Patents

Literature

1023 results about "Continuous type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

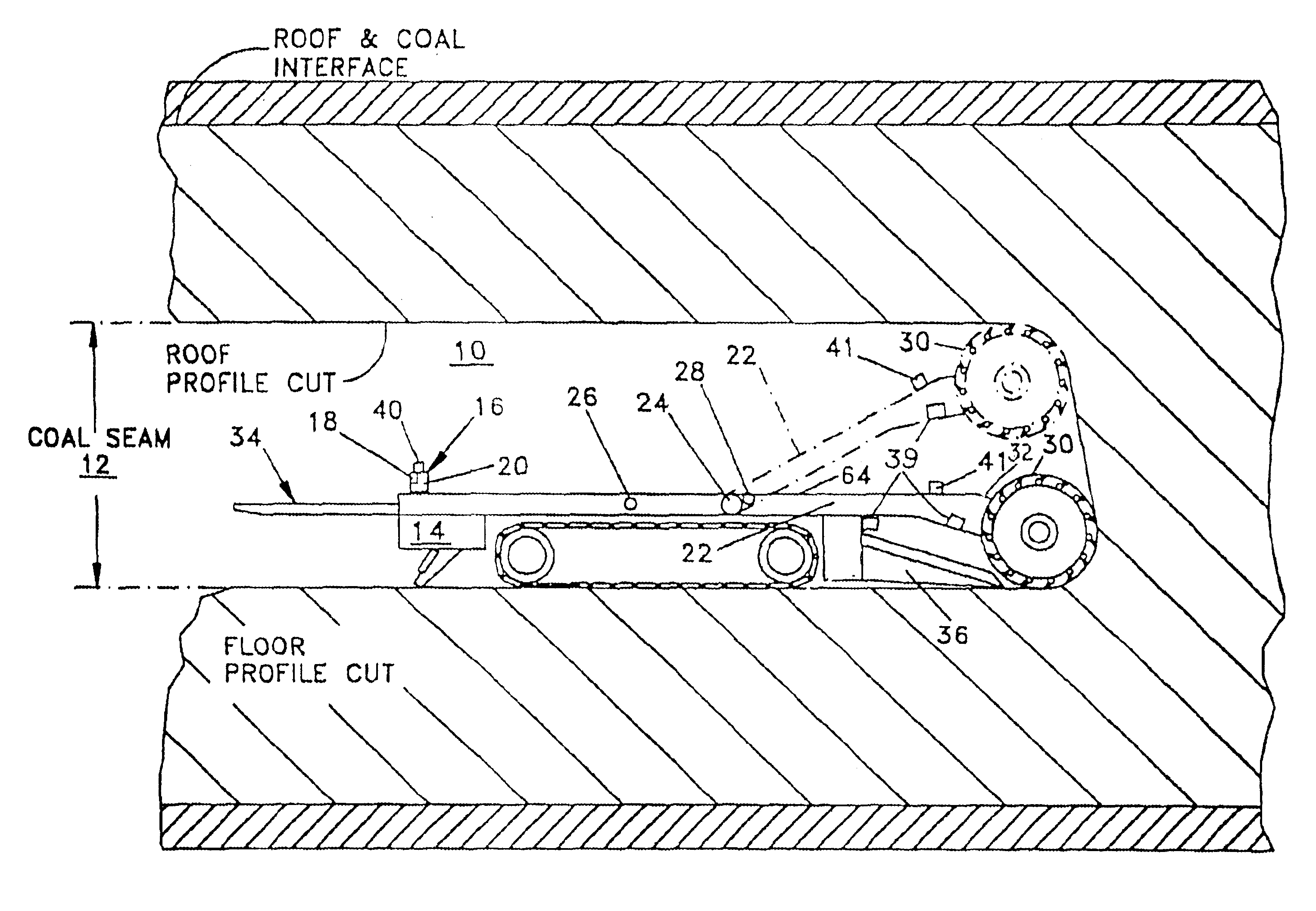

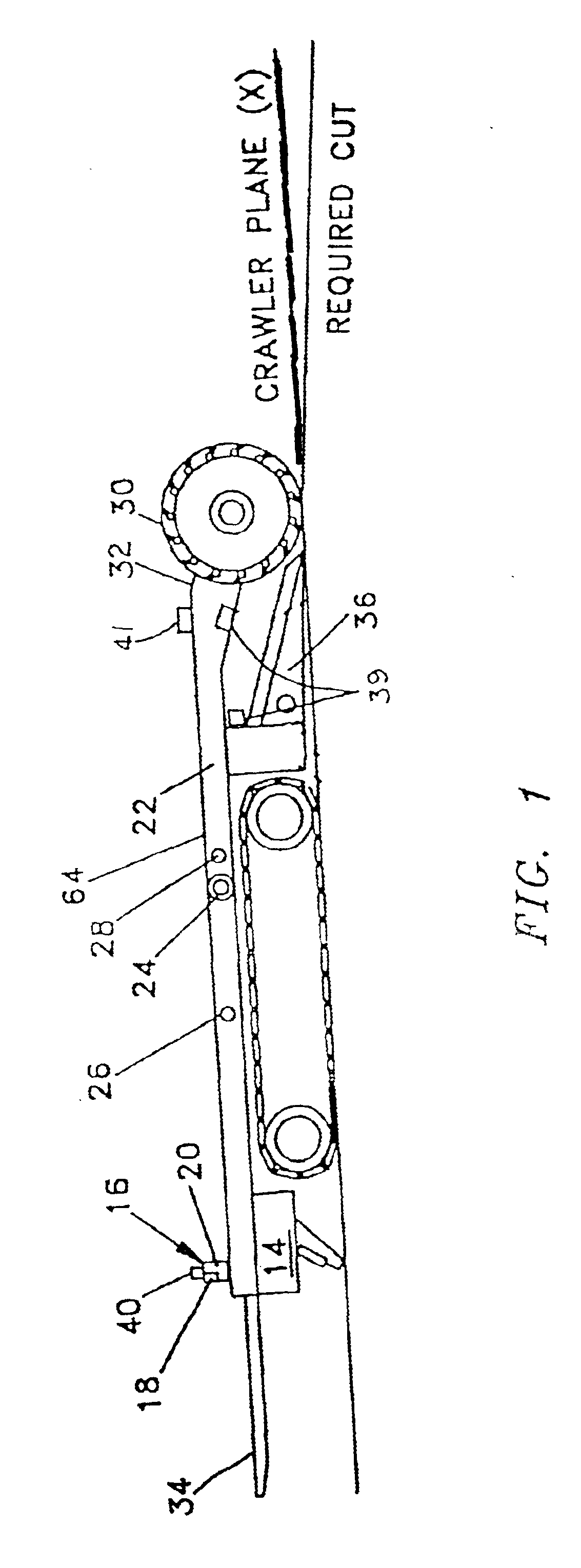

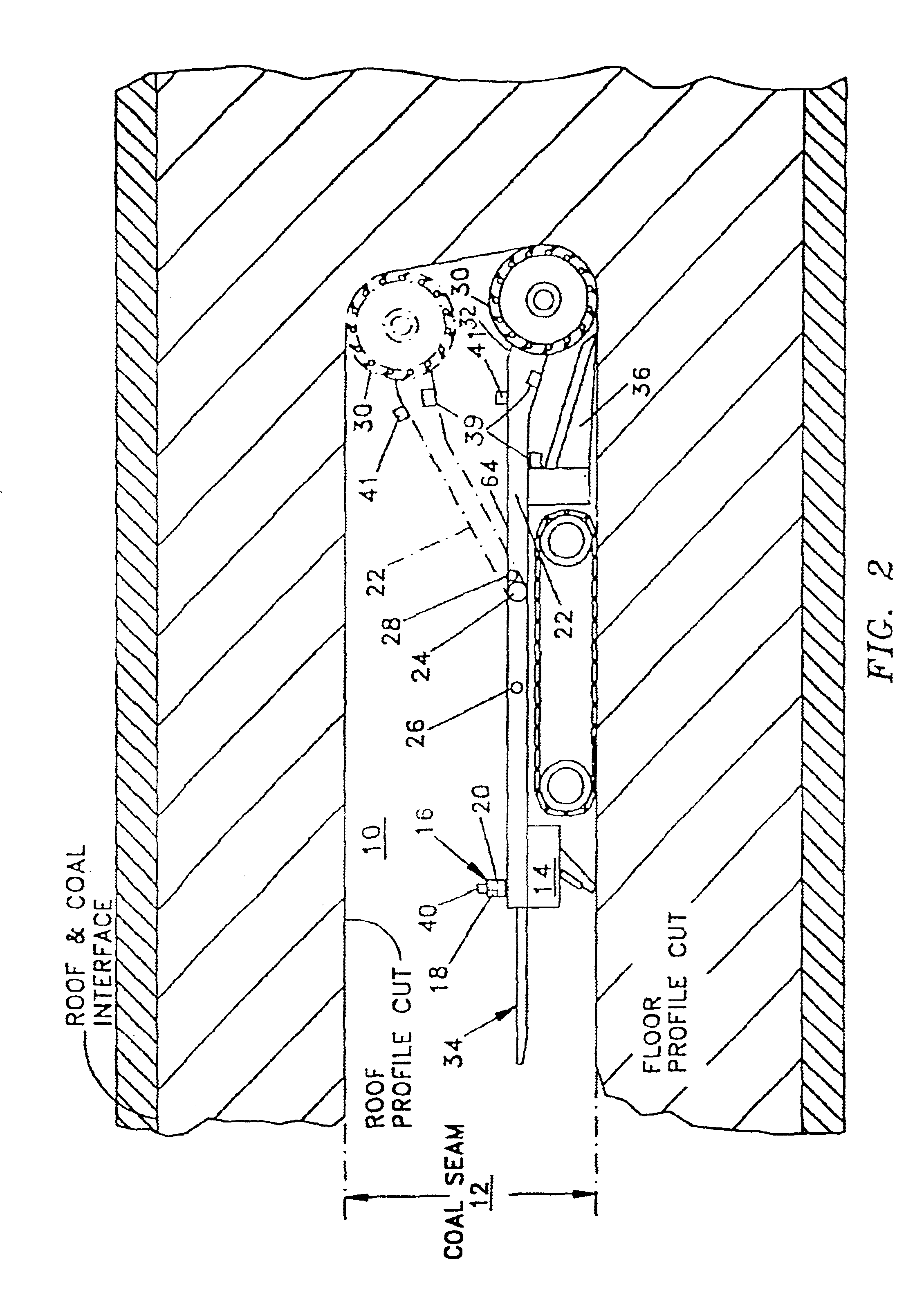

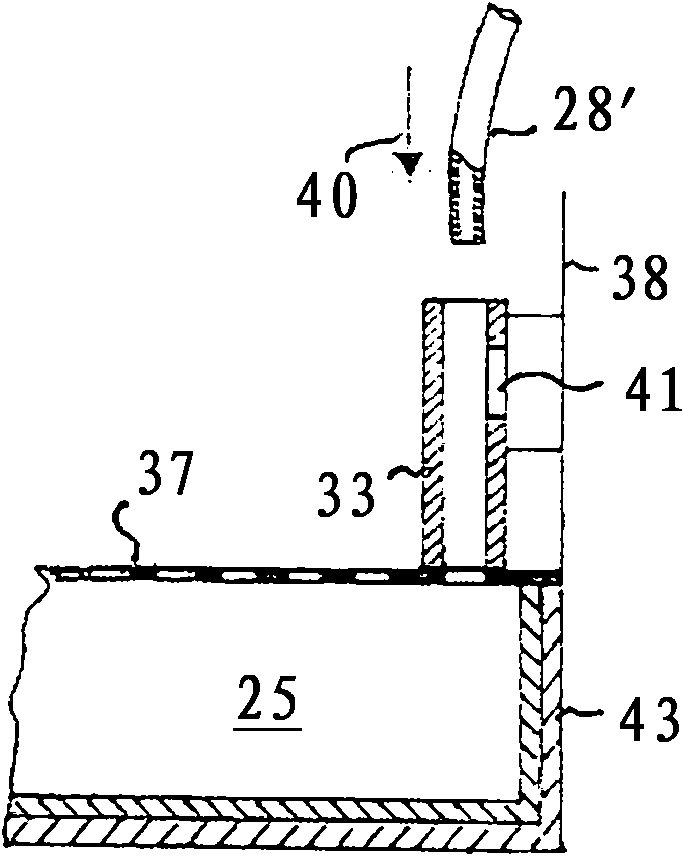

System for controlling cutting horizons for continuous type mining machines

InactiveUS6666521B1Improve continuous efficiencyImprove efficiencySlitting machinesHorizonControl system

A control system for continuous mining machine to control the mining horizons of roof and floor horizons relative to the rock boundaries of an underground coal seam or ore vein. The mining machine is provided with a cutting drum mounted on a pivoted arm to allow for vertical displacement of the cutter to control the mining height. A plurality of sensors is carried on the rotatable arm to locate the roof and floor boundaries. Attitude sensors are mounted on the machine for providing signals indicative of the inclinations of the body of the machine, and, a microprocessor receives the signals from the boundary sensors and the attitude sensors for calculating the required roof cut and floor cut. A display device receives the signals from the microprocessor and displays the calculated results to the machine operator.

Owner:AMERICAN MINING ELECTRONICS

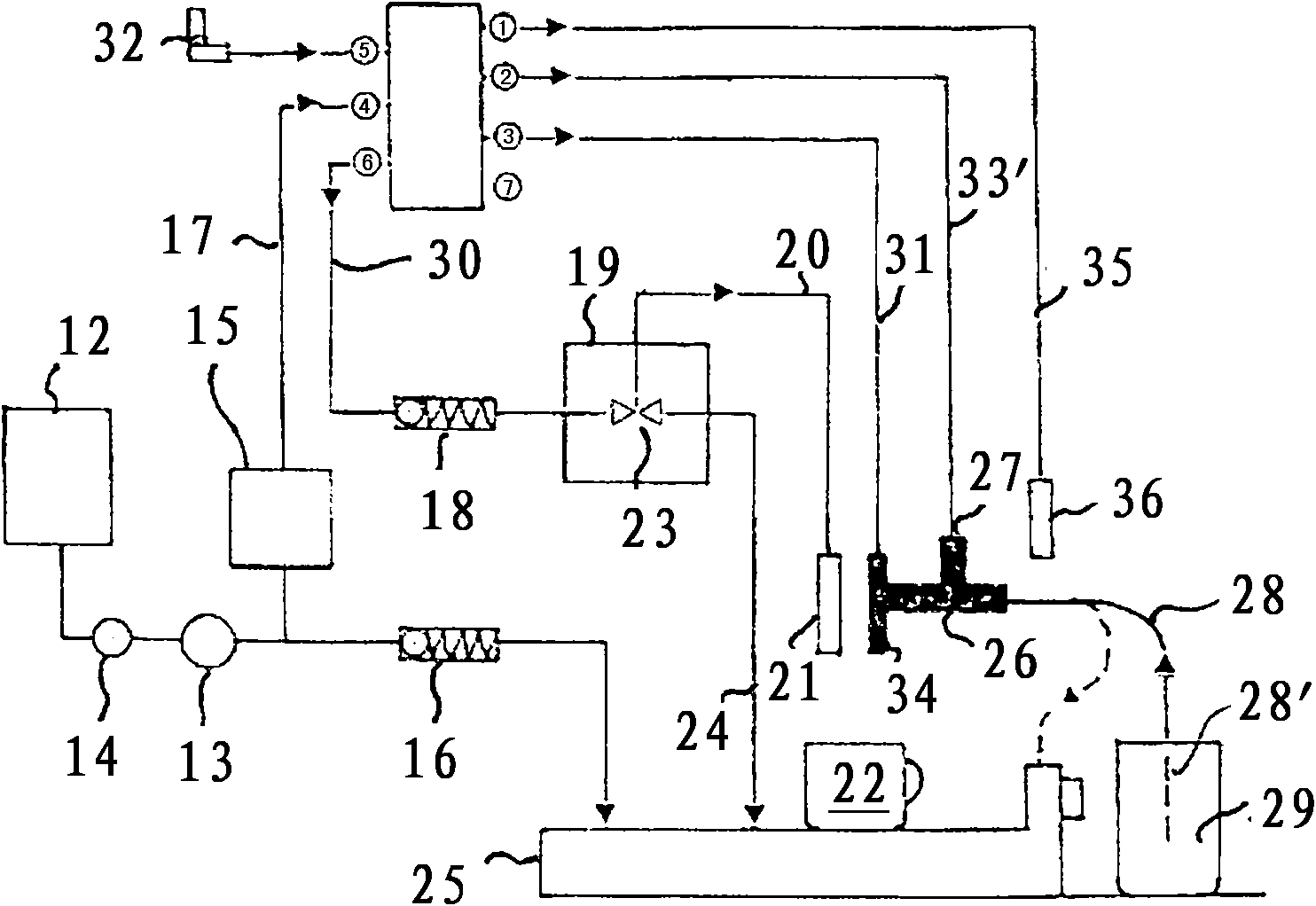

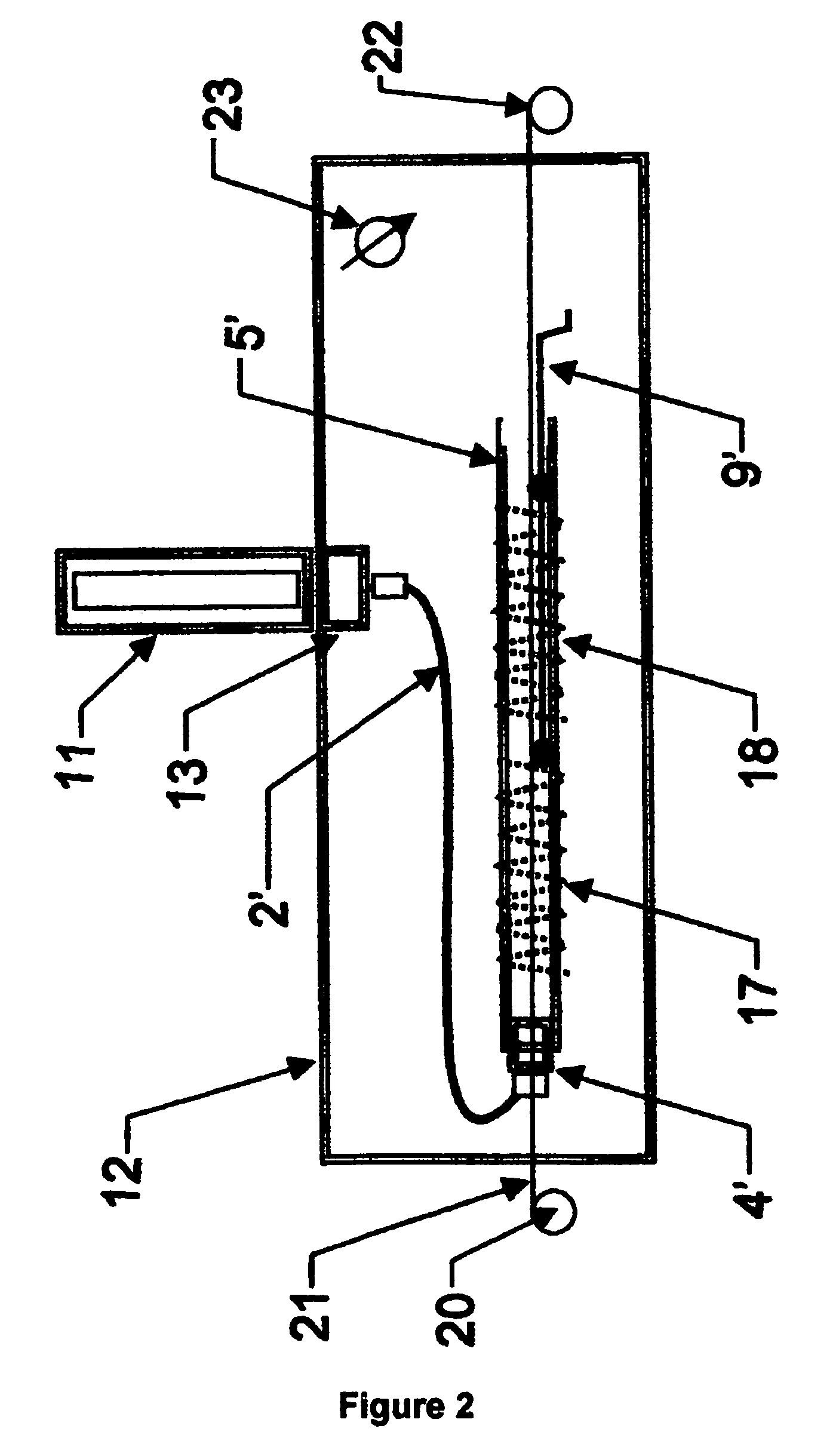

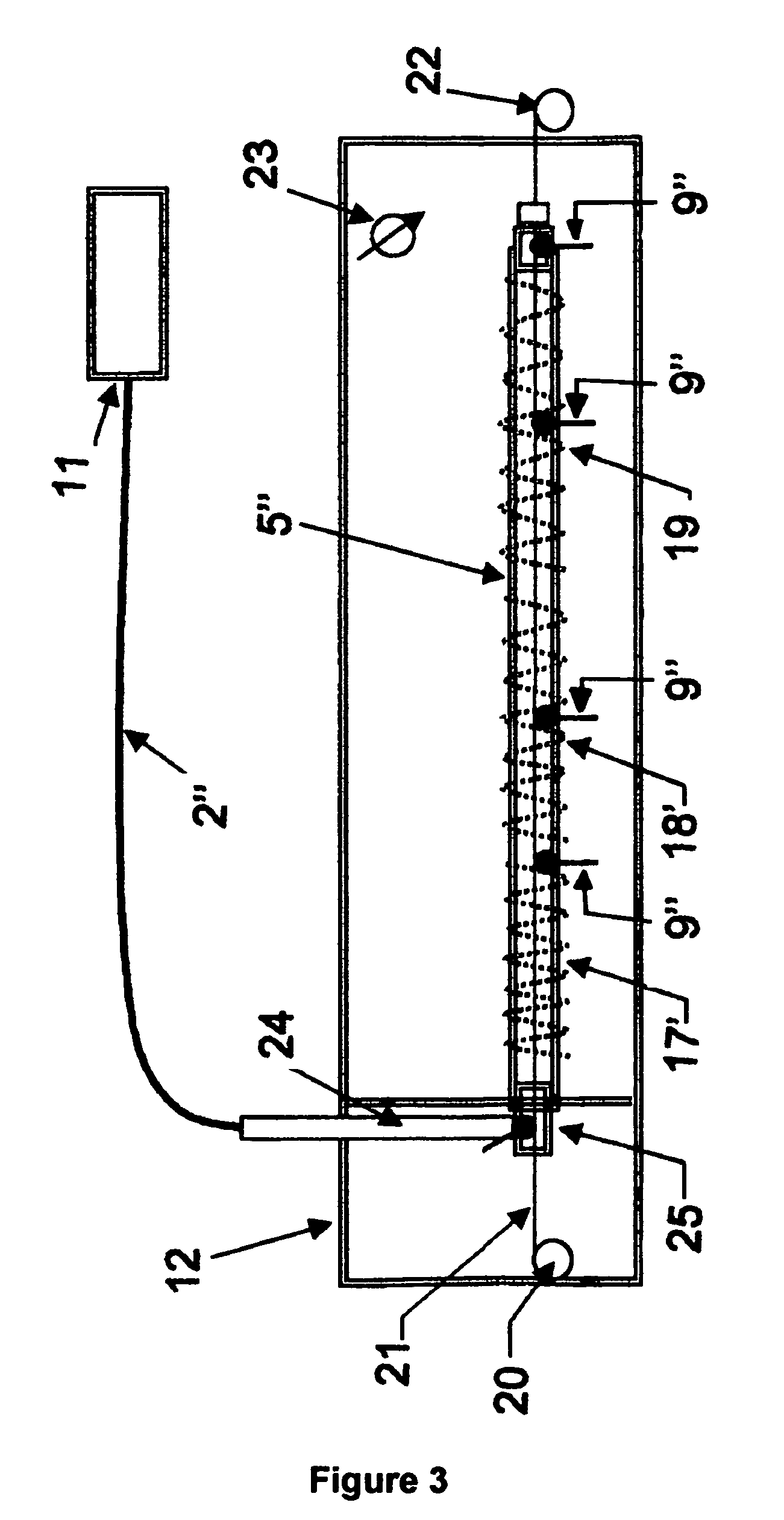

Coffee machine with frothing device and method for cleaning milk suction line

ActiveCN102144892ANo burn hazardReduce the temperatureBeverage vesselsEspresso coffeePulp and paper industry

The invention relates to a coffee machine with a frothing device, especially relates to an automatic espresso coffee machine. The frothing device is provided with an internal milk channel leading to a frothing chamber, a bypass air inlet for operable air supply for the frothing device, a movable milk suction line leading to a milk storing container, and a cleaning device which cleans the frothing device and the milk suction line by using flush water from a continuous type heater of the coffee machine. The flush water from the continuous type heater can be supplied to the bypass air inlet of the frothing device through a valve structure under control. Before the flush water is loaded at the bypass air inlet, the milk suction end of the milk suction line can be directly or indirectly communicated with a remaining water tank of the coffee machine. The invention also relates to a method for cleaning the movable milk suction line connected to the frothing device, especially to the frothing device of the coffee machine.

Owner:EUGSTER FRISMAG

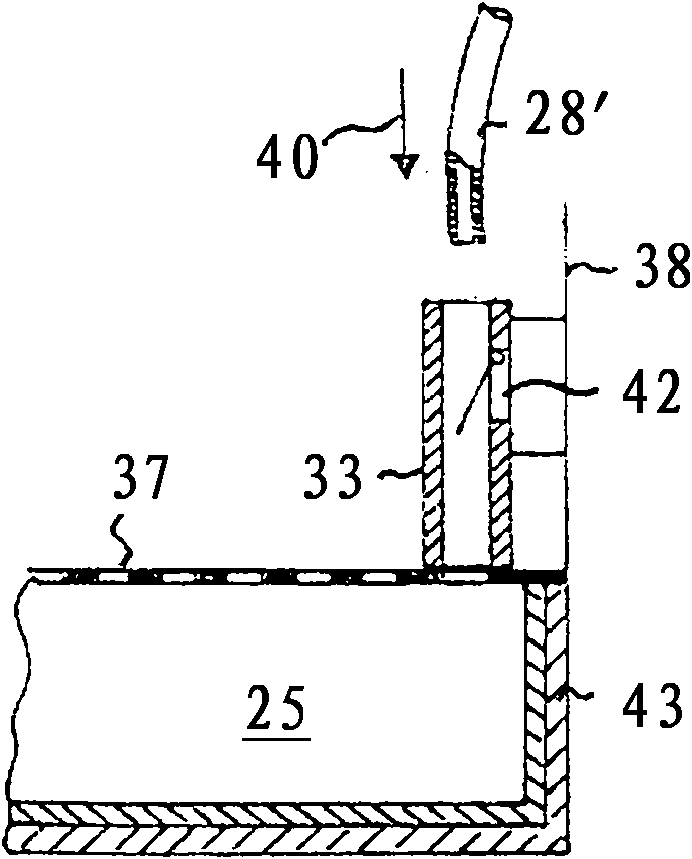

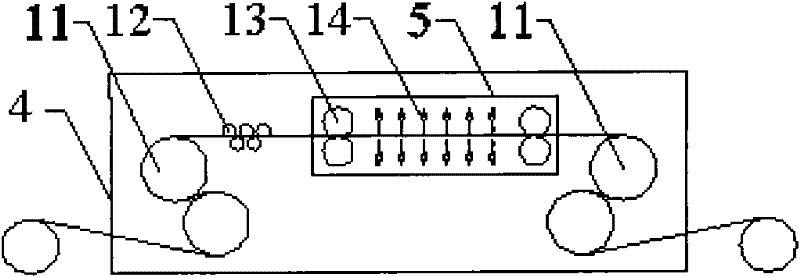

Cold metal plate strip cold continuous rolling production line and production method

InactiveCN102172835AImprove the effect of energy saving and emission reductionIncrease flexibilityWork treatment devicesOther manufacturing equipments/toolsProduction lineEngineering

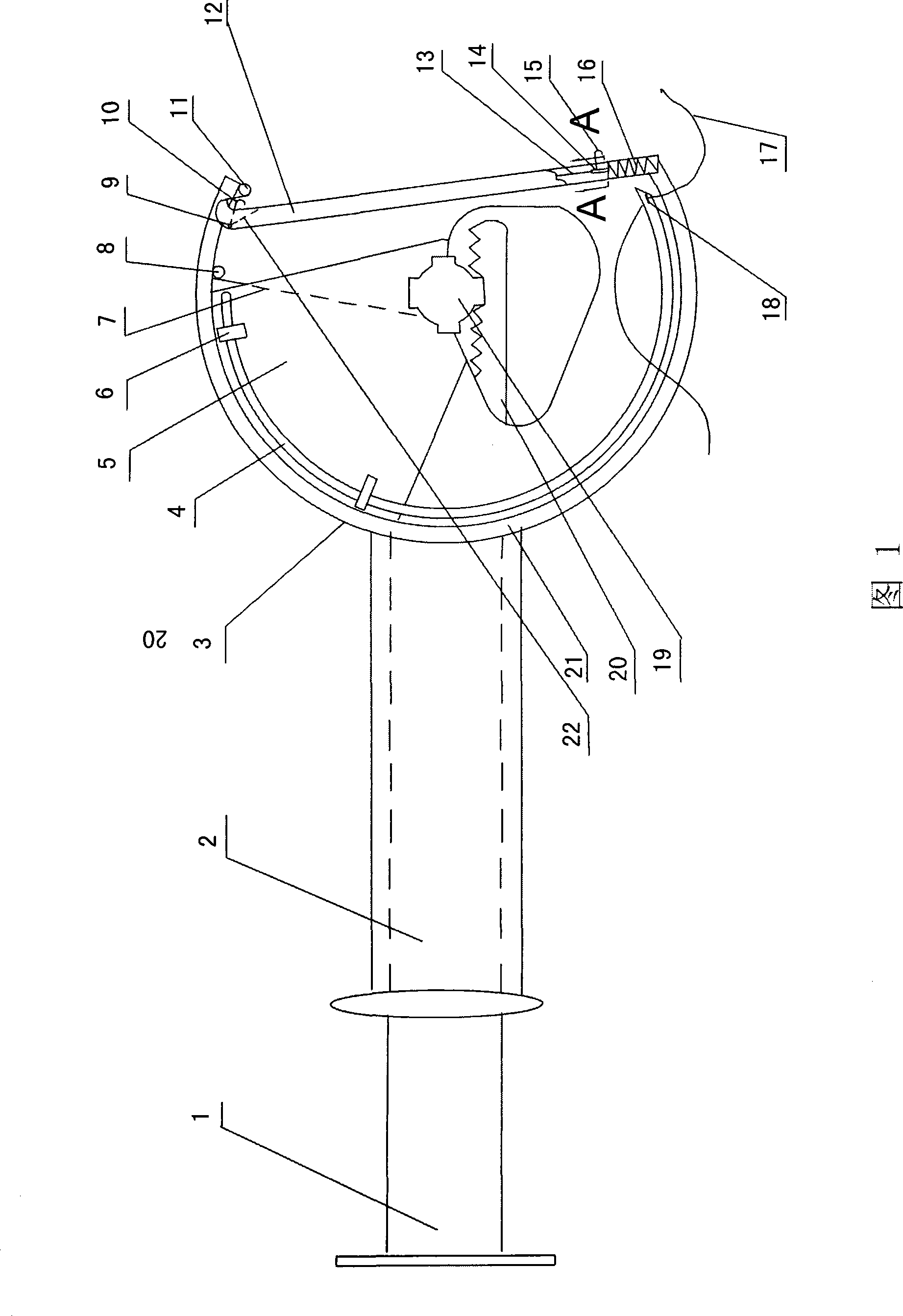

The invention relates to a cold metal plate strip cold continuous rolling production line, which comprises at least uncoiling machine (1), a plate strip head and tail cutting machine (2), welding equipment (17), a stretching and straightening device (4), at least one jet flow descaling unit (5), tension rolls (11), a trimming device (15), randomly selected cold continuous rolling machine set (9), flying shears (7), a coiling machine (8), and a movable sleeve device, wherein the stretching and straightening device (4) comprises at least two tension roll groups (11) and a bending roll group (12); the tension roll groups (11) are arranged in front and at back of the jet flow descaling unit (5) respectively; and the movable sleeve device is only welded between the welding equipment and the stretching and straightening device (4). When the continuous type metal plate strip cold continuous rolling production line and a high-pressure jet flow descaling mode are improved, the productivity of the cold continuous rolling line is improved obviously, the environmental-protection control index of the cold rolling process segment is obviously improved, and the floor area and maintenance cost of the production line are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

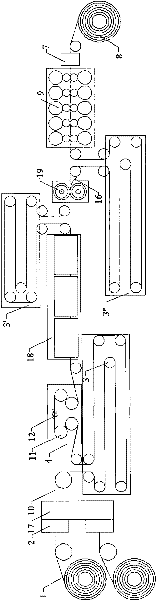

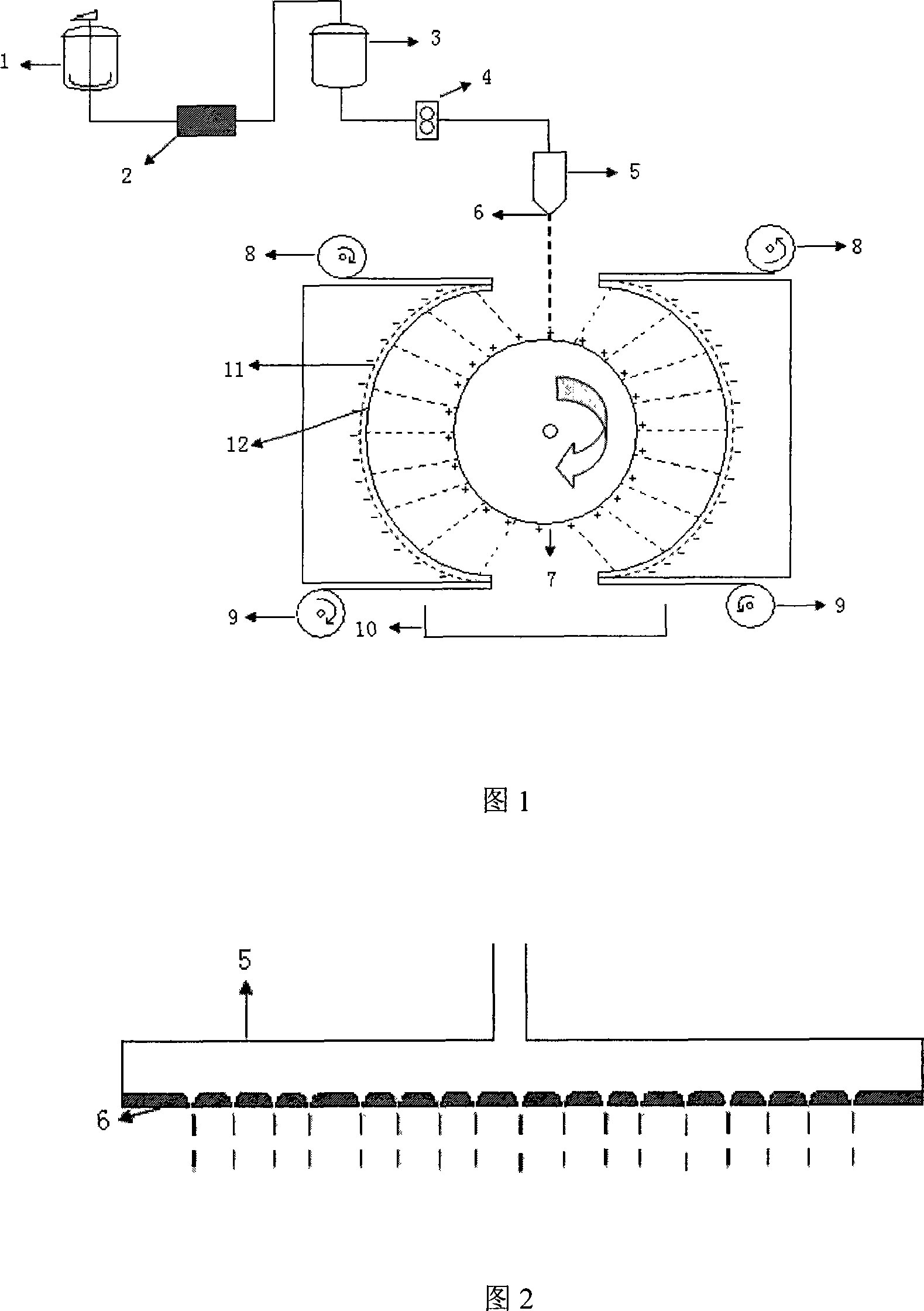

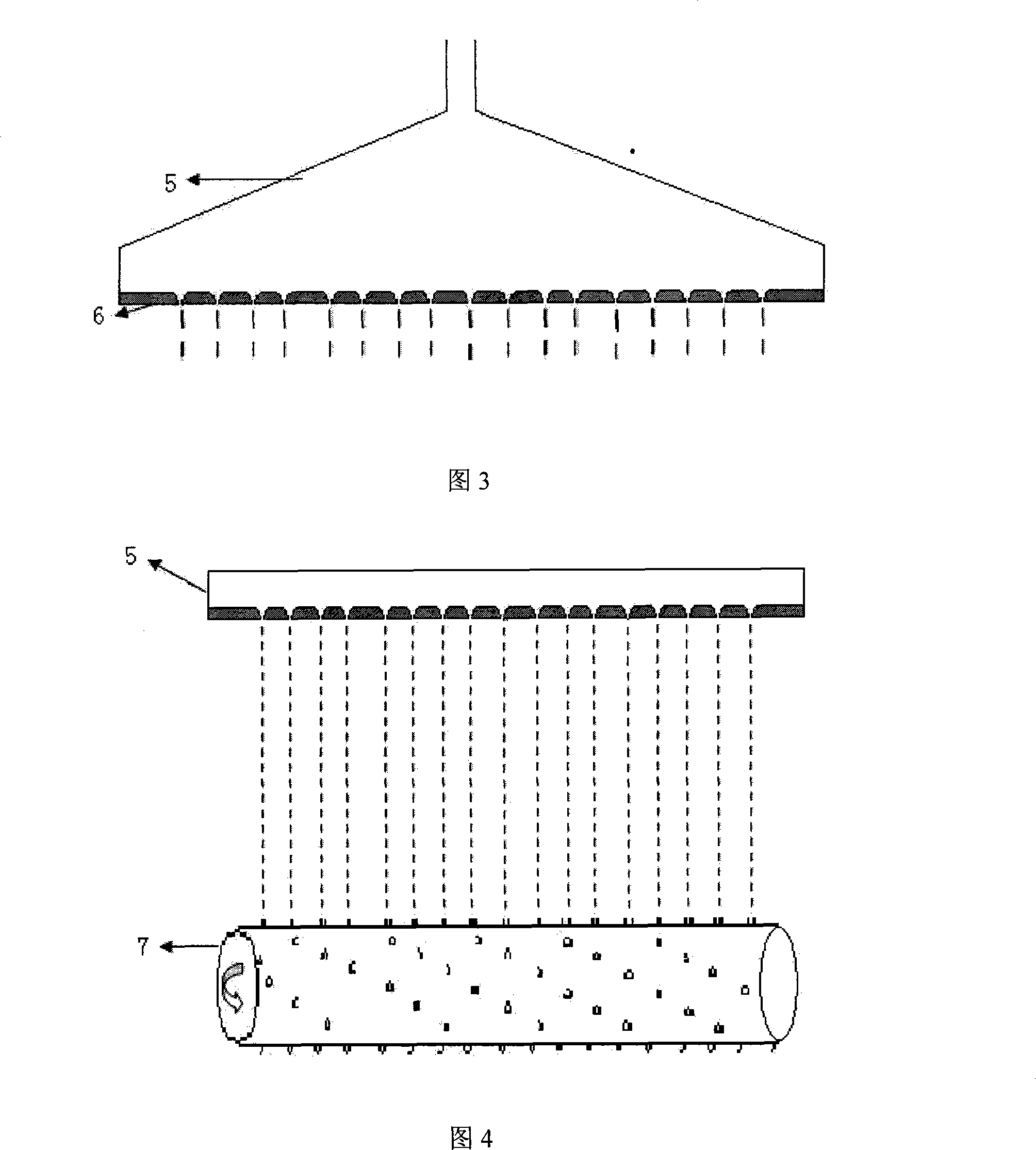

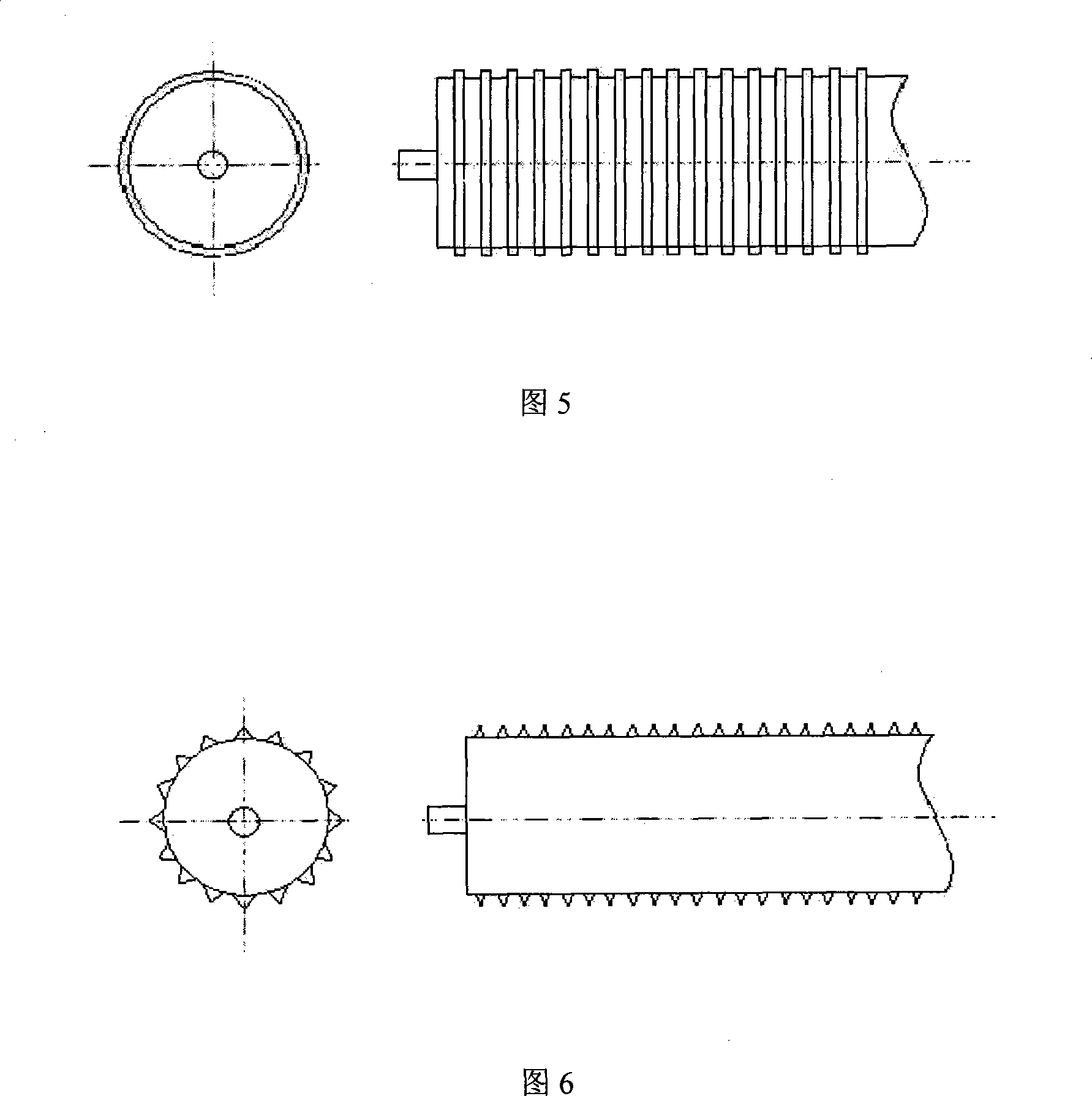

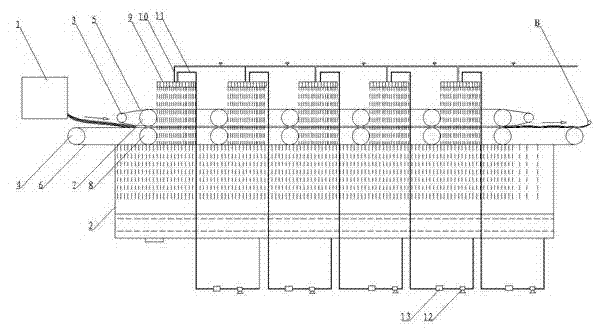

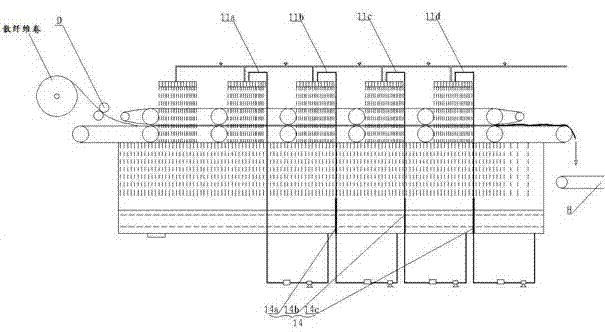

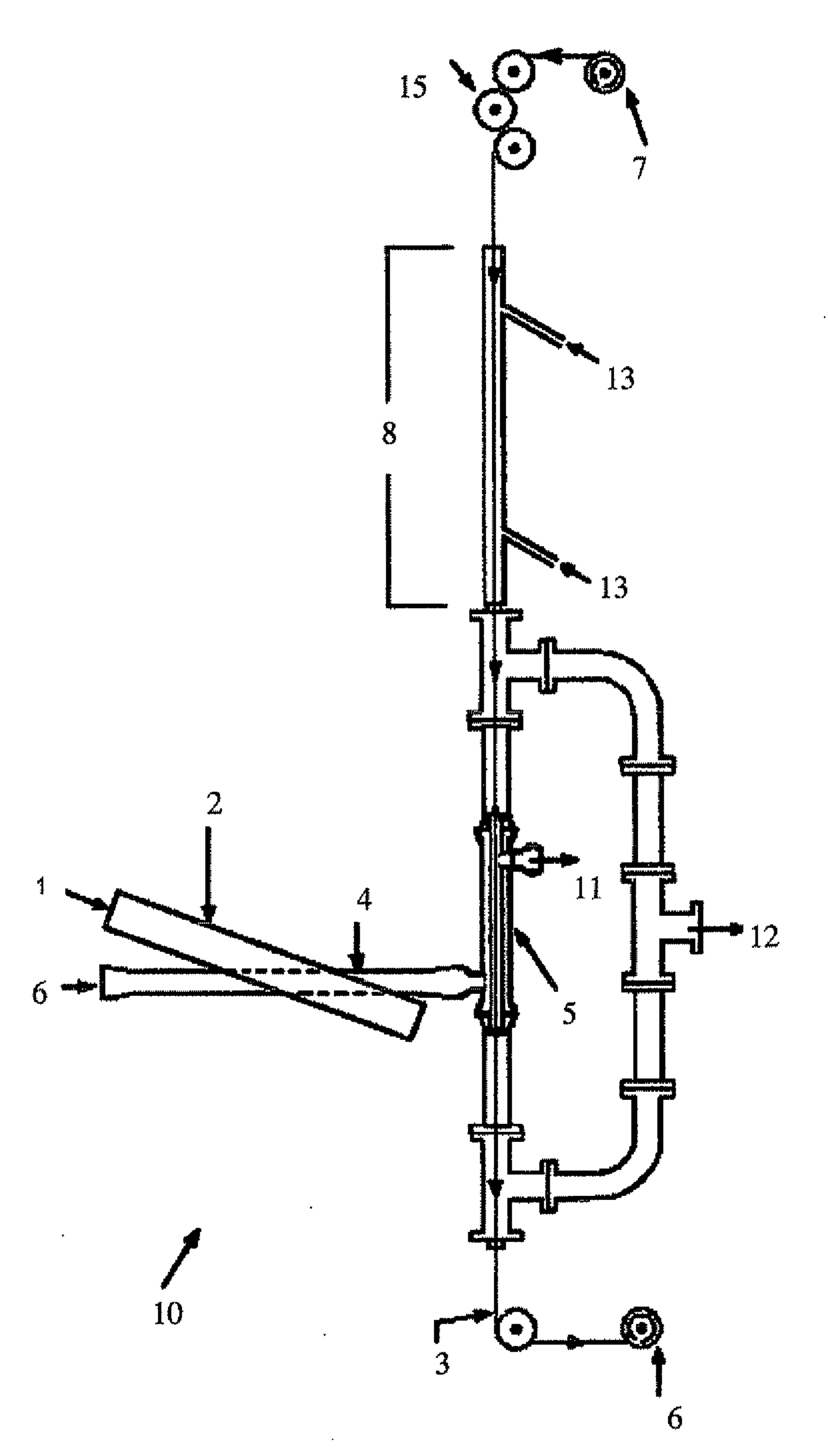

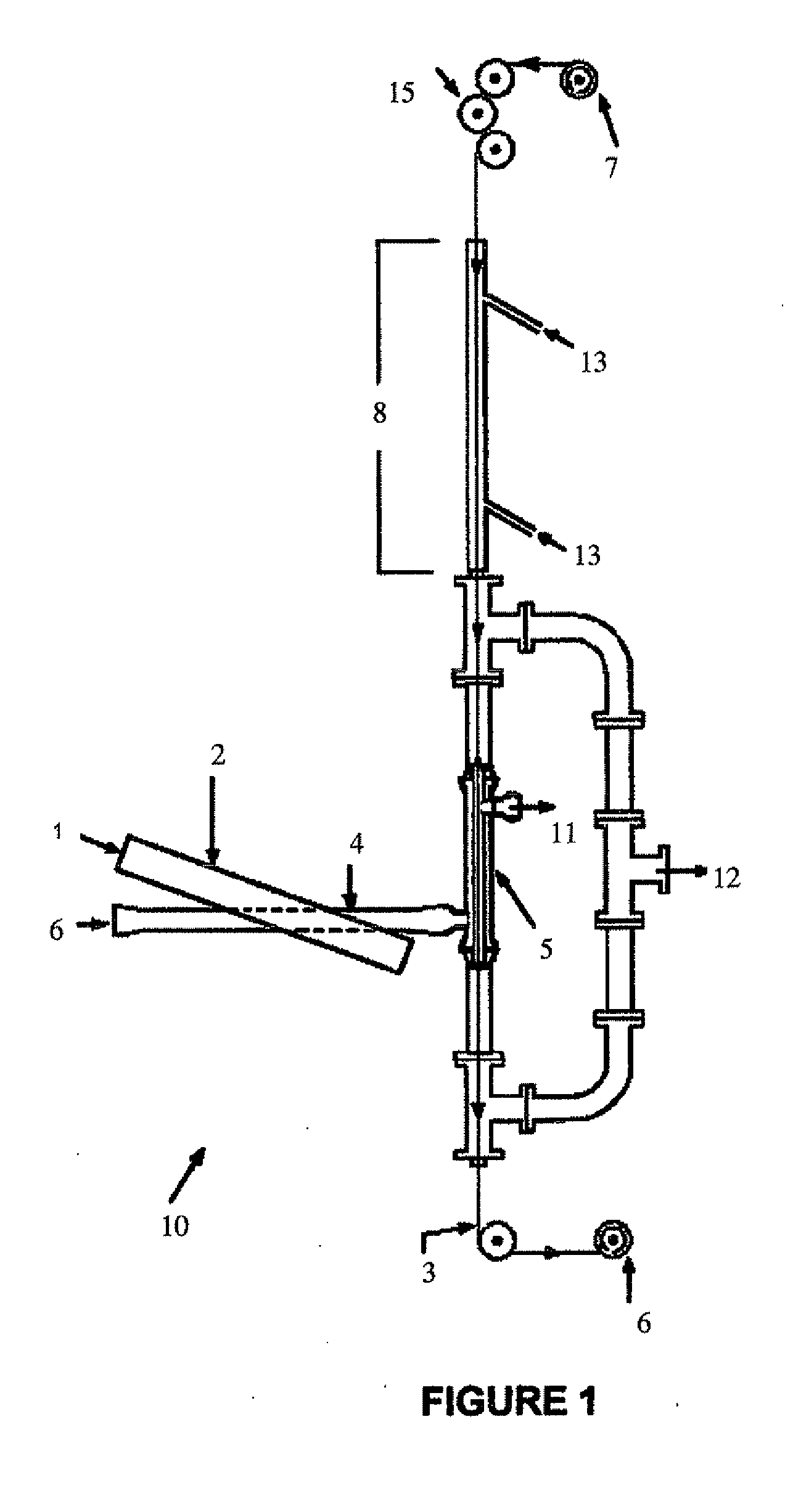

Device and method for preparing highly effective continuous electrostatic spinning nano fibre felt

InactiveCN101215762AGuaranteed continuous supplyEasily overcome surface tensionSpinning head liquid feederFilament/thread formingFiberLiquid storage tank

The invention relates to a preparing device of a high-effective continuous-type electro-spin nanometer fiber felt, the invention comprises a fluid supply system, a metal roller, a receiving device and a spinning fluid recycling groove. The process for preparing comprises firstly, preparing polymer spinning fluid with correct concentration in a dissolution kettle, temporarily storing in a liquid storage tank after passing through a filter, secondly, connecting the metal roller and the positive electrode of a high-pressure electrostatic generator, applying correct electrostatic pressure, leading an aluminium screen cloth to connect ground, thirdly, leading the metal roller to rotate in correct rotary speed, fourth, starting a measuring pump, feeding spinning liquid from the liquid storage tank to an even allotter, leading the spinning liquid to be evenly allocated to a spraying hole on the front end of the even allotter, sputtering from the spraying hole to the surface of a rotating metal roller to form Taylor awl, fifthly, leading a coiling drum to rotate to drive a fiber receiving net to move, and continuously receiving nanometer fiber felt. The process for preparation of the nanometer fiber felt of the invention has high production efficiency, which is suitable for scale production of electro-spinning.

Owner:DONGHUA UNIV

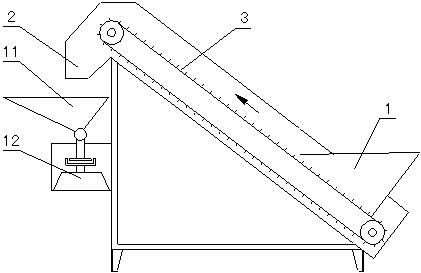

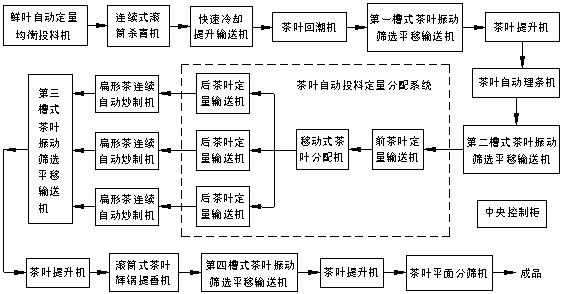

Full-automatic flow production line for flat tea and production method thereof

ActiveCN101946831AHigh degree of automationSuitable for large-scale productionPre-extraction tea treatmentProduction lineDistribution system

The invention discloses a full-automatic flow production device for flat tea and a production method thereof. The full-automatic flow production device for the flat tea comprises a tea frying device and a connection conveying device, wherein the tea frying device and the connection conveying device are both connected with a central control cabinet; the tea frying device comprises an automatic quantitative equilibrium feeding machine for fresh tea, a continuous type roller fixing machine, a quick-cooling lifting and conveying machine, a tea dampening machine, a tea automatic strip-finishing machine, a tea automatic quantitative feeding distribution system and 3 to 10 continuous automatic frying machines for the flat tea; and the continuous automatic frying machines for the flat tea are connected with a roller type tea twice-heating flavoring machine and a tea plane screening machine through a groove type tea vibration screening and translation conveyor. The invention effectively solves the problems of dispersal processing, irregular quality, and manpower and device resource waste in the traditional flat tea production and also solves the problems of impure tea taste and low quality in the traditional production device for the flat tea.

Owner:浙江丰凯机械股份有限公司

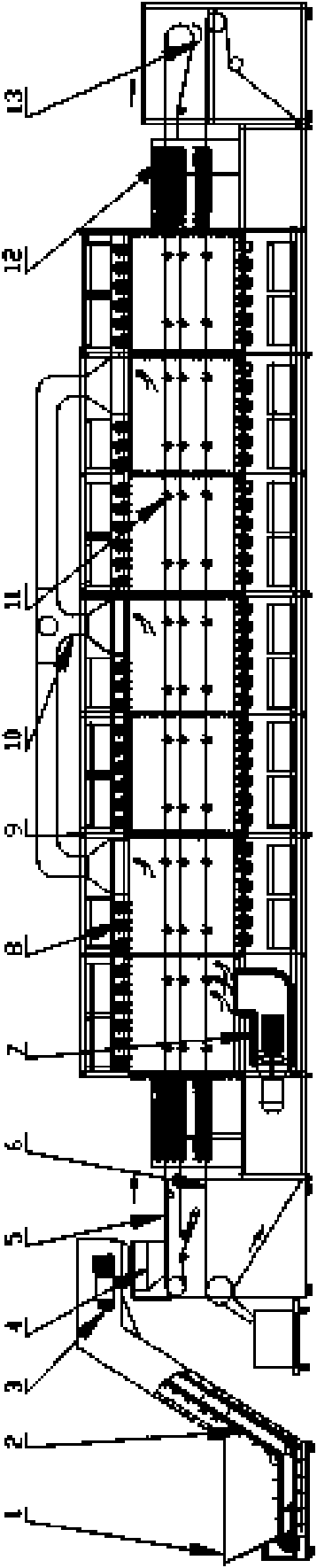

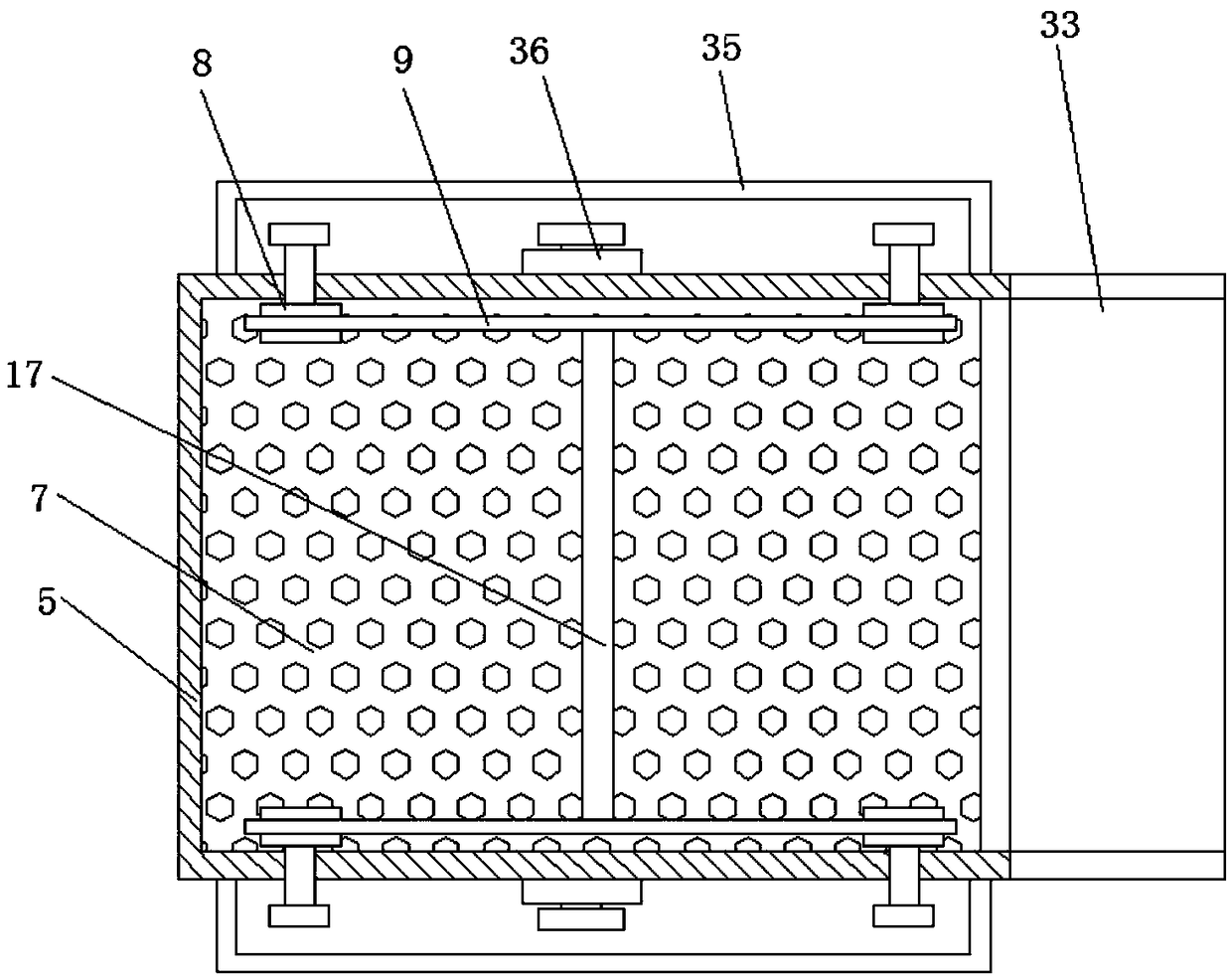

Continuous-type microwave hot air combined drying equipment

InactiveCN101581534AImprove efficiencySlow heatingSludge treatment by de-watering/drying/thickeningDrying solid materials with heatMicrowave tubeEngineering

The invention relates to continuous-type microwave hot air combined drying equipment which comprises a material lifting device, a lower hopper auxiliary device, an upper layer conveyer belt, a lower layer conveyer belt, a microwave case, a humidity-discharging device, a hot-air device; the upper layer conveyer belt and the lower layer conveyer belt are arranged in the microwave case in parallel; the microwave case is internally provided with a microwave tube; a discharge port of the material lifting device is arranged above the lower hopper auxiliary device which is positioned above the loading end of the upper layer conveyer belt; the discharge end of the upper layer conveyer belt is provided with a guide plate which is positioned above the loading end of the under layer conveyer belt; a humidity-discharging device is arranged on the top of the microwave case; and the hot-air device is arranged at the bottom of the microwave case. The equipment achieves the effect of energy-saving and high efficient by adopting the structure.

Owner:WENZHOU UNIVERSITY

Alumina ceramic and preparation method thereof

The invention provides alumina ceramics and a manufacturing method of the alumina ceramics. The main materials of the alumina ceramics are as follows: alumina micro mist or a superfine alumina micro mist which is formed by Gamma alumina and an Alpha alumina with an particle diameter of between zero point one to three point five micron and a purity of ninety-nine point nine percent or more than ninety-nine point nine percent according to certain proportion. One or a mixture of a small quantity of magnesia, yttria, lanthana, thulia and yttria stabilized zirconia is added into the micro mist as sinter accessory ingredient and is subject to dry pressing, grouting and isostatic cool pressing after being even mixed evenly, thus ceram green pressing is obtained. Only a little organic addition agent is needed to be added. After drying, the green pressing body does not need to be roasted and can be directly introduced to an ordinary high temperature si-mo rod resistance furnace or a continuous type si-mo rod electrothermal tunnel kiln to be sintered for one to three hours at a temperature below one thousand six hundred and seventy Celsius system. Therefore, the alumina ceramics can be obtained with high tightness, mechanical property and good dielectric property and with a nonconventional structure and a placode the size of which is zero point two to two hundred millimeter and a purity of ninety nine to ninety-nine point nine percent.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

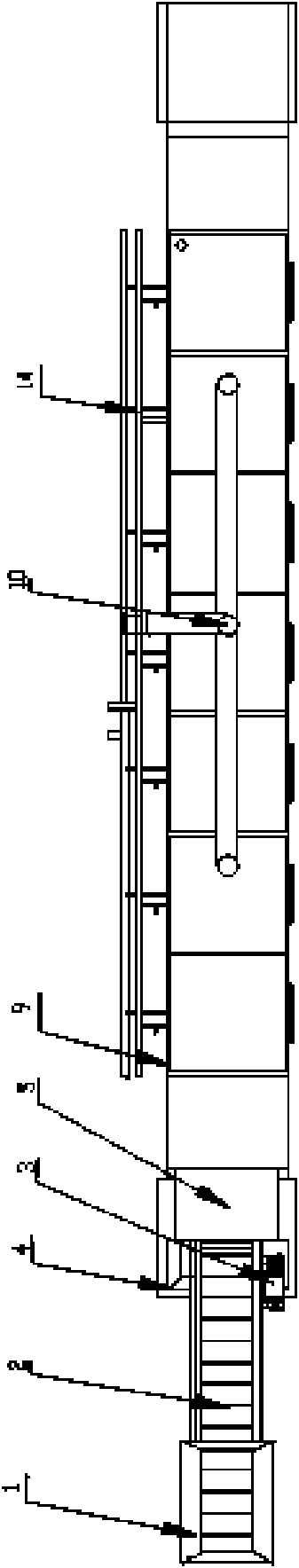

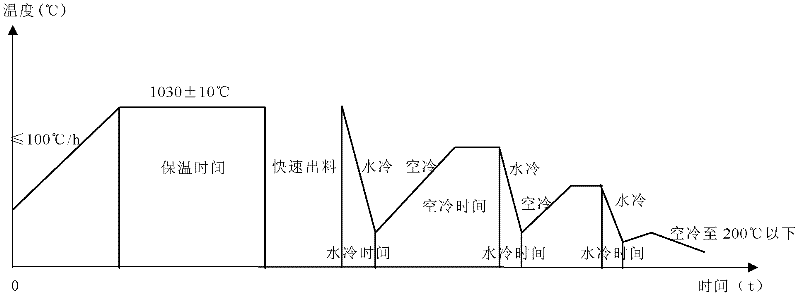

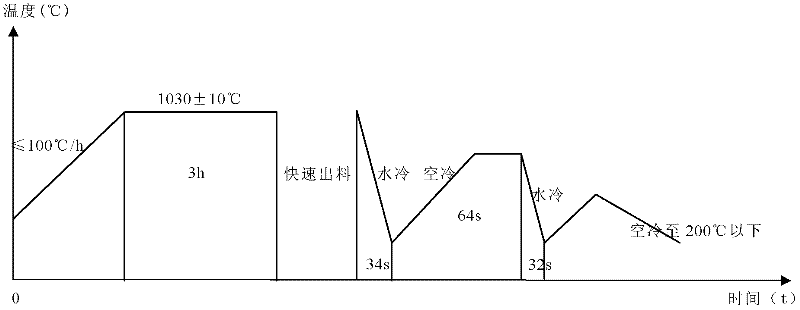

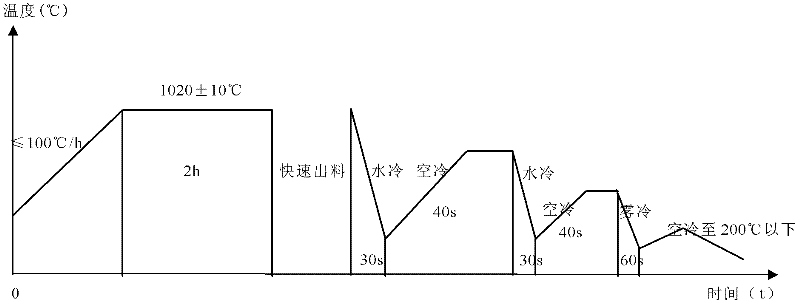

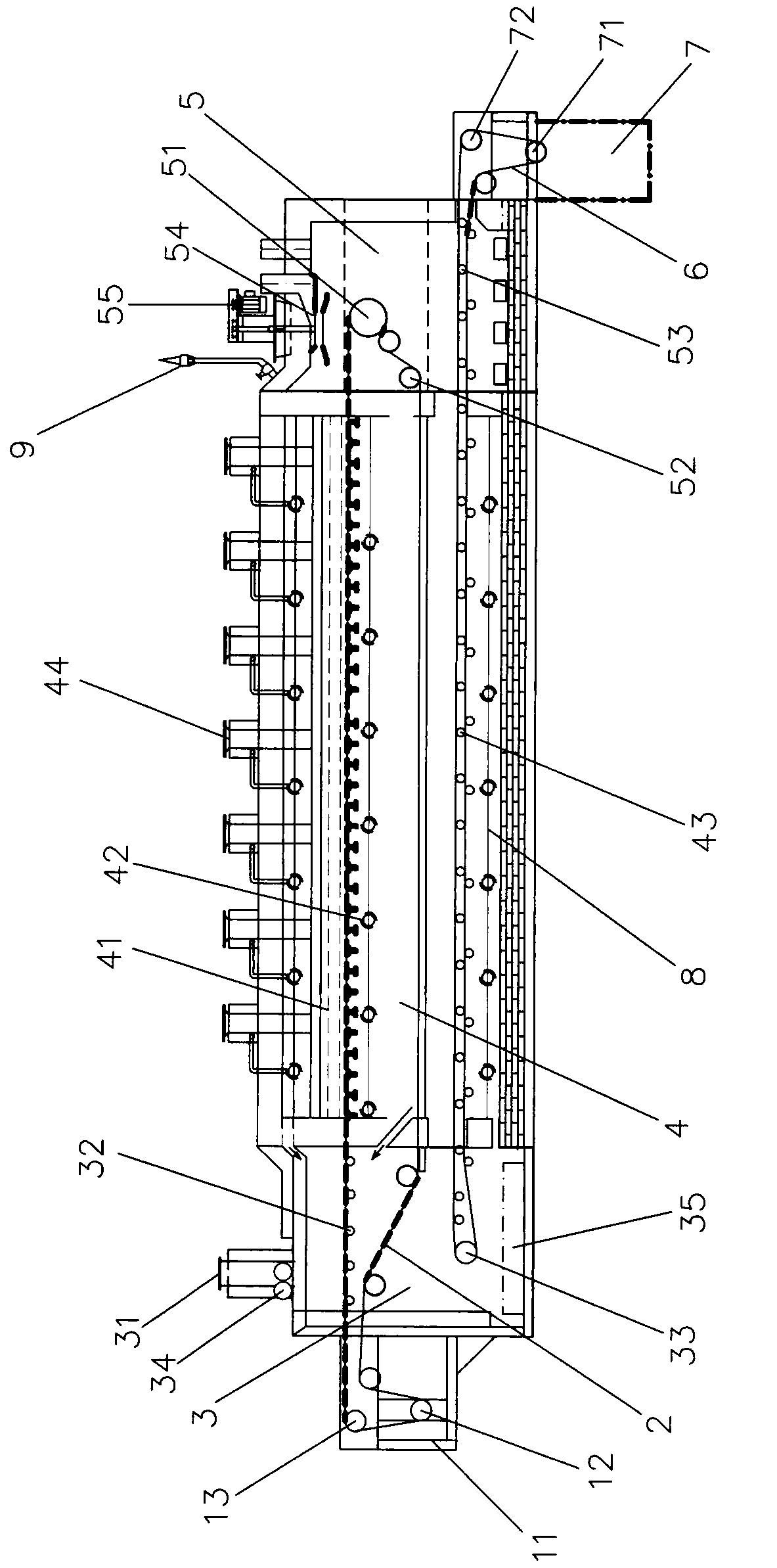

Continuous type alloy steel heat treatment line

The invention discloses a continuous type alloy steel heat treatment line, solving the problem existing in small-section ultra-long material workpiece heat treatment. The continuous type alloy steel heat treatment line is formed by connecting a continuous type roller hearth heating furnace, a roller hearth type quenching groove and electric heating continuous type roller hearth furnace in series.The heat treatment process comprises the following steps of: carrying out austenitization heating on a workpiece in the continuous type roller hearth heating furnace, rapidly discharging after reaching the process time and then entering into the roller hearth type quenching groove; automatically generating a non-continuous water cold process according to the chemical components and different standards of the workpiece, and rapidly cooling through an immersion or spray mode; and tempering the workpiece which is cooled to room temperature according to the process requirement. The continuous type alloy steel heat treatment line has the advantages that: 1, the quenching, solid solution and normalizing continuous heat treatment of the small-section ultra-long material workpiece are achieved, and the heat treatment is completed on roller beds which are located on the same height and axis; 2, a quenching medium is stable in the rising process, and the workpiece can be simultaneously cooled in the length direction; and 3, fire danger and lamp black pollution are precluded by adopting non-continuous water quenching.

Owner:FUSHUN SPECIAL STEEL SHARES

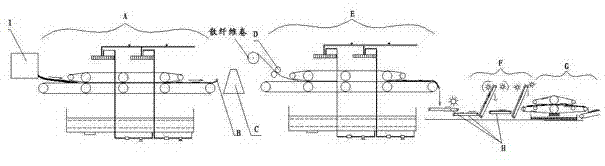

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

Low-temperature pretreatment process of full-cotton woven fabric

ActiveCN102220684AReduce qualityImprove refining effectBiochemical fibre treatmentDry-cleaning apparatus for textilesPulp and paper industryPre treatment

The invention relates to a continuous type low-temperature boiling-off and bleaching pretreatment process of full-cotton woven fabric. At present, the low-temperature boiling-off and bleaching of pre-treatment process exists, but are only the pre-treatment processing process for cotton and blended knitted fabric; research findings or patent documentation of pre-treatment process taking low-temperature boiling-off and bleaching of full-cotton woven fabric are not found at present. In the invention, hot water pre-treatment processing, biological enzyme processing, hot water washing and enzyme blanching and water washing process are firstly preformed on the full-cotton woven fabric, and then the low-temperature scouring and bleaching processing, the low-temperature steam bleaching processingand the water washing process are then performed to finish the pre-treatment of the cotton woven fabric. In the invention, the cotton woven fabric is pre-treated in combination with biological enzymedesizing and the low-temperature scouring and bleaching; the technology in the invention has a good effect without sizing agent residuals and residual cotton seed hulls, and the brightness achieves the effect of the traditional soda boiling and oxygenation bleaching technology.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

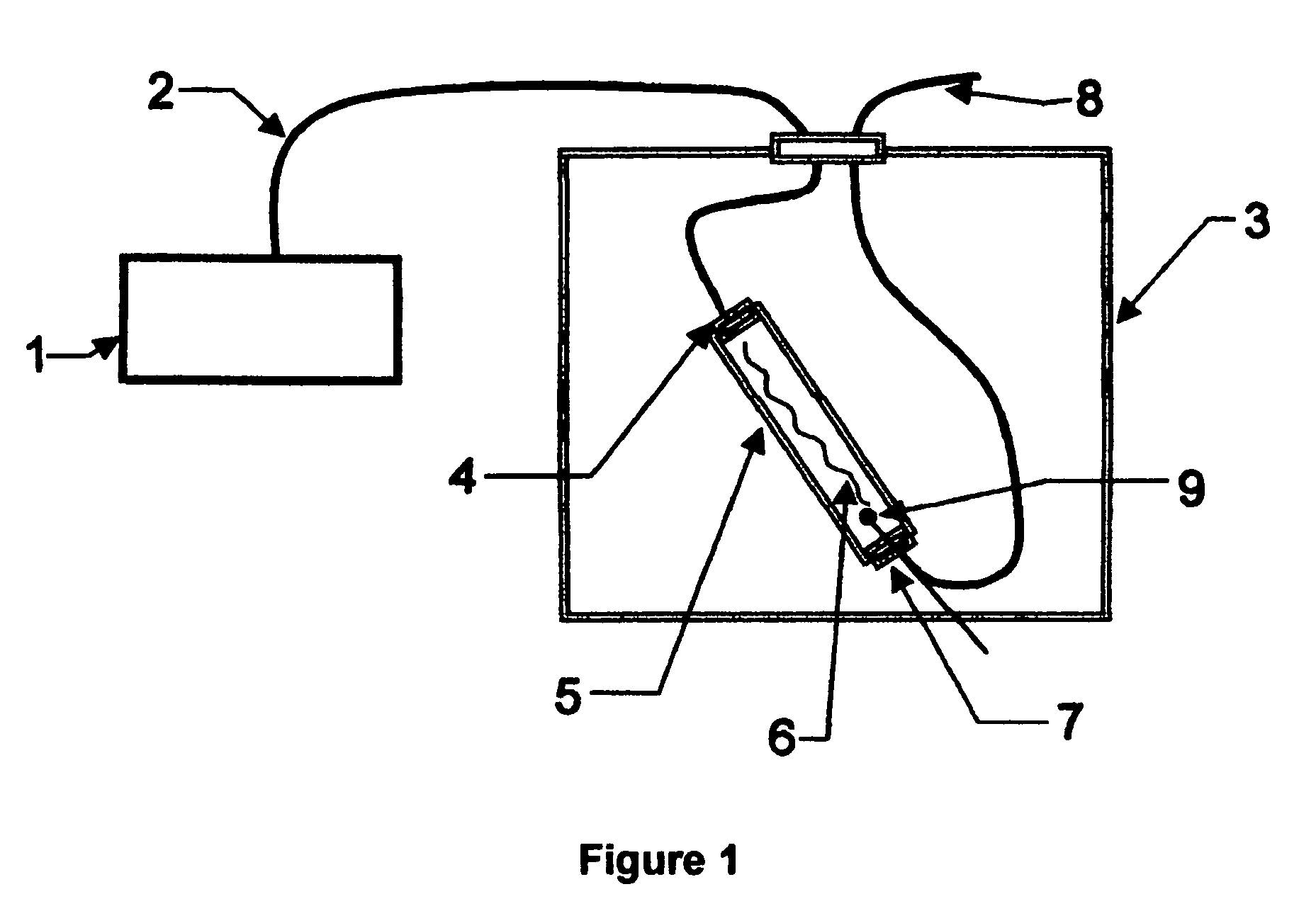

Apparatus and method for stabilization or oxidation of polymeric materials

An apparatus for treating polymeric materials comprises a treatment chamber adapted to maintain a selected atmosphere at a selected temperature; a means for supporting the polymeric material within the chamber; and, a source of ozone-containing gas, which decomposes at the selected temperature yielding at least one reactive oxidative species whereby the polymer is stabilized and cross linked through exposure to the oxidative species in the chamber at the selected temperature. The ozone may be generated by a plasma discharge or by various chemical processes. The apparatus may be configured for either batch-type or continuous-type processing. The apparatus and method are especially useful for preparing polymer fibers, particularly PAN fibers, for later carbonization treatments as well as to make flame-retardant fabrics.

Owner:4X INTPROP HLDG LLC +2

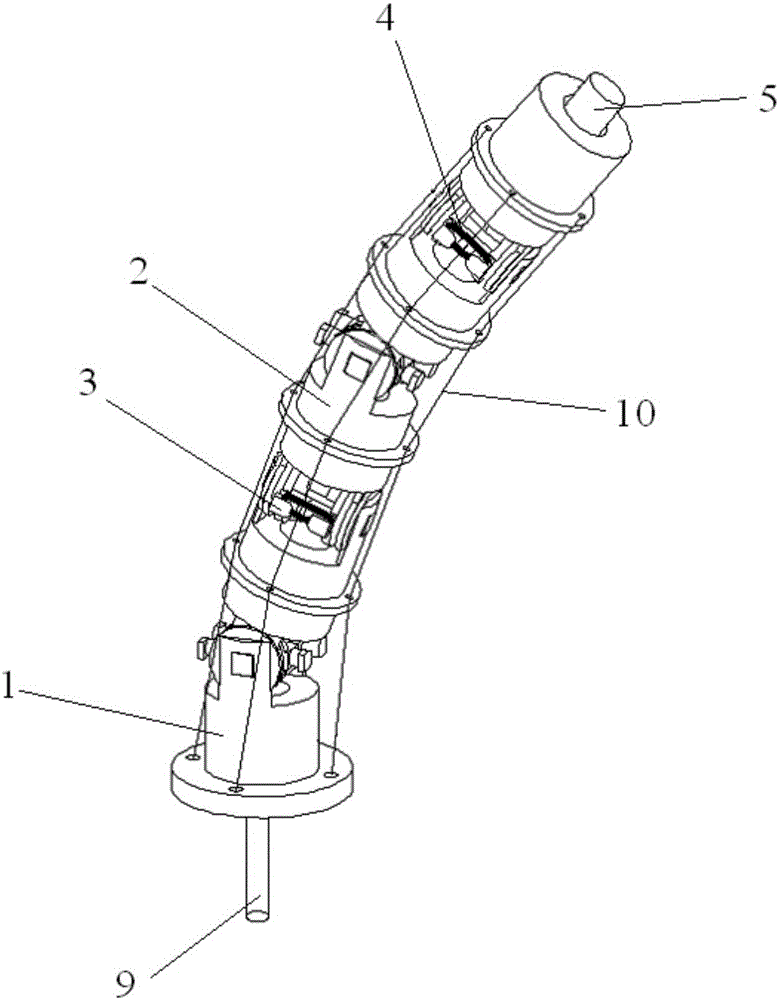

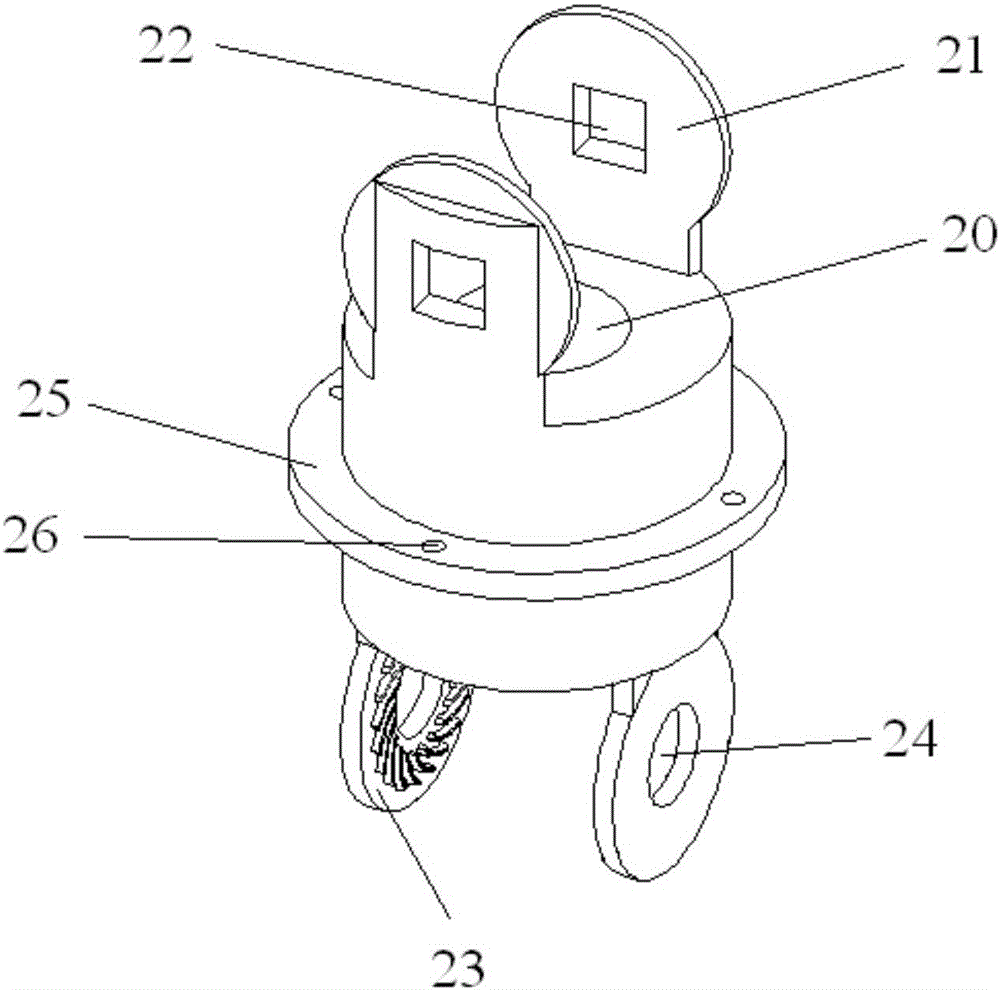

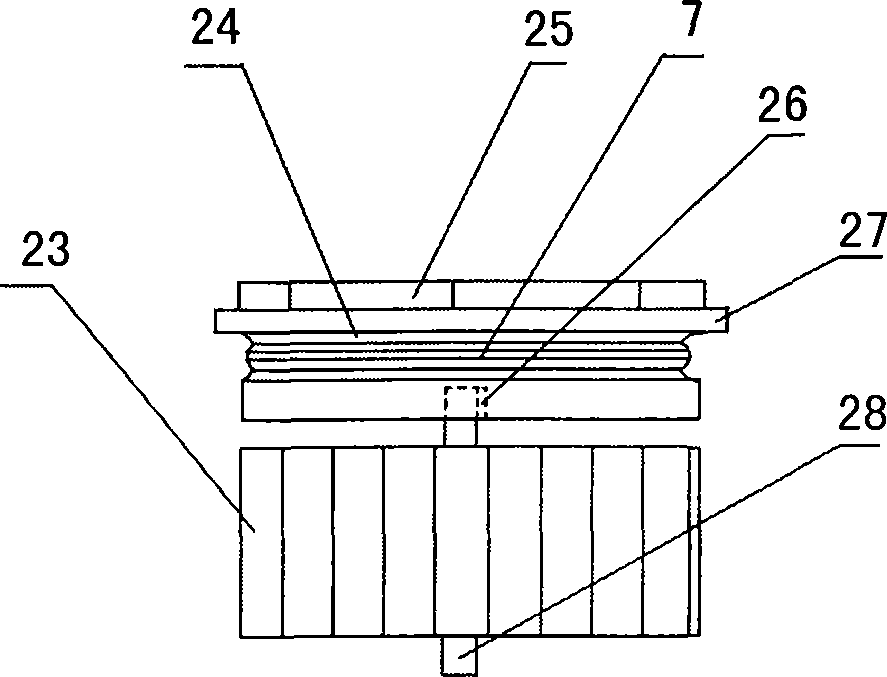

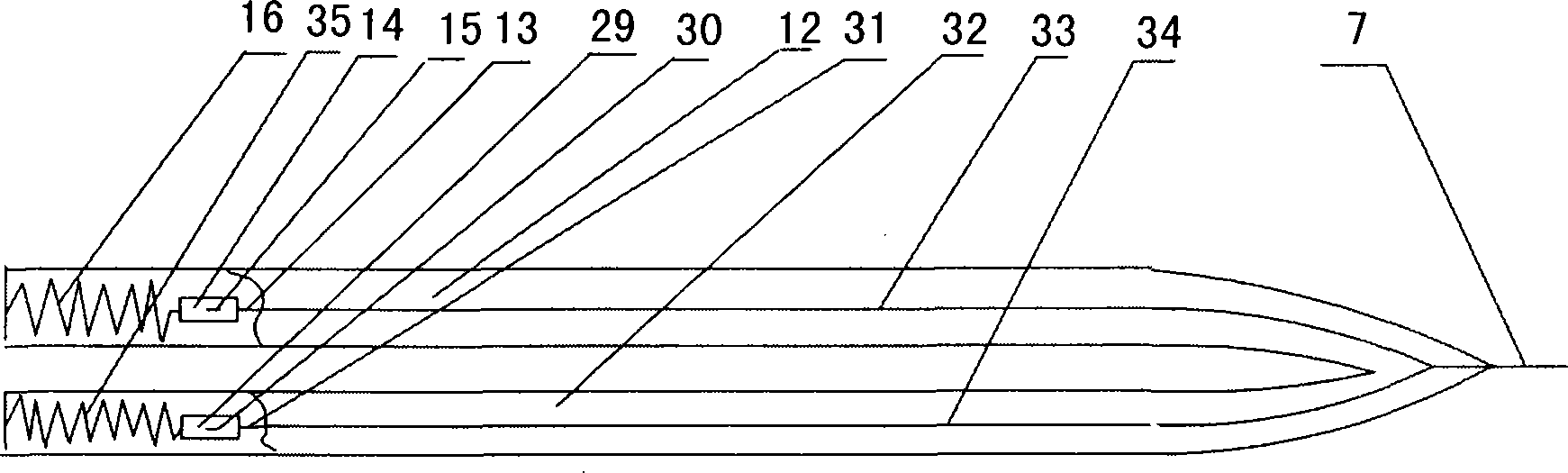

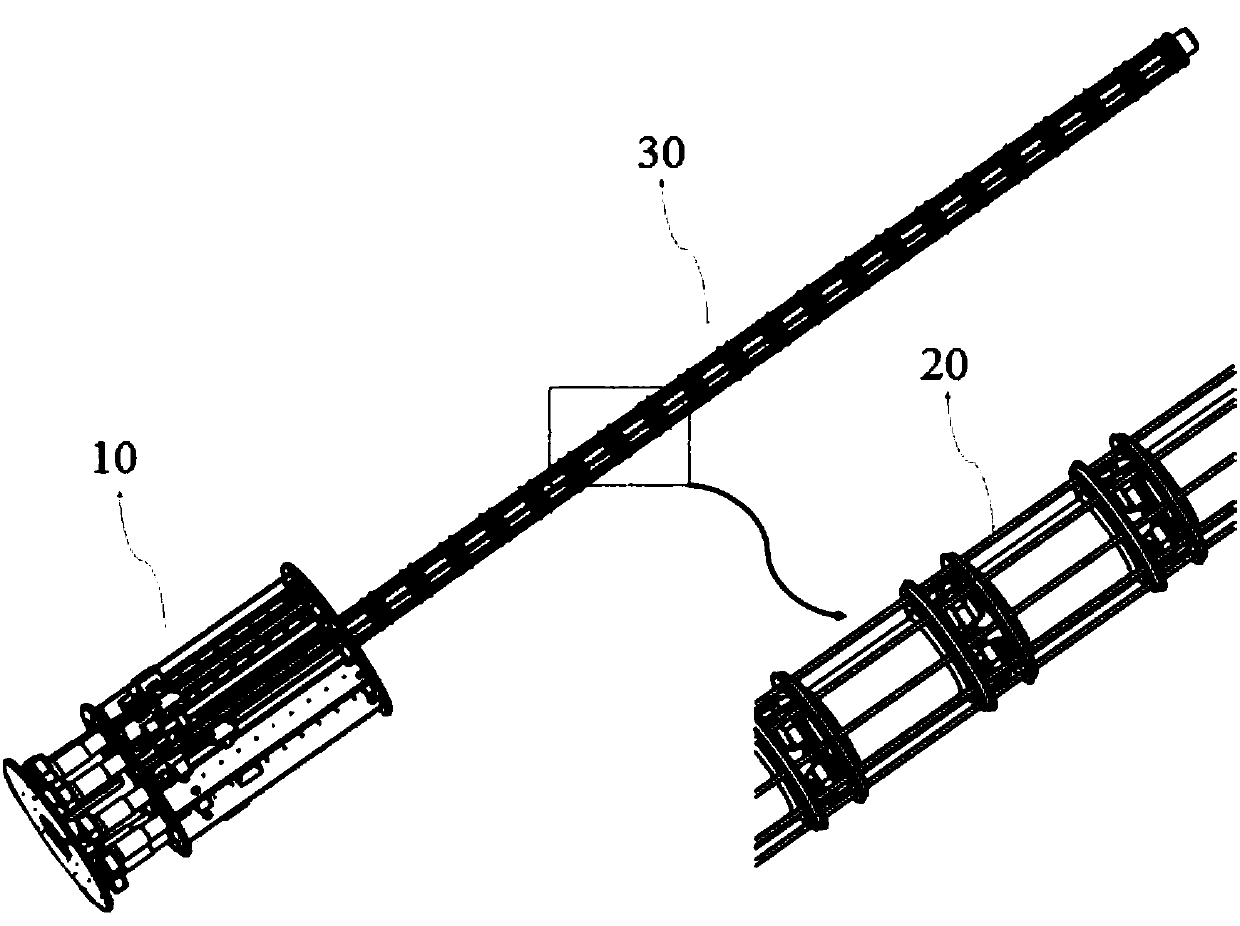

Variable-stiffness continuous type mechanism based on air pressure locking principle

InactiveCN105798896ATo achieve the purpose of lockingQuick responseProgramme-controlled manipulatorVariable stiffnessPositive pressure

The invention relates to a variable-stiffness continuous type mechanism based on an air pressure locking principle. The variable-stiffness continuous type mechanism comprises a continuous type mechanism body, a state switching device used for changing the stiffness and flexibility states of the continuous type mechanism body and a pose control system used for controlling the bending degree of the continuous type mechanism body; the continuous type mechanism body is formed by a base and joints through friction sliding blocks, the base and the joints are connected in series, one end of each joint is provided with a connecting disc with a square shaft hole, and the other end of each joint is provided with a first friction disk provided with a round shaft hole; and each friction sliding block comprises a second friction disk matched with the corresponding first friction disk. The state switching device comprises a cylindrical silica gel air bag, an air guide pipe and a port. The pose control system is composed of steel wires and a driving motor, one end of each steel wire is connected with the joints, and the other end of each steel wire is connected with the driving motor. By means of the variable-stiffness continuous type mechanism, the technologies of positive pressure control and air bag locking are adopted, the continuous type mechanism can be extremely high in stiffness in the locking state, the response speed is high, rigid and flexible state switching is rapid, and the beneficial effects that the stiffness is variable, the response speed is high, and the positioning stiffness is high are achieved.

Owner:TIANJIN UNIV

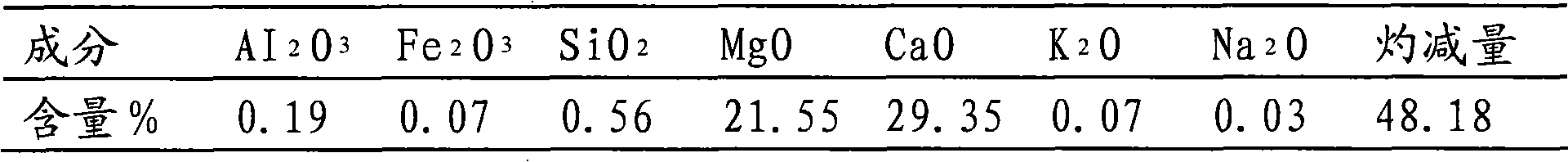

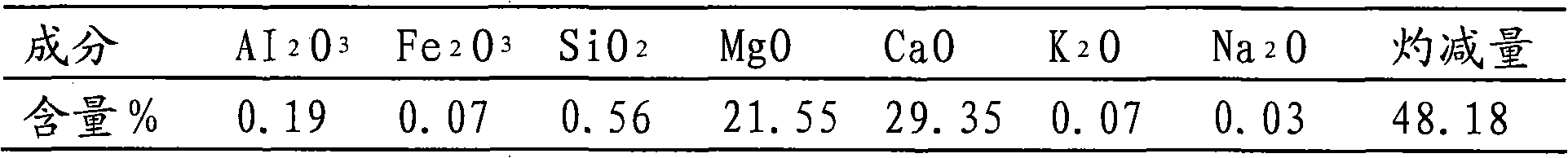

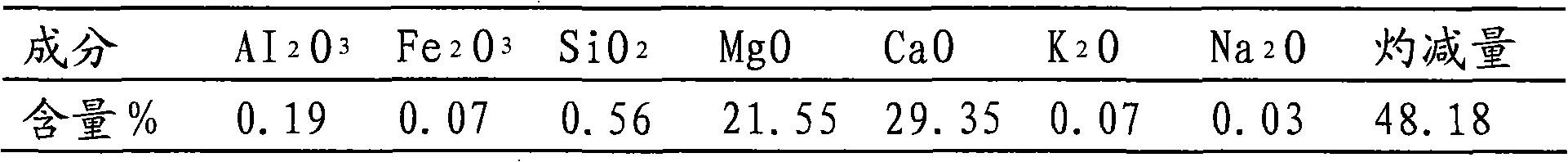

Method for preparing metal magnesium by using dolomite as raw material

The invention discloses a method for preparing metal magnesium by using dolomite as a raw material, and aims to solve the problems of low reducing efficiency, high energy consumption, long production period and serious pollution existing in the conventional method for preparing the metal magnesium. The method comprises the steps: crushing of dolomites, vacuum low-temperature light calcining and recycling of carbon dioxide, cooling and heat recovery, ball-milling of mixed materials, briquetting of mixed materials, vacuum high-temperature hot reduction, separation of magnesium blocks, and utilization of slag, wherein in the vacuum low-temperature light calcining, the crushed dolomites undergo light calcining in a continuous type vacuum calcining furnace for 1 to 3 hours at the calcining temperature of between 500 and 1,000 DEG C and under the furnace pressure of 10,000 to 60,000Pa, MgCO3 and CaCO3 in the dolomites are decomposed in sequence, the reaction expression is: CaMg(CO3)2=CaCO3+MgO+CO2(gas) and CaCO3=CaO+CO2(gas), and the mixture of carbon dioxide and magnesium oxide and calcium oxide is obtained; and the carbon dioxide which flows in the furnace and heats the dolomites is recycled.

Owner:JILIN UNIV

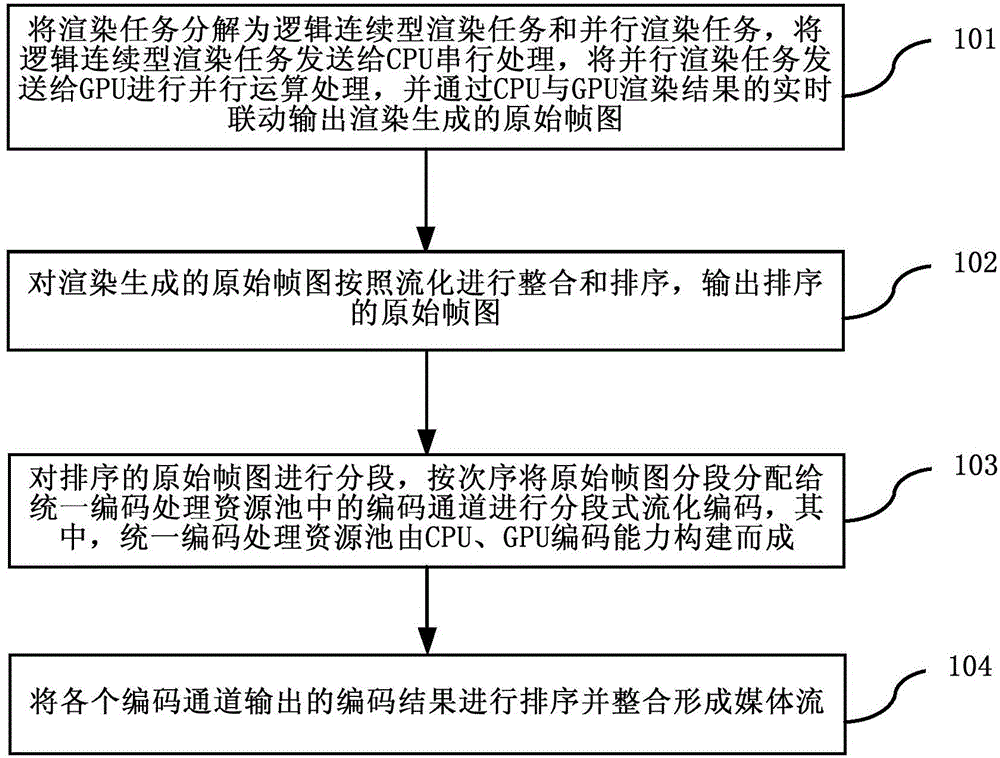

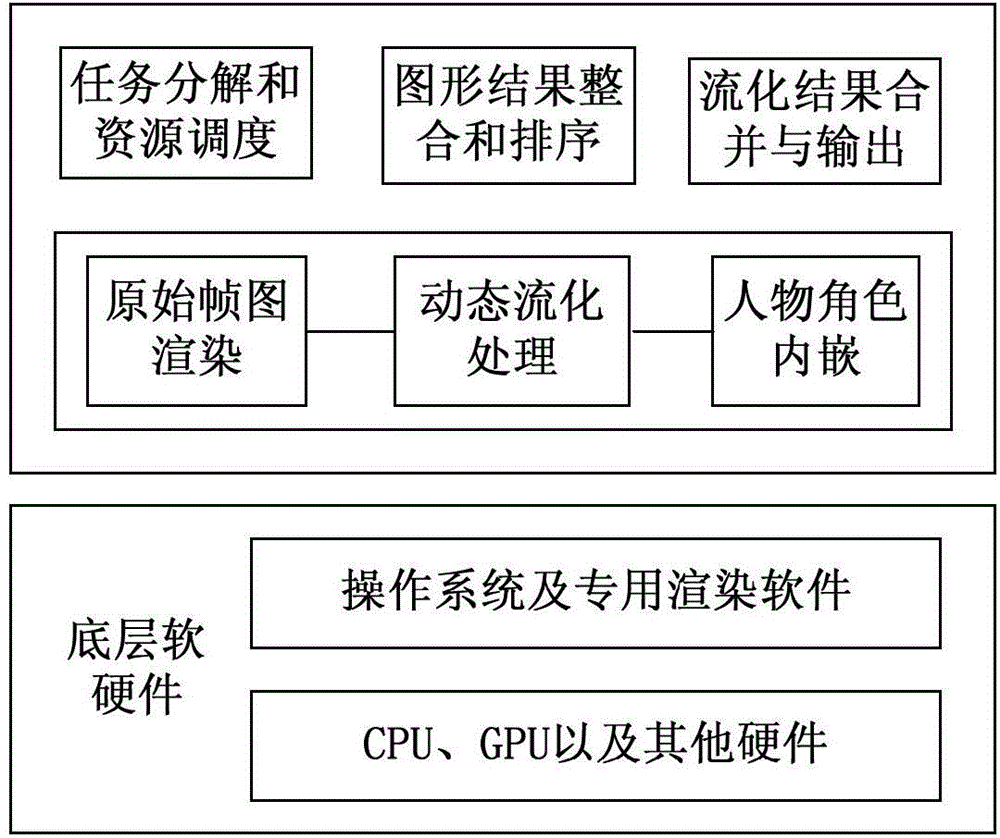

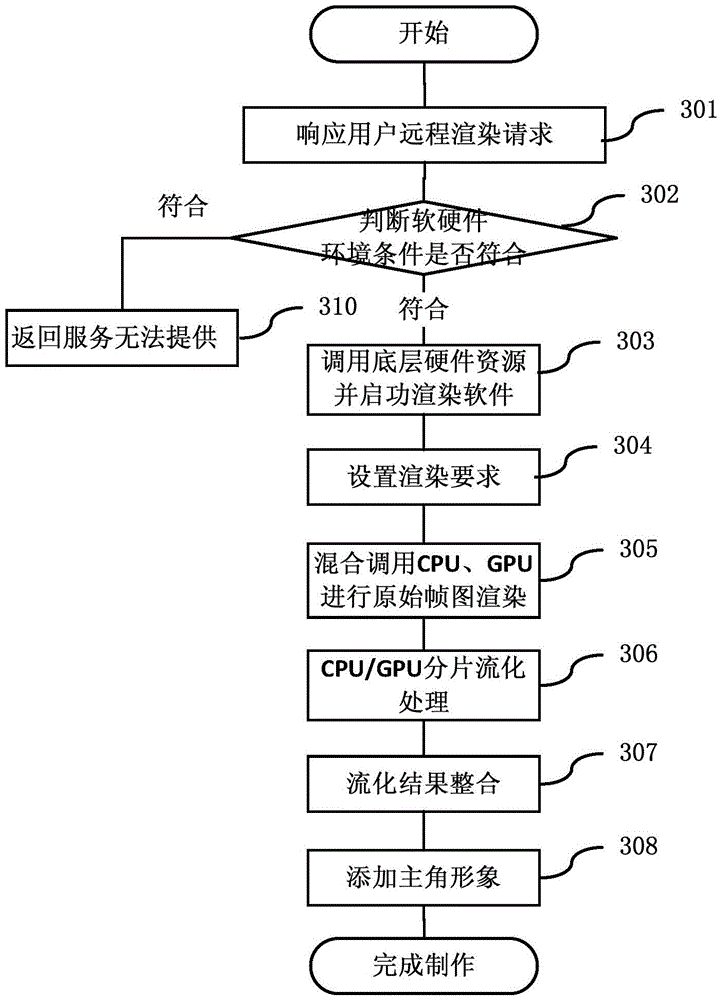

CPU and GPU hybrid cloud rendering method, device and system

ActiveCN104952096AImprove service qualityImprove service capabilitiesAnimationProcessor architectures/configurationQuality of serviceResource pool

The invention discloses a CPU and GPU hybrid cloud rendering method, device and system, and relates to the technical field of cloud computing. According to the method, a rendering task is decomposed into logic continuous type rendering tasks and parallel rendering tasks to be respectively transmitted to a CPU and a GPU to be processed, and original frame graphs are generated by linkage output rendering of the CPU and GPU rendering results; and the ordered original frame graphs are segmented and then allocated to coding channels in a unified coding processing resource pool in turn to perform segmented fluidization coding, and the coding results outputted by all the coding channels are integrated to form a media stream. A mode of CPU and GPU rendering capability integration, combination and focusing of labor division is adopted by the method, the device and the system, and the integrated solution scheme from picture rendering to fluidization is realized via unified segmented fluidization processing through the CPU and the GPU unified coding processing capacity resource pool. Compared with a single CPU and GPU rendering method, service quality and service efficiency can be effectively enhanced by the scheme.

Owner:CHINA TELECOM CORP LTD

Successive type deep tissue stitching instrument

InactiveCN101243985AEasy to operateEasy to replaceSuture equipmentsInternal osteosythesisOtolaryngology/ENTSuturing needle

The invention discloses a continuous deep tissue sutural unit, belonging to surgical medical instrument, which is characterized in comprising a casing, a driving device and a lock thread device; wherein, the casing comprises a lower and an upper parts through locking; the driving device comprises an inner rod, a rack and a central axis; the lock thread device comprises a thread jamming device, a high slide way and a low slide way; the high slide way and the low slide way are arranged in parallel at the front part of the casing and are combined together at the tail end of suture needle. The continuous deep tissue sutural unit can be widely applied in operation suturing upon patients such as surgery and otorhinolaryngology in large-size, middle-size and small-size hospitals and clinics. The continuous deep tissue sutural unit can be used in an endoscope if the sutural unit is made small enough. The continuous deep tissue sutural unit has the advantages of continuous operation, stable operation, convenience and swiftness, safe and easy replacement of vulnerable parts and simple production process.

Owner:田海

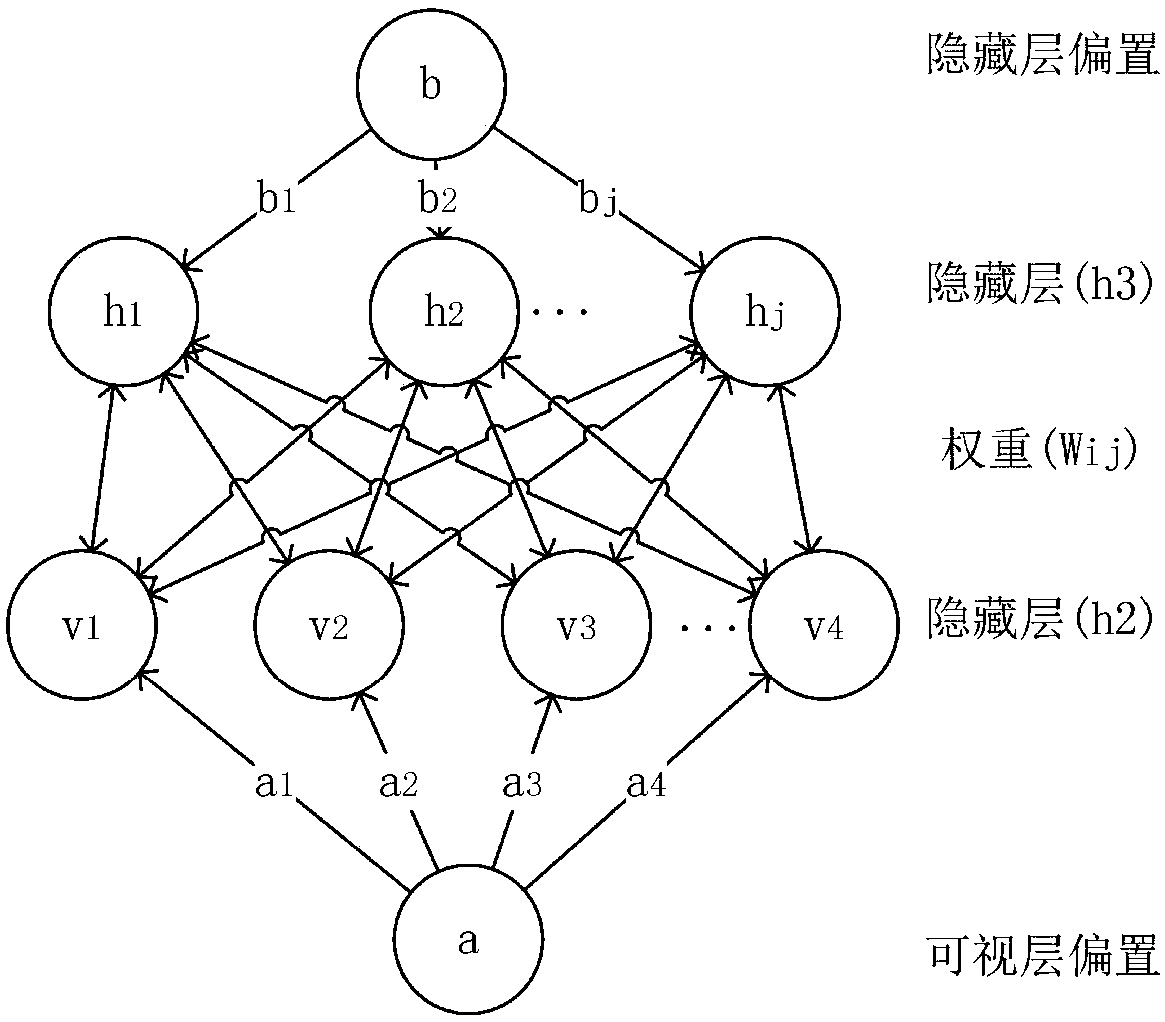

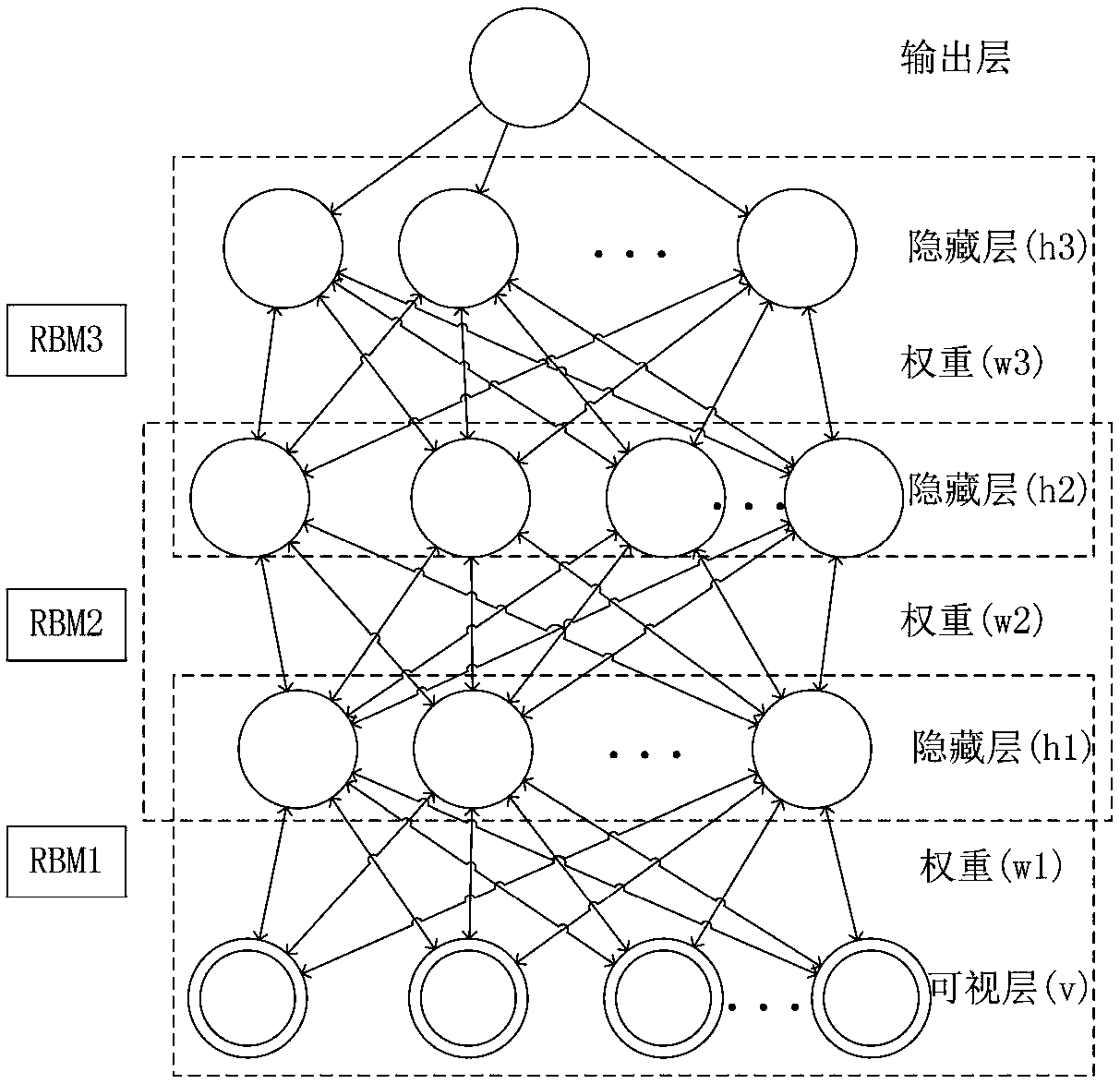

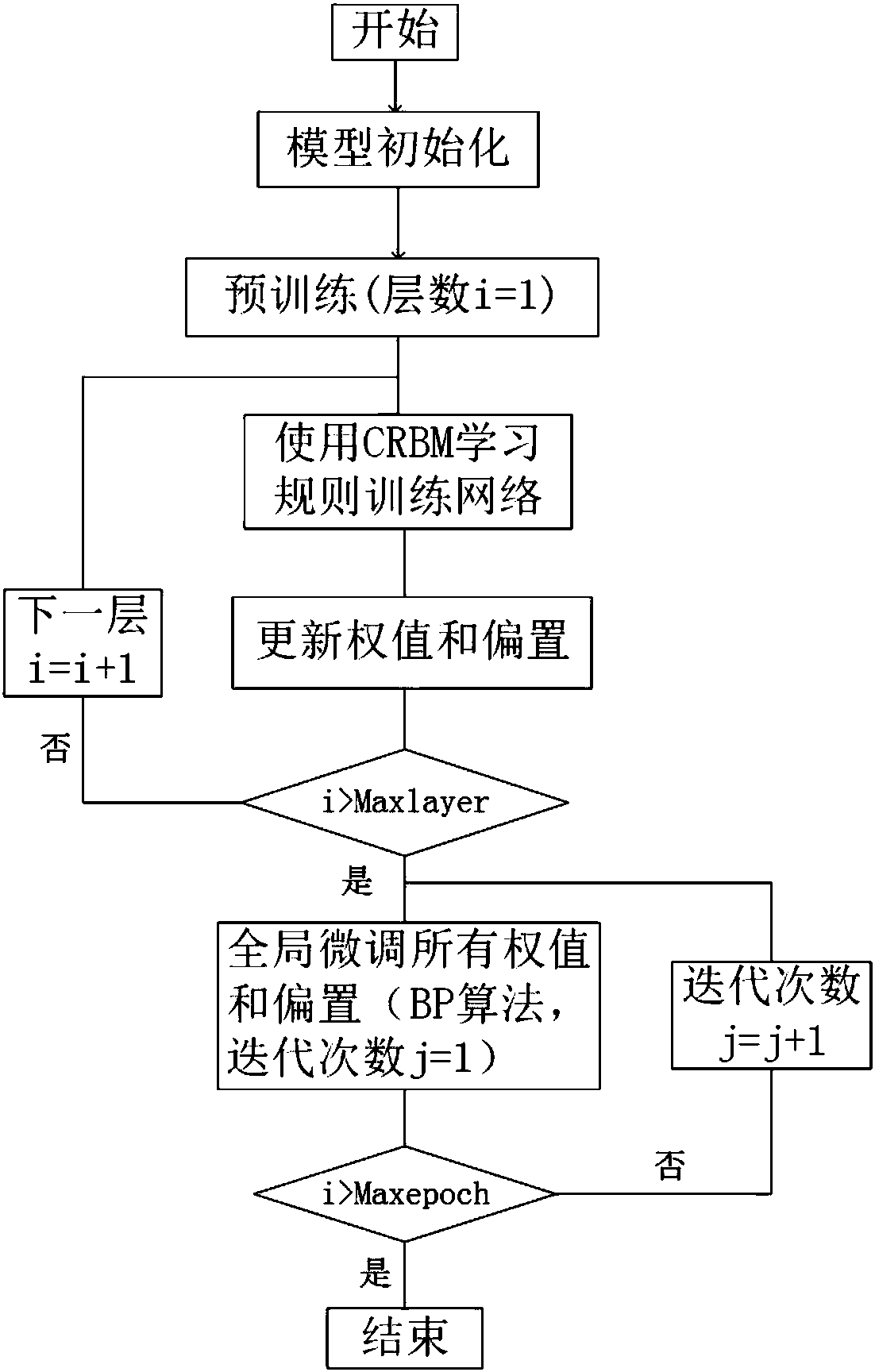

Fan fault detecting method based on depth belief network model

ActiveCN107725283AImplement fault detectionAccurate predictionEngine fuctionsMachines/enginesDeep belief networkSlide window

The invention discloses a fan fault detecting method based on a depth belief network model. The fan fault detecting method comprises that a fan flow forecast model is established by using depth beliefnetwork, state parameters related to the fan flow are selected to be used as the input variable of the model, and the flow of a fan is forecasted. The depth belief network is formed by staking multilayer continuous type limit Boltzmann machines, and an adaptive step length method is used to accelerate the algorithm training process. In addition, residual distribution characteristics are calculated according to a sliding window, when the mean value or standard deviation of the residual exceeds the threshold, alarm is issued. By means of the fan fault detecting method based on the depth beliefnetwork model, the flow of the fan can be accurately forecasted, meanwhile, the abnormal working state of the fan can be detected, and fault detection on the fan is achieved.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

Process for manufacturing bearing ring

The invention discloses a process for manufacturing a bearing ring, which belongs to the technical field of machining. The process comprises the following steps: manufacturing a bar stock, hot forging, annealing, turning, heat treating, grinding, assembling a finished product, and the like. A 3Crl3 material is used so as to meet the requirements on high hardness and wearing resistance of a product, and the convenience of machining the bar stock and the rust proof and anticorrosive performance of the finished product are simultaneously improved. Heat treatment is carried out for the bar stock in a continuous type bright quenching furnace under a vacuum condition, wherein the bar stock is firstly quenched at 1050-1080 DEG C and then is tempered at 600-680 DEG C; and after being tempered, the bar stock is cooled by water. The process greatly improves the hardness control capacity of the bar stock by controlling the quenching temperature, the deformation of the bar stock is improved to 0.0 5mm from 0.2 mm, a good foundation is provided for the machining the bearing ring in a subsequent working procedure, the stability of an interior tissue of the baring ring is guaranteed, the brittleness is reduced and the service life is prolonged.

Owner:嵊州市美亚特种轴承厂

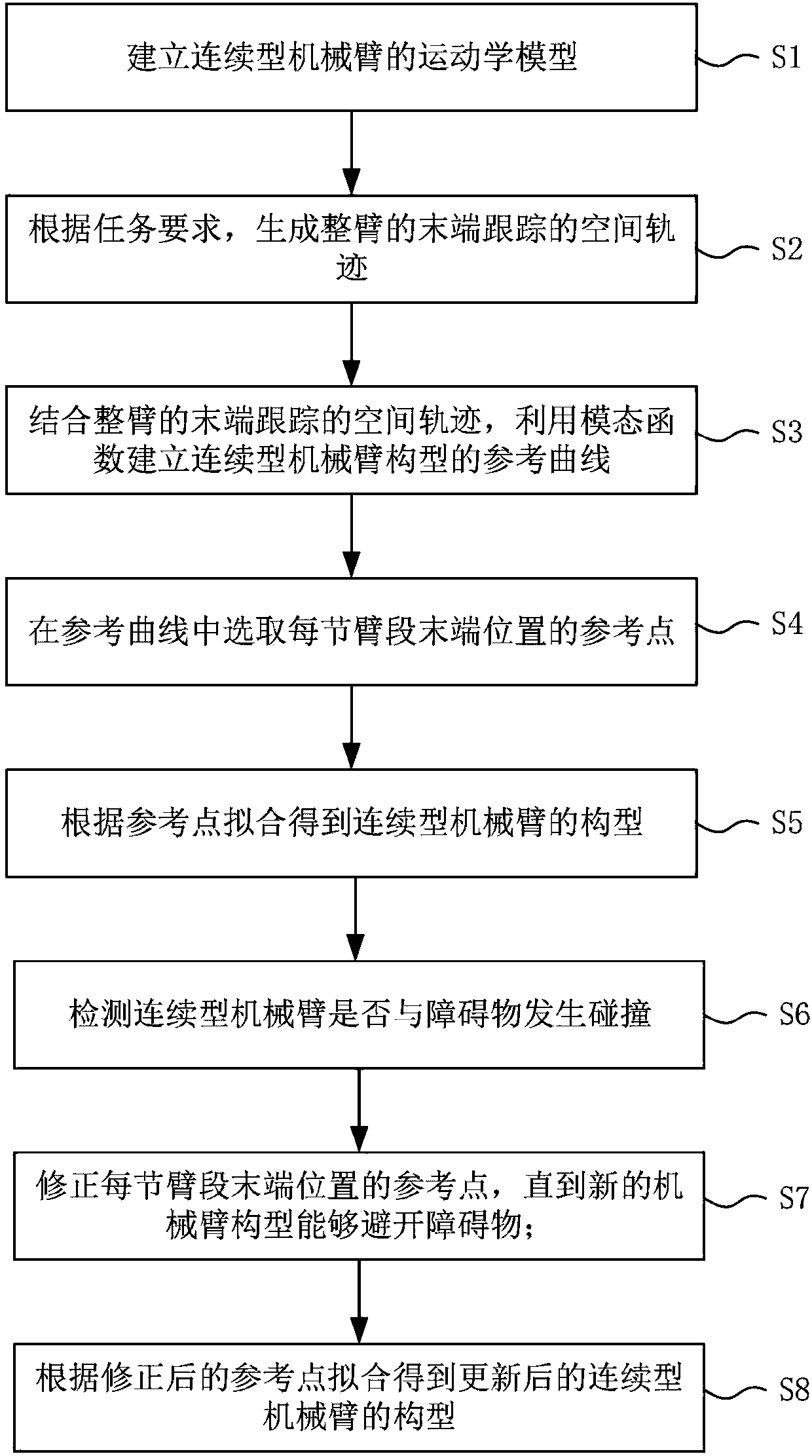

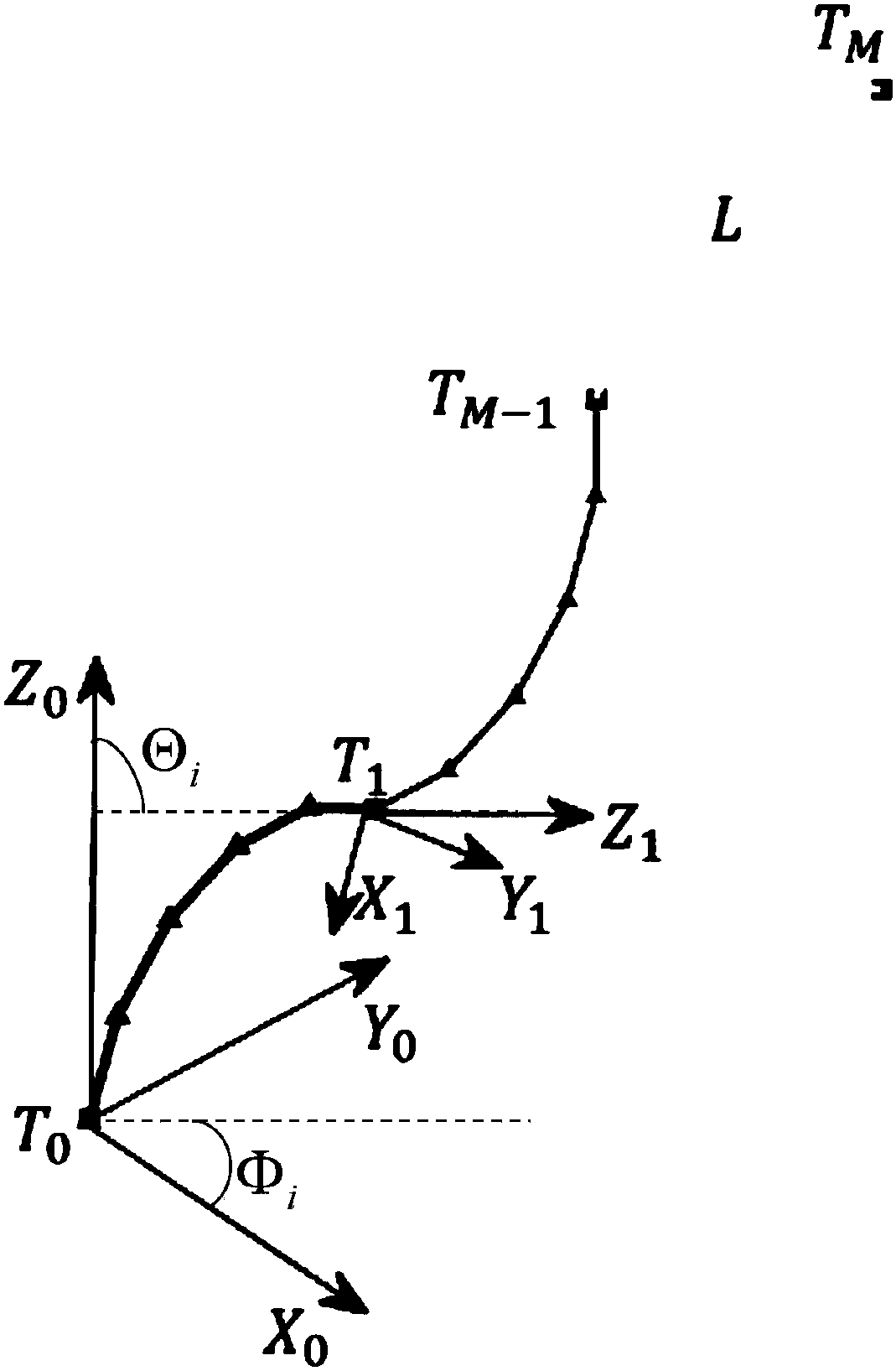

Continuous mechanical-arm space obstacle avoidance trajectory planning method

ActiveCN108237534AEasy to controlSimple algorithmProgramme-controlled manipulatorEngineeringObstacle avoidance

The invention discloses a continuous mechanical-arm space obstacle avoidance trajectory planning method. The continuous mechanical-arm space obstacle avoidance trajectory planning method comprises thefollowing steps that a kinematic model of a continuous mechanical arm is established, tail end space trajectories are generated according to task requirements, a space reference curve of mechanical-arm configuration is established utilizing a modal function, the tail end of the mechanical arm can be made to reach a desired position, the mechanical-arm configuration is fitted with the space reference curve according to deformation characteristics of a single section mechanical arm, the single section arm segment configuration is calculated according to reference fitting points, whether the continuous mechanical arm collides with an obstacle or not is detected, the mechanical-arm configuration is adjusted according to the obstacle avoidance strategy, and obstacle avoidance is realized. By means of the continuous mechanical-arm space obstacle avoidance trajectory planning method provided by the invention, the continuous mechanical-arm space obstacle avoidance trajectory planning can be realized.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

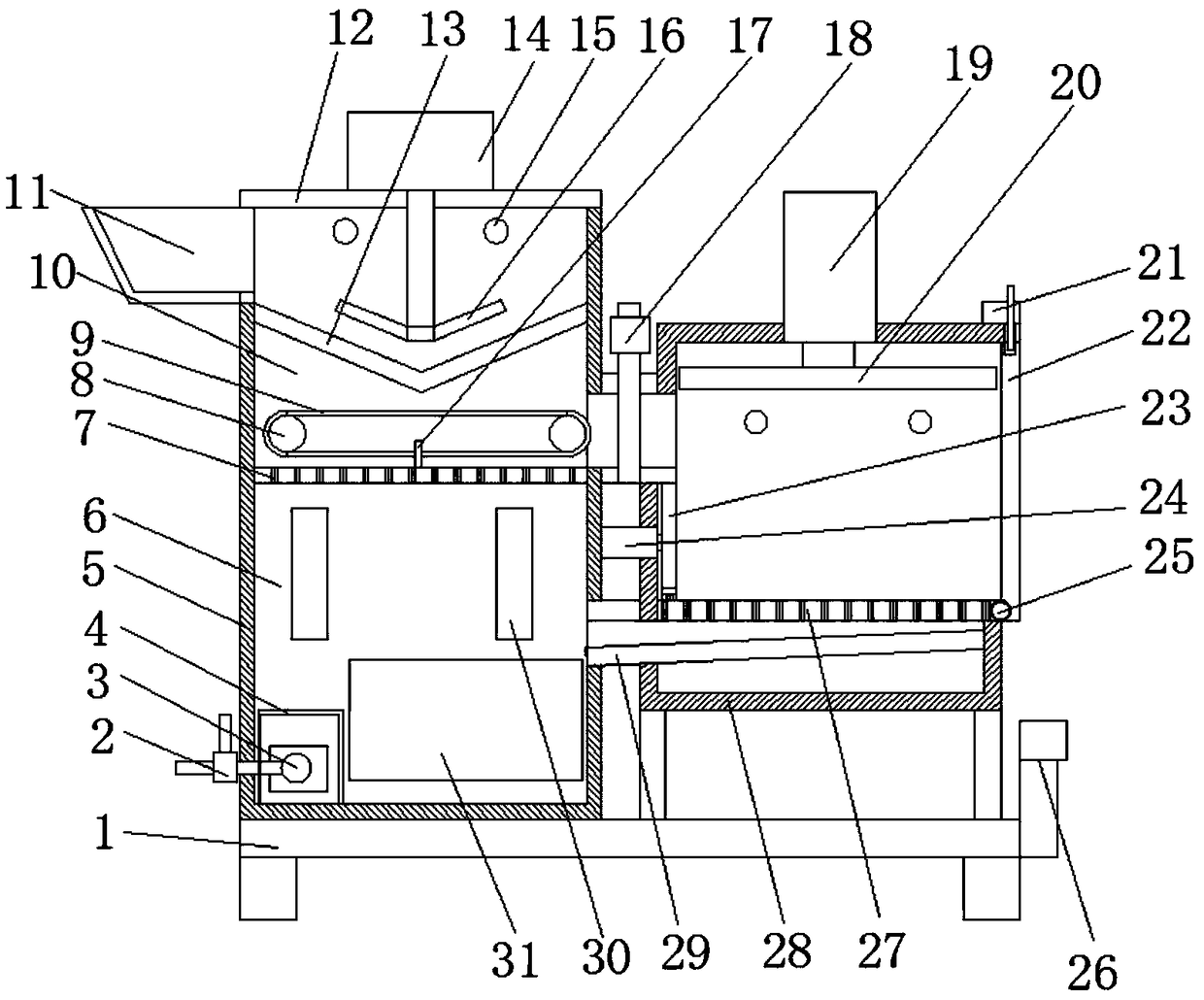

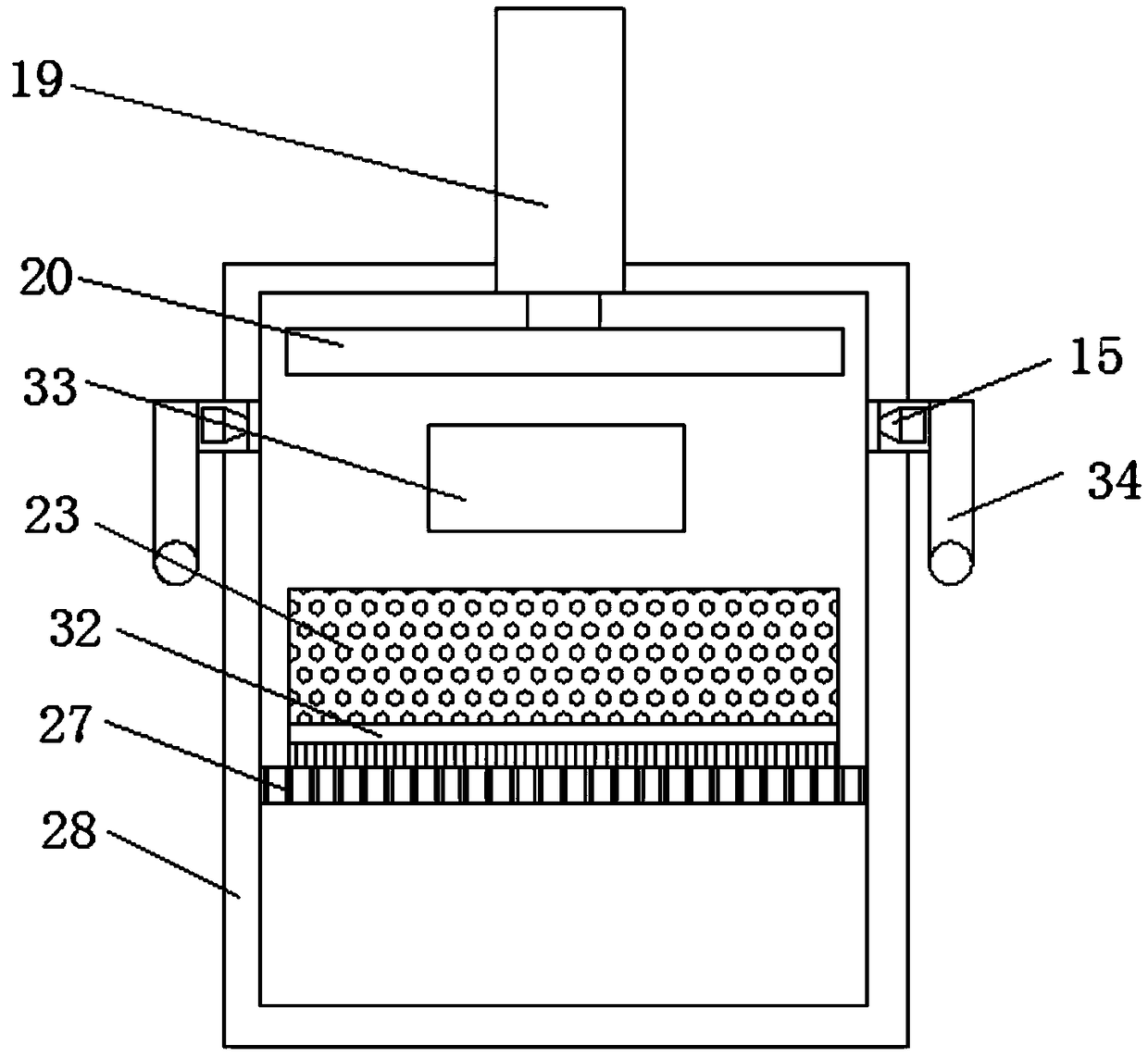

Continuous type transmission sludge burning caking furnace

The invention discloses a continuous type transmission sludge burning caking furnace which comprises a feeding device, a transmission wire belt, a furnace body system, a sideward discharging connecting wire belt and a wire belt naturally extending ditch. The feeding device comprises a support, a feeding machine and a feeding guide roller. The furnace body system comprises a preheating chamber, a heating chamber and a steam chamber. A preheating roller and a sideward discharging connecting wire belt driving roller are arranged inside the preheating chamber. A burner nozzle and a heatproof carrier roller are arranged inside the heat chamber. A transmission roller, a tensioning roller and a carrier roller are arranged inside the steam chamber. A driving roller and a support roller are arranged inside the wire belt naturally extending ditch. The transmission wire belt twines the feeding machine, the feeding guide roller, the preheating roller, the transmission roller and the tensioning roller and penetrates the heating chamber in the middle. The sideward discharging connecting wire belt twines the sideward discharging connecting wire belt transmission roller, the heatproof carrier roller, the driving roller and the support roller and penetrates the heating chamber and the steam chamber in the middle. High temperature smoke produced after burning is transmitted to the preheating chamber so that wet sludge is heated and then dried, waste heat is used, energy is saved and burning effect is good.

Owner:苏州瑞翔三禾科技有限公司

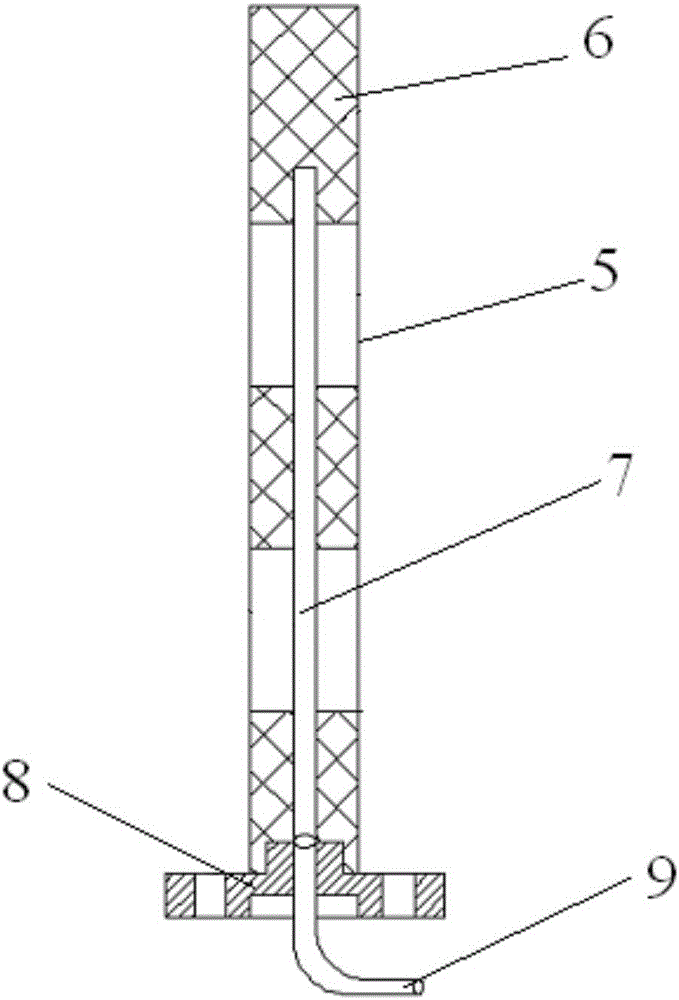

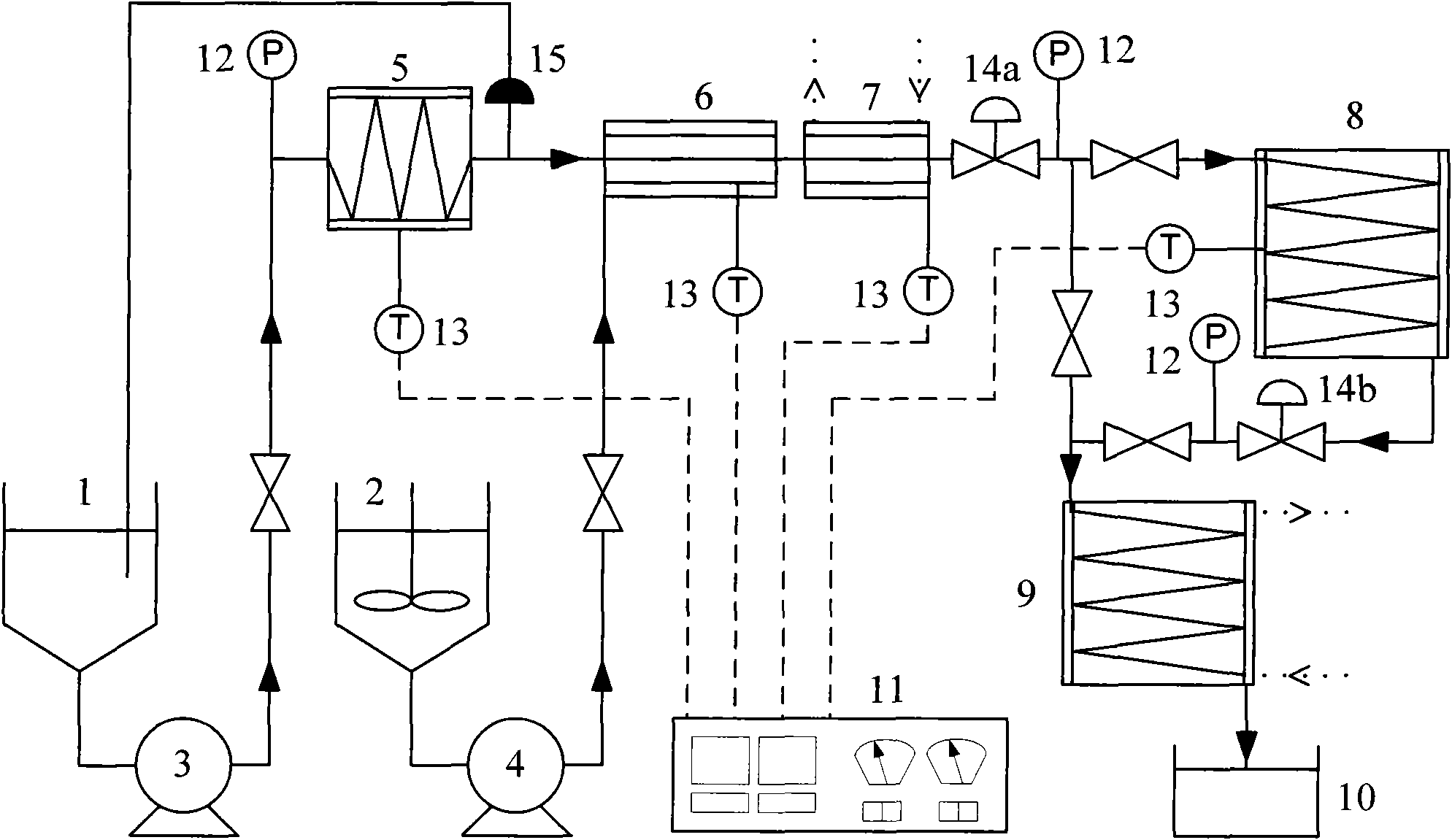

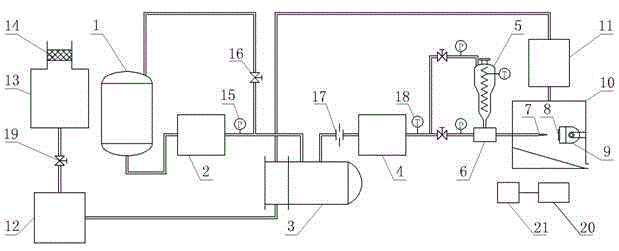

Biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and method

InactiveCN101613377AAchieving processing powerAchieve hydrolysis conversionSugar derivativesSugar derivatives preparationFiberElectronic temperature

The invention relates to biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and a method. The equipment comprises a water storage tank, a material storage tank with a stirring device, a preheating system, a supercritical reaction system, a primary cooling system, a subcritical reaction system, a final cooling system, a product collection system and an electronic temperature controlling system. The method comprises the following processing steps: water reaching preheat temperature and biomass material paste are rapidly mixed and then injected into the supercritical reaction system to be pretreated under supercritical condition; the reaction product is cooled through the primary cooling system and depressurized through a pressure reducing valve and then enters into the subcritical reaction system to be hydrolyzed sequentially, therefore fermentable sugars are continuously generated and collected. The invention utilizes the advantages of the supercritical method that the reaction is rapid, activator is not required and product inhibition does not exit, realizes that the continuous hydrolysis conversion of wood fiber biomass can generate fermentable sugars, is the foundation of subsequent resource recovery technologies, such as ethanol production by fermentation and the like, and has wide application prospect.

Owner:TSINGHUA UNIV

Waste recovery device facilitating unloading for processing of agricultural and sideline products

PendingCN109078956AEasy to recycleImprove recycling efficiencySolid waste disposalGrain treatmentsSlagEngineering

The invention belongs to the technical field of agricultural and sideline product processing, and particularly relates to a waste recovery device facilitating unloading for processing of agriculturaland sideline products. Aiming at the problems that when an existing waste recovery device is used, unloading is inconvenient, and consequently, the waste recovery efficiency is low, the following scheme is put forwards, specifically, the waste recovery device comprises a base; a first box is connected to one side of the top of the base through bolts, and a second box is connected to the other sideof the top of the base through bolts; and a communicating pipe of a rectangular structure is connected to the top of the junction of the second box and the first box through a flange. According to the waste recovery device facilitating unloading for processing of the agricultural and sideline products, initial separation of solid and liquid is completed, juice in a juice accumulating cavity is conveyed and recovered through a conveying pump, slag liquid is separated and recovered, recycling of waste is facilitated, and the recovering efficiency is improved; and a linear electric pushing rod and a pushing plate are utilized to slidably push caky residues into an unloading trolley along a sealing plate, thus unloading of the waste recovery device is easy and convenient, and the waste recovery efficiency is high through continuous operation.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Rolling method of dual-phase stainless steel hot continuous rolled coil

ActiveCN101648211ASolve edge crackSolve problems such as uncoiling breakageTemperature control deviceFurnace typesFurnace temperatureAcid washing

The invention relates to a rolling method of a dual-phase stainless steel hot continuous rolled coil, which comprises the following steps: I, grinding a casting blank, i.e. grinding the outer surfaceof the casting blank without macroscopic defects on the surface after the grinding; II, heating, i.e. heating with hot furnace temperature of 1200-1280 DEG C and furnace halting time of 180mm thick casting blank of 220-260min and 200 thick casting blank of 240-280min; III, rough rolling, i.e. placing the casting blank with the temperature is 1100-1150 DEG C before the rolling into a reversible type rolling mill to be rolled into a plate blank finished product with the thickness of 34-40mm; IV, finish rolling, i.e. placing the plate blank to a finishing mill group to be rolled with final rolling temperature higher than or equal to 950 DEG C into a coil finished product with the thickness of 4-12mm; V, rolling, i.e. placing the coil into a laminar flow to be cooled after the finish rolling,and ensuring rolling temperature to be 750-800 DEG C; VI, performing heat treatment on the coil, i.e. placing the coil into a continuous type heating furnace to be subjected to the heat treatment withheat treatment plate temperature of 1020-1100 DEG C, and water-cooling the coil after the coil is taken out of the continuous type heating furnace, wherein the temperature of the coil is generally lower than or equal to 100 DEG C after the coil is cooled; and VII, acid-washing the coil. The rolling method of the dual-phase stainless steel hot continuous rolled coil prevents the detects of the edge cracking, the decoiling and the fracture of the hot continuous rolled coil.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

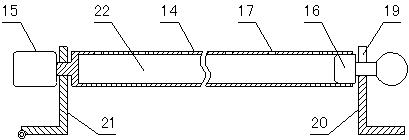

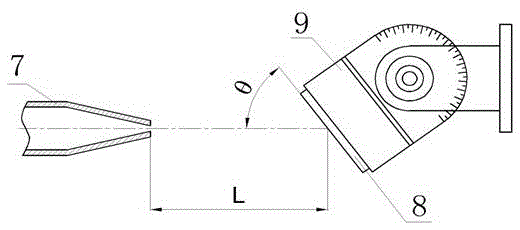

Continuous type high-temperature and high-speed gas-solid two-phase flow erosion abrasion test device

ActiveCN105628531AExtended service lifeRecovery conditionInvestigating abrasion/wear resistanceChemical industryTwo temperature

The invention discloses a continuous type high-temperature and high-speed gas-solid two-phase flow erosion abrasion test device. The device comprises a dehumidifier, an air compressor, an air heat exchanger, a heater, a storage tank, a mixing chamber, a nozzle, an experiment bench, an experiment box, a cyclone separator, an air cooler, a pond, a demister, three pressure gages, three ball valves, a flow gauge, two temperature gauges, a check valve, a high-speed camera and a computer. The continuous type high-temperature and high-speed gas-solid two-phase flow erosion abrasion test device is used for researching weight loss laws of the material under different influence factors in the presence of high-temperature and high-speed gas-solid two-phase flow erosion effect in the harsh working condition; the high-speed camera is used for observing and recording motion tracks of particle impact specimens; the erosion abrasion laws of the material under the different working conditions can be obtained by combining theoretical analysis with experiment data; the high-temperature erosion abrasion model is built; the high-temperature and high-speed gas-solid two-phase flow erosion abrasion mechanism and influence factors thereof are disclosed; a theoretical basis can be provided for material selection and structure optimization of pipelines and valves of the coal chemical industry and the petroleum chemical industry; the service life of the equipment is prolonged.

Owner:嘉兴市燕知网络科技有限公司

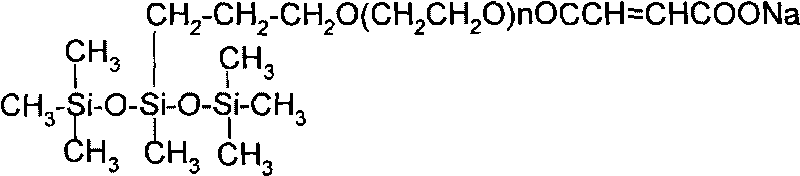

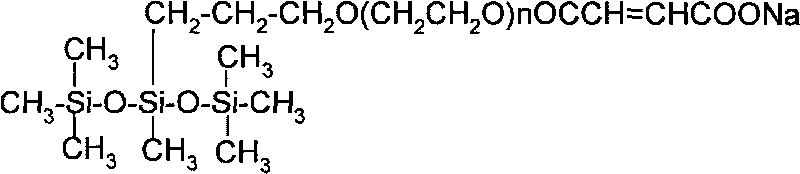

Polymer emulsion and preparation method thereof

The invention discloses polymer emulsion and a preparation method thereof. The polymer emulsion is characterized by using hard monomer, soft monomer and crylic acid as polymer monomers, using crylic acid long-chain alkyl ester as modified monomer, using polymerizable organosilicon emulsifier PMSC as the emulsifier of the system and using thermal decomposition initiator as the initiator to obtain high-performance polymer emulsion by semi-continuous type emulsion copolymerization. The polymer emulsion obtained by the method has favorable waterproofness, water resistance, weather resistance, adhesiveness and film coating effect, and can be widely used as paint, adhesive, fabric waterproof agent, and the like, thereby having bright development potential.

Owner:NANJING UNIV OF TECH

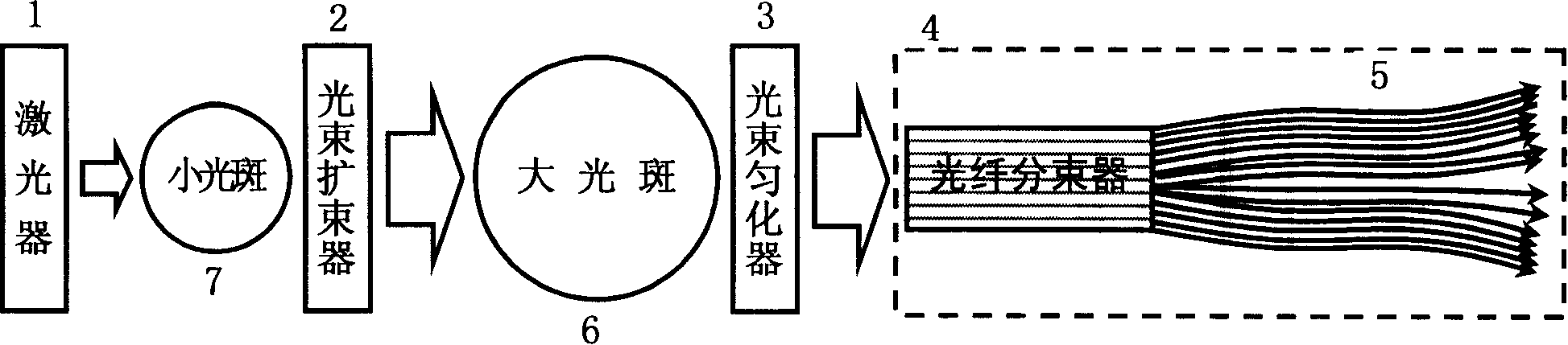

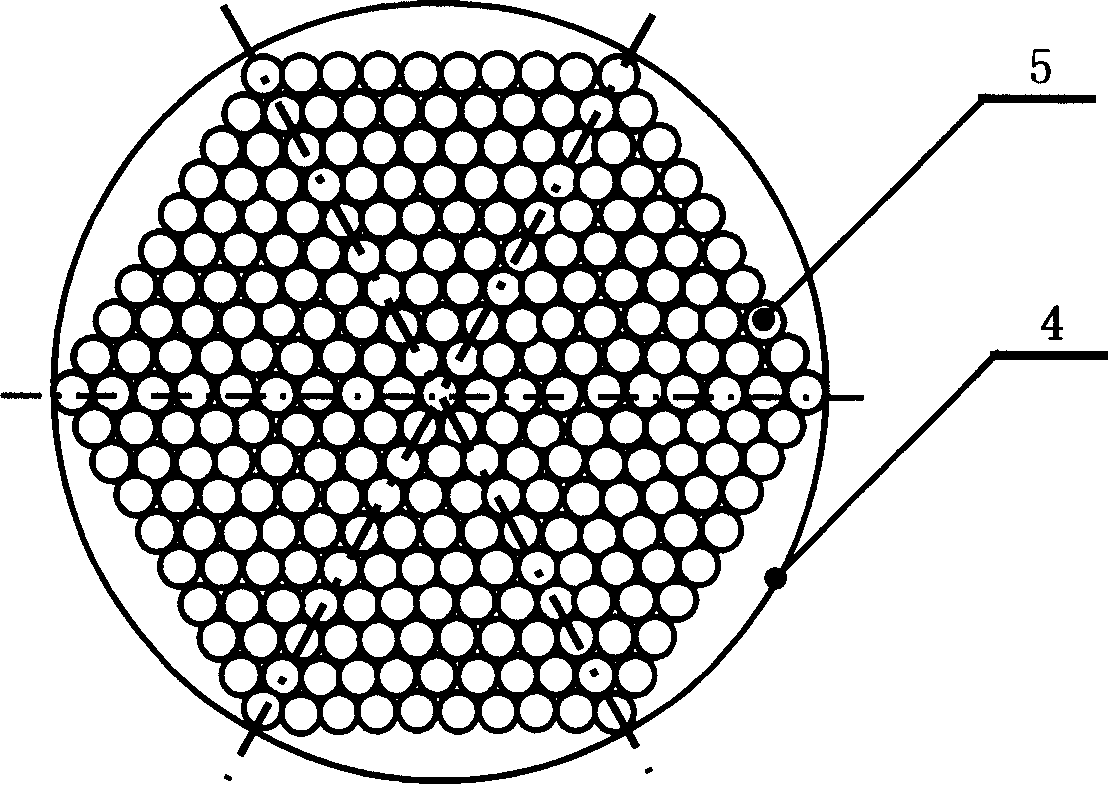

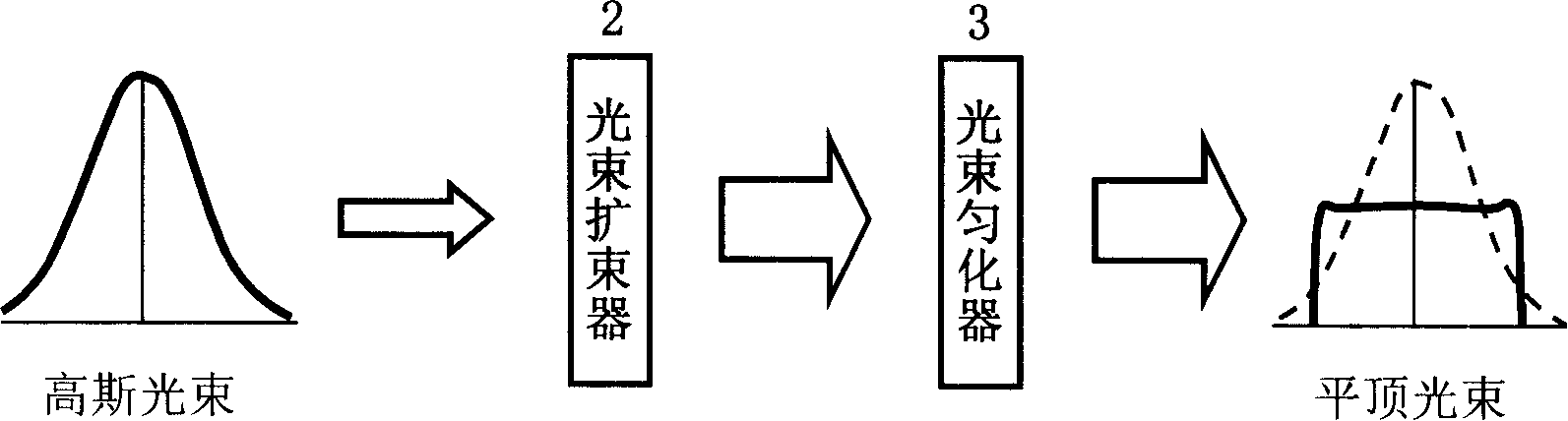

Large power multipath gauss laser beam optical fibre light splitting method and its equipment

InactiveCN101191971AUniform light distributionSave energyCoupling light guidesBundled fibre light guideBeam splitterHigh power lasers

The present invention expands the beams of gaussian distribution laser beams output by a laser through a light beam expander, then uses a light beam homogenizer to convert the laser beams with spatial energy in gaussian distribution into the laser beams with spatial energy in flat top distribution, and finally uses optical fiber beam splitters to execute multi-channel light distribution to homogenized laser. Adjusting the optical fiber length of each optical fiber beam splitter can control the phase output by each laser beam, so as to make the output laser beams inphase and synchronous. The present invention solves the technical problems that the prior art is huge in volume, high in cost, less in light path numbers, inconvenient to guide light beam direction, short in transmission distance and inapplicable to high-power laser occasions. The present invention is uniform in light distribution, optional in laser output positions, flexible and convenient to use, and capable of realizing hundreds or thousands of channels of the output phase uniform in energy or the laser output with fixed phase delay. The present invention can be used for high-power laser continuous type and pulse type laser light beam distribution and combination, and is especially applicable to the fields such as national defense electronic countermeasure and target recognition.

Owner:XIAN MICROMACH TECH CO LTD

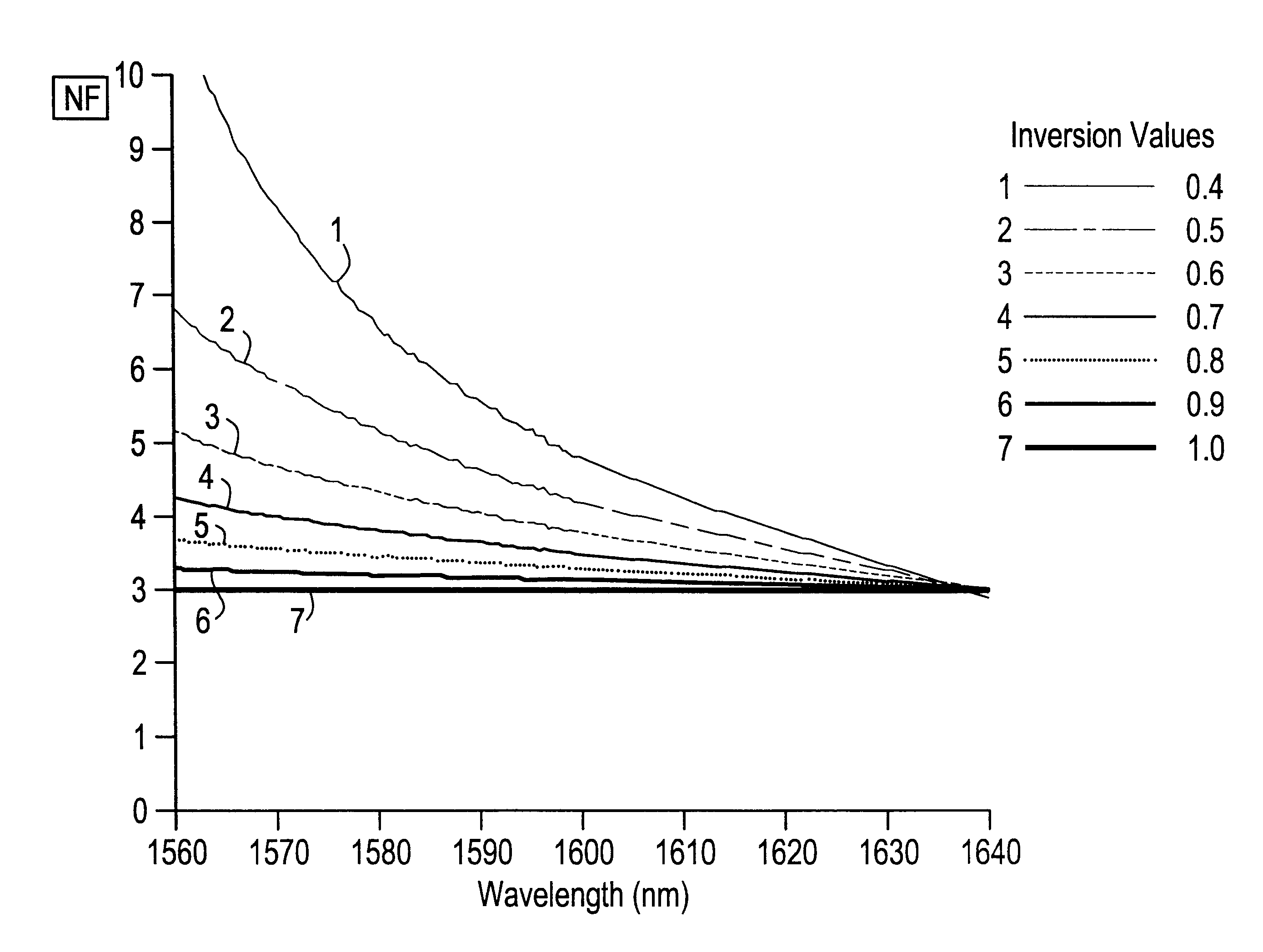

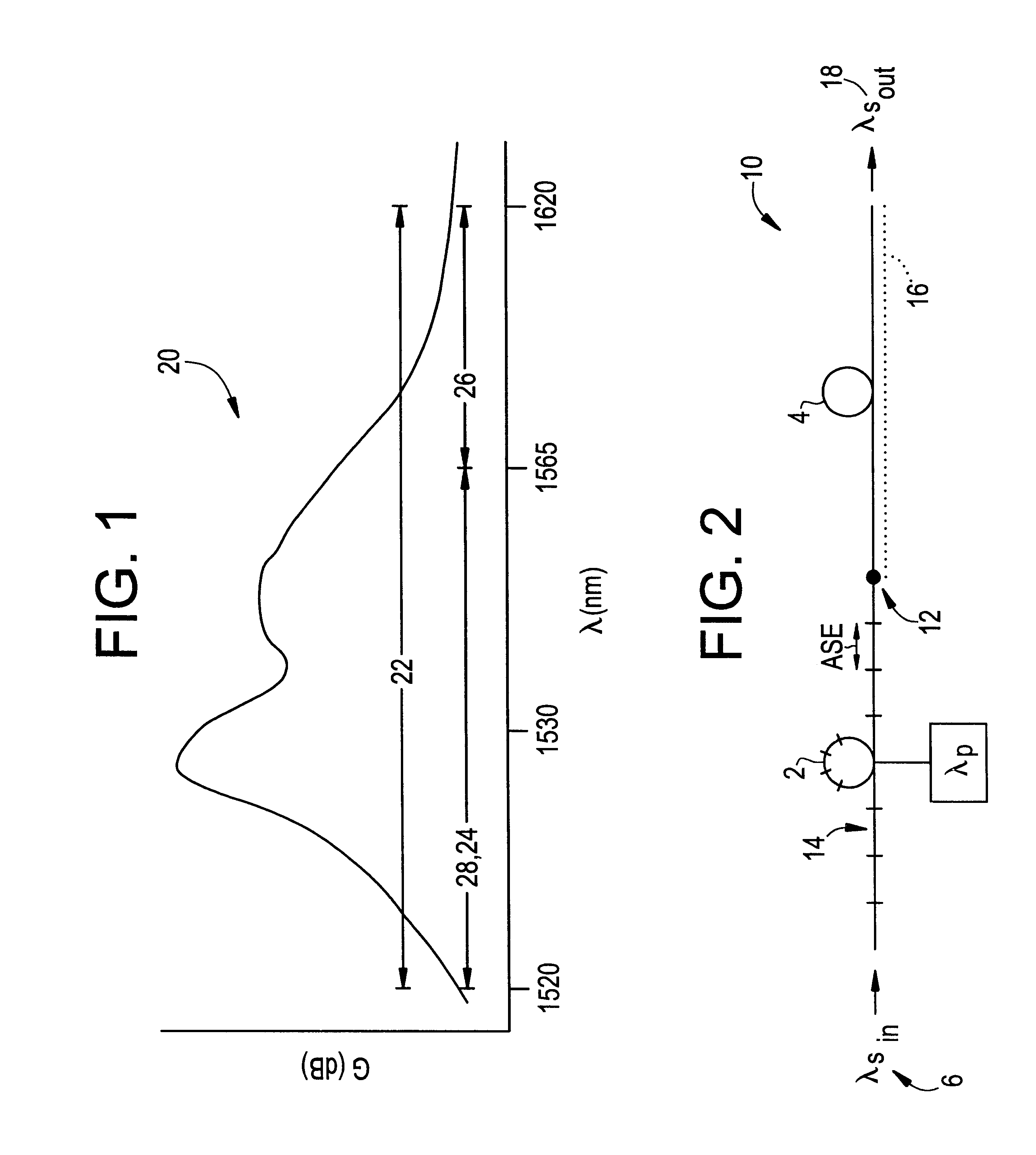

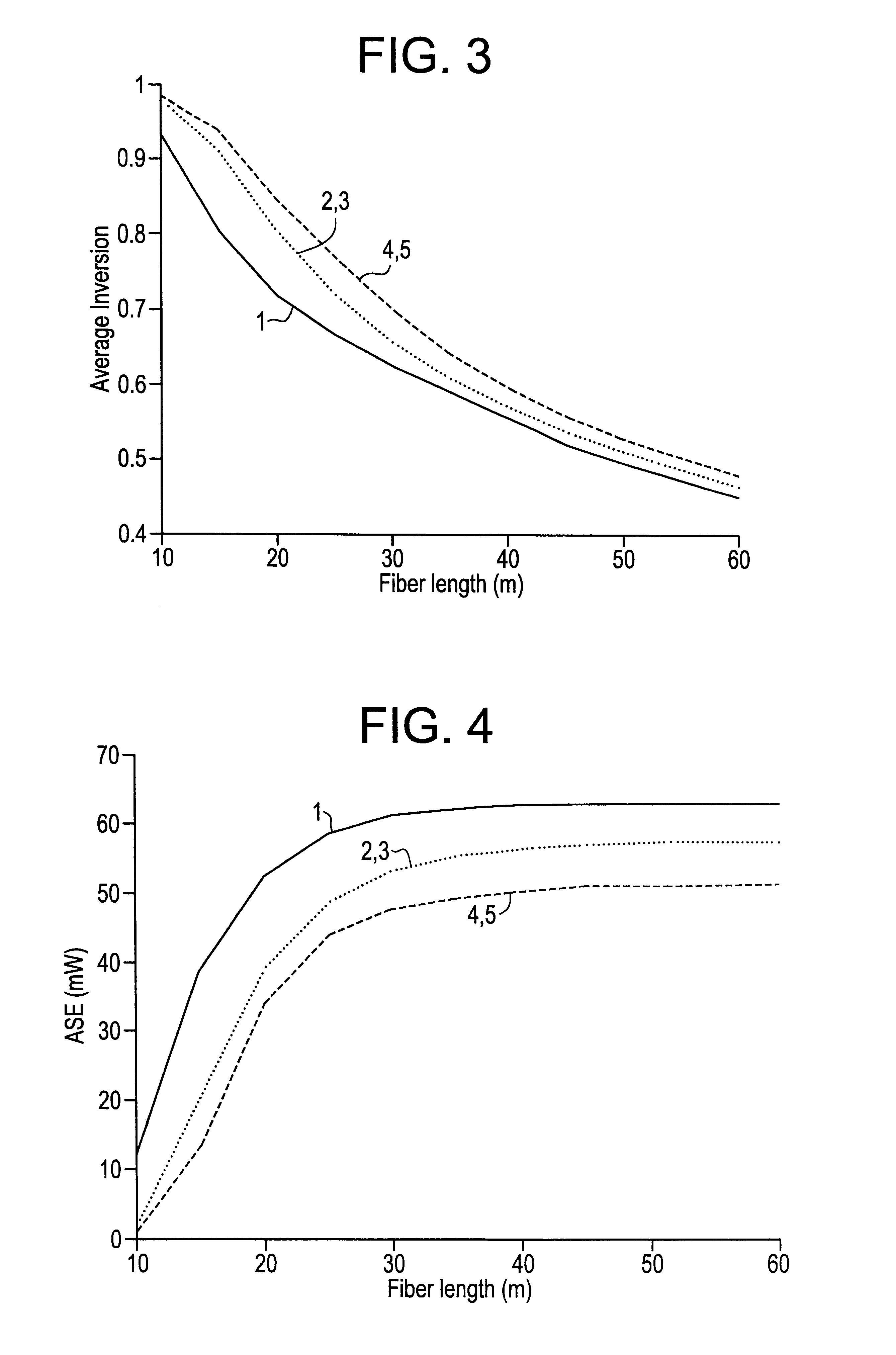

L band amplifier with distributed filtering

InactiveUS6459526B1Improve performanceEliminates the out-of-band ASE generatedActive medium materialFibre transmissionFiberAudio power amplifier

An L-band optical amplifier has a rare earth doped gain medium including a filter distributed over a finite physical portion of the gain medium. The filter is distributed over between about 25% to substantially the entire length of the gain medium. The distributed filter substantially eliminates out-of-band light emission (C-band ASE, 1520 nm-1565 nm) and thus improves the performance of L-band amplification (1565 nm-1620 nm). Examples of distributed filters include discrete type filters such as long period gratings, or continuous type filters such as rare earth doped, twin core fibers, non-adiabatically tapered fibers and coaxial resonant ring fibers.

Owner:II VI DELAWARE INC

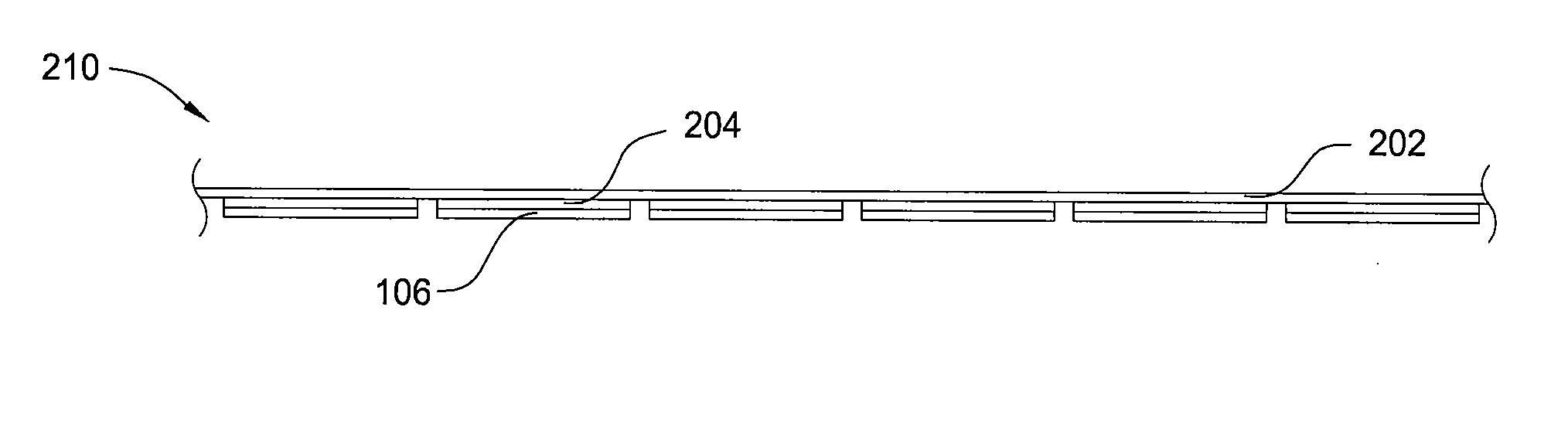

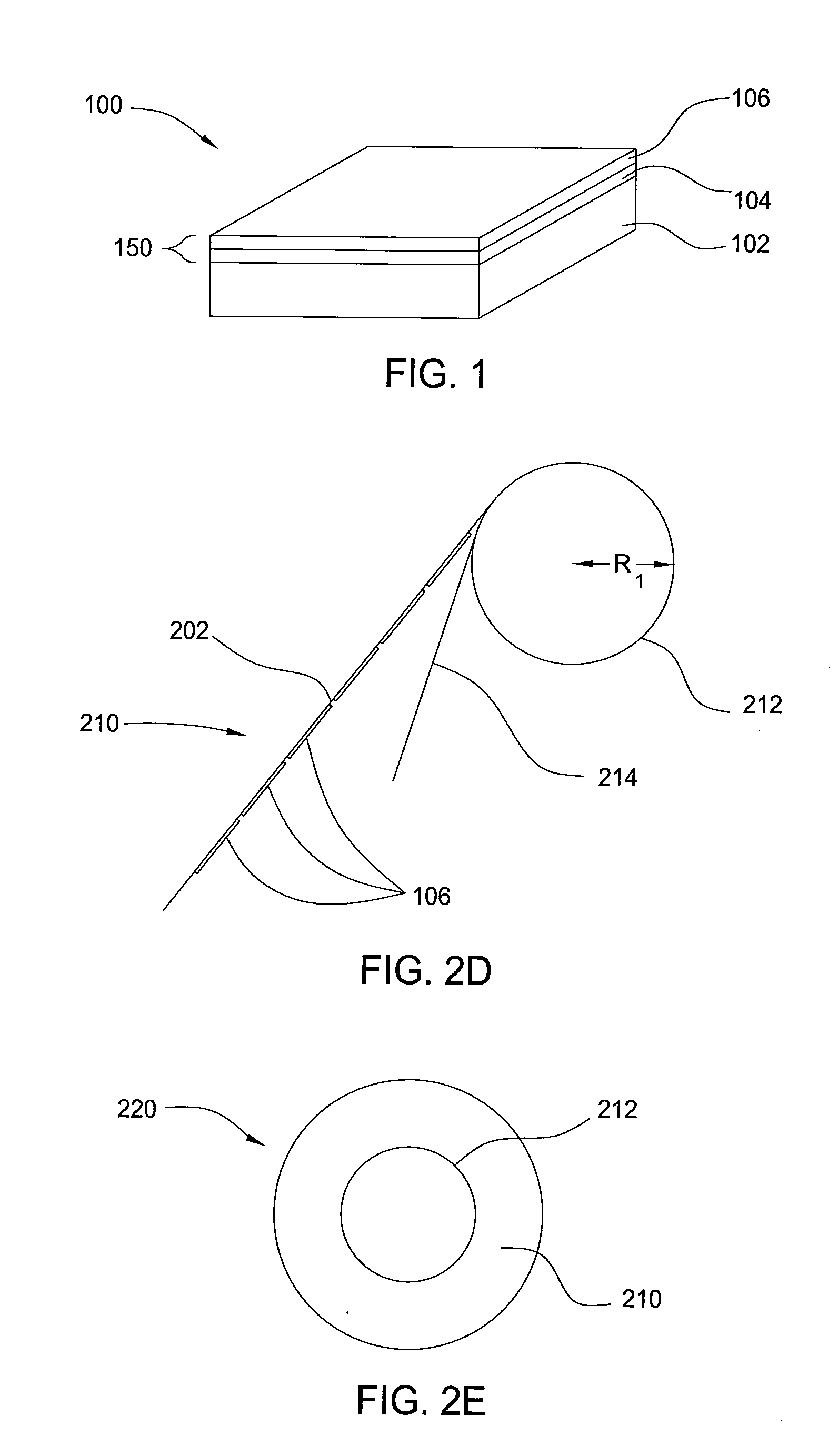

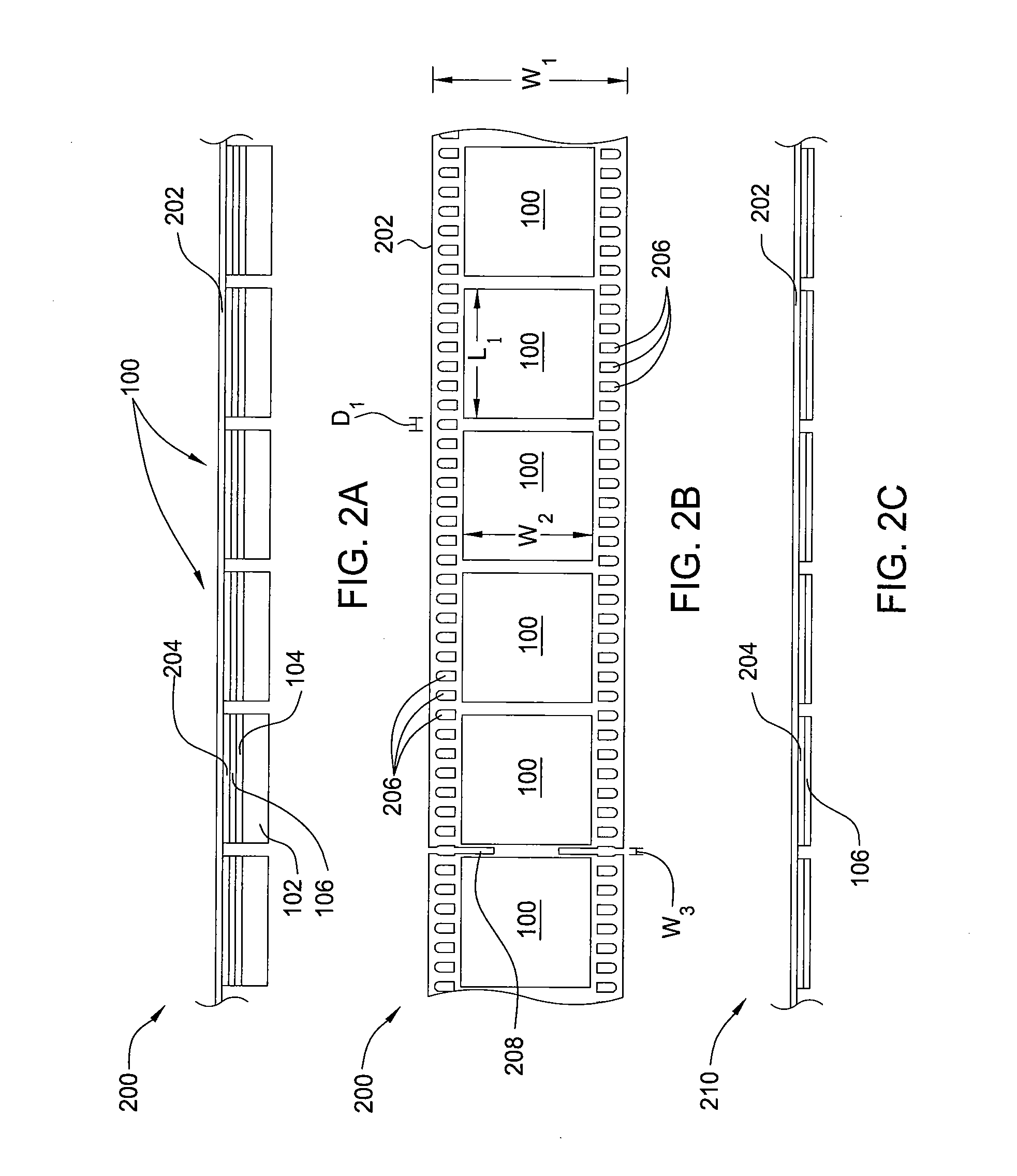

Tape-based epitaxial lift off apparatuses and methods

ActiveUS20100151689A1Solid-state devicesSemiconductor/solid-state device manufacturingWaferingEngineering

Embodiments of the invention generally relate to apparatuses and methods for producing epitaxial thin films and devices by epitaxial lift off (ELO) processes. In one embodiment, a method for forming thin film devices during an ELO process is provided which includes coupling a plurality of substrates to an elongated support tape, wherein each substrate contains an epitaxial film disposed over a sacrificial layer disposed over a wafer, exposing the substrates to an etchant during an etching process while moving the elongated support tape, and etching the sacrificial layers and peeling the epitaxial films from the wafers while moving the elongated support tape. Embodiments also include several apparatuses, continuous-type as well as a batch-type apparatuses, for forming the epitaxial thin films and devices, including an apparatus for removing the support tape and epitaxial films from the wafers on which the epitaxial films were grown.

Owner:ALTA DEVICES INC

Apparatus and method for oxidation and stabilization of polymeric materials

ActiveUS20090263295A1From normal temperature solutionsLiquid separation by electricityFiberCross-link

An apparatus for treating polymeric materials comprises a treatment chamber adapted to maintain a selected atmosphere; a means for supporting the polymeric material within the chamber; and, a source of plasma-derived gas containing at least one reactive oxidative species whereby the polymer is stabilized and cross linked through exposure to the oxidative species in the chamber at a selected temperature. The polymer may be directly exposed to the plasma, or alternatively, the plasma may be established in a separate volume from which the reactive species may be extracted and introduced into the vicinity of the polymer. The apparatus may be configured for either batch-type or continuous-type processing. The apparatus and method are especially useful for preparing polymer fibers, particularly PAN fibers, for later carbonization treatments.

Owner:REMAXCO TECH LLC +1

Continuous type live fish sorter in vacuum for starting up fishing

A vacuum fishing machine for continuously catching and classifying living fish without damage to fish is composed of water circulating suction pump, two negative-pressure fish-collecting tanks with sucking port, electric ball valve, electromagnetic valve for sucking, water level controlling switch and automatic fish discharging port, a rubber pipe for sucking fish, and an automatic control circuit.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

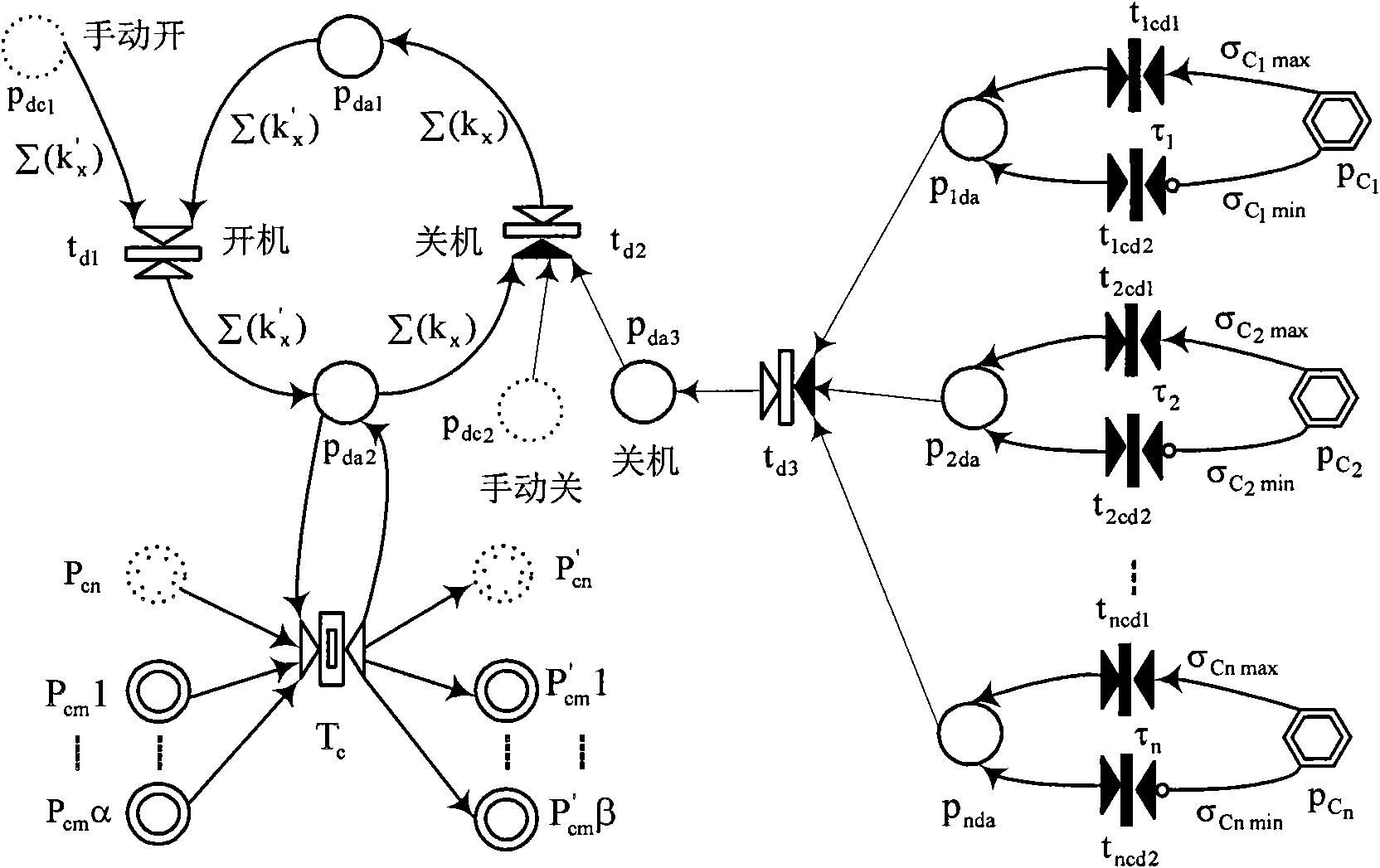

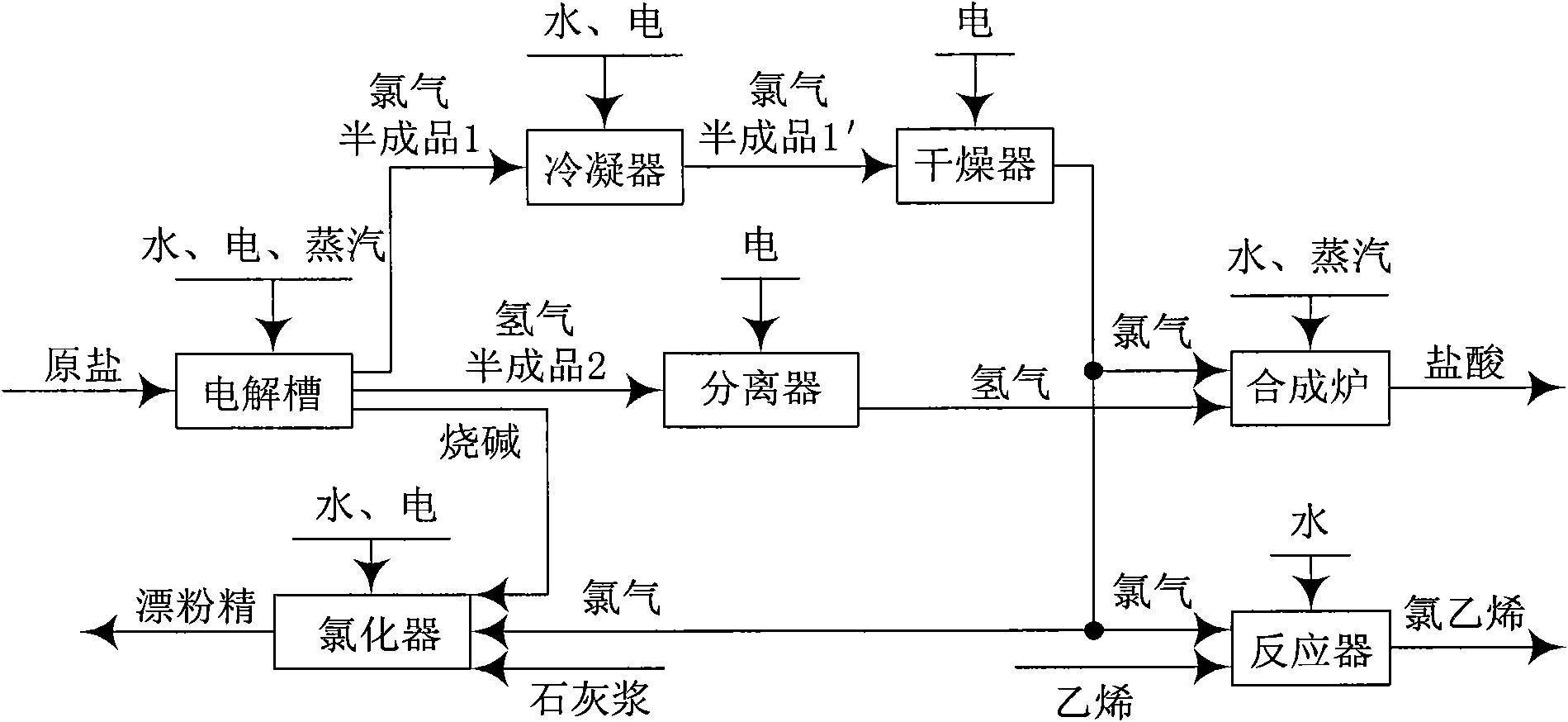

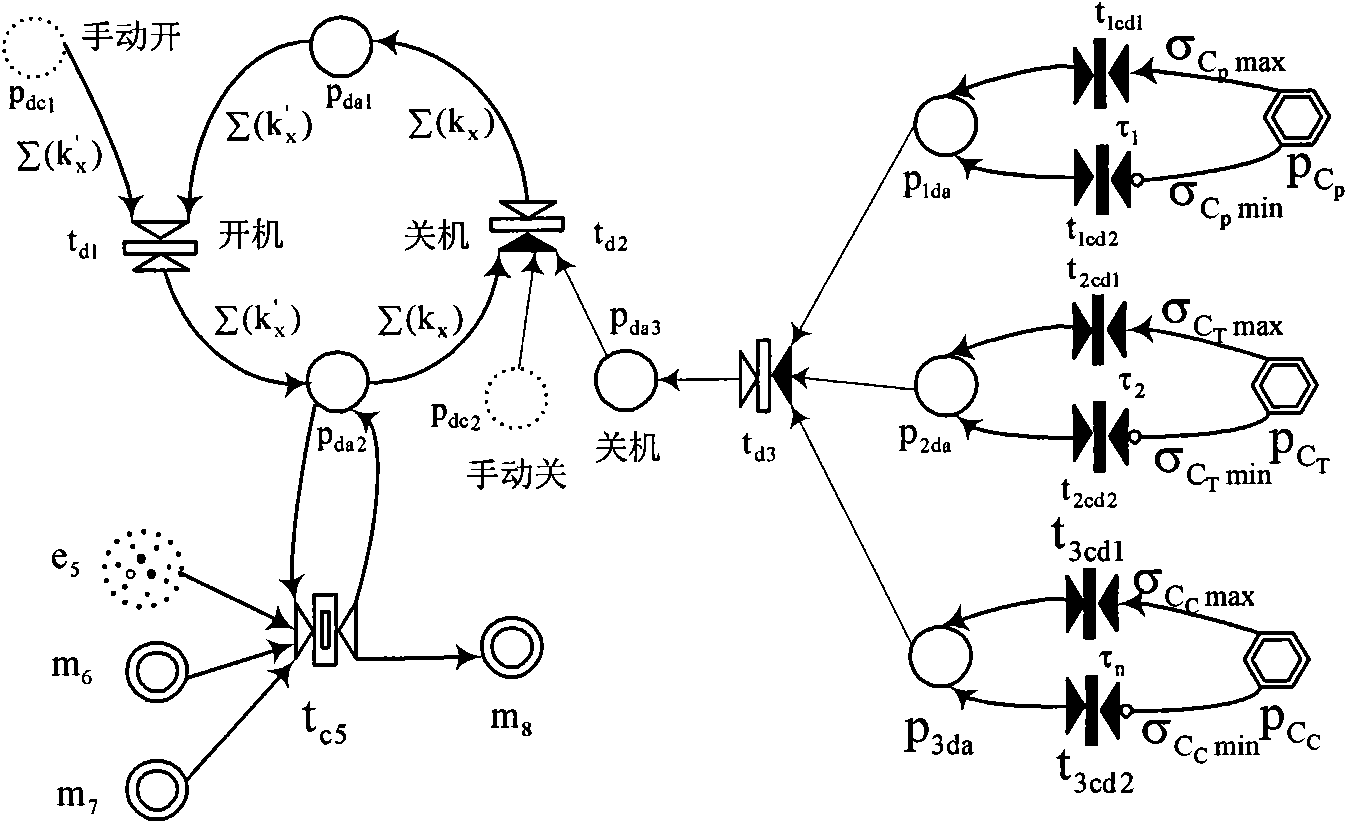

Optimization modeling method for coupling of production and energy of continuous enterprises

InactiveCN101887544ARealize dynamic simulationSuitable for useEnergy industryForecastingNetwork topologySimulation algorithm

The invention provides an optimization modeling method for coupling of production and energy of continuous enterprises. The method comprises the following steps: establishing a CEECOM unit model X; setting an information parameter of a CEECOM production dispatch velocity model psi to generate a CEECOM system model; determining the material type and listing a constraint equation according to the Petri network topology structure of the CEECOM system model; and running a simulation algorithm to calculate energy consumption and generate a corresponding curve. The method adopts a color expansion blending Petri network method, and gives consideration to energy flow, material flow and information flow. The modeling method of the invention has strict theoretical foundation, is concise, convenient and easy, and is suitable for practical use. The method realizes reoccurrence of energy consumption process of enterprise production by acquiring data from a DCS or database. Safety pre-warning is provided regarding unsafe information parameter of energy consumption equipment (unit) in enterprise production energy consuming activities, and the control model implements corresponding processing if a corresponding measurement cannot be obtained within the safety pre-warning time. The method can be jointed with an ERP so as to realize dynamic simulation in the enterprise production energy consuming process.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com