Pre-tensioning prestressed composite beam structural system and construction method thereof

A technology of prestressed and laminated beams, applied in truss structures, joists, girders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

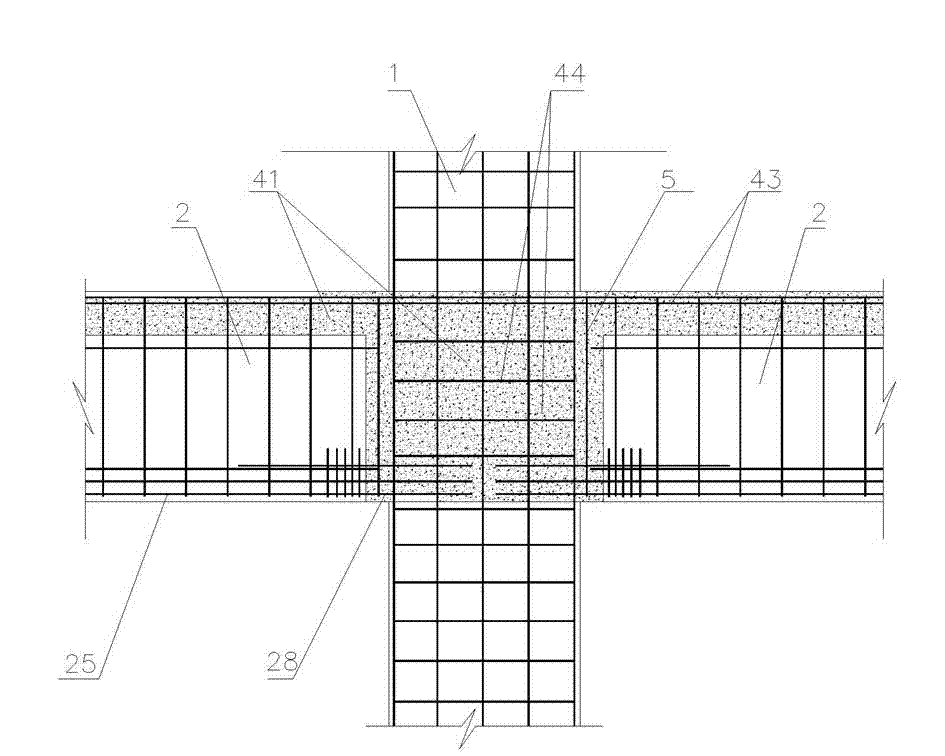

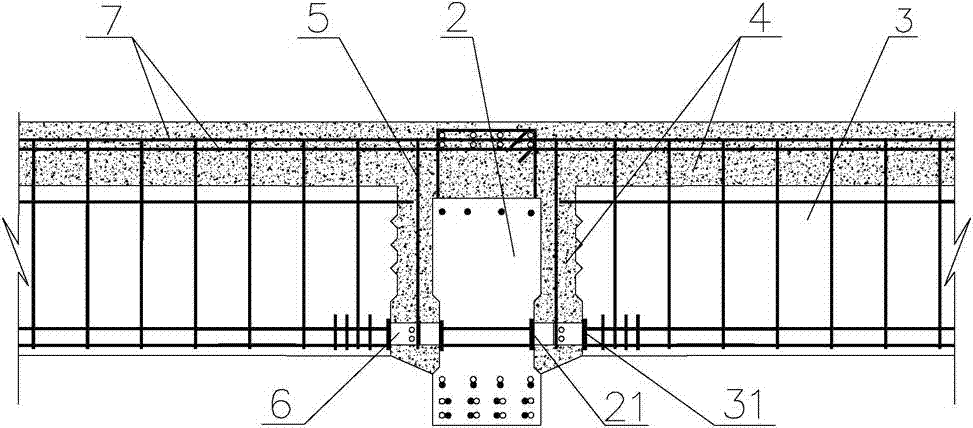

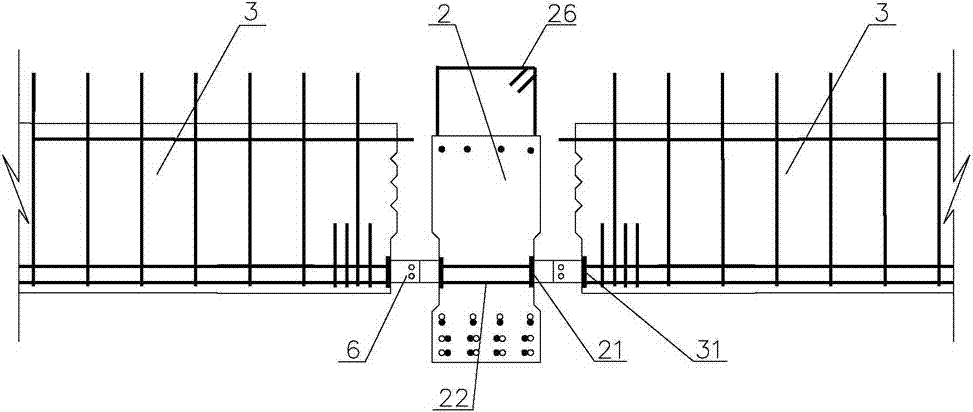

[0051] Please refer to the attached figure 1 to attach Figure 10 As shown, the present invention is a pretensioned prestressed composite beam structure system, which consists of frame columns 1, composite frame beam prefabricated components 2, composite secondary beam prefabricated components 3 and cast-in-place composite layers 4 and other parts composition.

[0052] Wherein, the composite secondary beam prefabricated component 3 is connected with the composite frame beam prefabricated component 2; the composite frame beam prefabricated component 2 is connected with the frame column 1; 41 is poured between and on the surface of frame column 1, laminated frame beam prefabricated component 2, laminated secondary beam prefabricated component 3, so that frame column 1, laminated frame beam prefabricated component 2, laminated secondary beam prefabricated component 3 and existing The cast laminated layers 4 are integrated into one body. The upper longitudinal reinforcement 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com