Beading and sealing device in heat pipe production ,and its processing method

A sealing device and manufacturing process technology, applied in the field of heat pipe manufacturing, can solve the problems of heat pipe leakage, heat pipe transmission failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

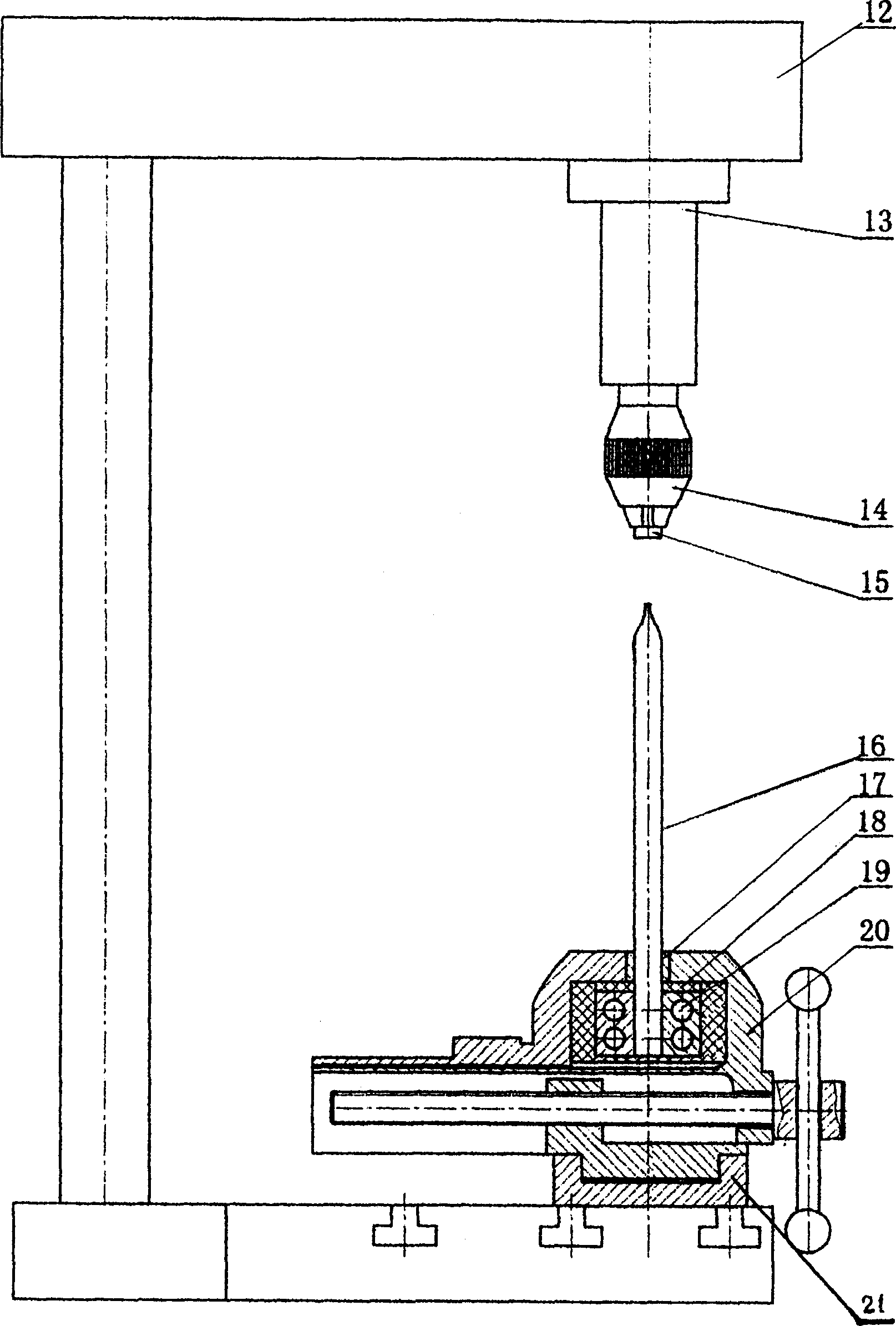

[0027] The shrinking and sealing device of the present invention includes a shrinking device and a sealing device.

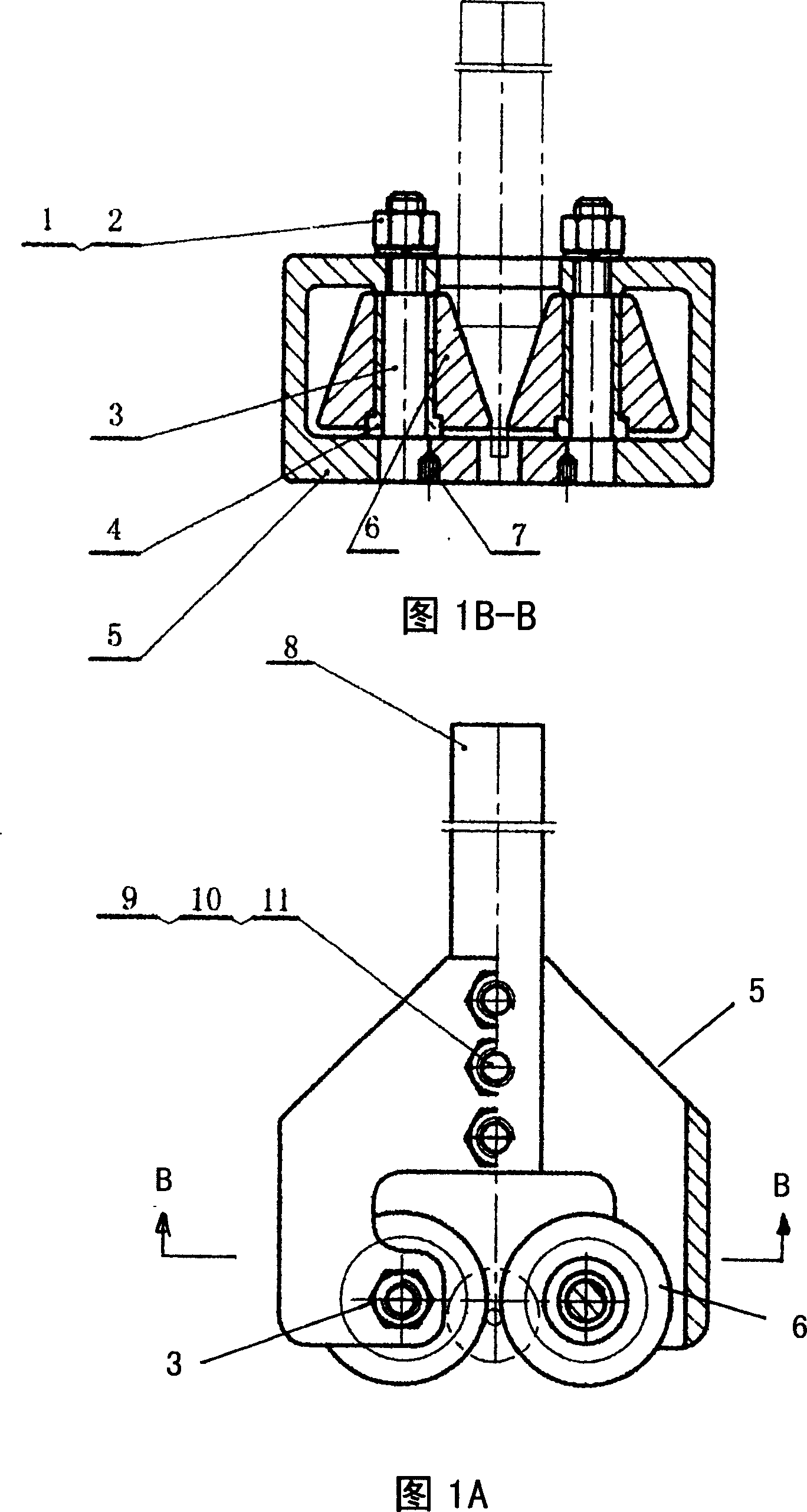

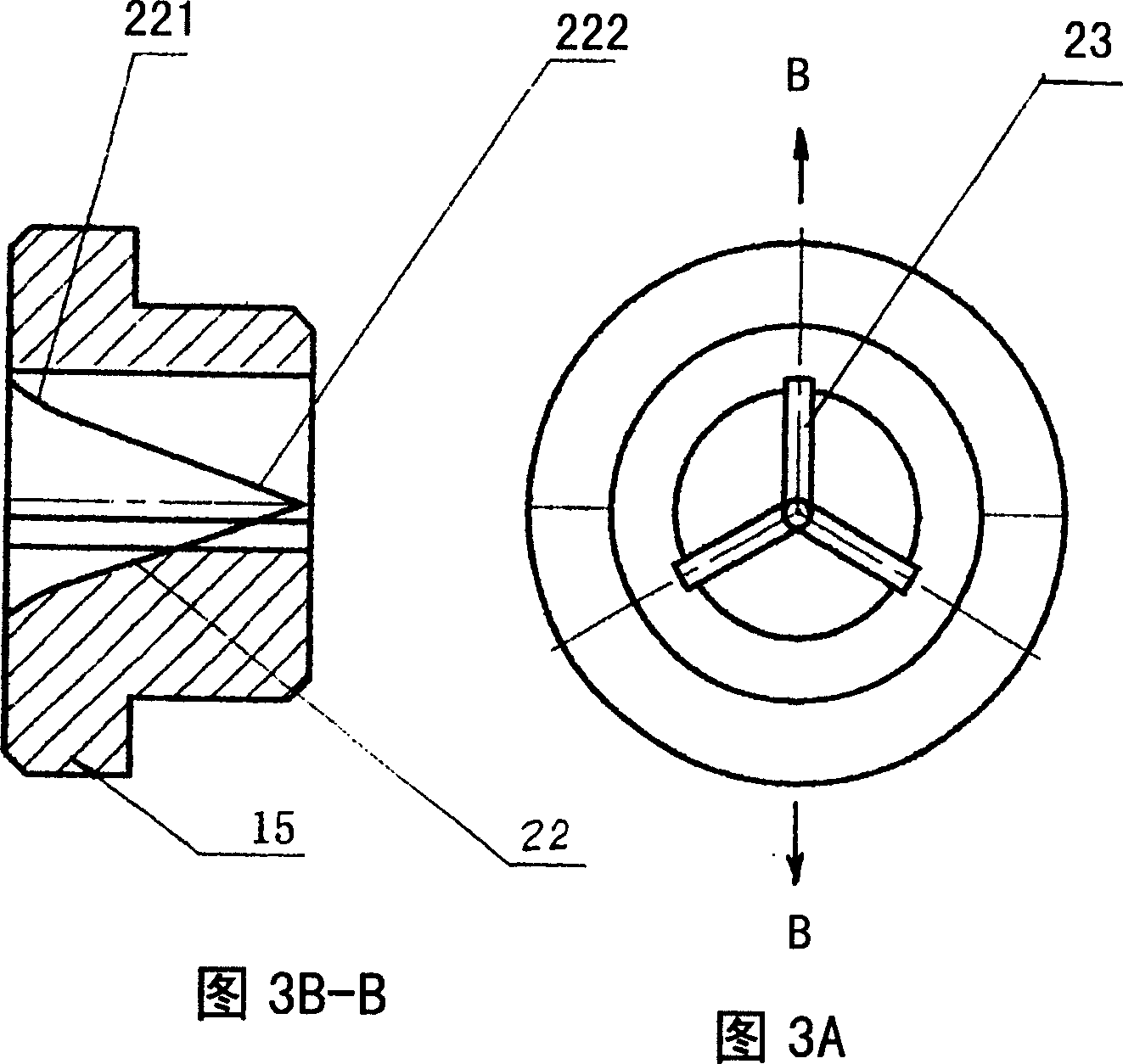

[0028] As shown in Figure 1, it is a schematic diagram of the structure of the necking device of the present invention, Figure 1A is a front view of the structure of the necking device, and Figure 1B-B is a B-B sectional view of the structure of the necking device in Figure 1A. 1A, 1B-B, the roller clamp 5 is a special-shaped frame, its upper part is a hollow trapezoidal platform, and its lower part is two L-shaped frames extending downward from the left and right ends of the rectangular platform. In the hollow trapezoidal platform body of roller clamp 5 tops, cutter bar 8 is fixedly equipped with washer 9, nut 10, bolt 11, and cutter bar 8 lower end is aligned with hollow trapezoidal platform body base, and the upper end stretches out one section of holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com