High-elongation skin-friendly cashmere yarn

A high elongation, cashmere technology, applied in yarn, liquid/gas/vapor fiber/sliver/roving treatment, biochemical fiber treatment, etc., to achieve the effect of smooth hand feeling, high strength and optimized reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Cashmere selection and cashmere opening: select cashmere fibers of about 16 μm, open the selected cashmere with a cashmere turbine, and open the cashmere through multiple light beating turbines.

[0042] (2) Enzyme treatment and washing:

[0043] Both papain and bromelain are food grade, with an activity of 500,000 u / g.

[0044] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 15 minutes;

[0045] The second time: 1.5% bromelain solution, the water temperature was kept at 55°C; the pH was controlled at 7, and the treatment time was 15 minutes;

[0046] After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0047] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

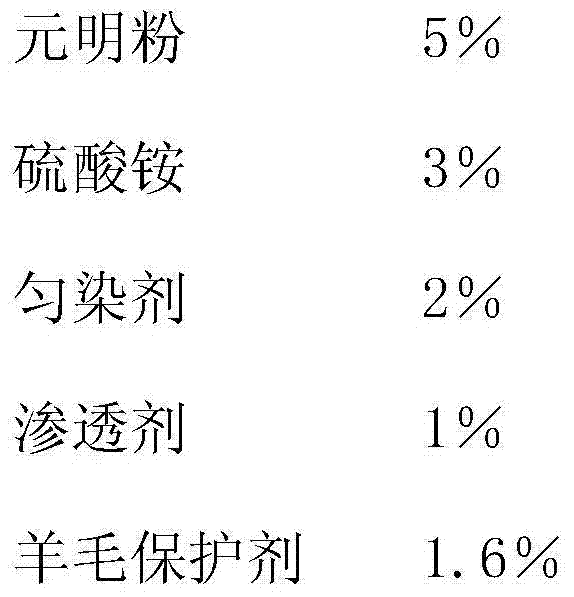

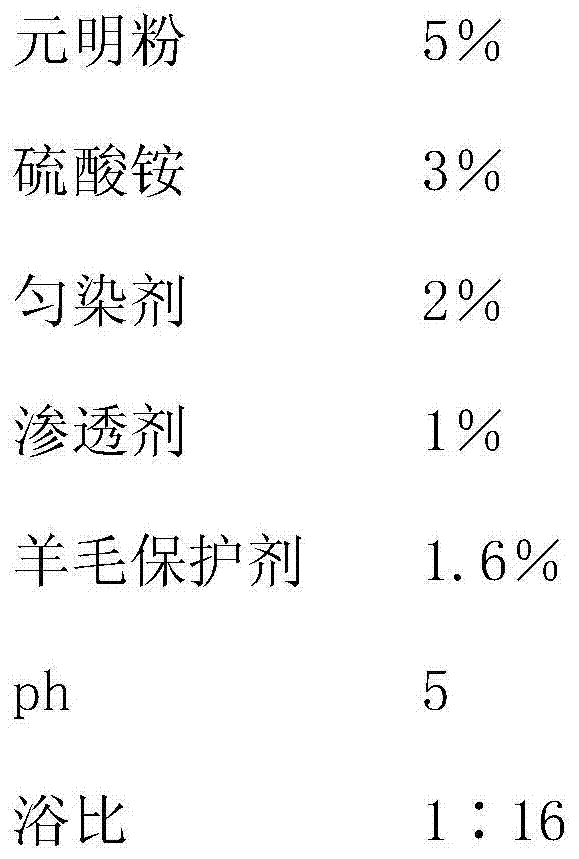

[0048] (3) low temperature dyeing:

[0049] Use reactive dyes for wool to dye cashmere, the dyeing temperature is controlled at 70°C, and t...

Embodiment 2

[0061] (1) Cashmere selection and cashmere opening: select cashmere fibers of about 16 μm, open the selected cashmere with a cashmere turbine, and open the cashmere through multiple light beating turbines.

[0062] (2) Enzyme treatment and washing:

[0063] Both papain and bromelain are food grade, with an activity of 500,000 u / g.

[0064] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 15 minutes;

[0065] The second time: 1.5% bromelain solution, the water temperature was kept at 55°C; the pH was controlled at 7, and the treatment time was 15 minutes;

[0066] After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0067] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

[0068] (3) low temperature dyeing:

[0069] Use reactive dyes for wool to dye cashmere, the dyeing temperature is controlled at 80°C, and t...

Embodiment 3

[0081] (1) Cashmere selection and cashmere opening: select cashmere fibers of about 16 μm, open the selected cashmere with a cashmere turbine, and open the cashmere through multiple light beating turbines.

[0082] (2) Enzyme treatment and washing:

[0083] Both papain and bromelain are food grade, with an activity of 500,000 u / g.

[0084] The first pass: 1% papain + 1% sodium bisulfite aqueous solution, the water temperature is kept at 50°C; the pH is controlled at 7, and the treatment time is 15 minutes;

[0085] The second time: 1.5% bromelain solution, the water temperature was kept at 55°C; the pH was controlled at 7, and the treatment time was 15 minutes;

[0086] After enzyme treatment, rinse with clean water and keep the temperature at 55°C;

[0087] Enzyme-treated cashmere removes all kinds of dirt and is chemically altered;

[0088] (3) low temperature dyeing:

[0089] Use reactive dyes for wool to dye cashmere, the dyeing temperature is controlled at 75°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com