Patents

Literature

168results about How to "Short dyeing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

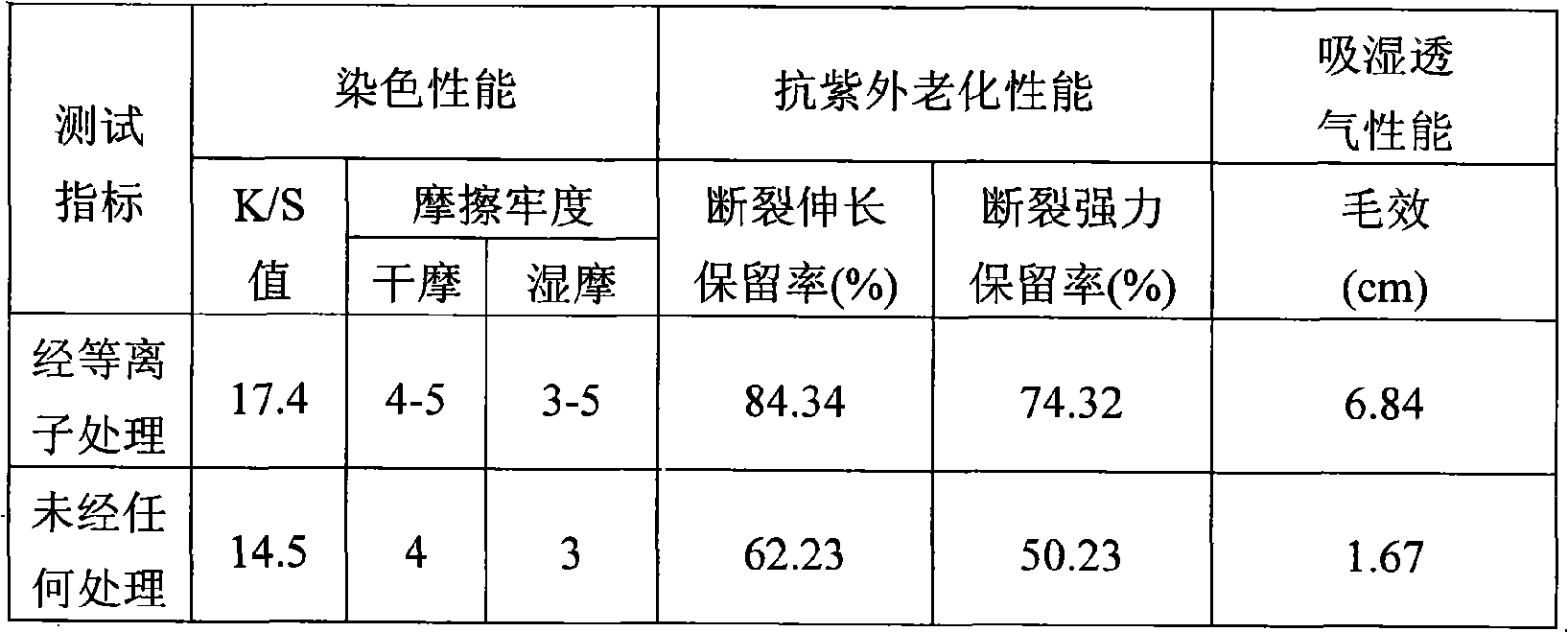

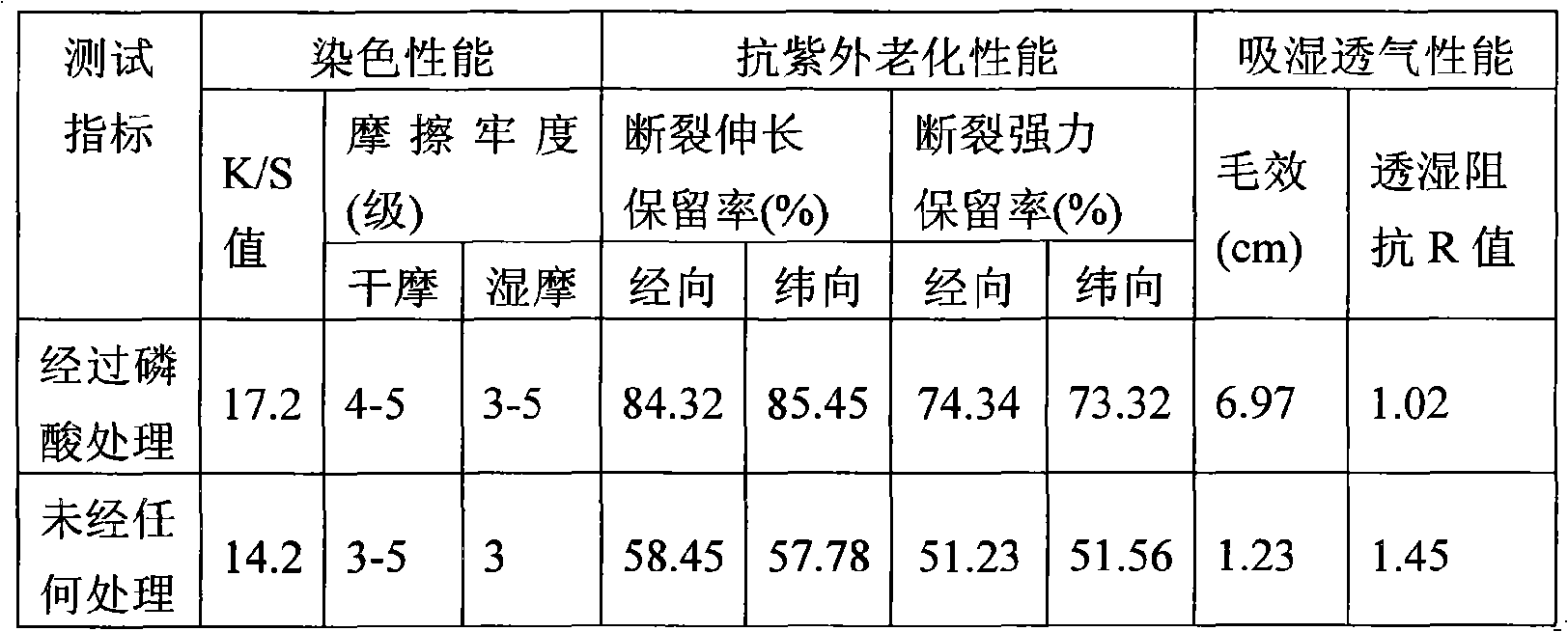

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

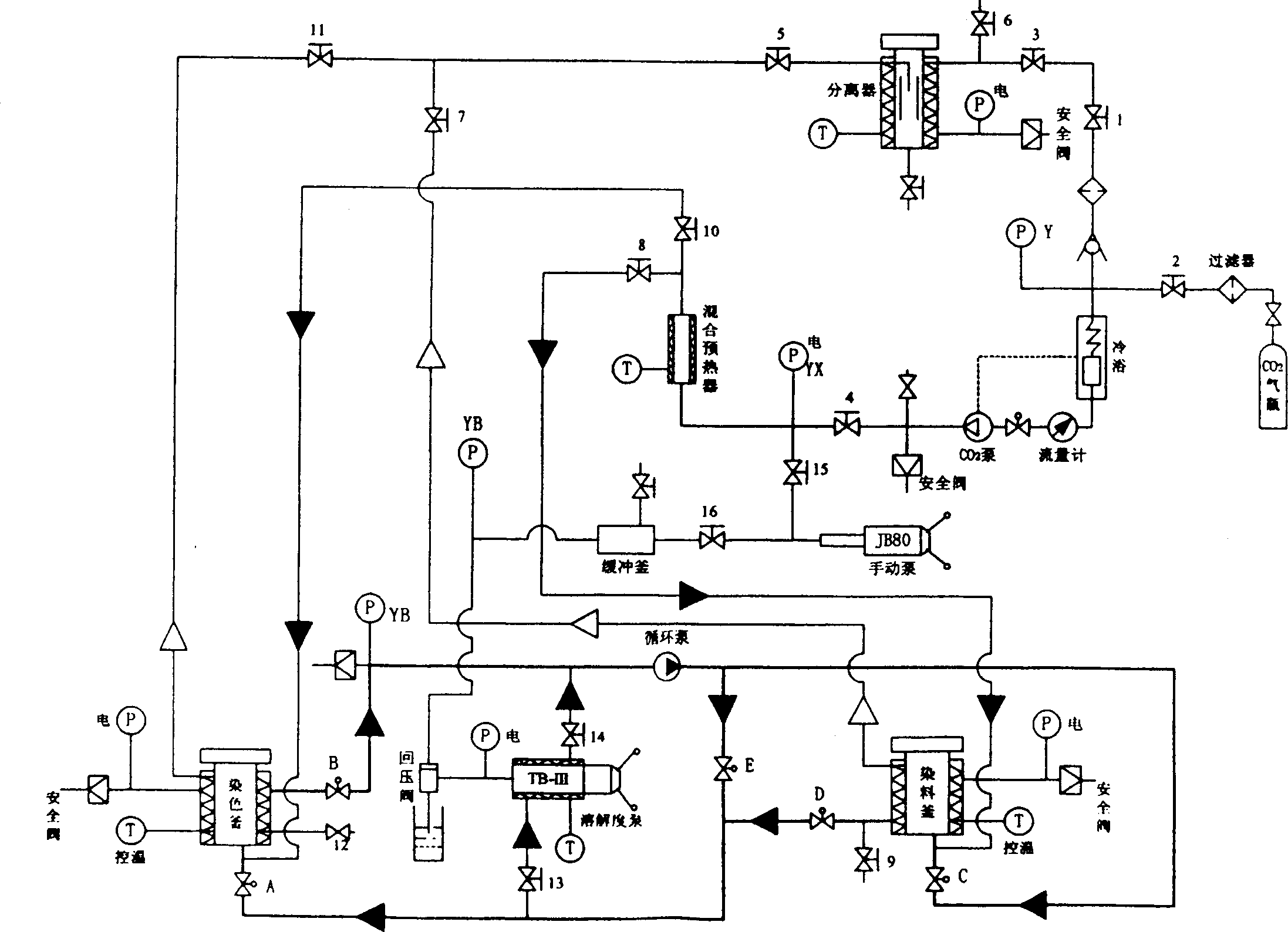

Super critical CO2 fluid dyeing technology

This invention discloses a supercritical carbon dioxide fluid dyeing technique. The carbon dioxide heated is suppressed into dye tank and mixed with the dye to form blending solution. Blending solution is pumped into dye tank after cycle. The solution is contacted to tissues in the tank, and then it is absorbed, dissolved, then twice again absorbed and dissolved, so the dyeing is finished. The rest blending solution after dyeing is pumped into separator through circulating pump, and then carbon dioxide and dye are separated. There is no assistant in all process, cost is saved, the carbon dioxide can be cycle used and no green house effect, the inhalation rate can reach 98%, and dyeing time is short. There is no need of reduction clearing after dyeing; the rest dyeing can be reverted to powder type, so the coloring utilization ratio can be increased.

Owner:NANTONG HUAAN SUPER CRITICAL EXTRACTION

Manufacturing process of grass cloth

InactiveCN102747436ALow residual glue rateImprove dye uptakeBleaching apparatusVegetable materialYarnBacillus alcalophilus

The invention discloses a manufacturing process of grass cloth. The process comprises the steps of pre-stage preparation, degumming, warp yarn preparing, weaving, bleaching, dehydrating, dyeing, finishing, and packaging. According to the invention, ramie is subjected to the degumming process by using bacillus alcalophilus, such that ramie residual gum content can be effectively reduced, product safety is improved, and cloth dye uptake can be improved. With modification upon the bleaching process, cloth color stability is ensured, and bleaching duration can be reduced, such that working efficiency can be improved. The grass cloth manufacturing process provided by the invention is advantaged in low environmental pollution, high dye uptake, high color fastness, and short dyeing duration. With the process, economic benefit can be improved. The process is suitable for industrialized productions.

Owner:TAICANG MINGLIU GARMENT

Dyeing finishing process of elastic jean fabric

InactiveCN104032595AShort dyeing timeImprove dyeing efficiencyDry-cleaning apparatus for textilesDyeing processAfter treatmentEngineering

The invention relates to the textile field and in particular relates to a dyeing finishing process of an elastic jean fabric. The dyeing finishing process comprises the steps of material selection, pretreatment, water washing, slacking treatment, dyeing, water washing, color fixation, heat setting and after-treatment. The dyeing finishing process is characterized in that the water washing and slacking treatment steps are added after the pretreatment step so that the jean fabric is more stable and subsequent dye homogeneity can be achieved more easily; in addition, as the color fixation step is added after the second time of water washing to further fix the dyeing of the fabric, the dyeing effect of the fabric can be improved; the dyeing finishing process has obvious beneficial effects and is suitable for popularization and utilization.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

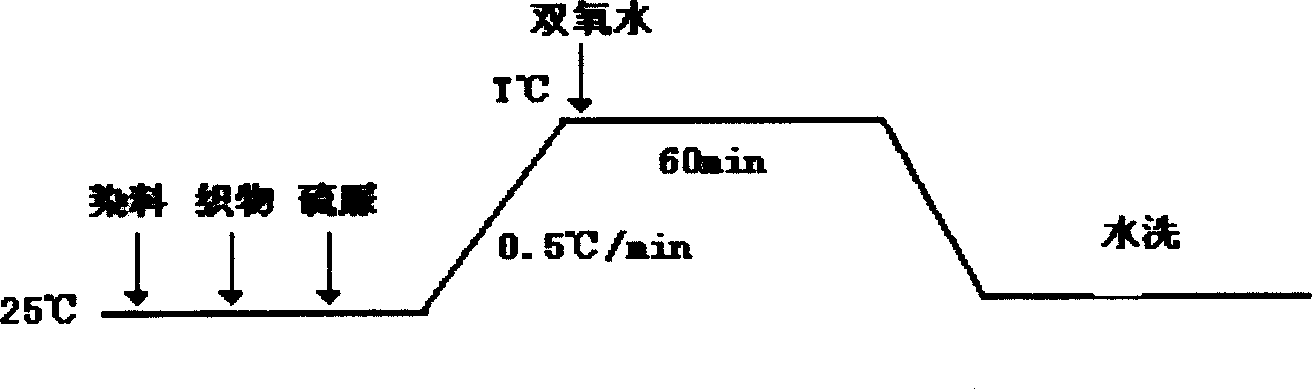

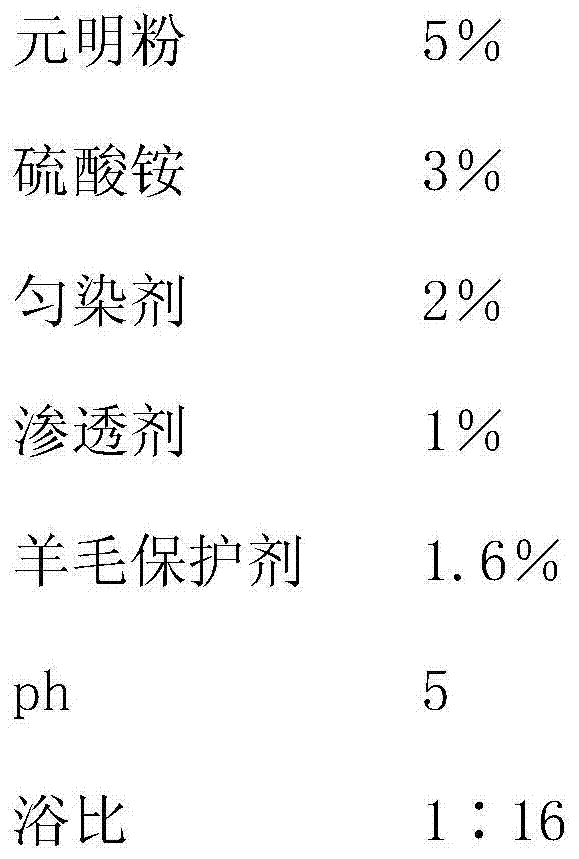

Wool low-temperature dyeing method

The invention discloses a low-temperature wool dyeing method, adding routine dye and assistant as well as reducer into the dye bath, then heating to 70-85 deg.C, adding in oxidizer and preserving heat and dyeing, where the ratio of the reducer to the oxidizer is 3 : 1. As compared with the existing techniques, it has advantages of high dyeing rate, good dyeing uniformity, high dye bath absorption ratio, short dyeing time, low dyeing temperature, etc. and it can be applied to wool dyeing with acidic and active dyes.

Owner:ZHEJIANG SCI-TECH UNIV

Method for dyeing fabric containing polyester fiber and tencel fiber

The invention discloses a method for dyeing a fabric containing polyester fiber and a tencel fiber. The method comprises the following steps of: (1)carrying out refining and polyester fiber dyeing to the fabric containing the polyester fiber and the tencel fiber in the first dyeing liquid containing dispersed dye and a refining agent for 20 to 40 minutes at 120 to 140 DEG C; (2) carrying out tencel fiber dyeing to the fabric dyed by the polyester fiber in the second dyeing liquid containing reactive dye for 45 to 75 minutes at 50 to 70 DEG C; and (3) processing the dyed fabric through pickling, soaping, pickling and hair removing in sequence. With the adoption of the method disclosed by the invention, dyeing time is shorter, water consumpton is less, therefore, energy consumption is greatly reduced; and moreover, the surface of the dyed fabric is smooth and clean and has no filoplume as well as no dyeing defect; quality of the fabric is promoted; and the method specifically has an obvious dyeing effect on bright color series, such as emerald green and bright blue.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

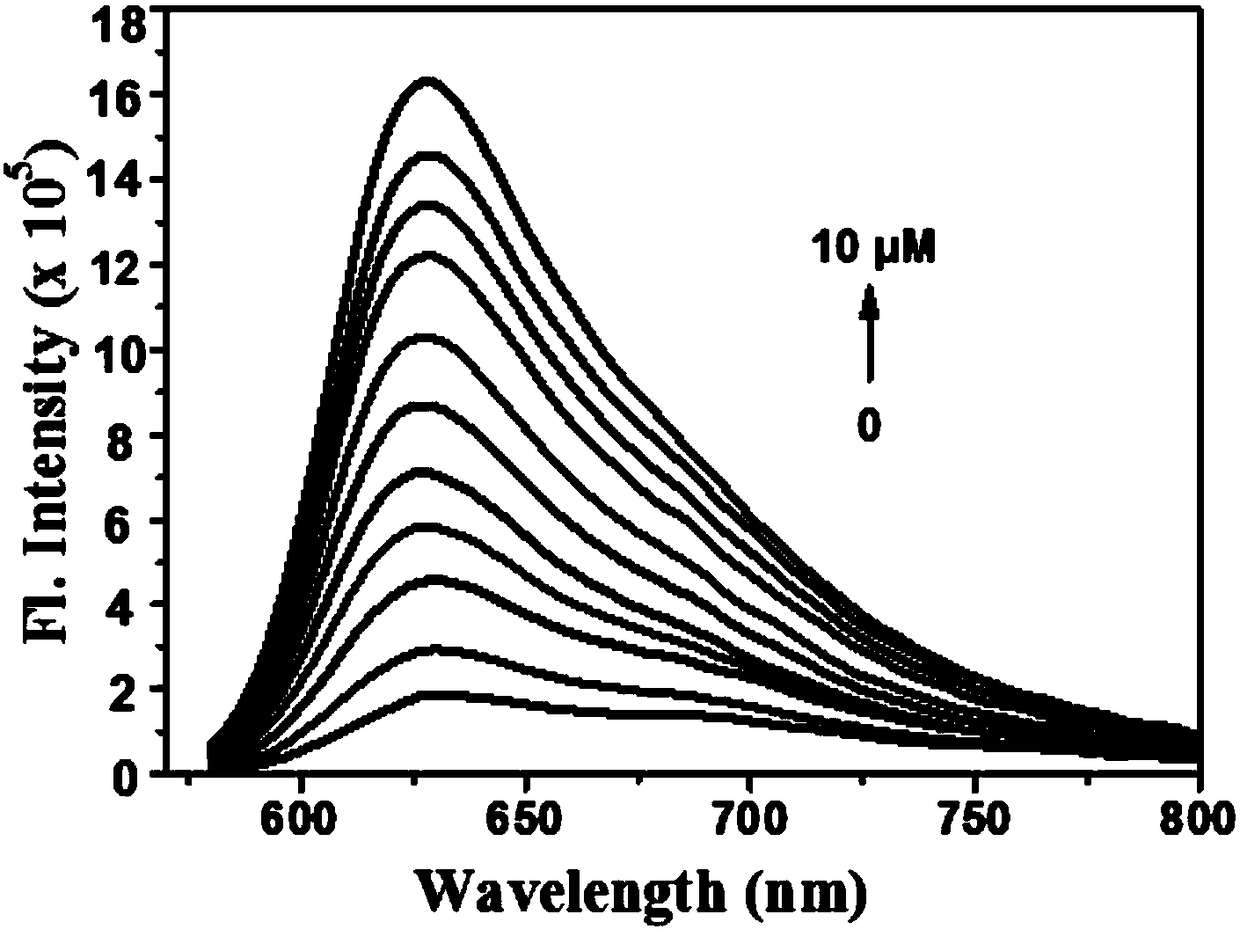

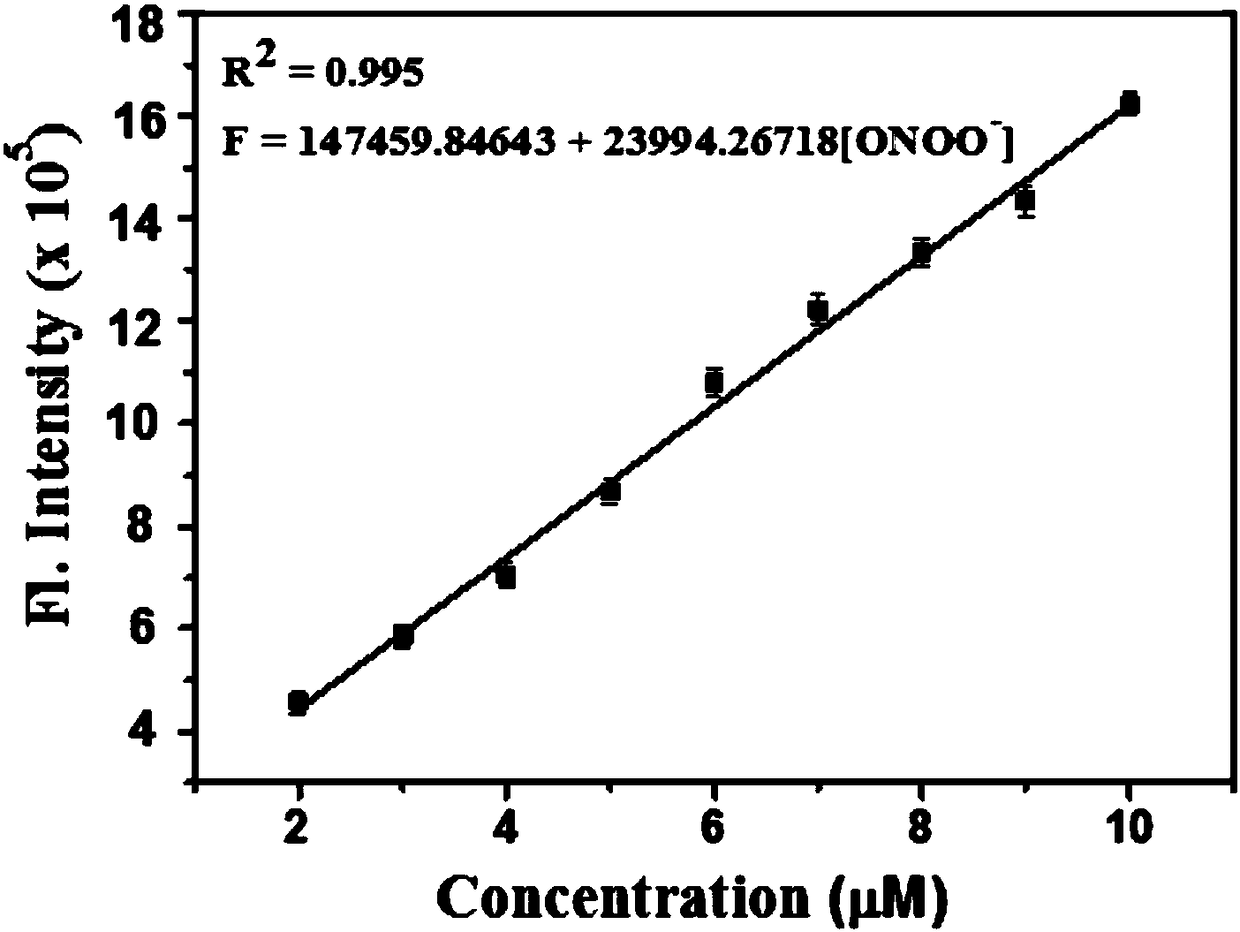

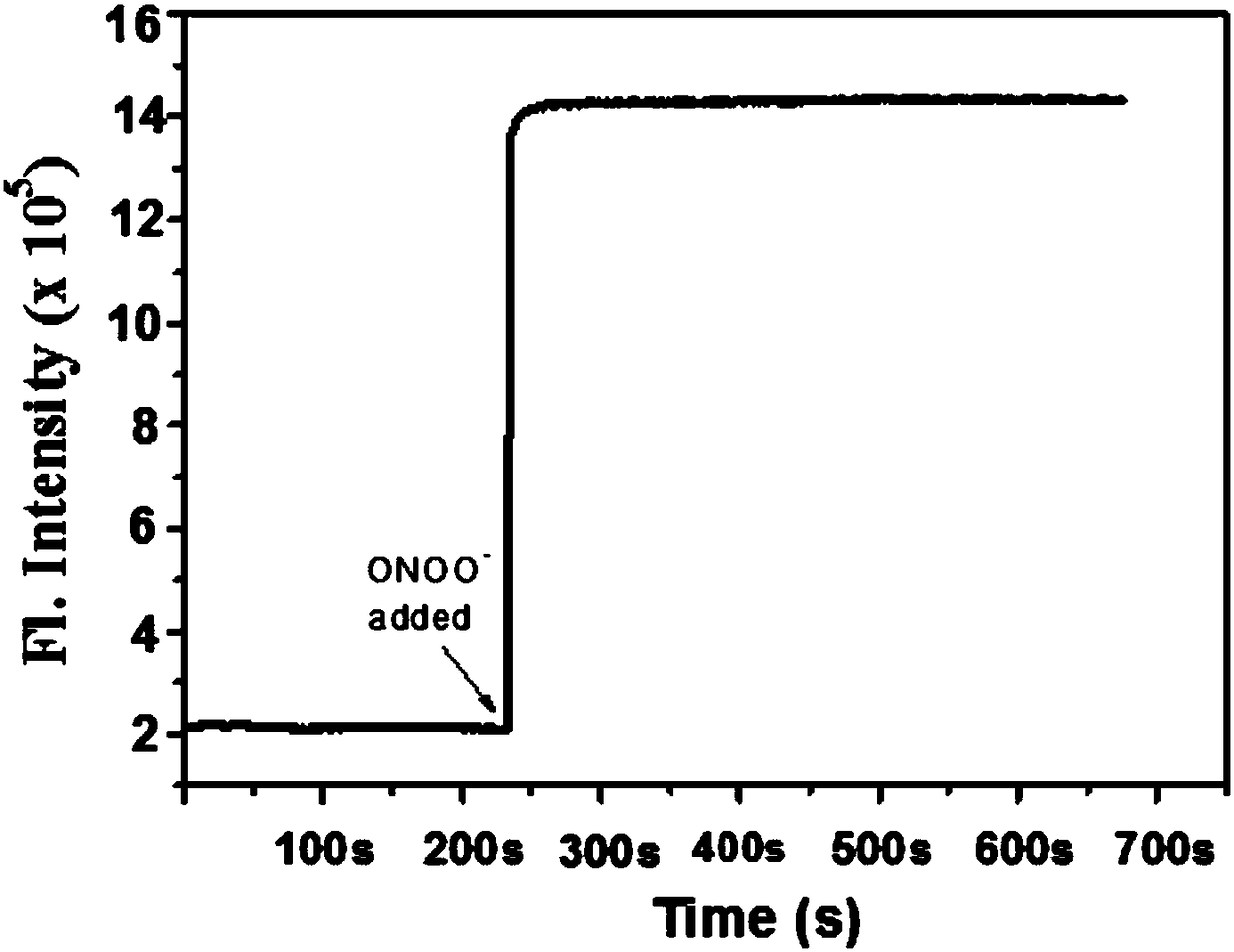

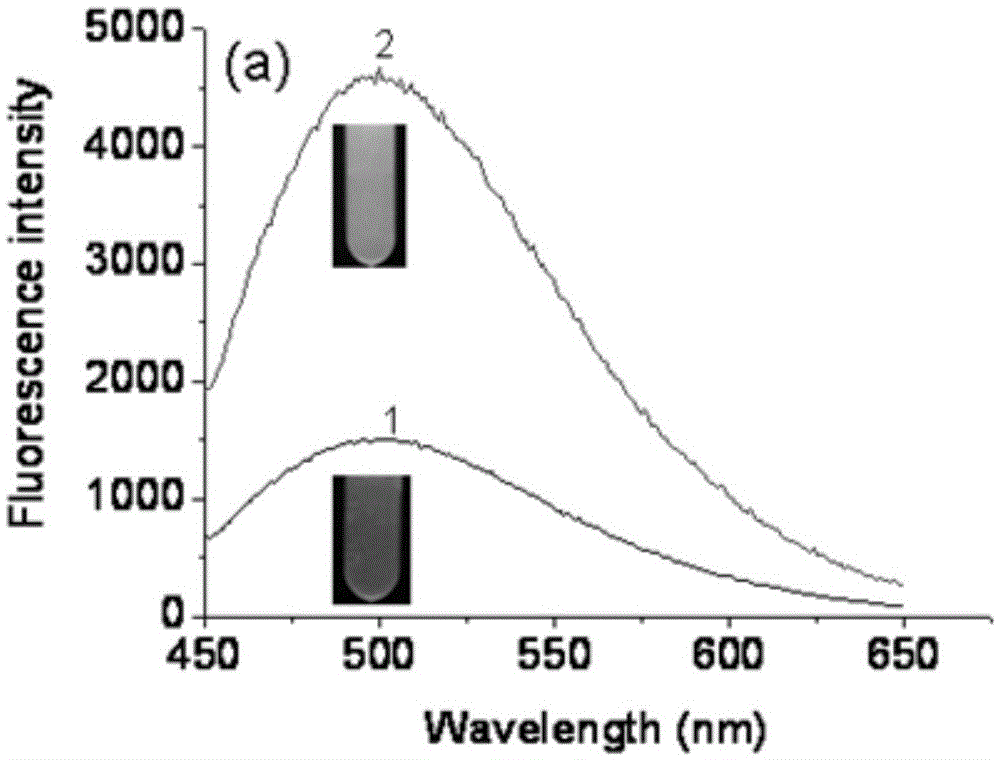

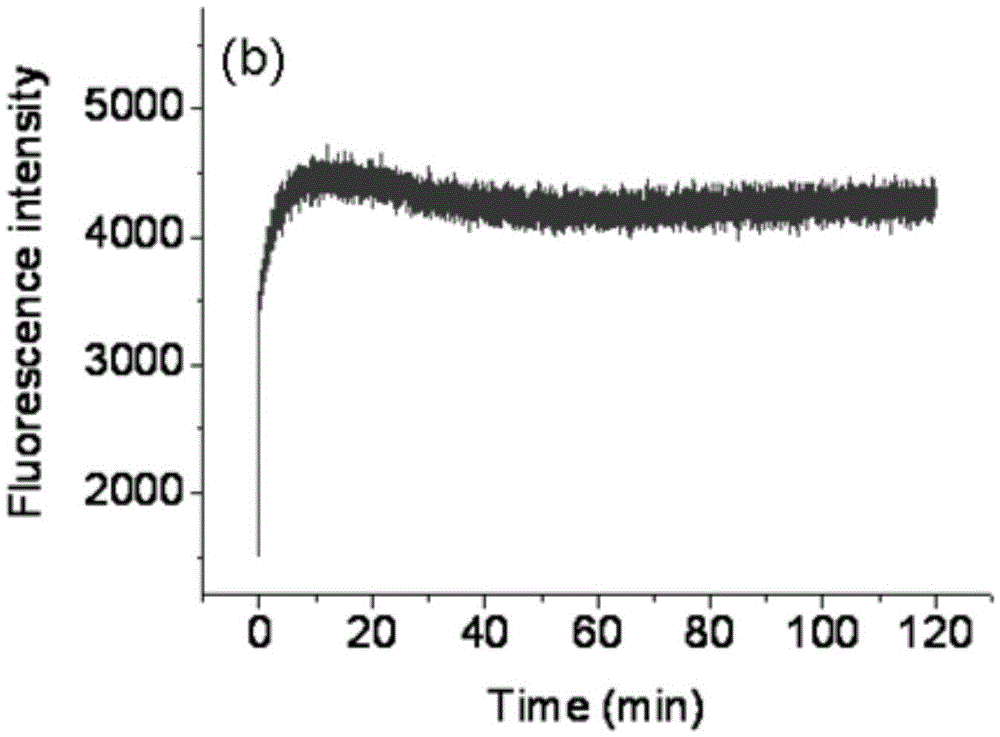

Two-photon fluorescence probe for detecting peroxynitrite as well as preparation method and application of two-photon fluorescence probe

ActiveCN108164494AIncrease penetration depthReduce self-absorptionOrganic chemistryFluorescence/phosphorescencePeroxynitriteStructural formula

The invention discloses a two-photon fluorescence probe for detecting peroxynitrite as well as a preparation method and application of the two-photon fluorescence probe. The two-photon fluorescence probe has the structural formula as shown in the description. The two-photon fluorescence probe is named as TPNIR-FP. The two-photon fluorescence probe adopts a Nile red derivative as a fluorescent group and an alpha-keto-amide functional group as an ONOO-reaction group, can rapidly respond to ONOO- (within 10 seconds), and in addition is high in sensitivity and good in selectivity. The two-photon fluorescence probe can be applied to imaging research on ONOO- in antharcycline antibiotic induced cardiac muscle cell and cardiac muscle tissue damage.

Owner:SHANDONG NORMAL UNIV

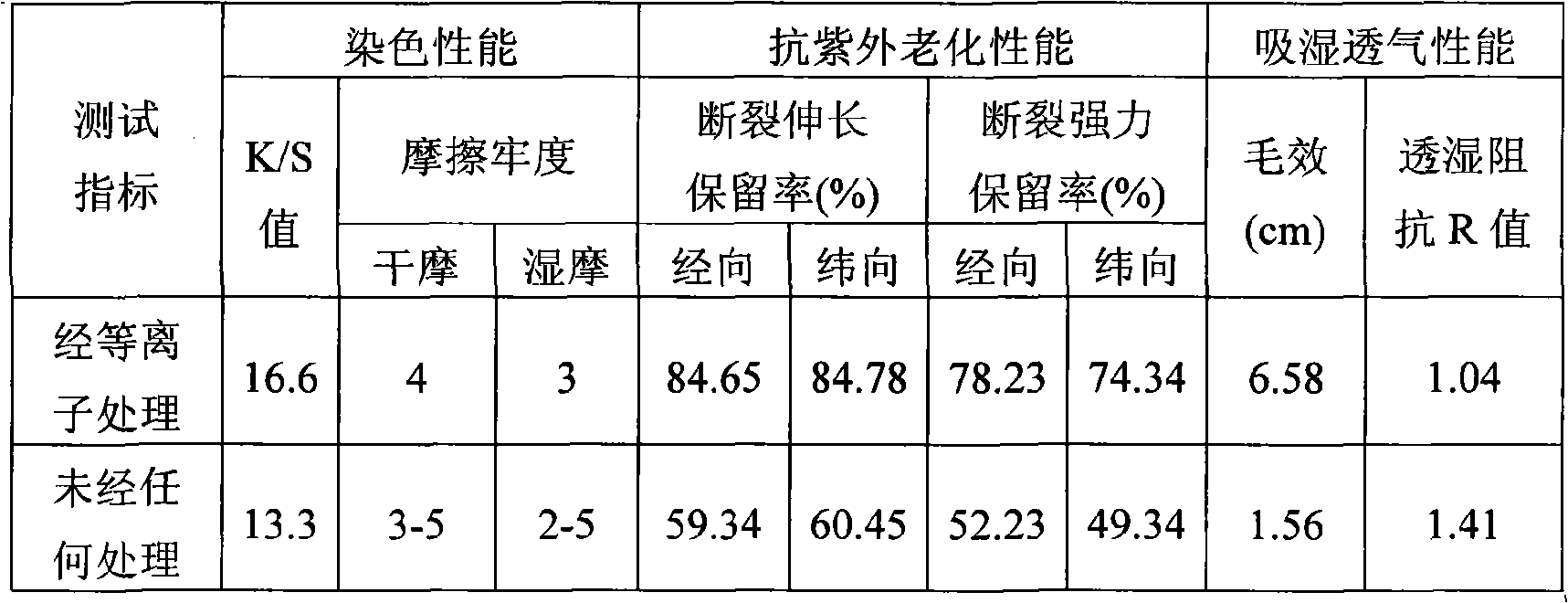

Supercritical carbon dioxide dyeing technology for low-temperature-plasma pretreatment of aramid fiber/viscose glue blended fabric

InactiveCN104278567AShort dyeing timeShorten the production cyclePhysical treatmentDyeing processPre treatmentDyeing

The invention relates to a supercritical carbon dioxide dyeing technology for low-temperature-plasma pretreatment of aramid fiber / viscose glue blended fabric. The technology employs supercritical CO2 as a medium to dye fabric, and is a novel waterless dyeing technology. Compared with conventional dyeing methods, the technology has the advantages of water saving, environment protection, energy saving, dispensing with auxiliary agents and the like, is short in dyeing time, and is capable of shortening production period and improving economic benefit.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

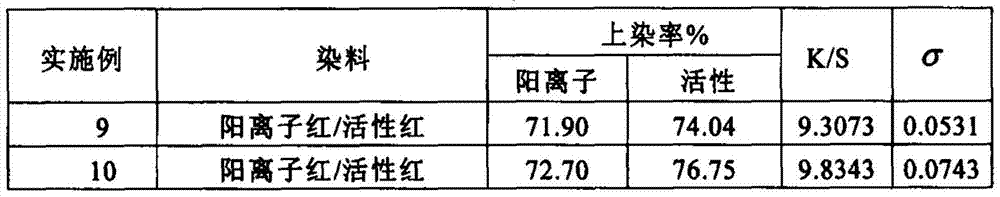

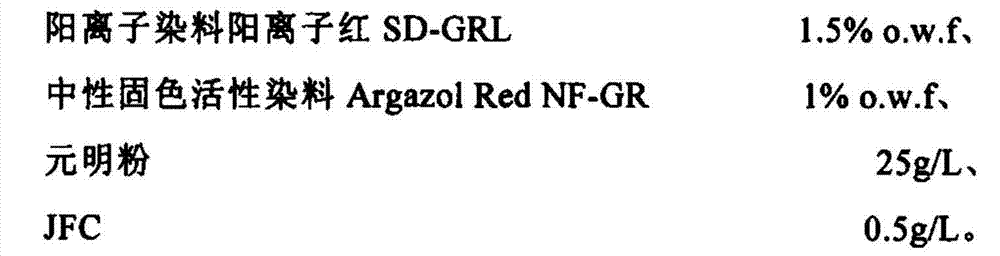

Dyeing method of cationic modified cellulose fiber fabric

InactiveCN105672003ASolve the problem of energy consumptionSolve pollutionHeating/cooling textile fabricsDyeing processCellulose fiberAmmonium

The invention relates to a dyeing method of a cationic modified cellulose fiber fabric. The method comprises the following steps of fiber modification, gray fabric pre-setting, reduction clearing, dyeing auxiliary formula design, preparation, dyeing process and fixation aftertreatment, wherein two cationic modifiers of a micromolecule quaternary ammonium salt modifier and a macromolecule quaternary ammonium salt modifier are used for conducting modification treatment on a cellulose fiber fabric, then dyeing is conducted, and dyeing auxiliaries with special components are added for promoting dyeing. The dyeing method of the cationic modified cellulose fiber fabric has the advantages that cationic modified cellulose fibers are adopted for dyeing, and meanwhile the dyeing auxiliaries with the special components are added to increase the exhaustion rate and fixation rate of dye and improve color fastness to washing of dyeing materials.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

Fluorescent probe for detecting peroxynitrite and preparation method and application thereof

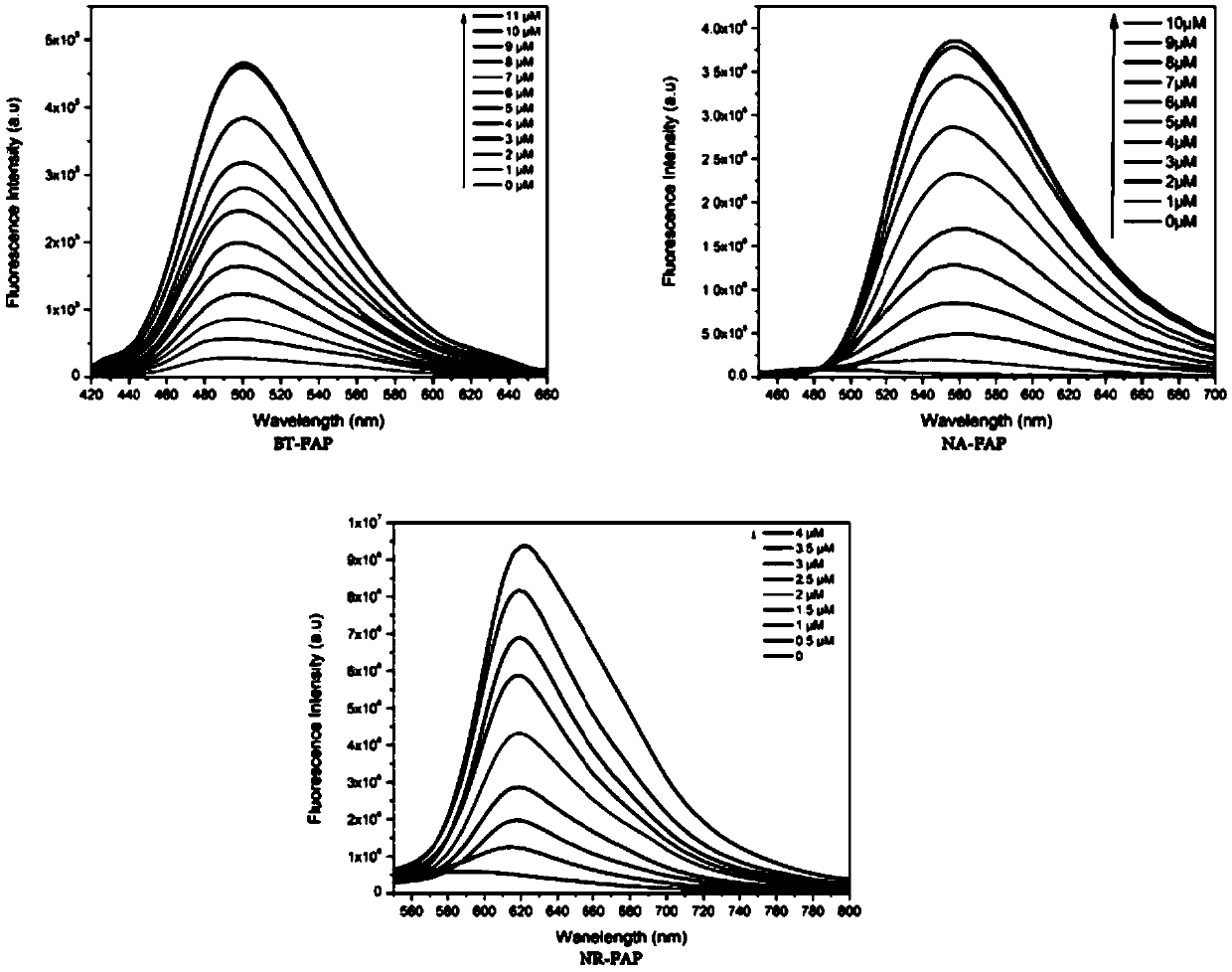

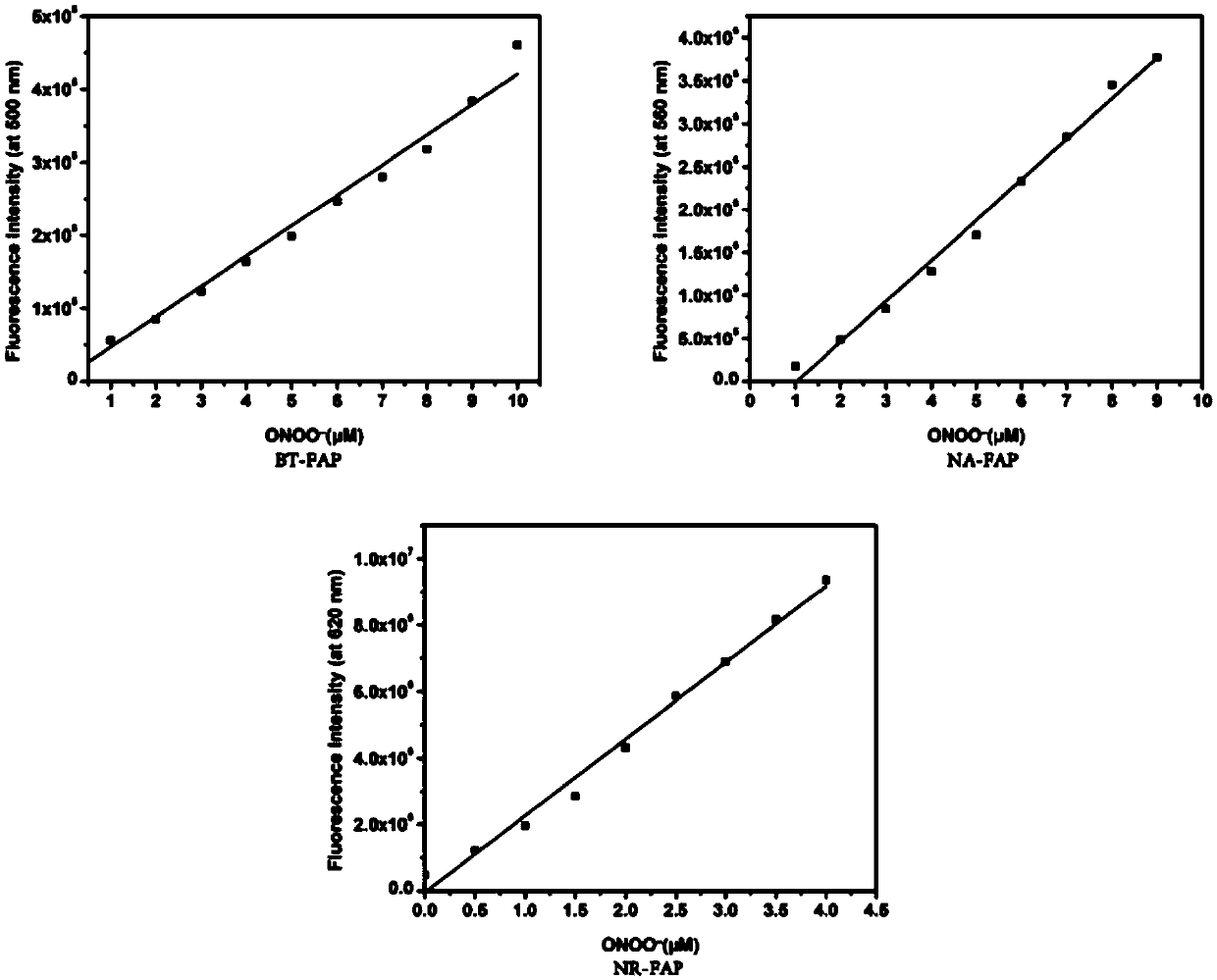

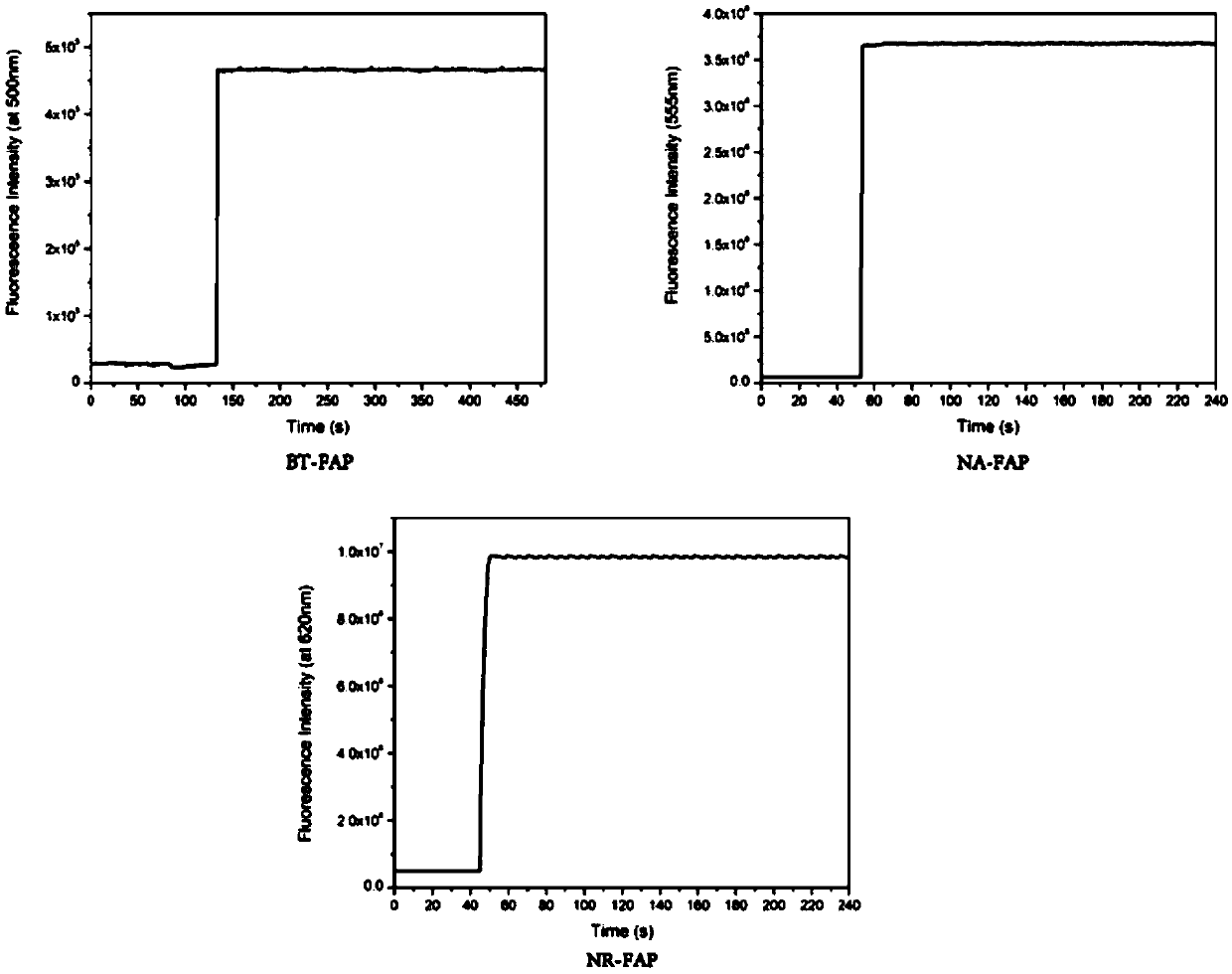

ActiveCN109608414AImprove accuracyReduce self-absorptionOrganic chemistryFluorescence/phosphorescenceNitriteImaging study

The invention belongs to the technical field of synthesis and detection, and particularly relates to a fluorescent probe for detecting peroxynitrite and a preparation method and application thereof. The invention provides a universal identification group for detecting peroxy nitrite, and three new fluorescent probes which are respectively named as BT-FAP, NA-FAP and NR-FAP are formed by connectingthe universal identification group with common fluorophores, wherein aminonaphthalene (BT), naphthalimide (NA) and benzophenoxazine (NR) are the fluorophores, and formamide (FAP) is the identification group to achieve the instant reaction with ONOO (all 4s), the fluorescent probe has high sensitivity and good selectivity, and is very suitable for ONOO fluorescence imaging studies in cells.

Owner:SHANDONG NORMAL UNIV

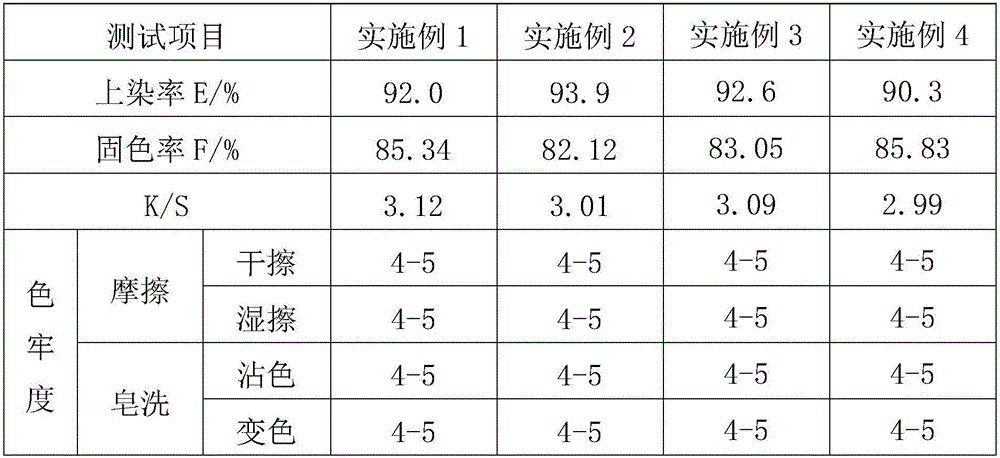

Cellulose fiber fabric cationic modification and salt-free alkali-free dyeing method

The invention relates to a cellulose fiber fabric cationic modification and salt-free alkali-free dyeing method. The method comprises following steps: adding soft water into a gas-liquid dyeing machine, adding cellulose fiber fabrics and a cationic modifier into the dyeing machine, starting the dyeing machine; adding sodium hydroxide into the dyeing machine from a material dissolving cylinder, adjusting the water level, running the dyeing machine, raising the temperature, discharging the modification liquid, washing the fabrics by a water solution of glacial acetic acid at a room temperature,taking out the fabrics, dehydrating the fabrics to obtain cation modified fabrics; adding soft water, adding cation modified cellulose fiber fabrics, dissolving active dyes, injecting the dyes into the dyeing machine, raising the temperature to the dyeing temperature, maintaining the temperature, discharging dyeing liquid, taking out the fabrics, and dehydrating and drying the fabrics. In the gas-liquid dyeing machine, cellulose fiber fabrics are modified under conditions: medium-low temperatures and a small bath ratio; the using amount of modifier is little; the surface and interior of fabrics are uniformly modified; the modified fabrics can be dyed without salt or alkali, furthermore, the dyeing time is short, the dyeing process is simple and controllable, the color is uniform and bright, and the color fastness meets the standards.

Owner:SOUTH CHINA UNIV OF TECH +1

High-elongation skin-friendly cashmere yarn

InactiveCN104726982ANo damageExcellent indicatorsBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnPolymer science

The invention discloses a preparation method of high-elongation skin-friendly cashmere yarn. Basically no chemical agents are added in the whole processing process of the high-elongation skin-friendly cashmere yarn. Biological enzymes especially papain and bromelain are fully utilized in the process. Operation is easy, and the optimal parameters of the technique are verified through a large number of experiments. Compared with indexes of cashmere yarn in the prior art, multiple indexes of the prepared cashmere yarn are greatly improved, and especially the advantages of the high elongation and the skin-friendly effect are achieved.

Owner:ZHEJIANG MIHUANG CASHMERE

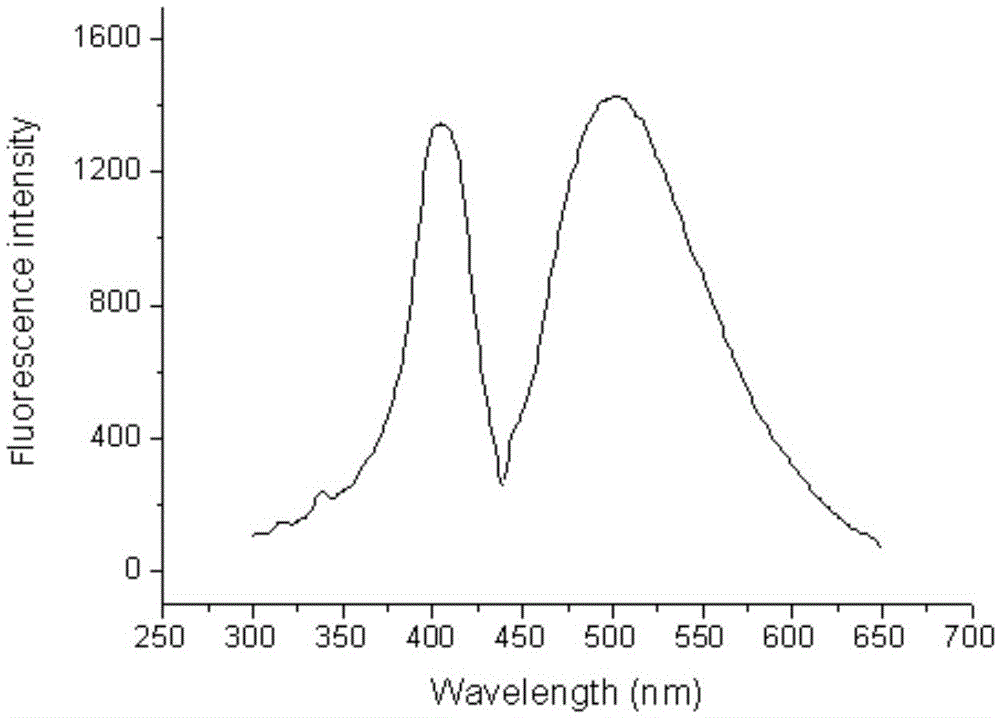

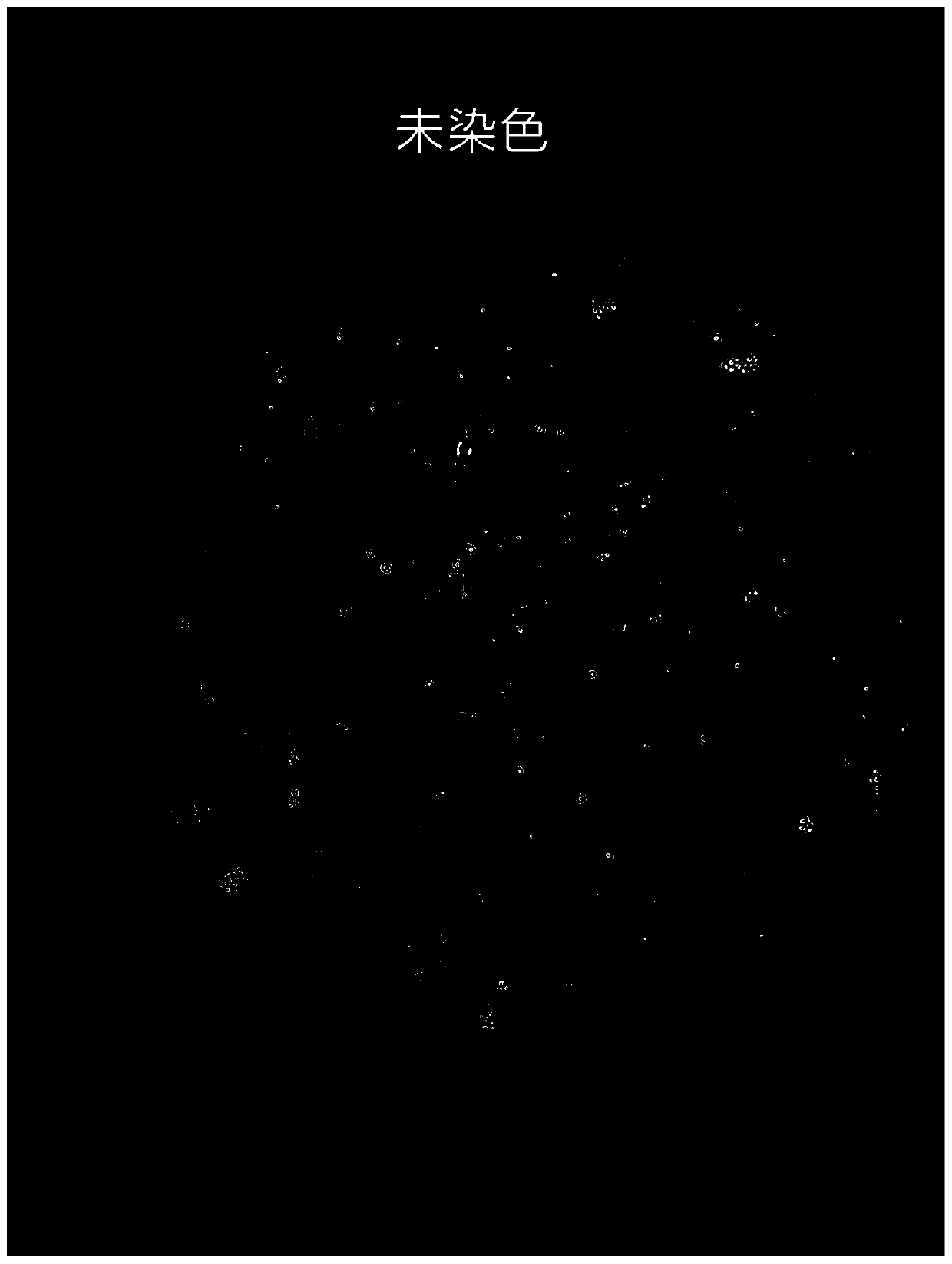

Fluorescent probe for rapidly responding to hydrogen peroxide as well as preparation method and application thereof

InactiveCN105482810AGood dyeing effectShort dyeing timeGroup 3/13 element organic compoundsFluorescence/phosphorescenceAggregation-induced emissionSolvent

The invention discloses a fluorescent probe for rapidly responding to hydrogen peroxide as well as a preparation method and application thereof. The structural formula of the fluorescent probe is shown in the specification. A raw material TPE-Br and bis(pinacolato)diboron are dissolved in a solvent, a reaction is carried out under a heating condition with a catalyst, the probe is obtained, and the probe is named TPE-BO. The probe molecule has an aggregation-induced emission property, and response time between the fluorescent probe and hydrogen peroxide is effectively reduced by 10 minutes. The dyeing effect for living cells is good, the dyeing time is short, and the dyeing efficiency is high. The synthesis steps are relatively simple, the yield is high and purification is easy.

Owner:SHANDONG NORMAL UNIV

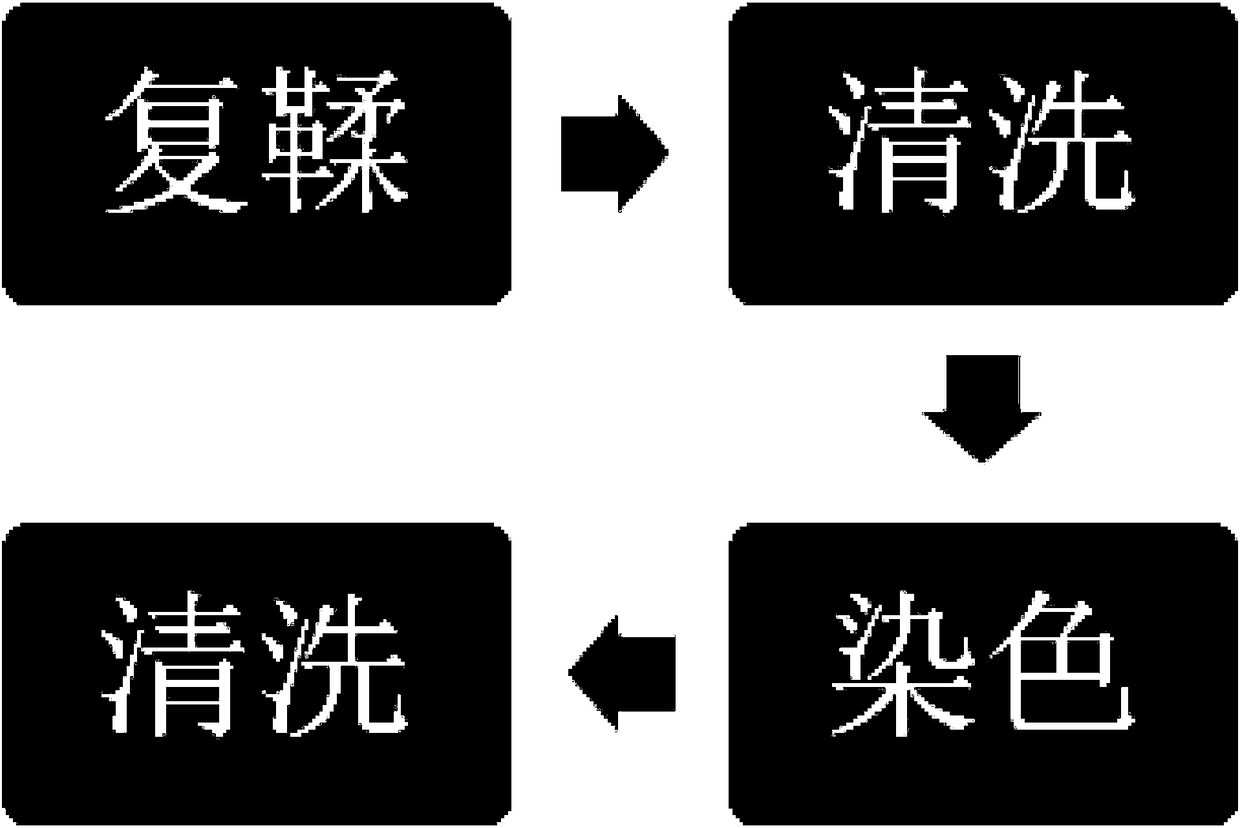

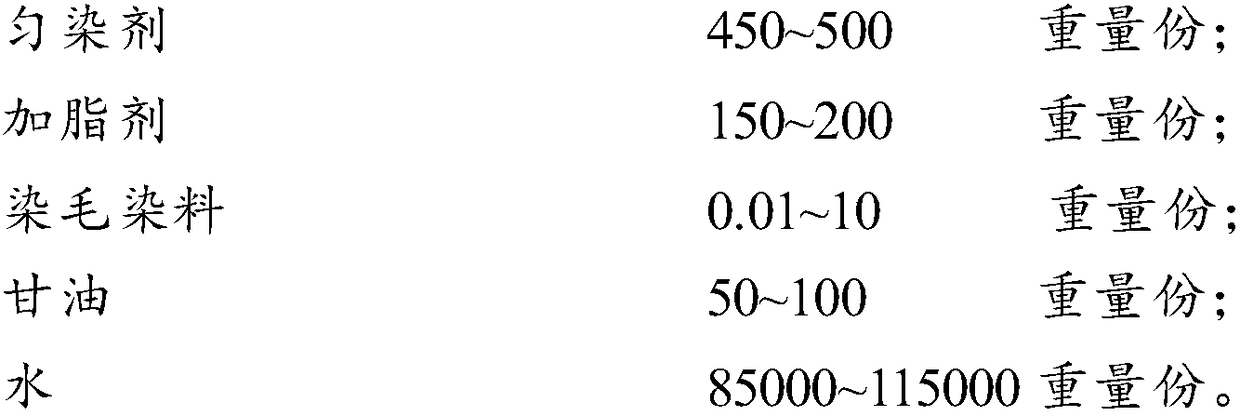

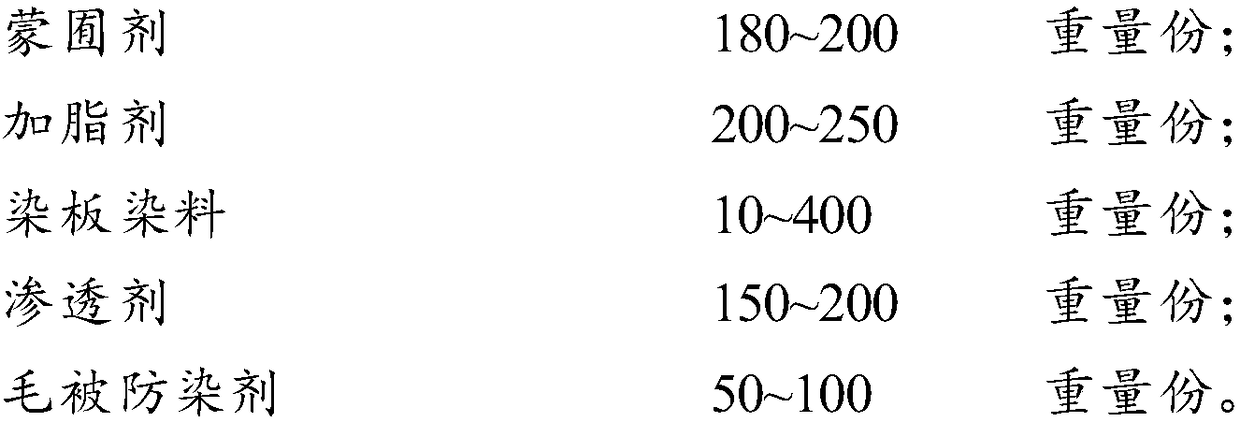

Coloring agent and dyeing process for double-faced leather

The invention provides a coloring agent for double-faced leather. A hair dyeing agent is prepared from the following components in parts by weight: 180 to 200 parts of a dye leveler, 150 to 200 partsof a fatting agent, 0.01 to 10 parts of hair dye, 50 to 100 parts of glycerin and 85000 to 115000 parts of water. The invention also provides a panel dyeing agent and a dyeing process for the double-faced leather. The coloring agent comprises the hair dyeing agent and the panel dyeing agent; the components and the proportions of the hair dyeing agent and the panel dyeing agent are adjusted, particularly the glycerin is added in the hair dyeing agent, and the temperature and a pH value of the dyeing process are controlled, therefore, the aims of synchronously adding a hair dye and a panel dye and dyeing in the same bath are achieved and the dyeing time is greatly shortened; in addition, the dyed hair panel has good color control degree and the quality of a finished product is improved.

Owner:隆丰革乐美时尚有限公司

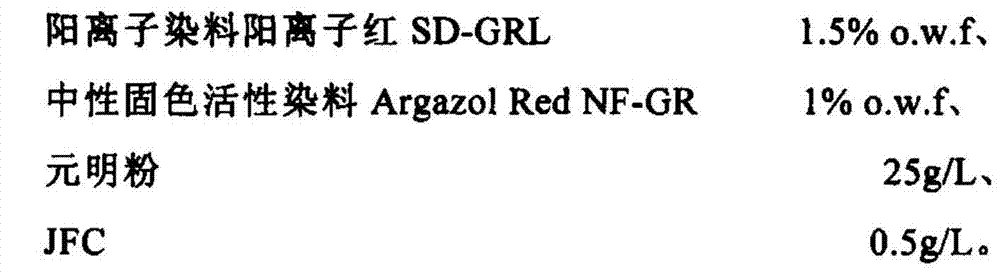

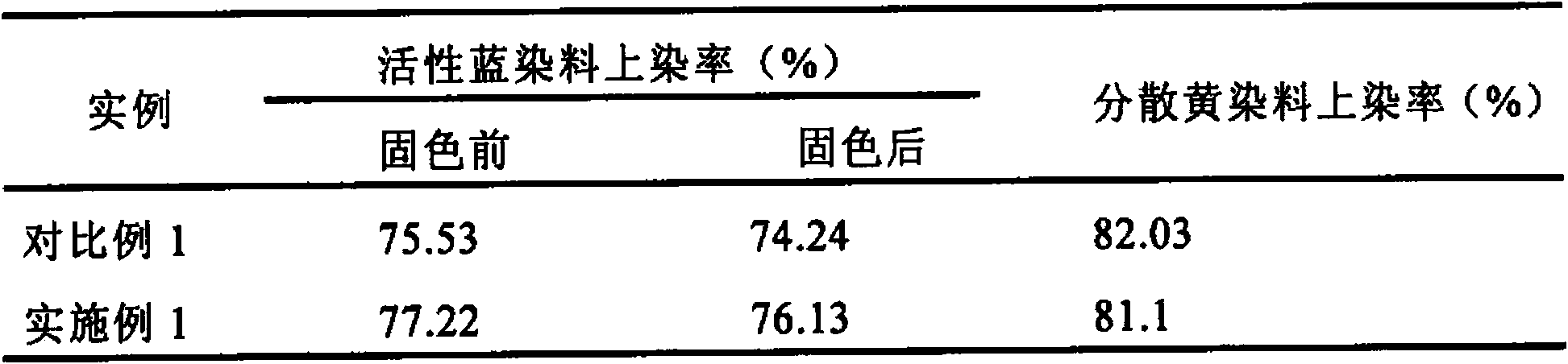

One-bath one-step dyeing method for dralon/cotton blended fabric

InactiveCN104499311AAddress reactivitySolve the problem of not being able to bathe togetherBleaching apparatusDyeing processWarm waterBleach

The invention relates to a one-bath one-step dyeing method for a dralon / cotton blended fabric. The method comprises the following steps: impregnating and dyeing the dralon / cotton blended fabric by adopting a neutral bath fixation reactive dye and a disperse type cationic dye; putting the dralon / cotton blended fabric into a solution with a surfactant for pre-treatment; then, soaking in a bleaching agent solution for bleaching treatment; then, dissolving the reactive dye and the cationic dye with warm water at 40 DEG C to prepare a dye liquid; fully stirring, adjusting the pH value to 4-8.5 by using a buffer liquid; putting the fabric into the dye liquid; controlling the dye bath ratio at 1: 10 to 1: 100; then, controlling temperature rise and insulation for 10-90 minutes; and then washing, soaping and drying. Compared with the prior art, the method can be used for solving the problem that the reactive dye and the cationic dye cannot be in a same bath as negative and positive charges of the reactive dye and the cationic dye react and also solving the problem of dyeing condition difference between the reactive dye and the cationic dye.

Owner:SHANGHAI UNIV OF ENG SCI

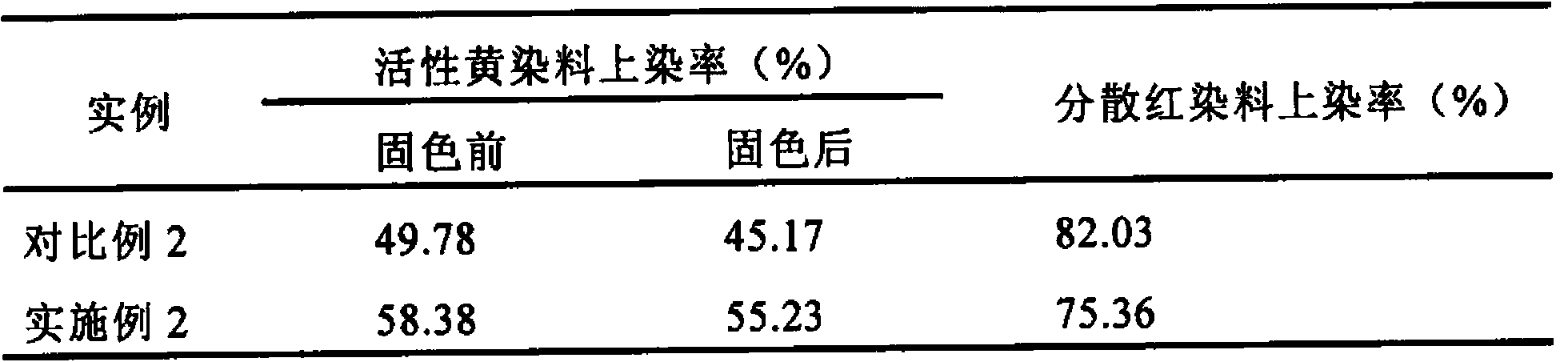

Nylon-cotton fabric one-bath dyeing method with activated dye

InactiveCN106758374ASoft touchImprove the finishDyeing processMicroballoon preparationRare earthSurface-active agents

The invention discloses a nylon-cotton fabric one-bath dyeing method with an activated dye. The method comprises the steps that a nylon-cotton fabric is soaked into a activated dye liquor, dyeing is conducted under the conditions that the bath ratio is adjusted to be 1:(5-20) and the temperature is 20-30 DEG C, the temperature is raised to 55-75 DEG C, heat preservation is conducted for 5-15 min, then the temperature is raised to 105-125 DEG C, heat preservation is conducted for 30-40 min, 1-5 g / L sodium carbonate is added, and heat preservation is conducted for 5-25 min at the fixing temperature of 60-90 DEG C, wherein the activated dye liquor comprises 1-5% owf of rare earth coordinated microencapsulated activated dye, 5-15 g / L of anhydrous sodium sulphate, 0.5-10 g / L of pH lubricating agent, 0.1-0.3 g / L of hydrozybenzene halogenide and 0.01-0.1 g / L of organic fluoride surface active agent. The dyeing method has the advantages of being high in fixation rate and good in leveling property and is simple in technology and short in dyeing time, the consumption of salt in the activated dye is greatly reduced, and environmental protection is achieved.

Owner:无为竟成服饰有限公司

Environment-friendly method for improving paper dye fastness

ActiveCN107178004APromote flocculationReduce pollutionPaper/cardboardColorants/pigments additionFiberColour fastness

The invention discloses an environment-friendly method for improving paper dye fastness. The method comprises the following concrete process steps of pretreating lignocellulose slurry through a mechanical method, and carrying out enzymolysis treatment, dyeing, and nanocrystallization grinding treatment on the pretreated material so as to obtain a nanocellulose-based dye. According to the environment-friendly method for improving the paper dye fastness provided by the invention, the dye is immobilized through nano fiber, so that the obtained nanocellulose-based dye can be uniformly dispersed in water but cannot lose color in water, and the pollution of the dye on water during a dyeing process can be effectively eliminated. In addition, after paper is dyed through the nanocellulose-based dye prepared by using the method provided by the invention, the dry friction fastness of the paper is remarkably improved, and the dyed paper cannot lose color after being soaked in water. The dyeing process is simple, environment-friendly and high-efficient, can be beneficial for effectively improving the industrial competitiveness of colored paper, and has favorable social benefit and economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

Method for dyeing blended fabric of polysulfonamide and viscose glue

ActiveCN103643547ASimple dyeing processShort dyeing timeBleaching apparatusDyeing processDisperse dyeWater discharge

The invention relates to a method for dyeing a blended fabric of polysulfonamide and viscose glue, comprising selecting neutral bath dye fixation active / disperse dyes for one bath dyeing, adding the blended fabric of polysulfonamide and viscose glue into a solution with a surfactant, controlling the temperature at 90-100 DEG C, water-washing and drying after 30min-1h of treatment, then immersing the blended fabric of polysulfonamide and viscose glue into a bleaching agent solution for bleaching treatment, water-washing and drying, again immersing the blended fabric of polysulfonamide and viscose glue into a dye liquid containing a neutral salt, a carrier, a leveling agent, a high temperature dispersant, a reactive dye and a disperse dye, regulating a pH value at 4-9, and a bath ratio of 1:(10-100), controlling the temperature at 80-130 DEG C, carrying out dyeing treatment for the blended fabric of polysulfonamide and viscose glue for 30-90min, and water-washing, drying and soaping to complete dyeing. Compared with the prior art, the method provided by the invention has advantages of simple technology, short dyeing time, high efficiency, low energy consumption, and few amount of waste water discharge.

Owner:SHANGHAI UNIV OF ENG SCI

Staining fluid and method for rapidly detecting novel cryptococcus

InactiveCN101724682AEasy to storeEasy to detectMicrobiological testing/measurementMicroorganism based processesAcetic acidStaining

The invention relates to staining fluid and a method for rapidly detecting novel Cryptococcus. The staining fluid comprises 0.5-3.0g of AZO-blue, 1.0-10.0g of glacial acetic acid and 90-110g of distilled water. The method for rapidly detecting novel cryptococcus comprises the steps of preparation of the staining fluid, mixing, detection, counting and the like. The invention has the advantages of simple, convenient, rapid, sensitive and accurate detection, high specificity, easy preservation of the staining fluid, short staining time and excellent staining effect.

Owner:东阳市人民医院

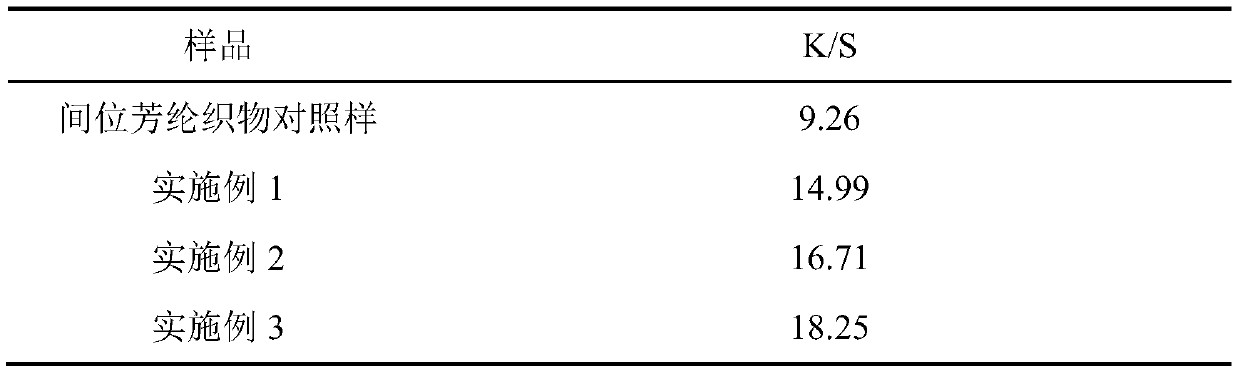

Method for dyeing meta-aramid fabric particle flow

InactiveCN110080014AOvercome electrostatic forcesIncrease the gapDyeing processDisperse dyeTextile printer

The invention relates to a method for dyeing a meta-aramid fabric particle flow, and belongs to the technical field of textile printing and dyeing. The method comprises the following steps: dissolvingdisperse dye with a mixed solvent of N,N-dimethyl acetamide and ethanol to form dyeing liquor; soaking meta-aramid fabric into the dyeing liquor, taking out the meta-aramid fabric, controlling the mangle expression to 100-200%, putting the meta-aramid fabric on plate vulcanization machine at the temperature of 165-205 DEG C, rapidly pressurizing and rapidly gasifying the dyeing liquor carrying the meta-aramid fabric under high temperature to form the particle flow, wherein ethanol in the particle flow can be insulated from air, so as to prevent the dye in the particle flow from being oxidizedby oxygen; the acting force of hydrogen bond between fiber macromolecules in the meta-aramid fabric is reduced by N,N-dimethyl acetamide in the particle flow, so as to help particles in the dye in the particle flow to enter fibers of the meta-aramid fabric; the meta-aramid fabric is dyed by the disperse dye in the particle flow. According to the method, the dyeing efficiency of the meta-aramid fabric can be effectively improved; in addition, the dyeing process is short, the bath ratio is smaller, and the production cost and the resource consumption are lowered.

Owner:WUHAN TEXTILE UNIV

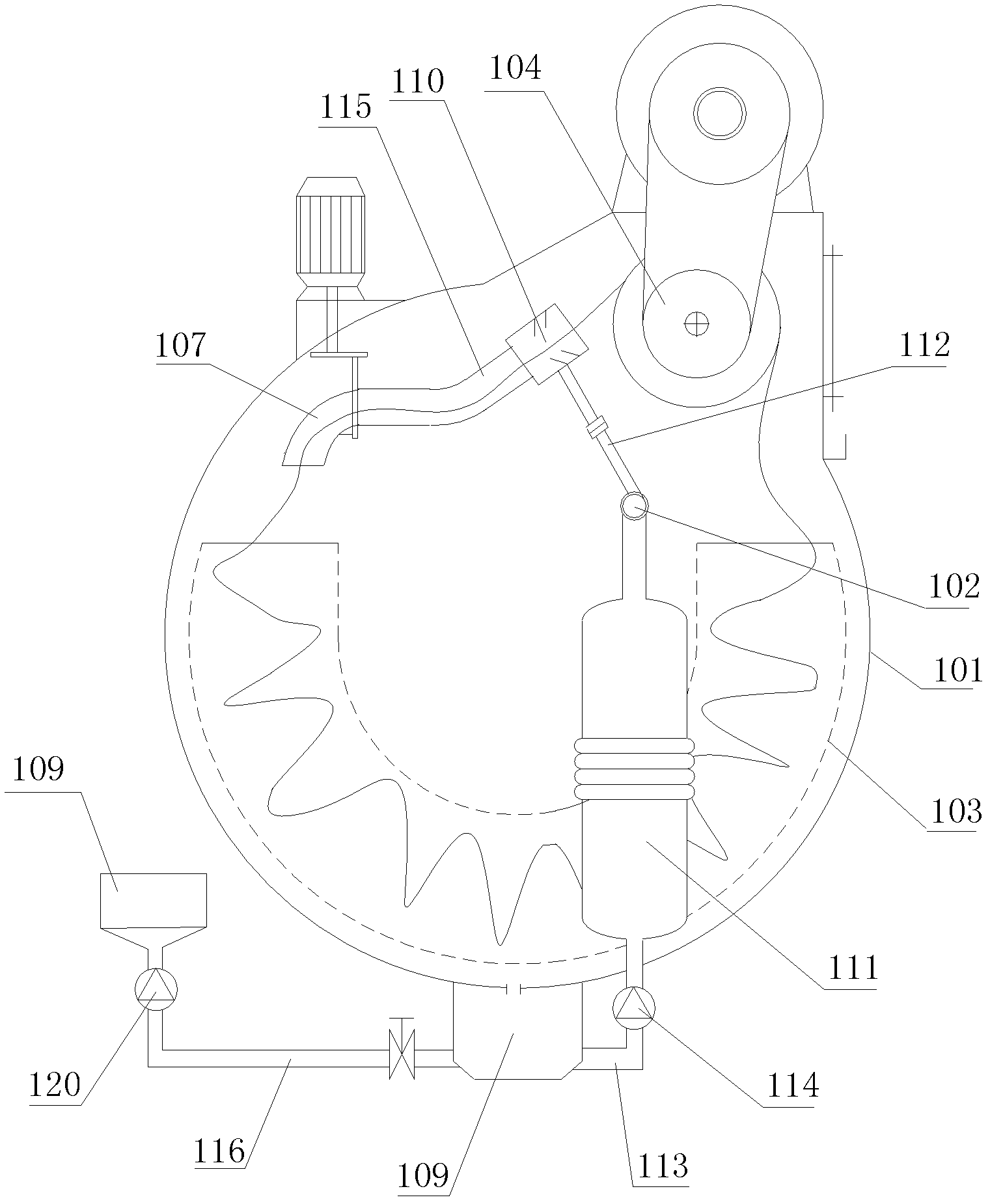

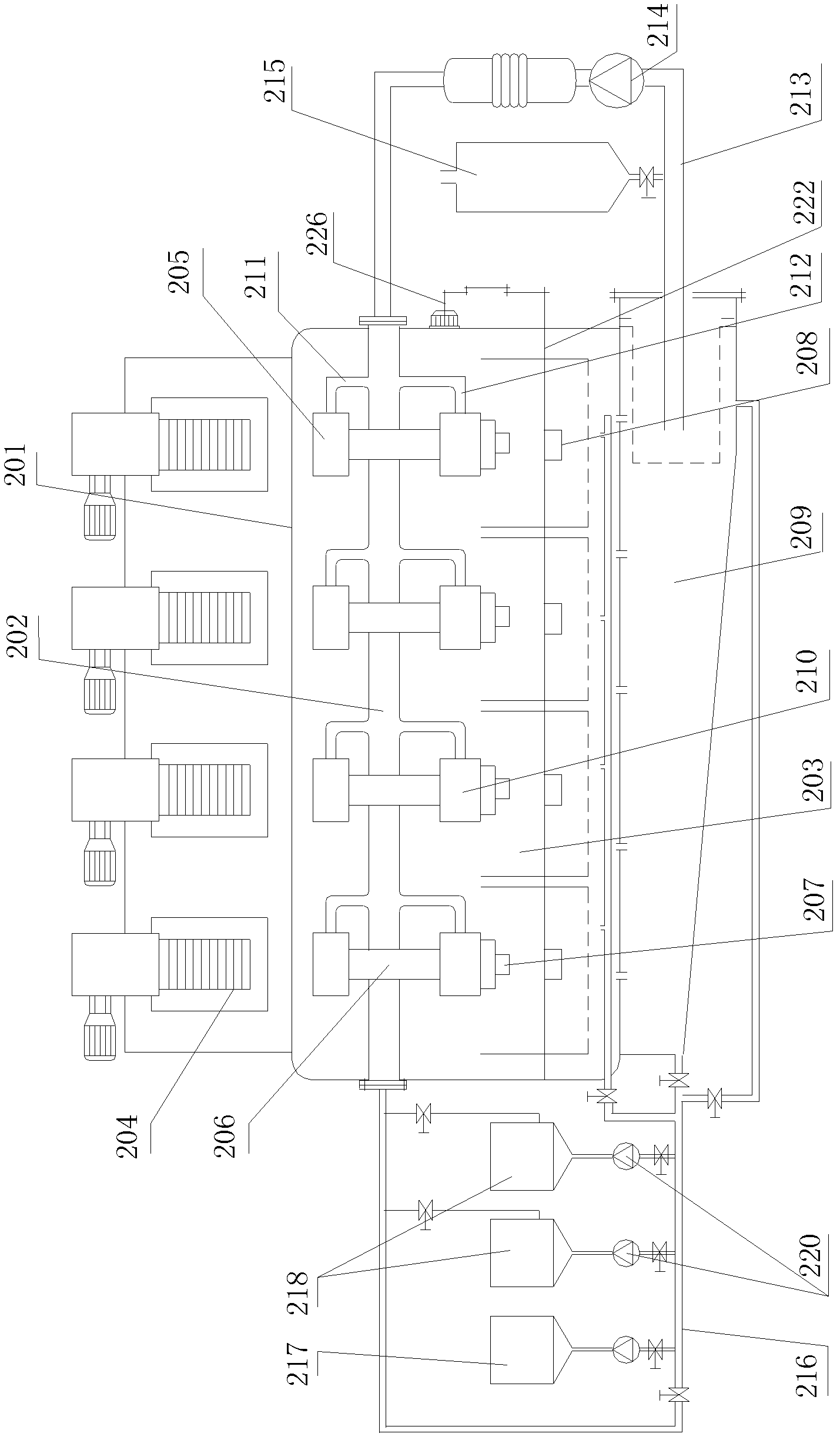

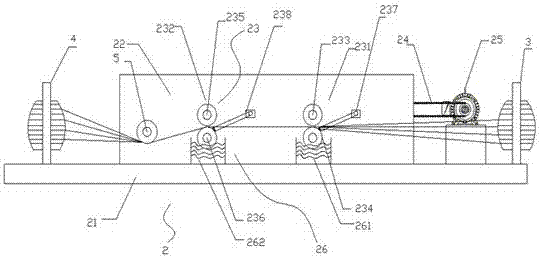

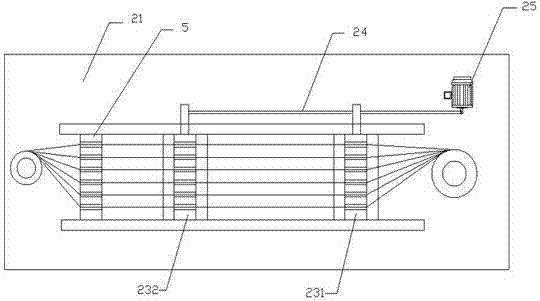

Overflow dyeing machine

InactiveCN103015090ASimple structureLower liquor ratioTextile treatment machine partsLiquid/gas/vapor treatment of indefinite length materialsDying processesSpray nozzle

The invention discloses an overflow dyeing machine which comprises a main machine body (201); a cloth storage tank (203) is arranged in the main machine body (201); a liquid diverter pipe (202) is arranged above the cloth storage tank (203), with one end connected with a spray nozzle (210) and the other end communicated with a liquid storage tank (209) through a circulating pipe (213); a material dissolving cylinder (218) is communicated with the circulating pipe (213) through a material dissolving pipe (216); a cloth lifting wheel (204) is arranged outside the main machine body (201); a cloth swinging bucket (207) is arranged below the spray nozzle (210); a piece of cloth (232) to be dyed passes through the spray nozzle (210) and the cloth swinging bucket (207) and then enters the cloth storage tank (203), and moves circularly under the action of the cloth lifting wheel (204) to be dyed; a circulating pump (214) is arranged on the circulating pipe (213); a dry powder feeding device (217) is arranged on the material dissolving pipe (216) and is connected in parallel with the material dissolving cylinder (218) on the material dissolving pipe (216). The overflow dyeing machine speeds up the feeding of dyestuff and auxiliaries, shortens the dying process, improves the drying quality and reduces the bath ratio.

Owner:田立法

Method for simply producing black rice by using vaccinium bracteatum thumb leaves

The invention relates to a method for simply producing black rice by using vaccinium bracteatum thumb leaves. Leaves of vaccinium bracteatum Thumb contain various ingredients beneficial to the human body and have a long edible and medicinal history in China, Jiangsu province and Zhejiang province have custom to produce the black rice by using the accinium bracteatum thumb leaves among people. The method of the invention simplifies the traditional black rice production method, directly utilizes fresh or freeze-stored accinium bracteatum thumb leaves juice to cook the rice, has a same dyeing effect with the traditional method, and also sufficiently utilizes pigments, volatile oil, polysaccharides and various nutrients in the leaves. The method comprises the following steps: crushing fresh or freeze-stored vaccinium bracteatum Thumb leaves and water in a ratio of 1: (5 to 15) to obtain vaccinium bracteatum Thumb leaf juice; sufficiently stirring and mixing the vaccinium bracteatum Thumb leaf juice and sticky rice or polished round-grained rice in a ratio of (2 to 2.5): 1, beginning to cook, re-stirring sufficiently when the mixture is boiled, and then stewing until the rice is well cooked. The black rice is bright in color, refreshed and fragrant, instant to eat, and capable of being further processed into products such as black rice wine, black rice beverage, vegetable carbon black substituent and the like.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

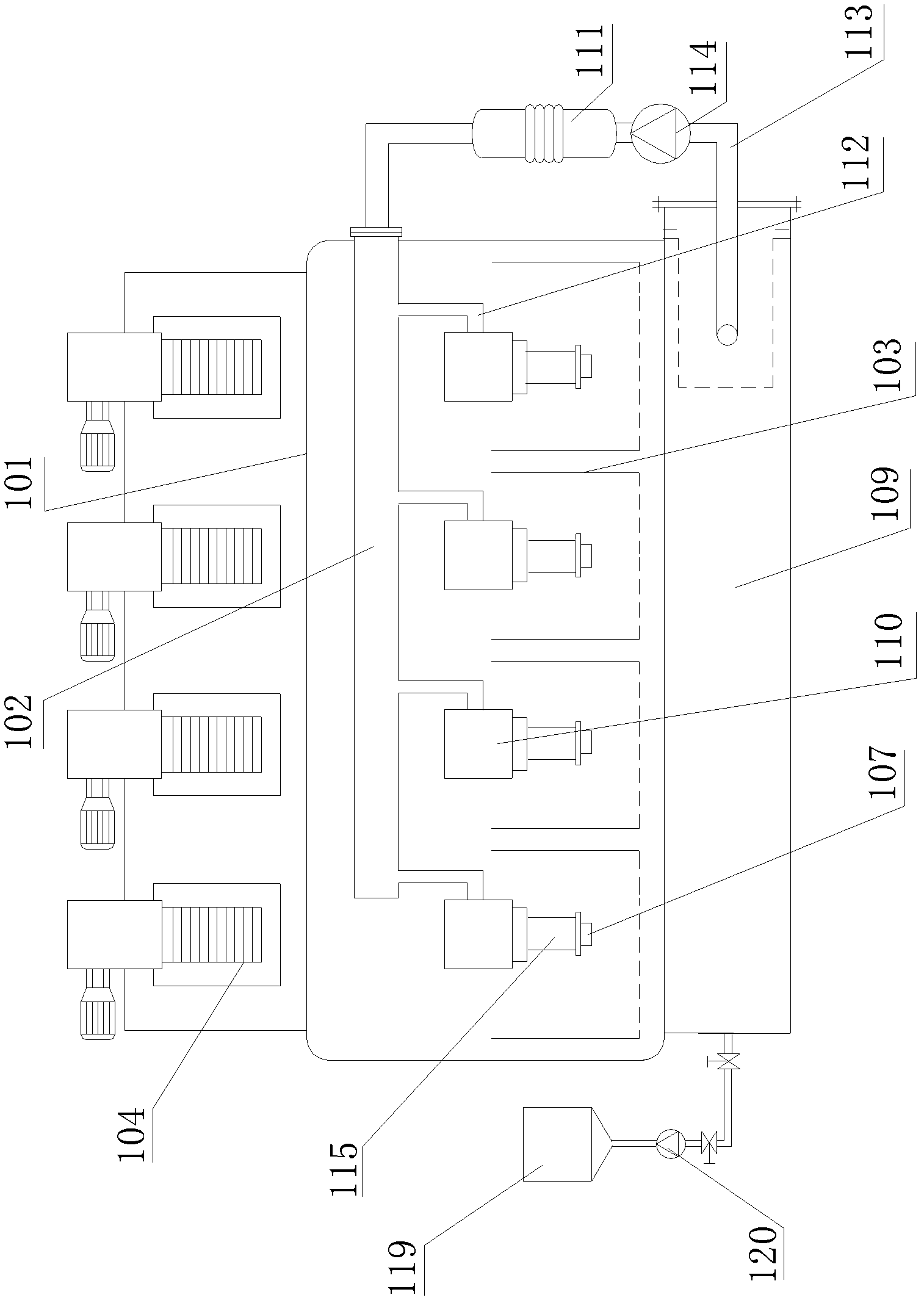

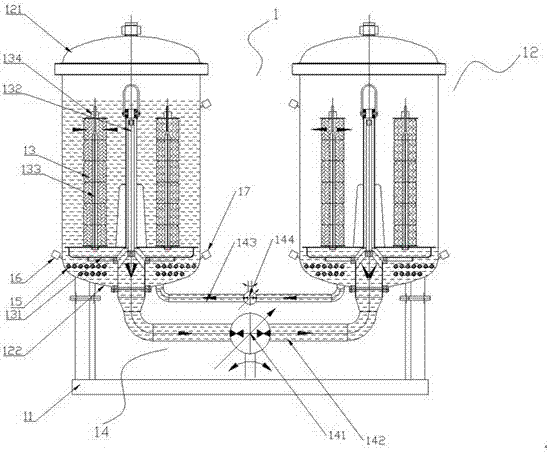

Cone yarn dyeing system

InactiveCN107338595AShort dyeing timeReduce energy consumptionTextile treatment containersTextile treatment machine arrangementsYarnEngineering

The invention relates to a cone yarn dyeing system which is characterized by comprising a high-pressure circular dip dyeing mechanism and a normal-pressure brush dyeing mechanism, wherein the high-pressure circular dip dyeing mechanism is connected in series with the normal-pressure brush dyeing mechanism; the high-pressure circular dip dyeing mechanism performs dip dyeing on cone yarns to achieve primary dyeing; and the cone yarns after the dip dyeing are subjected to brush dyeing by the normal-pressure brush dyeing mechanism to achieve secondary dyeing. According to the system, the traditional single vat dyeing is now changed into double vat yarn dyeing; with the adoption of a bidirectional circulation pump, the front and back dyeing of the yarns in two vats can be achieved; technical requirements are met; a dyeing effect is guaranteed; compared with the traditional dyeing machine, the dyeing system only requires half of a dyeing solution to dye the same quantity of the yarns; the consumption of the dyeing solution is greatly reduced; at the same time, the consumption of heating steam can also be reduced with the reduction of the consumption of the dyeing solution; and the production cost is greatly lowered.

Owner:朱爱民

Cationic modified dyeing method for polypropylene fibers

InactiveCN108951232ASolve the problem of energy consumptionSolve pollutionDyeing processState of artHigh energy

The invention discloses a cationic modified dyeing method for polypropylene fiber. The cationic modified dyeing method comprises the following steps: (1) modification of the fibers; (2) pretreatment;(3) pre-setting of a grey fabric; (4) reduction clearing; (5) preparation of a dyeing solution; (6) dyeing; and (7) post-treatment. Compared with the prior art, the cationic modified dyeing method ofthe invention has the beneficial effects that the dyeing method solves the problems of high energy consumption and serious water pollution in conventional dyeing processes for cationic modified fabrics; fabrics dyed by using the dyeing method of the invention has uniform and bright colors and are prolonged in service life; the dyeing method has few steps and short dyeing time; and a dye can be recycled after dyeing, so environmental pollution is reduced.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Annealing and dyeing integration process for producing flax

InactiveCN101338526AUniform dyeingWinding density requirements are not highDyeing processVegetal fibresSodium AcrylateDyeing

The invention provides an integral method of boiling and dyeing in production of flax, which comprises roving, acid rinsing, chlorite bleaching, oxygen bleaching, rinsing, boiling in poly-sodium acrylate, dyeing by high-efficiency surface tension depressant, penetrant and active dye, finally wet spinning spun yarn. The invention can directly dye in boiling pan after soda boiling and rinsing, and can combine the boiling with the dyeing into a whole. The invention has advantages that after boiling without dying and before spinning into spun yarn, the fibril surface void ratio is big and the gap between fibers is also big, which are convenient for dye molecules to diffuse towards intrafibre, the dyeing time is short, and the rate of dyeing is high; the invention can also save latter cloth dyeing devices.

Owner:DONGHUA UNIV

Fungus staining solution and method

ActiveCN109946140ASignificant progressImprove efficiencyPreparing sample for investigationMaterial analysis by optical meansDirect microscopyPHENOL LIQUID

Owner:三门县人民医院

Disperse/reactive dye modification one-bath dyeing technology for polyester-cotton/viscose fabric

The invention belongs to the technical field of textile printing and dyeing and in particular relates to a disperse / reactive dye modification one-bath dyeing technology for polyester-cotton / viscose fabric. The fabric is modified through color media or other modifiers, environment-friendly carriers are added into two disperse / reactive dye solutions, and a salt-free alkali-free or salt-free low-alkali normal temperature dyeing technology is implemented by using a one-bath two-step method. The technology has the advantages of simple process, convenience for operation and short dyeing time, a great amount of salt and alkali can be saved, energy sources are saved, and cost is reduced. By respectively adding a cross bond agent or a pH slippage agent or a small quantity of alkali agents into a dye bath, requirements for high fixation rate and high color fastness are met, and the technology is substantively changed and improved obviously by employing dye bath. Therefore, the technology has high social and economic benefits and a broad prospect.

Owner:绍兴董氏纺织印染技术开发中心

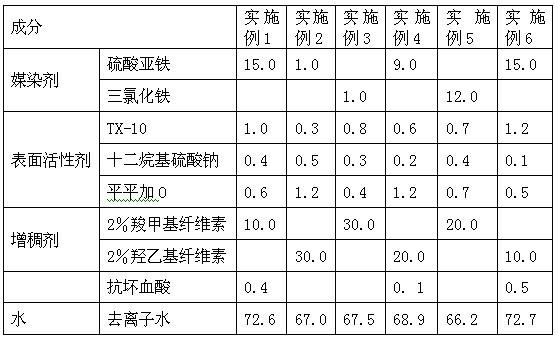

Wool ecological dye paste, preparation method thereof and dyeing method

InactiveCN102154854AShorten dyeing timeShort dyeing timeDyeing processAnimal fibresGallic acid esterFerrous salts

The invention discloses a wool ecological dye paste, a preparation method thereof and a dyeing method; the wool ecological dye paste comprises dye paste and mordant paste, wherein a coloring agent in the dye paste is gallic acid or tannic acid or a mixture of gallic acid and tannic acid, a mordant in the mordant paste is ferrous salt or ferric salt, and the ecological dye paste is used for dyeing the wool under a temperature of 35 to 45 DEG C. Compared with the prior art, the gallic acid or tannic acid of the ecological dye paste is an ecological dye extracted from natural plants; the mordant paste is ferric ions or ferrous ions, does not contain heave metal chromium ions and has no pollution to environments; the ecological dye paste is used for dyeing the wool at an alkaline condition, and the dyeing temperature is below 50 DEG C so as to avoid the damage of wool quality caused by high temperature dyeing and lead the dyeing time to be shortened to be within 50 min; and therefore, the dye paste has short dyeing time, low energy consumption, rapid dyeing rate and good level dyeing property.

Owner:贵州阿斯科科技开发有限公司

Low-temperature dyeing method of rabbit wool

The invention relates to the technical field of loose wool dyeing, in particular to a low-temperature dyeing method of rabbit wool. The method comprises the following steps: adding raw rabbit wool toa dyeing machine which is a normal-temperature dyeing machine; adding water based on the specified volume; then adding a penetrating agent and glacial acetic acid; stirring for 10min; adding dye, wherein the dye comprises reactive yellow 4RFN, reactive red W-DF and reactive deep blue M-2GE; stirring for 15min, and then increasing the temperature to be 85 DEG C; maintaining the temperature for 30min; washing; then adding a smoothing agent after washing; increasing the temperature to be 45 DEG C; maintaining the temperature for 20min; moving out of vat, thus finishing dyeing. According to the method, the rabbit wool can be dyed under the temperature of 95 DEG C, so that the damage to the rabbit wool fibers can be extremely reduced; moreover, the water, the electricity and the gas are saved,so that the energy consumption is decreased; the processes are simple; the dyeing costs a little time; the dyeing cost is reduced.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

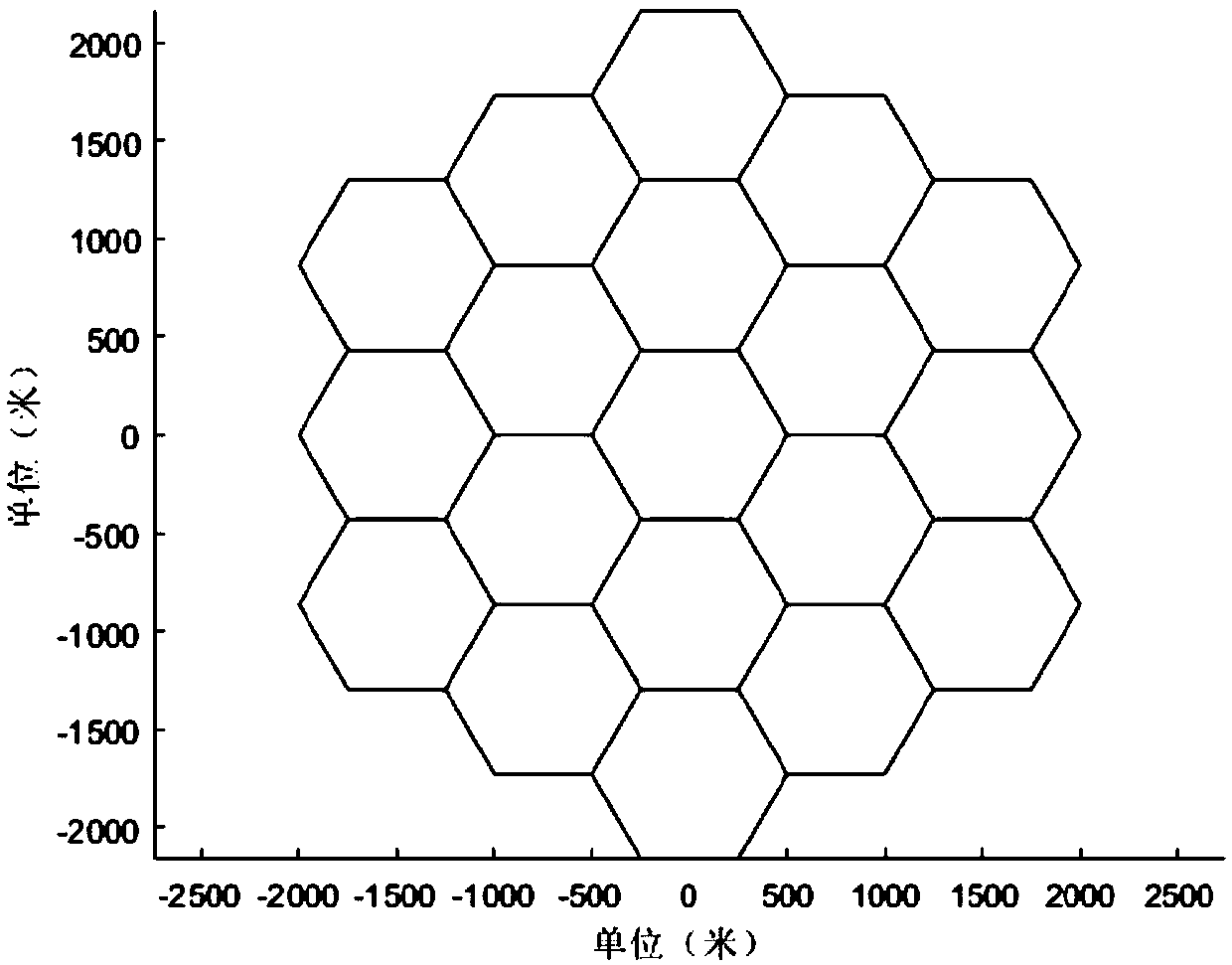

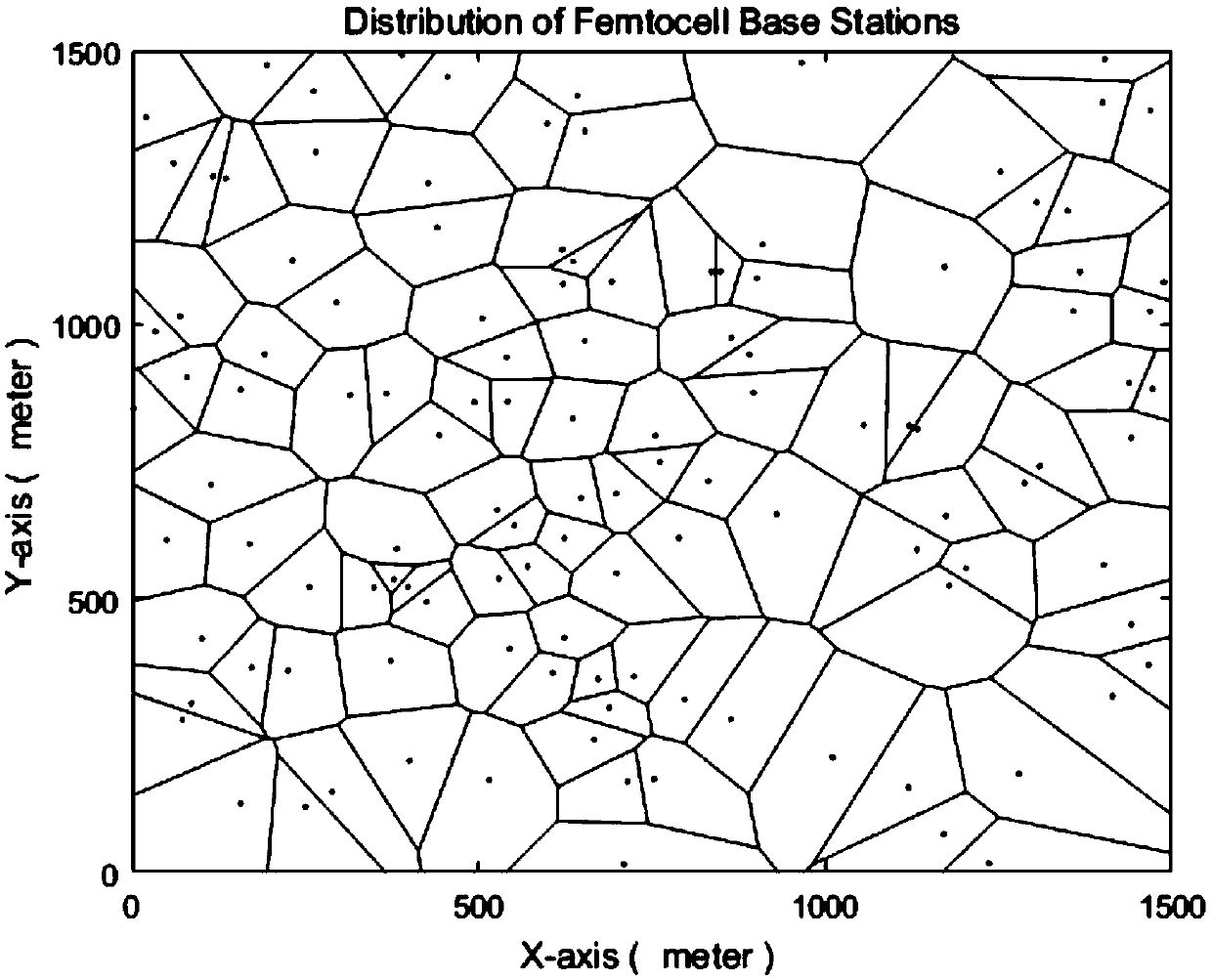

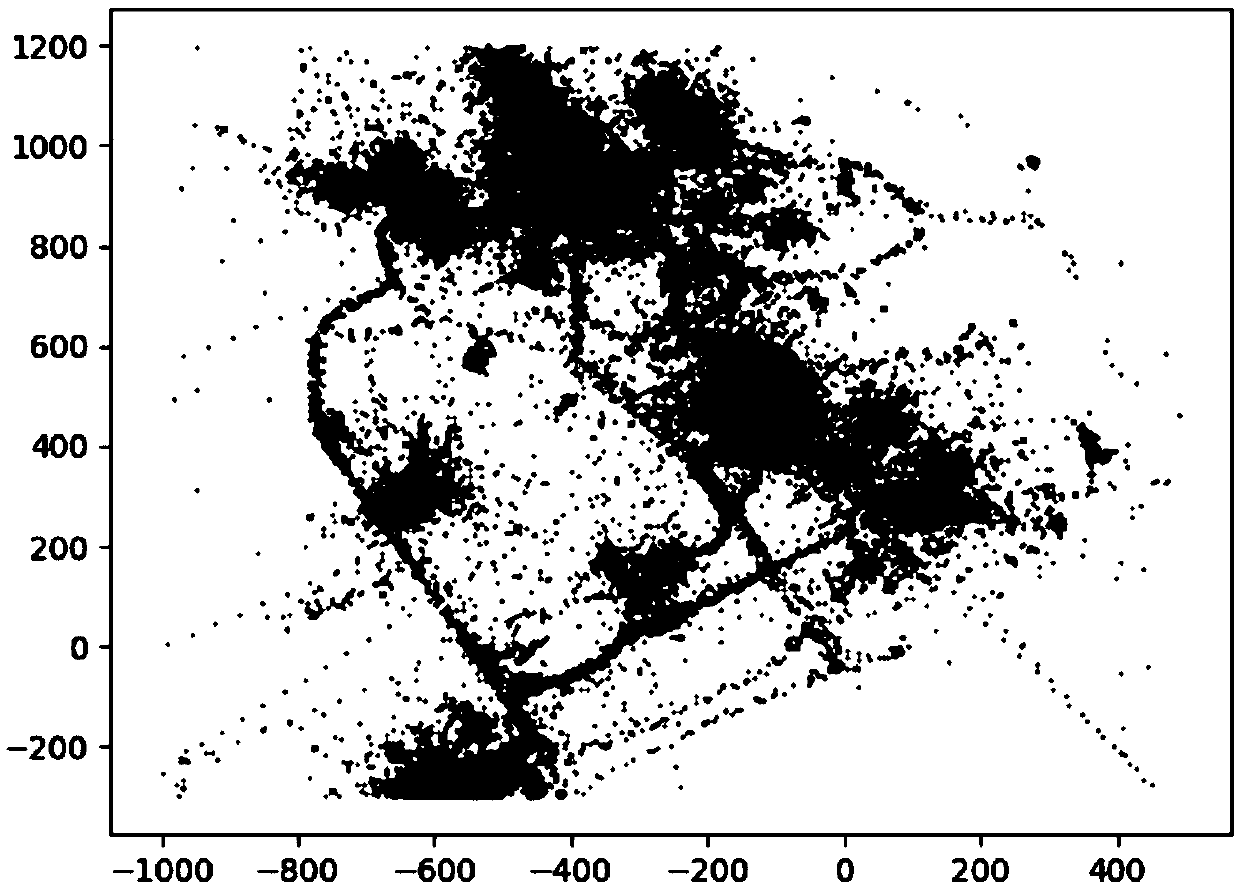

A physical cell identification distribution method based on a maximum priority dyeing algorithm

ActiveCN109600756ARealize OKSimplify the distribution processCharacter and pattern recognitionData switching networksCellular networkDyeing

The invention relates to a physical cell identification distribution method based on a maximum priority dyeing algorithm. The problem that in the small cellular network technology, due to an extremelylimited number of physical cell identification (PCI) used for identifying a cellular network base station, the network quality of service (QoS, Quality of Service) of a user is greatly influenced since the small cellular network cannot be deployed smoothly is solved. The method comprises the following steps: firstly, clustering massive network user mobile data by using a K-means clustering algorithm, and dividing and determining a hot spot region of a user; and performing PCI allocation and multiplexing on the cellular base stations in different hot spot regions based on a maximum priority dyeing algorithm. According to the method, PCI allocation and multiplexing can be rapidly and effectively carried out on the cellular base station, meanwhile, the conflict confusion probability of the PCI is reduced, and the QoS of users in a hot spot region is guaranteed.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com