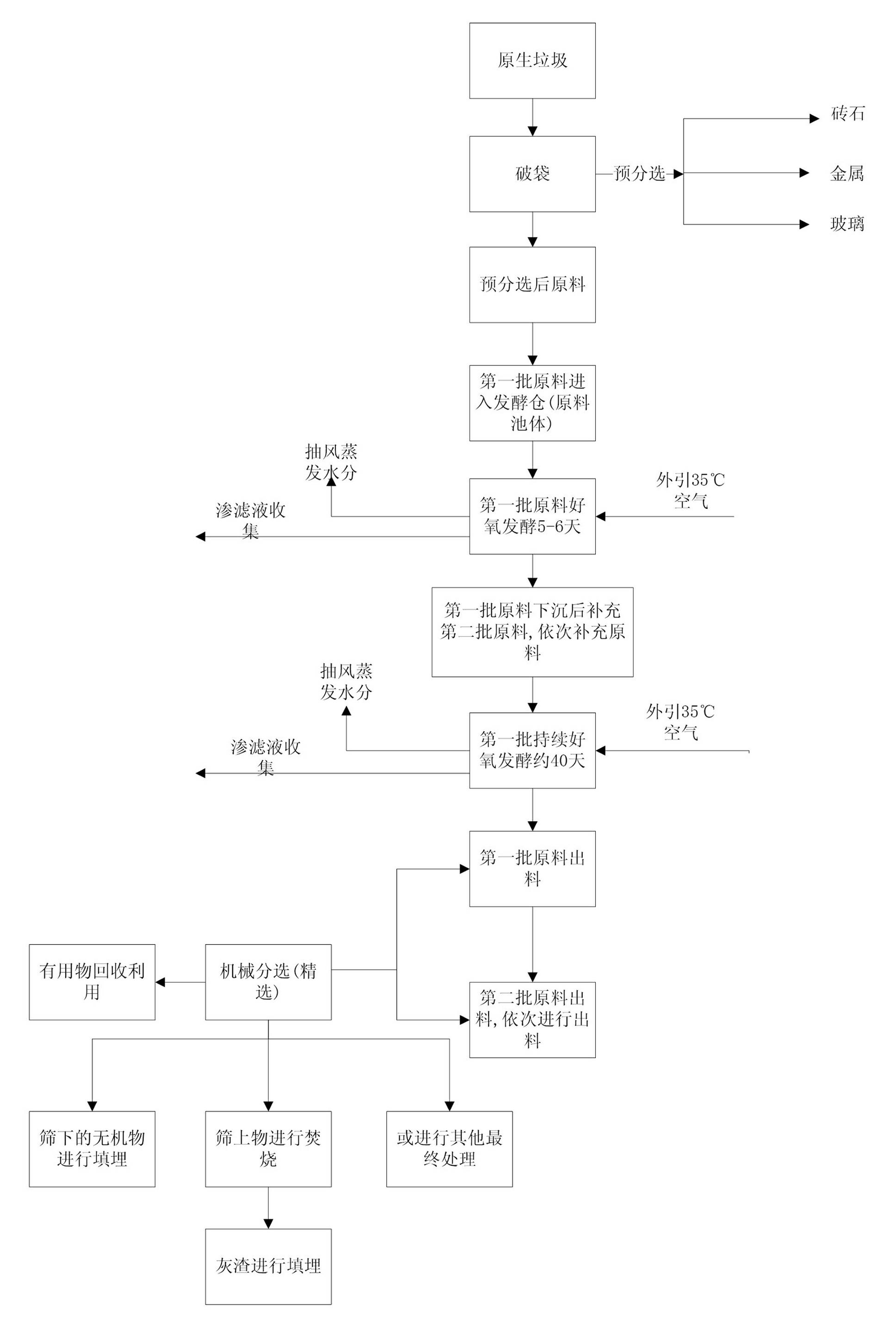

Device and method for large-scale pretreatment of domestic garbage

A technology for domestic waste and pretreatment, applied in the direction of solid waste removal, etc., can solve the problems of continuous feeding and continuous discharging, large occupied area of strips and stacks, and inability to form large-scale scale, so as to achieve streamlined operation and residence time. The effect of shortening, improving process efficiency and process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

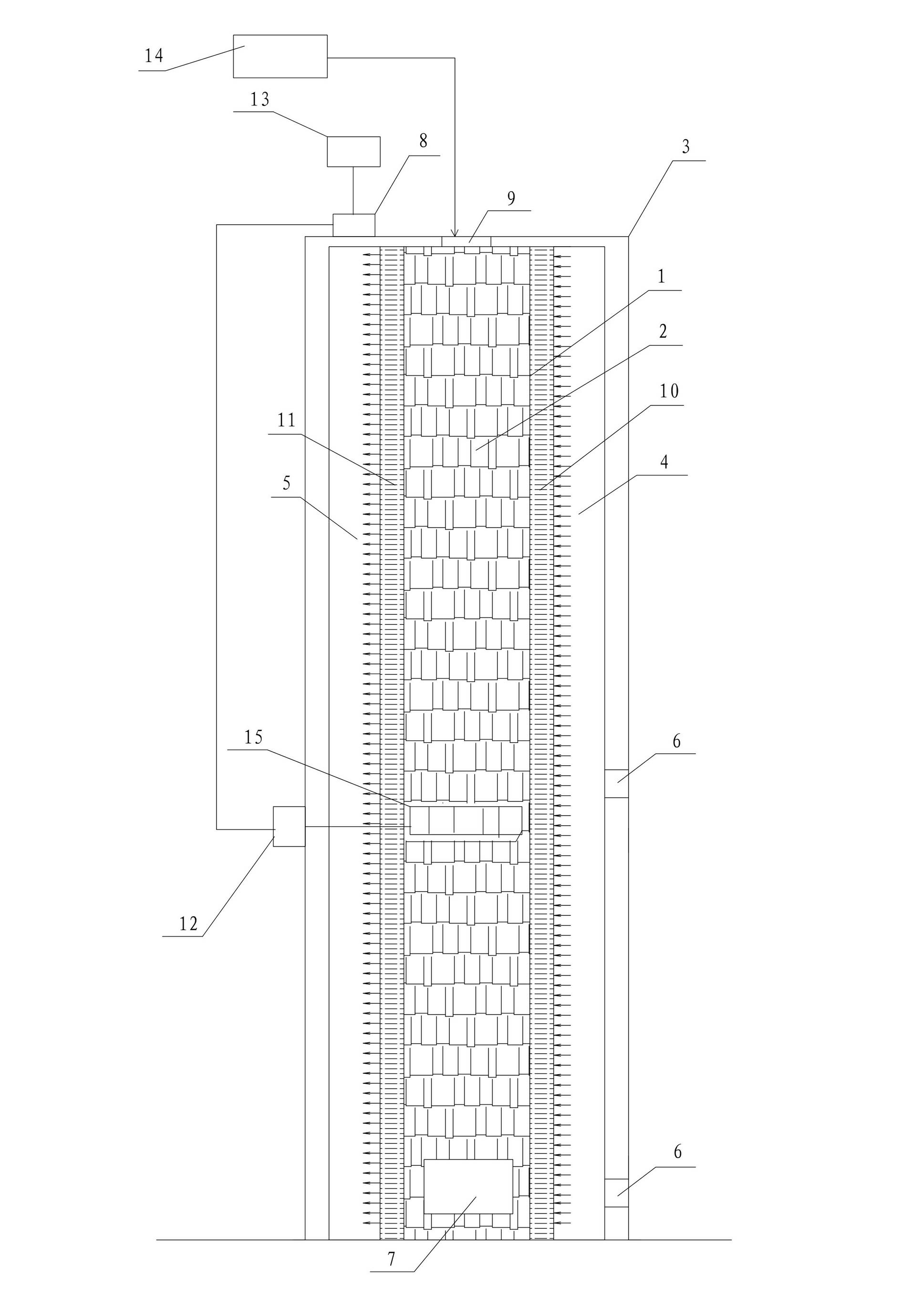

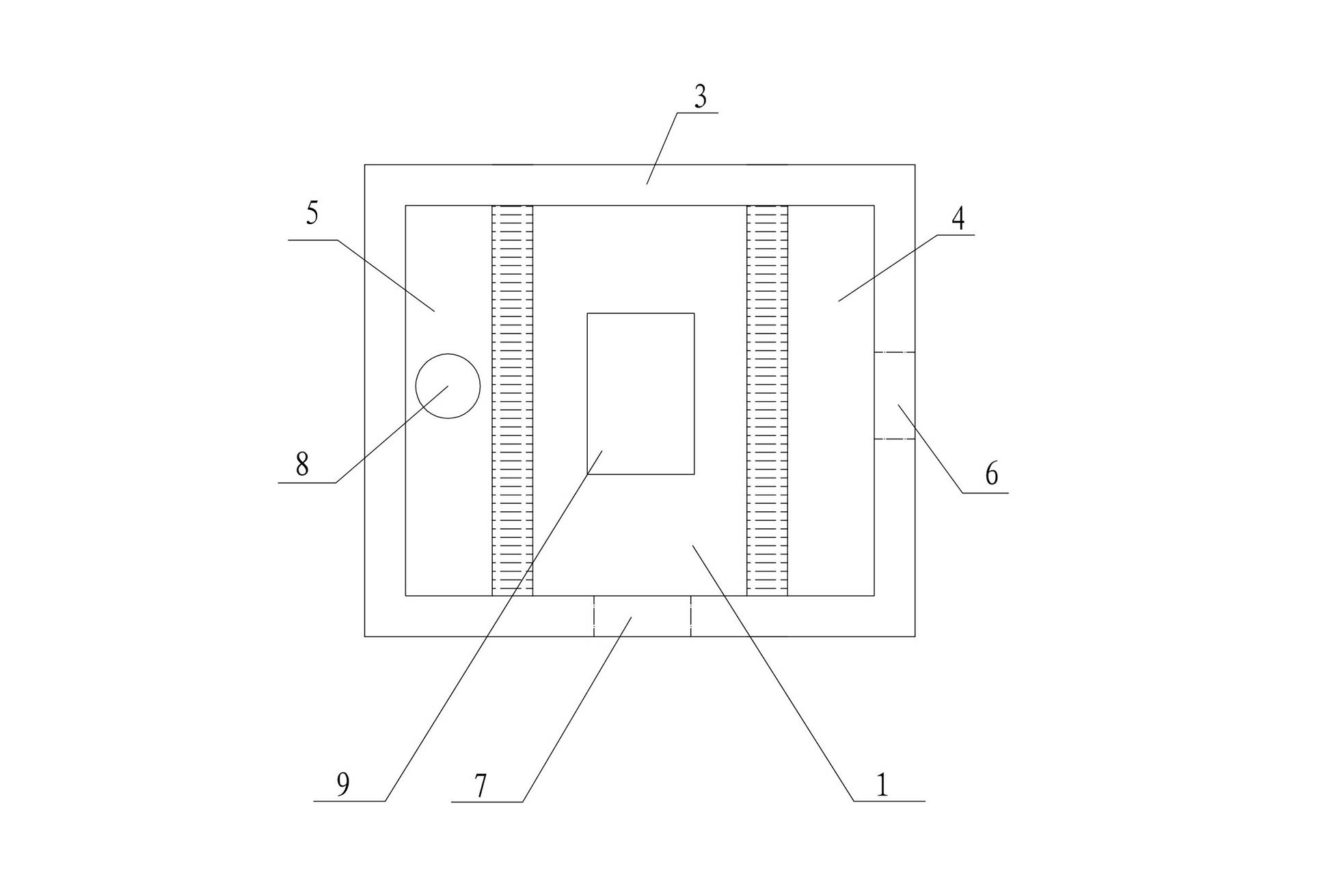

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] Such as figure 2 , image 3 , Figure 4 and Figure 5As shown, the device of the present invention for large-scale pretreatment of domestic waste includes a vertical cylinder 3 and an exhaust assembly 13 used to cooperate with the vertical cylinder 3, a double-screw discharge assembly, an automatic temperature control assembly, etc. . The automatic temperature control assembly includes a temperature sensor 15 installed in the vertical cylinder 3 and an automatic temperature controller 12 installed outside the vertical cylinder 3. The wires of the temperature sensor 15 pass through the vertical cylinder 3 and its outer insulation layer The sealed through hole on the top is connected to the automatic temperature controller 12 to realize the real-time monitoring of the fermentation temperature of the organic matter. The exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com