Patents

Literature

569results about How to "Soft and comfortable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

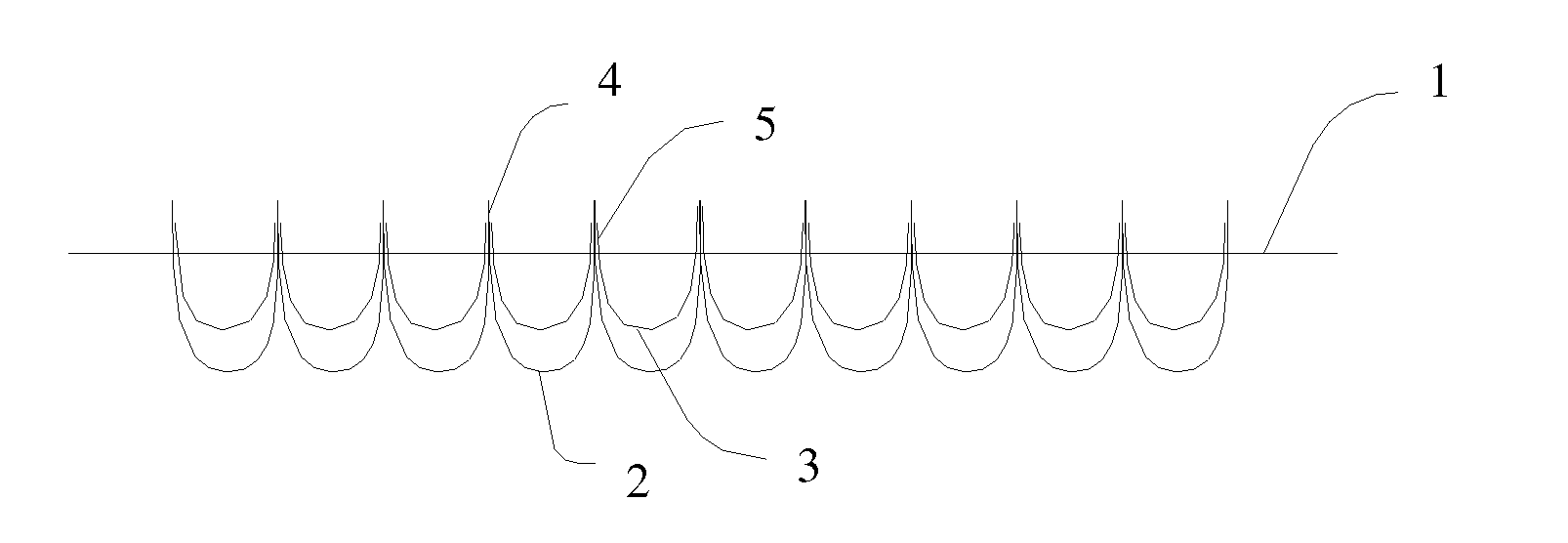

Moisture-absorbing quick-drying type jacquard fabric as well as hydrophilic quick-drying finishing agent and post processing method thereof

ActiveCN101994192ASoft and comfortableEasy to manufactureFibre treatmentWoven fabricsPolymer sciencePolymer chemistry

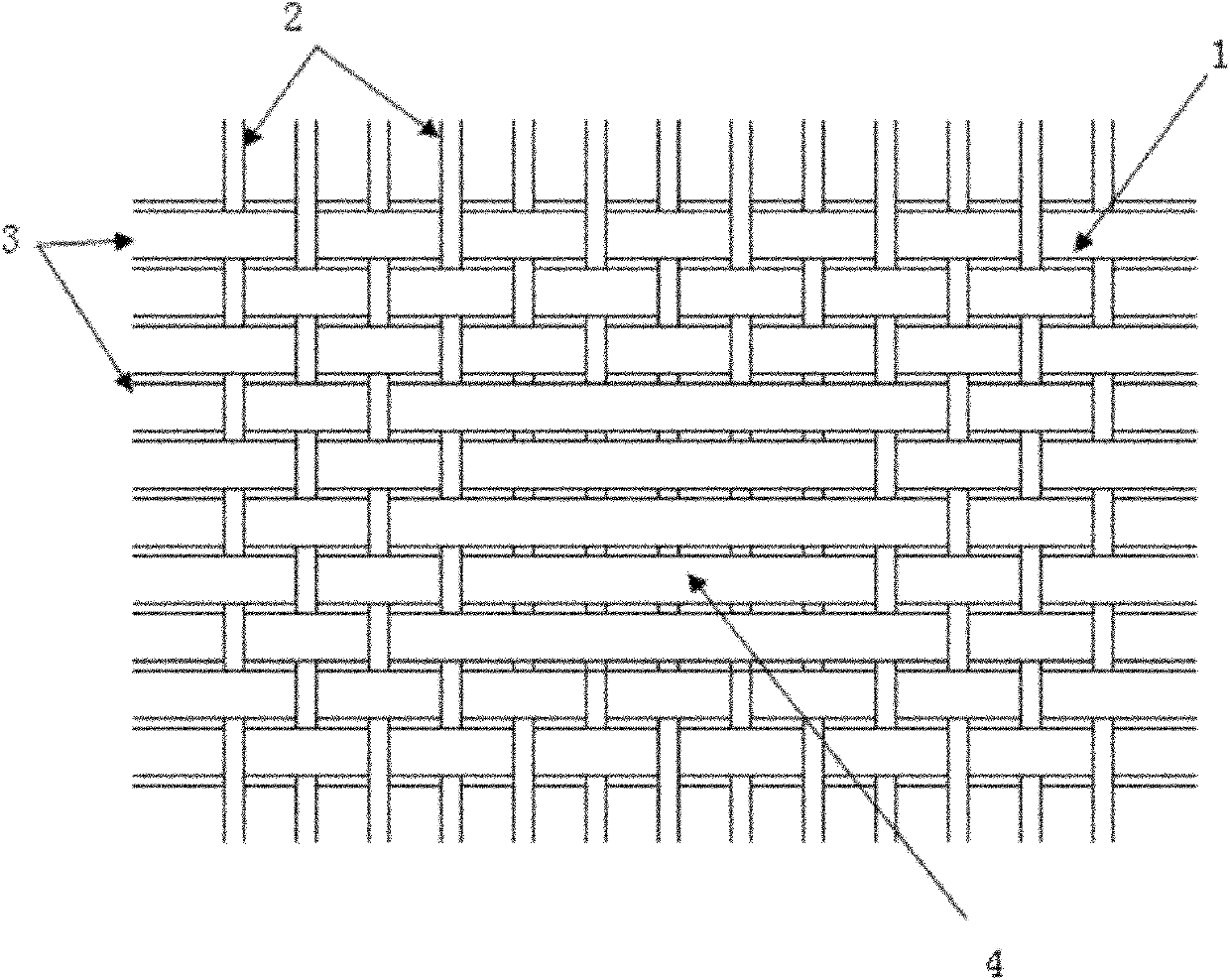

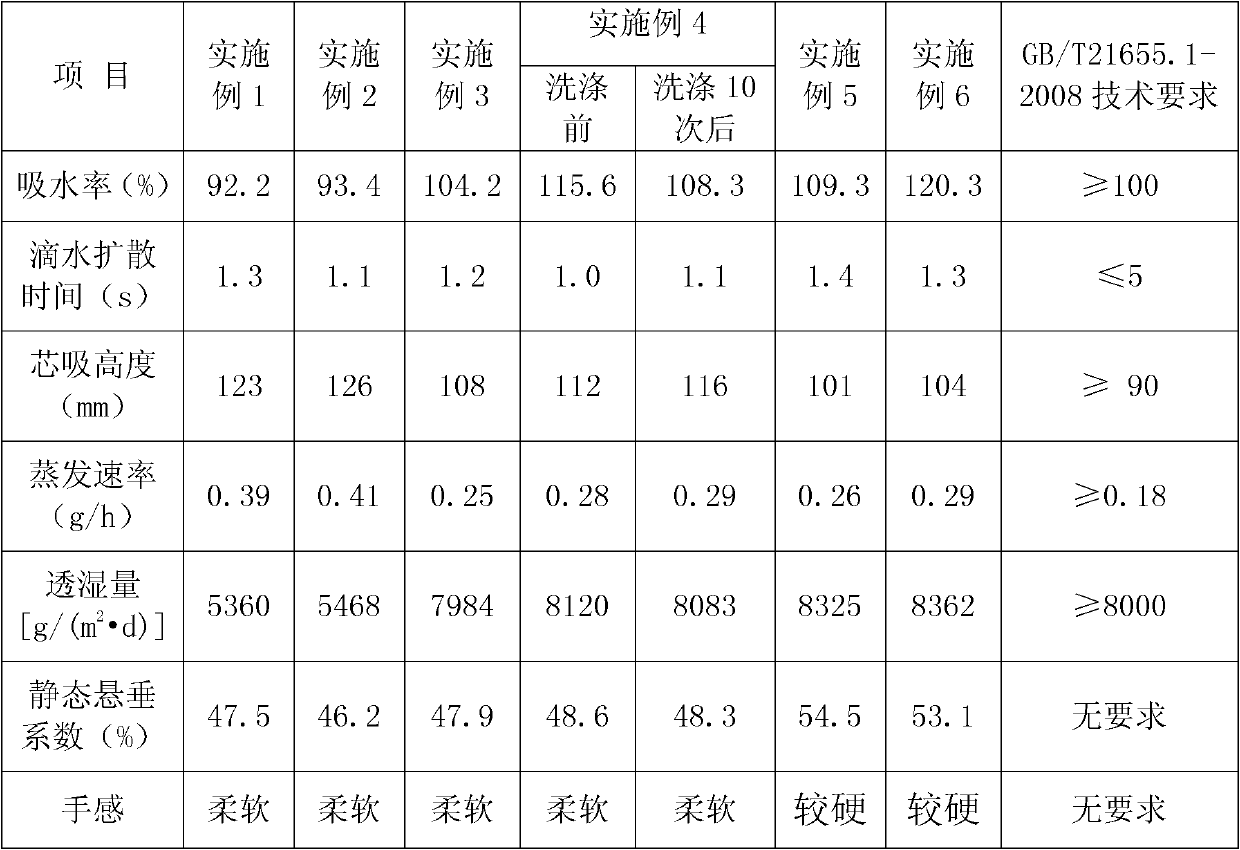

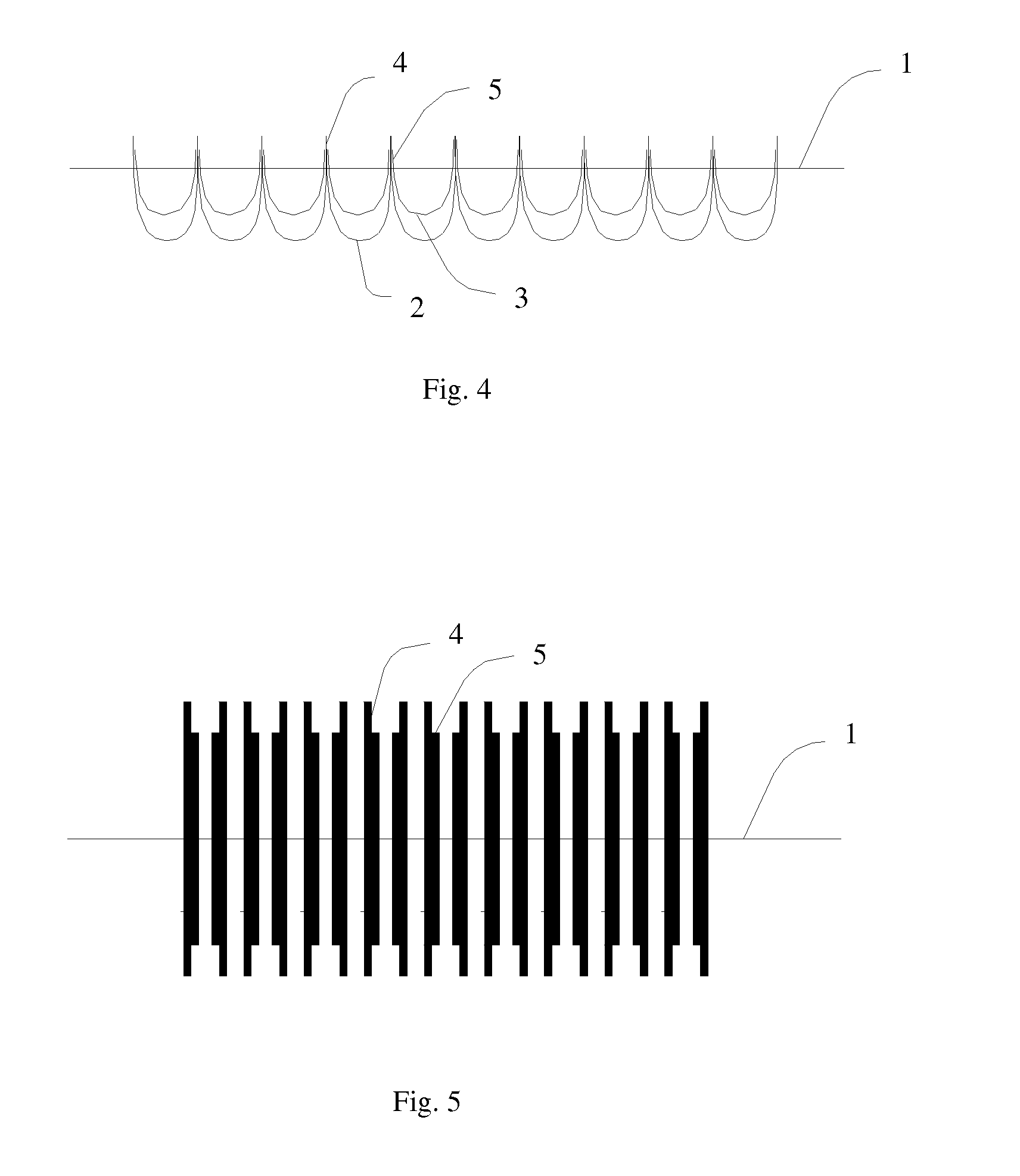

The invention relates to a moisture-absorbing quick-drying type jacquard fabric as well as a hydrophilic quick-drying finishing agent and a post processing method thereof. The moisture-absorbing quick-drying type jacquard fabric comprises a base cloth area and jacquard areas, wherein the jacquard areas are distributed in the base cloth area; the base cloth area is formed by mutually wavily interlacing warps and wefts; the waving intervals of the warps and the wefts of the jacquard areas are more than or equal to two; the warps are modified chinlon, and the wefts are fine denier cross-shaped sectional polypropylene fibers. Body surface moisture is rapidly delivered and dispersed to an external layer by utilizing the wicking action of the fine denier cross-shaped sectional polypropylene fibers when the jacquard surface of the fabric contacts with a human body and then evaporates without being absorbed by internal fibers; and in addition, the modified chinlon which is positioned on the surface layer of the fabric and has high hydrophilcity can further increase the transferring, dispersing and evaporating speed of the moisture so as to keep skin dry and comfortable.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

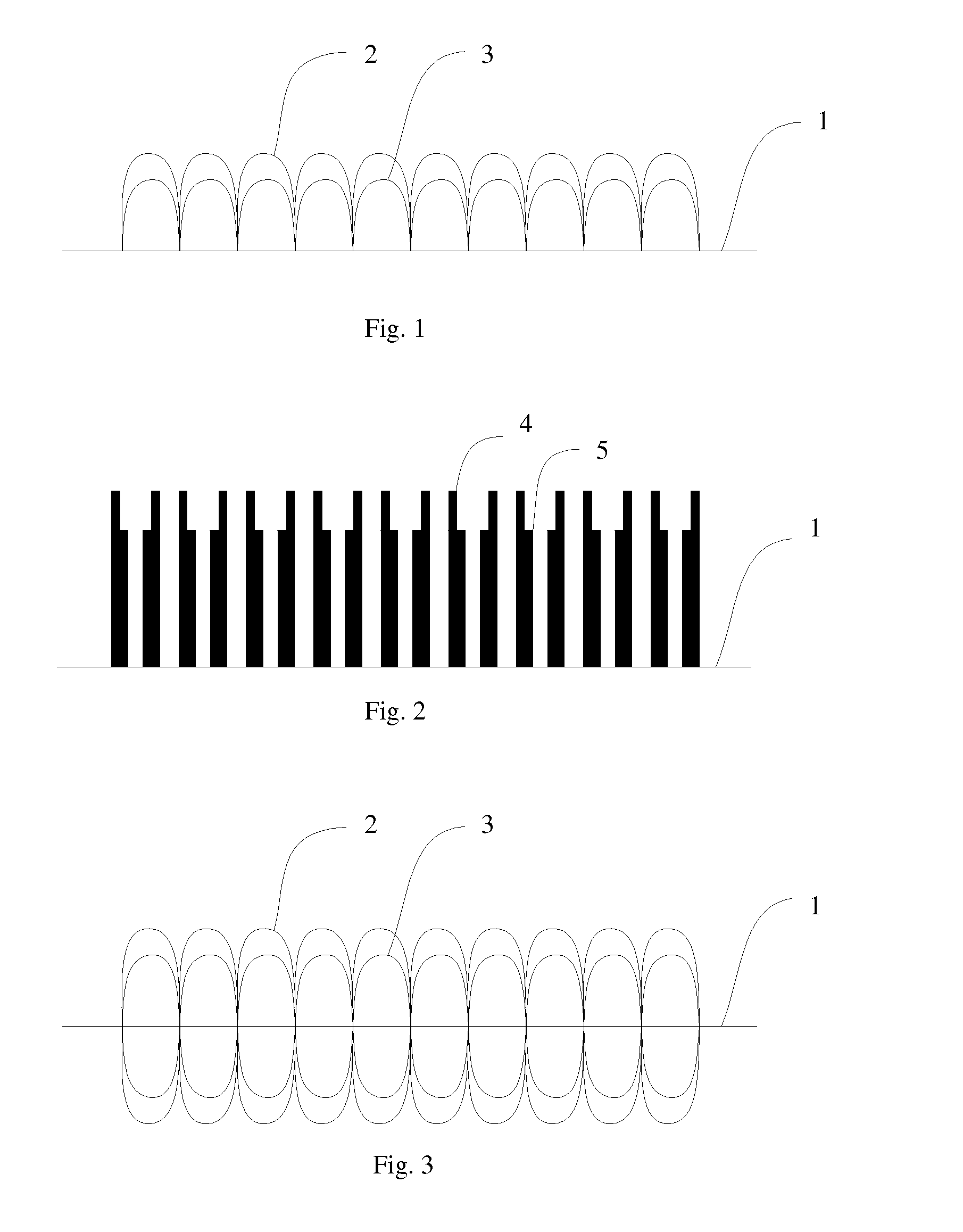

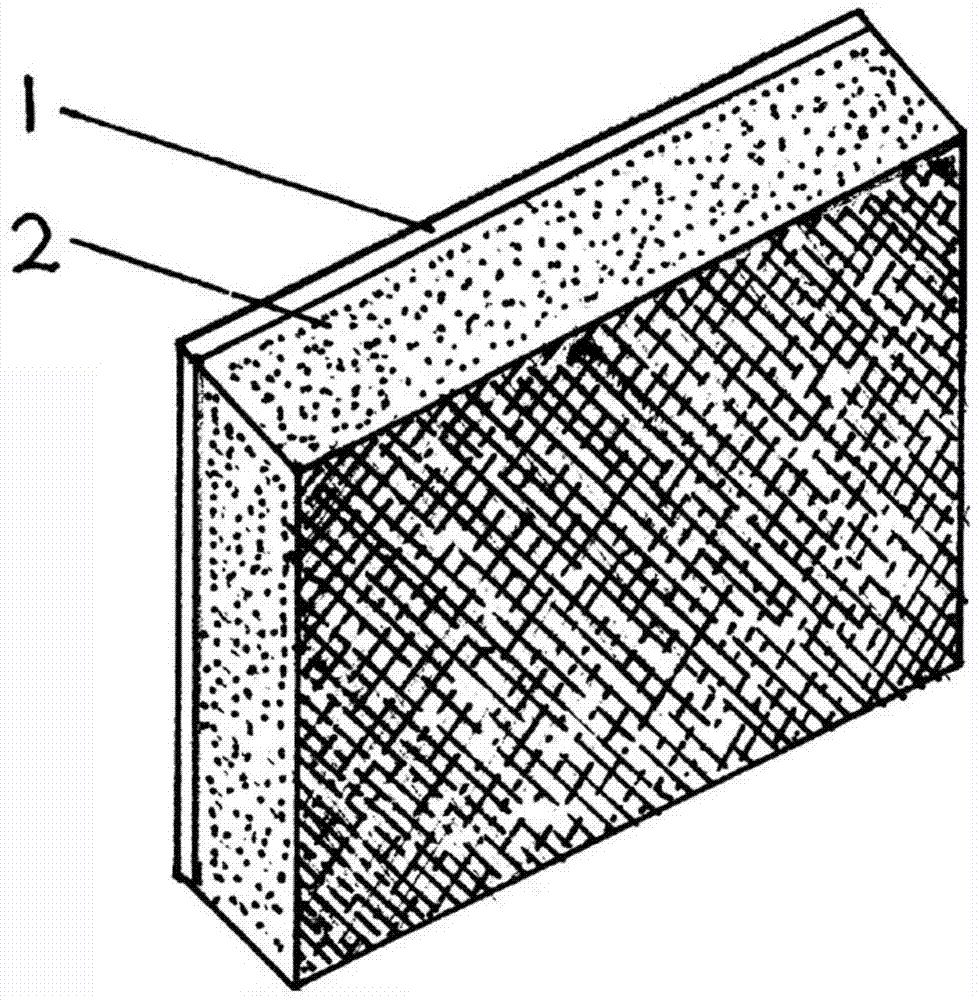

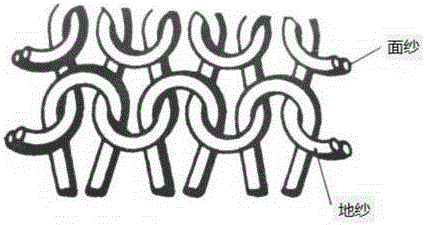

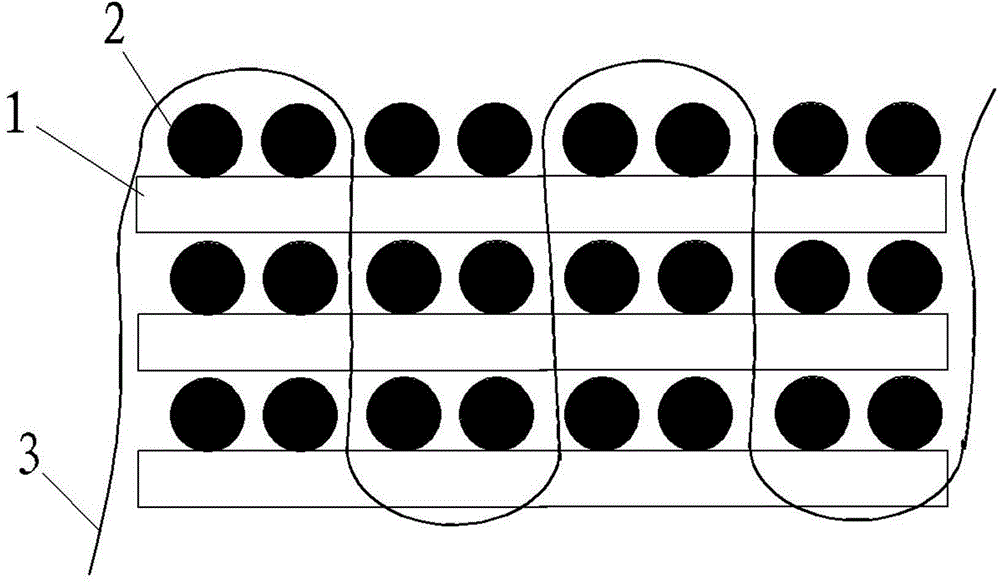

Fabrics having double layers of terry or pile

ActiveUS20120255643A1Good sense of layerImprove performancePile-fabric loomsCircular knitting machinesStructural engineeringNatural fiber

A fabric having a ground fabric, and a double layer terry or a double layer pile on either or both surfaces of the ground fabric, or a double layer terry on one surface and a double layer pile on the other surface. The double layer terry has an outer terry and an inner terry lower than the outer terry; the double layer pile has an outer pile and an inner pile lower than the outer pile. The outer terry or outer pile is a natural fiber, and the lower terry or lower pile is a microfiber. Methods of manufacturing the fabric are also disclosed.

Owner:DUAN HONGWEI

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

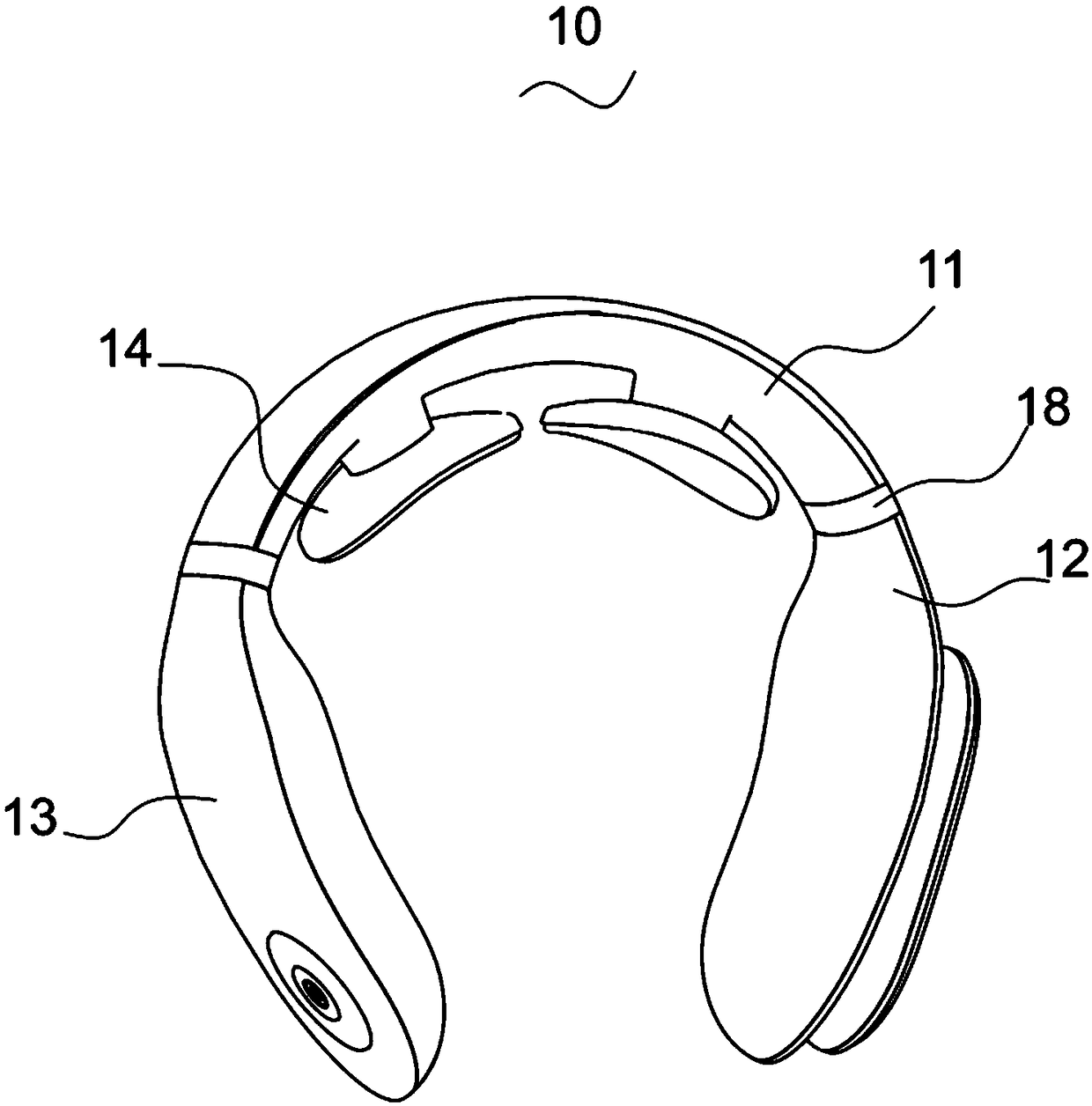

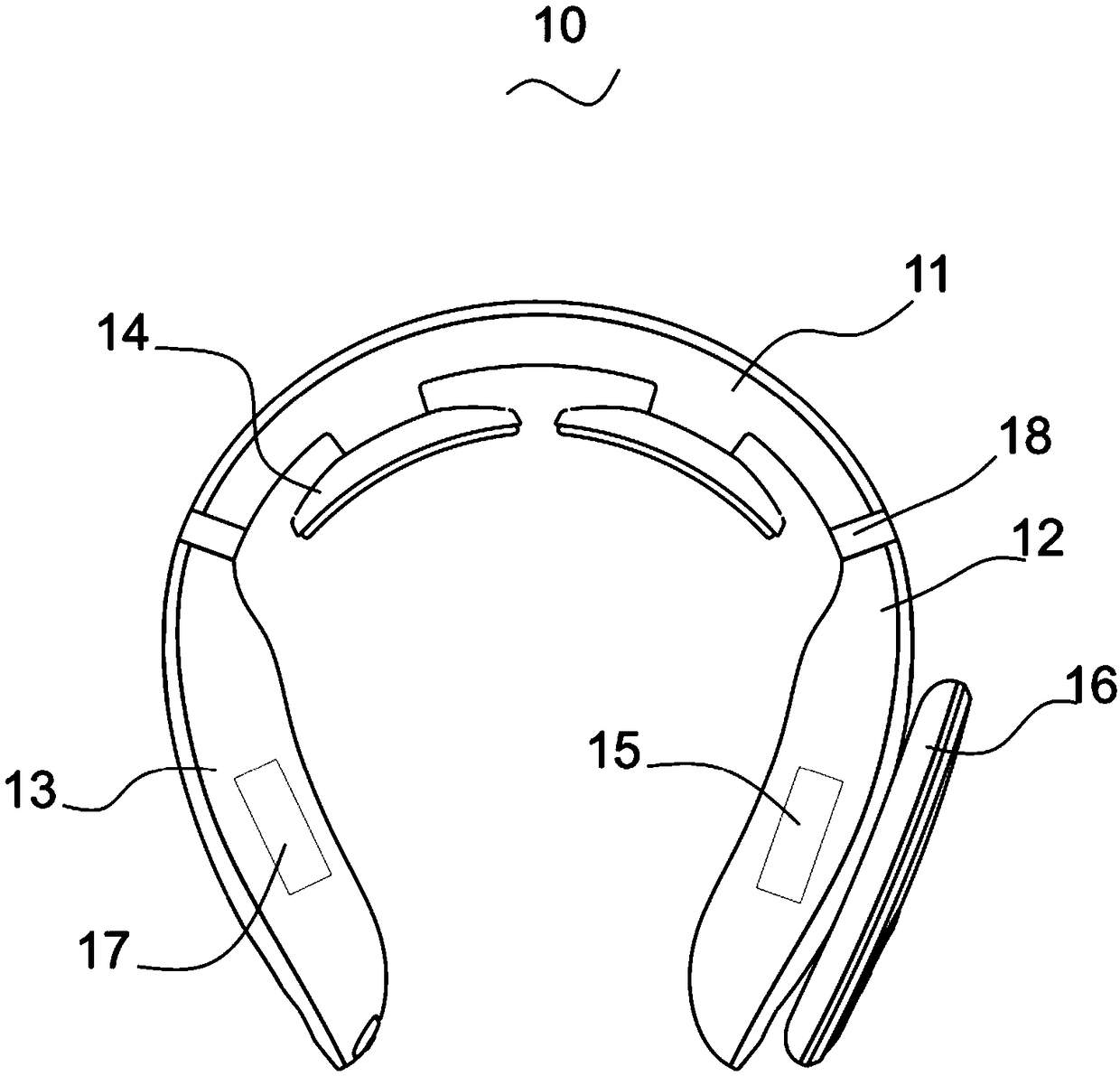

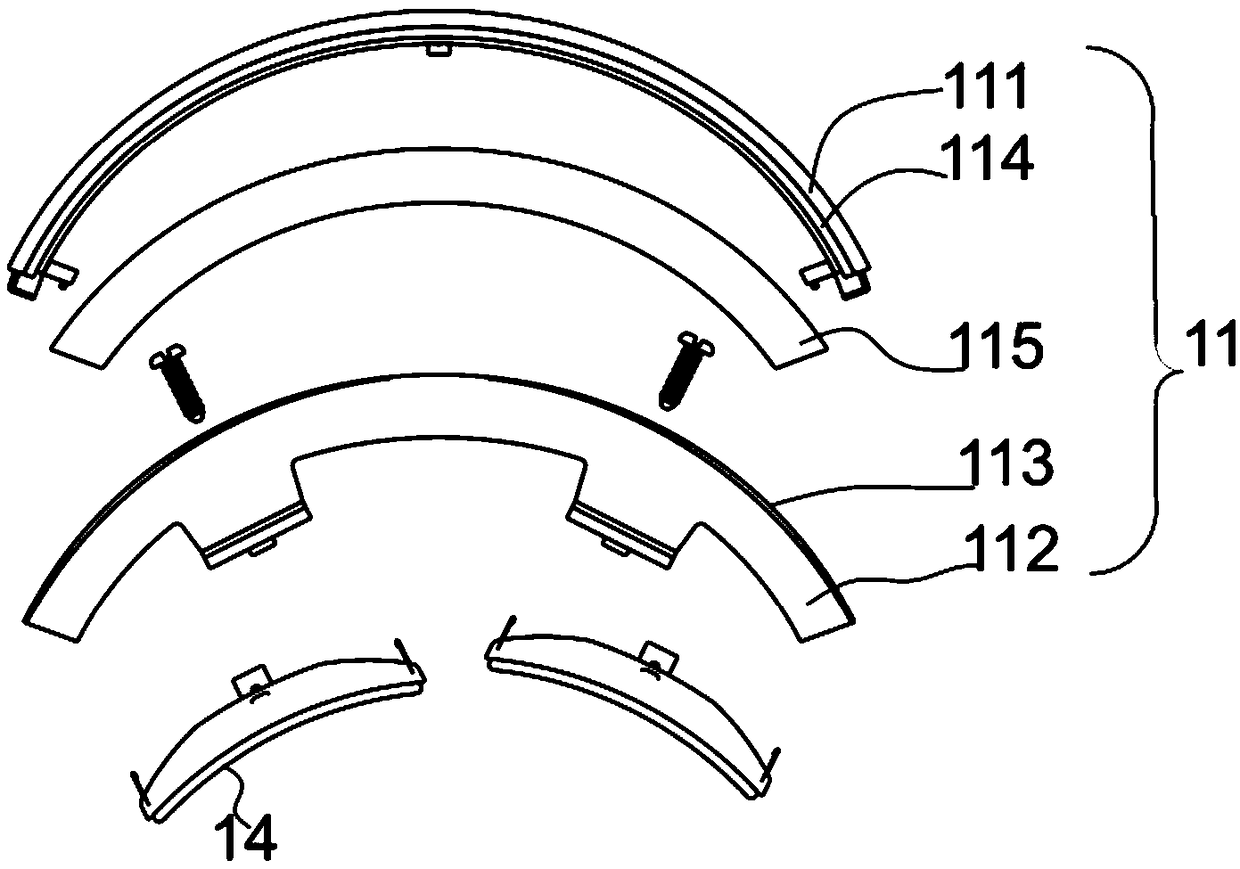

Neck massager easy to wear

The invention discloses a neck massager easy to wear. The neck massager easy to wear comprises an elastic arm, a first handle, a second handle, at least two electrode assemblies and electrical pulse generation devices, wherein the electrical pulse generation devices are electrically connected with the electrode assemblies. The first handle and the second handle are fixedly connected to the two sides of the elastic arm, a circular area S for holding a human neck is enclosed by the first handle, the second handle and the two electrode assemblies under the state of no stress, and the first handle, the second handle and the two electrode assemblies are arranged on the circumference of the circular area S. According to the neck massager easy to wear, the first handle, the second handle and thetwo electrode assemblies are arranged on the circumference of the circular area S under the state of no stress, and wearing is achieved by a mode of ''position clamping by four points''.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

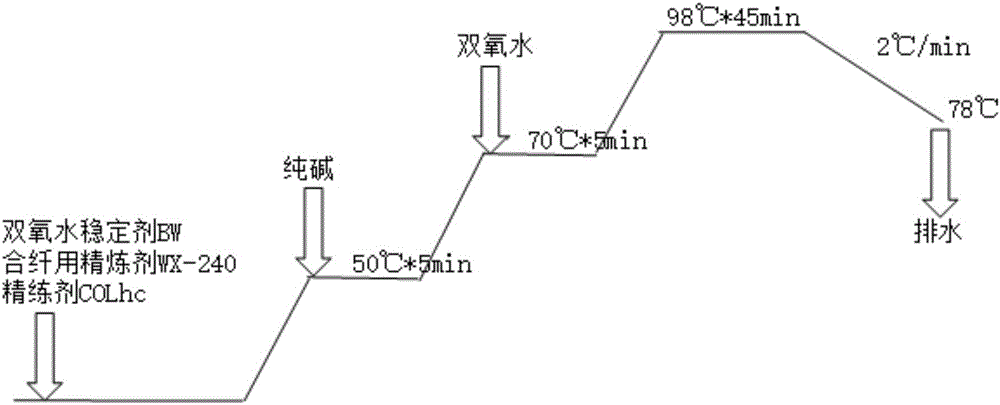

Weaving process of hemp towel

InactiveCN101671905ARetain antibacterial health care performanceSoft and comfortableBiochemical fibre treatmentBleaching apparatusRadiation resistantPerspiration

The invention discloses a weaving process of a hemp towel, comprising the steps of cheese winding, warping, weaving and grey cloth post treatment. The rotating speed of a cheese winding grooved drum is 1,200+ / -5r / min; the concentration of caustic soda in desizing boiled bleaching liquor subjected to the grey cloth post treatment is 5ml / L; the concentration of FLOW preliminary treatment agent is 3ml / L; the concentration of hydrogen peroxide is 7.8ml / L; and the temperature of the desizing is 95 DEG C and the boiled bleaching is carried out for 50 minutes. The towel manufactured by the manufacturing process has few filoplume and easy degradation as well as excellent moisture absorbing perspiration performances, natural bacteriostasis and health-care performances reservation of hemp, favorablesoft and comfortable performances, excellent uvioresistant and radiation-resistant performance, high-temperature resistant performance and odor-absorbing and blowdown performances, and is new generation of natural environment-friendly products.

Owner:SUNVIM GROUP

Thermoplastic elastomer for filming dacron cloth

InactiveCN1931918ASolving Adhesion ProblemsHigh peel strengthTextiles and paperFiberWeather resistance

The thermoplastic elastomer for filming Dacron cloth used as box lining, sportswear lining, etc. consists of matrix resin 10-80 wt%, filler oil 0-60 wt%, tackifier 5-50 wt%, mineral filler 0-25 wt%, coupling agent 0.1-0.8 wt%, machining assistant 0.1-2 wt%, and composite stabilizer 0.1-2 wt%. By means of the improved recipe and preparation process, the present invention solves the problem of adhering non-polar matrix with Dacron or other polar chemical fiber fabric, so that the film on the Dacron material has high peeling strength, soft and comfortable handing, high weather resistance, and high acid and alkali resistance and other advantages.

Owner:CGN JUNER NEW MATERIALS

An alginate dressing for treating bedsore and a preparing method thereof

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

Manufacturing method of high-elasticity cotton/polyurethane knitted fabric

ActiveCN106120125ASoft and comfortableGood hygroscopicityWeft knittingLiquid/gas/vapor textile treatmentYarnFunctional movement

The invention discloses a manufacturing method of high-elasticity cotton / polyurethane knitted fabric. The manufacturing method includes the steps of raw material preparation, wherein pima cotton and polyurethane filaments are prepared; the weaving technology, wherein the pima cotton serves as face yarn, the 40 D Lycra serves as bottom yarn, and the face yarn is always located on the front face of the fabric; the preshaping technology, wherein the manufactured fabric is preshaped, the temperature of a shaping machine is set to be 190-200 DEG C, and the speed of the shaping machine is 20-25 m / min; the dyeing technology, wherein the dyeing process includes pretreatment, cotton dyeing and aftertreatment technical flow processes; the afterfinish technology, wherein vibrating drying is carried out after dyeing is completed, the drying temperature is 130 DEG C, a softening agent is added after drying for final shaping, the shaping temperature is 130 DEG C, and the speed is 15-20 m / min. The manufacturing method has the advantages that the manufactured fabric is soft and comfort in handfeel, high in hygroscopicity and gas permeability and ultrahigh in elasticity and resilience and is suitable for manufacturing high-grade knitted underwear and specially functional sports clothes such as a kneecap support, an elbow support, waist support and a leotard.

Owner:湖北嘉麟杰纺织品有限公司

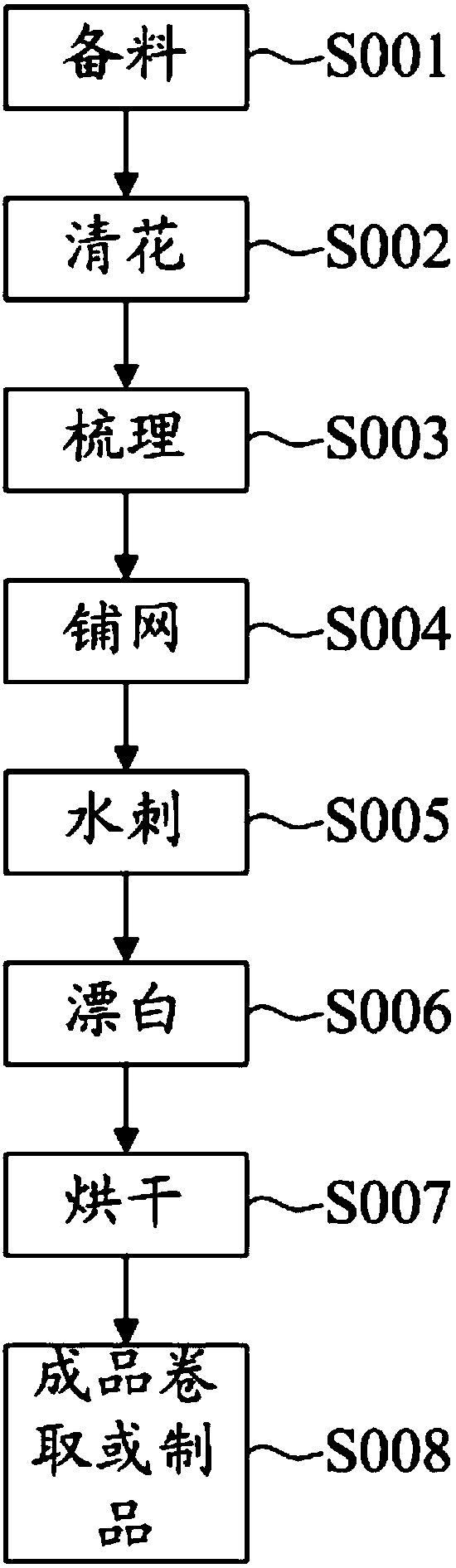

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

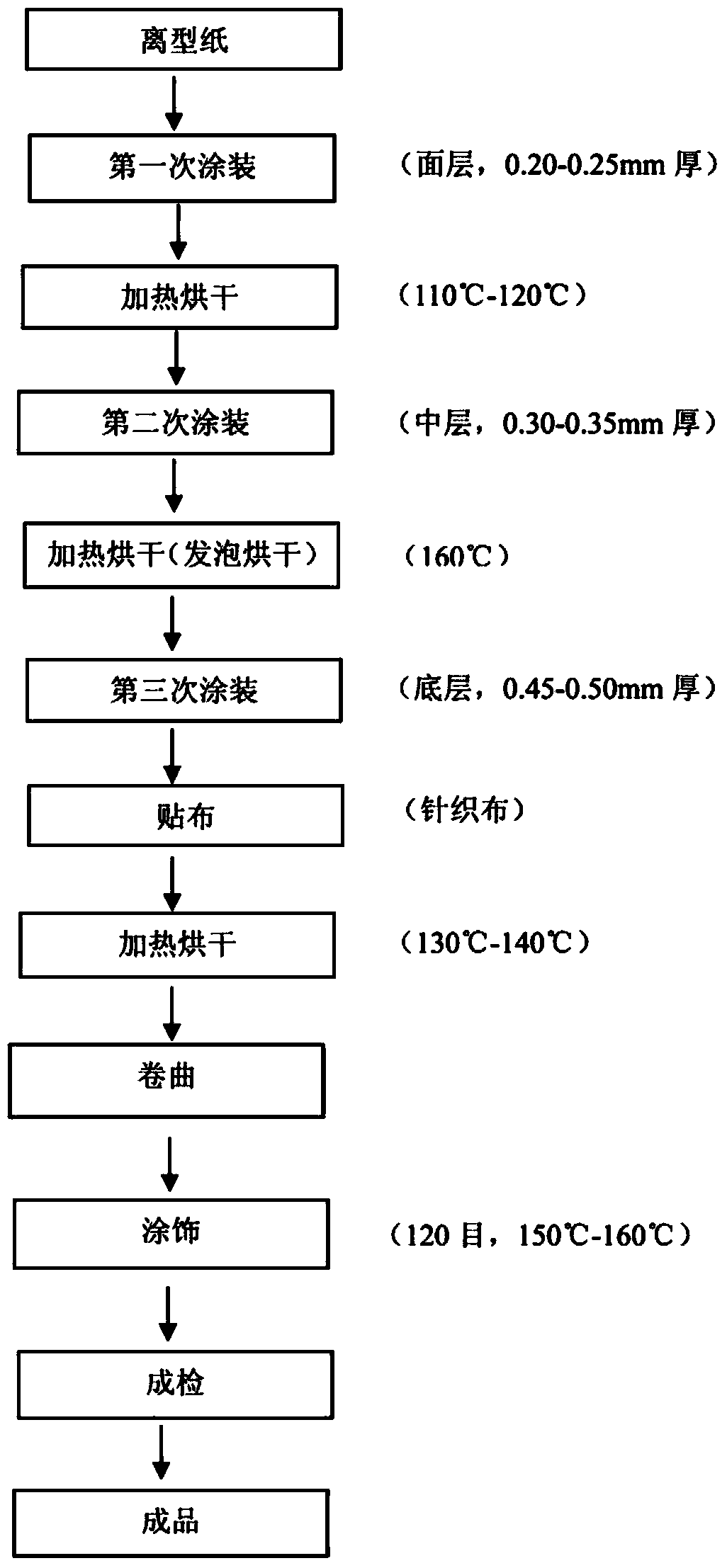

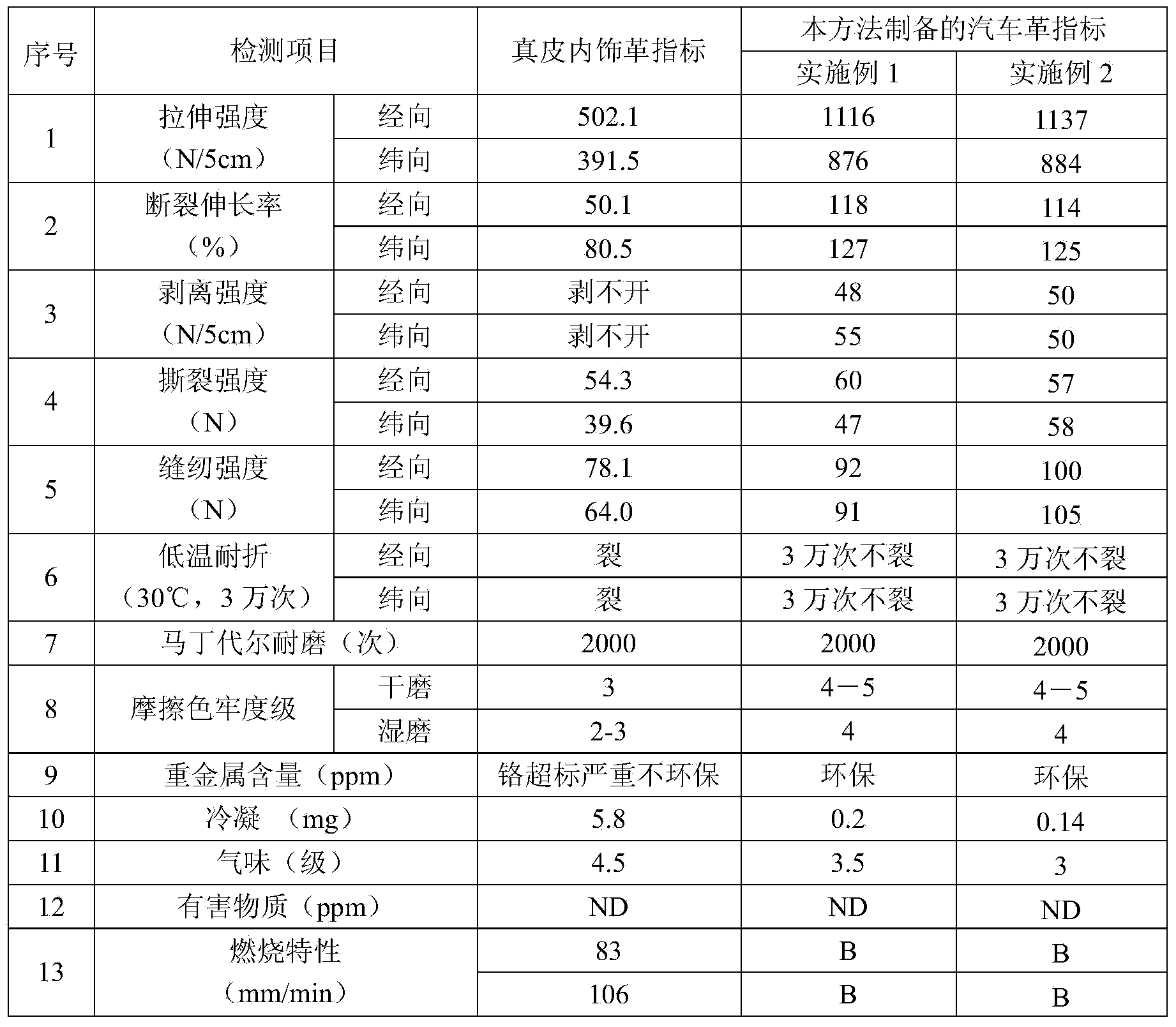

Preparation method of leather-imitating automobile leather

InactiveCN104313896AMeet needsClean manufacturingLamination ancillary operationsSynthetic resin layered productsFoaming agentSurface layer

The invention relates to a preparation method of leather-imitating automobile leather. The preparation method comprises the following steps: firstly designing a PU formula according to the purpose of the automobile leather, preparing slurry, coating the slurry on a piece of release paper to finish the coating process for the first time, and heating and drying the paper to obtain a surface layer of the automobile leather; secondly, adding a bridging agent, a leveling agent, a fire retardant and a microballoon foaming agent to high solid resin to be stirred uniformly, coating the prepared material on the surface layer of the automobile leather to finish the coating process for the second time, and foaming and drying to obtain an intermediate support foaming layer; coating the slurry prepared according to the PU formula on the obtained intermediate support foaming layer to finish the coating process for the third time; furthermore, adhering the formed coating to base cloth, heating and drying the cloth, and conducting separation and curling; finally, conducting postprocessing, finishing the surface, and heating and drying so as to obtain the leather-imitating automobile leather. The method disclosed by the invention is made from the environment-friendly materials during the production process, clean in production, soft and comfortable in product touch, easy to conduct post process, and capable of meeting requirements on automobile upholstery leather for customers.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

Manufacturing technique of flour-linen jacquard interval fabric mesh cloth

ActiveCN106560538AHigh pattern precisionImprove stabilityFabric breaking/softeningWarp knittingFiberYarn

The invention discloses a manufacturing technique of flour-linen jacquard interval fabric mesh cloth. The manufacturing technique comprises the first step of production and manufacturing of chemical fiber yarn, the second step of flower-type process design of the flour-linen jacquard interval fabric mesh cloth, the third step of weaving and manufacturing, and the fourth step of dyeing and finishing and sizing, wherein in the second step, the upper layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB1 to guide bar GB3; the middle layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB4; the lower layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB5 and guide bar GB6. According to the flour-linen jacquard interval fabric mesh cloth prepared through the manufacturing technique, distortion or deformation of the flower-type are not easily caused, the precision of the flower-type is high, the stability is good, after dyeing treatment of half matt gloss polyester yarn and terylene CD yarn on the upper layer of the mesh cloth, the surface of the finished product mesh cloth presents an effect of two-tone flour-linen, dyefastness is good, and a very good overall dyeing effect is achieved.

Owner:SINCETECH FUJIAN TECH CO LTD

Process for manufacturing textile fabric

InactiveCN102953221ASolve the problem of anti-pillingGreat elastic extensibilityWeft knittingHeating/cooling textile fabricsExtensibilityYarn

The invention relates to the technical field of textile processes, in particular to a process for manufacturing a textile fabric. The process is characterized in that a drawing technology is introduced in a spun yarn processing stage, two fiber rods comprising cellulous fiber rods and cotton are processed to obtain blended yarns comprising cellulous fibers and cotton fibers, the blended yarns used as base yarns and bare spandex yarns are woven by a weft plaint stitch and shovel weaving method, and one base yarn and one spandex yarn are woven into each woven system, so that a fabric with a single weft knitting face and plain plating stitches is obtained; then the fabric is heated to be preset at the temperature ranging from 190 DEG C to 195 DEG C, fine wrinkles of a textile are eliminated, and half-molten spandex is combined with the base yarns; and then dyeing and setting are carried out to obtain an anti-pilling weft-knitted fabric comprising the cellulose fibers. The process has the advantages that the blended fabric mainly comprising the cellulous fibers is anti-pilling and is high in elasticity and extensibility, and underwear woven from the fabric feels soft and comfortable.

Owner:刘发元

Preparation of cotton type memory leisure fabric

ActiveCN101481842ASoft and comfortableGood elastic recoveryHeating/cooling textile fabricsDry-cleaning apparatus for textilesWrinkleDyeing

The invention discloses a preparation method of cotton memory leisure fabric. The preparation method comprises the following steps: (1) preparation of superfine PTT filament fibers; (2) air-jet texturing composite; (3) weaving; and (4) dyeing and post finishing. The prepared fabric has the advantages of soft and comfortable hand feel, good elastic recoverability and good wrinkle resistance, the fabric is more elegant, attractive and has unique charm after being treated with advanced dyeing technique, the water diffusibility of the fabric is high, 0.1ml of water is dripped on the fabric, the absorption height reaches more than 70mm, residual moisture is less than 30% and antistatic property cloth face charge density is less than 6UC / M2 after dripping the water for 40 minutes according to a dryness factor measuring method, and in the weaving procedure, a Nissan double-jet electronic free woof selecting high-speed double-jet weaving machine with an electronic muzzle is employed to weave so as to meet the requirements of different cotton memory leisure fabrics.

Owner:DANYANG DANQI YUYUE TEXTILE

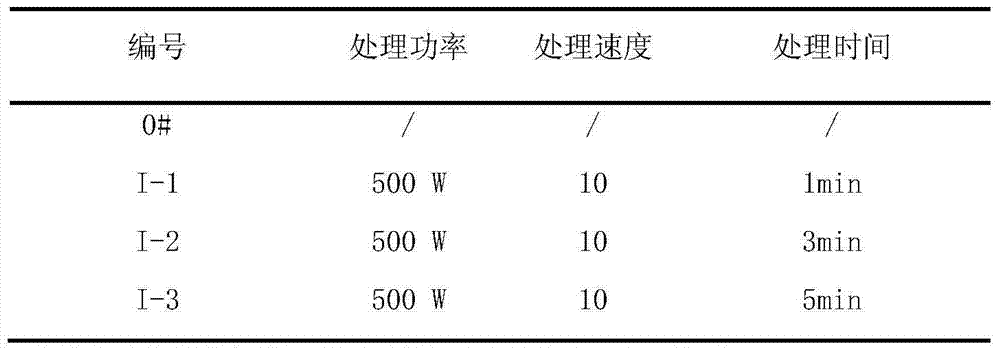

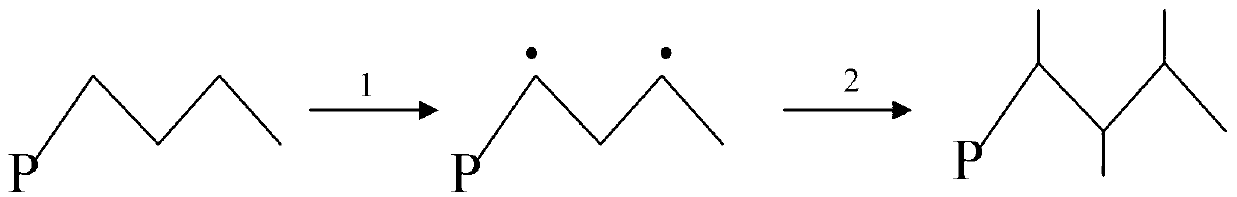

Method for improving felting resistance and pilling resistance of animal fibers or fabric thereof

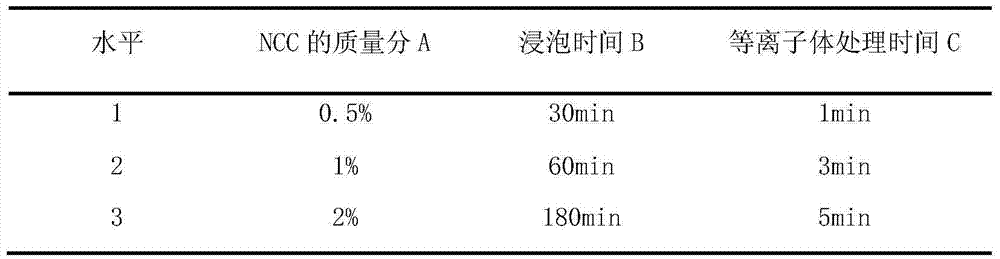

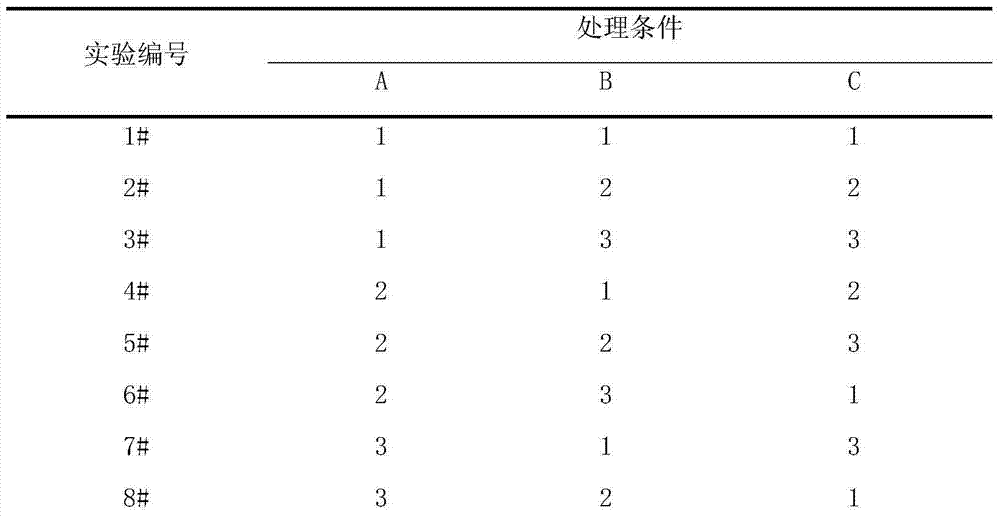

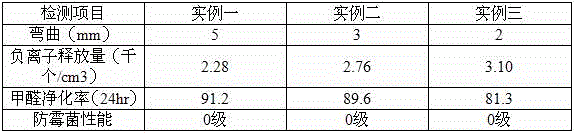

The invention discloses a method for improving felting resistance and pilling resistance of animal fibers or a fabric thereof. The method specifically comprises the following steps: performing plasma treatment on the animal fibers or the fabric thereof; and further treating the animal fibers or the fabric thereof by using cellulose. The method adopts the combination of normal pressure air plasma treatment and nano cellulose finishing to regulate and control the surface friction mechanical properties of the animal fibers such as wool, cashmere, rabbit hairs and other animal fibers with scale layers covering the surfaces, thereby improving the felting resistance and the pilling resistance of the animal fibers, and improving the hand feeling comfort of the products of the animal fibers.

Owner:JIAXING UNIV

Thermochromic fabric

InactiveCN103541115ASoft and comfortableGood moisture absorption and air permeabilityWoven fabricsYarnFiberPulp and paper industry

The invention discloses a thermochromic fabric which comprises thermochromic fiber, linen fiber and cotton fiber. The thermochromic fabric is formed by interweaving warp yarns and weft yarns, wherein the warp yarns is formed by blending the thermochromic fiber and the linen fiber and accounts for 48%-53% by weight of the thermochromic fabric, and the weft yarns is formed by blending the thermochromic fiber and the cotton fiber and accounts for 47%-52% by weight of the thermochromic fabric. By adopting the mode, the warp yarns and the weft yarns of the thermochromic fabric contain thermochromic fiber, and the thermochromic fabric can be changeable in color with the temperature change, is soft and comfortable in touch, good in sweet-absorbing and air-permeating performance, antibacterial and warm-keeping and is suitable for manufacture of child clothes or other featured clothes.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

Elastic warp weaving fabric and production method and application thereof

The invention discloses an elastic warp weaving fabric and a production method and an application thereof. The warp weaving fabric is formed by 20 to 100wt% of spandex coating yarns and 80 to 0wt% of fully-drawn yarns or false twisting yarns using nylon or polyester as raw material, wherein the spandex coating yarns are elastic yarns which consist of spandex bare yarns and the fully-drawn yarns or the false twisting yarns using the nylon or the polyester as the raw material. The fabric has the advantages that the transverse and longitudinal elastic elongation rates are respectively more than 60%, and the elastic elongation recovery rate is more than 80%; the handfeel is soft and fluffy, and the ventilation performance is good.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Plant fiber diatom ooze and preparation process thereof

The invention provides plant fiber diatom ooze and a preparation process thereof. The plant fiber diatom ooze comprises the following components in mass ratio: 10-40% of diatomite, 10-50% of plant fiber powder, 5-20% of kaoline, 1-5% of bentonite, 3-10% of anion powder, 3-10% of titanium dioxide, 3-10% of imidoketone, 5-25% of calcite powder, 5-25% of ash calcium, 5-25% of redispersible latex powder, 0.2-0.5% of powder defoaming agent, 0.2-0.5% of powder wetting agent, 0.2-0.5% of powder mildew preventive and 0.2-5% of hydroxypropyl methyl cellulose. By utilizing techniques of sorting, mixing, screening and the like, the produced diatom ooze has excellent elasticity and sound-absorption heat-insulating performance, soft and comfortable touching sense, and crack resistance and mildew resistance, and the produced diatom ooze is an indoor decoration wall material which has excellent combination performance integrating functionality, practicability and decorative performance.

Owner:FUZHOU BIMITER ENVIRONMENT FRIENDLY PROD

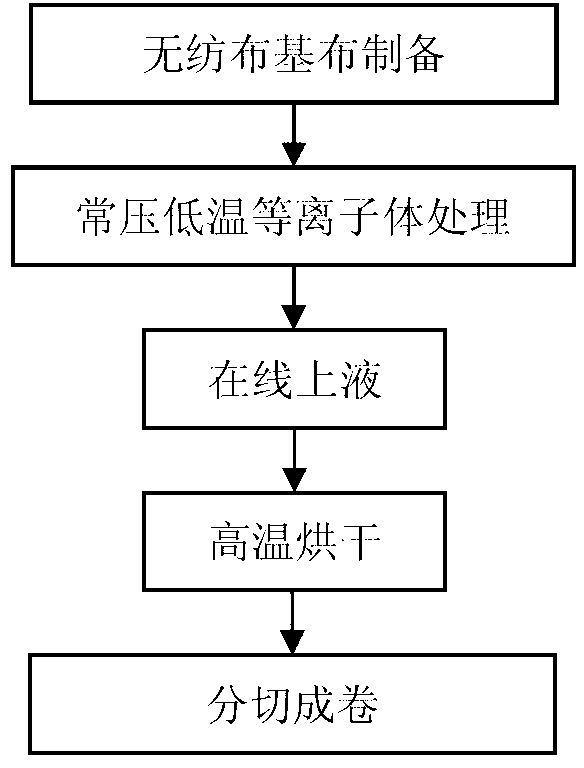

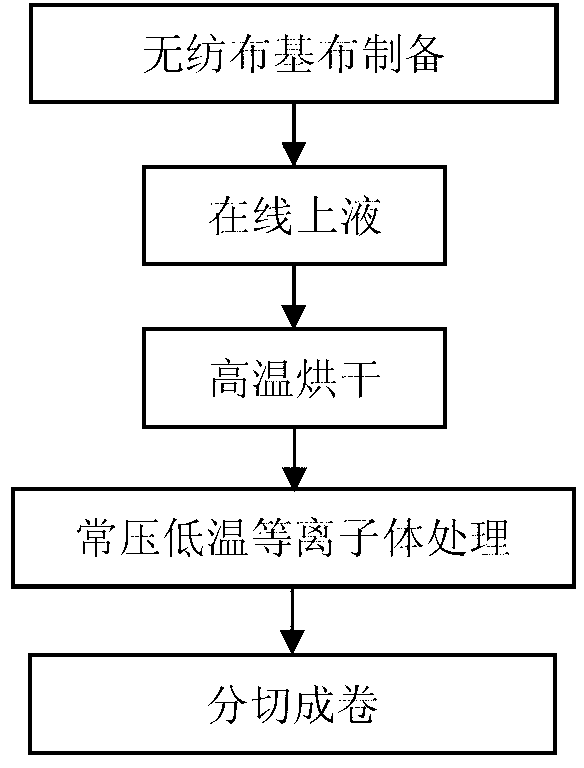

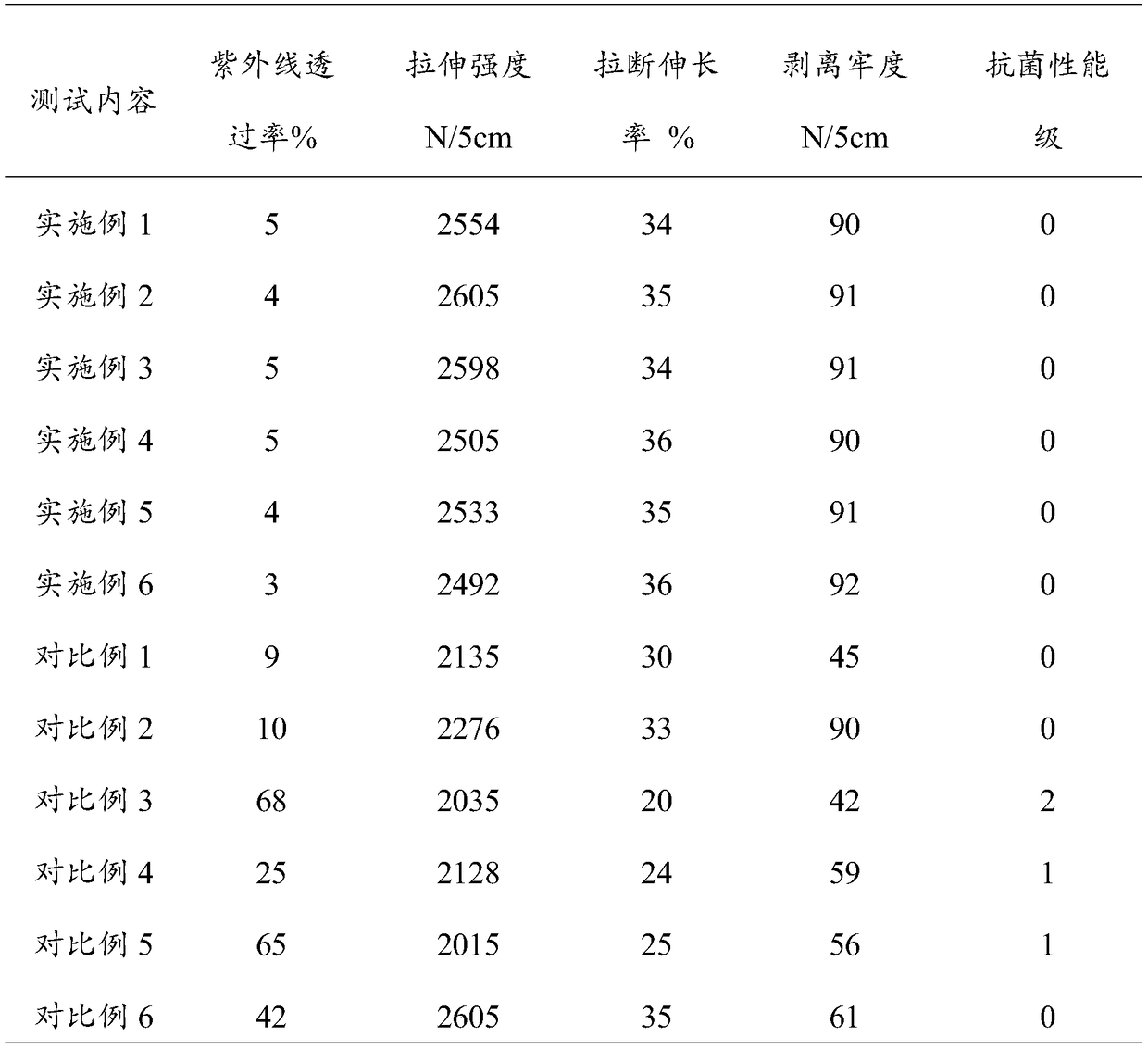

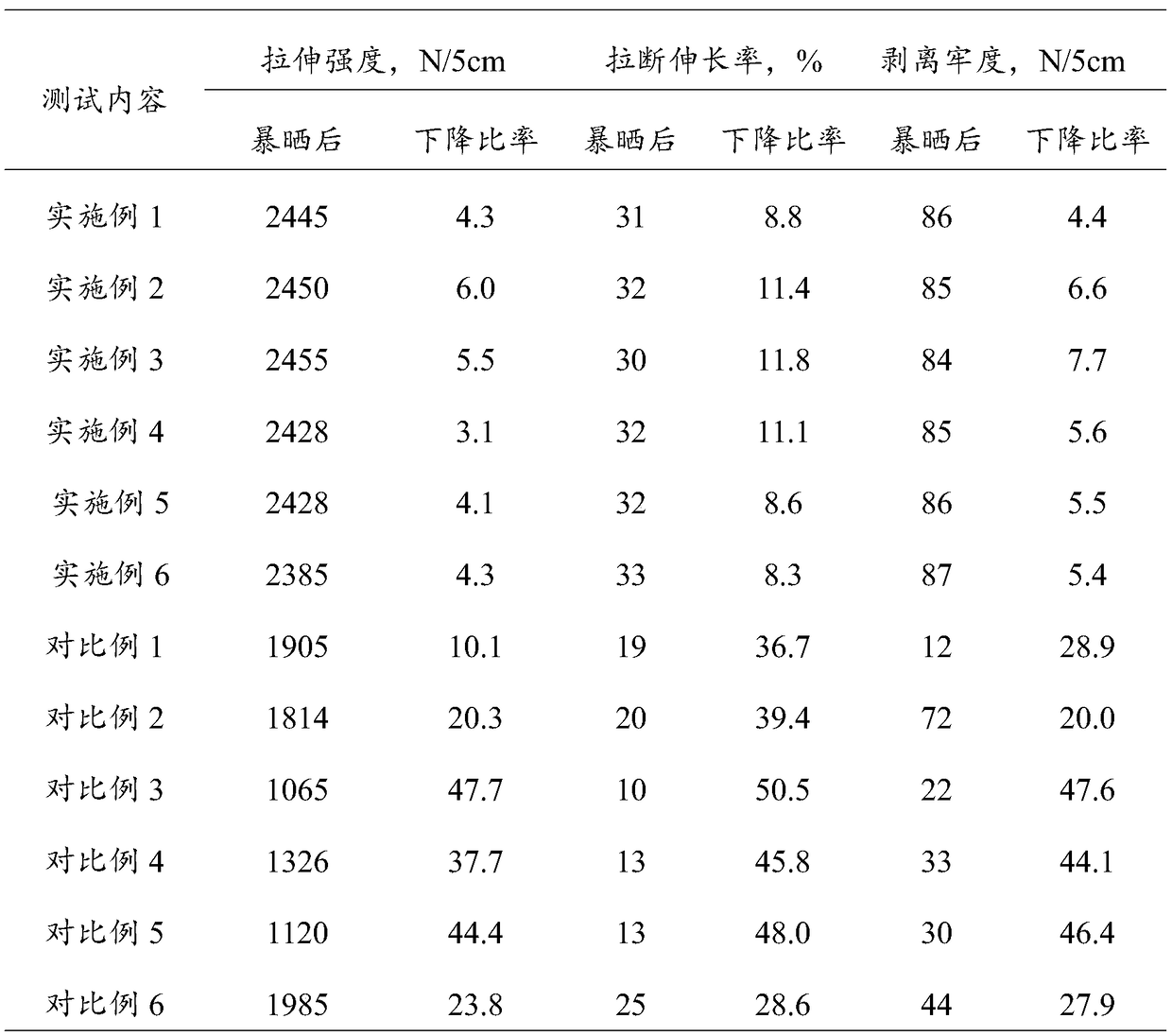

Finishing method for non-woven fabrics with high isolation performance and materials of non-woven fabrics with high isolation performance

ActiveCN102995400ALittle impact on air permeabilityReduce consumptionFibre treatmentAlcoholEngineering

The invention relates to a finishing method for non-woven fabrics with high isolation performance and materials of the non-woven fabrics with the high isolation performance. The finishing method combines on-line liquid feeding and normal-pressure low-temperature plasma processing, carries out normal-pressure low-temperature plasma processing before or after on-line liquid feeding, and forms a fluorine-containing polymer layer on the surface of the non-woven fabrics, so as to realize high isolation performance. The invention provides the finishing method for the non-woven fabrics which is novel, simple in process and good in finishing effect. Compared with the traditional saturated steeping, the finishing method has small influences on the non-woven fabrics, is high in production efficiency and has low energy consumption; compared with the existing plasma processing method, vacuum conditions are not needed, on-line liquid feeding is directly carried out, and low-temperature plasma processing is directly carried out under normal pressure, and other additional equipment conditions are not needed; and the contact angle between the prepared non-woven fabrics with high isolation performance and water can reach 120-160 degrees, and the prepared non-woven fabrics with high isolation performance has good air permeability and soft and comfortable feel, can reach requirements for resisting alcohol, oil and blood of each industry, and can well meet the large-scale industrial production.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

Composite cloth for curtain roller shutter and preparation method of composite cloth

ActiveCN109397806AWaterproof and breathableReduce tensionSynthetic resin layered productsLow-density polyethyleneUltraviolet protection

The invention discloses a composite cloth for a curtain roller shutter and a preparation method of the composite cloth. The composite cloth comprises a plasma-treated base cloth and a polyurethane TPUfilm attached to the base cloth, wherein the polyurethane TPU film is prepared by the following method that 70-80 parts of polyurethane TPU, 4-6 parts of low-density polyethylene (LDPE), 4-6 parts ofcarbon black, 4-6 parts of titanium oxide, 4-6 parts of nano glass micro-beads and 4-6 parts of phenyl salicylate are mixed evenly, then extruded and subjected to tape casting to form the film. By modifying the polyurethane TPU, the obtained composite cloth is soft and comfortable in hand feeling, environmental protection, shading, strong light irradiation resisting, ultraviolet protection, washing and dry-cleaning resisting and aging resistance are achieved, excellent light resistance and aging resistance are achieved, the adhesion fastness of a product is high, and the quality-guarantee service life is ten years or above. After the surface of the base cloth is activated, the modified polyurethane TPU film is composited in a hot-pressed mode, glue is not used, and thus real energy savingand environmental protection are achieved.

Owner:浙江鸿圣纺织科技有限公司

Manufacturing method of fuzz-pilling resistant cellulose fiber weft-knitted fabric

The invention provides a manufacturing method of a fuzz-pilling resistant cellulose fiber weft-knitted fabric, comprising the following steps: (1) processing spun yarn: synchronously drawing and spinning two ribbons consisting of cellulose fiber and cotton to obtain a blended yarn of the cellulose fiber and cotton fiber; (2) taking the blended yarn of the cellulose fiber and the cotton fiber, which is obtained in the step (1), as a wire gauze, and knitting the blended yarn with a naked spandex yarn by a weft plain knitting method, wherein each knitting system knits one wire gauze and one naked spandex yarn plating yarn together to obtain a weft-knitted single-face plain knitting platedwork fabric; and (3) heating and pre-shaping the weft-knitted single-face plain knitting platedwork fabric, and then dyeing and shaping the weft-knitted single-face plain knitting platedwork fabric to obtain the fuzz-pilling resistant cellulose fiber weft-knitted fabric. The invention not only solves the problem of fuzz-pilling resistance of a blended fabric taking the cellulose fiber as the main part, but also has large elastic extension and small elastic-restoring force, and also has soft and comfortable hand feeling after being knitted into clothes and trousers.

Owner:SHANGHAI THREE GUN GROUP +1

Firm and durable bobbin paper and production process thereof

ActiveCN105256639ALow costImprove production efficiencyCoatingsInorganic compound additionFiberBobbin

The invention discloses firm and durable bobbin paper. The firm and durable bobbin paper comprises a raw paper base layer and a coating wear-resisting layer, wherein the raw paper base layer is prepared from the following components in parts by weight: needle bush sulfite pulp, Chinese wild rye stem pulp, waste paper fibers, bamboo fibers, silicon dioxide, rosin size and melamine formaldehyde resin; and the coating wear-resisting layer is prepared from the following components in parts by weight: acrylic polyols, tetraethoxysilane, urotropine, polyacrylamide and carboxymethylcellulose. The firm and durable bobbin paper provided by the invention has the characteristics of convenience for utilization, relatively high hardness and intensity and relatively good wearing resistance and waterproof property, and has very good environment-friendly effect.

Owner:ZHEJIANG HUACHUAN IND GRP

Metal wire colored woven plus material

InactiveCN101191272ABright and full colorsGood moisture absorption and moisture conductivityLoomsWoven fabricsMetal filamentEngineering

The invention relates to a metal filament yarn dyed fabric and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads adopt terylen after blend dyeing and regenerated cellulose modal as raw materials; weft yarns adopt metal filament with two colors; the fabric adopts weave structure of double layers of textile; the warp threads are arranged on the reverse side of the textile, and the weft yarns are arranged on the right side of the textile. After being weaved by a multi-jet weaving machine, the invention has good effects of moisture absorption and wet permeability and also has good softness and comfort level. Moreover, because the textile adopts the weave structure of the double layers and the blended yarns are arranged on the reverse side of the textile, sweat exhausted from the human body can be quickly absorbed and transferred to the surface of the textile, and dryness and comfort when the textile contacts the skin are always maintained and people feel comfortable as well even the textile is worn next to the skin, thereby the weaved fabric not only can be used in fields like military industry, protection, leisure garment and so on but also is more suitable for making leisure undergarments which are worn next to the skin.

Owner:YANGZHOU JIYUAN TEXTILE

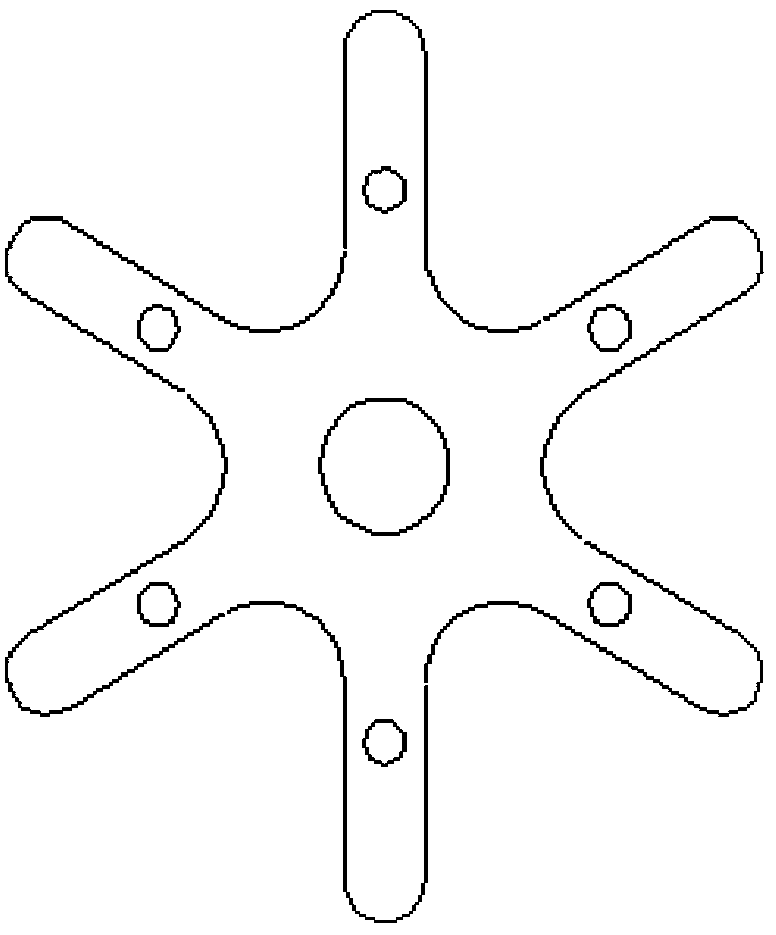

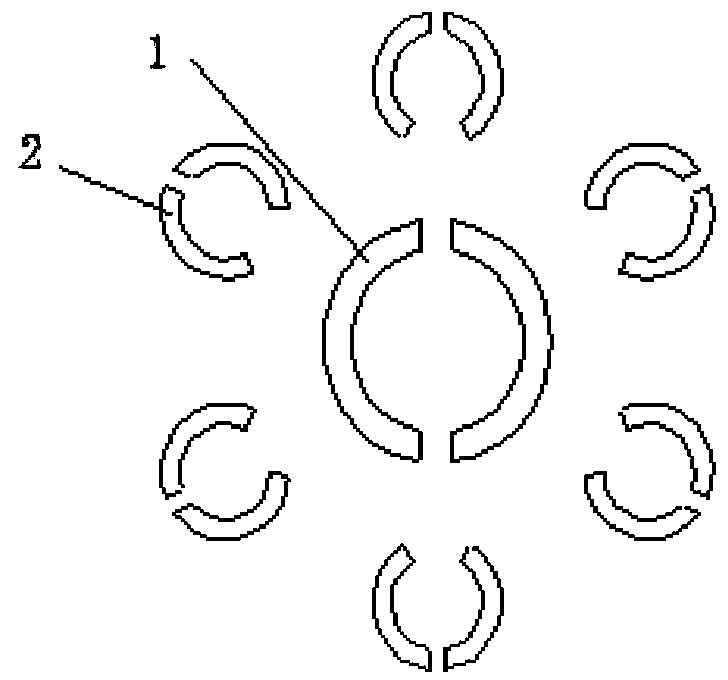

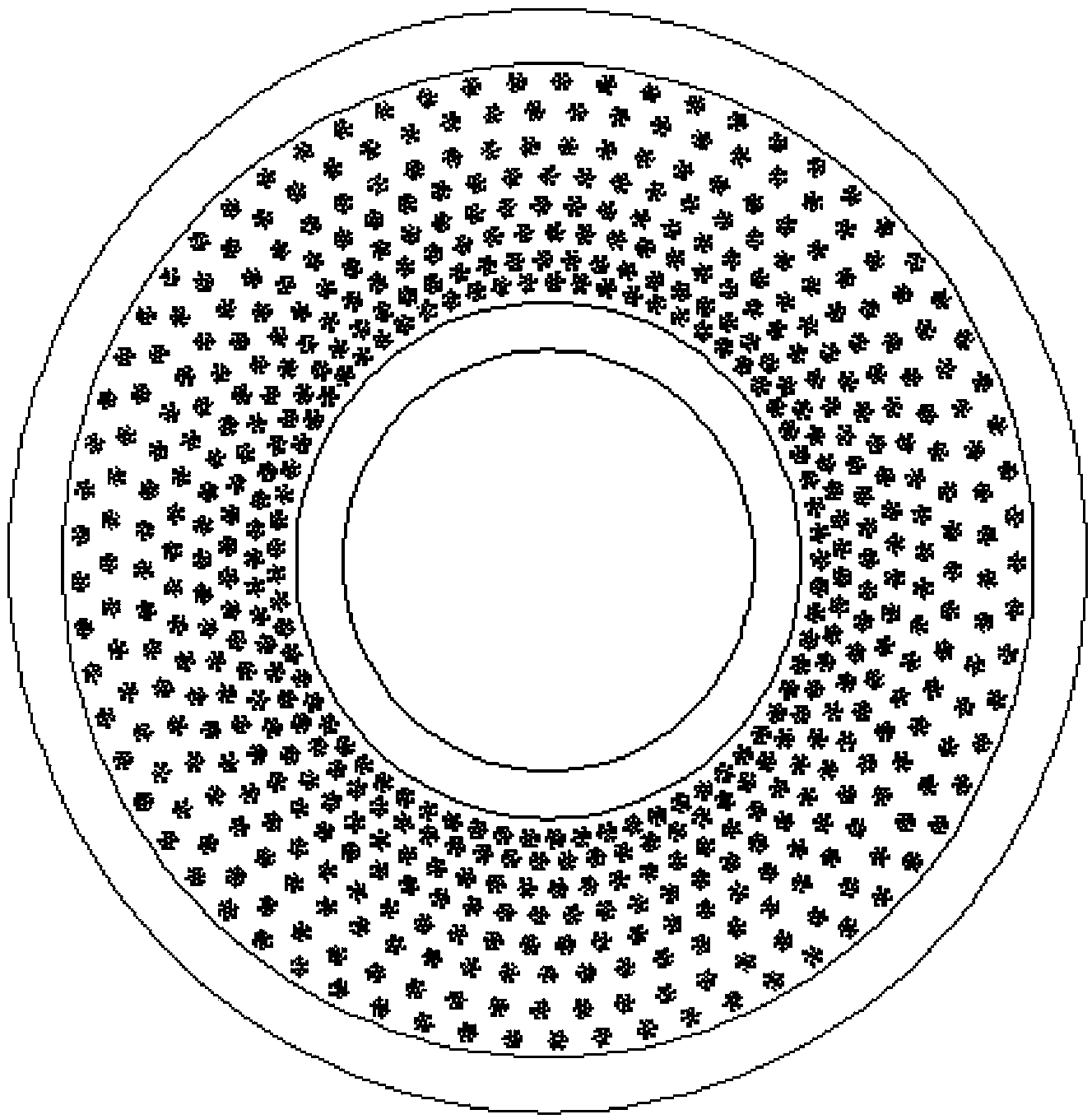

Preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes

ActiveCN104389036AEasy to shapeHigh degree of abnormalityHollow filament manufactureArtificial filament heat treatmentPolyesterPolymer science

The invention provides a preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes. The preparation method comprises the following steps: performing melt spinning on the renewable polyester bottle flakes after vacuum drum drying, enabling the renewable polyester bottle flakes to enter a spinning box body through screw extrusion, spinning out of spinneret orifices of a six-leaf porous hollow spinneret plate to obtain nascent fibers, cooling and forming through circulating air blowing, winding, bundling, drafting, crimping, oiling, loosening and heat setting, and cutting to obtain the six-leaf porous hollow staple fibers, wherein the spinneret orifices are formed in the six-leaf porous hollow spinneret plate and are arranged in arrays; inlets of the spinneret orifices are guide holes, and outlets of the spinneret orifices are spinning capillary holes; each spinning capillary hole comprises one central arc-shaped hole group and six peripheral arc-shaped hole groups; the six peripheral arc-shaped hole groups and the central arc-shaped hole group form a six-leaf structure. Through improvement of a spinning process and innovative design of the spinneret plate, the prepared six-leaf porous hollow staple fibers have the characteristics of high hollow degree, high rebound resilience, large specific surface area, good moisture-absorbing and breathable effect and the like.

Owner:江苏省科学技术情报研究所

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

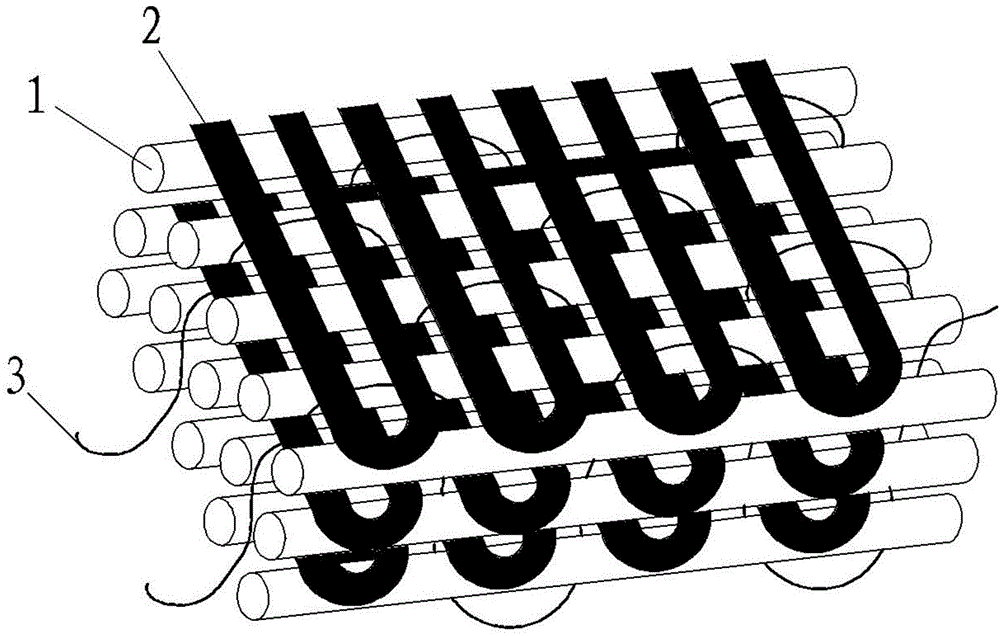

Three-dimensional oil suction fabric

The invention provides a three-dimensional oil suction fabric, which comprises three types of yarns in X, Y and Z directions. The yarns are selected from fibrilia, bamboo fiber, polylactic acid fiber and chitosan fiber, and woven according to three-dimensional weaving technology. The performances of the three-dimensional oil suction fabric are better than those of conventional non-woven fabric materials. The three-dimensional oil suction fabric has a crosslinking network structure, and is high in adsorption rate and adsorption quantity. The three-dimensional oil suction fabric can be recovered by simple extruding, the recovery rate is high, and the adsorption capability and resilience are excellent. The three-dimensional oil suction fabric can be repeatedly usable, and is durable. The fabric employs natural fibers and biodegradable chemical fiber as raw materials, and the fabric is soft and comfortable. The three-dimensional oil suction fabric is high in mechanical strength and wide in application scope, and has certain antibacterial function.

Owner:SUZHOU WILDER IND & TRADE

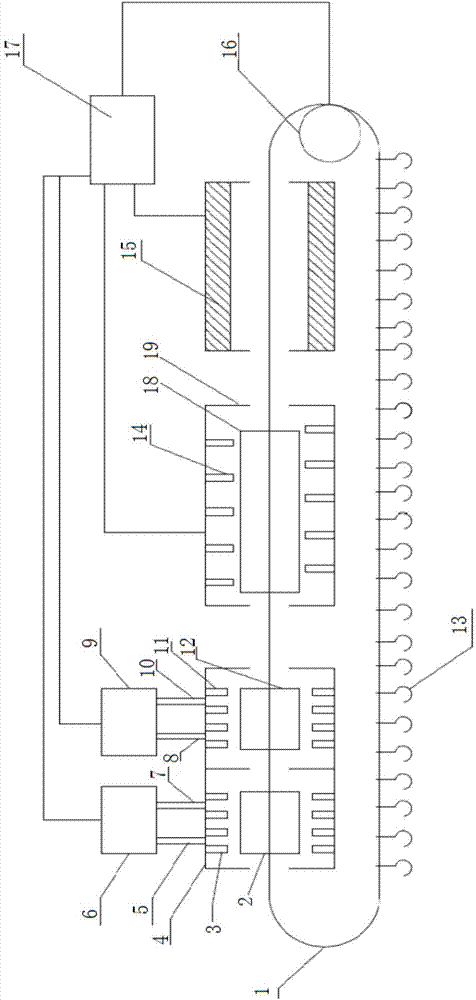

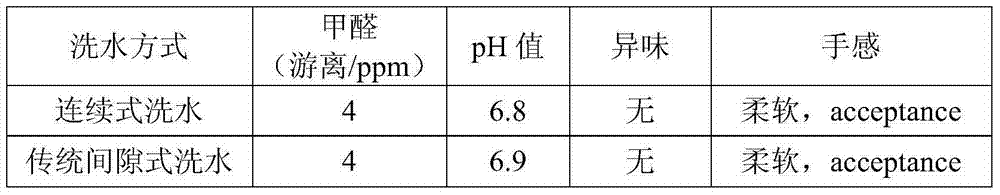

Method and equipment for water washing of clothes

ActiveCN104775247AReduce labor intensityReduce the number of employeesTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringPollution

The invention provides a method and equipment for water washing of clothes. The method comprises the following steps of pre-spraying, spraying material treatment, water removal, and suspension and drying, so as to complete the water washing process; in the pre-spraying process, a washing liquid is uniformly sprayed to the clothes by a spraying method; in the spraying material treatment process, a spraying material treatment liquid is uniformly applied to the clothes by the spraying method; preferably, in the pre-spraying and material spraying treatment process, the clothes are suspended. The invention also provides the water washing equipment using the method. By adopting the technical scheme, the method has the beneficial effects that the water washing procedures of the clothes are continuously performed, the residual liquid in the water washing procedure is recycled, the labor is saved, the water usage amount is reduced, the pollution is reduced, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Processing technology of cowhide leather

InactiveCN107858458AGood removal effectNot perishableTanning treatmentPre-tanning chemical treatmentCross-linkRemoving hair

The invention discloses a processing technology of cowhide leather. The technology comprises the steps of: cleaning, degreasing, hair removal, alkali dipping, deashing, softening, acid dipping and tanning. According to the invention, the ester removal agent used in degreasing treatment can remove the residual ester well, is beneficial to intracutaneous penetration of tanning agent molecules and combination with collagen molecule active groups in a follow-up tanning process, formation of a cross-linked protein fiber three-dimensional network, and improvement of the stability and chemical resistance, and the prepared leather does not rot or deteriorate easily. Through the treatment of alkali dipping, deashing, softening and other steps, mesenchymal protein fiber in cortex can be dissolved, the softness of finished leather can be improved, and the handfeel is comfortable.

Owner:ANHUI DINGHENG LEATHER PROD

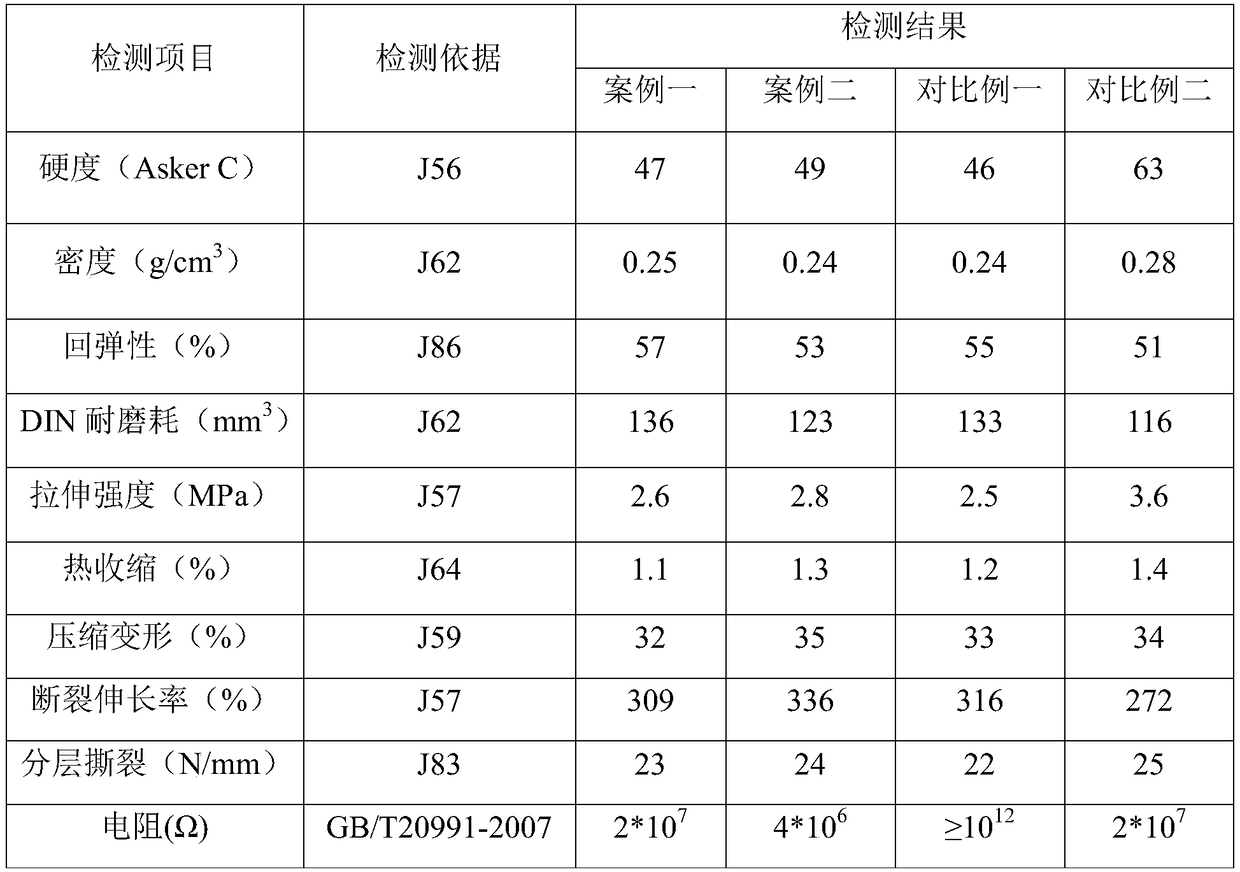

Soft high-elasticity wear-resisting electrostatic-discharge EVA (ethylene-vinyl acetate) composite foam material and preparation method thereof

The invention discloses soft high-elasticity wear-resisting electrostatic-discharge EVA (ethylene-vinyl acetate) composite foam material and a preparation method thereof. The soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material is made by material mixing, granulating and foaming; materials include, by weight, 25-50 parts of ethylene-vinyl acetate copolymer, 15-35parts of polyolefin thermoplastic elastomer, 15-25 parts of ethylene propylene diene monomer rubber, 10-20 parts of polyolefin block copolymer, 1-3 parts of graphene oxide, 3-8 parts of a wear resistant, 4-6 parts of a filling agent, 0.4-0.6 part of an activator, 0.7-1.2 parts of a crosslinking agent, 2.5-3.5 parts of a foaming agent, and 2.1-4.3 parts of aids, wherein vinyl acetate accounts for26-40% by mass of the ethylene-vinyl acetate copolymer. The soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material has good softness and comfort, excellent elasticityand excellent wear resistance, and has good electrostatic discharge performance; the preparation method of the soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material is simple and easily operable.

Owner:ANTA CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com