Jacketed heat exchanger

A technology of heat exchanger and jacket type, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger fixation, etc., can solve problems such as complex structure of tube sheet, vibration of heat exchange tubes, failure of welding joints, etc., to achieve Guarantee the connection quality, ensure the quality of the weld seam, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The jacketed heat exchanger of the present invention will be further described in detail below through specific embodiments.

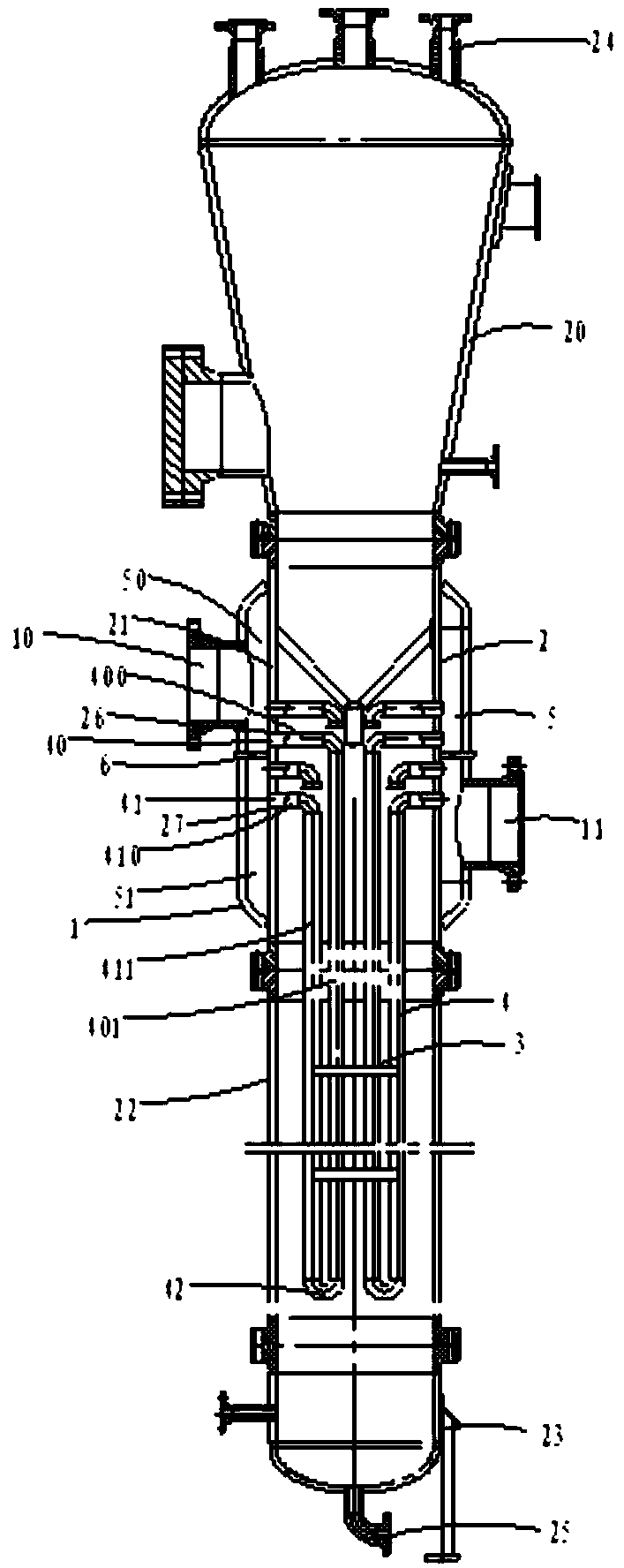

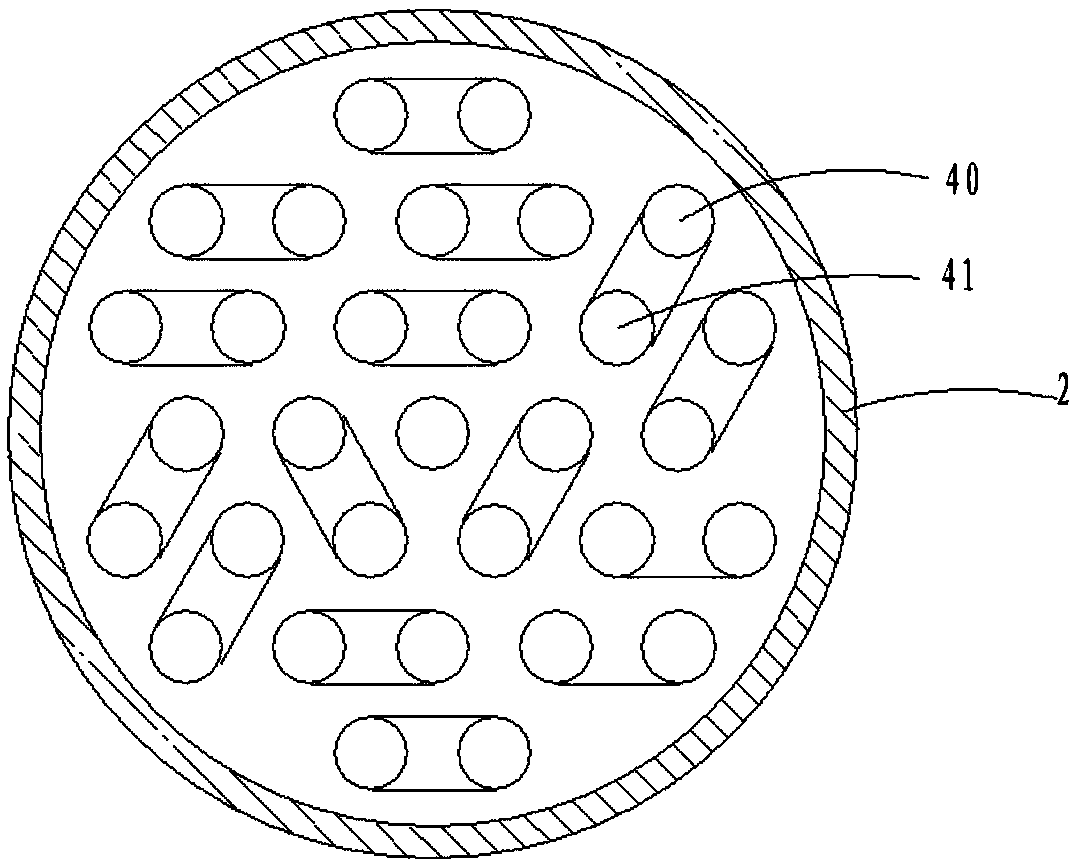

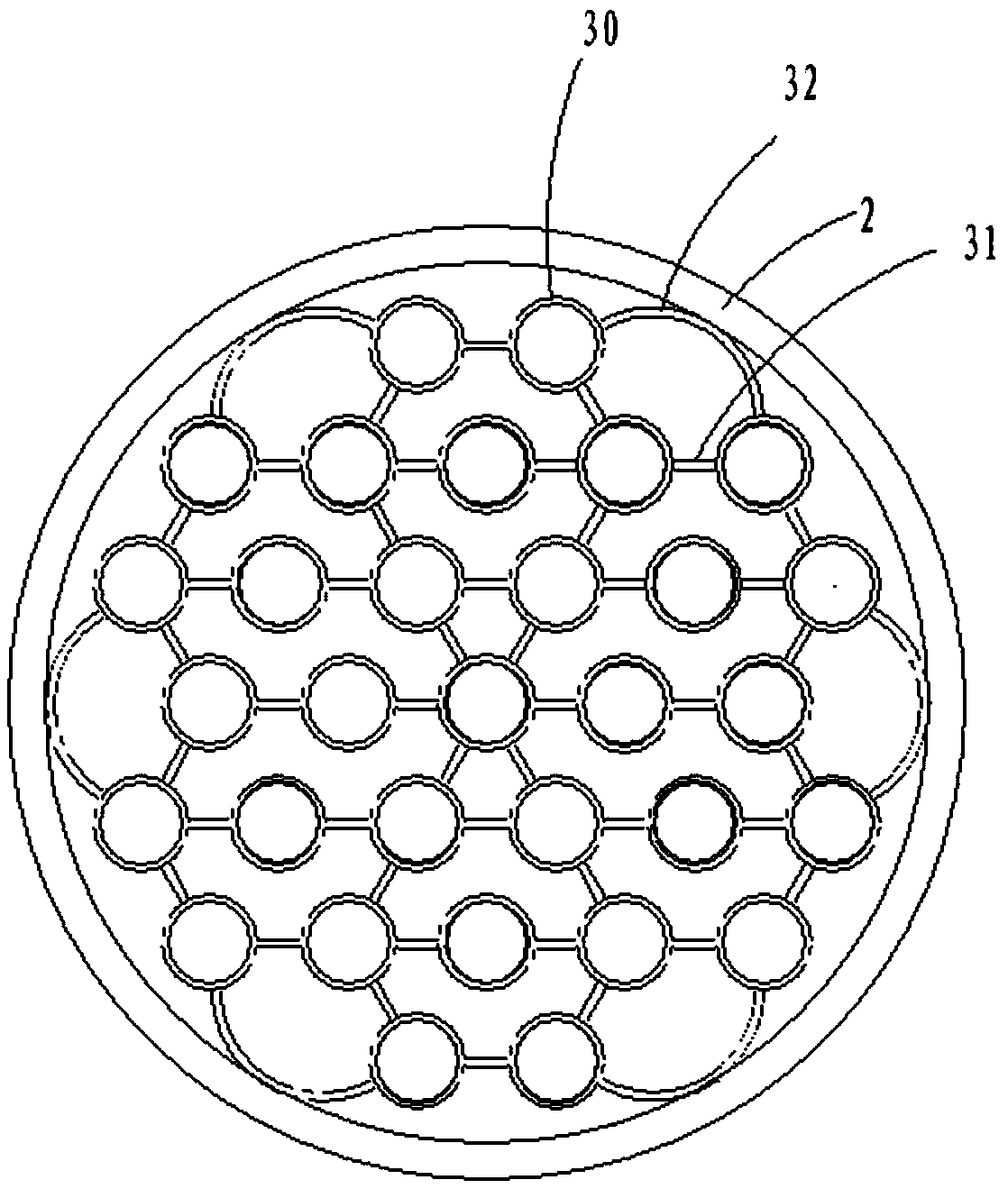

[0021] ginseng Figure 1 to Figure 4 , a jacketed heat exchanger, comprising: an outer shell 1, an inner shell 2, and a number of support mechanisms 3 and a number of heat exchange pipe fittings 4 arranged in the inner shell 2, the outer shell 1 being welded to the outer side of the inner shell 2 , the inner shell 2 includes a first head 20, a first shell section 21, a second shell section 22 and a second head 23, the first head 20 and the first shell section 21 are connected by a flange , the first shell segment 21 and the second shell segment 22 are connected by a flange, the second shell segment 22 and the second head 23 are connected by a flange, and the first head 20 is on the top The width and the lower part are conical, so that the operation space in the inner shell 2 can be enlarged, a jacket layer 5 is formed between the outer shell 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com