Continuous type stirring device

A technology of stirring device and stirring impeller, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of low work efficiency and large workload, and achieve the effect of improving efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

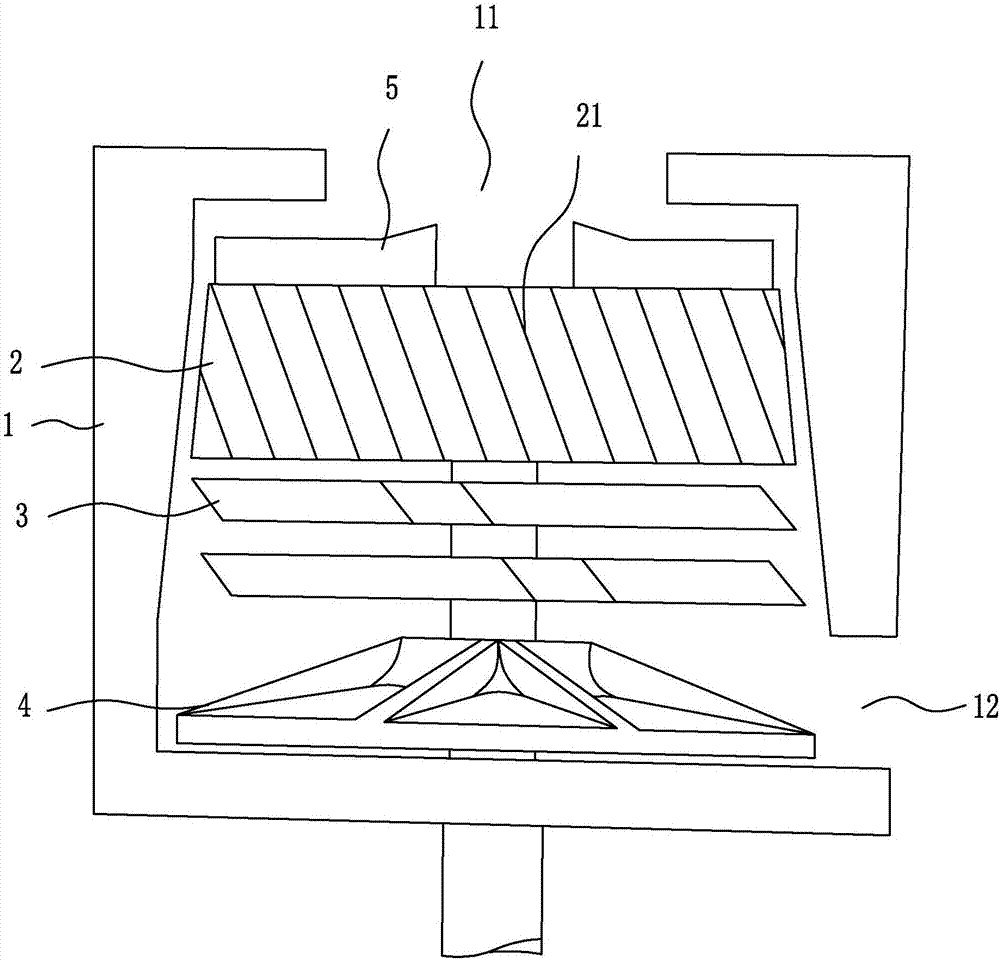

[0009] Such as figure 1 As shown, a continuous stirring device includes a casing 1 as a stator, a rotor 2 synchronously rotating in the casing 1, a stirring impeller 3 and a dialing impeller 4, and the casing 1 has a material inlet 11 at the top And the side discharge port 12 facing the transfer impeller 4 at the bottom, the stirring impeller 3 is arranged under the rotor 2 , and the transfer impeller 4 is arranged under the stirring impeller 3 .

[0010] The material enters from the material inlet, and with the rotation of the rotor 2, the material will enter from between the shell 1 and the rotor 2, and the material will be continuously friction and glued by the rotation of the rotor 2, and at the same time, the material will be driven down to play a role in the movement of the material. initial stirring action. When the material goes down to the mixing impeller 3, the rotating impeller will shake the material and throw the material to the surroundings, so that the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com