Quick-change ultrasonic vibration auxiliary sawing device

An ultrasonic vibration and sawing device technology, which is applied to glass cutting devices, fine working devices, glass manufacturing equipment, etc., can solve the problems of limited flexible manufacturing performance, sawing restrictions, and unfavorable replacement of ultrasonic vibration devices, so as to improve the ultrasonic Utilization rate, ensuring the overall effectiveness, and the effect that is conducive to effective delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments.

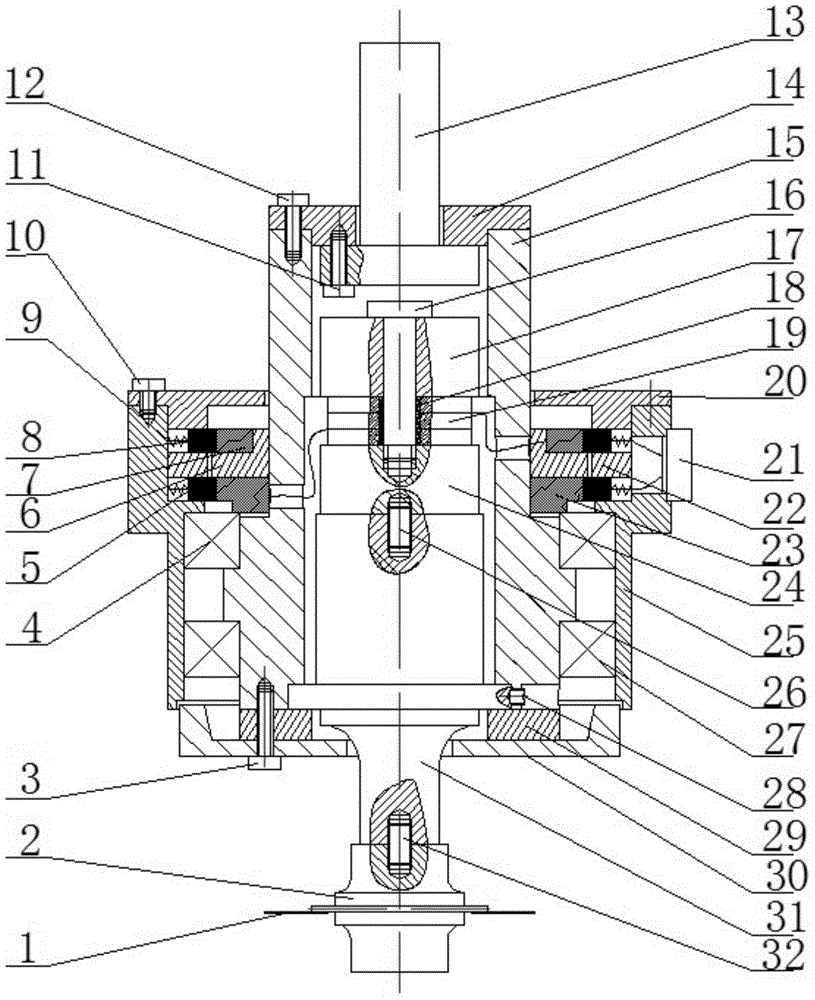

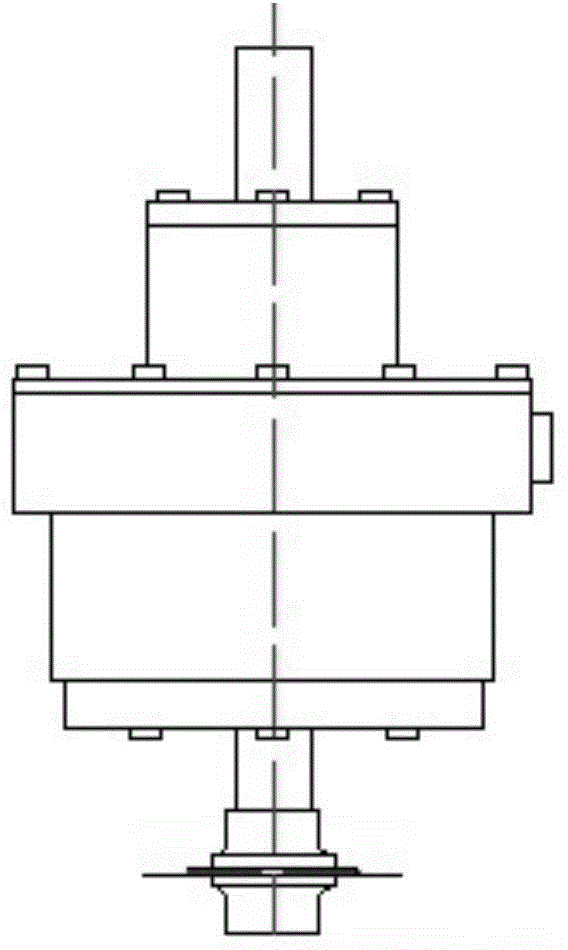

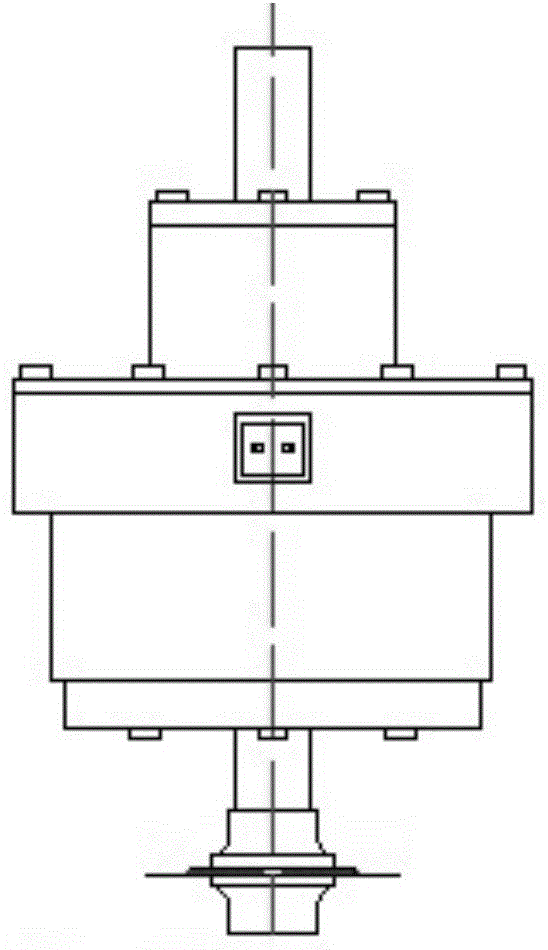

[0040] refer to Figure 1 to Figure 16 , a quick-change ultrasonic vibration auxiliary sawing device, suitable for various machine tools, including a tool handle connecting rod 13, an inner sleeve 15, an outer sleeve 25, an ultrasonic transducer 19, a current collecting device, and a primary amplification and variable amplitude Rod 31, symmetrical horn 2 and saw blade 1. What this knife handle connecting rod 13 adopts is a non-standard knife handle, and its top is connected (not shown in the figure) with the main shaft of machine tool by spring clamp, and the bottom end is provided with the first through hole 35. The upper end cover 14 is provided with a fourth threaded hole 41 and a fourth through hole 42, the third screw 11 passes through the first through hole 35 of the handle connecting rod 13 and is fixedly connected with the fourth threaded hole 41 of the upper end cover 14, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com