Method for preparing metal magnesium by using dolomite as raw material

The technology of dolomite and metal magnesium is applied in the preparation field of vacuum metallurgy technology, which can solve the problems of low magnesium reduction efficiency, long production cycle, large energy consumption, etc., and achieve the effects of reducing energy consumption, shortening reaction cycle and increasing purity

Inactive Publication Date: 2010-08-25

JILIN UNIV

View PDF7 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to overcome the problems of low magnesium reduction efficiency, high energy consumption, long production cycle and serious pollution in the prior art, and to provide a method for preparing metal magnesium using dolomite as raw material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

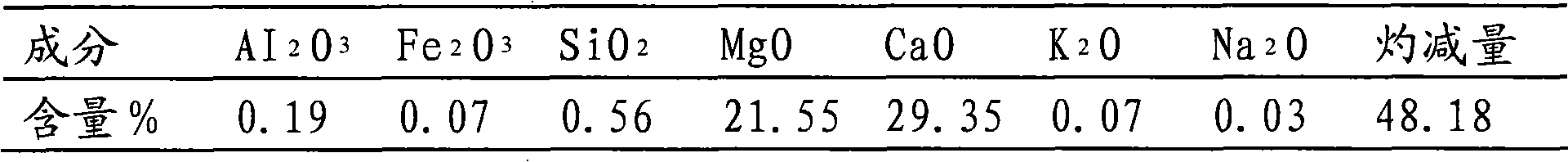

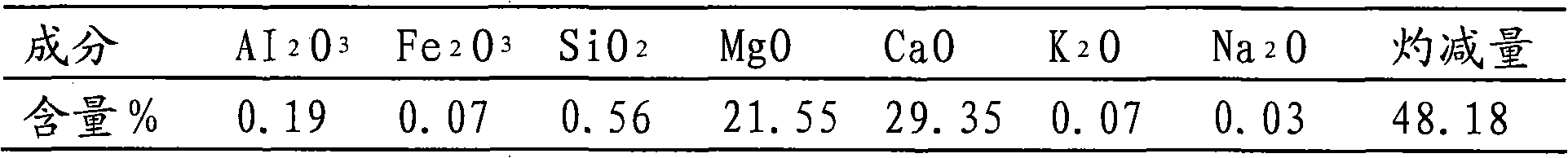

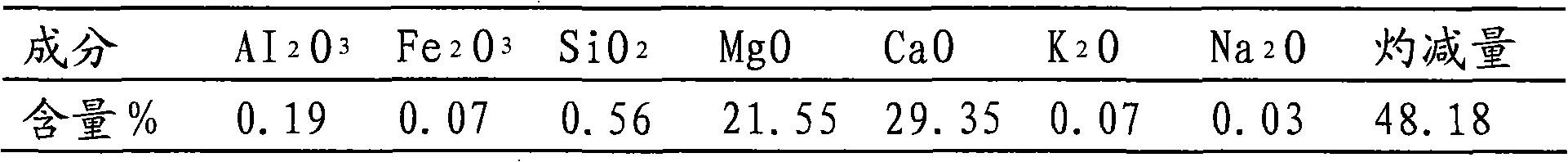

The invention discloses a method for preparing metal magnesium by using dolomite as a raw material, and aims to solve the problems of low reducing efficiency, high energy consumption, long production period and serious pollution existing in the conventional method for preparing the metal magnesium. The method comprises the steps: crushing of dolomites, vacuum low-temperature light calcining and recycling of carbon dioxide, cooling and heat recovery, ball-milling of mixed materials, briquetting of mixed materials, vacuum high-temperature hot reduction, separation of magnesium blocks, and utilization of slag, wherein in the vacuum low-temperature light calcining, the crushed dolomites undergo light calcining in a continuous type vacuum calcining furnace for 1 to 3 hours at the calcining temperature of between 500 and 1,000 DEG C and under the furnace pressure of 10,000 to 60,000Pa, MgCO3 and CaCO3 in the dolomites are decomposed in sequence, the reaction expression is: CaMg(CO3)2=CaCO3+MgO+CO2(gas) and CaCO3=CaO+CO2(gas), and the mixture of carbon dioxide and magnesium oxide and calcium oxide is obtained; and the carbon dioxide which flows in the furnace and heats the dolomites is recycled.

Description

technical field The invention relates to a preparation method in the technical field of vacuum metallurgy, more specifically, it relates to a method for preparing metallic magnesium by using dolomite as a raw material. Background technique Magnesium is a light, ductile and very active metal that is widely used in the automotive industry, 3C industry, military aviation and other industries. At present, the metal magnesium smelting methods are mainly divided into two types: one is the electrolysis method; the other is the silicothermal method (Pidgeon method). Molten salt electrolysis uses magnesium chloride as the raw material, metal alloy as the cathode and anode, under the melting of magnesium chloride, direct current is applied for electrolysis, metal magnesium is deposited on the cathode, and chlorine gas is released from the anode. The disadvantage is that the anode emits chlorine gas, which seriously pollutes the environment, and the equipment investment is large and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B26/22

Inventor 曹占义王冲陈永弟刘勇兵康雅丽

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com