Composite structure printed circuit board type heat exchanger core body

A technology of printed circuit boards and composite structures, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve problems such as inability to meet the stringent requirements of intermediate heat The effect of strong pressure capacity and small microchannel size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

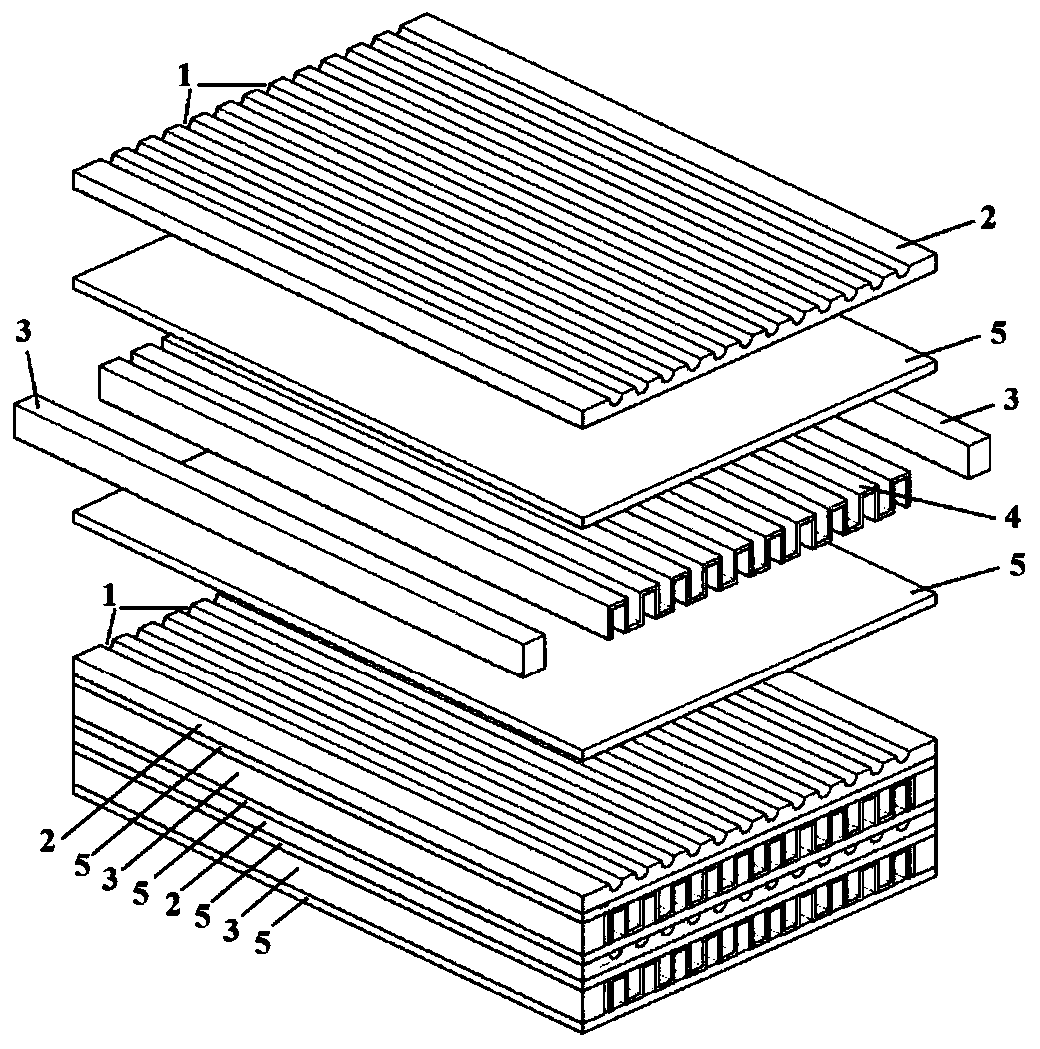

[0033] A core body of a printed circuit board heat exchanger with a composite structure, consisting of 3 etched plates 2, 3 partitions 5, 3 finned plates 4 and 3 partitions 5, which are sequentially arranged from top to bottom, closely bonded, and stacked After assembly, it is formed by diffusion welding.

[0034] The etching plate 2 is a 316L stainless steel sheet of 100mm×50mm×2mm, on which is provided 2 The micro-channel 1 through which the medium circulates; the micro-channel 1 is processed by a photochemical etching process, and is composed of 12 micro-channels arranged in parallel at equal intervals (1mm). 2mm semicircle.

[0035] The separator 5 is an 800HT nickel-based alloy sheet of 100mm×50mm×2mm.

[0036] The finned plate 4 is stamped and formed from a 0.2mm thick 800HT nickel-based alloy sheet. The straight fins have a height of 5mm and a pitch of 1.8mm. The finned plate 4 is 100mm long and 38.2mm wide.

[0037] The seal 3 is an 800HT nickel-based alloy square b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com