Non-contact wafer annealing device and method

A non-contact, annealing device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the electrical properties of semiconductor chips, uneven wafer heating temperature, uneven wafer annealing temperature, etc. Achieve highly automated flow operation, uniform wafer annealing temperature, and realize the effect of flow operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

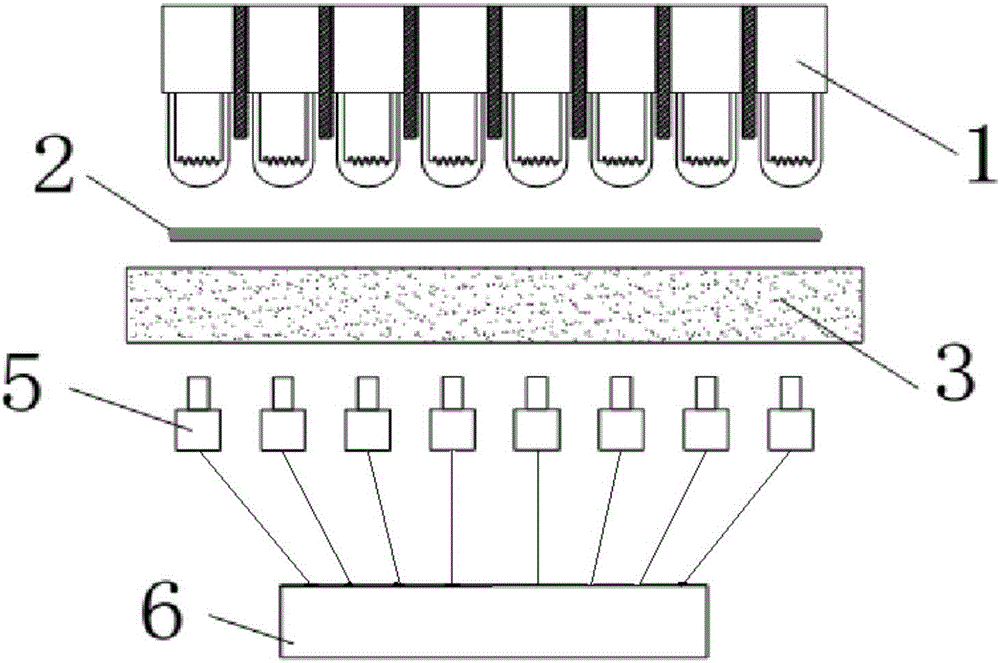

[0026] like figure 1 , 2 As shown, a non-contact wafer annealing device includes a wafer 2, an air bearing platform 3, a light source, an infrared temperature measuring probe 5, and a controller 6, wherein:

[0027] The light source is arranged in an array of lamp tubes 1, and different lamp tubes 1 illuminate different positions on the surface of the wafer 2;

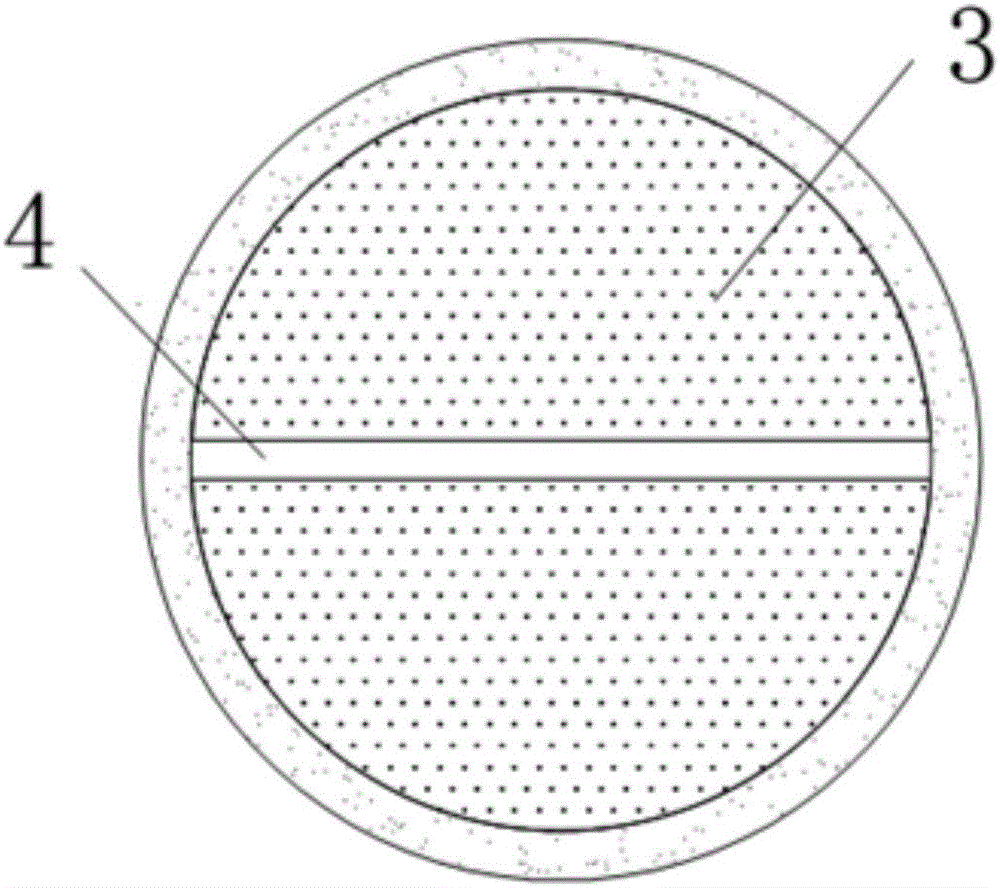

[0028] The cross-section of the air-floating stage 3 is circular, and a temperature measuring hole 4 is arranged in the middle, the temperature measuring hole 4 is located at the diameter of the air-floating stage 3, and the length of the temperature measuring hole 4 is greater than or equal to the diameter of the wafer 2 length. The width of the temperature measurement hole 4 is determined according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com