Patents

Literature

308 results about "Emerald" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emerald is a gemstone and a variety of the mineral beryl (Be₃Al₂(SiO₃)₆) colored green by trace amounts of chromium and sometimes vanadium. Beryl has a hardness of 7.5–8 on the Mohs scale. Most emeralds are highly included, so their toughness (resistance to breakage) is classified as generally poor. Emerald is a cyclosilicate.

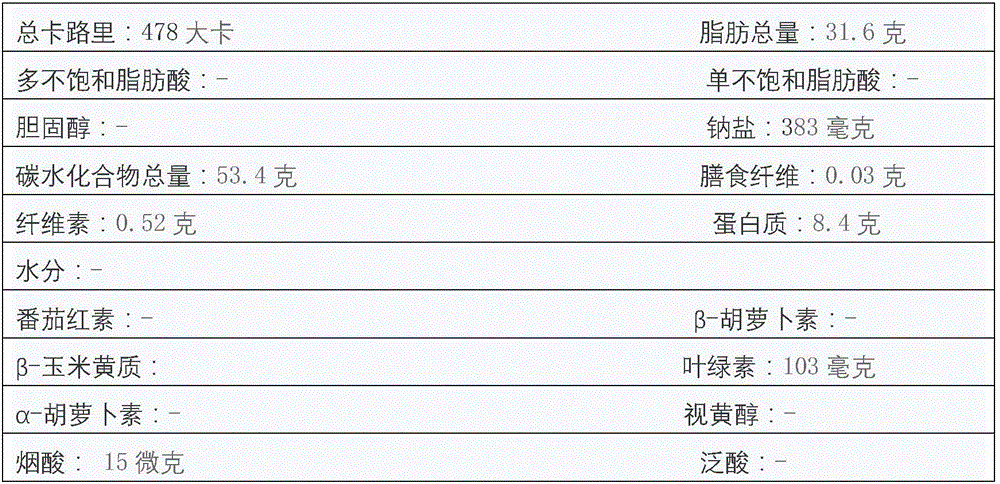

Enteromorpha potato chips and processing method thereof

InactiveCN105795395AGuaranteed qualityReduce moisture contentFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentMonosodium glutamateHazardous substance

The invention relates to the field of food, in particular to enteromorpha potato chips and a processing method thereof.The potato chips are full of seafood flavor, tasty in sour and sweet taste and slightly salty.The potato chips are golden matched with emerald green, and the color is very attractive and promotes appetite.The potato chips are unique in flavor, and have rich enteromorpha fresh flavor, and with the aromatic odor of orange juice, the potato chips can enable people to be full of energy and enhance appetite.Crisping of the potato chips is matched with flexibility of syrup, softness and hardness of the crisping sense are combined, and innovation and interest are added.The potato chips are safe and healthy, aginomoto and other hazardous substances are not added, and all indexes of enteromorpha powder conform to national safety standards.The potato chips are abundant in nutrition, and malnutrition, obesity and hazardous substance intake and other negative health problems caused when people eat a large number of potato chips are relieved.The potato chips have the healthcare function.

Owner:SHANGHAI OCEAN UNIV

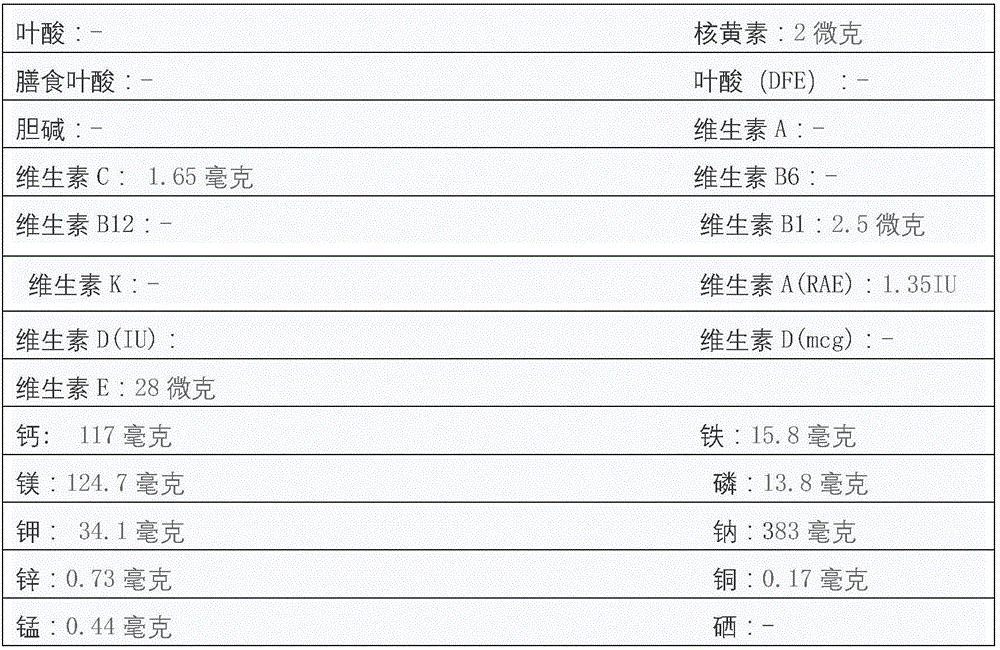

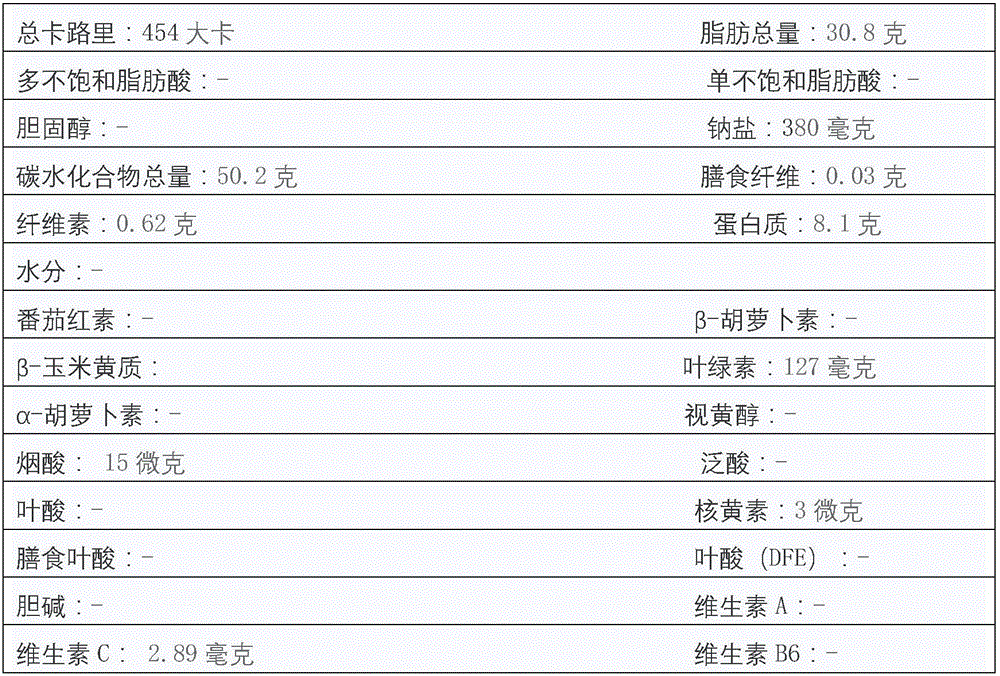

Cabbage-celery-kelp composite vegetable paper and preparation method thereof

A preparation method of cabbage-celery-kelp composite vegetable paper, which relates to the field of intensive processing of fruits and vegetables. The composite vegetable paper involved in the present invention contains cabbage pulp 45% to 55%, celery pulp 25% to 35%, and kelp pulp 20% to 30%. The mass percentage of various auxiliary materials and binders in the composite vegetable slurry is: soluble starch 5% to 8%, soy protein isolate 0.5% to 1.0%, glycerin 1.5% to 2.2%, carboxymethyl cellulose sodium 1.0% to 1.5%, sodium alginate 0.2% to 0.4%, gelatin 0.3% to 0.4%. The preparation method is to cut the cabbage, celery and kelp into pulp appropriately, grind them through a colloid mill, add auxiliary materials and binders, homogenize and smear them into shapes, bake and peel them off to make the cabbage-celery-kelp composite. Vegetable paper. The composite vegetable paper of the invention is emerald green, has a crisp texture and fragrant vegetable flavor, is rich in nutrients, is easy to carry, and can be used as a snack food.

Owner:SHANDONG UNIV OF TECH

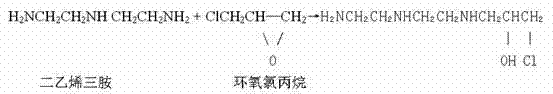

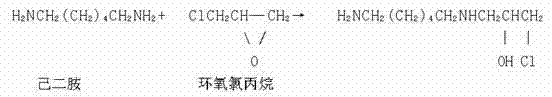

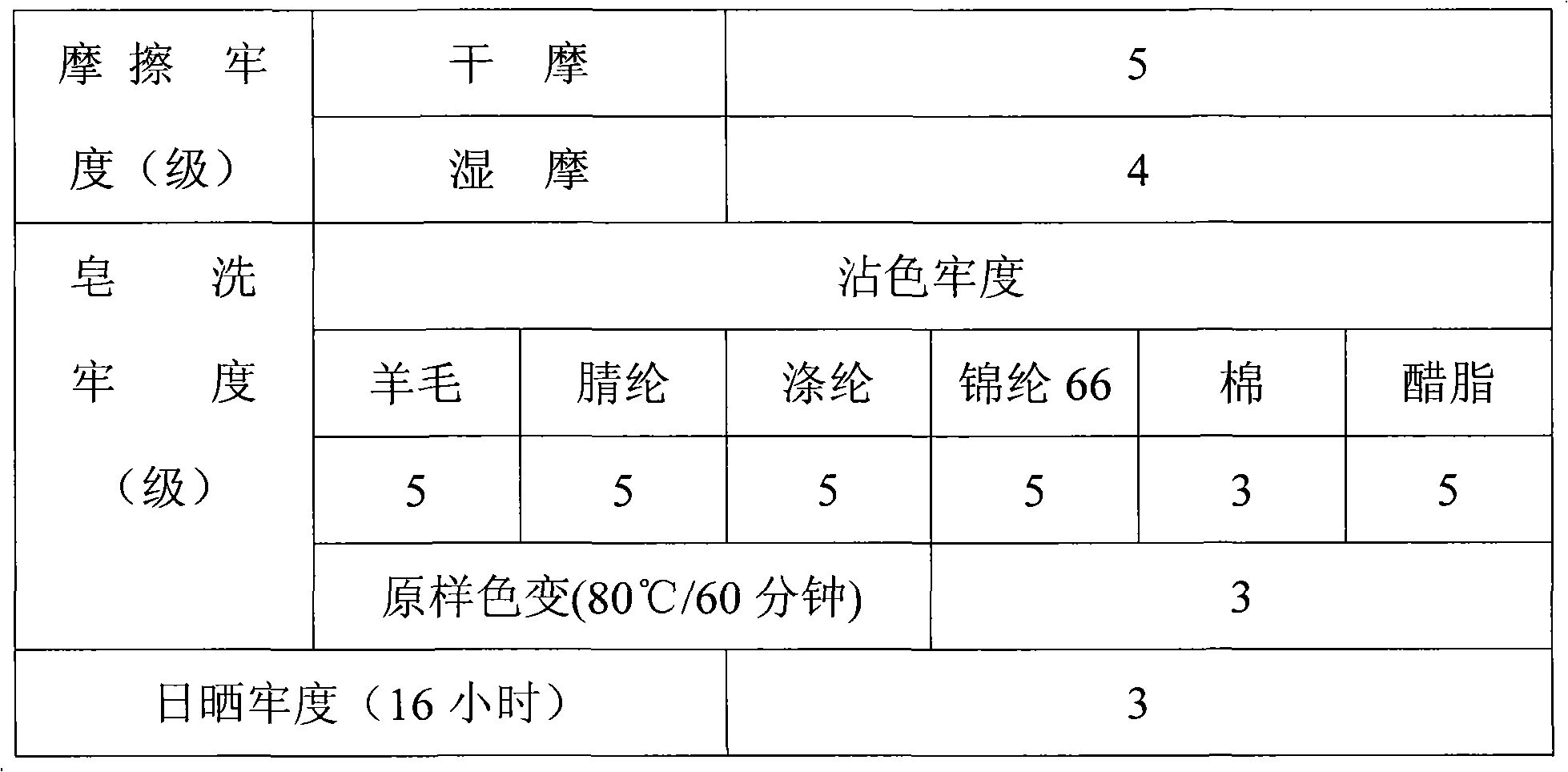

Preparation method of formaldehyde-free color fixative

The invention relates to a preparation method of a formaldehyde-free color fixative. The invention is characterized in that amines and epoxy chloropropane react to generate a condensate, wherein the amines are total amines and prepared by mixing hexamethylendiamine and other substances; and the other substances can be one or more of ammonia water, monomethyl amine, dimethyl amine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine, tetraethylenepentamine, ethylene diamine, urea and urea substitute. The color fixative has the advantages of high color fastness, small influence on sensitive color tone, low consumption, no environment pollution of formaldehyde, accessible raw materials and simple production technique, can enhance the dry / wet fastness to rubbing and the color fastness to water washing, and basically does not generate color phase variations when fixing emerald blue, bright blue and other sensitive color dyes.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

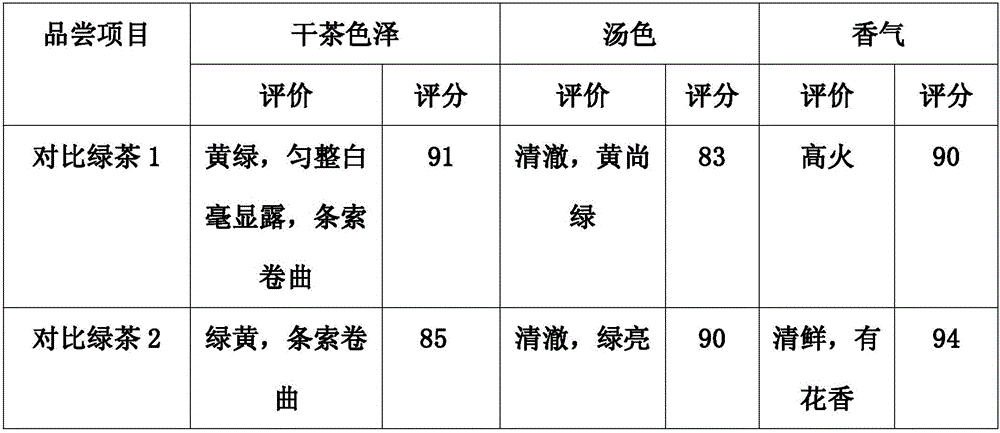

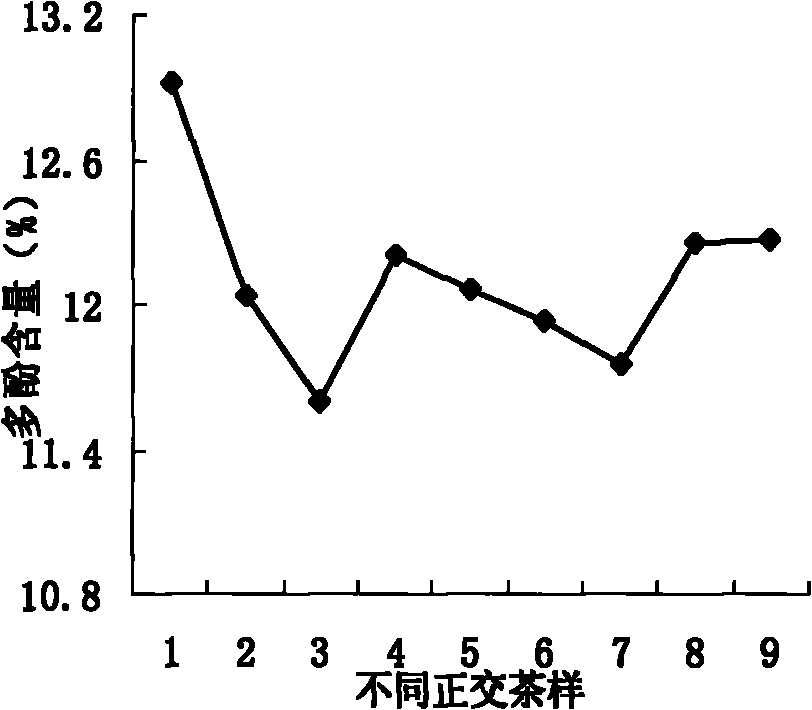

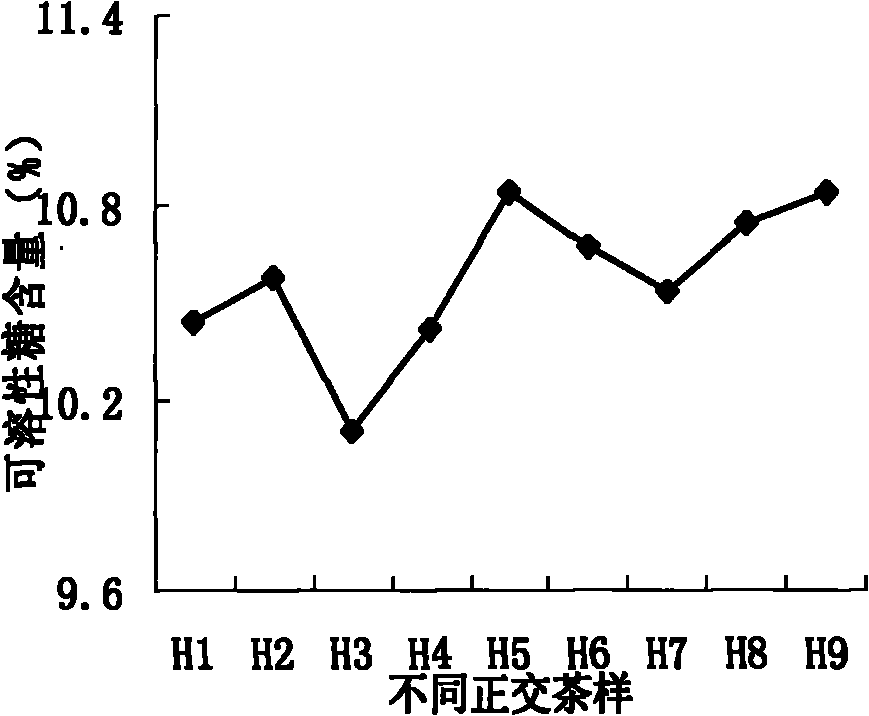

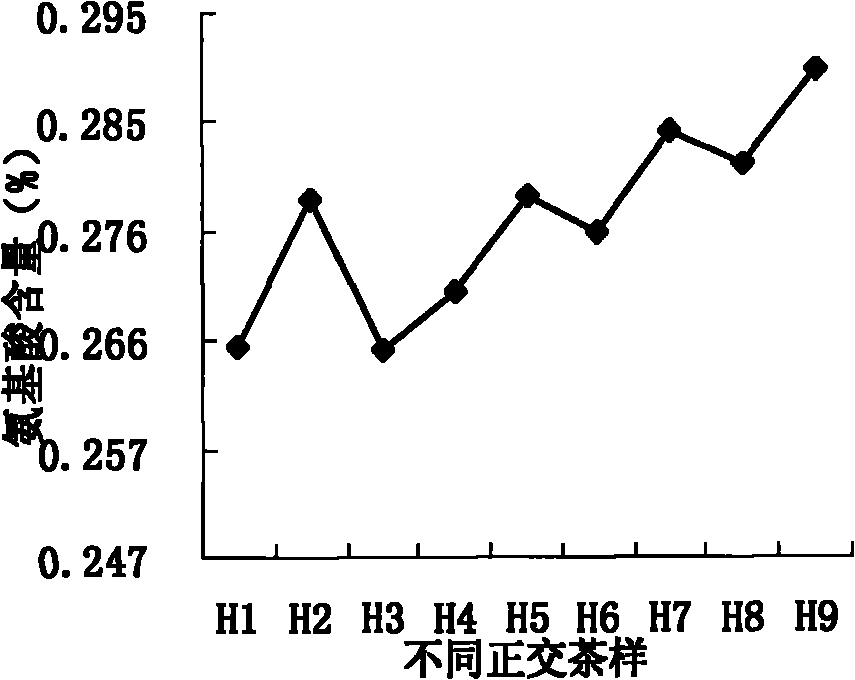

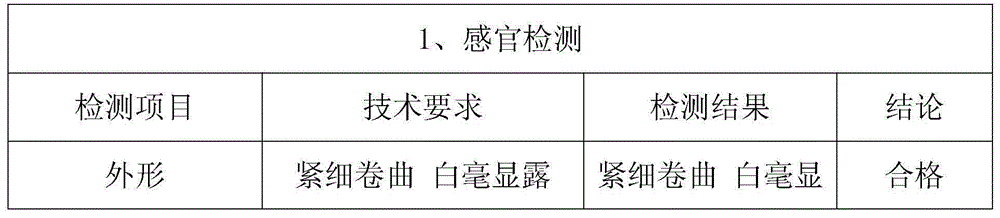

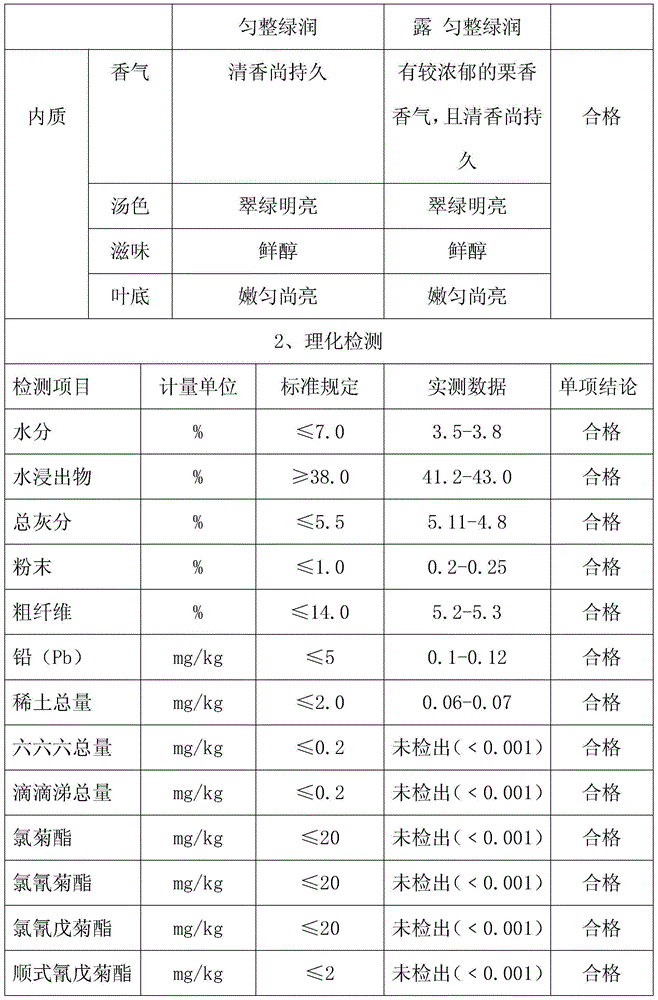

Green tea processing technology in summer

InactiveCN106035773AImprove qualityAmino acid highPre-extraction tea treatmentCooking & bakingPolyphenol

The invention provides a processing technology of green tea, which specifically includes picking, green tea spreading, killing green tea, spreading cold, rolling, initial frying, re-frying, drying, aroma enhancer to enhance the aroma, and the green tea produced has good quality and amino acid The higher the content, the lower the content of tea polyphenols, and the smaller the ratio of phenol to ammonia. The aroma of the finished finished tea lasts for a long time, the water content of the tea leaves is less than 5%, that is, the water content is low, the storage time is long, the color is emerald green, the appearance is even and the pekoe is exposed, the cord is curled, and the tea quality is good; the taste is mellow, the aftertaste is sweet, The soup is clear, and the bottom of the leaves is bright green.

Owner:遵义凤龙茶业有限公司

Method for producing battery-level refined nickel sulfate with electrolyte

The invention discloses a method for producing battery-level refined nickel sulfate with electrolyte. The method comprises the following steps: (1) concentrating and crystallizing: putting the nickel-containing electrolyte in which the copper is removed (nickel content is greater than or equal to 1 g / L) into a reaction kettle, steam-heating, concentrating and separating to obtain coarse nickel sulfate; (2) oxidizing to remove iron: dissolving the coarse nickel sulfate in water, and adding hydrogen peroxide; (3) vulcanizing to remove copper, lead and zinc: vulcanizing to remove copper, lead and zinc through the reaction of sodium sulfide and sulfuric acid; (4) concentrating to remove calcium and magnesium: removing calcium and magnesium by evaporation and concentration; (5) removing calcium and magnesium with sodium fluoride: under the action of mechanical stirring, adding second-grade sodium fluoride, and controlling the pH value with alkali liquid so that calcium and magnesium become fluoride precipitates to be removed; and (6) concentrating and crystallizing: concentrating the purified solution, and crystallizing to obtain the battery-level refined nickel sulfate. The product produced by the invention is an emerald granular crystal which is a square crystal, and the crystal grain diameter is greater than 2 mm and conforms to the HG / T2824-1997 standard.

Owner:中科铜都粉体新材料股份有限公司

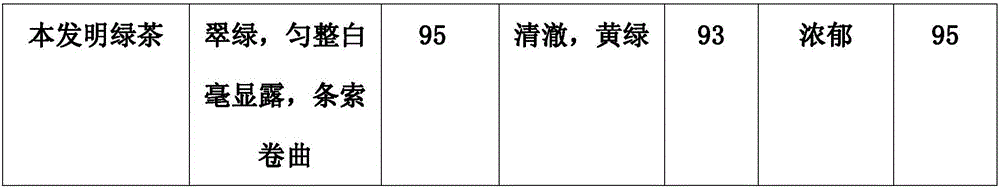

Processing technology of green tea

A processing technology of green tea mainly comprises a primary technical flow and a refining technical flow, and the processing technology is characterized in that the primary technical flow consists of steps of selection of raw materials, fresh leaves picking, grading, withering, killing out, rolling and primary baking; and the refining technical flow consists of steps of final roasting, sorting, grading and packing of the primary tea. The produced tea has the characteristics of emerald green tealeaves, olivine tea soup and light green leaf tea.

Owner:云南省腾冲清凉山茶厂有限责任公司

Biological seedling culture medium processed by papermaking sludge

InactiveCN102010260AImprove permeabilityImprove water retentionBio-organic fraction processingOrganic fertiliser preparationDiseaseSludge

The invention provides a biological seedling culture medium processed by papermaking sludge. The biological seedling culture medium comprises 30-50 percent of papermaking sludge biological compost, 10-20 percent of pearlite and the balance of vermiculite in volume ratio; 1-2kg / m<3> of functional bacteria is added, wherein the proportion of the compost is 40-50 percent preferably when in large seed culture, whereas the proportion of the compost is 30-40 percent preferably when in small seed culture; in the papermaking sludge biological compost, the papermaking sludge is taken as the main material and wheat bran or crop straw is taken as the auxiliary material, and 2-3kg / m<3> of compost rapid zymophyte strain is added to be evenly mixed with the main material and the auxiliary material to prepare a mixture, wherein the moisture content of the mixture is 50-60 percent, and the C / N (Carbon / Nitrogen) ratio is 25-30. In the invention, the fully fermented papermaking sludge is adopted to serve as the substitute material of turf in the seedling culture medium to prepare the industrial seedling culture medium with low cost and sufficient nutrition through the reasonable proportioning. Cultured by the medium, seedlings have emerald green leaves, strong stems, developed roots and robust growth. The biological seeding culture medium can also effectively control the diseases in the seedling stage.

Owner:河南无道理生物技术股份有限公司

Production technology of chinensis tea machining

InactiveCN101731375APay attention to health care functionFragrant tastePre-extraction tea treatmentTea substituesEmeraldEngineering

The invention discloses a production technology of chinensis tea machining, which is a novel technology for carrying out machining manufacture on chinensis by depending on the manufacture principle of tea leaves and adopting a machining technology. A finished chinensis tea is prepared by processing steps of choiceness, cleaning, dehydration, spreading, deactivating enzymes, rolling, block seperating, cutting up, drying, roasting and the like. The chinensis tea has the characteristics of three green and one high of green teas and the advantages of tight, strong and thin stripes, beauty, emerald color, verdure in tea soup, pure and lofty fragrance and fresh taste and has both favorable drinking effect and health function. The invention has purely natural raw materials, no residue of chemical pesticides, non industrial pollution, wide source and high scientific and technical content of the processing technology and provides a new and special natural drink with favorable health effect to daily health care and leisure entertainment of people.

Owner:吴大春 +1

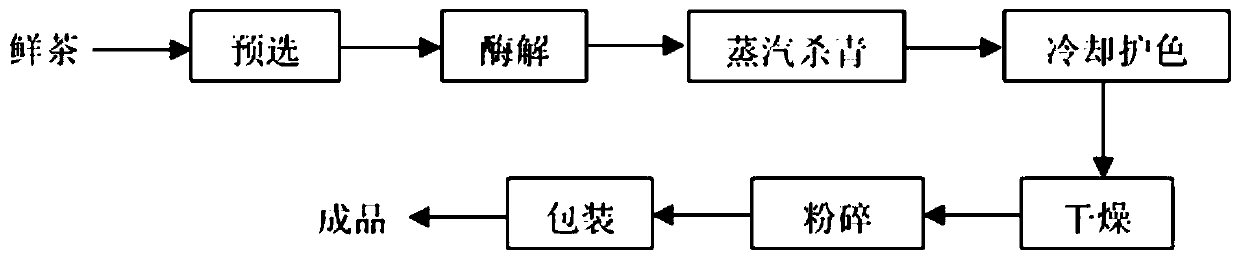

Superfine green tea powder preparing process

The present invention relates to the preparation process of one kind of superfine green tea powder. The preparation process includes spreading fresh tea, steam deactivating enzyme, hot blast dewatering, kneading, re-drying, coarse crushing and final superfine crushing. The steam deactivating enzyme and the hot blast dewatering reduce the water content of tea to 58-62 %, and kneading has one cell breaking rate of 10-15 %. The said preparation process can maintain the emerald of tea, and has fast water elimination and reduced loss of tea inclusion.

Owner:重庆市茶叶研究所

Ultrafinely pulverized green tea powder preparation method

The invention relates to the technical field of tea processing. A method comprises the steps of first washing and draining fresh tea, then pulverizing to large particles, spraying 1 / 10 enzymatic hydrolyzate on the surfaces of tea leaves, and turning the tea during enzymolysis; after the enzymolysis technology, performing enzyme deactivation by an enzyme deactivation machine until the fresh leavesare evenly and thoroughly evaporated to be free of grassy taste, then immersing the fresh leaves in a color protection solution at 20-25 DEC, repeatedly soaking in ice water for cooling, draining water, and then performing liquid nitrogen freezing treatment and vacuum freeze-drying treatment; after that, performing air jet pulverization at 15 DEC by an air flow ultrafine pulverizer to form ultrafinely pulverized green tea powder with an average particle diameter smaller than 20 microns. The ultrafinely pulverized green tea powder prepared by a preparation process provided by the invention usesconventional green tea as a raw material, thereby reducing production cost and labor cost; the final finished product is low in bitterness, moreover the green tea powder is more emerald green in color and better in solid fragrance and solubility, and can effectively maintain the original color and flavor quality of the tea, increase the quality of tea soup, and make the overall quality of the green tea powder closer to the quality of matcha.

Owner:SICHUAN UNIV

High-protein moringa oleifera nutritive noodles

InactiveCN104489504ARetain nutritionImprove absorption rateFood ingredient functionsFood preparationMORINGA OLEIFERA LEAFEmerald

The invention discloses high-protein moringa oleifera nutritive noodles. The high-protein moringa oleifera nutritive noodles consist of the following raw materials in parts by weight: 5-20 parts of moringa oleifera leaf superfine powder, 60-100 parts of high gluten flour, 0-3 parts of table salt, 0-3 parts of dietary alkali, 0-2 parts of algin, 3-12 parts of soybeans and 15-28 parts of water. The preparation method comprises the following steps: preparing full-bean milk by soybeans, adding moringa oleifera superfine powder, table salt, dietary alkali and algin into the full-bean milk, stirring uniformly, adding flour, kneading, curing, tableting, slitting and drying so as to obtain the high-protein moringa oleifera nutritive noodles. The nutritive noodles are emerald green in color, good in toughness and mouthfeel, do not enable soup to be muddy, and are rich in nutrition; the processing technology is simple, and industrialization can be realized easily.

Owner:刘祥义

Method for dyeing fabric containing polyester fiber and tencel fiber

The invention discloses a method for dyeing a fabric containing polyester fiber and a tencel fiber. The method comprises the following steps of: (1)carrying out refining and polyester fiber dyeing to the fabric containing the polyester fiber and the tencel fiber in the first dyeing liquid containing dispersed dye and a refining agent for 20 to 40 minutes at 120 to 140 DEG C; (2) carrying out tencel fiber dyeing to the fabric dyed by the polyester fiber in the second dyeing liquid containing reactive dye for 45 to 75 minutes at 50 to 70 DEG C; and (3) processing the dyed fabric through pickling, soaping, pickling and hair removing in sequence. With the adoption of the method disclosed by the invention, dyeing time is shorter, water consumpton is less, therefore, energy consumption is greatly reduced; and moreover, the surface of the dyed fabric is smooth and clean and has no filoplume as well as no dyeing defect; quality of the fabric is promoted; and the method specifically has an obvious dyeing effect on bright color series, such as emerald green and bright blue.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

Production process of asparagus tea

The invention discloses a production process of asparagus tea, which comprises the following steps of: (1) picking; (2) cleaning and air drying; (3) enzyme deactivation; (4) rolling; (5) drying. The production process of asparagus tea of the invention is characterized in that: (1) a potassium permanganate solution is used for sterilization, and sterile air is used to dry fresh asparagus tips (buds), which ensures that the asparagus tips (buds) are not contaminated by bacteria, ensures that nutritional components are not destroyed, and ensures that the asparagus tea does not contain peculiar smell caused by bacterial fermentation; (2) enzyme deactivation is performed after the leaves wither, which facilitates thorough and uniform deactivation, improves the toughness of the asparagus tea, allows tea juice to be not easy to be squeezed out during enzyme deactivation, maintains the emerald green color of finished tea, allows chemical components which exhibit green tea smell in fresh leaves to be volatilized and transformed, and improves the purity of the aroma of finished tea. The asparagus tea prepared by the process of the invention has the efficacy of cancer prevention and cancer resistance, has therapeutic effect on cardio cerebrovascular diseases, and has health care effect of aging resistance and human immunity improvement.

Owner:劳子明

Method for cultivating emerald pearl

The invention discloses a method for cultivating emerald pearl. The surface of the pearl formed by traditional growing method is off-white, yellowish-white, baby pink and the like; although the pearl has beautiful colored luster, the color is also monotonous, especially, the pearl cannot present the effect of emerald. The method in the invention uses animal gall juice, bamboo juice, parasitic plant juice, herminium lanceum (Thunb.) Vuijk juice, submarine stone solution, and vitamin B12 solution to prepare a pearl nucleus treating liquid; during practice, in the method, the treating liquid is used to treat the cultivated pearl nucleus, and then the pearl is cultivated through a conventional cultivating method for 1-2 year; the nacreous layer of the harvested pearl presents transparent or translucent emerald effect, and is glittering and translucent; the pearl is green and blue, and is round with beautiful colors; and the pearl has florid and exalted appearance, novel and beautiful appearance and colorful colors.

Owner:北海市源龙珍珠有限公司

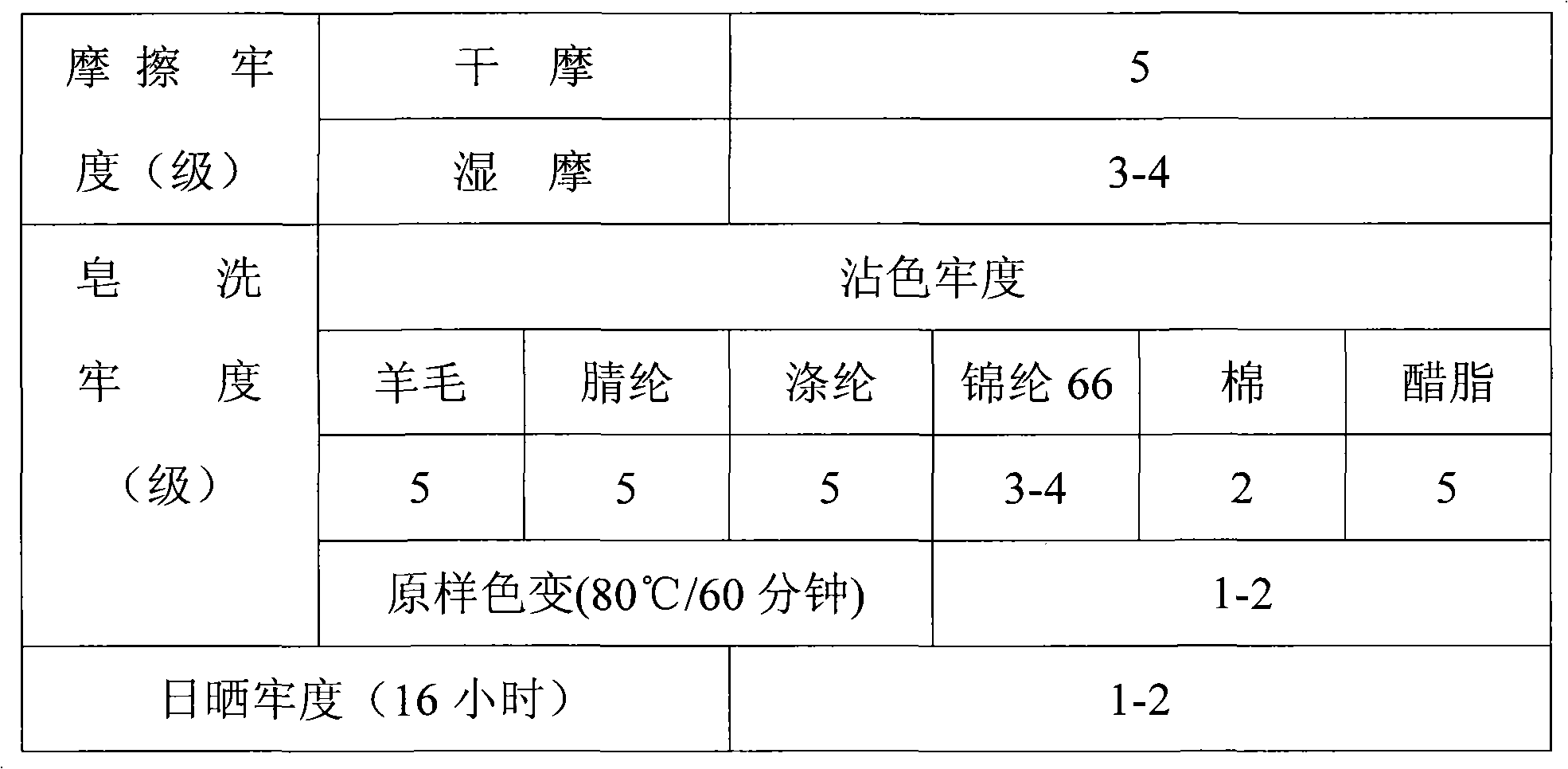

Method for dyeing vivid fluorescent green on cotton knitwear

InactiveCN101597867AMeet the requirements of bright colorMeet quality indicatorsDyeing processFluorescenceEmerald

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the method not only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Owner:ZHEJIANG YINHE PRINTING & DYEING

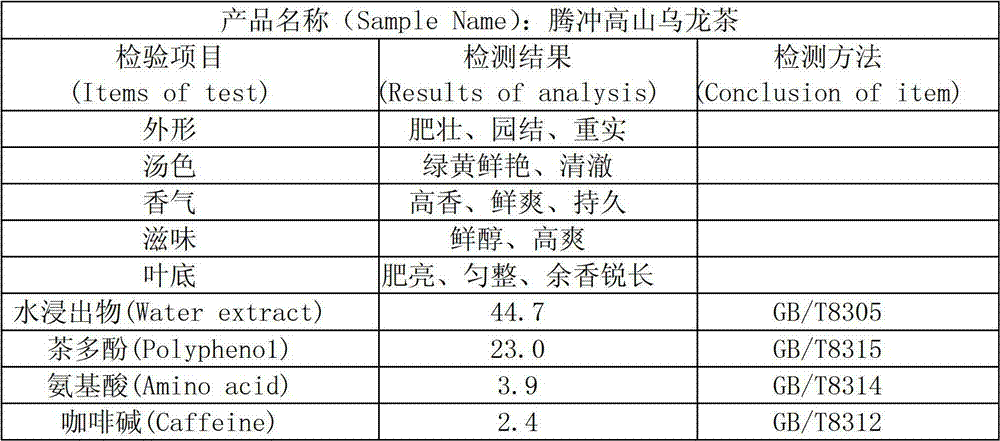

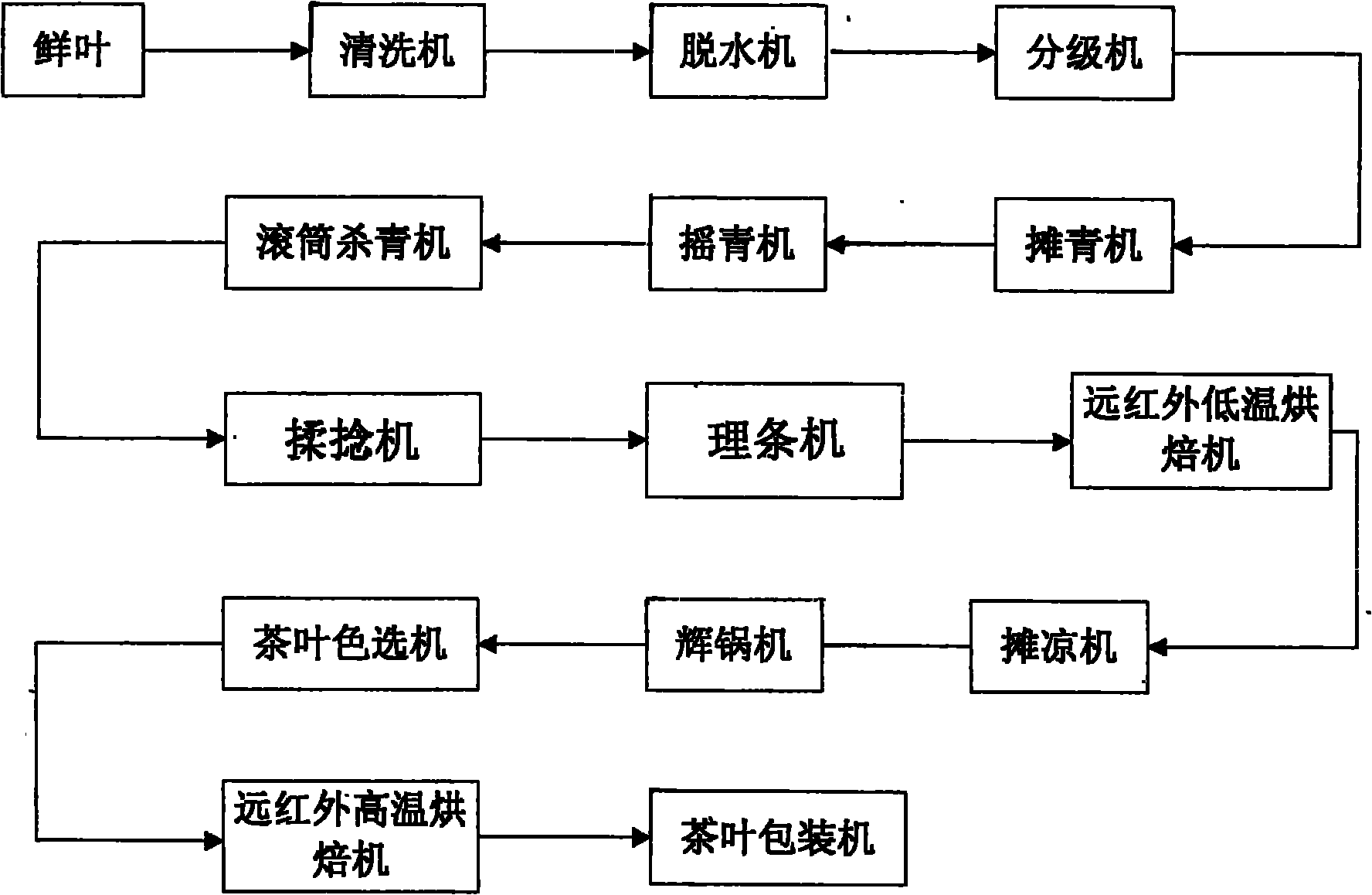

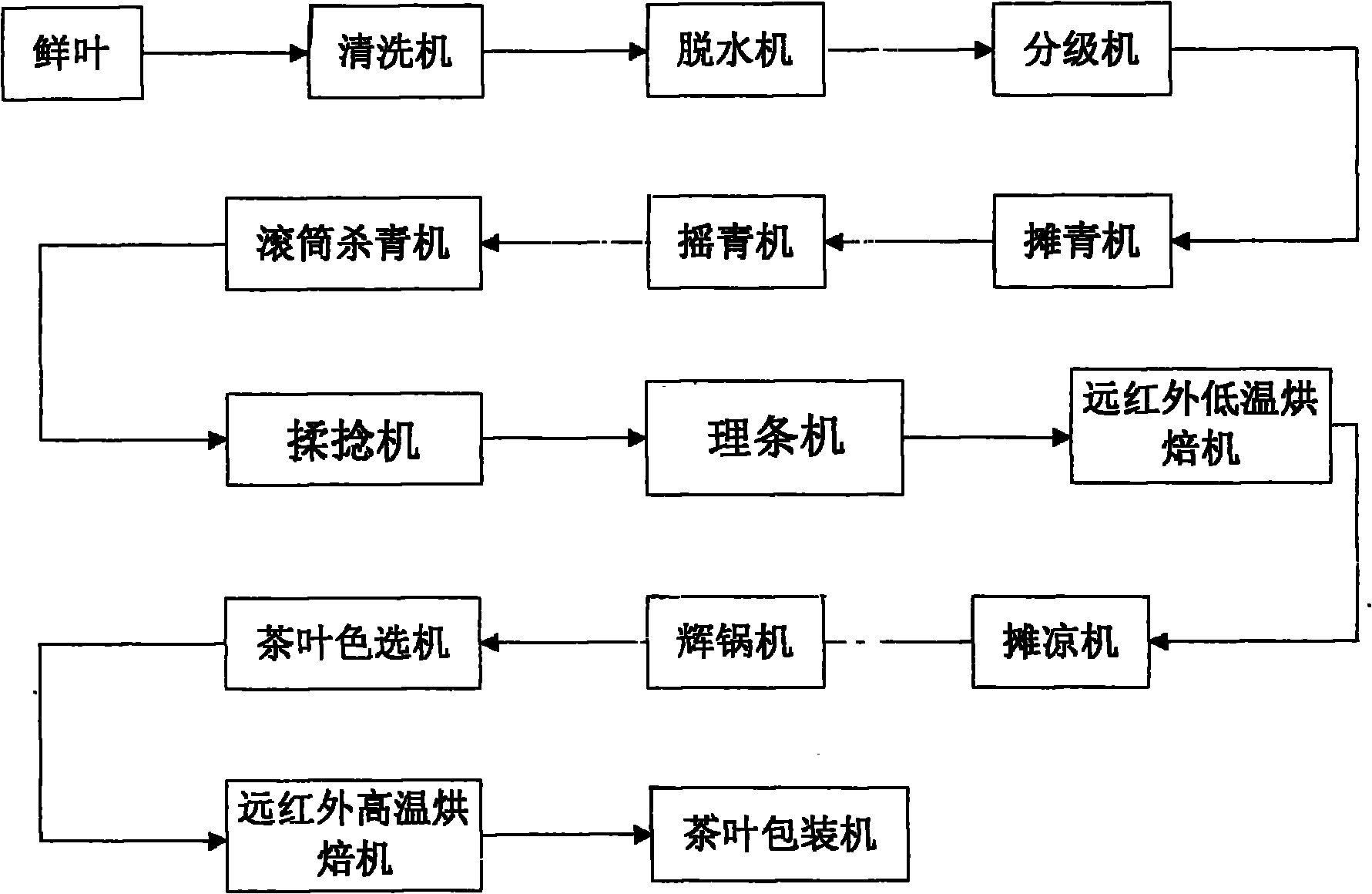

Manufacturing method of organic high-mountain oolong tea

ActiveCN102948501AAppearance cord fatEmerald green colorPre-extraction tea treatmentGreen yellowEmerald

The invention provides a manufacturing method of organic high-mountain oolong tea. Raw materials are qingxin oolong good fresh leaves at the elevation of 1900 to 2600 meters, and standard fresh leaves with buds or small open faces are one bud with two leaves or one tender bud with three leaves. The manufacturing method comprises the following steps of sunning, tedding, rocking of green leaves, standing, killing at high temperature, rolling, samming, balling, drying, cooling and the like. The high-mountain oolong tea has the advantages of strong, round and plump cord, emerald green color, obvious sand green, strong, fresh and permanent aroma, fresh, mellow and brisk taste, green-yellow, bright and clear liquid color, strong, bright and uniform leaf base and fragrance for a long time.

Owner:YUNNAN TAICHA TEA

Special diatom ooze paint for children as well as application and application method thereof

InactiveCN102603228AProtect physical and mental healthSimple production processFiberIron oxide black

The invention relates to a special diatom ooze paint for children as well as application and an application method of the paint. The paint comprises the following component in percentage by mass: 3-5% of adhesive powder, 20-35% of siliceous sand, 5-8% of wood fiber, 20-35% of diatomite, 10-15% of loess, 3-5% of clay, 5-8% of medical stone, 3-5% of zeolite, 2-3% of lazurite, 2-2.5% of onyx, 0.1-0.3% of emerald, 0.1-0.3% of jade, 0.3-0.5% of topaz, 1-1.5% of biotite, and 0.2-1% of toner, wherein the toner is one or more of iron red, ferrite yellow, iron oxide black and ultramarine. The invention also relates to application and the application method of the special diatom ooze paint for children in the children living environment. The paint can adjust the indoor air humidity, purity air and insulate sound and heat.

Owner:刘娜

Prepn process of instant green tea powder

The present invention discloses preparation process of instant green tea powder. Through low temperature slow freezing to form largest ice crystal destroying the cell tissue of fresh tea leaf, the present invention reaches the aim of raising leaching efficiency; and through enriching process, the present invention extracts the chlorophyll and effective components from fresh tea leaf. The present invention has simple operation and low cost, and the prepared instant green tea powder is emerald green, scent and high in tea polyphenol content.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Mechanical tea making process of Liuan Guapian

InactiveCN101953404AFlat and beautiful shapeIn line with the trend of industrialization developmentPre-extraction tea treatmentEmeraldEngineering

The invention discloses a mechanical tea making process of Liuan Guapian, which fully adopts the mechanical tea making process on the basis of simulating the traditional manual tea making process. The processed Liuan Guapian tea not only has the special characters such as emerald green color, frost during humidification, clear and green liquor color, lasting aroma, long aftertaste, and the like of the traditional manually processed Liuan Guapian tea, but also has the advantages of flat and elegant shape, natural curling, melon-seed shape and uniform quality; moreover, the mechanical tea making process is suitable for the standard, automated, continuous, clean and scale production, and beneficial to increasing the additional value of the product and strengthening the market competitive force, and accords with the industrial development trend of the Liuan Guapian.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

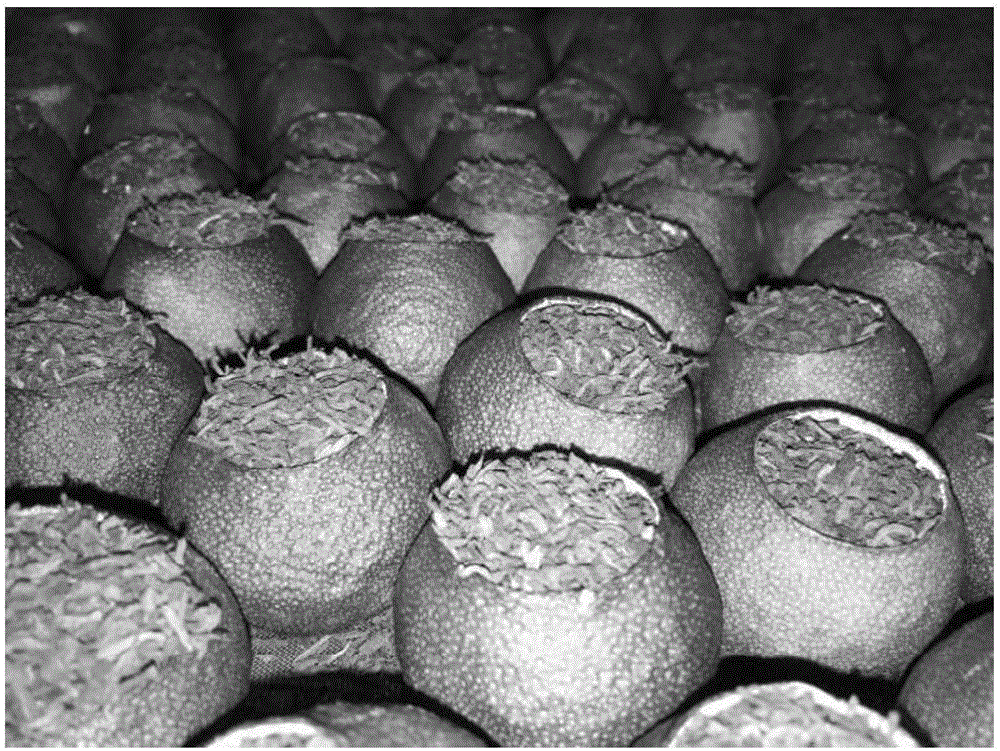

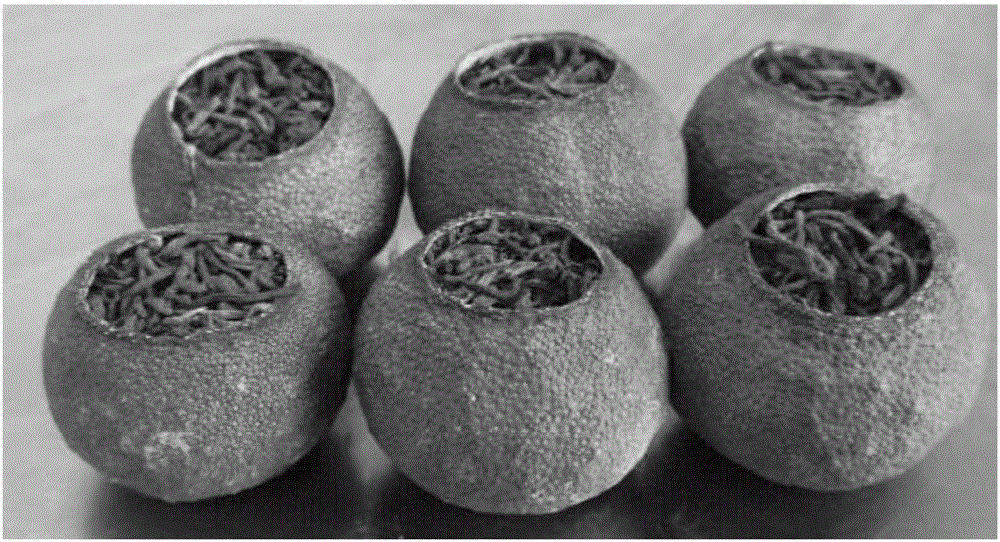

Preparation method of hesperidium aurantium tea

The present invention discloses a preparation method of hesperidium aurantium tea. The preparation method comprises the following steps: 1) fresh hesperidium aurantium is picked, the picked hesperidium aurantium is washed clean, and water content on the surfaces of the washed hesperidium aurantium is drained; 2) an opening is cut out on the hesperidium aurantium and the hesperidium aurantium is divided into two parts of a lid body and a hesperidium aurantium main body; fruit flesh in the hesperidium aurantium main body is dig out to obtain a hesperidium aurantium container; 3) the lid body and the hesperidium aurantium container are dried until no water is left; 4) the hesperidium aurantium container is taken out and filled with the tea leaves to obtain semi-finished products; and 5) the semi-finished products and lid body are put into a dryer; and an air inlet volume of the dryer is adjusted to be 1,500-2,100 m<3> / h, an air outlet volume of the dryer is 760-1360 m<3> / h, a temperature is controlled at 40-45 DEG C, the drying is conducted for 18-26 h, and the finished products are obtained. The preparation is less in steps and simple in processes. The hesperidium aurantium is emerald green in appearance. The hesperidium aurantium tea is uniform in color and luster, maintains the characteristics of the fresh hesperidium aurantium, is good in appearance, at the same time, maximally maintains the original taste of the hesperidium aurantium and tea leaves, and is fragrant, delicate and mellow in smell, and resistant to storage.

Owner:广东省壹柑园食品有限公司

Method for producing fragrant and fruity persimmon leaf tea

The invention belongs to the field of comprehensive utilization of horticultural products and relates to a method for producing fragrant and fruity persimmon leaf tea. The method comprises the following steps: 1) picking the fresh tender emerald green leaves of the persimmon tree without diseases and insect pests; 2) placing the fresh leaves into a tea kneading and cutting machine to be kneaded and cut, and repeating kneading and cutting twice to prepare the leaves into grains, thus obtaining the kneaded and cut leaves; 3) placing the kneaded and cut leaves with thickness of 15-20cm into a fermenting tray to be fermented under the conditions of temperature of 30-35 DEG C, relative humidity of 50-70% and stacking fermentation time of 12h to obtain fermented leaves; and 4) placing the fermented leaves into a dryer to be dried twice to obtain the finished persimmon leaf tea, wherein the first drying temperature is 100-120 DEG C and the water content of the persimmon leaves is 10-15%; and the second drying temperature is 80-90 DEG C and the water content of the persimmon leaves is 3-5%. The persimmon leaf tea is characterized in that the tea is strongly fragrant and fruity, the liquor is orange red or orange yellow, the taste is mellow sweet, etc. The persimmon leaf tea is suitable for mechanized production.

Owner:HUAZHONG AGRI UNIV

Making technology of green tea

The invention discloses a making technology of a green tea. The making technology comprises the following making steps: A, picking tea leaves; B, tedding the picked tea leaves; C, performing fixation; D, spreading the tea leaves after the fixation until the tea leaves are cooled; E, rolling the cooled tea leaves; F, frying the rolled tea leaves for the first time; G, screening the fried tea leaves; H, stir-frying tea cores; I, enhancing tea fragrance; J, screening out powder in the tea leaves with enhanced tea fragrance; and K, packaging finished products. The green tea prepared through the making technology disclosed by the invention has the full-bodied fragrance of chestnuts, besides, the fragrance can last for a long time, the preservation time of the green tea is long, and the green tea is emerald green in color and excellent in quality, so that the green tea can achieve and surpass a first class.

Owner:黔南州梅渊商贸有限公司

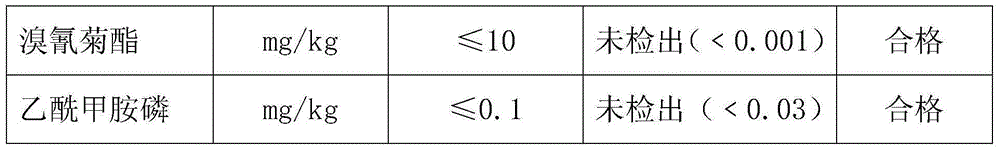

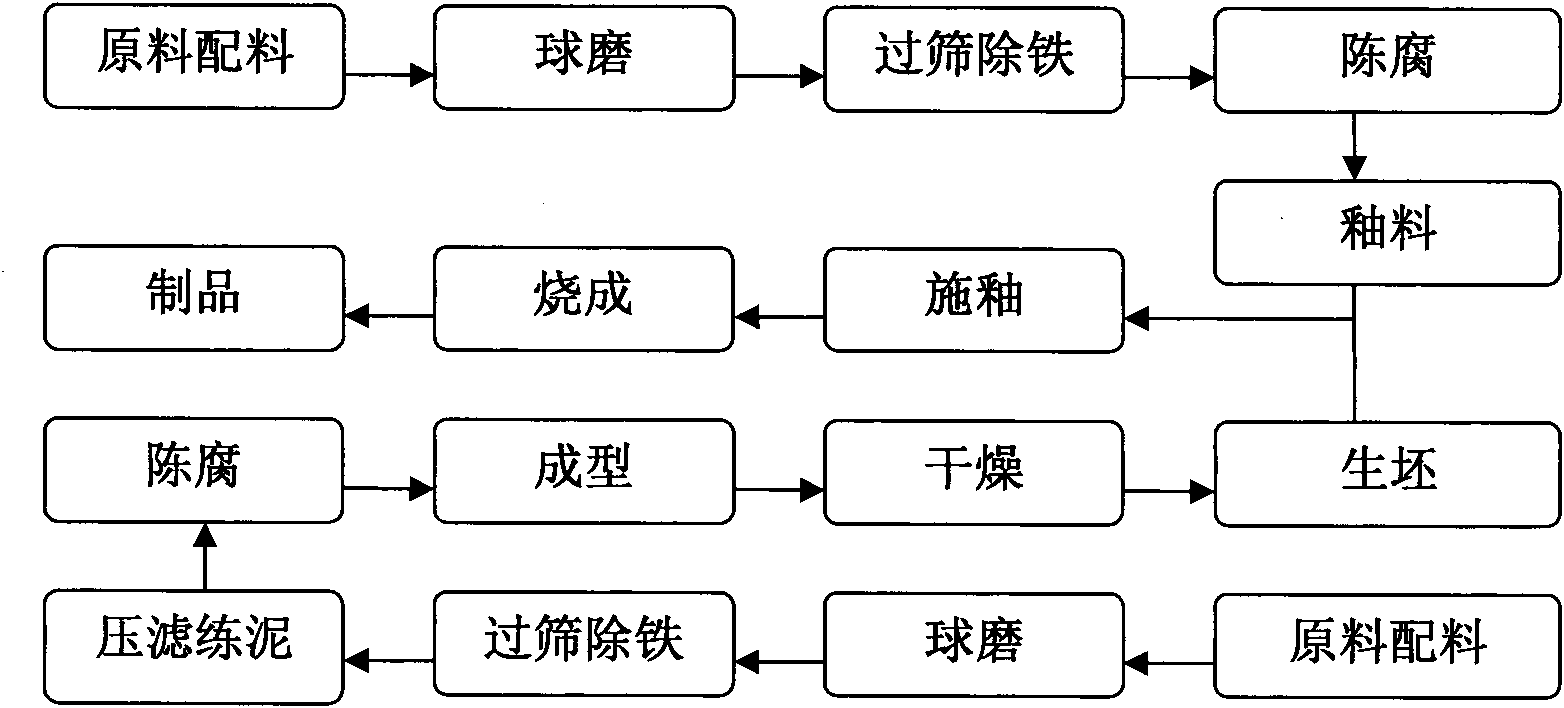

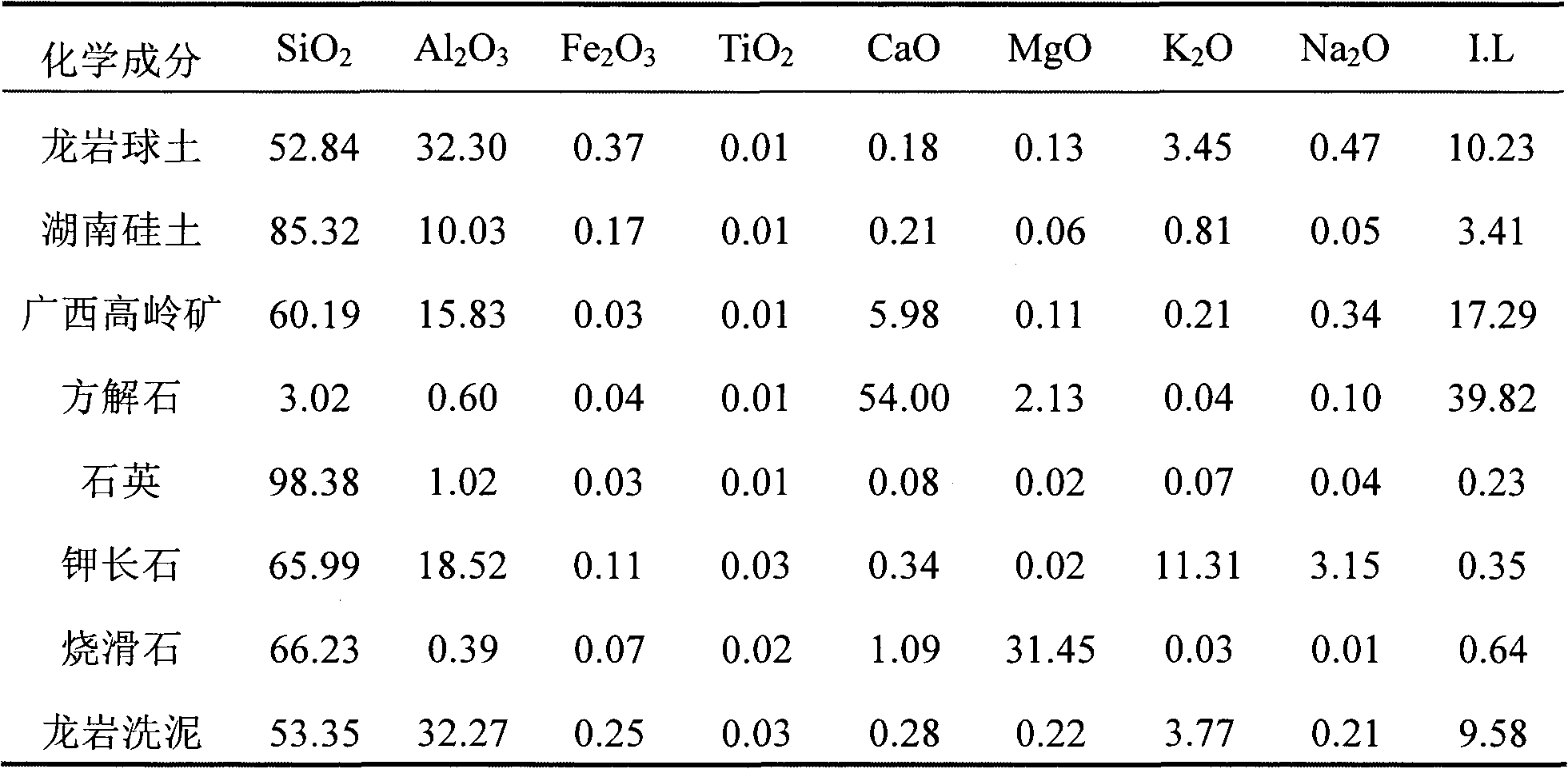

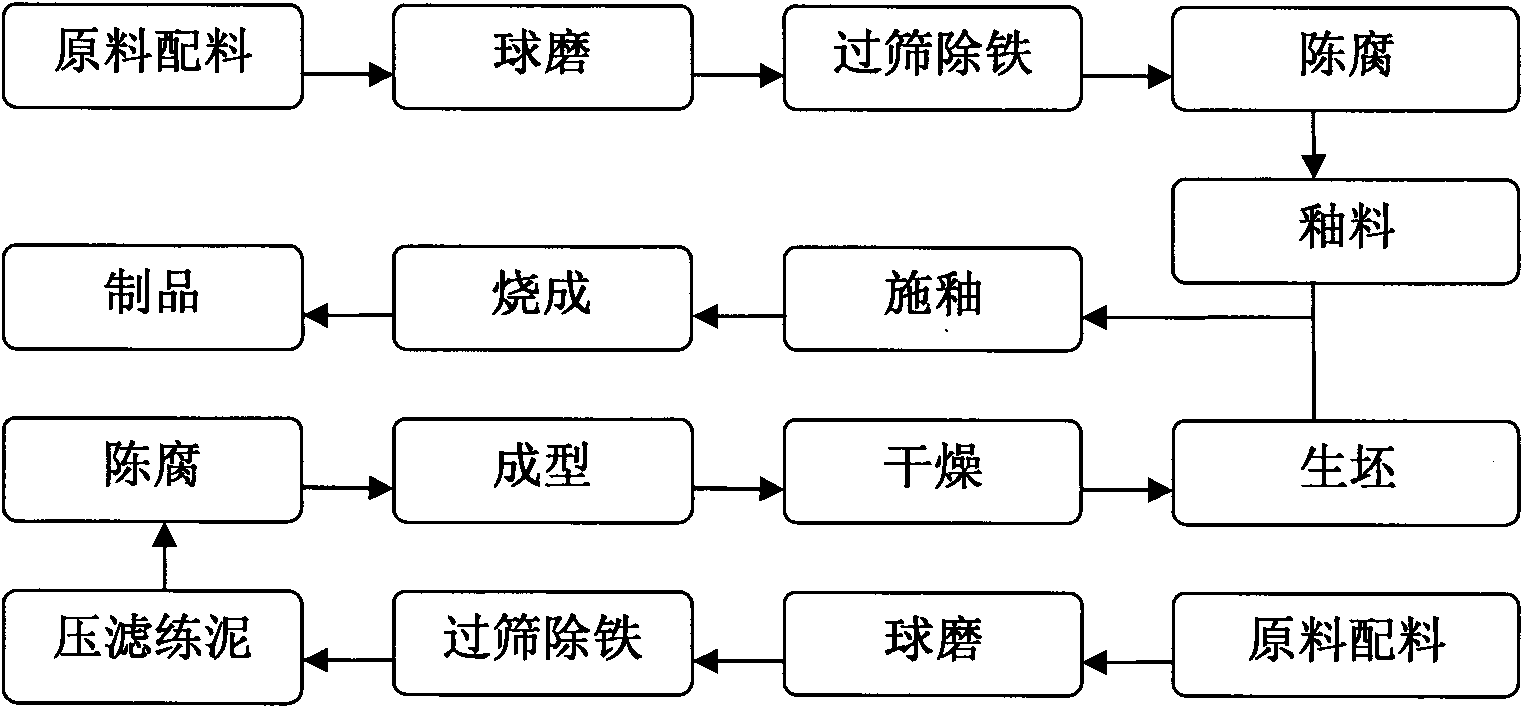

Preparation method of emerald ceramic

The invention discloses a preparation method of emerald ceramic, which comprises the steps of: (1) weighing raw materials according to a formula, mixing quartz, Guangxi Kaolinite and calcite for carrying wet-method ball-grinding, adding high-plasticity clay and low-plasticity clay for carrying out wet-method ball-grinding; (2) sieving and dewatering, ageing mud for 4-6 days, drying at a temperature of 80-110 DEG C after carrying out plastic forming; and (3) glazing, insulating the temperature at a temperature of 1240-1280 DEG C for 1-1.5h in an oxidizing atmosphere, and then cooling. The prepared emerald ceramic has the advantages of better permeability, light green color, emerald texture, high strength, good heat stability, lower production cost and better application value.

Owner:SOUTH CHINA UNIV OF TECH

Ginkgo tea and production method thereof

The invention discloses ginkgo tea and a production method thereof. The method includes the steps of removing petioles from emerald green ginkgo leaves which are picked and grow for 3-4 years, cutting the ginkgo leaves into strip shapes with the widths of 3-5 mm, removing the water of the ginkgo leaves, mixing and rolling the ginkgo leaves and fresh tea leaves after water removing according to the weight part ratio of (7-4): (3-6), stacking, fermenting and drying the leaves, and obtaining the ginkgo tea. The ginkgo tea is prepared according to the method. The ginkgo tea combines drink with functions of ginkgo medication and health care and is black bloom in the color, the shape of the ginkgo tea is similar to that of green tea, and the ginkgo tea has a fresh and cool taste of green tea, asweet and mellow taste of black tea and a lasting memorable taste, is convenient to drink, and is accepted by consumers easily. The production method is unique and simple, material mixture ratio is reasonable, and the ferment process plays a key role on improvement of product taste and sense effect.

Owner:陕西汉南茶业有限责任公司

New method for drying oolong

The invention provides a new method for drying oolong during the oolong processing. The method is characterized in that the oolong to be dried is not pre-frozen and directly put into a vacuum freeze drier to be dehydrated and dried in the conditions of low temperature (40 to 60 DEG C), vacuum (vacuity 100 plus or minus 30 Pa) and refrigeration (condenser frosted), without subliming process. The product has emerald green color, dense scent, pure flavor and good quality. Compared with traditional heated air drying, although the drying time is slightly longer and the energy consumption is slightly higher, the quality of the product is greatly improved. Compared with traditional vacuum freeze drying, the method not only also reduces the loss of the scent of the oolong and the oxidation of heat sensitive substances, but also improves the pure feeling of the flavor of the oolong, and the total quality is equivalent to the oolong prepared by traditional vacuum freeze drying. Moreover, the method does not require pre-freezing and subliming process, not only equipment and a larger amount of power required by pre-freezing are saved, but also 70 to 80 percent of drying time in the mass is reduced, the production efficiency is improved, and the technical practicability is higher.

Owner:GUANGXI GUILIN TEA RES INST

Cultivation liquid for emerald pearls

InactiveCN102177859ASolve monotonous colorsClimate change adaptationPisciculture and aquariaPink colorVitamin B12

The invention discloses cultivation liquid for emerald pearls. Surfaces of pearls formed by the conventional growth method are in an off-white color, a yellowish-white color, a baby pink color and the like, although the pearls have beautiful colored luster, the colors are still monotonous, and particularly the emerald effect of the pearls cannot be shown. The cultivation liquid for the pearls is prepared from animal biliary liquid, bamboo juice, parasitic plant juice, ophiuros juice, seabed stone solution and vitamin B12 solution. In the practice process, after cultivated pearl nuclei are processed by the cultivation liquid, the pearls are cultivated by the conventional cultivation method for 1 to 2 years, and nacreous layers of the obtained pearls achieve the transparent or semitransparent emerald effect, the pearls are glittering and translucent, round as the pearls and smooth as jade, gorgeous and noble, beautiful and colorful, and mainly take green and blue colors.

Owner:北海市源龙珍珠有限公司

Production method of selenium-enriched green tea

The invention discloses a production method for selenium-enriched green tea. Selenium content in green tea can be significantly increased by utilizing the production method. The production method is implemented through the following technical scheme: spraying mixture of 100g of humic acid selenium titanium fertilizer and 40-50kg of water to tea tree leaf surface per mu before tea picking, and 8-15 days after fertilization, finishing fresh leaves picking. The production method comprises the following steps of: 1) spreading and airing for 3-4 hours; 2) carrying out enzyme deactivation at temperature of 285-340 DEG C for 55-65 seconds; 3) tidying tea strip at 220-240 DEG C for 3-5 minutes; 4) reshaping at 185-195 DEG C and gently pressing for 55-65 seconds; 5) drying at 75-195 DEG C twice, 9-11 minutes each time; and 6) refining: spreading dried tea, removing stalks, and sieving and finally packaging. The prepared green tea has high selenium content and emerald green color and luster.

Owner:镇江市丹徒区上党墅农茶叶专业合作社

Processing and making method of sweet potato leaf tea

The invention relates to a processing and making method of sweet potato leaf tea. The processing and making method is characterized by comprising nine steps as follows: picking, stripping, tedding, fixation, drying with wind, rolling, sieving, aroma-increasing, dehydration and the like. The processing and making method has the beneficial effects that in appropriate seasons, fresh and tender sweet potato leaves are picked, and leaf stems and crude veins are stripped, so that clean and pure degrees of the sweet potato leaf tea can be maintained, and steam of the leaf stems and the crude veins is used for performing steam fixation, and pure fragrance of the sweet potato leaf tea can be further guaranteed; fixation and drying with wind can be performed through a conveyor belt, so that the shape of leaf blades can be maintained, and shapes, appearances and dimensions of the formed tea are uniform; rolling is performed when the dried tea is hot, so that perfect models can be obtained, bitterness in the sweet potato leaves can be removed, and after the aroma increasing, the bitterness can be further covered. The sweet potato leaf tea made in the manner is tidy in appearances, emerald green in color, clean, pure and strong in fragrance, dark green and transparent in color of tea soup, fresh, tender and mellow in taste of the tea soup, and elegant and fragrant in smell of the tea soup. The quality of sweet potato leaf tea products is greatly improved.

Owner:聂洪品

Process for drying green tea

ActiveCN102763738AKeep the shape and colorIncrease aromaPre-extraction tea treatmentFlavorFreeze-drying

The invention discloses a process for drying green tea, comprising the steps of low-temperature vacuum drying and hot-air drying. The process is characterized by comprising the following steps: putting the green tea which is rolled by adopting the conventional techniques into a vacuum freeze-drying machine directly, heating to dehydrate in the vacuum environment, taking the green tea out of the vacuum freeze-drying machine after the content of the moisture in the green tea is reduced to 20-28%, and drying by adopting the traditional hot-air drying method until the content of the moisture in the green tea is reduced to 6% or lower. The low-temperature vacuum drying mode and the hot-air drying mode are both used, the advantages of the two drying modes are absorbed, and the disadvantages are discarded. The green tea can be kept green in appearance and tastes more aromatic, and the bitter and puckery flavor of the green tea is improved. The product is emerald green, has mild or chestnut and flower fragrance and mellow taste. The green tea water is greenish yellow and bright, and the tea leaves are green and bright. Due to the adoption of the process, the quality of the product is improved greatly, and the production efficiency is improved. The process is easy and convenient to operate and practical.

Owner:广西昭平县古书茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com