; and finally, the insulation pull rod is obtained. According to the production process of the insulation pull rod, the technical defects of a production process of the insulation pull rod that air gaps, micro-cracks, concentrated stress and layering are easy to generate, the connection of the connector is not reliable, the air gaps are easy to generate in a bonding layer of the connector and the insulation pipe and the like are overcome.

Owner:MOTIC XIAMEN ELECTRIC GRP

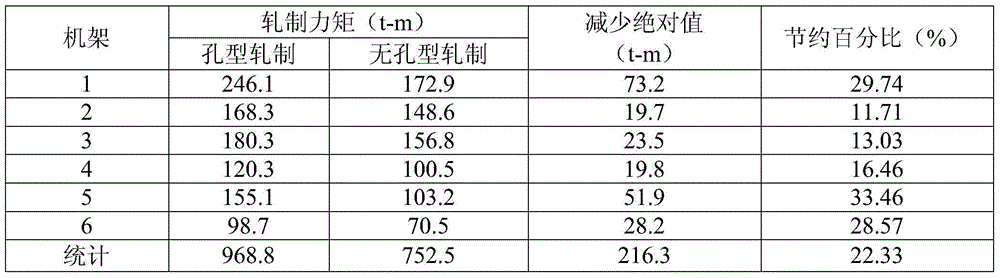

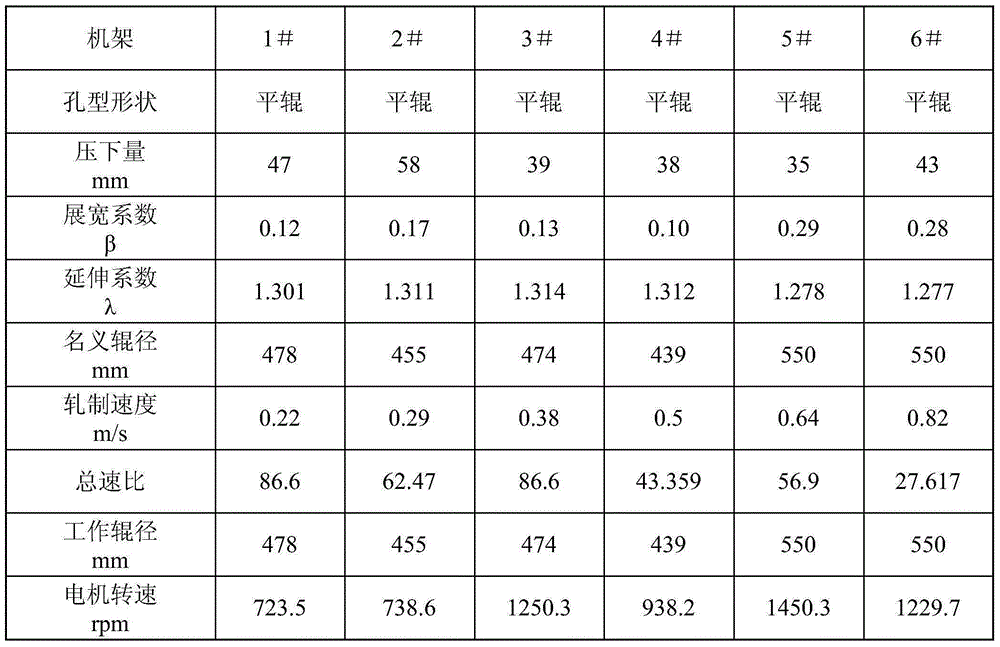

Production process for grooveless rolling of 82B wire rod by high-speed wire mill

ActiveCN104084421ASharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodEconomic benefits

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

Porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and preparation method thereof

InactiveCN102515828AEmission reduction benefits are obviousImprove absorbencySolid waste managementCeramicwareMineralogyMining engineering

The invention relates to a porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and a preparation method of the porous heat-insulation material. The porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings is characterized by being prepared from the following components in percentage by weight: 30-60% of iron tailing powder, 20-50% of iron ore surrounding rock powder, 0.5-10% of foaming agent, 0-1% of cosolvent and 0.1-9% of foam stabilizer by uniformly mixing, then adding water, mixing and pulping, carrying out microwave calcining and cooling. The preparation method of the porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings has high utilization rates of iron ore surrounding rock and iron tailings; and the prepared porous heat-insulation material has low density and excellent heat-insulation performance.

Owner:WUHAN UNIV OF TECH

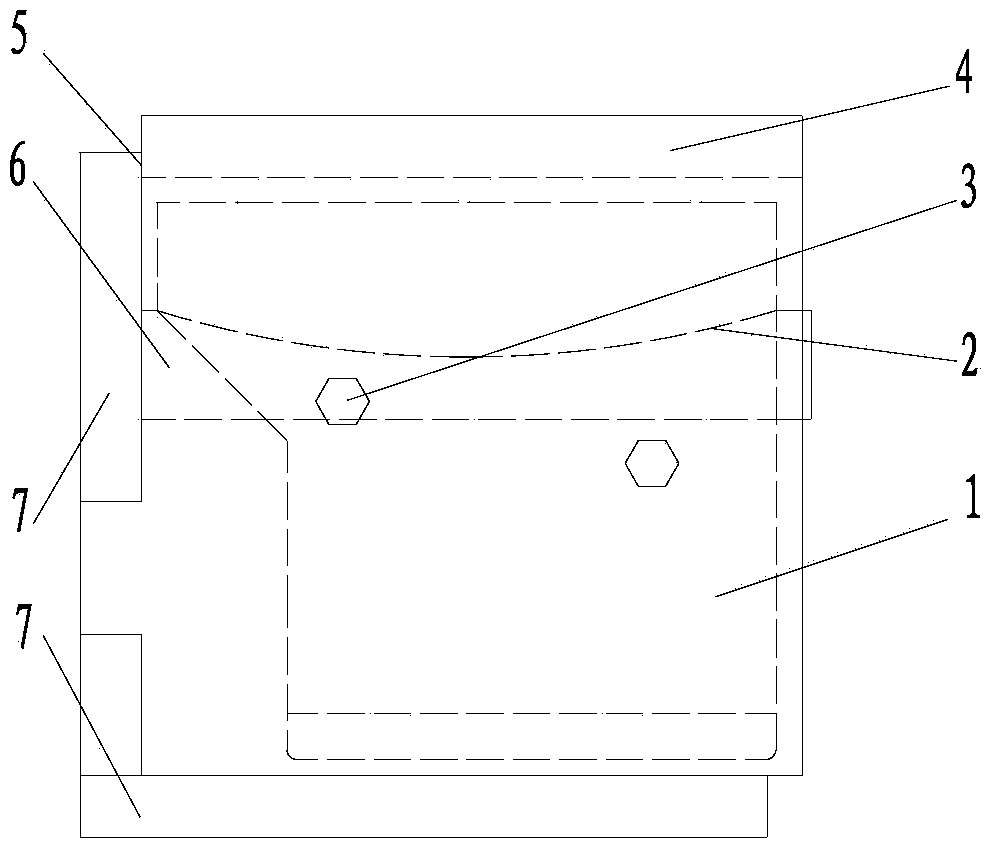

Dewatering, drying and coating equipment for microwave waterborne wood paint furniture, and coating method

The invention provides dewatering, drying and coating equipment for microwave waterborne wood paint furniture. The dewatering drying and coating equipment is characterized by comprising a box body, wherein a conveyer belt for conveying the furniture is arranged in the box body; a metal conveyer belt supporting plate is arranged below the conveyor belt; at least one group of side microwave generator units and at least one side three-edged microwave reflecting plate are respectively arranged at the left side and the right side of the box body; and at least one group of top microwave generator units and at least one top three-edged microwave reflecting plate are arranged at the top of the box body. The invention also provides a dewatering drying and coating method for microwave waterborne wood paint furniture by adopting the dewatering, drying and coating equipment for microwave waterborne wood paint furniture. Furniture subjected to the microwave treatment have relatively uniform heating temperature and water content in spite of the volume, the unique and complex shape, the non-uniform thickness of graving plate and the multi-layer baffles on the external surface layer and the internal layer on the back; and the furniture has no cracking, warping and deforming, thereby thoroughly solving the problem that the waterborne wood paint of furniture is hard to dry and dewater.

Owner:上海志鹤水性涂料科技有限公司

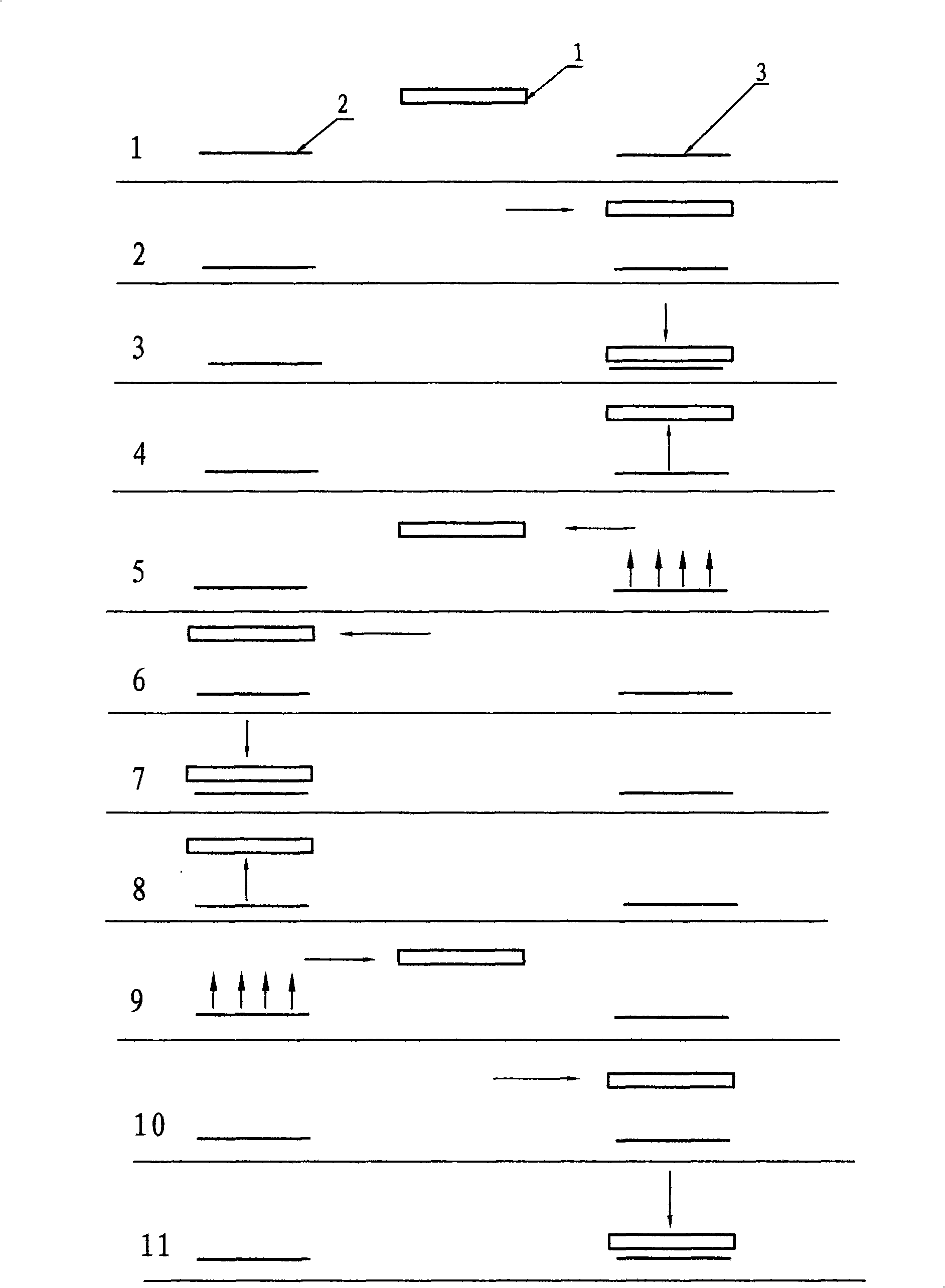

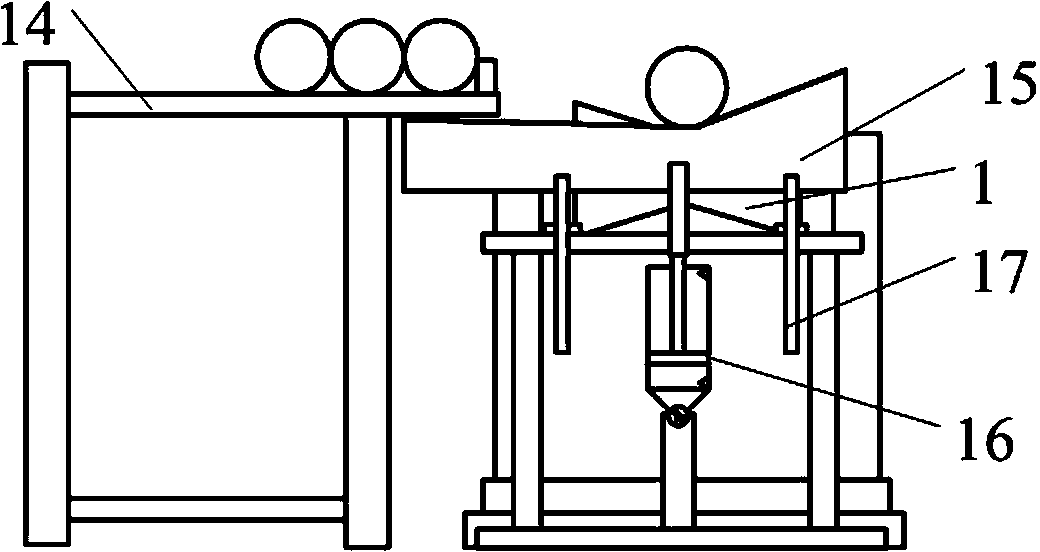

Efficient double-line suction plastic production method and device

The invention provides a high-efficiency dual-line plastic suction production method, comprising the steps as follows: 1) a bidirectional movable plastic suction heating furnace is arranged; the left side and the right side right below the plastic suction heating furnace are respectively provided with a set of vacuum forming processing line; 2) the plastic suction heating furnace is moved to the initial position and electrified to a given temperature, and the temperature is kept; 3) after the plastic suction heating furnace is transversely moved to one side right above the hot forming working position of the vacuum forming processing line, the plastic suction heating furnace vertically runs downwards to a given height H1 and remained for the time t1 so as to heat the material on the side of the processing line hot forming working position; 4) after the prearranged heating time t1 is reached, the plastic suction heating furnace runs upwards vertically and recovers transversely, and stops for a time t3; 5) the plastic suction heating furnace is moved to another processing line, runs downwards vertically by a height H2 and stops for a time t2; 6) the plastic suction heating furnace runs upwards vertically, transversely recovers and stops for a time t4; 7) the step 3) to step 6) are repeated. The invention also discloses a device which realizes the method of the invention.

Owner:DONGGUAN FUCAI PACKAGING PROD

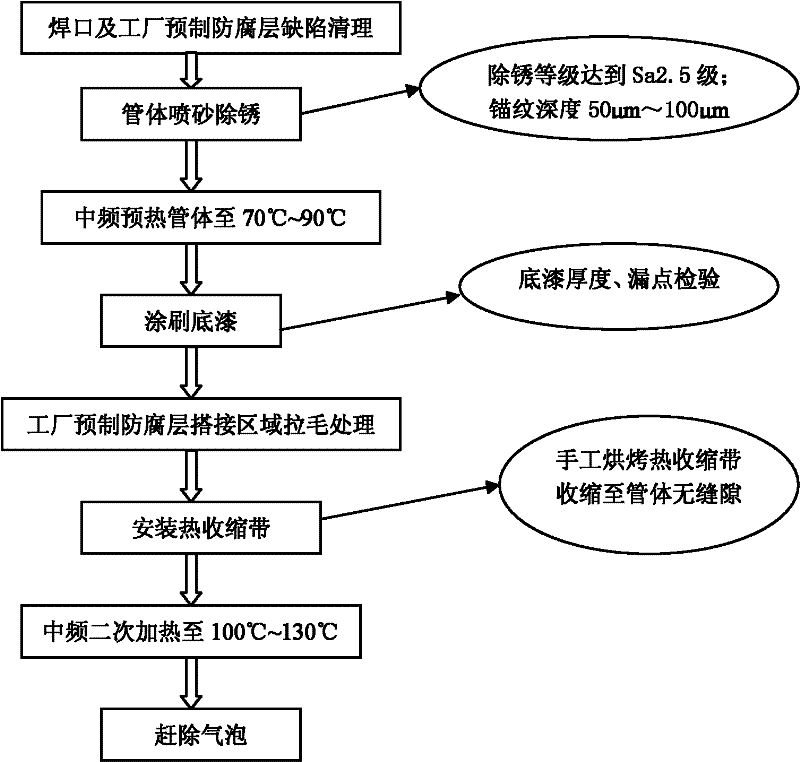

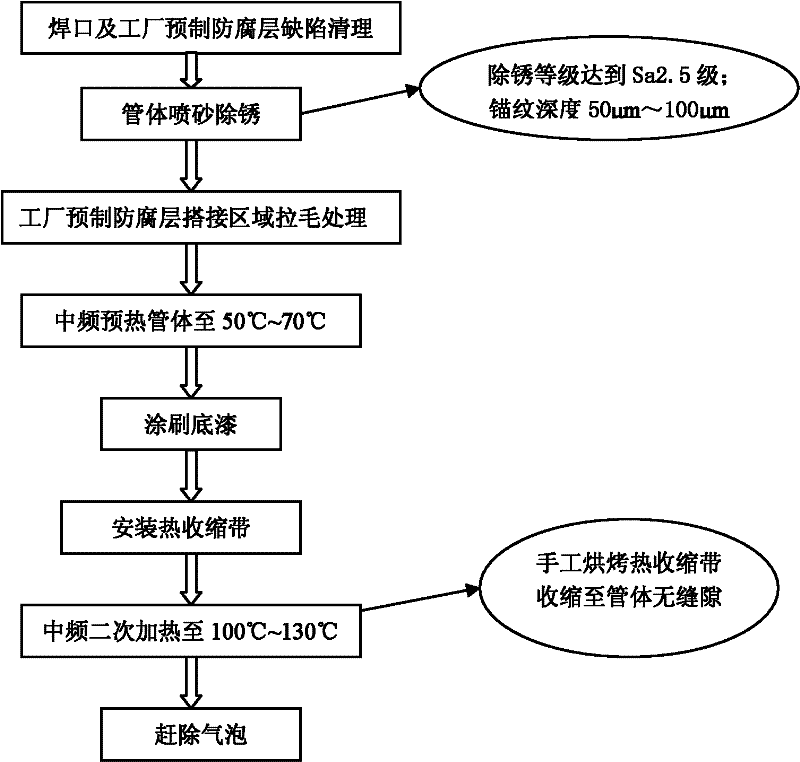

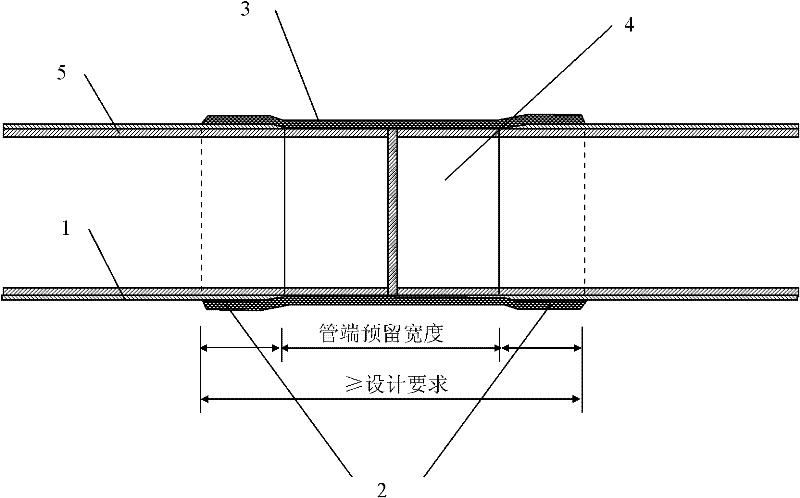

Intermediate-frequency heating repaired opening construction technology for thermal contraction band of buried steel pipeline

InactiveCN102679086ARealize flow operationAvoid secondary pollutionPipe elementsSand blastingIntermediate frequency

The invention relates to an intermediate-frequency heating repaired opening construction technology for a thermal contraction band of a buried steel pipeline. The construction technology comprises the following steps: 1) cleaning flaws of a welded junction and an anticorrosive layer prefabricated in a factory; 2) performing sand-blasting and de-rusting on a pipe body, wherein a de-rusting level is Sa2.5 level and an anchoring grain depth is 50 microns to 100 microns; 3) performing intermediate-frequency heating on the pipe body, wherein a preheating temperature is at 50-90 DEG C; 4) painting a primer, wherein the thickness of the primer is above 200 microns; 5) performing napping treatment on the surface of the anticorrosive layer prefabricated in the factory, in a flame manual steel wire brushing napping mode; 6) mounting the thermal contraction band: winding the thermal contraction band at the repaired opening, sticking a fixing sheet, and baking the surface till the thermal contraction band is completely and seamlessly covered on the pipe body; 7) secondarily intermediate-frequency heating under a secondary heating temperature at 100-130 DEG C, till fully melting a hot melt adhesive; and 8) removing air bubbles. According to the construction technology provided by the invention, the heating temperature is uniform, the influences of personal factors on construction quality are reduced and the efficiency and quality of repaired opening construction are greatly increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

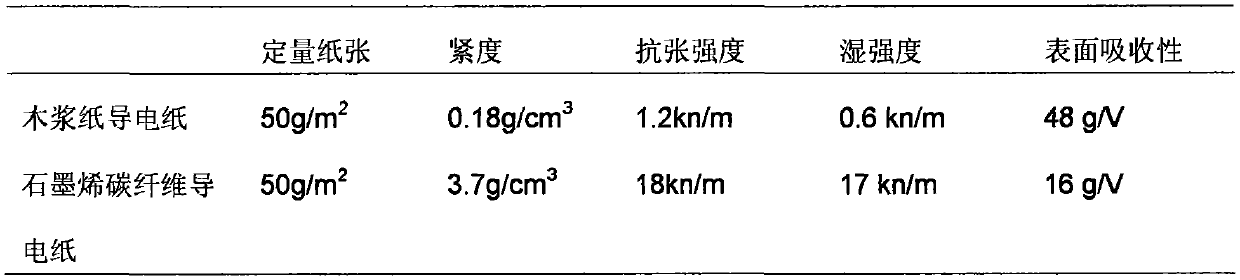

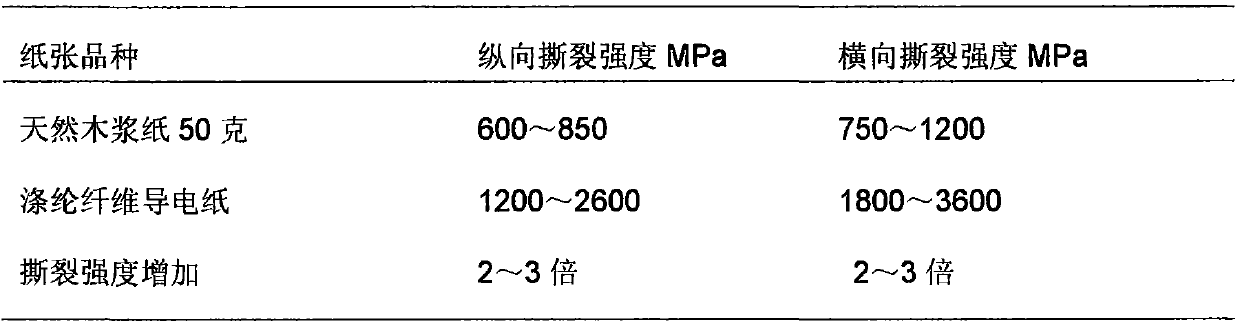

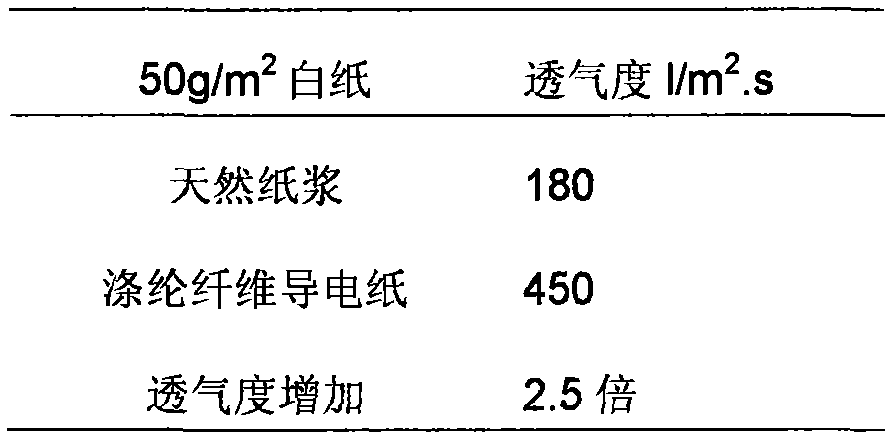

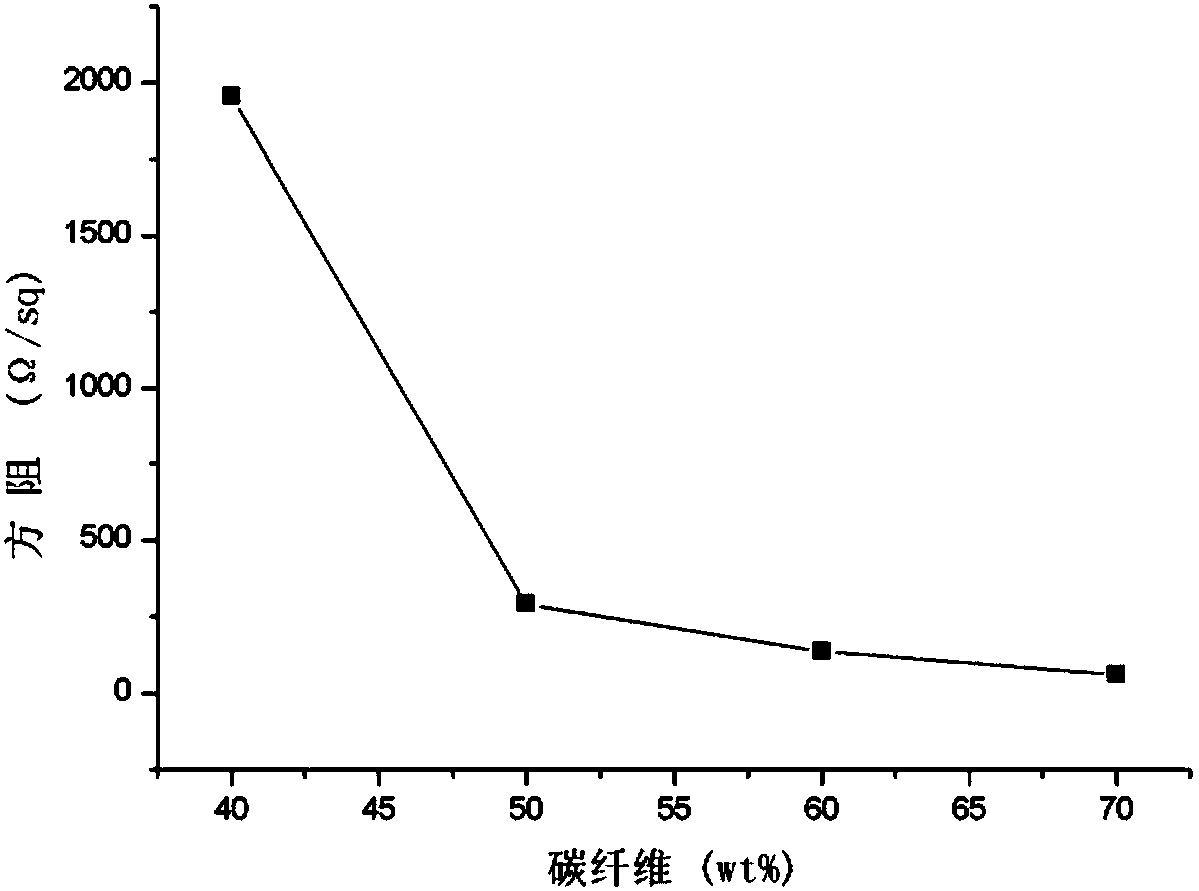

High-electrical-conductivity graphene carbon-fiber electrical-conductive paper and preparation method thereof

ActiveCN105369686AEvenly distributedUniform thicknessSpecial paperWater-repelling agents additionPolyesterFiber

The invention relates to a manufacturing technology of an electrical-conductive exothermic material, in particular to high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and a preparation method thereof. The electrical-conductive paper comprises chopped carbon fibers, polyester super-short fibers, graphene powder and wood pulp fibers, and the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper is obtained by conducting permeabilization treatment, defibering and dispersing, pulping treatment, mixing and papermaking on all the materials. According to the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and the preparation method thereof, the fibers are uniformly distributed, the thickness is uniform, the strength is high, water resistance is achieved, the air permeability is good, high electrical conductivity is achieved, the transition heat efficiency is high, the heat efficiency of the product is improved, the service life of the product is prolonged, and the electrical-conductive paper is a novel leap-upgrading and transformational breakthrough in the electrical exothermic material technology.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

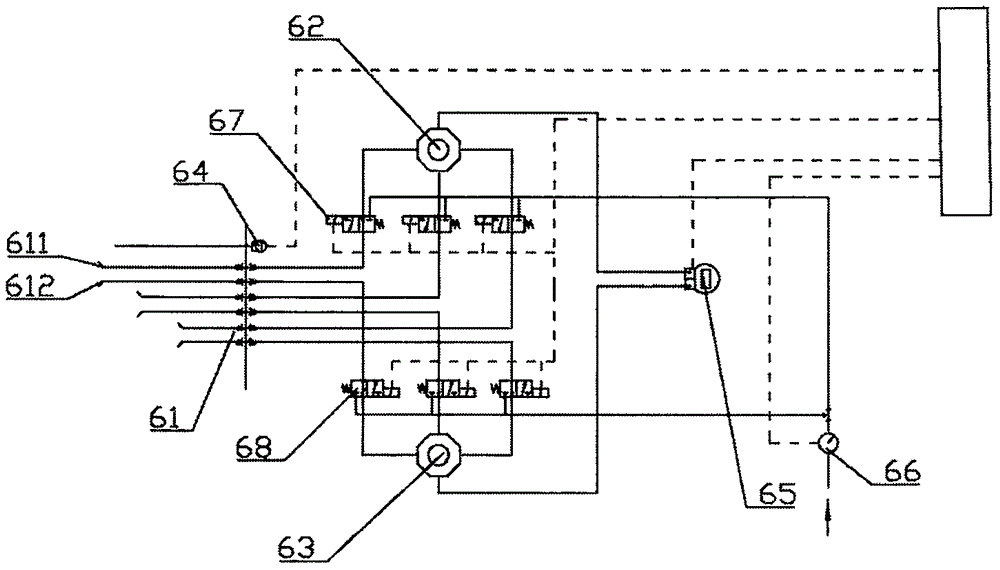

Online monitoring system of ultralow-concentration smoke and analysis method thereof

ActiveCN106770951AAvoid dissolution lossNo lossAnalysing gaseous mixturesData acquisitionHandling system

The invention belongs to the technical field of smoke detection and particularly relates to an online monitoring system of ultralow-concentration smoke and an analysis method thereof. The online monitoring system of ultralow-concentration smoke disclosed herein comprises a smoke sampling system, a gas pretreatment system, a dried compressed air generating system, a gas component analysis system, a temperature-pressure flow measuring system. The invention also discloses the analysis method relating to the online monitoring system of ultralow-concentration smoke. The online monitoring system of ultralow-concentration smoke and the analysis method have the advantages that the gas sampling system provides thermal treatment, dissolution loss of measured gas due to high-humidity environment in a flue is prevented effectively, flow speed measuring is stable and reliable, the flow speed can reflect working conditions better, the sample gas pretreatment system is researched and designed independently, the special material selected can remove moisture in smoke within a short time, gas component loss is avoided, operation configuration software has a friendly interface, data are visually displayed, and operation is simple and feasible for a user.

Owner:汇众翔环保科技股份有限公司

Scraping plate drum dryer

InactiveCN105588407AReduce lossUniform heating temperatureDrying solid materialsDrying machines with non-progressive movementsInorganic saltsContinuous/uninterrupted

The invention discloses a scraping plate drum dryer. The scraping plate drum dryer comprises a drum cylinder, a rotary shaft, a power device, a feed liquid tray, a feed liquid stirring device, a scraper and a slag collection device, wherein the drum cylinder and the rotary shaft are coaxial. The rotary shaft is connected with the power device. The drum cylinder comprises an inner cylinder body and an outer cylinder body, wherein the inner cylinder body and the outer cylinder body are coaxial. The feed liquid tray is located below the drum cylinder. The feed liquid stirring device comprises a stirrer located above the feed liquid tray. The scraping plate drum dryer can be used for material drying and solid-liquid separation and is particularly suitable for extracting and collecting volatile substances from a system containing dissolvable or indissolvable inorganic salt. In the whole operating process, the state of materials is stable, layering or the dramatic change of the solid-to-liquid ratio is avoided, the heating temperature is uniform, the drying effect is excellent, and the high heat and mass transfer efficiency can be kept all the time; in addition, continuous work can be achieved, the energy loss is small, the drying time is short, and the scraping plate drum dryer is suitable for large-scale industrial production.

Owner:CATHAY R&D CENT CO LTD +1

Multifunctional heat treatment system for steel pipe

ActiveCN104032112AMeet heat treatment process requirementsCompact designFurnace typesHeat treatment furnacesElectrical resistance and conductanceUltra fast

The invention discloses a multifunctional heat treatment system for a steel pipe. The heat treatment system comprises six groups of roller paths, a medium-frequency induction furnace device, a high-temperature resistance furnace device, an ultra fast cooling device, an outward sprinkling and inward spraying device and a low-temperature resistance furnace device, wherein the six groups of roller paths consist of a feeding roller path group, a medium-frequency induction heating roller path group, an air cooling roller path group, an ultra fast cooling roller path group, an outward sprinkling and inward spraying roller path group and a discharging roller path group which are arranged in sequence; the medium-frequency induction furnace device is arranged between two adjacent roller paths of the medium-frequency induction heating roller path group; the high-temperature resistance furnace device is arranged on one side of the air cooling roller path group; the ultra fast cooling roller path group is arranged in the ultra fast cooling device; the outward sprinkling and inward spraying device is arranged on one side of the outward sprinkling and inward spraying roller path group; and the low-temperature resistance furnace device is arranged on one side of the discharging roller path group. According to the system, the whole process line is compact in design, the operation is simple and convenient, needed equipment can be combined and selected according to process requirements, and various heat treatment process requirements of the steel pipe are met.

Owner:沈阳科安捷材料技术有限公司

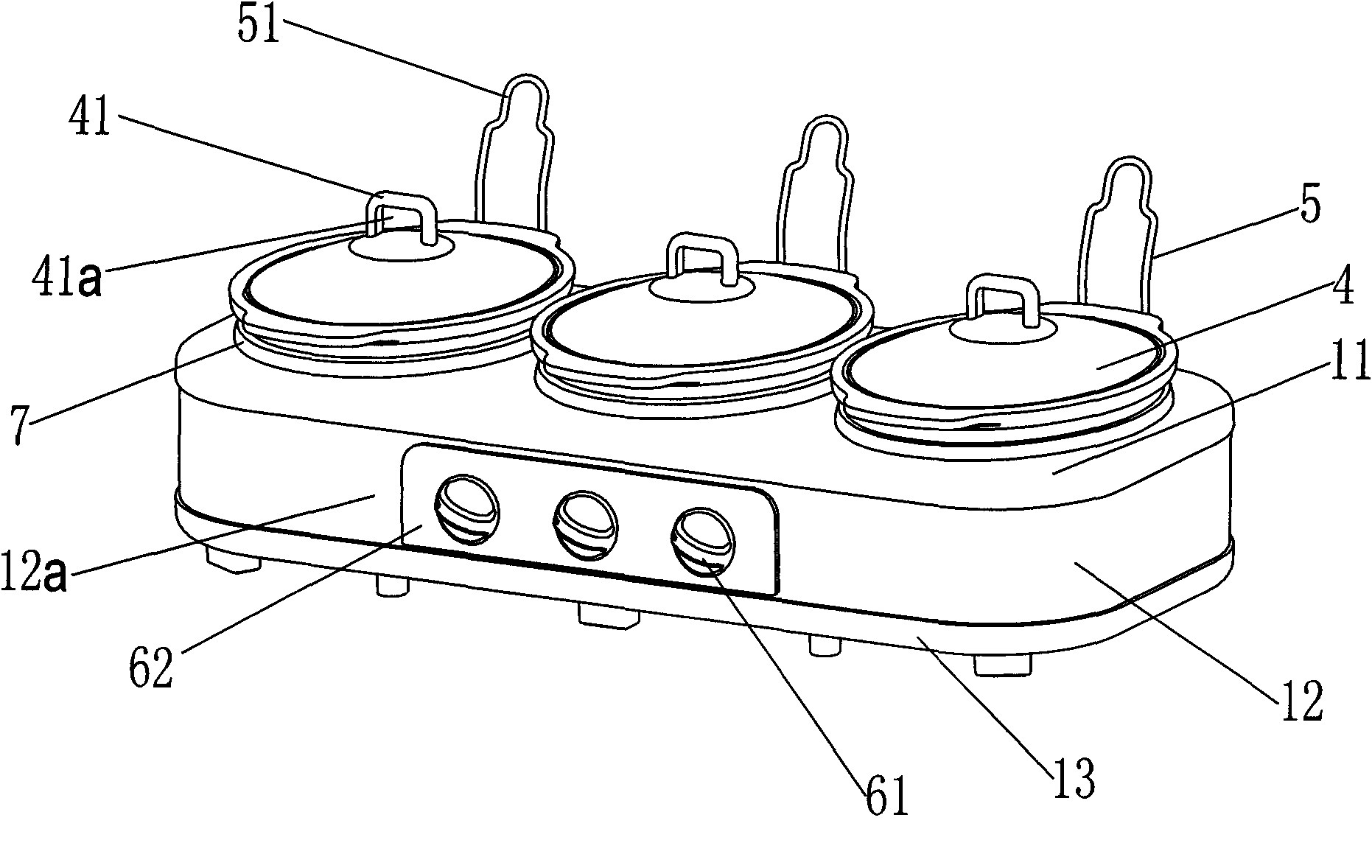

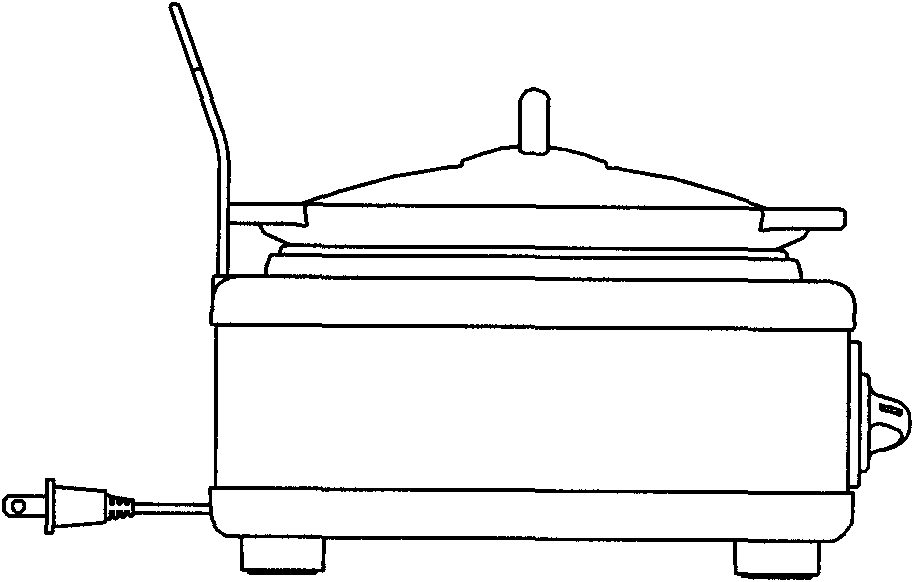

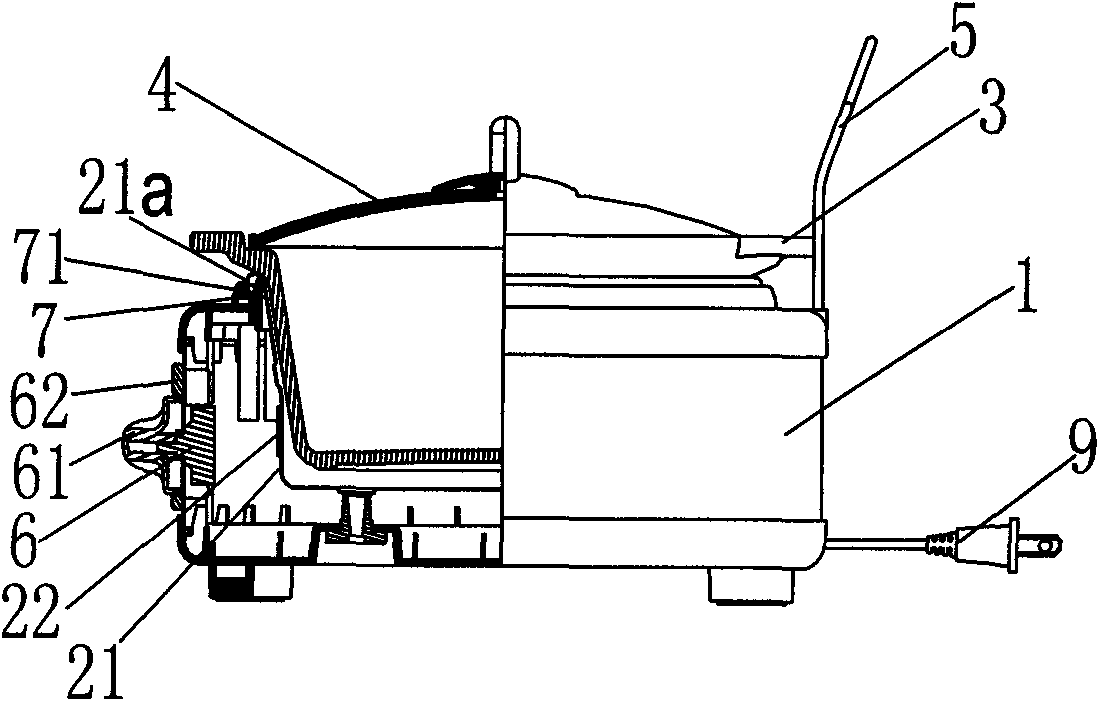

Novel slow cooker of combined structure

InactiveCN102172316ANice appearanceNot easy to burnWarming devicesEnergy consumptionHeating temperature

The invention discloses a novel slow cooker of a combined structure. The slow cooker comprises a stove body, wherein the stove body is equipped with three oval cooker site holes side by side which take the width direction of the stove body as long half shafts and the length direction of the stove body as short half shafts, and the inner chamber of the stove body is internally equipped with three heating elements matched with the shape of the cooker site holes through the three cooker site holes; and a pottery liner with an oval cross section is sheathed in each heating element in a suspension manner, each heating element is independently equipped with a switch knob for timing, regulating and controlling the operating time and heating temperature of the heating elements, and the circuit for the heating elements is connected with a power line. The novel slow cooker has the advantages of unique design, novel and beautiful appearance, controllable cooking time, constant temperature and less energy consumption, and can meet the dietary need of a plurality of persons at the same time.

Owner:宁波亿达电器有限公司

Heat radiation type welding method and device applied to solar battery pieces

ActiveCN103801781AReduce crackingRealize automatic controlFinal product manufactureHeating appliancesInfraredHeat-affected zone

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

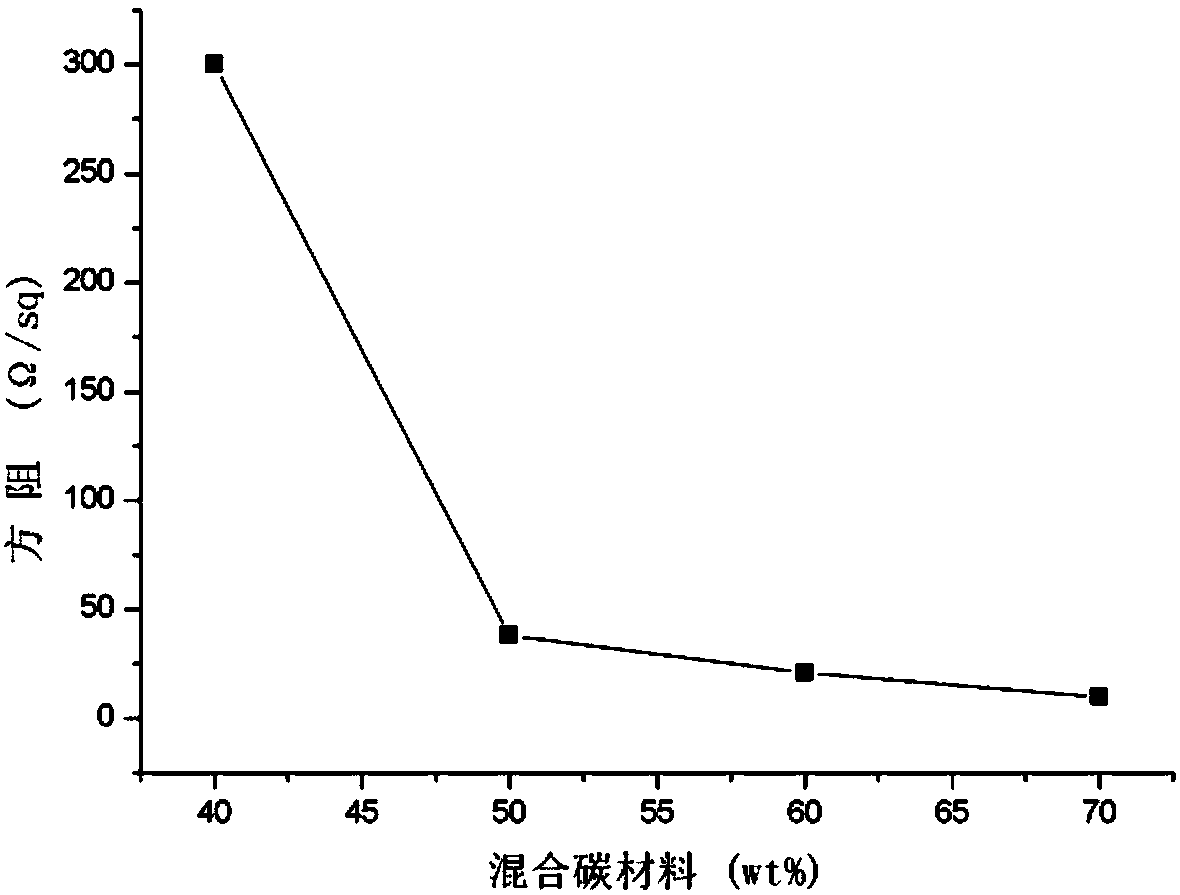

Environment-friendly low-resistance graphene carbon fiber conductive carbon paste and preparation method thereof

InactiveCN108039225AStable resistance valueUniform heating temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureFiberCarbon fibers

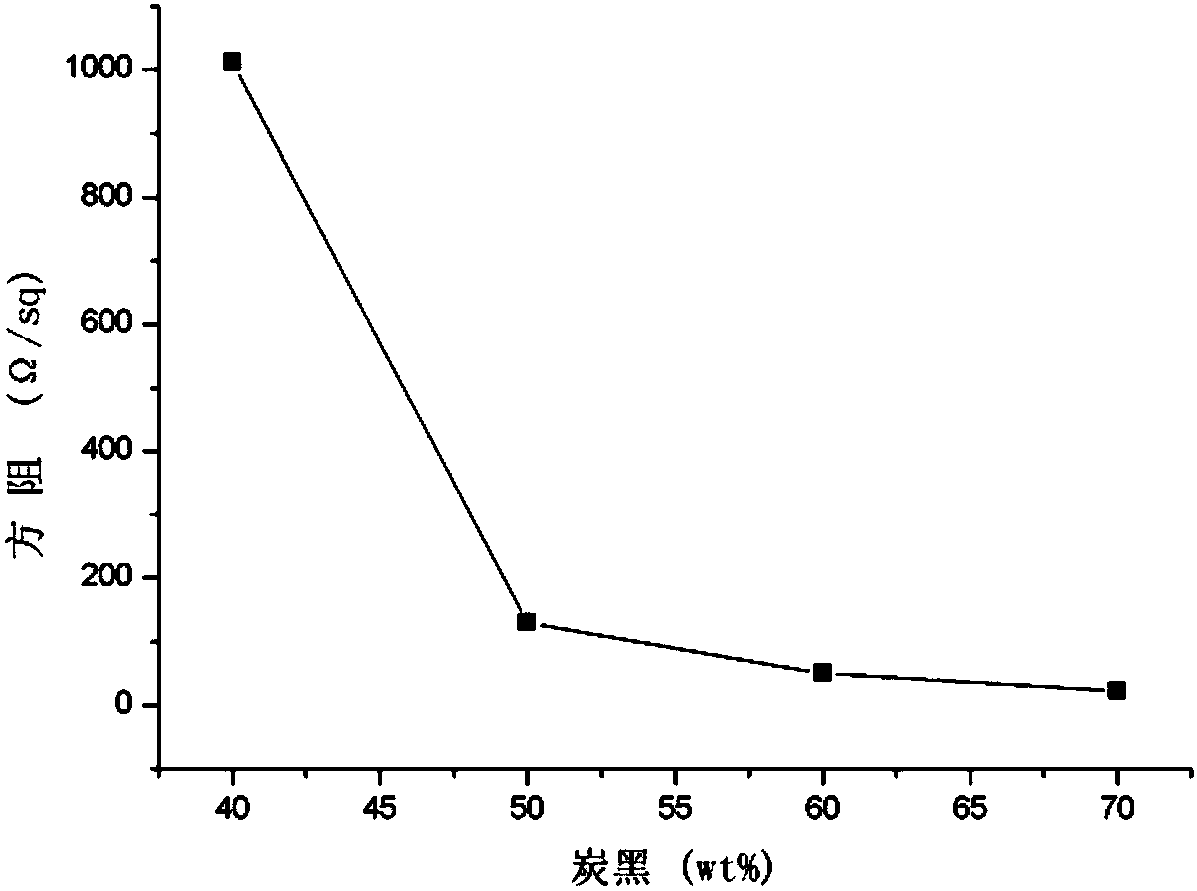

The invention relates to the technical field of conductive carbon paste preparation, in particular to environment-friendly low-resistance graphene carbon fiber conductive carbon paste comprising the following components: 30 to 70 parts of resin, 20 to 40 parts of carbon fiber, 1 to 10 parts of graphene microchip, 10 to 30 parts of conductive carbon black, 20 to 50 parts of solvent, 1 to 3 parts ofdispersant, 1 to 3 parts of adhesion promoter, and 1 to 3 parts of defoamer. Thermal conductive carbon paste using graphene and carbon fiber as the main carbon materials has the characteristics of good electrical conductivity, small internal resistance, uniform distribution of carbon material, and easy coating.

Owner:CHANGZHOU XICAI CARBON MATERIAL TECH CO LTD

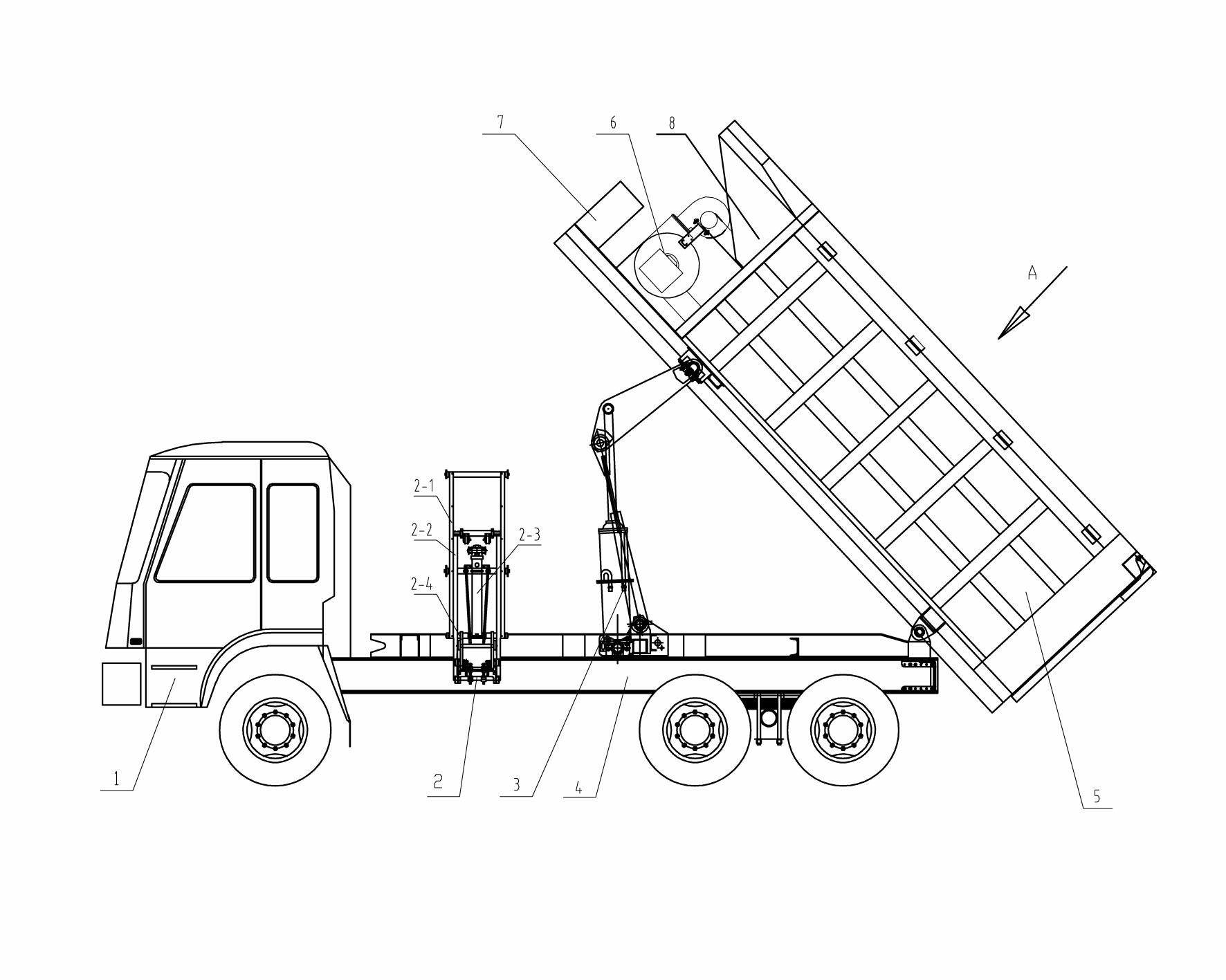

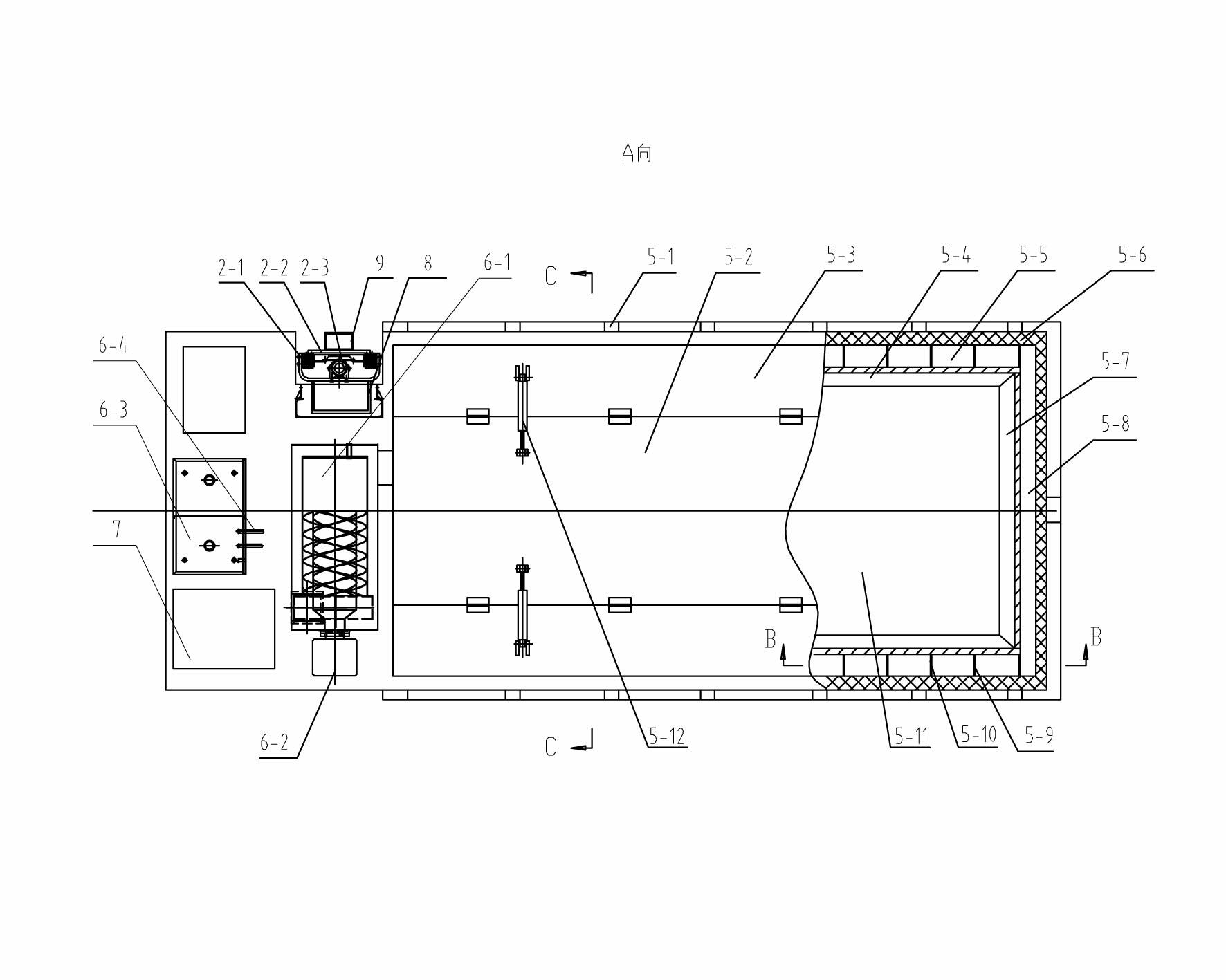

Heat insulation recycling transport vehicle for hot air circulation asphalt mixture

InactiveCN102660917AIncrease the heating areaReduce lossesConcrete transportationRoads maintainenceHeat conservationElectric control

A heat insulation recycling transport vehicle for hot air circulation asphalt mixture comprises a vehicle chassis, an asphalt mixture bin, a bin lifting mechanism, an excess material recycling transport mechanism, a follow charging hopper and an electric control device. The asphalt mixture bin is a tipper-hopper discharge type hot air circulation heating heat insulation bin mechanism, the heat insulation bin mechanism comprises a flipping frame, a heat insulation bin, a hot air circulation furnace device and a generator set, a feeding hopper is arranged on the heat insulation bin and is in butt joint with the follow charging hopper, the heat insulation bin comprises a heat insulation box, a bottom hot air channel, a tail hot air channel, two side wall hot air channels, two groups of spoilers and an inner bin, and the hot air circulation furnace device comprises a diesel tank, a diesel supply device, a hot air furnace and a high-temperature circulation fan. The heat insulation recycling transport vehicle has the advantages that heating is quick and uniform, the heat efficiency is high, hot air with waste heat can be recycled, loading transport heat insulation effects are fine, and the best laying temperature and quality of the asphalt mixture are constantly ensured.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

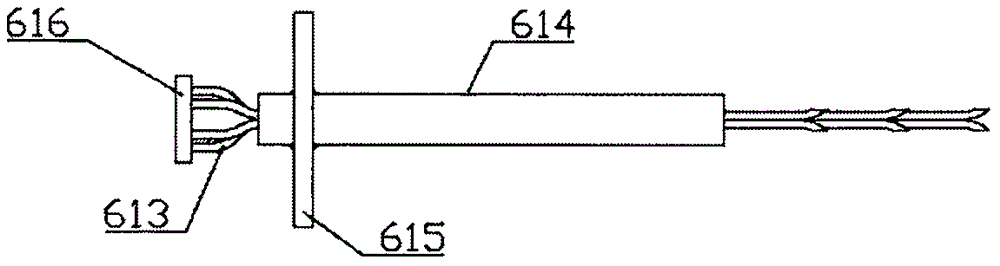

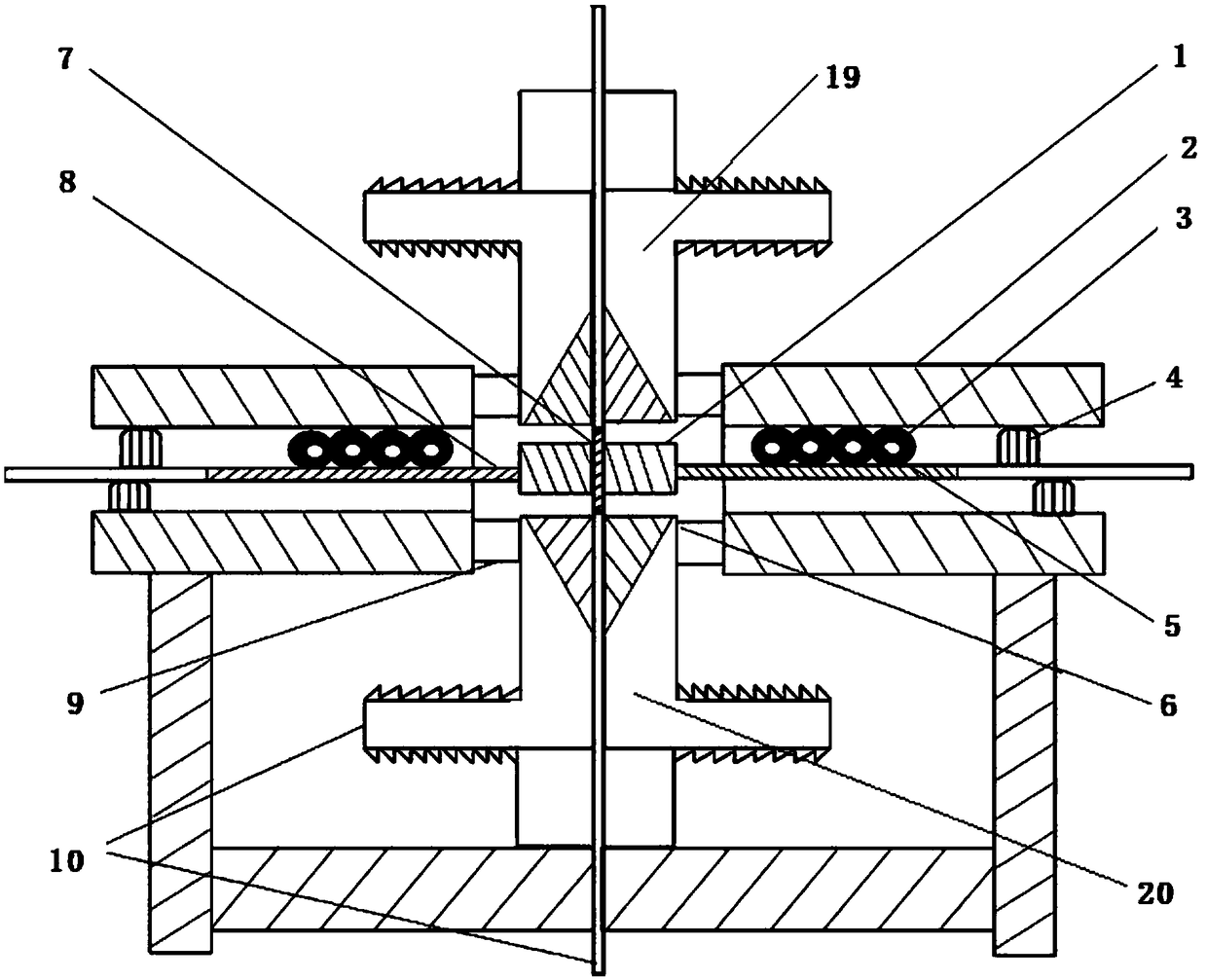

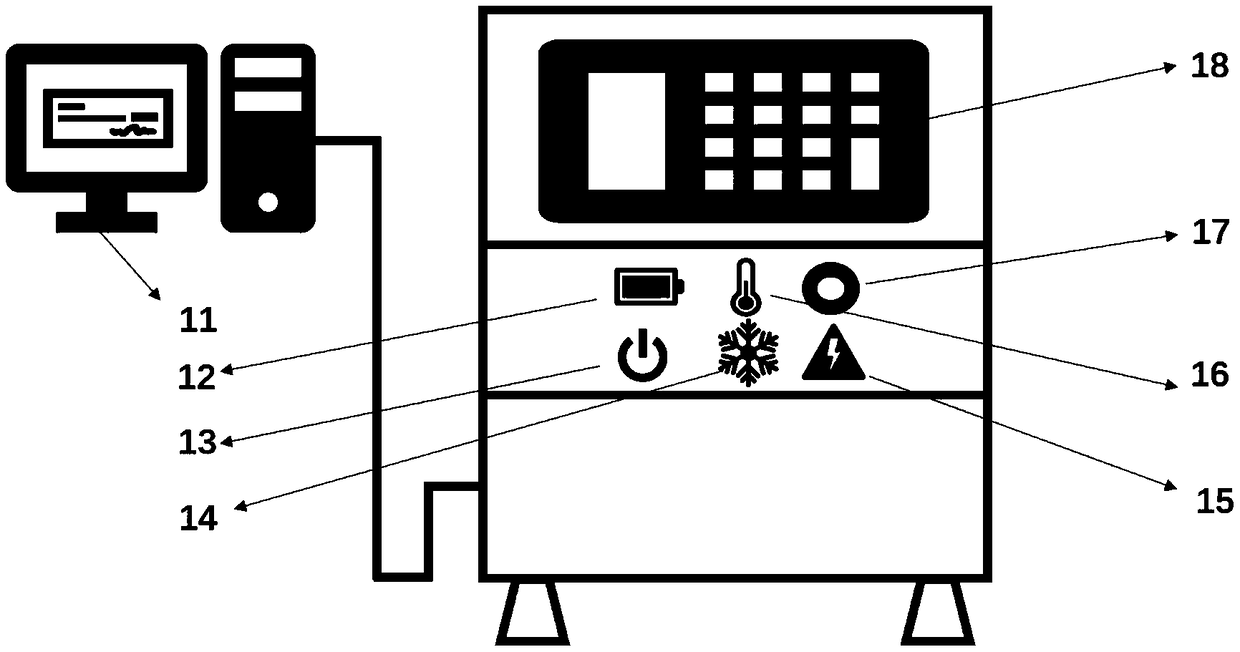

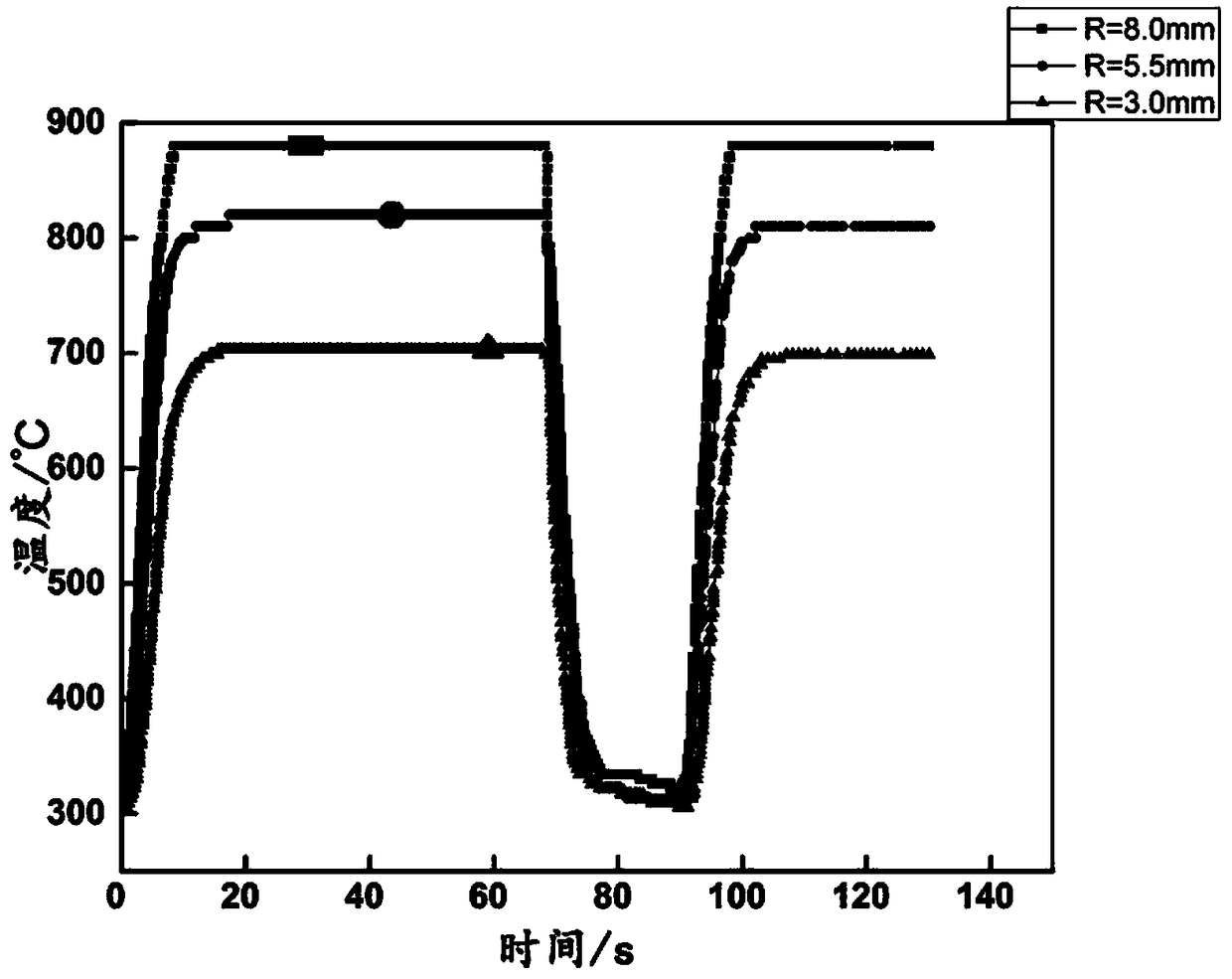

Experimental device used for thermal fatigue of turbine blade material

The invention discloses an experimental device used for the thermal fatigue of a turbine blade material. The device comprises an experiment test bench, an induction coil heating system, a temperaturetesting and collecting system, a cooling system and an experiment control platform, wherein the induction coil heating system, the temperature testing and collecting system, the cooling system and theexperiment control platform are independently connected with the experiment test bench; a specimen is fixed on a fixture; cooling gas passes through a first cooling gas channel and a second cooling gas channel to cool the surface, the end part and the inner side of the specimen; a thermocouple is independently arranged on a position with a surface radius of 3.5mm, a position with a surface radiusof 6.5mm, a position with a surface radius of 8.5mm and a specimen inner ring; the thermocouple is connected with a temperature display instrument and a computer host; and the inner ring of the induction coil is provided with an induction coil cooling water channel, cooling water flows in from one side of the induction coil and flows out from the other side. The device has the advantages that thermal fatigue working environment, where the turbine blade is positioned, with alternating circulation under different working states can be simulated, and in addition, important experiment data can beprovided for the thermal fatigue failure mechanism and the reliability of the turbine blade material.

Owner:NANCHANG HANGKONG UNIVERSITY

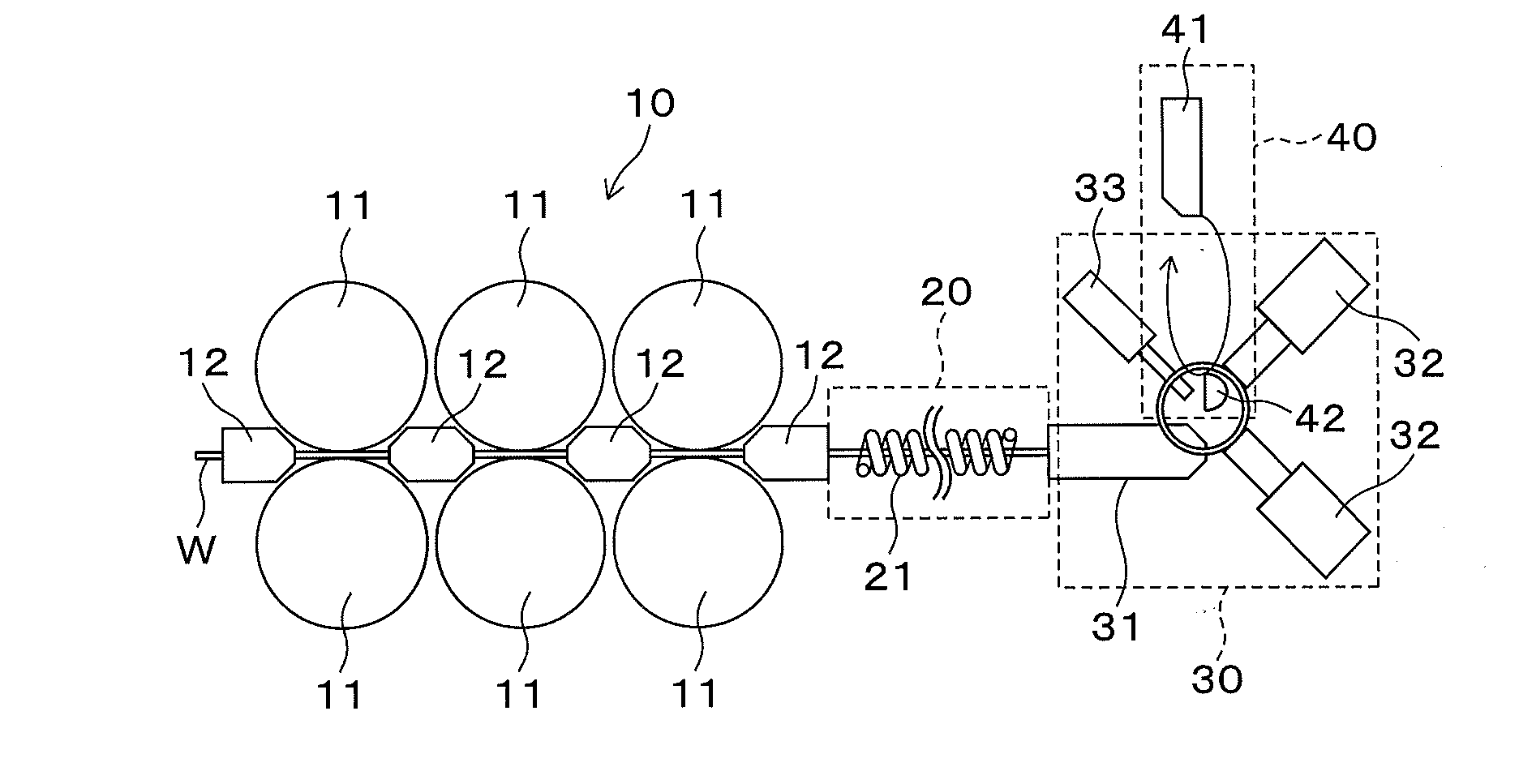

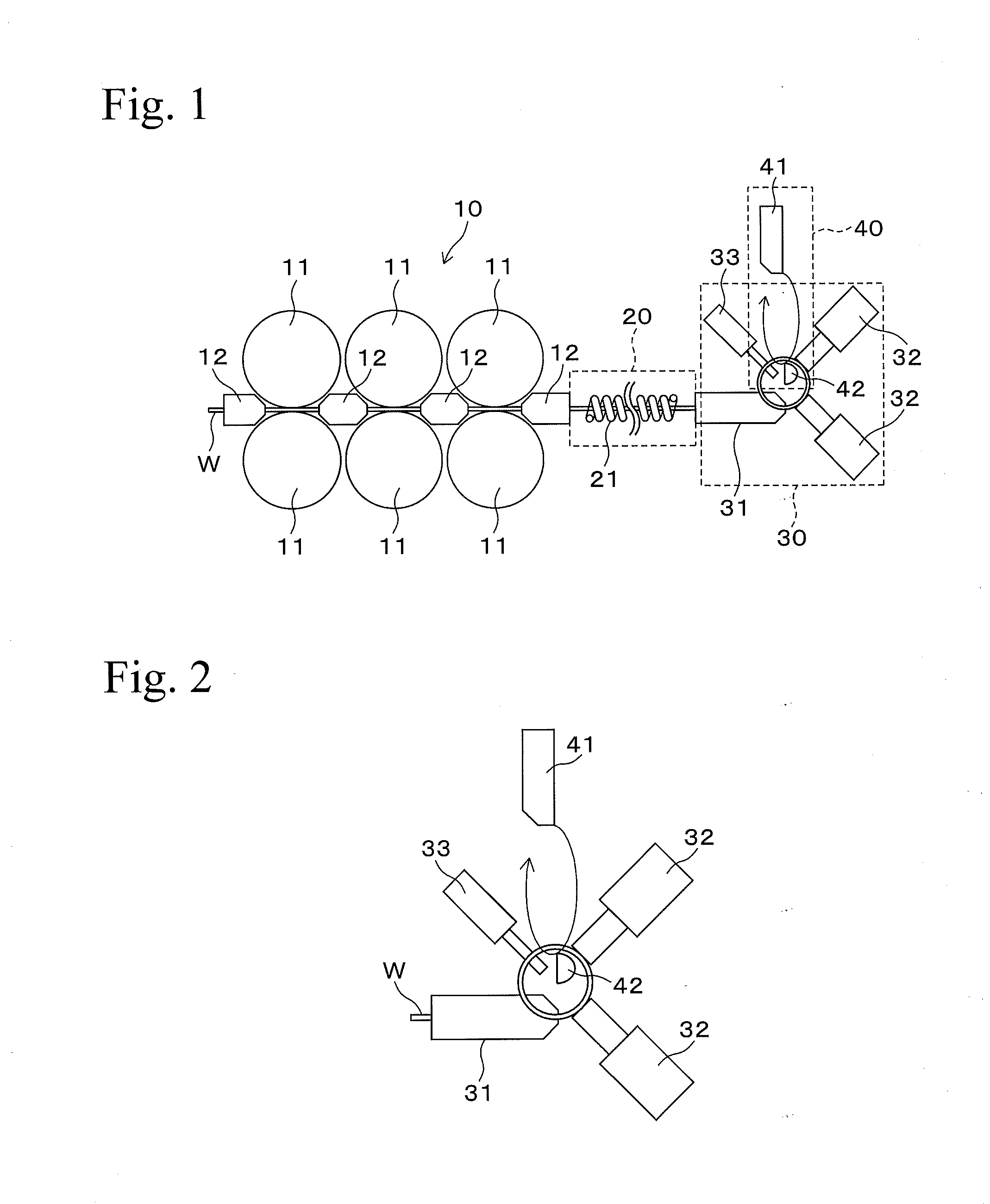

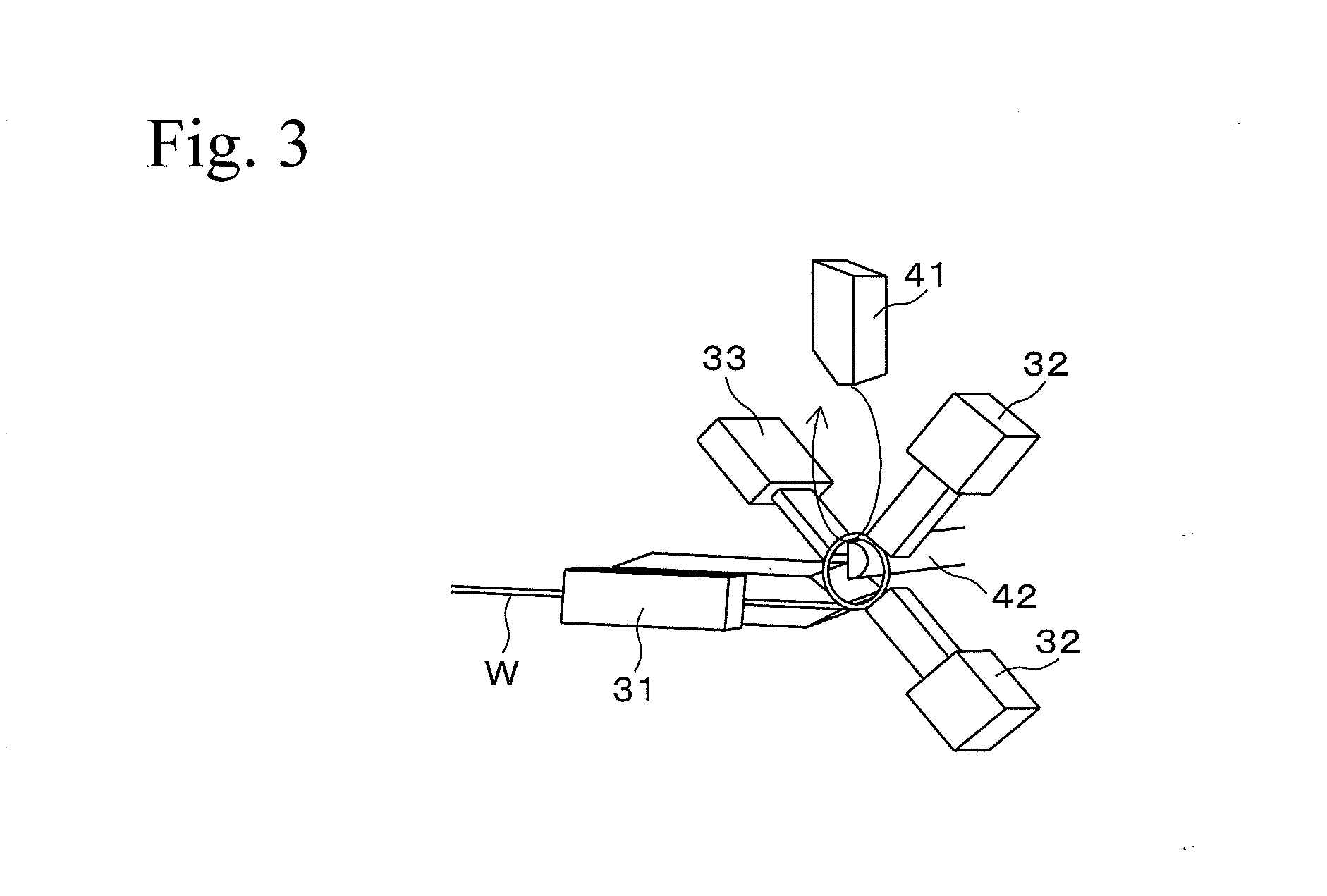

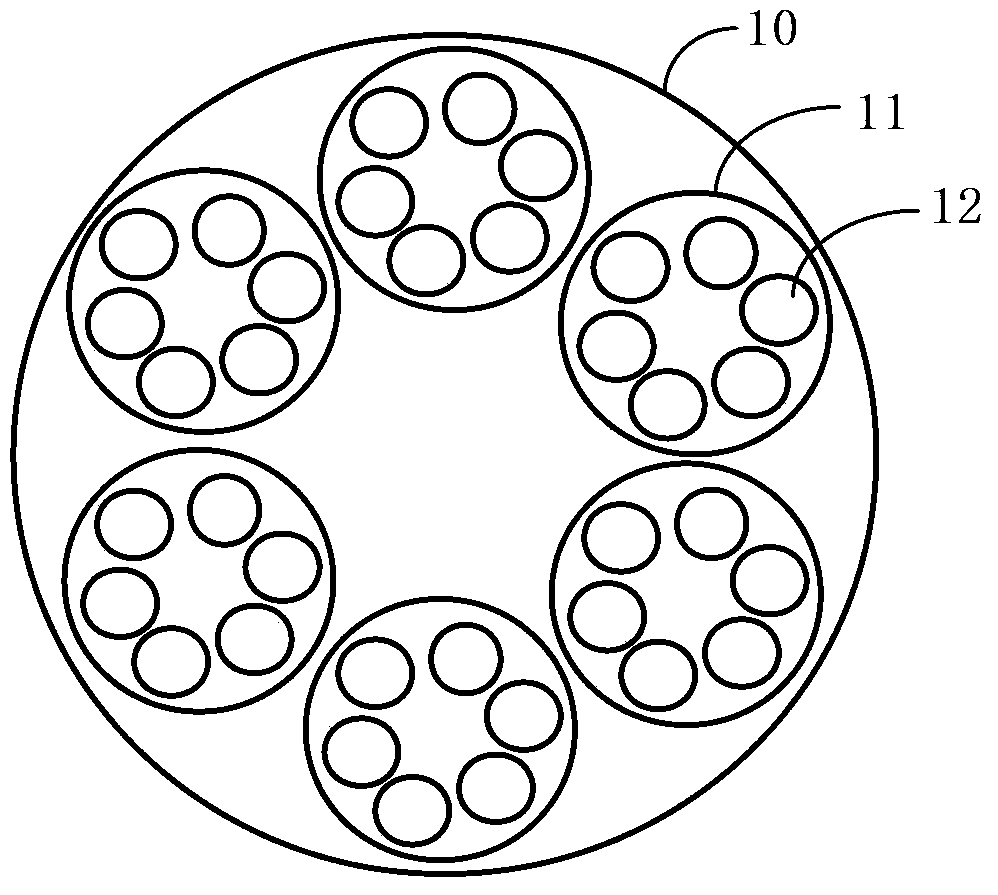

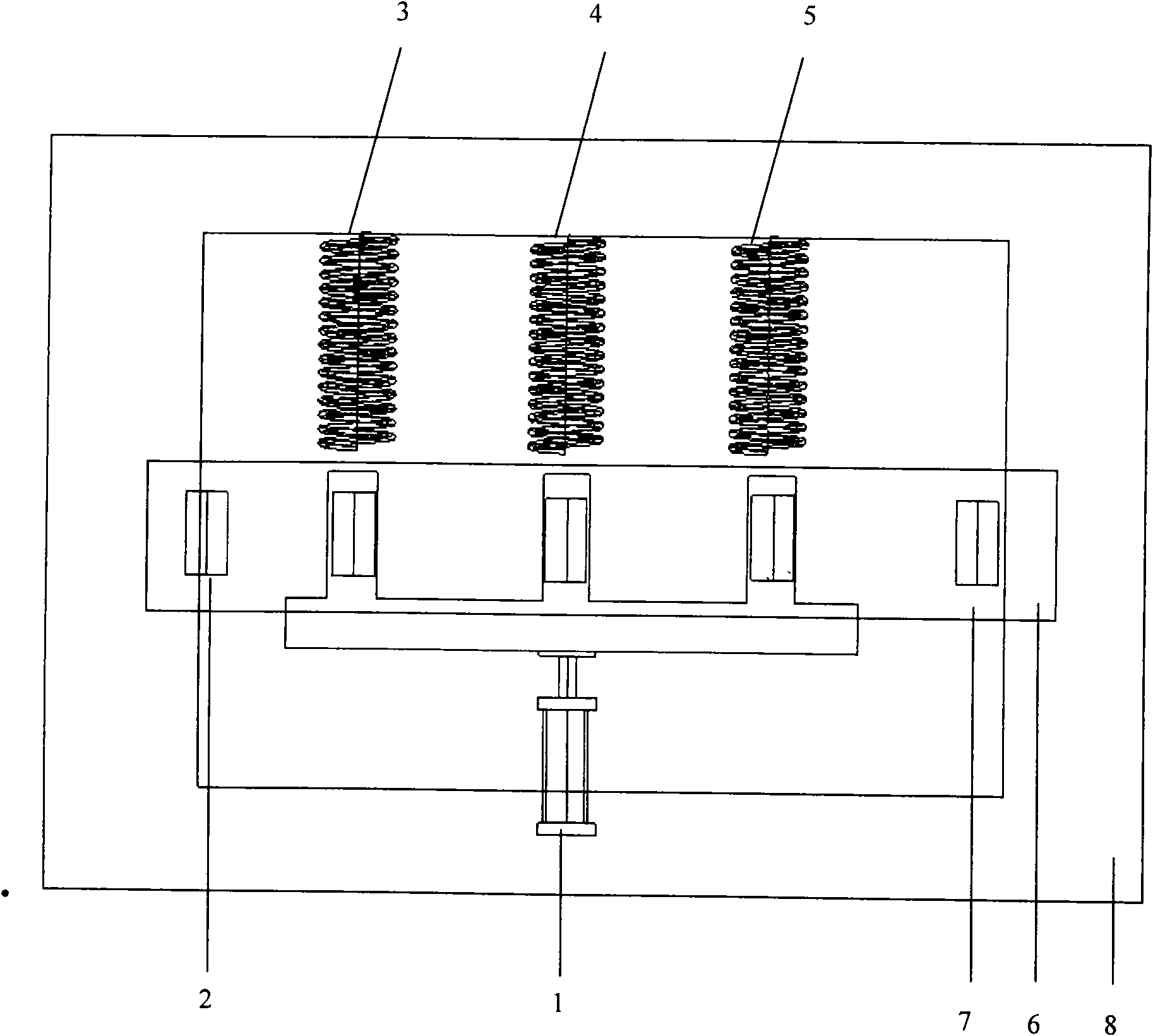

Spring forming device and forming method therefor

InactiveUS20160243607A1Heating evenlyNon-uniformity of heating time of the steel wire by the heating mechanism is preventedWire springsInduction heating apparatusMetallurgy

A spring forming device in which the steel wire can be continuously cut off without stopping the feeding of the steel wire in cutting, and in which the steel wire can be uniformly heated, is provided. The spring forming device has a wire supplying mechanism for supplying a steel wire using a plurality of feeding rollers, a heating mechanism for heating the steel wire, a coiling mechanism for forming in a coil state the heated steel wire, and a cutting mechanism for cutting the steel wire coiled at a given number of turns off the steel wire remained backward. A cutting blade of the cutting mechanism follows tracks having a speed Va that moves to the receiving blade and a speed Vc that moves in an axial direction of the coiled steel wire, in cutting of the steel wire.

Owner:NHK SPRING CO LTD

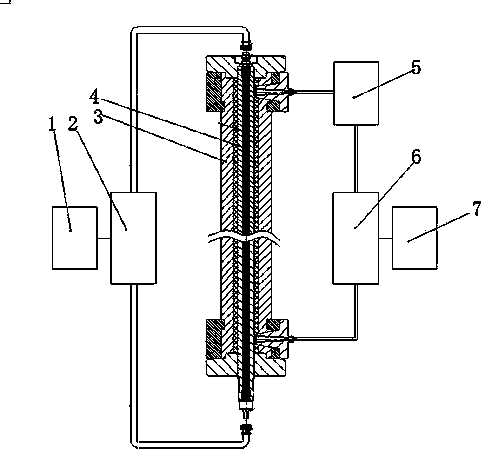

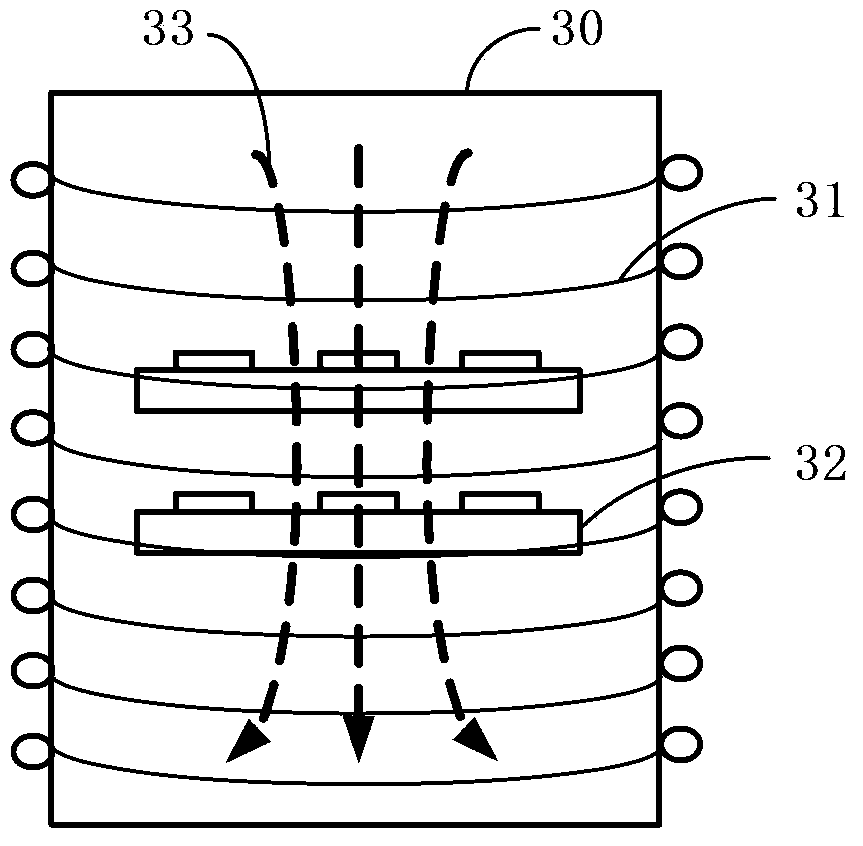

MOCVD apparatus and MOCVD heating method

ActiveCN103628040AUniform heating temperatureImprove uniformityFrom chemically reactive gasesChemical vapor deposition coatingEngineeringElectrical and Electronics engineering

The present invention discloses a MOCVD apparatus and a MOCVD heating method. The MOCVD apparatus comprises a reaction chamber, an induction coil and a tray, wherein the induction coil is positioned outside the reaction chamber, the tray is positioned inside the reaction chamber, the induction coil is provided for generating a magnetic field and heating the tray through the magnetic field, and the tray is provided for placing a substrate and generating a relative movement between the tray and the magnetic field so as to make the substrate alternately pass through the magnetic force line sparse area and the magnetic force line dense area in the magnetic field. According to the embodiment of the present invention, the substrate on the tray alternately passes through the magnetic force line sparse area and the magnetic force line dense area in the magnetic field, such that heating temperatures of different areas on the tray are uniform, and temperature uniformity on the substrate is increased so as to improve epitaxial wafer quality and achieve large epitaxial wafer processing.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

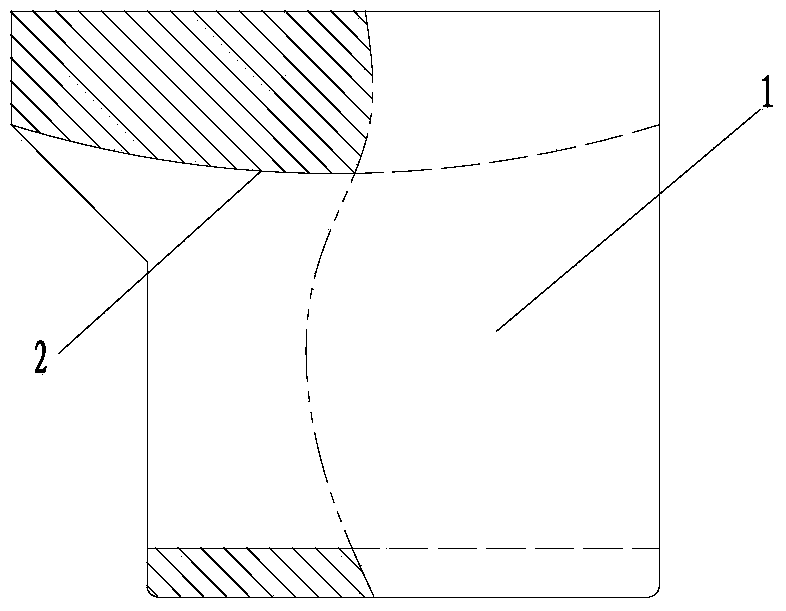

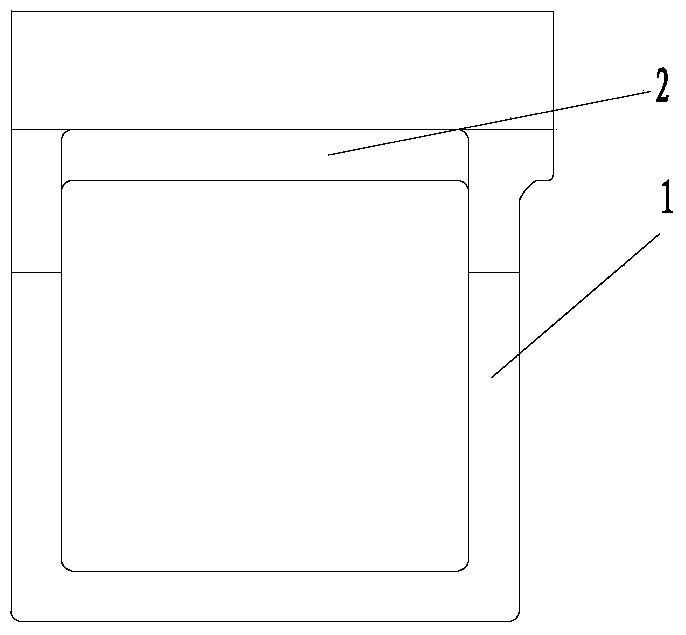

Lining plastic pipe cast iron pipe and manufacturing method thereof

The invention provides a lining plastic pipe cast iron pipe and a manufacturing method thereof. The lining plastic pipe cast iron pipe comprises a cast iron pipe body and a plastic composite pipe material; the plastic composite pipe material is composes of an outer layer hot melt glue layer and an inner layer plastic pipe; the plastic composite pipe material is manufactured on line; the inner wall of the cast iron pipe body is subjected to sand blasting, shot blasting or shot throwing treatment after being ground; the plastic composite pipe material is pulled into the treated cast iron pipe body; the two ends of the plastic composite pipe material are subjected to sealing and gas filling; after heating treatment, cooling is performed; and the cast iron pipe body and the plastic composite pipe material are cemented, and trimming, spraying and marking are performed. The invention further discloses the manufacturing method of the lining plastic pipe cast iron pipe. By means of the lining plastic pipe cast iron pipe and the manufacturing method thereof, the defects of an existing cement mortar lining modular cast iron pipe and epoxy resin and epoxy ceramic lining modular cast iron pipes can be overcome, and the lining plastic pipe cast iron pipe is suitable for the water supply, fuel gas, water discharging, sewage discharging, heating and other fields, and is a most ideal water delivery pipe material product at present.

Owner:HUNAN ZHENHUI PIPE IND

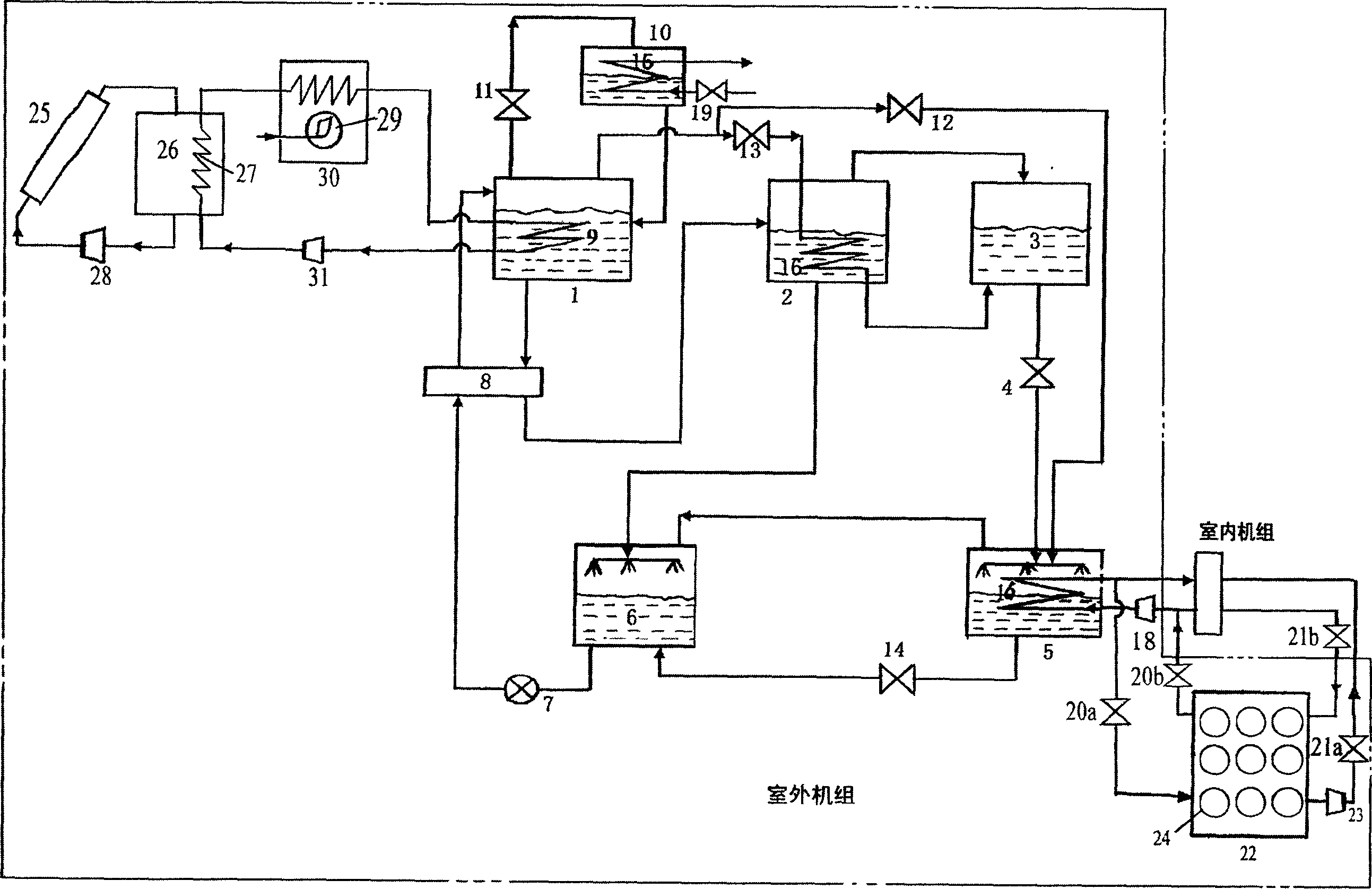

Solar-natural gas combined driven energy-saving air condioner

InactiveCN101000181AEnvironmentally friendlyEnergy savingClimate change adaptationEnergy efficient heating/coolingWater cyclingCollector device

The invention discloses a solar energy-natural gas combined driven energy saving air-conditioner, where the outdoor machine set comprises solar heat collector, solar heat storer and natural gas heater; a heat exchanger pipe coil in the solar heat collector is connected with the two ends of the other heat exchanger in the high pressure generator through the natural heater and circulating pump to drive indoor machine set to work. And it uses heat source as drive energy, integrating refrigeration, heating and living hot water supply; the condenser and absorber in the machine set adopt wind cooling, omitting the cooling water circulating system so as to be used at home and in medium- and small-sized buildings; and its performance coefficient can be up to above 1.5, reducing energy consumption and making full use of renewable energy source. In addition, it has characters of environmental protection, saving energy, and safety.

Owner:NANJING UNIV

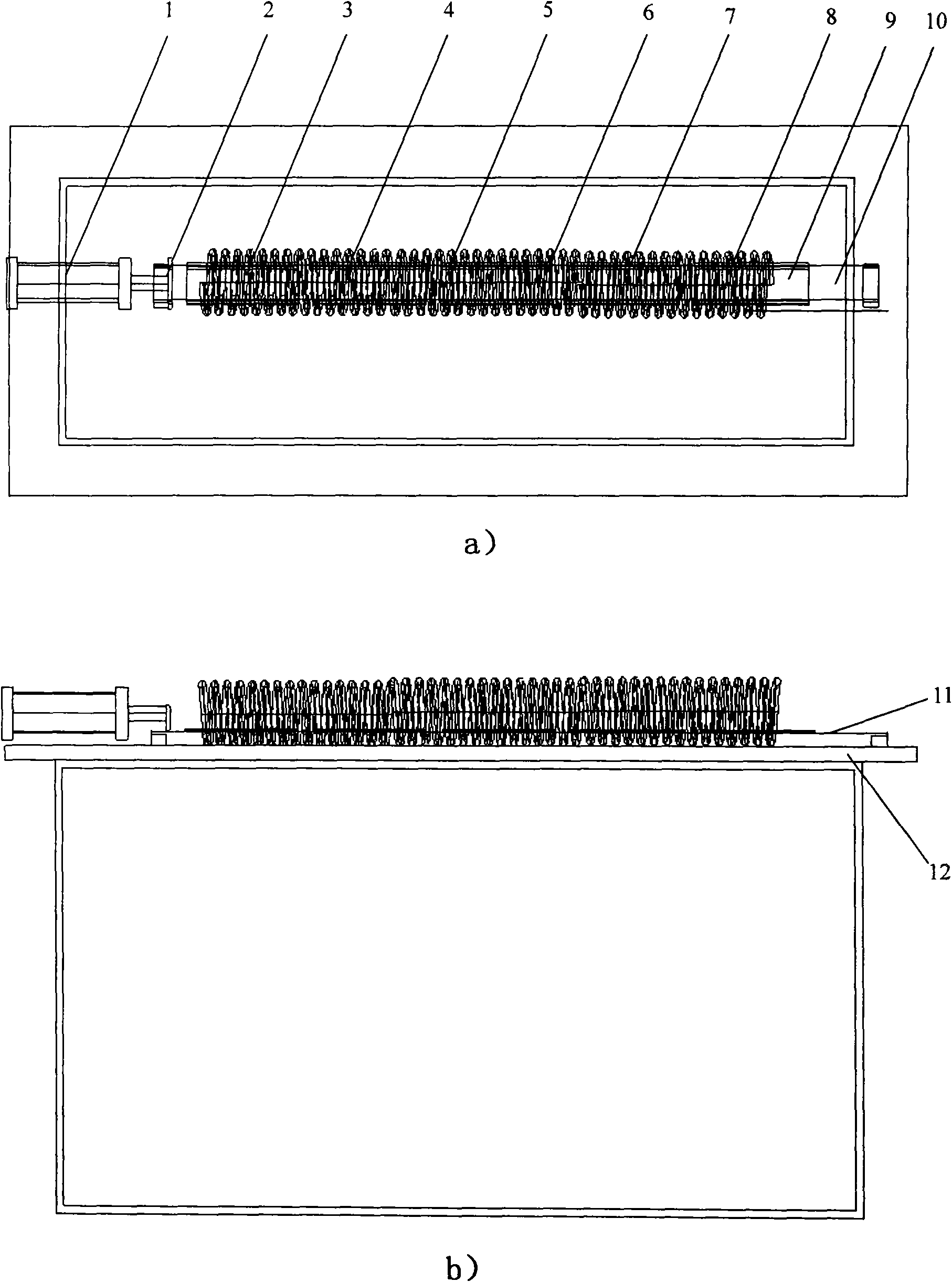

Horizontal type device for reheating semi-solid metal blank material

The invention relates to a horizontal type device for reheating a semi-solid metal blank material, which comprises an induction heating power supply, an induction heating mechanism, and a blank material carrying mechanism, and is provided with five stations, such as at least three material heating stations, a material placing station and a material discharging station, wherein the induction heating mechanism adopts three sections of induction heating coils which are separately and horizontally arranged, and all the induction heating coils are mutually electrically communicated and arranged on the three material heating stations respectively; the blank material carrying mechanism comprises a feed mechanism and a blank material transporting device; the blank material transporting device is a delivering device processing in front of each station; and the feed mechanism is positioned in front of each induction heating coil. The induction heating three-section heating mode is selected to make the heating of the blank material and the distribution of the temperature field more even and reasonable. The horizontal structure is adopted, the blank material cannot collapse or discharge fluid, and the blank material transportation is simple and convenient because of a large contact surface between the blank material and a supporting part. The blank material is allowed to have a higher liquid phase fraction, which is convenient for the thixotropic forming of more complicated parts.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

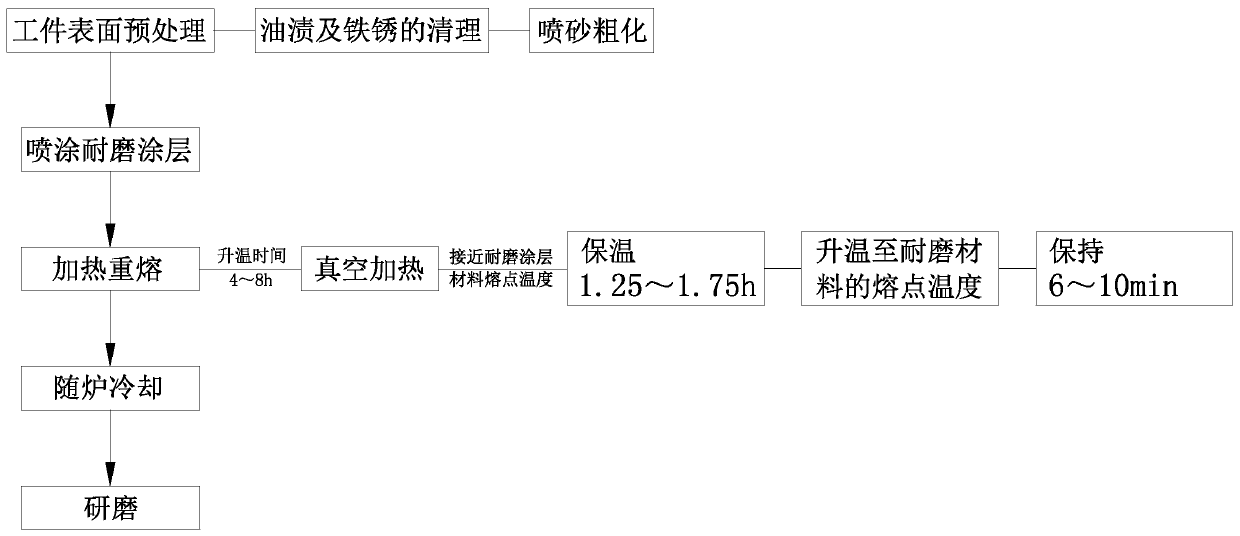

Manufacturing process of metal seated ball valve nickel-based tungsten carbide wear-proof coating

InactiveCN111455306AAvoid crackingImprove compactnessMolten spray coatingSurface cleaningWear resistance

The invention discloses a manufacturing process of a metal seated ball valve nickel-based tungsten carbide wear-proof coating. The manufacturing process includes the following steps that S1, the surfaces of workpieces are pre-treated, wherein a machined ball body and a machined valve seat are subjected to surface cleaning and coarsening; S2, a wear-proof coating is sprayed, wherein a wear-proof coating powder material is evenly sprayed to the surfaces of the ball body and the valve seat through a hypersonic flame spraying process; S3, heating and remelting are carried out, wherein the sprayedball body and the sprayed valve seat are put in a vacuum furnace in batches for heating and remelting, and the ball body and the valve seat are metallurgically bound with the wear-proof material; S4,cooling is carried out, wherein after being remelted, the ball body and the valve seat are slowly cooled along with the vacuum furnace; and S5, grinding is carried out, wherein the cooled ball body and the cooled valve seat are precisely ground in sequence through a grinding device. The strength of the wear-proof coating on the sealing face of a ball valve can be improved, then the wear-proof performance of the sealing face of the ball valve is enhanced, and the service life of the ball valve is prolonged.

Owner:CHAODA VALVE GRP

Induction quenching system and method for bearing cylindrical face of self-limiting seat of heavy truck plate spring

InactiveCN103421934APrecise positioningStable positionFurnace typesIncreasing energy efficiencyTransformerLiquid tank

The invention discloses an induction quenching system and method for a bearing cylindrical face of a self-limiting seat of a heavy truck plate spring. The induction quenching system comprises a quenching machine tool, an inductor, a quenching circulating cooling liquid tank, a medium-frequency power supply and a quenching transformer. A locating tool set is installed on the quenching machine tool, the locating tool set can move up and down along a support of the quenching machine tool, the locating tool set is used for locating a work piece, the inductor is connected to the medium-frequency power supply through a quenching transformer, the inductor is further matched with the locating tool set of the quenching machine tool to heat the work piece, the locating tool set is driven by a driving device, the driving device is controlled by a controller, and the quenching circulating cooling liquid tank is arranged on one side of the quenching machine tool. The induction quenching system combines a fixed-point heating method and a scanning heating method to heat repeatedly and circularly, so that the heating temperature of the whole heating face is relatively even, and quenched products can meet the requirements for the depth and the hardness of a hardened layer. Meanwhile, the induction quenching system can achieve the purpose of using small-power-output equipment to process large products and reduces fund investment.

Owner:SINO TRUK JINAN POWER

Multilayered baking oven system

ActiveCN102589264AImprove baking efficiencyImprove feeding efficiencyDrying chambers/containersDrying machines with progressive movementsProcess engineeringEngineering

A multilayered baking oven system comprises a conveying portion and a baking oven communicated with the conveying portion. At least two layers are arranged inside the baking oven from top to bottom, and the conveying portion is connected with the baking oven by a lifting system. The multiple layers of the baking oven can run simultaneously, a plurality of workpieces are baked at the same time, and baking efficiency of the baking oven is effectively improved; the conveying portion conveys the workpieces into the baking oven, manual intervention of operators is omitted, conveying efficiency is improved, and labor cost is also lowered; and heating temperature inside the baking oven is uniform, and a baking effect is good.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

Whole vehicle HVAC system and air conditioning mode conversion method

InactiveCN108437746AImprove comfortReduce the overall heightAir-treating devicesVehicle heating/cooling devicesLow speedAir volume

The invention aims to provide a whole vehicle HVAC system and an air conditioning mode conversion method. The whole vehicle HVAC system comprises an air conditioning device, an HVAC controller and a whole vehicle auxiliary heating device, wherein the air conditioning device comprises a shell, an air conditioning mode conversion device, two air inlet boxes, a linkage driving device, an evaporator and an air conditioning heater; the shell is provided with an air outlet cavity and two air inlet holes; the air conditioning mode conversion device is arranged in the air outlet cavity; the two air inlet boxes are provided with internal and external circulating air mode conversion devices and connected to the outer ends of the air inlet holes in a one-to-one matching manner; the linkage driving device is provided with two air-blast impellers extending into the inner ends of the air inlet holes in a one-to-one matching manner; the evaporator and the air conditioning heater are arranged in the air outlet cavity; a blowing-face air outlet is arranged at the front end of the shell; and a defrosting air outlet is arranged at the upper end of the shell. The whole vehicle HVAC system has lower speed of an air blower and higher efficiency of the air blower under the same air volume requirement so as to facilitate energy saving and noise reduction. In the cold weather, the whole vehicle auxiliary heating device is used for assisting in heating, so that the heating temperature and heating speed can meet the needs.

Owner:ZHIDOU ELECTRIC VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com