Cutter and cutting method

A technology of slitting machine and slitting knife, which is applied in metal processing and other directions, can solve the problems of poor reliability, high manufacturing cost, and inability to solve the problem of plastic adhesion, etc., and achieve the effect of novel structural design and free slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

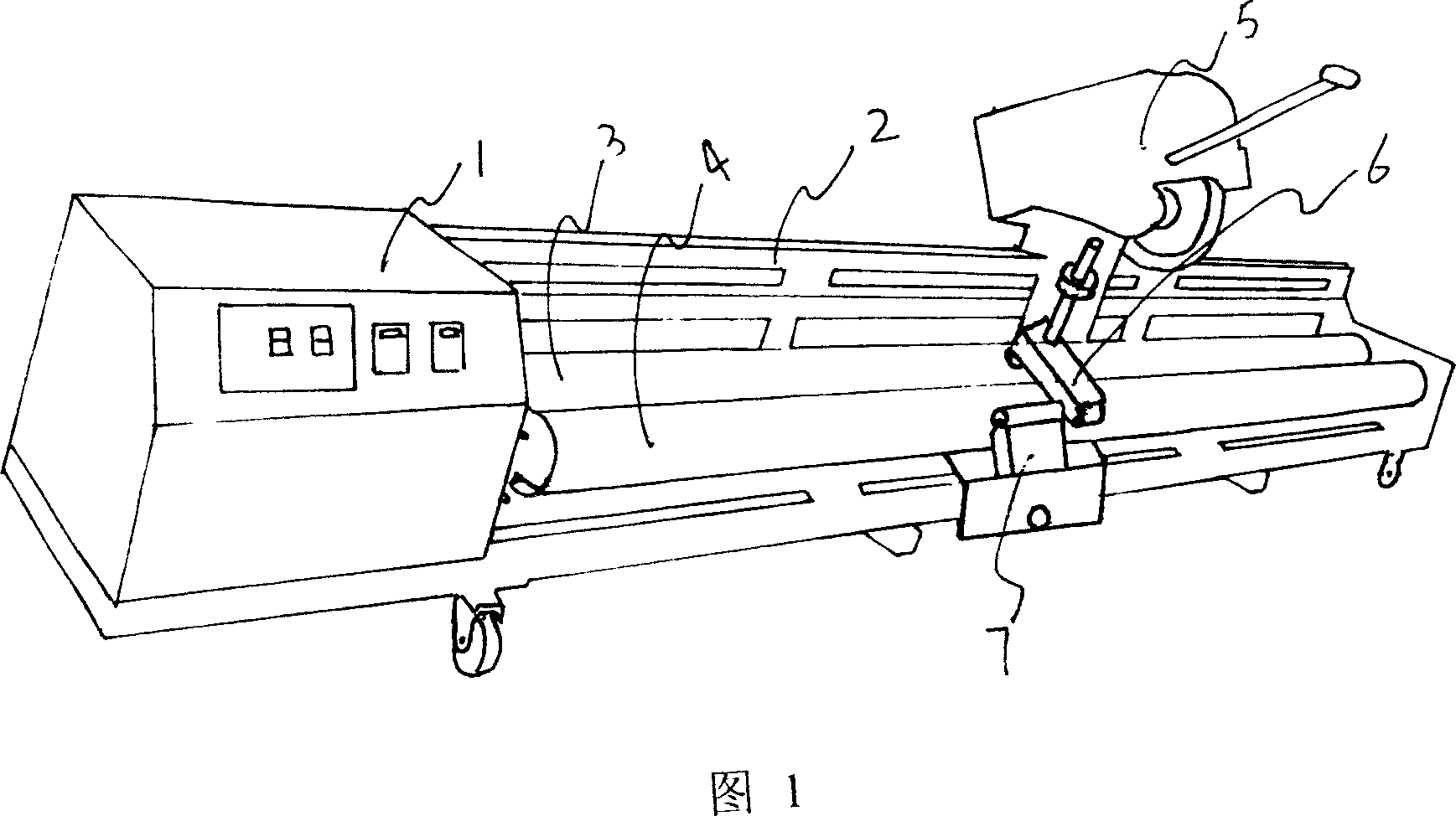

[0009] Embodiment 1: with reference to accompanying drawing 1. The slitting machine, the driving roller 3 and the driven roller 4 are manufactured using the prior art and the two ends of the driving roller 3 and the driven roller 4 are respectively located in the shaft seats at the two ends of the frame 2, and the driving roller 3 or the driven roller 4 pass through The transmission 1 is driven by a motor, and the driving roller 3 and the driven roller 4 are in clearance fit. Slitting knife assembly 5 is positioned at the roller surface that driving roll and driven roll form and can move back and forth along the crossbeam of frame, and slitting knife assembly 5 can move downward around the axis under the effect of external force. The waste cloth guide mechanism 7 is located on the frame before the driven roller 4 and can move back and forth along the frame beam. The roller surface of the cloth guide roller in the waste material guide mechanism 7 is in contact with the roller s...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the slitting method of the slitting machine, the slit roll cloth or roll tape or roll film is placed between the roll surface formed by the driving roll and the driven roll, and the slitting knife is always The pressing mechanism in the process moves down and presses the cut cloth or tape or film. The motor drives the driving roller to rotate through the transmission and drives the cloth or tape or film to rotate. The cutter head in the cutter mechanism In the process of the cutter mechanism moving down step by step under the action of external force, the slit roll cloth or tape or roll film is cut, and the slit waste cloth located between the two cutter heads enters the guide roller and the waste cloth guide mechanism. Between the driven rollers and under the action of the driven roller and the guide roller, the waste cloth is led out until the cut cloth or tape or film is cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com