Patents

Literature

68results about How to "Solving Adhesion Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

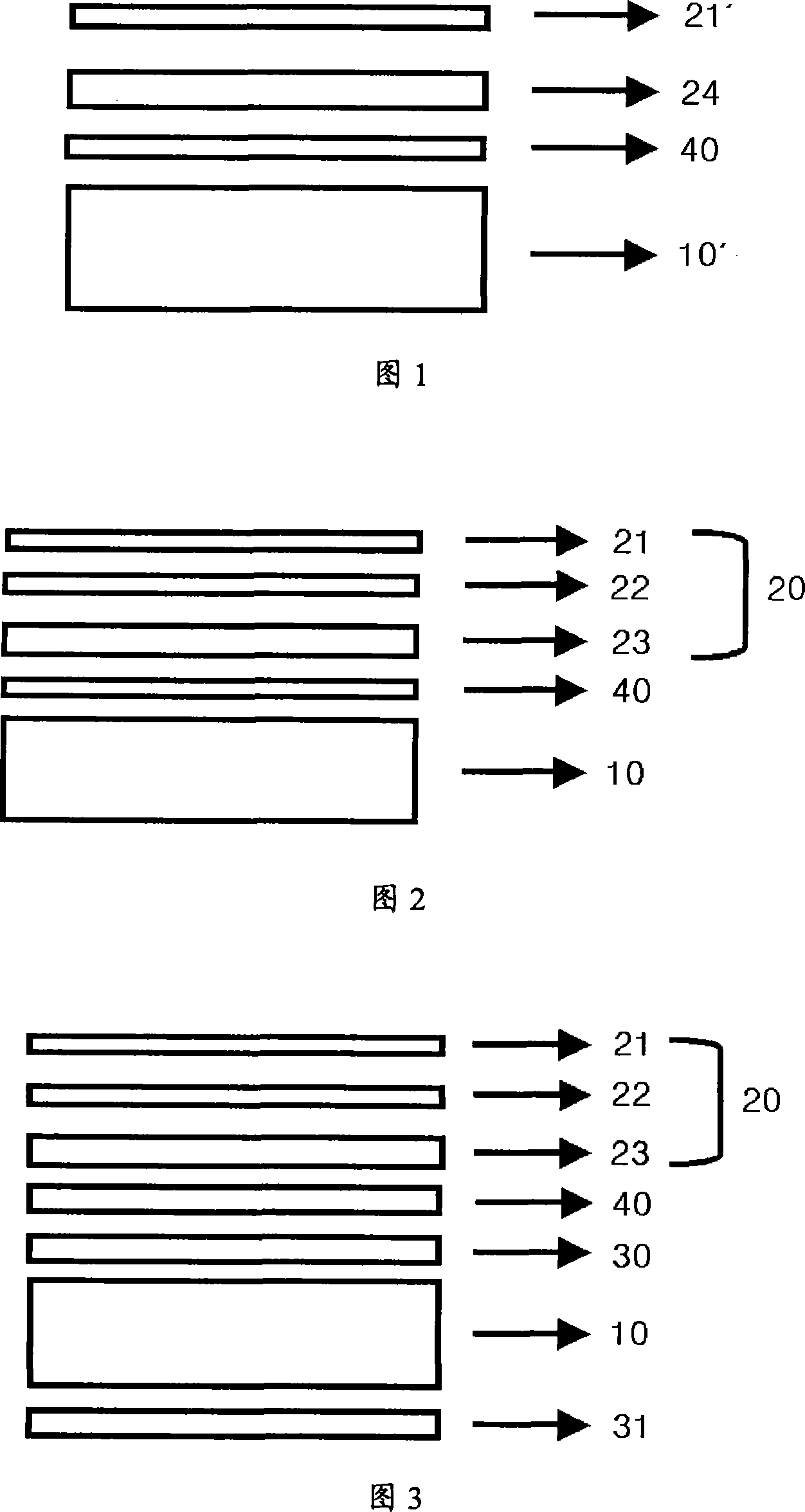

Vacuum plating paint, and preparation and construction methods thereof

ActiveCN102167950AImprove reliabilityControl shrinkage of photocuring reactionSynthetic resin layered productsVacuum evaporation coatingPolyesterPhosphate

The invention discloses a vacuum plating paint, and preparation and construction methods thereof. The vacuum plating paint is composed of a priming coat, an undercoat and a finish coat, wherein the priming coat is prepared from polyurethane acrylate resin, acrylate, photoinitiator, organosiloxane leveling agent, butyl acetate, ethyl acetate and isopropanol; the undercoat is prepared from polyester-modified polyurethane acrylate resin, polyurethane acrylate resin, phosphate acrylate, photoinitiator, butyl acetate, ethyl acetate and isopropanol; and the finish coat is prepared from polyurethaneacrylate resin, acrylate, phosphate acrylate, photoinitiator, organosiloxane leveling agent, butyl acetate, ethyl acetate and isopropanol. By adopting imported environment-friendly raw materials, thevacuum plating paint has the advantage of low toxicity; no high-temperature high-pressure process is carried out in the production process, so the vacuum plating paint has the advantage of high safety; the vacuum plating paint does not need to be diluted, and thus, can be directly used conveniently; and the priming coat, undercoat and finish coat are cured under ultraviolet, so the vacuum platingpaint has the advantage of high production efficiency.

Owner:江西赐彩新材料股份有限公司

Formula of adhesive agent for aircraft tire renewing

ActiveCN101200625AHigh adhesion retentionMeet performance requirementsNatural rubber adhesivesSulfurGasoline

The present invention discloses a prescription of an adhesive used for an aircraft tire retreading. The adhesive considers caoutchouc as the main material and also contains the main auxiliary materials of styrene butadiene rubber, adhesion promoter, adhesive, high abrasion furnace black, high dispersion white carbon black, ketoamine age inhibitor, indiscerptible sulfur and sulfenamide accelerant. The main material and the main auxiliary materials are made into gross rubber according to certain weight portion ratio, and the gross rubber is mixed with gasoline by certain proportion to be made into the adhesive. The adhesive of the prescription has the advantage that the adhesive solves the problem of sticking an old tire body with a retreading component when the aircraft tire is retreaded, which ensures that the aircraft tire does not have the problem of the delamination of the glue material between the old tire body and the retreading component, bulging and other quality problems during the use course, and the tire is safe for using.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

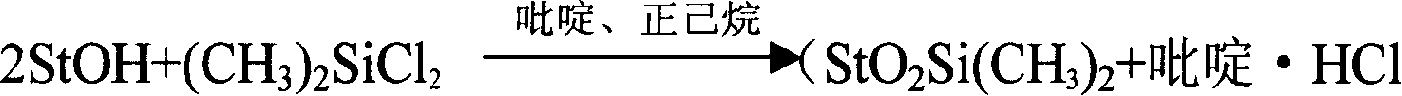

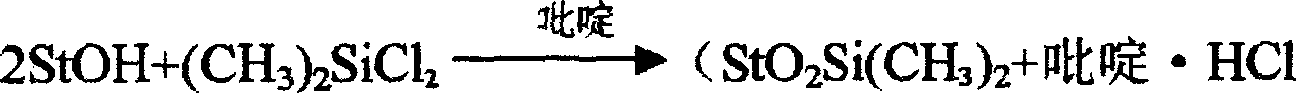

Thermoplastic elastomer for filming dacron cloth

InactiveCN1931918ASolving Adhesion ProblemsHigh peel strengthTextiles and paperFiberWeather resistance

The thermoplastic elastomer for filming Dacron cloth used as box lining, sportswear lining, etc. consists of matrix resin 10-80 wt%, filler oil 0-60 wt%, tackifier 5-50 wt%, mineral filler 0-25 wt%, coupling agent 0.1-0.8 wt%, machining assistant 0.1-2 wt%, and composite stabilizer 0.1-2 wt%. By means of the improved recipe and preparation process, the present invention solves the problem of adhering non-polar matrix with Dacron or other polar chemical fiber fabric, so that the film on the Dacron material has high peeling strength, soft and comfortable handing, high weather resistance, and high acid and alkali resistance and other advantages.

Owner:CGN JUNER NEW MATERIALS

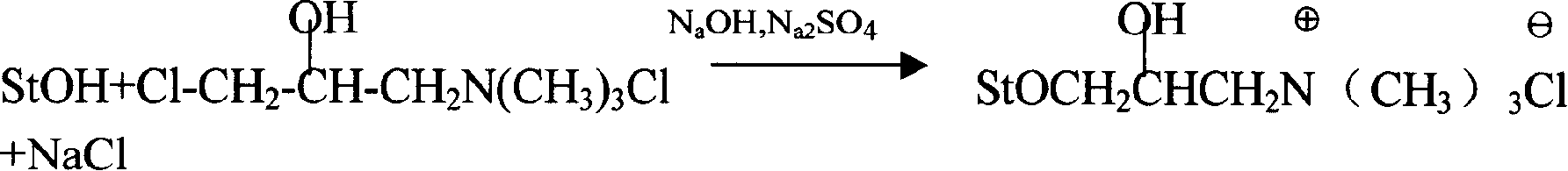

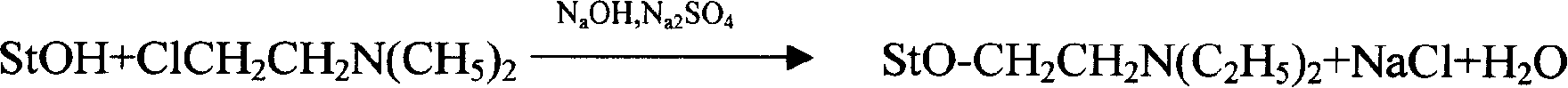

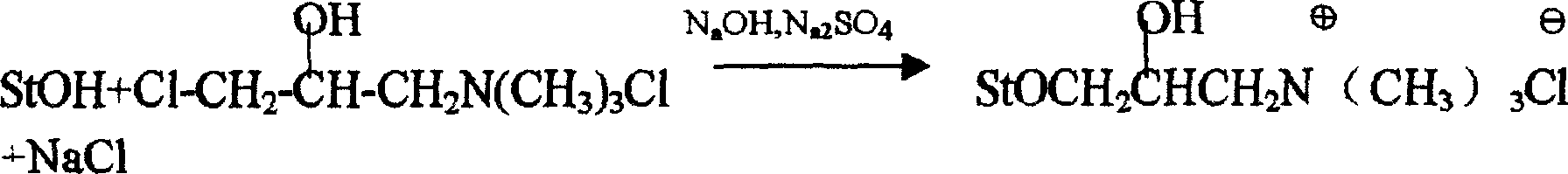

Cation branched-chain starch wood binder and its production

InactiveCN1982395AImprove stabilityImprove water resistanceAmylose/amylopective derivative adhesivesCross-linkAdhesive

A cationic branched-chain starch wood adhesive and its production are disclosed. The process is carried out by adding cross-linking agent, etherifying agent and oxidant into branched-chain starch, cross-linking reacting, etherification reacting and low-degree oxidation reacting. Its advantages include excellent adhesion, water-resistance, fluidity and anticoagulant performance, long storage period and fast dry speed.

Owner:莫元烈

Wood flooring laminated with high pressure veneer and impregnated low weight printing paper

InactiveCN101006234AImprove surface strengthGood printabilityCovering/liningsSpecial ornamental structuresThermoplasticWood veneer

Disclosed herein is a UV surface-coated laminate wood flooring for an under-floor heating system comprising a back-grooved base, an adhesive layer and a printed wood veneer layer wherein the printed wood veneer layer is produced by impregnating and coating a low-basis weight printed paper with a thermoplastic or thermosetting resin, integrally forming the paper layer with a low-price reinforcing layer by pressing under high pressure, treating the surface of the paper layer with an acryl based primer, and coating the primer-treated paper layer with a solvent-free type UV coating paint, and wherein the back-grooved base and the printed wood veneer layer are adhered to each other by the adhesive layer.

Owner:LG CHEM LTD

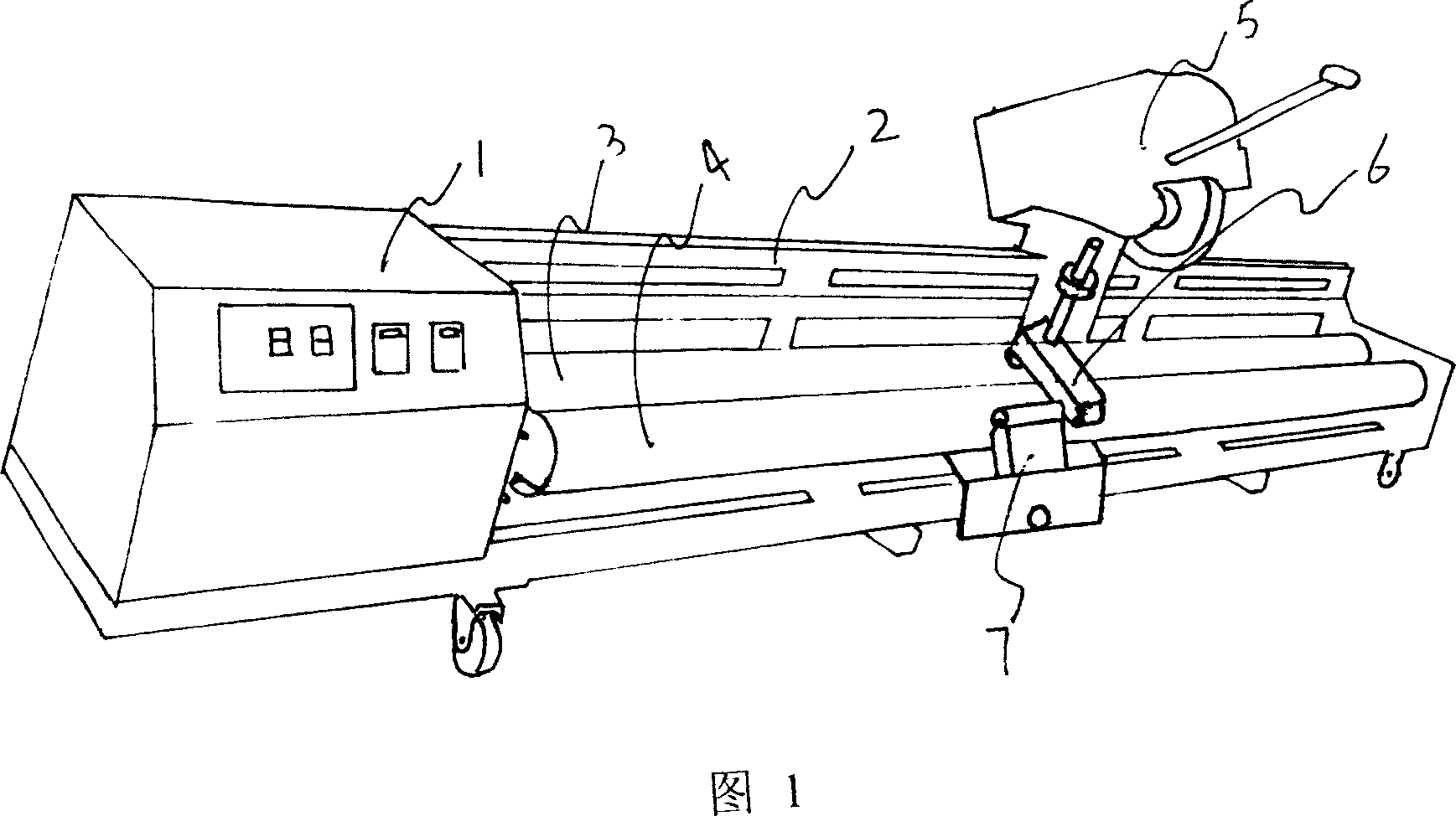

Cutter and cutting method

InactiveCN101073889ASolving Adhesion ProblemsEasy to implement cuttingMetal working apparatusMotor driveEngineering

Owner:杭州中凌广告器材有限公司

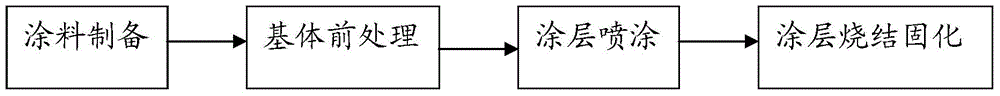

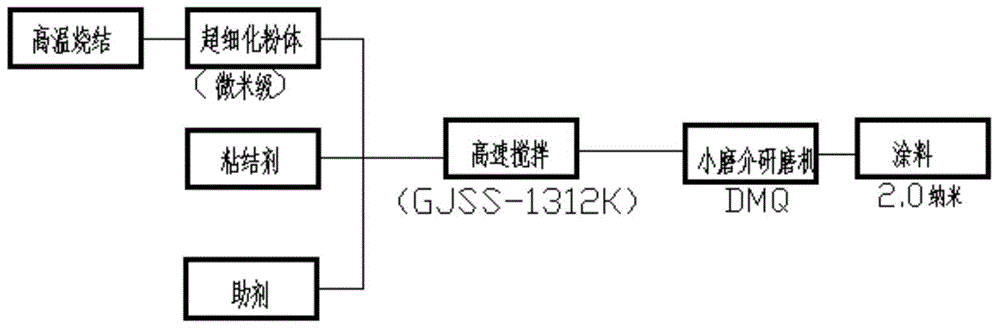

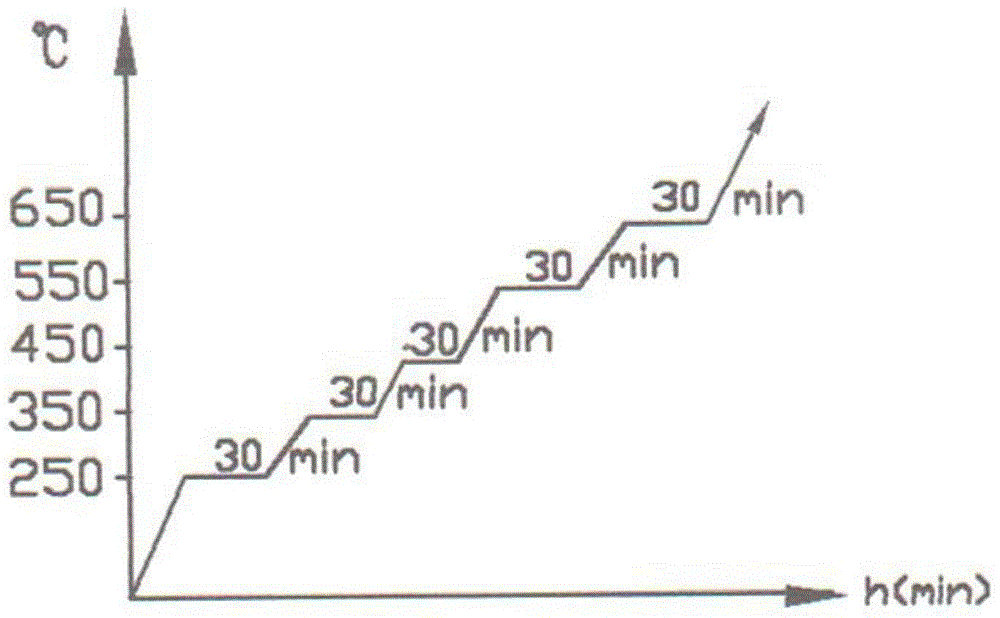

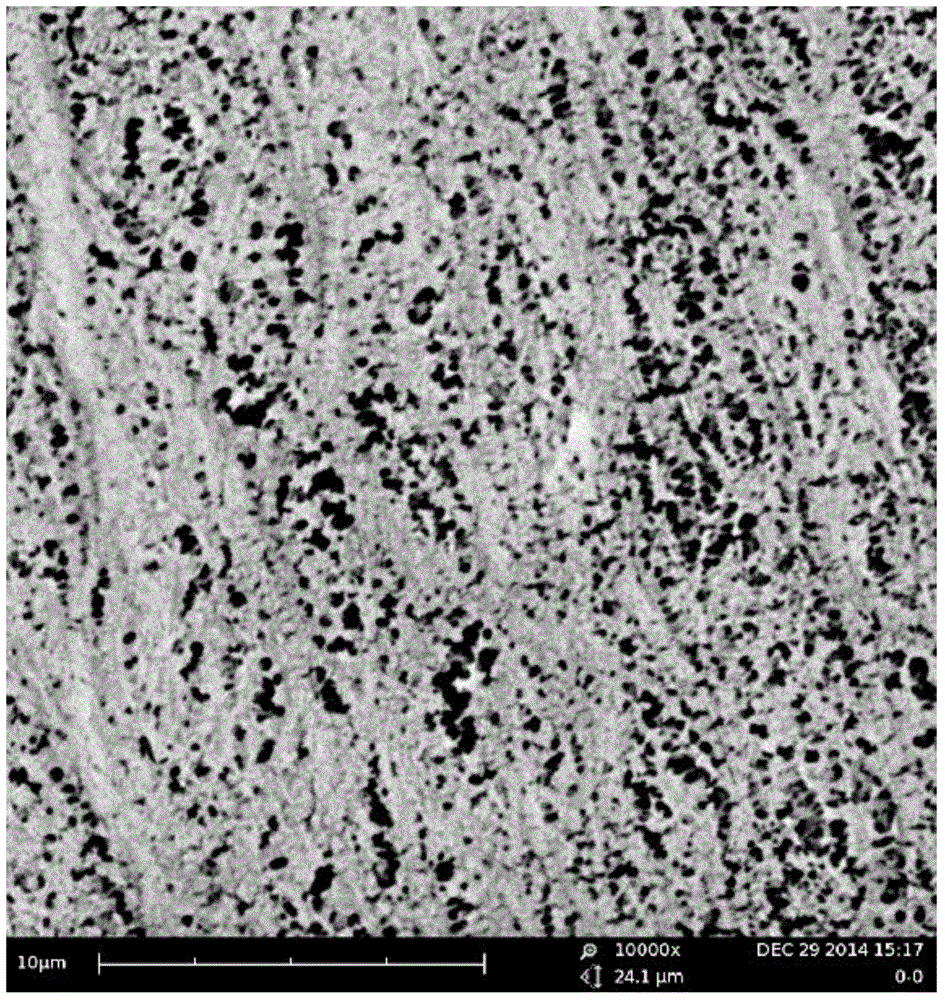

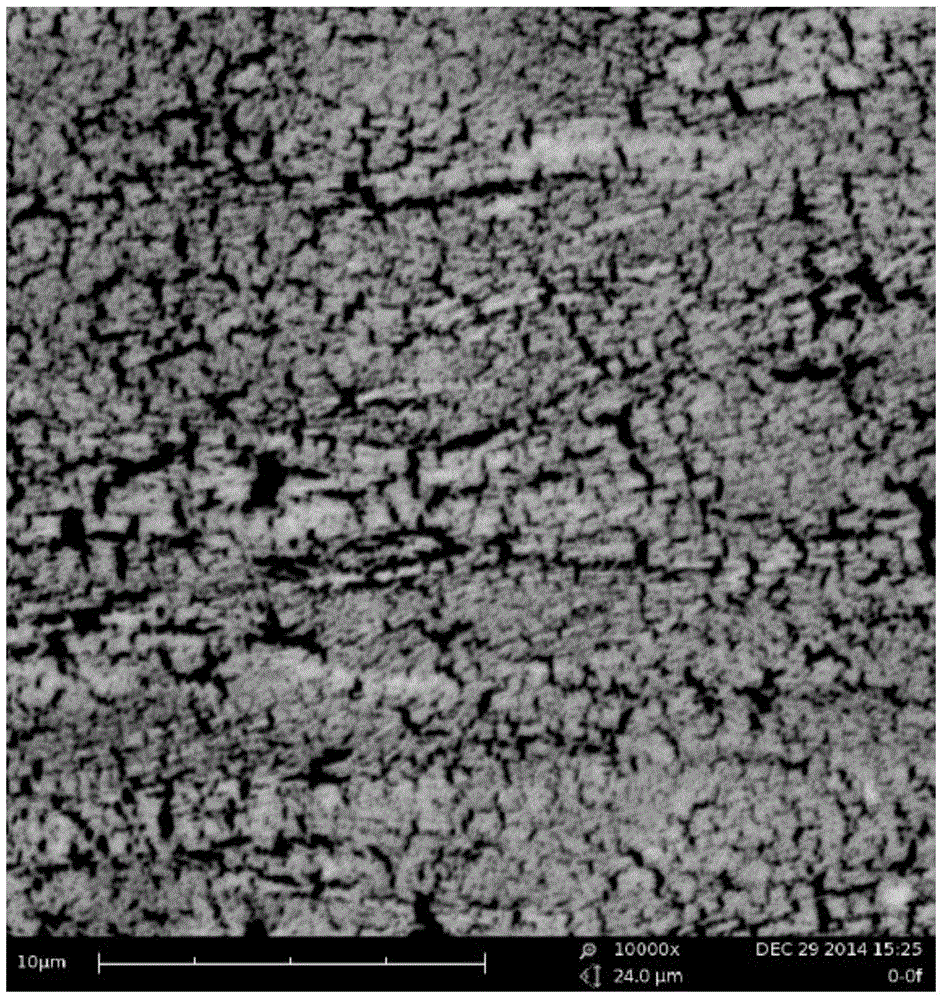

Preparation method of high-emissivity energy-saving infrared radiation coating

ActiveCN104098936AEnhanced radiation heat transferIncrease surface temperatureChemical industryCoatingsEmissivityCeramic coating

The invention discloses a preparation method of a high-emissivity energy-saving infrared radiation coating. The preparation method comprises steps as follows: step one, preparation of coating materials; step two, pretreatment of a base body; step three, spraying of the coating; and step four, sintering and curing of the coating. The coating is stable in structure under high-temperature sintering, performance is comprehensively promoted, the emissivity of the coating cannot be attenuated and aged during use, and the service life of the coating is longer than six years; glazing ceramic coating with a compact structure is formed on the furnace lining surface, the service life of a furnace is prolonged by more than two times, and maintenance and overhaul workload of a furnace lining, consumption of raw materials and maintenance cost are reduced.

Owner:北京恩吉赛威节能科技有限公司

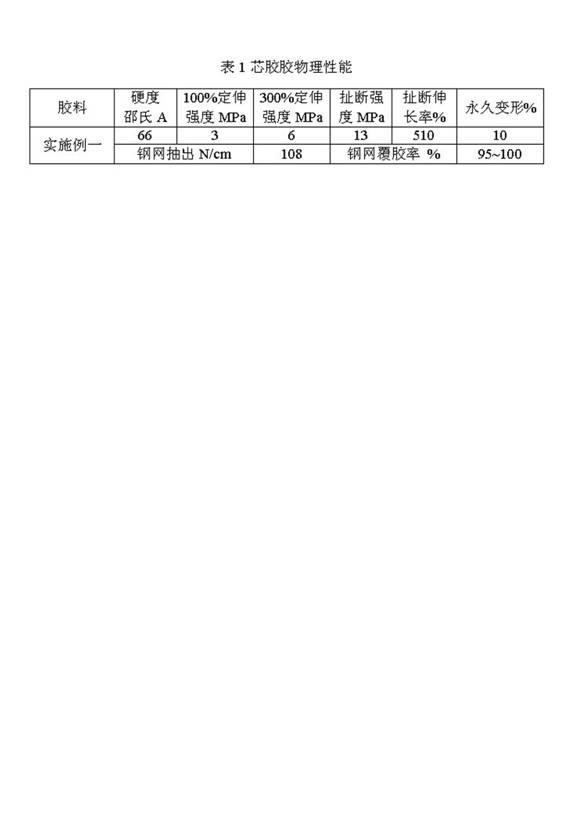

Preparation method of core glue for high-temperature resistant steel mesh conveyor belt

The invention relates to a preparation method of core glue for a high-temperature resistant steel mesh conveyor belt, comprising the following process steps of: (1) mixing: adding ethylene propylene rubber, chloroprene rubber and carbon black in an internal mixer for mixing; (2) internal mixing by two stage: adding zinc oxide, stearic acid, aging inhibitorn aging inhibitor RD, an accelerator CZ, a binding agent RS, white carbon black, calcium carbonate, cobalt boroacylate and rubber oil in glue stock obtained from internal mixing, carrying out the first-stage internal mixing on the internal mixer and adding insoluble sulfur, the binding agent RA and zinc methacrylate in the obtained glue stock which is stood for 6-8 hours for the second-stage internal mixing; (3) discharging colloid obtained by two-stage internal mixing into an open mill for back mixing; and (4) pressing the colloid subjected to back mixing on an extruder into a sheet and obtaining the core glue. The invention can solve the problem that the core glue is bonded with the steel mesh under the high-temperature condition.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

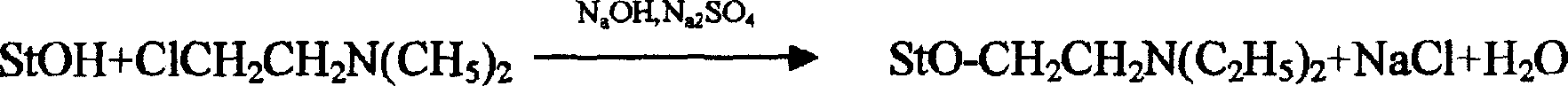

Cationic branched-chain starch wood adhesive and its preparing method

InactiveCN1775885AImprove stabilityImprove water resistanceAmylose/amylopective derivative adhesivesAdhesiveWater soluble

The invention discloses a positive ion branched chain starch wood adhesive and the method to manufacture. It adopts low oxidation to increase the starch aldehyde group after reaction to solve the strong cementing force of the adhesive. It adds cross linking agent etherifying agent, and oxidizing agent to branched chain to make the invention has strong cementing force, good water resistance, fluidity, and stability.

Owner:莫元烈

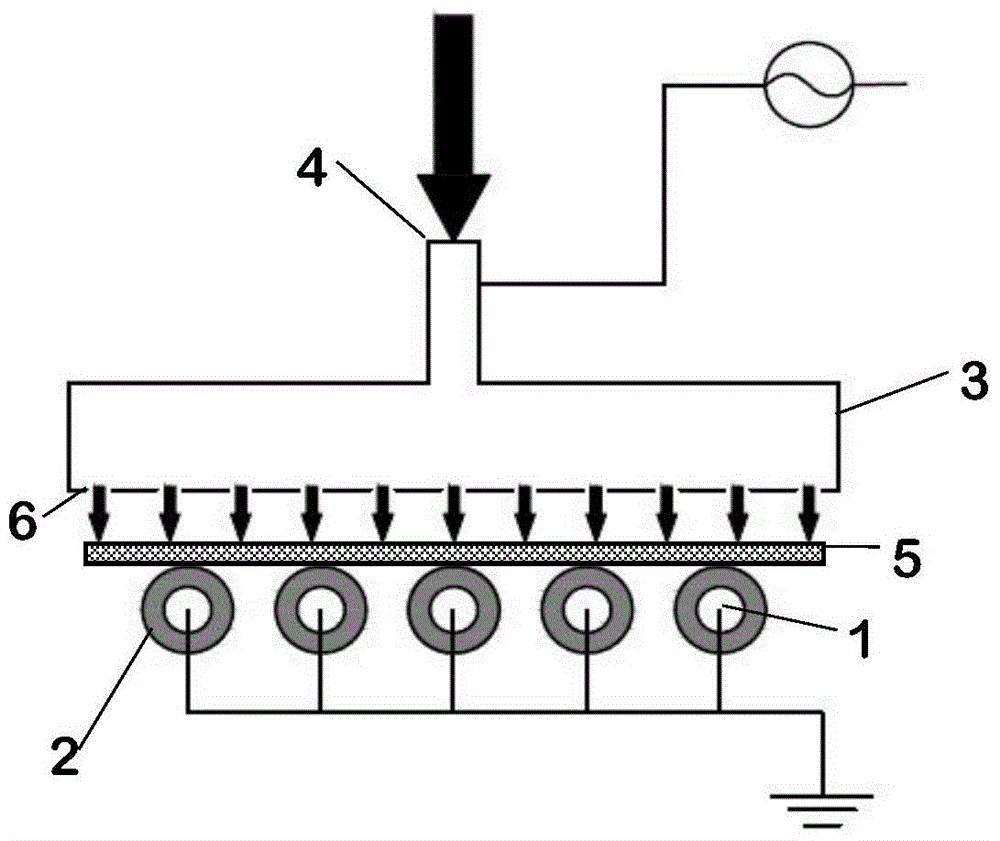

Preparation method of heat-shrinkage-resistant power battery separator

ActiveCN104810495ASolving Adhesion ProblemsGood adhesionCell seperators/membranes/diaphragms/spacersSecondary cellsPower batteryProcess engineering

The invention relates to a preparation method of a heat-shrinkage-resistant power battery separator. The method comprises steps as follows: discharge gas is fed into a DBD (dielectric barrier discharge) plasma reactor, the high-voltage alternating current enables the discharge gas to discharge to produce plasma, a precursor is sent into a plasma area for a reaction by the aid of carrier gas and reaction gas, a reaction product deposits on a substrate, and the heat-shrinkage-resistant power battery separator is obtained. The method is simple and easy to implement, manufacturing and production equipment is simple, shorter time is taken, preparation is convenient, and no catalyst or template is required; during preparation, energy consumption is low, pollution is low, the deposition rate is high, no other solvent is used in the separator deposition treatment process, the preparation method is an environment-friendly dry method, and the feasibility of industrial application is increased.

Owner:DONGHUA UNIV

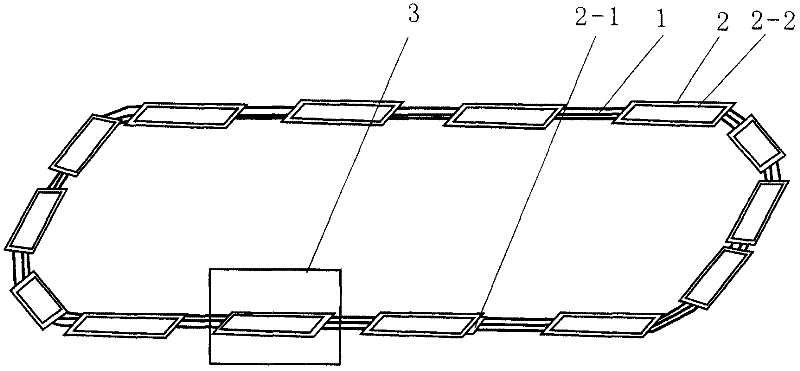

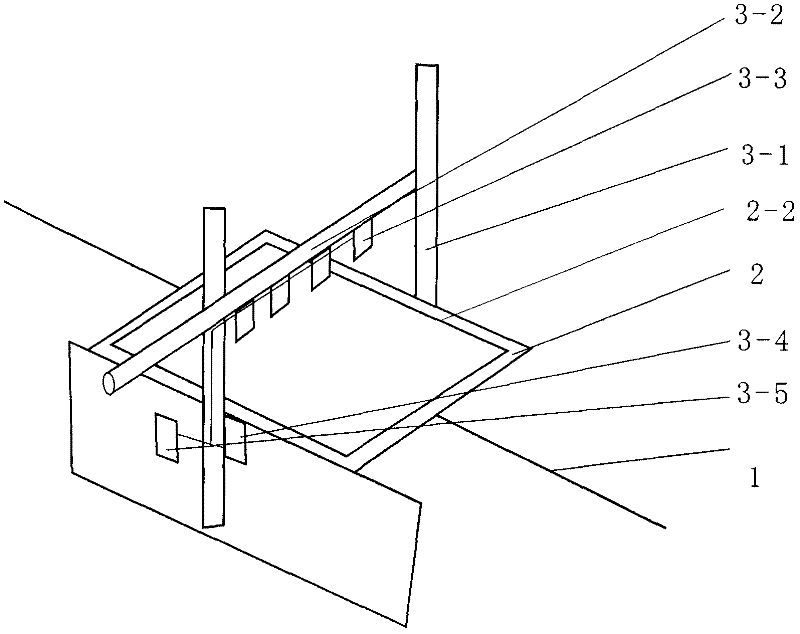

Manufacturing method of soft glue mat and glue filling device

InactiveCN102642372ASolving Adhesion ProblemsSuitable for mass productionLaminationLamination apparatusEngineeringLogging

The invention discloses a manufacturing method of a soft glue mat, which comprises the following steps of: preparing materials, cutting fabrics, cutting sponge, smelting, filling glue, sticky coating the sponge, and pressing sides. An adopted glue filling device comprises a guide rail, glue dispensing working tables and a glue dispensing area, wherein the guide rail is annular; more than two glue dispensing working tables are arranged and are mutually connected, and at least one glue dispensing working table is provided with a driver; each glue dispensing working table is provided with a model frame; the glue dispensing area is arranged on the guide rail and is provided with a glue spraying support; a glue conveying pipe is arranged on the glue spraying support and is provided with a plurality of glue-smelting nozzles; and the glue dispensing area is also provided with a sensor and a controller, and the controller is respectively in signal connection with the sensor and the glue-smelting nozzles. The soft glue mat has favorable rebound resilience, favorable tactility, functions of skid resistance, resistance to water logging and the like, and reasonable process, and is suitable for batch production. The glue filling device has the characteristic of high working efficiency, the labor cost can be saved, and the production effectiveness is improved.

Owner:上虞舜美高分子材料有限公司

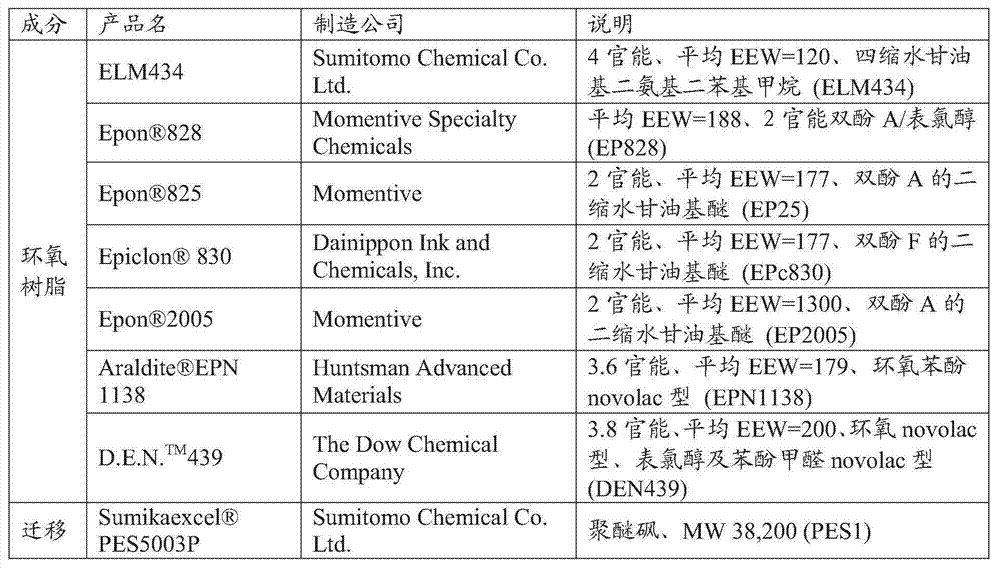

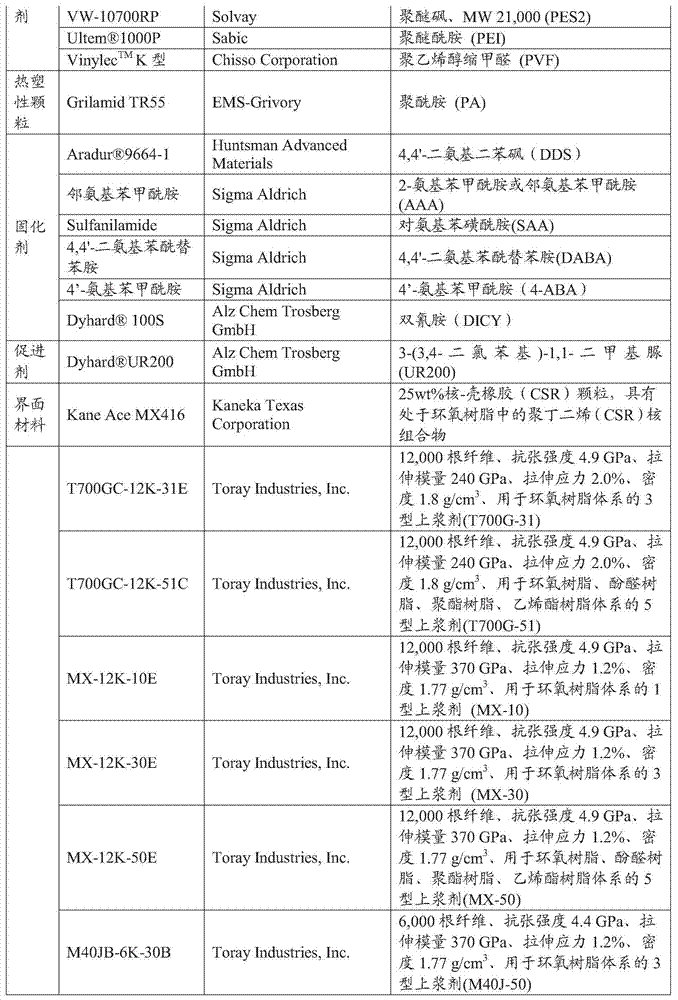

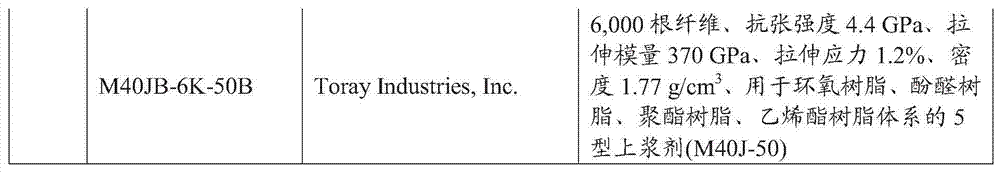

High modulus fiber reinforced polymer composite

A fiber reinforced polymer composition is provided comprising a fiber and an adhesive composition, wherein the adhesive composition comprises at least a thermosetting resin and a curing agent, the reinforcing fiber has a tensile modulus of at least 300 GPa and the cured adhesive has a resin modulus of at least 3.2 GPa, and the adhesive composition when cured makes good bonds to the reinforcing fiber. Additional embodiments include a prepreg comprising the fiber reinforced polymer composition and a method of manufacturing a composite article by curing the adhesive composition and a reinforcing fiber.

Owner:TORAY IND INC

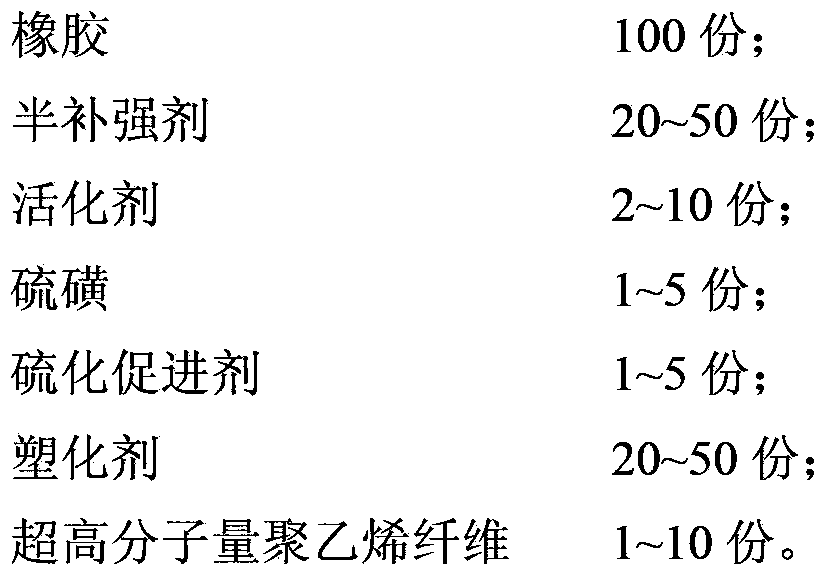

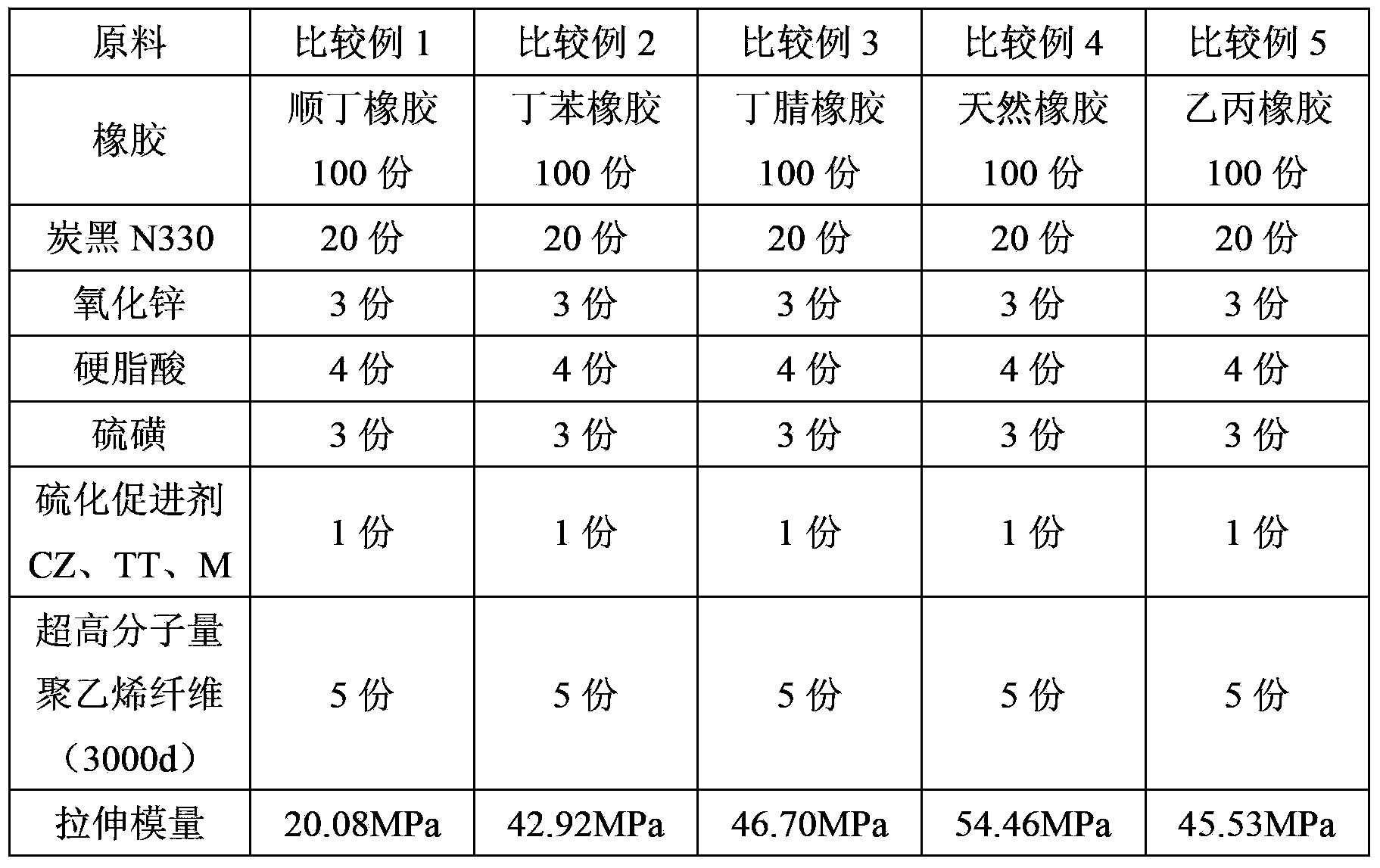

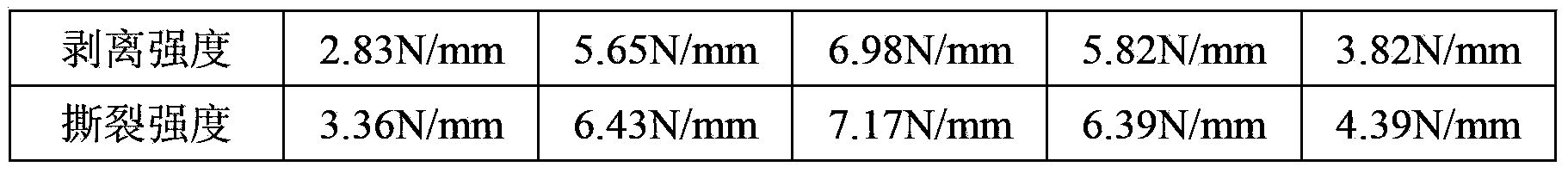

Ultrahigh molecular weight polyethylene fiber/rubber composite material and preparation method thereof

The invention relates to an ultrahigh molecular weight polyethylene fiber / rubber composite material and a preparation method thereof. The composite material comprises, by mass, 100 parts of rubber, 20-50 parts of a semi-reinforcing agent, 2-10 parts of an activator, 1-5 parts of sulfur, 1-5 parts of a vulcanization accelerator, 20-50 parts of a plasticizer , and 1-10 parts of an ultrahigh molecular weight polyethylene fiber. The preparation method comprises the steps of mixing above raw materials except the ultrahigh molecular weight polyethylene fiber in an open rubber mixing machine to obtain a semi-finished rubber product, and carrying out composite vulcanization on the semi-finished rubber product with the ultrahigh molecular weight polyethylene fiber. The composite material maintains the original mechanical properties of the rubber and the fiber, and the shear effect of the composite material improves the bonding performance of the fiber in the rubber, so the problem of difficult bonding of the fiber to the rubber due to the smooth surface of the fiber is solved; the composite material allows a matrix material to be directly firmly combined with the fiber, and is suitable for anti-aging low saturation rubber; and the preparation method has the advantages of simplicity, reduction of the raw materials and the consumption of energy in the process, cost saving, and suitableness for industrial mass production.

Owner:NINGBO UNIV

Process for producing a multilayer coating

ActiveCN104549944ASolving Adhesion ProblemsImprove adhesionPretreated surfacesPolyurea/polyurethane coatingsCross-linkPolyaspartic acid

The invention relates to a productive process for multilayer coating, in particular for multilayer repair coating of metal substrates, such as vehicle bodies and vehicle body parts. The process comprises the steps 1. pretreating the metal substrate to be coated with an acidic aqueous composition comprising a) phosphate ions and / or b) at least one water-soluble titanium and / or zirconium compound, and c) water; 2. optionally flashing off the pretreated metal substrate, 3. applying a surfacer layer of an organic-solvent based surfacer coating composition comprising A) at least one polyaspartic acid ester, B) at least one polyisocyanate cross-linking agent with free isocyanate groups, C) pigments and / or extenders, and D) at least one organic solvent; and 4. curing the surfacer layer. Subsequently a top coat layer of a top coat coating composition is applied.

Owner:AXALTA COATING SYST GMBH

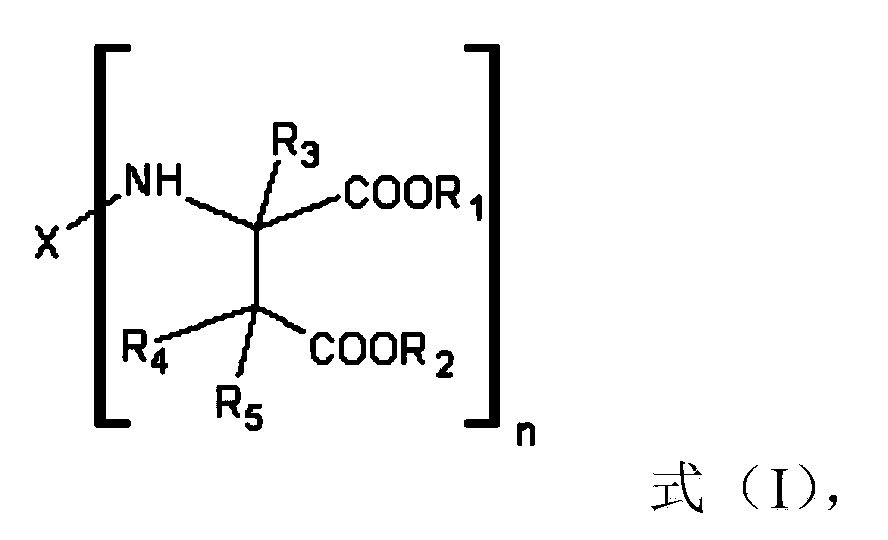

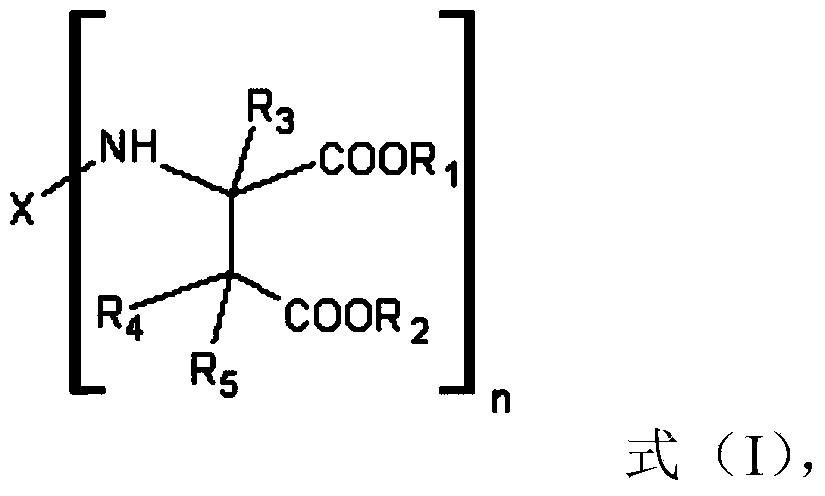

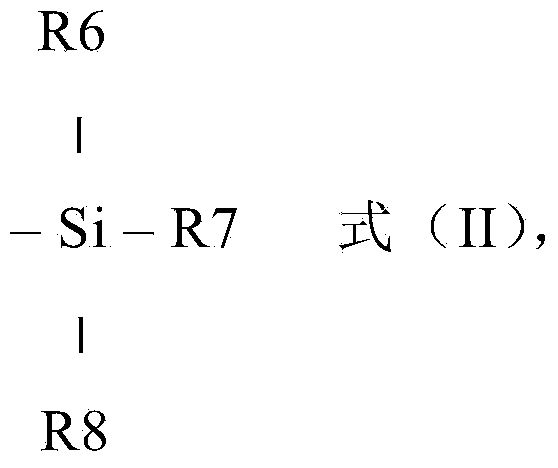

Preparation method of high-bonding waterborne polyurethane resin applied to PET film

InactiveCN105968313AImprove adhesionSolving Adhesion ProblemsPolyureas/polyurethane adhesivesInksPolyesterPropanoic acid

A preparation method of high-bonding waterborne polyurethane resin applied to a PET film comprises the steps of dissolving 30-45 mole parts of aliphatic isocyanate, 5-10 mole parts of polyester polyol, 5-15 mole parts of polyether polyhydric alcohols and 1-5 mole parts of fluorine-containing polyhydric alcohols into acetone and reacting at a temperature of 70-90 DEG C for 1.5-3h to obtain prepolymer; warming to a temperature of 70-75 DEG C, adding 1-5 mole parts of dimethylol propionic acid and 1-5 mole parts of ethylene glycol, carrying out chain extension for 0.5-1.0h, cooling to a room temperature, adding 2-5 mole parts of triethylamine in high-speed stirring, adding water to emulsify, reducing pressure and distilling to remove the acetone, thus obtaining the high-bonding waterborne polyurethane resin applied to the PET. A fluorine functional group is introduced into the waterborne polyurethane resin, so that the attachment of the waterborne polyurethane resin and that of the PET film are improved. When being applied to the surface of the PET film material, the high-bonding waterborne polyurethane resin has the advantages of being free of toxicity, good in film forming property, high in bonding force, high in attachment and the like; furthermore, the high-bonding waterborne polyurethane resin successfully solves the problem of difficulty in realizing bonding attachment of waterborne polyurethane ink and waterborne polyurethane glue on the PET film.

Owner:ANHUI SINOGRACE CHEM

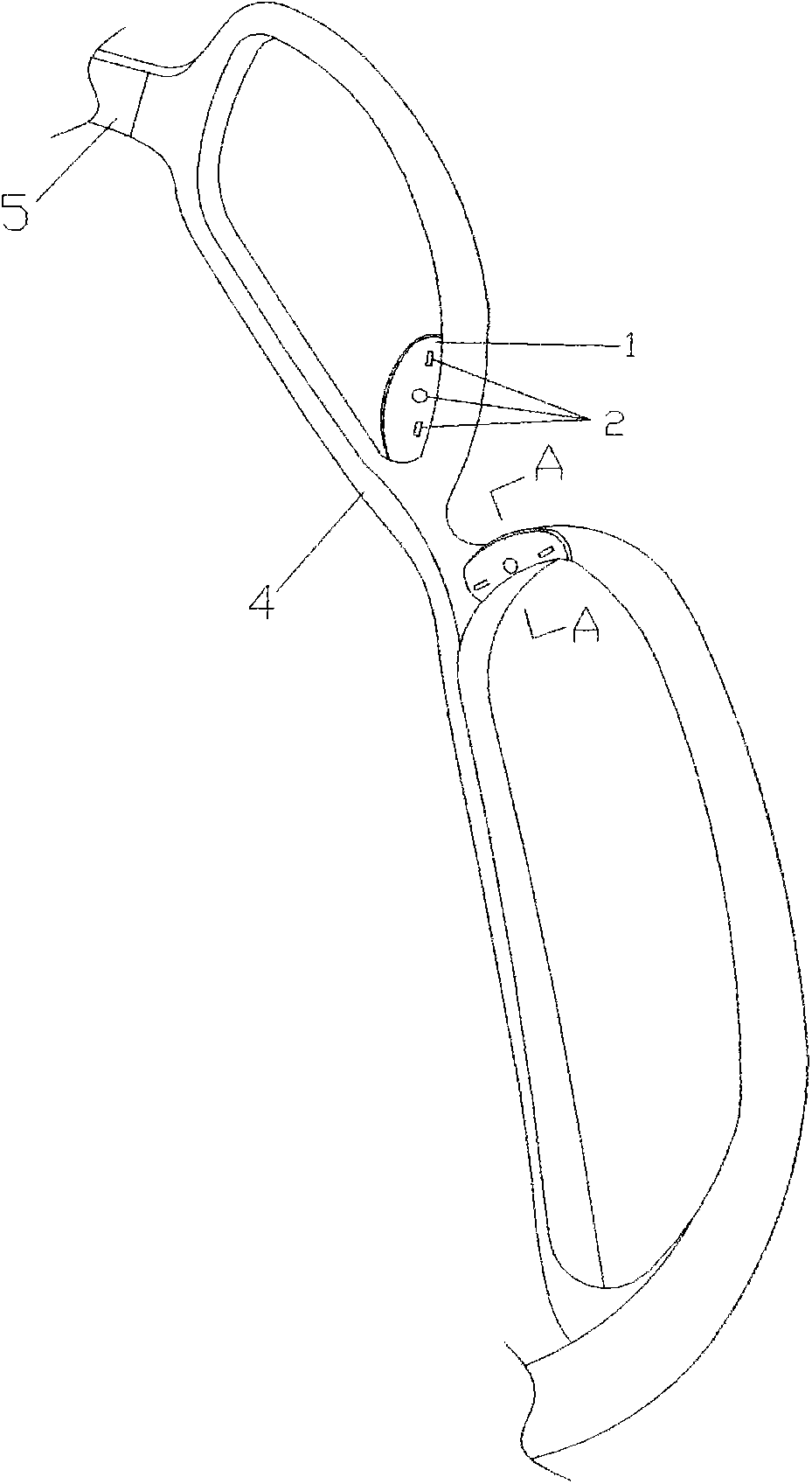

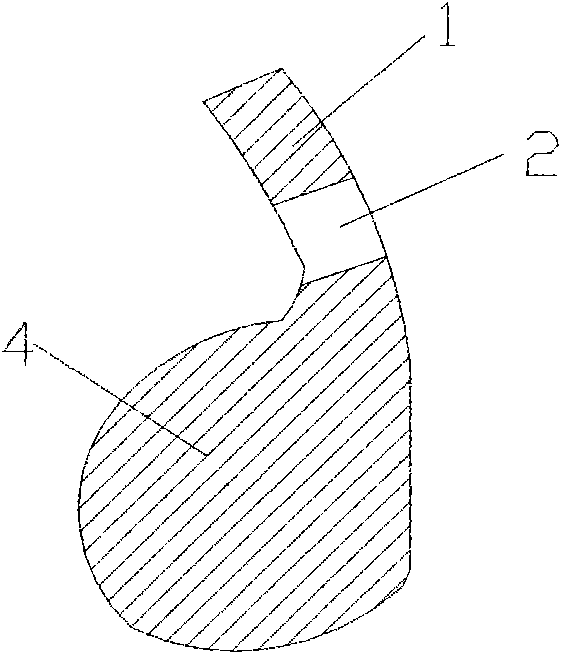

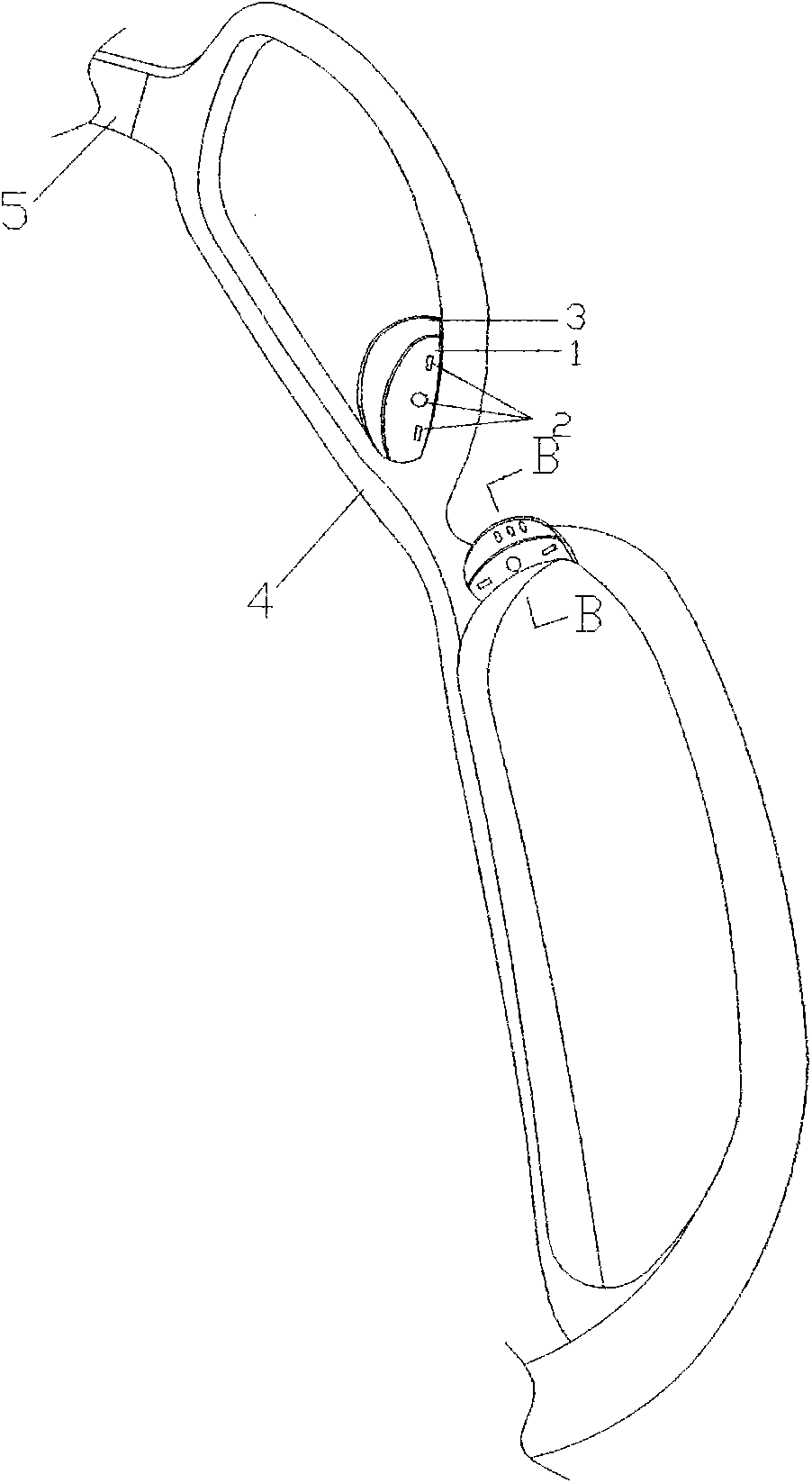

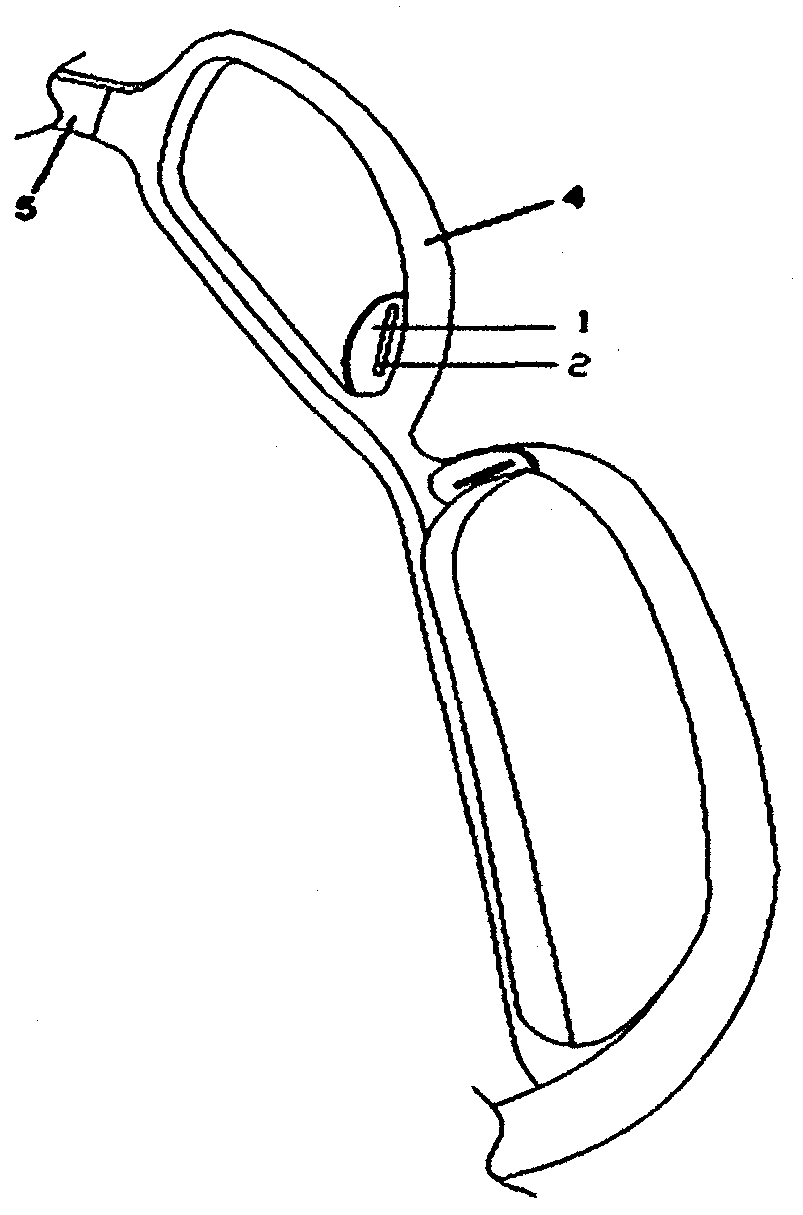

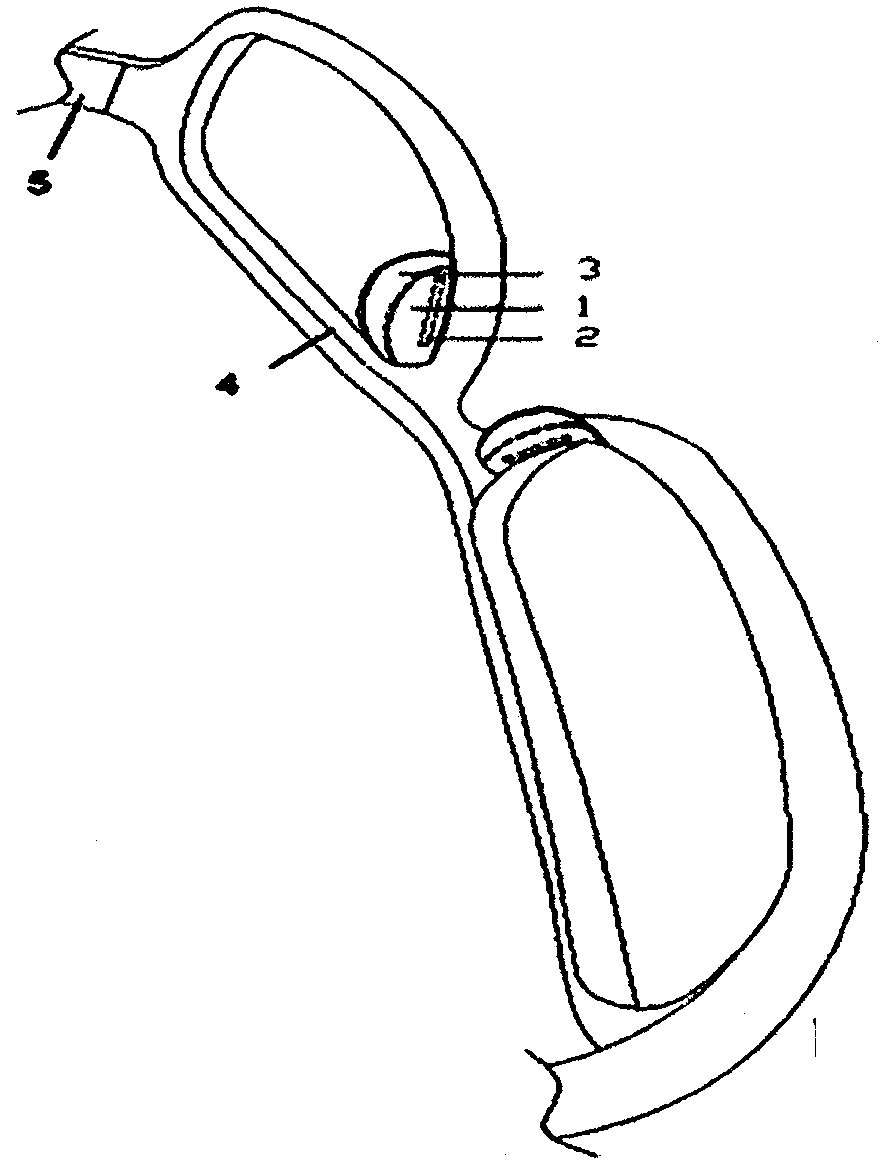

Production method of secondary ejection nose pad spectacles and structure thereof

The invention discloses a production method of secondary ejection nose pad spectacles and a structure thereof, and discloses a production technological method of spectacles with nose pads and a spectacle structure manufactured by utilizing the technological method. The production method comprises the following steps: 1) carrying out primary injection of spectacle framework with nose pad fixing lugs on spectacle framework raw materials under high-temperature liquid state in a spectacle framework mold, cooling, molding and finishing; 2) putting the nose pad fixing lugs of the molded spectacle framework at corresponding parts of nose pad molds, carrying out secondary injection, injecting the nose pad raw materials at high-temperature liquid state into the nose pad molds, injecting the nose pad raw materials onto the lugs of the spectacle framework, cooling, fixing and molding so as to form nose pads fixed on the lugs; 3) injecting spectacle legs into spectacle leg molds, cooling, molding and demolding; 4) assembling the spectacle frame with the spectacle legs to form a finished product. The invention also discloses a spectacle structure manufactured by the method. According to the invention, secondary injection is adopted, so that the nose pads and the spectacle framework form a favorable fixing effect; moreover, the manual cost is reduced; the efficiency is improved.

Owner:王宏晶

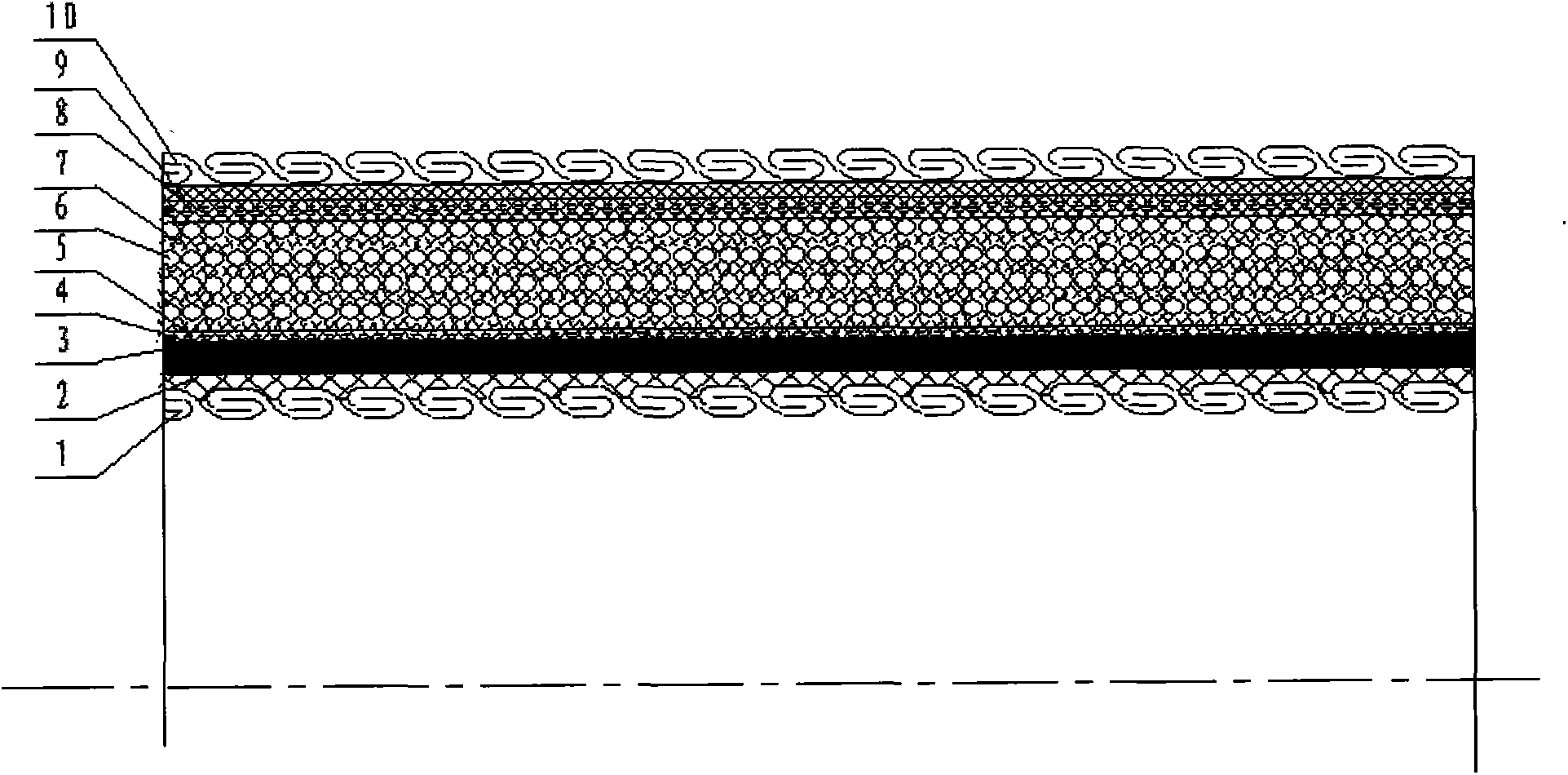

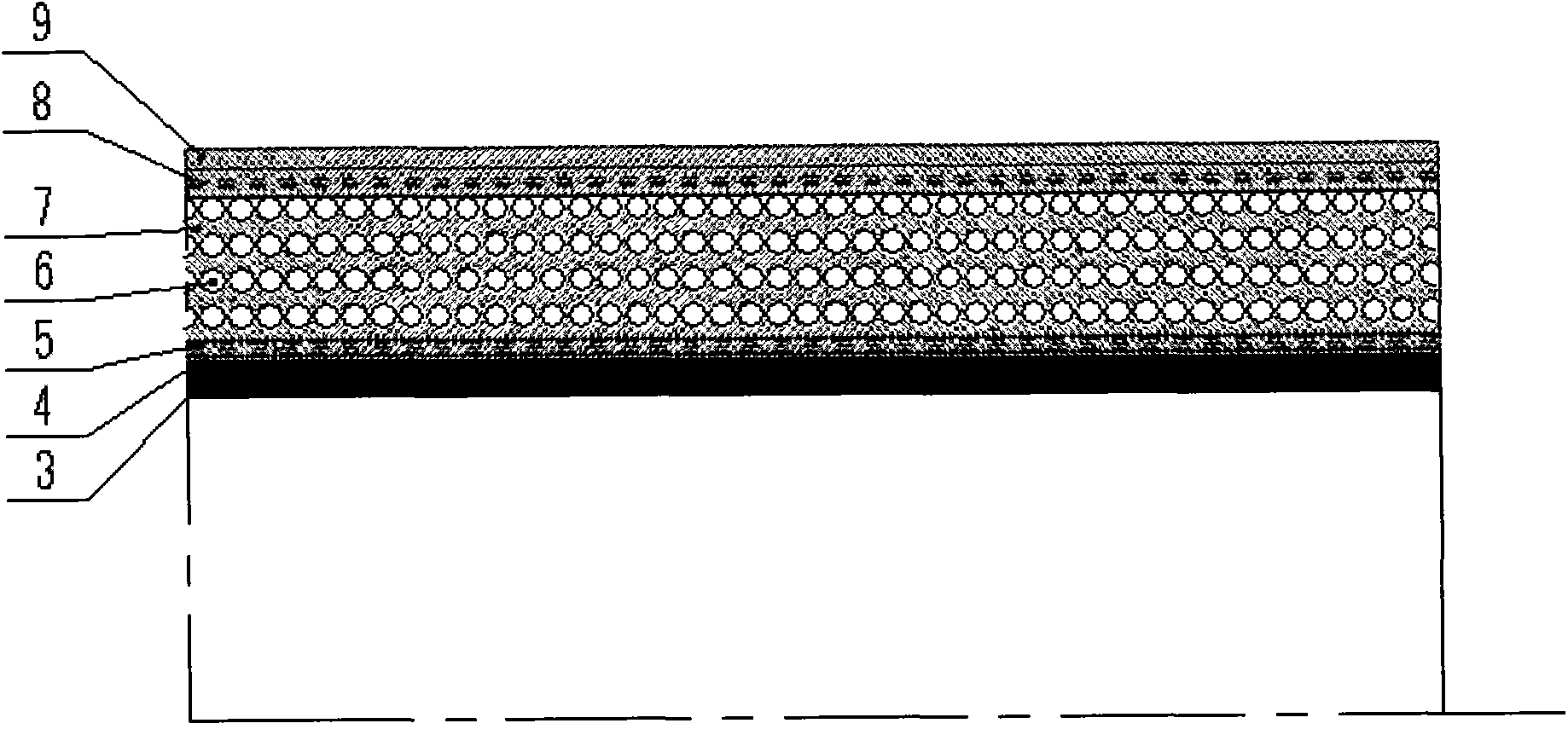

High-pressure flexible rubber hose and joint connecting method thereof

ActiveCN103398241ASolving Adhesion ProblemsNo creep phenomenonFlexible pipesThermoplasticPolymer science

The invention provides a high-pressure flexible rubber hose and a joint connecting method of the high-pressure flexible rubber hose. The high-pressure flexible rubber hose comprises an inner hemihedral-crystal-shaped thermoplastic plastic lining, an inner adhesive tape layer, a steel wire rope reinforcing layer, a middle bonding buffering glue layer, a heat insulating layer and a fire-proof inflaming retarding layer from inside to outside. When connection is carried out, the end portion of the high-pressure flexible rubber hose is inserted into a connection and sealing area of a joint and completely connected with a sealing part, resin having the cross linking function and a metal joint into a whole. The high-pressure flexible rubber hose has the excellent flexibility, the high-pressure resistance, the gas permeability resistance and the high-temperature resistance in use.

Owner:山东悦龙橡塑科技有限公司

Production technology of instant cap cord fabric strip

The invention relates to a production technology of an instant cap cord fabric strip applied to a tire cap ply. The production technology comprises the steps as follows: 1) yarn twisting: high-strength nylon 66 industrial yarn is twisted firstly and twisted yarn is prepared; 2) plying twisting: the twisted yarn is subjected to plying twisting and cords are prepared; 3) weaving: the cords subjectedto plying twisting are woven and fabric edges are subjected to edge locking treatment; 4) impregnation: cord fabric is subjected to special glue impregnation and special glue absorption treatment, and after impregnation, drying, drawing and setting treatment are performed, passive rolling and packaging are performed; 5) width separation; 6) strip separation and packaging. The instant cap cord fabric strip can be directly applied to tire forming and replace a calendered rubber cord fabric cap strip, multiple tire manufacturing processes are omitted, the consumption of tire cap ply rubber is reduced, and the production cost and the raw material cost of a tire plant can be substantially reduced.

Owner:青岛康威化纤有限公司

Production method for glasses with secondary-injected nose support and structure of glasses

The invention relates to a production method for glasses with a secondary-injected nose support and a structure of the glasses and discloses a production technical method for the glasses with the nose support and a glasses structure manufactured by the technical method. The method comprises the following steps of (1) performing disposable injection on a glasses framework raw material in a glasses framework mold at the temperature of 150-220 DEG C to form a glasses framework with a nose support fixing convex block, and cooled-molding and shaping the glasses framework; (2) arranging the nose support fixing convex block of the molded glasses framework at a position corresponding to a nose support mold, performing secondary injection on a nose support raw material at the temperature of 150-220 DEG C to form a nose support, injecting the nose support on the convex block of the glasses framework, and performing cooled and fixed molding on the nose support; (3) injecting glasses legs on the glasses leg mold, and cooled-molding and demolding the glasses legs; and (4) assembling the glasses framework and the glasses legs to form a finished product. By adopting secondary injection, the nose support and the glasses framework achieve an extremely good fixing effect; furthermore, the labor cost is saved, and the efficiency is improved.

Owner:王宏晶

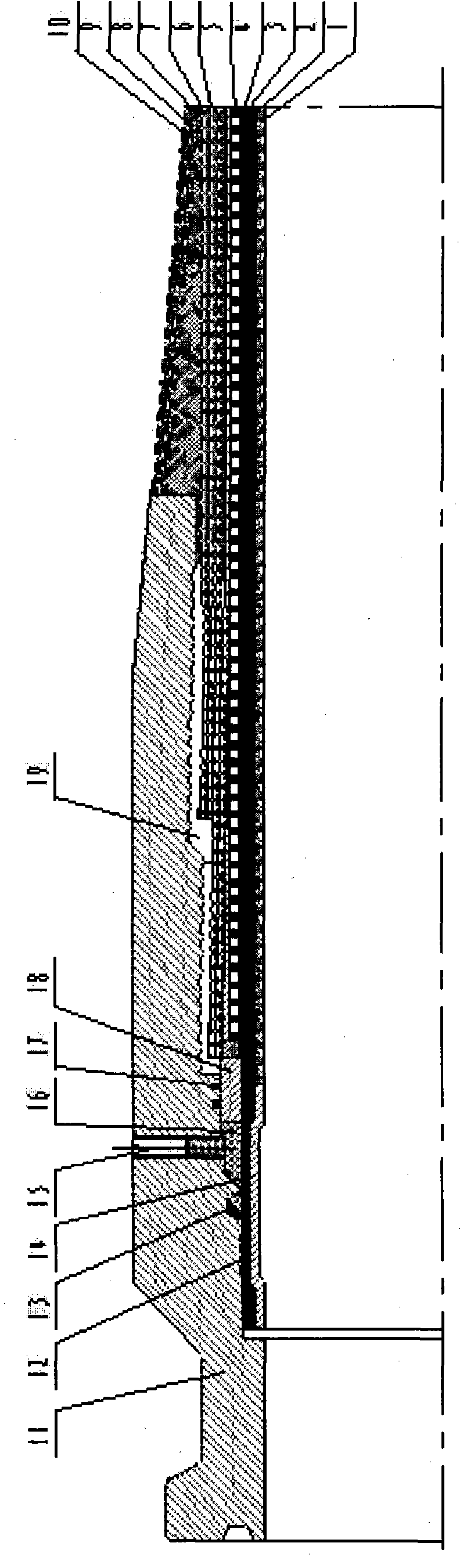

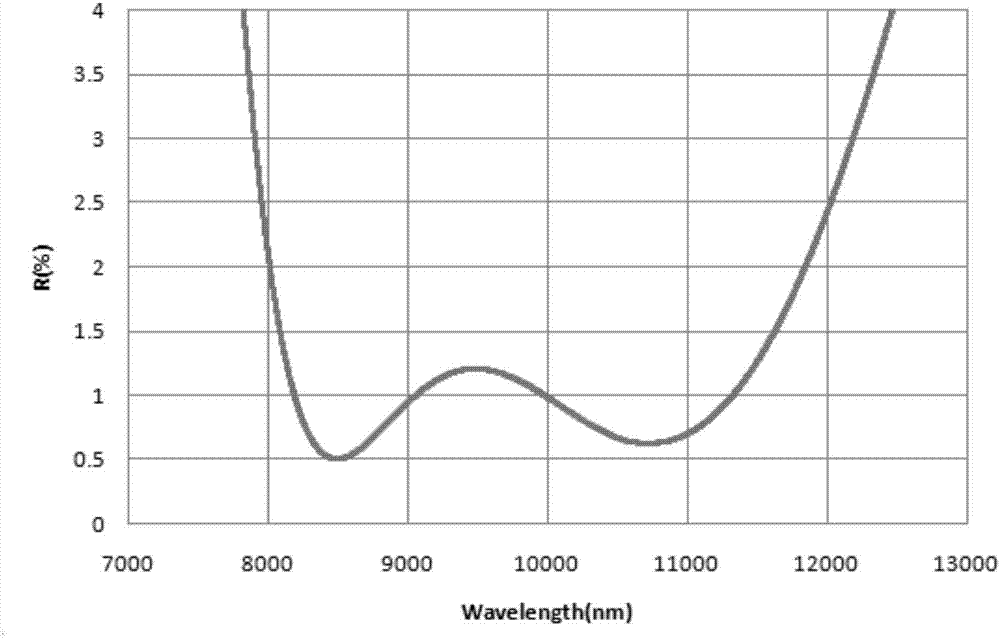

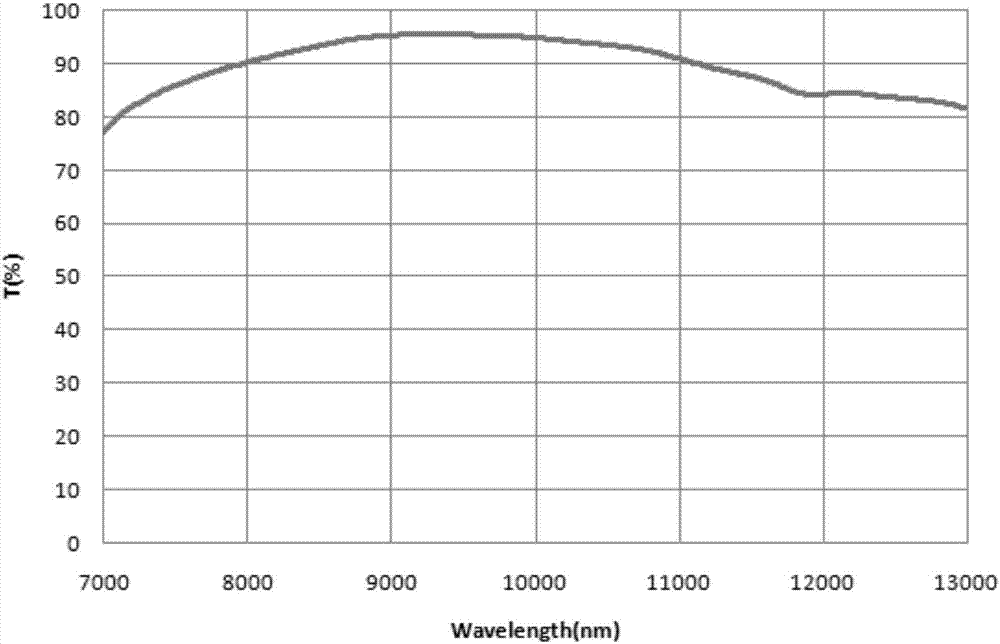

Anti-reflection DLC film with sulfur-series infrared glass as substrate and preparation method of anti-reflection DLC film

ActiveCN107227460AScratch resistantSolving Adhesion ProblemsVacuum evaporation coatingSputtering coatingSulfurOptoelectronics

The invention discloses an anti-reflection DLC film with sulfur-series infrared glass as the substrate and a preparation method of the anti-reflection DLC film. The anti-reflection DLC film with the sulfur-series infrared glass as the substrate comprises a sulfur-series infrared glass substrate layer, a DLC film layer and bonding layers arranged between the sulfur-series infrared glass substrate layer and the DLC film layer, and the bonding layers comprise alternating ZnSe layers and Ge layers, and 2-5 layers of the ZnSe layers are arranged. The anti-reflection DLC film with the sulfur-series infrared glass as the substrate has an excellent anti-reflection effect, temperature resistance, mechanical strength and adhesive force and is simple in preparation and easy to operate.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD +1

Grid plate preparation method

InactiveCN101875104ASolving Adhesion ProblemsRapid coolingElectrode carriers/collectorsFoundry mouldsAlloyPlate method

The invention relates to the field of storage batteries, in particular to a grid plate preparation method. The method is implemented by a technical scheme that the grid plate method comprises the following steps in turn: (1) preparing a molten lead-based alloy; (2) pouring the molten lead-based alloy obtained by the step (1) into a mould cavity of a nickel-based alloy grid plate mould; (3) cooling the mould by using gasified water; and (4) removing the mould. The method is mainly used for preparing grid plates of storage batteries.

Owner:长兴诺力电源有限公司

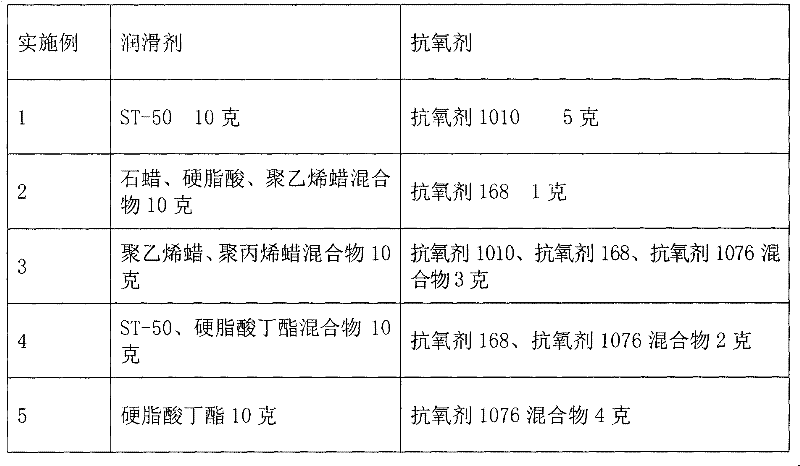

Hot melt adhesive for steel plastic composite pipeline and production method of hot melt adhesive

InactiveCN102399519ASolving Adhesion ProblemsRing flexibility qualifiedNon-macromolecular adhesive additivesMaleic anhydrideSolvent

The invention relates to a hot melt adhesive for a steel plastic composite pipeline and a production method of the hot melt adhesive. The hot melt adhesive comprises the following raw materials in percentage by weight: 95 to 98 percent of high-density polyethylene, 0.9 to 2.0 percent of maleic anhydride, 0.02 to 0.2 percent of peroxide, 0.09 to 0.5 percent of antioxidant and 0.9 to 4.0 percent of solvent. The production method comprises the following steps of: adding the high-density polyethylene and the antioxidant into a mixing machine; controlling the temperature of a stirring machine to be between 35 and 40 DEG C and stirring for 2 to 7 minutes; and granulating by using an intermediate-speed cutting combined double-screw extrusion granulator, wherein the extruding temperature is between 170 and 180 DEG C and the temperature of a machine head is between 190 and 200 DEG C. The hot melt adhesive is used for solving the bonding problem between a steel belt and plastic during production of the steel plastic composite pipeline. Based on detection required indexes according to the industrial standard CJ / T225-2006, the peeling strength meets the standard; the ring flexibility is qualified; and the product is qualified after passing a sunlight insolation test. All the indexes meet the industrial standard.

Owner:SHANDONG DONGHONG PIPE IND

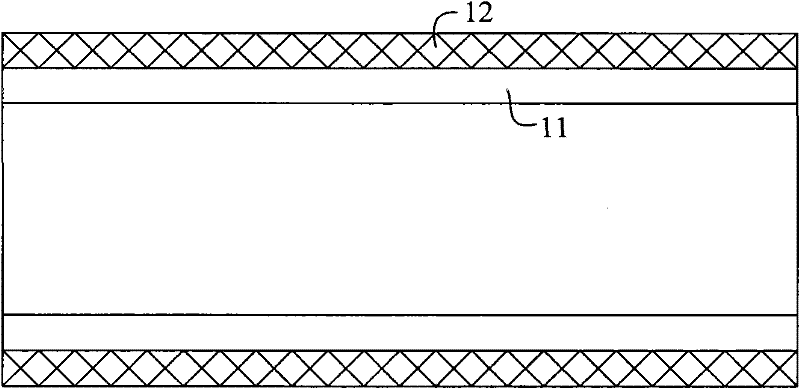

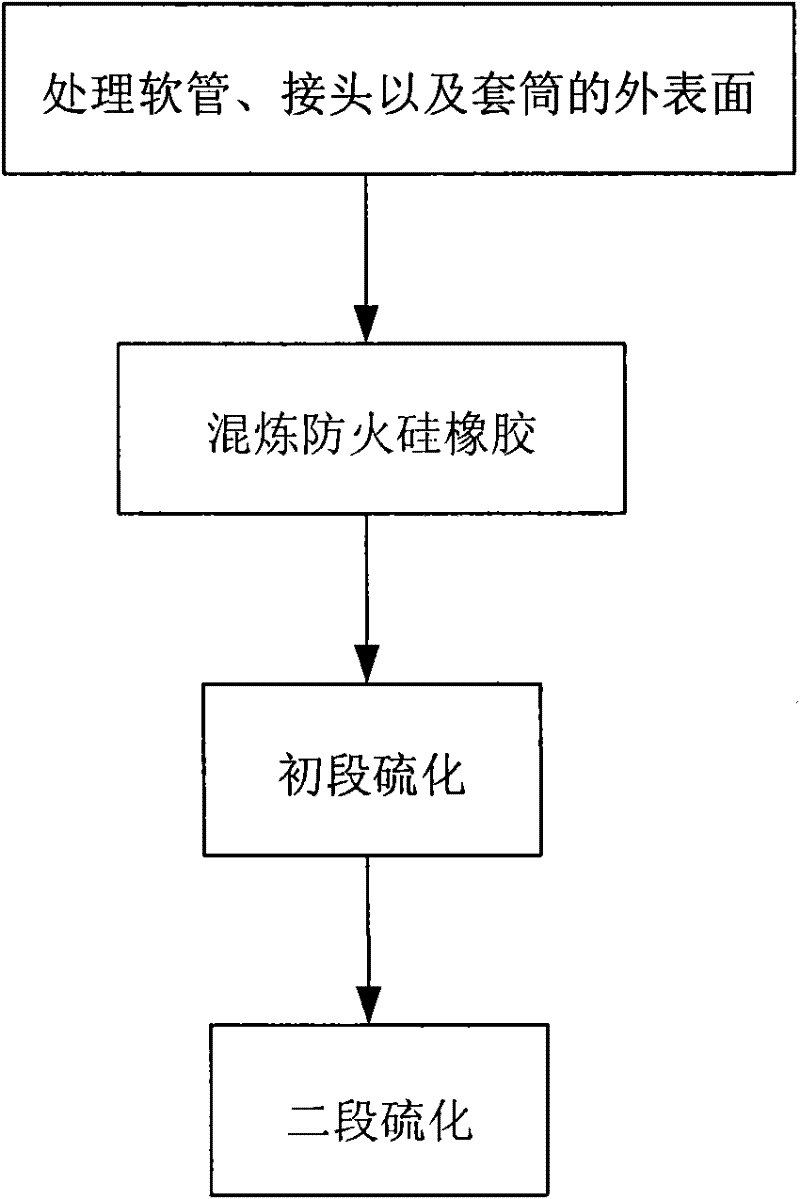

Manufacturing method of fireproof conveying pipe

ActiveCN102221116APerformance is not affectedSolving Adhesion ProblemsFlexible pipesVulcanizationThermal compression

The invention discloses a manufacturing method of a fireproof conveying pipe, comprising the steps of: cleaning the outer surfaces of a metal-woven plastic hose, a joint and a sleeve; coating first coats on the outer surfaces of the metal-woven plastic hose, the joint and the sleeve; coating a sealing agent on the surfaces of the first coats after the first coats are volatized; mixing fireproof silicon rubber; thermally pressing the fireproof silicon rubber into the centre place of the outer surface of the metal-woven plastic hose in a vulcanizing machine by using a die; installing the joint and the sleeve onto the metal-woven plastic hose; thermally pressing the fireproof silicon rubber onto the outer surface of the sleeve in the vulcanizing machine by using a die; and performing the two-stage vulcanization in a drying box. According to the manufacturing method of the fireproof conveying pipe, the fireproof material and the metal-woven plastic hose, the fireproof material and the stainless steel, and the fireproof material and the fireproof material can be well bonded, so the fireproof performance is good.

Owner:上海新艺塑料厂有限公司

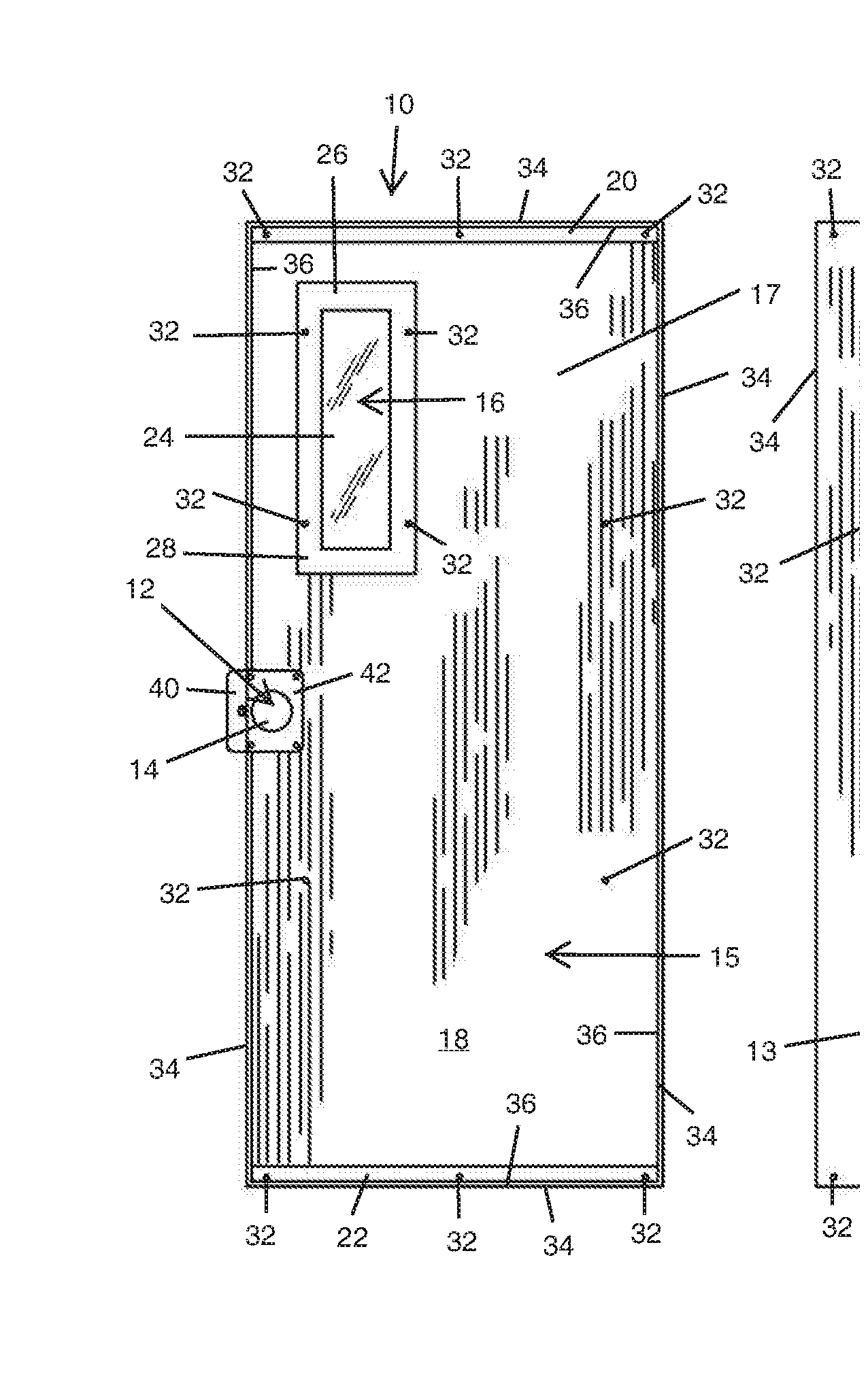

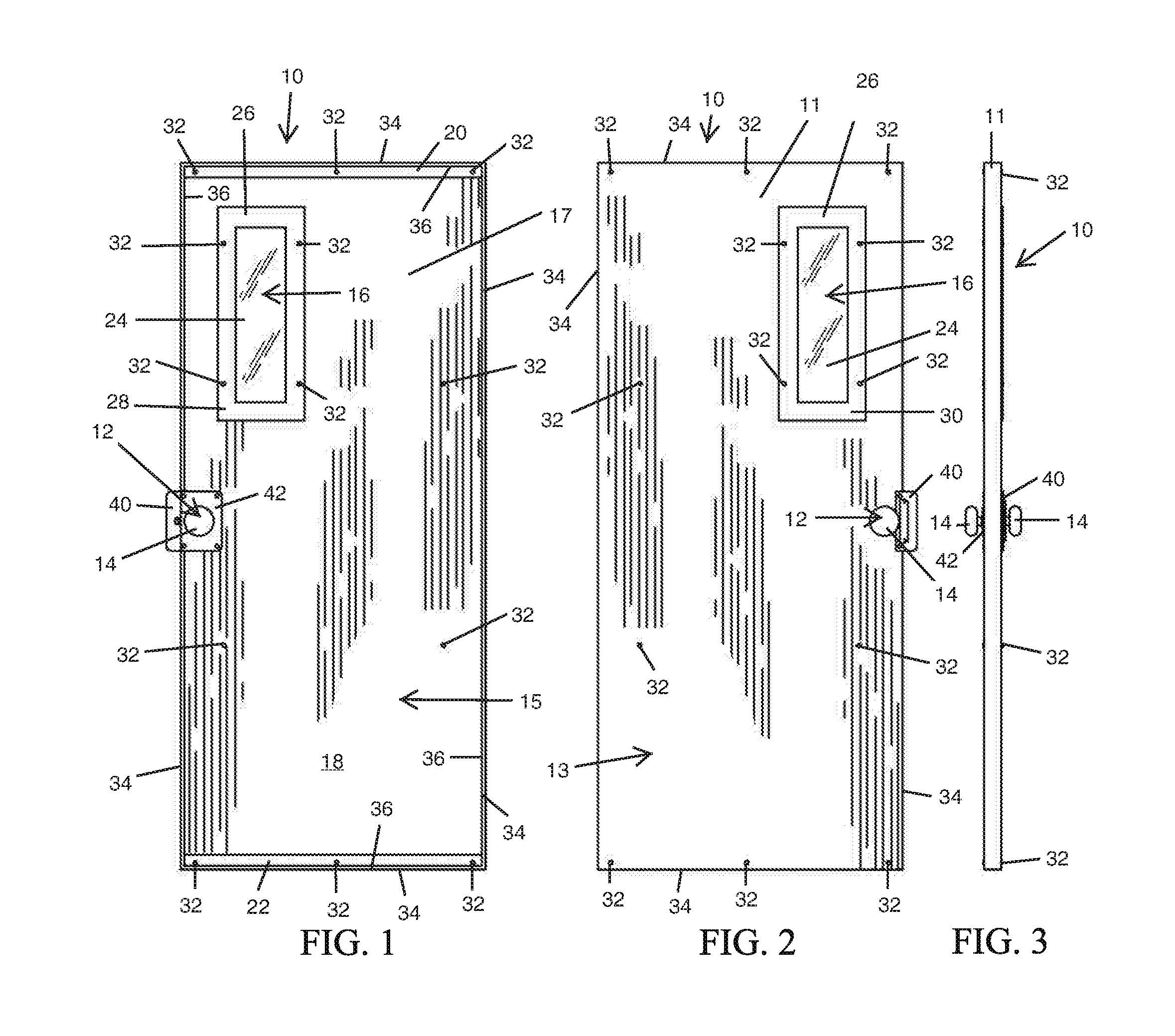

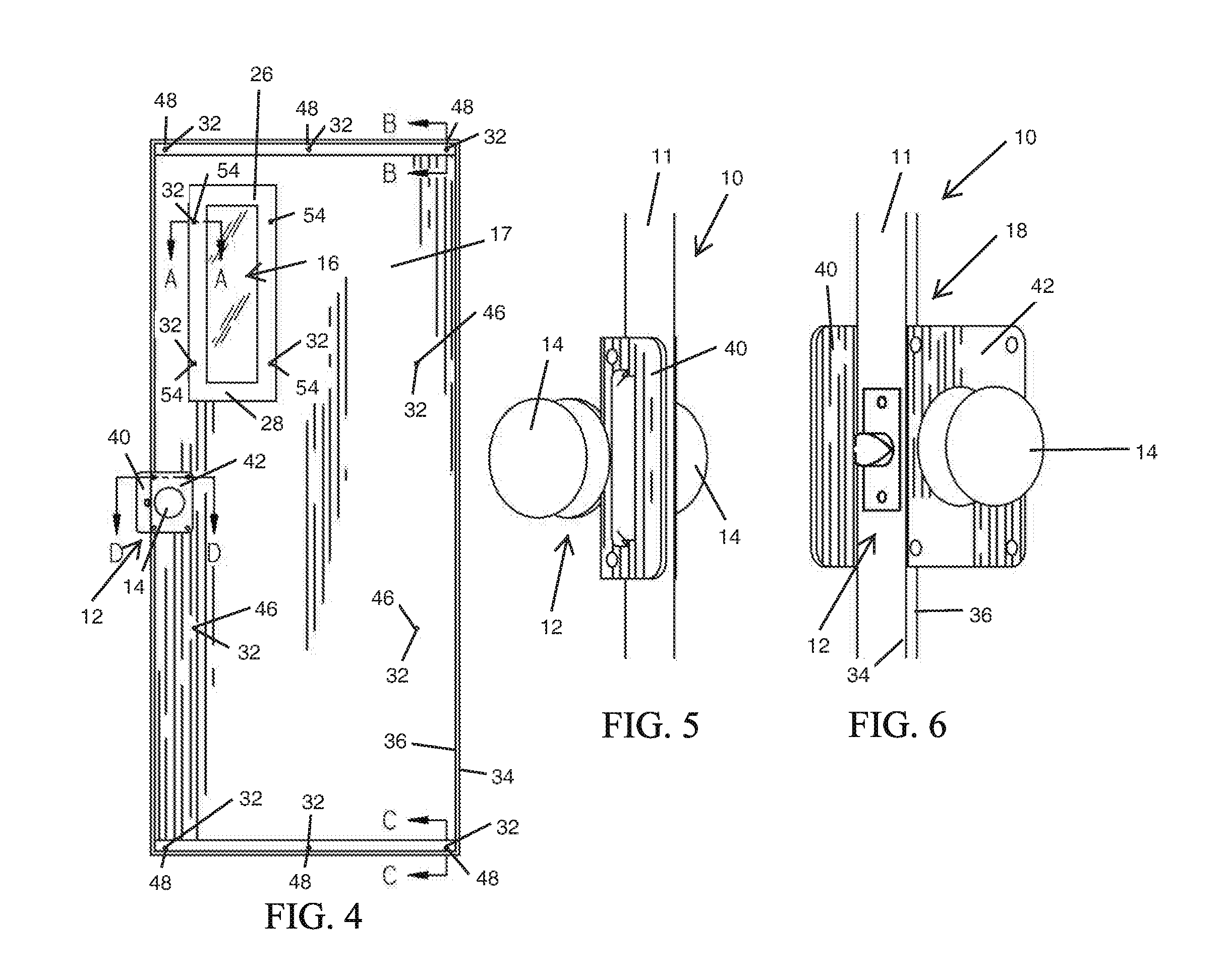

Classroom retrofit barriers

A ballistic door providing barrier-of-entry shielding blocks a doorway in certain emergency situations to shield against active shooters, while not inhibiting, impeding, or changing the safe egress through the ballistic door. A ballistic assembly may be secured to the non-threat side of an existing door, by retrofit installation or by new construction installation. The ballistic assembly has a ballistic skin, a top ballistic skin clamp, and a bottom ballistic skin clamp. The top and bottom ballistic skin clamps secure the ballistic skin against the non-threat side of the door. The ballistic door has at least a N.I.J. Level IIIA of protection against gunfire.

Owner:DAW TECH

Hot melt acrylate dot-shaped reflection marked line and preparation method thereof

ActiveCN108384405AWon't fall offImprove adhesionPolyurea/polyurethane coatingsTraffic signalsBenzoyl peroxideAcrylic resin

The invention discloses an acrylate hot melt dot-shaped reflection marked line. The acrylate hot melt dot-shaped reflection marked line comprises free radical polymerization type thermosetting base gel and acrylate type hot melt reflection marked line coating, wherein the free radical polymerization type thermosetting base gel is prepared from activated resin, an activated monomer, an adhesion promoter, N,N-dimethyl-p-toluidine and benzoyl peroxide paste; the acrylate type hot melt reflection marked line coating is prepared from solid acrylic resin, polyterpene phenolic resin, a plasticizer, polyamide wax, a pigment, a reflection material, heavy calcium carbonate, quartz sand and a rheological control agent. By adopting the hot melt acrylate dot-shaped reflection marked line with the structure and the preparation method thereof, the binding power on different road surfaces, especially old road surfaces and cement road surfaces, can be improved.

Owner:保定市科顺达交通设施有限公司

Submerged arc bead welding technique

InactiveCN101549424AReduce manufacturing costImprove product production qualityArc welding apparatusFurnace typesSubmerged arc weldingBonding problems

The invention discloses a submerged arc bead welding technique which comprises the following steps: the outer surface of the bead welding body is machined to be a certain smaller thickness, a fatigue layer, defects or cracks on the bead welding body surface are removed, and the bead welding body is pre-heated, when the temperature reaches about 250 DEG C, NH-69S is used as the welding material, the bead welding body is rolled-position welded under certain conditions of welding parameters, the welded bead welding body is cooled down to 100 DEG C and kept for a certain period of time, and continue to cool down below 50 DEG C, after that the cooling rate is not controlled, the gained bead welding body is processed for tempering, and finally the bead welding body after tempering is slowly cooled down with the furnace. The submerged arc bead welding technique has the advantages that the bonding problem between the steel coil and the cradle roll is solved by using the bead welding technique, the production costs are saved, and the production quality of the product is improved.

Owner:CHANGZHOU JINAN METALLURGICAL EQUIP

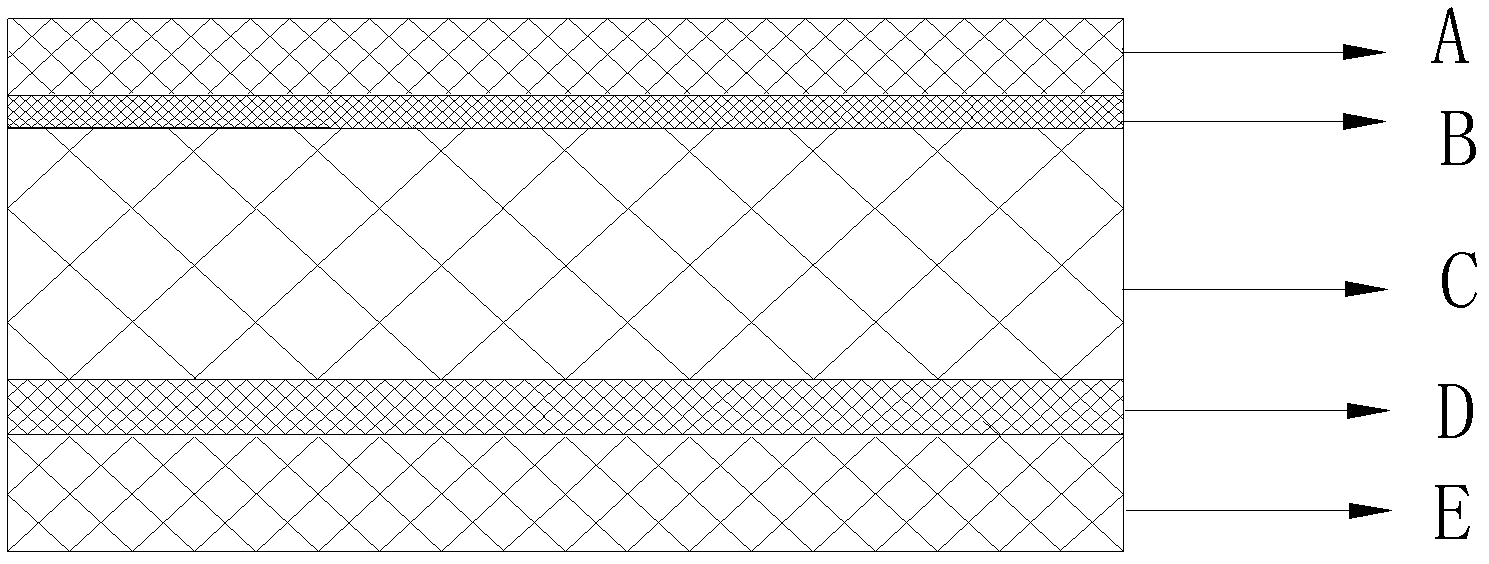

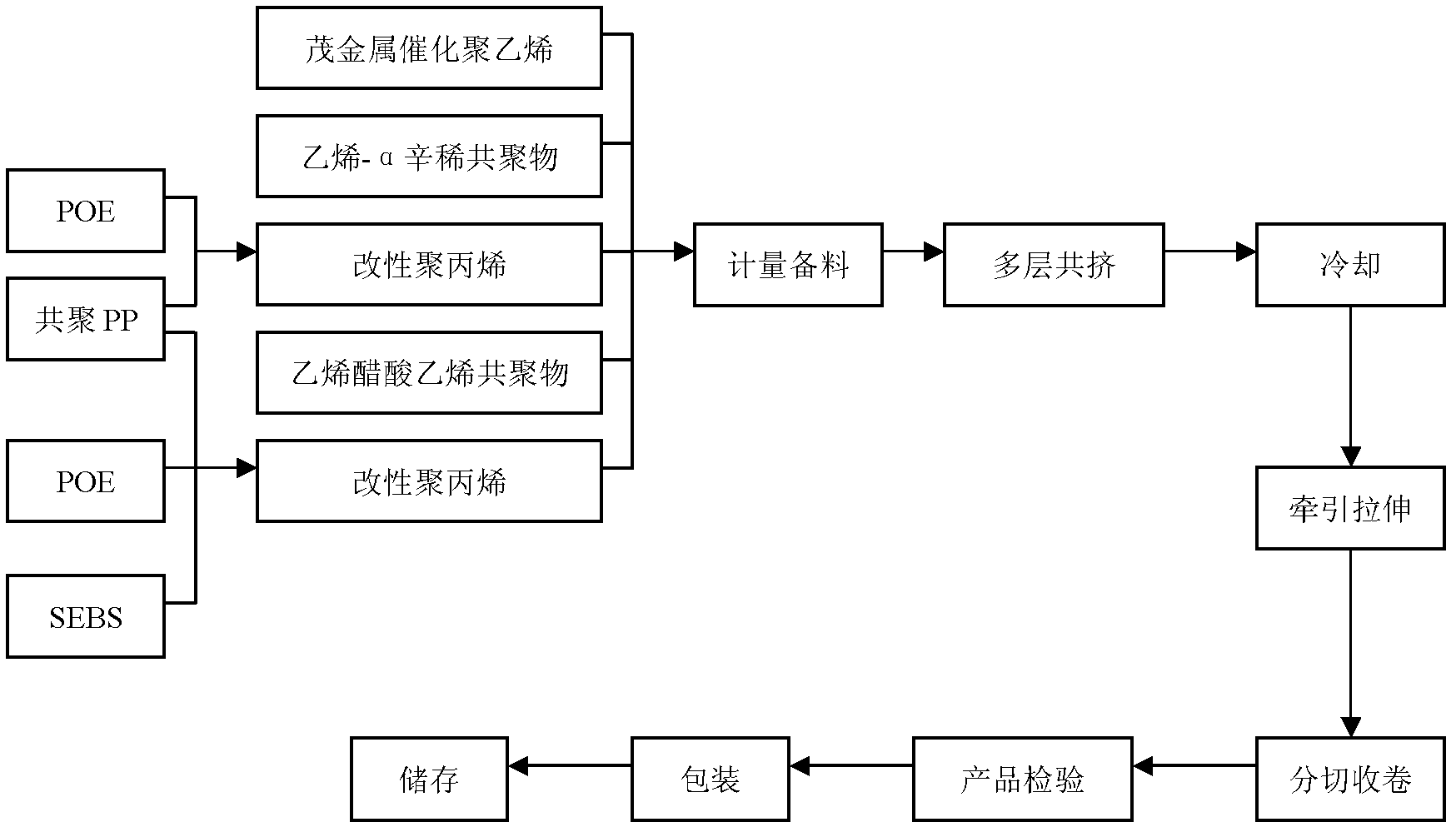

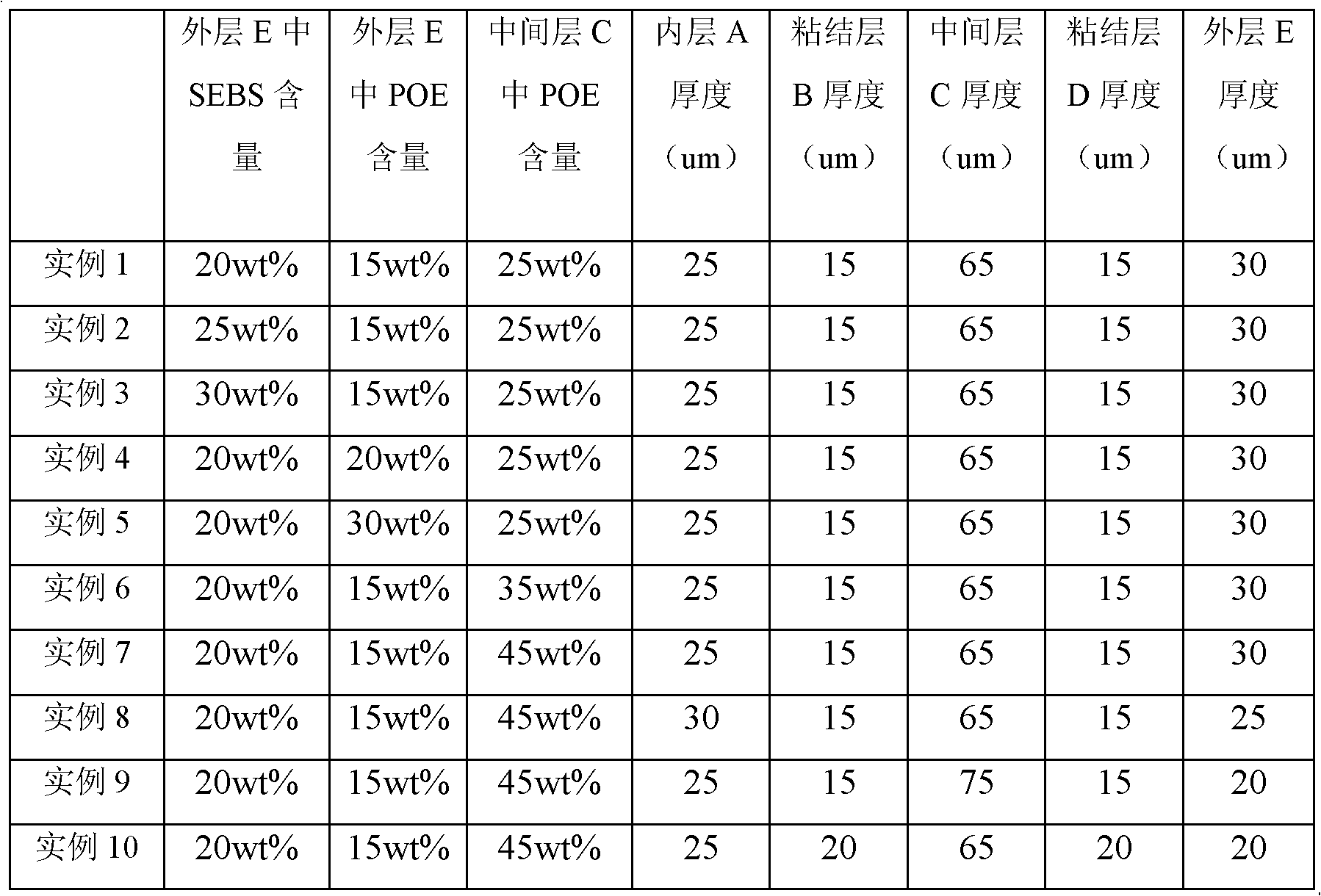

Novel multilayer co-extrusion medical transfusion film and preparation method thereof

ActiveCN102602094AGood flexibilitySelf-shrinkingSynthetic resin layered productsWeather resistanceMedicine

The invention relates to a novel multilayer co-extrusion medical transfusion film and a preparation method of the novel co-extrusion medical transfusion film. The materials of the novel multilayer co-extrusion medical transfusion film are divided into five layers in composition, wherein the first layer is an internal layer A and the ingredient of the internal A is polypropylene catalyzed by metallocene; the second layer is a bonding layer B and the ingredient of the bonding layer B is an ethylene-vinyl acetate copolymer; the third layer is a core layer C and the ingredient of the core layer C is mixed resin composed by random copolymerization polypropylene and an ethylene-alpha-octylene copolymer; the fourth layer is a bonding layer D and the ingredient of the bonding layer D is an ethylene-alpha-octylene copolymer; and the fifth layer is a weather-resistant layer E and the ingredient of the weather-resistant layer E is mixed resin composed by a random copolymerization polypropylene material, a styrene-ethylene-bivinyl rubber-styrene copolymer, and an ethylene-alpha-octylene copolymer. A multilayer co-extrusion technology is adopted in the preparation. The multilayer co-extrusion medical transfusion film provided by the invention has the advantages of high transparency, good weather-resistance and flexibility, wear resistance and the like, and is particularly appropriate for use as a packaging material in the field of medicine.

Owner:CHANGZHOU UNIV

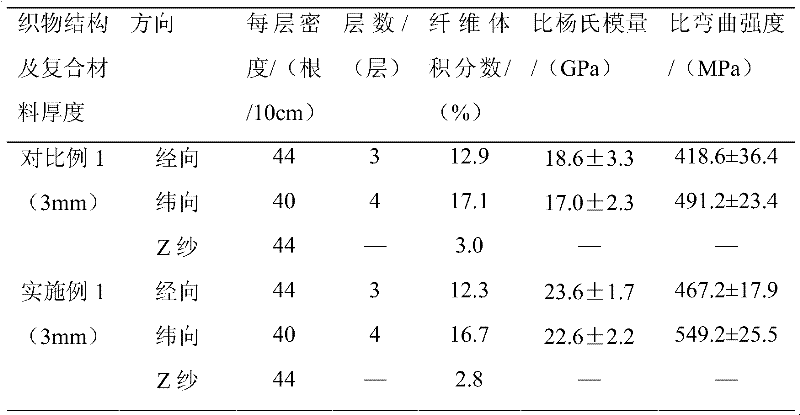

Preparation method of spun yarn fabric for enhancing thermoplastic resin

The invention relates to a preparation method of a spun yarn fabric for enhancing a thermoplastic resin. The preparation method comprises the following steps: a thermoplastic resin emulsion with the weight of 1-8% of the weight of the spun yarn fabric is adopted to dip the fabric, and the dipped fabric is taken out, is subjected to superfluous emulsion removal and is dried to obtain the resin-infiltrated spun yarn fabric. The preparation method which has the advantages of convenient operation, low cost and no presence of organic solvents in the whole process is an environmentally friendly processing technology; resins with any vitrification points, even thermal crosslinking resins can be prepared through the emulsion polymerization, so yarns have various viscoelasticities, thereby the absence of the organic solvents is endowed in the preparation process of composite materials with various excellent performances; and a problem that molten resins are difficult to infiltrate the spun yarn is solved, so fibers of the yarn can be bonded, thereby the preparation method, which allows mechanical performances of the composite materials to be obviously improved when the preparation method is applied to the composite materials, has a good application prospect.

Owner:DONGHUA UNIV

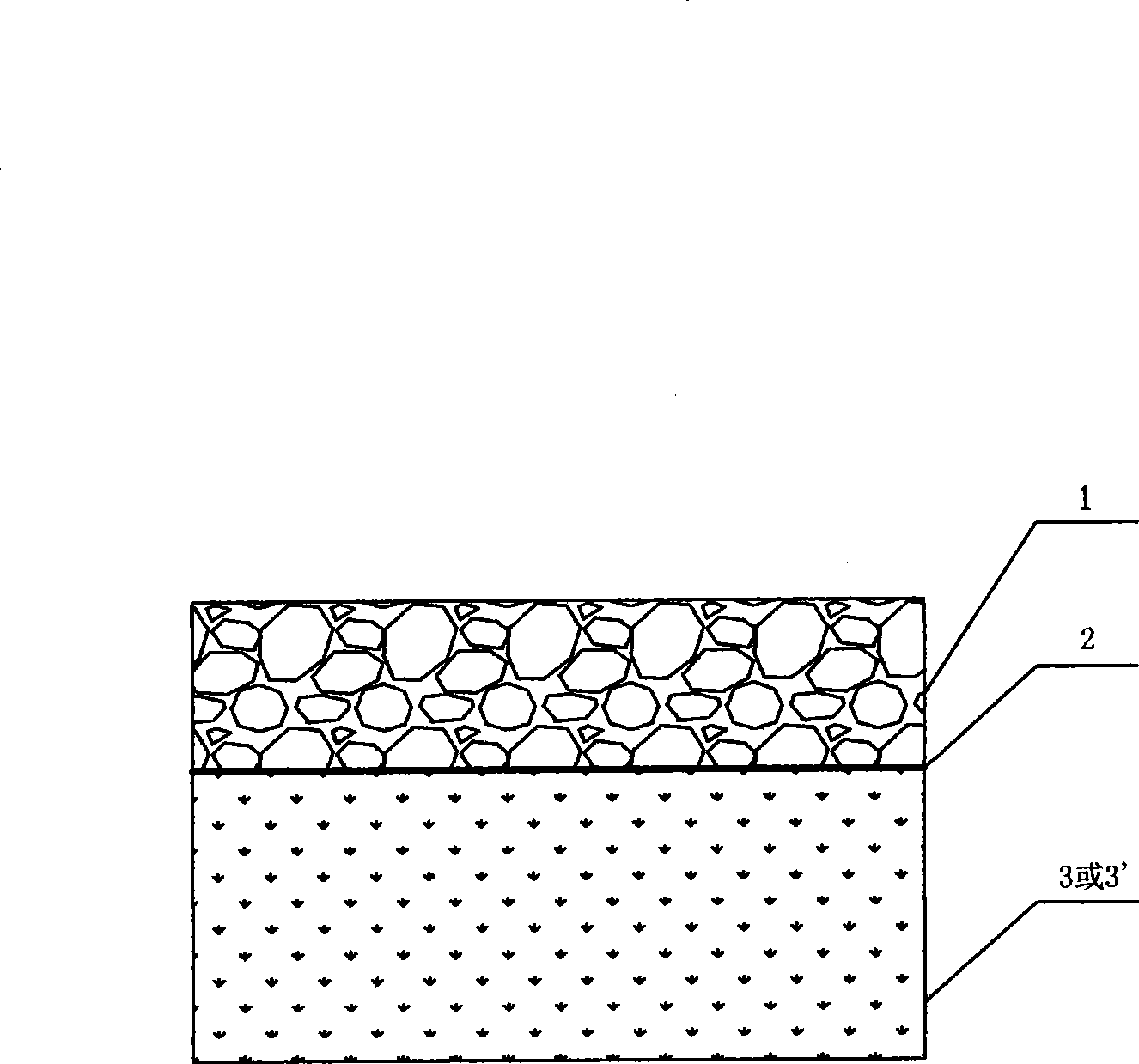

Translucent natural marble composite board and method for producing the same

InactiveCN101397839AEasy to manufactureGood optical performanceLamination ancillary operationsCovering/liningsWeather resistanceComposite plate

The invention discloses a light-previous natural marble composite board and a producing method thereof, wherein, a light-previous natural marble board 1 is laminated with an inorganic glass board 3 or an organic glass board 3'; an epoxy adhesive 2 is coated on the laminating interfaces respectively; and the thickness of the marble board 1 is about 1.5mm to 10mm; the thickness of the inorganic glass board 3 or the organic glass board 3' ranges from 8mm to 25mm. The laminated composite board is maintained for 10h to 30h at absolute vacuum of 80MPa to 95MPa and the temperature of 10 DEG C to 30 DEG C to obtain the products of the invention. The composite board has easy and simple manufacturing method, good optical performance, excellent weather resistance and hard aging. The method solves the problem that bubbles generally appear in a bonding layer, and has good product mechanical performance. The light-previous natural marble composite board is applicable to screen wall materials and advertisement and building decoration.

Owner:云浮市云城区创利达石材厂

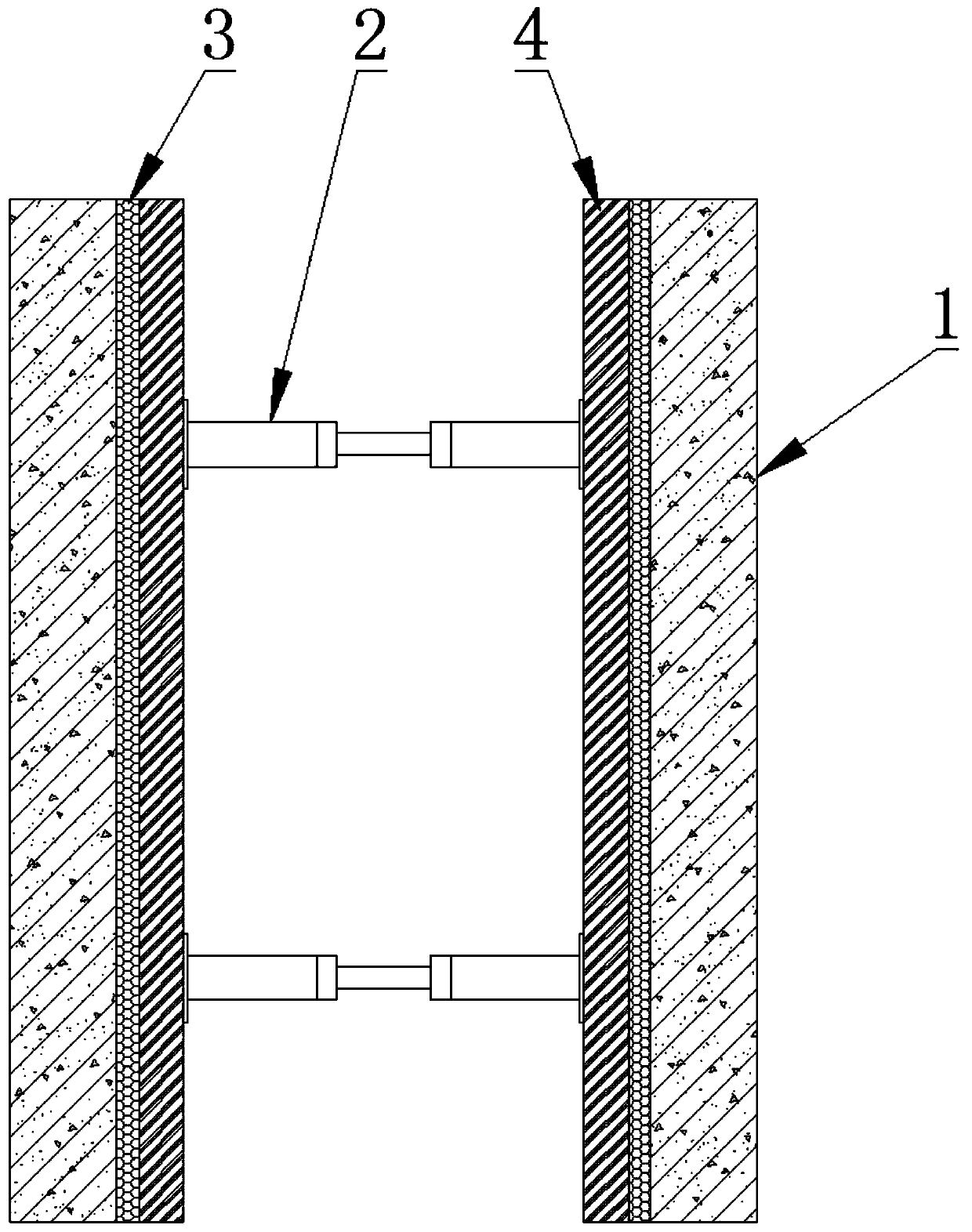

Interlayer formwork for aseismatic joint construction, and mounting method of interlayer formwork

PendingCN110130632AReduce construction difficultySolving Adhesion ProblemsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksRebarReinforced concrete

The invention provides an interlayer formwork for aseismatic joint construction, and a mounting method of the interlayer formwork. The interlayer formwork comprises a formwork body for formwork erecting and a supporting device connected with one side of the formwork body and used for supporting the formwork body, and a non-stick plate connected with a wall body is connected to the other side of the formwork body. By adopting a perlite plate, reinforced concrete does not make direct contact with an aluminum formwork, and thus the problem of cohesive force is solved. By adopting the aluminum formwork, a certain space is reserved for demounting the formwork. By adopting an adjustable screw rod, the construction difficulty is lowered.

Owner:TIANHE COLLEGE GUANGDONG POLYTECHNIC NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com