Patents

Literature

120results about How to "Realize flow operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

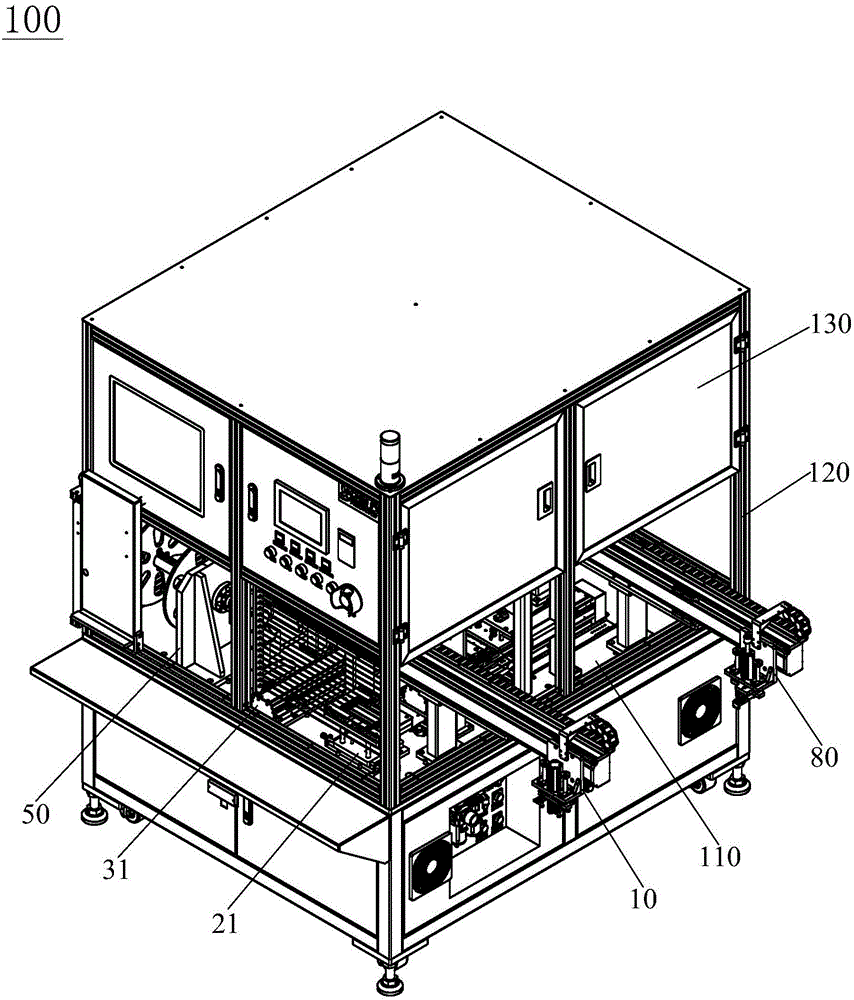

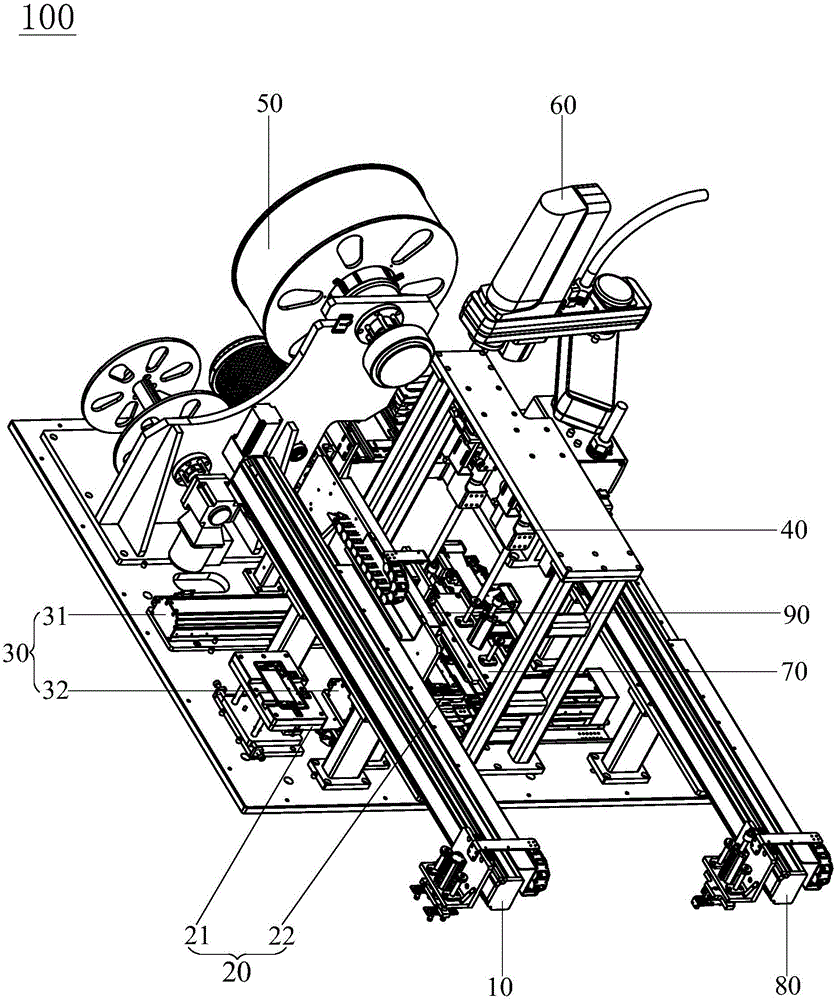

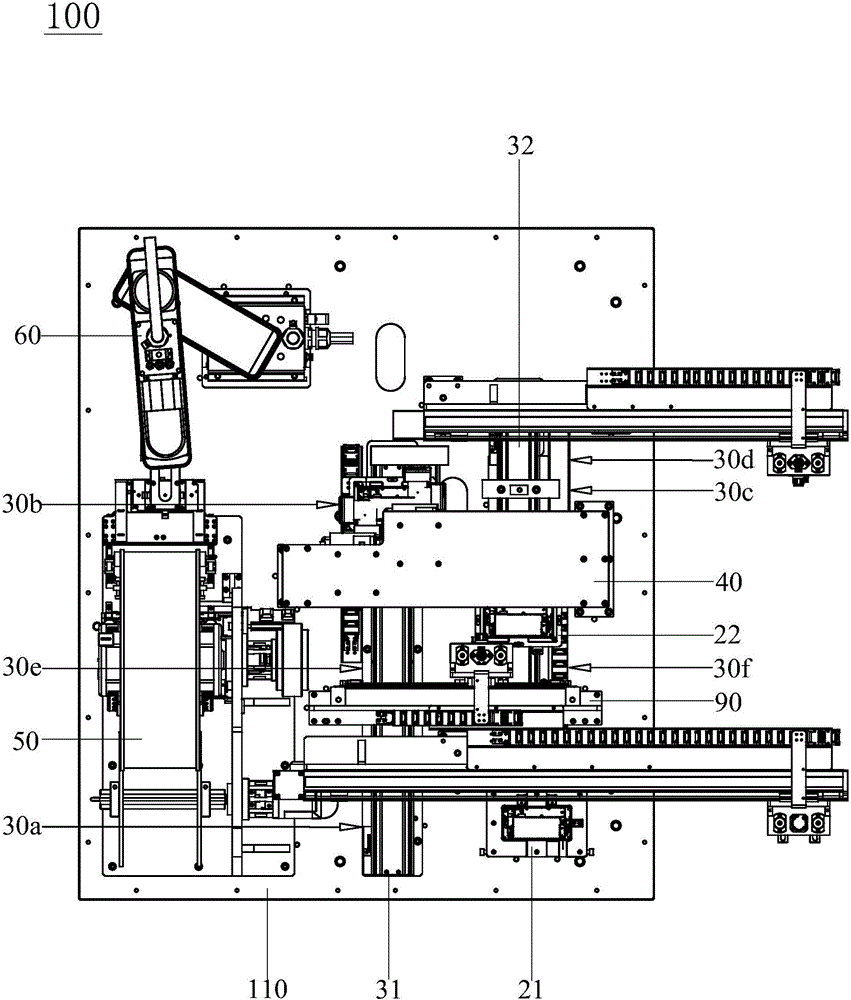

Fully-automatic film laminator

The invention discloses a fully-automatic film laminator. The fully-automatic film laminator comprises a feeding device, a first positioning jig, a second positioning jig, a conveying guide rail, a CCD detection device, a peeling device, a gluing device, a pressure holding device and a discharging device, wherein mobile phone shells are conveyed onto the first positioning jig by the feeding device, positioned by the first positioning jig for the first time and then are transversely conveyed to the second positioning jig; after being positioned by the second positioning jig for the second time, the mobile phone shells are conveyed on the conveying guide rail; films are peeled from tape materials by the peeling device so as to expose the viscous layers of the films; the gluing device conveys the films with the exposed viscous layers onto the mobile phone shells and primarily glues the films with the mobile phone shells; the CCD detection device carries out recognition and feedback on the three-dimensional coordinates of the mobile phone shells and the films in the gluing process; the pressure holding device carries out pressure holding on the films and the mobile phone shells, primarily glued; and the discharging device conveys and discharges the films and the mobile phone shells, subjected to pressure holding. The fully-automatic film laminator is simple in structure and high in efficiency and realizes automatic assembly line production.

Owner:DONGGUAN WORLD PRECISION MACHINERY

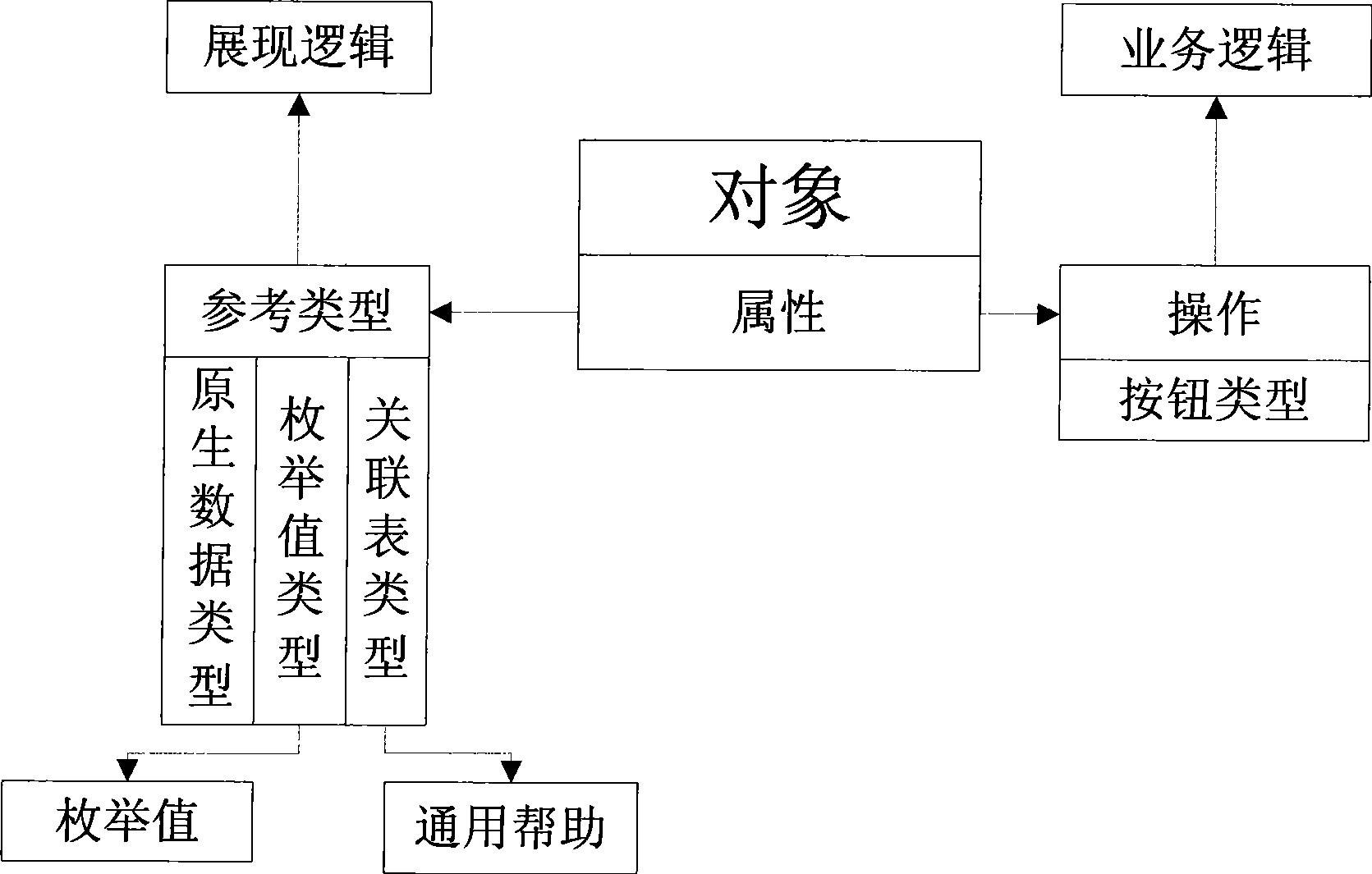

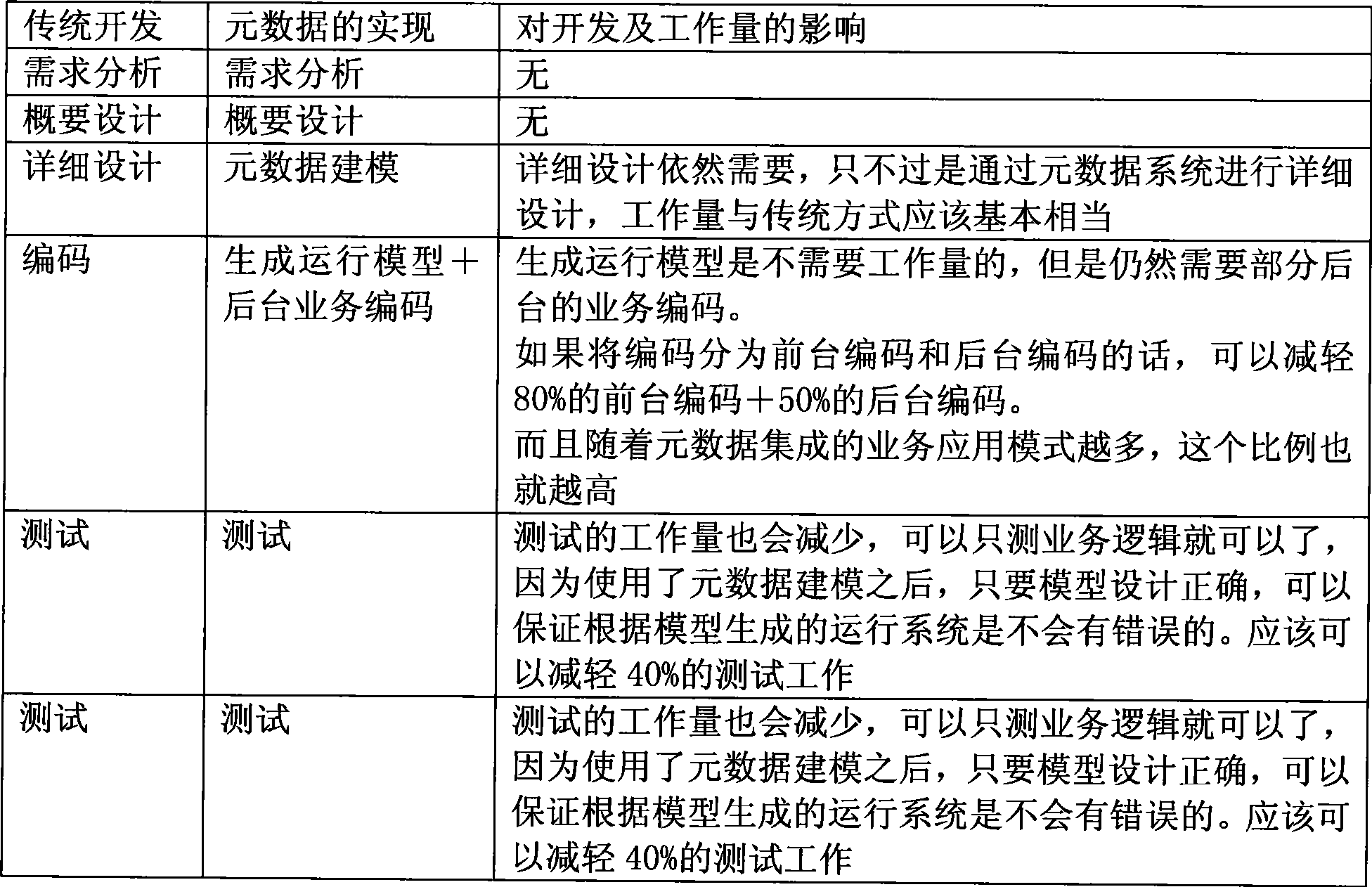

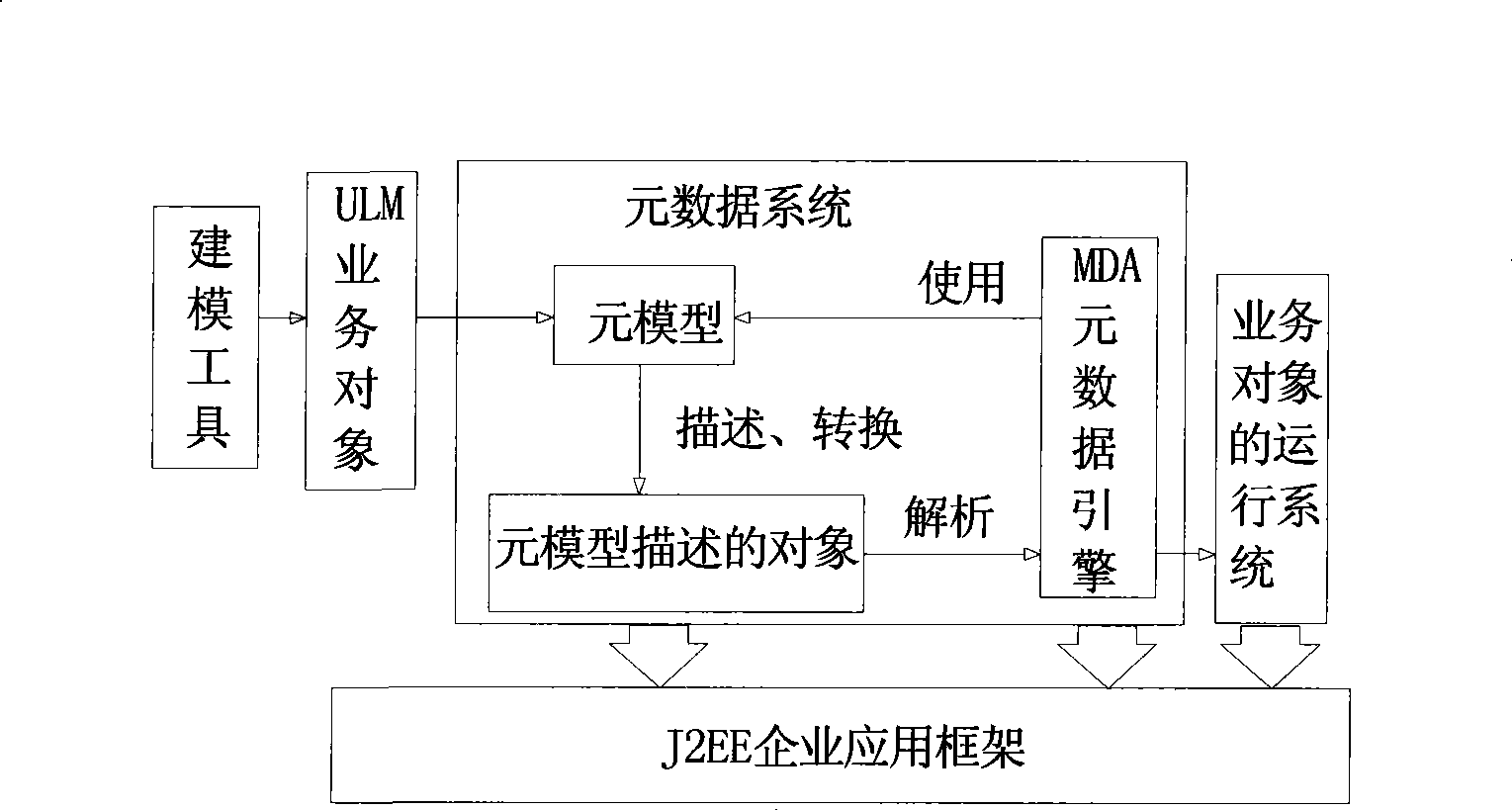

Model-driven software development method used for dynamically changing system behavior

InactiveCN101477462AQuick customizationSimplify the design processSpecific program execution arrangementsSoftware development processModel-driven software development

The invention provides a method for developing model-driven software capable of dynamically changing system behavior. The method is characterized in that the traditional development mode is changed; the direct operation of a model is realized; an operation system of a business object can be obtained by just using a metadata system to describe the model of the business object, without the need of the programmer encoding, so that the manner of programming codes by the programmer is changed, the substitute is that the business rules and relevant logics are edited by business experts of various industries in a graphic interface manner, and the new functions automatically become effective under the condition that the business is not interrupted.

Owner:INSPUR SOFTWARE CO LTD

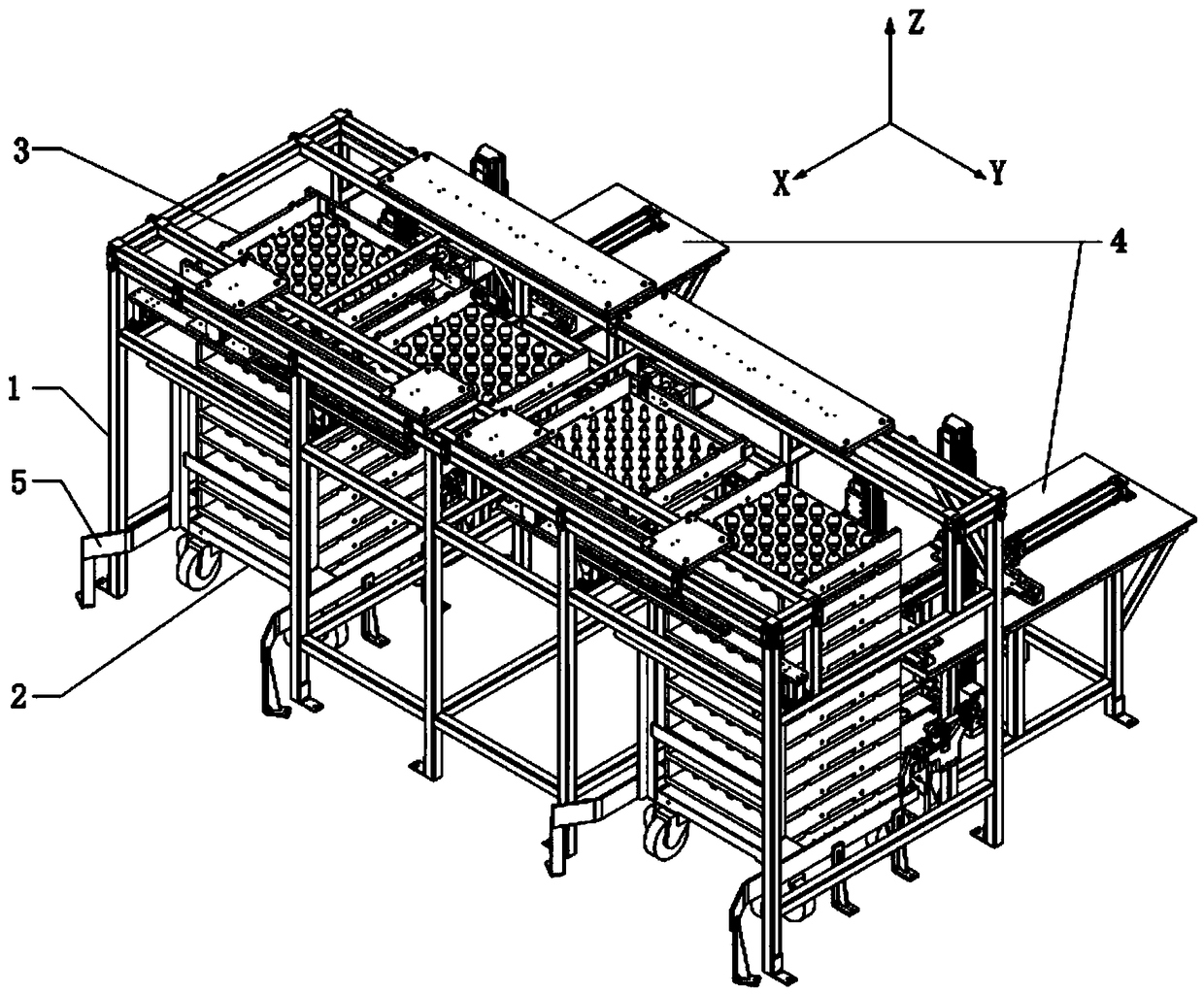

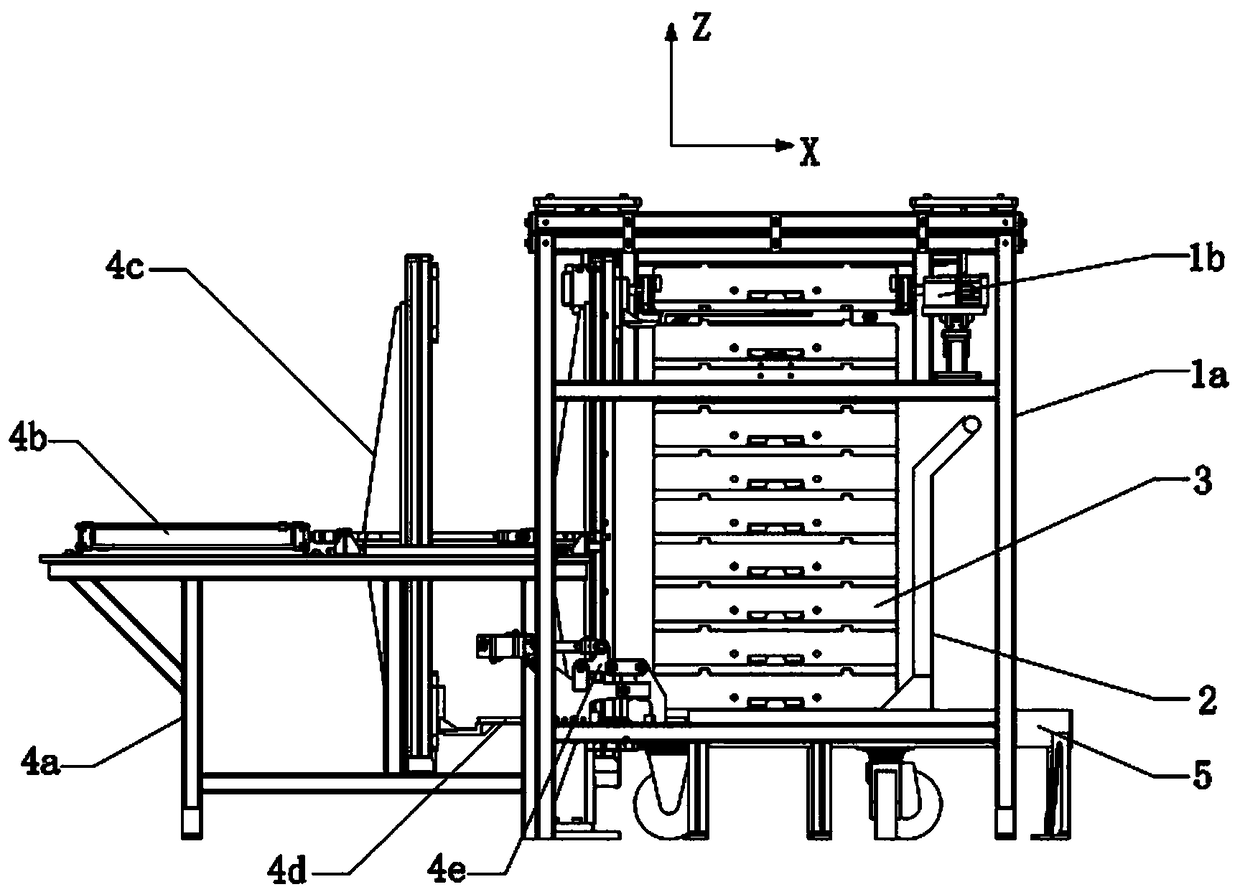

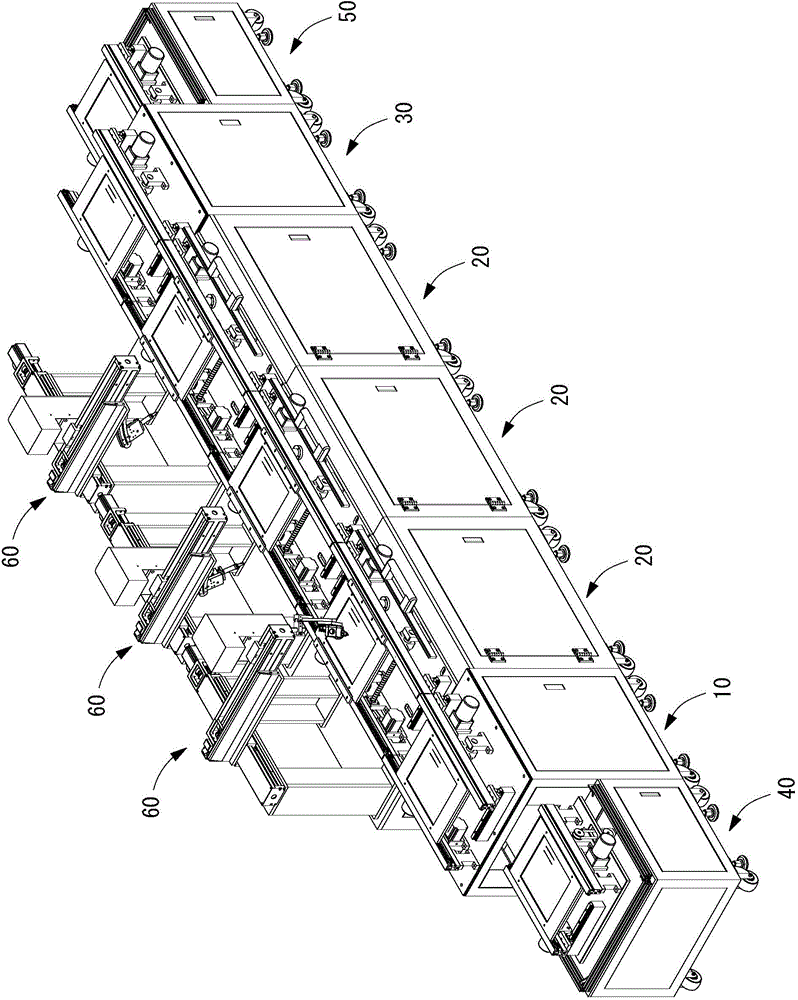

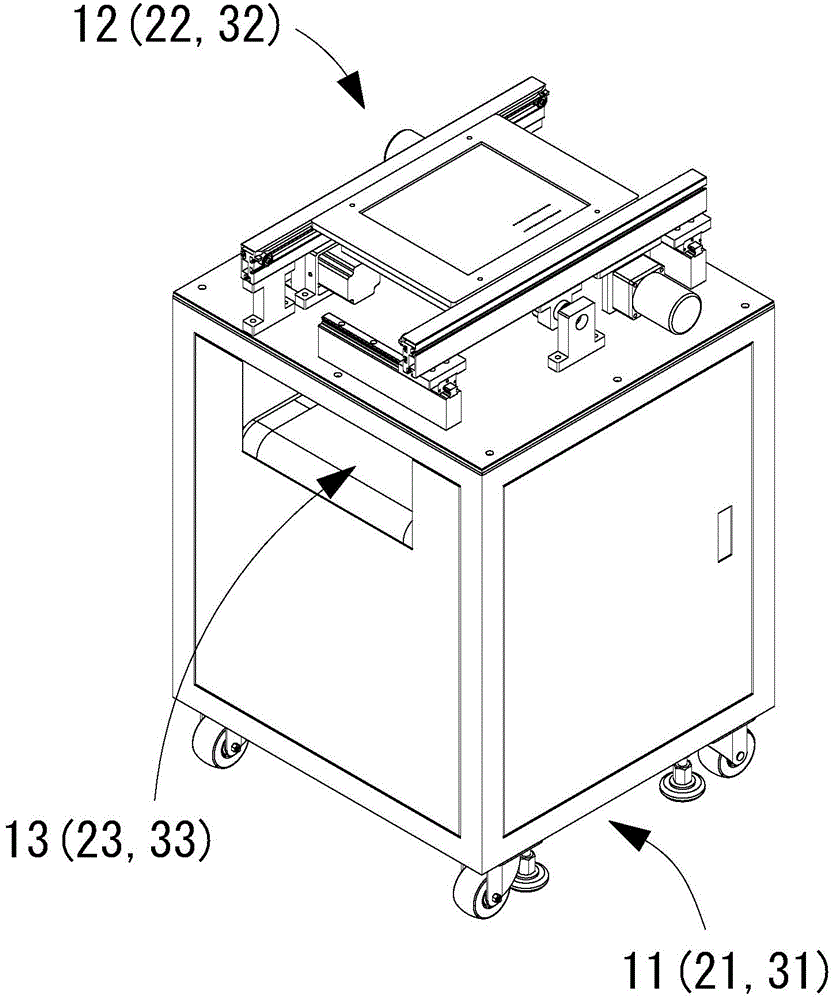

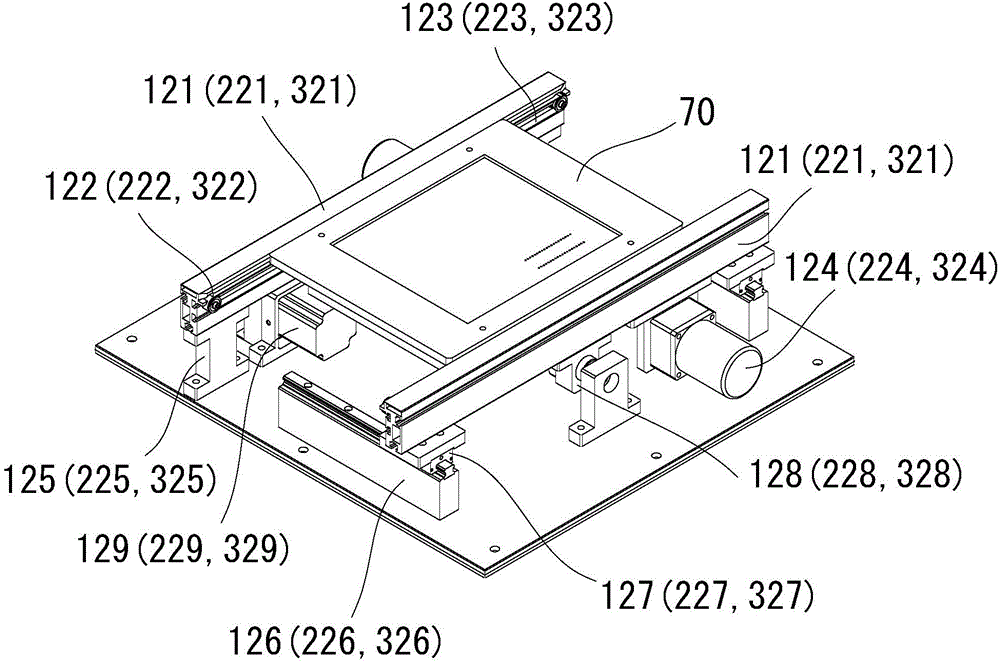

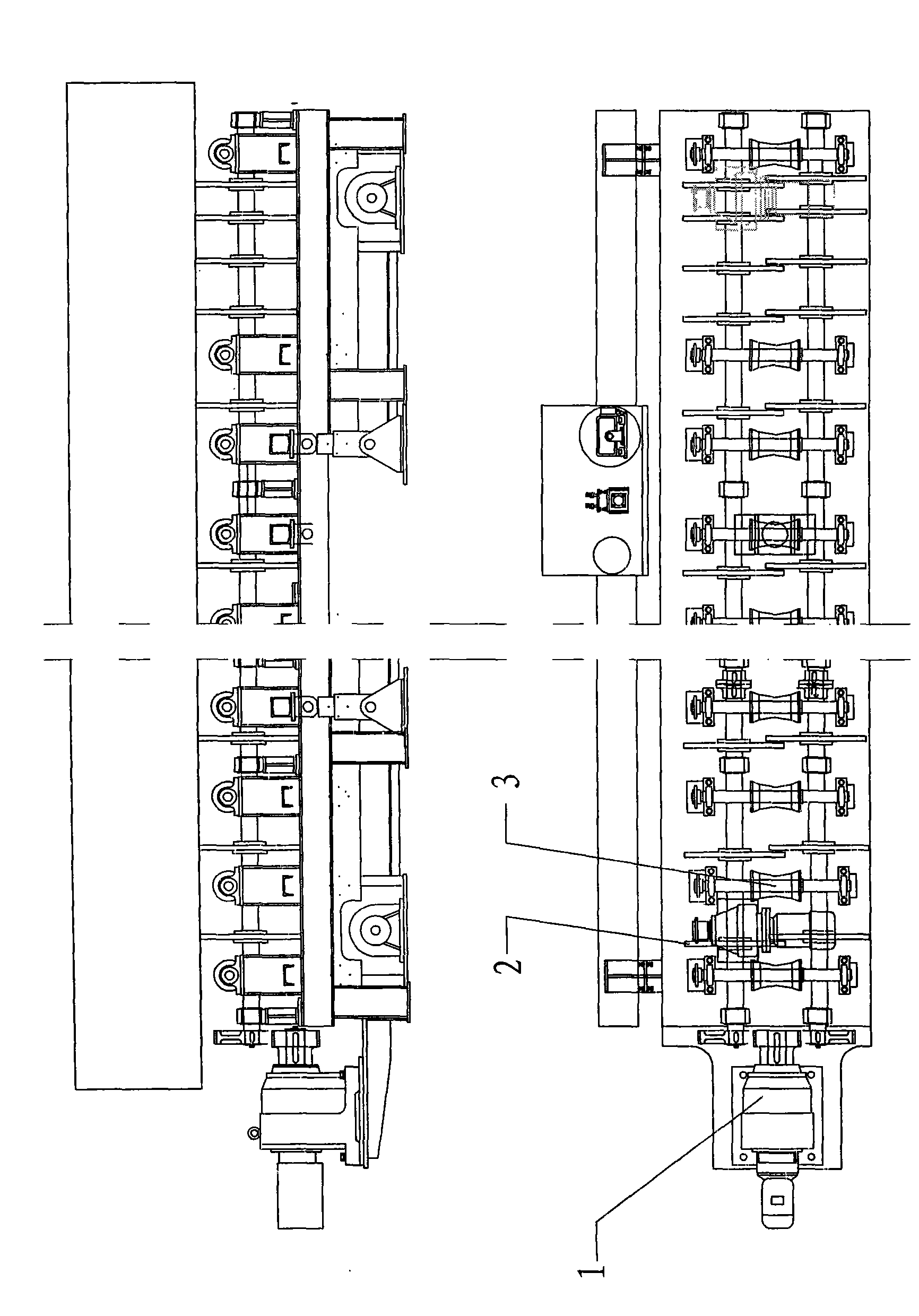

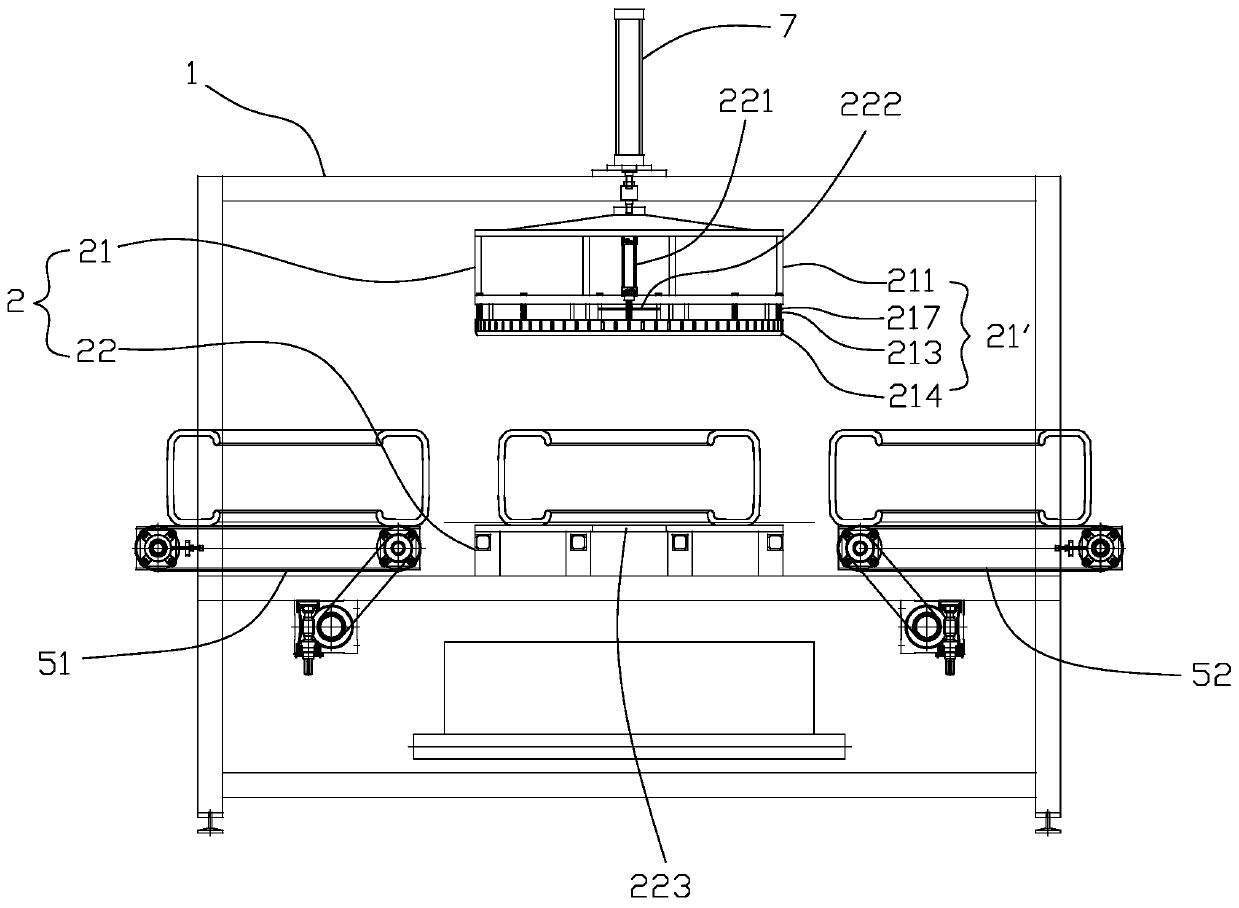

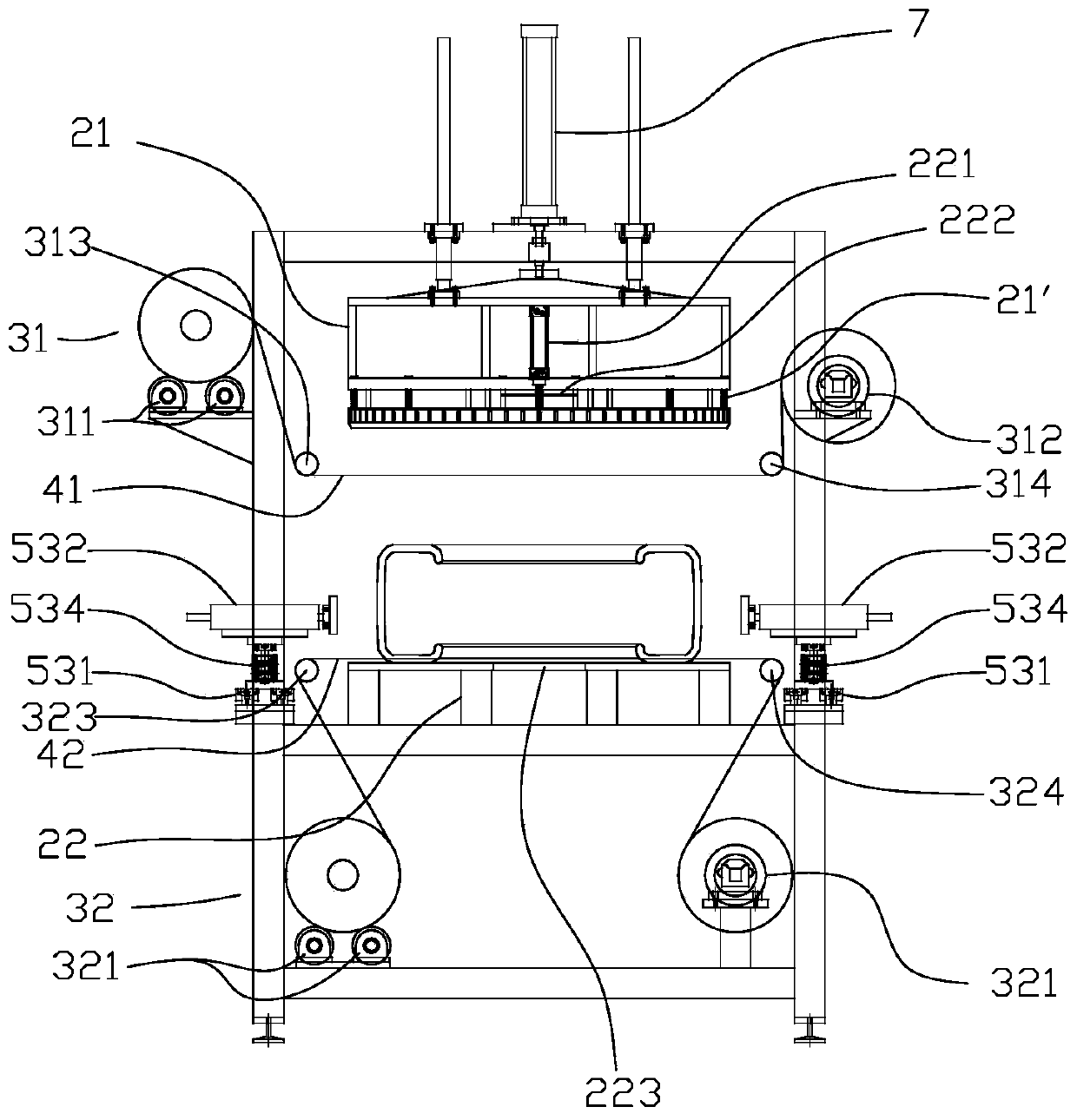

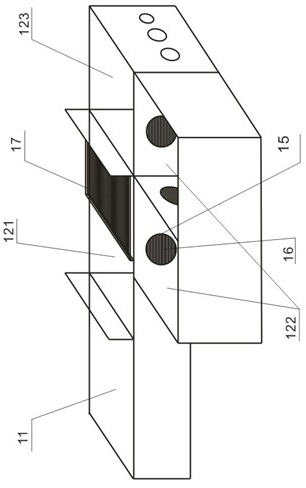

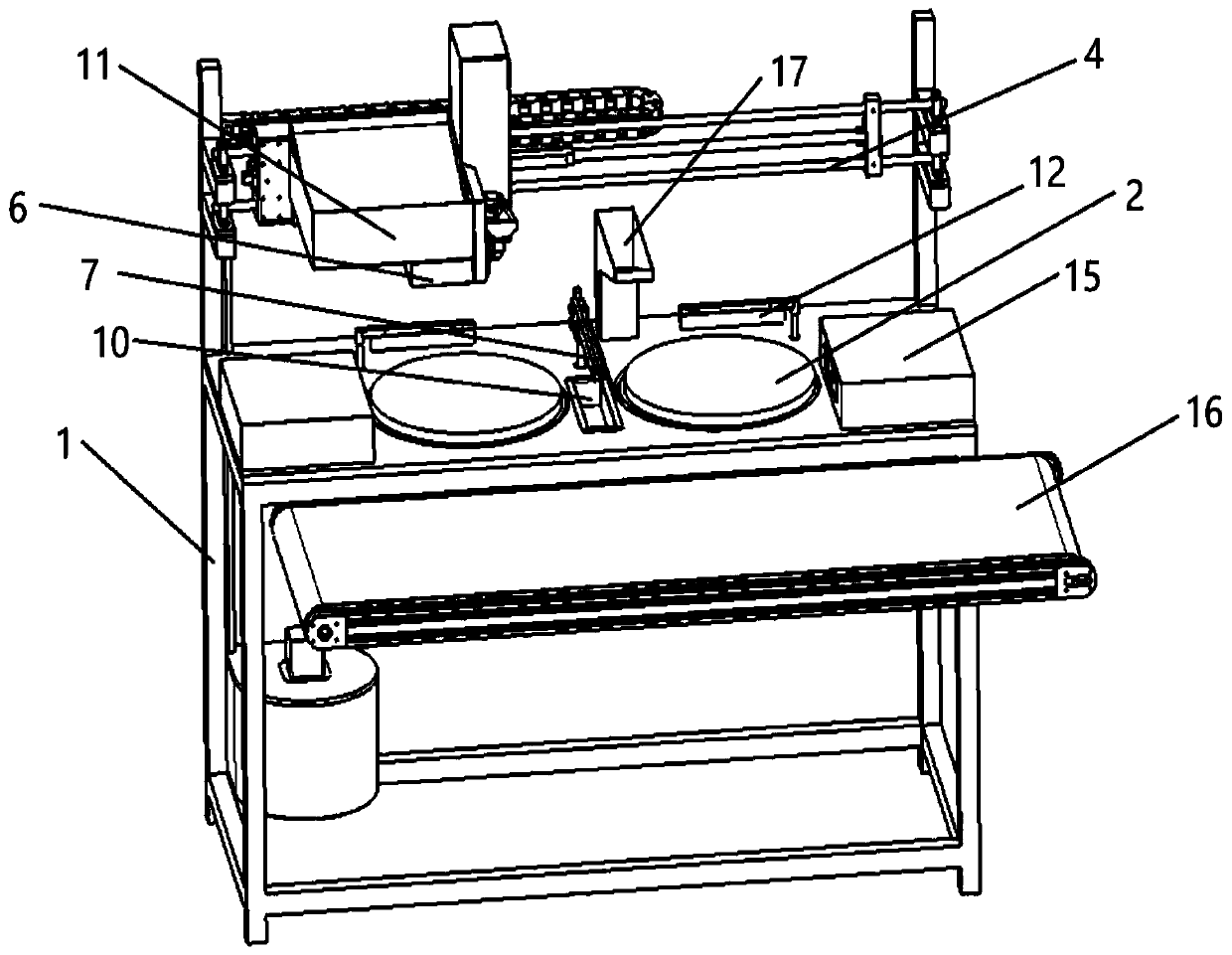

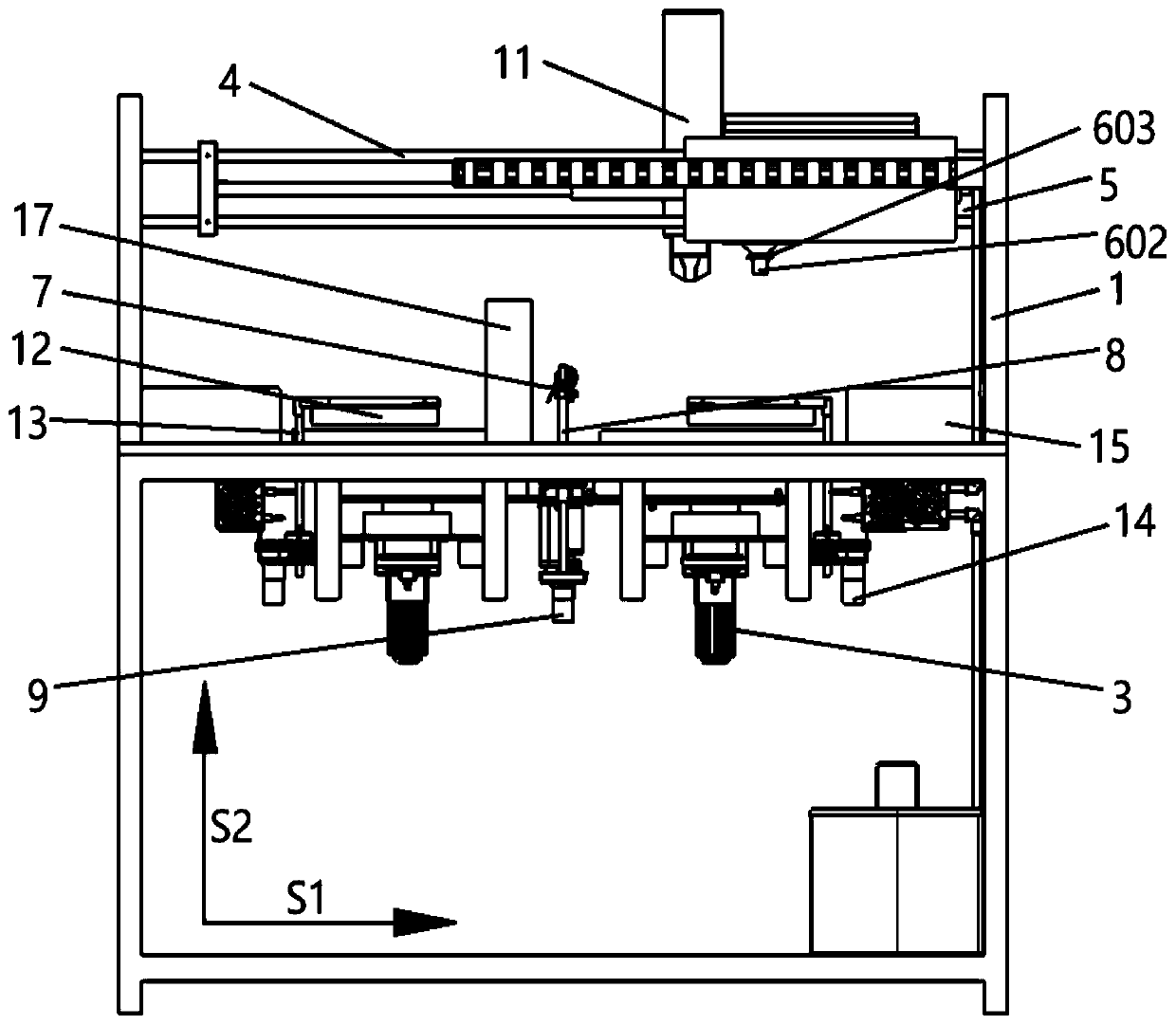

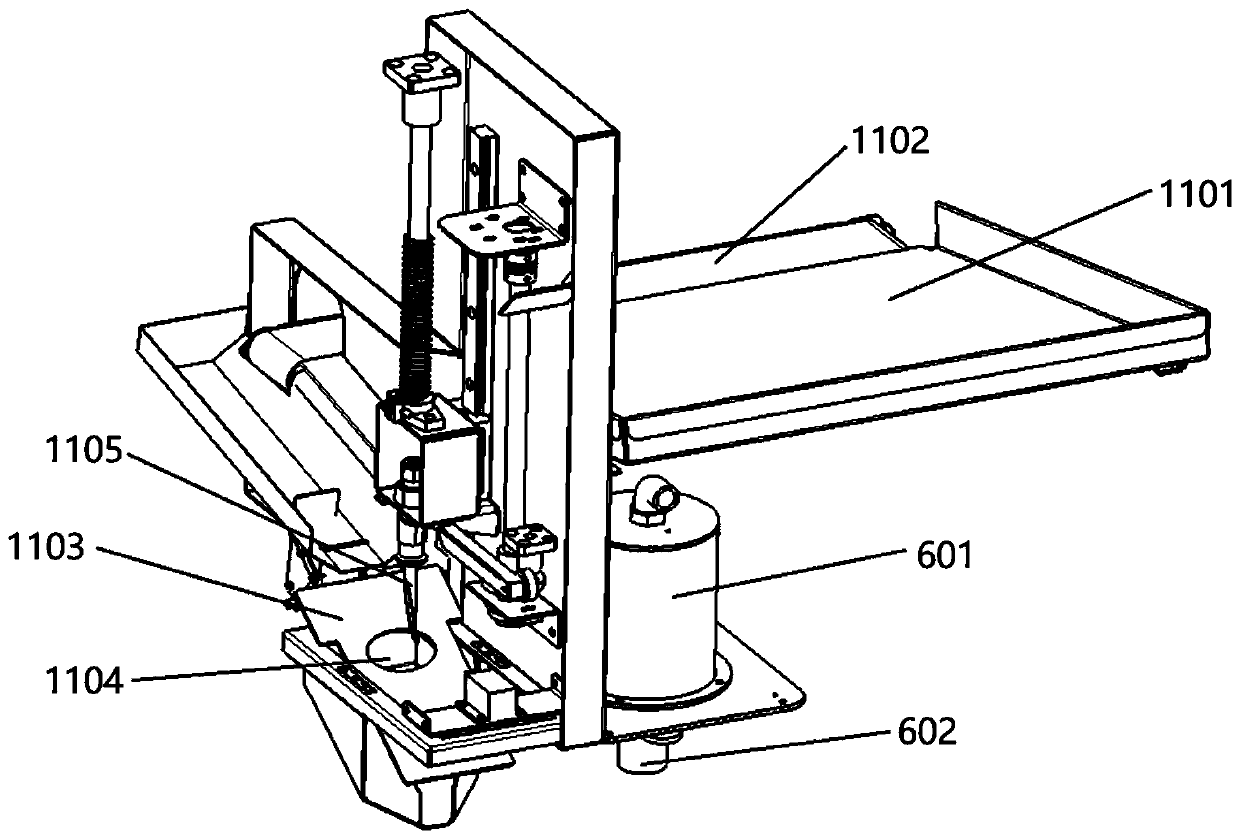

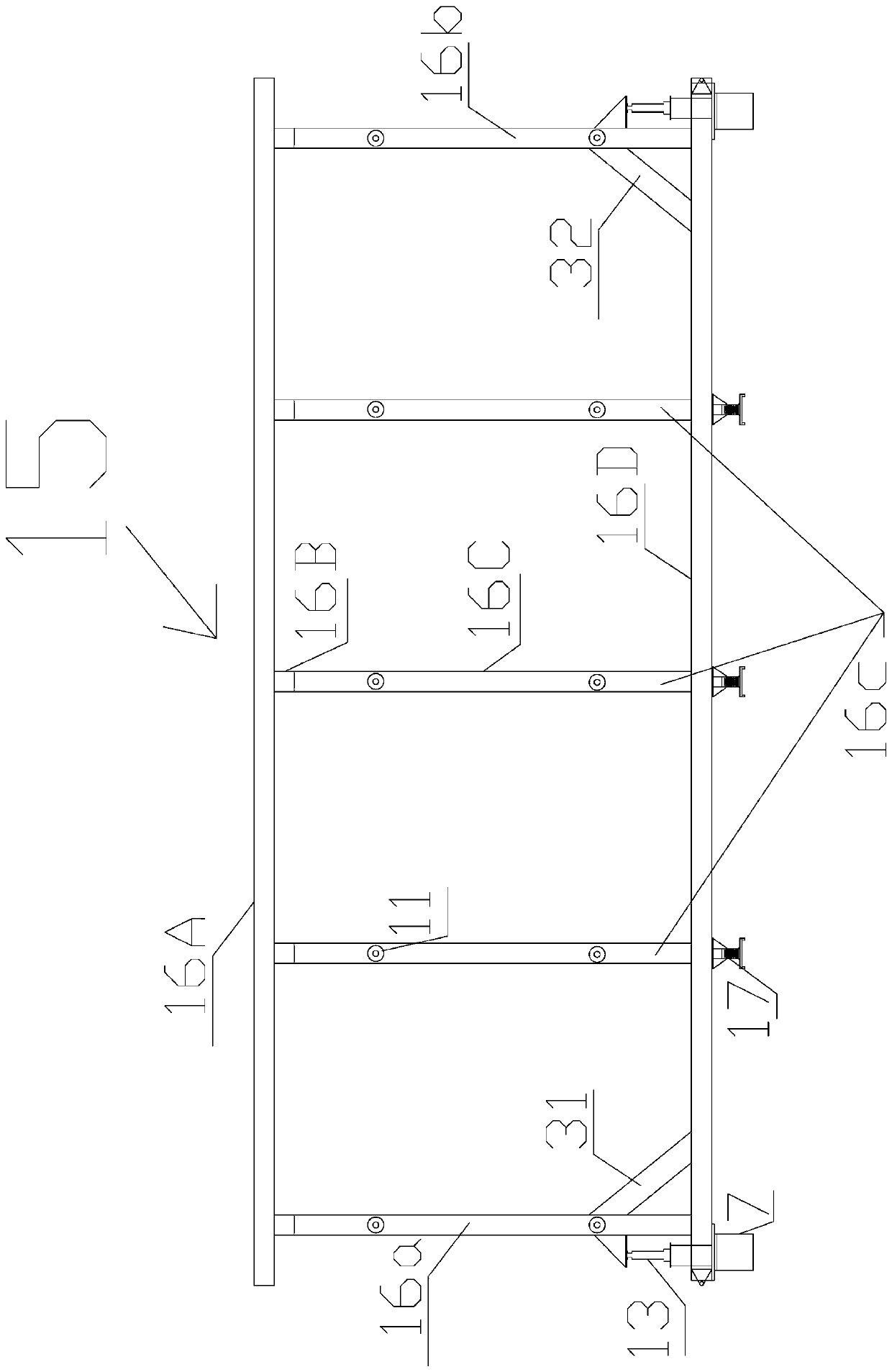

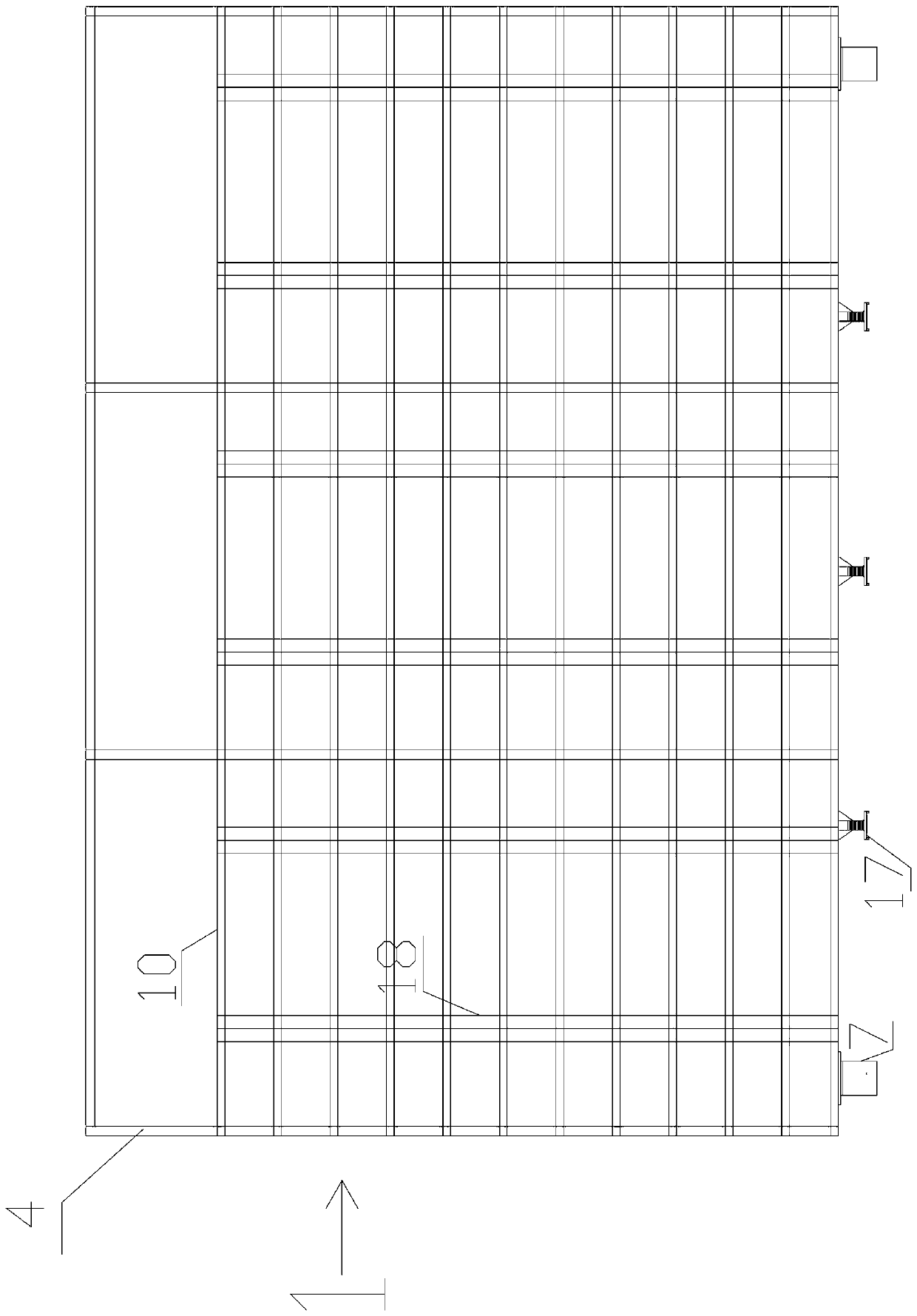

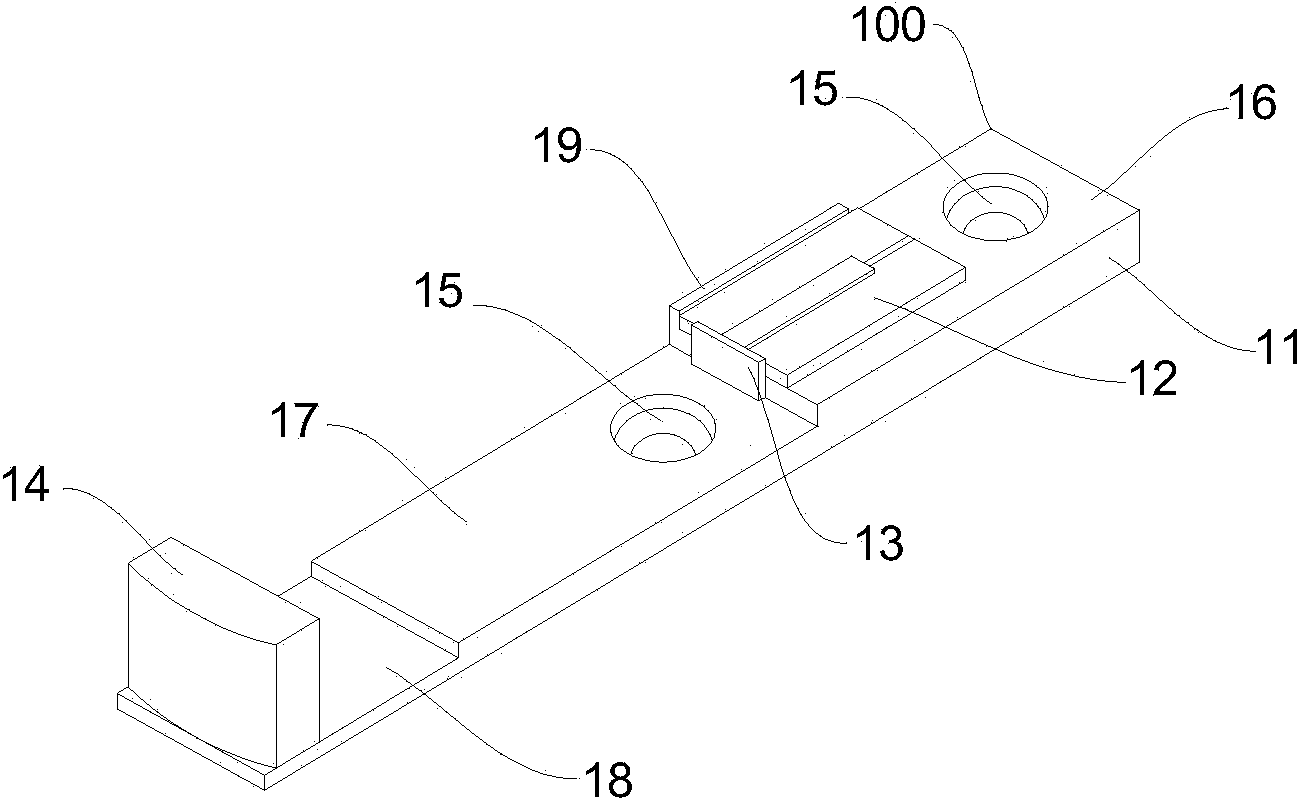

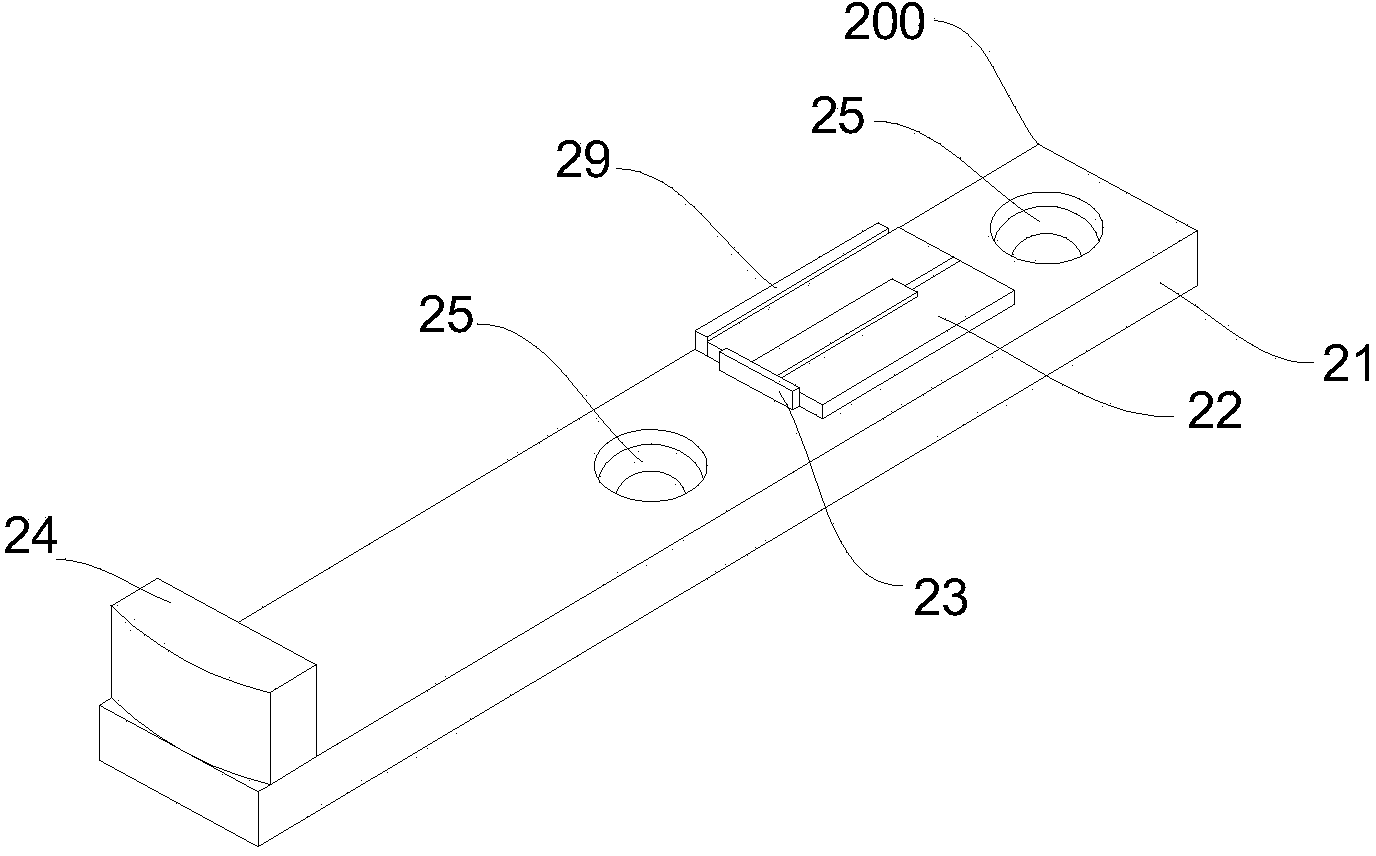

Tray conveying and switching system on automatic production line

ActiveCN109018951AMeet delivery needsSmall footprintTotal factory controlConveyor partsProduction lineManufacturing cost reduction

The invention relates to a tray conveying and switching system on an automatic production line. The tray conveying and switching system comprises a supporting unit, trolleys, trays and tray lifting units. The supporting unit comprises a supporting frame, a tray Y-direction translation clamping mechanism and a tray locating mechanism. The supporting frame comprises a feeding station, a grabbing station, a reassembly station and a discharging station. The two tray lifting units are mounted on the back face of the supporting frame, one tray lifting unit is aligned to the back face of the feedingstation, and the other tray lifting unit is aligned to the discharging station. The number of the trolleys is two, one trolley is pushed in from the front face of the supporting frame and is fixed below the feeding station, and the other trolley is pushed in from the front face of the supporting frame and fixed below the discharging station. The multiple layers of trays are stacked on the trolleylocated below the feeding station, and the tray lifting units can move the trays in the direction Z. The tray conveying and switching system has the advantages of being simple in structure, convenientto mount and small in occupied area, reducing the manufacturing cost and achieving automatic line production.

Owner:GUANGZHOU ZSROBOT INTELLIGENT EQUIP CO LTD

Online tin soldering machine

ActiveCN104551303ARealize fully automatic weldingRealize automatic reflowPrinted circuitsMetal working apparatusEngineeringManipulator

The invention relates to an online tin soldering machine comprising a first conveying platform, second conveying platforms, a third conveying platform, tin soldering manipulators, a first lifting platform and a second lifting platform. Each of the first, second and third conveying platforms comprises a table rack, a forward conveying mechanism mounted on the table rack and a return conveying mechanism mounted on the table rack and located under the forward conveying mechanism. The first lifting platform is mounted on one side of the first conveying platform, and the second lifting platform is mounted on one side of the third conveying platform. According to the online tin soldering machine, jigs can be conveyed forward among the first lifting platform, the first conveying platform, the second conveying platforms, the third conveying platform and the second lifting platform, and full-automatic soldering can be realized. Meanwhile, empty jigs can be conveyed backward to realize automatic return of the jigs, the whole soldering process is operated fully automatically, and working efficiency is higher.

Owner:深圳市联合创新实业有限公司

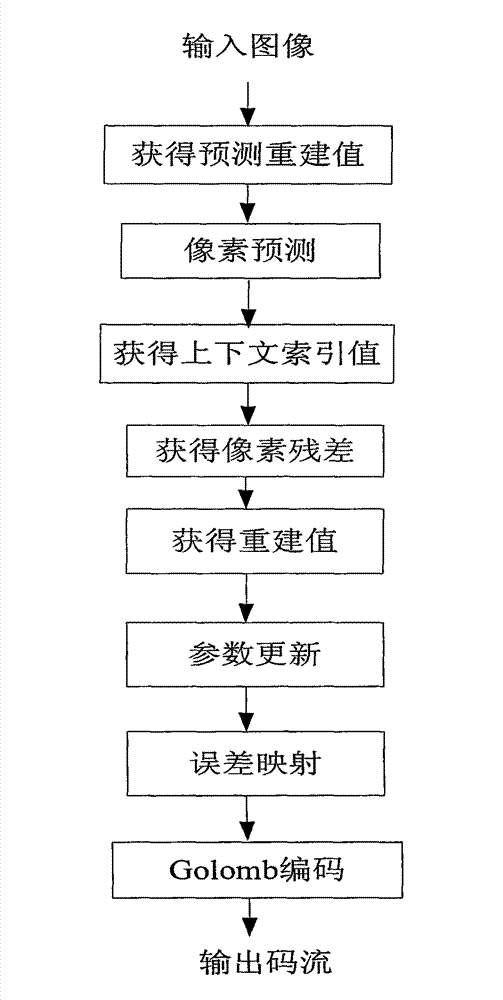

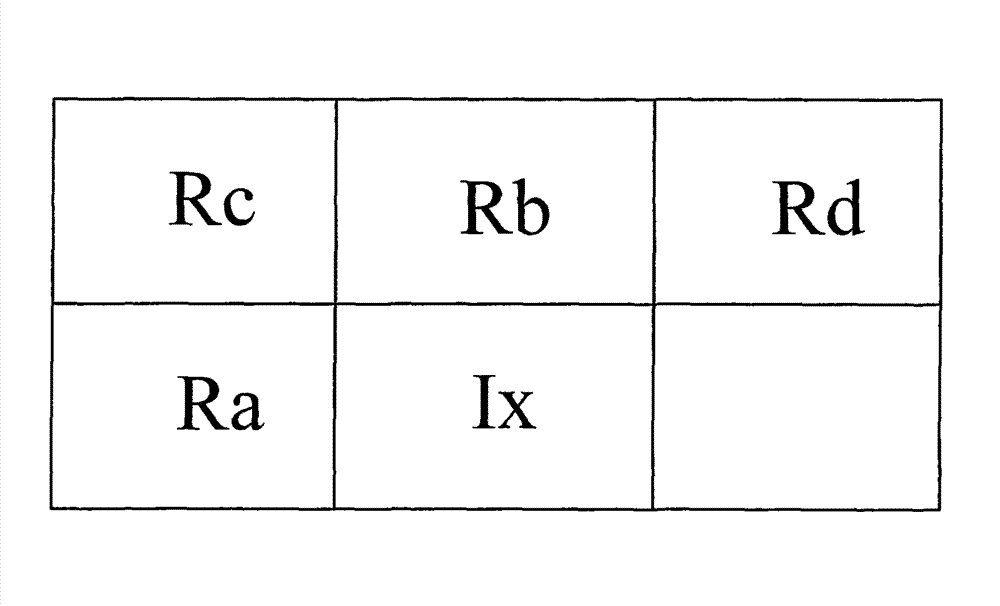

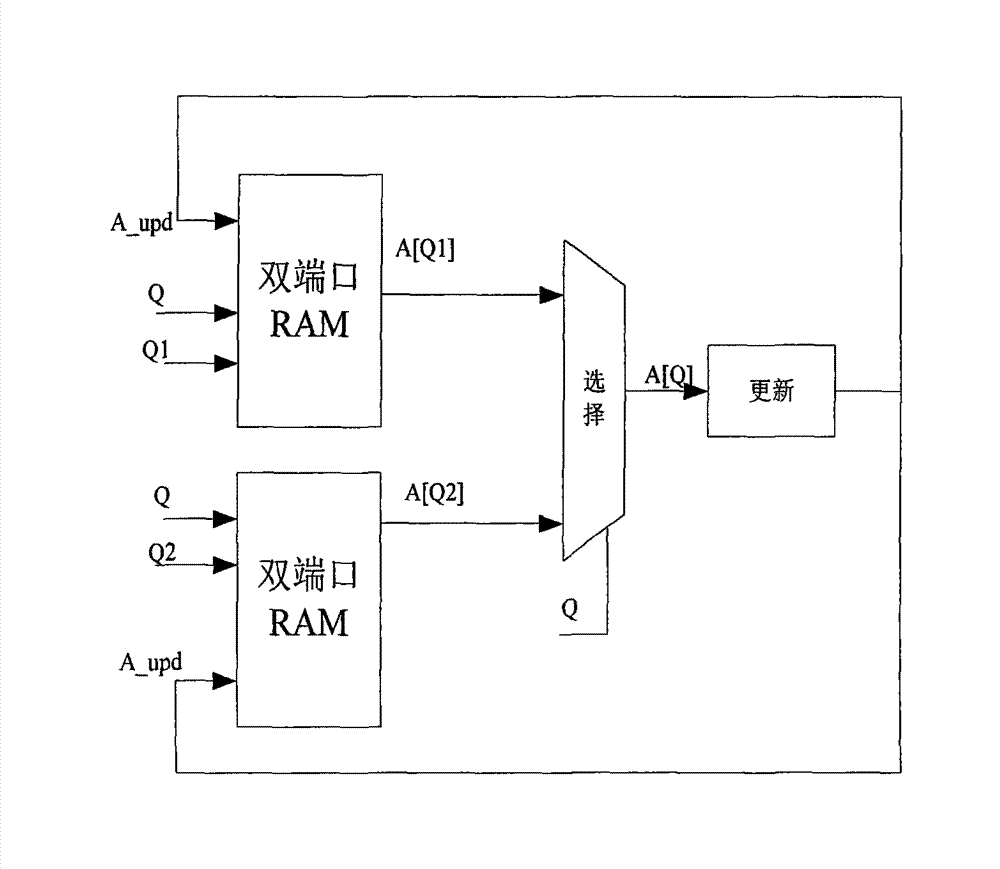

Method for implementing near-lossless image compression encoder hardware based on joint photographic experts group lossless and near-lossless compression of continuous-tone still image (JPEG-LS)

InactiveCN102970531AProcessing speedRealize flow operationTelevision systemsDigital video signal modificationContinuous toneJPEG

The invention discloses a method for implementing near-lossless image compression encoder hardware based on JPEG-LS and overcomes defects of slow processing speeds and poor compression performances of encoders in the prior art. The method comprises obtaining prediction reconstruction values; predicting pixels; obtaining context index values; obtaining pixel residual errors; calculating reconstruction values; updating parameters; mapping errors and encoding Golomb. Compared with the prior art, the method has the advantages of being rapid in processing speed, good in compression performance and low in hardware implementation complexity.

Owner:XIDIAN UNIV

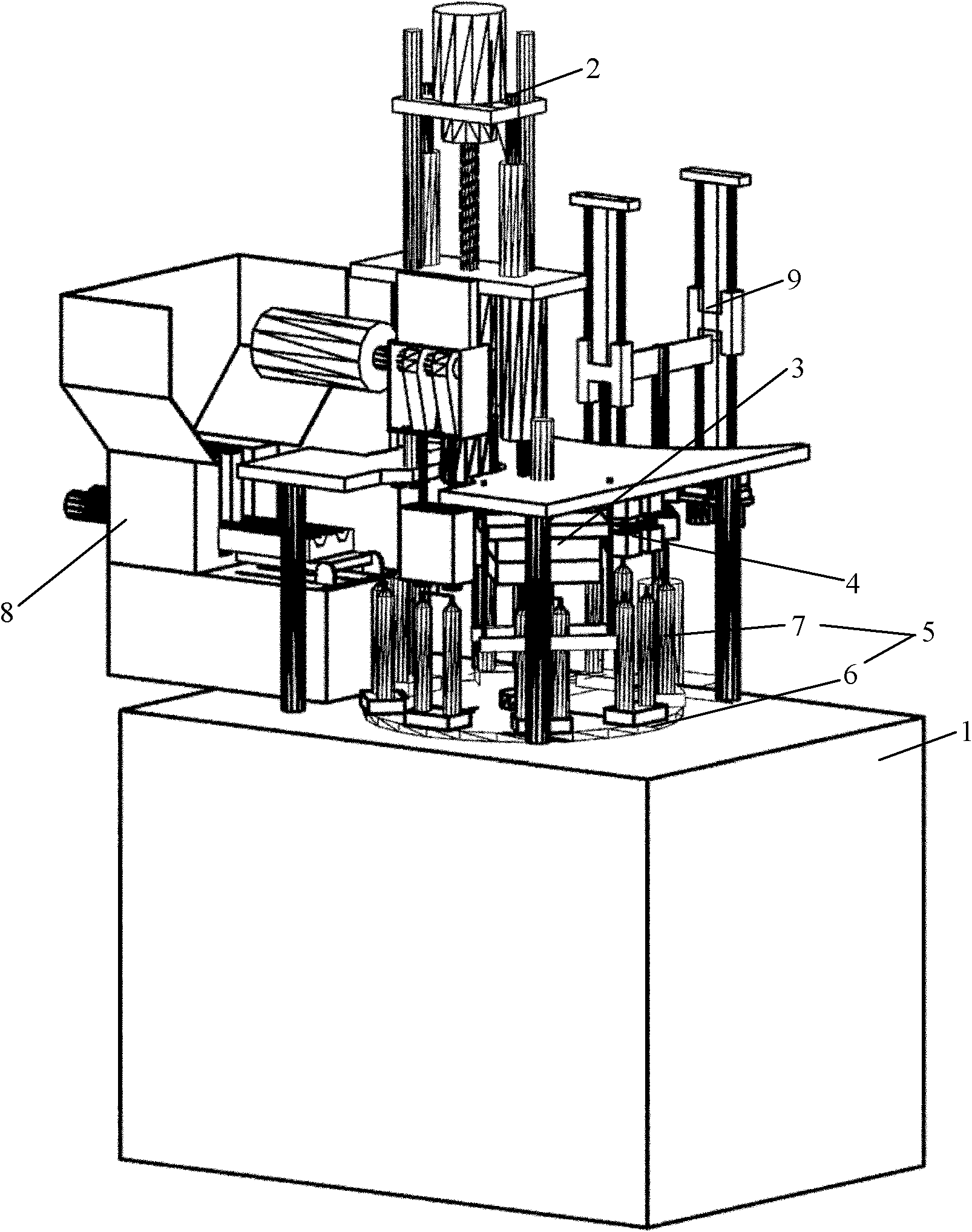

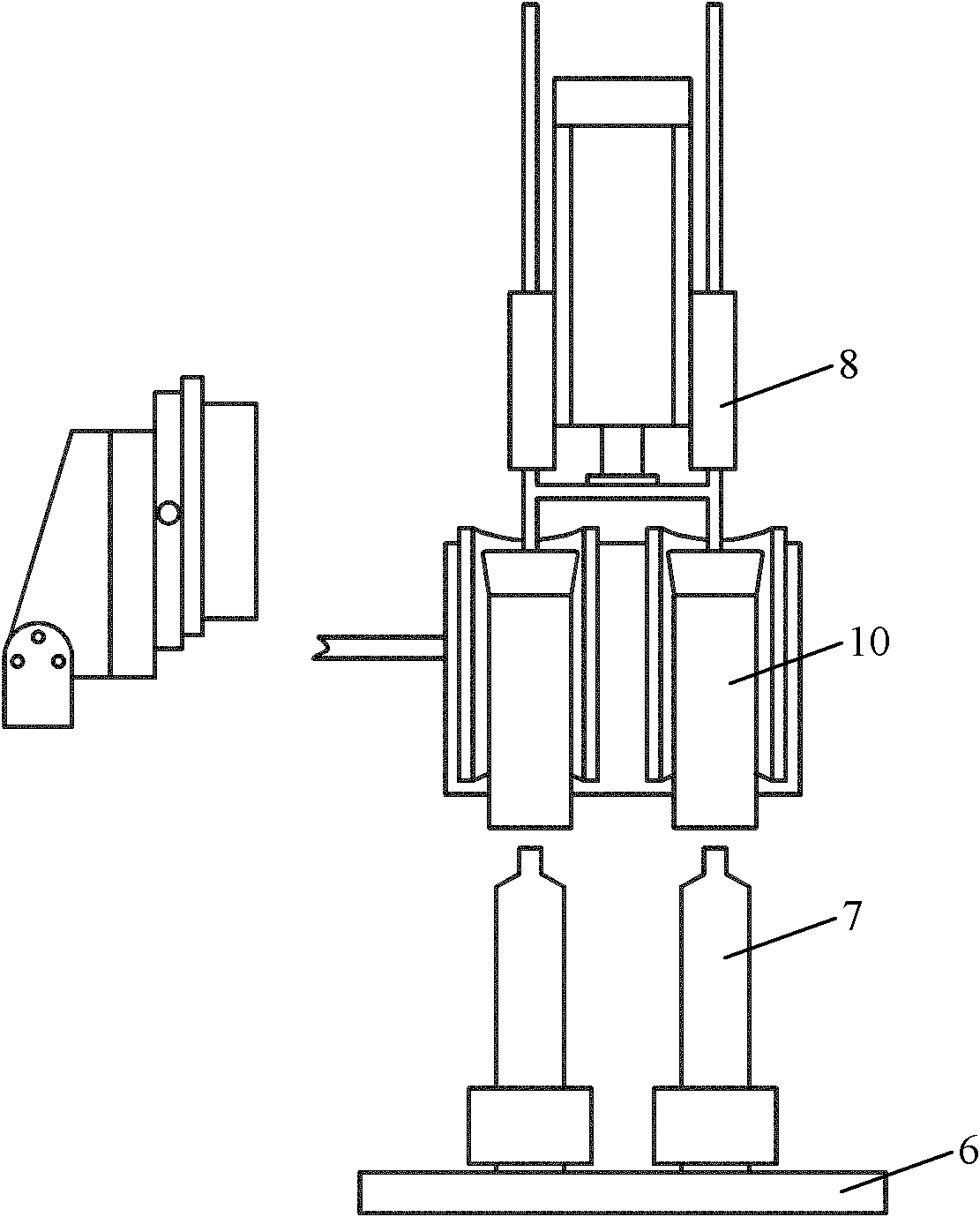

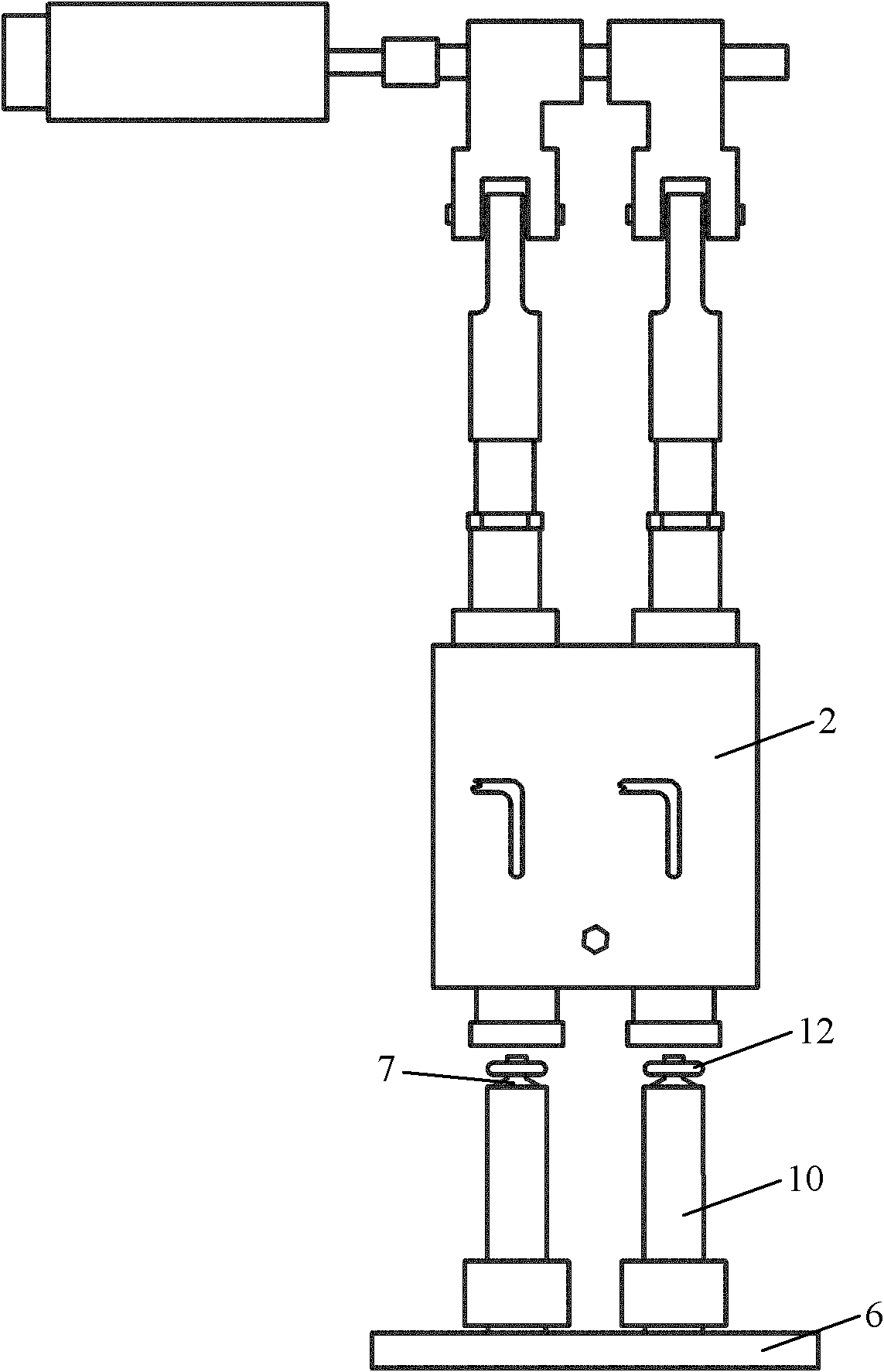

Shoulder injecting device and related shoulder injecting method for hose upper part

ActiveCN102114712AShoulder injection speedImprove efficiencyTubular articlesCompression moldingEngineering

The invention relates to a shoulder injecting device for a hose upper part, comprising a controlling mechanism, a stand, an injection molding and discharging mechanism, a hose shoulder compression molding mechanism, a cooling molding mechanism, a turntable assembly and a driving part, wherein the injection molding and discharging mechanism, the hose shoulder compression molding mechanism, the cooling molding mechanism, the turntable assembly and the driving part are arranged on the stand, the turntable assembly comprises a turntable and a plurality of core rods, the core rods are arranged on the turntable and circularly arrayed relative to the center of the turntable, the driving part is connected with the turntable and used for driving the turntable to rotate, the injection molding and discharging mechanism, the hose shoulder compression molding mechanism and the cooling molding mechanism are arrayed to form a circle and respectively located above different core rods, the controlling mechanism is respectively and electrically connected with the injection molding and discharging mechanism, the hose shoulder compression molding mechanism, the cooling molding mechanism and the driving part, and preferably, the shoulder injecting device further comprises an automatic hose feeding mechanism and an automatic hose detaching mechanism. The invention further provides a related shoulder injecting method for the hose upper part. The shoulder injecting device for the hose upper part, provided by the invention, is skillful in design and concise in structure, has the advantages of high speed and high efficiency when used for shoulder injecting, and is suitable for large-scale popularization and application.

Owner:三樱包装(江苏)有限公司

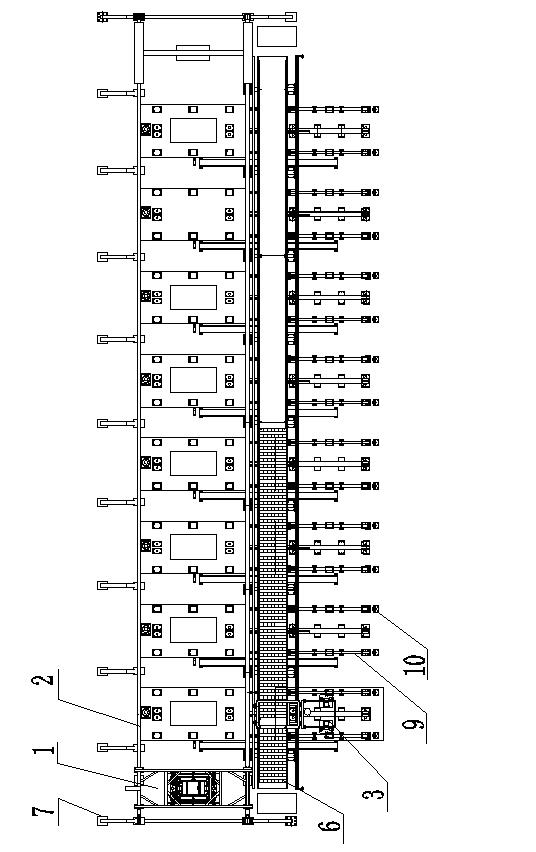

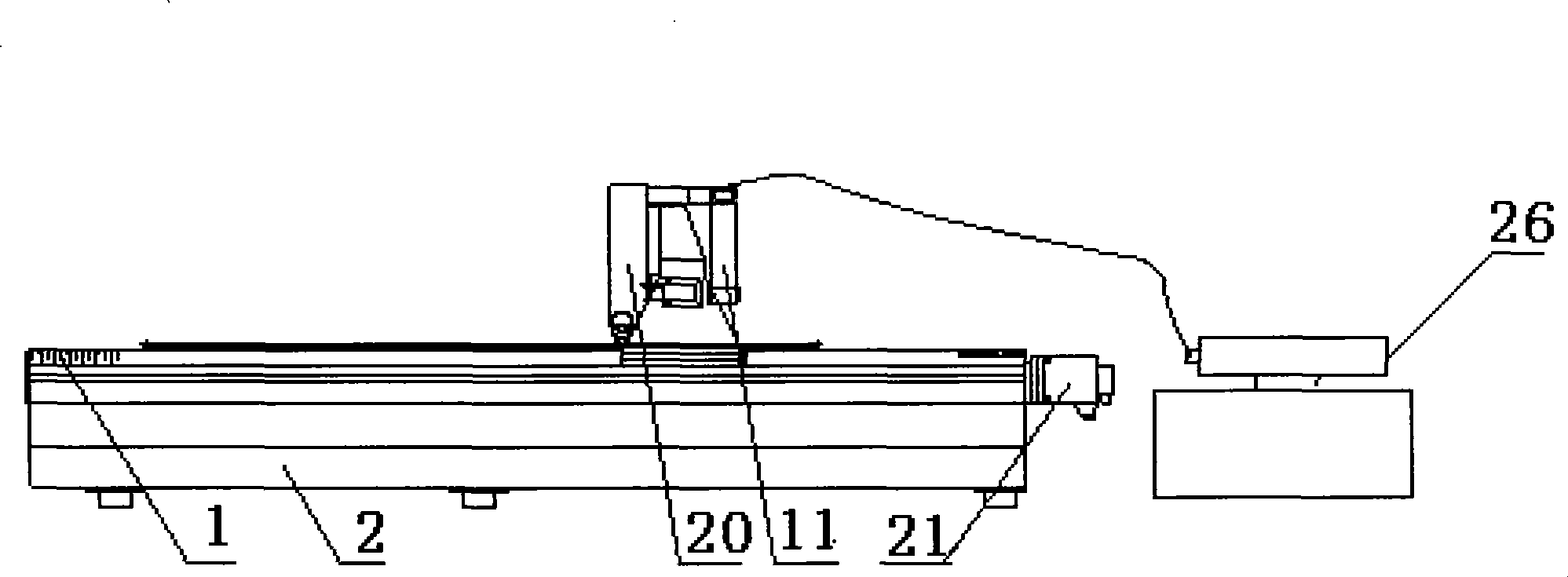

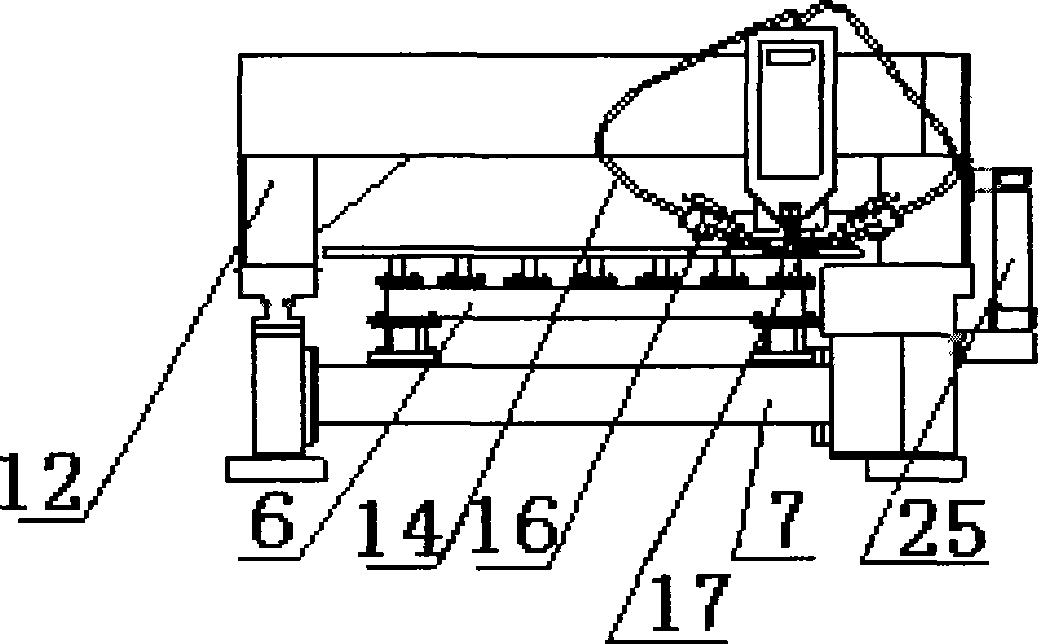

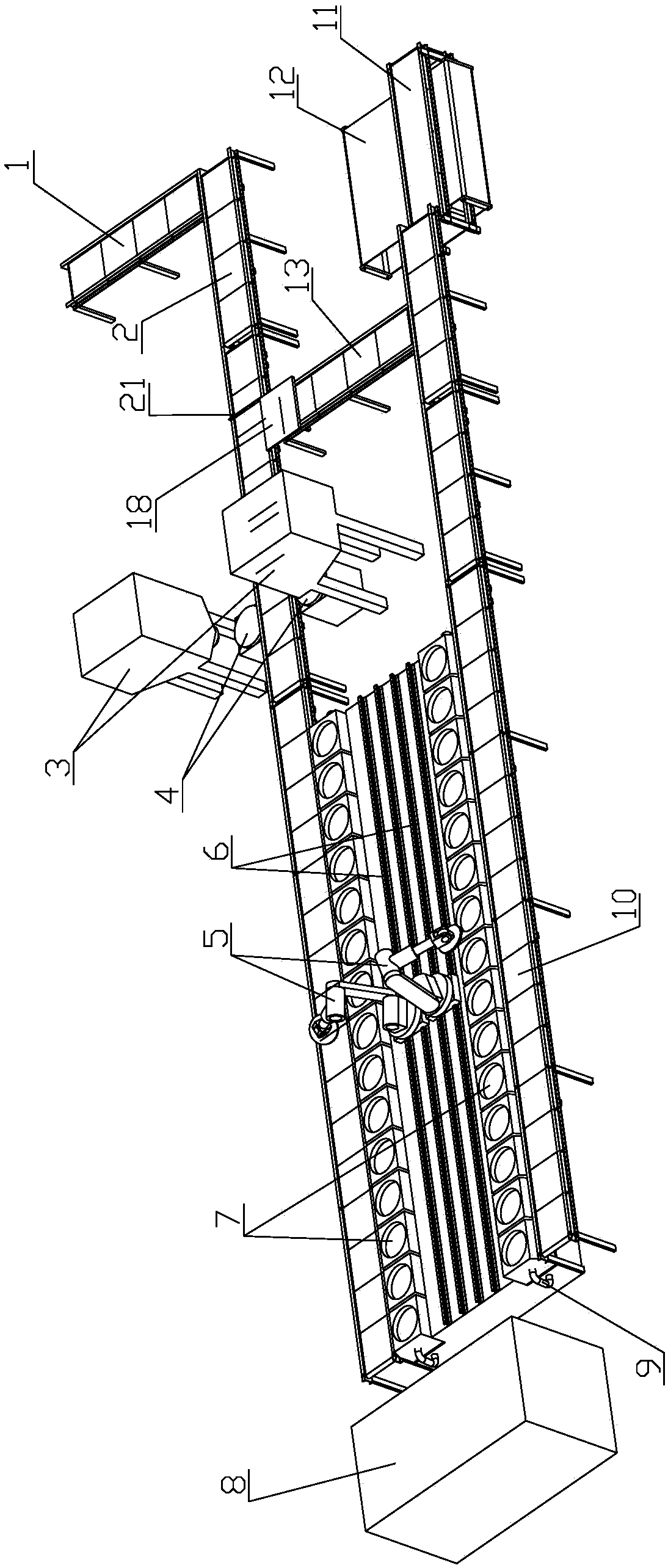

Rolling disc type two-axis numerical control pipeline cutting machine

InactiveCN101653872ARealize flow operationImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlRolling disk

The invention discloses a rolling disc type two-axis numerical control pipeline cutting machine which is characterized by comprising a numerical control controller, a plasma power supply, a pair of rolling discs and a revolving device thereof, a lifting conveying roller way arranged on the machine station working face, a liner guide rail arranged at the horizontal lateral of the machine station working face, a trolley, an axial shifter and a cutting unit with adjustable height, wherein the pair of rolling discs and the revolving device thereof are arranged at the same horizontal height on themachine station working face; the trolley and the axial shifter are slidingly connected with the liner guide rail, the cutting unit is arranged in an integration way with the trolley and is arrangedabove the rolling discs, and the sliding direction of the trolley is parallel to the axial direction of the rolling discs. The rolling disc type two axis numerical control pipeline cutting machine isapplied to carry out cutting operation on a process pipeline, the rolling discs are driven by a numerical control driver to drive the pipeline to revolve and the trolley to axially move, thereby realizing two-axis program motion, finishing continuous cutting work and intersecting line cutting work of a pipe fitting, and having higher cutting efficiency and cutting accuracy. In addition, combined with a logistics conveying roller way, the invention can realize batch streamline cutting processing of the pipe fitting.

Owner:NANJING AUTO ELECTRIC

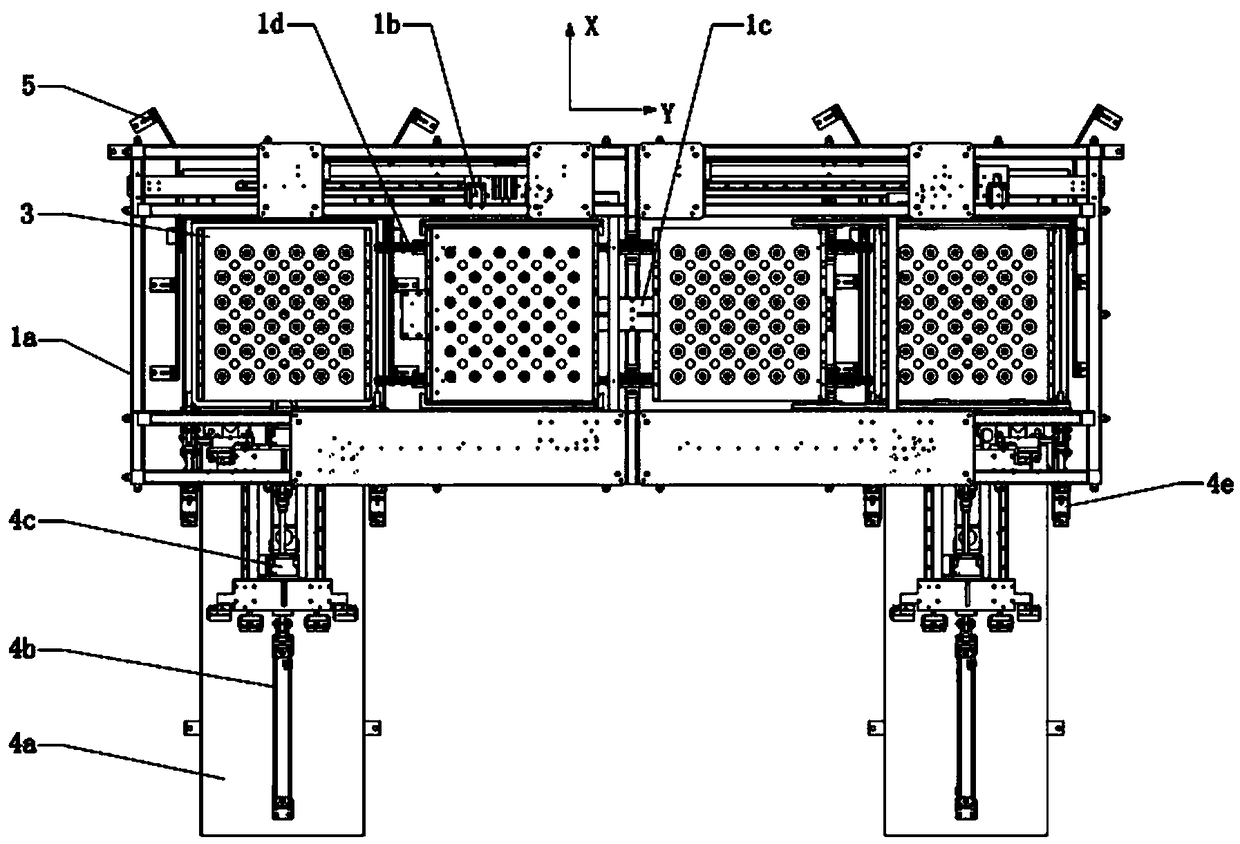

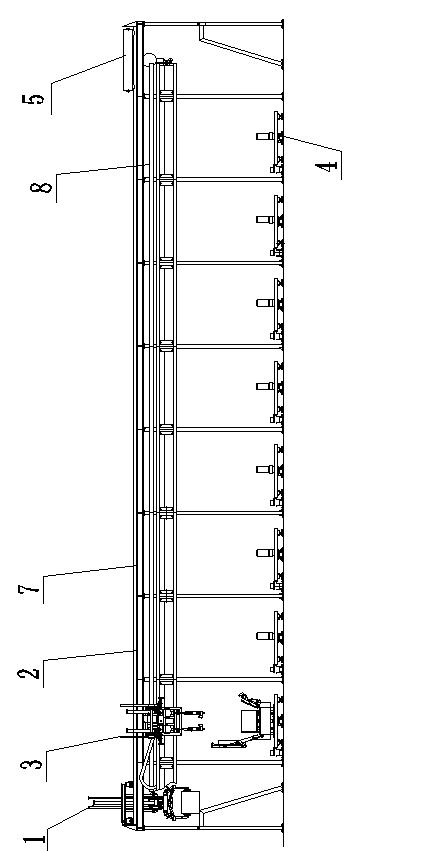

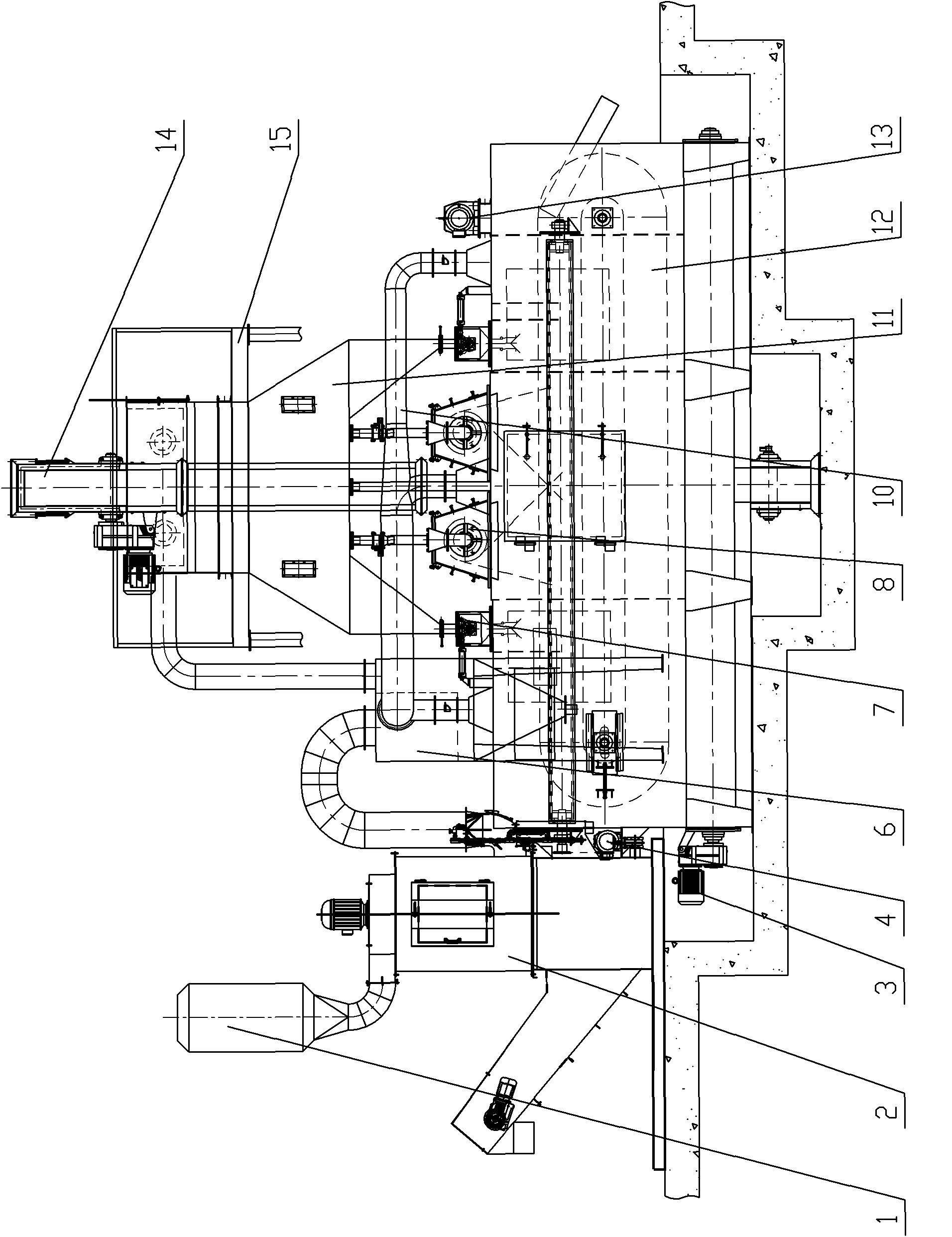

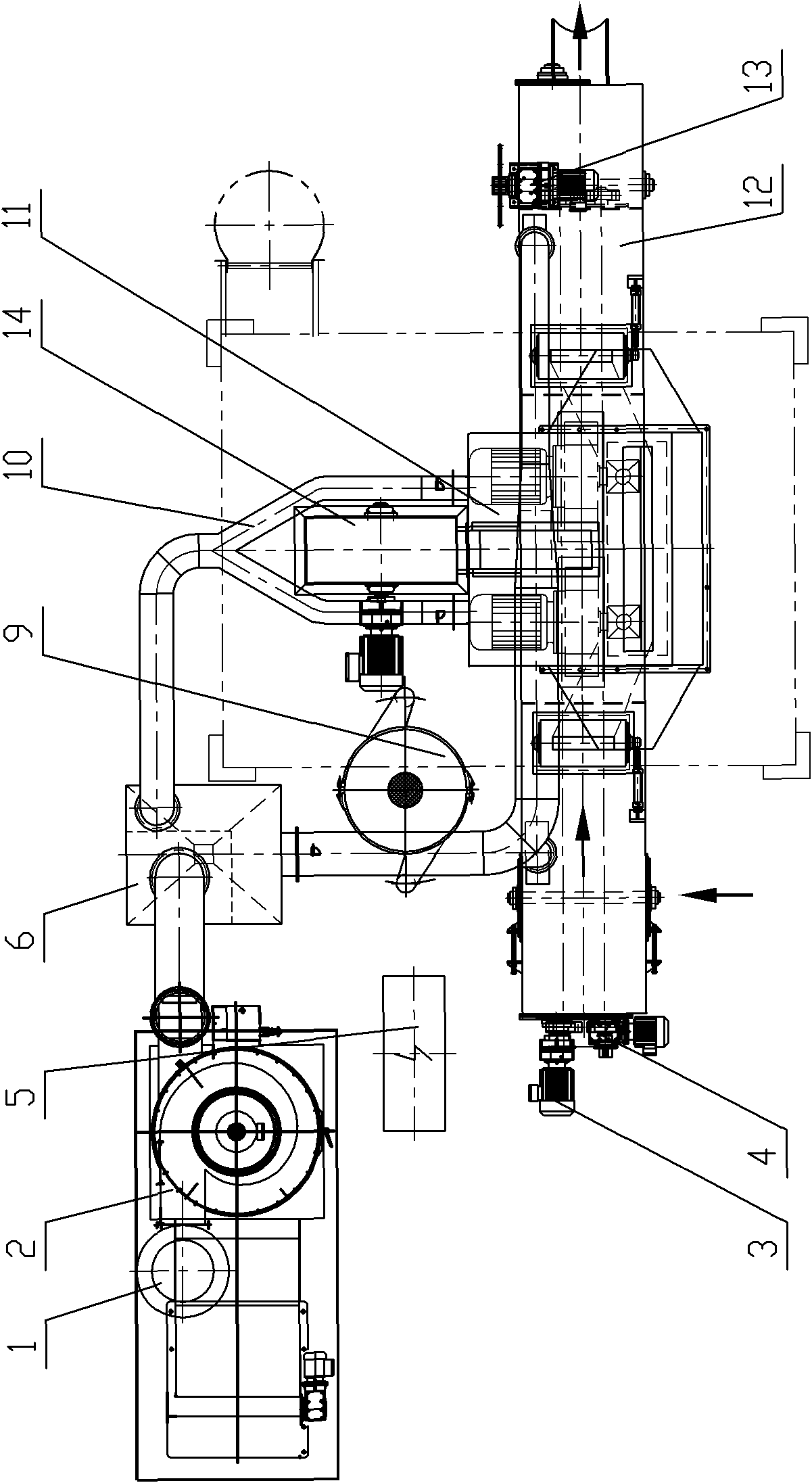

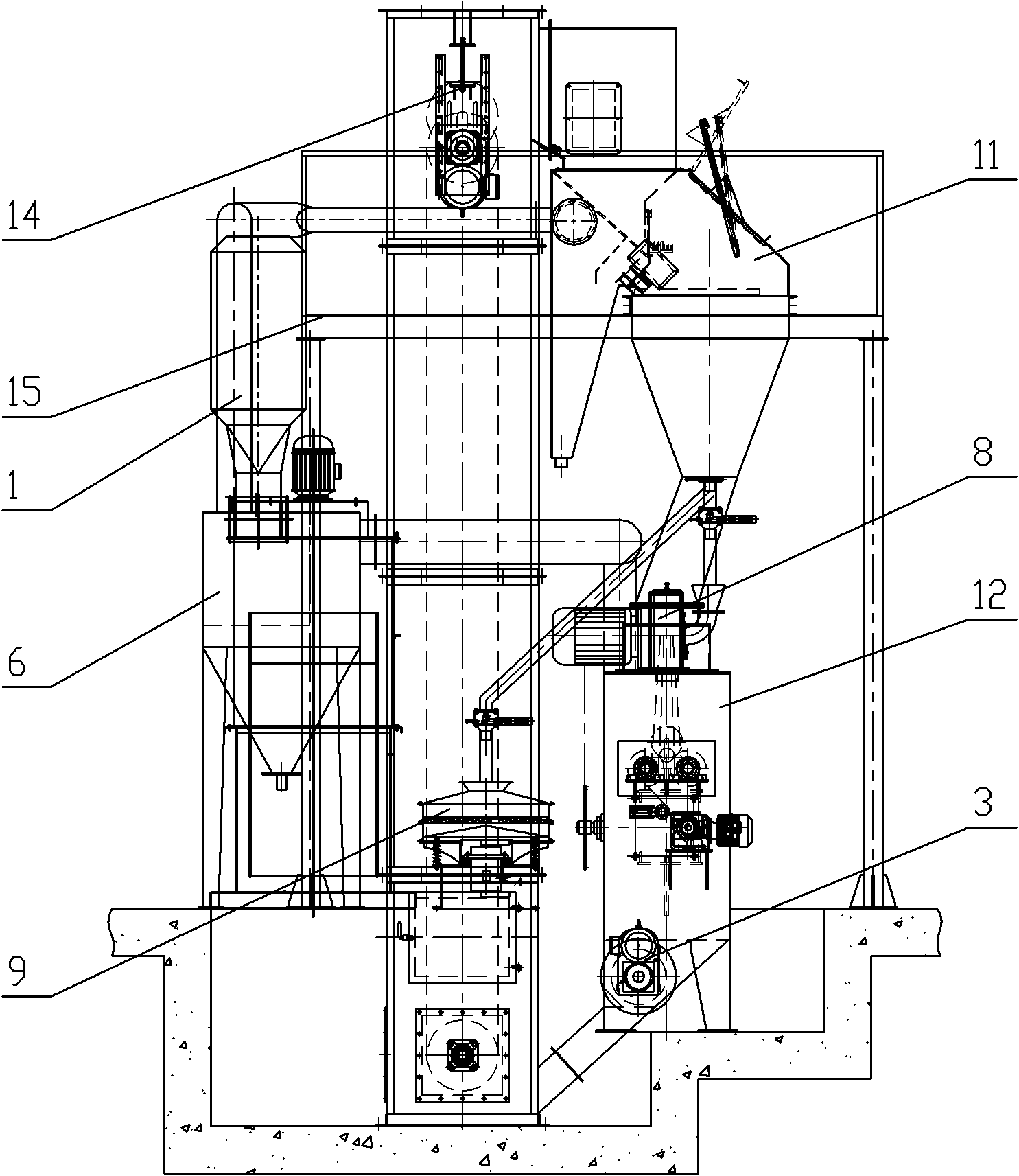

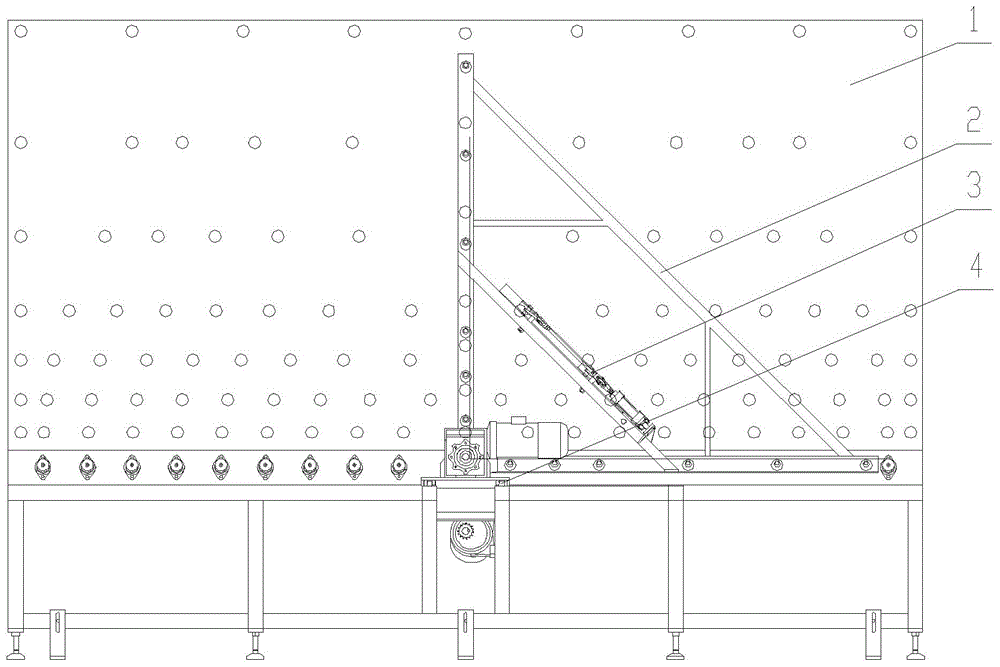

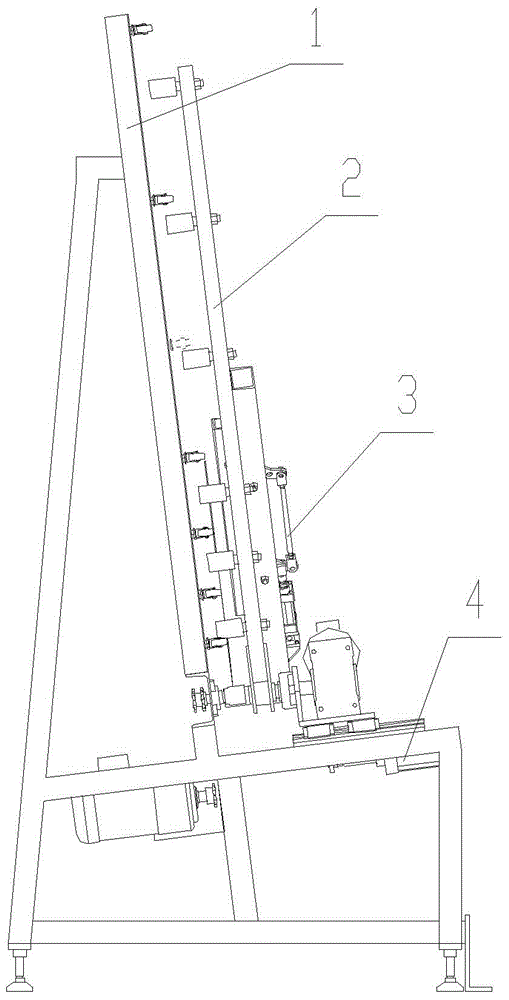

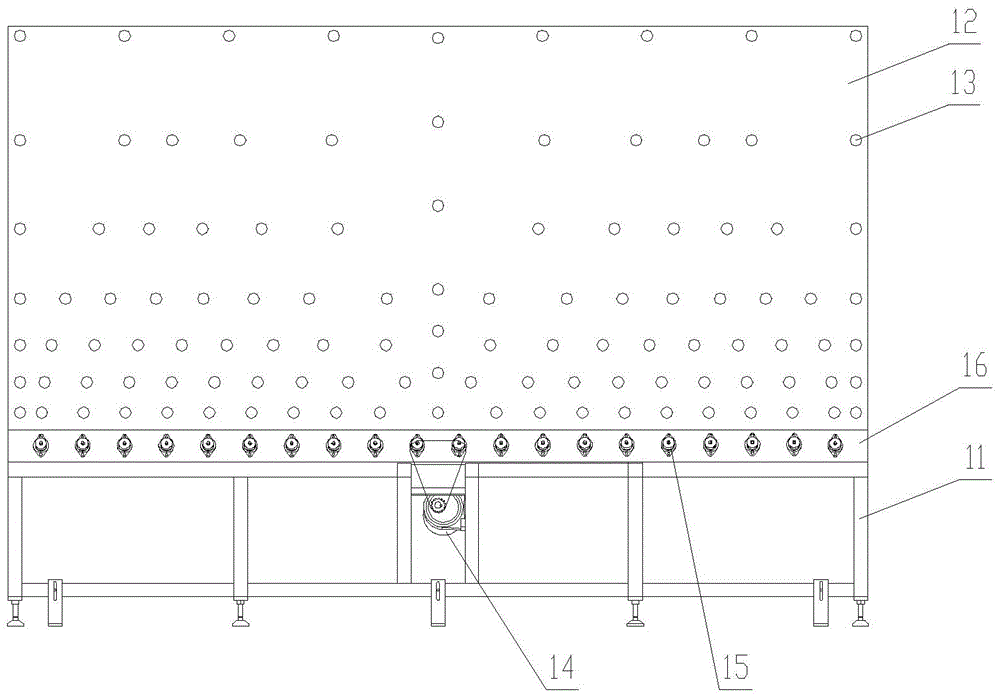

Multi-station refrigerator body foaming production line equipment

The invention discloses multi-station refrigerator body foaming production line equipment. A track and a trolley track are arranged on a rack, a die trolley rail is arranged on a foundation, a die trolley conveys a foaming die to a foaming station by gear rack transmission, a foaming manipulator runs to the foaming station on the trolley track, and a foaming mixing head is driven to lift by the lifting of a cylinder so that the foaming mixing head generates foam for the refrigerator body on the foaming station; and meanwhile, a taking manipulator runs on the track, the taking manipulator drives a vacuum sucking disc to work by stretching of the lifting cylinder and a link mechanism to lift up the foaming refrigerator body in a foaming die so as to realize the scheme that the foaming mixing head continuously generates foam for the refrigerator body on a plurality of foaming stations. The equipment overcomes the defects of high cost and complex control of the fixed refrigerator body production line and single type of the produced refrigerator products. The equipment is suitable for batch production of foaming products of various industries.

Owner:HUNAN JINGZHENG EQUIP MFG

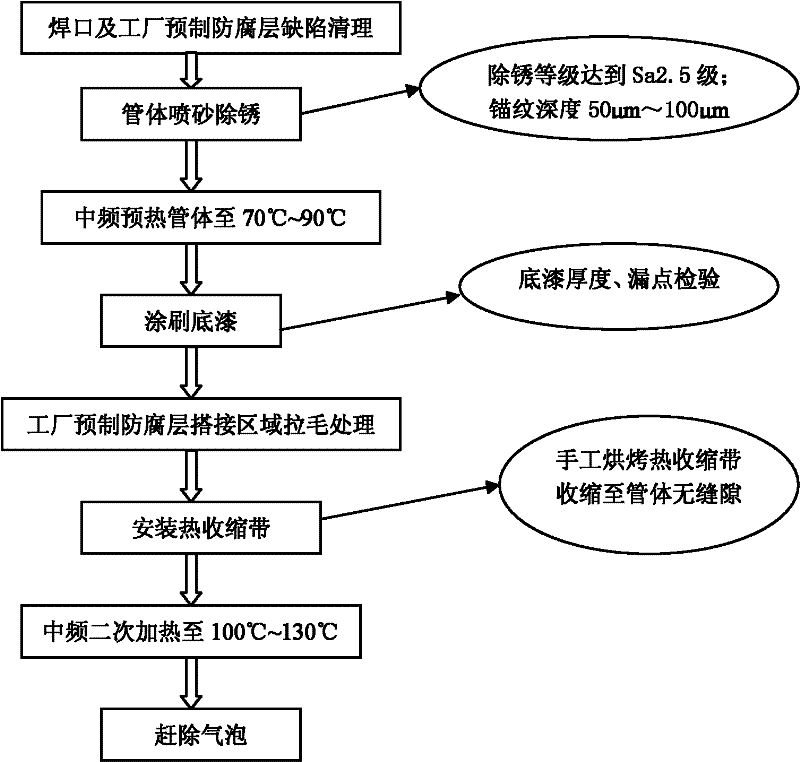

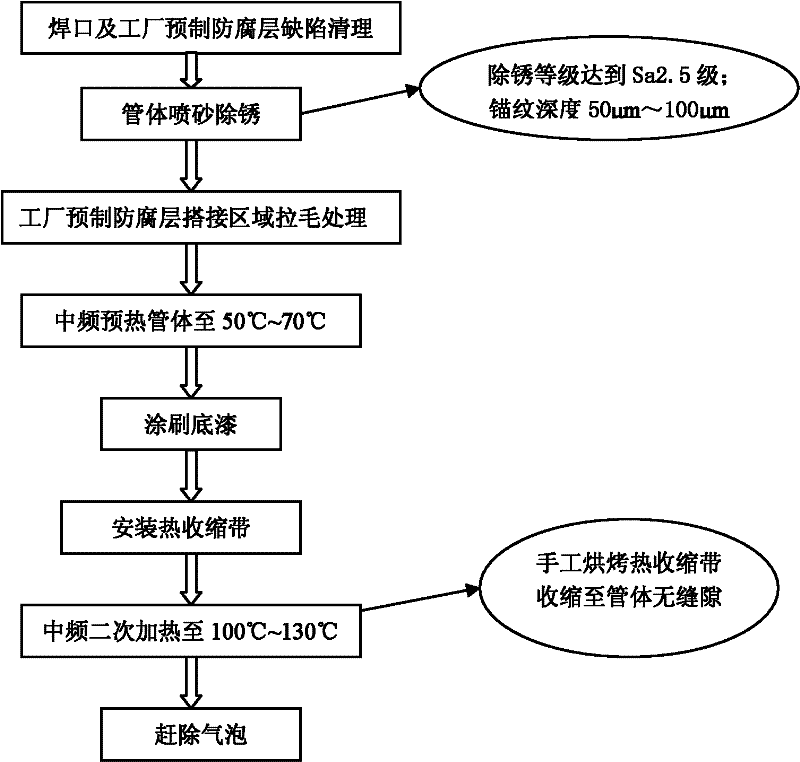

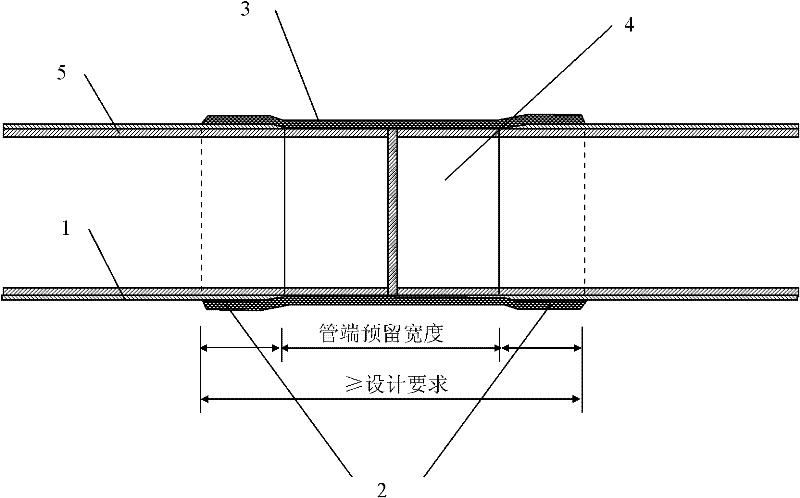

Intermediate-frequency heating repaired opening construction technology for thermal contraction band of buried steel pipeline

InactiveCN102679086ARealize flow operationAvoid secondary pollutionPipe elementsSand blastingIntermediate frequency

The invention relates to an intermediate-frequency heating repaired opening construction technology for a thermal contraction band of a buried steel pipeline. The construction technology comprises the following steps: 1) cleaning flaws of a welded junction and an anticorrosive layer prefabricated in a factory; 2) performing sand-blasting and de-rusting on a pipe body, wherein a de-rusting level is Sa2.5 level and an anchoring grain depth is 50 microns to 100 microns; 3) performing intermediate-frequency heating on the pipe body, wherein a preheating temperature is at 50-90 DEG C; 4) painting a primer, wherein the thickness of the primer is above 200 microns; 5) performing napping treatment on the surface of the anticorrosive layer prefabricated in the factory, in a flame manual steel wire brushing napping mode; 6) mounting the thermal contraction band: winding the thermal contraction band at the repaired opening, sticking a fixing sheet, and baking the surface till the thermal contraction band is completely and seamlessly covered on the pipe body; 7) secondarily intermediate-frequency heating under a secondary heating temperature at 100-130 DEG C, till fully melting a hot melt adhesive; and 8) removing air bubbles. According to the construction technology provided by the invention, the heating temperature is uniform, the influences of personal factors on construction quality are reduced and the efficiency and quality of repaired opening construction are greatly increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

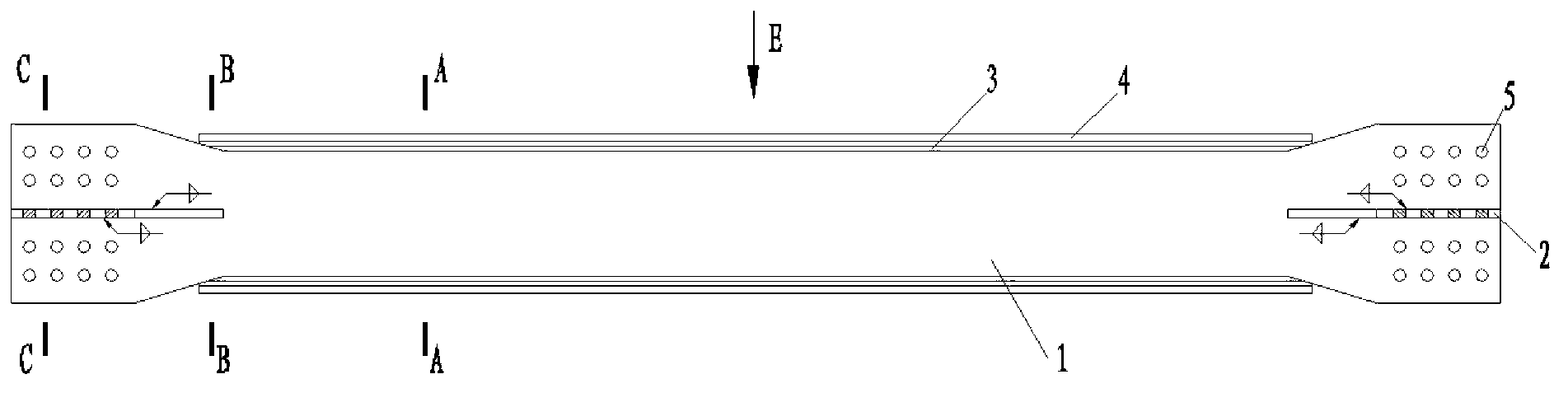

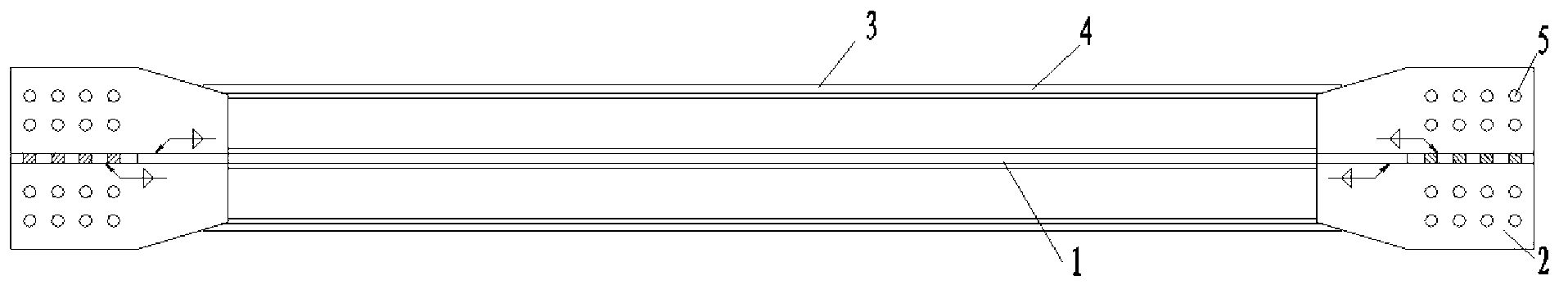

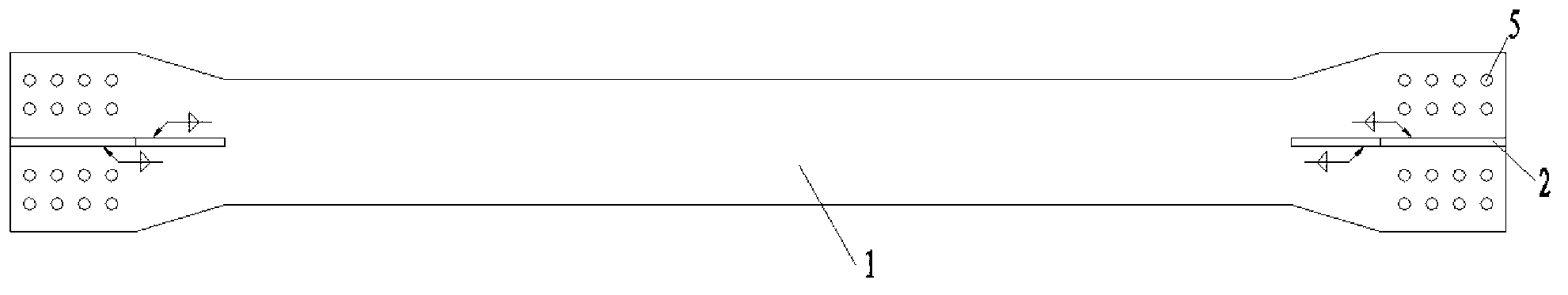

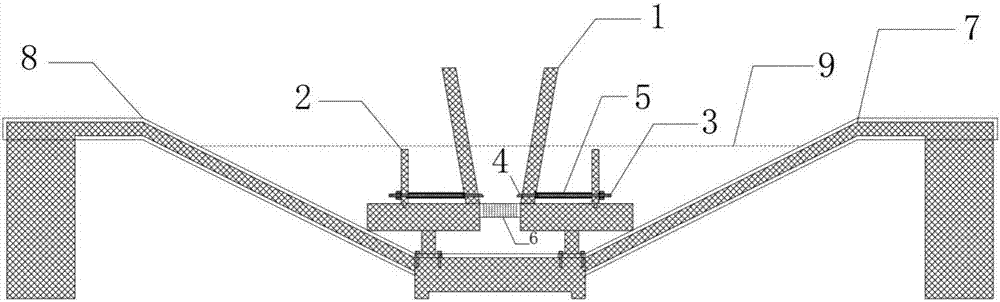

Fiberglass-reinforced plastics (FRP) section bar buckling-resisting supporting structure

ActiveCN103216023AReduce the weight of componentsSimple structureShock proofingSteel platesStructural element

The invention belongs to the technical field of civil engineering structural damping, and particularly relates to a fiberglass-reinforced plastic (FRP) section bar buckling-resisting supporting structure of rapid industrialization production. A core energy-consumption element is a line-type steel plate, and sectional faces of two end portions of the core energy-consumption element are expanded in the width direction. A steel plate is perpendicularly welded with the two end portions of the line-type steel plate to form a cross-shaped structure which can be connected with a structural member conveniently. Two FRP hollow ribbed bars are respectively clamped at two sides of the line-type steel plate, FRP cloth materials are wound on the outer rings of the FRP hollow ribbed bars, and multi-hole foam materials are filled between the line-type steel plate, the FRP hollow ribbed bars and the FRP cloth materials. Connecting structures used for being connected with structures are arranged on two ends of the line-type steel plate and the steel plate. The FRP section bar buckling-resisting supporting structure achieves energy consumption by utilizing rolled steel good in plastic deforming capability, especially mild steel, and achieves hysteretic energy consumption by utilizing axial deformation of the rolled steel. The FRP section bar buckling-resisting supporting structure is novel and reasonable in structure, easy to process, convenient and flexible to use, strong in adaptability, capable of effectively improving seismic performance of building structures, and wide in marketing popularization and application prospect.

Owner:TSINGHUA UNIV

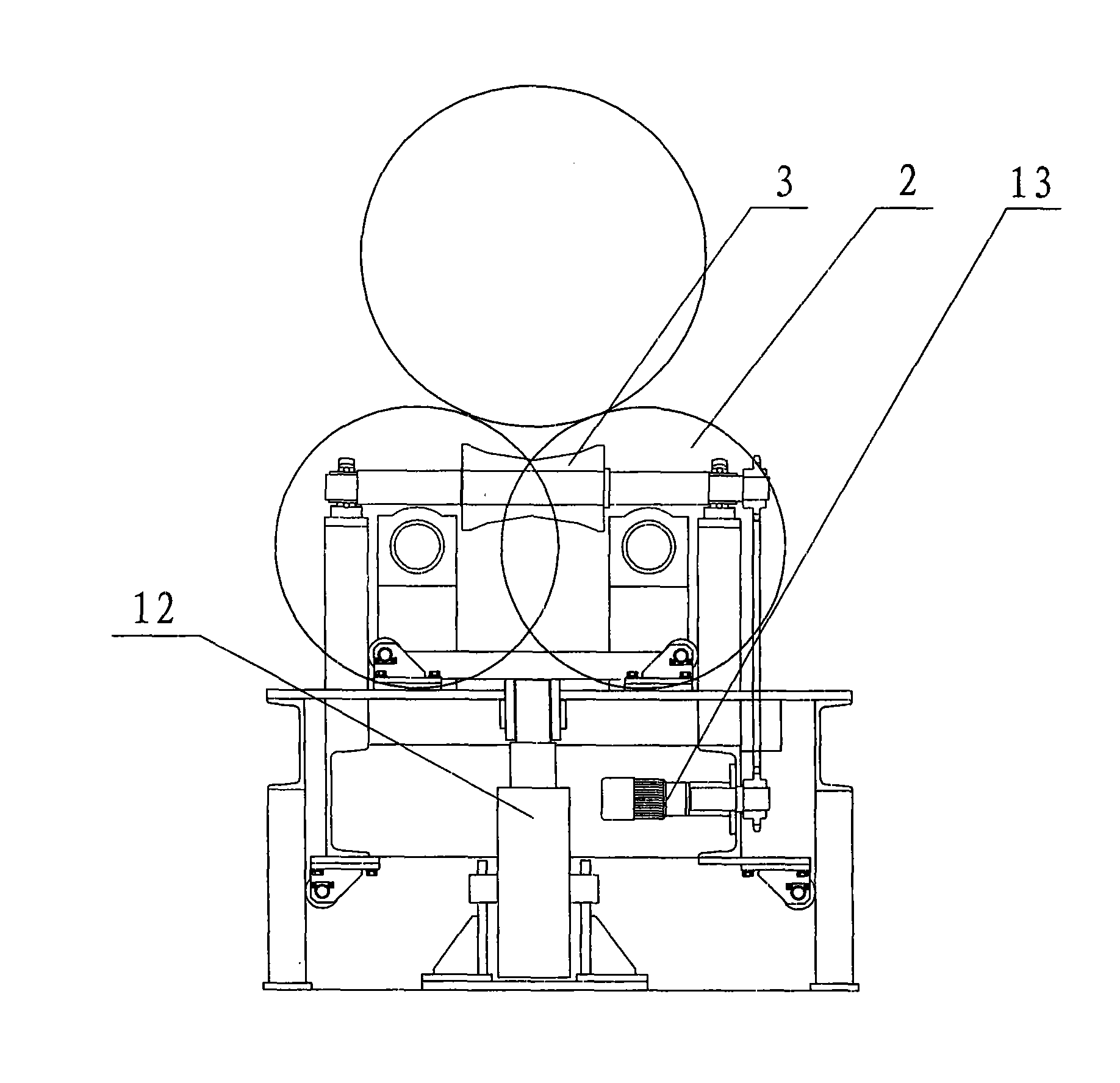

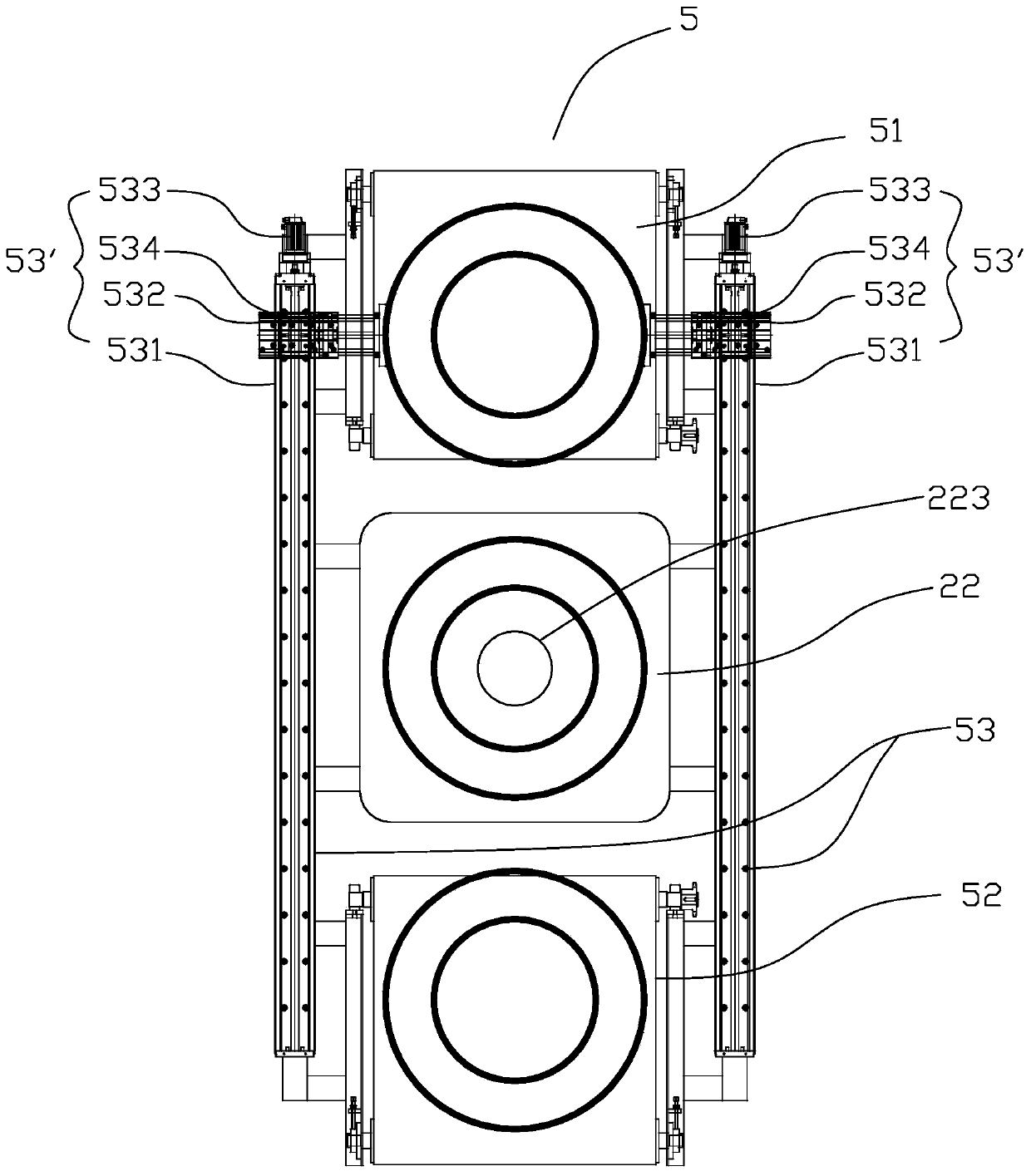

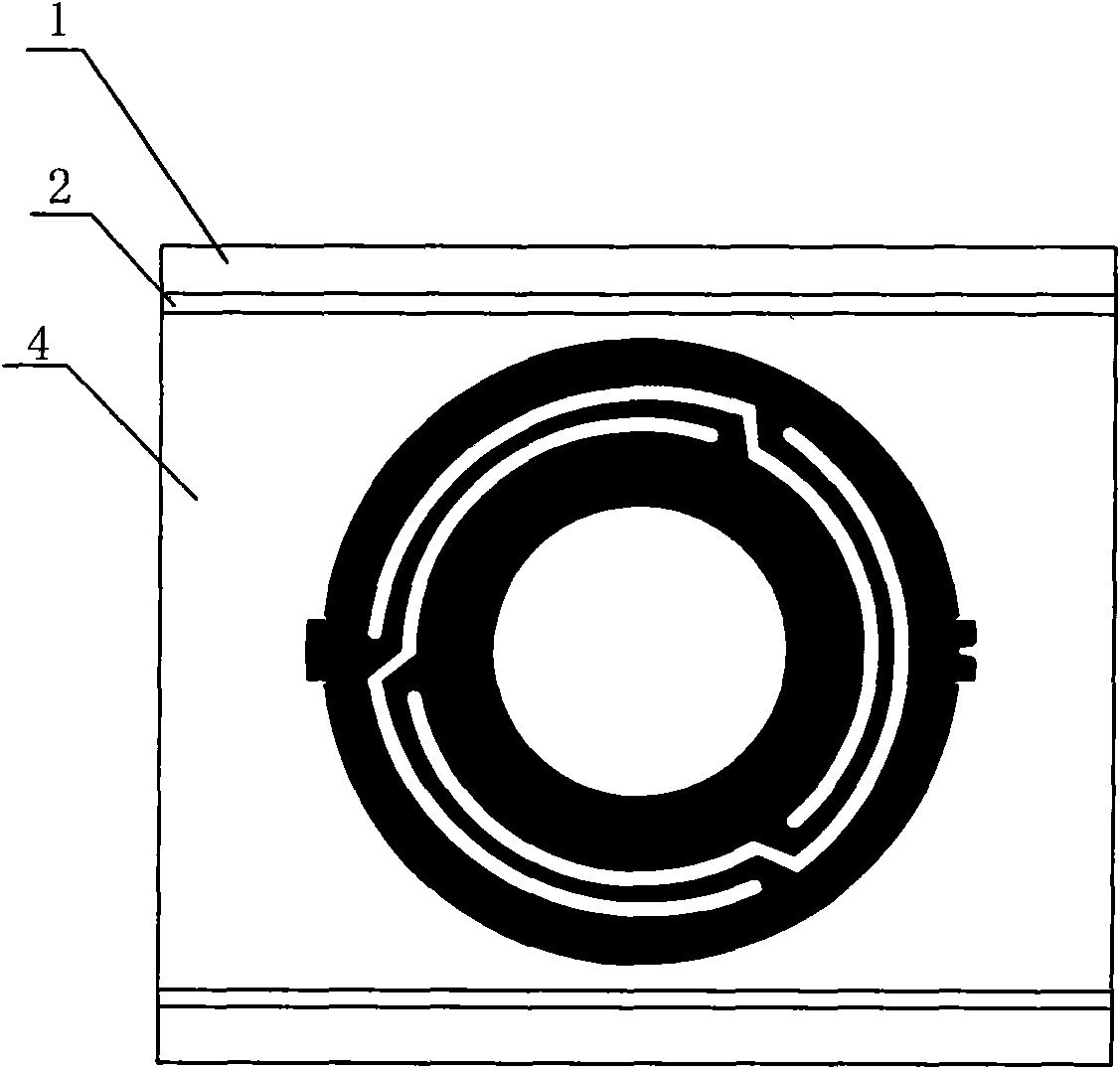

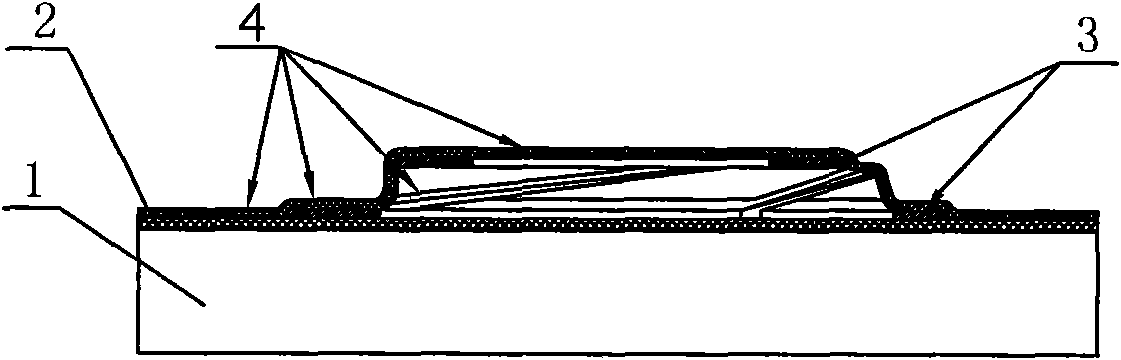

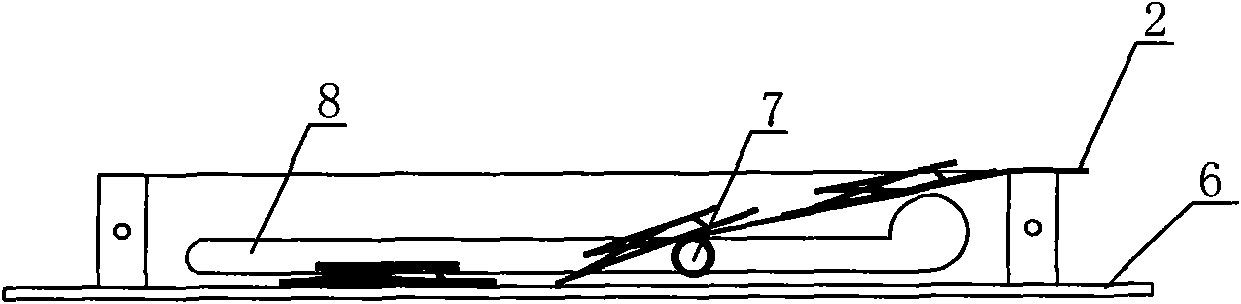

Tire film laminating packaging machine

PendingCN110040291AHigh speedSimple structureWrapping material feeding apparatusWrappingEngineeringPackaging machine

The invention discloses a tire film laminating packaging machine which comprises a film sealing unit and a film sending unit which are installed on a rack. The film sealing unit comprises an upper dieand a lower die. The film sending unit comprises an upper film sending device and a lower film sending device. The upper film sending device comprises an upper conveying roller and an upper collection roller, wherein the upper conveying roller and the upper collection roller are located on the two sides of the film sealing unit correspondingly. The lower film sending device comprises a lower conveying roller and a lower collection roller, and the lower conveying roller and the lower collection roller are located on the two sides of the film sealing unit correspondingly. The upper die is provided with laminating parts which are used for pressing an upper film and a lower film on the lower die to conduct hot sealing, and the two laminating parts are in a cylinder shape and are coaxially arranged. By means of the tire film laminating packaging machine, due to laminating of the upper die and the lower die, the upper film and the lower film can be subjected to hot bonding and wrap a tire,the structure of the equipment is simple, in addition, running steps are few, the film laminating packaging speed is high, and the packaging work efficiency is high.

Owner:青岛科力达机械制造有限公司

Spare part membrane-coating method before partially plating gold on reed

The invention relates to a spare part membrane-coating method before partially plating gold on a reed, which overcomes the defects of high cost, incapable batch operation and easy replacement dot generation phenomenon to affect the gold plating effect existing in the prior art. The method comprises the following steps: coating a dry membrane on a flat plate; using and placing at least one reed on the dry membrane, wherein the reed part to be plated with gold faces to the dry membrane upwards; coating an optical-sensitive wet membrane on the dry membrane and the reed part not to be plated with gold; stationary flowing; releasing the dry membrane, the reed and the optical-sensitive wet membrane from the flat plate, stripping the reed and the optical-sensitive wet membrane from the dry membrane onto a metal net, and enabling the reed part to be plated with gold to face to the metal net; drying the metal net, the reed and the optical-sensitive wet membrane together; enabling the optical-sensitive wet membrane to face an optical source to carry out optical fixing; cleaning the dry membrane and the wet membrane remained on the surface of the reed part to be plated with gold; and plating gold on the reed coated with the optical-sensitive wet membrane after being optically fixed. The invention has the advantages of low cost, and the like.

Owner:XIAN SENSHE ELECTRONICS TECH CORP

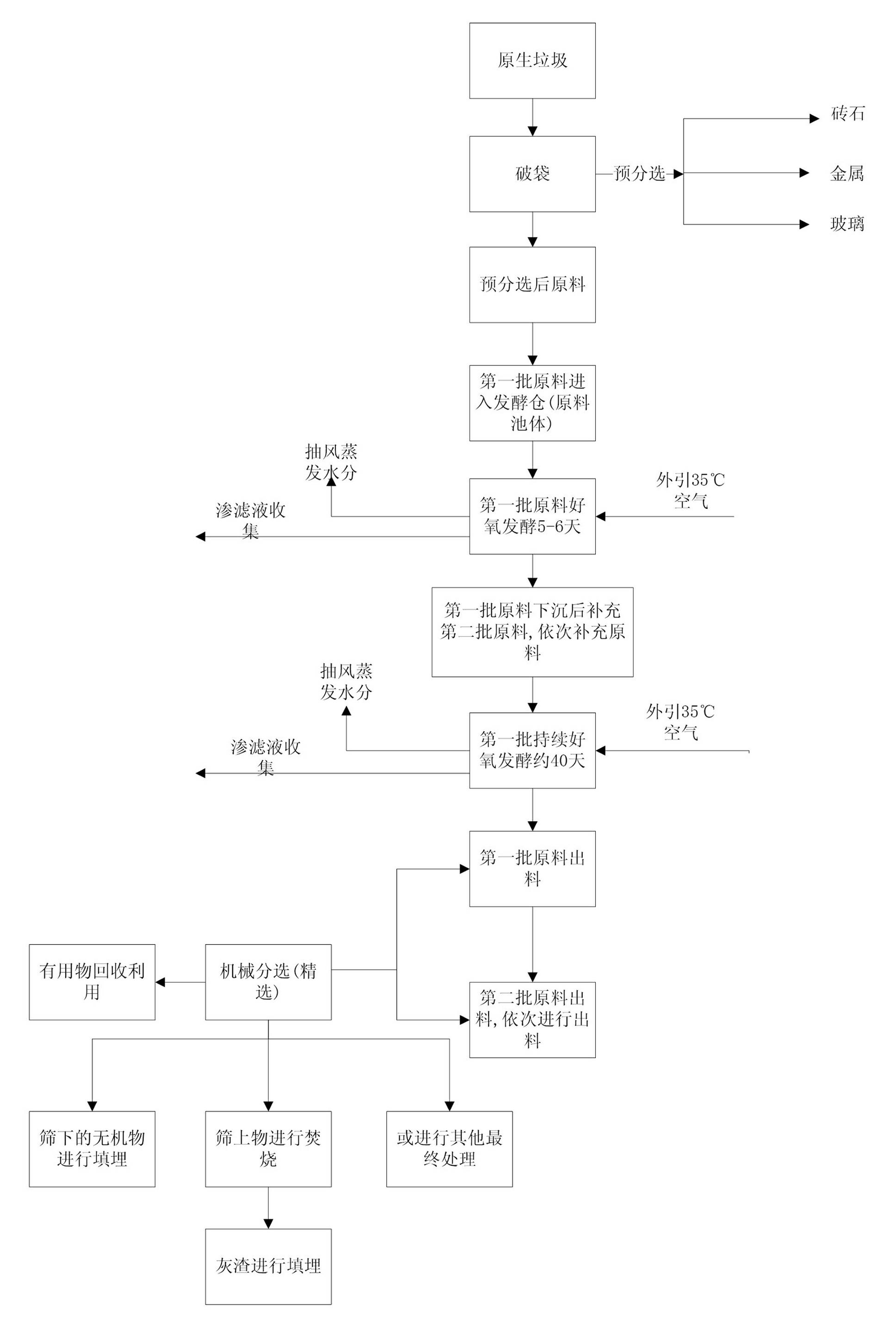

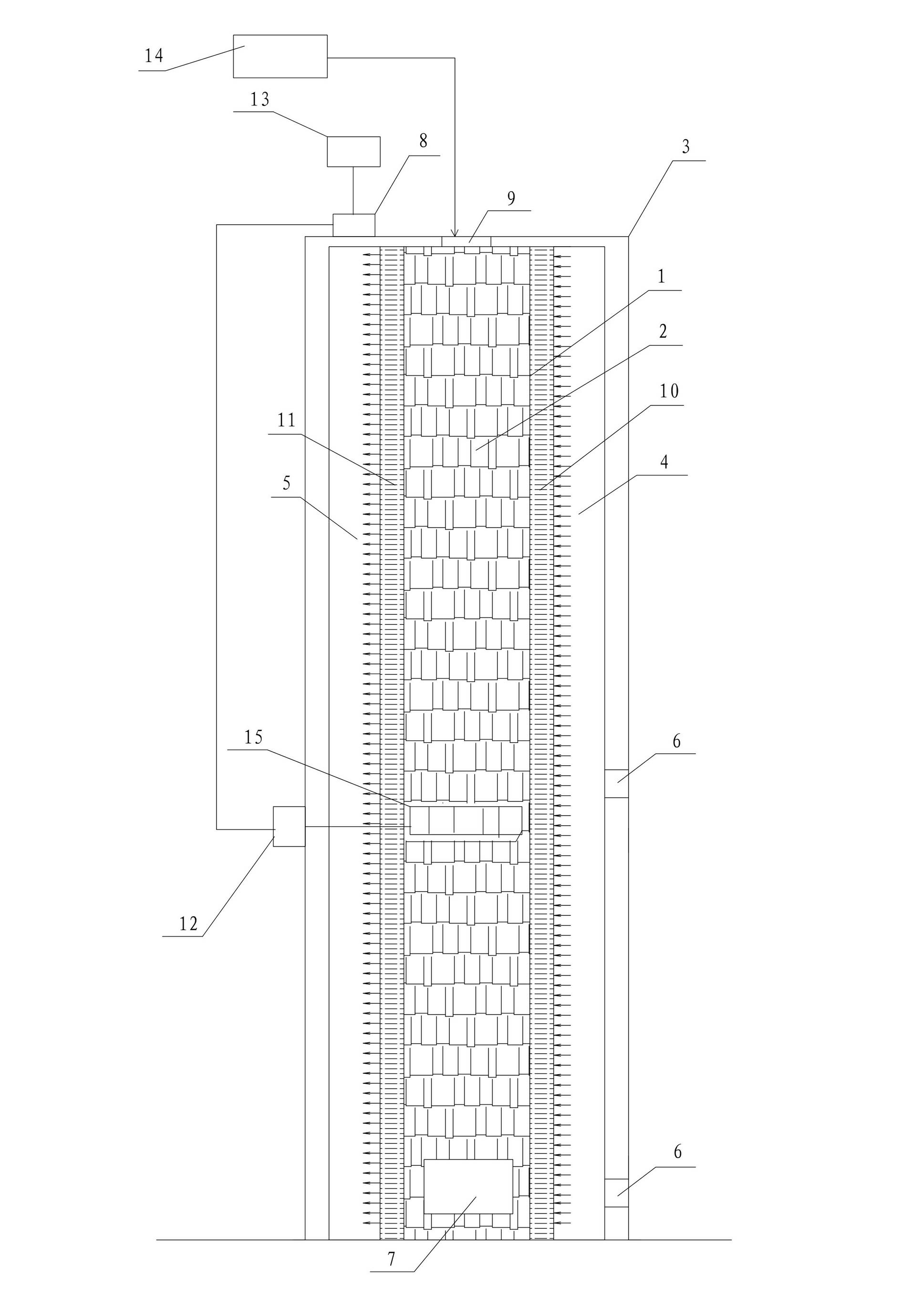

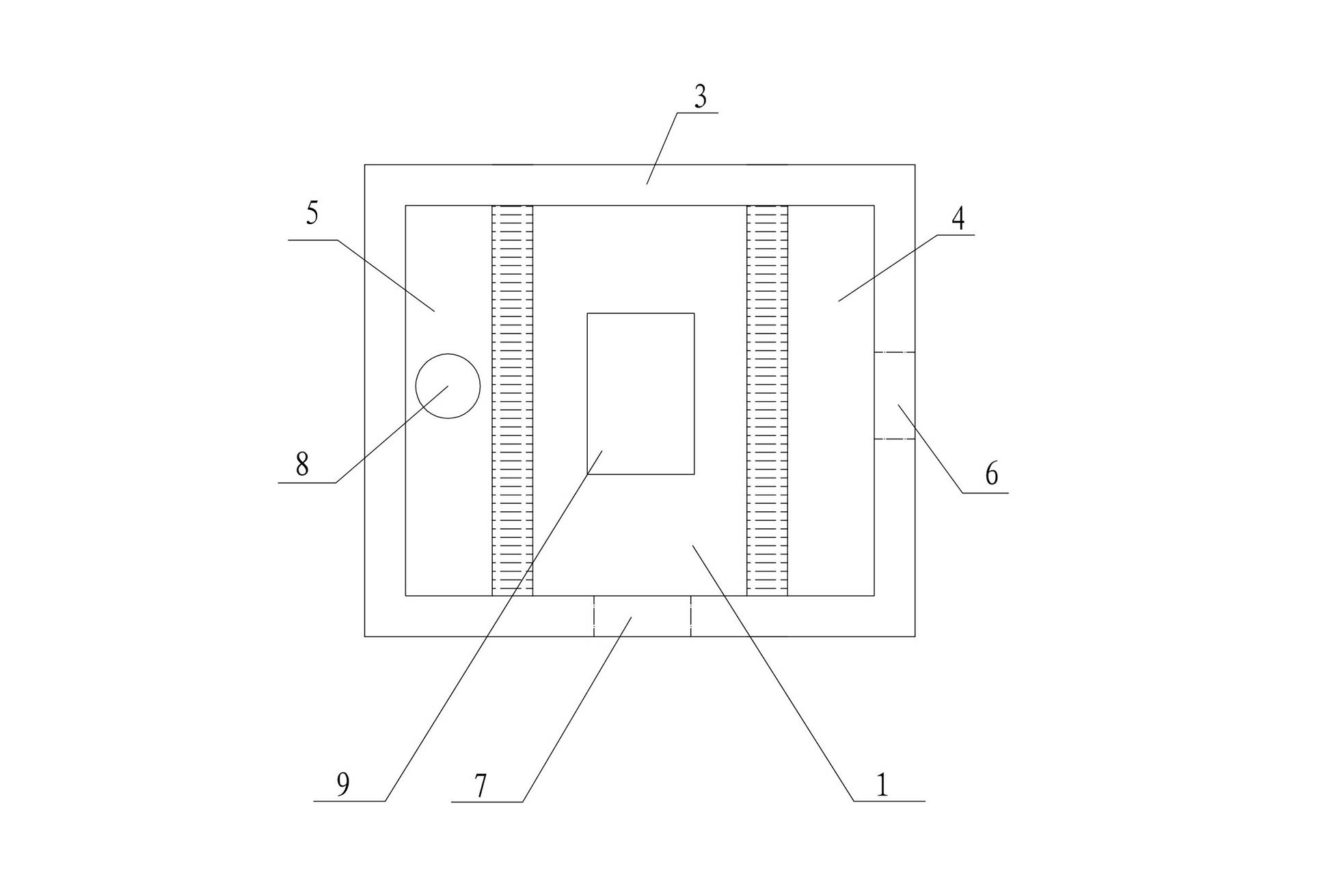

Device and method for large-scale pretreatment of domestic garbage

ActiveCN102626710AReduce moistureImprove low heatSolid waste disposalAutomatic controlSmall footprint

The invention discloses a device and a method for large-scale pretreatment of domestic garbage. The device comprises a vertical cylinder, an air suction component, a double-screw discharge component and a temperature automatic control component, wherein the air suction component is matched with the vertical cylinder; a raw material cavity, an air inlet duct and an air outlet duct are arranged in the vertical cylinder; the air inlet duct and the air outlet duct are oppositely arranged at the two ends of the raw material cavity; the face of the air inlet duct facing the raw material cavity is provided with a plurality of air inlet holes which are communicated with the raw material cavity; the face of the air inlet duct far away from the raw material cavity is provided with more than one air inlet; the face of the air outlet duct facing the raw material cavity is provided with a plurality of air outlet holes which are communicated with the raw material cavity; and the face of the air outlet duct far away from the raw material cavity is provided with more than one air outlet. According to the method, the garbage material is continuously filled into the raw material cavity of the vertical cylinder lot by lot, fermented by intake air and continuously discharged lot by lot. The device has the advantages of simple and compact structure, small floor area and the like; and large-scale, industrial, engineered and continuous flow line production of the pretreatment of the domestic garbage can be realized.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

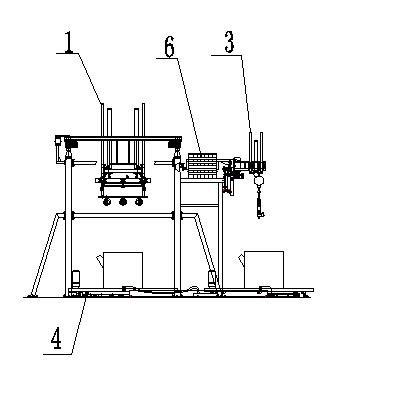

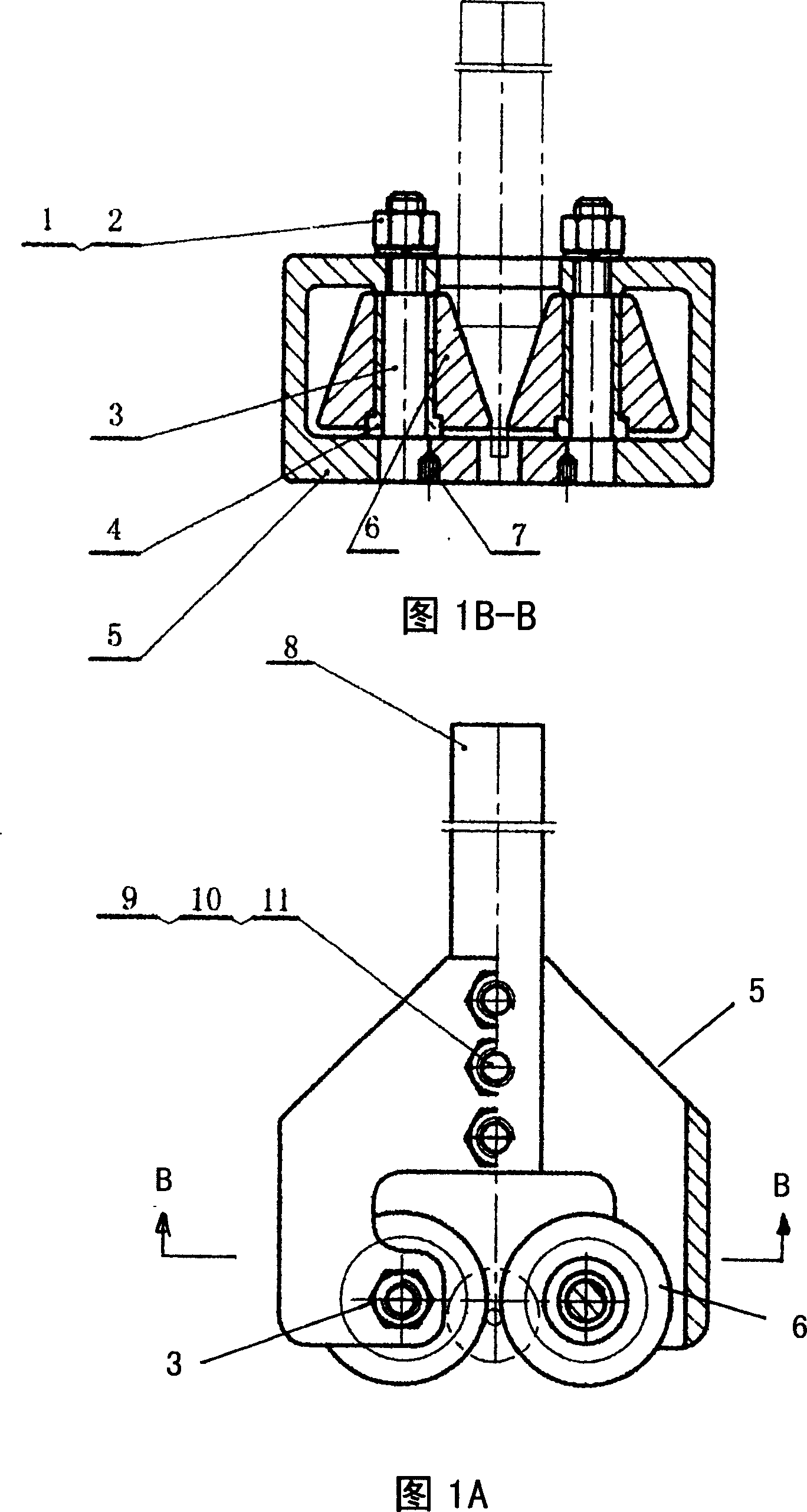

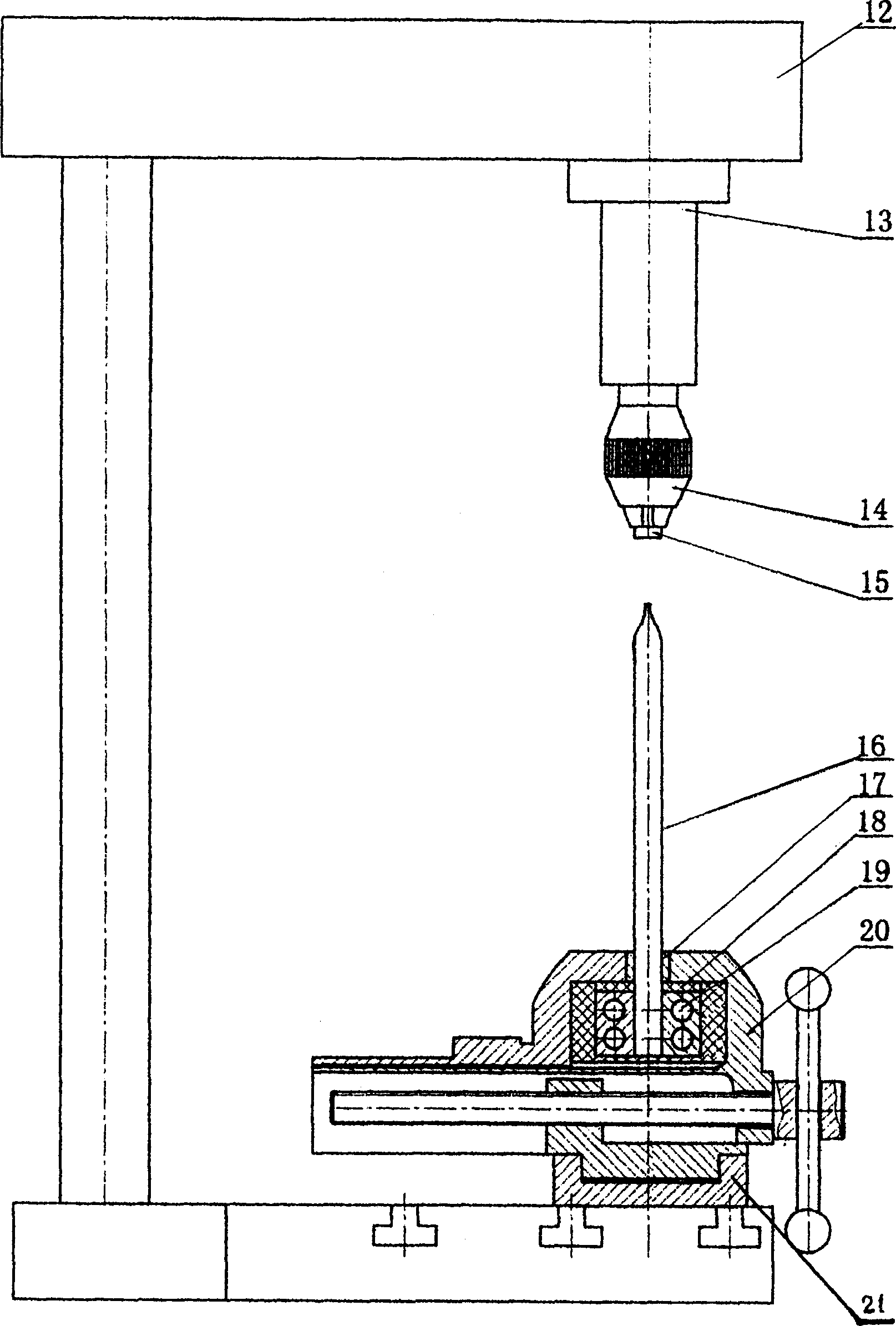

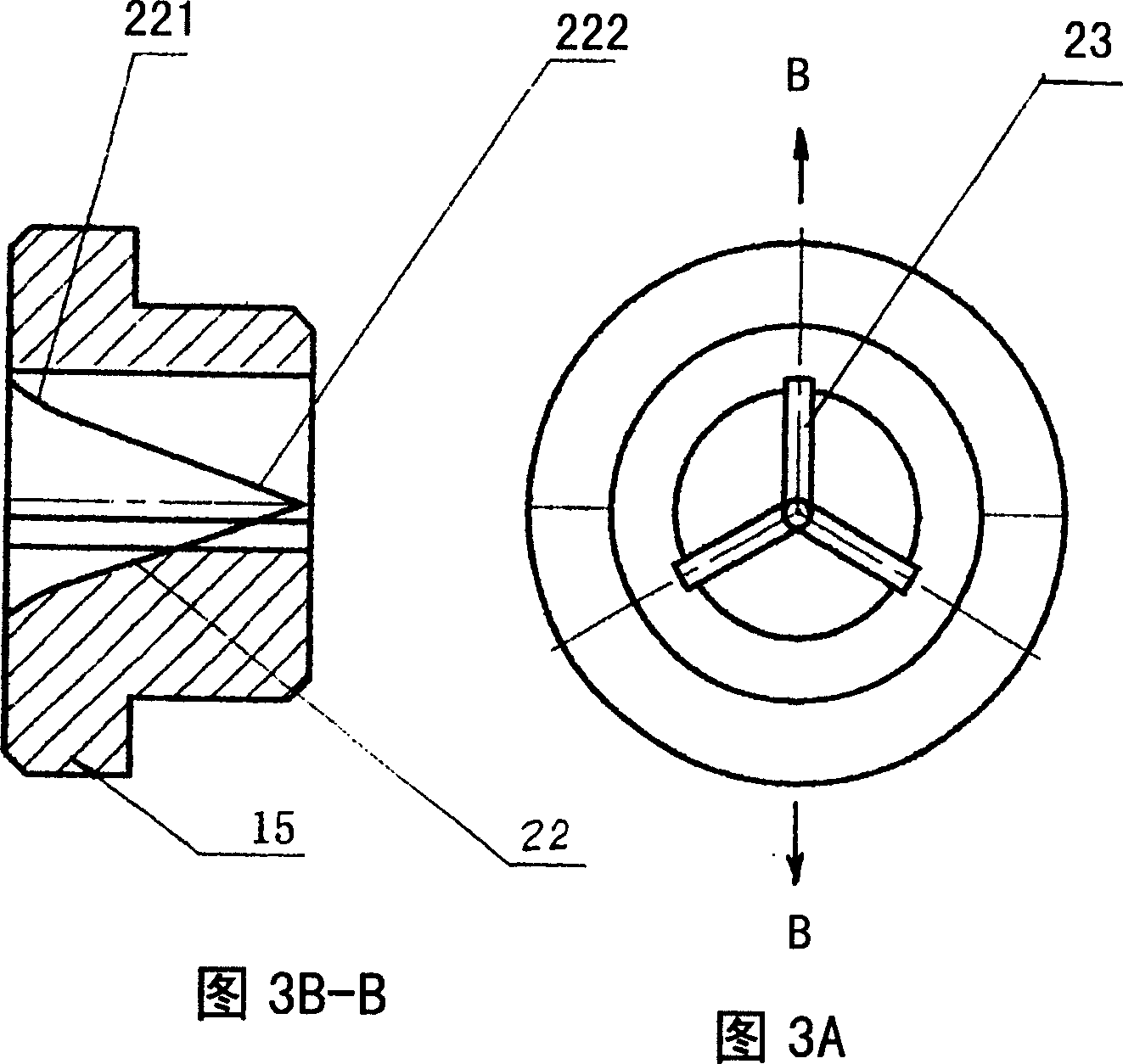

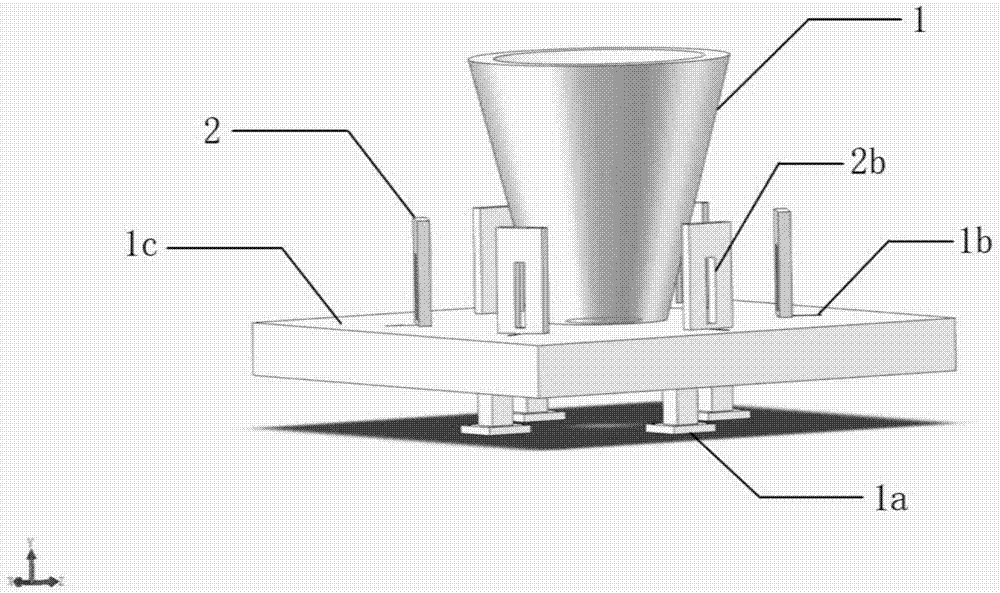

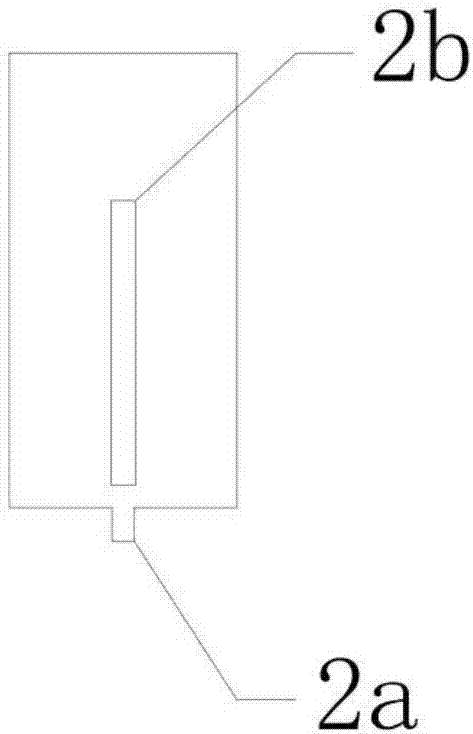

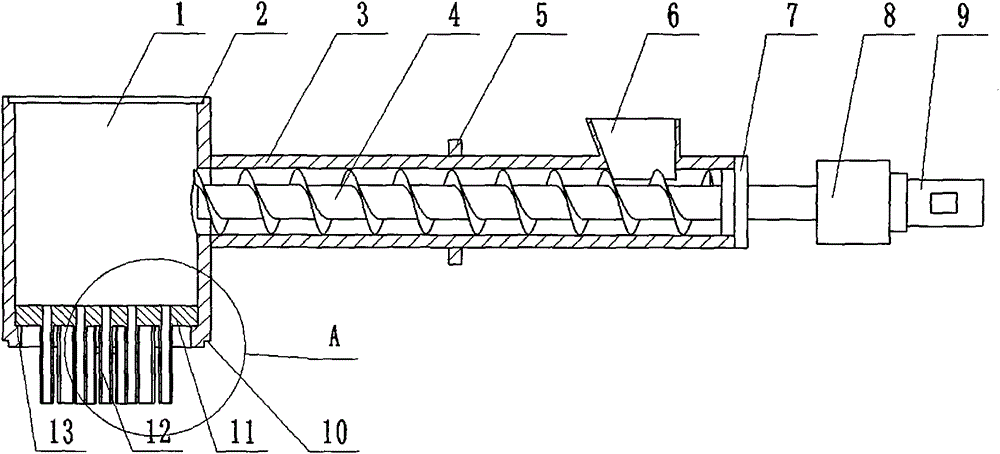

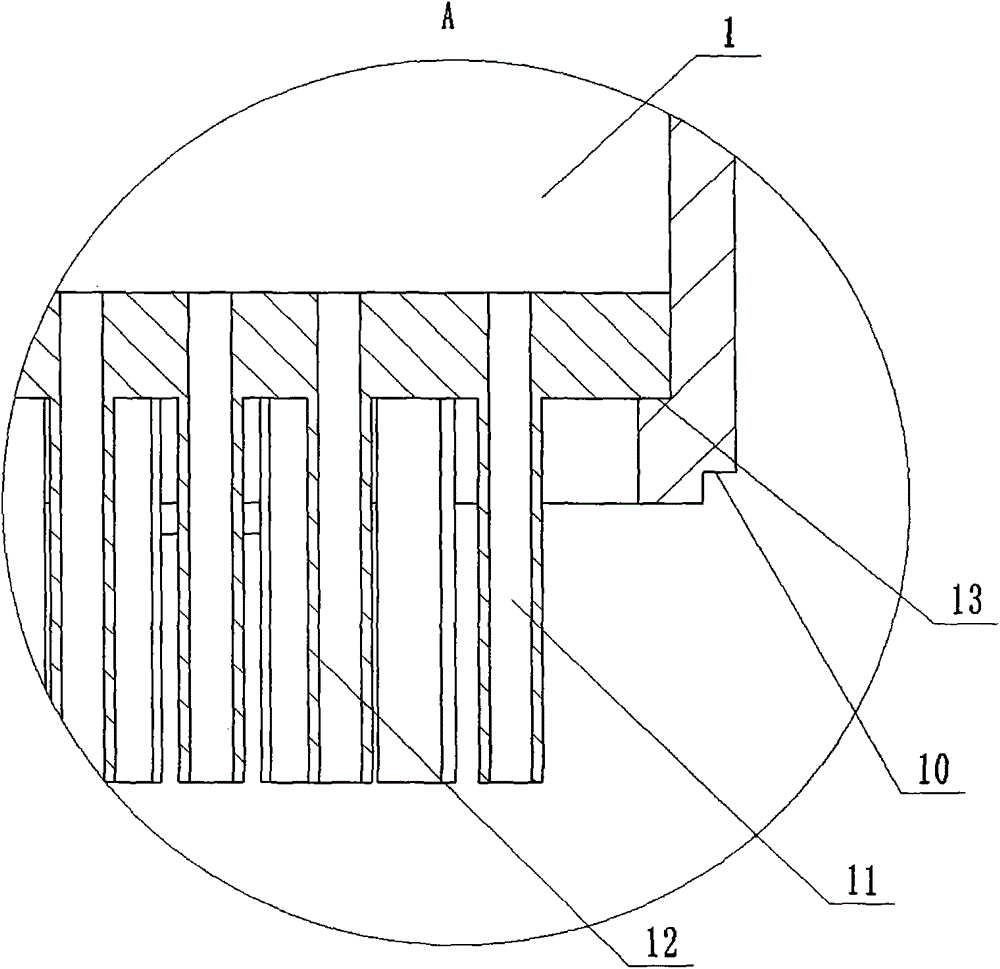

Beading and sealing device in heat pipe production ,and its processing method

The invention discloses a reducing and sealing device in the preparation of heat pipe and the method for production of the heat pipe, and relates to the art of preparation of heat pipe. The reducing and sealing device can process reducing and sealing in the preparation of heat pipe, the reducing device, which comprises a pair of conical rollers, a knife bar, a roller clamp, a screw nut and a screw, proceeds the reducing of the heat pipe in a high-velocity lathe, and the sealing device, which comprises a high-velocity vertical drill and a heat clamping device, proceeds the sealing. With the invented device, it can avoid the electrogas welding in the preparation of heat pipe, and it is easy to realize assembly-line operation, and the device is especially suit for the preparation of siphon heat pipe.

Owner:中科思道(南京)储能技术有限公司

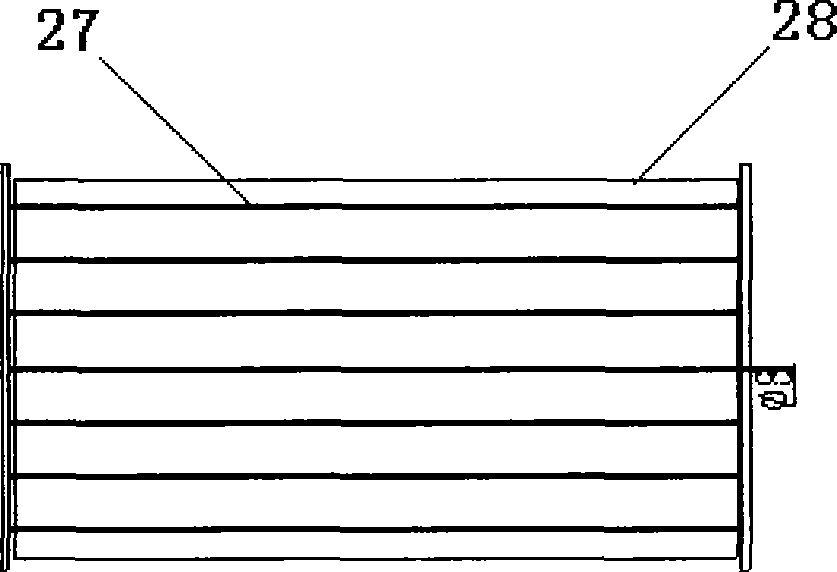

Automatic cleaning and disinfecting system for floating seedling-raising disks

InactiveCN102319700AReduce breakage rateFast cleaningCleaning using toolsCleaning using liquidsWater resourcesBreakage rate

The invention discloses an automatic cleaning and disinfecting system for floating seedling-raising disks. The system comprises a frame, a conveying device, a cleaning device, a disinfecting device and a driving device, wherein the conveying device comprises a support rail, a transmission shaft, a chain wheel, two chains arranged in parallel and a disk pushing device arranged on the chains; the cleaning device comprises a cleaning brush, a pre-wetting pipe with a water outlet hole on the bottom surface, a flushing pipe and a rinsing pipe, and the pre-wetting pipe, the flushing pipe and the rinsing pipe are sequentially arranged on the frame from front to back; and the disinfecting device comprises a disinfecting box and a disinfecting pipe with the water outlet hole on the bottom surface. The automatic cleaning and disinfecting system can enable cleaning and disinfecting work to realize flow operation, complete cleaning and disinfection once, realize thorough cleaning, good disinfection effect, low breakage rate, fast cleaning speed and high efficiency, use water in a circulating manner and save water resources, and is portable, convenient and flexible; and furthermore, the automatic cleaning and disinfecting system is reasonable in design, easy to manufacture and simple to operate.

Owner:云南省烟草公司楚雄州公司

Pancake machine

InactiveCN111149820AEvenly heatedRealize flow operationOil/fat bakingPancakes bakingPhysicsMechanical engineering

The invention provides a pancake machine, and relates to the technical field of food processing equipment. The invention aims to optimize the operation flow of pancake baking to a certain extent and reduce manual intervention so as to improve the operation efficiency. The pancake machine provided by the invention comprises a frame, a baking device, a feeding device and a scraping device, wherein the frame is arranged in a horizontal direction; the feeding device is arranged on the frame and used for conveying a feed liquid to the baking device; the baking device comprises a griddle, a heatingmechanism and a first driving mechanism; the griddle is arranged in a horizontal direction; the first driving mechanism can drive the griddle to rotate relative to the frame; the heating mechanism isused for heating the griddle; and the scraping device is arranged on the frame and can make contact with or be separated from the griddle.

Owner:UROICA GUANGDONG PRECISION INFORMATION ENG TECH RES INST CO LTD

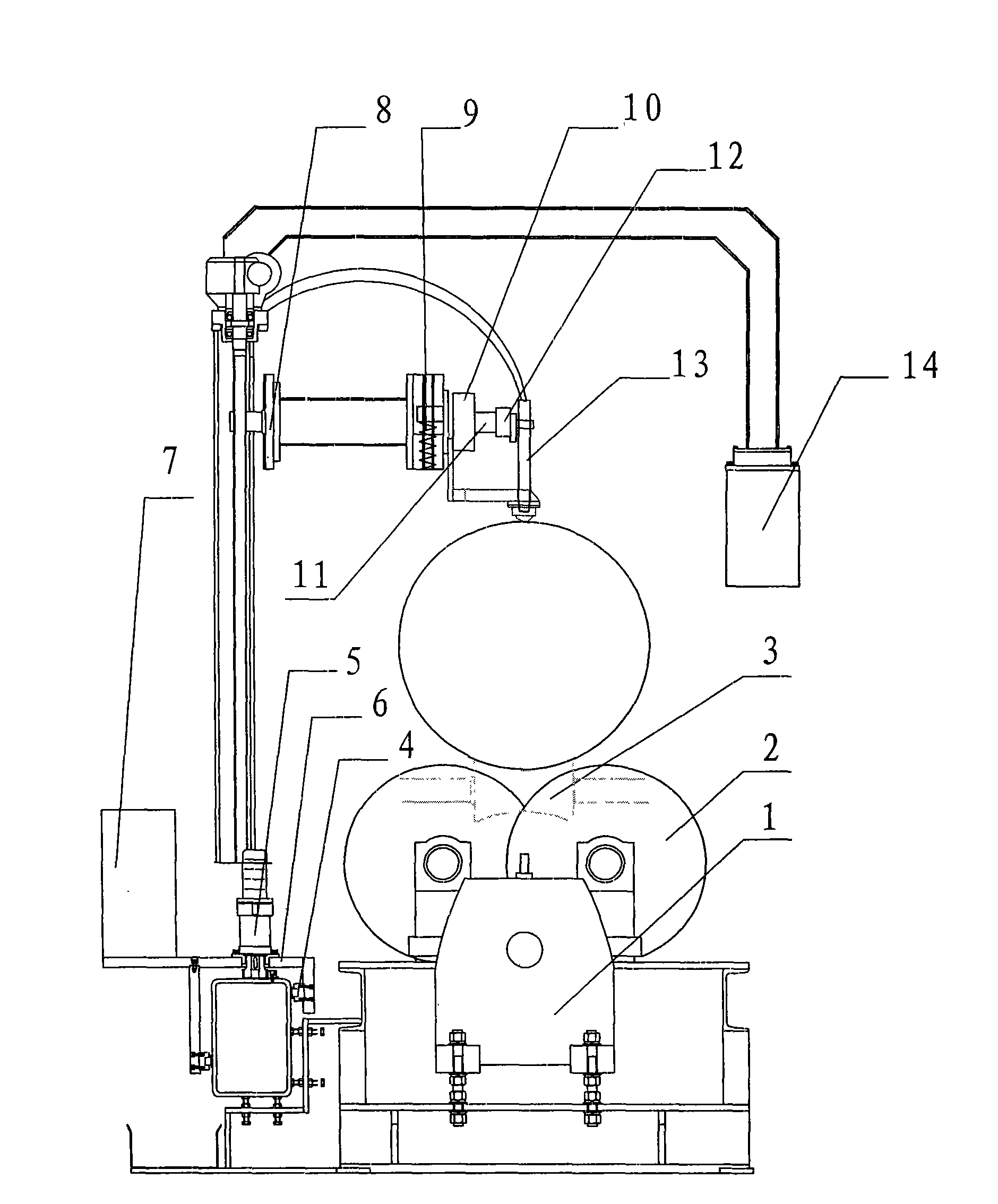

Double light path optical-fiber laser bonding machine for plate-type solar thermal absorber

InactiveCN101380695AQuality improvementFast welding speedLaser beam welding apparatusLaser bondingEngineering

The invention relates to a laser welding machine. The invention discloses a double-light path fiber laser welding machine used for a plate solar heat absorber which includes a laser, a fiber and a focusing system. The laser is connected with the focusing system by the fiber. The invention also includes a base device and a goal-post device; wherein, the goal-post device is arranged on the base device; the focusing device is arranged on the goal-post device for inducing the laser emitted by the laser between the goal-post device and the base device. Aiming at the position of a workpiece to be welded, the focusing system can move along the three directions of X, Y and Z; wherein, X and Y refer to a horizontal direction parallel to the ground; Z refers to a direction vertical to the ground. The welding machine solves the welding difficulty between a copper tube and an aluminum plate and changes the manufacturing technique flow of a solar heat absorber, thus leading the quality of the solar heat absorber to be greatly improved.

Owner:武汉楚天激光(集团)股份有限公司

Safety-type spring intensification shot blasting machine

InactiveCN102189497APrevent splashReduce power consumptionAbrasive blasting machinesMechanical engineeringEngineering

The invention relates to a safety-type spring intensification shot blasting machine, which comprises a shot blasting cleaning chamber and a shot blasting device, wherein a steel shot classifier is fixed above the shot blasting cleaning chamber; the longitudinal two sides of the shot blasting cleaning chamber are provided with an auxiliary chamber respectively; a set of steel shot flow curtain sealing device is arranged in each auxiliary chamber and comprises a box body with an upper opening and a lower opening; the upper opening of the box body is connected with a steel shot separator; a shot flow channel which is fixedly connected with the upper opening is formed in the box body; a material control mechanism is arranged at the outlet of the shot flow channel; a flow guide box body is arranged below the lower opening of the box body; and an adjustment mechanism is arranged at the outlet of the flow guide box body. In the invention, a novel steel shot flow curtain sealing device is used, steel shots which are circulated inside the shot blasting machine are used to form a steel shot curtain in the shot blasting cleaning chamber, and a good sealing property is realized, so that the steel shots can be effectively prevented from hurting people by splashing, and the shot blasting machine is safe and reliable.

Owner:无锡国达机械设备有限公司

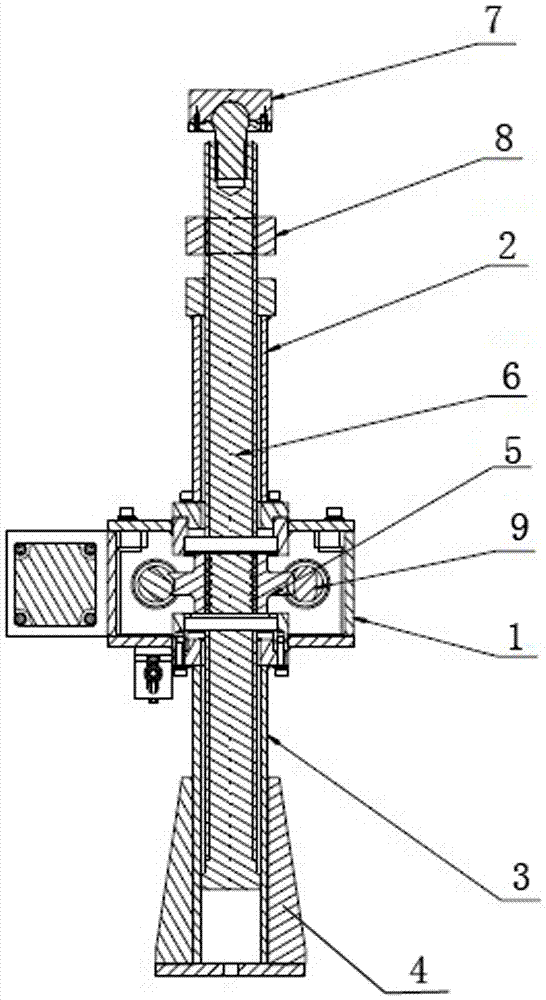

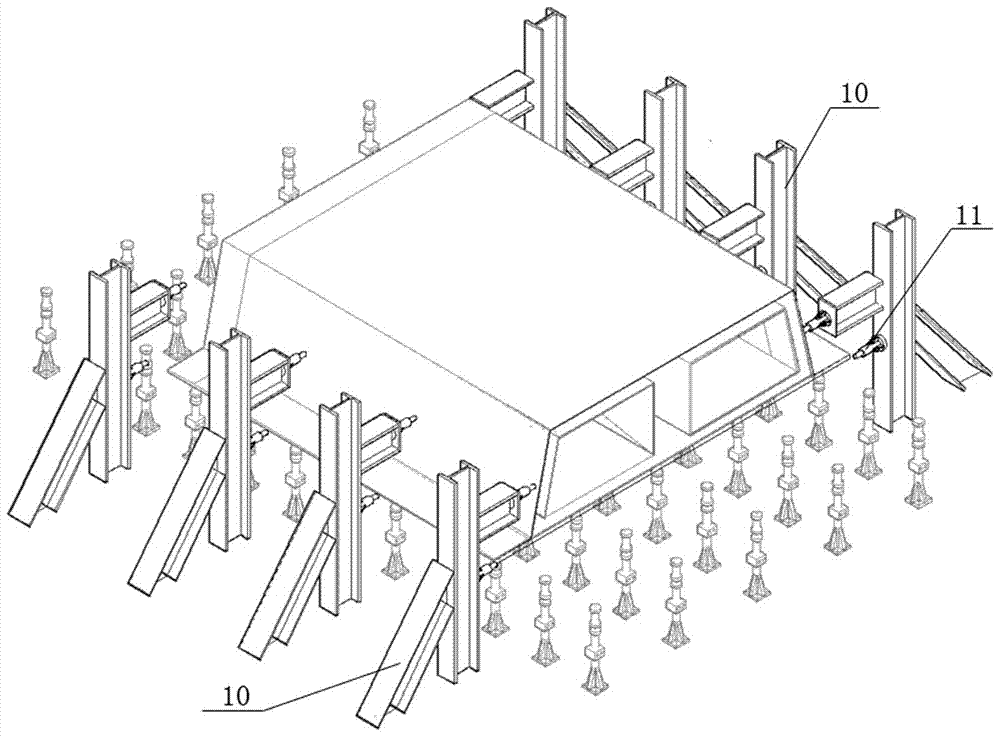

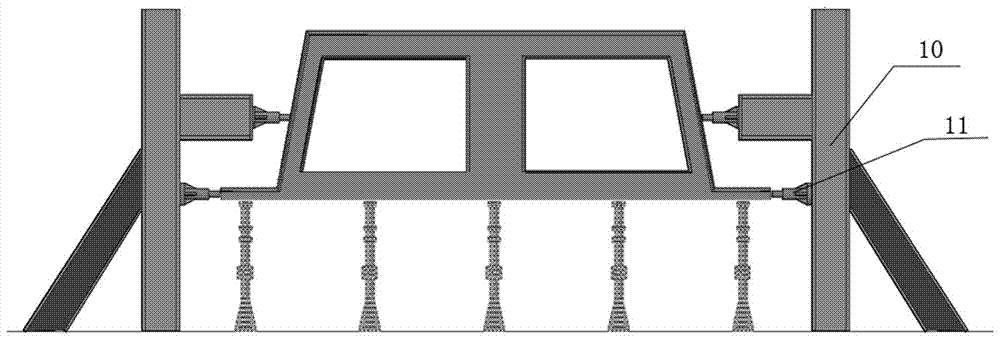

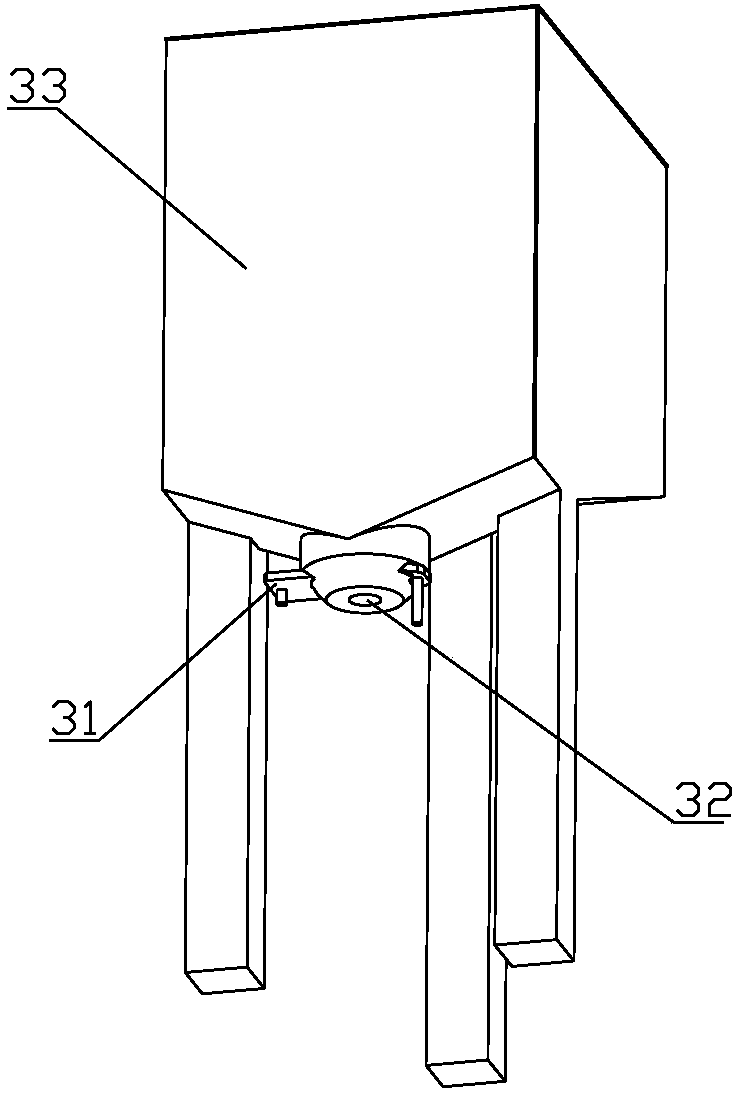

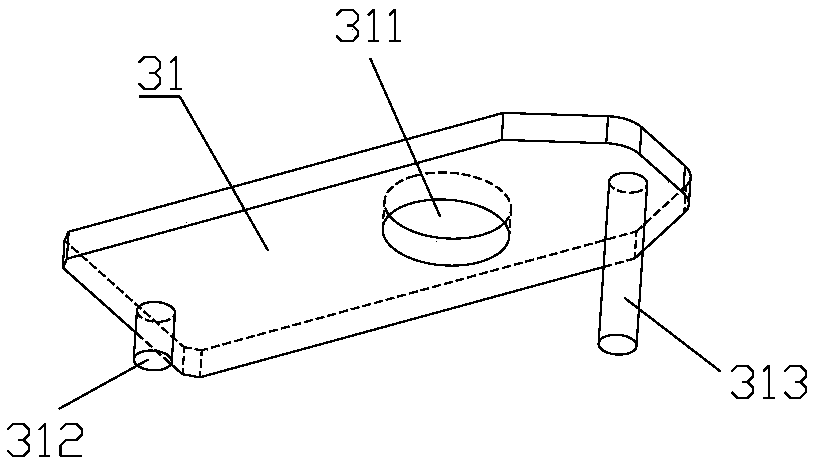

Tool installation mould for upside-down construction of multi-curve superimposed steel box girder and construction method thereof

PendingCN107386130AMeet sizeFulfil requirementsBridge erection/assemblyBridge materialsScrew positionArchitectural engineering

The invention relates to the field of general assembly of girder sections of steel box girders, in particular to a tool installation mould for upside-down construction of a multi-curve superimposed steel box girder and a construction method thereof. The tool installation mould for the upside-down construction of the multi-curve superimposed steel box girder includes a box body, an upper column and a lower column are fixed to the box body and located on and under the box body respectively, and the lower end of the lower column is fixed into a base; the box body is internally provided with a worm wheel and worm mechanism, lead screws positioned inside the upper column and the lower column are arranged on worm wheels, and the top portions of the lead screws are provided with supporting heads. The adjustable mould has excellent universality, and by utilizing the self-locking and adjustable properties of the adjustable mould, the adjustable mould can serve as an adjustable moulding bed support for changes of curved section frame lines and be adjusted in the vertical direction.

Owner:CHINA RAILWAY SIXTH GROUP +1

Paper bag packaging machine for packaging medical gauze

PendingCN107902148AThe process of entering the paper bag is smoothDoes not damage the structureWrapper twisting/gatheringPackaging machinesPulp and paper industryFront and back ends

The invention belongs to the field of packaging, and discloses a paper bag packaging machine for packaging medical gauze. The packaging machine comprises a working table, a transferring module, an unfolding module and a packaging module, wherein the transferring module is arranged on the working table. The transferring module is used for realizing the longitudinal movement and the transverse movement of a first sucker, so that the transferring of a paper bag is completed. The unfolding module comprises a forming cavity, an unfolding sliding block, a shaping plate and a second sucking disc, theforming cavity is used for containing the paper bag to be machined, the second sucking disc is arranged below the forming cavity, and the paper bag is separated from the paper bag by the combined action of the first sucking disc and the second sucking disc. The unfolding sliding block and the shaping plate are oppositely arranged at the front end and the rear end of the forming cavity, a slidingrail penetrating through the forming cavity is arranged in the forming cavity, the shaping plate and the unfolding sliding block move on the sliding rail to achieve the unfolding of the paper bag. Thepackaging module is used for packaging the packaged paper bag. According to the packaging machine, the process of packaging the gauze by a double-layer paper bag is realized, and the use is convenient. The packaging machine is compact in structure, convenient to manufacture and use and wide in application range.

Owner:HUAZHONG UNIV OF SCI & TECH

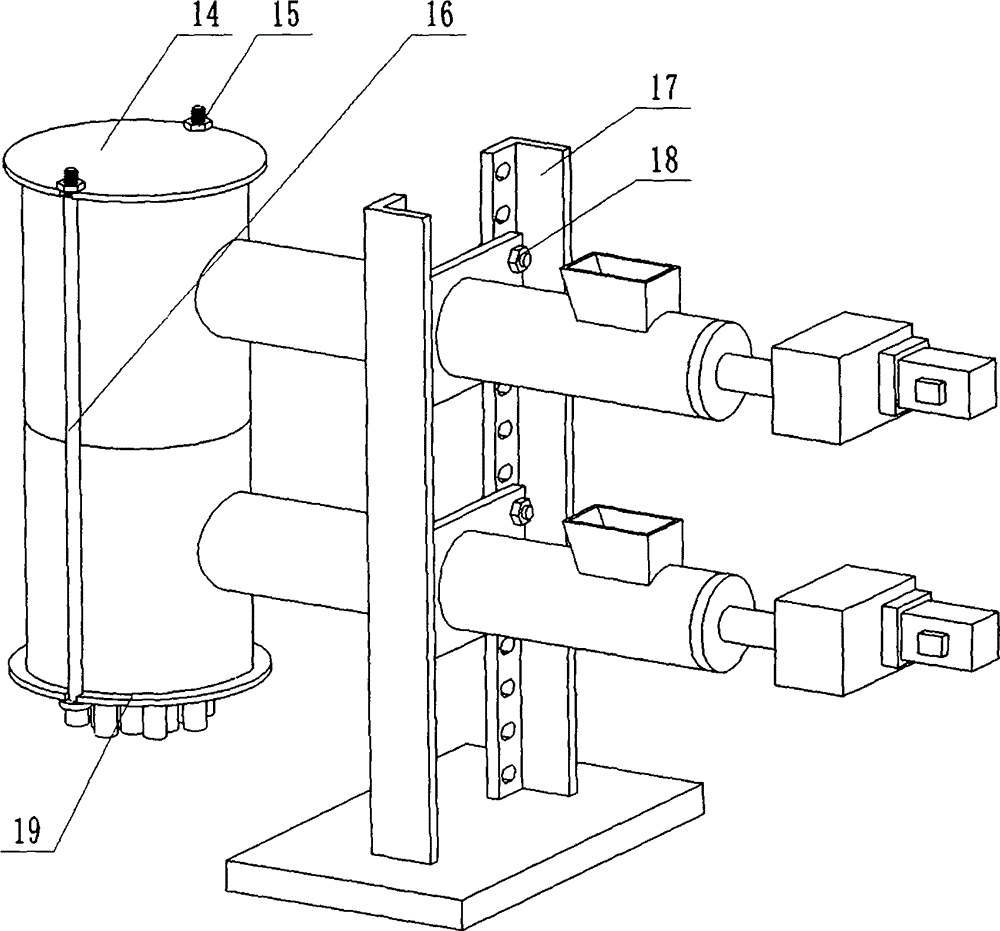

High voltage electropulse breakup reaction tank for line production

ActiveCN107350056AShipped out in timeStructural solutionGrain treatmentsElectric dischargeEndurance capacity

The invention discloses a reaction tank adopting high voltage electropulse in-water electric discharge to break up polycrystalline silicon rods. The reaction tank comprises a guiding fixing barrel, a sieve, electrode structures, a water tank and a conveying belt. Each electrode structure comprises an electrode frame plate, an electrode stem and an electrode head, wherein the electrode frame plate is provided with an adjusting groove so that the electrode spacing can be guaranteed, the electrode height can be adjusted and the demand for breakup of silicon rods which are different in diameter can be met. The electrode stems are wrapped with insulating layers correspondingly so that the situation that electric discharge occurs among the electrode stems, current leaks and consequently energy loss is caused can be prevented. A stainless steel material is used as an electrode material so that the current endurance capacity and mechanical strength needed by a breakup electrode can be guaranteed, and meanwhile loss of the electrode due to electric discharge is low. Holes slightly larger than expected broken polycrystalline silicon blocks are formed in the sieve, so that broken finished products are exposed and discharged and conveyed to the next stage by the conveying belt.

Owner:HUAZHONG UNIV OF SCI & TECH

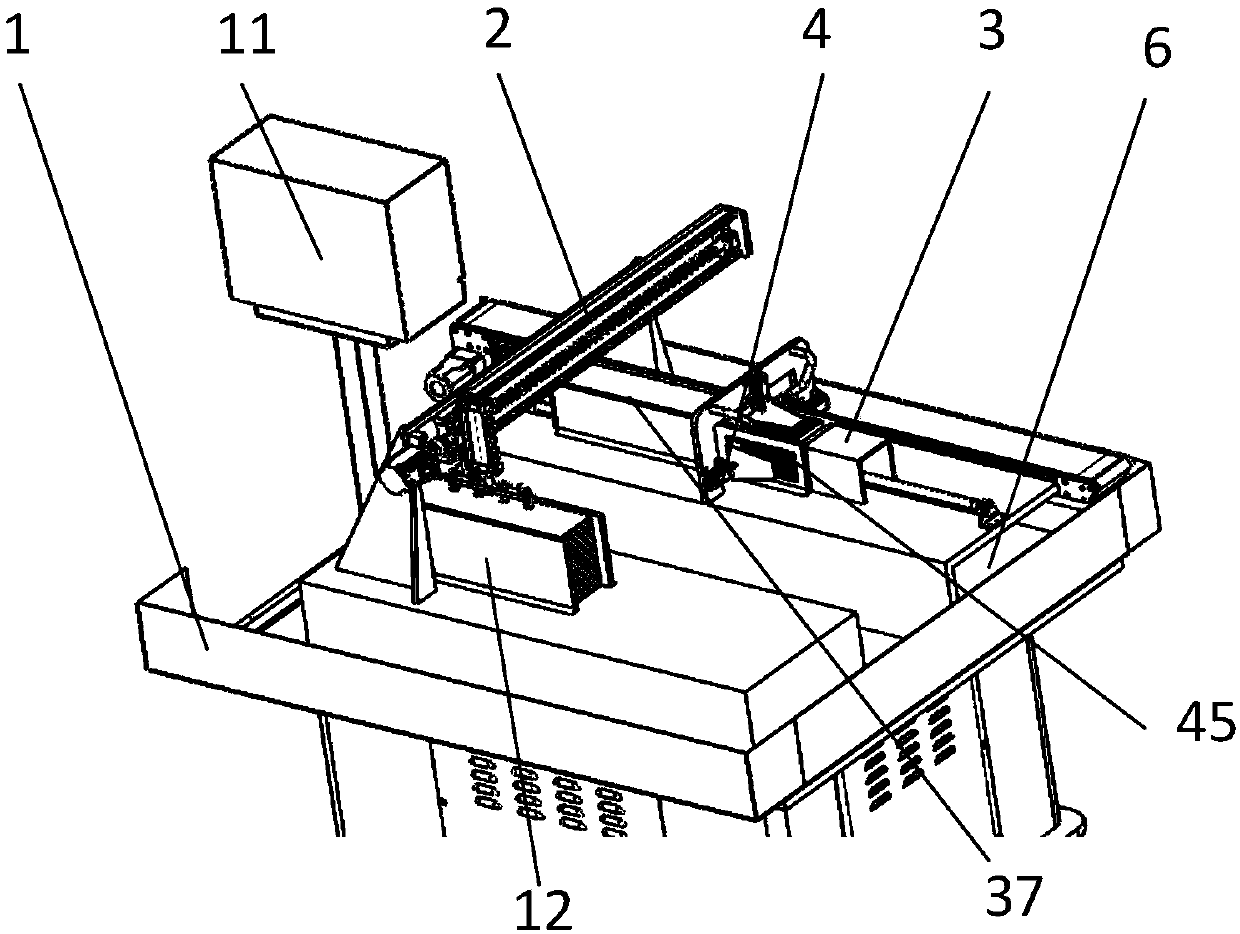

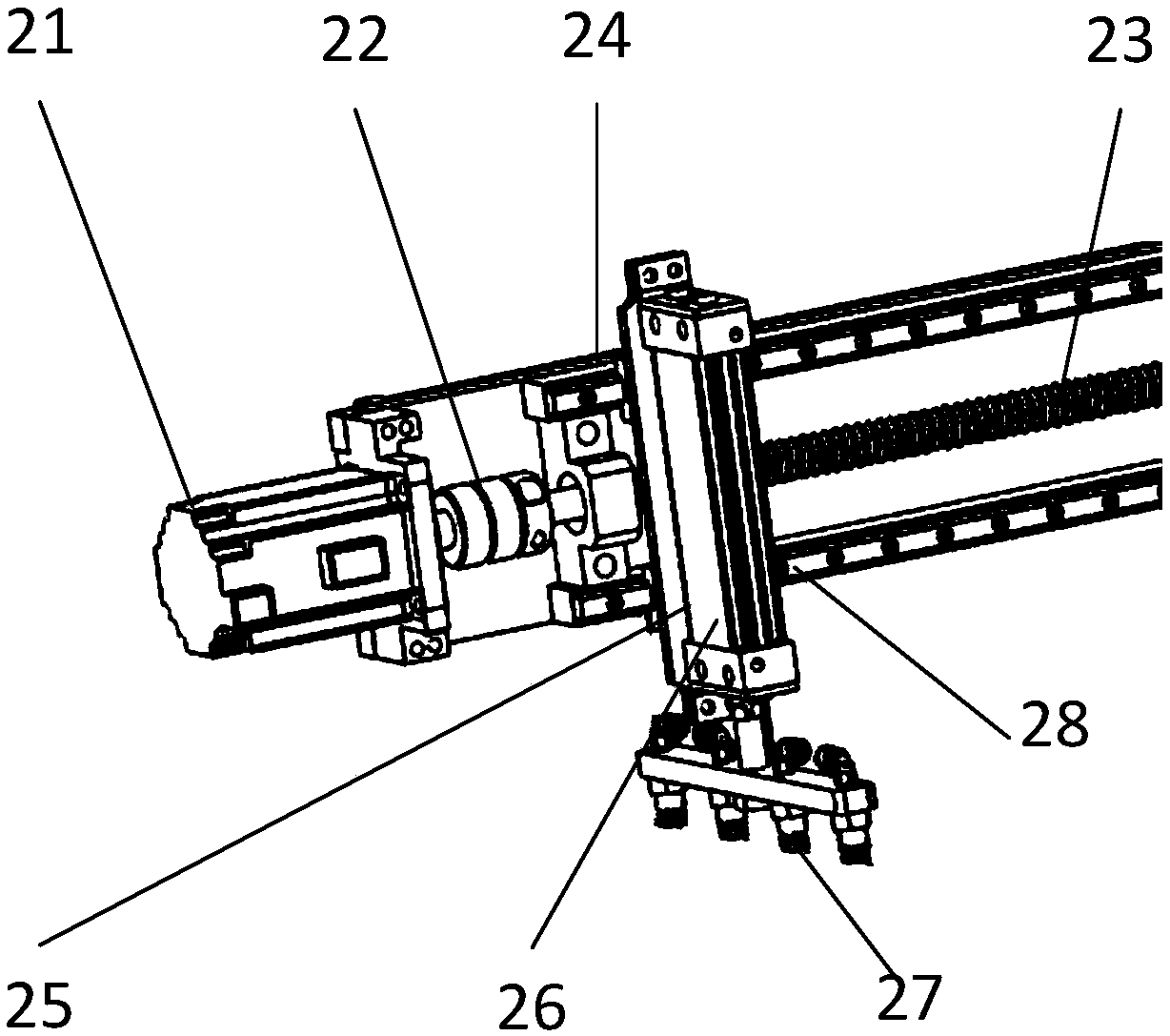

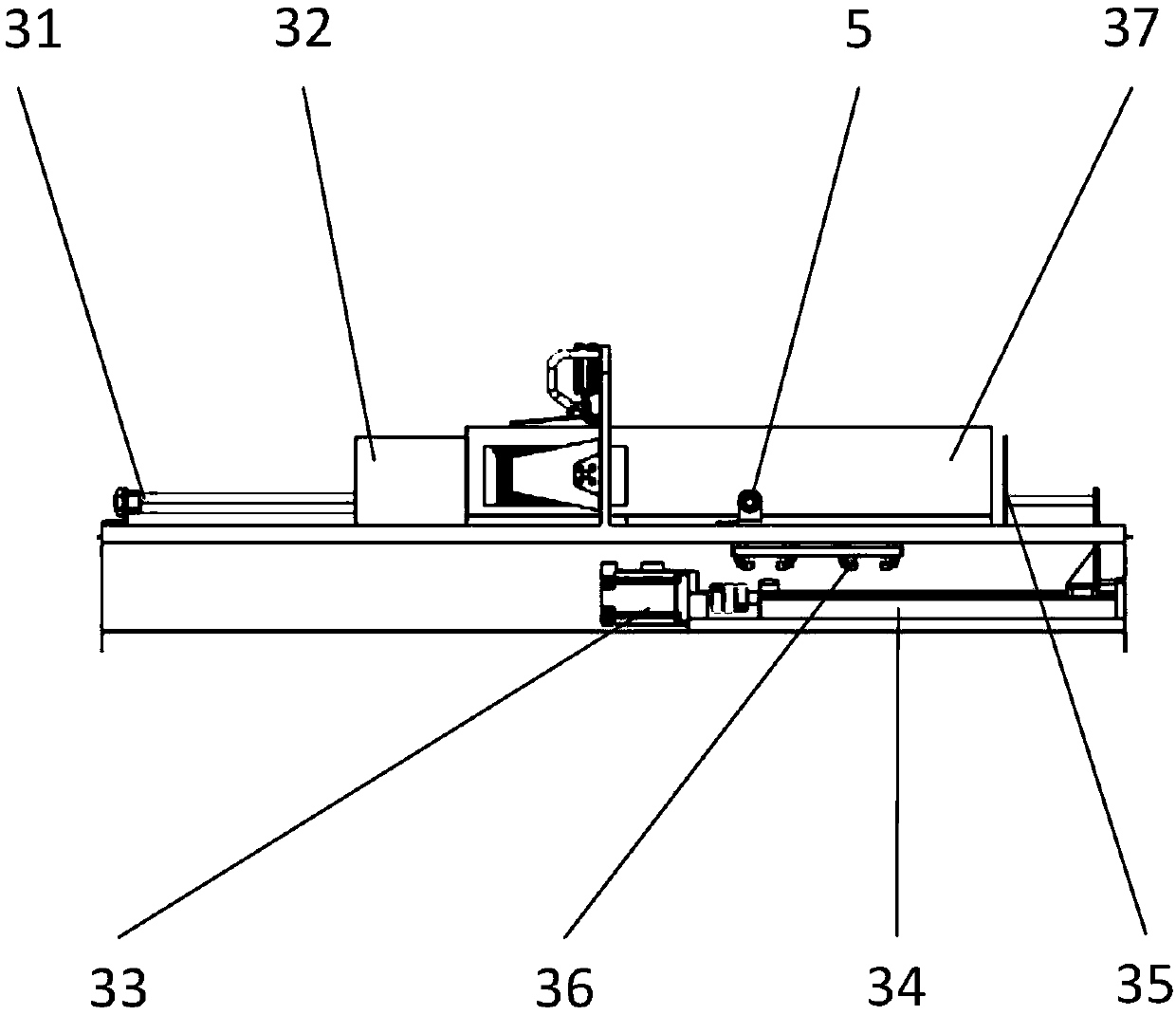

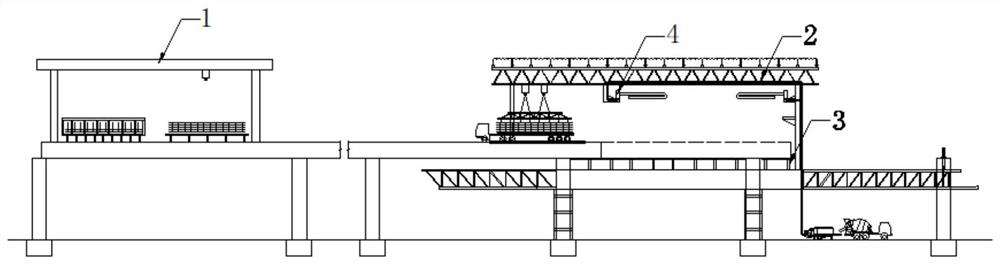

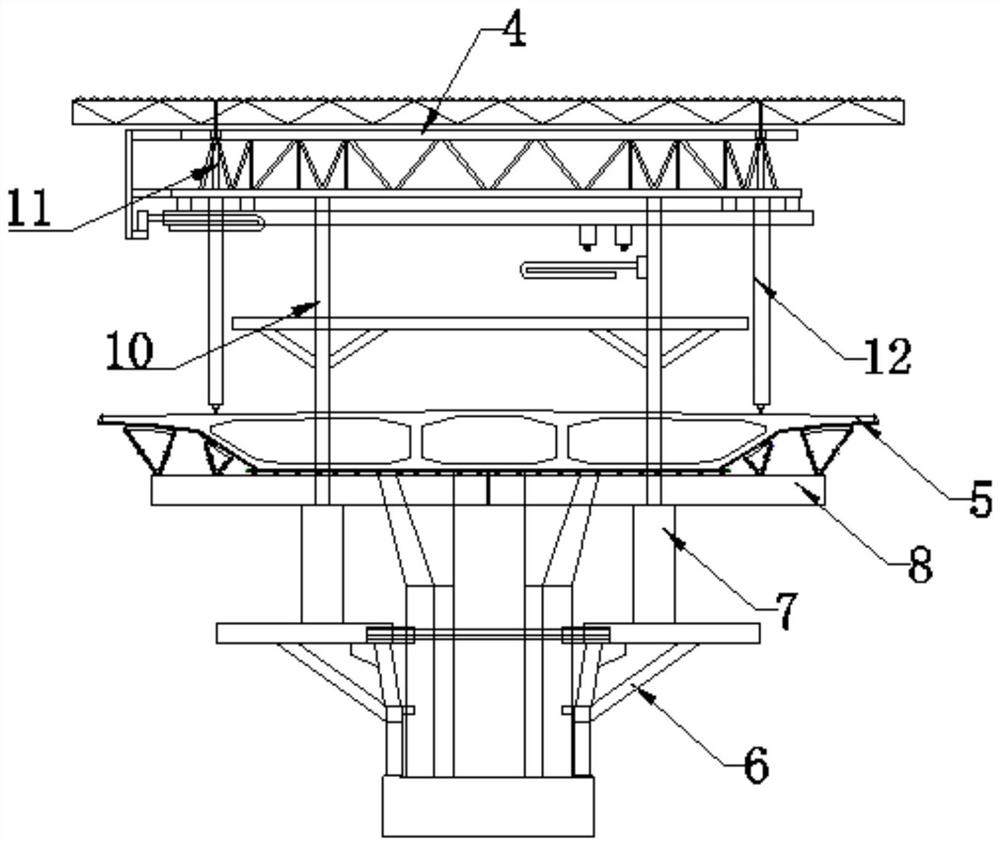

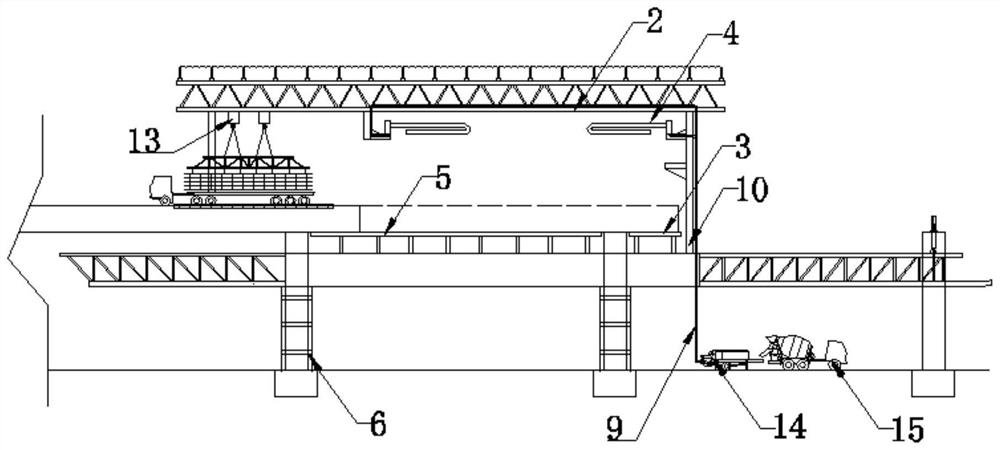

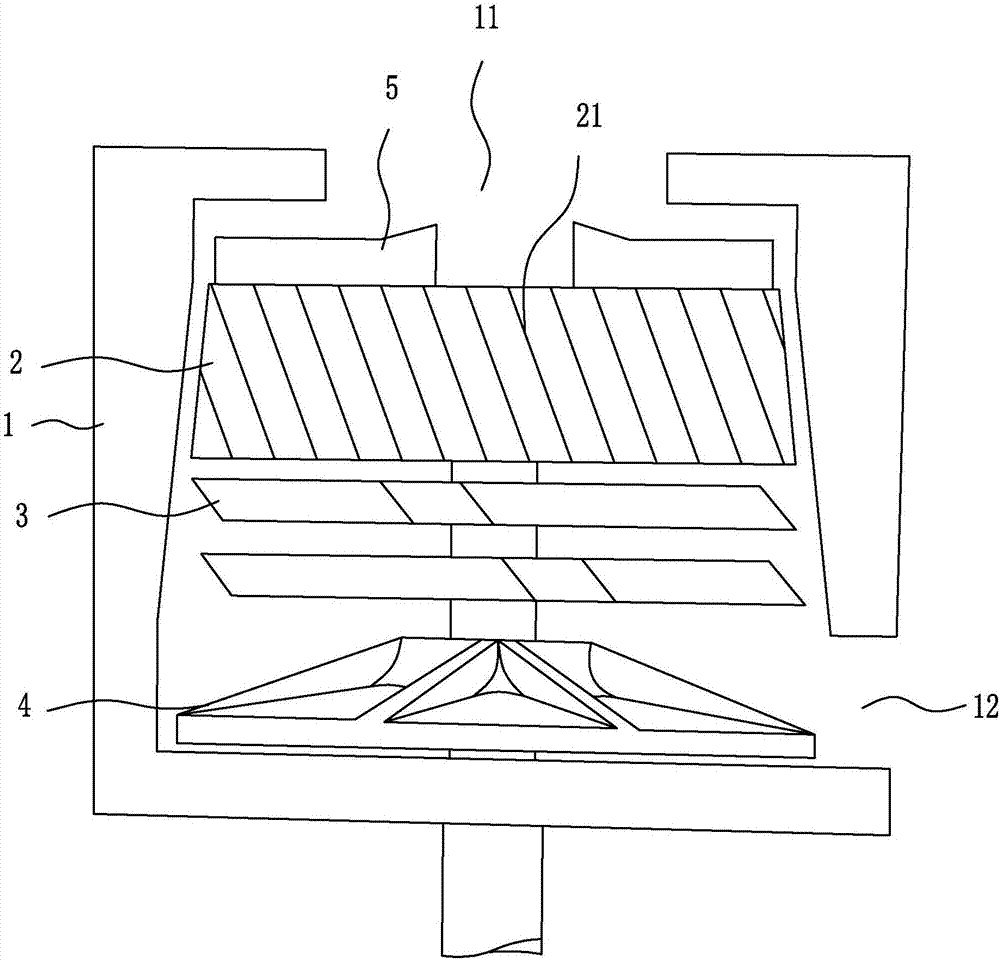

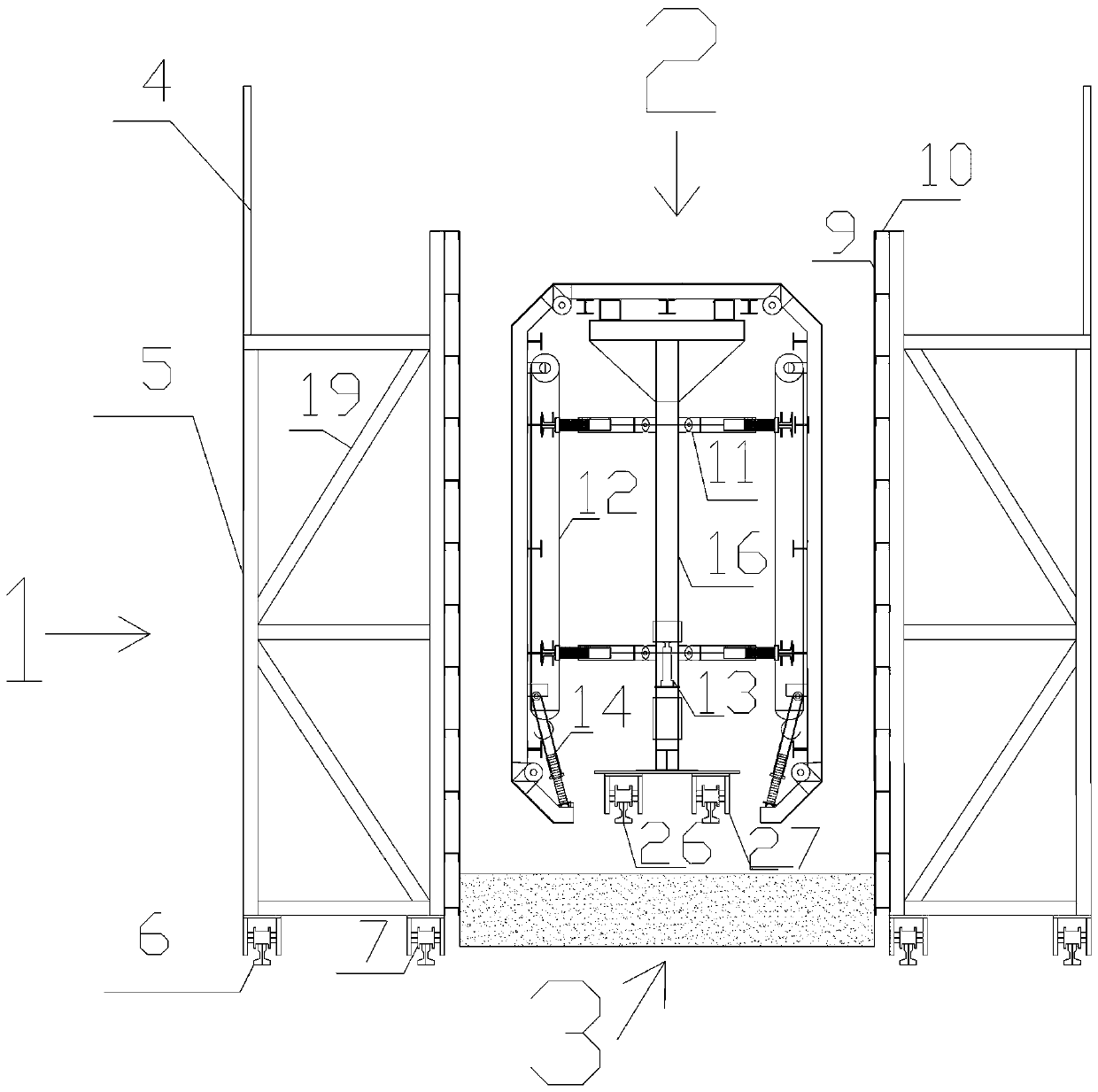

Cast-in-place box girder integrated construction equipment and construction method thereof

InactiveCN111996916ARealize factory constructionImprove automationBridge erection/assemblySurface finishArchitectural engineering

Owner:CCCC SECOND HARBOR ENG +1

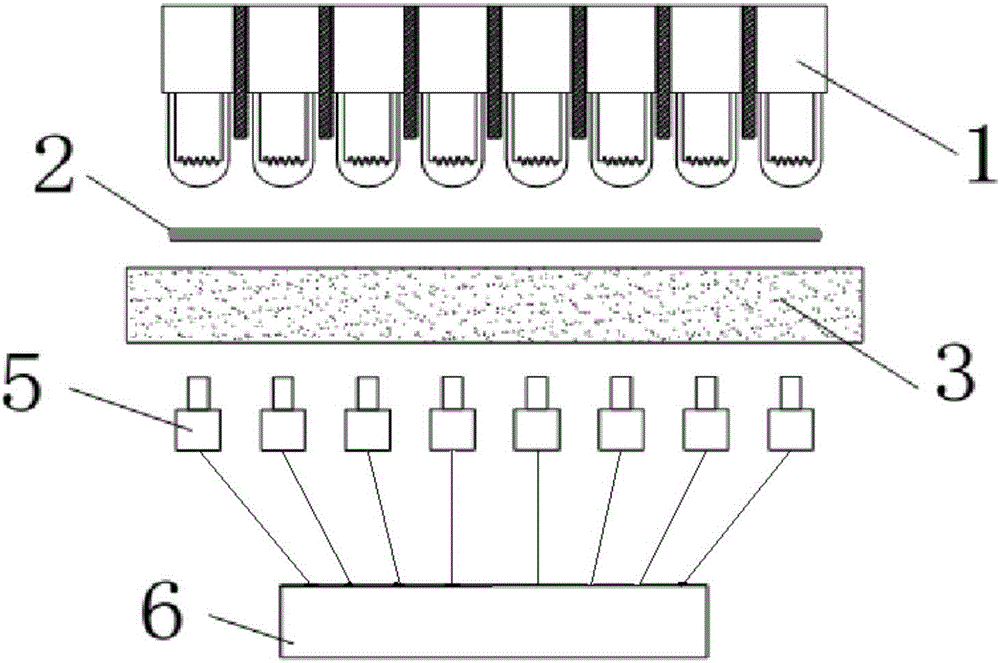

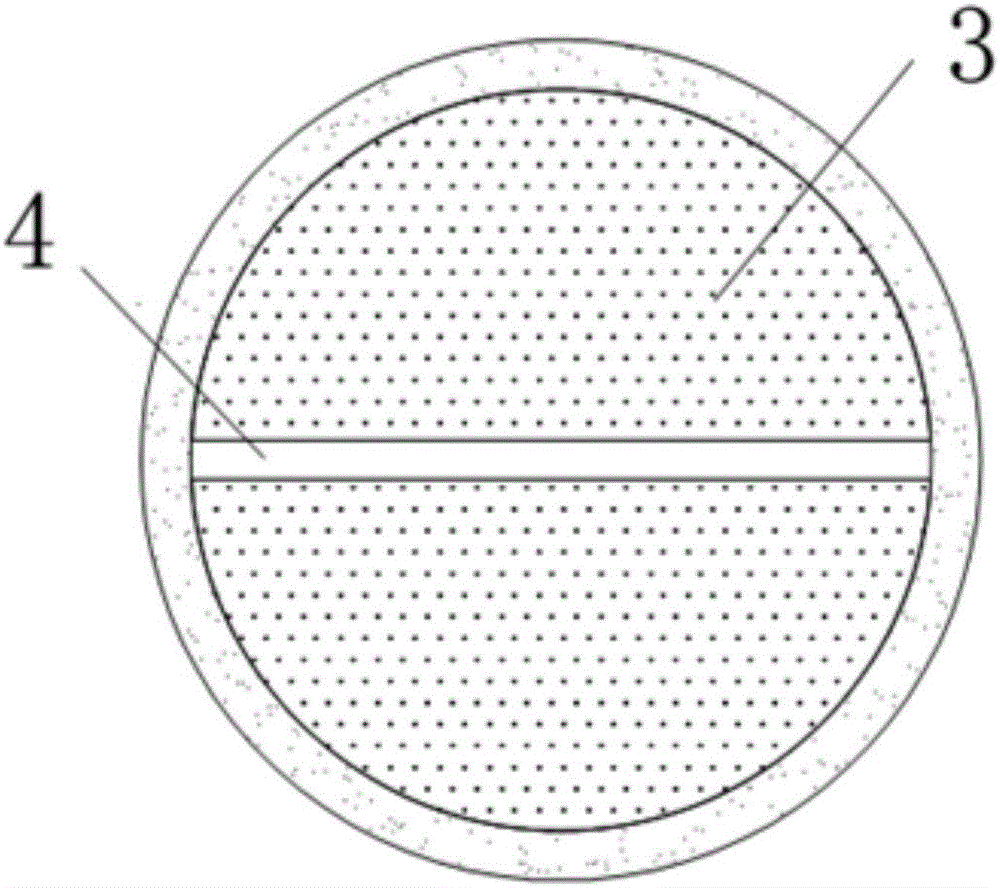

Non-contact wafer annealing device and method

PendingCN106409730AAvoid damageHeating evenlySemiconductor/solid-state device manufacturingEngineeringFloating platform

The present invention discloses a non-contact wafer annealing device and method. The device comprises a wafer, an air floating platform deck, a light source, an infrared temperature measurement probe and a controller. A plurality of air holes are uniformly distributed on the air floating platform deck, air is pumped in from the air holes to form an air cushion for supporting the wafer; the light source is arranged right above the wafer, and the wafer is heated through radiation; the infrared temperature measurement probe is arranged at the right below the air floating platform deck, and the temperature of the wafer is measured through the temperature measurement hole arranged at the diameter of the air floating platform deck; and the controller is connected with the infrared temperature measurement probe. The non-contact wafer annealing device and method are simple to perform, the annealing temperature is uniform, the measurement precision is high, and the non-contact wafer annealing device and method can avoid damaging the wafer and perform annealing of the back surface of the wafer while the fashioned front surface and the edges of the wafer do not damaged and can realize the automation operation.

Owner:珠海鼎泰芯源晶体有限公司

Sandwich food machine

InactiveCN103976461ARapid productionIncrease productivityFood coatingFood shapingCircular discEngineering

The invention discloses a sandwich food machine which comprises a plurality of food machine units, a connecting device, a bracket and an attached device, wherein each food machine unit comprises a shell; one ends of feeding barrels of the shells are fixed on the side surfaces of extrusion heads; extrusion nozzles are formed in the extrusion heads; each extrusion nozzle comprises a disc with a hole and a discharging pipe; steps are arranged in the extrusion heads; the discharging pipes of the extrusion nozzles face down and the discs are clamped on the steps; screw rods are arranged in the feeding barrels; driving devices are arranged at one ends of the screw rods; an end cover is arranged at the top end of the extrusion head of the food machine unit at the uppermost end of the food machine; a tension sleeve is arranged at the bottom end of the extrusion head of the food machine unit at the lowermost end of the food machine; a tension device is arranged between the end cover and the tension sleeve; the discharging pipes of any two food machine units connected with each other are opposite to each other, the upper discharging pipe is inserted into the lower discharging pipe, and a certain gap is formed between the two discharging pipes. According to the food machine, sandwich foods such as sandwich steamed buns, sandwich cakes and sandwich noodles and linear foods such as noodles can be quickly produced, the production efficiency is high, the labor intensity is low, and the flow line production can be realized.

Owner:李志学

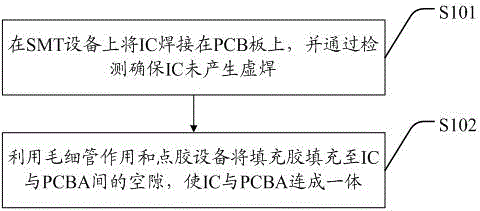

Bottom filling method for preventing cold solder joint of BGA IC

InactiveCN104979225AEnhanced resistance to mechanical stressImprove thermal stressSemiconductor/solid-state device testing/measurementSolid-state devicesThermal conductivityEngineering

The present invention discloses a bottom filling method for preventing a cold solder joint of BGA IC. The method comprises the steps of: soldering an IC on a PCB board and ensuring that the IC does not generate a cold solder joint by detection; and filling a filling rubber into a gap between the IC and PCBA by utilizing capillary action and a glue dispensing device to integrate the IC with the PCBA. According to the present invention, the IC and the PCBA are integrated in a glue filling manner, so that mechanical stress resistance of the IC can be strengthened; meanwhile the gap between the IC and the PCBA is eliminated and the thermal conductivity of the glue is extremely higher than that of air, so that the thermal stress of the IC can be significantly improved and the miniaturization of a machine core board can be implemented; and by using the bottom filling method, arrangement space of the PCB is not occupied, so that line production can be implemented and the soldering process is not influenced; by using an injection glue dispensing manner, the production efficiency can be effectively improved; furthermore, by using the bottom filling method, the cold solder joint can be detected in advance to prevent defective products from flowing into the subsequent process.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

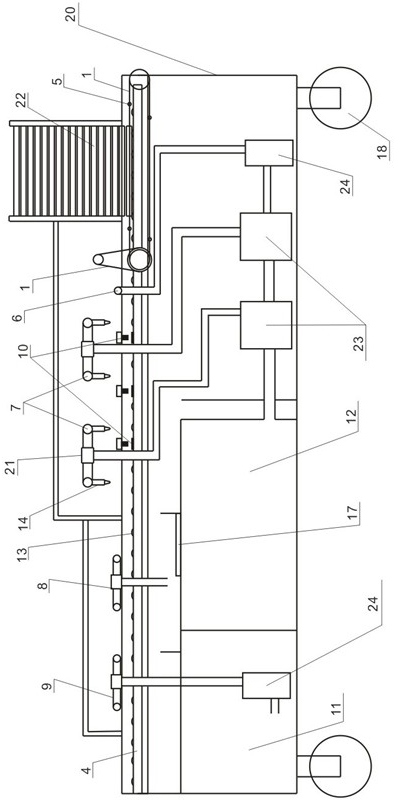

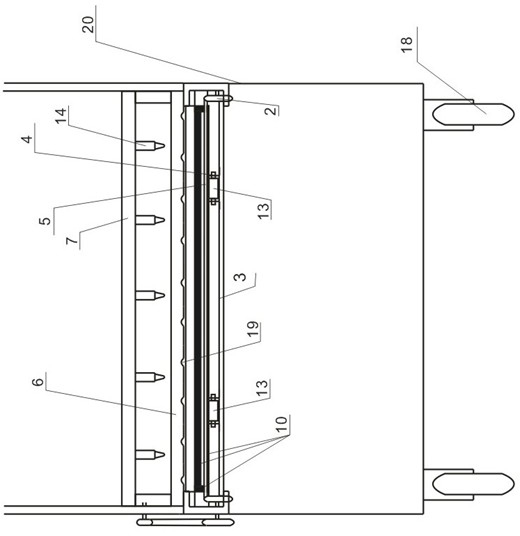

Plane magnetic grinding machining assembly line and machining method for inner surface of elbow

ActiveCN107932277ARealize flow operationImprove processing efficiencyEdge grinding machinesPolishing machinesEngineeringAssembly line

The invention relates to plane magnetic grinding machining assembly line and machining method for an inner surface of a elbow. The assembly line is characterized in that a feeding station, a machiningstation and a discharging station are connected through a plurality of conveying belts, and grinding material filling devices are arranged on the two sides of the side, close to the machining station, of a feeding conveying belt, and grinding material filling rotary magnetic discs are arranged at the bottom of part, below grinding material discharging ports at the bottoms of the grinding materialfilling devices, of the feeding conveying belt; and the machining station is provided with a plurality of magnetic grinding machines and two mechanical arms; the tail end of a discharging conveying belt is also provided with a stainless steel wire mesh conveying belt and an grinding material collecting conveying belt, the grinding material collecting conveying belt is arranged below the stainlesssteel wire mesh conveying belt, and a grinding material collecting rotary magnetic disc is arranged at the bottom of the grinding material collecting conveying belt. According to the assembly line and the method, grinding and polishing of the inner wall of the elbows with irregular cross sections, the inner wall of the elbows with variable diameters and the inner wall of the welded elbows is realized, the line production of magnetic grinding machining on the inner surface of the elbow is also realized, so that the batch machining of workpieces is facilitated, and the production efficiency isimproved.

Owner:UNIV OF SCI & TECH LIAONING

Continuous type stirring device

PendingCN107261919ARealize flow operationImprove automation production efficiencyRotary stirring mixersTransportation and packagingImpellerAssembly line

The invention discloses a continuous type stirring device. The continuous type stirring device comprises a shell body, a rotor, a stirring impeller and a dialing impeller, wherein the shell body serves as a stator, and the rotor, the stirring impeller and the dialing impeller synchronously rotate in the shell body; and the shell body has a material inlet in the top and a lateral material outlet which is formed in the bottom and is over against the dialing impeller, the stirring impeller is arranged below the rotor, and the dialing impeller is arranged below the stirring impeller. According to the continuous type stirring device disclosed by the invention, charging and discharging can be carried out uninterruptedly, assembly line operation of continuously stirring materials is achieved, and thus, the efficiency of automated production is greatly increased; and large-sized space equipment is not required, so that the production cost is reduced.

Owner:广东友为实业有限公司

Vertical 90-degree glass rotating table for single-side edge grinding machine

InactiveCN104647201AReasonable structureFree laborEdge grinding machinesGrinding machine componentsEngineeringAssembly line

The invention discloses a vertical 90-degree glass rotating table for a single-side edge grinding machine and relates to the technical field of glass edge grinding assisting machines. The vertical 90-degree glass rotating table is characterized by comprising a framework conveying mechanism, a rotating mechanism, a positioning mechanism and a rotary moving mechanism, wherein the rotating mechanism is arranged at the side part of the framework conveying mechanism through the rotary moving mechanism; the positioning mechanism is arranged on the rotating mechanism; the framework conveying mechanism comprises a base frame, a bottom plate, universal wheels, a conveying motor and conveying wheels; the rotating mechanism comprises a rotary motor base, a rotary motor, a rotating shaft, a rotating frame and rotating wheels; the positioning mechanism comprises a positioning air cylinder, a connecting rod, swing rods and a positioning rod; the rotary moving mechanism comprises a rotary moving air cylinder and linear guide rails. The vertical 90-degree glass rotating table disclosed by the invention is reasonable in structure, stable and reliable; full-automatic assembly line process of glass single sides is realized, labor force is liberated, the production efficiency is improved, vertical 90-degree rotation for glass with different thicknesses and various model numbers can be realized, the production efficiency is improved, and safety accidents are greatly reduced.

Owner:ANHUI ZHICHENG NC TECH CO LTD

Prefabricated pipe gallery mechanical and hydraulic combined type overall installation and disassembly steel formwork and installation method

PendingCN109972655ASave materialSolve the difficult problem of installation and disassemblyArtificial islandsUnderwater structuresSupporting systemReinforced concrete

The invention discloses a prefabricated pipe gallery mechanical and hydraulic combined type overall installation and disassembly steel formwork and an installation method. An outer mold steel pulley matched with an outer mold steel track is installed under an outer support truss of an outer mold support system. An inner mold steel formwork of an inner mold support system includes a top mold, sidemolds and lower chamfering molds which are hinged as a whole; a first mechanical spiral expansion machine of an inner mold installation and disassembly system is connected with a vertical frame body and the side molds, a second mechanical spiral expansion machine is mounted on the vertical frame body, and a third mechanical spiral expansion machine is connected with the side molds and the lower chamfering molds; and the inner mold installation and disassembly system further includes chain blocks with one ends fixed to the side molds and the other ends used for hooking the lower chamfering molds during demolding. The installation and disassembly steel formwork can solve the technical problems that one-time overall pouring molding cannot be achieved, the formwork joint is not tight, the formwork installation dimensional accuracy is not high, the formwork is difficult to install and disassemble, the formwork is prone to deforming and large-scale machines need to be matched with the formwork installation when a standard prefabricated reinforced concrete box-type component bottom plate and a wall top plate use a chamfer steel mold and wood mold system and a normal steel formwork.

Owner:中铁二十二局集团第三工程有限公司 +1

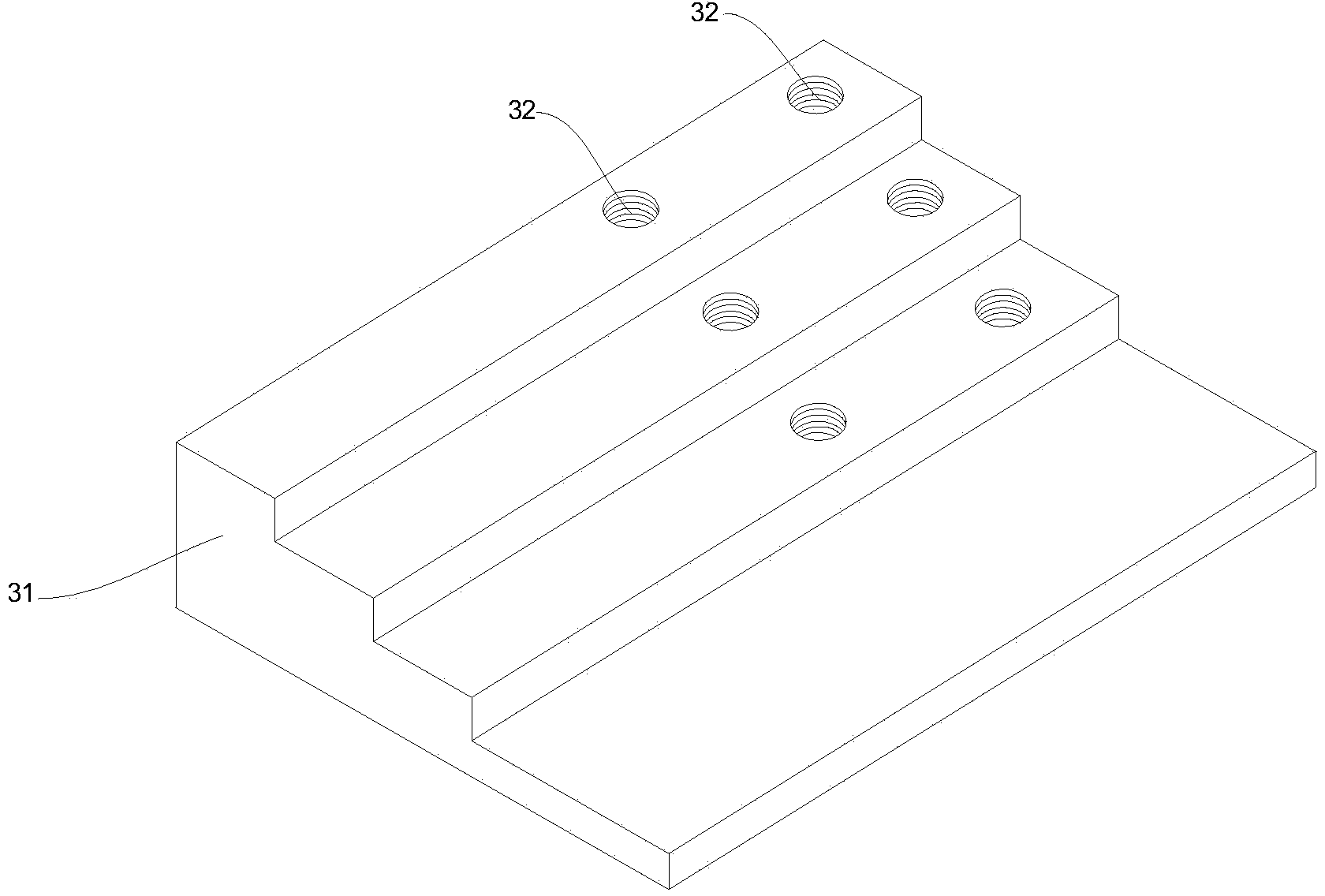

Single-chip optical path module and multi-die semiconductor laser

InactiveCN104112979ARealize mass productionSolve the generality problemLaser detailsSemiconductor lasersOptical axisLight beam

The invention relates to the technical field of laser, and particularly relates to a single-chip optical path module and a multi-die semiconductor laser. The single-chip optical path module comprises a heat sink module, a semiconductor laser chip CoS with auxiliary heat sink, a fast axis collimating lens and a slow axis collimating lens. The CoS, the fast axis collimating lens and the slow axis collimating lens are sequentially fixed on one surface of the heat sink module; and the optical axis of the output beam of the CoS, and the optical axis of the fast axis collimating lens and the optical axis of the slow axis collimating lens are in the same line. The multi-die semiconductor laser comprises a step-shaped bottom board and the plurality of single-chip optical path modules, wherein the plurality of single-chip optical path module are fixed to the different steps of the step-shaped bottom board respectively. According to the single-chip optical path modules and the multi-die semiconductor laser, modularization of a plurality of single-chip optical paths are realized; in the multi-die semiconductor laser, the single-chip optical path modules can be fixed in a detachable manner, so that different lasers are allowed to use one type of module; and process repeatability and stability are improved.

Owner:BWT BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com