Sandwich food machine

The technology of a food machine and a discharge pipe is applied in the coating of food, the forming of food, food science and other directions, which can solve the problems of low production efficiency, high labor intensity, inconvenient flow operation and batch production, etc., and achieve high production efficiency. , Reduce labor intensity and achieve the effect of assembly line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

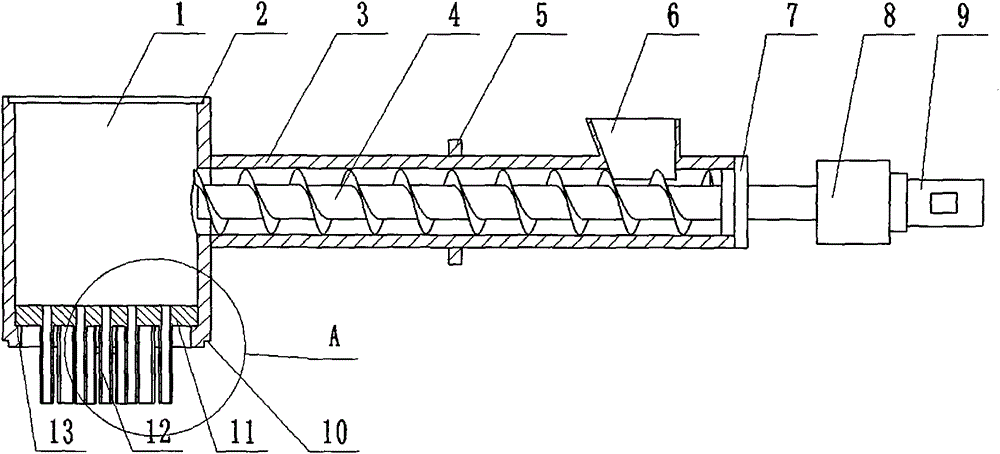

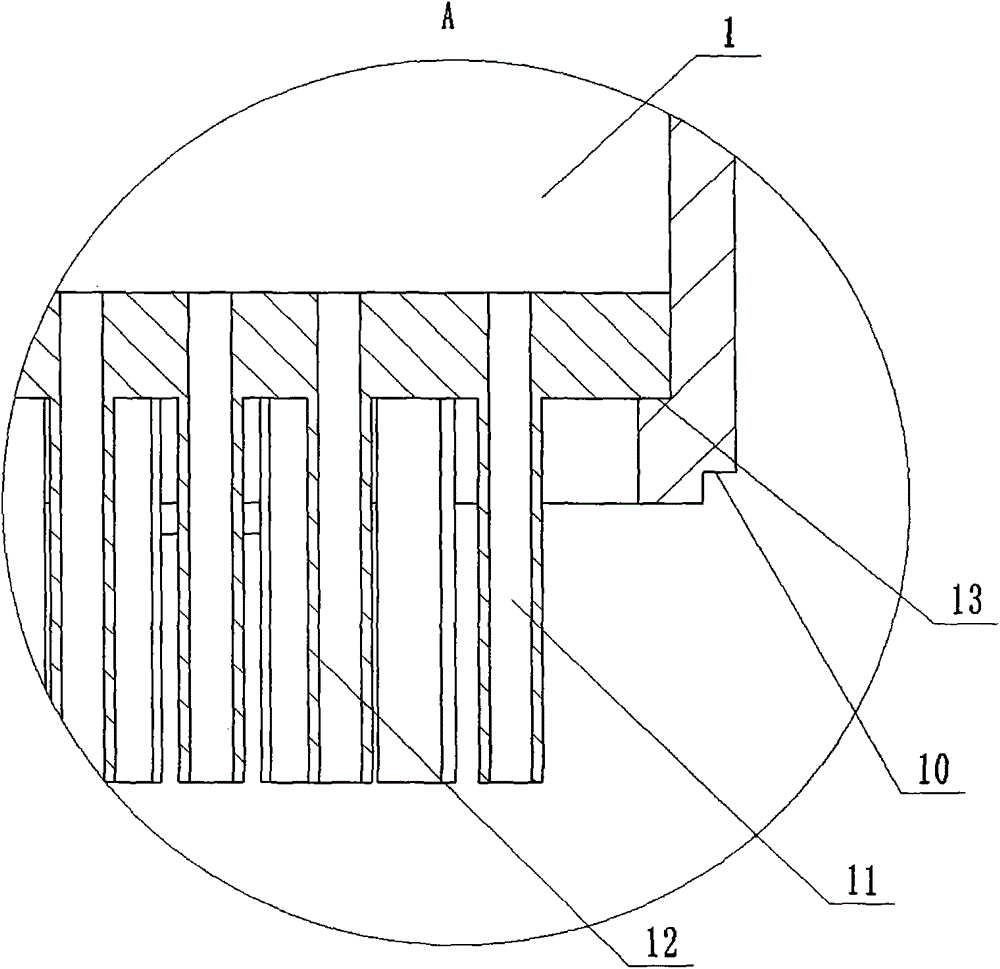

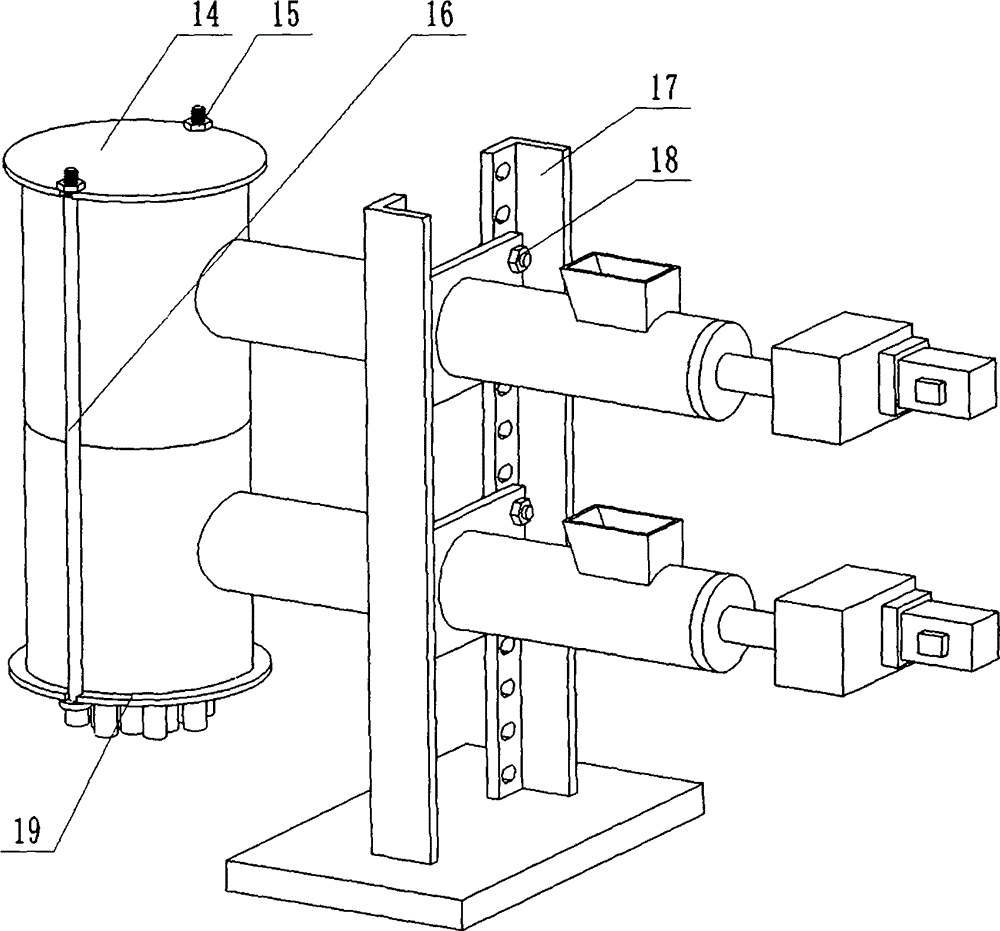

[0027] Example: such as image 3 , Figure 4 , Figure 5 , Image 6 As shown, the food machine comprises two food machine units, an end cover 14 is arranged at the top of the extrusion head of the upper side food machine unit, and a tightening ring 19 is arranged at the bottom of the extrusion head of the lower side food machine unit, and the end cover 14 and the tightening hoop The outer edge of the ring 19 is correspondingly provided with a plurality of U-shaped mouths, and long bolts 16 and nuts 15 are arranged between the end cover 14 and the corresponding U-shaped mouths of the tightening ring 19 to lock the two food machine units. The discharge pipes of the unit extrusion nozzles are correspondingly distributed, the size of the discharge pipes of the upper extrusion nozzle 26 is smaller than that of the discharge pipes of the lower extrusion nozzle 27, and the discharge pipes of the upper extrusion nozzle 20 are inserted into the discharge pipes of the lower extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com