Fan fault detecting method based on depth belief network model

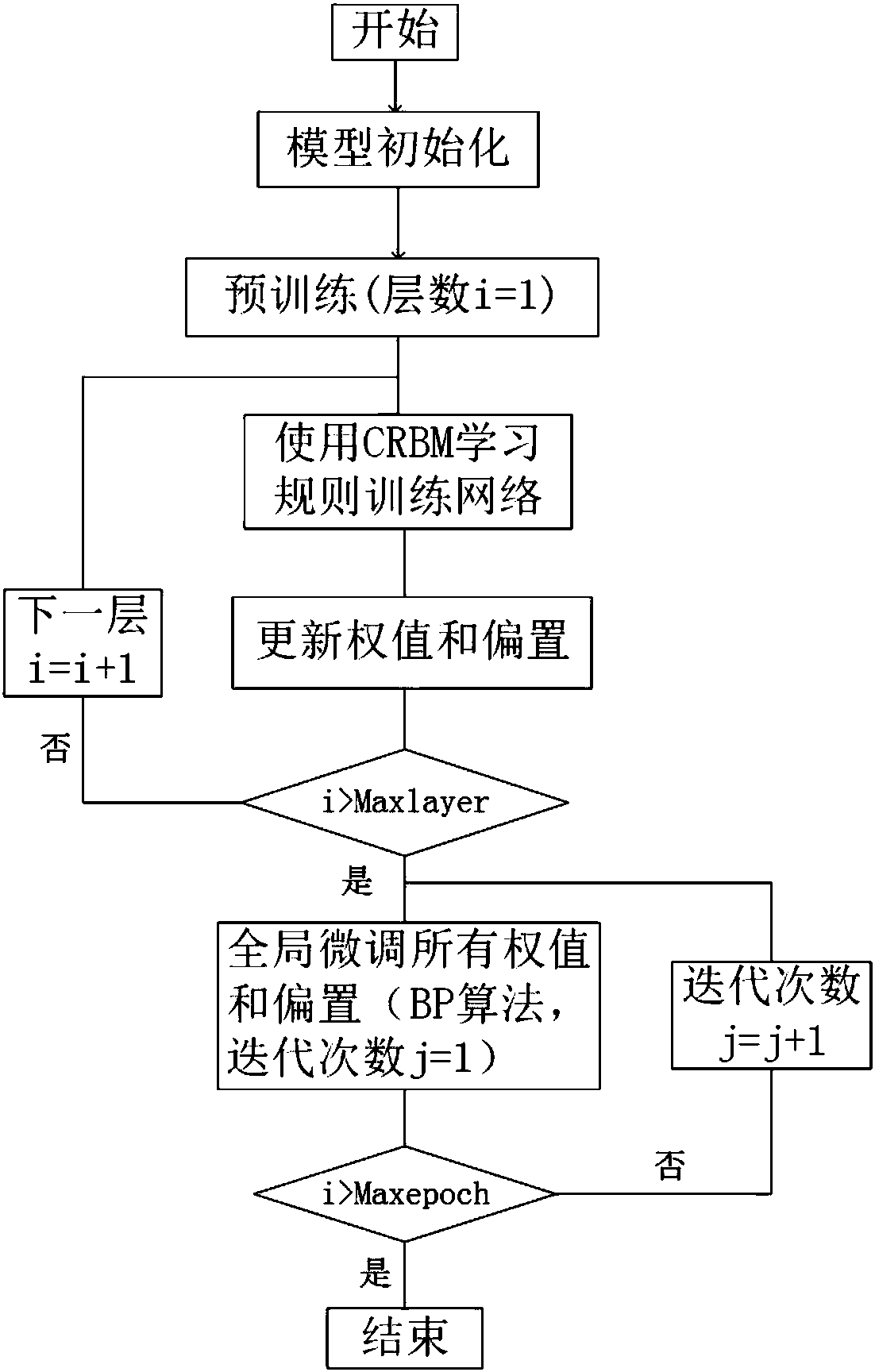

A deep belief network and fault detection technology, applied in wind turbines, engines, mechanical equipment, etc., can solve problems such as long computing time, easy to fall into local optimum, and complex neural network training methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] Select the data for fan status detection. To select the flow rate as the prediction vector, it is necessary to determine the fan parameters related to the fan flow rate as the modeling variables in the observation vector. The Pearson correlation coefficient is used to measure the variable correlation. The Pearson correlation coefficient of each fan status parameter and air volume signal is shown in Table 1.

[0116] Table 1

[0117] parameter name

Pearson correlation coefficient

Fan outlet pressure

0.9592

Fan current (hardwired)

0.8399

Motor coil temperature

0.7351

Motor drive end bearing temperature

0.6467

Motor free end bearing temperature

0.6243

Fan outlet air temperature

0.6169

fan vibration

0.5493

Bearing temperature

0.4827

Fan inlet air temperature

0.4430

Fan oil supply temperature

0.1989

Fan oil tank temperature

0.1004

[0118] Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com