Patents

Literature

767results about "Liquid/gas/vapor fibres/slivers/rovings treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

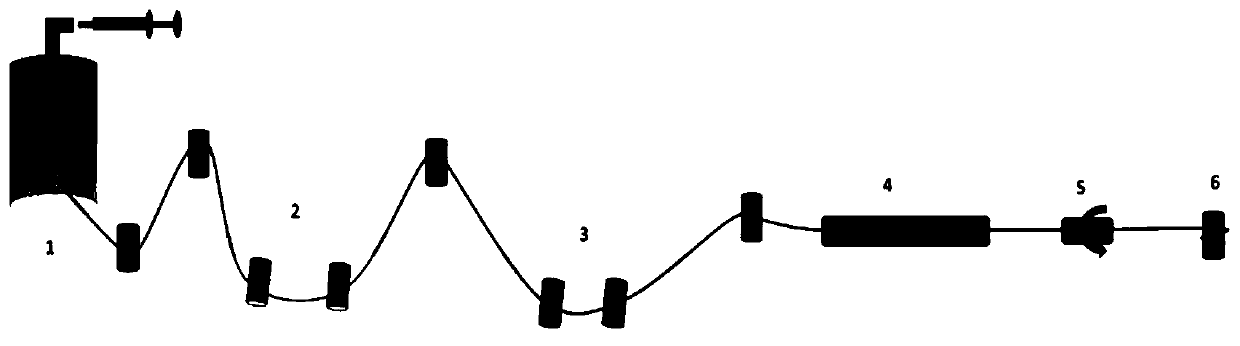

Process for manufacturing resin-coated fibers composite and an application thereof

InactiveUS6270851B1Prevent fracture of the fiber filamentsMaximize molten resin penetrating timeLiquid surface applicatorsCoatingsEngineeringFibrous composites

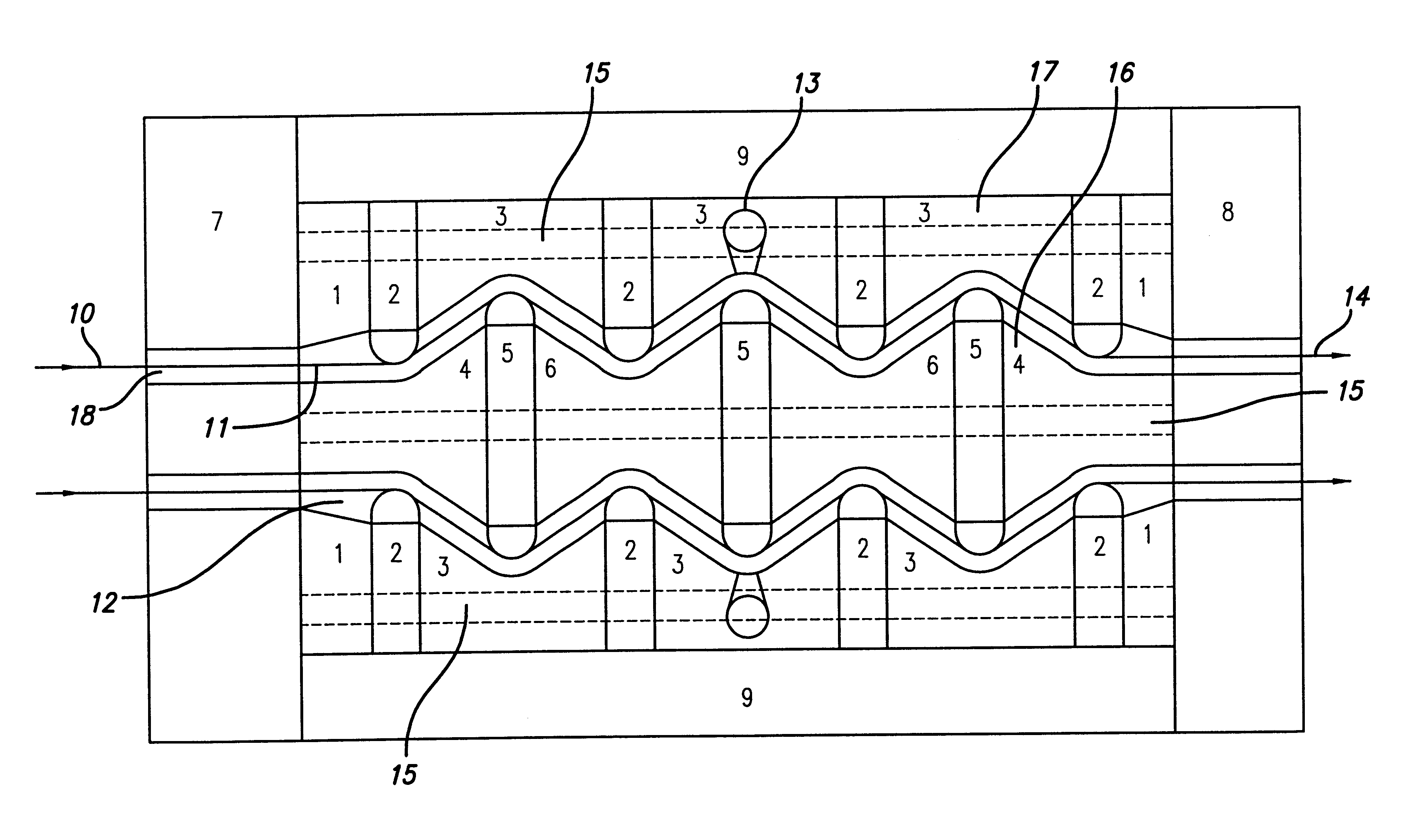

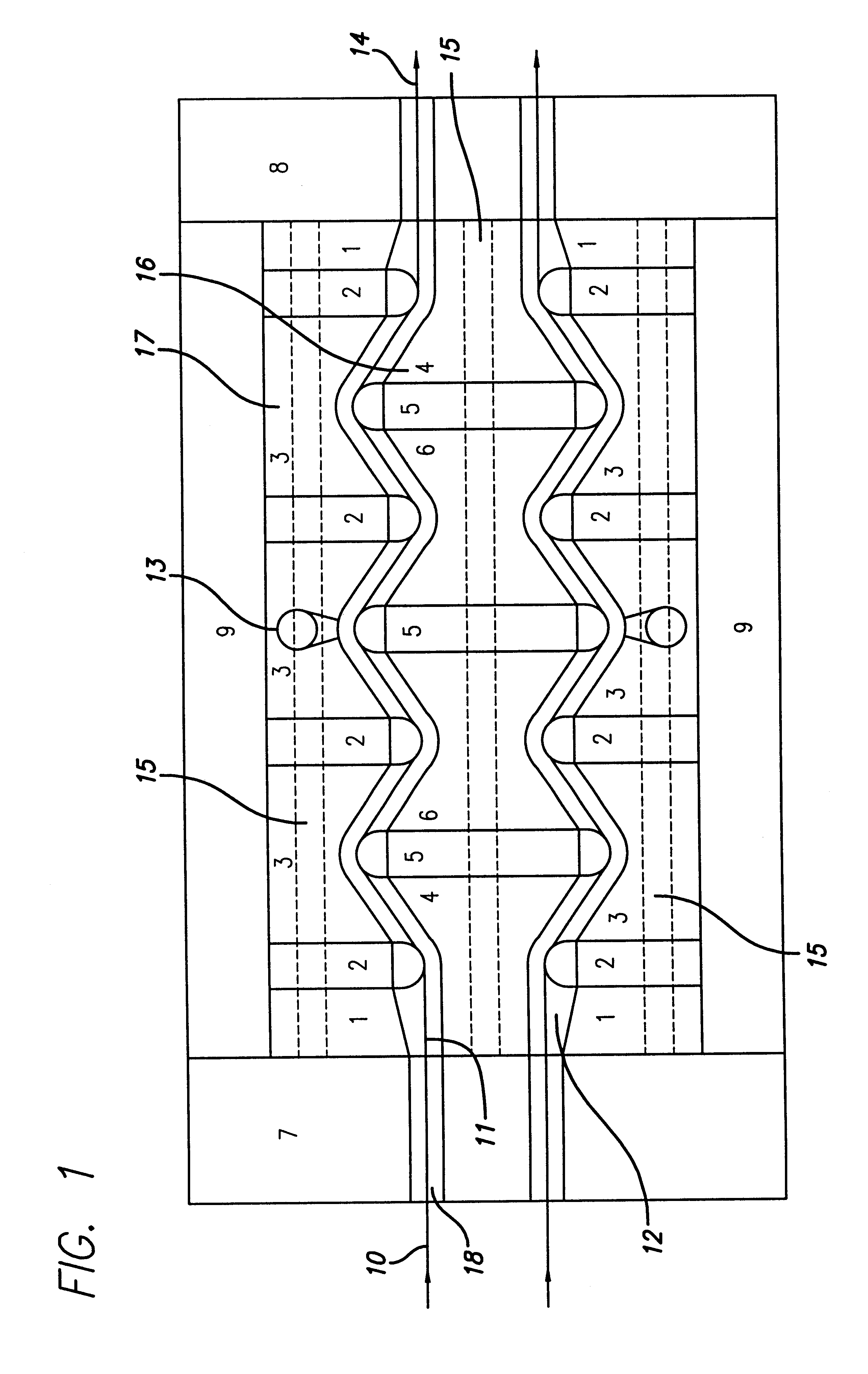

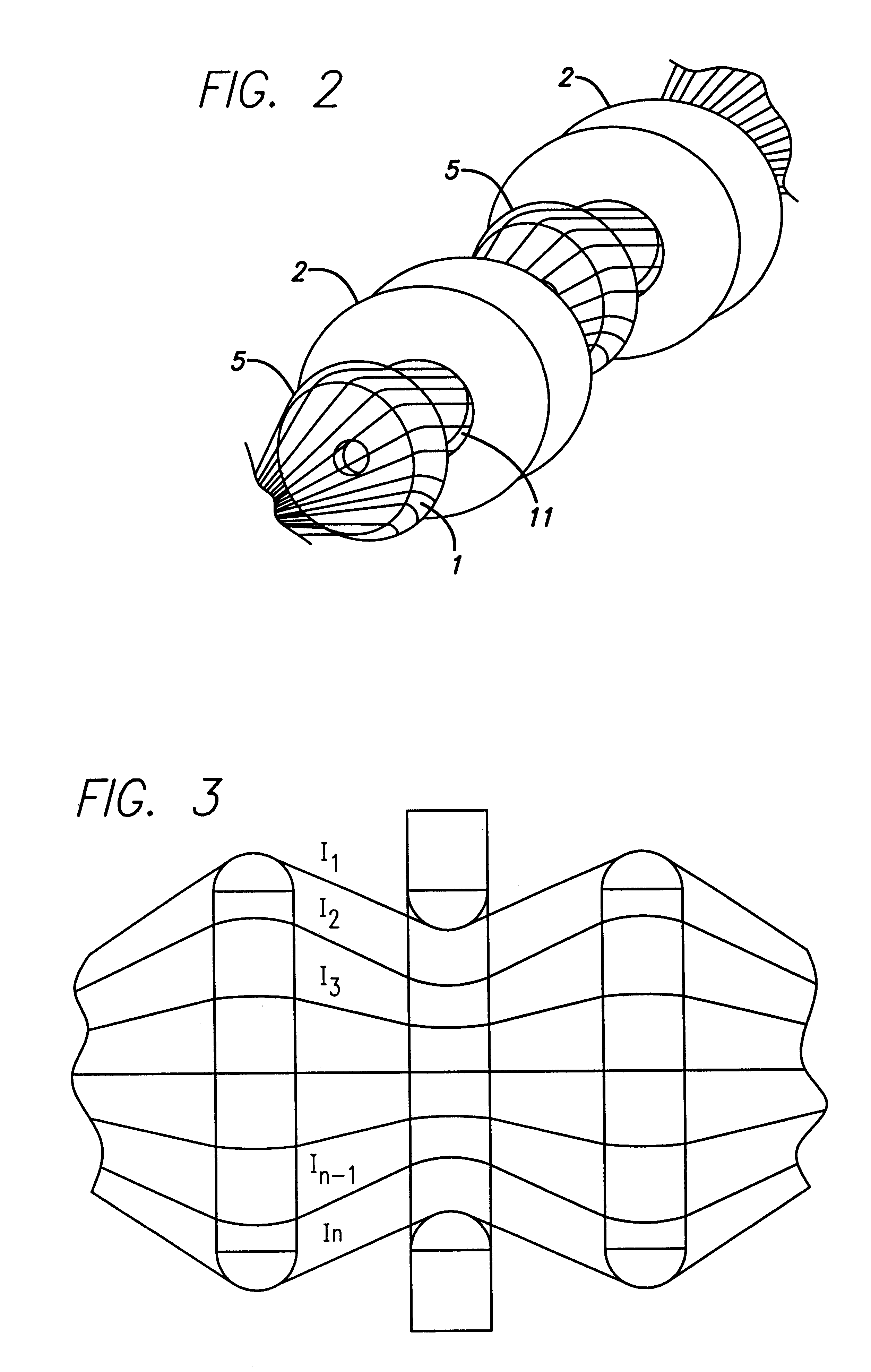

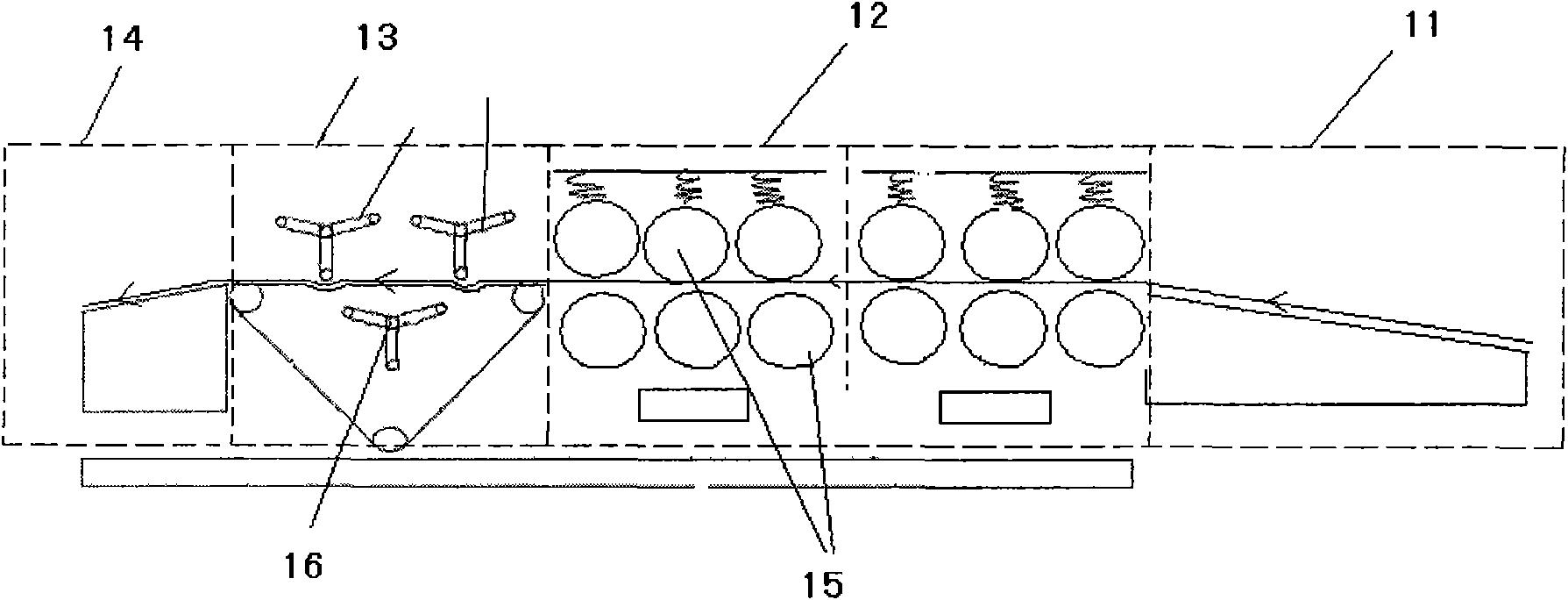

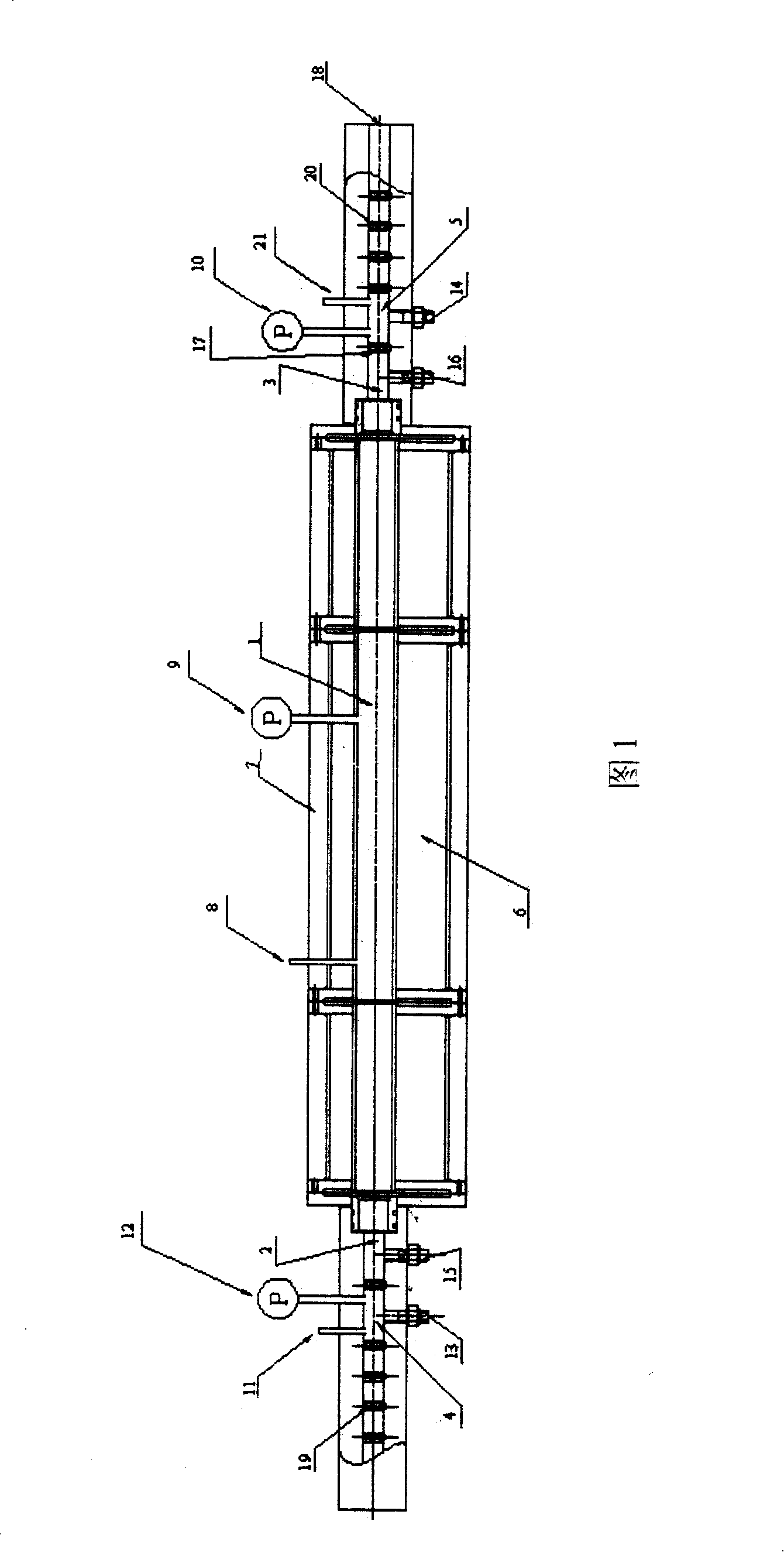

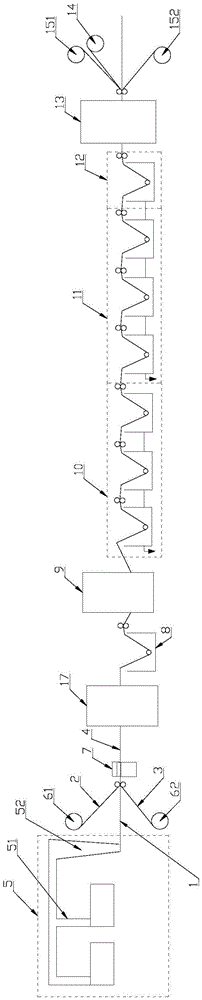

An apparatus for producing a resin coated fiber composite of a rod shape, tubular-shape or plate shape comprises a plurality of first members having an annular shape with a semi-circular ring shaped internal surface, second members having a disc shape with a semicircular ring shaped external surface, first connectors for assembling the first members, second connectors for assembling the second members, an outer die member semi-assembled with the first members and connectors, an inner die member semi-assembled with the second members and connectors, a heater, an inlet nozzle and an outlet nozzle, a zigzag shaped tunnel formed between the inner and outer die members for providing a narrow flow path of the fiber filaments, and resin inlet ports to fill the molten resin in the zigzag shaped tunnel and pressurize the flow path of the fiber filaments. A process for preparing a resin coated fiber composite of a rod-shape, tubular-shape or plate-shape comprises steps of spreading fiber filaments by passing the fiber filaments through a first member having a convex-concave portion to prevent fracture of the fiber filaments, and sequentially tensioning through a series of first and second members all along a narrow flow path to maximize molten resin penetrating surface area, impregnating pressurized molten resin into the fiber filaments continuously by passing the fiber filaments through a series of the first and second members all along the narrow flow path of a zigzag shaped tunnel to maximize molten resin penetrating time, and wherein pressurization of the molten resin maximizes penetration of molten resin into pores of the fiber filaments and minimizes possibility of resin degradation, stranding the resin-coated fiber filaments through a final set of the first members having the convex-concave portion for strengthening the fiber filaments, and integrating and pultruding the resin-coated fiber filaments continuously by passing the fiber filaments all along the narrow flow path of the zigzag shaped tunnel to form a desired diameter through the outlet nozzle.

Owner:SAMBARK LFT

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

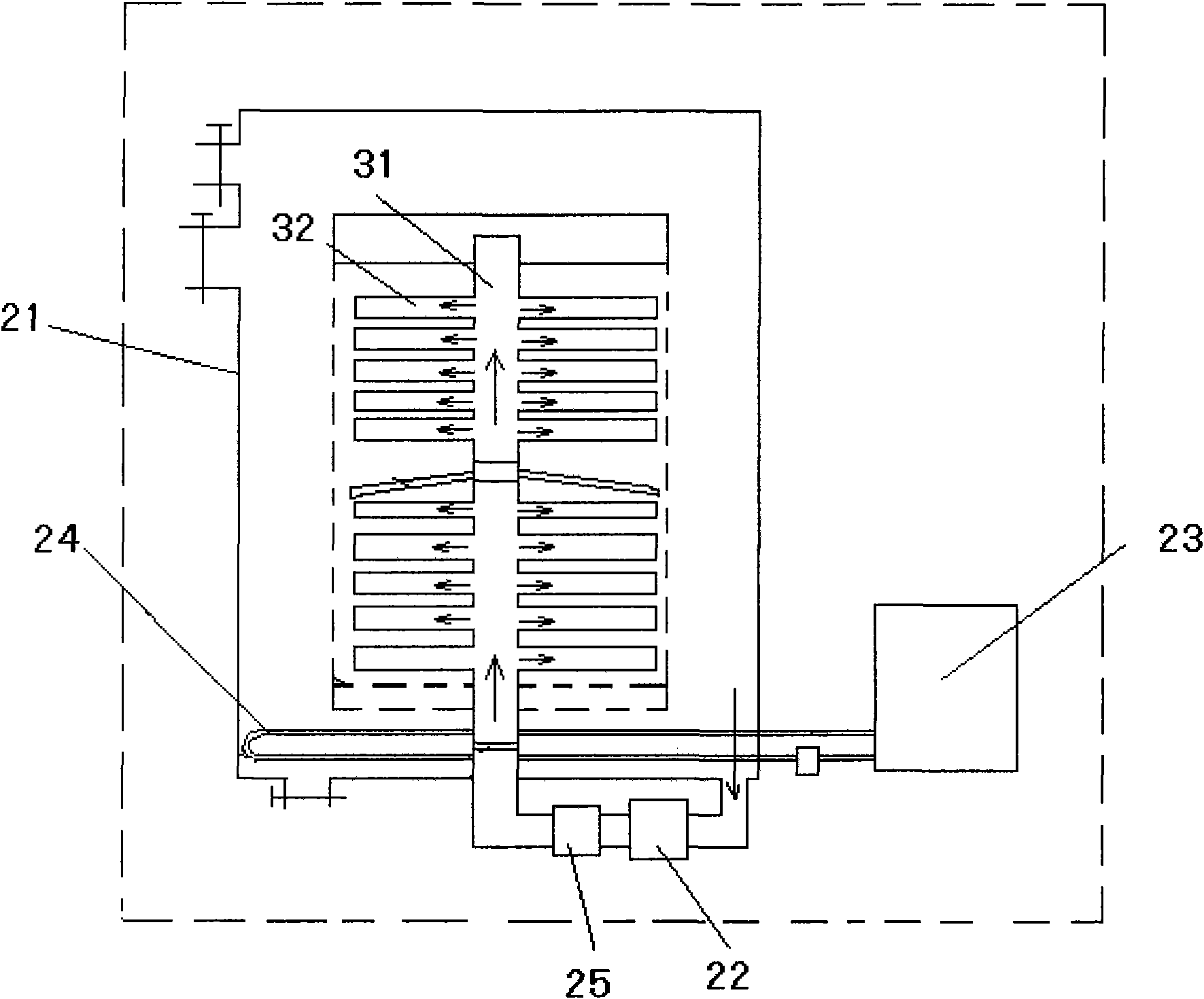

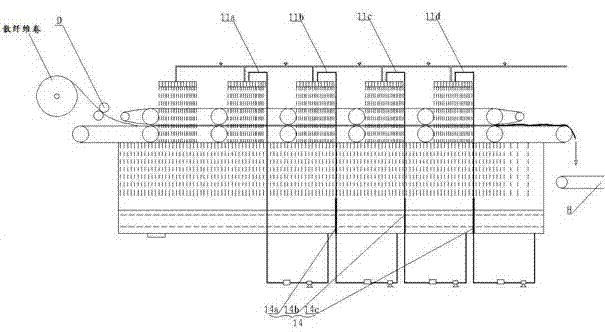

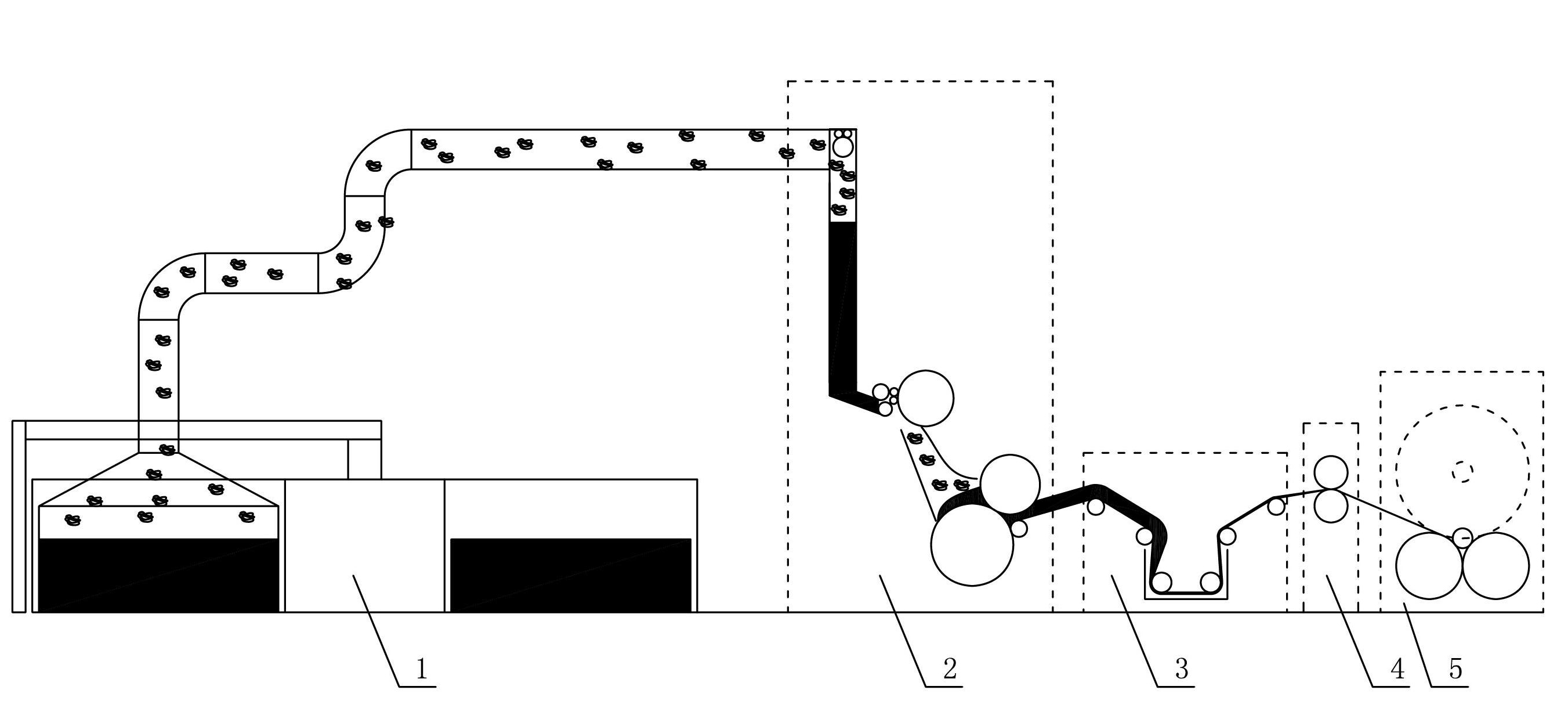

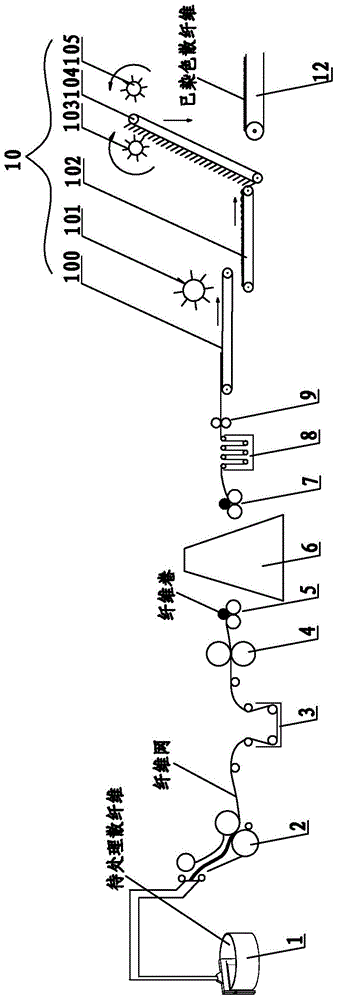

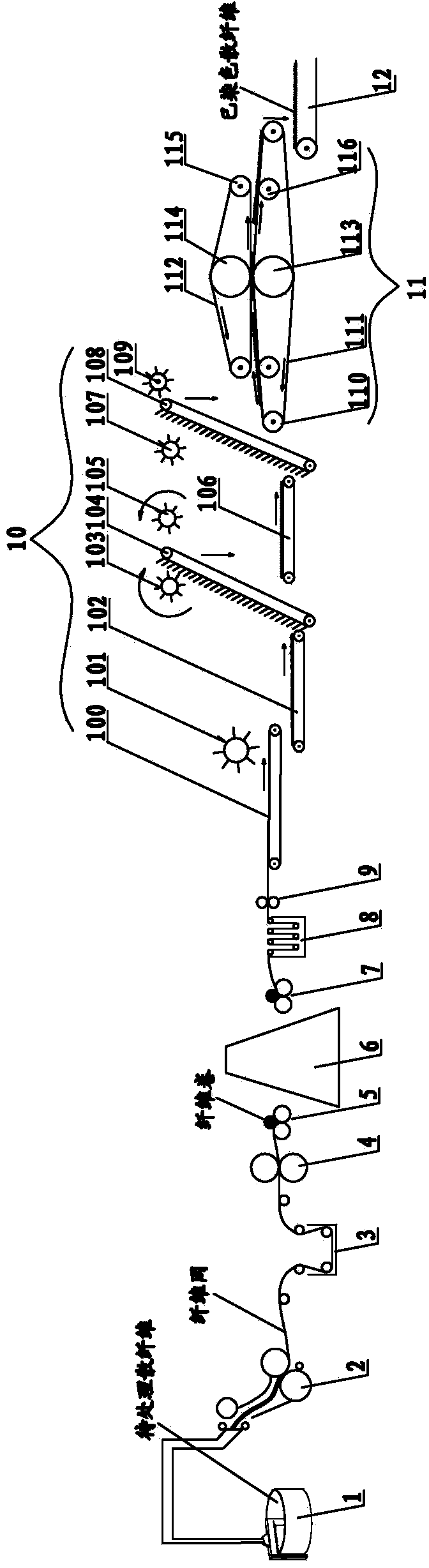

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

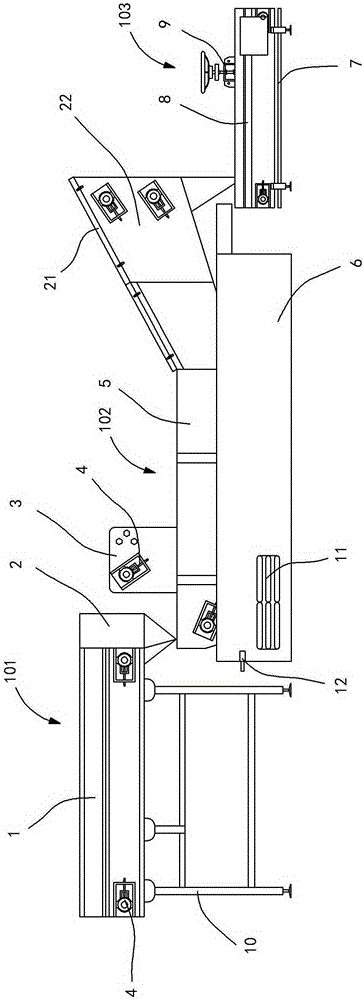

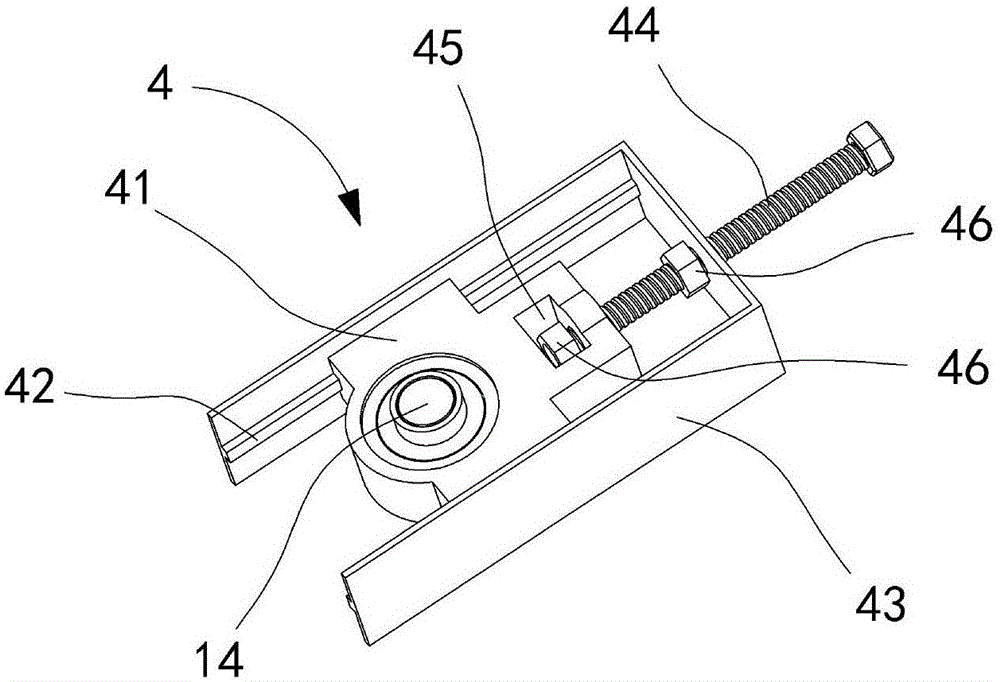

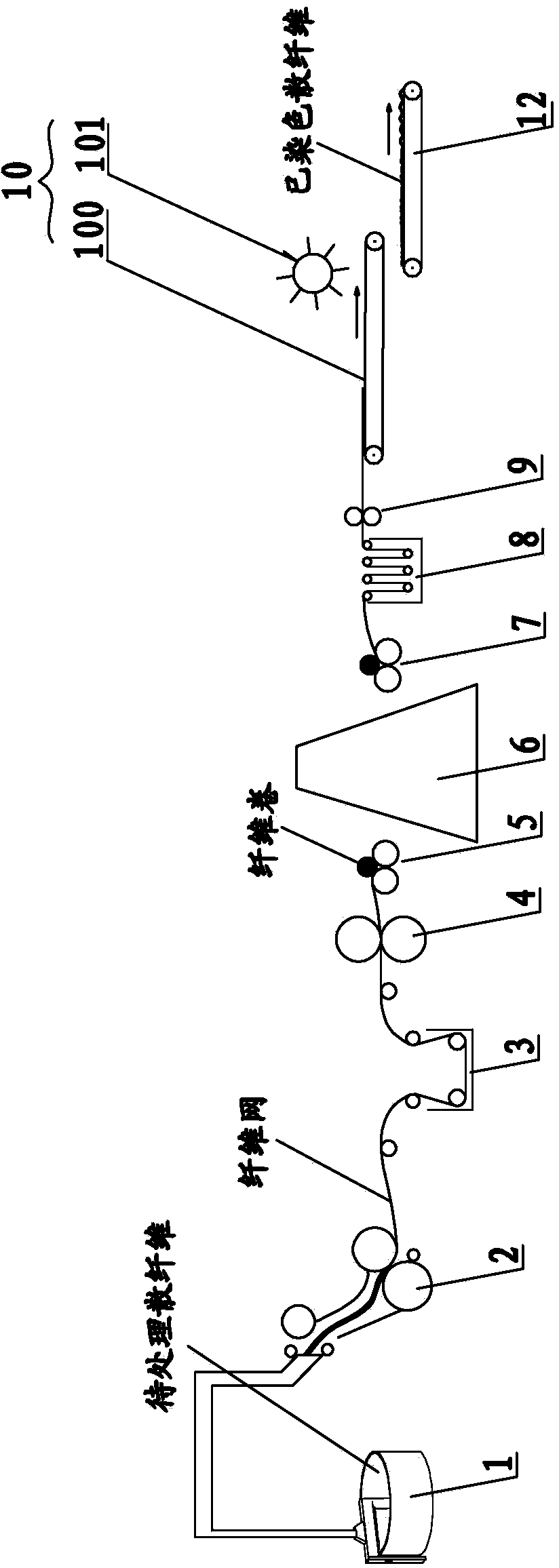

Fiber after-treatment equipment

ActiveCN105113160AIncrease productivityImprove qualityLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberAfter treatment

The invention discloses fiber after-treatment equipment which comprises a fiber input mechanism (101), a fiber soaking mechanism (102) and a fiber output mechanism (103). An outlet of the fiber input mechanism (101) is formed in an inlet of the fiber soaking mechanism (102). An outlet of the fiber soaking mechanism (102) is formed in an inlet of the fiber output mechanism (103). The fiber after-treatment equipment improves the production efficiency, greatly improves the quality of products, and reduces the product reject ratio in the production process.

Owner:JIANGSU XILUN NANO BIOTECH CO LTD

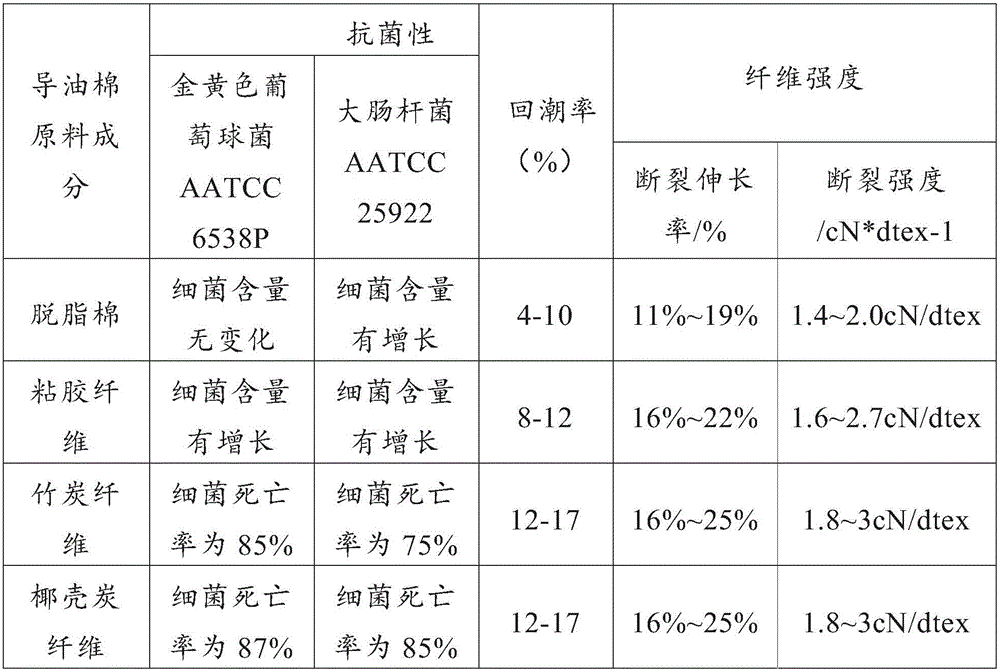

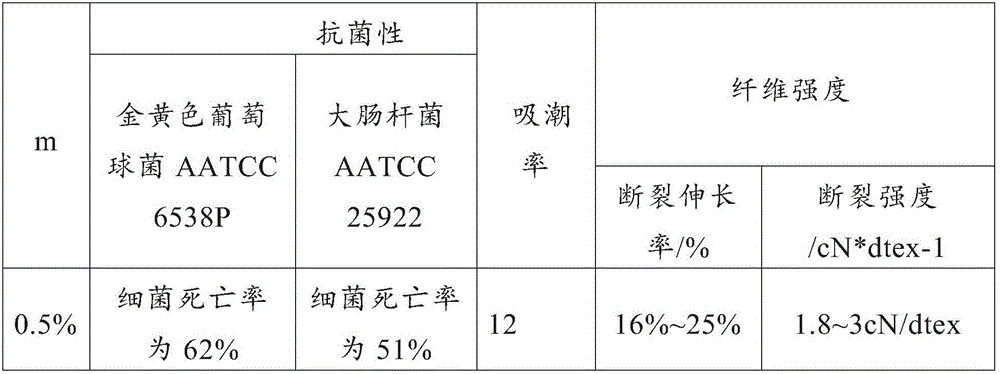

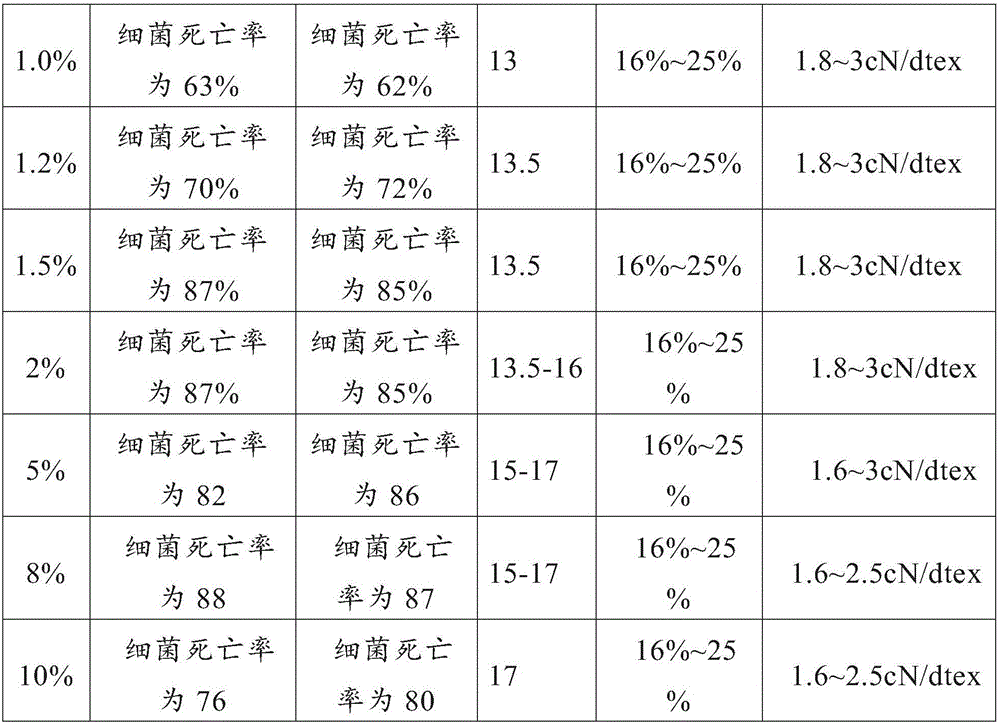

Oil guiding cotton for electronic cigarettes and preparation method for oil guiding cotton

ActiveCN105747277AHas antibacterial functionFast absorbingMonocomponent cellulose artificial filamentTobacco devicesAdditive ingredientCotton fibre

The invention relates to oil guiding cotton and particularly relates to the oil guiding cotton for electronic cigarettes and a preparation method for the oil guiding cotton. Raw material ingredients of the oil guiding cotton for the electronic cigarettes comprise plant charcoal micropowder, wherein the plant charcoal micropowder contains bamboo charcoal micropowder. The preparation method for the oil guiding cotton for the electronic cigarettes comprises the step of carrying out preparation by adopting the plant charcoal micropowder as a raw material, wherein the plant charcoal micropowder contains the bamboo charcoal micropowder. The oil guiding cotton for the electronic cigarettes, provided by the invention, has a micropore structure and a honeycomb structure, and the oil absorbency can reach 6 to 10 times that of the existing oil guiding cotton prepared from cotton fibers; the oil guiding cotton prepared by the method can faster absorb and release tobacco tar, so that an atomizer is effectively prevented from oil-free dry burning. Meanwhile, the oil guiding cotton provided by the invention has a bacteriostatic function, so that bacteria cannot survive for a long time and can disappear or be reduced in a short time.

Owner:唯它(北京)科技有限公司

Preparation of nano black carbon and use of nano black carbon in fabric dyeing

InactiveCN101348618ASimple preparation processLow costInorganic pigment treatmentDyeing processPigment dispersionCellulose fiber

The invention relates to a nano-carbon black preparation method and an application of nano-carbon black in fabric dyeing, belonging to the technical field of textile chemical engineering. The preparation method is characterized in that an ultrasonic technique is utilized to prepare the nano-carbon black, so as to obtain a nano-carbon black pigment dispersion system with good dispersivity and high stability; the prepared nano-carbon black pigment dispersion system can be used for dyeing natural cellulose fiber and regenerated cellulose fiber fabrics; and the dyed fabrics are pure in color, good in jet-black degree and excellent in color fastness. The preparation method has the advantages of simple process, low cost and little pollution.

Owner:JIANGNAN UNIV

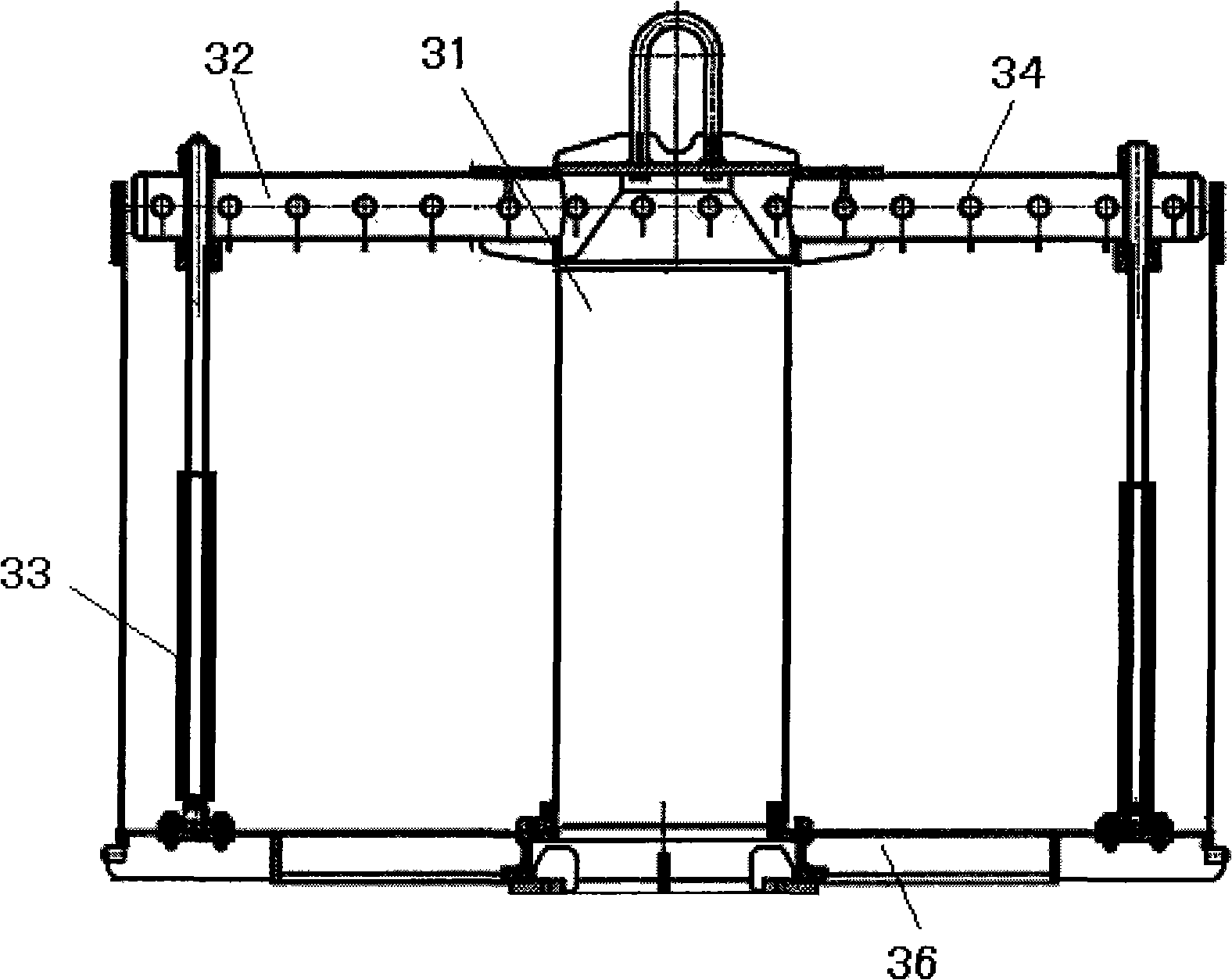

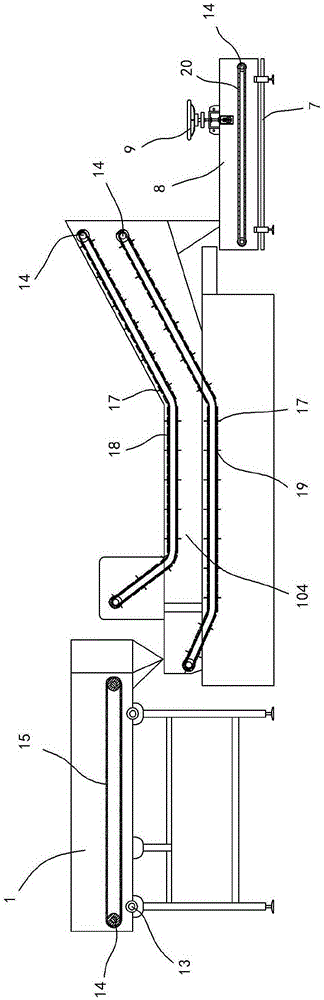

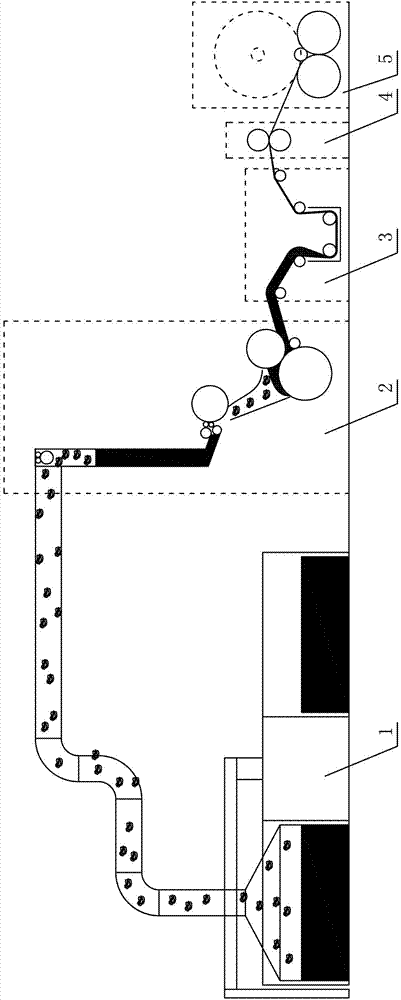

Polyacrylonitrile fiber steam drafting device and sealing method for the device

InactiveCN101235568AGuaranteed tightnessReduce the temperatureLiquid/gas/vapor fibres/slivers/rovings treatmentCarbon fibersWater vapor

The invention relates to a vapor pressure sealing device which is used to draft fiber vapor and in particular relates to the vapor pressure sealing device which is used to draft polyacrylonitrile fiber which is used to produce carbon fiber precursors with high performance and a sealing method for realizing the vapor pressure sealing device. Two ends of a water vapor drafting chamber adopt a high temperature gas sealing chamber whose pressure is same to that of the water vapor drafting chamber to connect, since the water vapor pressure and the temperature in the high temperature sealing chamber are same to the water vapor pressure and the temperature in the water vapor drafting chamber, great differences in the temperature and the pressure between the water vapor drafting and external interface are effectively reduced, temperature lowing and water vapor penetration and concentration can be effectively reduced, and thereby the temperature and the pressure in the water vapor drafting chamber can be effectively guaranteed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

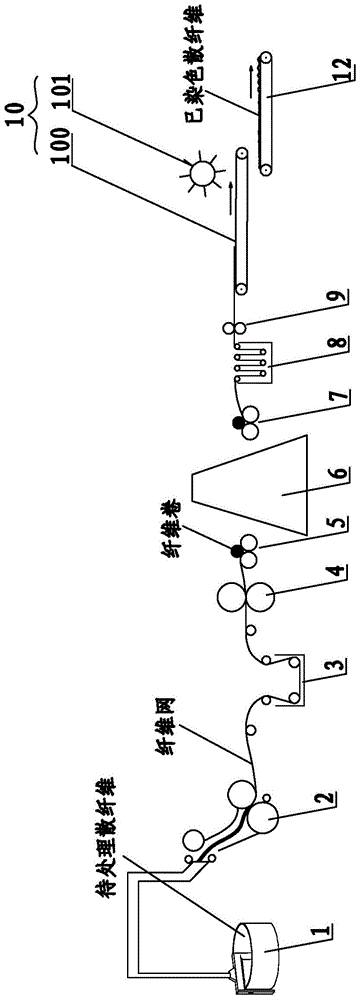

Cotton fiber continuous dyeing and bleaching method and equipment

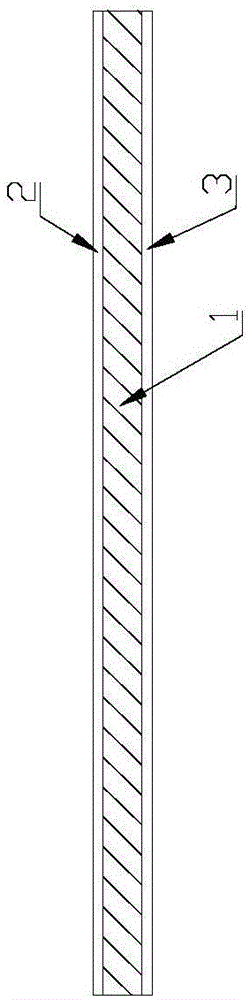

ActiveCN105155166AIncrease productivityLow costTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentBiochemical engineeringCotton fibre

The invention relates to a cotton fiber continuous dyeing and bleaching method and equipment. The equipment comprises a cotton fiber tidying device an unrolling device, a stitching device and a continuous bleaching or dyeing device, wherein to-be-bleached or dyed cotton fibers are tidied and evenly paved into a flat cotton bed; then the cotton bed is clamped between an upper clamp layer and a lower clamp layer; the upper clamp layer, the cotton bed and the lower clamp layer are stitched together via the stitching device to form a stitched body capable of continuously transmitting; the stitched body is continuously transmitted to follow-up continuous dyeing or bleaching device to be dyed or bleached according to cotton fiber dyeing or bleaching technology; and complete dyed or bleached cotton fibers can be achieved when the stitching lines, the upper clamp layer and the lower clamp layer are detached. The beneficial effects of the method and the equipment are that the method is a continuous production method, has high production efficiency, low cost and reduces energy consumption and carbon emission.

Owner:杨立新

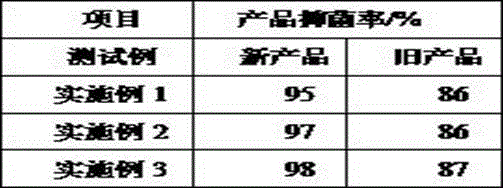

Natural antibacterial bamboo fiber sock

The invention discloses a natural antibacterial bamboo fiber sock. The natural antibacterial bamboo fiber sock is formed by blending the following raw materials including 90% of bamboo fibers, 3% of Lilion, 4% of aloe fibers, 2% of milk fibers and 1% of alginate fibers. According to the natural antibacterial bamboo fiber sock, the method that the bamboo fibers, the Lilion, the aloe fibers, the milk fibers and the alginate fibers are blended is adopted. The sock is pliable, close to skin, resistant to wear and free of pilling, the sock is good in antibacterial performance and protects the skin, and the sock has the functional advantages of moisture permeability, acarus killing, deodorization, ultraviolet ray resistance and blood circulation promotion. Natural finishing agent chitosan is adopted in the postprocessing process, and the antibacterial effect of fabric is further enhanced. Antibacterial agents are totally from plant extracts. Antibacterial substances are diversified so that the sock can be safe and comfortable, and the problem that the color of the sock changes later is avoided. Natural materials are adopted in the whole manufacturing process of the natural antibacterial bamboo fiber sock, and the natural antibacterial bamboo fiber sock is environmentally friendly, safe, low in cost, high in grade and good in comfort level.

Owner:JIESHOU SHUANGXIN TEXTILE

Cold-pad batch dyeing process for bulk fiber

InactiveCN102817192AReduce fluid volumeReduce laborLiquid/gas/vapor removalTextile treatment machine arrangementsBleachMaterials science

The invention relates to the field of bulk fiber dyeing, in particular to a cold-pad batch dyeing process for bulk fibers, which comprises the steps of: (1) bulk fiber web formation: forming a uniform fiber layer with bulk fibers by an automatic bale plucker and a web forming machine; (2) padding: controlling a bleaching mangle expression to be 100-120 percent and a dyeing mangle expression to be 120-140 percent, only adding a refining agent and a bleaching agent for pretreatment into an immersion solution tank during bleaching, and adding dyes, a penetrant and an alkaline agent into the immersion solution tank during dyeing; (3) stacking after uniform padding and rolling: performing stacking on a cold-pad batch unit after the fiber layer is rolled so as to complete bleaching or dyeing; and (4): washing and drying: making the fibers treated by a washing machine and a soaping tank after dying and then treated by a drying machine. The cold-pad batch dyeing process has the advantages of little pollution and low energy consumption.

Owner:ZHEJIANG CHUNLANFANG TRADE

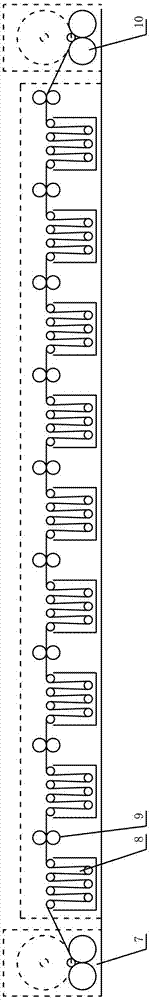

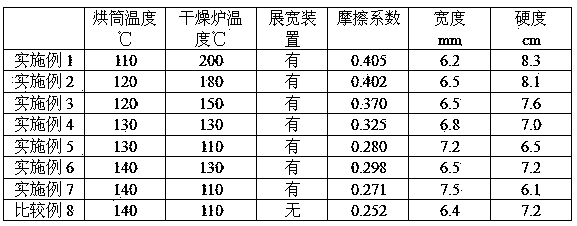

Drying method for carbon fiber having been subjected to sizing

ActiveCN104195766ASimple structureSmall footprintDrying using combination processesTextile treatment machine partsFiberCarbon fibers

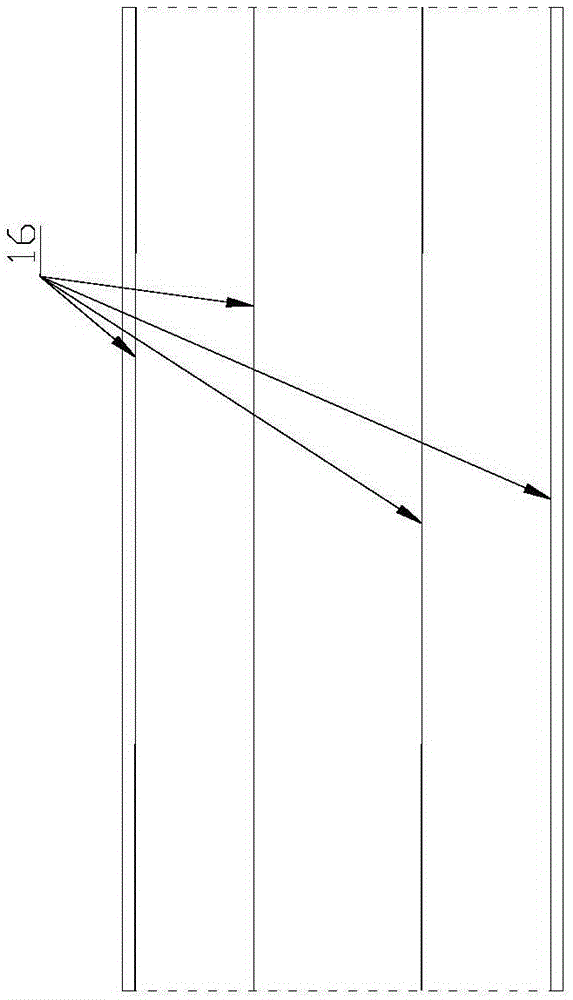

The invention discloses a drying method for carbon fiber having been subjected to sizing. First, tows of the carbon fiber having been subjected to sizing are pre-dried in a contact mode through a drying roller, the wrap angle of the tows of the carbon fiber on the drying roller is larger than 180 degrees, the contact time ranges from 10 s to 60 s, the surface temperature of the drying roller ranges from 100 DEG C to 150 DEG C, the tows, with the water content smaller than or equal to 1%, of the carbon fiber are obtained after pre-drying, and sizing agent is made to form film on the surfaces of the tows of the carbon fiber; then, the pre-dried tows of the carbon fiber penetrate through a drying oven to be dried in a non-contact mode, the temperature in the drying oven ranges from 100 DEG C to 250 DEG C, then, the tows, with the water content smaller than or equal to 0.1%, of the carbon fiber are obtained, the resin film can be drier and more comfortable, and the tows of the carbon fiber can be kept flat and thus are convenient to lay flat and wind. The dried tows of the carbon fiber is good in quality, hardness and widening performance of the tows can be enhanced, broken filaments are reduced, and large-scale production can be achieved.

Owner:ZHONGFU SHENYING CARBON FIBER

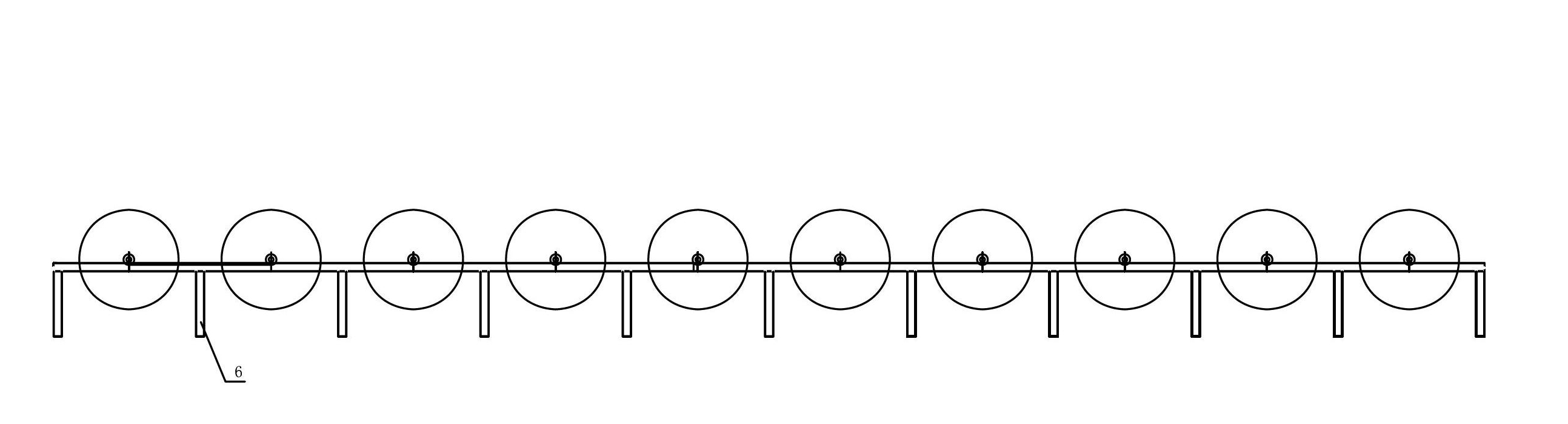

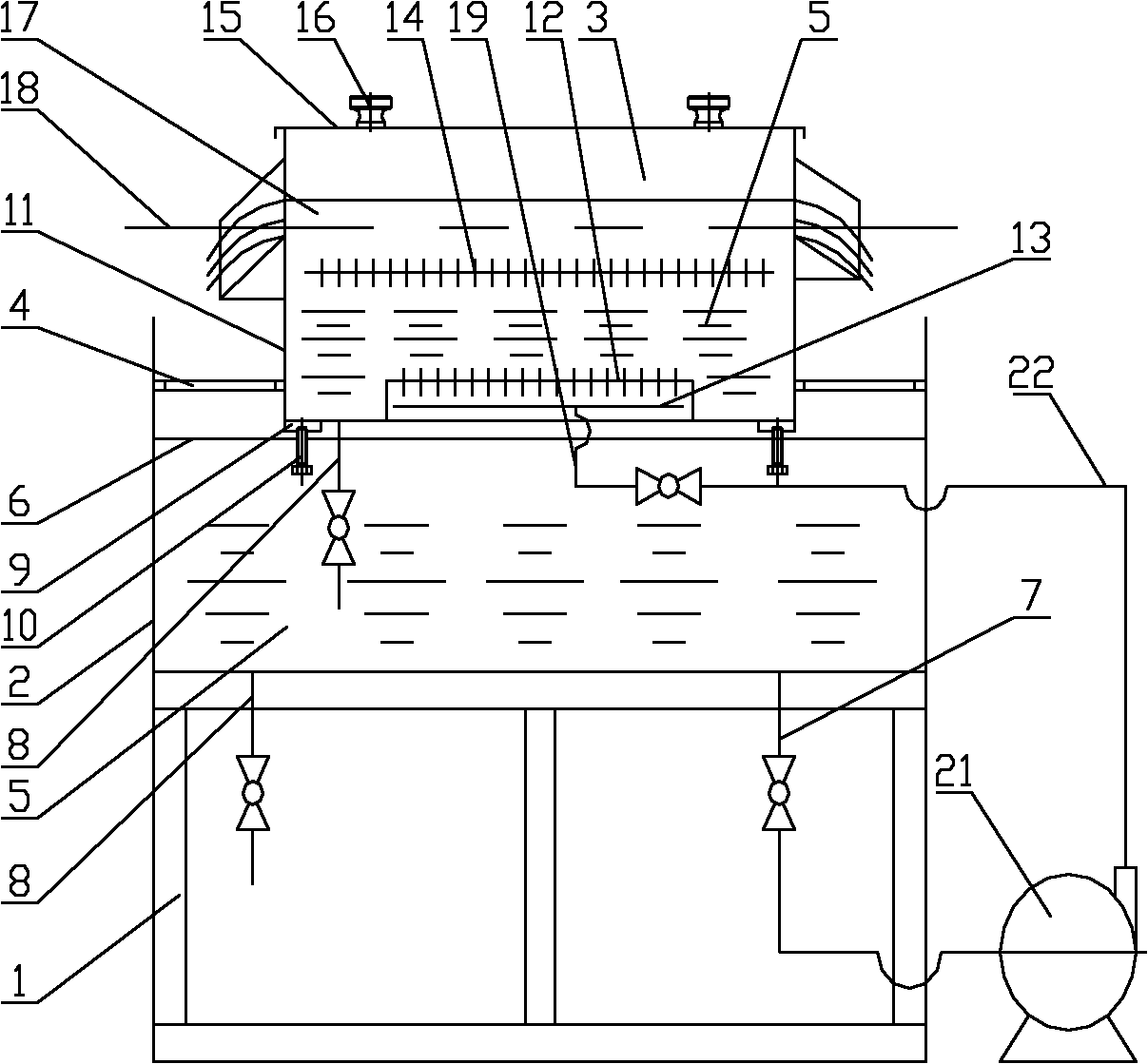

Loose fiber cold pad-batch dyeing machine

ActiveCN102660846AContinuous productionReduce fluid volumeTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsElectricityFiber

The invention relates to a loose fiber cold pad-batch dyeing machine which sequentially comprises an automatic bale plucker, a lapper, an immersion liquid tank with an automatic dosing system, an evenness calender, a coiling machine I, a cold pad-batch unit, an uncoiling machine I, a washing machine, a water calender, a coiling machine II, an uncoiling machine II, a drying machine and a packaging machine; in a bale storage box of the lapper, a centrifugal fan is arranged below a foot nail roller and communicated with the foot nail roller through a circulating air flue; a high-speed circulating spray pipe is mounted at the bottom of the immersion liquid tank; and a spray head on the high-speed circulating spray pipe is directly opposite to a fiber layer above the spray head. The machine provided by the invention has the advantages of high production efficiency, uniform dyeing, low water, electricity and energy consumption and low production cost.

Owner:浙江华晨印染有限公司

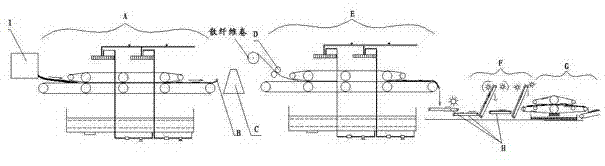

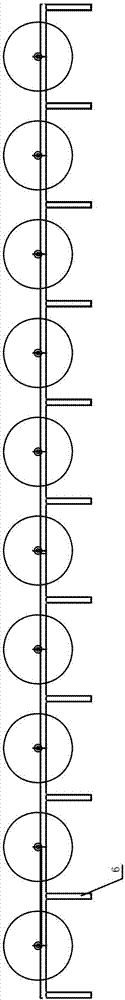

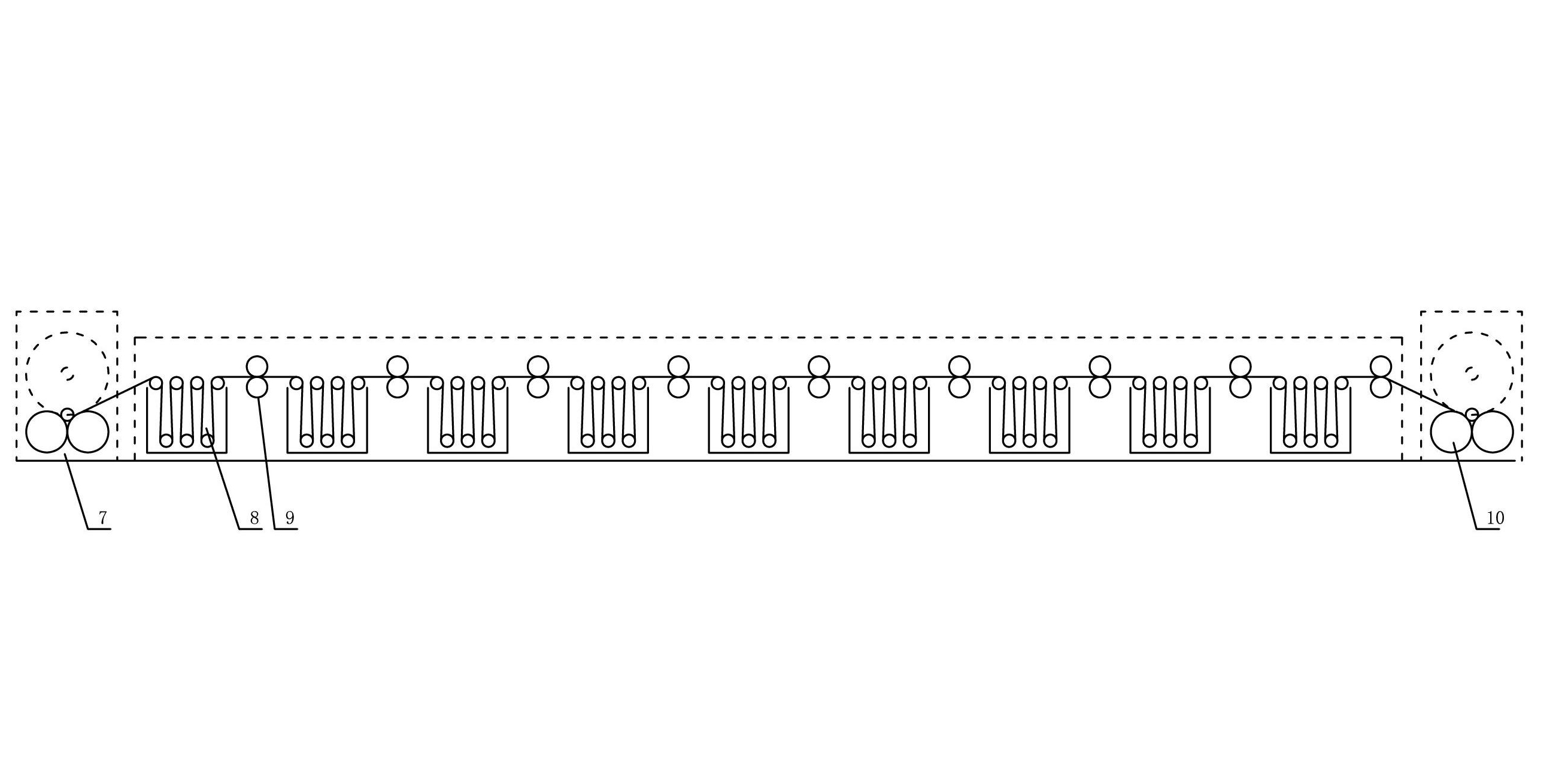

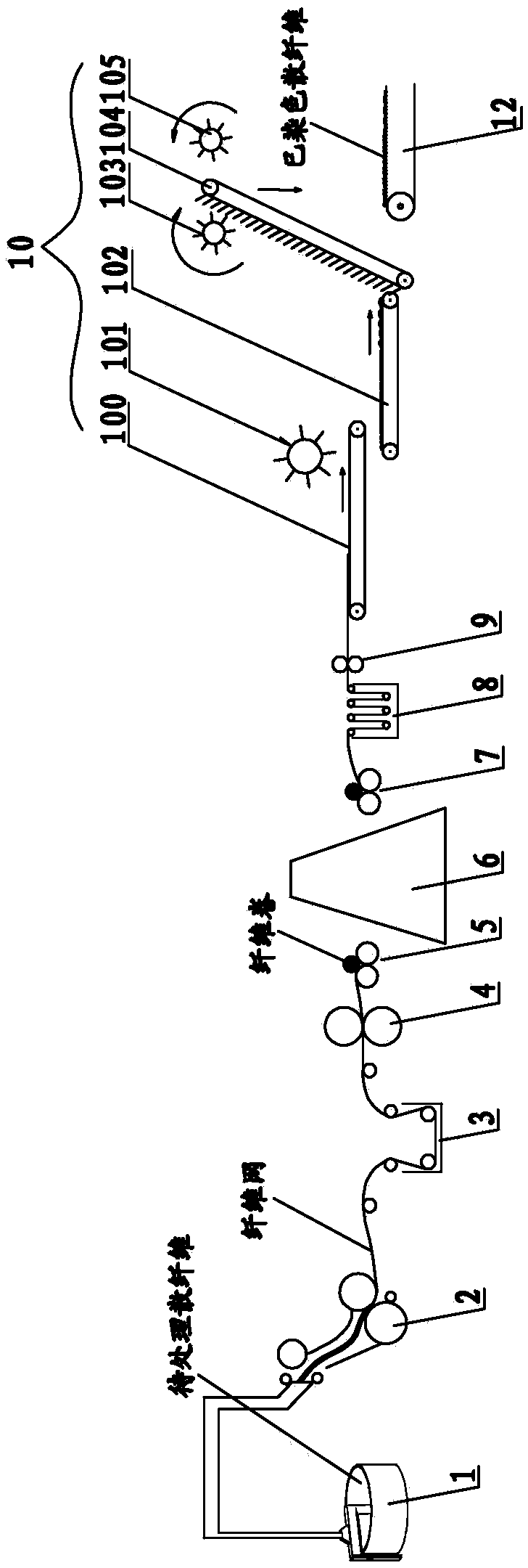

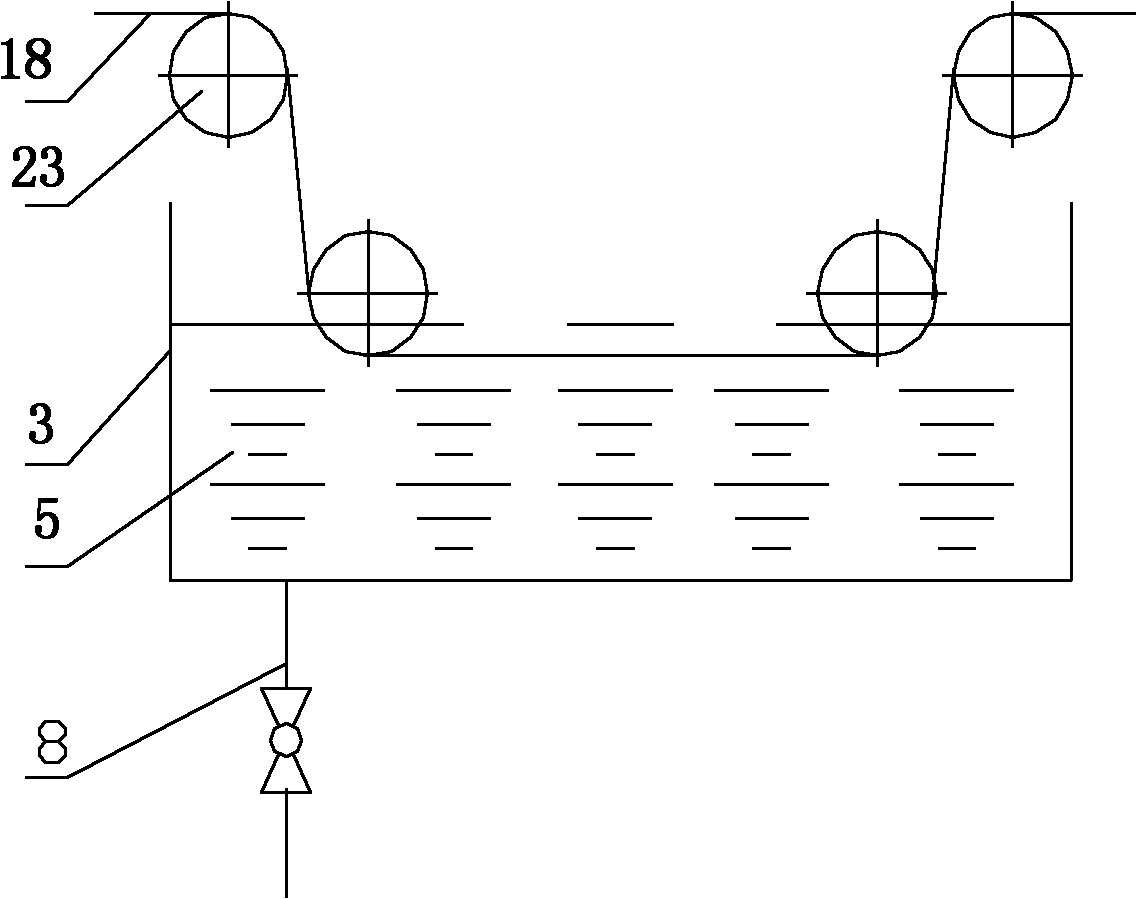

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Blended yarn with hemp and cotton multifunctional fiber reinforced by graphene fiber

ActiveCN105951237AHigh strengthImprove toughnessBiochemical treatment with enzymes/microorganismsFibre chemical featuresYarnPectinase

The invention discloses blended yarn with hemp and cotton multifunctional fiber reinforced by graphene fiber. The blended yarn is prepared from the following steps that 1, hemp fiber is placed in a pectinase solution to be soaked at normal temperature, continues to be soaked in a chitosan aqueous solution, and then is dehydrated and dried; 2, the hemp fiber, bamboo fiber, wool fiber and cotton fiber are placed in acetone to be soaked while ultrasonically oscillated and are washed, dehydrated and dried to prepare the hemp and cotton multifunctional fiber; 3, the hemp and cotton multifunctional fiber and graphene fiber are mixed uniformly and entwisted into the blended yarn. As the graphene fiber is added for blending, strength and tenacity of the hemp and cotton multifunctional fiber blended yarn are improved, and the specific resistance of the blended yarn is about 10-103 omega*m; after mild biological enzyme treatment, the hemp fiber has the degumming effect and avoid retting degumming caused by chemicals, natural phenolic substances and derivatives thereof contained in the hemp fiber are well reserved, and the effective and natural antibacterial function is achieved.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

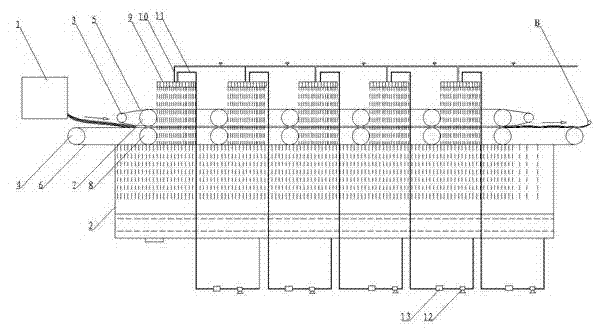

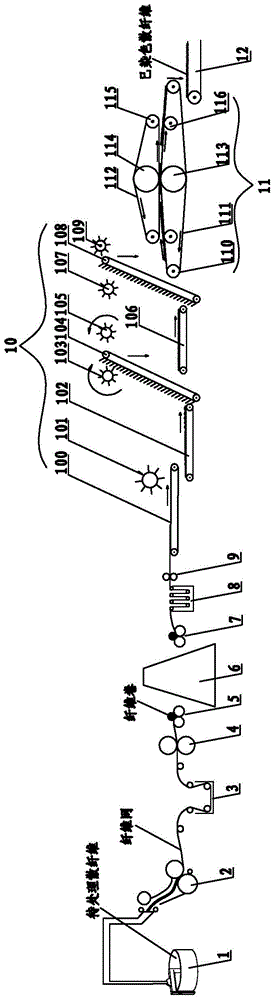

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Preparation method of cold black suiting

InactiveCN102618992AAvoid damageImprove insulation effectFibre treatmentDyeing processColour fastnessPolyester

The invention relates to a preparation method of cold black suiting. In the suiting, 52% of polyester fiber and 48% of polyester fiber by weight are used as raw materials; and the suiting is prepared by top dyeing and recombing, spinning, weaving and after-treatment. The method comprises the following steps of: before dyeing wool, performing pretreatment on wool; adjusting the pH value with alkali to adjust the wool to a neutral state; dyeing, wherein the dye adopts a Nylosan dyeing agent produced by the Clariant cooperation, the dyeing is started at 40 DEG C, and the temperature is increased to 100 DEGE C and kept for 60 minutes before after-treatment; performing cold black auxiliary treatment on the dyed wool, wherein the cold black auxiliary is the CWF cold black auxiliary produced by the Clariant cooperation; performing a dip dyeing technology, heating to 100 DEG C, and treating for 45-55 minutes at the temperature; and cleaning with an efficient cleaning agent ND-9 produced by the Nigeria Mita Auxiliaries Co., Ltd., Jiangyin. Through the invention, the prepared cold black suiting has good color fastness and low ultraviolet transmittance and is cool and suitable for summer.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

Method for processing mercerized cotton strip

ActiveCN102493142AGuaranteed alkaline dippingGuaranteed stretchMercerising of sliversLiquid/gas/vapor removalPolymer scienceSpinning

The invention relates to a method for processing a mercerized cotton strip in the weaving field. The method comprises the following production steps: processing a cotton strip, and manufacturing into the required shape; shaking the cotton strip: shaking the processed cotton strip into the twisting shape according to the set circle number and a frame length, tying and fixing; and mercerizing: mercerizing the cotton strip on a hank-mercerizing machine according to the specific technology. According to the method for processing a mercerized cotton strip, which is disclosed by the invention, the industrial problem that the cotton fiber can not be mercerized is mainly solved, a feasible full set of processing method for mercerizing, dyeing and spinning the cotton strip is provided, and cotton silk mercerization, cotton wool mercerization and high-depth color spinning can become true.

Owner:无锡市鳌尊生态科技有限公司

Suede elastic tweed fabric and production method thereof

InactiveCN102704145AImprove wearing effectReduce manufacturing costHeating/cooling textile fabricsDyeing processFiberEngineering

The invention relates to a suede elastic tweed fabric, which is characterized in that warps and half of wefts of the fabric are formed by mixedly spinning wool and anti-pill fiber Trevira, and the other half of wefts are covering yarns made of FREEFIT elastic fibers and single wool yarns; and the fabric comprises 40-50 wt% of wool, 45-55 wt% of anti-pill fiber Trevira and 1-5 wt% of FREEFIT elastic fibers. The invention also relates to a production method of the suede elastic tweed fabric. The invention has the advantages that the production cost of the wool or cashmere fabric can be reduced, and the wearability of the fabric is improved.

Owner:JIANGSU SUNSHINE GRP CO LTD

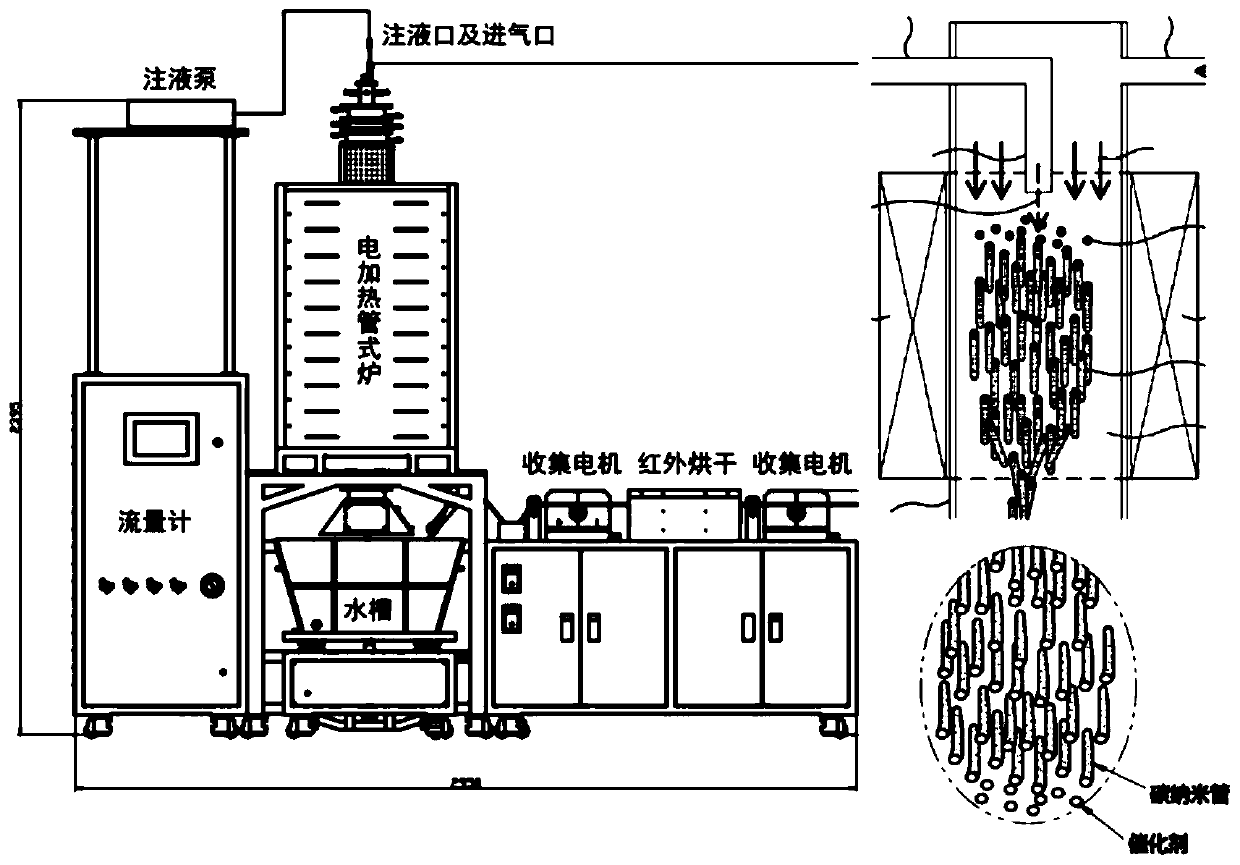

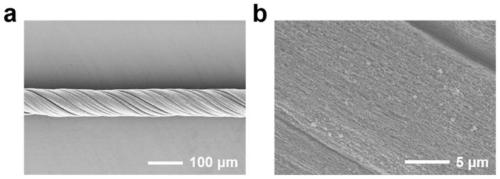

Method for improving orientation degree and conductivity of carbon nanotube fiber

InactiveCN111155217AGood orientationImprove compactnessCarbon fibresLiquid/gas/vapor removalFiberSpinning

The invention discloses a method for improving the orientation degree and conductivity of a carbon nanotube fiber. The method comprises the steps of preparing a continuous carbon nanotube fiber by a floating catalytic chemical vapor deposition method; then, immersing the carbon nanotube fiber into a solvent to fully expand; performing proper stretching, so that the carbon nanotube fiber is rearranged to improve the axial orientation; next, immersing the carbon nanotube fiber into a coagulating bath; driving phase separation through solubility differences; extruding the solvent from the carbonnanotube fiber; then, performing online washing and drying to form a compact carbon nanotube fiber; and finally, twisting the carbon nanotube fiber to form a multistage spiral structure. The method has the advantages that the primary carbon nanotube fiber prepared by a direct spinning method is swelled and shrunk, and the orientation degree and compactness of the fiber are well improved, so that the electrical conductivity and the mechanical strength of the fiber are greatly improved; the preparation process is simple; the preparation conditions are mild; the cost is low; the production efficiency is high; and the method is suitable for industrial production.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

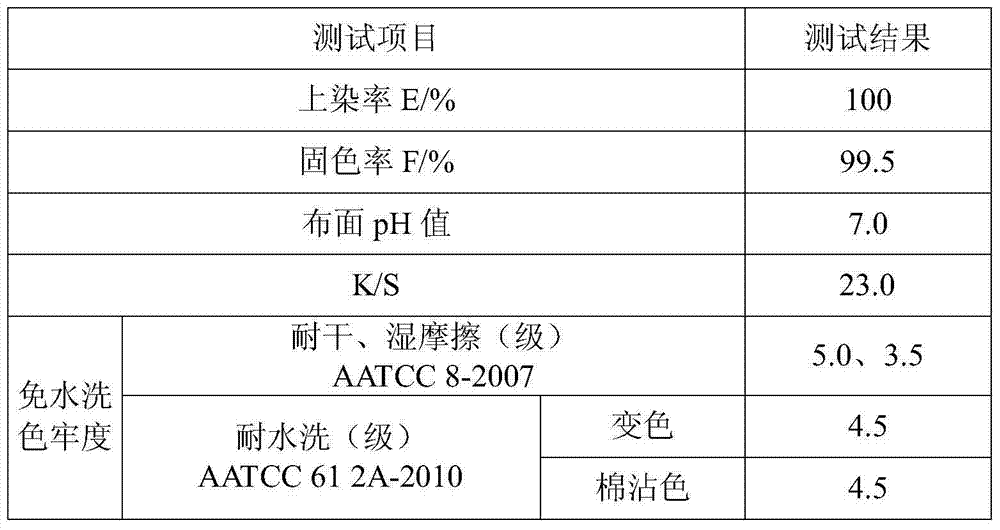

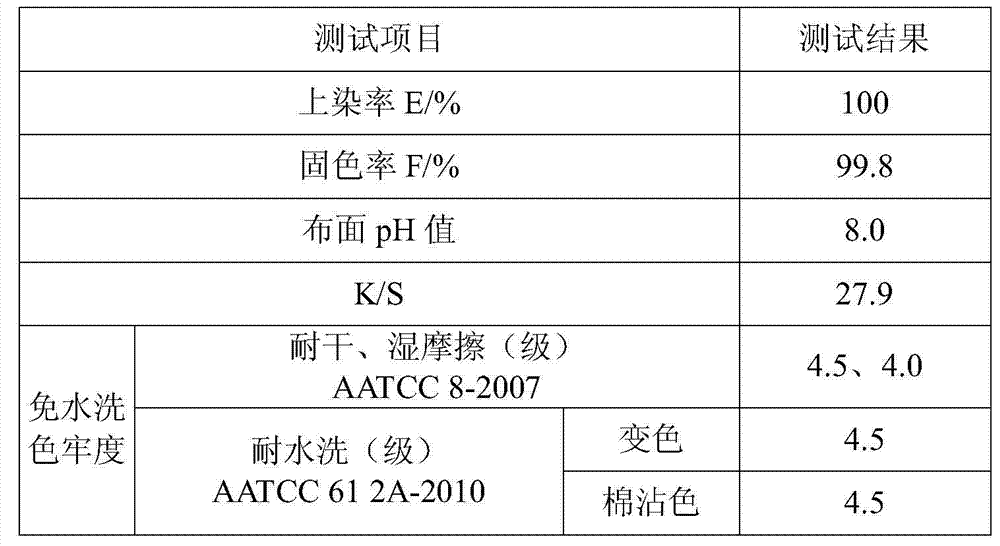

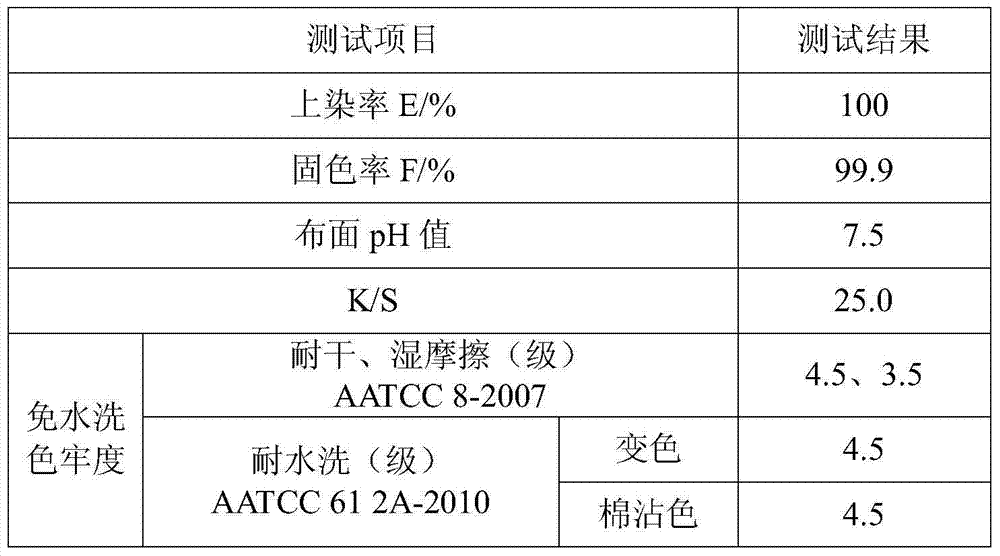

Non-aqueous solvent dyeing method of washing-free reactive dye

ActiveCN104746361AControl contentReduce coefficient of frictionDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberYarn

The invention provides a non-aqueous solvent dyeing method of a washing-free reactive dye. The non-aqueous solvent dyeing method comprises the following steps: 1. carrying out full swelling on loose fibers, yarns, fabric or garments in a water solution of alkaline substances, controlling the take-up rate and drying; 2. mixing the dried loose fibers, yarns, fabric or garments with a reactive dye and a good solvent of the reactive dye to form a mixing system, heating the mixing system, adding a poor solvent of the reactive dye to the mixing system before heating or in the heating process, heating to dyeing temperature and then carrying out heat preservation; and 3. carrying out heat preservation on the loose fibers, yarns, fabric or garments treated in the step 2 in the non-polar or weak-polar poor solvent of the reactive dye containing a cation reagent, drying and thus finishing dyeing. According to the method, the loose fibers, yarns, fabric or garments can be completely dyed or subjected to fixation by the reactive dye, and do not need to be washed and neutralized after being dyed, so that the dyeing cycle is short and the energy consumption is low.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Textile fabric with antisepsis and anti-inflammation functions

InactiveCN105350298AHas antibacterial and anti-inflammatory functionsWith moisture absorption and breathable functionLiquid/gas/vapor removalVegetal fibresTextile technologyTextile fiber

A textile fabric with antisepsis and anti-inflammation functions relates to the technical field of textiles and is produced by the following processes: cleaning wormwood with purified water, placing the cleaned wormwood in distilled water, and heating to be boiled, wherein the mass ratio of wormwood to distilled water is 1: (100-200) (a heating device is equipped with a backflow device, so that steam generated by heating can flow back into the heating device); after heating for 30-60 min, cooling and filtering; removing slag and taking the liquid to obtain a scouring liquid; placing textile fibers, such as cotton fibers, ramie fibers, animal fibers, silk fibers and the like into the scouring liquid to be soaked for 7-14 days at the room temperature, wherein the mass ratio of the textile fibers to the scouring liquid is 1: 1,000; fishing out the soaked textile fibers, naturally airing at the room temperature, and then placing the aired textile fibers into a drying oven to be dried; weaving the dried textile fibers by the textile technology to form the fabric. Besides the functions of moisture absorption and air permeability, the textile fabric also has the antisepsis and anti-inflammation functions, and the prepared fabric is more preferred.

Owner:HENAN XINYE TEXTILE

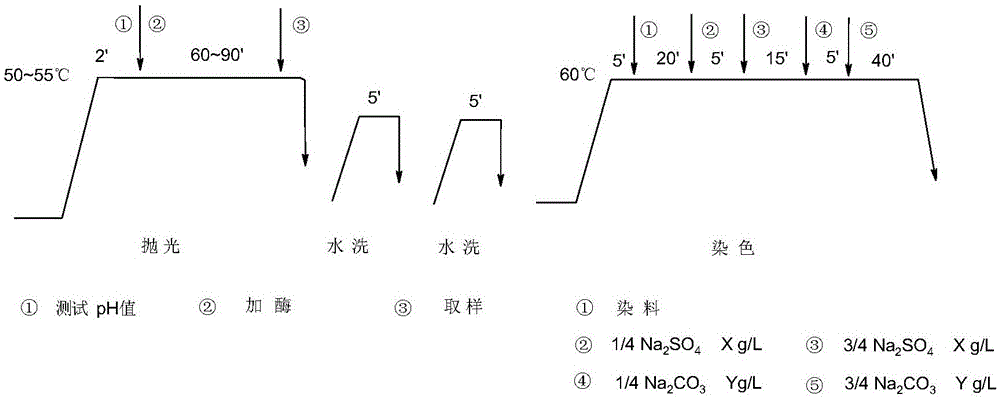

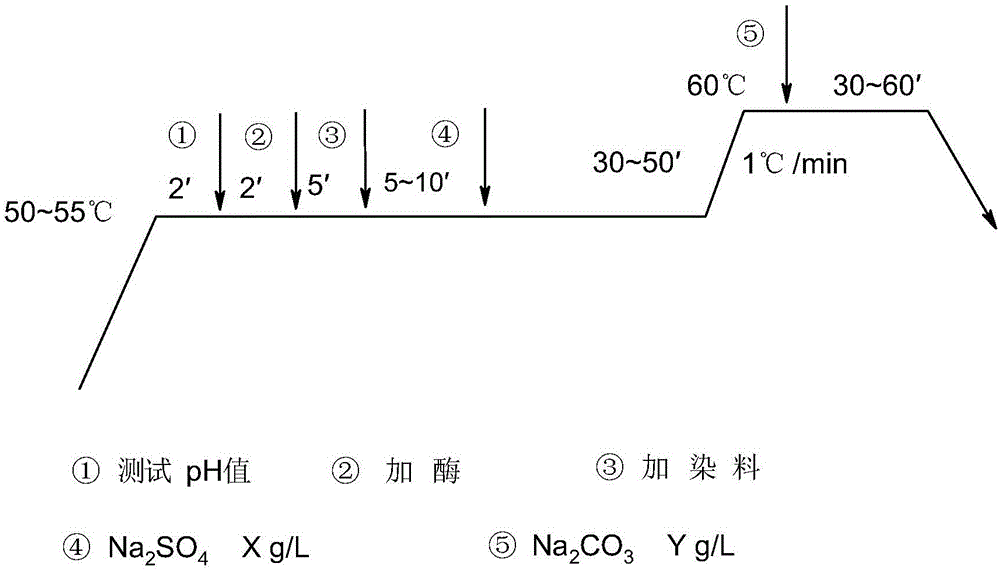

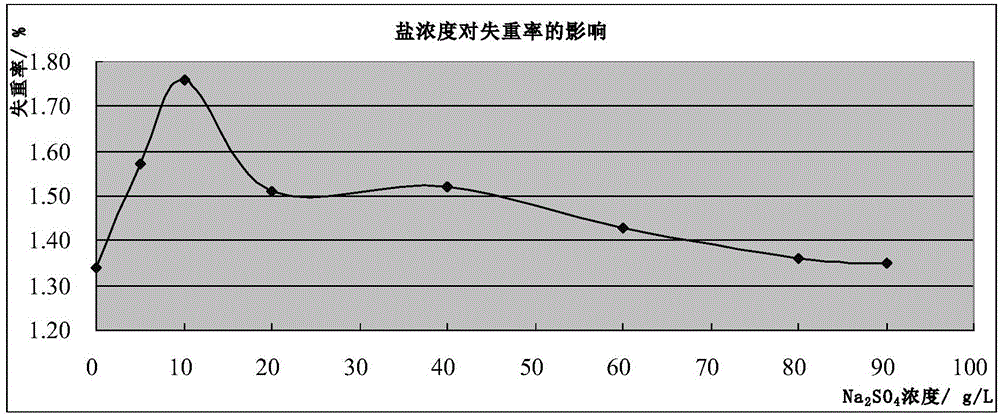

Application of thermophilic Chaetomium cellulose to polishing, dyeing and one-bat technology

ActiveCN105155167AImprove polishing effectReduce dosageTextile treatment machine arrangementsEnzymesHigh concentrationChaetomium

The invention discloses an application of thermophilic Chaetomium cellulose to polishing, dyeing and one-bat technology. The thermophilic Chaetomium cellulose is expressed via Trichoderma reesei or pichia pastoris; the thermophilic Chaetomium cellulose is neutral cellulose having a halophilic function; salt with high concentration has obvious lifting action on activity of neutral cellulose; the optimal action temperature of the neutral cellulose is 57 to 63 DEG C, so polishing temperature and dyeing temperature are the same; during the polishing, even dyeing can be achieved and guaranteed.

Owner:希杰尤特尔(湖南)生物科技有限公司 +1

Dipping machine for producing continuous carbon fibers

InactiveCN101967735ANo mechanical damageLow processing and manufacturing costsTextile treatment containersTextile treatment machine arrangementsFiberCarbon fibers

The invention relates to a dipping machine for producing continuous carbon fibers. The dipping machine comprises a dipping tank, a liquid storage tank and a circulating pump, wherein the dipping tank is positioned above the liquid storage tank; an inlet of the dipping tank is connected with an outlet of the liquid storage tank by the circulating pump; a concave overflow port is formed on two tank walls of the dipping tank vertical to a fiber running direction respectively; and circulation fluid in the dipping tank flows into the liquid storage tank through the overflow port. The dipping machine solves the technical problem that the conventional dipping equipment causes mechanical damage to fiber surfaces, and has the advantages of no mechanical damage to fibers, simple equipment structure, low manufacturing cost, good treatment effect and high treatment efficiency.

Owner:西安航科等离子体科技有限公司

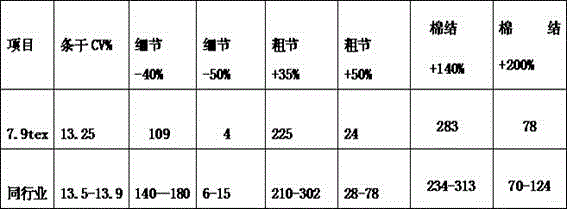

Method for producing extra high count compact spinning yarn by using superfine denier tencel fiber

The invention discloses a method for producing extra high count compact spinning yarn by using superfine denier tencel fiber. The tencel fiber is adopted, wherein the fineness of the tencel fiber is less than or equal to 1.0 dtex, and the length of the tencel fiber is 38 mm. The method includes: pretreatment of raw material, blowing, cotton carding, drawing, roving, spinning and spooling; the method is short in process, cotton carding can strictly control short fiber of cotton slivers, spinning can control stability of fiber strand on a coagulating tank through compact spinning, a part of yarn defects are cleared up during spooling, and 70-180 extra high count compact spinning yarns can be produced. The relative humidity of the production environment is 50%-60% during each process; the obtained yarns are compact in structure, are less in hairiness, are high in strength of the yarns, are few in defects, are energy-saving and environment-friendly, and can be produced into various high-grade spinning ready-made garment.

Owner:JIHUA 3542 TEXTILE CO LTD

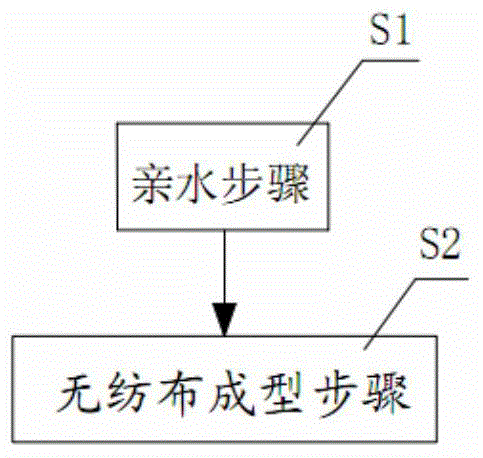

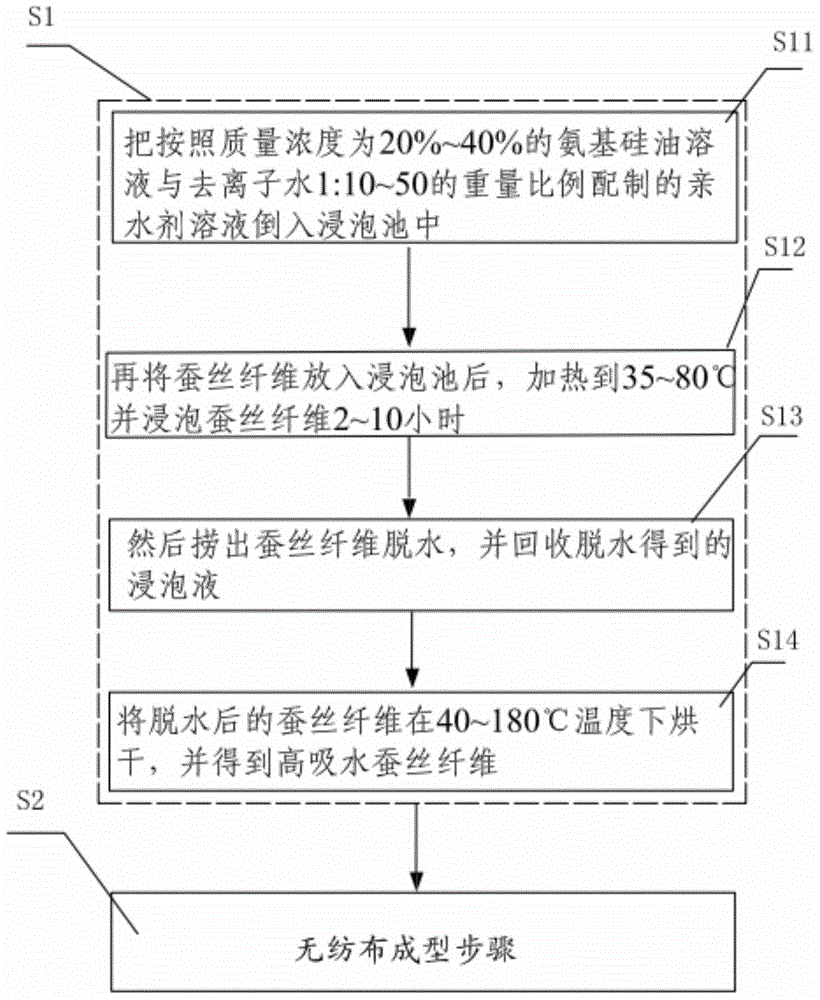

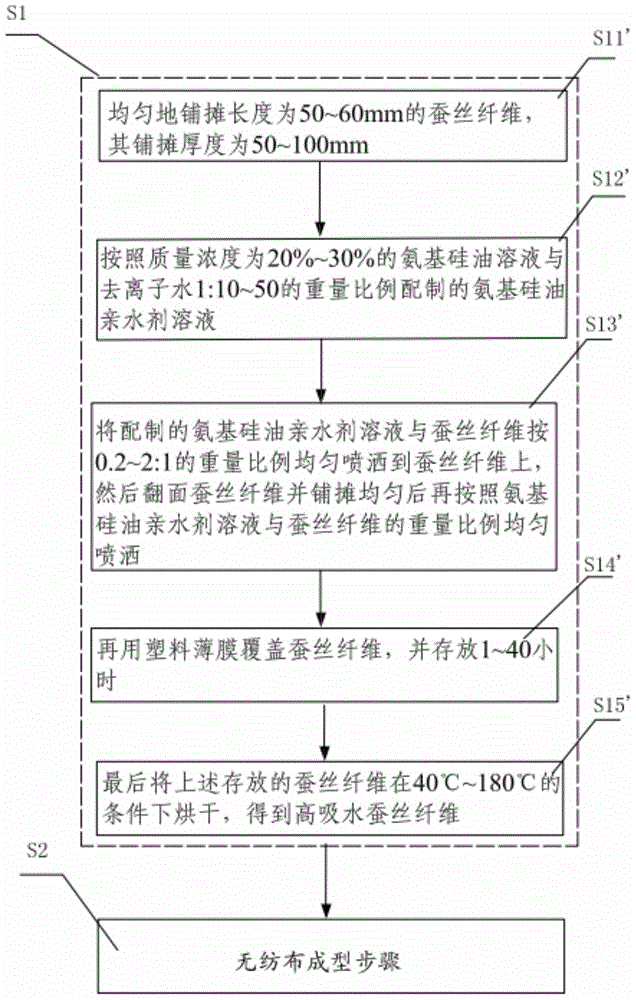

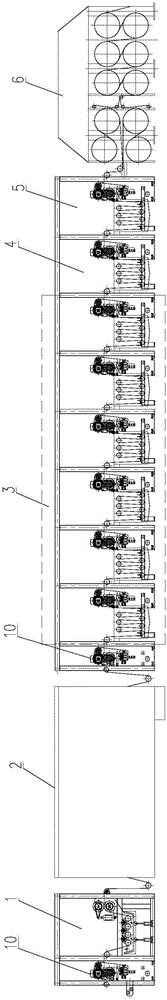

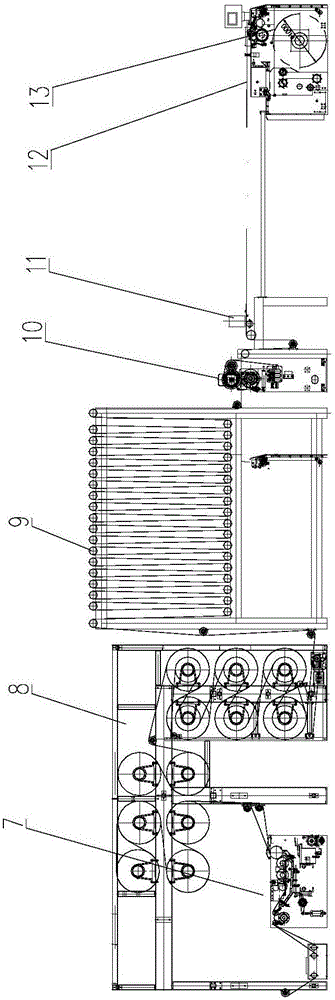

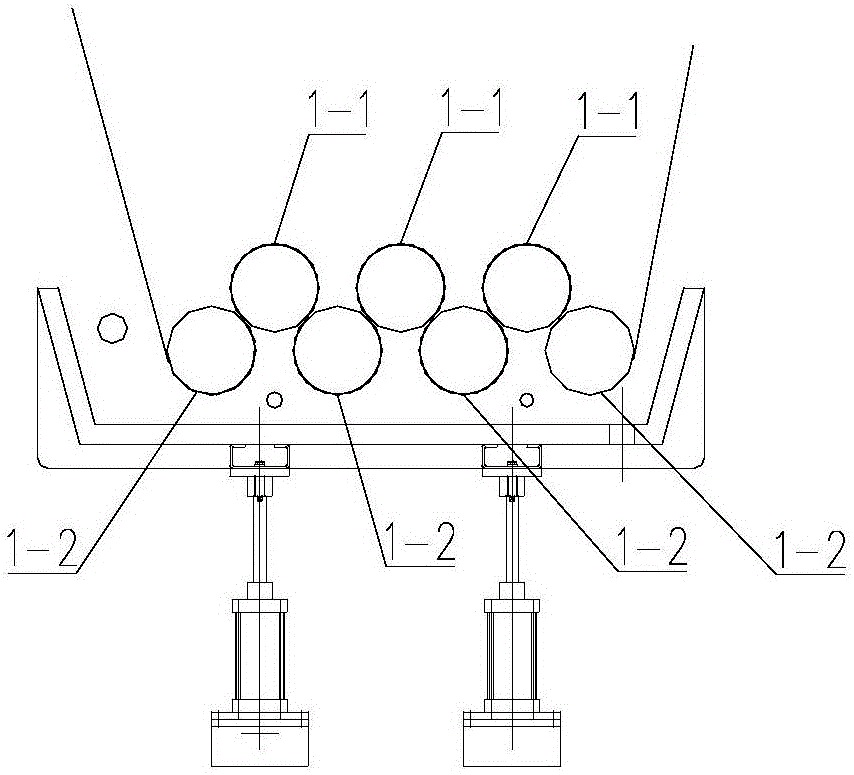

Technology for producing high water absorption silky non-woven fabric

ActiveCN104593945AImprove water absorptionSoft and comfortableLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringNonwoven fabric

The invention discloses a technology for producing high water absorption silky non-woven fabric. According to the technology, a hydrophilc agent solution is used for spraying and soaking or padding silk fibers or silk water non-woven fabric under the conditions of different concentrations, temperatures and time periods, the water absorption performance of the silk fibers is greatly improved, and hence the non-woven fabric can be widely popularized when being applied to the beauty field or the medical auxiliary material field. Meanwhile, the non-woven fabric can be used for producing facial masks, adhesive bandages, medical auxiliary materials and the like, and the non-woven fabric is made to have the advantages of health care, moisturizing and good soft comfort.

Owner:唐懿

Worsted and rove composite cashmere fiber yarn and manufacturing method of knitwear thereof

The invention discloses a technology for manufacturing worsted and rove composite cashmere fiber yarn. The technology comprises the steps of (A) manufacturing rove, (B) manufacturing worsted, (C) conducting doubling on the rove and the worsted in a composite mode, and (D) obtaining the worsted and rove composite cashmere fiber yarn after heating is conducted through steam. Compared with the prior art, composite doubling at different ratios is conducted on cashmere rove single yarn and cashmere worsted single yarn which are different in thickness, and then the worsted and rove composite cashmere fiber yarn with different hand feels is formed. The manufactured worsted and rove composite cashmere fiber yarn integrates the characteristics that the rove yarn and knitwear made of the rove yarn are soft in hand feel and fluffy and the worsted yarn and knitwear made of the worsted yarn are clear in grain and good in elasticity, and overcomes the defects that according to the rove yarn and the knitwear made of the rove yarn, hairiness is too much, the yarn is loose and fuzzing and pilling are prone to occurrence; in addition, different pieces of manufactured worsted and rove composite cashmere fiber yarn with different mixing ratios have different elasticity degrees and different softness degrees, and therefore different types of cashmere knitwear can be produced.

Owner:CONSINEE GRP CO LTD

Aftertreating flame retarding method for fiber precursors

InactiveCN105316881ASignificant positive effectImprove flame retardant performanceLiquid/gas/vapor removalLiquid/gas/vapor fibres/slivers/rovings treatmentPolyesterFiber

The invention relates to an aftertreating flame retarding modification method for precursors of viscose fibers, cotton fiber and polyester fibers. The aftertreating flame retarding modification method for the fiber precursors comprises the following steps that 1, the fiber precursors absorb an inorganic flame retardant solution through a steeping technology; 2, the remaining inorganic flame retardant solution is removed through a dewatering technology; 3, the fiber precursors are dried. According to the aftertreating flame retarding method for the fiber precursors, the fiber precursors are permeated, precipitated and adsorbed through the inorganic flame retardant solution to obtain non-durable flame retardant fibers; the flame retarding modification treatment of the fiber precursors is achieved on fiber aftertreating production equipment, the finished fibers are excellent in flame retardance and good in strength retention rate.

Owner:王西平

Manufacture method of machine-washable wool-cashmere blended woolen knitting cashmere sweater

The invention discloses a manufacture method of a machine-washable wool-cashmere blended woolen knitting cashmere sweater. The method comprises steps of selection of fibrous materials, pre-treatment of the fibrous materials, spinning of blended woolen knitting yarn, weaving of ready-to-wear clothes and afterfinish of the cashmere sweater, wherein the fibrous materials comprise, in percentage by weight, 30%-40% of mercerized wool with the length being 36-40 cm and the fineness being 90-100 counts, 30%-35% of pretreated sheep cashmere with the length being 24-32 cm and the fineness being 16-17.5 mu m and 30%-35% of pretreated cashmere with the length being 30-34 cm and the fineness being 15-17 mu m. A cashmere sweater product produced with the method can meet the standard of machine washability, is not prone to pilling when worn and has good fluffy and elastic hand feeling, and the silky feeling approaches to the level of a pure woolen knitting cashmere product.

Owner:CHIFENG KAILAN CASHMERE PROD

Continuous cold-rolling and steaming dyeing process and equipment of active dyestuff

PendingCN106638038AReduce consumptionReduce pollutionSucessive textile treatmentsTextile treatment machine arrangementsYarnAcid washing

Owner:杨立新

Production process of wool terylene blended smooth double-faced woolen goods

ActiveCN108456965AEasy to organizeHair to smoothLiquid/gas/vapor treatment of propelled fabricsDyeing processYarnPulp and paper industry

The invention provides a production process of wool terylene blended smooth double-faced woolen goods. The production process of the smooth double-faced woolen goods includes the steps: sufficiently mixing wool fibers and terylene fibers; spinning the mixed wool fibers and terylene fibers into yarns of 13 / 1 metric number by an open-end spinning frame; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, anti-shrinking finishing, dyeing, softening finishing, scalding, cutting, decating and the like on a woven gray fabric to prepare a finished product. The total number of warp yarns is 6100-6300, the acting reed width is 195-200cm, porter / permeating number is 35 / 9, weft density is 285-290 yarns / 10cm, and theweight of a fabric billet is 930-950g / m<2>. The fabric is fine, smooth and soft in hand feeling, compact in texture, bright in color and high in color fastness and does not easily felt after being washed with water.

Owner:江阴市长泾花园毛纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com