Patents

Literature

92results about How to "Meet high temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

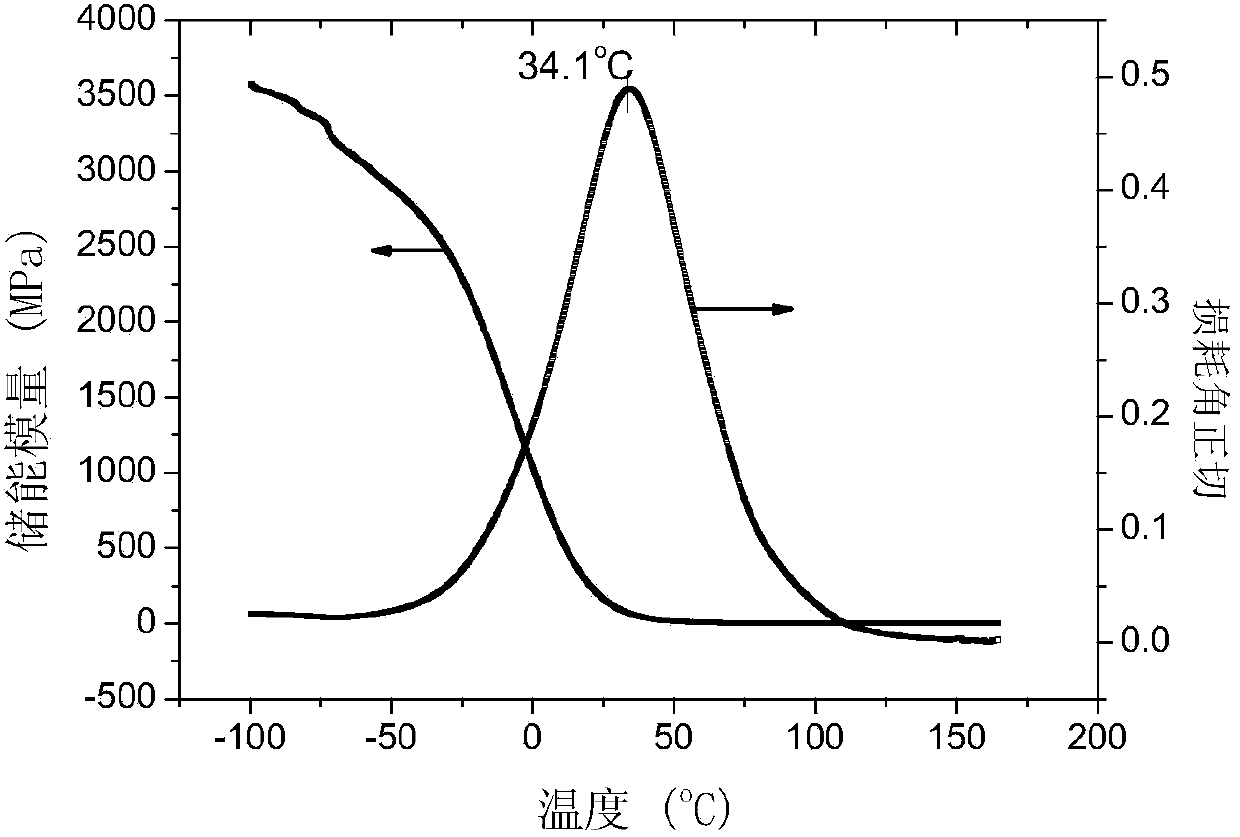

Anstatic agent and antistatic urethane elastomer material thereof

InactiveCN101486890AImprove antistatic performanceMeet high temperature requirementsOther chemical processesPolyurethane elastomerAntistatic agent

The invention relates to an antistatic agent and polyurethane elastomer material containing the antistatic agent. The invention discloses an antistatic agent which is characterized by comprising materials of the following weight portions: 1 to 6 of emulsifier, 1 to 6 of nonpolar solvent, 1 to 3 of quaternary ammonium salt and 1 to 3 of metal salt. The invention also discloses polyurethane elastomer materials including 0.5 to 3.5 percent of the antistatic agent. The polyurethane elastomer material produced by using the antistatic agent has good antistatic performance; the surface resistivity reaches 10 to 10ohm, with high-efficiency and durable antistatic performance; besides, the antistatic agent has a good compatibility with other additives of the polyurethane elastomer products, meets the high-temperature requirement during the production process of the product and has no mutual impact on respective physical and chemical properties.

Owner:SHANGHAI UNIV OF ENG SCI

Ethylene propylene rubber with high temperature resistance and low compression deformation

The invention discloses ethylene propylene rubber with high temperature resistance and low compression deformation, which is prepared from the following raw materials in mass part: 30-80 parts of ethylene propylene rubber, 70-20 parts of ethylene propylene terpolymer rubber, 1-3 parts of anti-aging agent, 2.5-5 parts of phenolic resin, 5-8 parts of zinc oxide, 2.5-5 parts of white carbon black, 50-80 parts of carbon black N550, 45-90 parts of carbon black N774, 10-20 parts of paraffin oil, 1-3 parts of Rhine wax, 1-2 parts of polyethylene glycol, 0.5-1 part of stearic acid, 2-4 parts of cross-linking agent, 2 parts of cross-linking addictive and 0.2-0.5 part of accelerating agent. According to the invention, the ethylene propylene rubber and the ethylene propylene terpolymer rubber are used in combination, and co-vulcanization is performed to the ethylene propylene rubber and the ethylene propylene terpolymer rubber by means of adjusting a vulcanization system, so that the requirement for high temperature resistance can be met and the rubber can obtain lower compression permanent deformation; and moreover, the highest use temperature of the ethylene propylene rubber vulcanized by the vulcanization system can achieve 150 DEG C, can resist the temperature of 175 DEG C in short-time or intermittent use, and has good heat resistance, chemical stability and lower compression deformation.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

Intermediate adhesive for high-heat-resistant conveying belt and preparation method of intermediate adhesive

ActiveCN102585732AGood bonding transitionAvoid delaminationNatural rubber adhesivesConveyorsChemistryPlasticizer

The invention relates to an intermediate adhesive for a high-heat-resistant conveying belt and a preparation method of the intermediate adhesive. The prepared product has good heat resistance and adhesion property. The preparation method comprises the following steps of: carrying out plastication on natural rubber on an open mill and inputting the prepared plastified rubber, ethylene propylene rubber and butadiene styrene rubber into an internal mixer to be subjected to banburying; then opening an upper ejector plug and adding reinforcement fillers, a vulcanizing activator, a vulcanization accelerator, a coupling agent, a plasticizer and an age resister to be subjected to banburying and carrying out stirring processing, chip discharging and normal temperature fan cooling to obtain a primary rubber compound; and carrying out secondary mixing, inputting the prepared primary rubber compound and a vulcanizing agent into the internal mixer to be subjected to mixing and carrying out stirring, chip discharging and normal temperature fan cooling to obtain the product, i.e. the intermediate adhesive for the high-heat-resistant conveying belt. After the intermediate adhesive for the high-heat-resistant conveying belt, which is disclosed by the invention, is used, not only is the requirement of the material conveying process in cement plants and steel mills on high temperature resistancemet, but also the intermediate adhesive can take a good adhesion transition effect on cover rubber and core rubber of the high-heat-resistant conveying belt, the delamination is prevented, the service life of the conveying belt is greatly prolonged and high economic benefits are realized.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

High temperature resistant core glue for conveyer belt and preparation method thereof

InactiveCN102775688AMeet high temperature requirementsAvoid delaminationConveyorsPlasticizerEconomic benefits

The invention relates to high temperature resistant core glue for a conveyer belt and a preparation method of the high temperature resistant core glue, belonging to the technical field of high temperature resistant conveyer belt. The method comprises the steps of inputting ethylene propylene rubber parts into an internal mixer for banburying, inputting reinforcement padding, vulcanizing an activator, a coupling reagent, a vulkacit, a plasticizer and an anti-aging agent in an internal mixer, closing a top bolt for banburying, discharging slices after turning over, and cooling through a normal temperature fan to obtain a section of rubber compound; inputting the section of rubber compound which is cooled to the room temperature in the internal mixer, inputting a vulcanized agent and a bonding agent, discharging slices after banburying and turning over, and cooling through the normal temperature fan to obtain the high temperature resistant core glue. The high temperature resistant core glue overall considers aspects such as anti-aging performance, bonding performance and processing performance of the conveying core glue, and a formula system of the selected high temperature resistant core glue for the conveyer belt can achieve good effects. After use, the high temperature resistant core glue meets requirements for high temperature resistance in cement plants and steel mills for material conveying, prevents canvas from delaminating, the service life of the conveyer belt is prolonged greatly and the good economic benefits are achieved.

Owner:WUXI BOTON TECH CO LTD

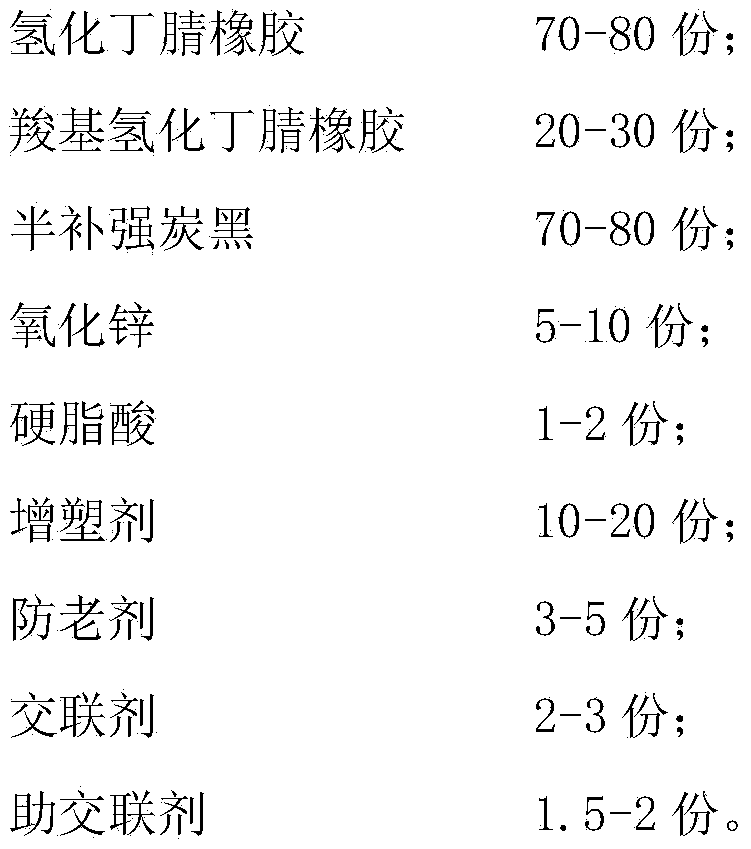

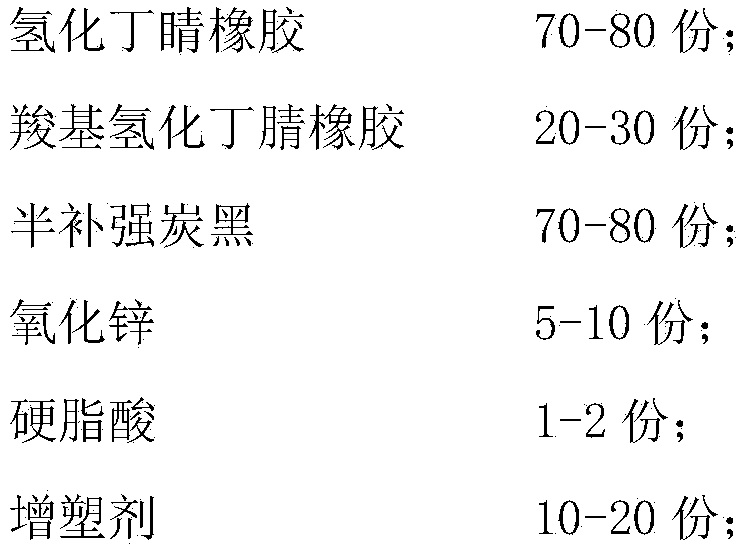

High-temperature stator rubber material and preparation method thereof

The invention discloses a high-temperature stator rubber material and a preparation method thereof and belongs to the field of the rubber material and the preparation method thereof. The rubber material is prepared from, in parts by weight, 70-80 parts of hydrogenated butadiene-acrylonitrile rubber, 20-30 parts of carboxyl hydrogenated butadiene-acrylonitrile rubber, 70-80 parts of semi-reinforcing carbon black, 5-10 parts of zinc oxide, 1-2 parts of stearic acid, 10-20 parts of plasticizer, 3-5 parts of anti-aging agent, 2-3 parts of cross-linking agent and 1.5-2 parts of auxiliary cross-linking agent. The high-temperature stator rubber material is prepared from hydrogenated butadiene-acrylonitrile rubber and carboxyl hydrogenated butadiene-acrylonitrile rubber, the hydrogenated butadiene-acrylonitrile rubber and carboxyl hydrogenated butadiene-acrylonitrile rubber are co-vulcanized so that the high-temperature stator rubber material is capable of meeting the requirement on high temperature resistance, the hydrogenated butadiene-acrylonitrile rubber which is vulcanized by a sulfur-free vulcanization system is capable of resisting the high temperature of 180 DEG C at most, and the vulcanized product has excellent heat resistance, chemical stability and bonding strength, and furthermore, the rubber material has excellent bonding strength.

Owner:南京金三力橡塑有限公司

Elastomer modified asphalt waterproof coiled material and preparation method thereof

InactiveCN106183217AMeet high temperature requirementsGood extensibilitySynthetic resin layered productsBuilding insulationsPolyesterExtensibility

Elastomer-modified asphalt waterproofing membrane and preparation method thereof, elastomer-modified asphalt waterproofing membrane, is characterized in that it comprises base layer, petroleum asphalt layer, isolation material layer; base layer is covered with petroleum asphalt layer, petroleum asphalt The outer surface of the layer is covered with an isolation material layer; the petroleum asphalt layer is composed of: 40 parts of 10# asphalt, 15 parts of 90# asphalt, 3 parts of machine oil, 9 parts of modifier SBS, 6 parts of talcum powder, Guma 5 parts of Long resin, 7 parts of graphite, 7 parts of asphalt modified tackifier, and 8 parts of high-density polyethylene; the base layer is composed of 20 parts of polyester felt, 30 parts of glass fiber felt, Reinforced polyester felt is composed of 50 parts; it has good elongation performance, high high and low temperature resistance, water impermeability can reach 0.7MPa, and the product's low temperature flexibility can reach ‑40 ° C without cracks.

Owner:潍坊市宇虹防水材料(集团)有限公司

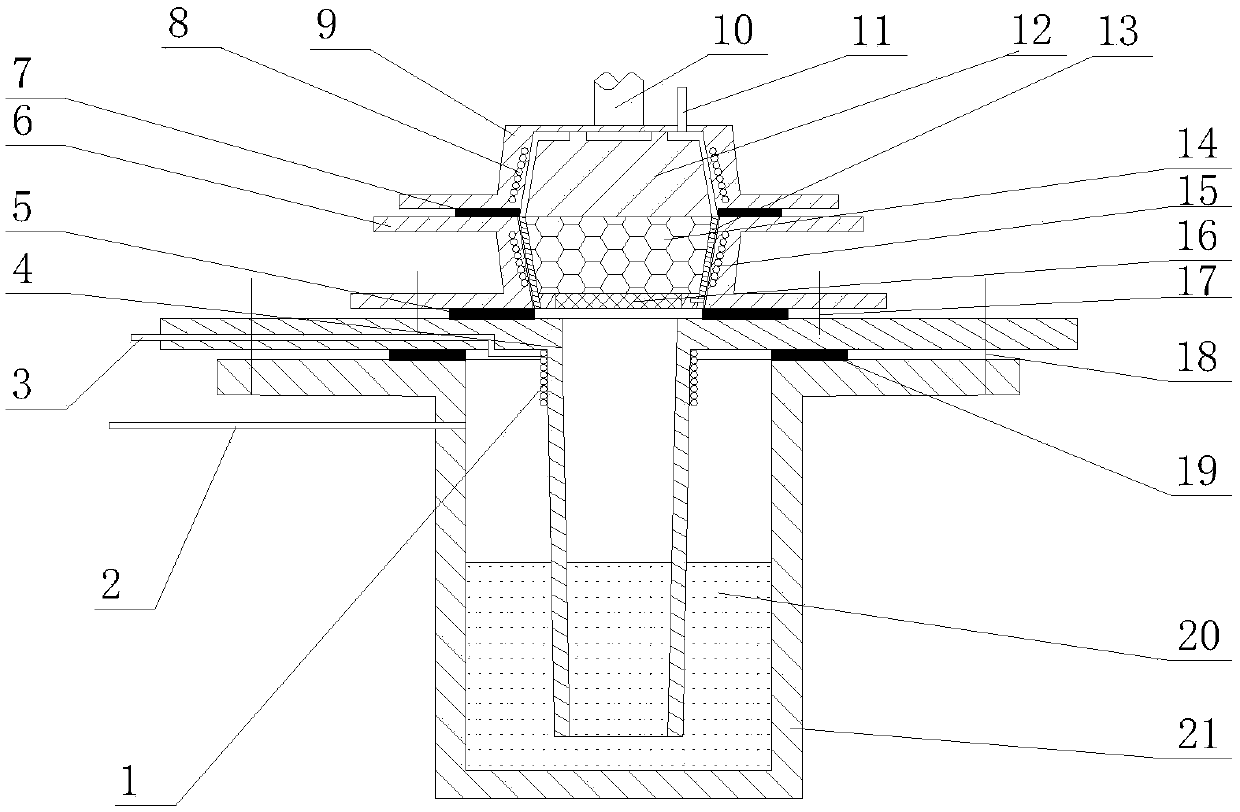

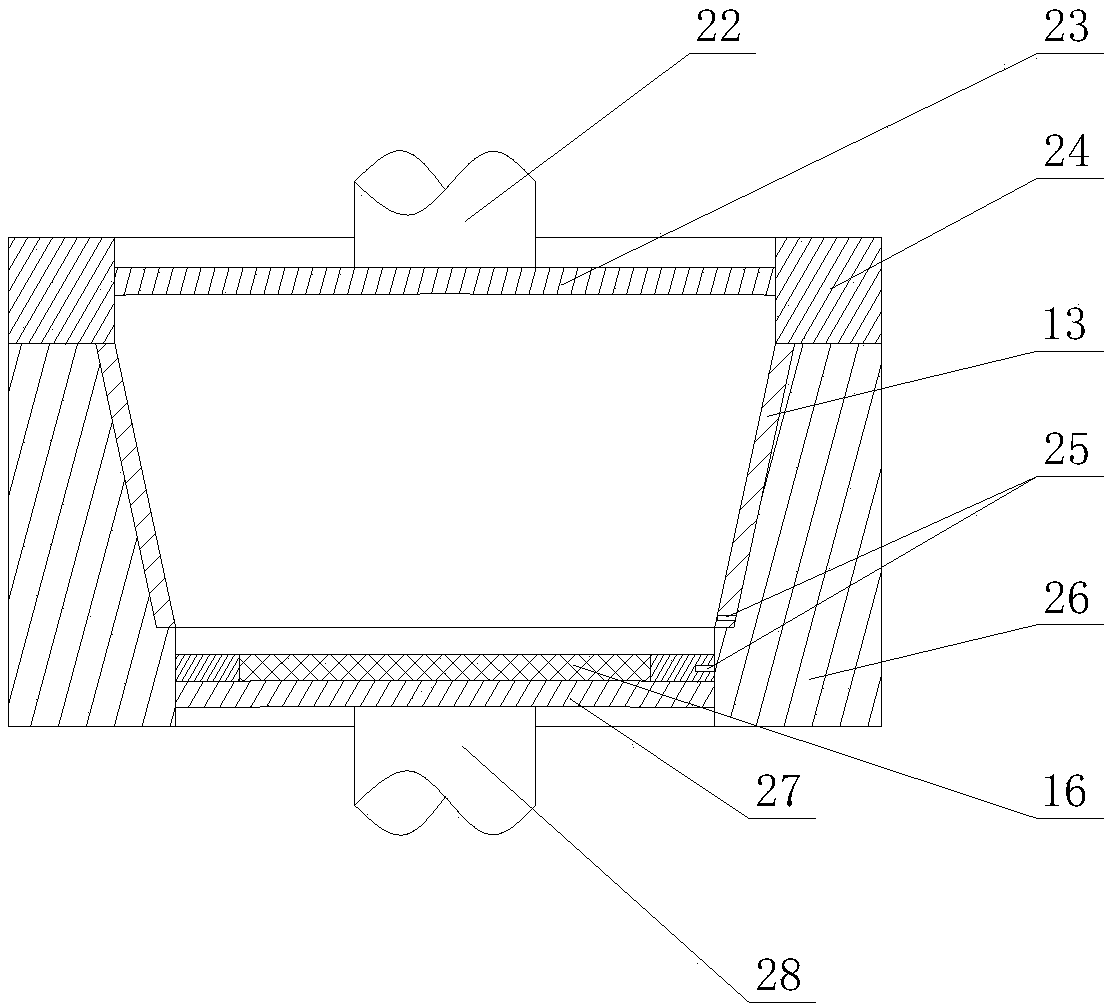

Device for preparing aluminum foam and copper foam and preparation method thereof

ActiveCN107695322AMeet high temperature requirementsMeet environmental protection requirementsCrucibleAluminum can

The invention discloses a device for preparing aluminum foam and copper foam. The device comprises an inner die, an outer die, a crucible and a liquid raising pipe, wherein compacted seepage particlesare stored in the inner die; a stainless steel net grid and a screen mesh are arranged at the bottom end of the inner die which is arranged in an empty chamber of the outer die; the outer die is positioned on the crucible and communicates with the crucible; the liquid raising pipe is positioned in the crucible in which molten aluminum is stored; the outer edge of the liquid raising pipe is connected to the bottom end of the outer die, and the liquid raising pipe is fixed to the top end of the crucible; an air feeding pipe is connected to the outer wall of the crucible. According to the device, a vacuum-pumped hood is arranged; the molten aluminum or molten copper can flow only along a seam which is formed through a mould weight and the hood at the end of seepage, so as to prevent the molten aluminum or molten copper from overflowing; circulating water pipes are arranged and increase the molten aluminum cooling speed, thus the backflow is avoided, and the structure and performance stability of the aluminum foam and the copper aluminum can be ensured; the stainless steel net grid and the screen mesh are movably arranged, so that the seepage particles in the inner die can maintain uniform compactness after being compacted.

Owner:张贝昂

Electrostatic resistance rubber material and preparation method thereof

InactiveCN101260203AImprove antistatic performanceGood compatibilityOther chemical processesRubber materialPolymer science

The invention provides antistatic rubber material and a preparation method thereof, wherein the antistatic rubber material contains antistatic agent of 3 to 5 weight percent with reference to rubber matrix of 100 weight percent; the antistatic agent is a mixture and comprises compositions according to the following weight ratio: emulsifying agent: polar solvent: organic amine: metal salt is equal to 3:3:1-2:1-2; and the metal salt is selected from lead acetate, mercury bichloride, copper sulphate, iron chloride, antimonic chloride, stannic chloride or silver nitrate. The rubber material prepared by the antistatic agent has excellent antistatic performance, surface resistivity reaching 10<6> ohm to 10<8> ohm as well as high-efficient and persistent static resistance; moreover, the rubber material has ideal compatibility with other additives of rubber products, thereby meeting the requirements of high temperature during manufacturing the rubber products without influencing the physical property and the chemical property of one another.

Owner:SHANGHAI UNIV OF ENG SCI

Split type vortex street effusion meter

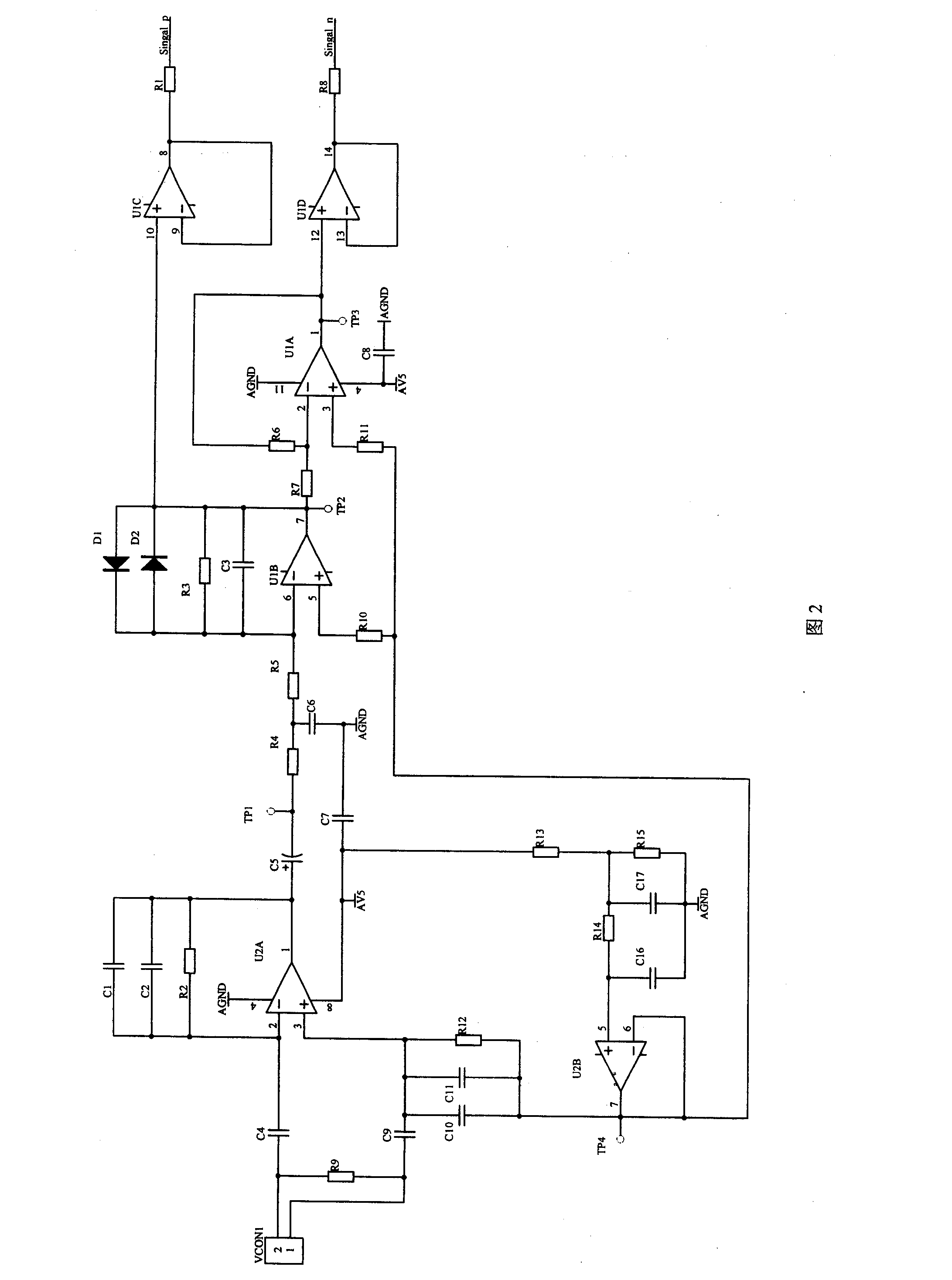

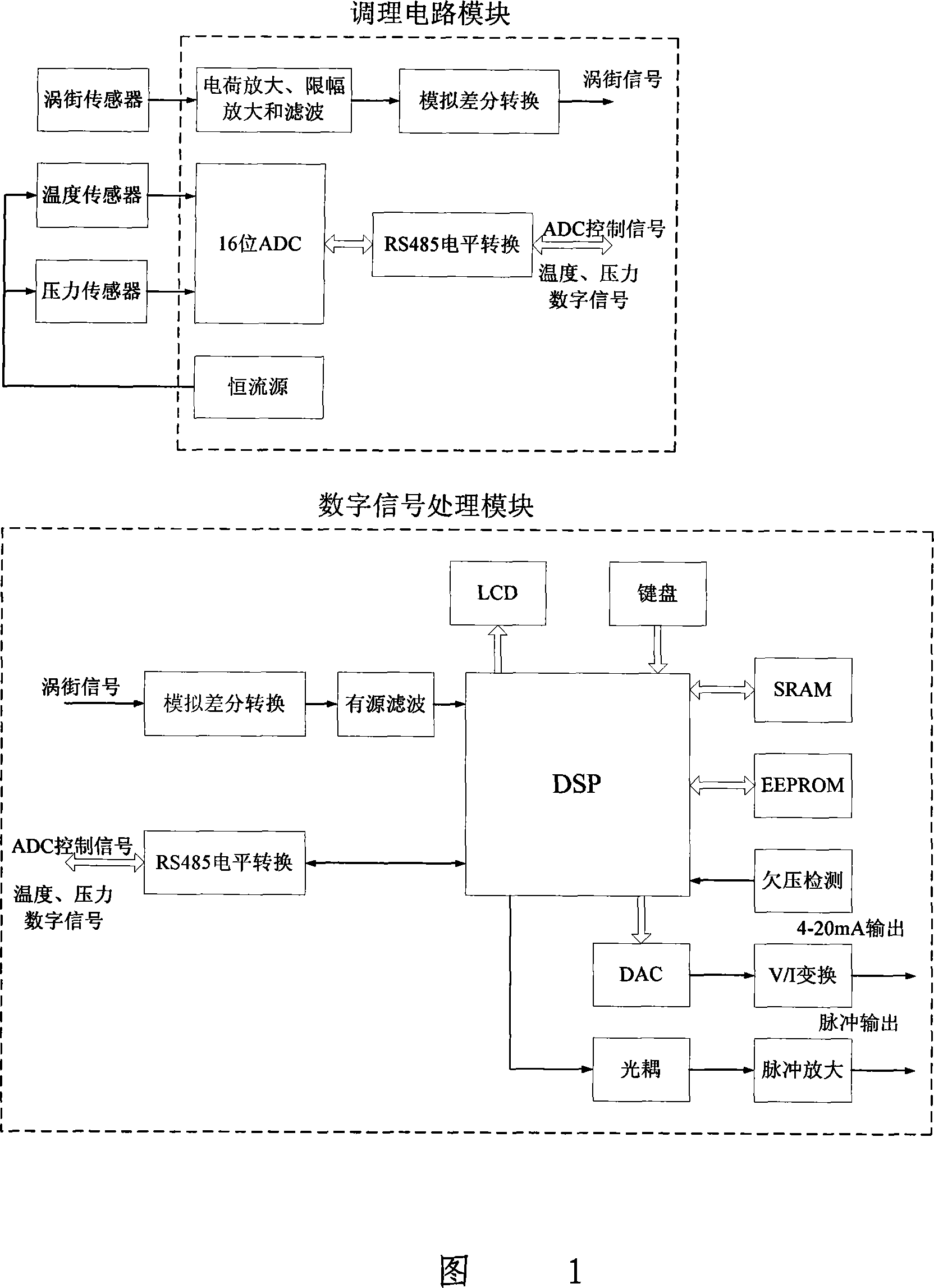

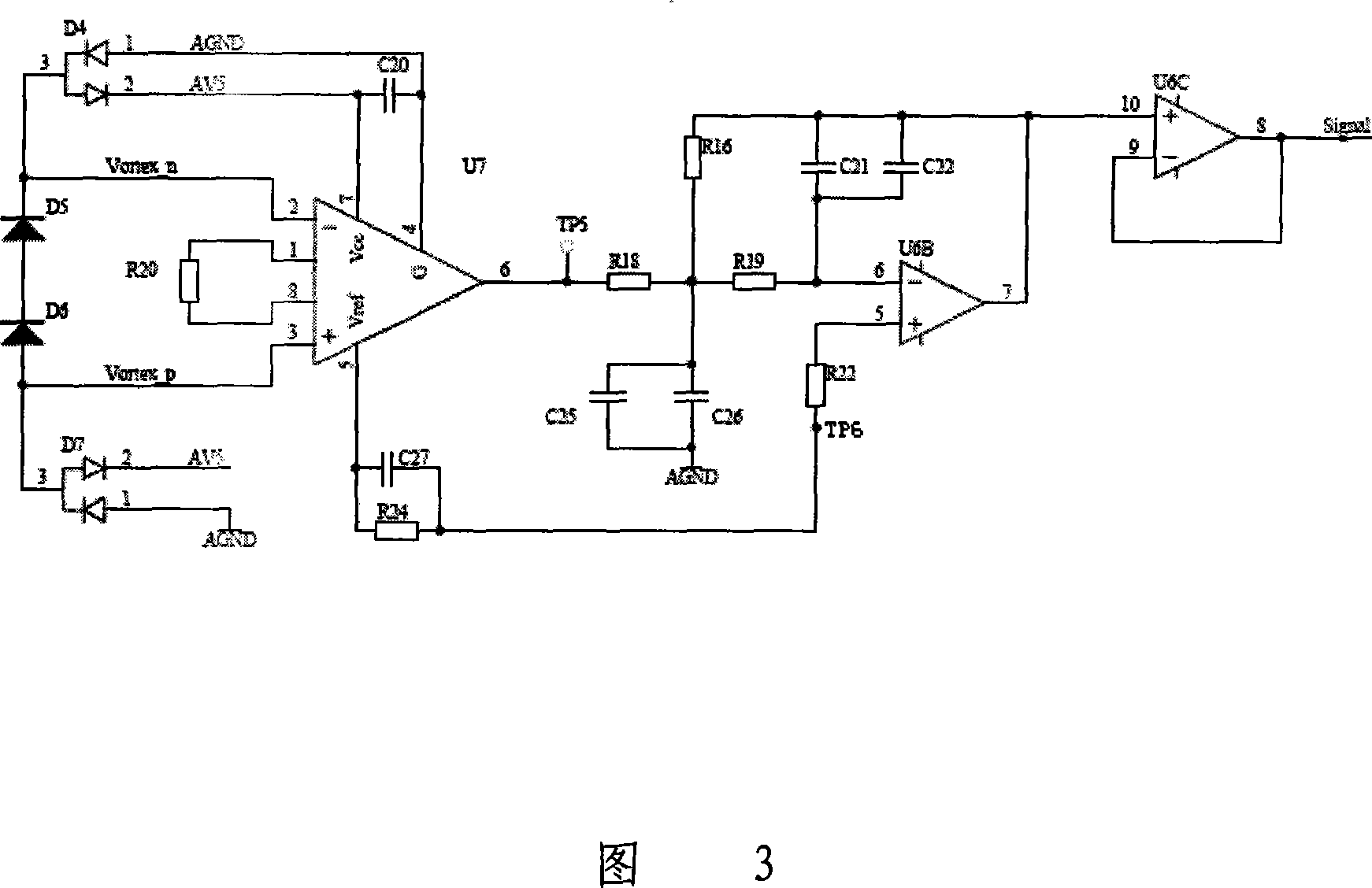

InactiveCN101158594AGuaranteed to workMeet the high temperature environmentVolume/mass flow by dynamic fluid flow effectShielded cableDigital signal processing

The invention relates to a flowmeter, in particular to a split-typed vortex flowmeter. The invention consists of sensors, a conditioning circuit module and a digital signal processing module, three kinds of sensors and the conditioning circuit module are positioned at a high temperature measured field, while the digital signal processing module is positioned in normal temperature environment, the modules are connected to each other through a shield cable, the signals are transformed in the form of differential signal. The invention solves the technical problem that original techniques can not be applied in high temperature environment; the invention can be applied in high temperature environment and special occasions which needs split-typed flowmeter. The invention has the advantages of good anti-jamming capability and high reliability.

Owner:HEFEI UNIV OF TECH

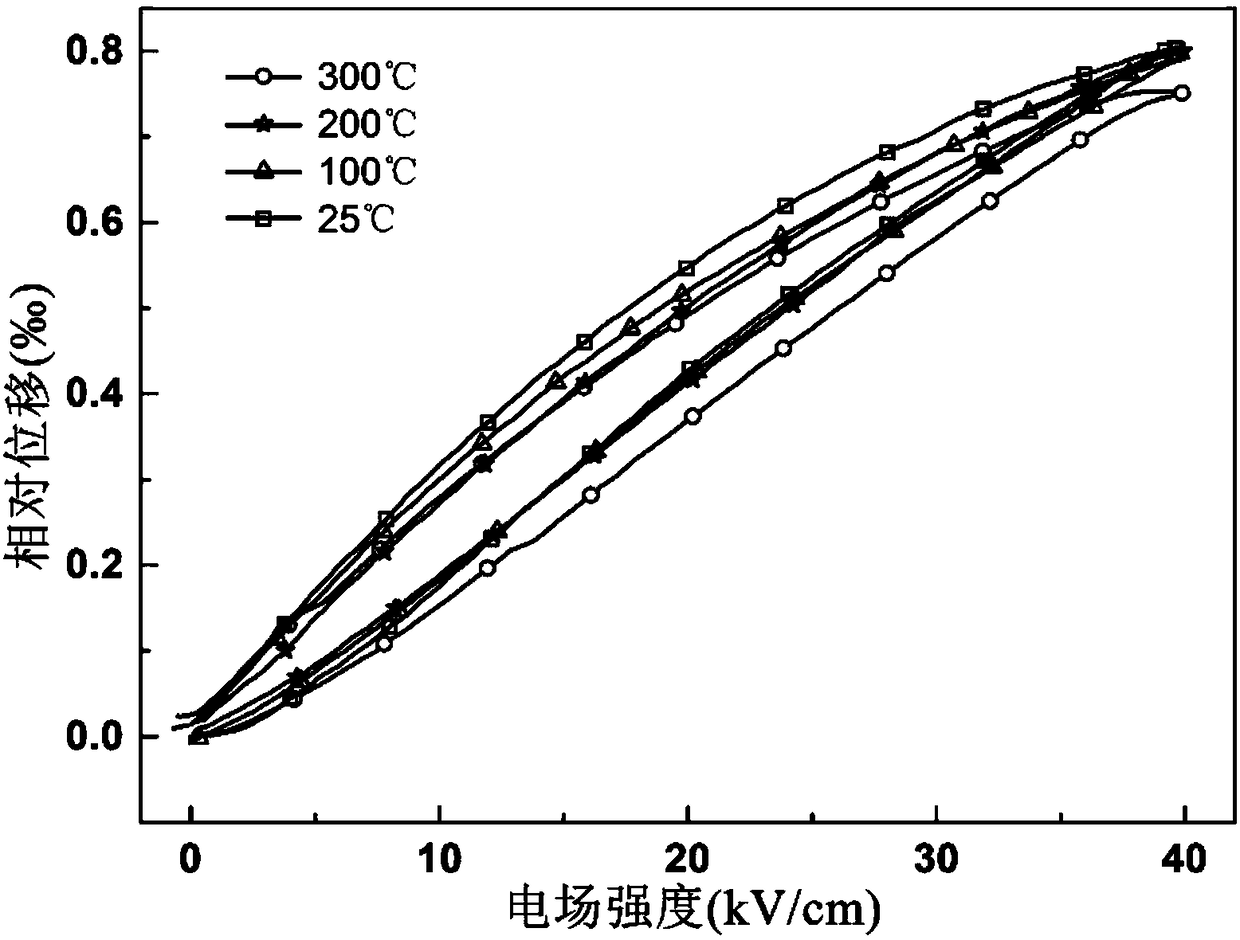

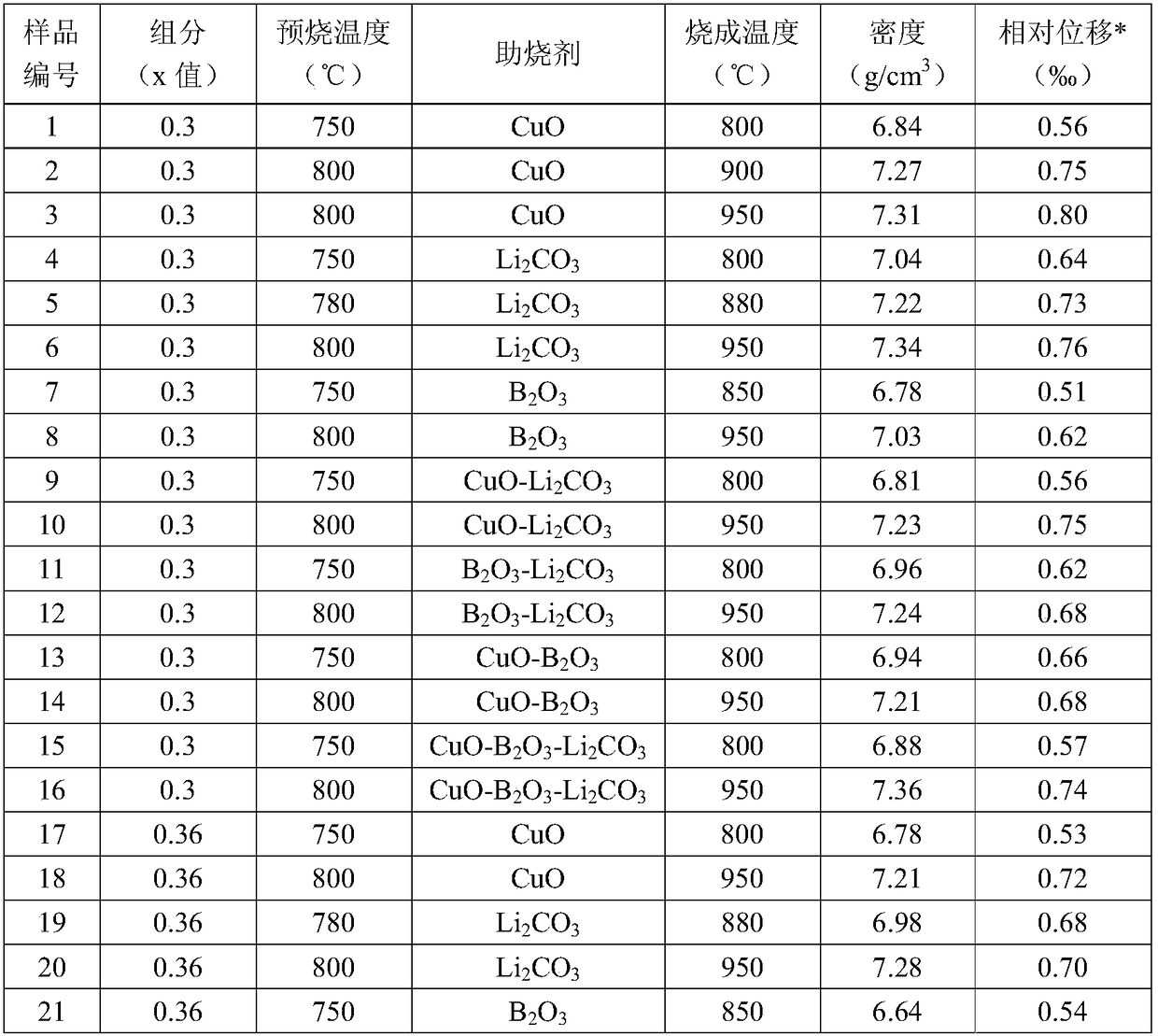

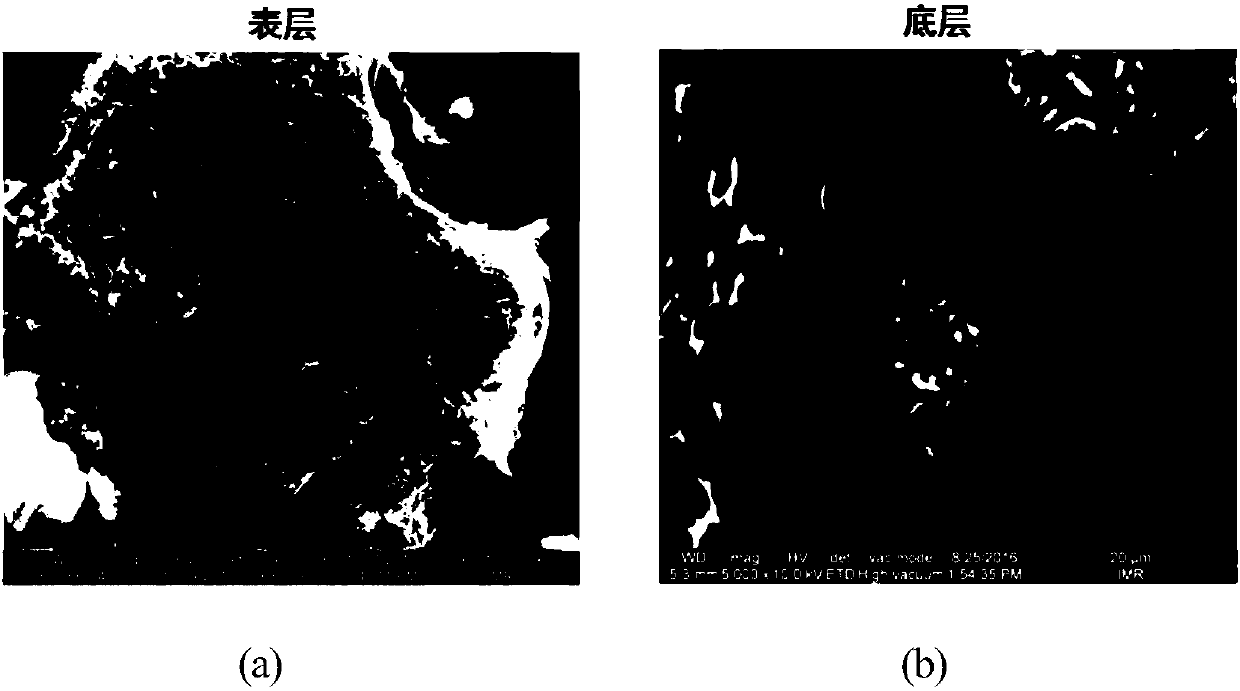

High temperature resistant multilayer piezoelectric ceramic actuator and preparation method and use thereof

InactiveCN108470824AIncrease working temperatureImprove high temperature resistancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionOperating temperature rangeActuator

The invention discloses a high temperature resistant multilayer piezoelectric ceramic actuator and a preparation method and a use thereof. A piezoelectric ceramic layer in the piezoelectric ceramic actuator comprises a piezoelectric ceramic material and a sintering agent, and the piezoelectric ceramic material is bismuth scandate-lead titanate binary piezoelectric ceramic material of the formula xBiScO3-(1-x)PbTiO3. The preparation method comprises the following steps: 1) mixing a bismuth source, a scandium source, a lead source and a titanium source, performing crushing to obtain a raw material mixture, and performing calcining to obtain a calcined powder; 2) mixing the sintering agent with the calcined powder, performing crushing, and molding the obtained mixture to obtain a piezoelectric ceramic diaphragm; and 3) preparing an internal electrode on the surface of the piezoelectric ceramic diaphragm, laminating and firing the obtained piezoelectric ceramic diaphragm with internal electrodes, preparing an external electrode and performing polarization to obtain the piezoelectric ceramic actuator. The piezoelectric ceramic actuator is suitable for the operating temperature range of25 DEG C to 300 DEG C and is low in cost.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Crude oil composite type emulsification viscosity reducing agent and preparation method thereof

ActiveCN101121882AMeet high temperature requirementsSolve the problem of crude oil viscosity reductionDrilling compositionChemistryFluorocarbon

The invention relates to a raw oil composite emulsification viscosity reducing agent, applied to maintenance of oil wells in oil-fields. The raw materials include (calculated by weight percent) A. oleate polyoxyethylene (5) ester: 0.5 to 1.5 percent; B. petroleum cyclocarboxylic alkanolamide sulfate 3 to 8 percent; C. fatty alcohol-polyoxyethylene ether 5 to 15 percent; D. sodium hydroxide 0.5 to 1.5 percent; E. soda 1.0 to 2.0 percent; F. sodium bicarbonate 1.5 to 3; G. FC-3B fluorocarbon surfactant 0.05% to 0.1 percent; H. water (the remainder). During daily maintenance of an oil well, addition of 100mg / l to 200mg / l of such agent can not only meet the requirement of daily viscosity reducing agent on high-temperature resistance, but also meet the requirement of anti-mineral salt. The invention can well reduce the viscosity of raw oil in oil-wells.

Owner:PETROCHINA CO LTD

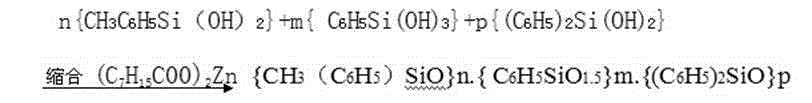

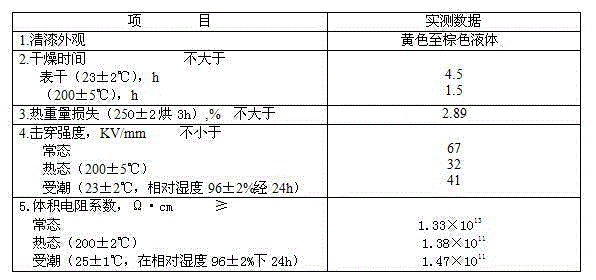

Insulating varnish and preparation method thereof

ActiveCN104087163AHigh insulation levelMeet high temperature requirementsCarboxylic acid salt preparationCoatingsTemperature resistanceZinc

The invention discloses an insulating varnish and a preparation method thereof, belonging to the technical field of paints. The invention mainly overcomes the technical problem that a conventional insulating varnish does not have ideal insulating properties under the condition of high temperature. The insulating varnish comprises, by weight, 3 to 5.1% of dichloromethyl phenylsilane, 4 to 6.9% of monophenyltrichlorosilane, 2 to 3.5% of diphenyltrichlorosilane, 0.01 to 0.02% of zinc octoate and 20 to 30% of xylene, with the balance being tap water. The preparation method for the insulating varnish comprises the following steps: hydrolysis; washing; concentration; condensation; etc. The insulating varnish provided by the invention has a high insulation grade, strong high temperature resistance and a wide application scope.

Owner:西安经建油漆有限责任公司

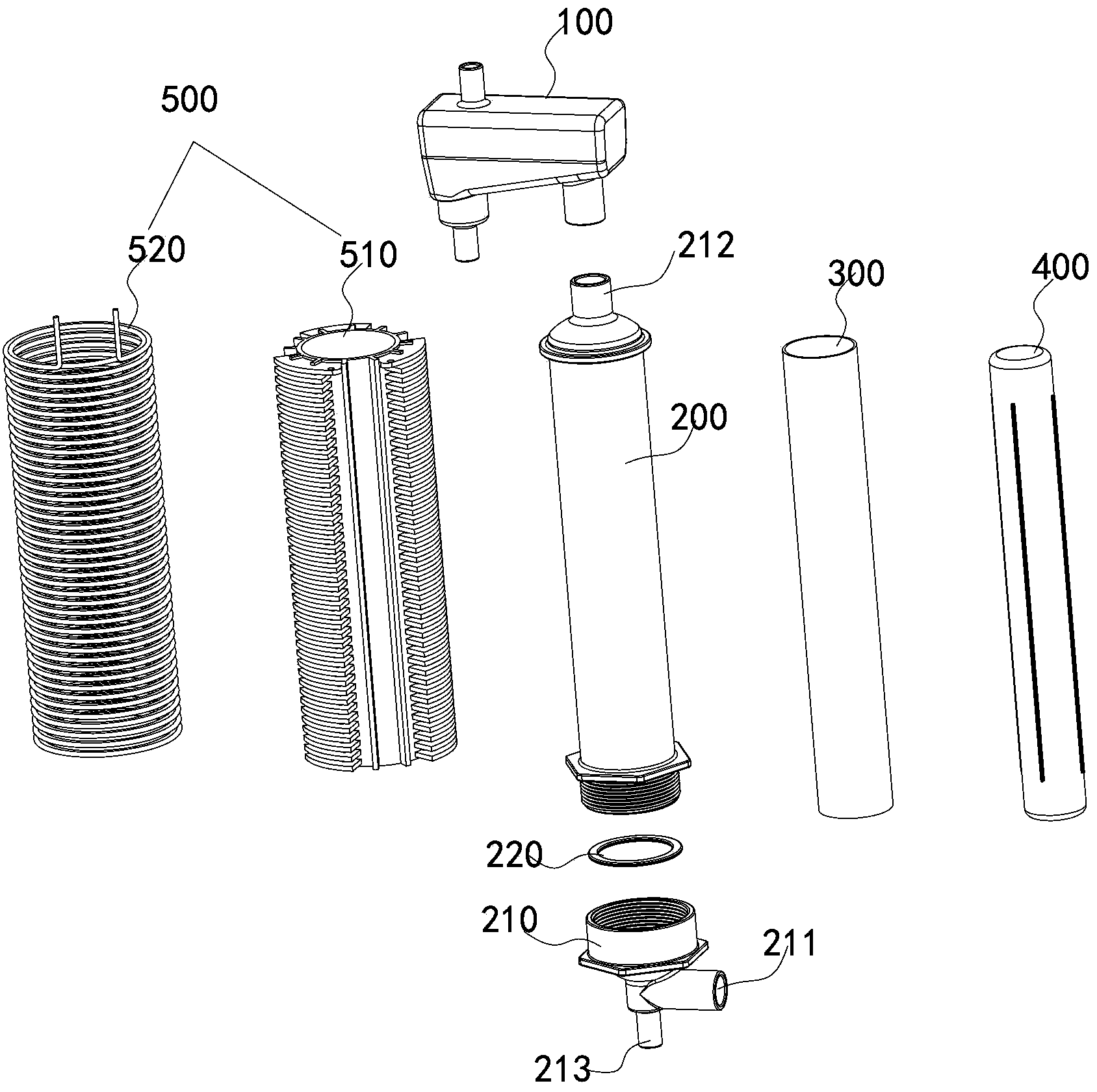

Drinking water heating device with water outlet nozzle in bypass connection with water storage cavity

InactiveCN102563835AImprove thermal insulationAvoid direct exposure to airBeverage vesselsWater heatersEngineeringWater tanks

The invention discloses a drinking water heating device with a water outlet nozzle in bypass connection with a water storage cavity. The drinking water heating device comprises a shell provided with the water outlet nozzle. The drinking water heating device is characterized in that a heater, a balanced water tank and a water pump are further arranged on the shell, one end of the water pump serves as a water pumping port, the other end of the water pump is communicated with the balanced water tank, the balanced water tank is connected with an inlet of the heater, an outlet of the heater is communicated with the water outlet nozzle, an outlet of the water outlet nozzle is connected with the water storage cavity, a water outlet is arranged on the water storage cavity, and a water outlet valve is mounted at the water outlet. The drinking water heating device has the advantages of large water outlet amount, low power requirement and diversity options of the heater.

Owner:罗伟林

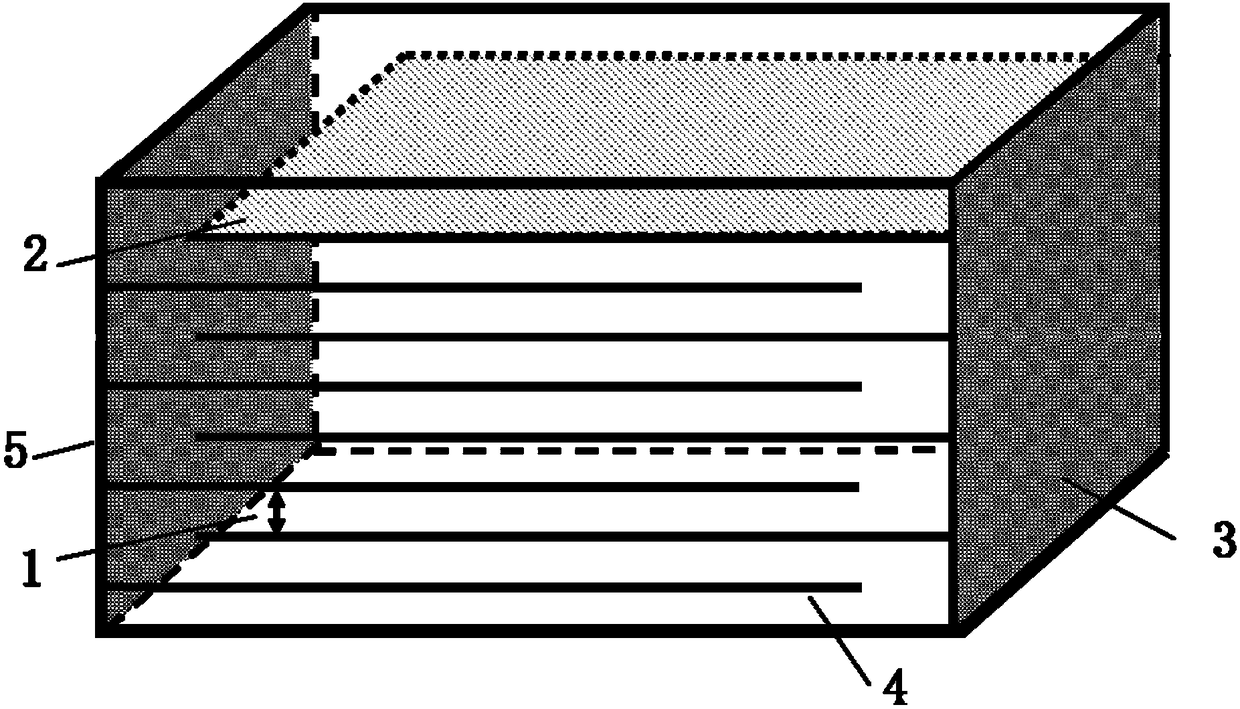

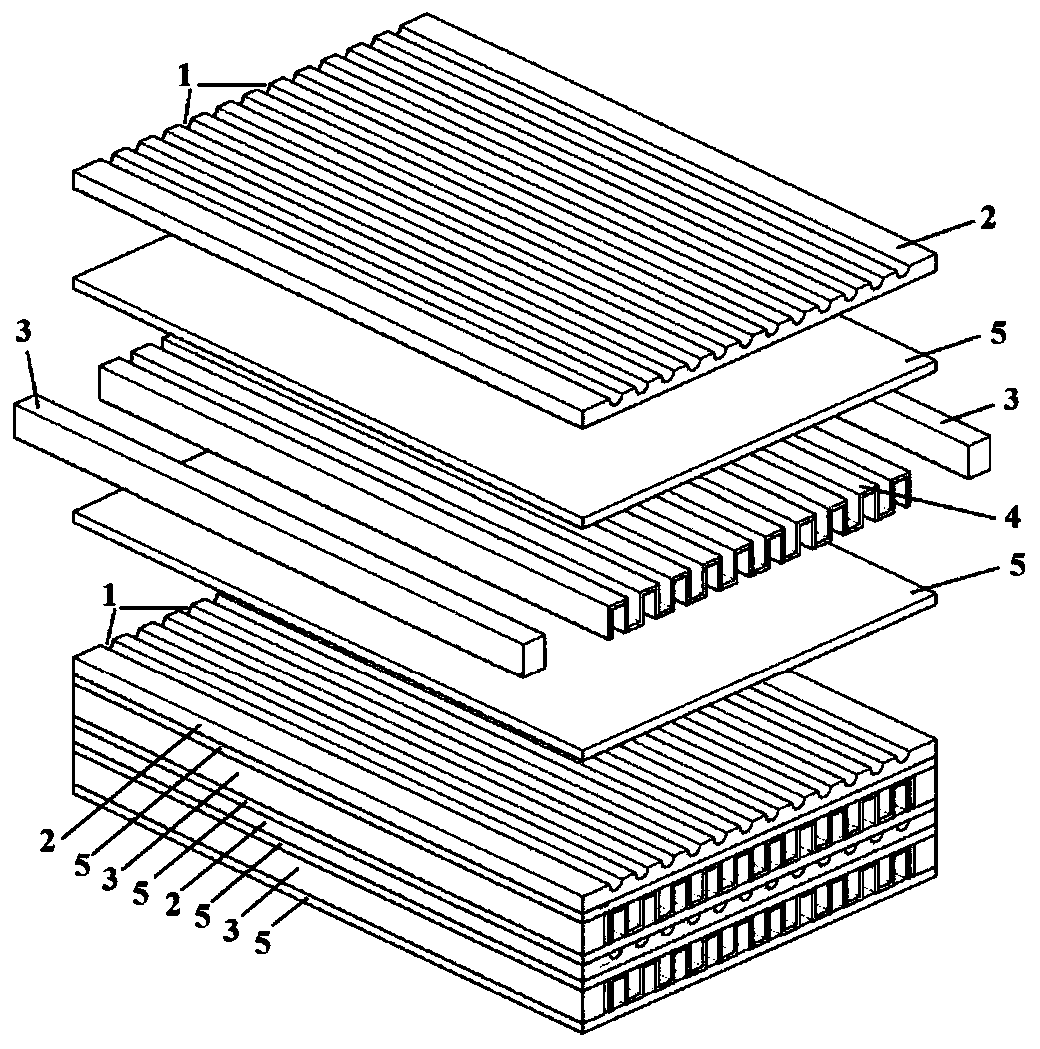

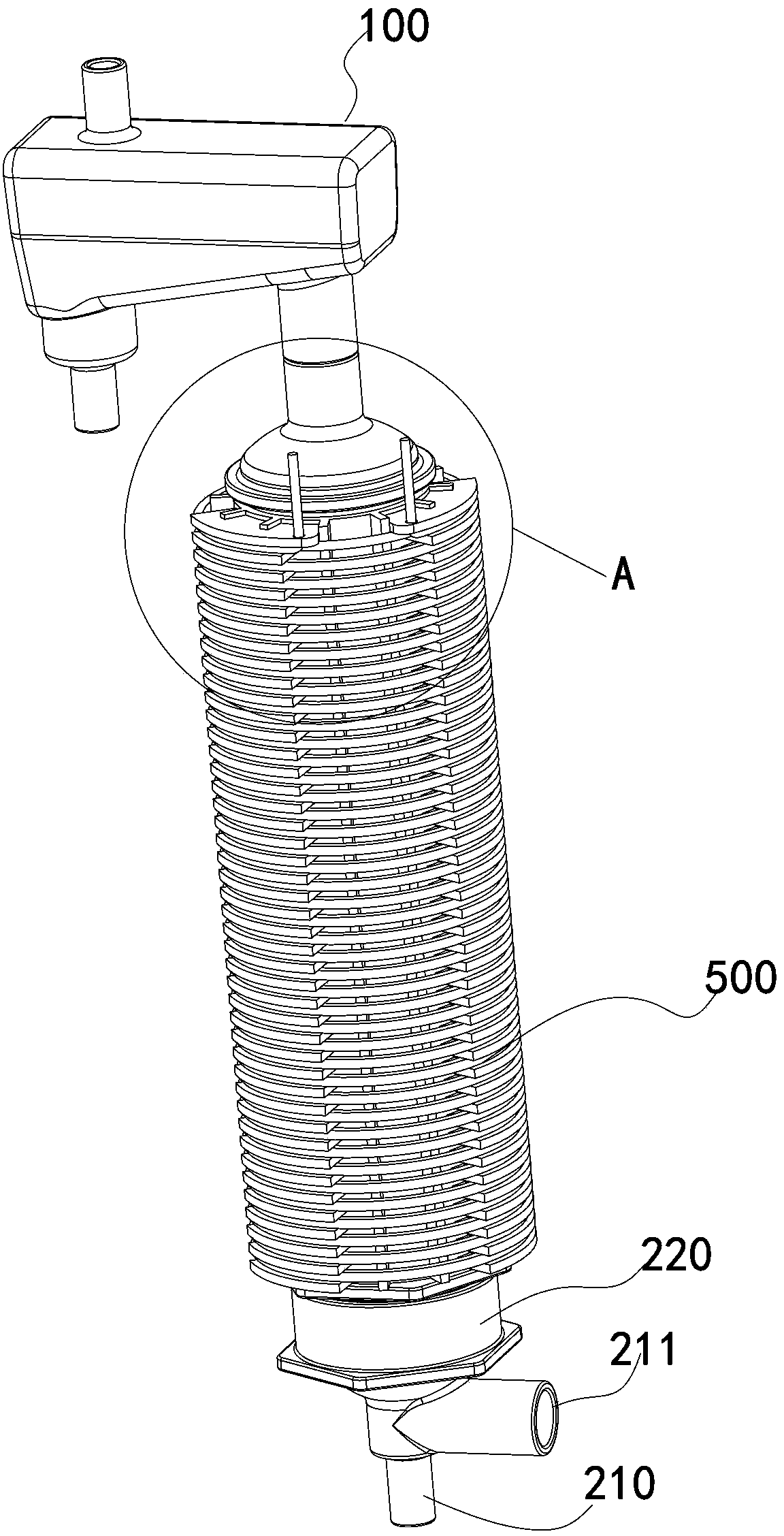

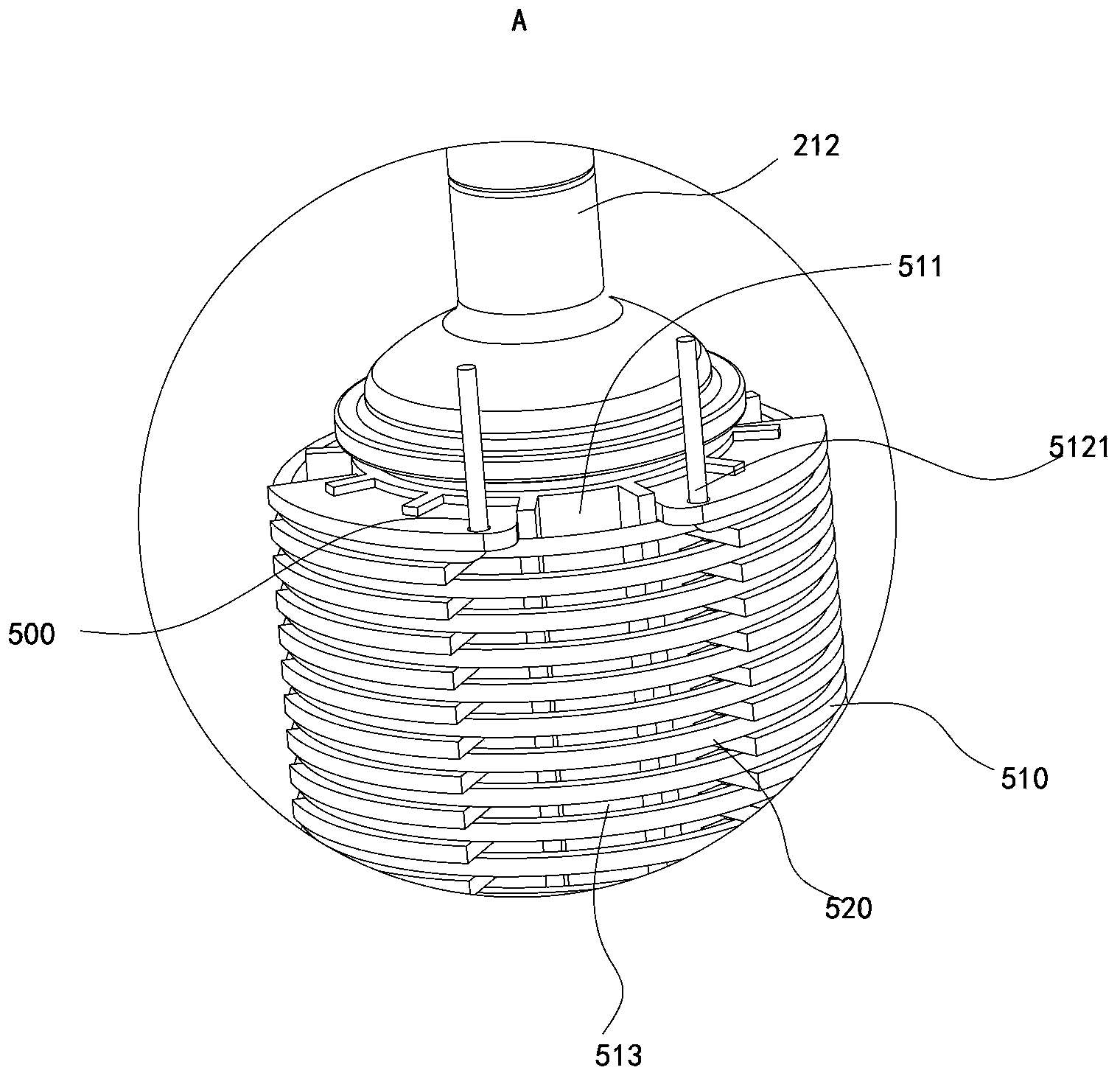

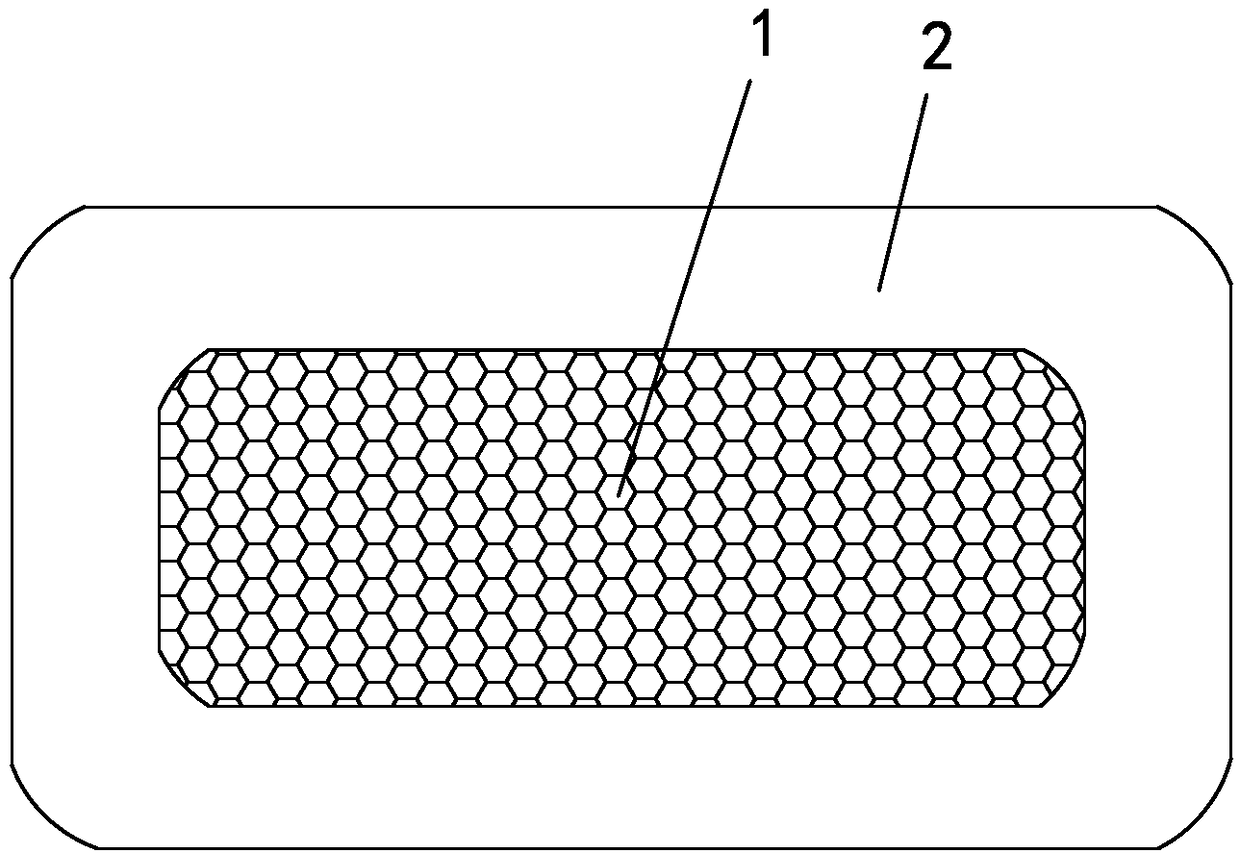

Composite structure printed circuit board type heat exchanger core body

PendingCN111059934AMeet high temperature requirementsImprove high temperature resistanceLaminated elementsStationary plate conduit assembliesHeat flowMolten salt

The invention relates to a composite structure printed circuit board type heat exchanger core body. A plurality of etching plates, fin plates and septa are alternately stacked and arranged in the height direction, the upper surfaces of the etching plates are etched with micro-flow channels for sCO2 medium to flow, seals are arranged on the left and right sides of the fin plates, an interlayer is formed by each fin plate, the seals on the left and right sides and the septa on the upper and lower sides, and a channel for molten salt or liquid metal medium to flow is formed. The composite structure printed circuit board type heat exchanger core body can be resistant to high temperature, high pressure and large pressure difference, and has the characteristics of large heat load, high heat fluxdensity, compactness and high efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

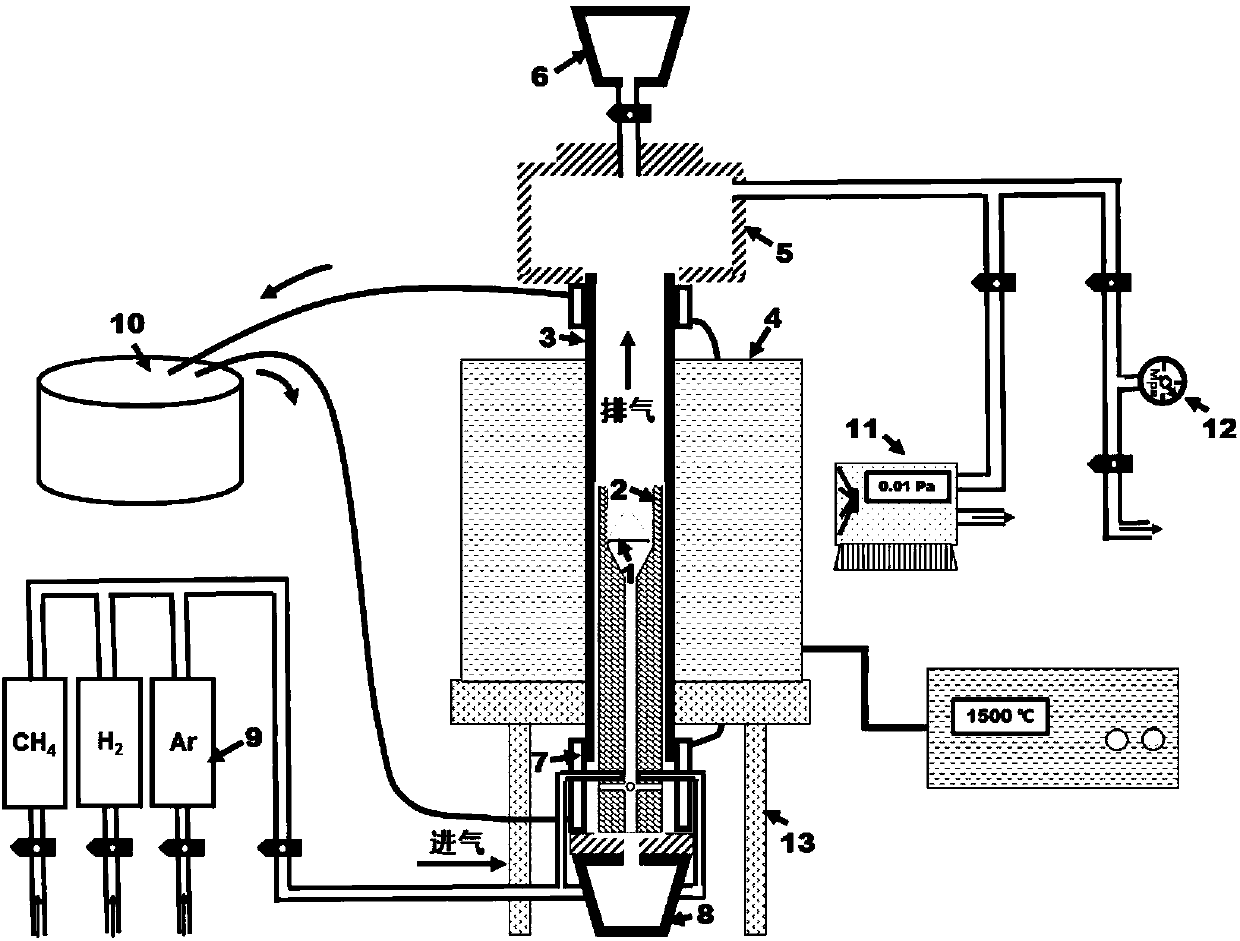

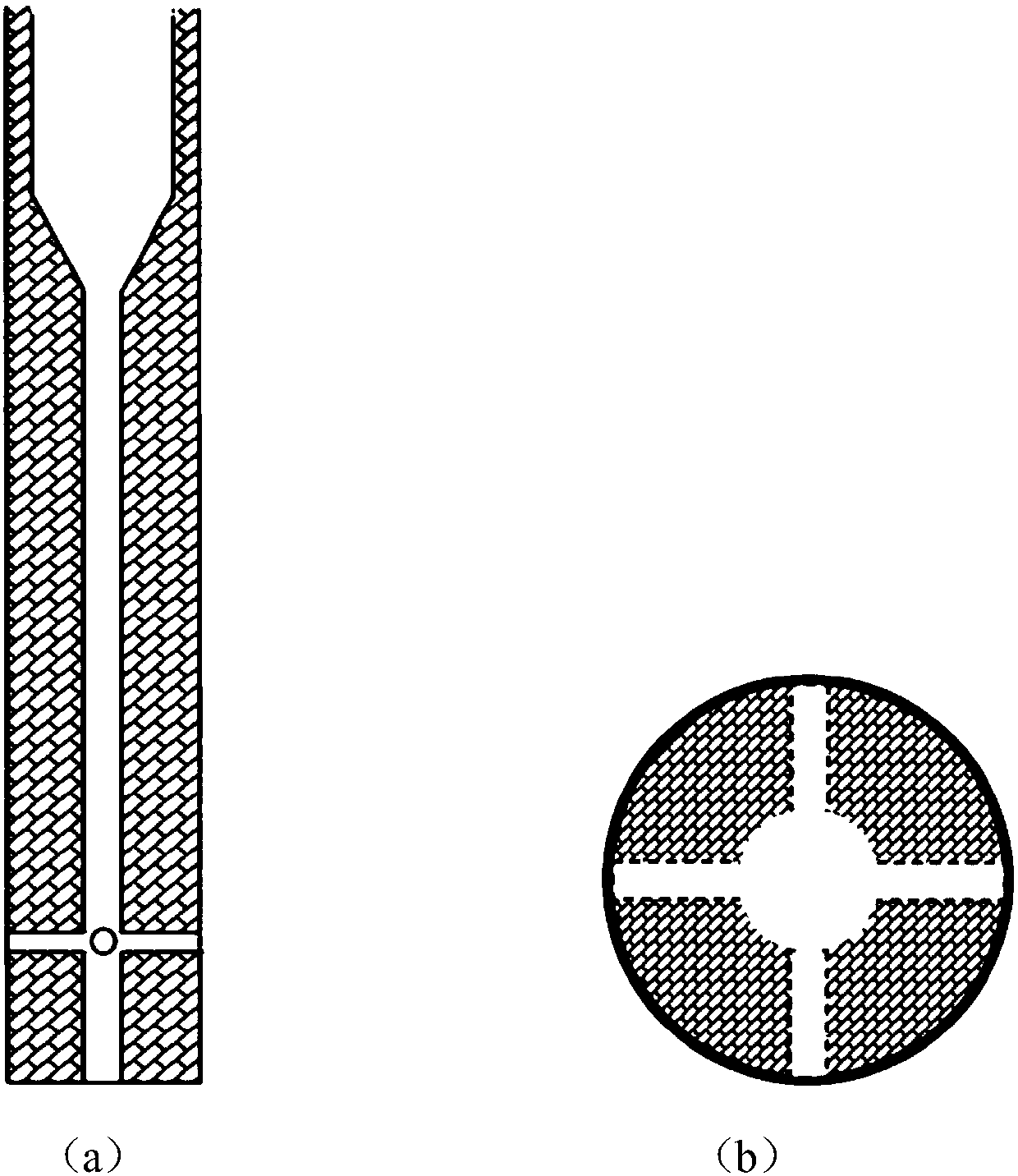

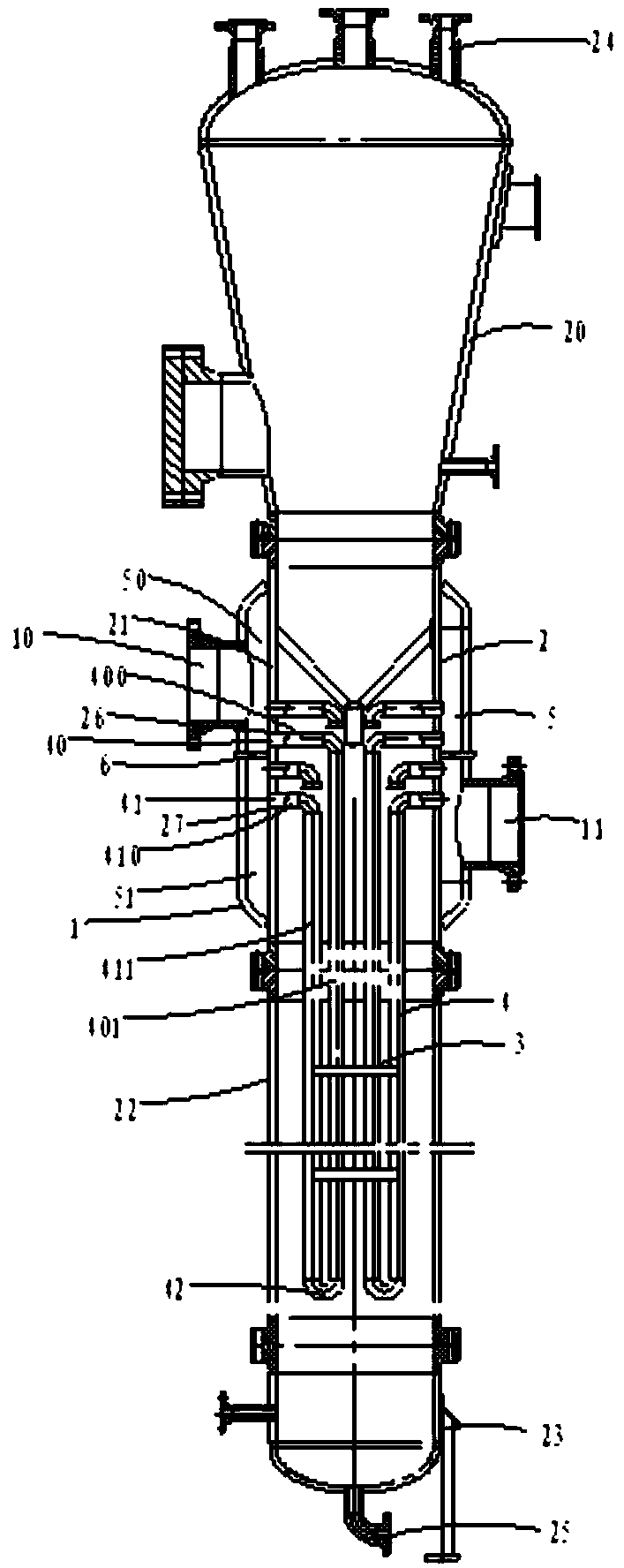

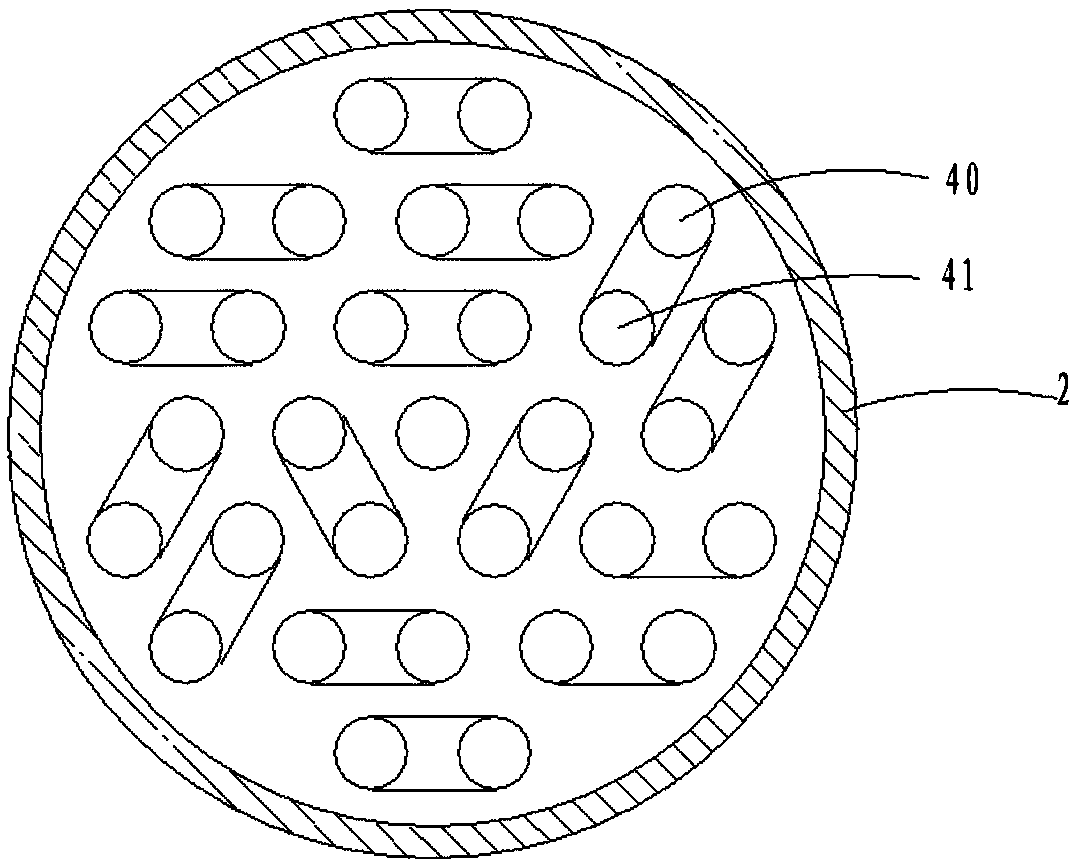

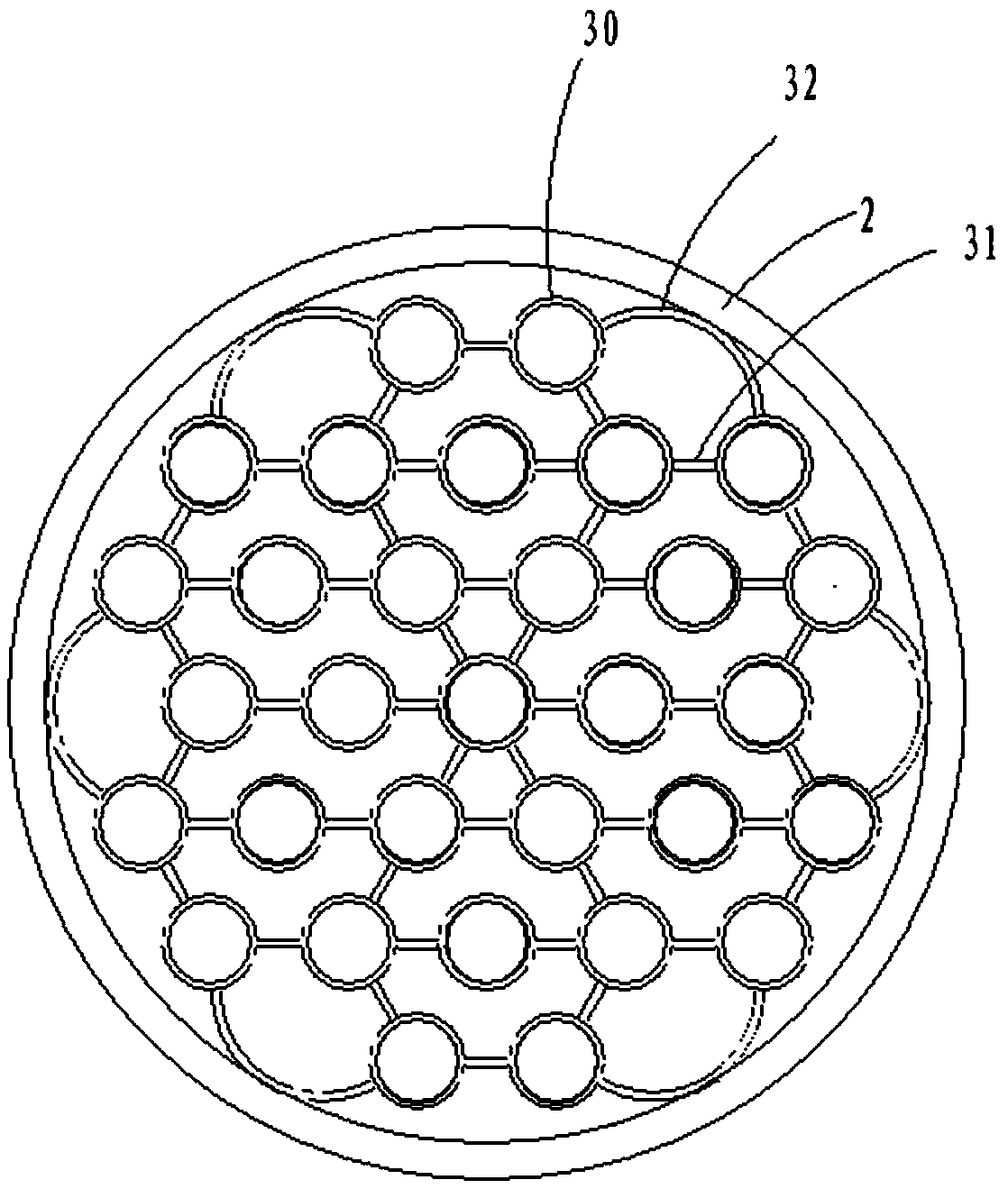

High-temperature fluidized bed reaction device

PendingCN107899520ASymmetrical and even airflowMeet high temperature requirementsChemical/physical processesTemperature resistanceAirflow

The invention discloses a high-temperature fluidized bed reaction device, and belongs to the technical field of powder material production. The device comprises a high-temperature heating furnace body, a feeding cabin, an upper sealing flange, a high-temperature-resistance furnace pipe, an airflow regulator, and air distributor, a lower sealing flange and a discharging cabin, wherein the inner cavity of the high-temperature-resistance furnace pipe is served as a fluidized bed reaction cavity; the feeding cabin is connected with the top end of the high-temperature-resistance furnace pipe through the upper sealing flange; the bottom end of the high-temperature-resistance furnace pipe is connected with the discharging cabin through the lower sealing flange; the airflow regulator and the gas distributor are arranged in the high-temperature-resistance furnace pipe. According to the device, power material fluidization can be realized under a high-temperature environment, and the problems ofthe powder layering, hardening and the like of a conventional device in a reaction process due to an uneven atmosphere condition are avoided. Meanwhile, since a controllable feeding cabin and a controllable discharging cabin are designed, continuous material loading and unloading and quick material cooling can be realized, production efficiency is greatly improved, and production cost is lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

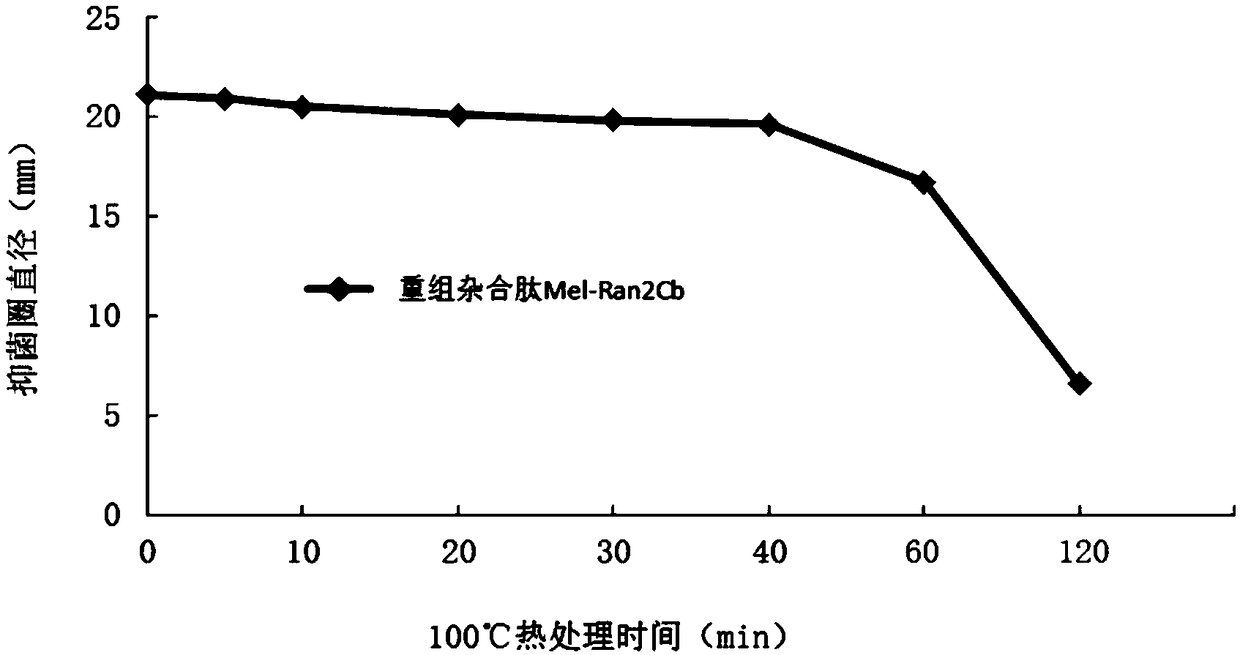

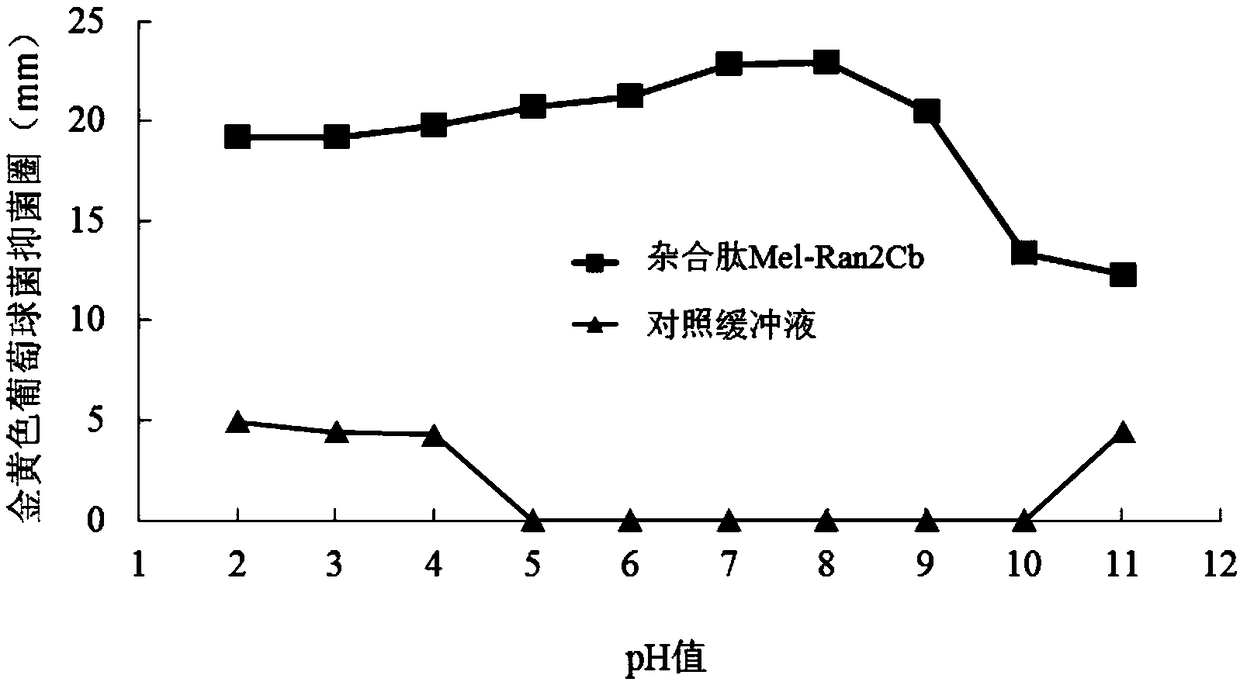

Hybrid peptide and application thereof in bacteriostasis

ActiveCN108690140AMeet the high temperature requirements of granulationMeet high temperature requirementsAntibacterial agentsPeptide/protein ingredientsThermal stabilityPathogenic bacteria

The invention discloses a hybrid peptide and an application thereof in bacteriostasis. The hybrid peptide has a broad-spectrum antimicrobial activity and can inhibit most gram-positive bacteria and gram-negative bacteria to certain degrees. Compared with original antibacterial peptides, the bacteriostatic activity of the hybrid antibacterial peptide on common pathogenic bacteria is obviously enhanced. The hybrid peptide has the characteristics of thermal stability and acid stability, and has a good application prospect in fields such as food preservation, disease control, animal feed additive,and the like.

Owner:GUANGZHOU GLAM BIOTECH

Method for manufacturing photovoltaic connector

ActiveCN102118000AMeet high temperature requirementsWide choiceContact member cases/bases manufacturePlastic materialsEngineering

The invention provides a method for manufacturing a photovoltaic connector, comprising the following steps of: connecting a connector conductive body with a cable conductive body; placing the connector conductive body and the cable conductive body in a forming mold I, melting plastic I and then injecting into the forming mold I, cooling and taking out to finish the injection molding of a connection layer so as to form a connector body, wherein the melting temperature of the plastic I is between 180 DEG C and 250 DEG C; melting plastic II and then injecting into a forming mold II, cooling and taking out to finish the injection molding of a tapered end so as to form the tapered end, wherein the melting temperature of the plastic II is between 160 DEG C and 230 DEG C; and placing the tapered end and the connector body in a forming mold III, melting plastic III and then injecting into the forming mold III, cooling and taking out to finish the injection molding of a sealing layer so as to form the finished connector product, wherein the melting temperature of the plastic III is between 100 DEG C and 150 DEG C. In the invention, the technical process is simple; and the components of the plastic materials are not limited and are wider in choice, thereby having high flexibility in the actual production and being beneficial to controlling the cost.

Owner:CHANGSHU FRIENDS CONNECTOR TECH

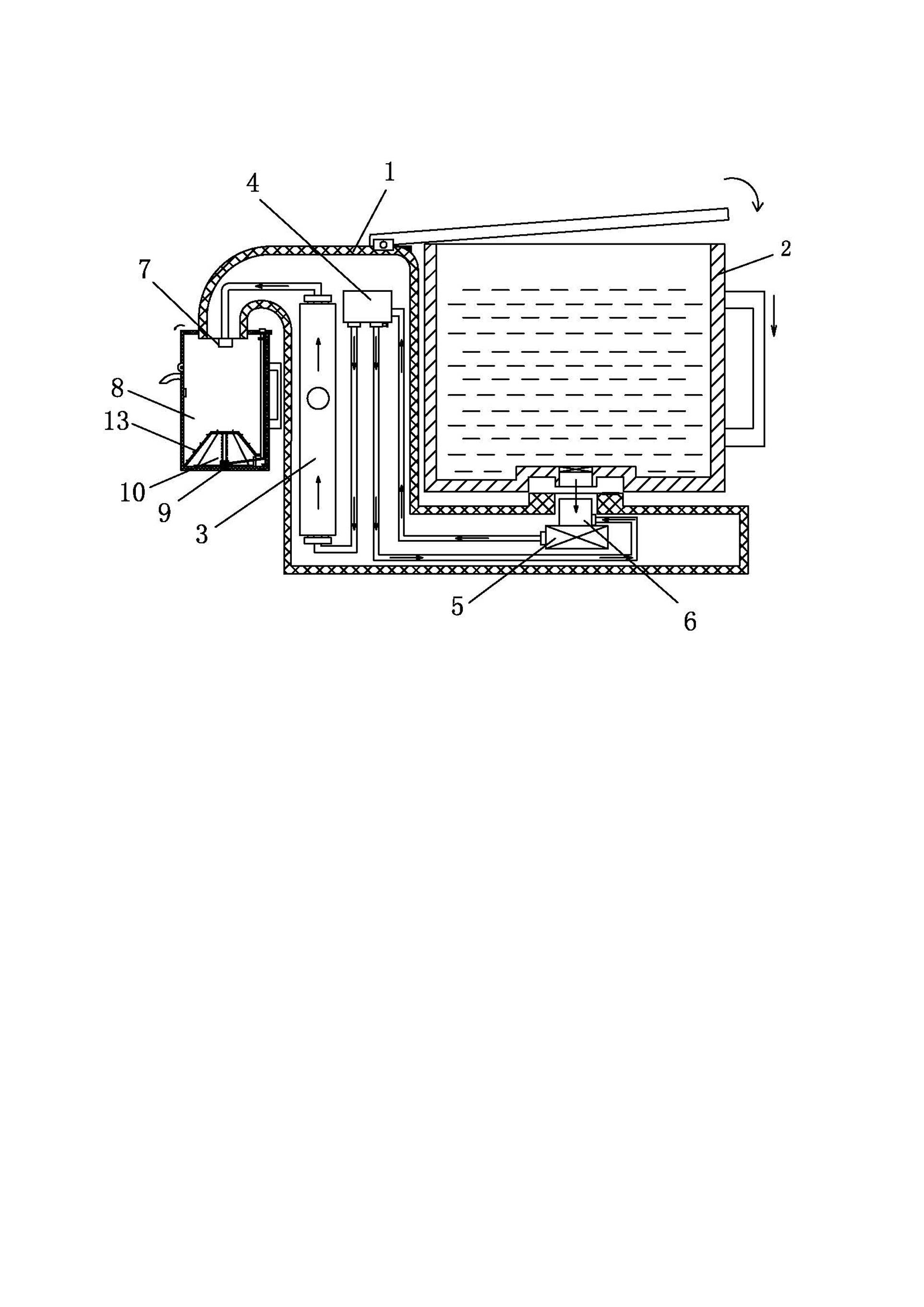

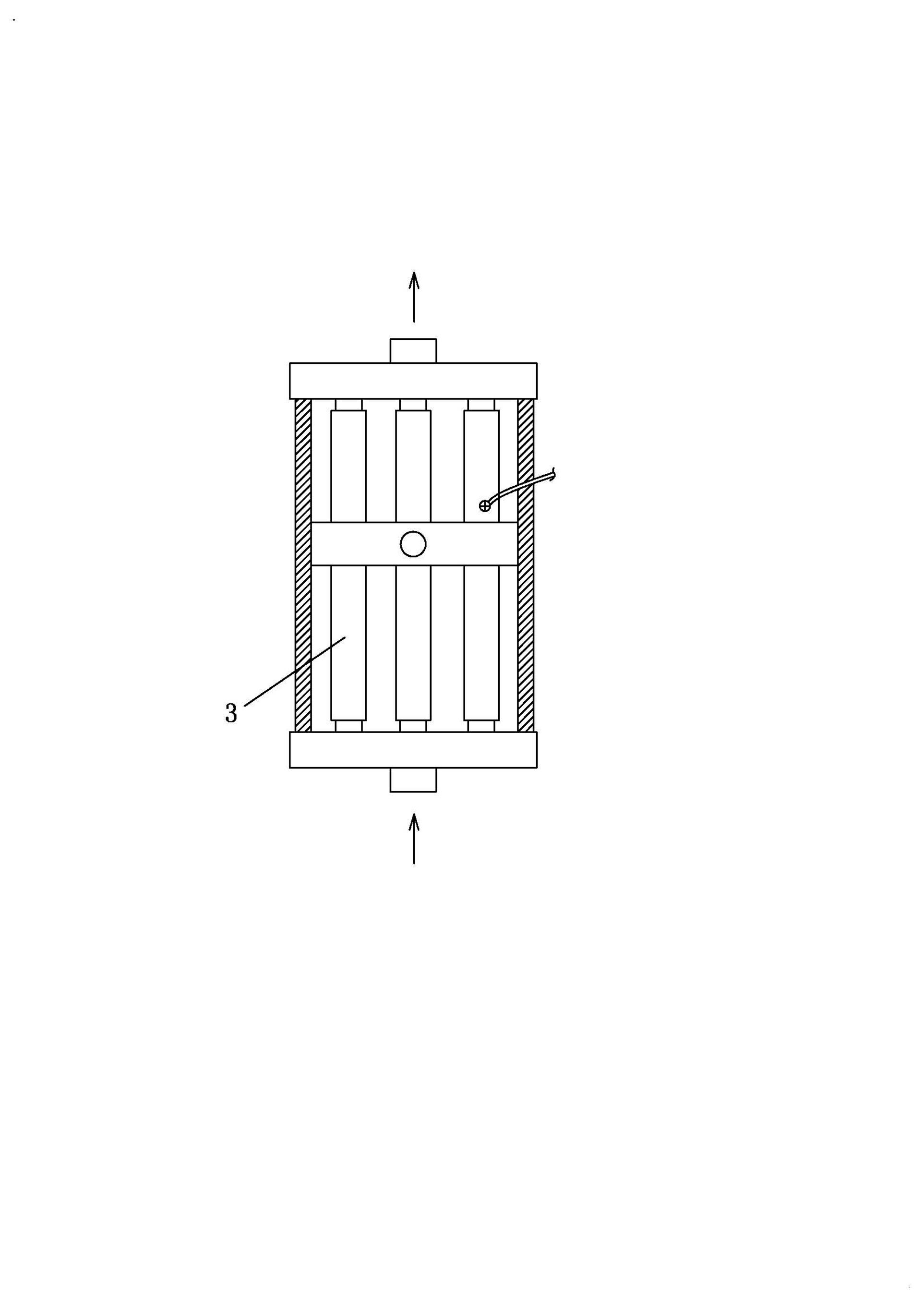

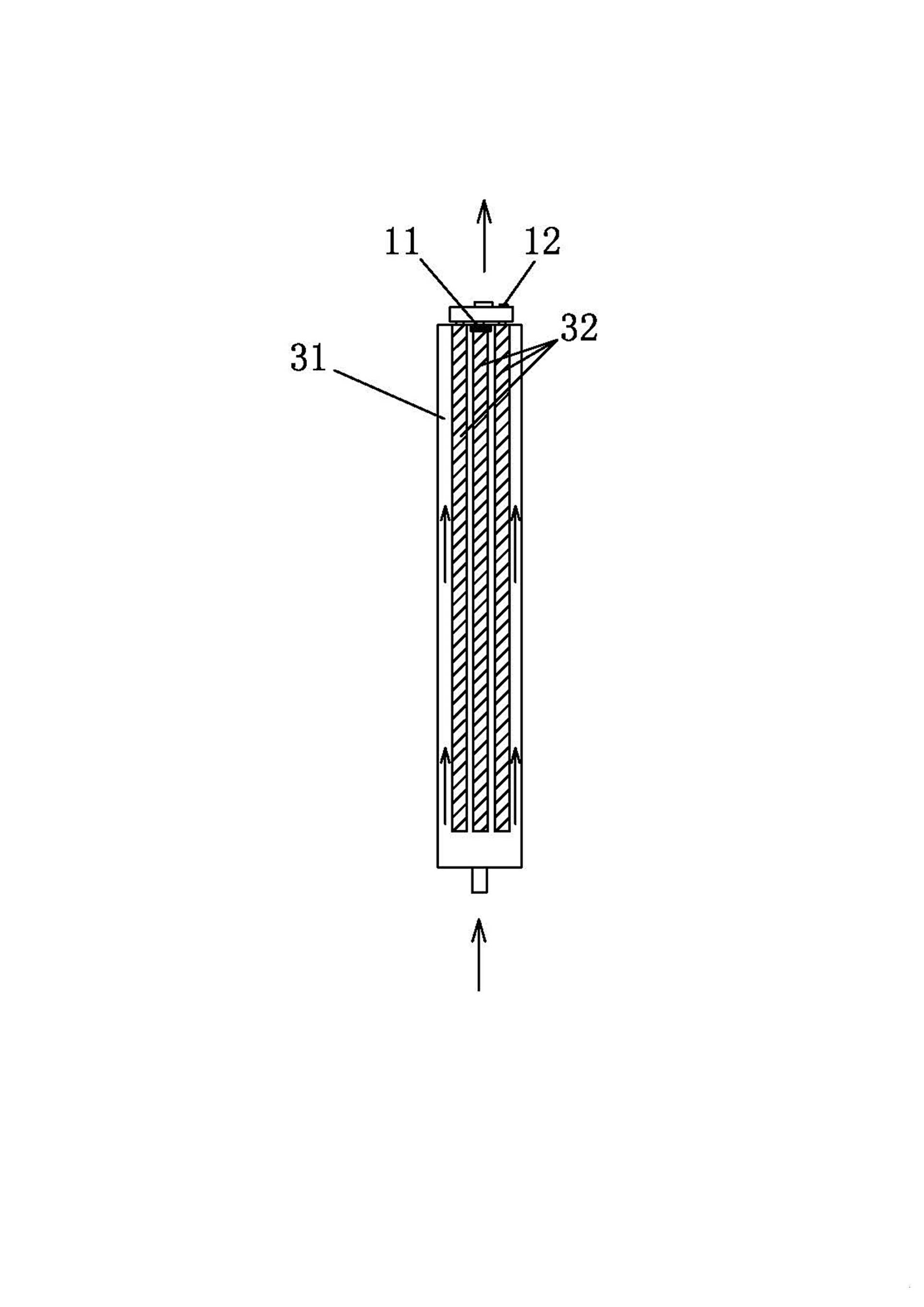

Electromagnetic induction heating device and water dispenser with same

InactiveCN104344540AMeet high temperature requirementsMeet hygiene requirementsBeverage vesselsWater heatersEngineeringElectromagnetic shielding

The invention discloses an electromagnetic induction heating device and a water dispenser with the same. The electromagnetic induction heating device comprises a water pipe, a metal heating element, a flow guide part and an electromagnetic coil component, wherein the metal heating element is arranged in the water pipe, the flow guide part is arranged in the water pipe, and the electromagnetic coil component is arranged outside the water pipe and used for heating the metal heating element through electromagnetic induction. According to the electromagnetic induction heating device, by the aid of the electromagnetic induction heating technology, water temperature is increased to the temperature needed by boiling, and used materials can meet the requirements for high temperature resistance and sanitation.

Owner:MIDEA GRP CO LTD +1

Method for manufacturing photovoltaic connector

ActiveCN102118000BMeet high temperature requirementsWide choiceContact member cases/bases manufactureEngineeringMelting temperature

The invention provides a method for manufacturing a photovoltaic connector, comprising the following steps of: connecting a connector conductive body with a cable conductive body; placing the connector conductive body and the cable conductive body in a forming mold I, melting plastic I and then injecting into the forming mold I, cooling and taking out to finish the injection molding of a connection layer so as to form a connector body, wherein the melting temperature of the plastic I is between 180 DEG C and 250 DEG C; melting plastic II and then injecting into a forming mold II, cooling and taking out to finish the injection molding of a tapered end so as to form the tapered end, wherein the melting temperature of the plastic II is between 160 DEG C and 230 DEG C; and placing the taperedend and the connector body in a forming mold III, melting plastic III and then injecting into the forming mold III, cooling and taking out to finish the injection molding of a sealing layer so as to form the finished connector product, wherein the melting temperature of the plastic III is between 100 DEG C and 150 DEG C. In the invention, the technical process is simple; and the components of theplastic materials are not limited and are wider in choice, thereby having high flexibility in the actual production and being beneficial to controlling the cost.

Owner:CHANGSHU FRIENDS CONNECTOR TECH

Special-shaped flat aluminum alloy conductor cable for new energy automobile

InactiveCN109461524AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsConductive materialElectrical conductorInsulation layer

The invention discloses a special-shaped flat aluminum alloy conductor cable for new energy automobile. The special-shaped flat aluminum alloy conductor cable comprises a center conductor and an insulation layer; the center conductor is a flat conductor compressed by annealing aluminum alloy, the aluminum alloy is prepared from the following raw materials in parts by weight: 25-35 parts of aluminum, 0.4-0.6 part of iron, 0.06-0.08 part of silicon, 0.15-0.3 part of copper, 0.02-0.05 part of magnesium, and less than 0.3 part of impurity; the insulation layer is prepared from crosslinking TPE material, and the crosslinking TPE material is prepared from the following raw materials: 25-35 parts of SEBS, 20-30 parts of polypropylene, 20-30 parts of phosphorous-nitrogen system fire retardant, 5-10 parts of nano-silicon dioxide, 5-15 parts of naphthenic oil, 5-10 parts of crosslinking agent, 2-5 parts of lubricant, 2-3 parts of master batch, and 0.2-1 part of antioxidant. The conductor cable disclosed by the invention has excellent tension strength, elongation at break and tearing strength. Compared with the existing copper cable, the cost is lower and the mass is lighter in the premise ofguaranteeing the electric property.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

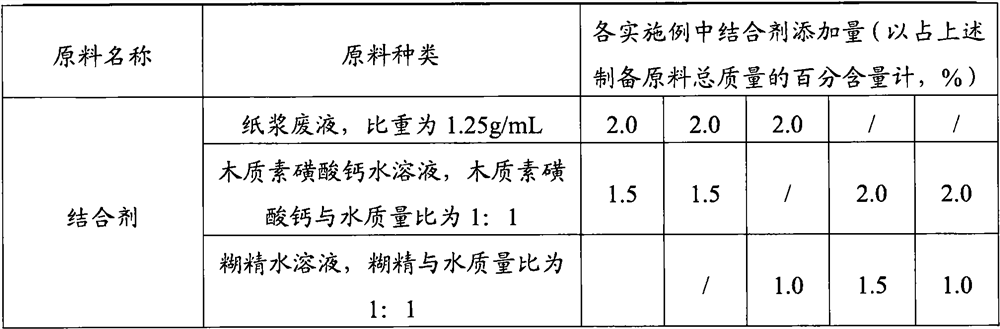

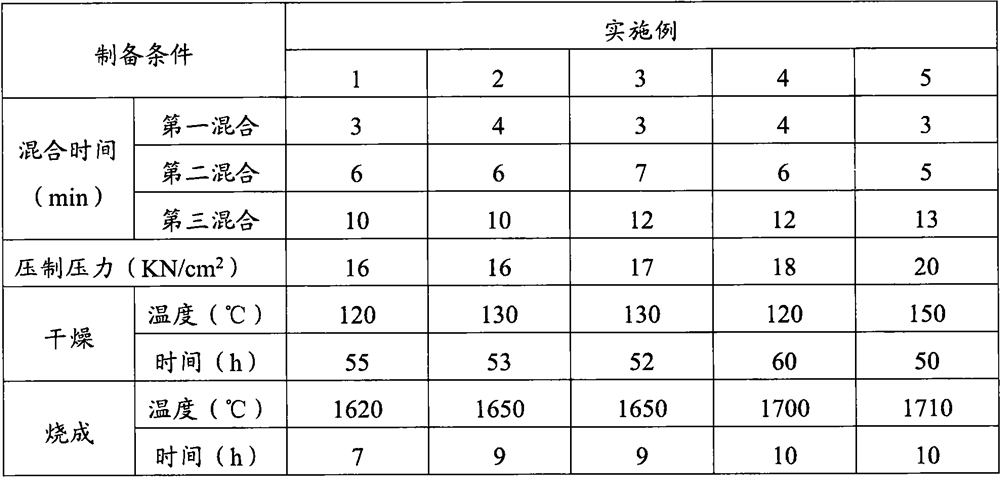

Low-thermal-conductivity spinel refractory homogeneous brick as well as preparation method and application thereof

The invention provides a low-thermal-conductivity spinel refractory homogeneous brick as well as a preparation method and application thereof, and belongs to the technical field of refractory materials. The low-thermal-conductivity spinel refractory homogeneous brick provided by the invention is prepared from the following raw materials: magnesia particles, magnesia fine powder, magnesium aluminate spinel particles, light hollow spheres, additive micro powder and a binding agent. The low-thermal-conductivity spinel fire-resistant homogeneous brick provided by the invention is uniform in material, the hidden danger that weak parts are easy to appear in a composite structure formed by different materials is avoided, and the problem that the composite brick is broken in the use process is avoided. Meanwhile, the low-thermal-conductivity spinel refractory homogeneous brick provided by the invention takes a periclase-spinel system as a matrix, is stable in high-temperature performance, is resistant to corrosion of alkali metals, volatile salts and the like, and is suitable for severe environments of rotary cement kilns or lime calcining kilns.

Owner:MARVELS REFRACTORIES ANSHAN CO LTD

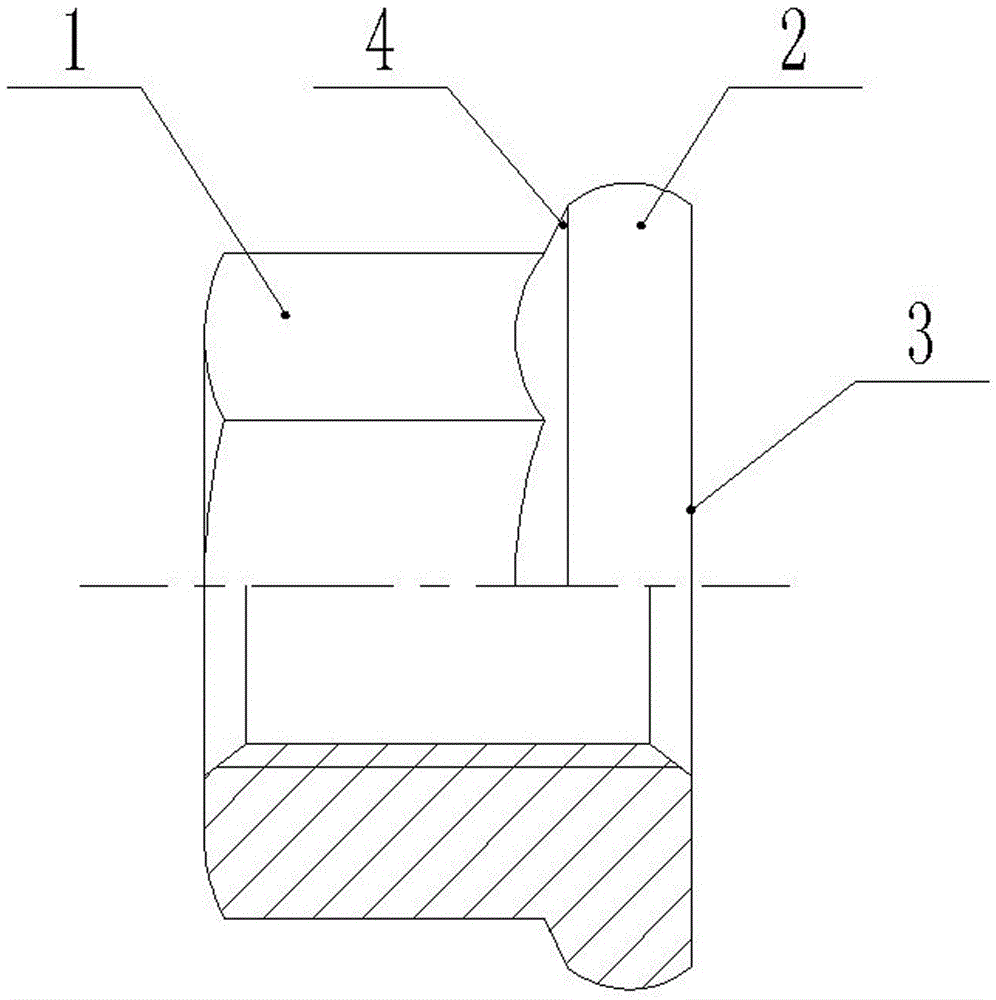

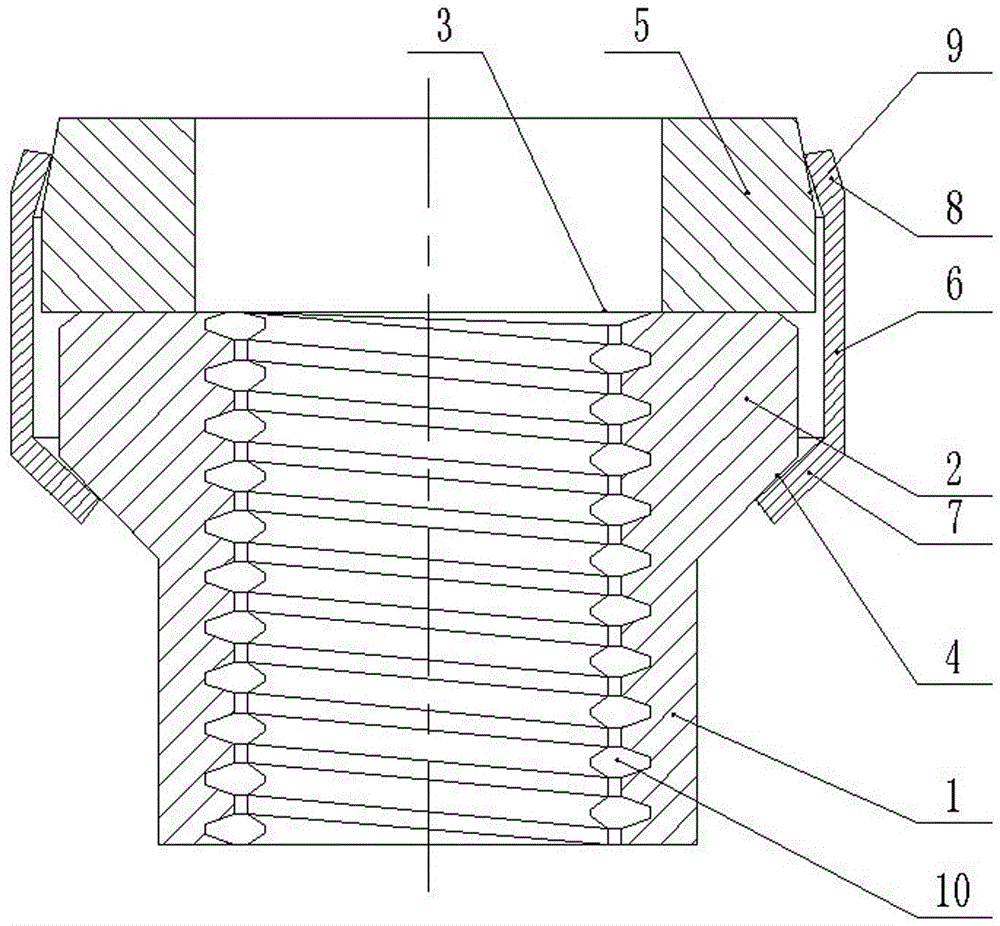

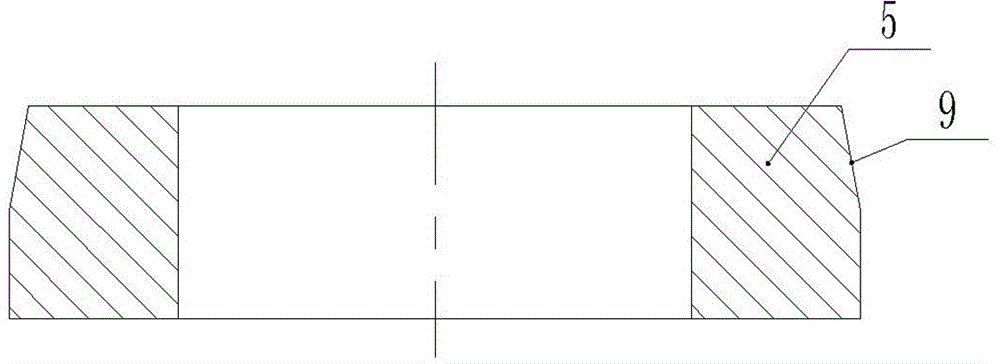

Flange nut-washer assembly

The invention provides a flange nut washer assembly to solve the problem of inconvenient operation when the flange nut and the washer are installed separately. The flange nut washer assembly includes a flange nut and a washer coaxially arranged, one end face of the washer is attached to the flange end face of the flange nut, and the end of the washer away from the flange nut is provided with an outer chamfer, The flange nut washer assembly also includes a clip-type structure for preventing axial relative displacement of the flange nut and the washer, and the clip-type structure includes a first pressing portion and a pressing portion for pressing the annular skirt of the flange nut. Tighten the second pressing part of the outer chamfer of the washer. The first pressing part and the second pressing part of the clip-type structure produce an axial clamping force on the flange nut washer assembly, so that the washer and the flange nut will not have axial relative displacement, so that the washer is fixed on the flange on the flange end of the nut. When installing, flange nuts and washers can be installed together for easy operation.

Owner:河南航天精工制造有限公司

High temperature resistant and low-cost ethylene propylene rubber

The invention discloses high temperature resistant and low-cost ethylene propylene rubber which comprises the following components in parts by weight: 10-30 parts of ethylene propylene monomer, 10-20 parts of ethylene propylene diene monomer, 3-6 parts of a vulcanizing agent, 5-8 parts of zirconium oxide, 6-10 parts of polyamide wax micro powder, 10-12 parts of acetylene carbon black, 2-4 parts of nano attapulgite and 3-5 parts of engine oil. According to the invention, the ethylene propylene monomer and ethylene propylene diene monomer are simultaneously adopted, and enabled to be subjected to co-vulcanization through adjusting a vulcanization system, so that the requirement of high temperature resistance is satisfied, the rubber material has relatively low compression set, the vulcanizate has excellent heat resistance, chemical stability and effect of low compressive deformation, and white carbon black and phenolic resin are adopted, so that the processing fluidity of the rubber material is improved.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

Ethylene propylene rubber

The invention relates to ethylene propylene rubber. The ethylene propylene rubber is prepared from the following components in parts by weight: 15-35 parts of ethylene-propylene methylene copolymer, 15-25 parts of ethylene-propylene-diene-terpolymer rubber, 1-6 parts of vulcanizing agent, 1-5 parts of anti-aging agent, 1-5 parts of white carbon black, 5-15 parts of acetylene black, 1-5 parts of attapulgite, 0.1-2 parts of stearic acid, 1-5 parts of cross-linking agent and 0.1-1 part of accelerator. The ethylene propylene rubber has the advantages that ethylene-propylene methylene copolymer and ethylene-propylene-diene-terpolymer rubber are used at the same time, and a vulcanization system is adjusted, so that the ethylene-propylene methylene copolymer and the ethylene-propylene- diene-terpolymer rubber are vulcanized at the same time, and the high temperature resistance requirement is met; the ethylene propylene rubber obtains low compression set, and a vulcanized product has good heat resistance, chemical stability and low compression deformation; white carbon black and phenolic resin are adopted, so that the processing fluidity of the ethylene propylene is improved.

Owner:李雪红

Special sand mold coating material produced from alumina powder as main raw material

The invention relates to a special sand mold coating material produced from alumina powder as a main raw material. The technical scheme is as follows: the special sand mold coating material comprisesthe following raw materials by weight: 5.3kg to 6.7kg of water, 10.75kg to 14.75kg of alumina powder, 6g to 10g of xanthan gum and 38g to 42g of polyethylene. According to the special sand mold coating material, the production cost of an electrically-fused brick sand mold coating material is greatly reduced, and the coating material cost of electrically-fused bricks per ton can be saved by about 200 RMB; the alumina powder has refractoriness capable of reaching 2,010 DEG C to 2,050 DEG C, and thus, the requirements of high-temperature resistant coating materials of electrically-fused brick sand molds on high-temperature resistance can be met; the market price of the alumina powder per ton is 3,200 RMB, and the use cost of the coating material can be greatly reduced as the electrically-fused brick sand mold coating material; and by using the alumina powder as the sand mold coating material, the fitness is higher, a layer of crust is formed after the coating material is sintered, thus, gas generated from resin combustion is prevented from polluting brick faces, crusts formed by the coating material at high temperatures will successfully and naturally fall off during brick discharging, the brick faces are more convenient in cleaning, and the efficiency of cleaning of the brick faces is increased.

Owner:郑州远东耐火材料有限公司

Novel high-temperature-resistant epoxy resin adhesive as well as preparation method and use method thereof

PendingCN112500820AMeet high temperature requirementsHigh temperature resistantAdhesive processesEpoxy resin adhesivesPolymer scienceFirming agent

The invention discloses a novel high-temperature-resistant epoxy resin adhesive as well as a preparation method and a use method thereof, and relates to the technical field of novel adhesives, the novel high-temperature-resistant epoxy resin adhesive comprises the following substances in parts by mass: 8-12 parts of epoxy resin, 0.9-1.3 parts of aromatic amine high-temperature-resistant curing agent and 3-4 parts of epoxy curing agent, by adopting the processes of novel configuration, centrifugal defoaming, glue filling and the like, the produced epoxy resin glue has the advantages of high temperature resistance and no bubbles, and compared with the prior art, the patent of the invention adopts novel raw materials, a novel ratio and a novel process, tests show that the insulating propertyis excellent under different humidity and temperature, and the condition that the insulating resistance is reduced does not occur; the requirements of dielectric voltage resistance and insulation resistance of products can be met, and the application prospect is wide.

Owner:SHAANXI HUADA SCI TECH

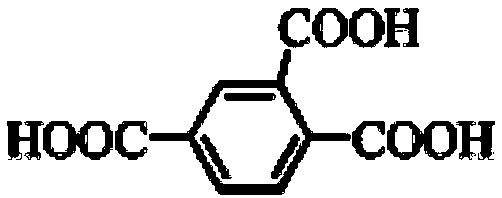

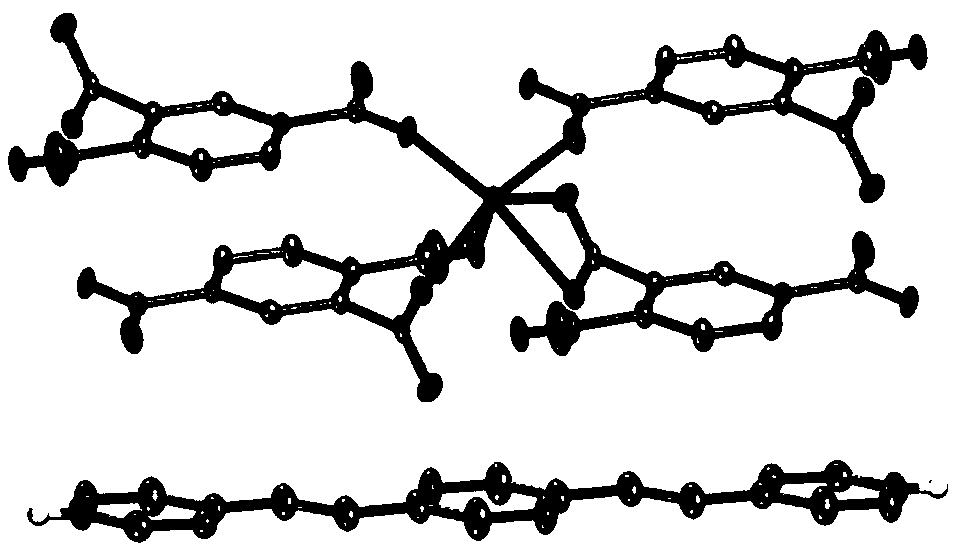

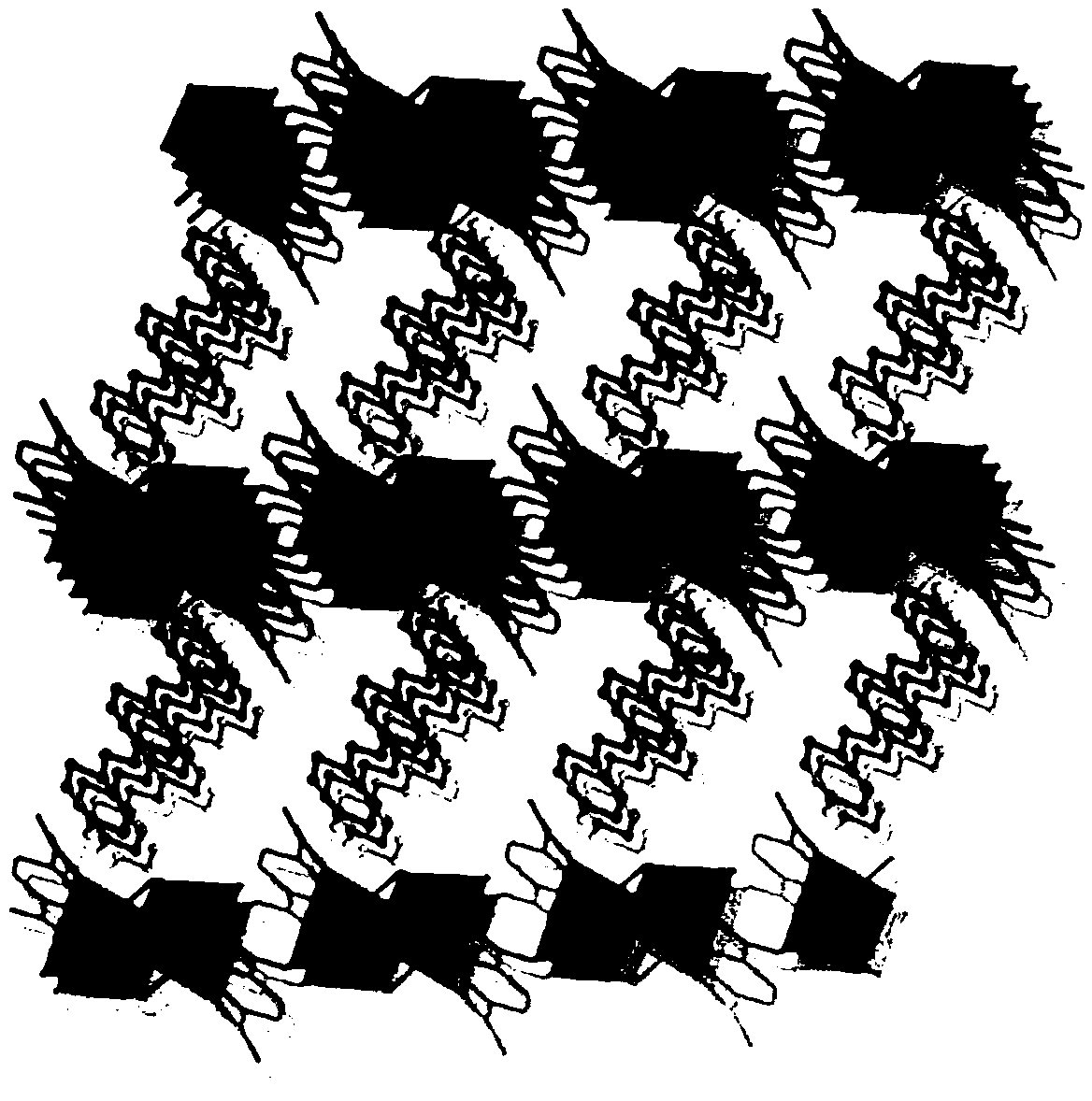

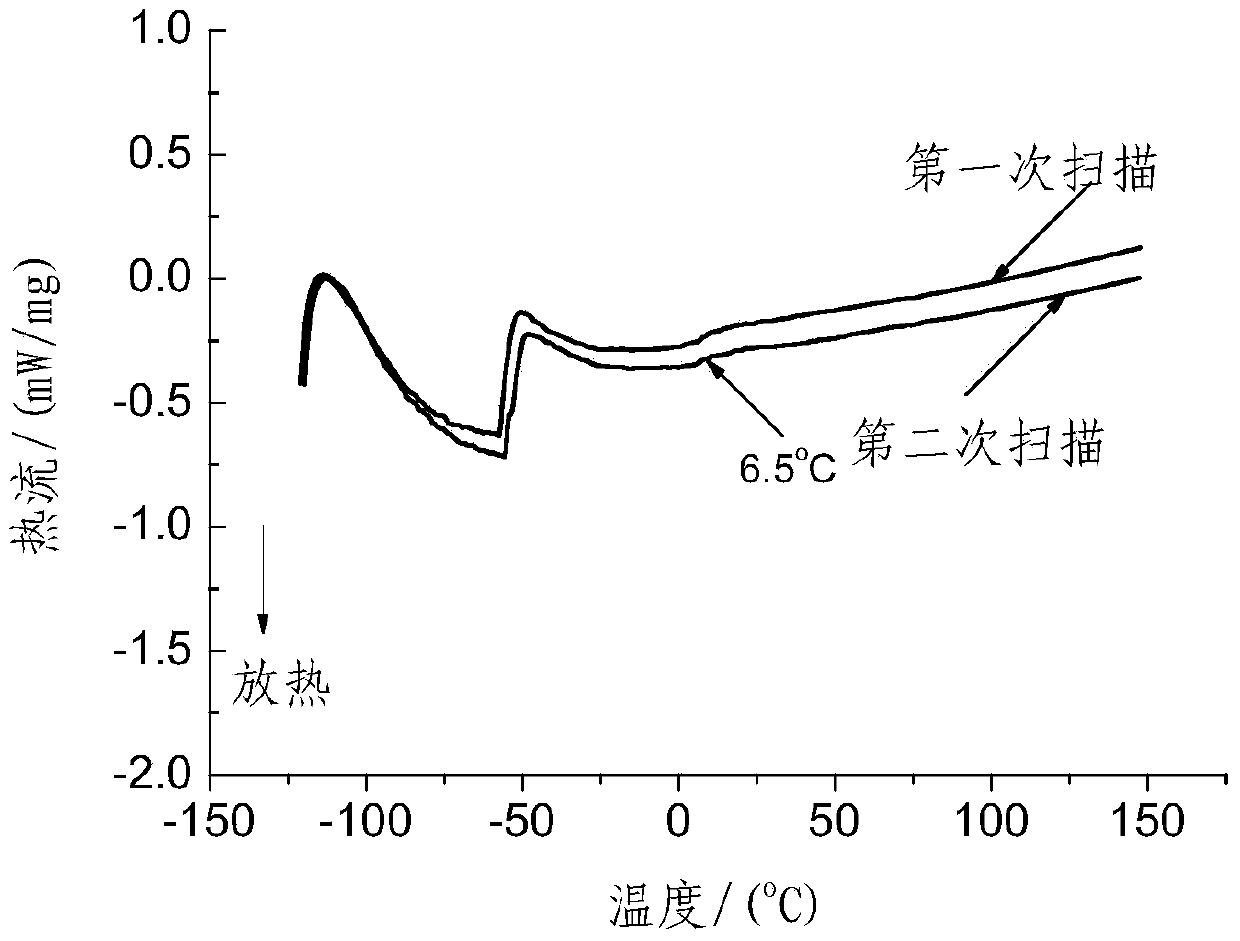

Blue-green fluorescent sandwich-type manganese coordination polymer, preparation method and application thereof to positive ion detection

ActiveCN109054036AHigh thermal stabilityMeet high temperature requirementsFluorescence/phosphorescenceAlcoholFluorescence

The invention relates to the field of materials, in particular to a blue-green fluorescent sandwich-type manganese coordination polymer, a preparation method and application thereof to positive ion detection. The new manganese coordination polymer can emit bimodal glue-green fluorescence under excitation of ultraviolet light, meanwhile, the thermal stability of the polymer is high, and the polymeris degraded at the temperature of approximately 400 DEG C, and meets the high temperature requirement for additive in the processing of light conversion plastics. The polymer can further serve as a detection reagent to explore whether positive ions such as Pb2+, Al3+ and Pr3+ exist in a solution or not through a ultraviolet visible spectrophotometer, and thus can have the application prospect inthe field of positive ion detection. The preparation method prepared by the invention is easy to operate, the yield of the product can be maintained within the range of 57-63%, and because the coordination polymer {[Mn2(tma)2](H2bpeb)}n is insoluble in solvents such as water, ethyl alcohol and acetonitrile, the preparation method can be utilized for enriching and recycling Mn.

Owner:CHONGQING NORMAL UNIVERSITY

Water-based vehicle lamp reflecting cover film-coating paint and preparation method thereof

InactiveCN103740223AImprove adhesionImprove heat resistanceEpoxy resin coatingsEpoxyDiacetone alcohol

The invention discloses water-based vehicle lamp reflecting cover film-coating paint and a preparation method thereof, relating to vacuum film-coating paint. The paint consists of the following components in percentage by mass: 100 percent of acrylate resin, 15-30 percent of epoxy resin and 20-35 percent of amino resin, wherein the acrylate resin consists of the following components in percentage by mass: 100 percent of butyl acrylate, 18-22 percent of hydroxyethyl methylacrylate and 8-12 percent of methacrylic acid. The preparation method comprises the following steps: adding the butyl acrylate, the hydroxyethyl methylacrylate and the methacrylic acid into a container, adding a mixed solvent of diacetone alcohol and n-butyl alcohol, stirring at 95-105 DEG C, dissolving benzoyl peroxide in a diacetone alcohol solvent, adding a benzoyl peroxide-diacetone alcohol solution, and reacting to obtain an acrylate resin solution; adding the epoxy resin and the amino resin into the mixed solvent of diacetone alcohol and n-butyl alcohol, adding an obtained epoxy resin-amino resin solution into the acrylate resin solution, reacting to obtain solvent type paint, and adding distilled water to obtain a product.

Owner:XIAMEN UNIV

Jacketed heat exchanger

PendingCN108645262ASimple structureEasy to installIndirect heat exchangersHeat exchanger casingsPlate heat exchangerPipe fitting

The invention relates to a jacketed heat exchanger. The jacketed heat exchanger comprises an outer shell and an inner shell and further comprises a plurality of supporting mechanisms and a plurality of heat exchange pipe fittings, all of which are arranged in the inner shell. The outer shell is arranged on the outer side of the inner shell. A jacket layer is formed between the outer shell and theinner shell. A pass partition plate is arranged between the outer shell and the inner shell and divides the jacket layer into a first cavity and a second cavity. The outer shell is provided with a tube pass inlet communicating with the first cavity and a tube pass outlet communicating with the second cavity. Each heat exchange pipe fitting comprises an inlet pipe communicating with the first cavity, an outlet pipe communicating with the second cavity, and a connecting pipe used for connecting the inlet pipe with the outlet pipe. The inner shell is provided with a shell pass inlet and a shell pass outlet. The jacketed heat exchanger is simple in structure and convenient to install; and a jacketed structure is adopted, and the dual effects of outer heating and heat preservation can be achieved.

Owner:ZHANGHUAJI SUZHOU HEAVY EQUIP CO LTD

Hybrid antibacterial peptide Mel-MytB and application thereof

ActiveCN108752431AGood thermal stabilityHigh antibacterial activityAntibacterial agentsFungiBroad spectrumExpression vector

The invention discloses a hybrid antibacterial peptide Mel-MytB and an application thereof. A hybrid antibacterial peptide Mel-MytB gene is cloned into a pPICZalpha-A vector to construct a secretory recombinant yeast expression vector pPICZalpha-A-MEM, and a P. Pastoris receptor bacterium X-33 is transformed. The Mel-MytB hybrid antibacterial peptide having a molecular weight of about 3.0 kD is expressed under the control of an alcohol oxidase promoter. Antibacterial property researches show that the expressed product has broad-spectrum antibacterial activity, and has good antibacterial activity against most G- bacteria and G+ bacteria; and the hybrid antibacterial peptide has significantly better inhibition activity to common pathogenic bacteria than original antibacterial peptides. The hybrid antibacterial peptide Mel-MytB has thermal stability and acid stability. All above characteristics make the recombinant antibacterial peptide Mel-MytB have good application prospects in fields of disease prevention and control and animal feed additives.

Owner:GUANGZHOU GLAM BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com