Super critical CO2 fluid dyeing technology

A supercritical and fluid technology, applied in the field of dyeing technology, can solve the problems of lowering the dyeing uniformity of fabrics, lack of circulation function, slow dyeing speed, etc., and achieve the effect of improving the utilization rate of dyes, reducing energy consumption, and shortening the dyeing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

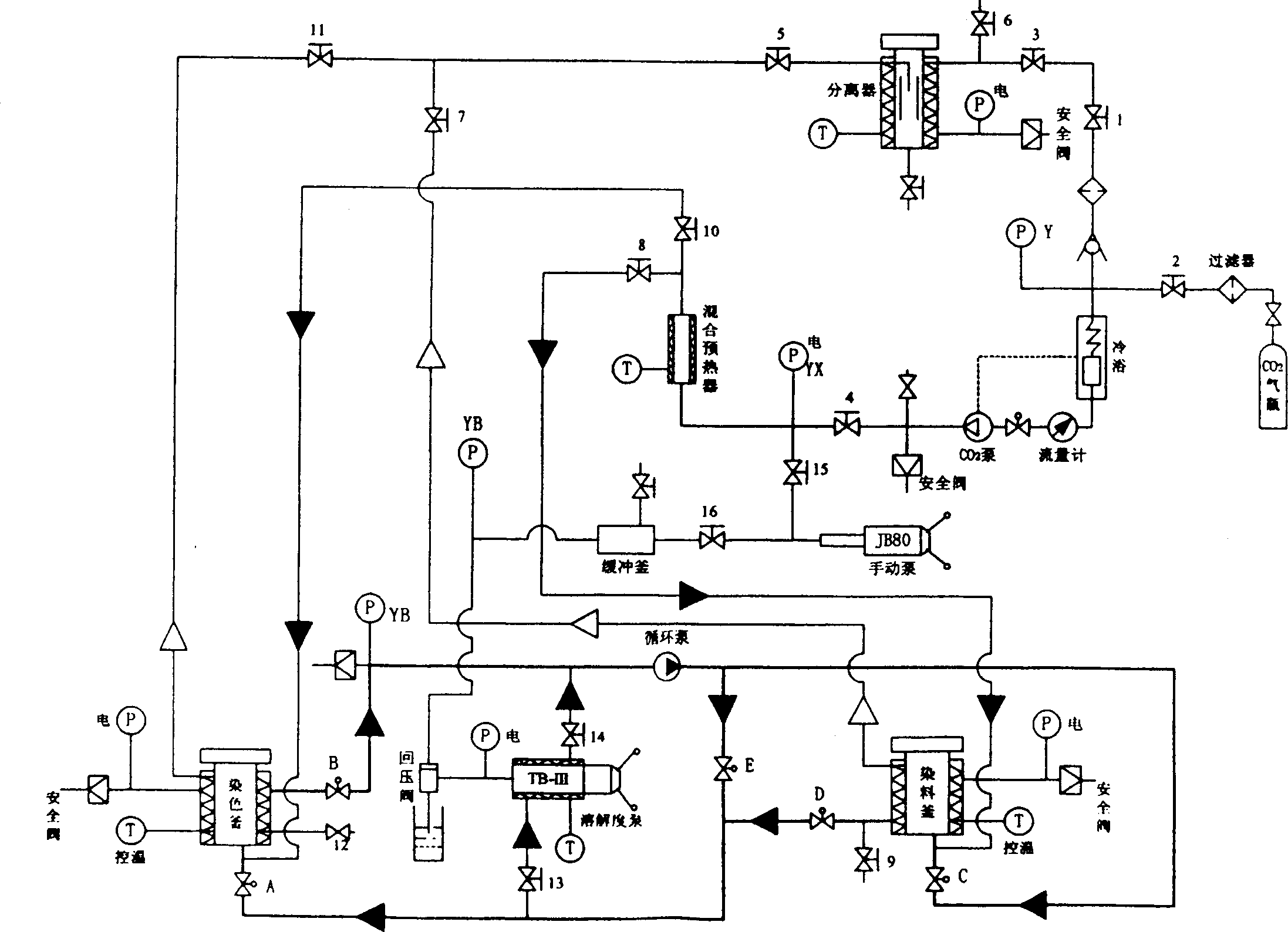

[0015] like figure 1 As shown, the dyeing kettle and the dye kettle are connected through a circulation pump, a ball valve and corresponding pipelines, the outlet valve B (G) of the dyeing kettle is connected to the inlet of the circulation pump, the outlet of the circulation pump is connected to the valve C to the dye kettle (valve E), and the dye kettle The outlet valve D is connected with valve A (F) to the dyeing kettle for circulation.

[0016] 1. Forward circulation (diffusion from inside to outside of the active core of the dyeing kettle): circulation pump-→valve C→dye kettle→valve D→valve A→dyeing kettle→valve B→circulation pump.

[0017] 2. Reverse circulation (diffusion of the active inner core of the dyeing kettle): circulation pump→valve C→dye kettle→valve D-→valve F→dyeing kettle→valve G→circulation pump.

[0018] 3. Late circulation (when required by a specific process, the dye kettle does not participate in the circulation): circulation pump → valve E → valve A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com