Novel multilayer co-extrusion medical transfusion film and preparation method thereof

A multi-layer co-extrusion and infusion film technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of patients' health hazards, poor transparency of polyamide, and people's health hazards, etc., to achieve Avoid bacterial contamination, facilitate transportation, and ensure hygienic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

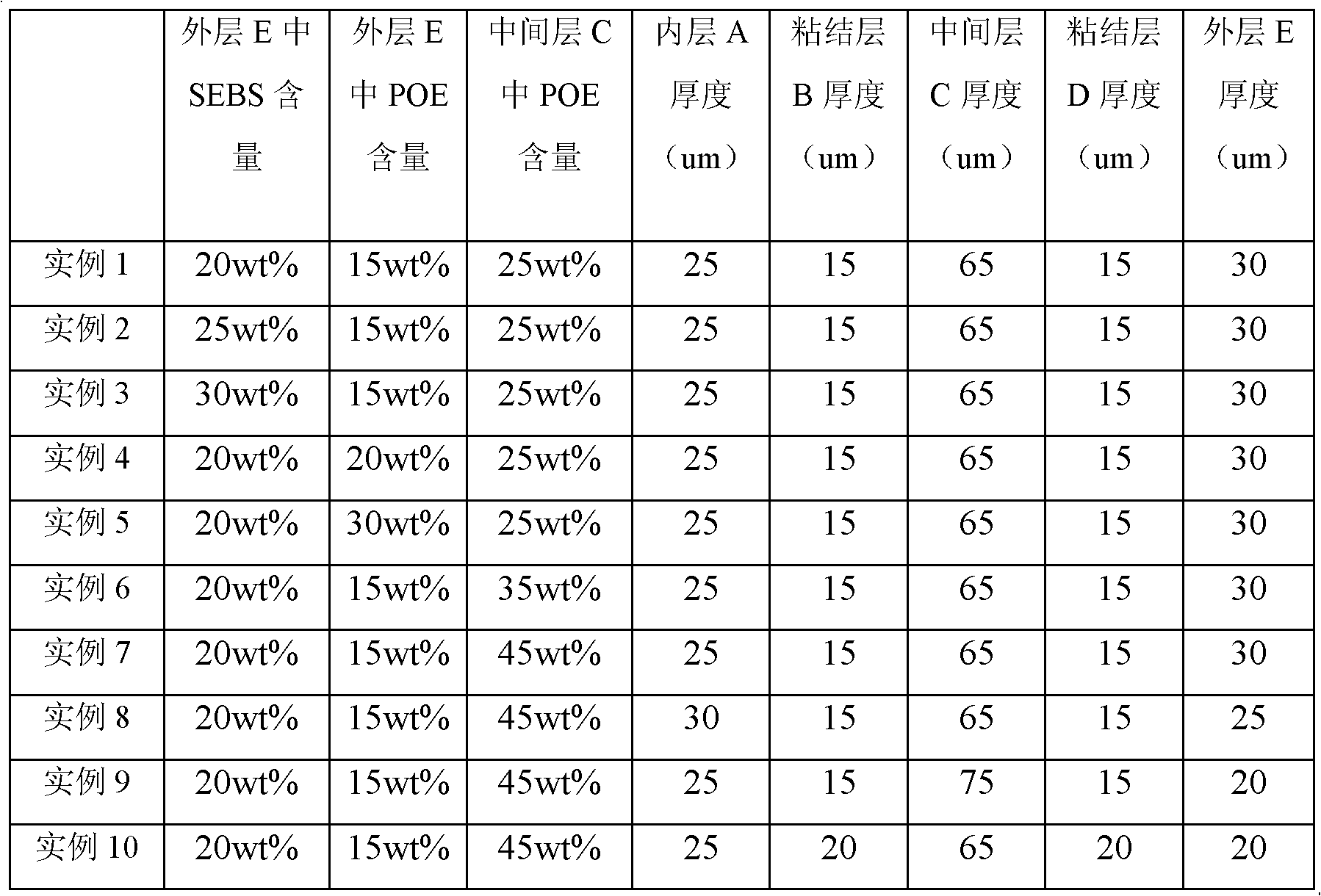

[0044] The present invention is described in detail below through specific examples, but the protection scope of the present invention is not limited.

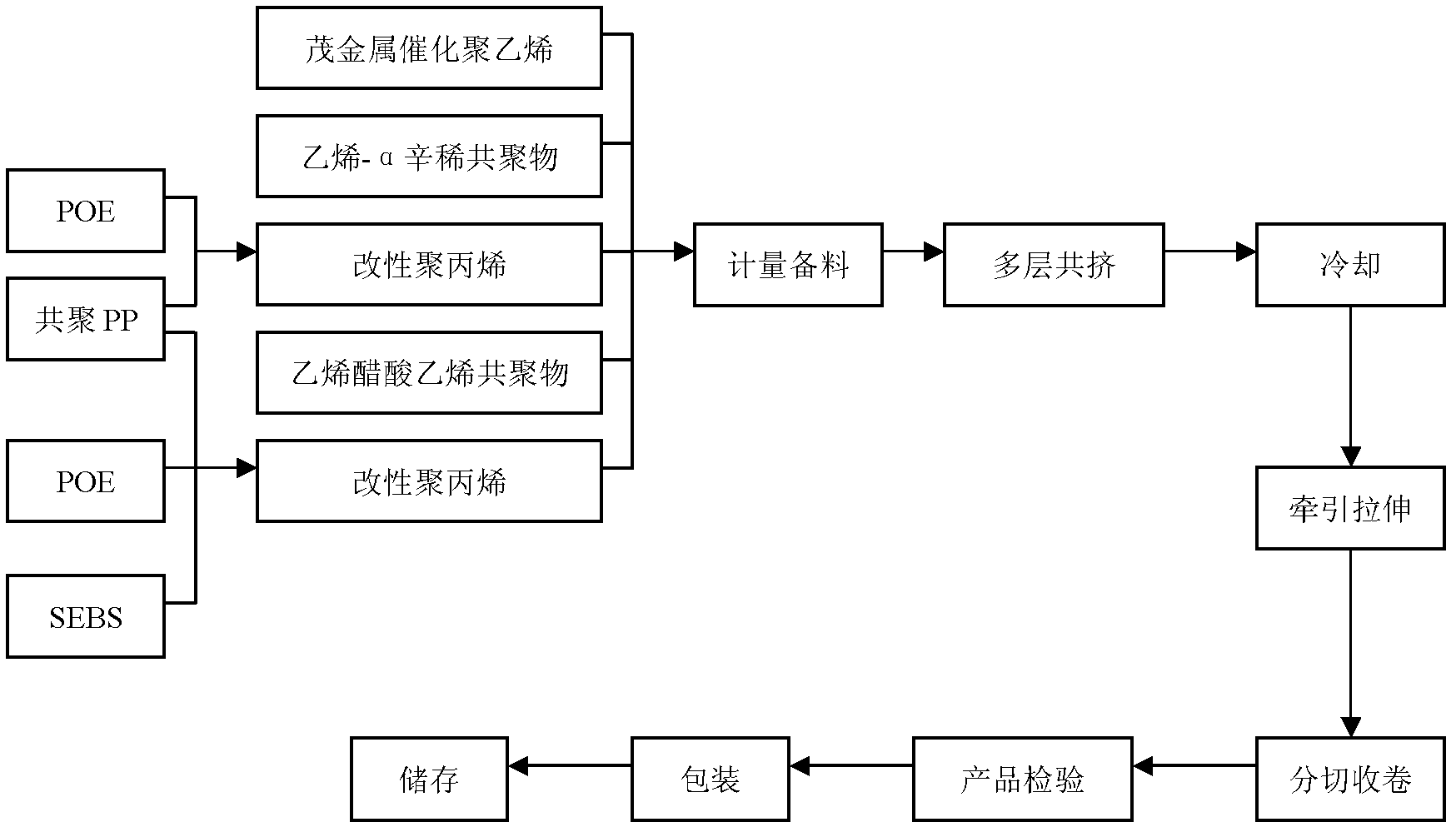

[0045] The main production equipment used to make the multi-layer co-extrusion infusion film in the present invention is a five-layer co-extrusion blow molding unit. Other devices, unless otherwise specified, adopt conventional production equipment in this field.

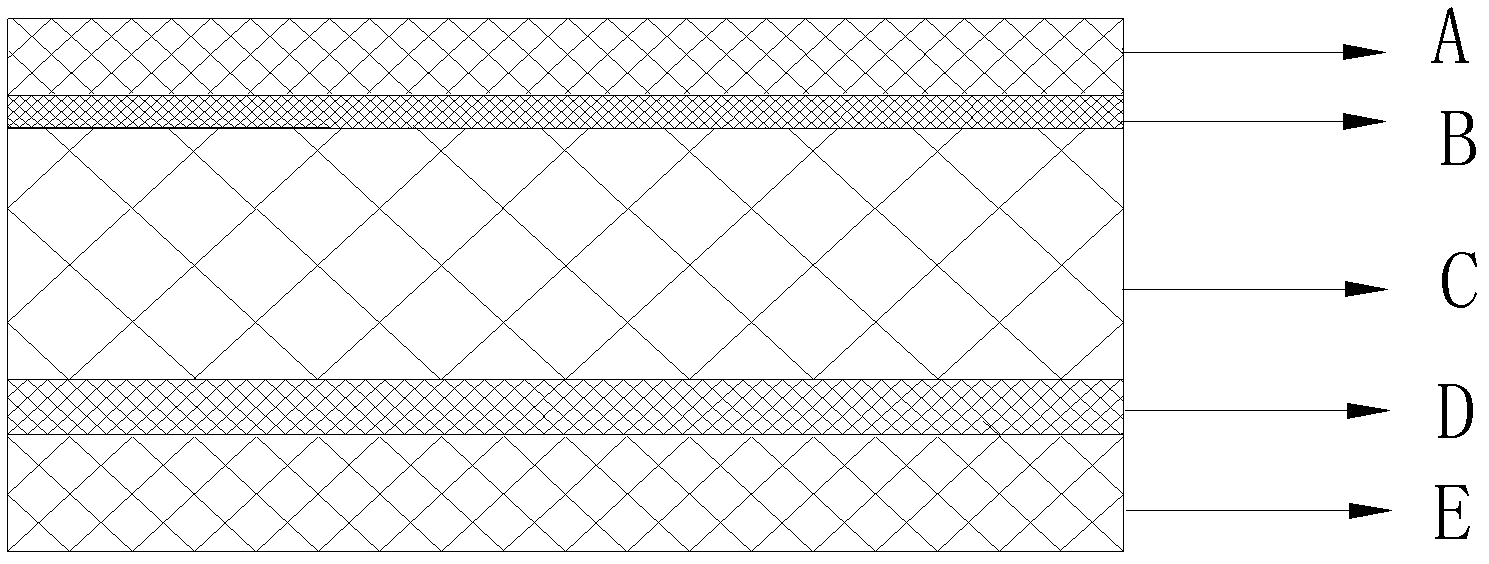

[0046] Such as figure 1 Shown is the distribution of each layer of the multilayer co-extruded infusion solution film of the present invention. Depend on figure 1 It can be seen that the multi-layer co-extrusion infusion film of the present invention has a five-layer structure in terms of structure and composition, which are inner layer A, adhesive layer B, middle layer C, adhesive layer D and outer layer E. The materials used for each layer are:

[0047] The metallocene catalyzed polypropylene used in the inner layer A has a melt index of 2-10 g / min and a densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com