Full-automatic flow production line for flat tea and production method thereof

A flat-shaped tea, fully automatic technology, applied in tea processing before extraction, etc., can solve the problems of impure taste and low quality of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

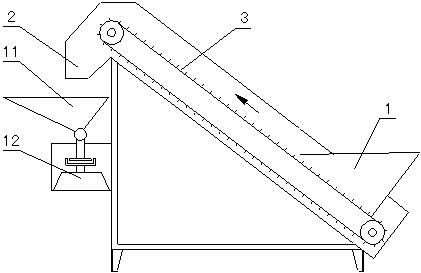

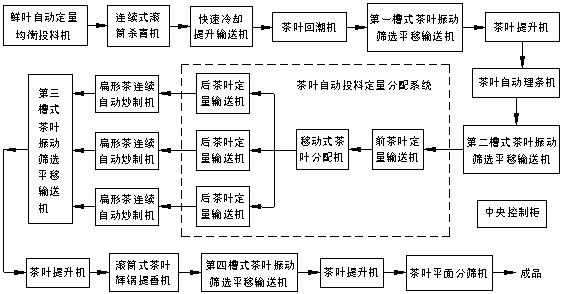

[0034] figure 1 It is a block diagram of the production process of Example 1 of the present invention, a fully automatic production line for flat tea, including tea roasting equipment and connecting and conveying devices, both of which are connected to the central control cabinet, and the flat tea is fully The automatic flow production line includes an automatic quantitative and balanced feeding machine for fresh leaves (see figure 2 ), the automatic quantitative balance feeder for fresh leaves includes a conveyor belt 3 that is set at an angle, the low end of the conveyor belt is the feed end 1, and the high end is the discharge end 2, and a material limiting device is installed above the middle of the conveyor belt. Adjust the limit plate 4 and the return wheel 5 that is arranged close to the adjustable limit plate, the adjustable limit plate is connected to the lifting motor 26, the length of the adjustable limit plate and the return wheel is suitable for the width of the ...

Embodiment 2

[0046] The number of flat tea continuous automatic frying machines in Example 2 is 6, and the automatic quantitative feeding and distribution system for tea leaves includes a front tea quantitative conveyor. The front tea quantitative conveyor is connected to 6 rear tea quantitative conveyors through a mobile tea distribution machine. , the mobile tea distribution machine is set on the guide rail through rollers, and the front and rear tea quantitative conveyors are equipped with a conveyor belt with an inclined structure. The low end of the conveyor belt is the feeding end, and the high end is the discharging end. A feed hopper is provided, and a rotatable discharge hopper 11 is provided below the discharge end of the conveyor belt, and the discharge hopper is arranged on a weighing mechanism 12 (see Figure 4 ). The upper part of the mobile tea distribution machine is equipped with a rotatable receiving hopper, the lower part is equipped with a roller drive mechanism, and th...

Embodiment 3

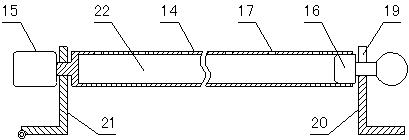

[0049] The flat tea continuous automatic frying machine quantity of embodiment 3 is 9, and the frame of the flat tea continuous automatic frying machine is provided with automatic oiling mechanism 13 (see Image 6 ), the automatic refueling mechanism includes a pipe body 14 arranged above the wok and a motor 15 that drives the pipe body to rotate, one end of the pipe body is closed and connected to the motor, the other end is open and provided with a plug 16, and the side of the pipe body is provided with There is a discharge hole 17, the discharge holes are arranged in a straight line in the axial direction of the pipe body, the tea oil is placed in the cavity 22 of the pipe body, and the automatic oiling mechanism is arranged on the first part of the flat tea continuous automatic frying machine. Above the frying pan 18, the length direction of the body of pipe is consistent with the length direction of the frying pan, and the open end of the body of pipe is arranged on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com