Patents

Literature

302results about How to "Guaranteed connection quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

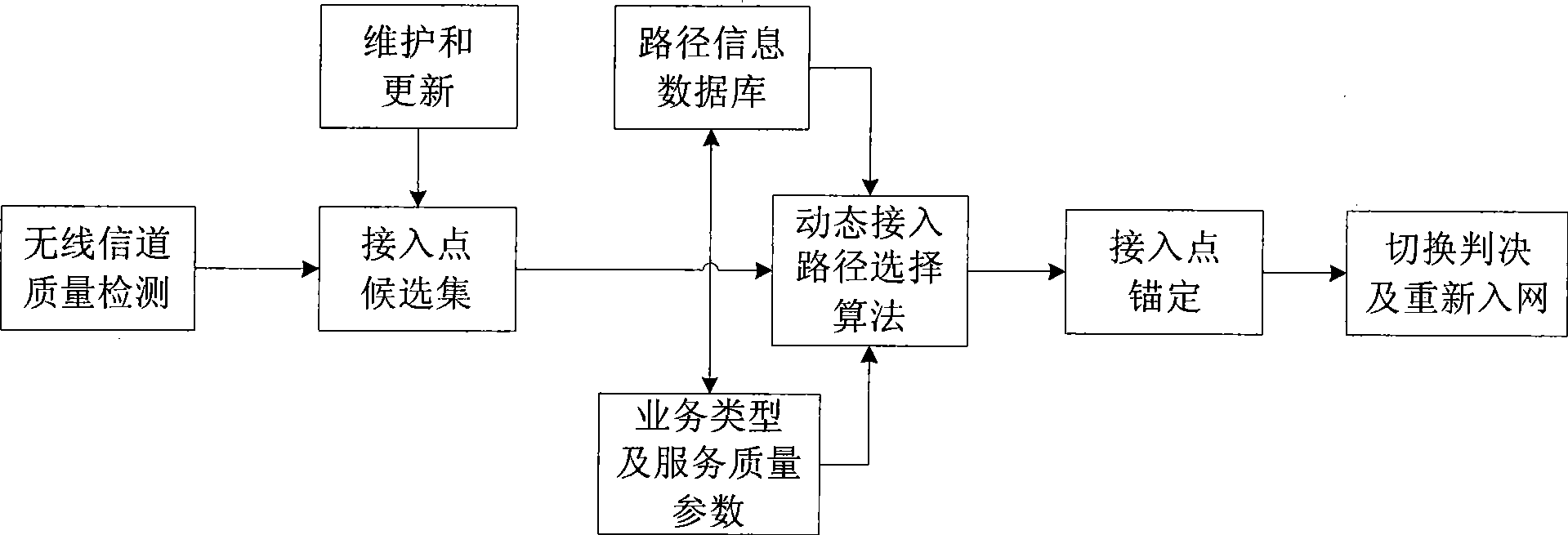

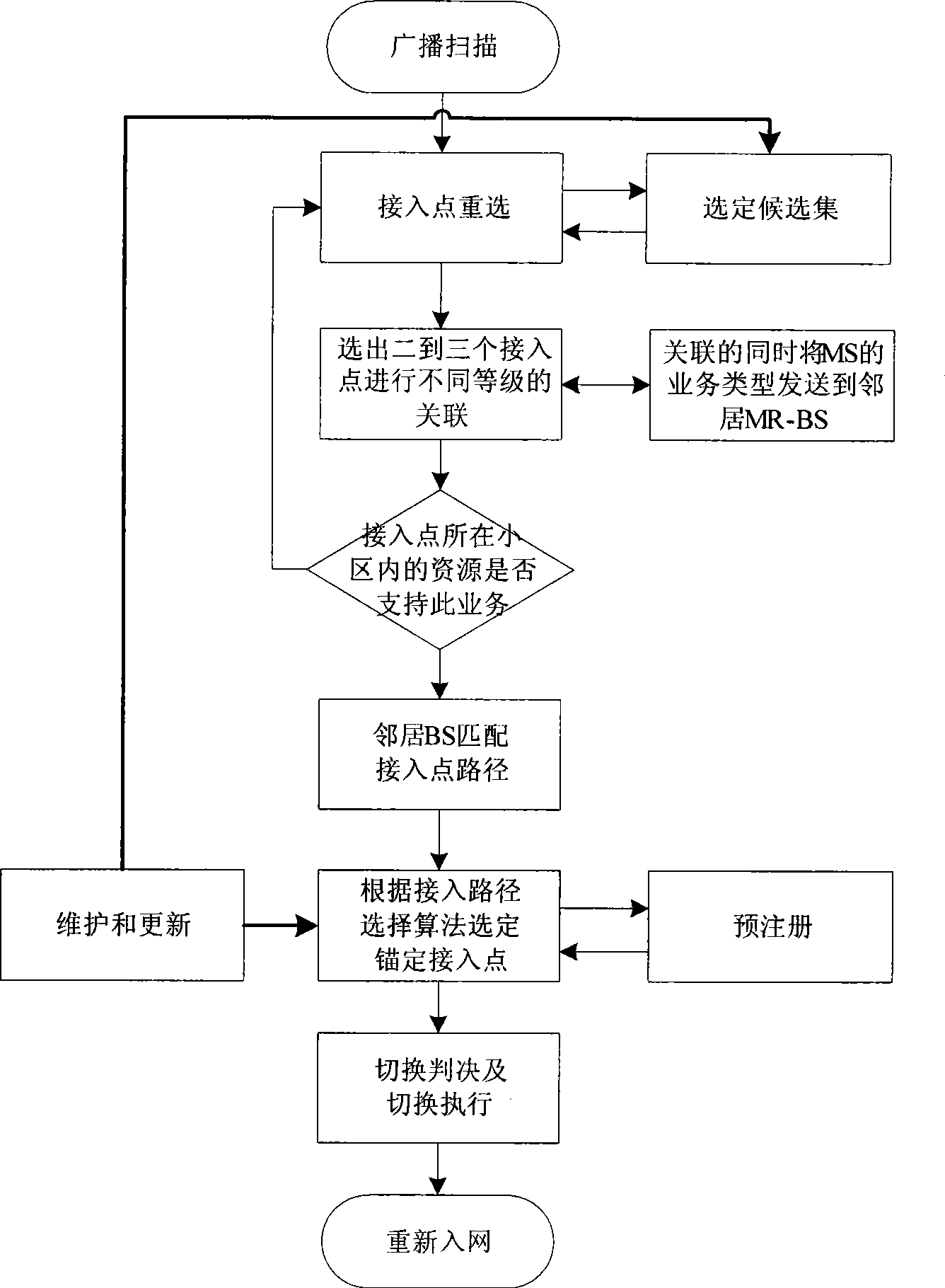

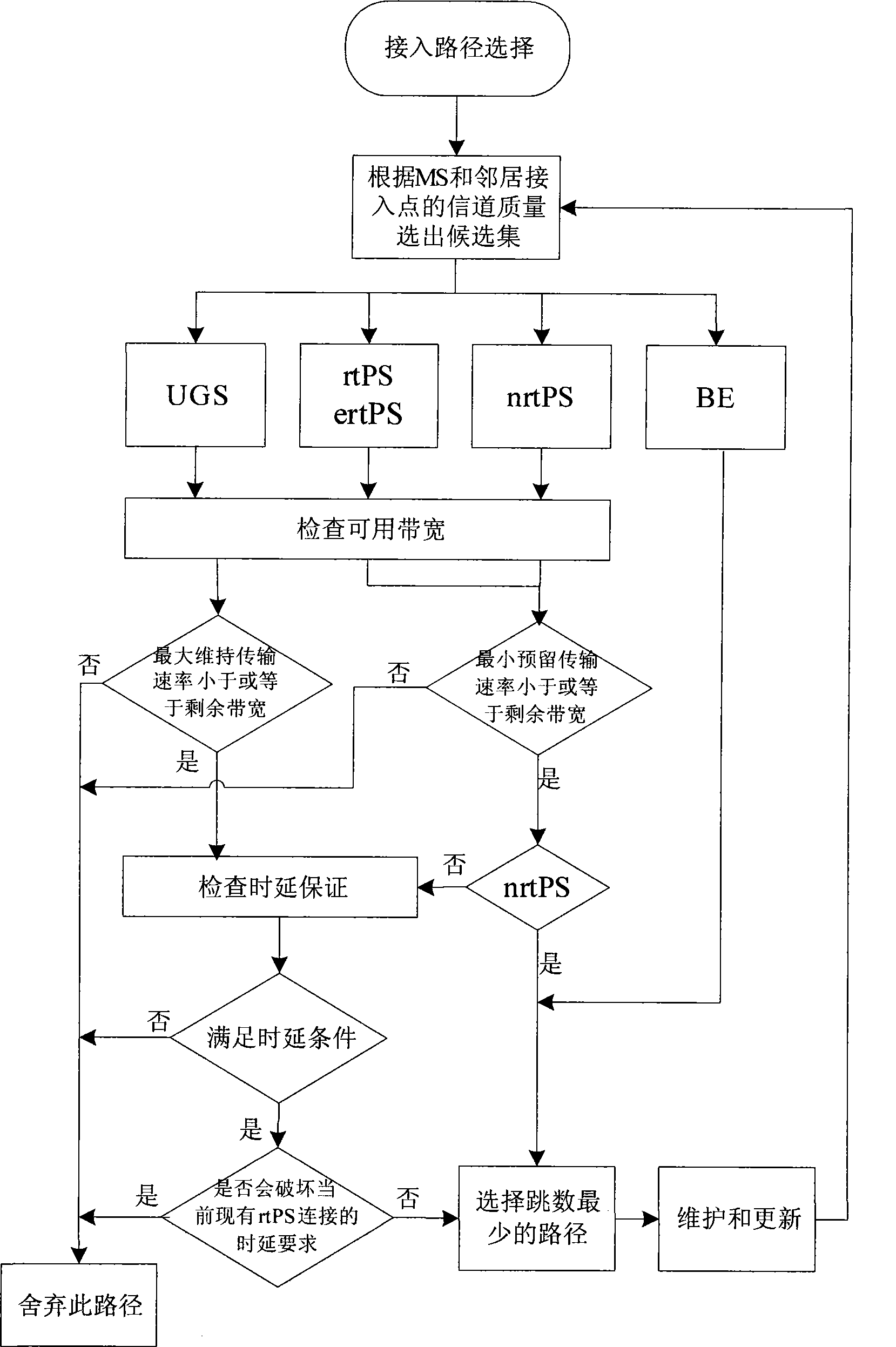

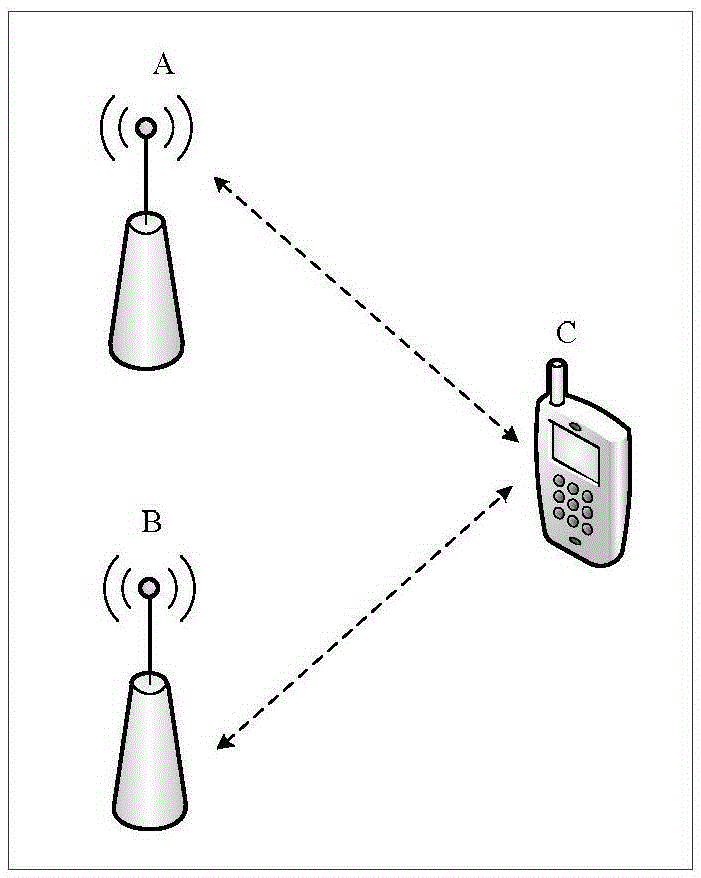

Fast access point switching method based on dynamic access path selection mechanism

InactiveCN101483893AGuaranteed connection qualityReduce switching delayWireless communicationQuality of serviceUser needs

The invention discloses a rapid access point switching method based on a dynamic access path selection mechanism, wherein, in a multi-hop relay broadband radio access network, each district exists a plurality of access points, including a base station and a delay station, a mobile user dynamically and rapidly switches to the access point of an adjacent district in a moving process according to the quality of a current radio channel with the aid of access path selection algorithm. By means of access point reselection, information such as the bandwidth, delay and hop count of a candidate access point path, and the current connection business type of the mobile user and service quality parameter thereof, the method of the invention selects the access path that satisfies current traffic condition from the candidate access points, and according to a best anchoring access point selected from business information obtained beforehand from a reserved network, the best access path is determined. When the mobile user needs switching, a target access point is switched rapidly, and the rapid access point switching method reduces switching delay, and different treatment on business with different priority improves switching connection rate.

Owner:TONGJI UNIV

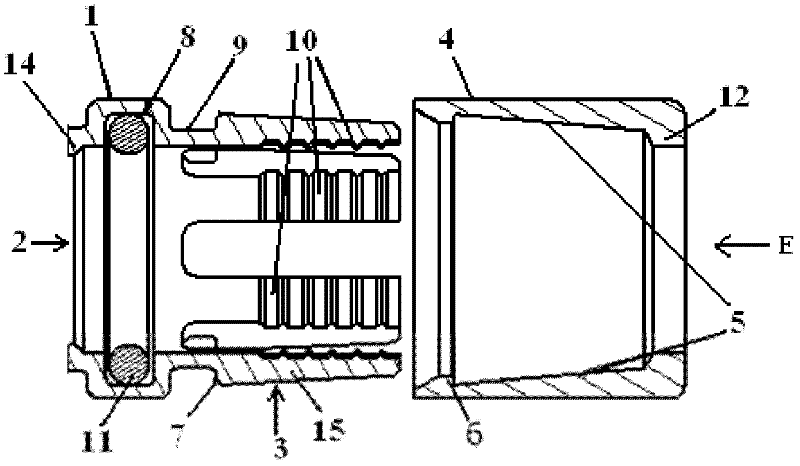

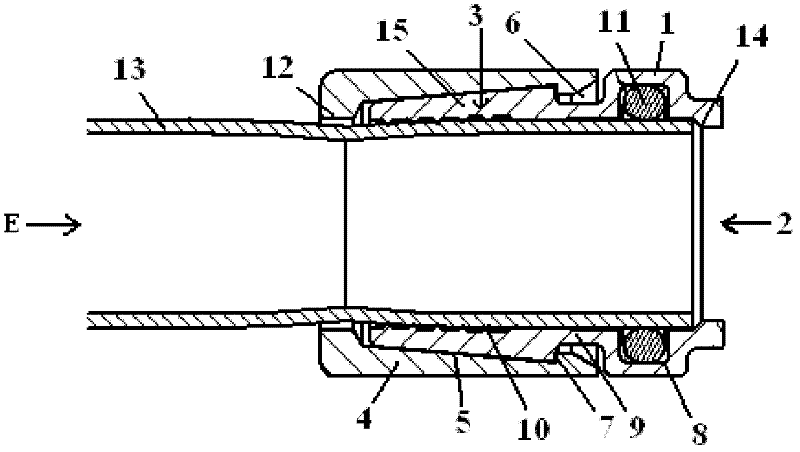

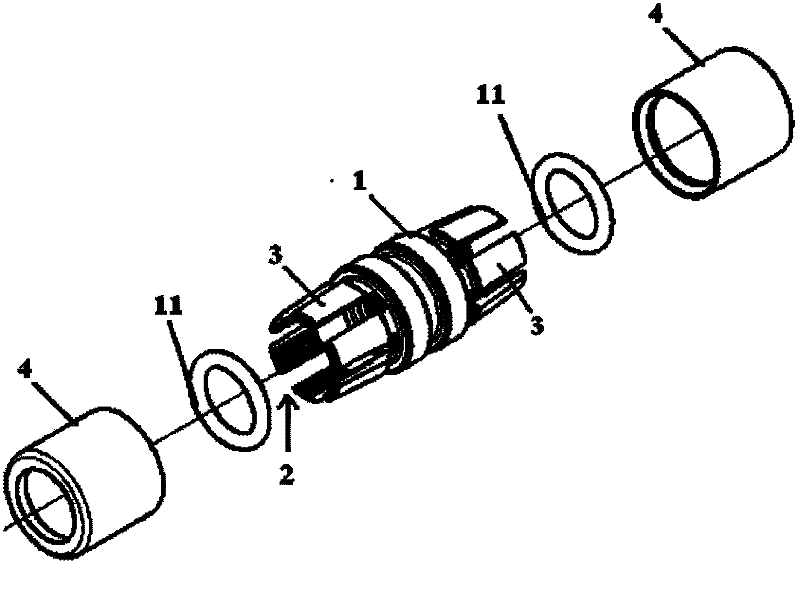

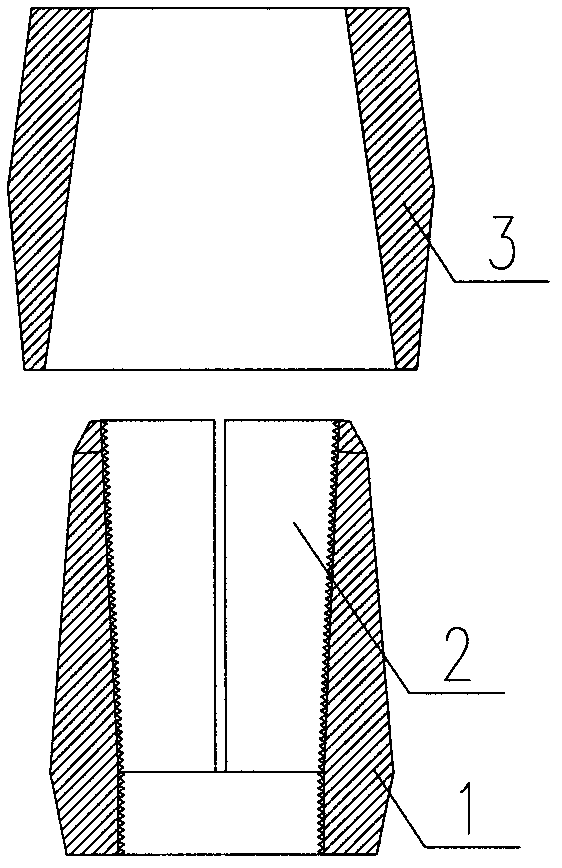

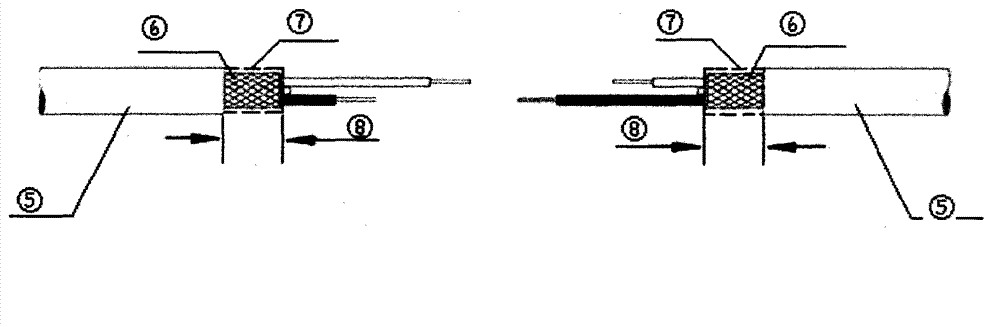

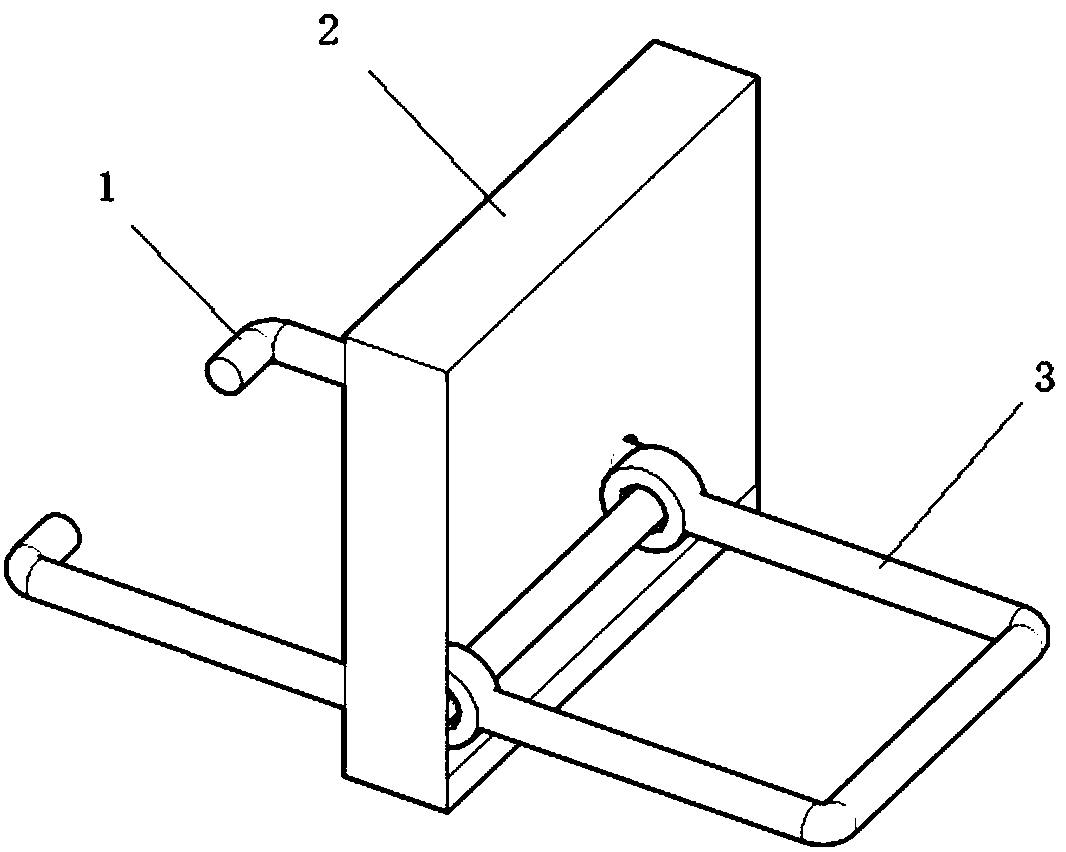

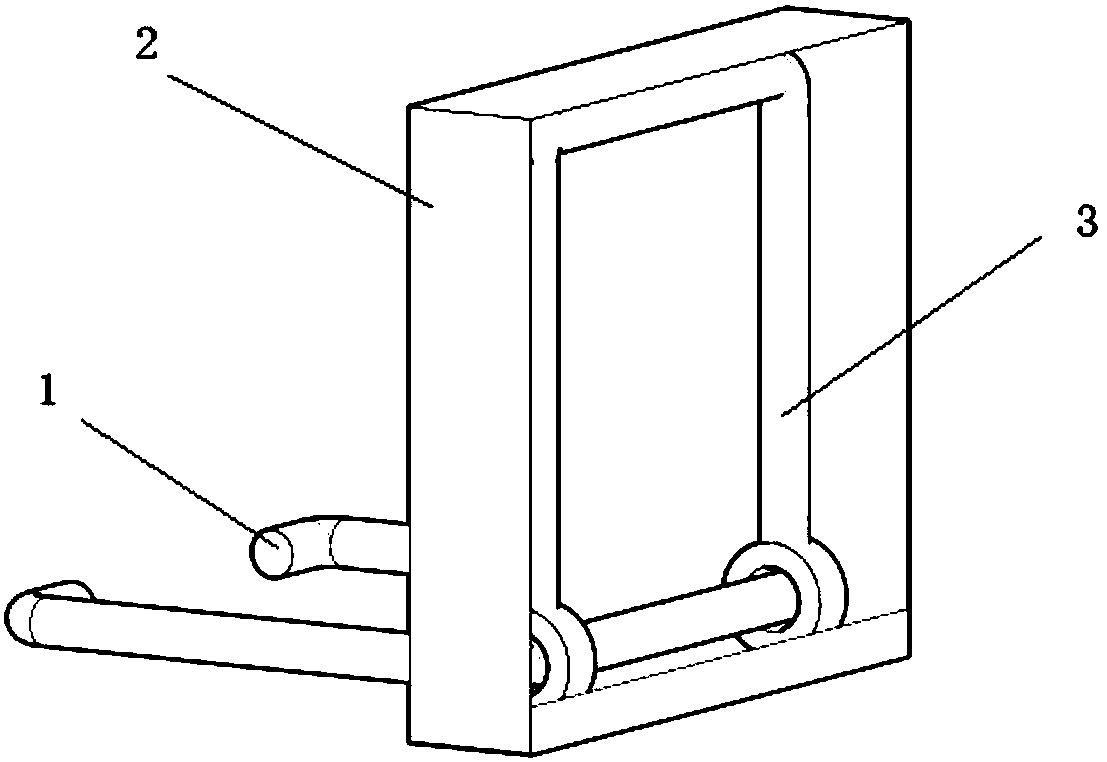

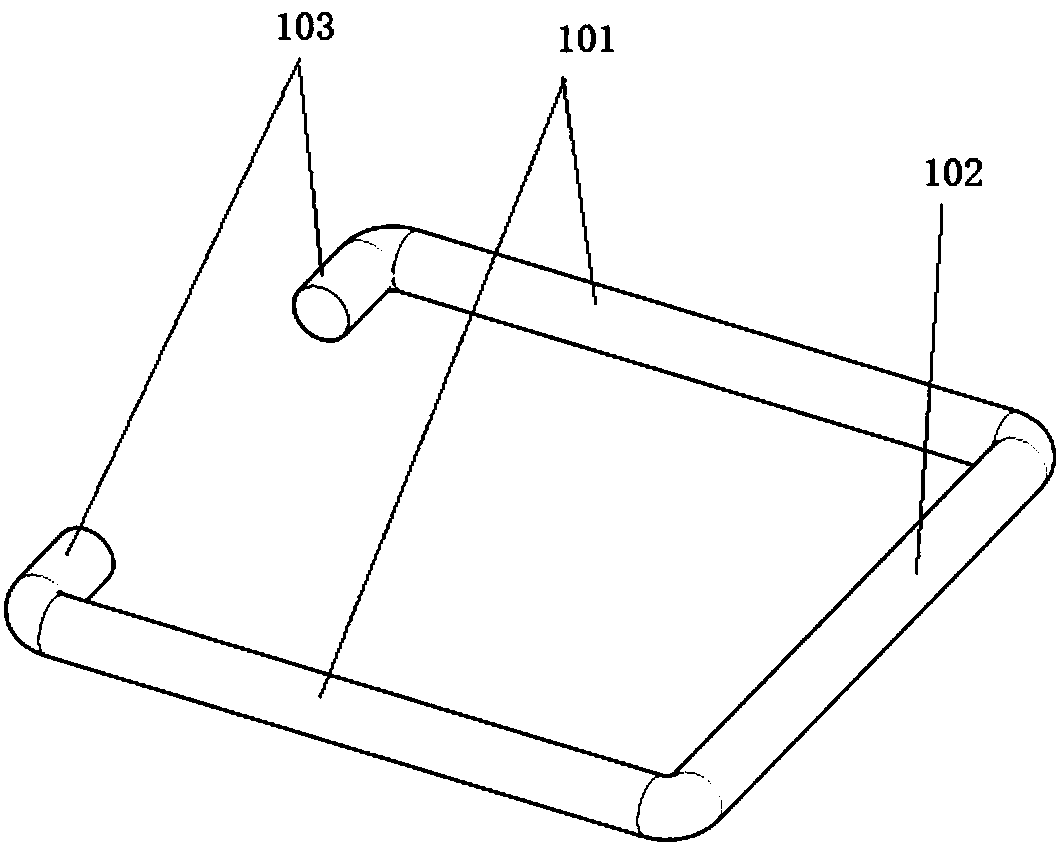

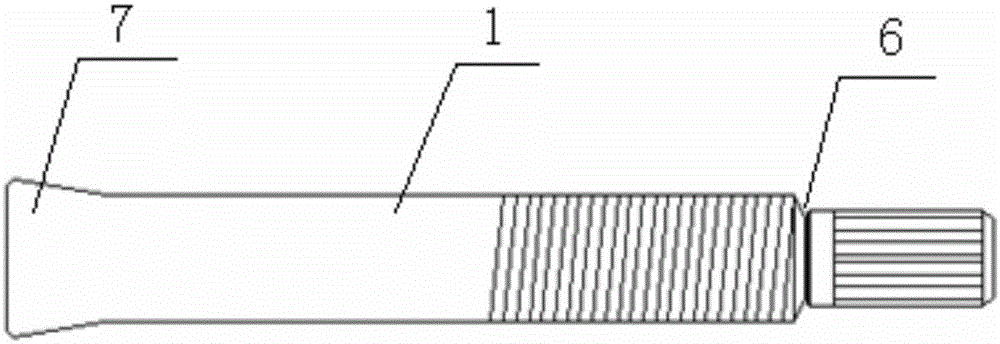

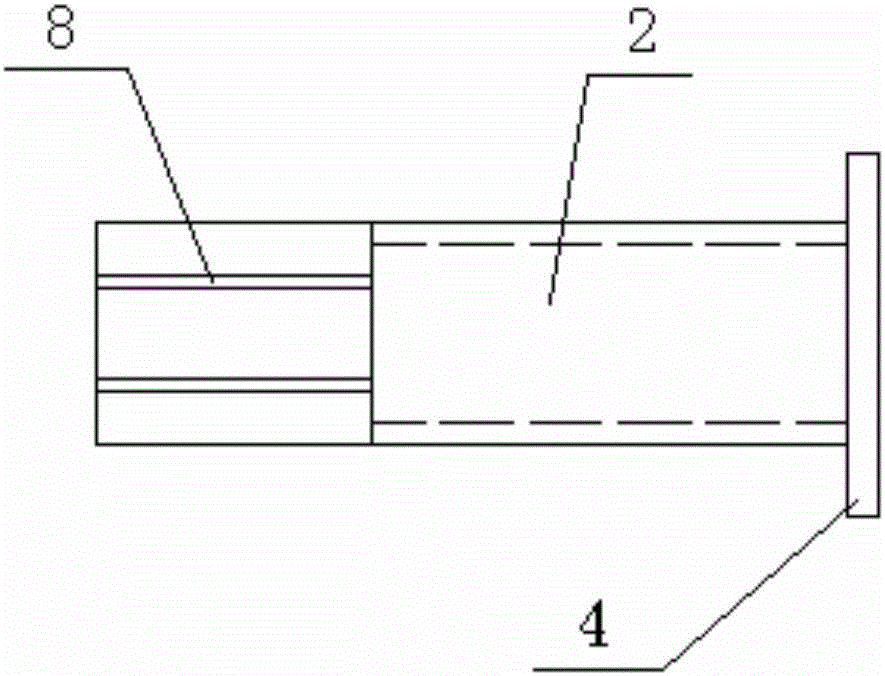

Pipeline connecting device

ActiveCN102359674APrevent misassemblyEasy to assembleEngine sealsJoints with sealing surfacesEngineeringConical surface

The invention discloses a pipeline connecting device which comprises a joint body, a plurality of elastic strips, a locking nut, a first stop part and a second stop part, wherein the joint body is provided with a channel; the elastic strips are circumferentially distributed at the port of the channel of the joint body; one end of each elastic strip is fixedly connected with the joint body; the elastic strips are used for clamping a pipeline inserted into the channel; the locking nut is provided with a first end close to the joint body and a second end opposite to the first end; a conical surface is formed on the inner wall of the second end; the inner diameter of the conical surface is gradually increased along the entering direction of the pipeline; the conical surface is matched with the outer walls of the elastic strips to clamp the pipeline; the first stop part is arranged on the outer wall of the joint body or the outer walls of the elastic strips; and the second stop part is arranged on the inner wall of the first end of the locking nut and is used for being matched with the first stop part to stop the locking nut from being separated from the joint body or the elastic strips.

Owner:KING INDUSTRIES INC

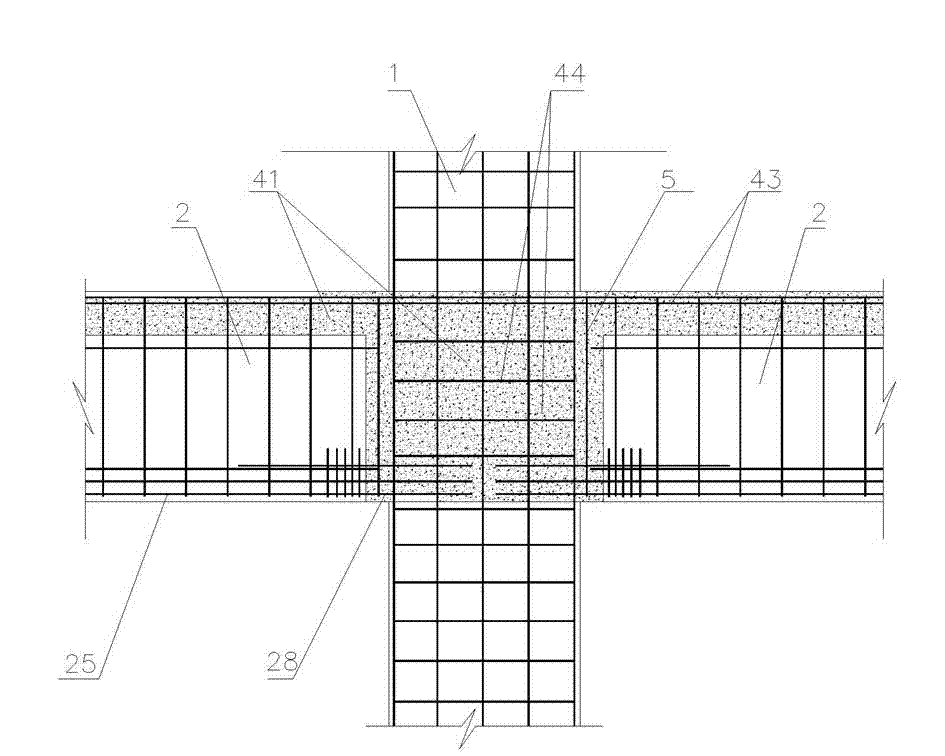

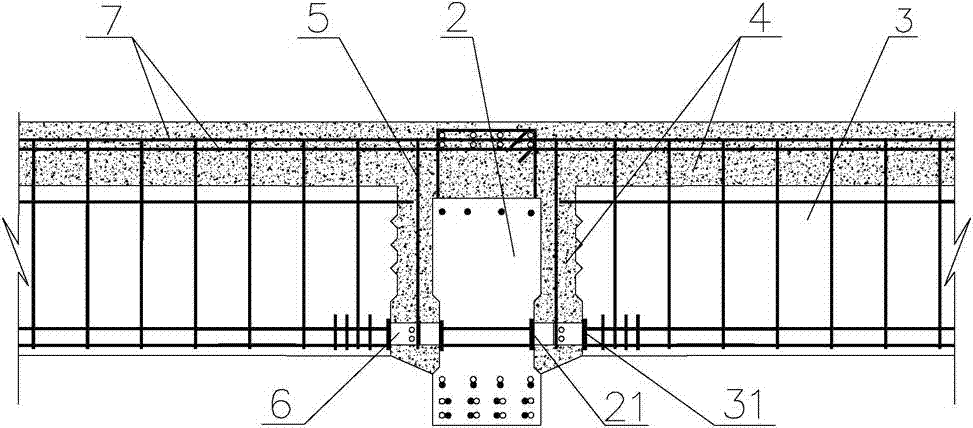

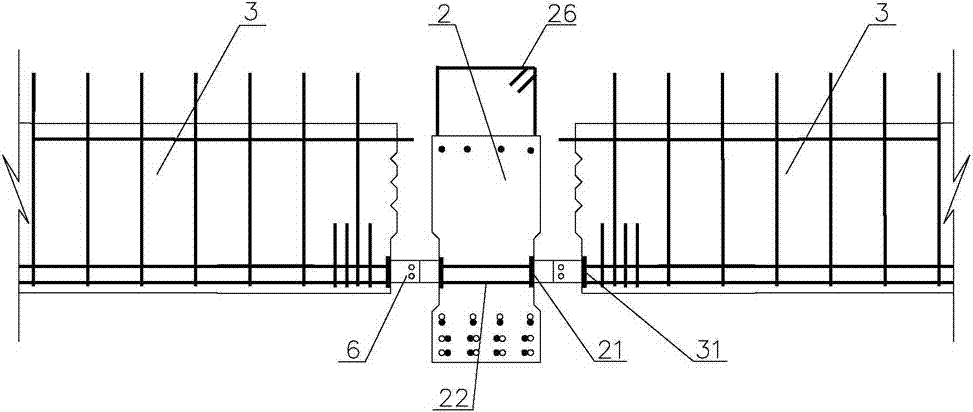

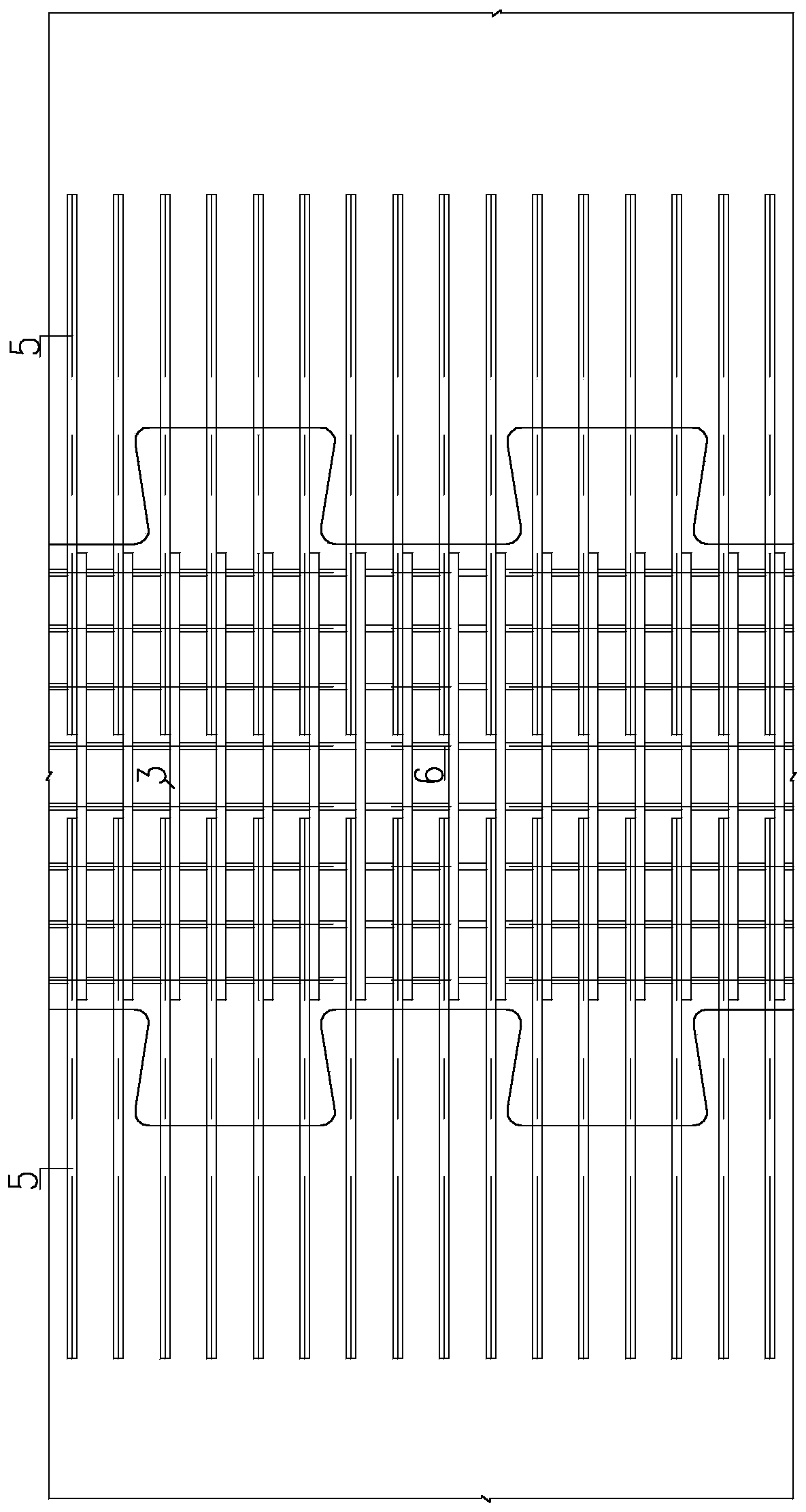

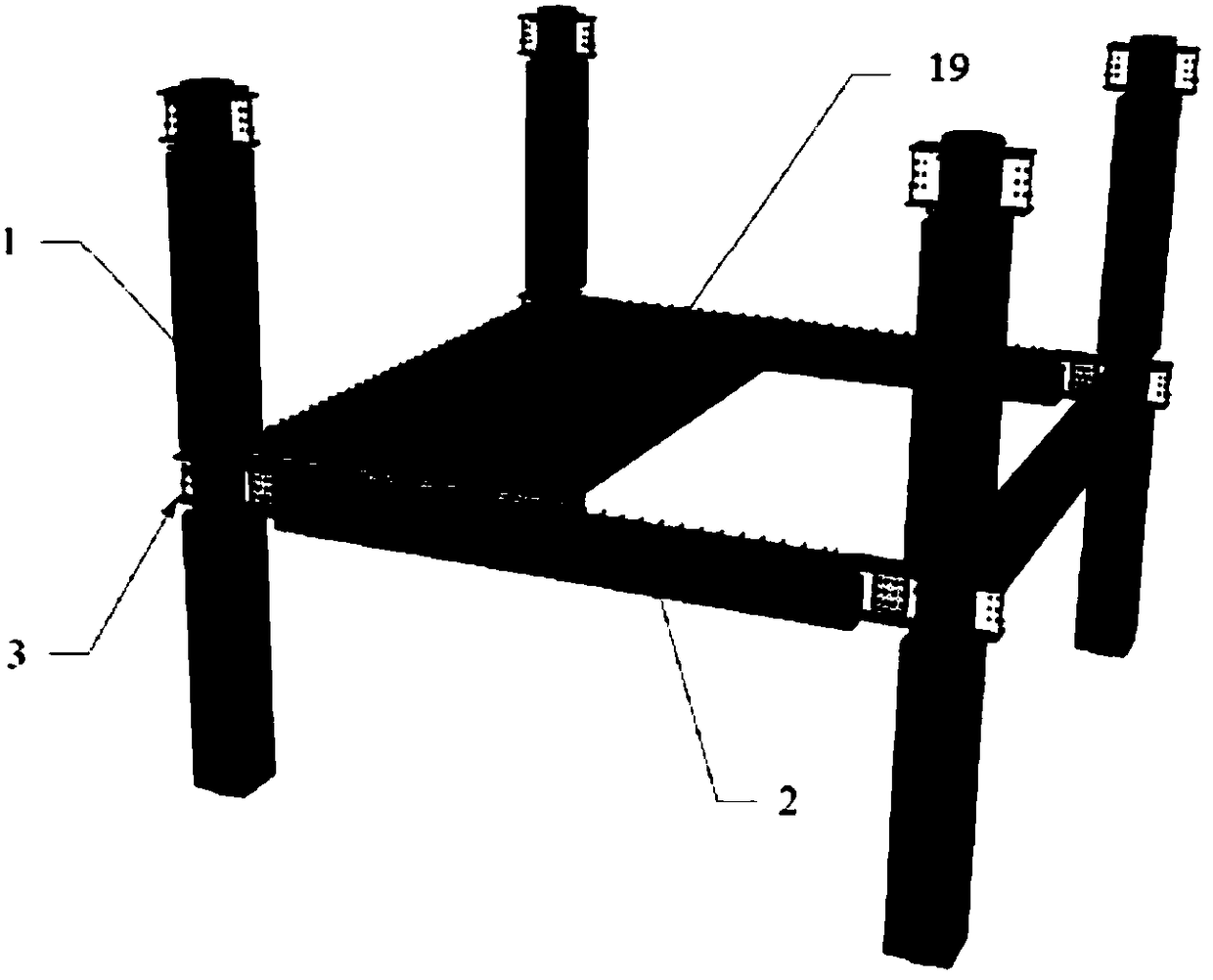

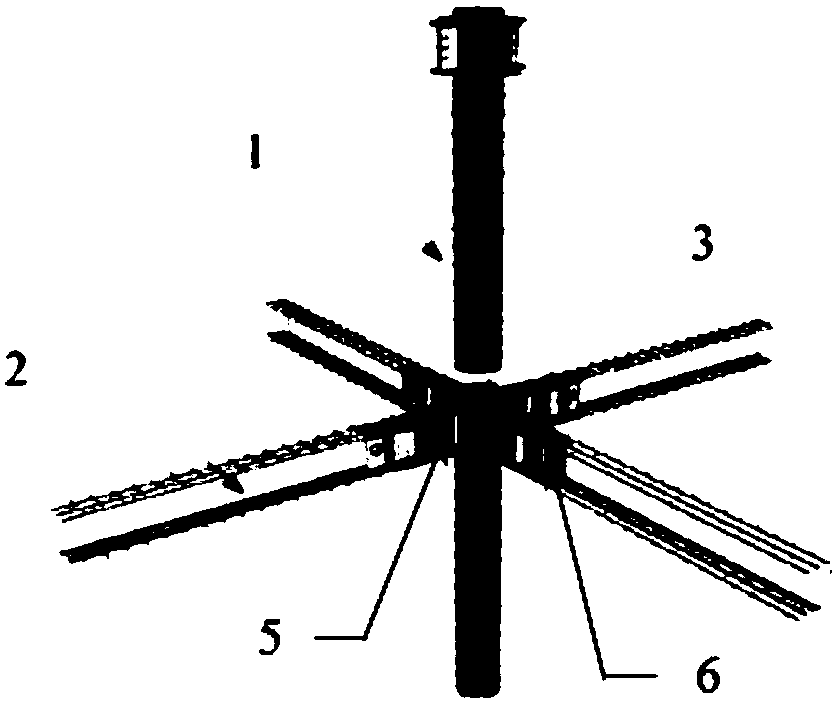

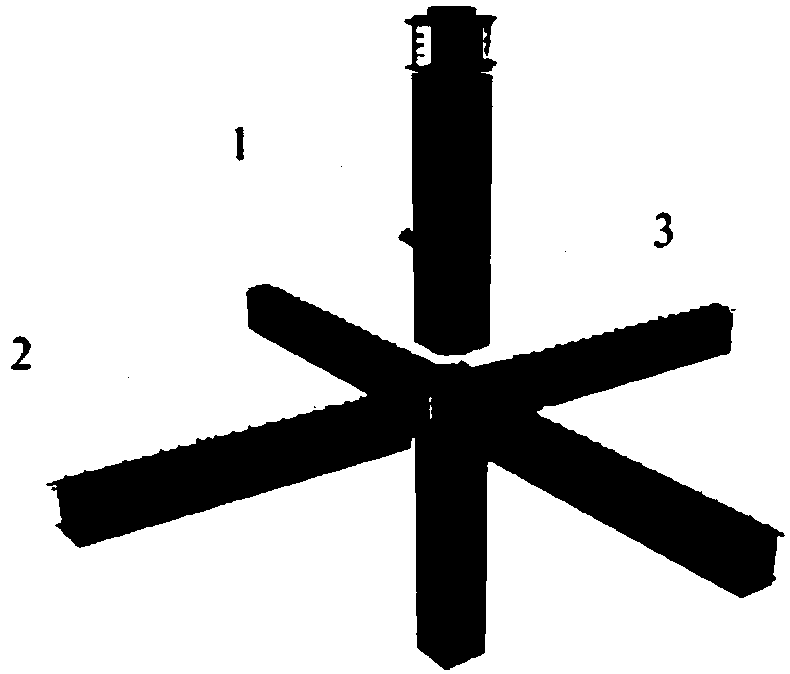

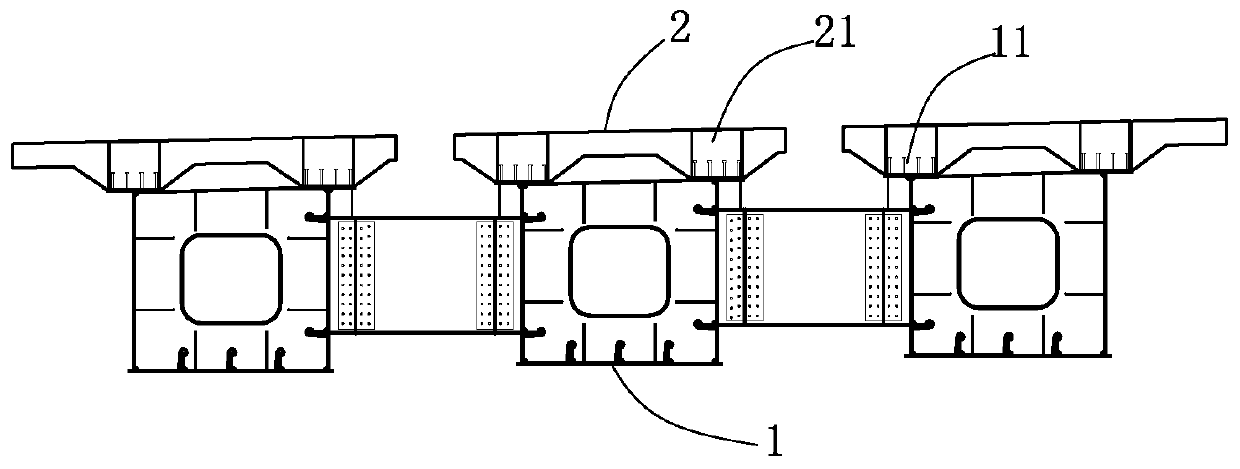

Pre-tensioning prestressed composite beam structural system and construction method thereof

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

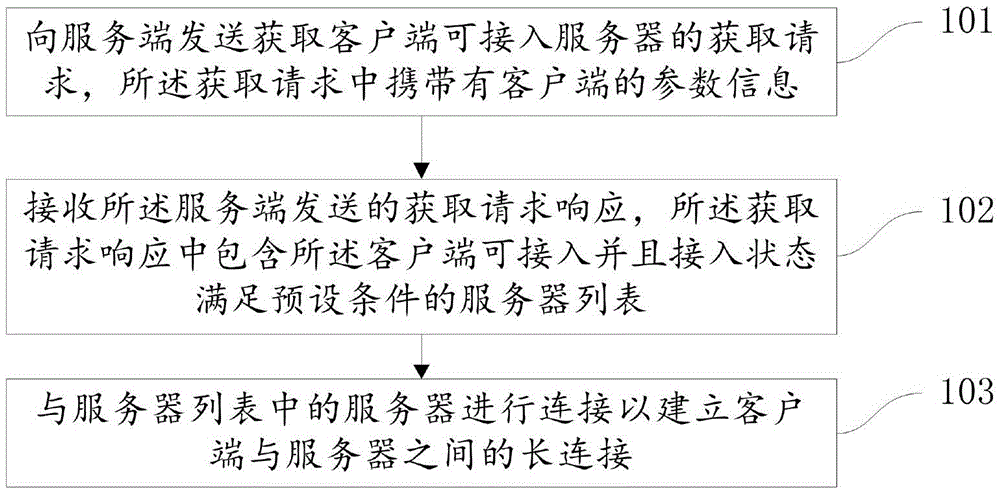

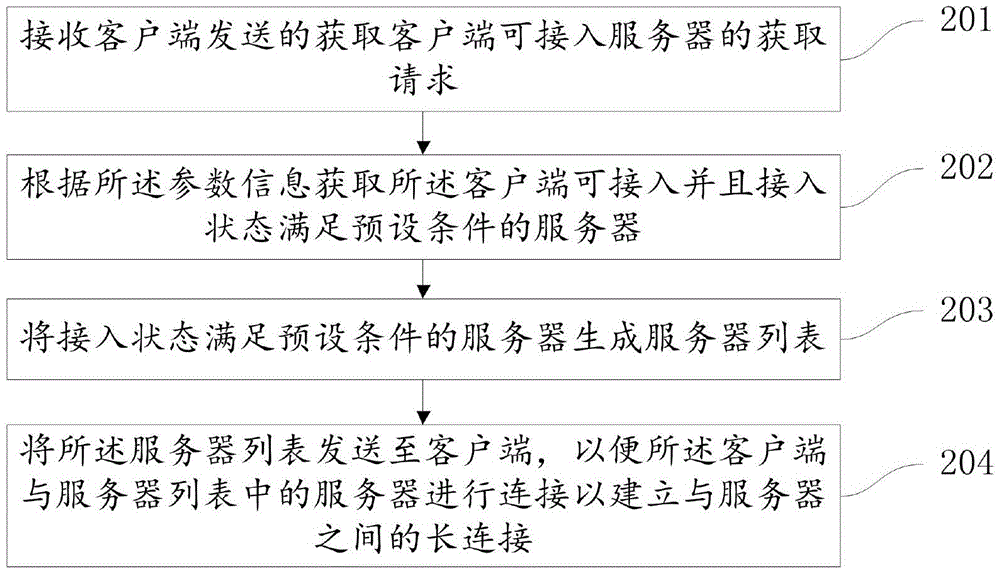

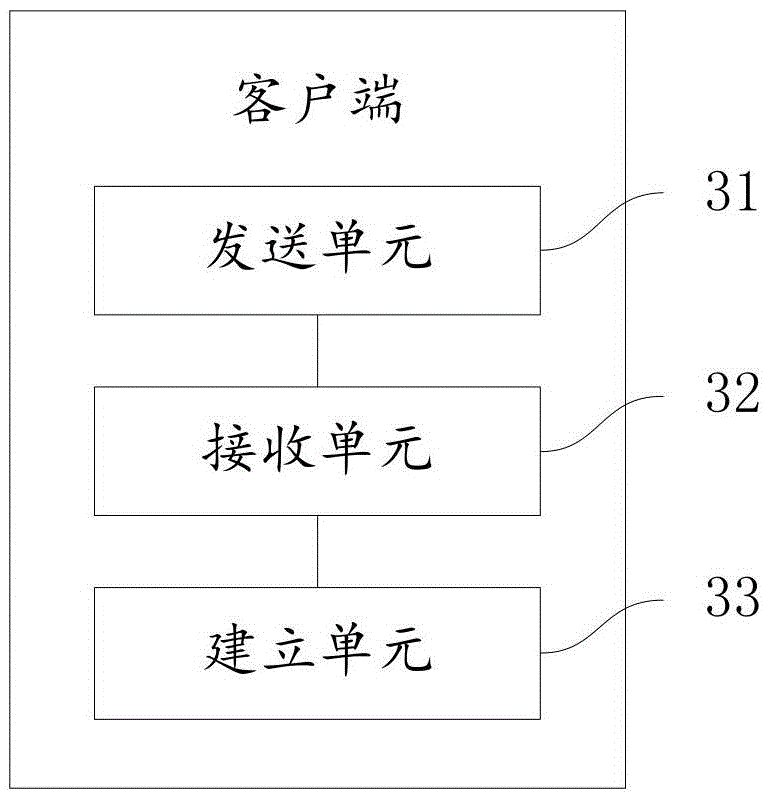

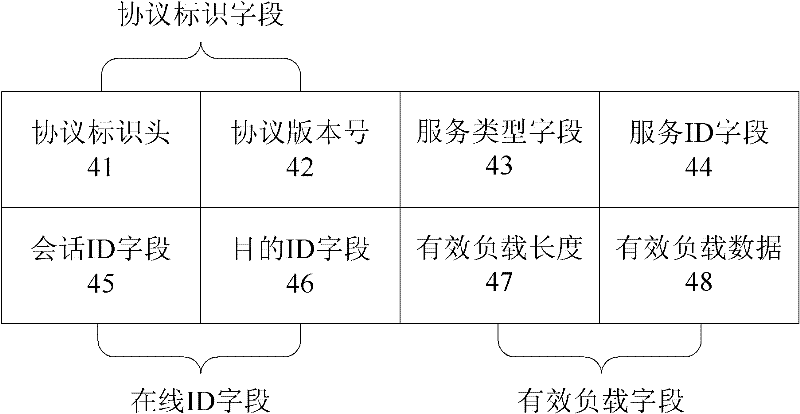

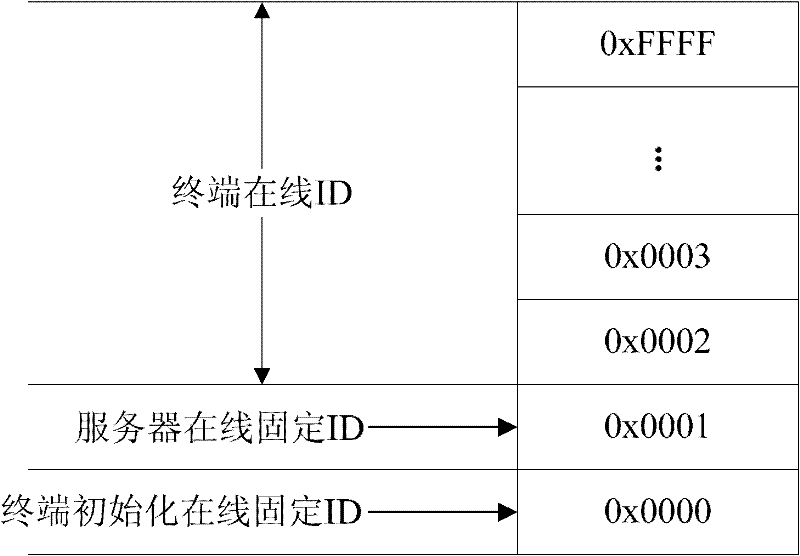

Long connection establishment method and system, and devices

InactiveCN105871977AGuaranteed connection qualityImprove connection efficiencyTransmissionClient-sideServer-side

The embodiment of the invention provides a long connection establishment method and system, and devices, relates to the technical field of communication, and mainly aims at ensuring connection quality of a client and a server when long connection is carried out on the client and the server, and moreover improving the connection efficiency of the long connection. The technical scheme used by the embodiment of the invention comprise that the client sends an obtaining request for obtaining client accessible servers to a server side, wherein parameter information of the client is carried in the obtaining request; the server side receives the obtaining request for obtaining the client accessible servers sent by the client, obtains the client accessible servers of which access states satisfy a preset condition according to the parameter information, generates a server list according to the servers of which access states satisfy the preset condition and sends the server list to the client; and the client receives the server list sent by the server side and is connected with the server in the server list, so that the long connection between the client and the server is established. The method, the devices and the system are applied to establishment of the long connection.

Owner:LETV SPORTS CULTURE DEV (BEIJING) CO LTD

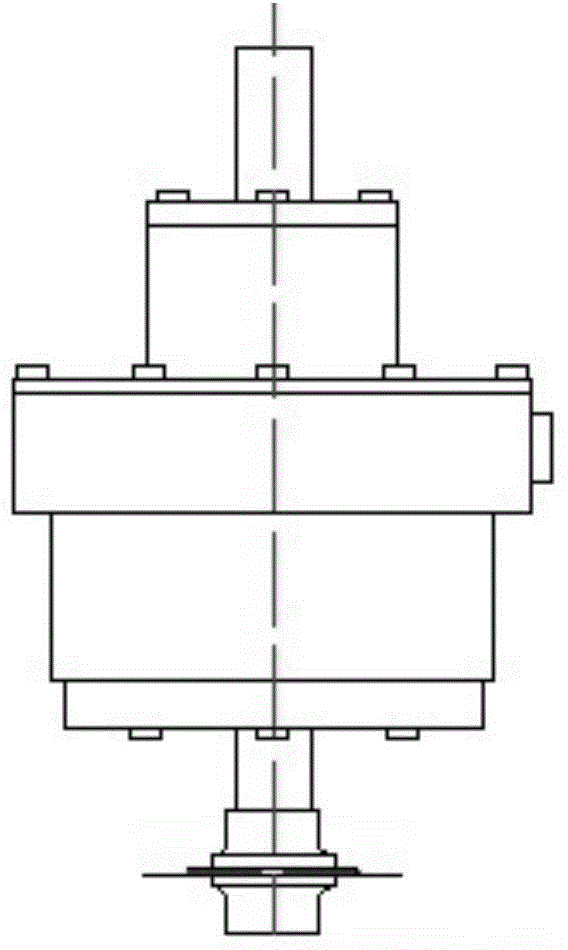

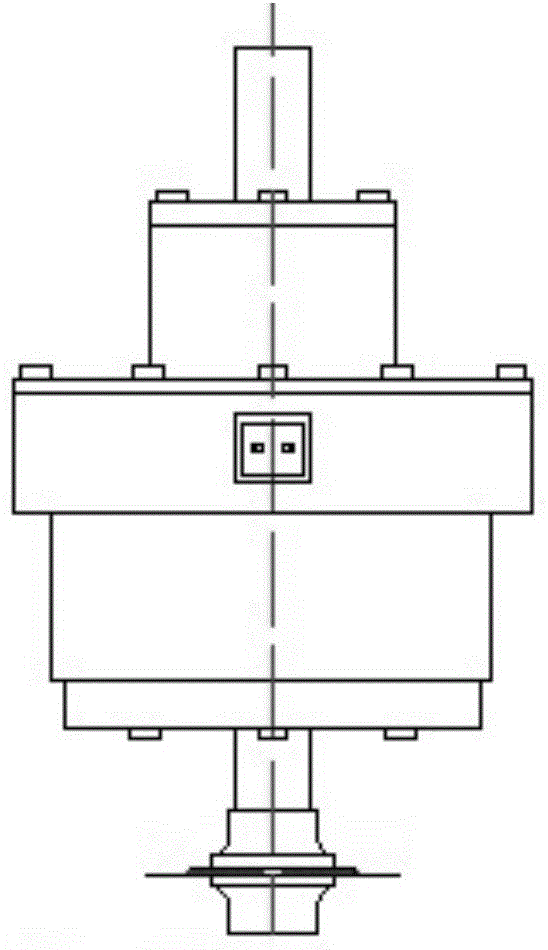

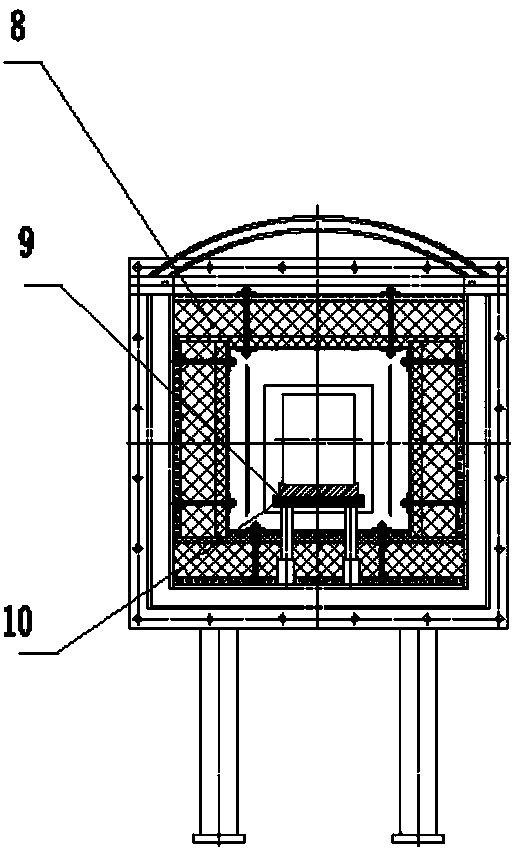

Transverse magnetic (TM) mold dielectric filter

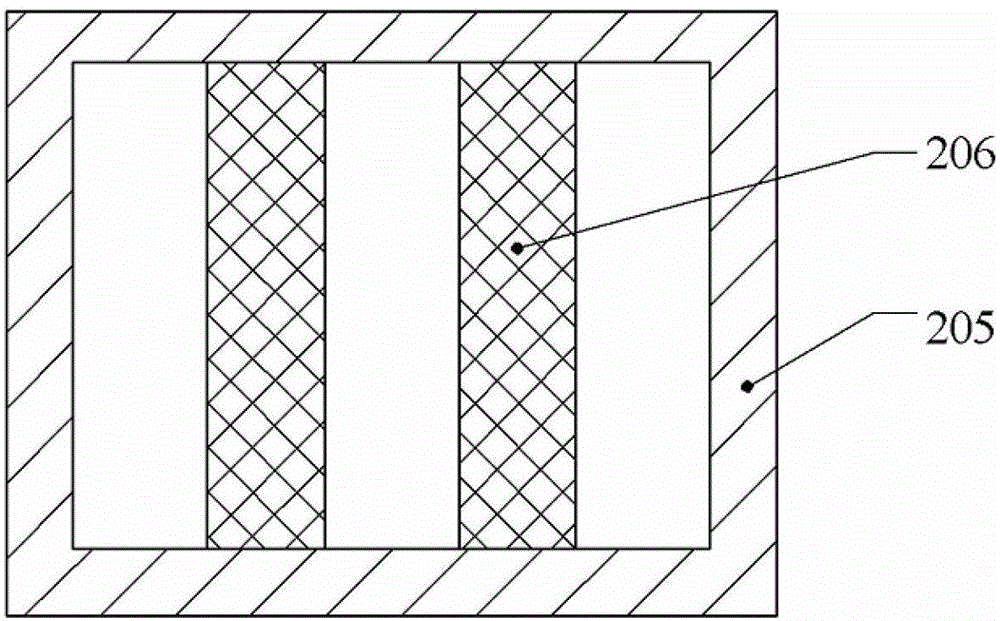

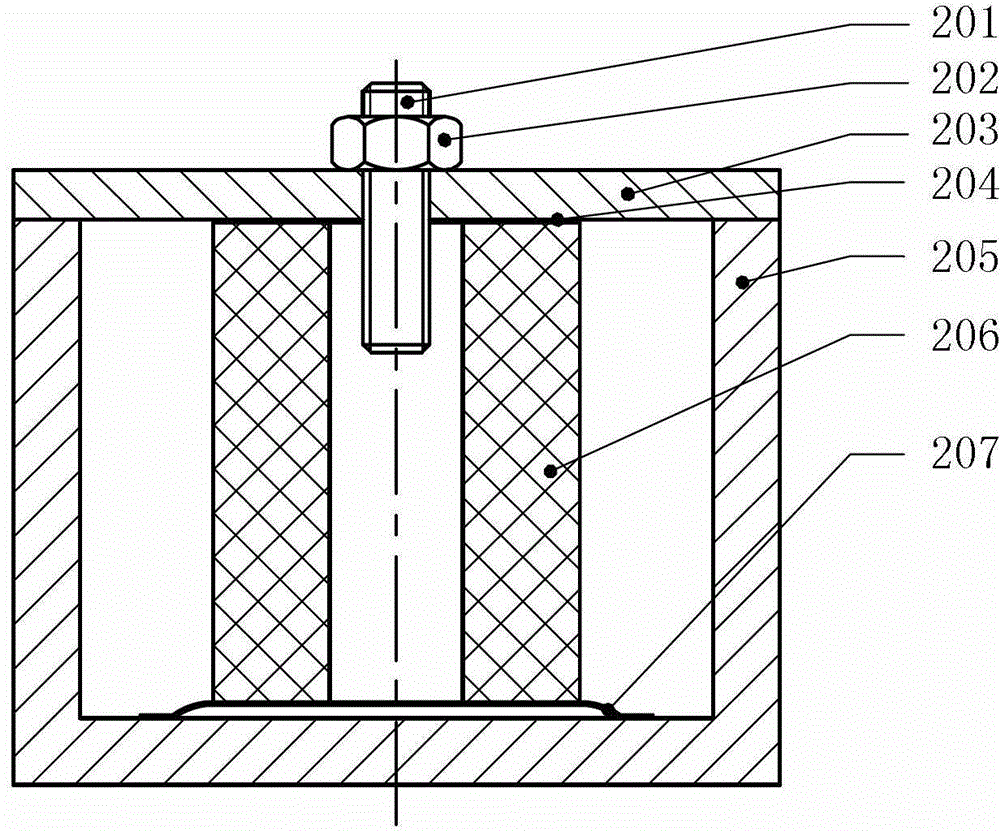

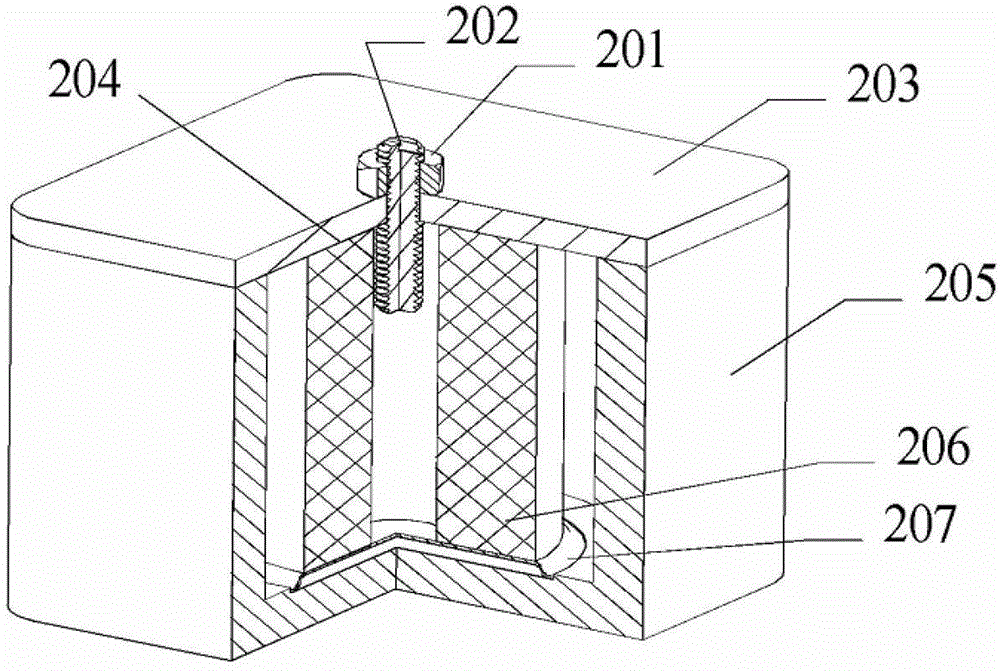

ActiveCN103151581AWith electrical coupling performanceElectrical coupling performance achievedWaveguide type devicesResonanceDielectric resonator

The invention is applied to the technical field of electron, and provides a transverse magnetic (TM) mold dielectric filter. The TM mold dielectric filter comprises a cavity body, a cover body, a connecting seat and dielectric resonators, wherein the cavity body is provided with one or more concave cavities serving as resonance cavities, the cover body is assembled in the cavity body, the connecting seat has electric conduction capacity, and the dielectric resonators are column-shaped, are provided with hole structures, and are arranged in the concave cavities. After the upper portion of each dielectric resonator is fixed on the connecting seat, the upper portion of each dielectric resonator is installed on the lower surface of the cover body, and the bottom of the dielectric resonator is connected with the bottom of each concave cavity. The height produced after the dielectric resonator is fixed with the connecting seat is slightly larger than the distance between the lower surface of the cover and the bottom of the concave cavities, and predeformation is produced on the cover body after the cover body is assembled on the concave cavities. therefore, the TM mold dielectric filter has the advantages of being good in electric performance and good in reliability.

Owner:MOBI TECH SHENZHEN CO LTD +3

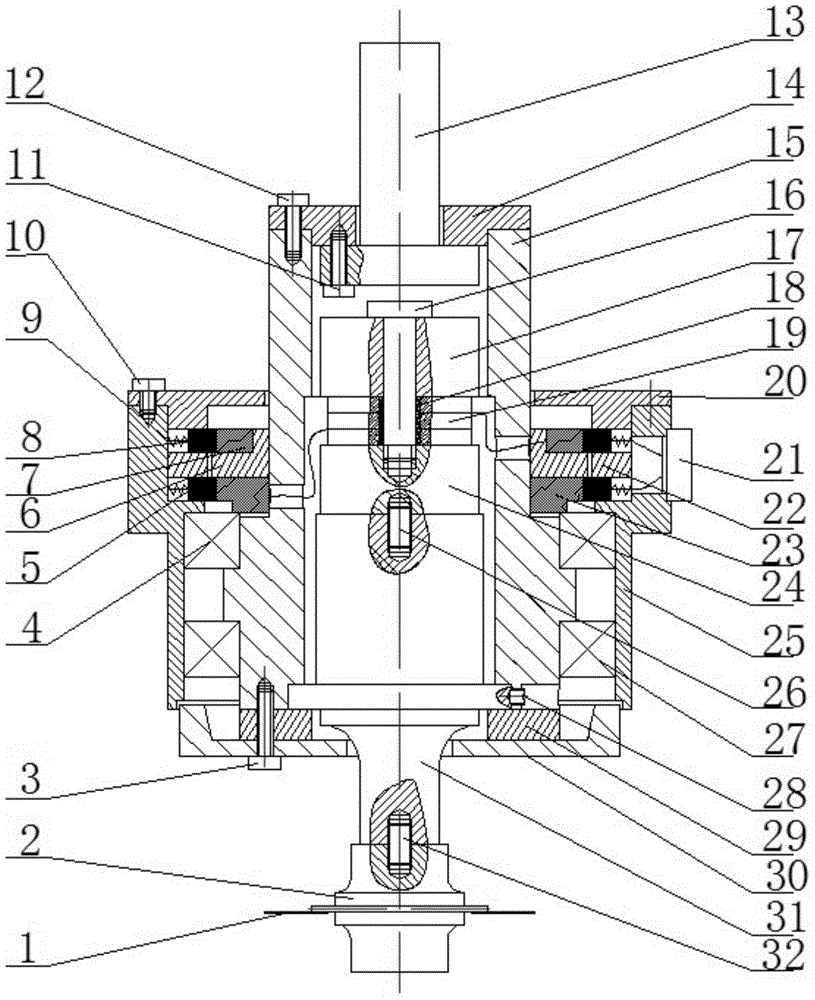

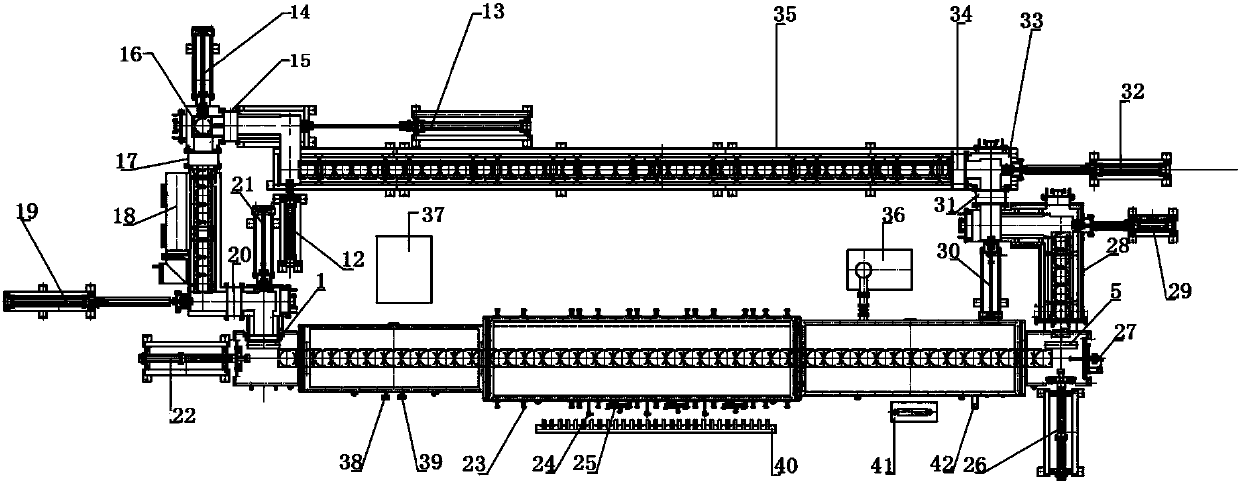

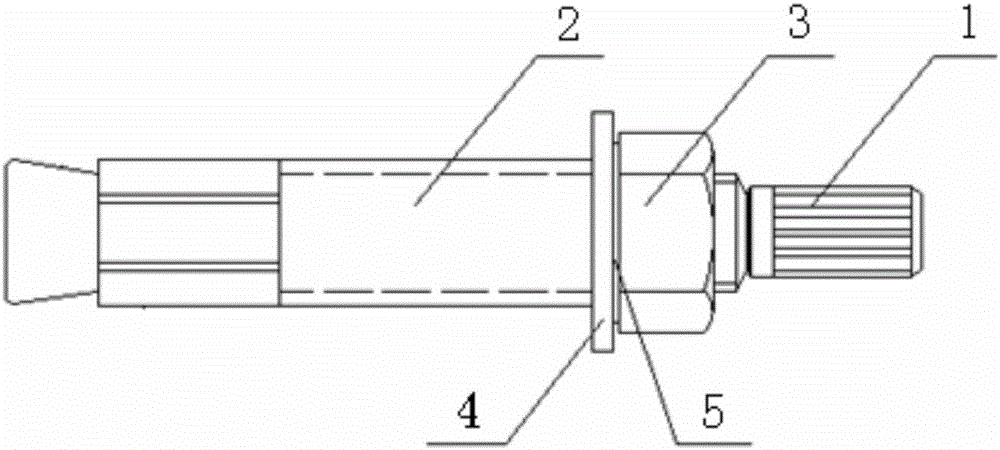

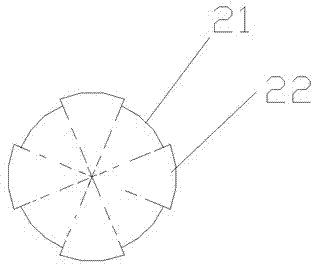

Quick-change ultrasonic vibration auxiliary sawing device

InactiveCN103978560ARealization of complete machine tool accessoriesQuick changeWorking accessoriesFine working devicesMaterial consumptionUltrasonic vibration

The invention discloses a quick-change ultrasonic vibration auxiliary sawing device which is suitable for various machine tools. The quick-change ultrasonic vibration auxiliary sawing device comprises a knife handle connecting bar (13), an inner sleeve (15), an outer sleeve (25), an ultrasonic transducer (19), a current collecting device, a primary amplification amplitude-change pole (31), a symmetrical amplitude-change pole (2) and a saw blade (1). According to the quick-change ultrasonic vibration auxiliary sawing device, high-frequency signals are generated through an ultrasonic generator and transmitted to the ultrasonic transducer (19) through the current collecting device to generate ultrasonic vibration, the ultrasonic vibration is amplified through the primary amplification amplitude-change pole (31), the amplified ultrasonic vibration is transmitted to the wave loop position of the symmetrical amplitude-change pole (2) to generate radial vibration, and the radial vibration acts on the saw blade. The quick-change ultrasonic vibration auxiliary sawing device can be flexibly butted with various machine tools, so that the processing application of the traditional machine tool is expanded; the quick-change ultrasonic vibration auxiliary sawing device realizes to use the ultrasonic vibration to assist in sawing hard and brittle materials, solves the problems of big sawing force, high material consumption, and serious edge breakage and so on of the traditional hard and brittle material sawing, and has broad application prospect.

Owner:HUAQIAO UNIVERSITY

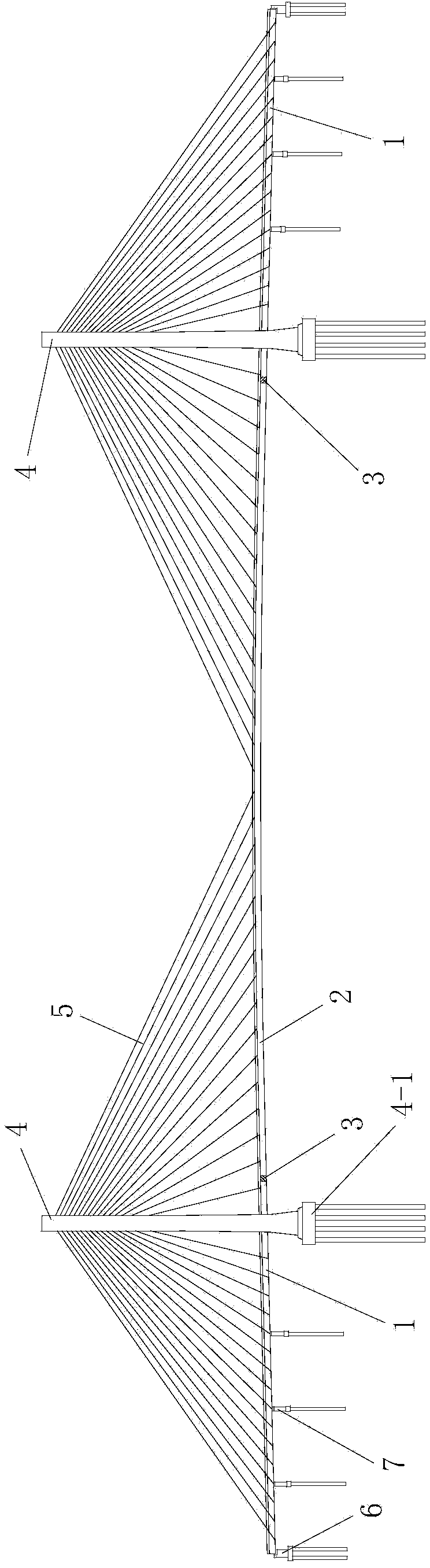

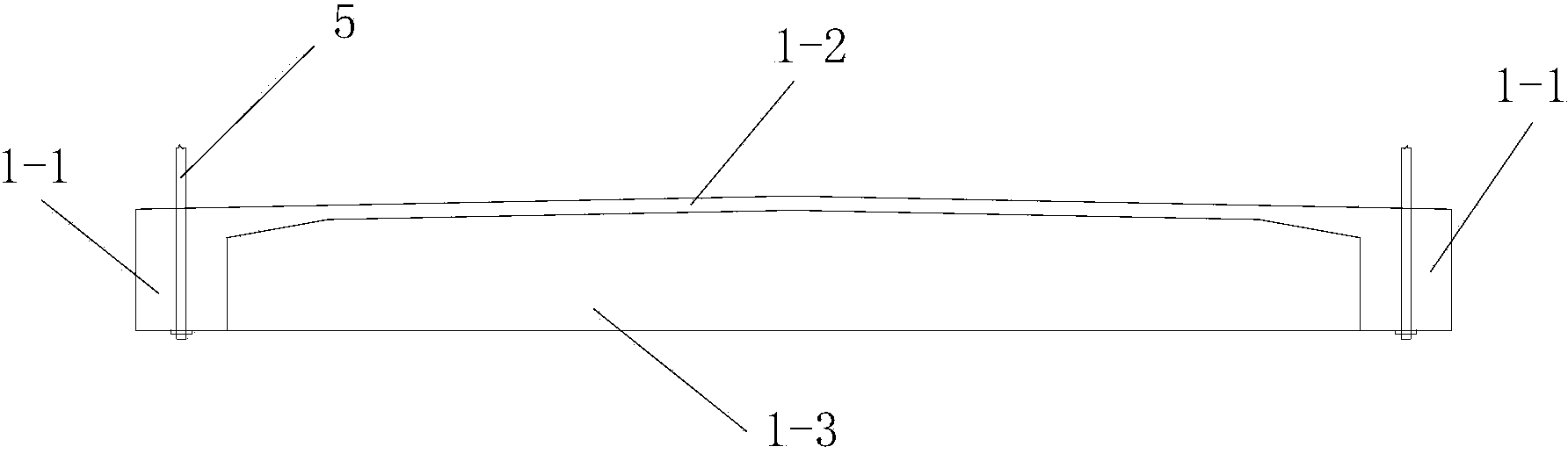

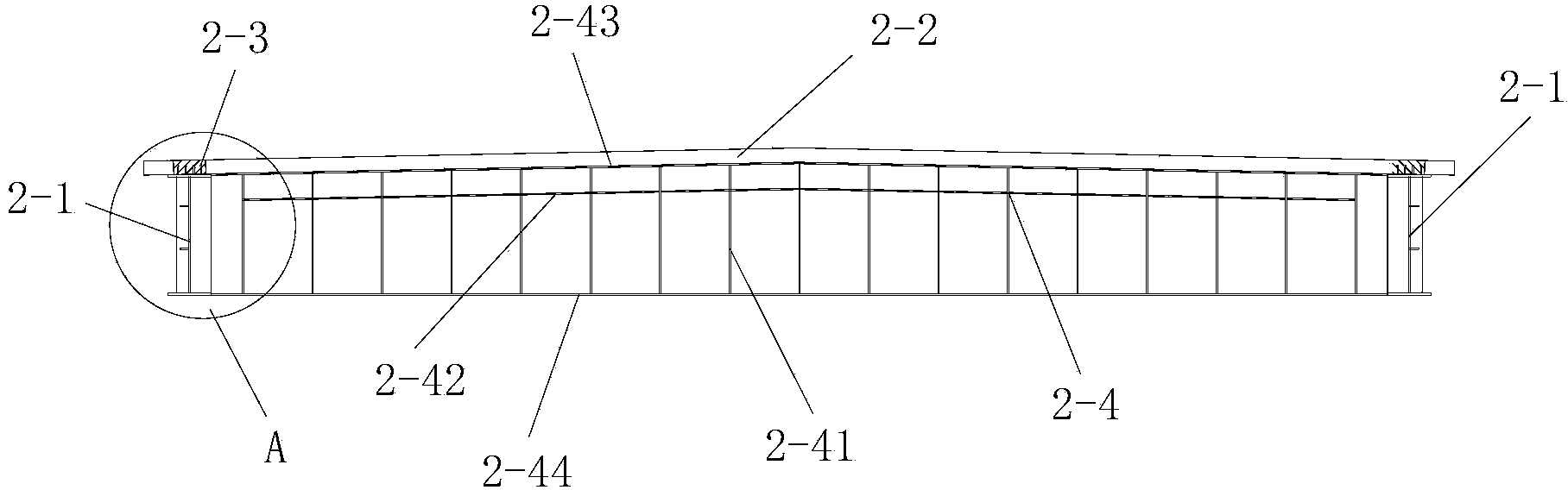

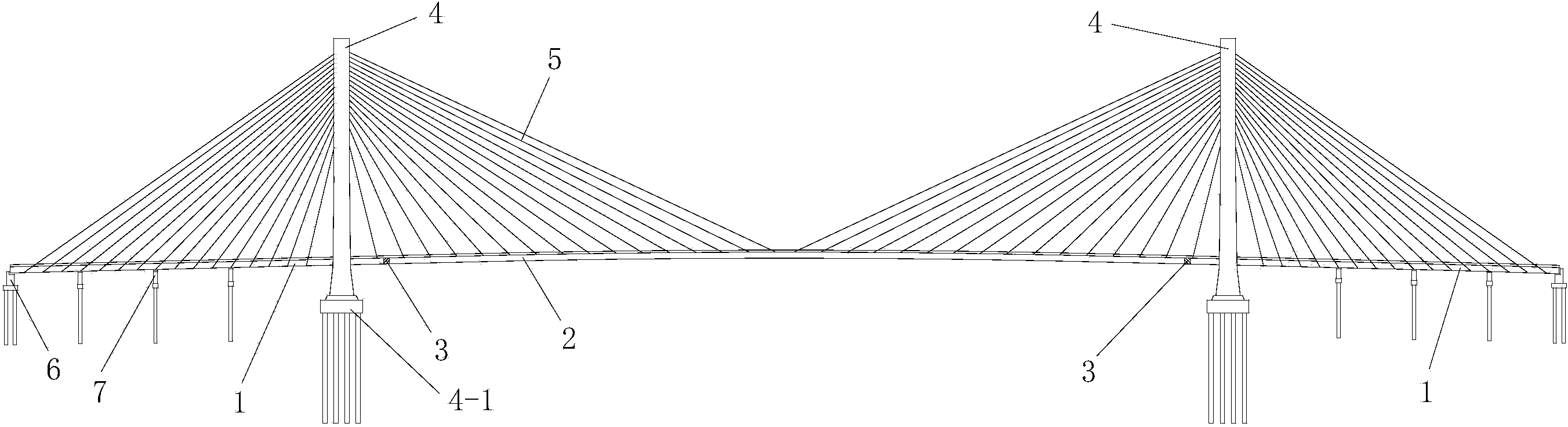

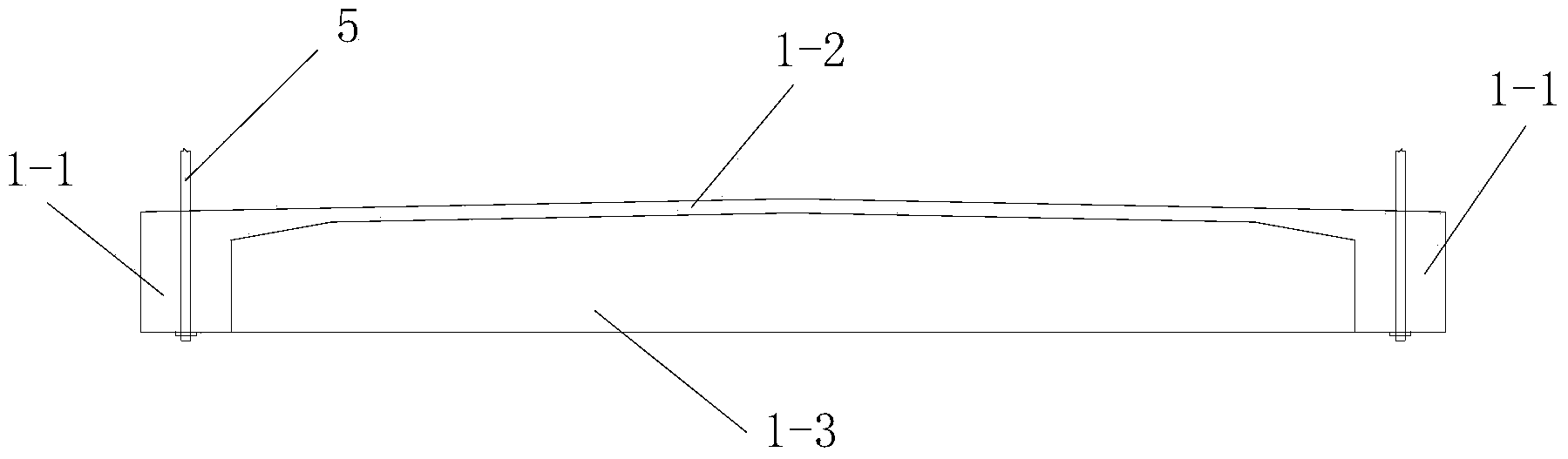

Double-tower hybrid beam cable-stayed bridge system and construction method thereof

InactiveCN104294747ASimple structureReasonable designCable-stayed bridgeBridge erection/assemblyCable stayedConcrete beams

The invention discloses a double-tower hybrid beam cable-stayed bridge system. The double-tower hybrid beam cable-stayed bridge system comprises a hybrid beam composed of a concrete beam and a composite beam. The concrete beam and the composite beam are connected through a joint section. The concrete beam is a bilateral ribbed beam and comprises two concrete beam ribs. The composite beam comprises two main steel beams, and the main steel beams are each of an I shape and each comprise a main steel beam top plate, a main steel beam bottom plate and a main beam steel web. The joint section comprises a concrete beam rib-main steel beam connection structure composed of a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web, and the main steel beam top plates and the main steel beam bottom plates stretch into the concrete beam ribs. The double-tower hybrid beam cable-stayed bridge system is reasonable in structural design, convenient to construct, high in construction speed, good in use effect and good in connection effect of a steel-concrete joint part. Meanwhile, the invention further discloses a construction method of the double-tower hybrid beam cable-stayed bridge system. The construction method includes the steps of lower portion supporting structure and main tower construction and hybrid beam construction. The construction method is simple, easy to implement, short in construction period and good in construction effect.

Owner:TONGJI UNIV

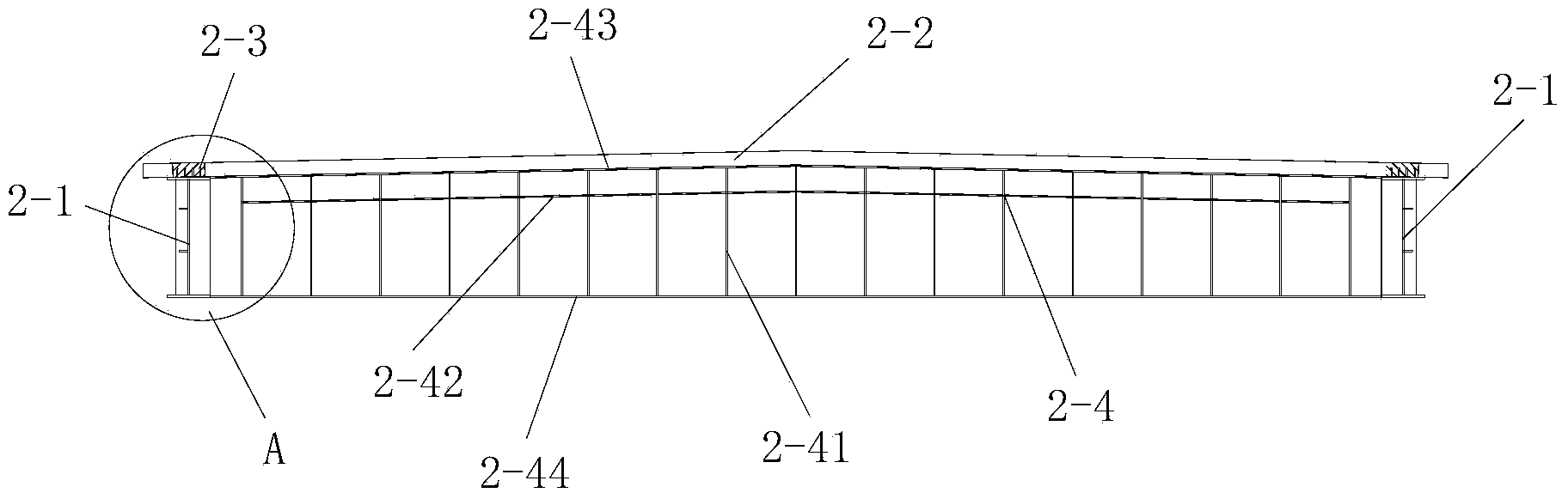

Joint section structure for hybrid beam cable-stayed bridge and construction method thereof

InactiveCN104294748ASimple structureReasonable designCable-stayed bridgeBridge structural detailsConcrete beamsCable stayed

The invention discloses a joint section structure for a hybrid beam cable-stayed bridge. The joint section structure comprises a concrete beam-combined beam connecting structure connected between a concrete beam and a combined beam, wherein the combined beam comprises steel girders distributed in the longitudinal direction of the bridge, the steel girders are I-shaped and comprise steel girder top plates, steel girder base plates and steel girder web plates. The steel girder top plates and the steel girder base plates extend into the concrete beam, and the concrete beam-combined beam connecting structure comprises a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web plate. The joint section structure is simple, reasonable in design, high in construction speed and good in using effect, and the problems of complicated structure, poor joint effect and the like existing in a steel-concrete joint portion structure can be solved. The invention further discloses a construction method of the joint section structure. The construction method comprises the steps of 1 erecting a construction support; 2 hoisting a steel structure; 3 constructing the concrete beam-combined beam connecting structure; 4 casting concrete. The construction method is simple in step, reasonable in design, convenient to construct, high in construction speed and good in construction effect.

Owner:TONGJI UNIV

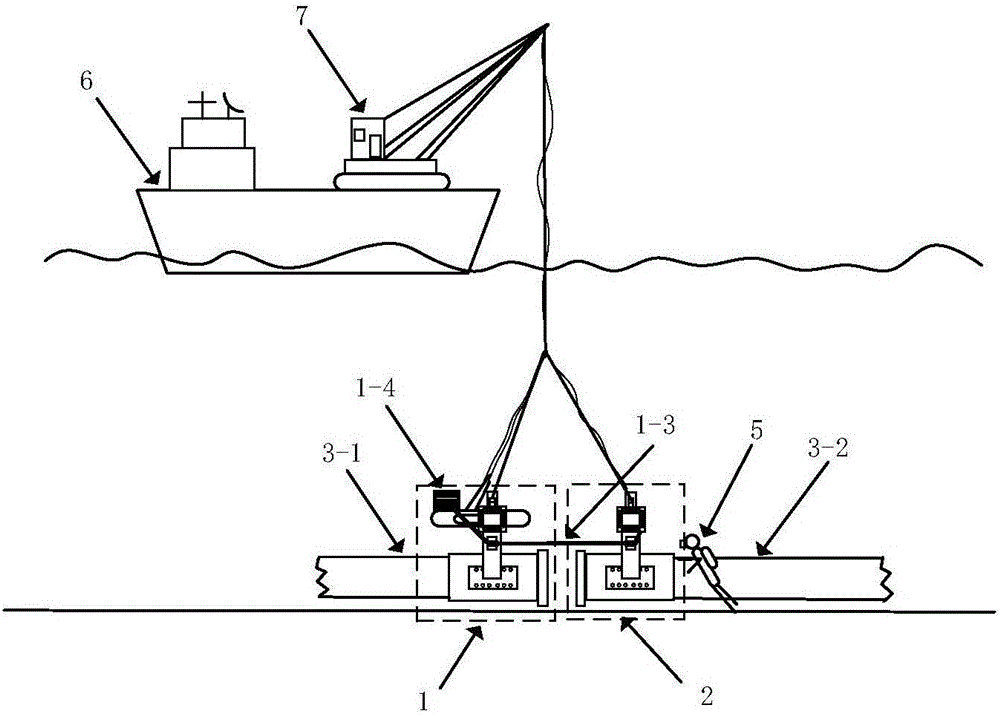

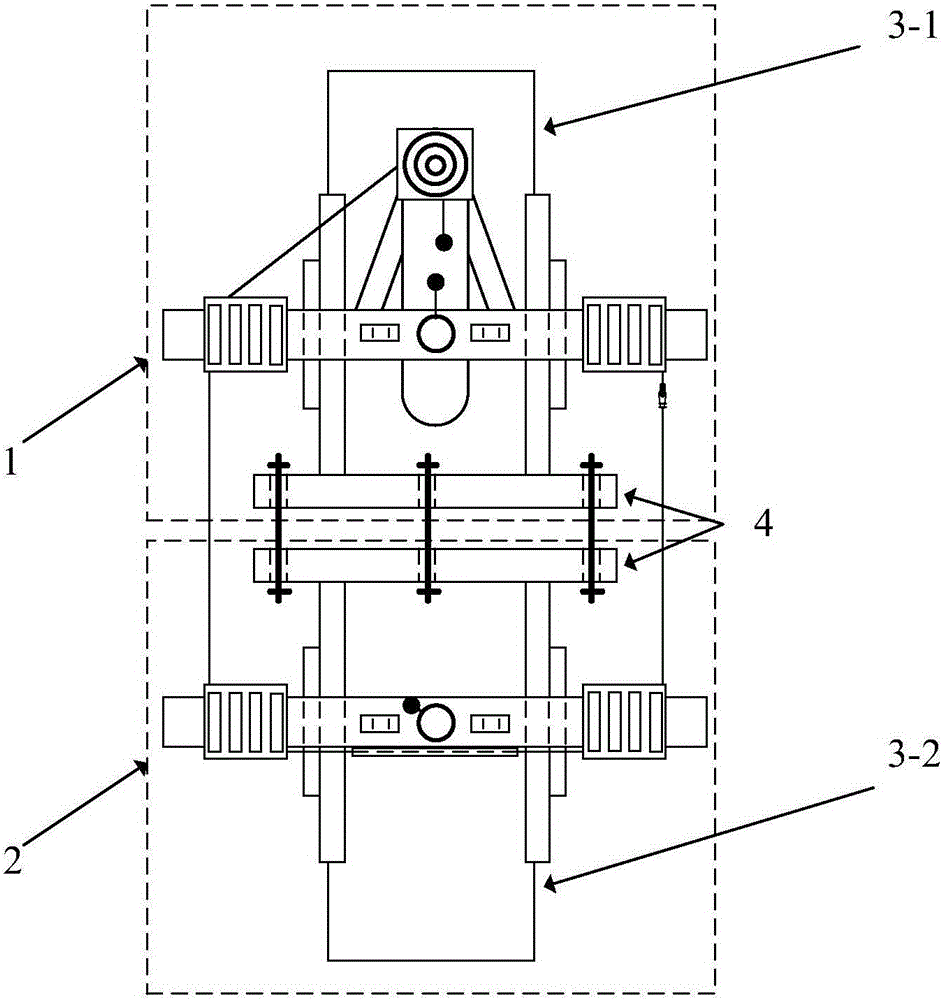

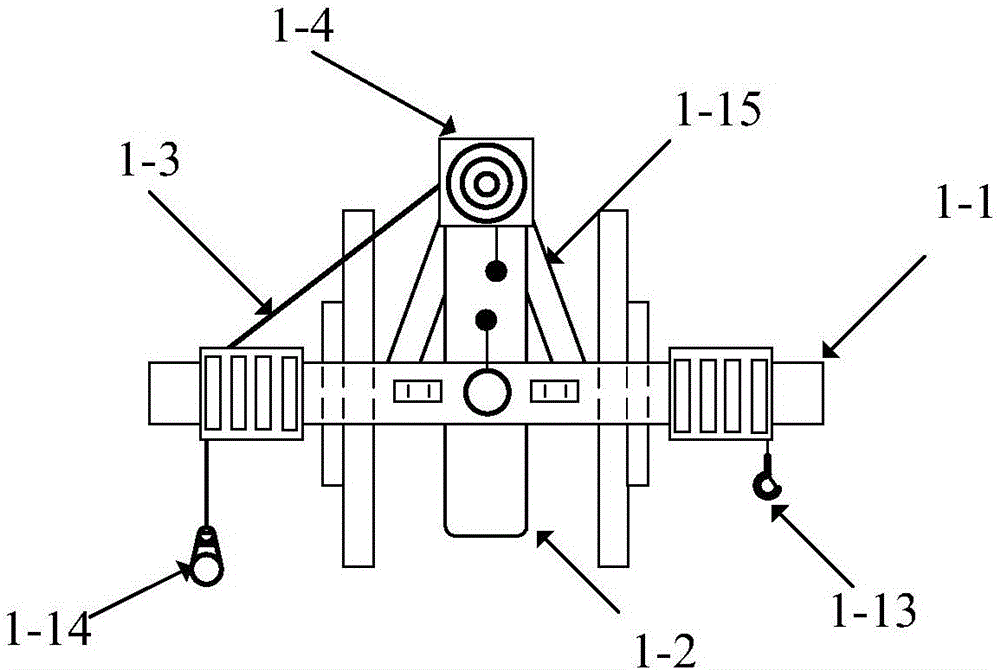

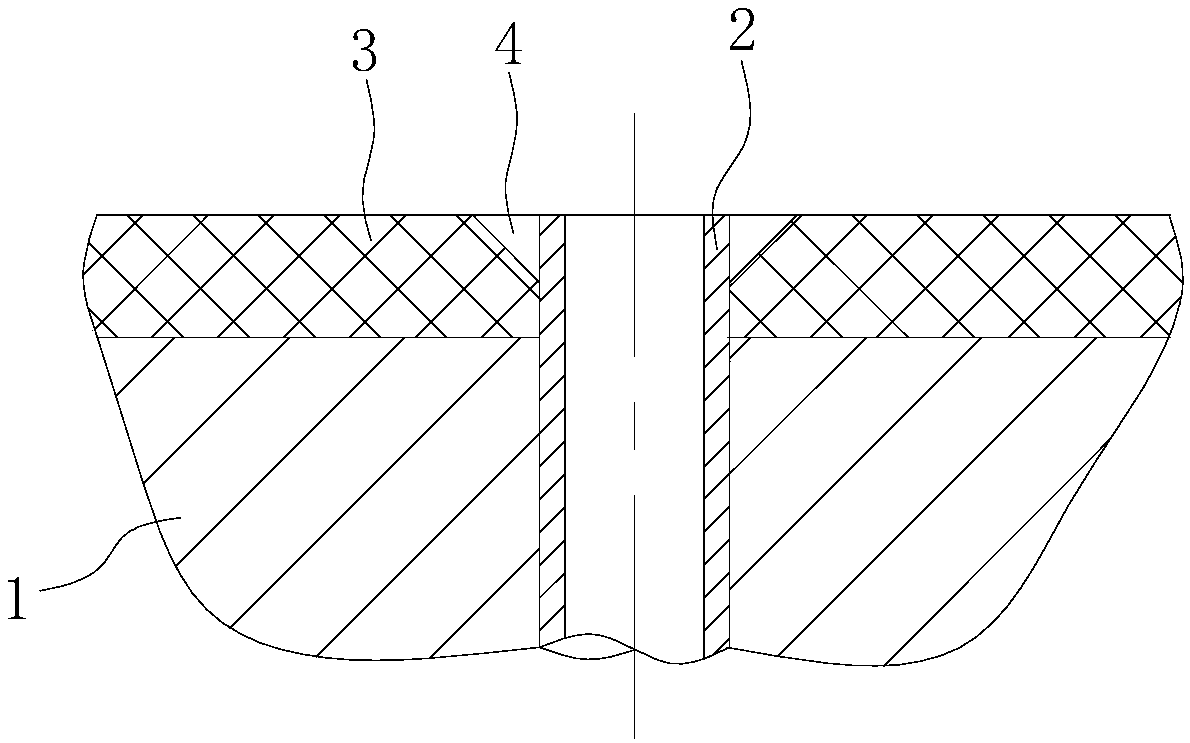

Submarine pipeline flange underwater abutting joint installation method

The invention discloses a submarine pipeline flange underwater abutting joint installation method. A main flange connecting device is installed on the abutting joint end of a submarine pipeline A, an auxiliary flange connecting device is installed on the abutting joint end of a submarine pipeline B, the submarine pipeline A to be butted and the submarine pipeline B to be butted are connected together through the main flange connecting device and the auxiliary flange connecting device, the negative influence of the marine condition on underwater flange connection can be removed, the influence of ship shake on the movement of the submarine pipeline A and the submarine pipeline B can be removed, underwater adjusting steps of a diver can be reduced, the diver can adjust the positions of the submarine pipeline A and the submarine pipeline B conveniently, the underwater operation difficulty degree of the diver can be reduced, the underwater operation time of the diver can be shortened, the case that flanges get close to each other in an aligned manner can be ensured, the force applied to a gasket of each flange is consistent, uniform deformation is generated, and the leakproofness of the flanges can be improved. The flange connection quality can be improved, the operating time of the support ship can be saved, the construction period of the whole fleet can be shortened, the working efficiency is improved, and the installation cost is saved.

Owner:CNOOC ENERGY TECH & SERVICES

Connecting processing technology for tube and tube plate

ActiveCN108971710AClosely connectedImprove wear resistanceWelding accessoriesCorrosionHeat exchanger

The invention discloses a connecting processing technology for a tube and a tube plate. The technology comprises the following steps: performing bead weld on the tube plate, and forming a bead weldinglayer; chamfering a tube hole of the bead welding layer on the tube plate; enabling the tube to penetrate into the tube hole in the tube plate, wherein the end part of the tube is aligned to the beadwelding layer; performing expanded connection on a welding area of the tube and the tube plate; welding the tube and the tube plate, and welding by using an autopulse argon tungsten-arc welding filling wire; and performing the expanded connection on a non-welding area of the tube and the tube plate. The connecting processing technology for the tube and the tube plate is capable of increasing wearresistance and corrosion resistance of the tube plate through the bead welding layer, eliminating a gap of the welding area of the tube and the tube plate through the first expanded connection beforewelding, improving welding quality, welding by using the chamfering filling wire, reducing a leakage risk, eliminating a gap of the non-welding area of the tube and the tube plate through the secondexpanded connection after welding, preventing liquid or impurities from entering so that corrosion is generated to cause a failure welding joint, through the previous and later two times of the expanded connection and chamfering filling wire welding, guaranteeing connecting quality of the tube and the tube plate. The connecting processing technology for the tube and the tube plate is suitable forthe field of heat exchangers.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

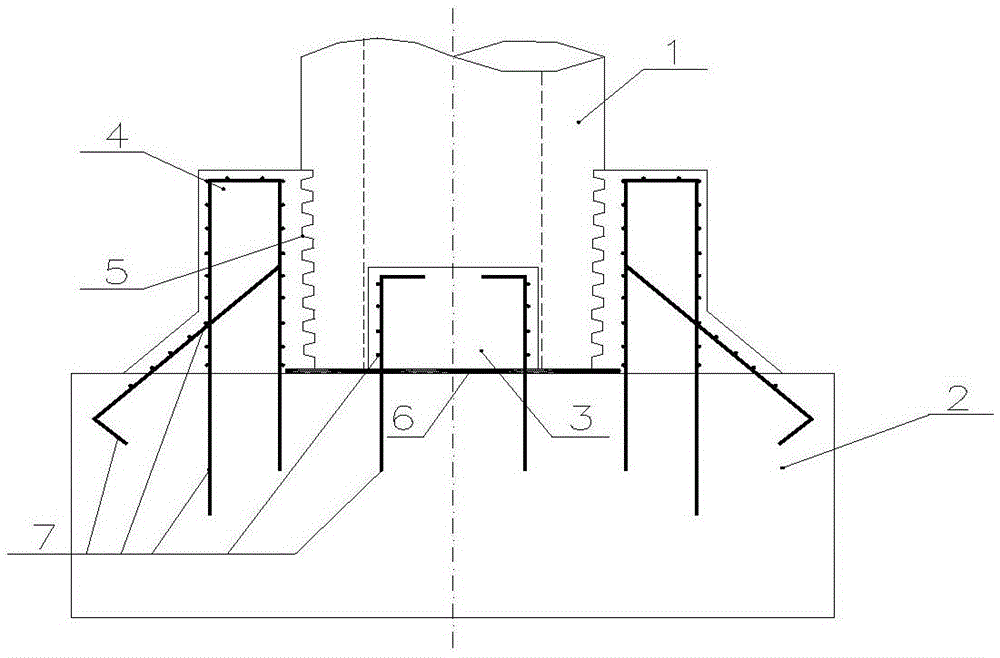

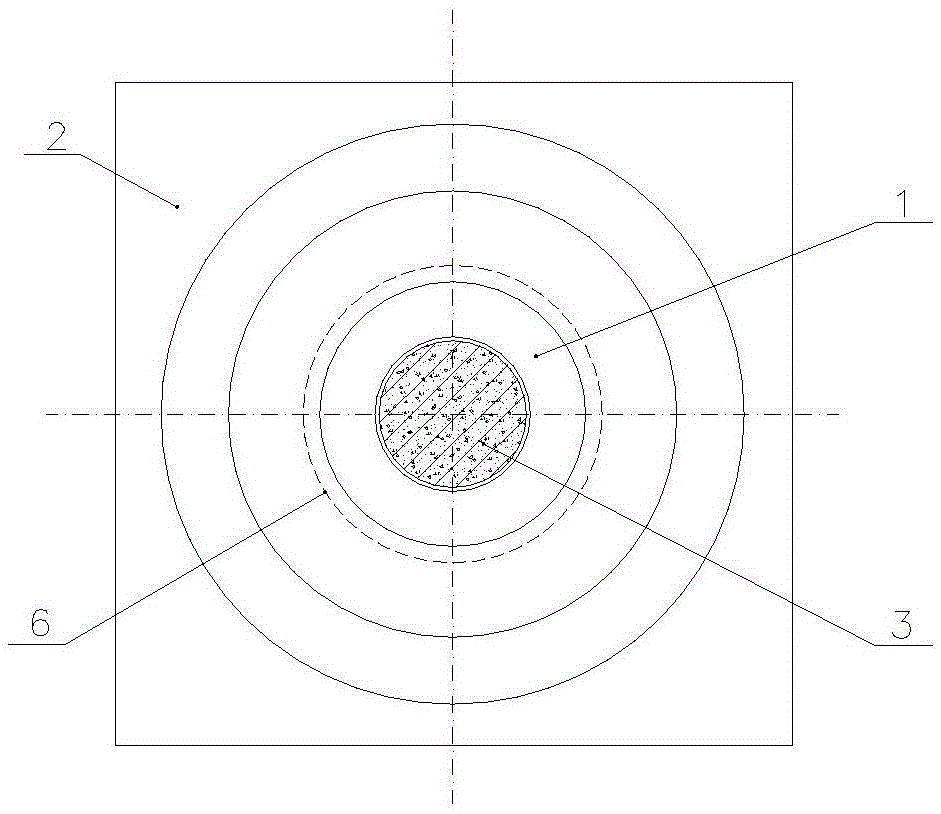

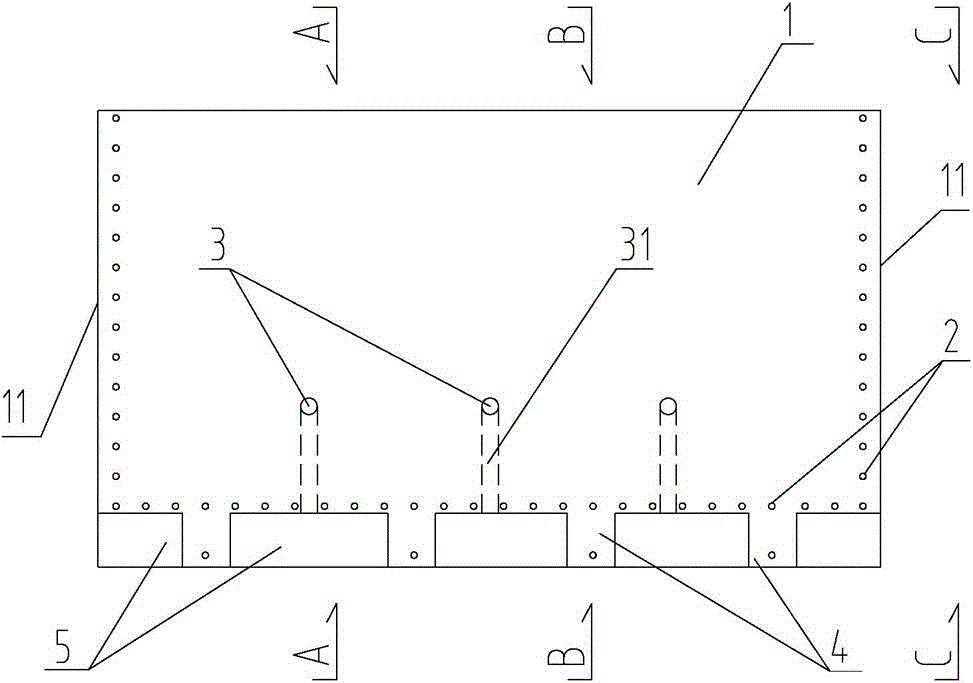

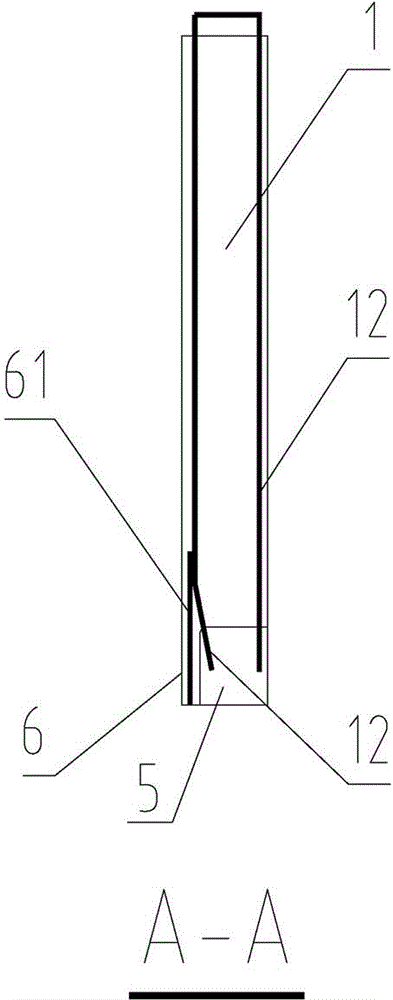

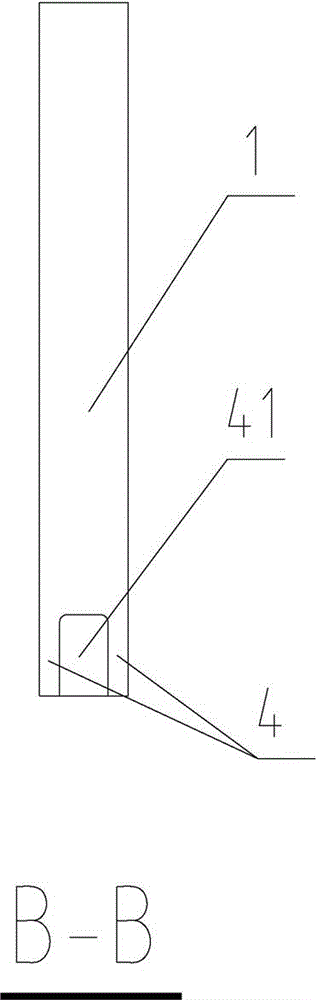

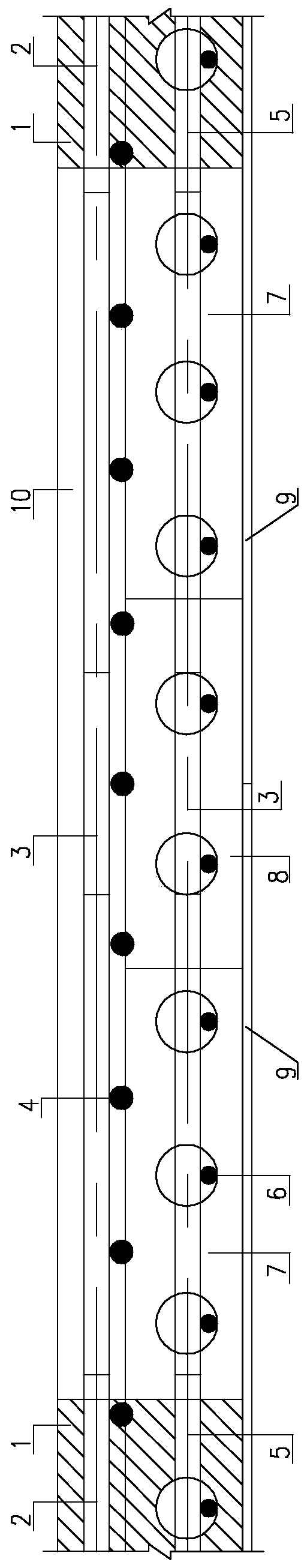

Connection structure of precast pier with annular section and bearing platform and construction method of connection structure

InactiveCN105544381AImprove shear resistancePrecise positioningBridge structural detailsBridge erection/assemblyCastingWelding

The invention discloses a connection structure of a precast pier with an annular section and a bearing platform. The connection structure is characterized in that the pier is positioned by a positioning pier, and is connected with the bearing platform through mounting islands, and the pier and the bearing platform are integrated; shearing rings in mutual effects are arranged between a connecting segment at the bottom of a pier body and the mounting islands. The connection structure disclosed by the invention has the technical characteristics and the effects that the bottom of the precast pier sleeves the positioning pier, so that the positioning of the pier body is facilitated; within the scope of the cup rim mounting islands, a trapezoidal concave-convex pattern structure is arranged on the connecting segment at the bottom of the pier body, and roughcasting is performed, so that sufficient engaging of concrete is facilitated, the shear resisting property of connecting positions is reinforced, and the stress property of a pier column is effectively improved; the pier and the bearing platform are connected through the annular mounting islands, and the shearing rings are arranged at the connecting positions, so that the shear resisting property of the connecting positions is reinforced. Through the adoption of the connection structure disclosed by the invention, the connection between the pier and the bearing platform is reliable in stress, convenient to construct, simple to operate and easy to control, the pier is simple to position, the workload of site welding and concrete casting can be effectively reduced, and the construction progress is accelerated.

Owner:中铁二十四局集团安徽工程有限公司 +1

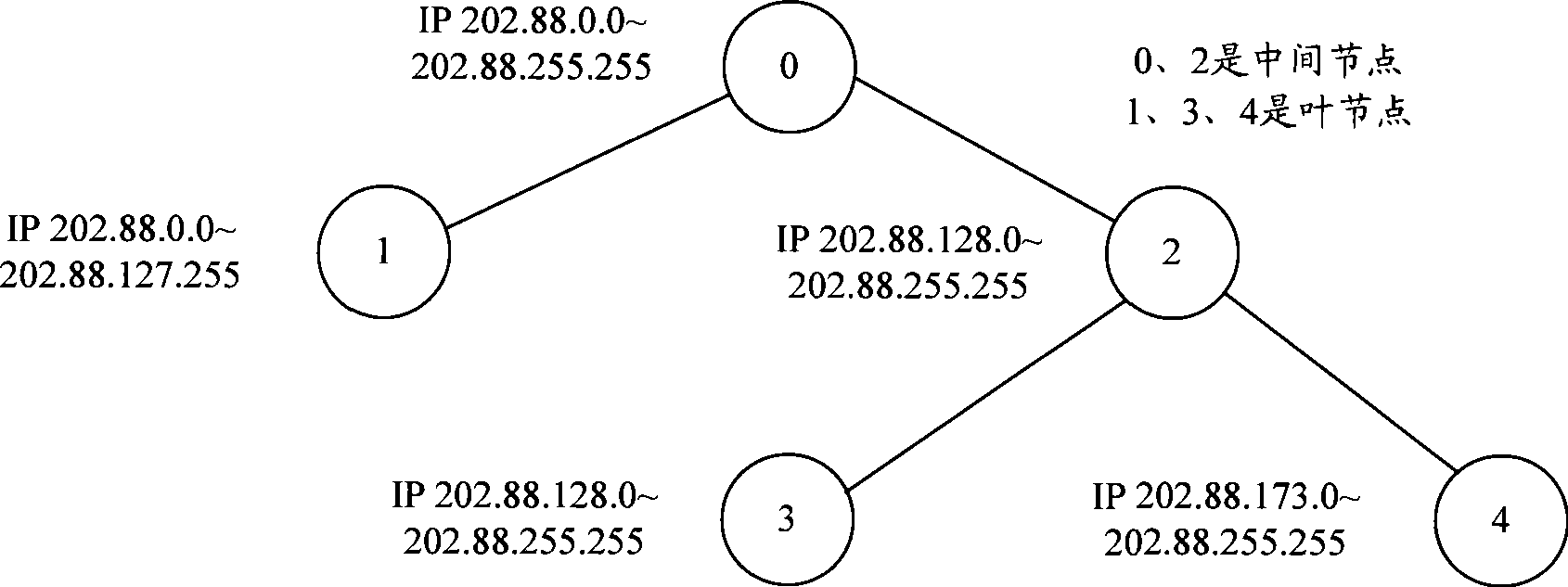

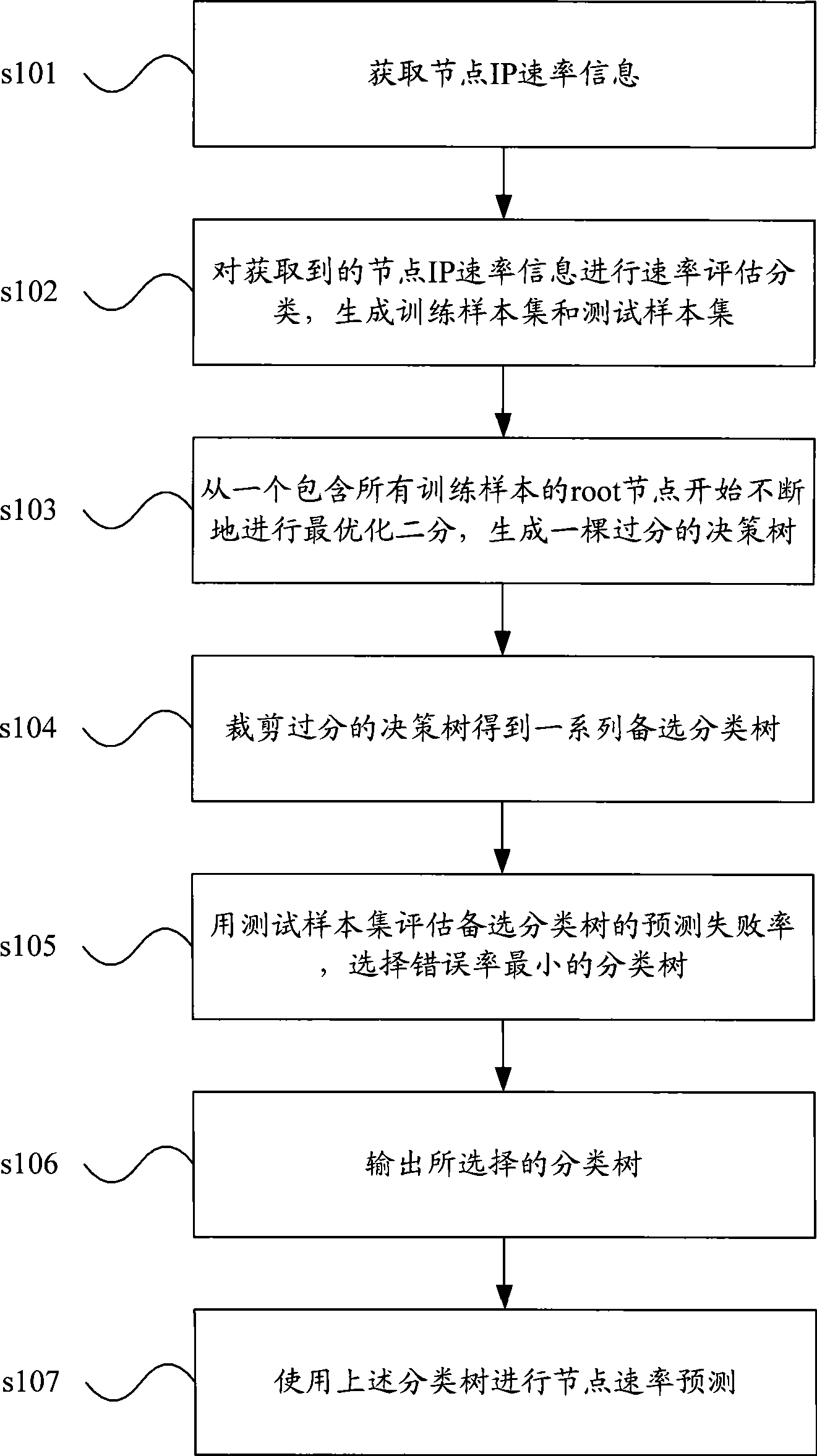

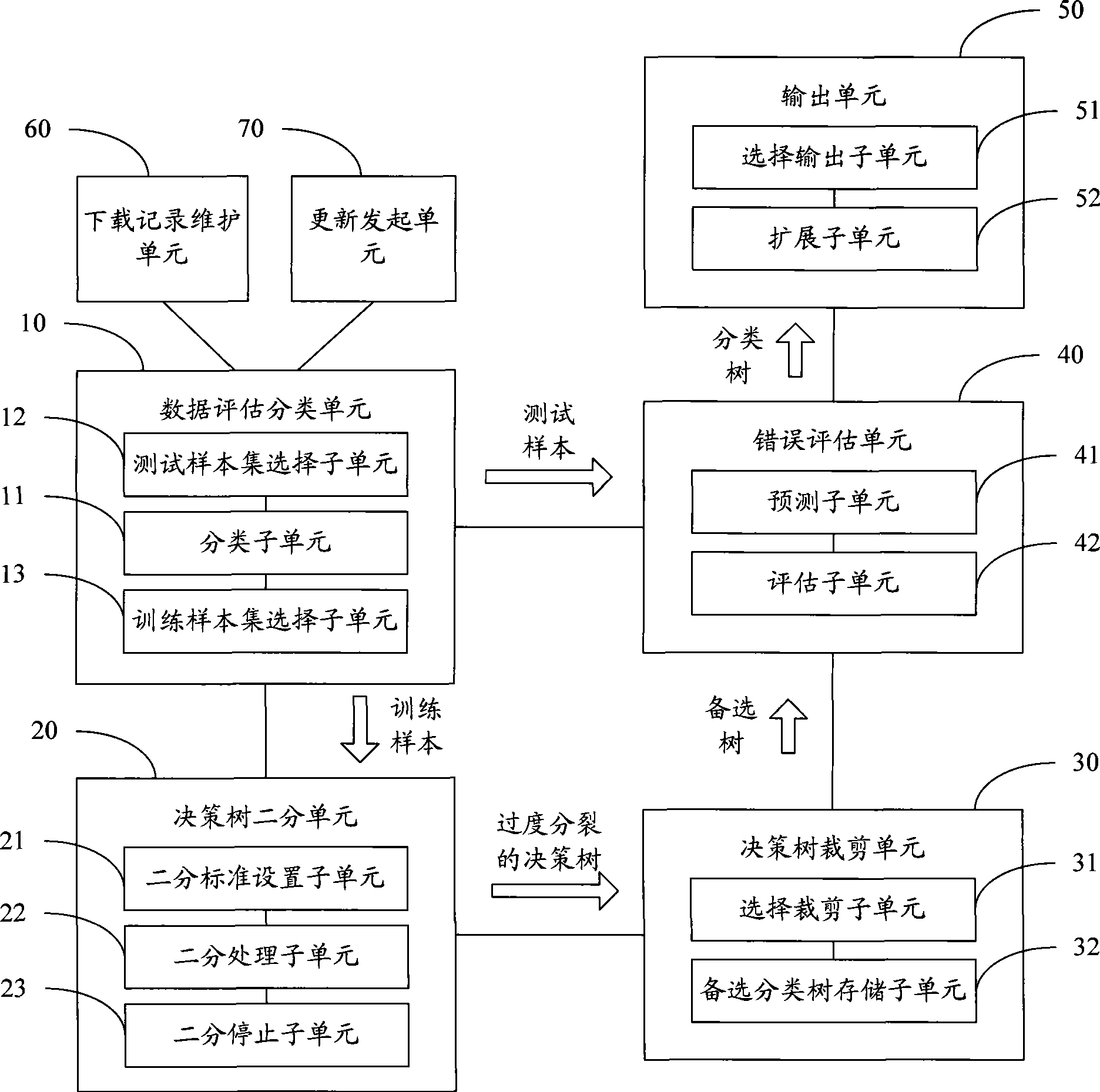

Method, system and equipment for Internet IP address classification and bandwidth prediction

InactiveCN101453368AReduce blindnessHigh bandwidthData switching networksDownload ratePredictive methods

The embodiment of the invention discloses a method for classifying Internet IP addresses and forecasting rate of a target node. The method is applied to any node in the network to classify IP address ranges, wherein each class comprises continuous IP address ranges and addresses in the class have approximate transmission rate for the node; and the method forecasts data download rate of the target node. The embodiment of the invention also discloses a device for classifying the Internet IP addresses and forecasting the rate of the target node. By using the embodiments, when a network application program needs to select from a plurality of communication nodes, the method can improve possibility of selecting the node with the maximal bandwidth and most guaranteed connection quality, so as to reduce blindness of the application program in network communication, and reduce load and consumption caused by communication blindness in a network.

Owner:HUAWEI TECH CO LTD

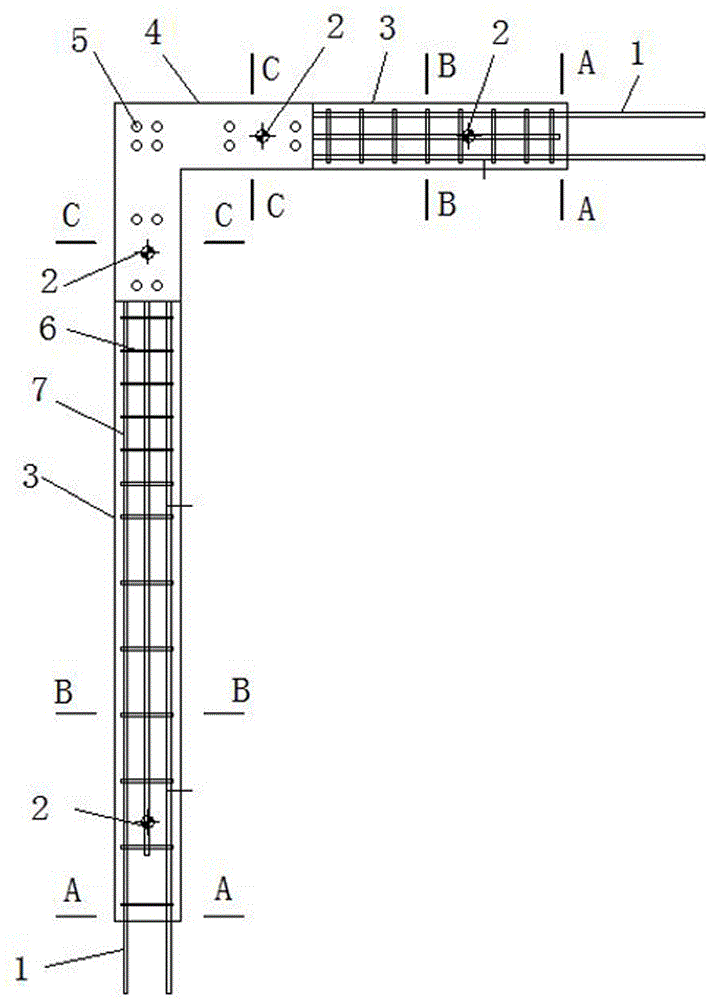

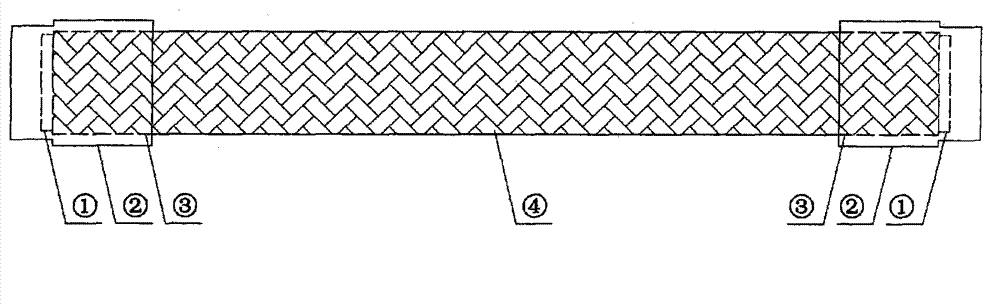

Prefabricated shear wall in cast-in-situ connection mode

ActiveCN105604208AEasy constructionGuaranteed connection qualityConstruction materialWallsRebarThreaded pipe

The invention relates to a prefabricated shear wall in a cast-in-situ connection mode. The prefabricated shear wall comprises a wall, pier heads, bottom upper concave sections and a bottom outer side plate. Side edges are respectively arranged on two sides of the wall, and a groove is formed in the middle of each side edge and is vertically perforated through the wall; wall vertical reinforcing bars are arranged in the wall; the bottom upper concave sections are uniformly distributed at the bottom of the wall; each pier head is arranged between the two corresponding adjacent bottom upper concave sections; air holes are formed in positions above the middles of the bottom upper concave sections; the air holes are communicated with the bottom upper concave sections via pipelines; the thicknesses of the pier heads are identical to the thickness of the wall, and holes are formed in the pier heads; the bottom outer side plate and the wall are integrated with each other, and the bottom outer side plate is positioned on the outer sides of the bottom upper concave sections; internally threaded pipes are embedded in positions close to the side edges of the wall, above the bottom upper concave sections and on the pier heads. The prefabricated shear wall in the cast-in-situ connection mode has the diversified advantages of firm structure, convenience in construction, reliability in connection and the like.

Owner:华汇工程设计集团股份有限公司

Assembling-type beam-column joint connection structure for concrete special-shaped column frame

ActiveCN105756191AAchieve connectionGuarantee support systemBuilding reinforcementsShaped beamSlurry

Owner:河北省建筑科学研究院有限公司

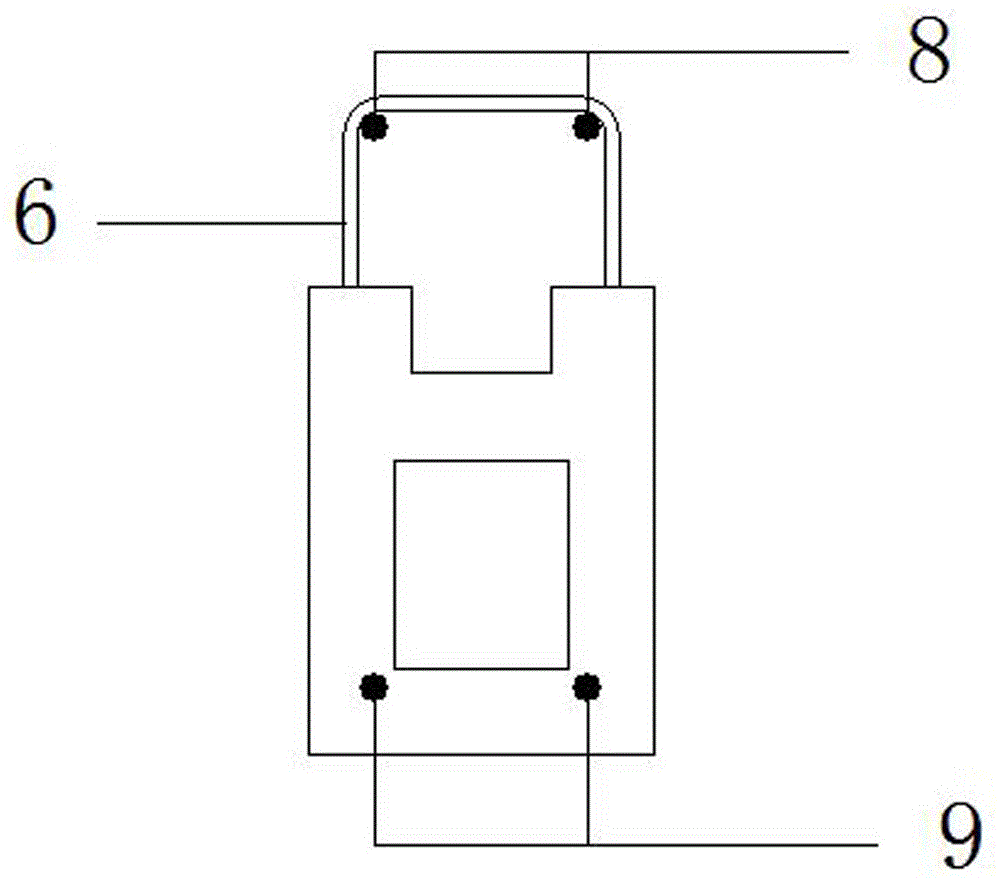

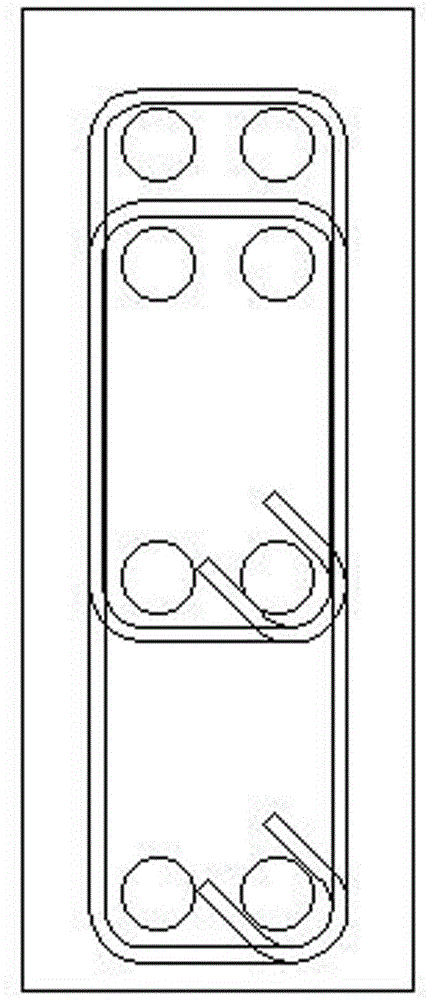

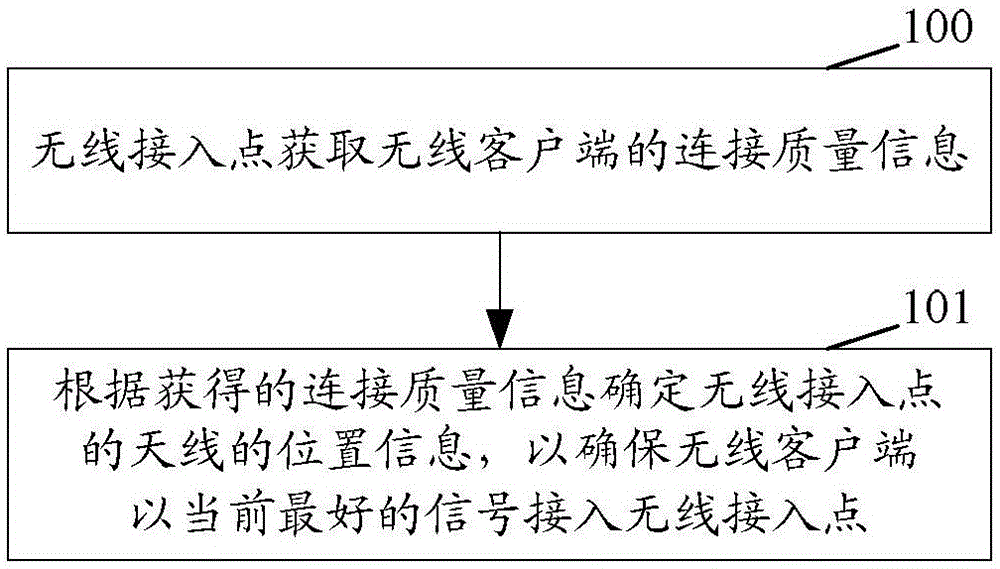

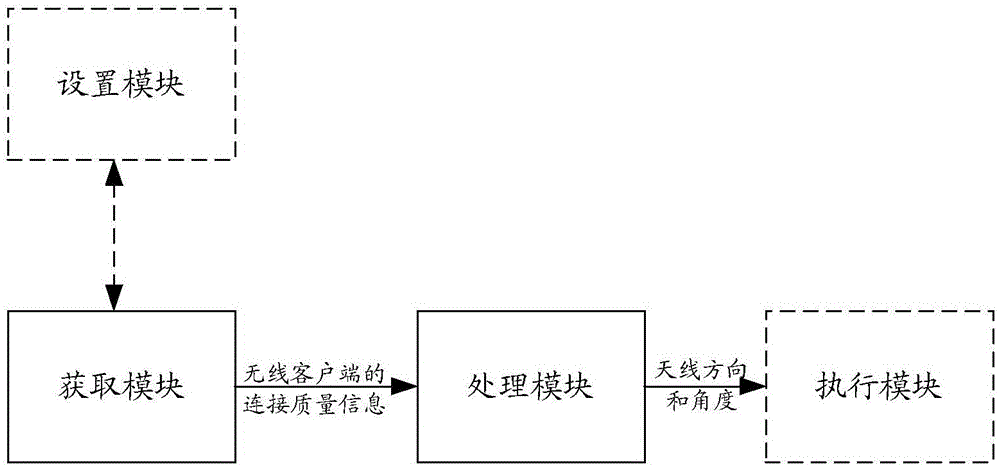

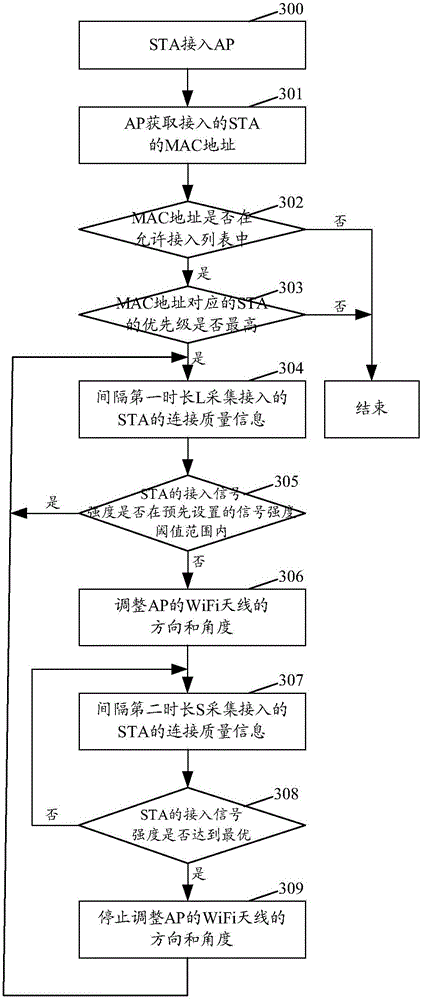

Wireless local area network access method and wireless access point

ActiveCN105142179AGuaranteed connection qualityImprove experienceWireless communicationAccess methodWireless access point

The invention discloses a wireless local area network access method and a wireless access point. The wireless local area network access method comprises the following steps: a wireless access point acquires connection information of a wireless client; and the position of an antenna of the wireless access point is determined according to the acquired connection information so as to ensure that the wireless client accesses a wireless local area network via the best signal currently. According to the technical scheme provided by the invention, by monitoring the connection information (such as access signal intensity) of the wireless client and adjusting the position (such as angle) of the antenna of the wireless access point, that the wireless client accesses a wireless local area network via the best signal currently is ensured, quality of WLAN connection is ensured, and the user experience is improved.

Owner:ZTE CORP

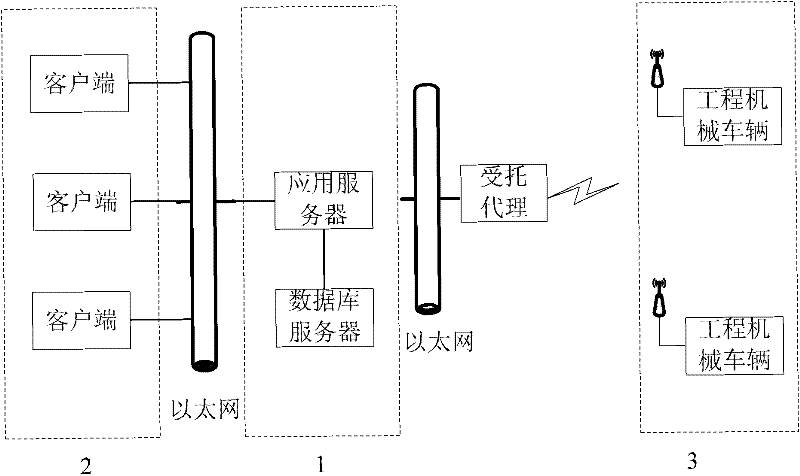

Engineering mechanical vehicle networking and communicating method and engineering mechanical vehicle networking system

InactiveCN102333071AGuaranteed connection qualityGuaranteed service qualityData switching by path configurationService protocolComputer terminal

Owner:ZHEJIANG UNIV

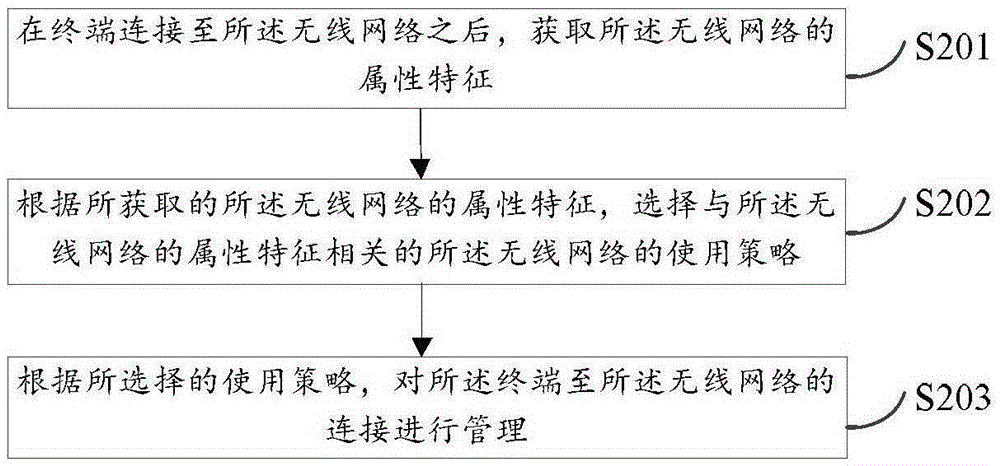

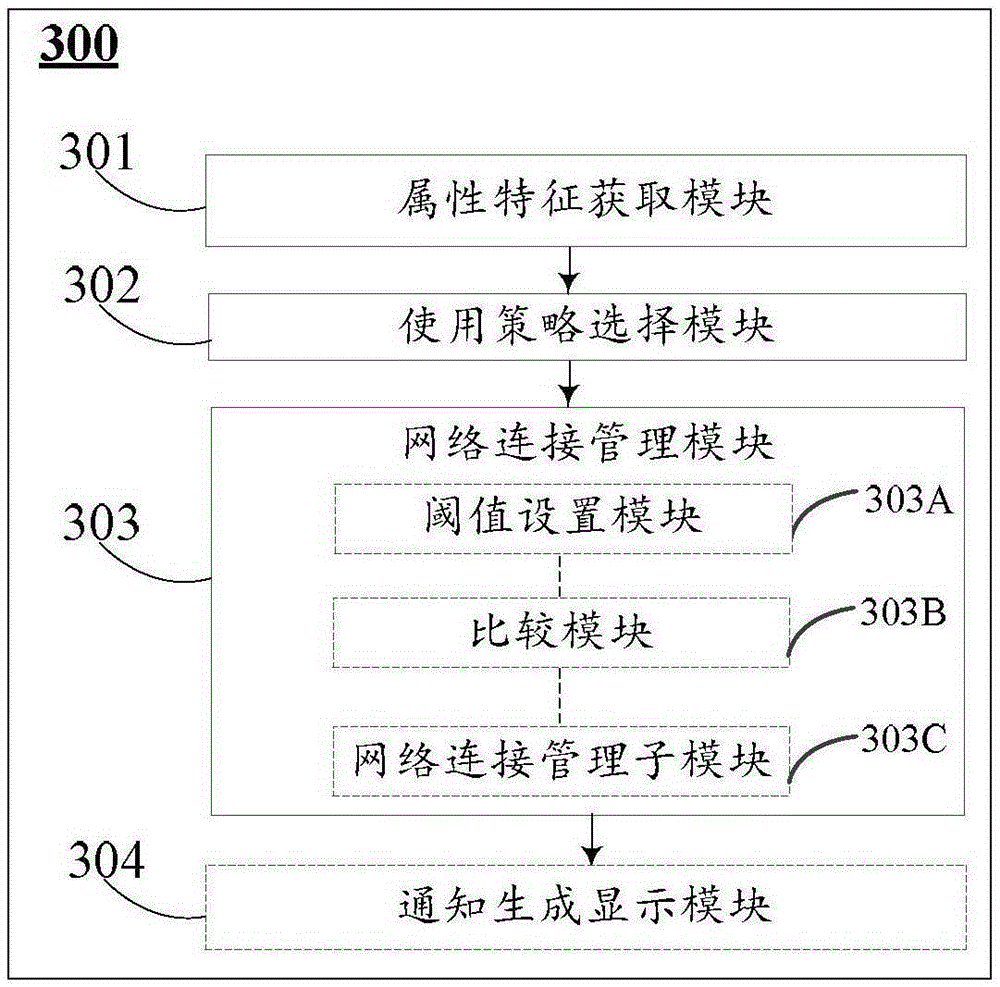

Method and device for managing connection of wireless network

ActiveCN105338550AAvoid time or trafficAvoid feesPower managementAccounting/billing servicesReal-time computingWireless network coding

The embodiment of the invention provides a method and device for managing the connection of a wireless network. The method comprises steps of: acquiring the attribute characteristic of the wireless network after a terminal is connected with the wireless network; selecting a usage strategy, correlative with the attribute characteristic of the wireless network, of the wireless network according to the acquired attribute characteristic of the wireless network; and managing the connection between the terminal and the wireless network according to the selected usage strategy.

Owner:NETEASE MEDIA TECH BEIJING

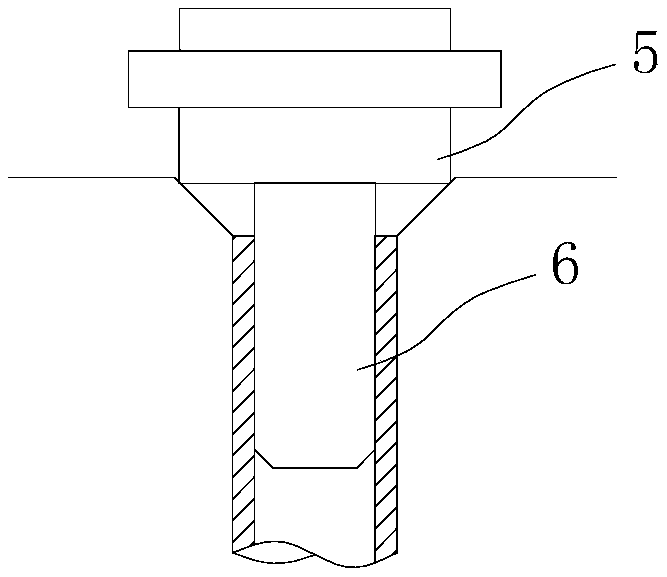

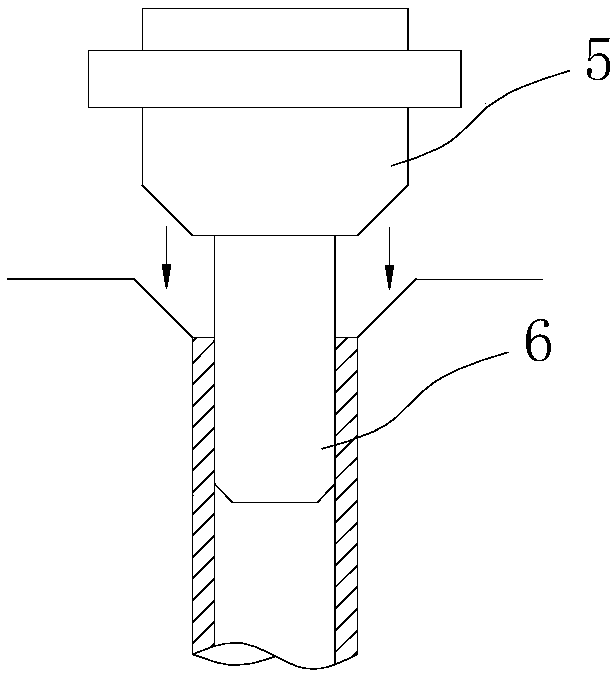

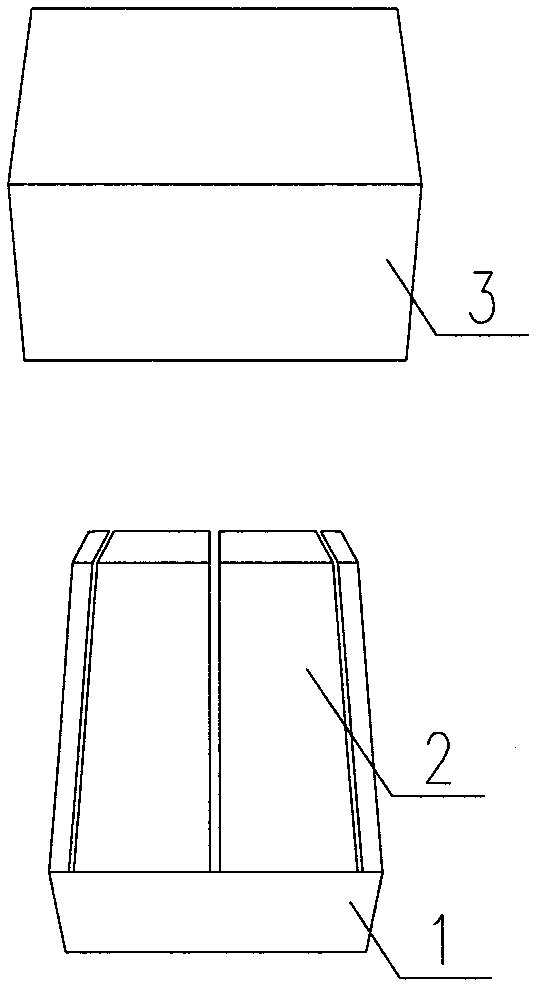

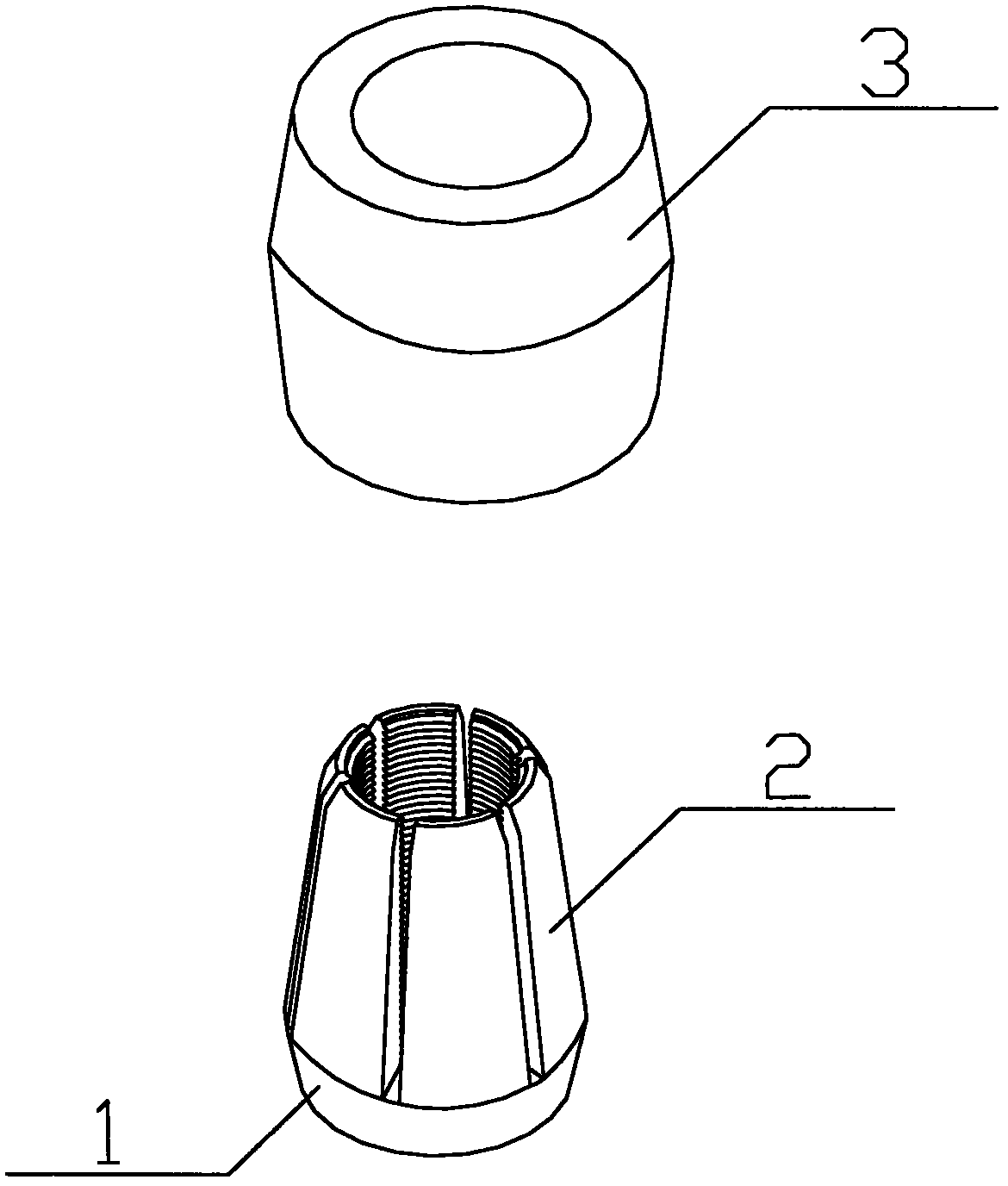

Extruded steel bar straight thread connecting sleeve

InactiveCN102433964AFirmly connectedGuaranteed connection qualityBuilding reinforcementsSteel barScrew thread

The invention discloses an extruded steel bar straight thread connecting sleeve, which comprises two parts, namely an inner steel sleeve and an outer steel sleeve, wherein the upper part and the middle part of the inner steel sleeve are cut into 4 to 12 steel sections and are hollow inverted truncated cones, and the lower part of the inner steel sleeve is connected into a whole and has an inverted truncated cone shape or a cylindrical shape; screw threads are wholly sleeved on an inner side of the inner steel sleeve and are used for meshing with steel bars; an inner side of the outer steel sleeve is a truncated cone surface which has the same slope as that of the outer side of the middle part of the inner steel sleeve; and the upper half part of the outer side of the outer steel sleeve is a truncated cone, and the lower half part of the outer side of the outer steel sleeve has an inverted truncated cone shape or a cylindrical shape. By the steel bar straight thread connecting sleeve, the steel bars can be rapidly and conveniently connected, the connecting quality is effectively guaranteed, and connecting operation can be performed in a small space.

Owner:张厚

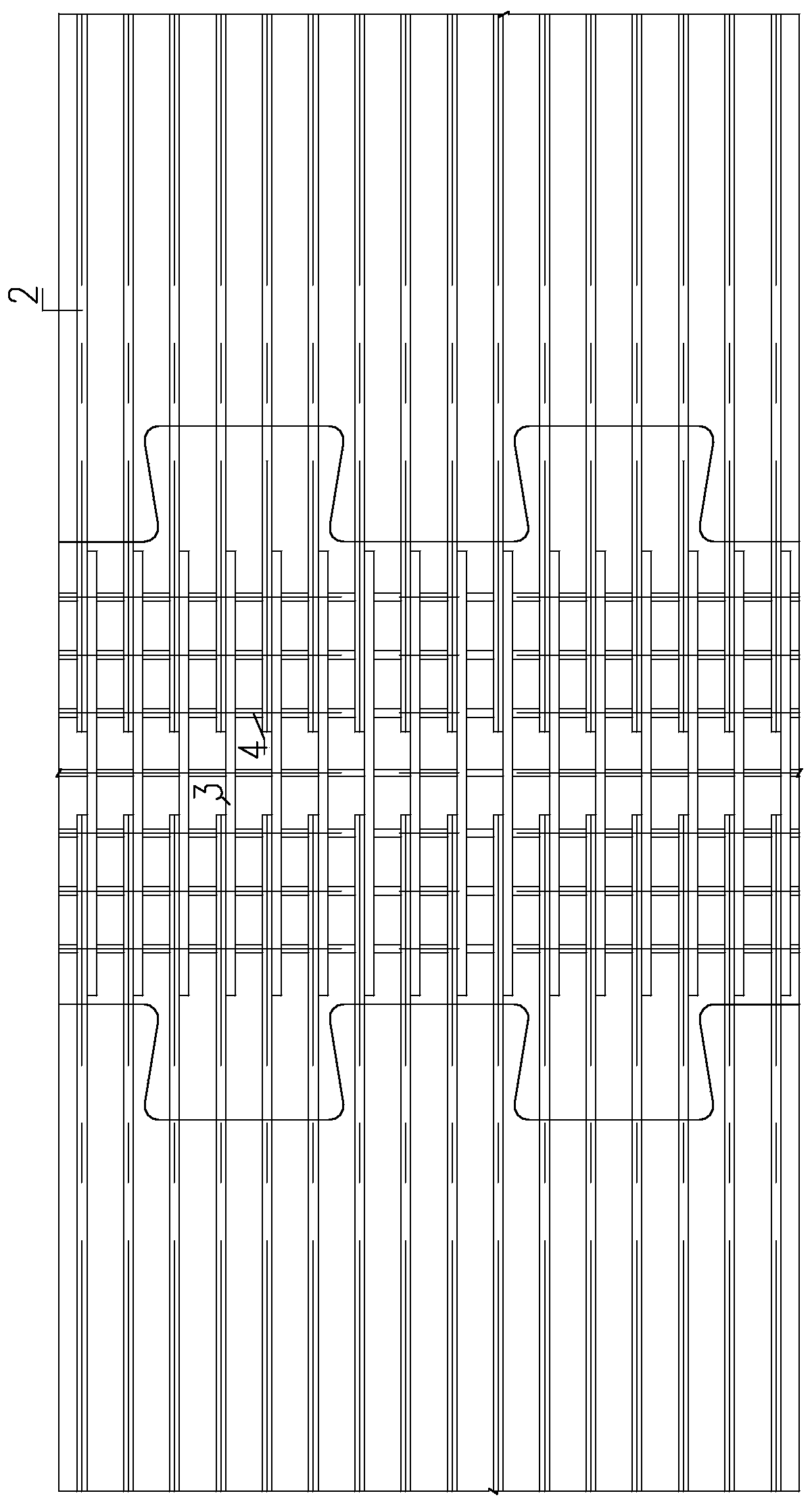

Ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with template

InactiveCN110952446AHigh tensile strengthHigh compressive strengthBridge structural detailsButt weldingArchitectural engineering

The invention discloses an ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with a template, which comprises a prefabricated section, a wet joint sectionand a steel bottom template; the prefabricated section bridge deck slab is made of an ultra-high performance concrete material; the steel bottom template is an extension section of the prefabricated section bridge deck slab bottom template, butt welding is conducted in the middle of the wet joint, and the steel bottom template serves as a bottom template of the wet joint section; the wet joint section is supported on the steel bottom template and connected with the steel bottom template and the prefabricated section in a pouring mode, the wet joint section is laid continuously, the thickness of the wet joint section is equal to that of the bridge deck slab, and the wet joint section is made of ultra-high performance concrete materials the same as those of the bridge deck slab. The wet joint is provided with the template, is high in tensile strength and compressive strength and good in durability, can effectively guarantee the performance continuity of the ultra-high performance concrete at the wet joint interface, has the advantages of being effective in steel bar connection, convenient to construct and easy to maintain, and can solve the problem of the connection quality of the ultra-high performance concrete wet joint.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

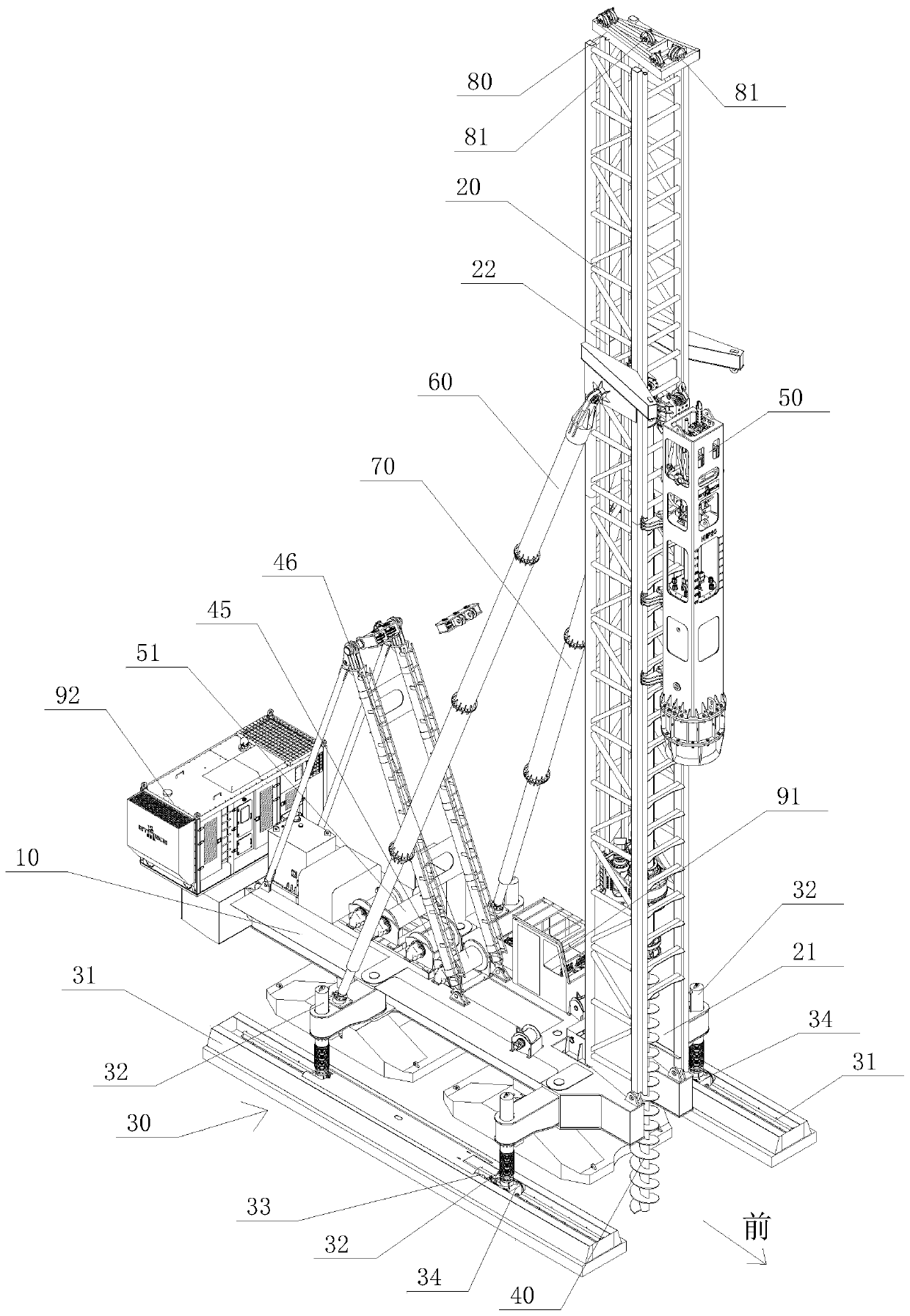

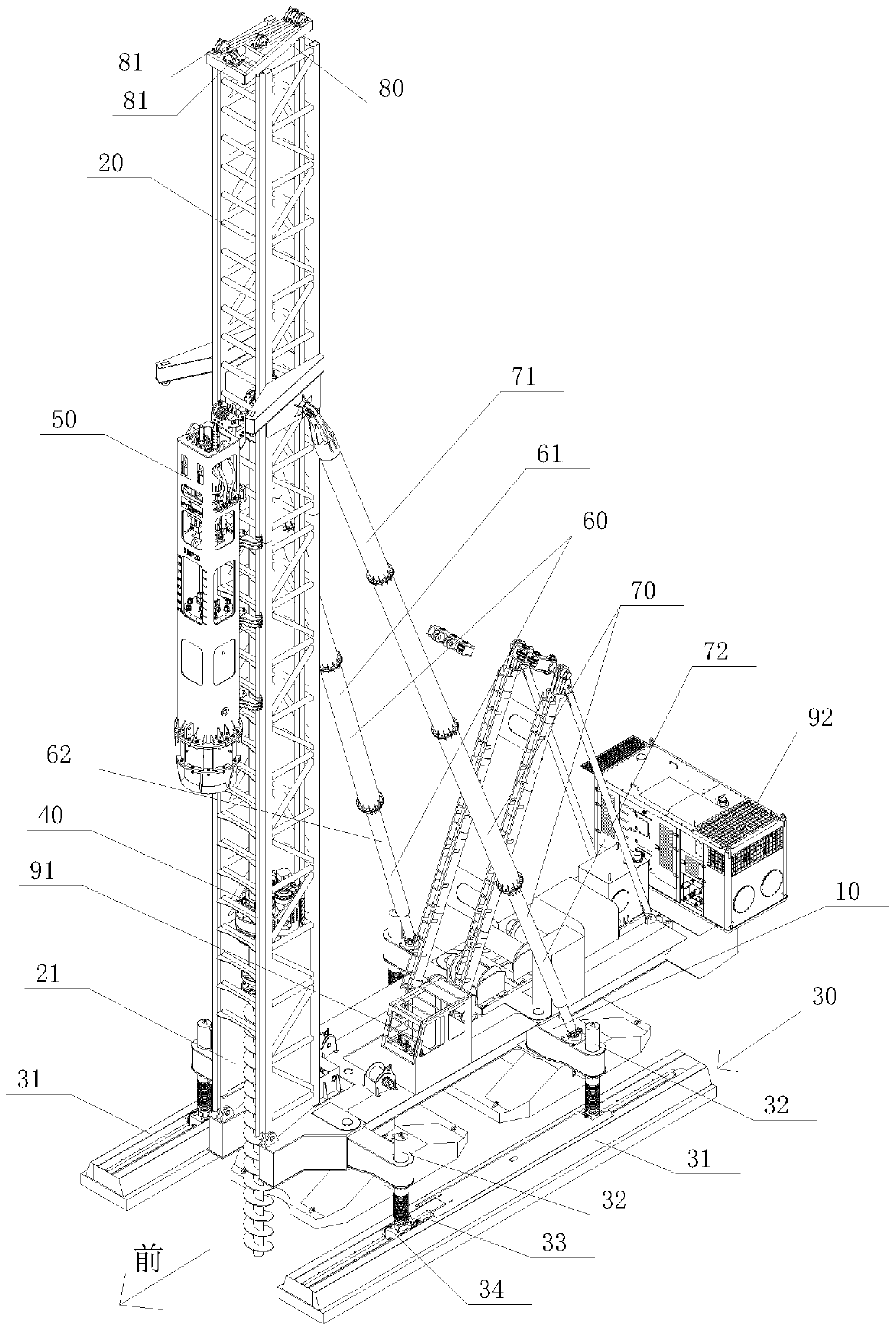

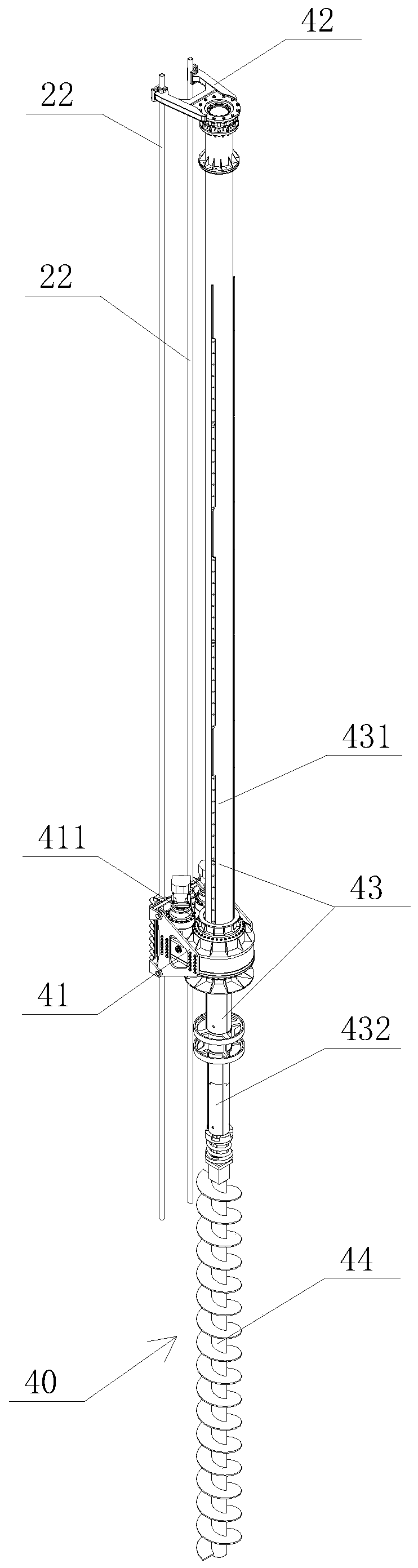

Construction method of big-diameter PHC prefabricated pipe pile and piling machine for implementing method

PendingCN110952552APrecise control of tilt angleSolve difficult-to-sink problemsBulkheads/pilesTowerPipe

The invention discloses a construction method of a large-diameter PHC prefabricated pipe pile. The method comprises the following steps of putting the piling machine in place; regulating an inclination angle; mounting the large-diameter PHC prefabricated pipe pile; performing hammering pile conveyance through a soft soil layer; aligning a guide hole; internally drilling the guide hole; performinghammering alignment; and performing hammering pile conveyance to a hard soil layer. The invention also discloses piling equipment for implementing the method. A hammering mode is used for pile foundation construction in the soft soil layer of a foundation; a large-diameter PHC pipe pile is sunk into the soft soil layer; the lateral friction resistance between the upper part of the pile foundationand the soft soil layer is ensured; the bearing force of the pile foundation is improved; a mode of firstly forming the guide hole and then performing hammering is used on the hard soil layer of the foundation; the problem of a plugging effect of the hard soil layer on the large-diameter PHC pipe file is solved, so that the large-diameter PHC pipe pile can be smoothly sunk into the hard soil layer; by regulating the inclination angle of a tower frame, the inclination angle of the large-diameter PHC pipe file is accurately controlled; and the precise and high-efficiency construction of the large-diameter PHC pipe file with the set inclination angle is realized.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

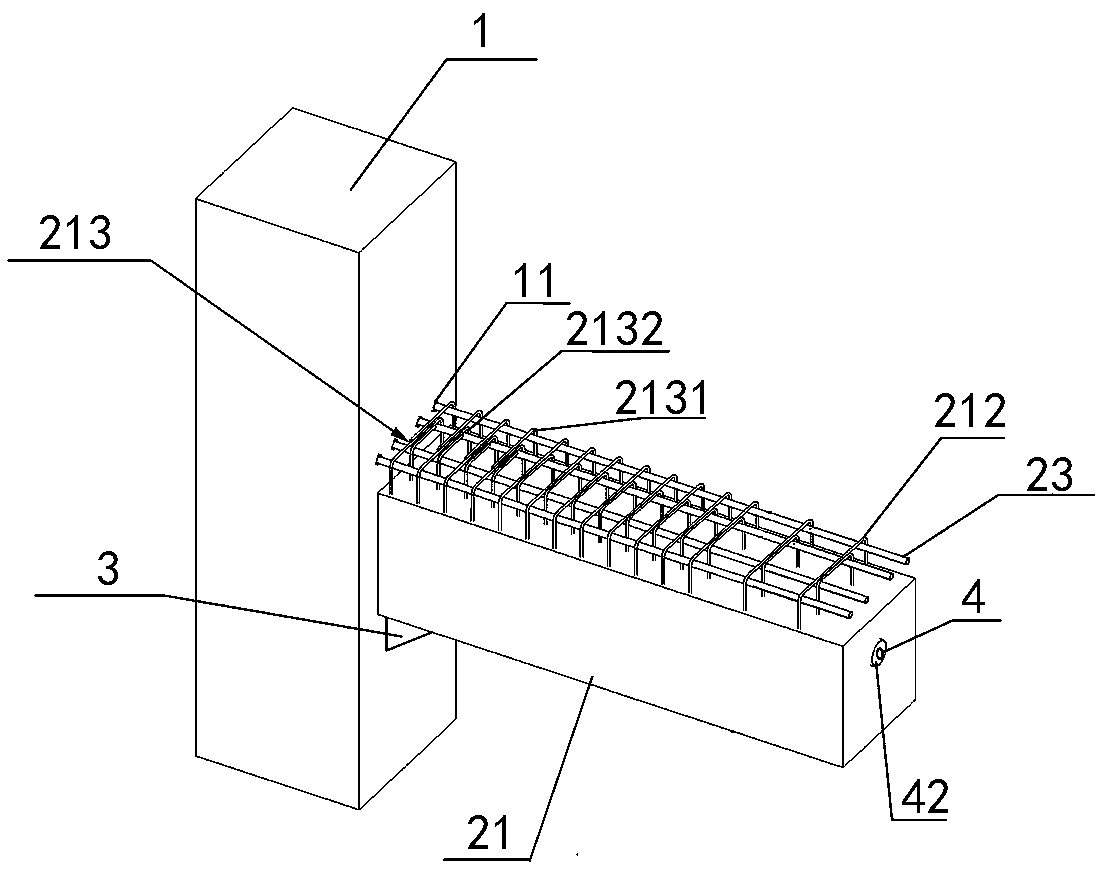

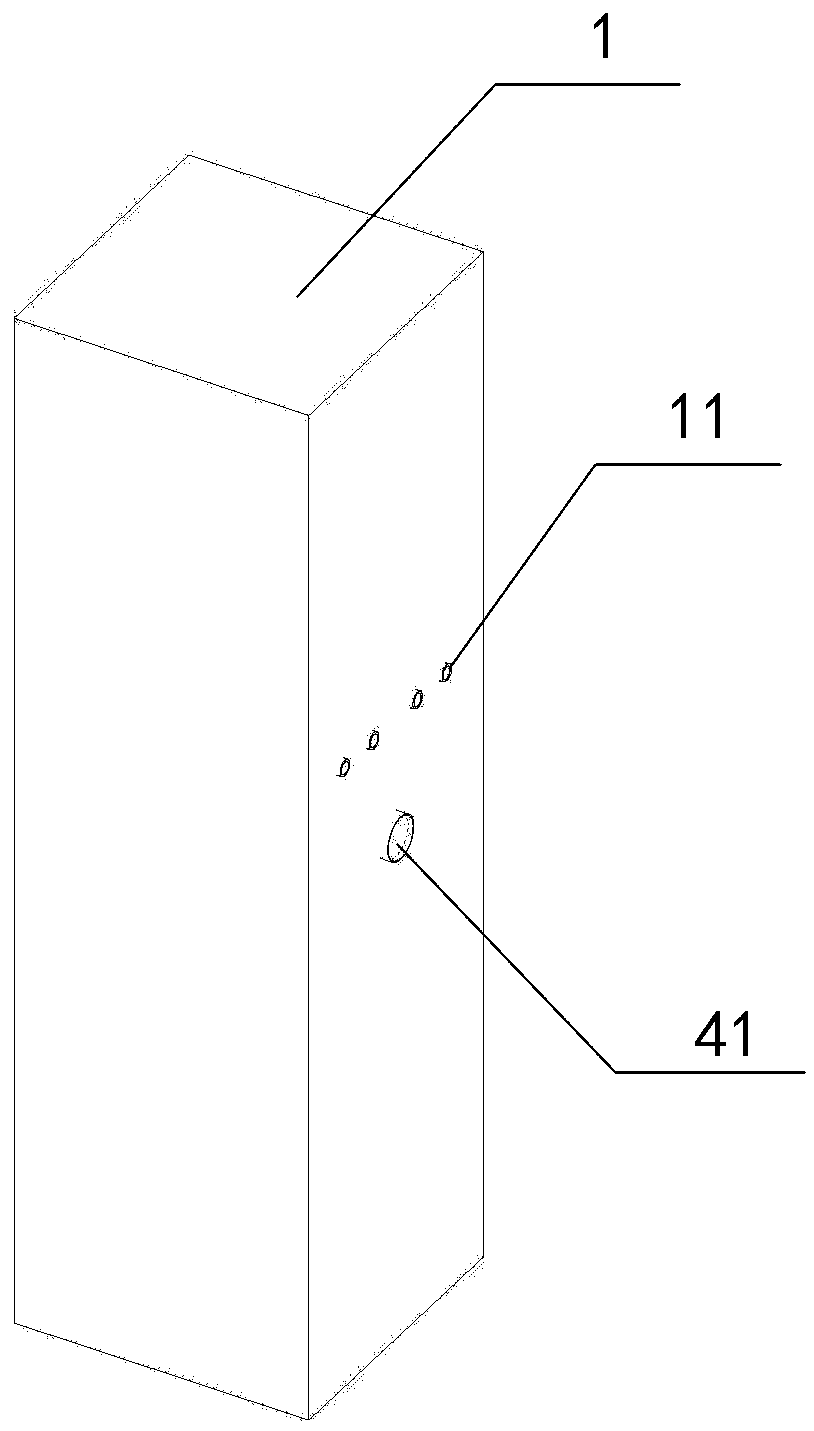

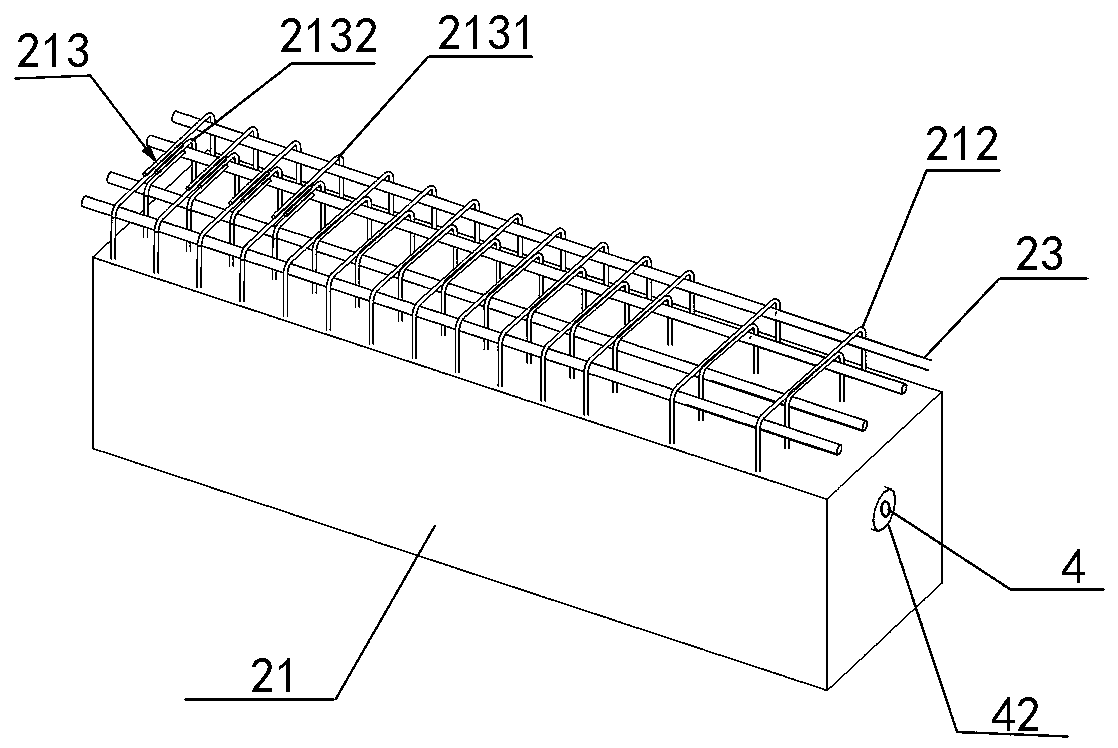

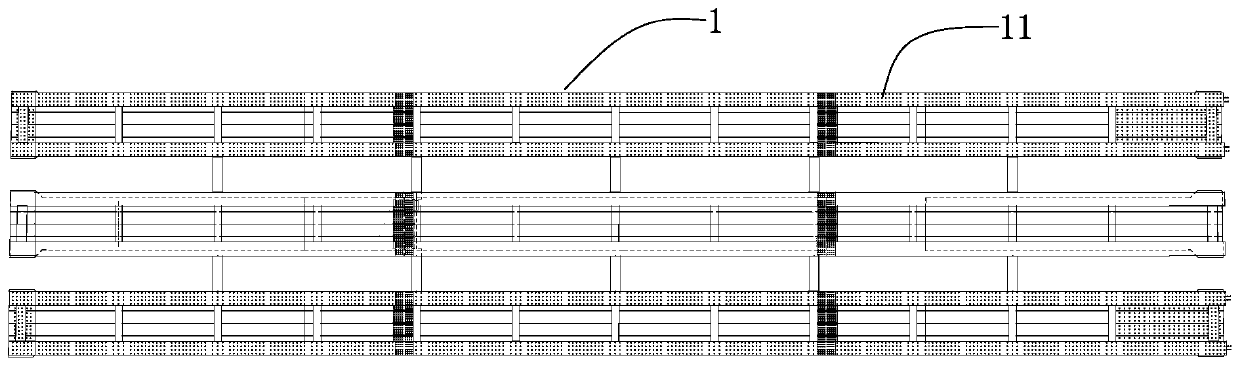

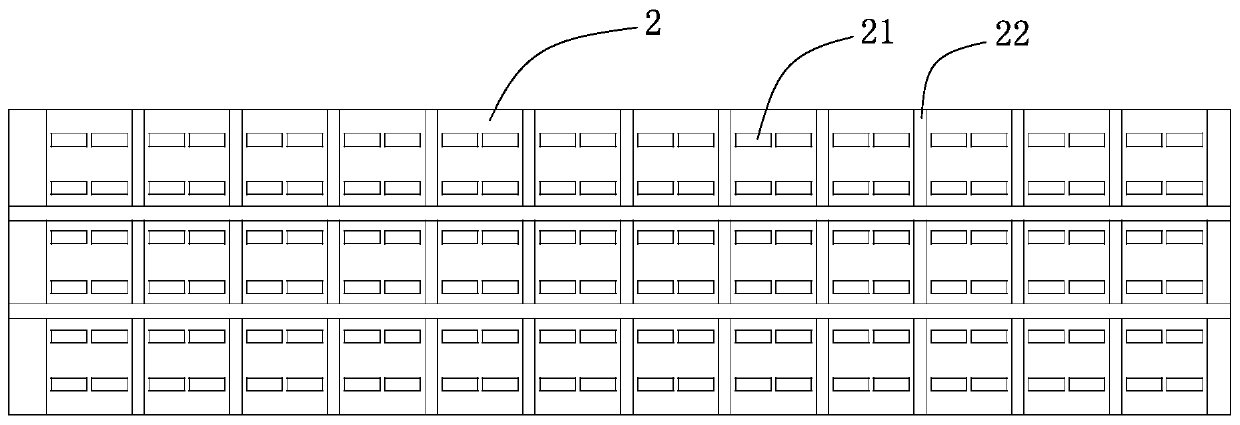

Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

PendingCN108457422AReduce shipping weightSave on rental costsLoad-supporting elementsFloor slabSurface layer

The invention discloses a prefabricated pre-stressed beam member, a fabricated combined frame structure and an installation method of the fabricated combined frame structure. The fabricated combined frame structure comprises prefabricated column members with hollow steel pipes inside, prefabricated pre-stressed beam members, cast-in-place concrete inside the prefabricated column hollow steel pipes, a laminated floor slab prefabricated base plate and laminated surface layer concrete. The middle sections of the hollow steel pipes of the prefabricated column members are covered with concrete, anda beam-column joint zone provided with short H-shaped steel beams is arranged at both ends of each middle section. The prefabricated pre-stressed beam member comprises a concrete laminated pre-stressed beam and interposed H-shaped steel beams at both ends of the pre-stressed beam. The short H-shaped steel beams in the beam-column joint zone and the interposed H-shaped steel beams of the prefabricated pre-stressed beam member are combined by bolt welding or connected by bolting. Joints of the hollow steel pipes of the upper and lower sections of the prefabricated column members are connected by welding. The fabricated combined frame structure integrates the advantages of a steel structure and a prefabricated concrete structure, and has high installation efficiency and good safety, and manpower and material resources are greatly saved.

Owner:SOUTHEAST UNIV +2

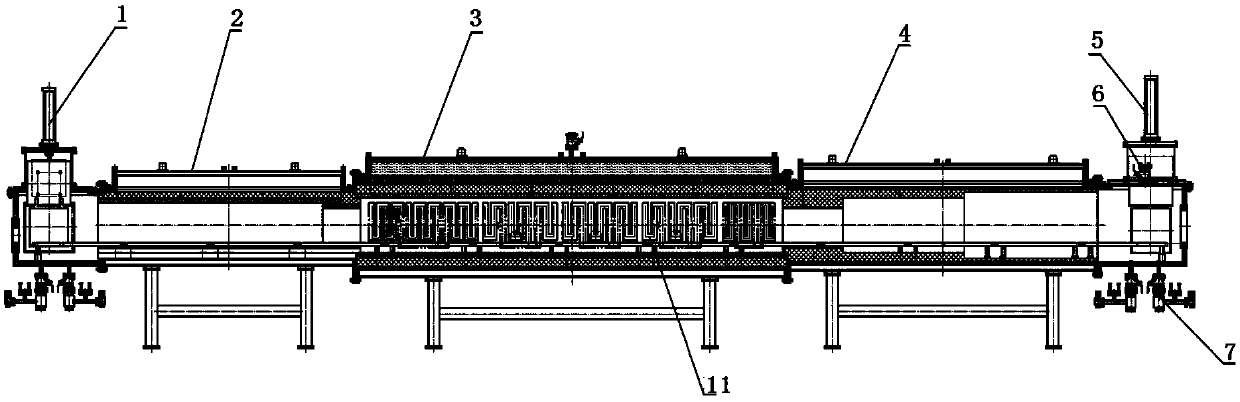

Ultra-high-temperature nitriding continuous tunnel furnace

ActiveCN108020081ASolve the problems of long length, large space occupation and large energy lossRealize fully automatic closed loopFurnace typesEngineeringOxygen

The invention discloses an ultra-high-temperature nitriding continuous tunnel furnace. The furnace comprises an aerobic charging area, a feeding area, a furnace body and a discharging area, wherein the areas are connected in sequence to form a rectangular loop structure, and the areas are independent from one another; the feeding area, the furnace body and the discharging area are of a sealed cavity structure, and the aerobic charging area is of a non-sealing structure; and rails are laid in all the areas, and the materials enter and exit from the areas in a one-way mode. The sintering temperature of the ultra-high-temperature nitriding continuous tunnel furnace can reach 2000 DEG C, and the unique annular structure layout realizes the full-automatic closed circulation of the materials ascompactly as possible, rapid cooling and independent feeding and discharging of the materials in the furnace can be realized, the size is small, and the atmosphere in the furnace is uniform; the circulating production process of discharging the material at one end and feeding the material at the other end can be realized, and the nitriding process of the batch materials is realized; hydraulic propelling is adopted, the whole process is controlled by computers, manual intervention is not needed, and automatic continuous operation is realized; and the furnace is stable and reliable in material running, high in safety performance and low in labor intensity.

Owner:钢研工程设计有限公司

Cable shielding layer splicing method

ActiveCN102904140AReliable contactGuaranteed connection qualityLine/current collector detailsSolderingFusion welding

The invention discloses a cable shielding layer splicing method which belongs to the technical field of electric installation and connection and specifically relates to a shielding layer splicing process aiming at cables. Through the shielding layer splicing method, improvement is carried out on the original shielding sleeve processing method, namely, before fusion welding is carried out on soldering tin rings of shielding mesh sleeves of two spliced cables, tinning is carried out on welding parts of shielding layers and the shielding mesh sleeves of the spliced cables so as to infiltrate the soldering tin into the shielding layers of the cables to ensure that the contact between the soldering tin and the shielding layers of the cables is reliable; and the soldering tin rings at two ends of the shielding mesh sleeves are heated through a hot air gun and then the soldering tin rings and the soldering tin at the tinning parts of the shielding layers of the spliced cables are integrally connected due to melting by heating, so that the shielding layers and shielding mesh sleeves of the two spliced cables can contact reliably and the splicing quality of the shielding layers of the cables is ensured.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Pre-stressed assembled beam column node beam-end welding stirrup structure and mounting method

PendingCN108867858AGuaranteed connection qualityAdequate operation and adjustment spaceGirdersJoistsLateral deflectionRebar

The invention provides a pre-stressed assembled beam column node beam-end welding stirrup structure. The structure comprises prefabricated concrete columns, prefabricated concrete beams and superimposed beam top longitudinal bars; the superimposed beam top longitudinal bars penetrate through reinforced steel bar couplers pre-embedded in the prefabricated concrete columns, and are then connected with in-column anchoring reinforced steel bars pre-embedded in the prefabricated concrete columns; the prefabricated concrete beams comprise prefabricated concrete beam bodies, common outward extensionclosed stirrups, beam-end outward extension opened stirrups and superimposed beam bottom longitudinal bars; the common outward extension closed stirrups hoop the superimposed beam bottom longitudinalbars and the superimposed beam top longitudinal bars, two opened ends of each beam-end outward extension opened stirrup are in mutual lap joint, the single faces of the beam-end outward extension opened stirrups form closed stirrups, and then the superimposed beam top longitudinal bars and the superimposed beam bottom longitudinal bars are hooped together. By means of the structure, sufficient operating and adjusting space is provided for the connection of the superimposed beam top longitudinal bars and the reinforced steel bar couplers, and the reinforced steel bar connecting quality is wellguaranteed; meanwhile, lateral deflection of the superimposed beam top longitudinal bars is effectively prevented, and the anti-seismic property of the structure is improved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Rotatable pre-embedded external member and prefabricated assembly type wall structure

The invention relates to the technical field of connection of building walls, in particular to a rotatable pre-embedded external member and a prefabricated assembly type wall structure. The rotatablepre-embedded external member comprises a pre-embedded C type anchor bar, a pre-embedded box set and a U-shaped reinforcing steel bar, wherein the pre-embedded C type anchor bar comprises a first vertical part and a first transverse connecting part; the U-shaped reinforcing steel bar comprises a second vertical part and a second transverse connecting part; the first transverse connecting part is arranged in the pre-embedded box set; the first vertical part penetrates through a through hole and is arranged on the outside of the pre-embedded box set; the second vertical part is rotatably connected with the first transverse connecting part; and the U-shaped reinforcing steel bar is rotatably stored in the pre-embedded box set. The rotatable pre-embedded external member is simple in structure,convenient to construct, and convenient to mount, transport and store; the construction speed is increased; the engineering cost is reduced; integrity of a connection part between shear walls is high,and the stress property is good; anti-seismic and safety characteristics are achieved; field wet operation is reduced; and environmental protection is facilitated.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Torsional shear type self-locking high-strength one-way bolt connecting pair and using method thereof

InactiveCN106286524AEasy to installConnection quality guaranteedNutsBoltsMaximum diameterSelf locking

The invention belongs to the field of civil engineering, is suitable for industrial and civil buildings, bridges, tower and mast structures, boiler steel structures, hoisting machines and other steel structures, and particularly relates to a torsional shear type self-locking high-strength one-way bolt connecting pair and a using method thereof. According to the technical scheme, the torsional shear type self-locking high-strength one-way bolt connecting pair comprises a torsional shear type bolt rod, a sleeve, a nut, a flat washer and a spring washer; a torsional shear groove is formed in one end of the torsional shear type bolt rod, and a conical expanded bottom is arranged at the other end; an open groove is formed in one end of the sleeve; the maximum diameter of the conical expanded bottom is smaller than the outer diameter of the sleeve. The torsional shear type self-locking high-strength one-way bolt connecting pair and the using method thereof are suitable for being installed on a closed section or a section allowing single-face operation only, and it is avoided that structural section is weakened.

Owner:SHENYANG JIANZHU UNIVERSITY

Construction method for high-pier large-span bridge steel mixing beam in mountainous area

ActiveCN110820573AImprove assembly qualityHigh positioning accuracyBridge erection/assemblyButt jointArchitectural engineering

The invention relates to a construction method of a high-pier large-span bridge steel mixing beam in a mountainous area. The construction method comprises the following steps that a steel mixing composite beam is prefabricated in a rear field, the prefabricated structure is optimized, a steel box girder and a concrete bridge panel are ensure to be subjected to force to resist the large cross-pathbeam body down-warping; detachable telescopic joints are additionally arranged on a front supporting leg and a rear supporting leg of a bridge erecting machine, and the bridge erecting machine can adapt to the erection of the bridge with slope below 4%; when the bridge erecting machine passes through holes, a girder transporting vehicle is connected through a crown block as the counterweight, so that a cantilever of the bridge erecting machine can be shortened, and the weight of the whole machine is reduced; and transverse moving wheel sets are arranged below a support in the bridge erecting machine, so that beam sheets can be transversely moved through a full-width machine, and accurate positioning and butt joint of the same-hole multi-piece beams can be realized. According to the construction method, the erection efficiency of the steel mixing combined beam can be effectively improved, the positioning precision and the assembling quality of the steel mixing combined beam are guaranteed, and the steel mixing combined beam is promoted to be applied in the mountainous area high pier large-span bridge.

Owner:ROAD & BRIDGE INT +1

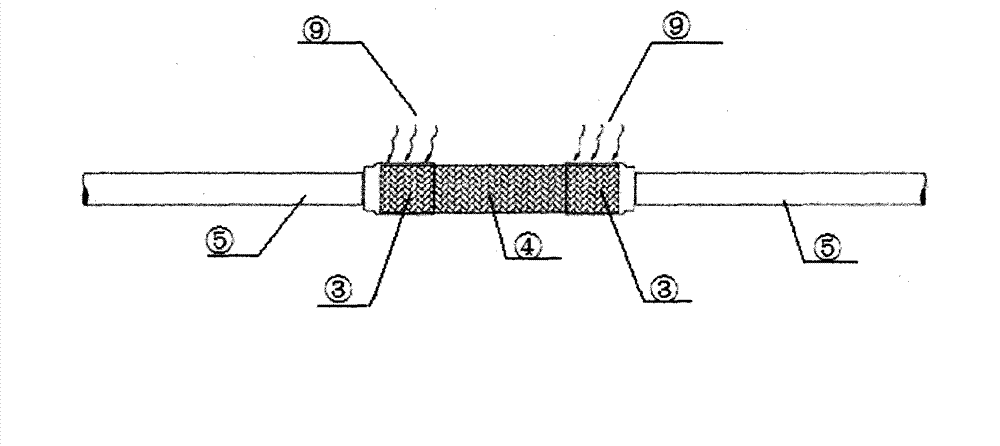

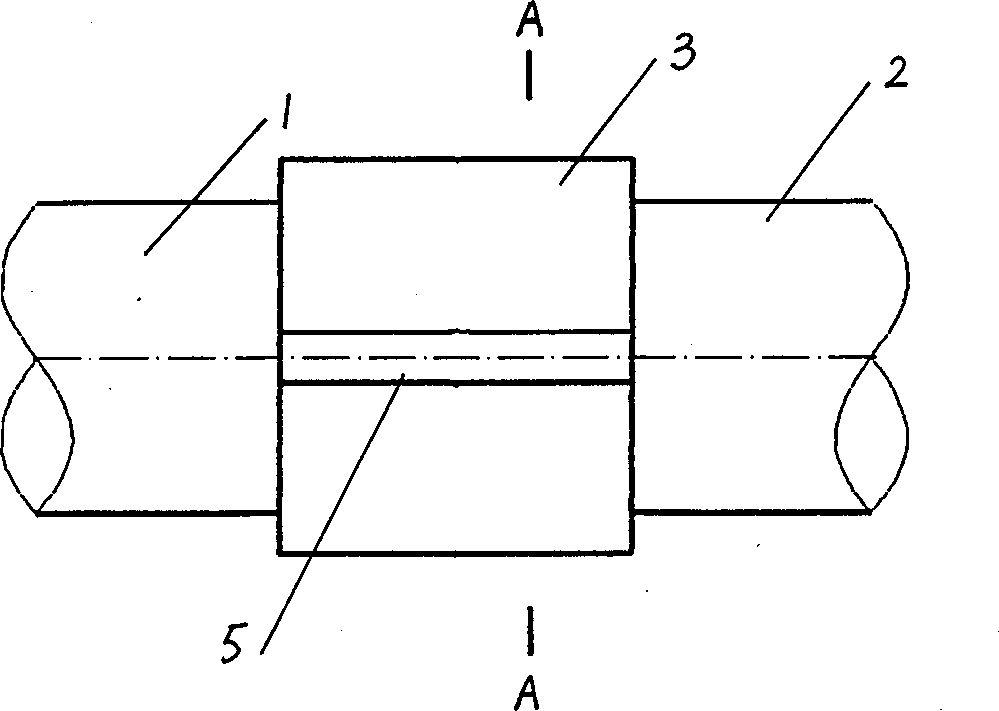

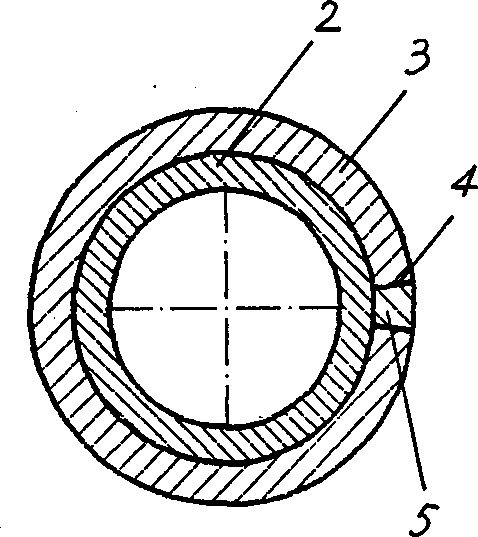

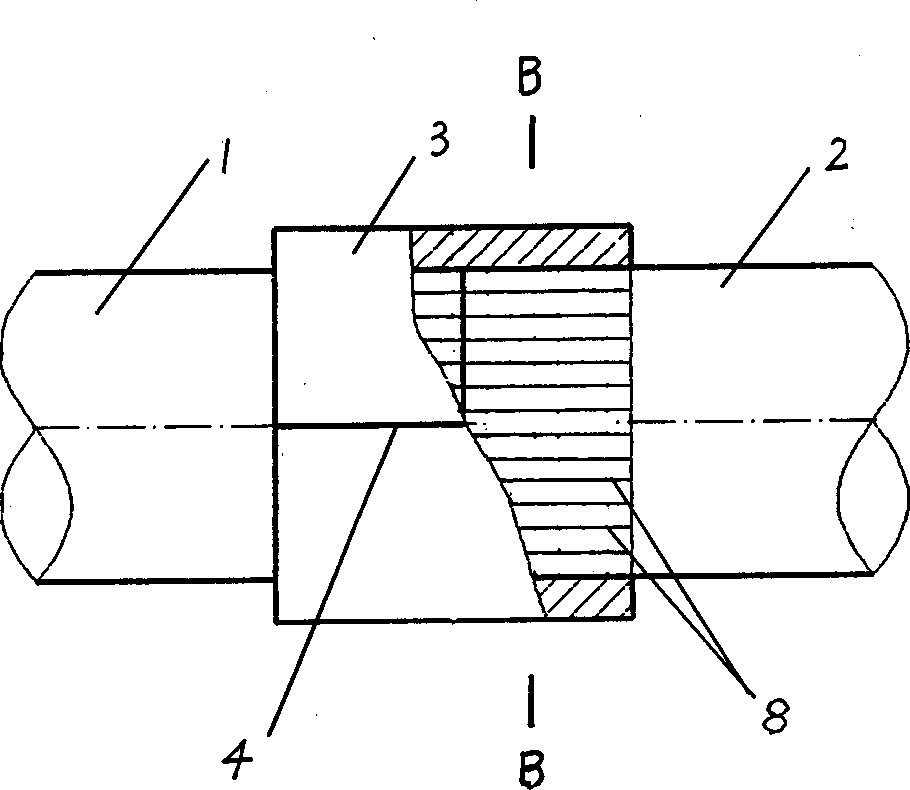

Method for connecting large-diameter composite metal-plastic pipes

InactiveCN1342860AEliminate connection quality issuesGuaranteed connection qualityPipe connection arrangementsEngineeringBlocking layer

A method for the connection between two large-diameter composite metal-plastic pipes includes such steps as moving them closely while aligning them for butt connection, and adhering a splicing layer on the external surface of both ends to be connected for cladding them. Its advantages include easily making said splicing block layer composed of splicing units, easy operation and high connection reliability.

Owner:罗荣尧

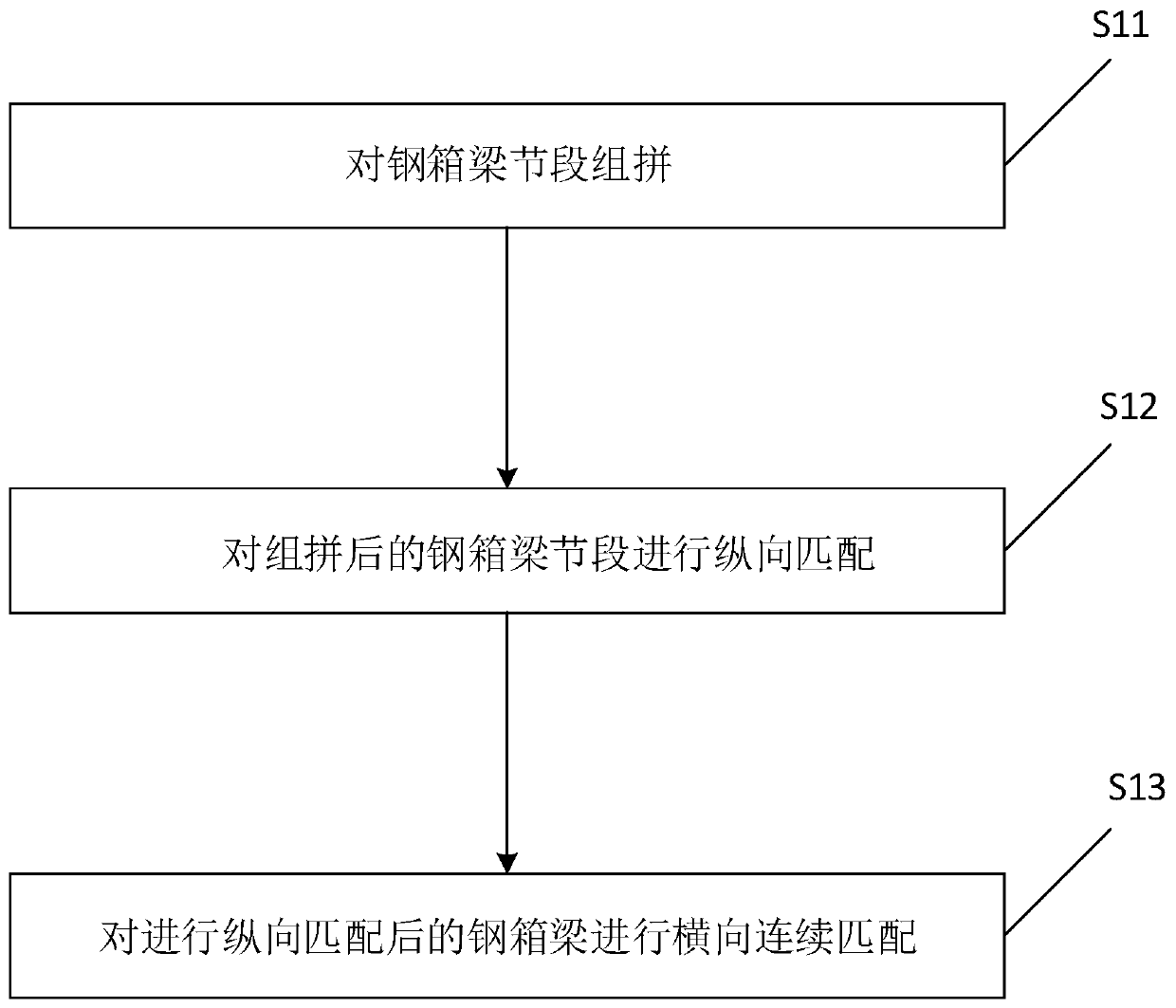

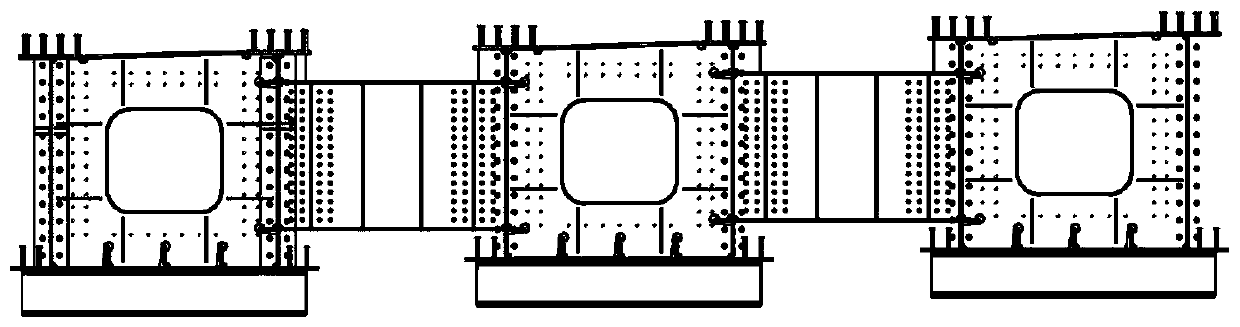

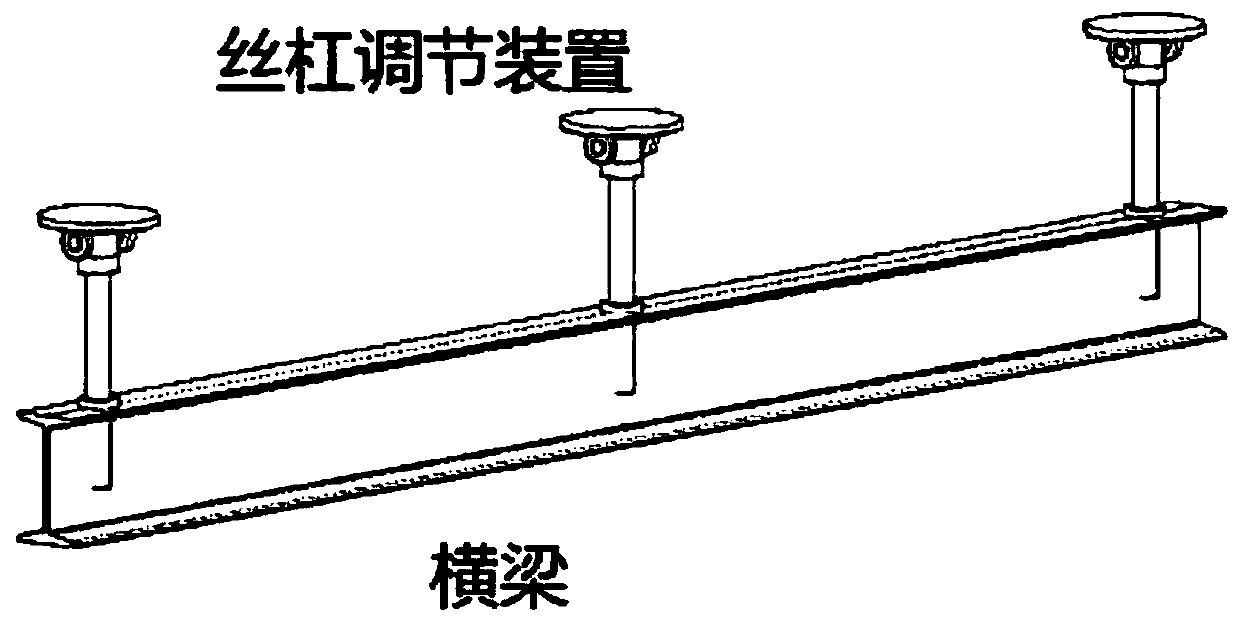

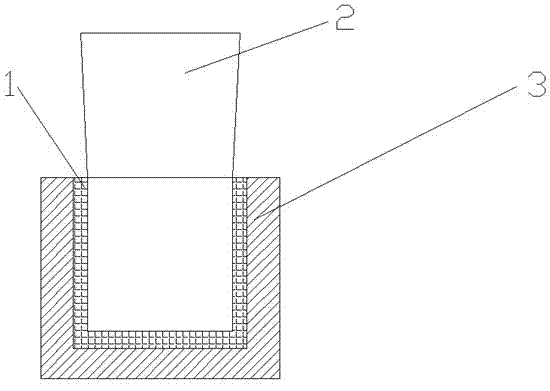

In-plant steel box girder segment continuous matching construction method

InactiveCN111254835AImprove positioning and installation accuracyImprove beam erection efficiencyBridge erection/assemblyBridge materialsConcrete beamsConstruction engineering

The invention discloses an in-plant steel box girder segment continuous matching construction method. The method comprises the steps of: assembling and splicing steel box girder segments; carrying outlongitudinal matching on the assembled and spliced steel box girder segments; and conducting transverse continuous matching on the steel box girder obtained after longitudinal matching. The continuous matching construction method is applied to in-plant processing and manufacturing of steel beams. By means of the method, the steel beam machining precision can be effectively improved, the steel boxsegment on-site assembly and steel-concrete composite beam installation work efficiency is improved, the connection quality between steel box segments and between boxes is guaranteed, the high-altitude adjustment risk is avoided, the positioning installation precision of the steel-concrete beams and the overall beam erecting efficiency are further improved, and the man-machine cost is reduced.

Owner:ROAD & BRIDGE INT +1

Method for processing aluminum alloy cap

InactiveCN103522020AReduce processing burdenGuaranteed connection qualityThread cutting machinesClosure capsMetallurgyMaterials science

Disclosed is a method for processing an aluminum alloy cap. The method includes a vertical rib processing step and an inner thread processing step. The vertical rib processing step includes extruding an extruding head into a cap blank slowly from the opening of the cap blank, accordingly extruding a concave part and a convex part on the inner side of the cylindrical side wall of the cap blank, and acquiring the cap blank with the concave part and the convex part. The inner thread processing step includes assembling an executing component on the inner side of the cylindrical side wall of the cap blank with the concave part and the convex part, starting a hydraulic lifting device and a rotary motor, forming a thread on the convex part accordingly, and obtaining the aluminum alloy cap.

Owner:青岛亚华制盖有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com