Patents

Literature

118 results about "Laminated beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

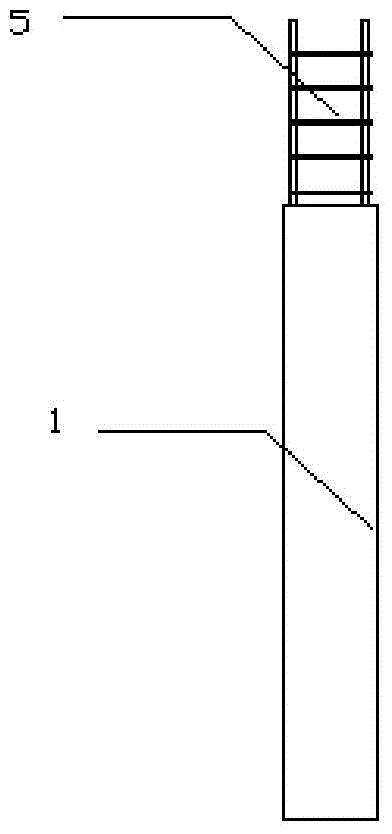

Prefabricated, assembled and integrated type special-shaped column structure and jointing construction method thereof

InactiveCN103850350AImprove integrityEliminate weaknessBuilding material handlingWhole bodyBolted joint

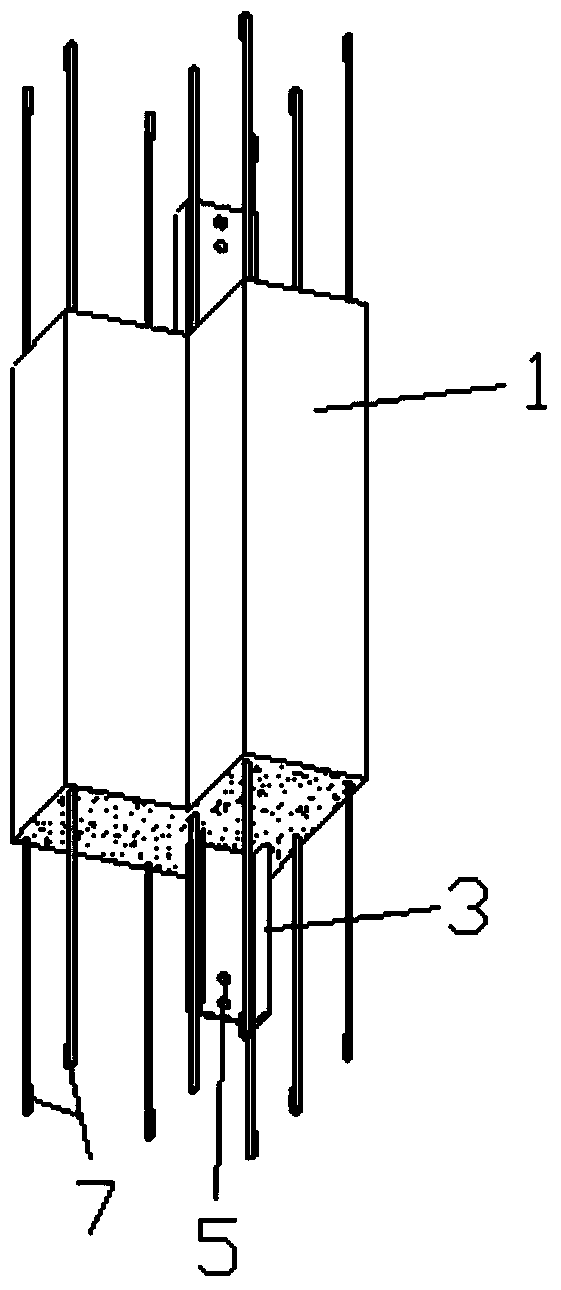

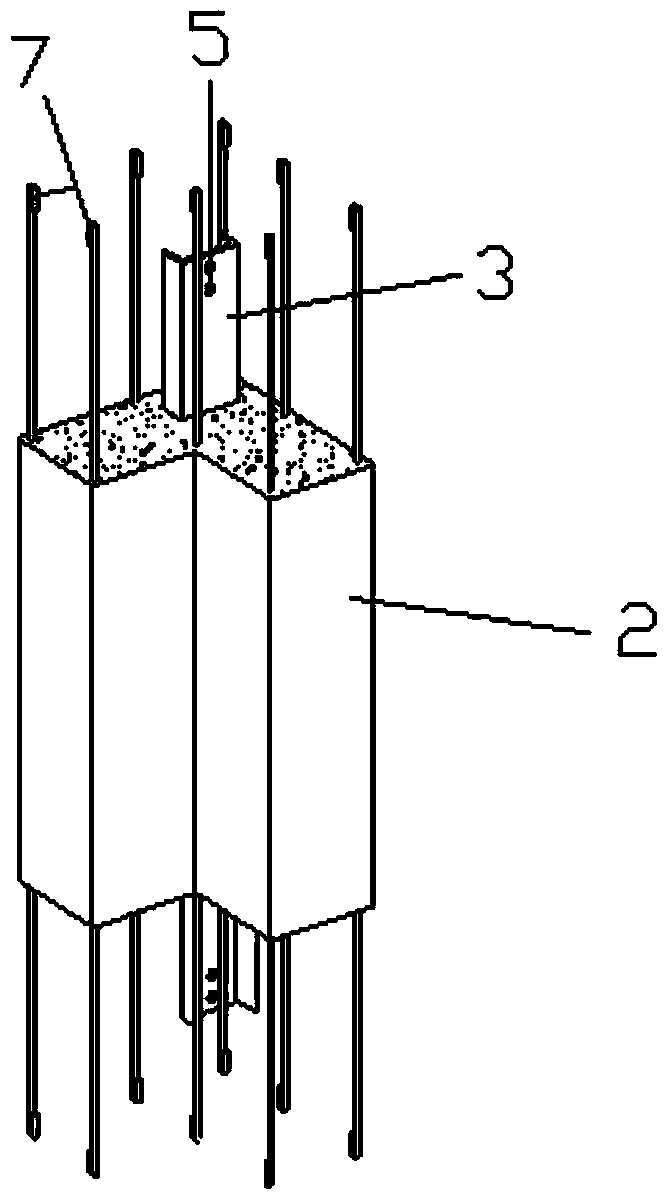

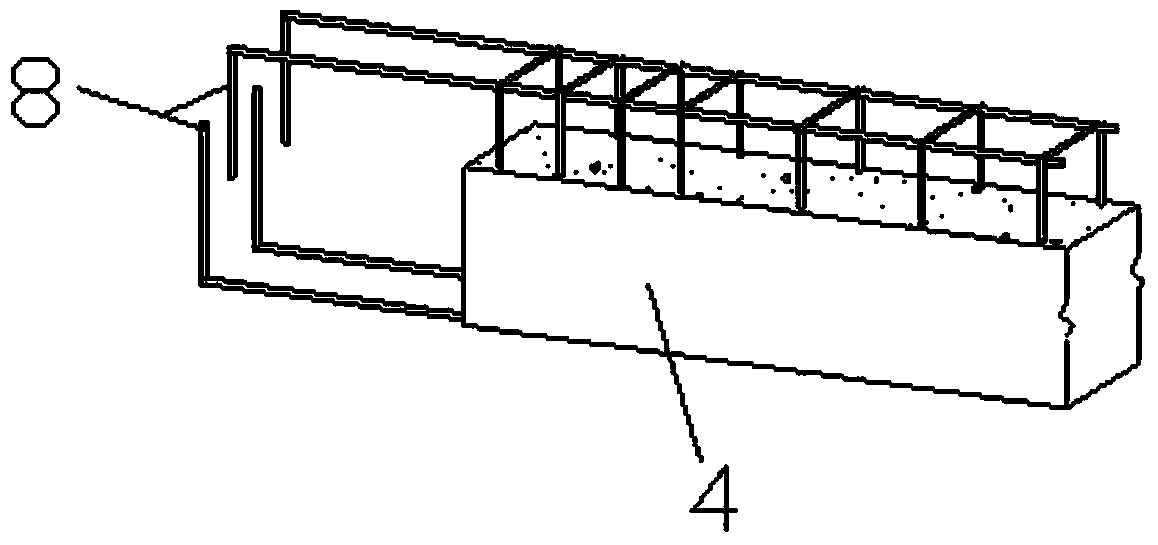

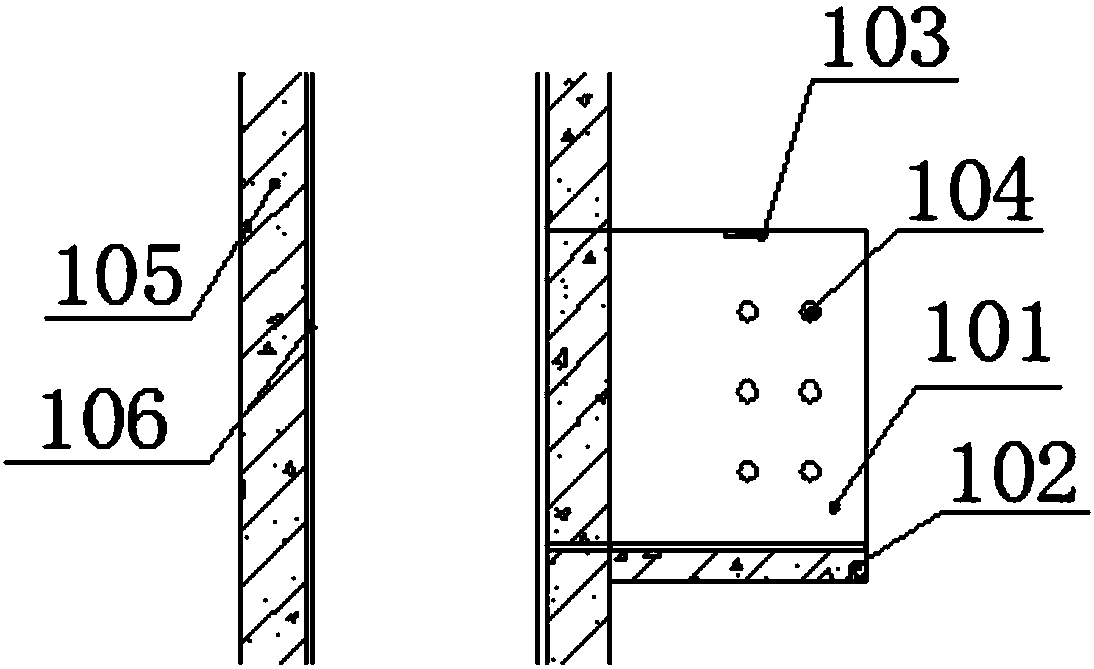

The invention discloses a prefabricated, assembled and integrated type special-shaped column structure and a jointing construction method of the column structure. The prefabricated, assembled and integrated type special-shaped column structure comprises a prefabricated upper column, a prefabricated lower column and a prefabricated laminated beam, wherein the prefabricated upper column and the prefabricated lower column are respectively provided with channel steel in an embedding manner, reserved bolt holes are formed in each channel steel, the adjacent prefabricated upper column and prefabricated lower column are connected through the channel steel by bolts to form an upper and lower through special-shaped column provided with a cast-in-place area, and reinforcing hoops are arranged in the cast-in-place area; the prefabricated laminated beam is anchored in the abnormal column through a longitudinal rib of the prefabricated laminated beam; cast-in-place concrete is injected in the cast-in-place areas of the adjacent two prefabricated upper column and prefabricated lower column and a part, not pouring the concrete, of the prefabricated laminated beam, so as to form a beam and column combined whole body. According to the prefabricated, assembled and integrated type special-shaped column structure and the jointing construction method of the column structure, which are disclosed by the invention, the problems that the vibration of concrete in joint core area of the special-shaped column is not dense and is difficult can be remarkably modified, so that the vibration resistance of joints can be improved; furthermore, the construction speed further can be increased, the construction period is shortened, and the development of building industrialization is facilitated.

Owner:NANJING TECH UNIV +1

Stoploy type self circulation open-channel test groove

InactiveCN1588491AMinimize and simplifySave experimental layout spaceEducational modelsCalipersWaste management

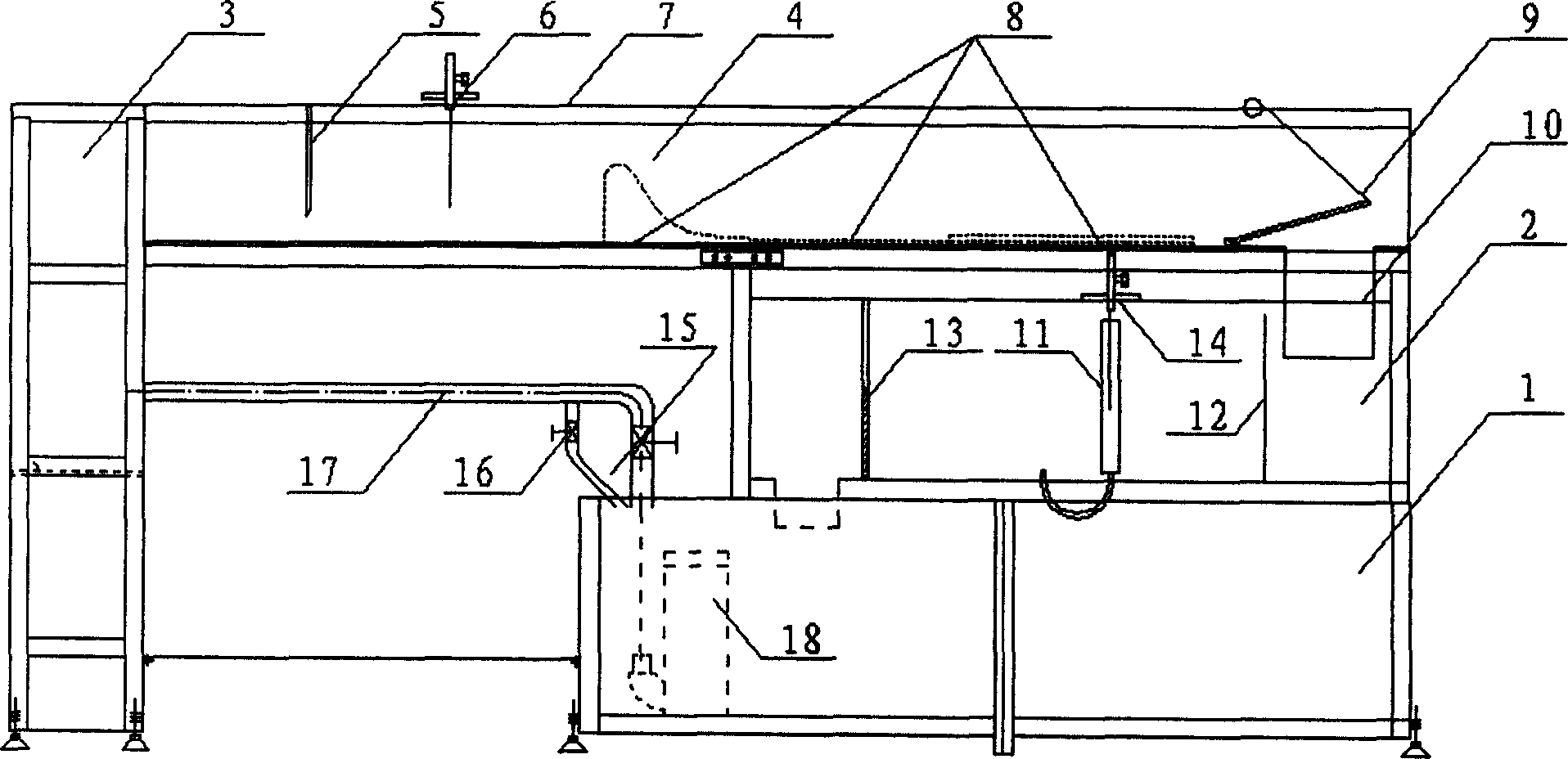

The invention discloses a laminated beam self-circulating open channel test tank, which has a self-circulating water supply tank, there is a diving pump in the water supply tank, a V-notch weir water measuring tank is arranged on the water supply tank, there is a me measuring cylinder, a water stabilizing plate and a V-notch weir arranged in the water measuring tank, the water stabilizing plate are water-stabilizing holes in the side direction, the top of the measuring cylinder is provided with water-measuring weir probe, a stable-pressure water tank is connected with the diving pump through a hydraulic pipe, the top of the water measuring tank is arranged with a test water tank, the head of the test water tank is connected with the stable-pressure water tank, the tail of the test water tank is provided with a porous tail door and a downflow water tank, the bottom plate of the test water tank is provided with many model installation holes, the side wall of the test water tank is provided with a water gate groove, the top of the test water tank is arranged with measuring railway, and the probe of the test water tank is installed on the measuring railway, the V-notch weir is additionally arranged with a V-notch water measuring calipers.

Owner:ZHEJIANG UNIV

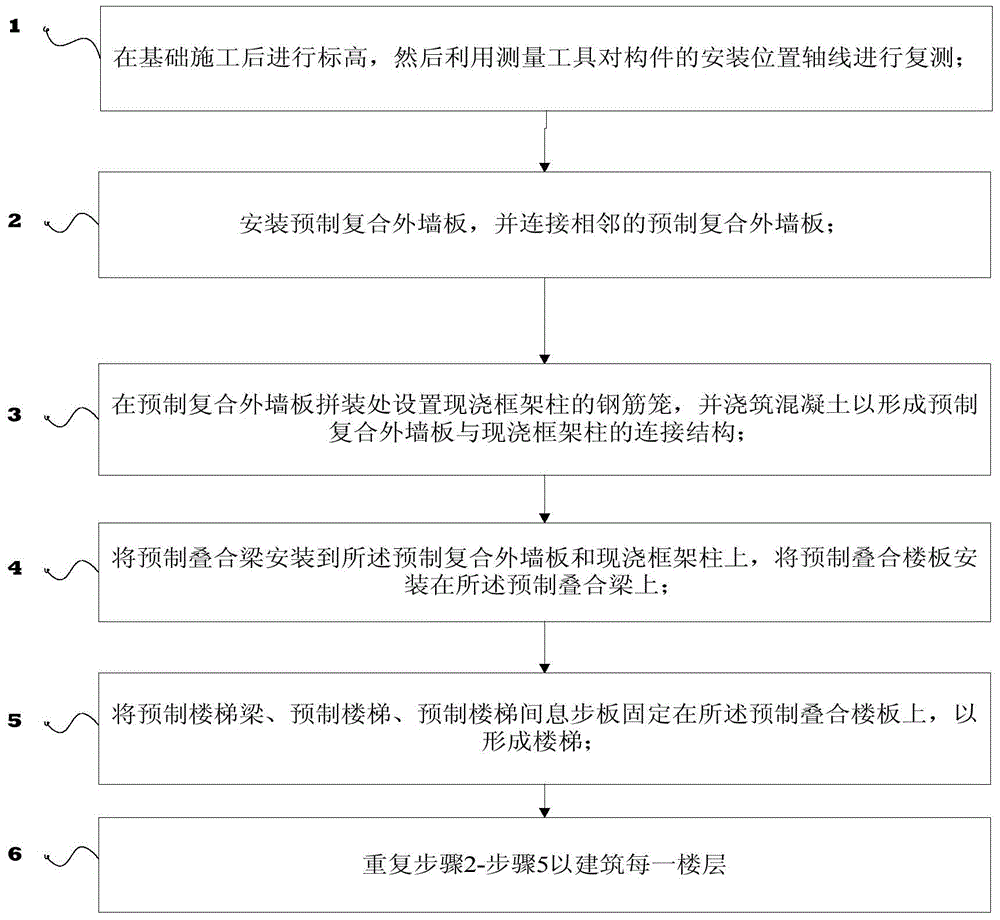

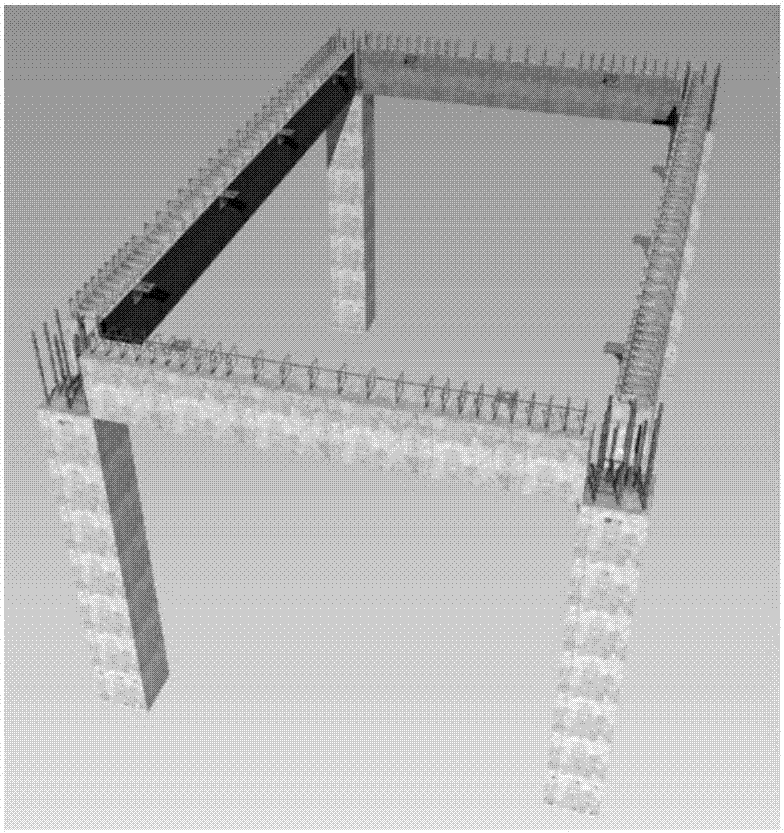

Method for constructing reinforced-concrete prefabricated element fabricated building with frame structure system

InactiveCN103982041AReduce construction costsShorten the construction periodBuilding material handlingReinforced concreteEngineering

The invention provides a method for constructing a reinforced-concrete prefabricated element fabricated building with a frame structure system. The method comprises the steps: (1) carrying out elevation after foundation construction, and then, re-measuring axes of element mounting positions by using a measuring tool; (2) mounting prefabricated composite external wall panels, and connecting adjacent prefabricated composite external wall panels; (3) arranging steel reinforcement cages of cast-in-place frame columns at splices of the prefabricated composite external wall panels, and casting concrete, so as to form prefabricated composite external wall panel and cast-in-place frame column connecting structures; (4) mounting prefabricated laminated beams on the prefabricated composite external wall panels and the cast-in-place frame columns, and mounting prefabricated laminated floors on the prefabricated laminated beams; (5) fixedly arranging prefabricated stair beams, prefabricated stairs and prefabricated stair step gap plates on the prefabricated laminated floors, so as to form a staircase; (6) repeating the steps (2 to 5), so as to construct every floor of the building.

Owner:杜景云

Fabricated prestressed concrete large-span frame system and construction method thereof

The invention relates to a fabricated prestressed concrete large-span frame system and a construction method thereof. The fabricated prestressed concrete large-span frame system comprises a foundation, a precast column of reinforced concrete, a laminated beam of the reinforced concrete, a floor slab and an externally-hung precast wall plate. The laminated beam comprises a beam precast part and a beam laminated layer. A beam prestressed hole channel is formed in the beam precast part, the beam prestressed hole channel is formed in the lower part of a plate body, and a column prestressed hole channel is formed in the precast column. The column prestressed hole channel is aligned with the beam prestressed hole channel. Steel bar bundles are arranged in the column prestresse hole channel and the beam prestressed hole channel in a penetrating mode. Combined steel bars of the beam laminated layer are anchored into the position between the precast column and the beam laminated layer for anchored connecting. The combined steel bars comprise energy consumption steel bars and shear resisting steel bars. The energy consumption steel bars are provided with unbonded sections. The fabricated prestressed concrete large-span frame system can further be used by combining lateral force resisting components such as a lateral support and a shear wall, and suitable for multi-high-rise public buildings such as schools, office buildings, apartments and hospitals.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

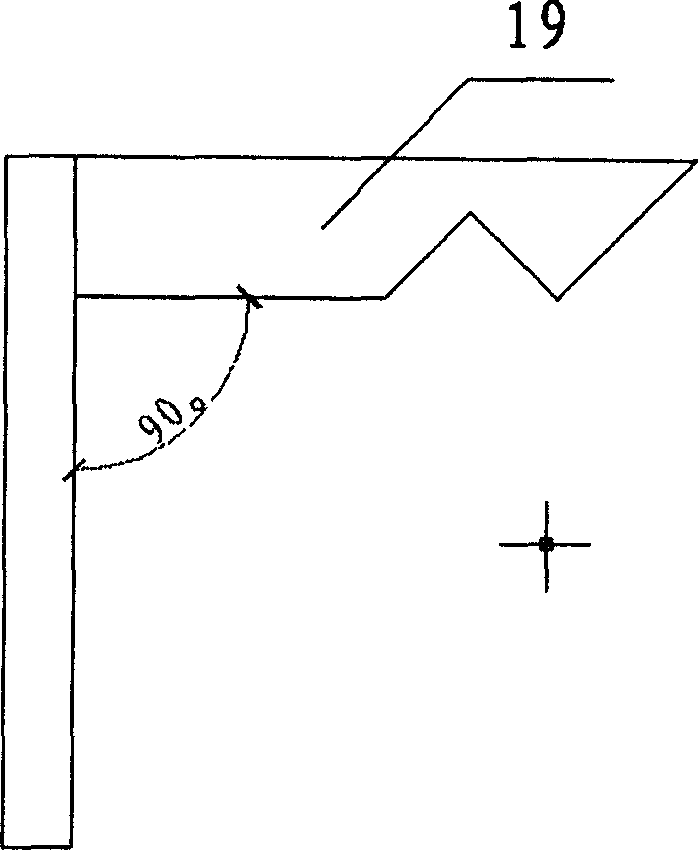

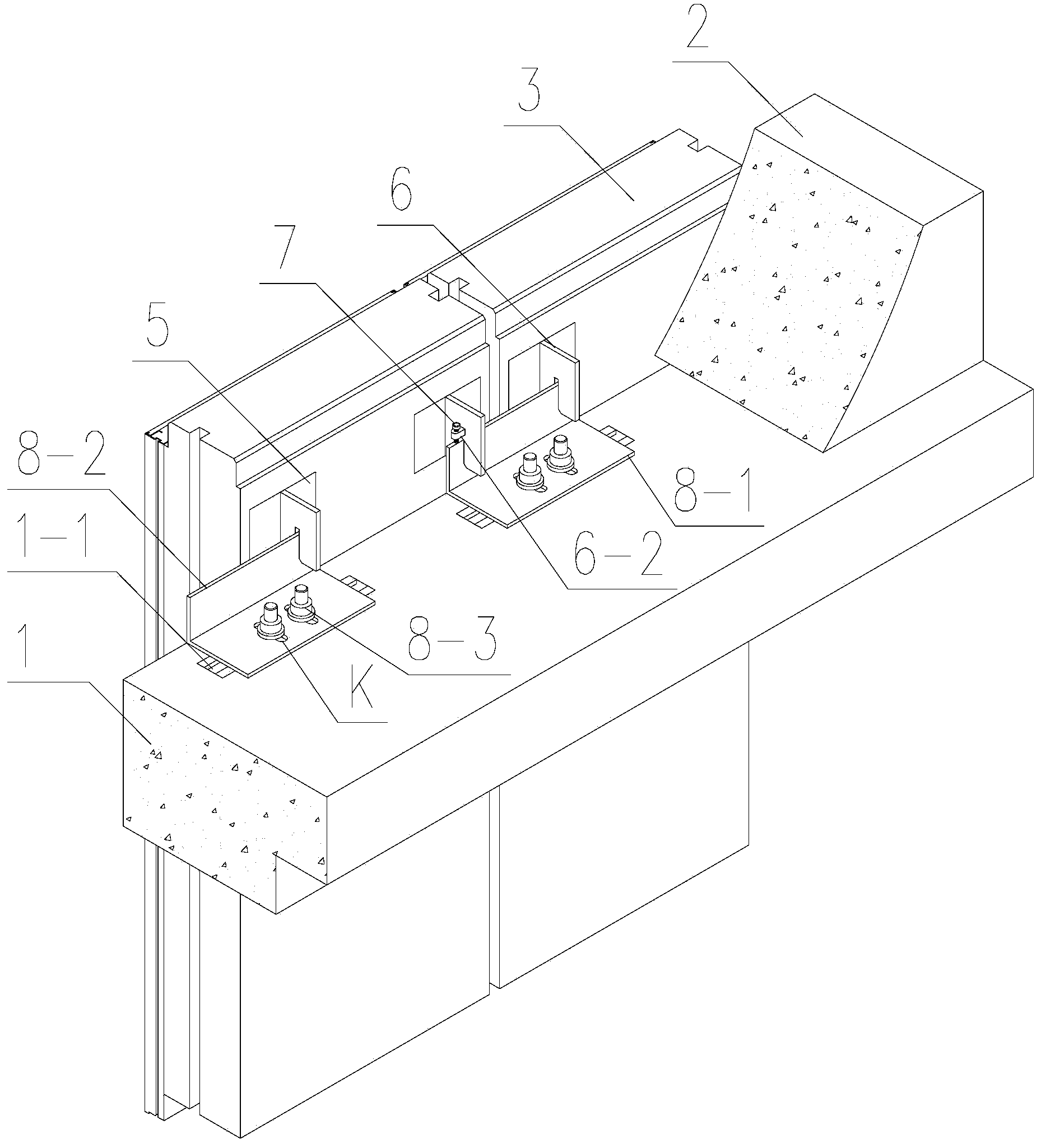

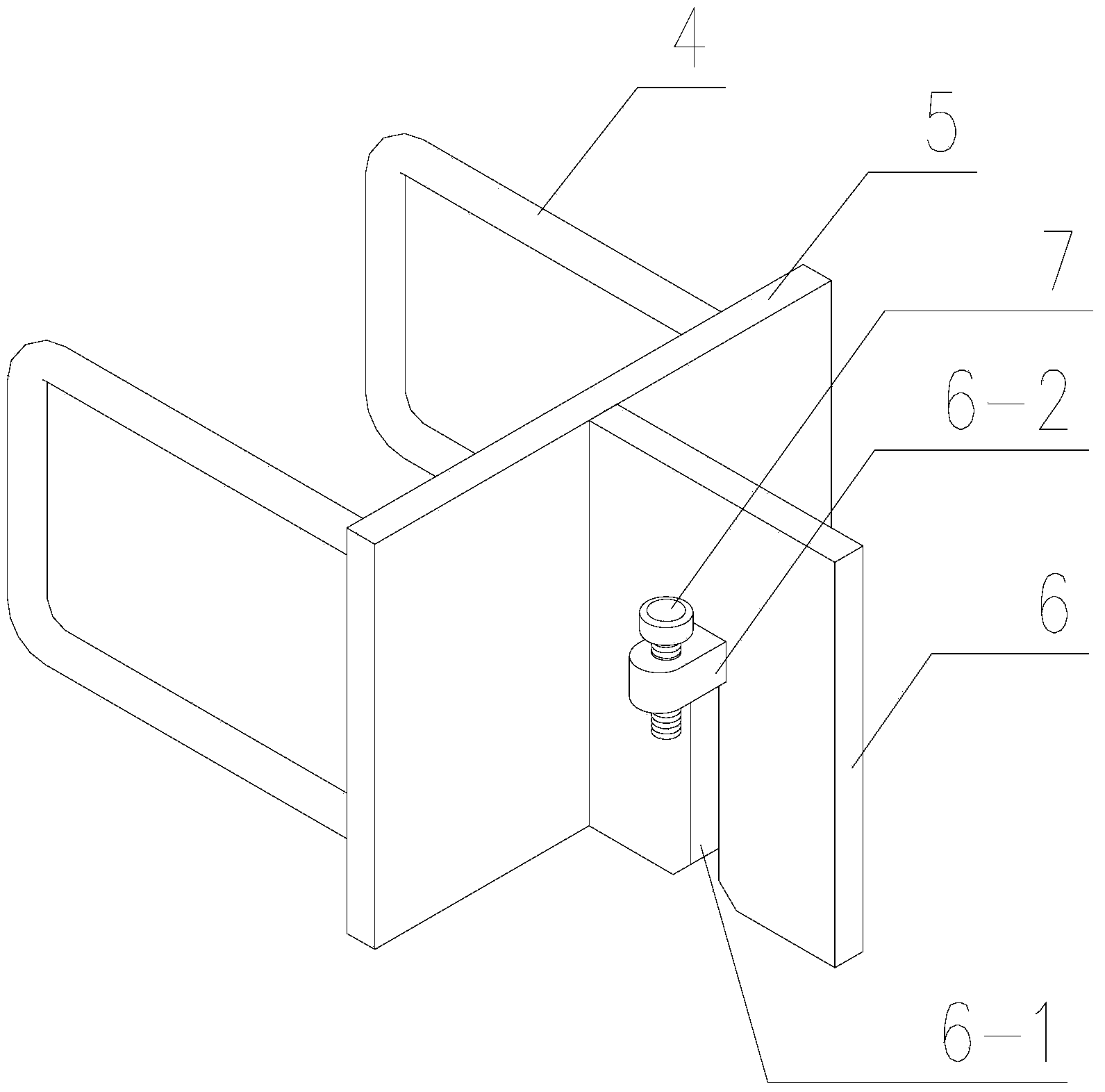

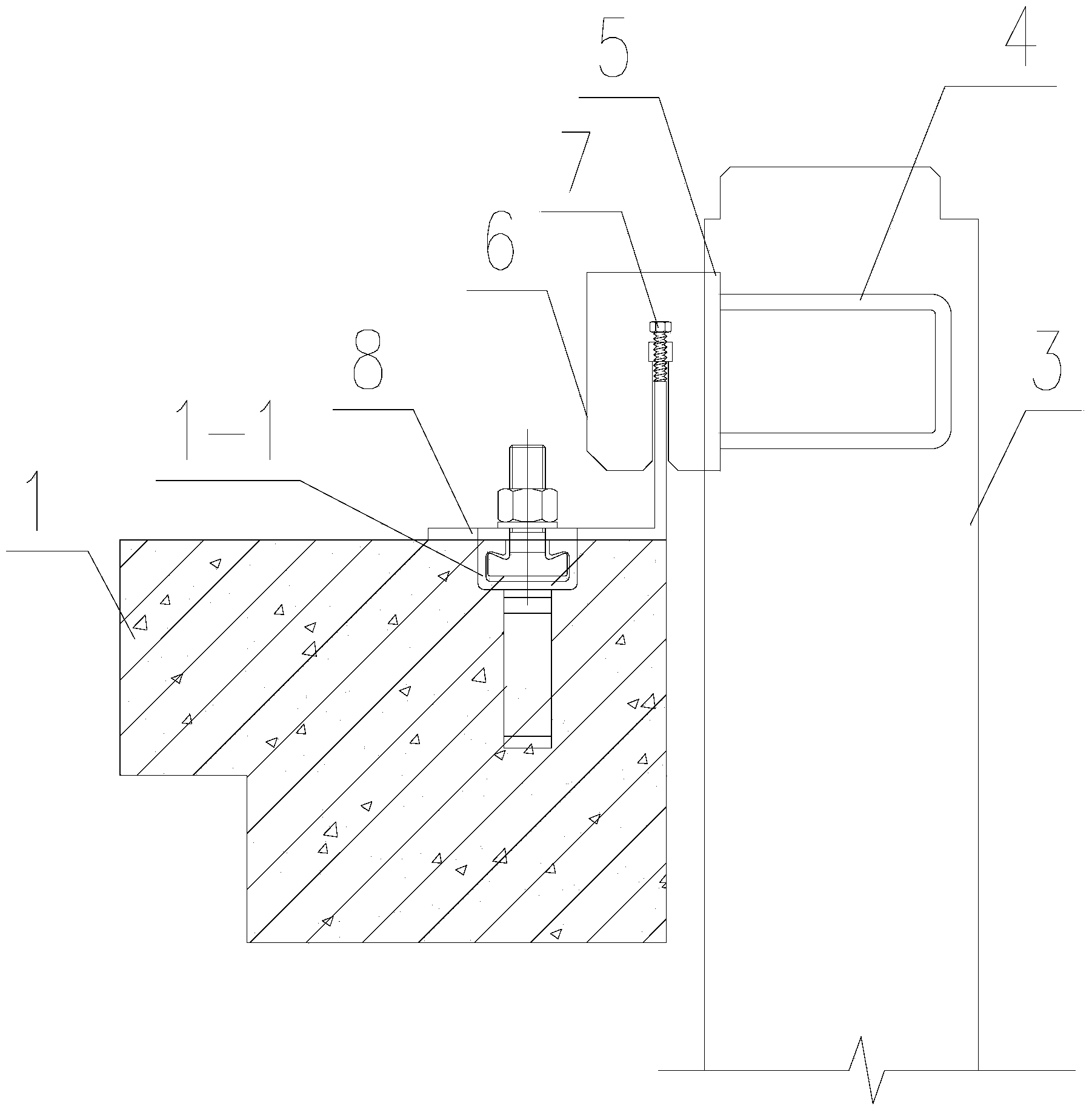

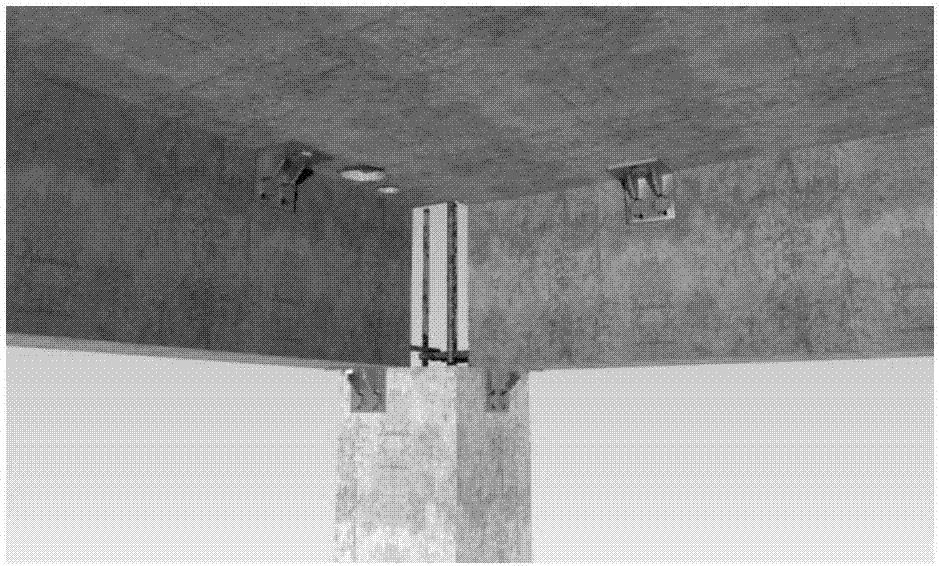

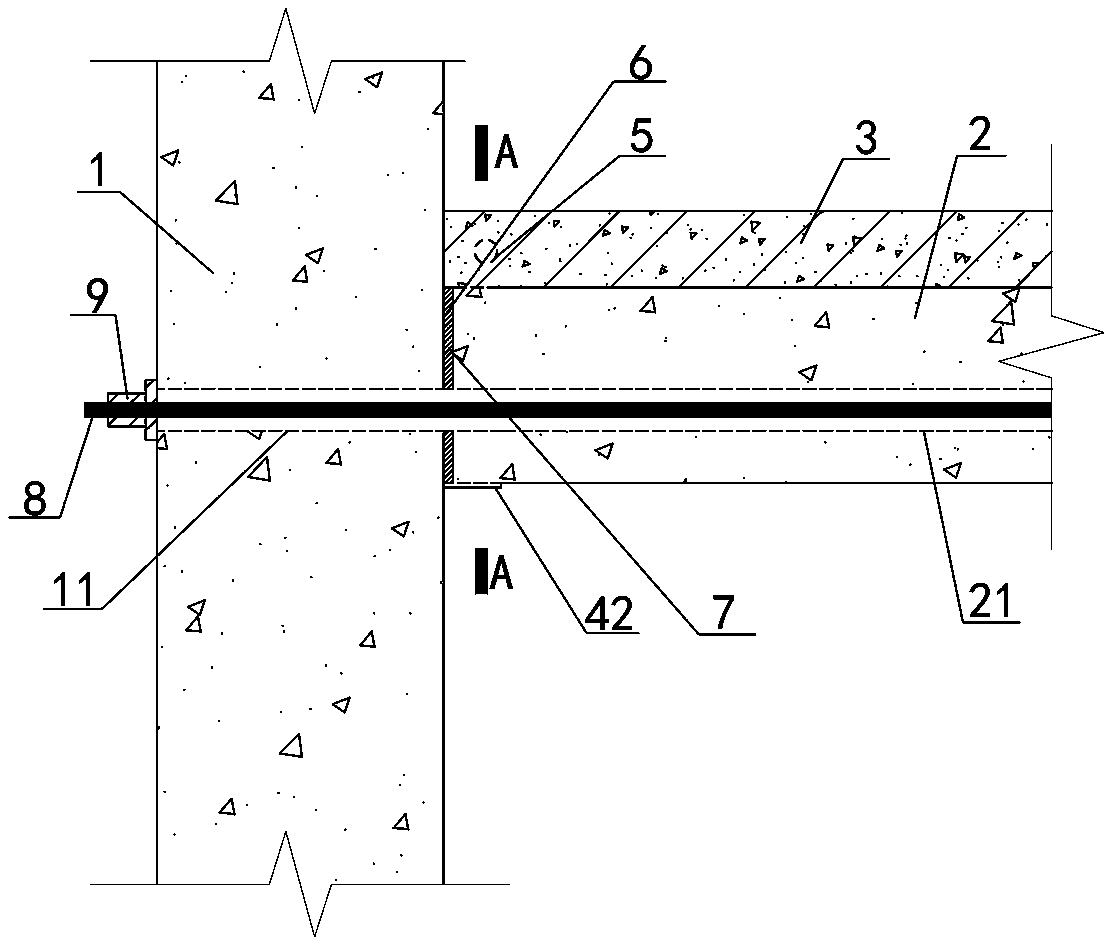

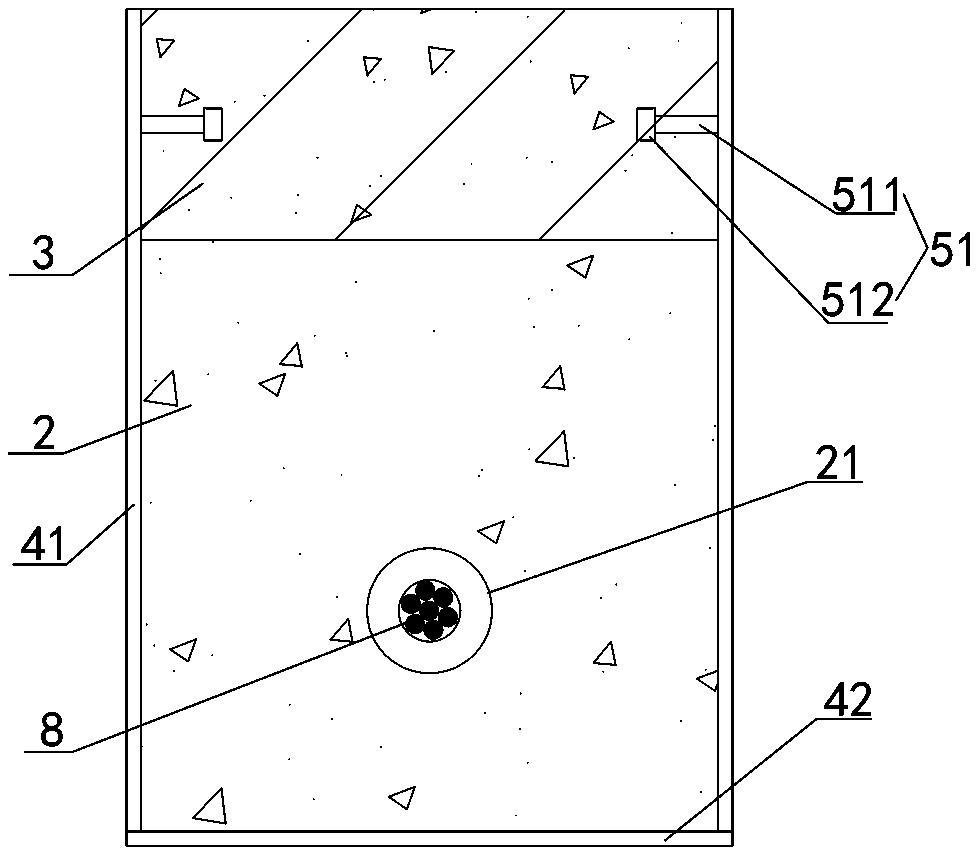

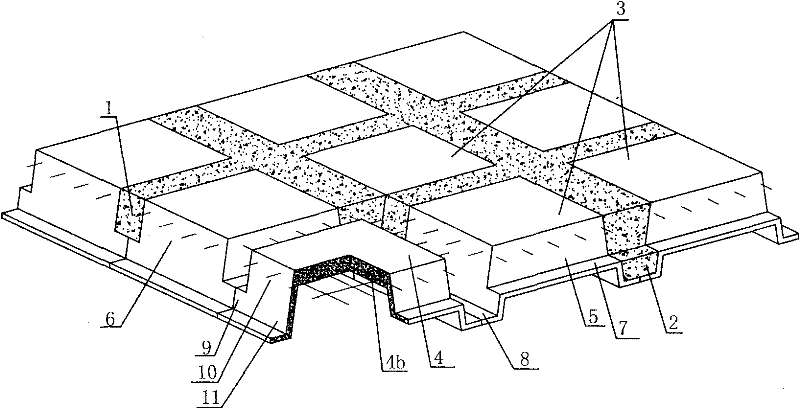

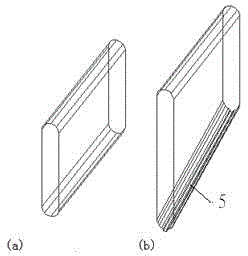

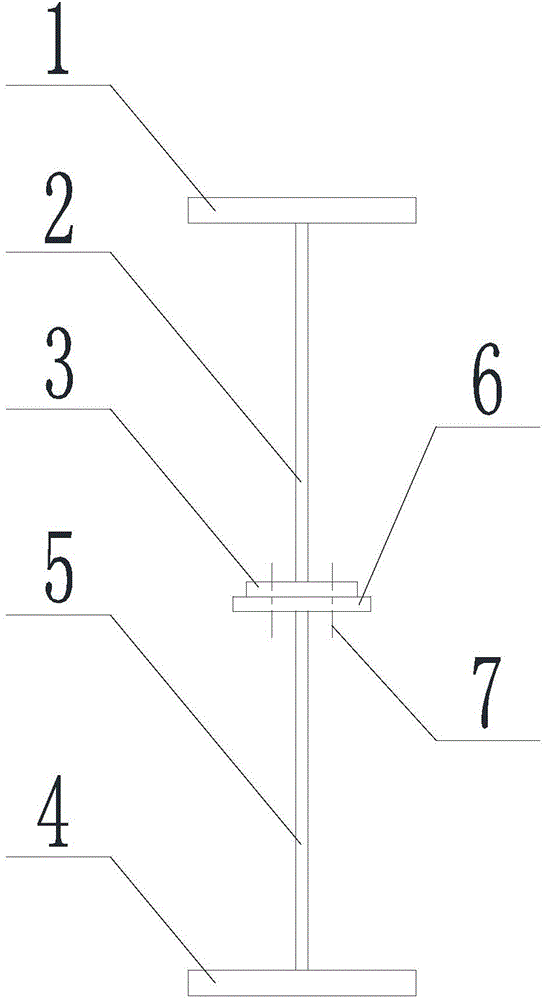

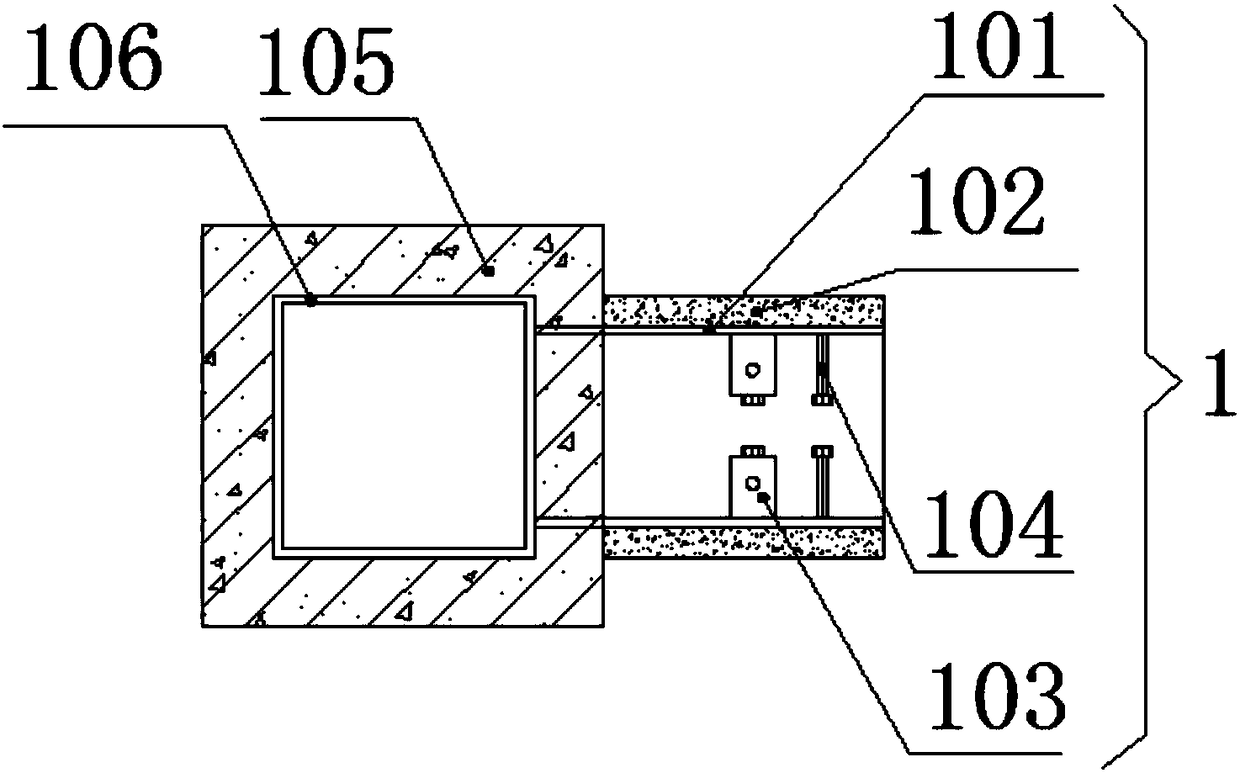

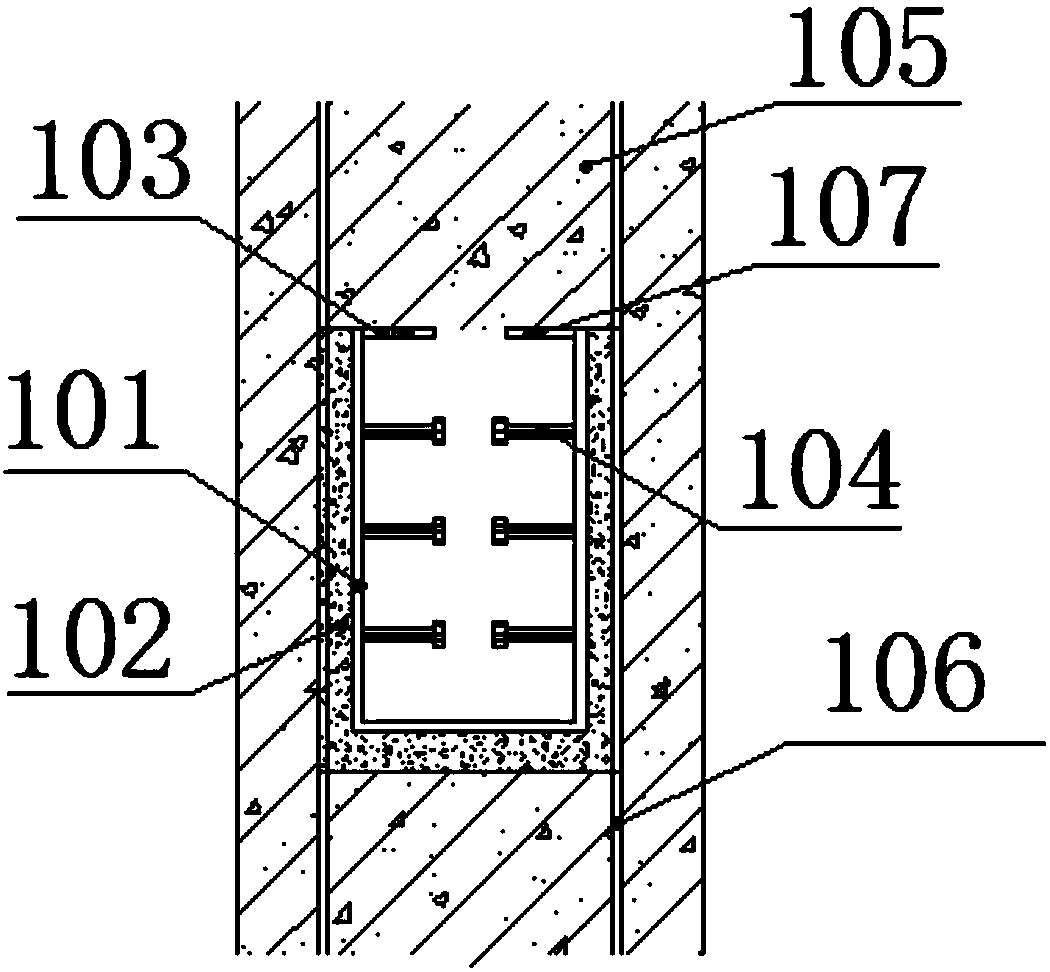

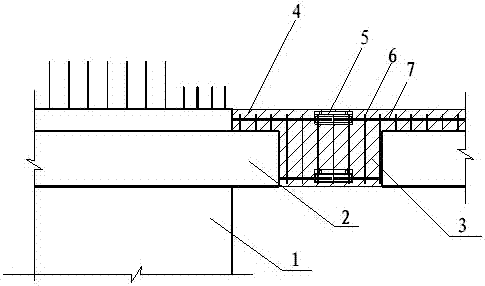

Three-dimensional adjustable mounting connecting structure of assembled wallboard and laminated beam

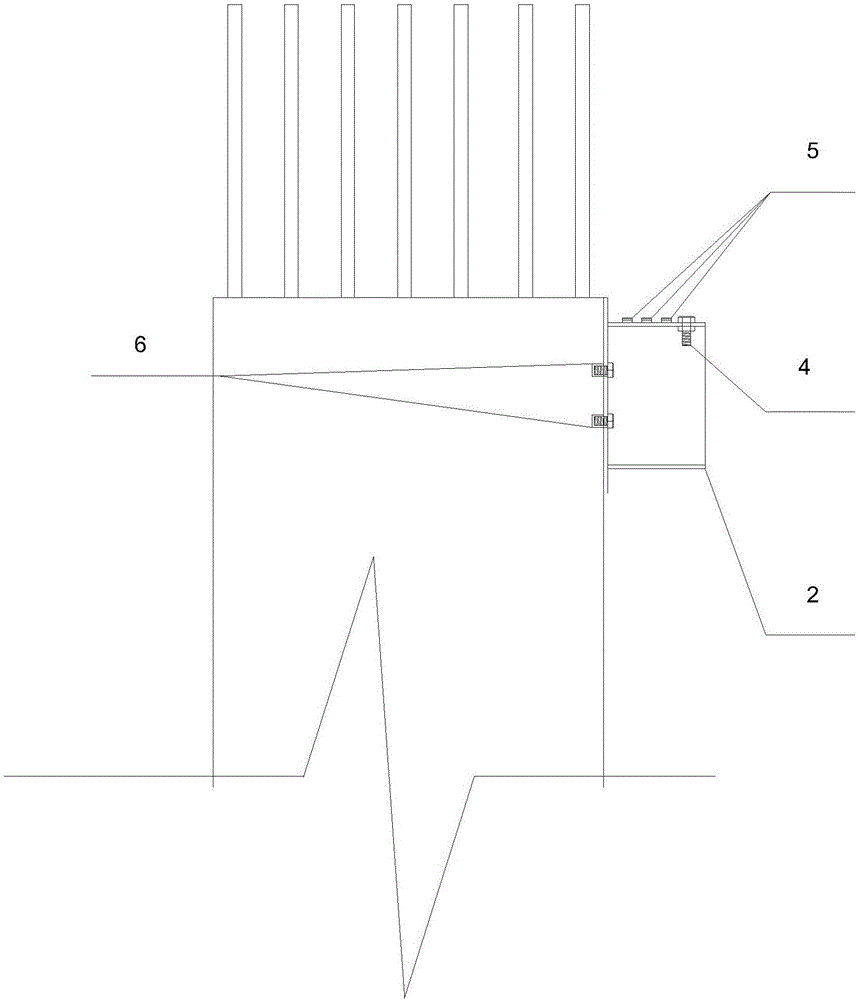

InactiveCN103953119APrecise flatness controlReduce the amount of aerial workBuilding constructionsBeam switchingWall plate

The invention discloses a three-dimensional adjustable mounting connecting structure of an assembled wallboard and laminated beam, and belongs to the field of assembled building connection structures. The mounting connecting structure comprises the laminated beam, the wallboard, a wallboard embedded connecting component and a wall beam switching member, wherein the beam switching member is provided with horizontal connecting surfaces of long-strip elliptical holes, and is correspondingly connected with embedded C-shaped steel chutes of a lower precast beam below the laminated beam through bolts; the wall beam switching member is moved, adjusted and fastened in the directions of a longitudinal beam and a beam relative to the lower precast beam; a vertical suspension socket of a connecting plate of the wallboard embedded connecting component is correspondingly spliced with a vertical connecting surface of the wall beam switching member, advancing and retracting of an adjusting bolt at the upper end of the vertical suspension socket of the connecting plate is screwed, and the wallboard is adjusted to be moved and fastened in the vertical direction relative to the lower precast beam, therefore, three-dimensional adjustable fastening and mounting of the assembled wallboard and laminated beam are realized. The overall mounting structure of the invention is simple in structure and accurate in controlling the wallboard flatness, and obviously improves the mounting and construction efficiency and the construction quality.

Owner:HUBEI HONGYI STEEL CONSTR ENG

Fabricated concrete frame structure locally reinforced through prefabricated ultra-high performance concrete (UHPC) shells

PendingCN108612189AImprove mechanical propertiesImprove deformation abilityStrutsGirdersEngineeringRebar

The invention discloses a fabricated concrete frame structure locally reinforced through prefabricated ultra-high performance concrete (UHPC) shells. The fabricated concrete frame structure comprisesthe annular prefabricated UHPC shell at the column foot, a prefabricated concrete column, the U-shaped UHPC shell at the beam end and a prefabricated concrete laminated beam; the annular prefabricatedUHPC shell is arranged at the column foot of the prefabricated concrete column; the annular prefabricated UHPC shell at the column foot, a stirrup and grouting sleeves are prefabricated into a whole;the beam end of the prefabricated concrete laminated beam forms a U-shaped key groove through the U-shaped prefabricated UHPC shell; the U-shaped UHPC shell at the beam end and the stirrup are prefabricated into a whole; the lower portion of the prefabricated concrete laminated beam adopts small-specification high-strength rebars; and after the laminated beam is placed in place, beam upper rebarsare bound, and then laminated layer concrete is poured on site to form an overall structure. The prefabricated UHPC shell with excellent performance is used for the maximum force-bearing position ofthe fabricated frame component, advantages of the prefabricated UHPC shell and the fabricated frame component are combined, the manufacturing cost is reduced, the structural form of the fabricated concrete frame structure is innovated, and the seismic performance of the fabricated frame structure is improved.

Owner:SOUTHEAST UNIV

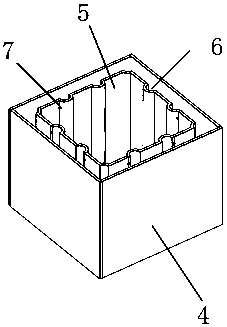

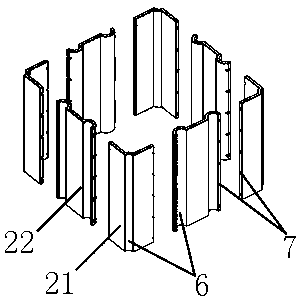

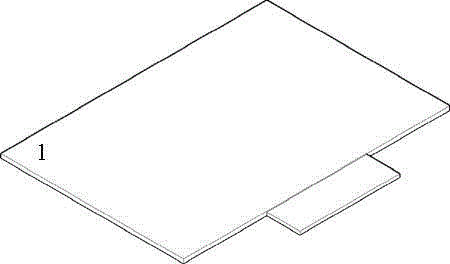

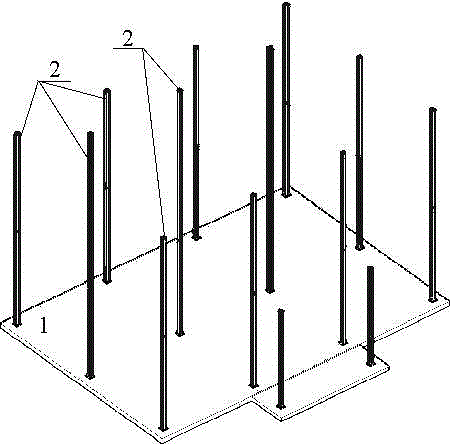

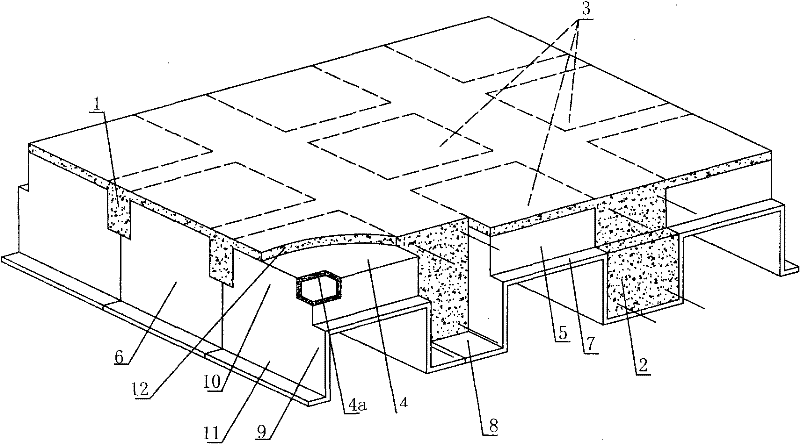

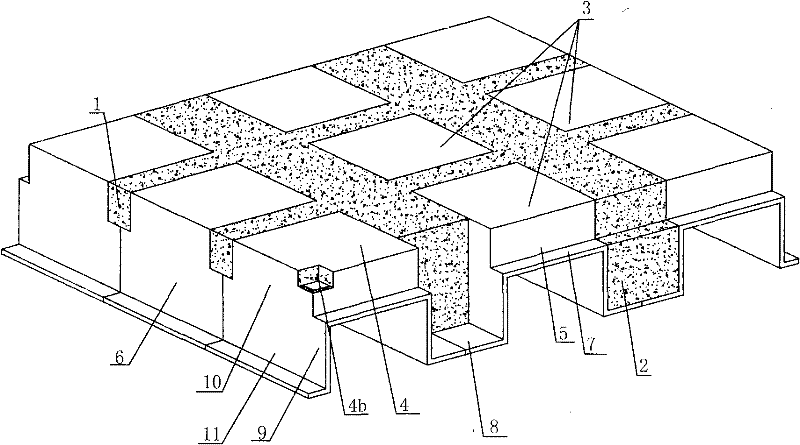

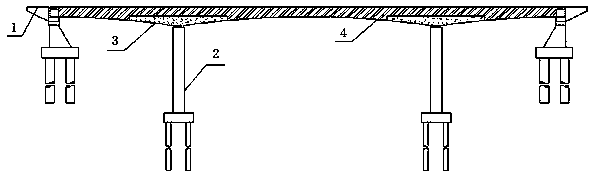

Fabricated integrated building and production method thereof

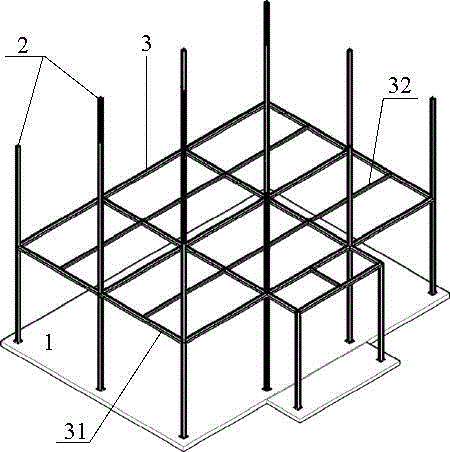

InactiveCN106703201AReduce the need for technical expertiseQuality improvementBuilding componentsBuilding material handlingLaminated beamBuilding construction

The invention relates to the field of building, in particular to a fabricated integrated building and a production method thereof. The fabricated integrated building comprises a basis (1) laid on the foundation. The fabricated integrated building is characterized in that the building comprises a stand column (2), a floor laminated beam (3), a floor laminated board (41), a floor composite board (42), an external wall panel (51), an internal wall panel (52), a roof truss (61) and a roof boarding (62). The production method of the fabricated integrated building is characterized in that the steps are carried out as following: a, the stand column arrangement; b, the roof beam erection; c, the floor laying; d, the wallboard laying; e, the roof erection. The fabricated integrated building has the advantages of tight structure, convenient installation, stable quality, strong adaptation, friendly environmental protection, fast project progress as well as short construction term.

Owner:迅筑建筑科技(上海)有限公司

Fabricated reinforced concrete angle brace frame and construction method thereof

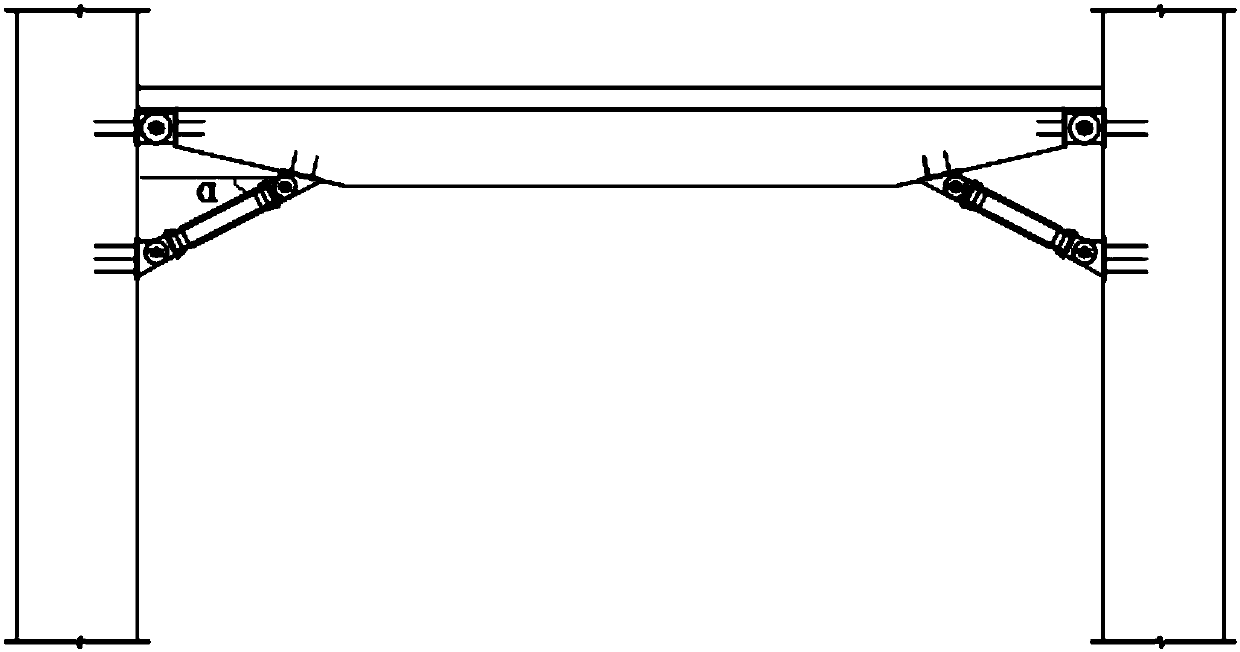

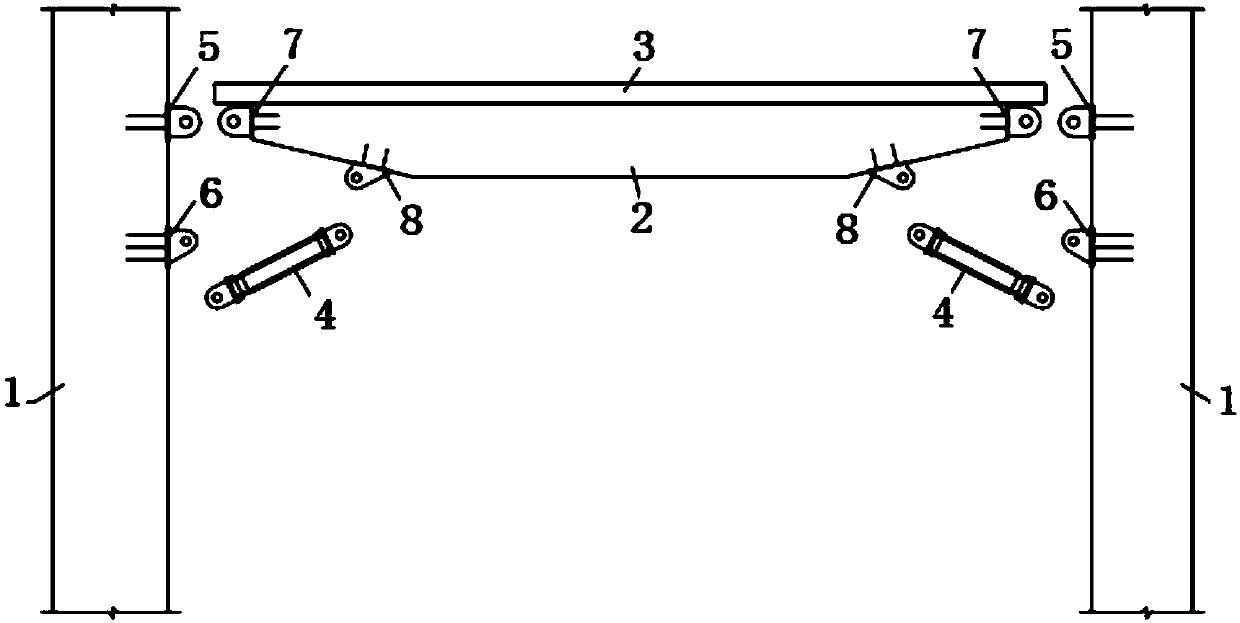

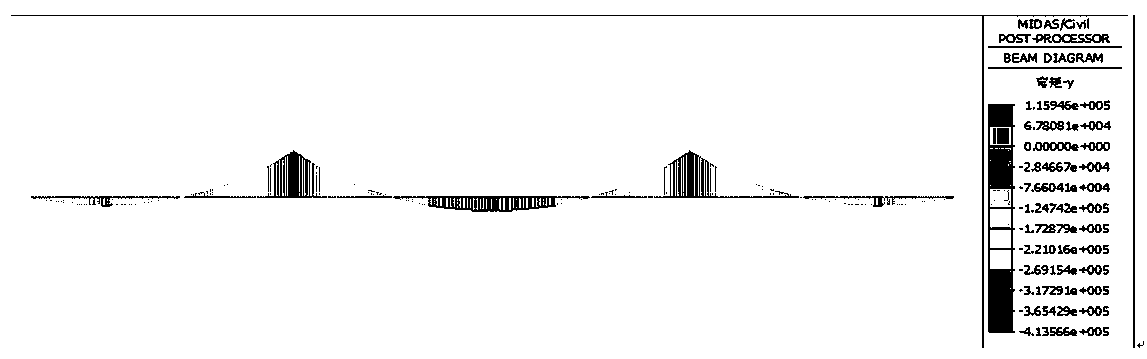

PendingCN107761950AReduce bending momentReduce shearGirdersJoistsReinforced concreteArchitectural engineering

The invention discloses a fabricated reinforced concrete angle brace frame and a construction method thereof. The fabricated reinforced concrete angle brace frame comprises precast columns, a laminated beam and anti-buckling supports, the laminated beam comprises a precast beam and post-poured concrete, and the two ends of the precast beam are hinged to the precast columns located on both sides; and one anti-buckling support which is slantly arranged is arranged on each side of the two sides of the bottom of the precast beam, one end of each anti-buckling support is hinged to the bottom of theprecast beam, and the other end of each anti-buckling support is hinged to the corresponding precast column. In the fabricated reinforced concrete angle brace frame, the beam and the columns are connected by adopting pin shafts, and real fabricated construction is realized; and at the same time, under the condition that the borne load is invariable, the height of the beam is greatly reduced, thestorey height of a building is decreased by 5-8%, and the net height of the interior of a house is increased by 200-300 mm. In addition, the precast length of each precast column is not limited by cast-in-place of storeys, the precast length of each precast column can be lengthened, and batches of sleeve grouting connection can be reduced according to requirements such as transportation conditions, so that the construction quality of the columns is improved, and the construction period is shortened.

Owner:南京百西思建筑科技有限公司

Supporting-free mounting method of prefabricated components of prefabricated assembly type building

ActiveCN107034989AAccurate locationEasy to processFloorsBuilding reinforcementsSupporting systemPipe support

The invention relates to the technical field of building construction, in particular to a supporting-free mounting method of prefabricated components of a prefabricated assembly type building. According to the mounting method, setting brackets are fixed to the tops of prefabricated columns and prefabricated laminated beams to support the components of the prefabricated laminated beams, laminated plates and the like, and a mounting method for the prefabricated components of the assembly type building without erecting of an adjustable independent supporting system or a steel pipe fastener supporting system is achieved. After the components are mounted in place, according to the load operation condition or the stacking condition on the laminated plate structure, adjustable independent supports, or steel pipe supports or the like can be additionally arranged below the laminated beams and the laminated plates, and the method is flexible, convenient and fast. The supporting brackets at the tops of the prefabricated columns and on the sides of the prefabricated beams can be removed and recycled after pouring and tamping of a whole pouring layer of the structure floor are completed, and the structure floor is maintained to reach the framework removing strength.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Novel manufacturing and installing method for prefabricated laminated beam board

InactiveCN107386512AGuaranteed accurate constructionEasy to set upConstruction materialFloorsArchitectural engineeringEngineering

The invention provides a novel manufacturing and installing method for a prefabricated laminated beam board, and belongs to the technical field of construction engineering. The method for manufacturing and installing laminated prefabricated beam components comprises the steps that in order to ensure that upper laminated board reinforcing steel bars enter the in-beam supporting base, after laminated beam reinforcing steel bars are bind through hoop bars, bottom bars and web bars of reinforcing steel bars of an laminated beam are bind, concrete pouring is conducted; laminated beam upper main bars are bind after installing of the laminated board prefabricated components is finished; the prefabricated laminated beam is hoisted; the method for manufacturing and installing laminated board components comprises the steps that the laminated board components are installed, and prefabricated board lower steel supports are erected; the prefabricated laminated board components are installed; form erecting is conducted on laminated board post-pouring belts, cast-in-site beam bottoms and the laminated beam; construction is conducted on the prefabricated concrete laminated board post-pouring belts and board end supporting base reinforcing steel bars; line pipes are laid in cast-in-site boards on the prefabricated laminated boards; and binding is conducted on the cast-in-site reinforcing steel bars. According to the novel manufacturing and installing method for the prefabricated laminated beam board, accurate construction for engineering work is guaranteed effectively, establishing for the construction standard specification is facilitated, and the construction quality is ensured effectively.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

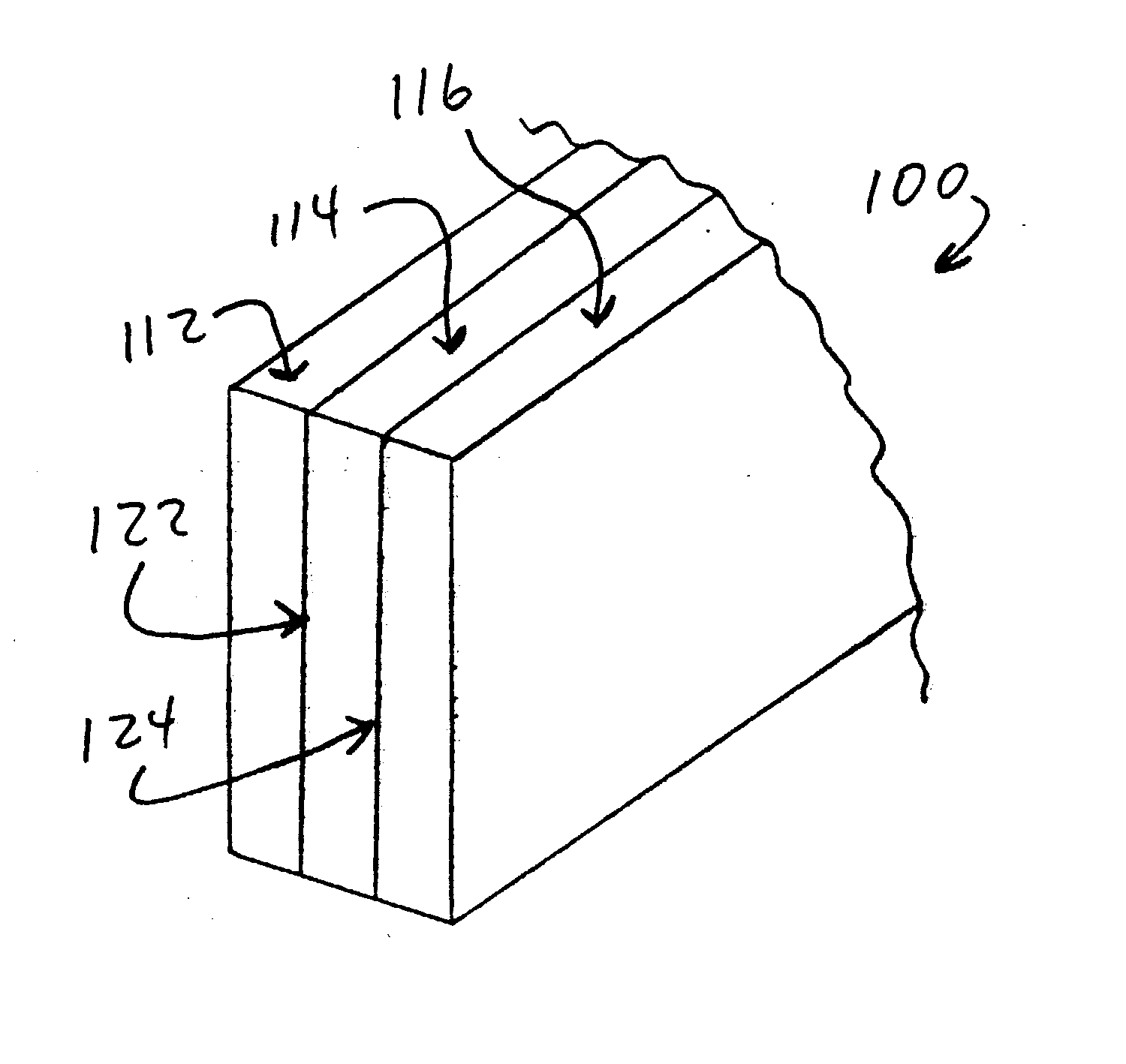

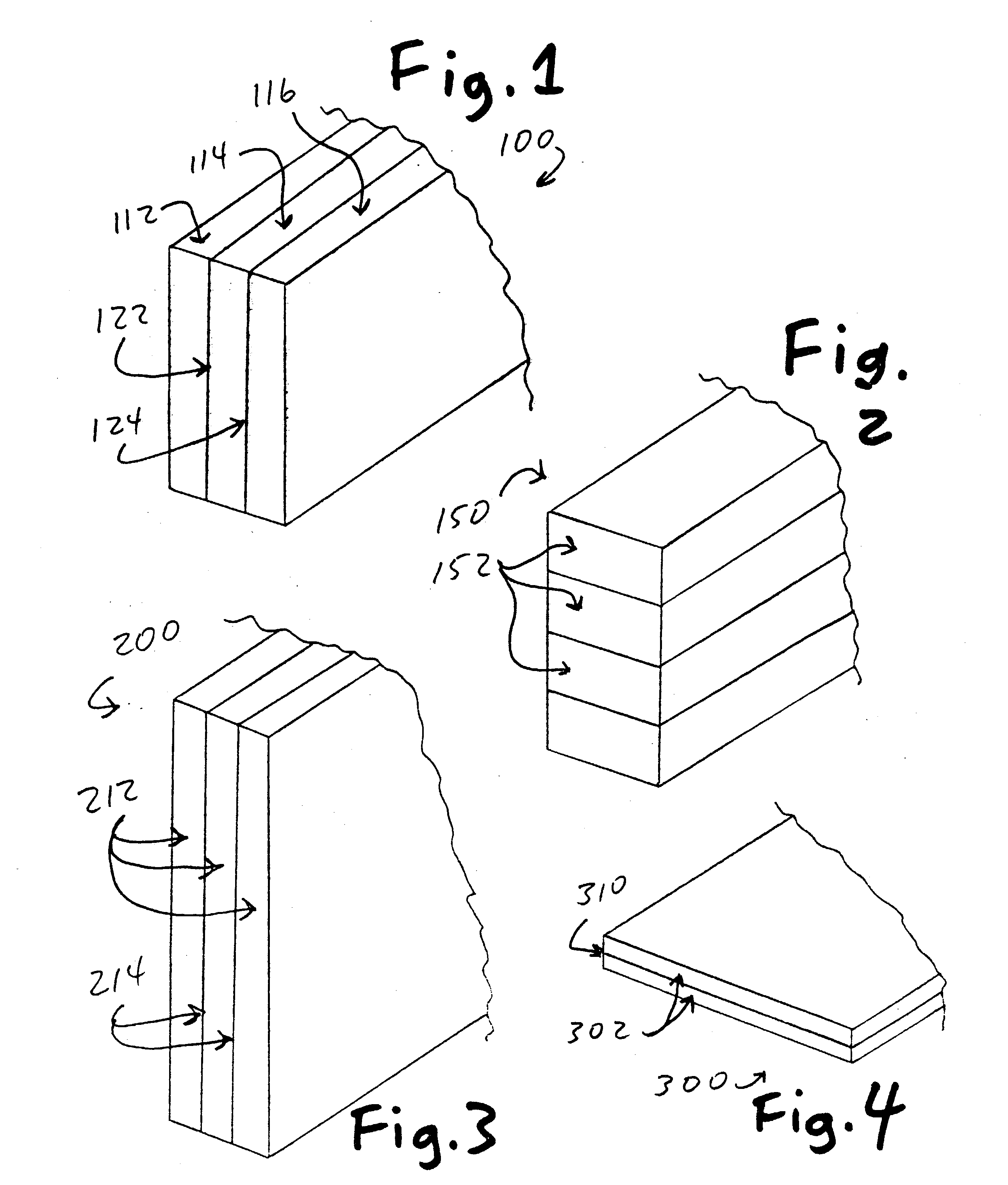

Laminated beams, boards, planks, and rails with enhanced stiffness and strength, made from nylon fiber composites

InactiveUS20050170166A1Increase stiffnessGreat strength and durabilitySynthetic resin layered productsThin material handlingAdhesiveBuilding design

Synthetic fiber composites (preferably containing nylon fibers obtained from recycled carpets) are made in laminated forms that can substitute for wooden boards, and even for structural beams (including studs, rafters, joists, etc.) in a framed house or other building. These laminates can be made from needle-punched fiber mats, which provide more extensive fiber intertwining than air-laid, bat-formed, or other fiber mats. In a preferred method of manufacture, sheets or wide strips are glued together, under pressure and using a non-foaming adhesive, to form oversized laminates having any desired thickness and desired length. The laminated sheets or strips are then sawed (such as by gang-ripping) into desired widths, to form edges that will not need additional trimming to remove excess adhesive. If suitable adhesives are used to form the adhesive layers, lamination can provide increased stiffness, compared to single-layer sheets having the same thickness. This increased stiffness can provide these laminated items with greater ability to withstand bending moments, torsional forces, and heavy longitudinal compression. These materials can also enable improved building designs and constructions that use less material, such as by increasing the spacings between adjacent studs, joists, and rafters.

Owner:BACON FORREST C +1

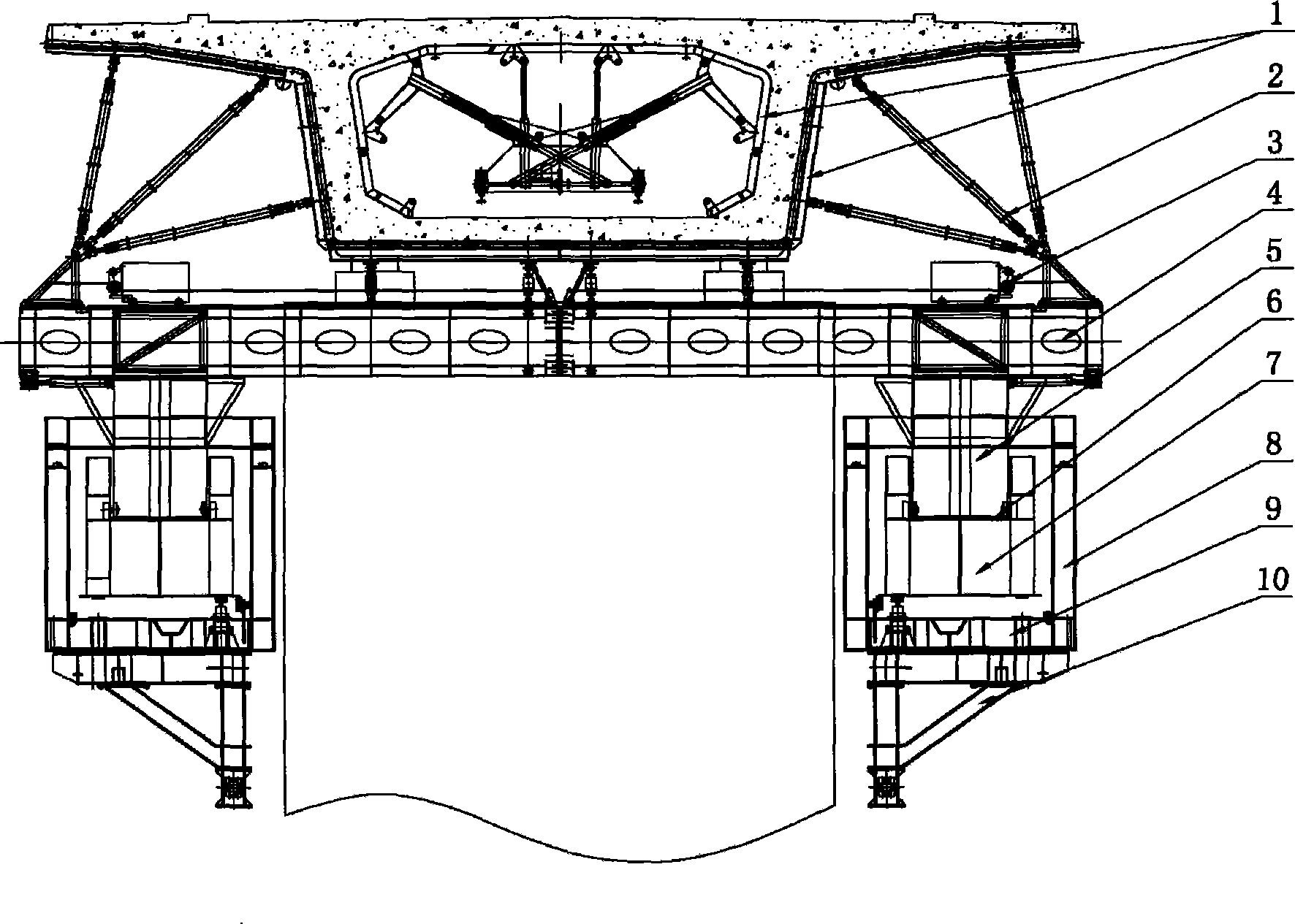

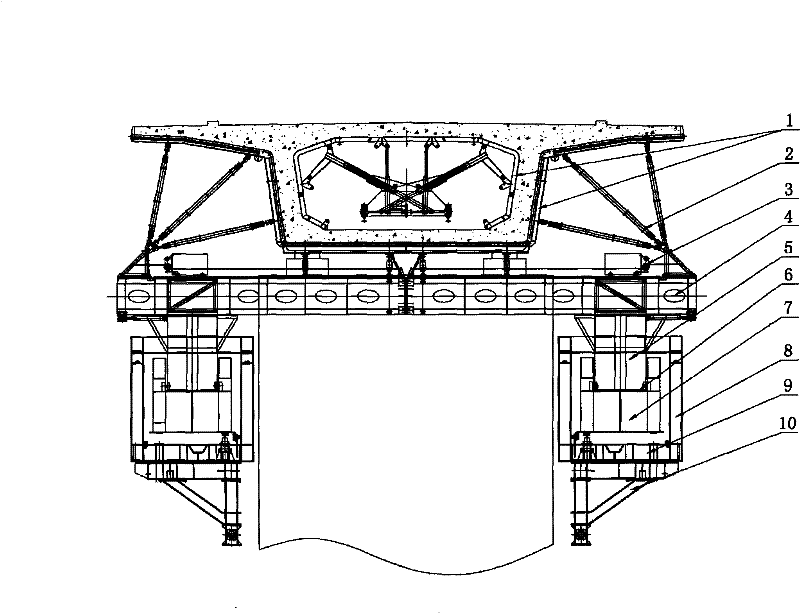

Overlap beams downstriker movable mould frame bridging machine

InactiveCN101509230AFunction increaseImprove securityBridge erection/assemblyBuilding material handlingStructural engineeringLaminated beam

The invention relates to a bridging device, in particular to a laminated beam descending type movable mold base bridge fabrication machine which belongs to the engineering plant. The bridge fabrication machine essentially consists of a main beam, a guiding beam, a comb shape crossbeam, a pier side bracket, a trolley, a counter weight dolly, a hydraulic system template system, etc. The guiding beam is arranged above the trolley. A hydraulic oil cylinder is arranged between the trolley and the guiding beam. The main beam is arranged in the guiding beam. A combination surface of the guiding beam and the main beam is provided with air cushions which are arranged uniformly. The movable mold base bridge fabrication machine changes the upper structure of the prior bridge fabrication machine and ensures that guiding beam and a bearing main beam form movable laminated beams, and the comb shape crossbeam can move independently when opening a mold, thereby increasing the function of the bridge fabrication machine, improving the safety, the reliability and the working efficiency of the equipment and reducing the weight and the cost of the equipment.

Owner:浙江众磊起重设备制造有限公司

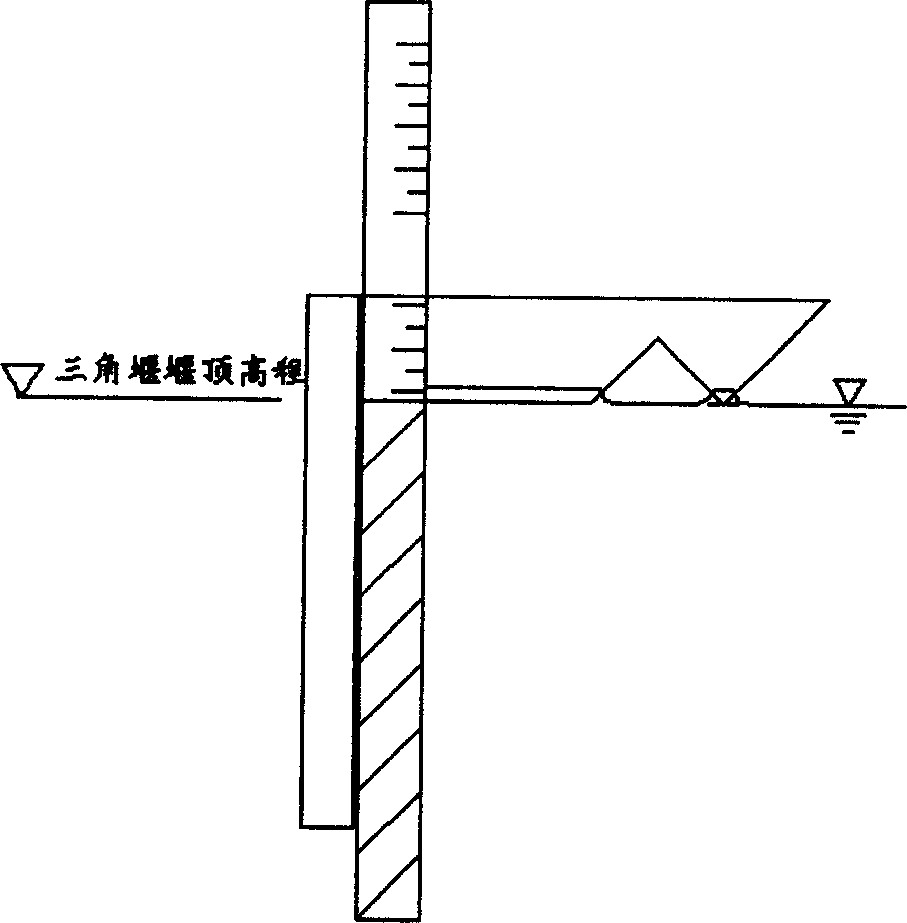

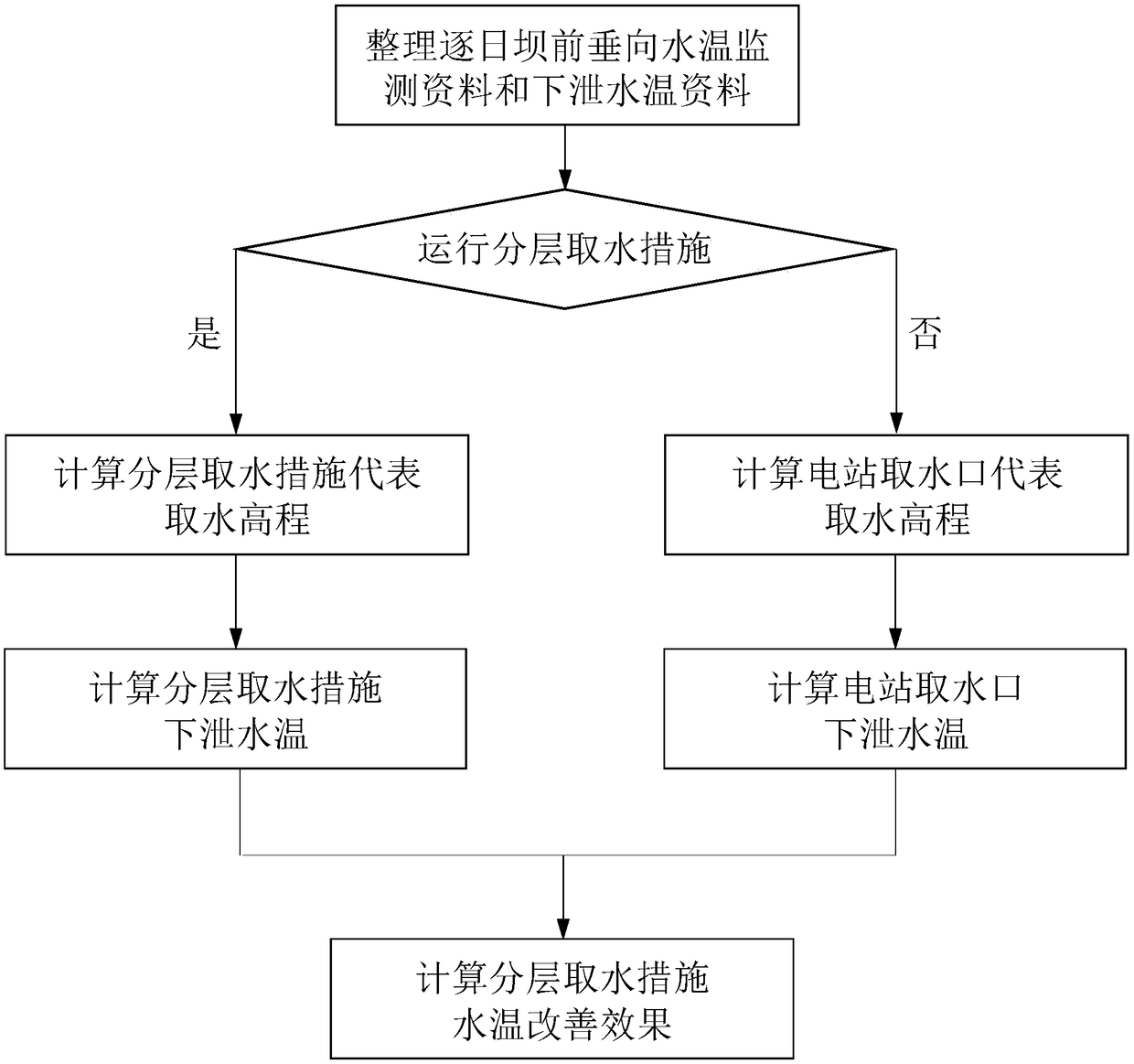

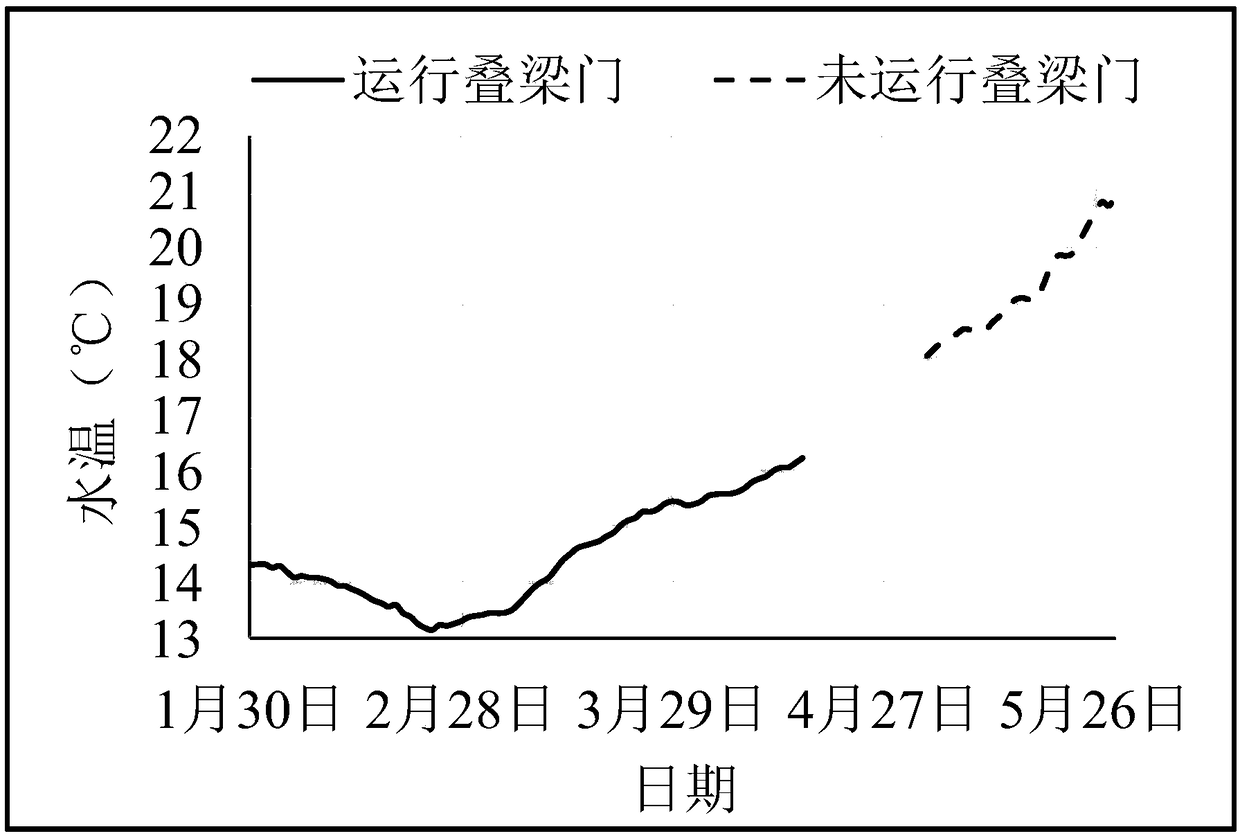

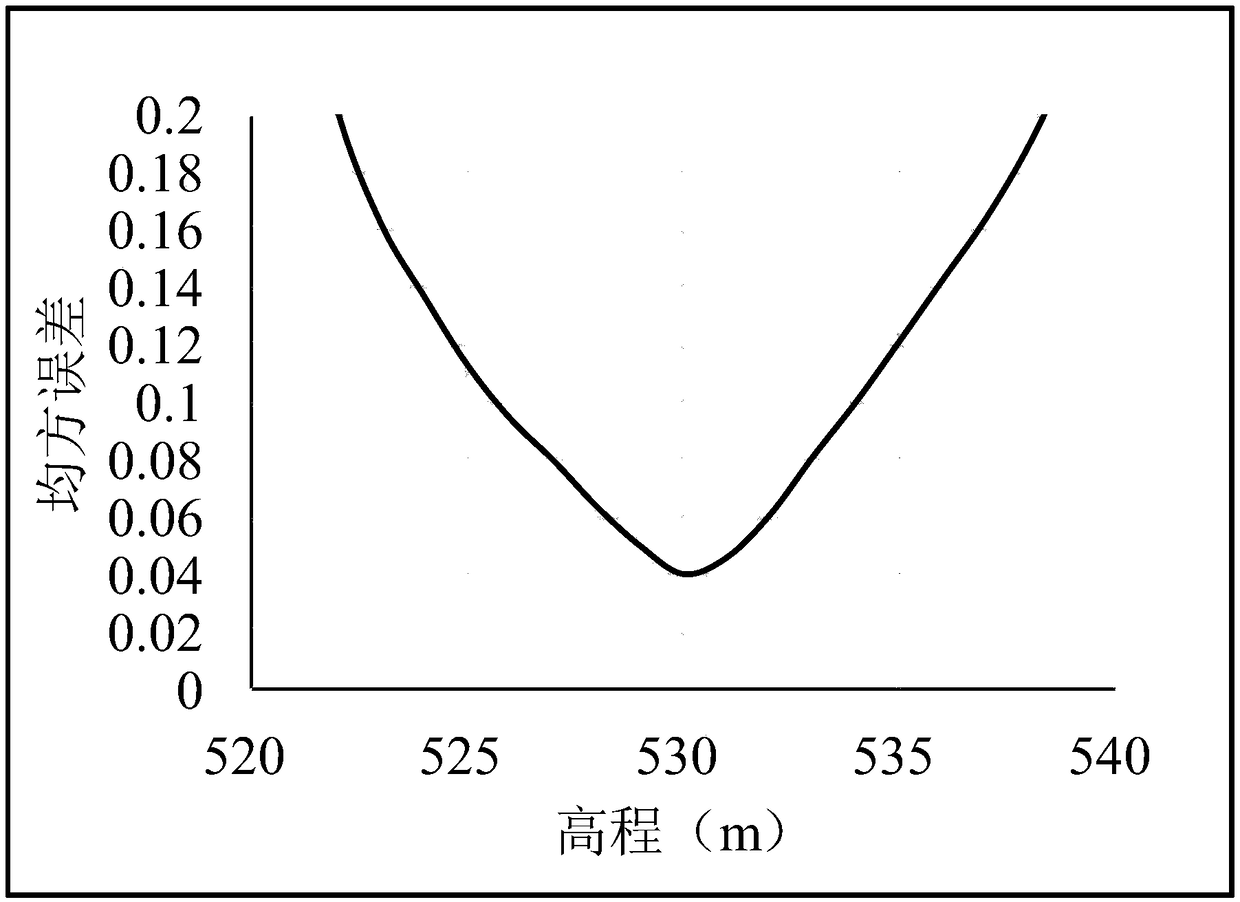

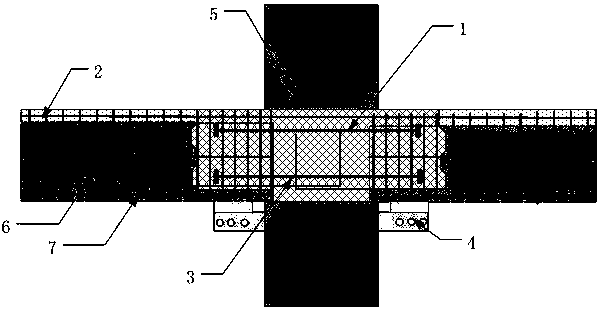

An analysis method of water temperature improvement effect of laminated beam gate

Owner:POWERCHINA ZHONGNAN ENG

Energy dissipation and seismic mitigation joint of assembly type RPC/concrete group frame

PendingCN107905402AReduce steel consumptionSmall sectionProtective buildings/sheltersShock proofingReinforced concrete columnHigh energy

The invention discloses an energy dissipation and seismic mitigation joint of an assembly type RPC / concrete group frame. A reinforced concrete column is used as the column. The column can be precastedor casted-in-place. A prefabricated beam with a keyway is used as the beam and the upper portion of the beam is provided with a laminated layer of a certain thickness. A PC steel bar is used as the beam bottom carrying bar and the bar extends a certain length at the end of the beam. The prefabricated beam is of a partial prestressing force structure. In a prefabricated beam keyway and joint area,reactive powder concrete (RPC) with high strength and toughness is used to conduct pouring. The laminated layer on the upper portion of the beam uses normal concrete to conduct pouring. After pouringof pouring areas behind the joint are all finished, a friction damper is arranged on the beam and column junction of the beam bottom. According to the energy dissipation and seismic mitigation joint,high strength materials such as RPC or PC steel bars are taken full advantage of, the section sizes of prefabricated assembly members can be reduced, the self weight of the prefabricated members arereduced, and meanwhile, combining with the energy dissipation and seismic mitigation technology, the problem that high-strength bars consume less energy can be fully solved. The energy dissipation andseismic mitigation joint has obvious technical advantages and has large-scale promotion and application prospects.

Owner:YANGZHOU UNIV

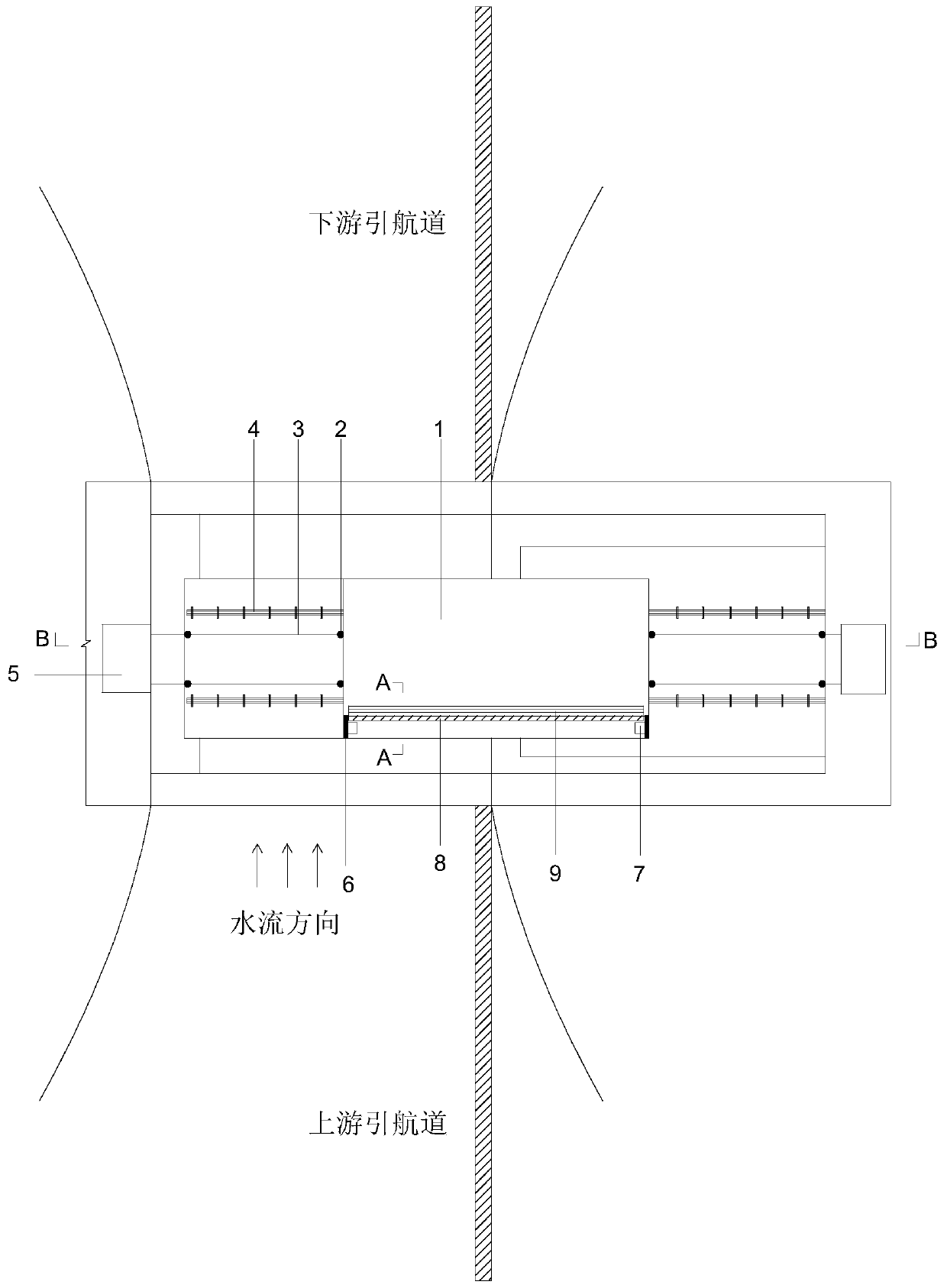

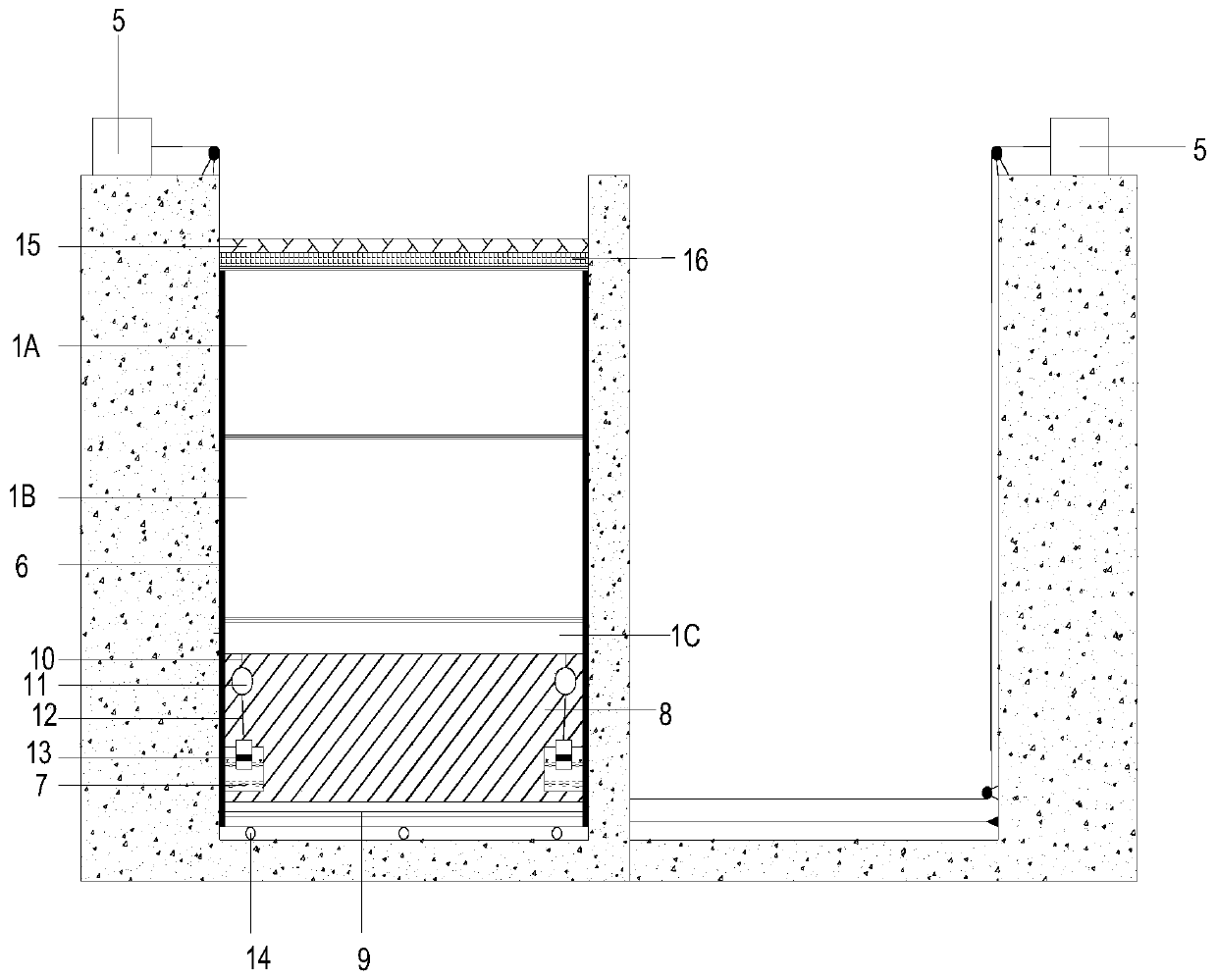

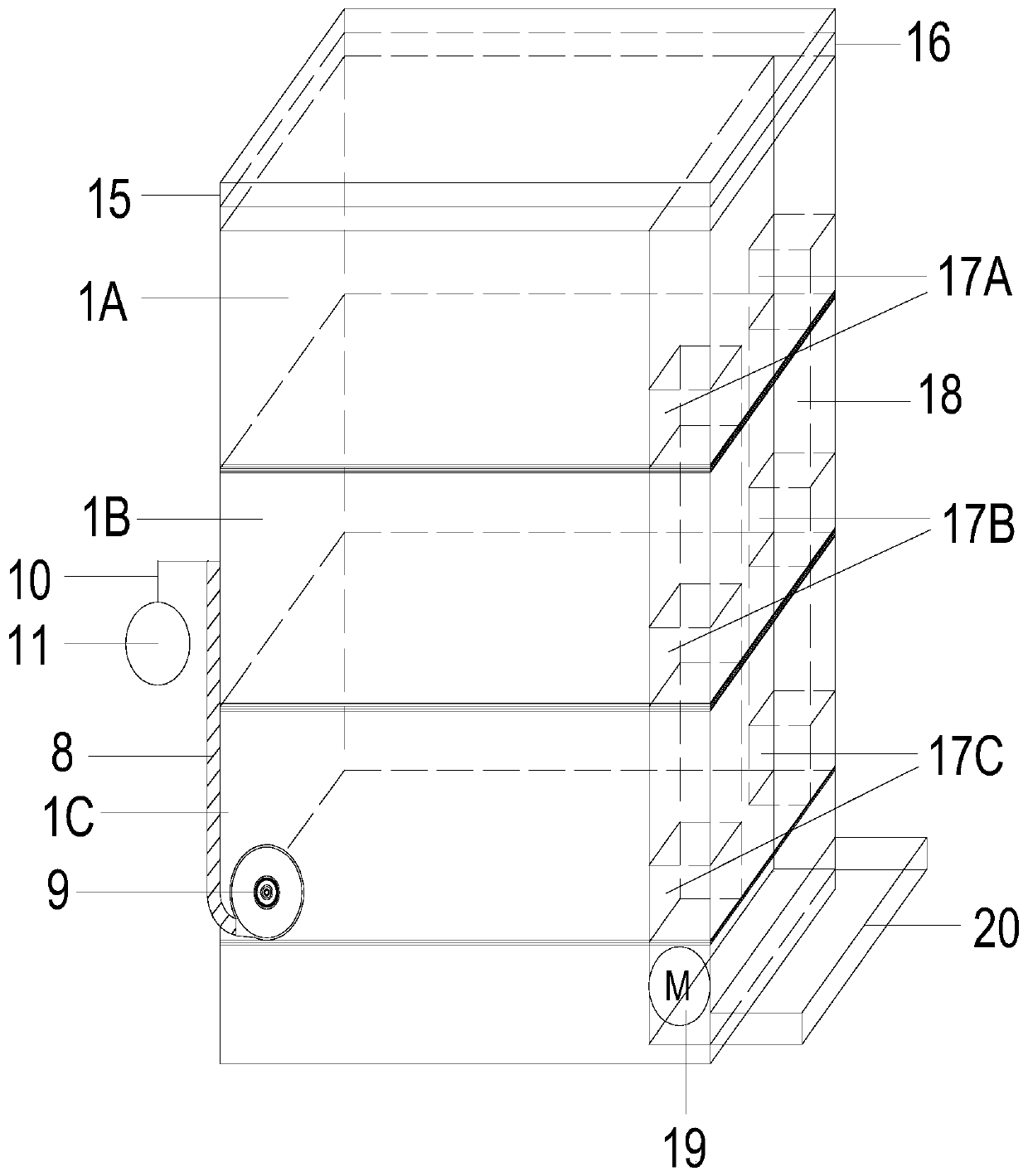

Rope-type overall-horizontal-pull ecological water sluice gate with laminated beams and operation method of water sluice gate

ActiveCN111305162AGenerates small torqueGuaranteed uptimeBarrages/weirsBatteries circuit arrangementsWater dischargeBlock and tackle

The invention relates to a rope-type overall-horizontal-pull ecological water sluice gate with laminated beams and an operation method of the water sluice gate. The water sluice gate comprises a gateframe, a sluice chamber, a gate chamber, power mechanisms and rails. The gate frame is composed of multiple layers of empty case gate laminated beams. The two power mechanisms are fixed to the tops ofouter side walls of the sluice chamber and the gate chamber respectively and drive the gate frame to slide along the rails through a steel wire rope and a pulley block respectively, so as to change the horizontal opening degree of the gate frame. An empty case gate of the most bottom layer is provided with a detachable roller shutter door box, the detachable roller shutter door box is located onthe upstream side, a shutter door leaf is arranged in the detachable roller shutter door box, a floating ball is connected to the top of the shutter door leaf, the water level of the upstream area changes to drive the floating ball, so that the shutter door leaf ascends or descends, and thus the vertical opening degree of the gate frame is changed. According to the water sluice gate, through a flexible rope part, normal opening and stable operation of the sluice gate are guaranteed. By adopting an empty case gate form, purification devices are arranged in the water sluice gate, and thus the quality of the water discharged to the downstream area is guaranteed.

Owner:YANGZHOU UNIV

Manipulator device driven on basis of photo-induced shape memory polymers and method thereof

The invention relates to a manipulator device driven on the basis of photo-induced shape memory polymers and a method thereof. One end of a photo-induced shape memory polymer laminated beam is fixedly arranged in a clamping groove between a base and a fixture block; a metal protection sheet is adhered to the other end of the photo-induced shape memory polymer laminated beam in order to protect the photo-induced shape memory polymers; a claw arm is the photo-induced shape memory polymer laminated beam and comprises three layers; the top layer and the bottom layer are made of the photo-induced shape memory polymers; the middle layer is an elastic beam; the layers are mutually adhered by high-intensity viscous materials; the fixture block and a fastening bolt are arranged on the base; the end part where the fastening bolt is arranged is matched with a screw thread hole of the base after passing through a through hole of the base; the clamping groove formed between the fixture block and the base is used for fixing the end part of the photo-induced shape memory polymer laminated beam; a gap of the clamping groove can be regulated according to the thickness of the photo-induced shape memory polymer laminated beam. The manipulator has the characteristics of simple and intelligent structure, non-contact control, light weight and the like and is suitable for a common micro electro mechanical system.

Owner:ZHEJIANG UNIV

Reinforce structure of prefabricated beam-column compression joint and construction method thereof

PendingCN108179807ASolve grouting difficultiesSolving insufficient concrete constraints at beam endsBuilding constructionsBeam columnLaminated beam

The invention relates to a reinforce structure of a prefabricated beam-column compression joint and a construction method thereof. The reinforce structure of the prefabricated beam-column compressionjoint comprises a prefabricated column and a laminated beam, wherein the laminated beam comprises a prefabricated lower portion and a cast-in-place upper portion; the end portion of the laminated beamat a beam-column connecting joint is wrapped with a joint strengthening device; the joint strengthening device comprises a U-shaped support piece and an anchor rod; a gap is reserved between the prefabricated column and the prefabricated lower portion; the U-shaped support piece is used as a template in the gap to be filled with grouting materials; and the anchor rod is integrally anchored into the cast-in-place upper portion. According to the reinforce structure of the prefabricated beam-column compression joint and the construction method, the amount of on-site construction modulus is reduced and the construction speed is high; the concrete bearing capacity of the bottom of the beam end can be effectively improved by creating an additional restraining effect on a beam end concrete, andtherefore the seismic performance of the joint is improved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

cast-in-place concrete slab

InactiveCN102277919AImprove waterproof performancePrevent water seepageFloorsReinforced concreteThin slab

The cast-in-place concrete slab is characterized in that the cast-in-place concrete slab includes cast-in-place reinforced concrete laminated ribs, cast-in-place reinforced concrete laminated beams, and prefabricated components, and the prefabricated components include a roof, a rib mold, a beam mold, a roof, a rib mold It forms a member with one side open with the beam formwork, the lower end of the rib formwork protrudes outwards to form the rib base formwork, and the lower end of the beam formwork protrudes outwards to form the beam base formwork. There are two opposite beam forms on the prefabricated component. The lower end of the rib formwork is lower than the lower end of the rib formwork. There is a beam-rib connecting formwork between the rib formwork and the beam formwork. The part of the beam formwork that is flush with the rib formwork is the beam upper formwork, and the part of the beam formwork that is lower than the rib formwork is the lower hanging beam formwork. The top plate is a forming mold for post-cast concrete, on which there is a cast-in-place concrete structural thin plate, and the beam bottom molds of the prefabricated components on both sides of the same line are adjacent to each other, and form a cast-in-place reinforced concrete composite beam together with the cast-in-place concrete. The rib molds are arranged adjacent to each other, together with the cast-in-place concrete to form a cast-in-place reinforced concrete laminated rib, and there are more than two cast-in-place reinforced concrete laminated beams arranged in the cast-in-place concrete slab.

Owner:湖南华廷筑邦住宅工业有限公司

Method for intercepting by utilizing temporary construction traffic bridge

InactiveCN104805808AAvoid or mitigate productionAvoid or ease transportationBarrages/weirsBridge applicationsWinchBerm

The invention discloses a method for intercepting by utilizing a temporary construction traffic bridge. The method is realized by adopting the temporary construction traffic bridge, intercepting piers, a laminated beam and an intercepting berm. According to the technical scheme, a closure gap in the most difficult intercepting time period is arranged between the two piers of the temporary construction traffic bridge; the closure is realized by mounting the laminated beam on the piers; when the construction traffic bridge is designed, the requirement on intercepting is taken into consideration, and the piers at the two dike head ends of the closure gap is reformed to a certain degree, wherein the upstream end part of each pier is changed from a vertical surface into an inclined surface with a certain slope, and a slideway is arranged in the inclined surface; sliding grooves are formed in the two ends of the laminated beam, so that the laminated beam and the slideway are positioned and are engaged; the laminated beam is placed to a preset position under the control of a winch which is arranged on a bridge surface. According to the method, the laminated beam is placed for intercepting by utilizing the temporary construction traffic bridge, so that the success closure of a high-difficulty intercepting project can be realized quickly; the method has the characteristics of high safety, reliability, and rapidness.

Owner:WUHAN UNIV

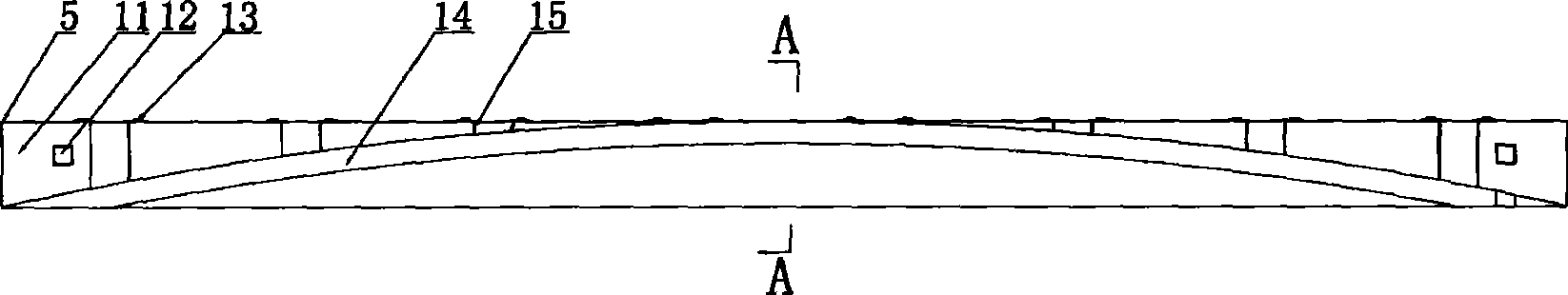

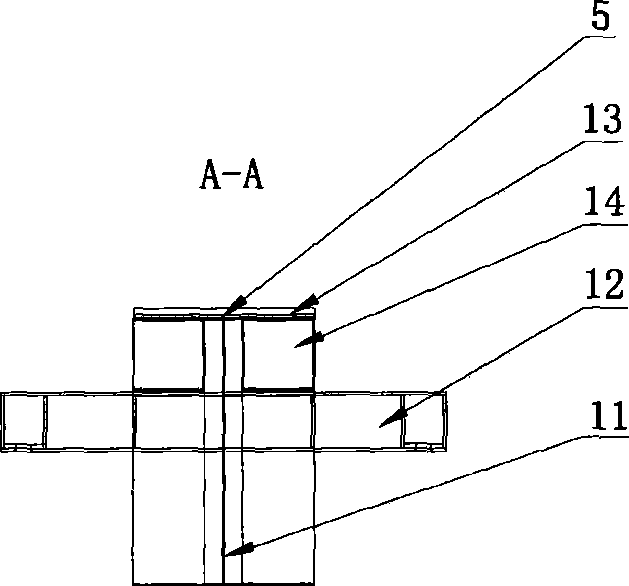

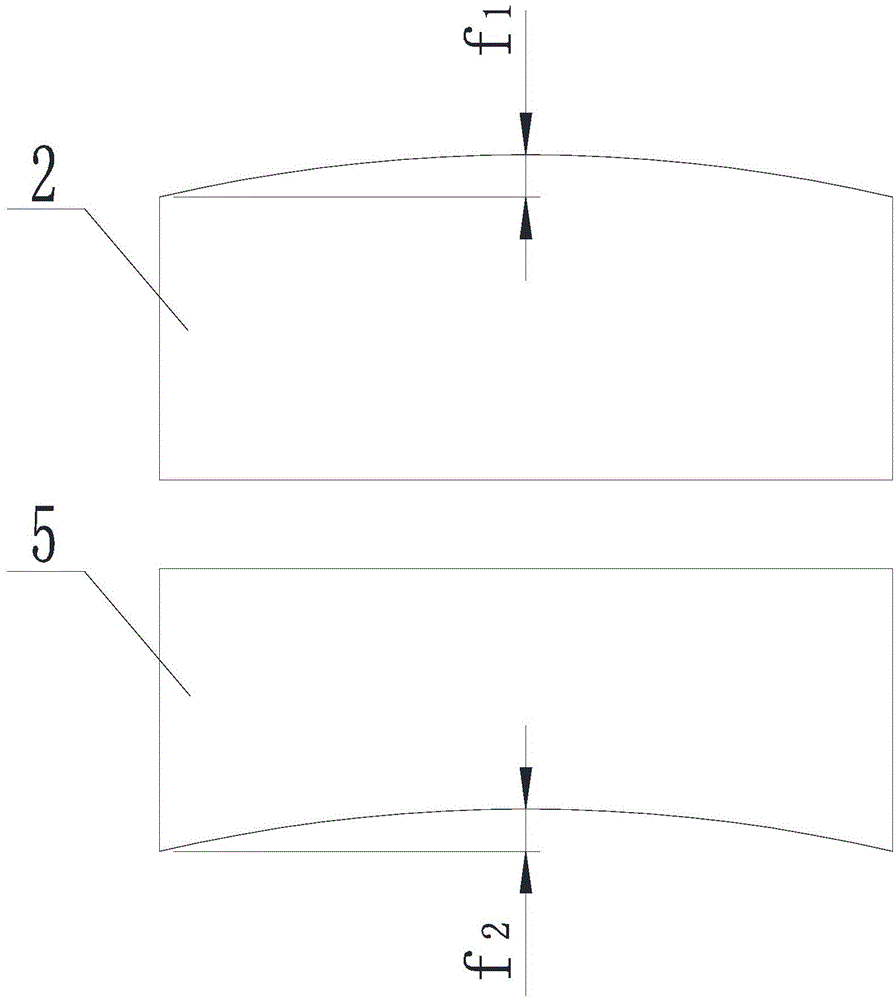

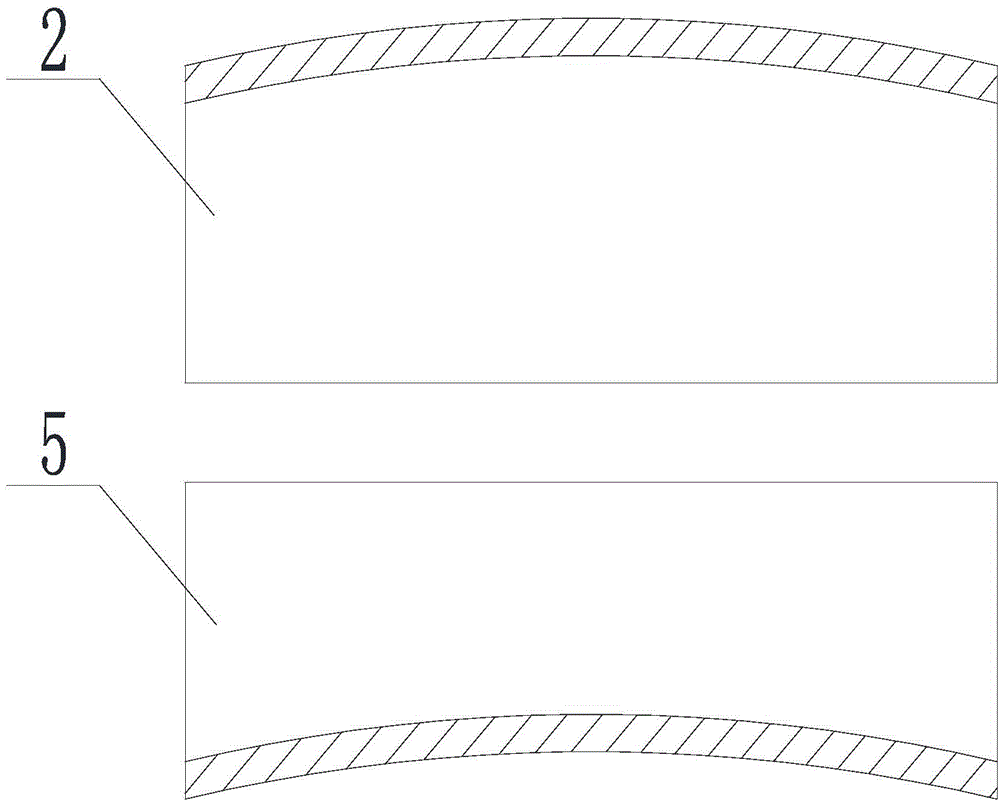

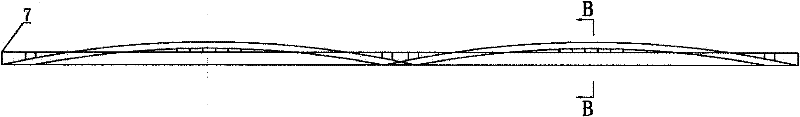

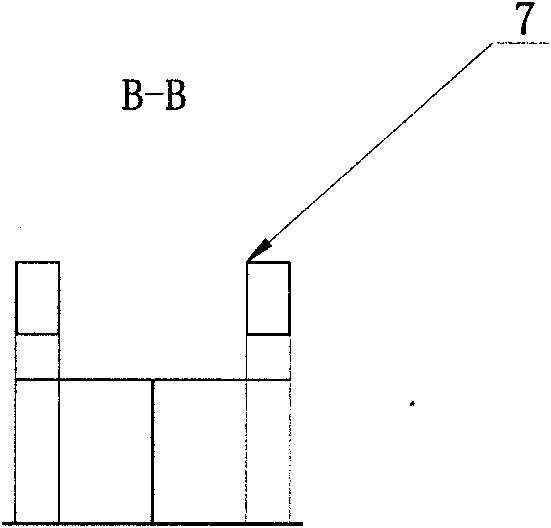

Method for prefabricating camber of large-scale steel laminated beam web

The invention provides a method for prefabricating the camber of a large-scale steel laminated beam web. The method comprises the steps that firstly, one side, arranged at the side of an upper beam flange plate, of an upper beam web body and one side, arranged at the side of a lower beam flange plate, of a lower beam web body are blanked according to an ideal curve for prefabricating the camber, and one side, arranged at the side of an upper beam laminated plate, of the upper beam web body and one side, arranged at the side of a lower beam laminated plate, of the lower beam web body are blanked according to a straight line; strip heating is carried out on the side, arranged at the side of the upper beam flange plate, of the upper beam web body and the side, arranged at the side of the lower beam flange plate, of the lower beam web body, and due to thermal stress, the upper beam web body and the lower beam web body generate compression plastic deformation, and then the side, arranged at the side of the upper beam laminated plate, of the upper beam web body and the side, arranged at the side of the lower beam laminated plate, of the lower beam web body form the camber of the approximately ideal curve; and finally a full-automatic vibration aging way is utilized for performing the vibratory residual stress relief onthe upper beam web body and the lower beam web body, and stability of the camber size is ensured. According to the method, flatness of the laminated beam laminated plates is effectively ensured, and the method can be widely applied to the technology for prefabricating the camber of the large-scale steel structure laminated beam web of a supercritical or ultra-supercritical thermal generator set.

Owner:NO 9 METALLURGICAL CONSTR

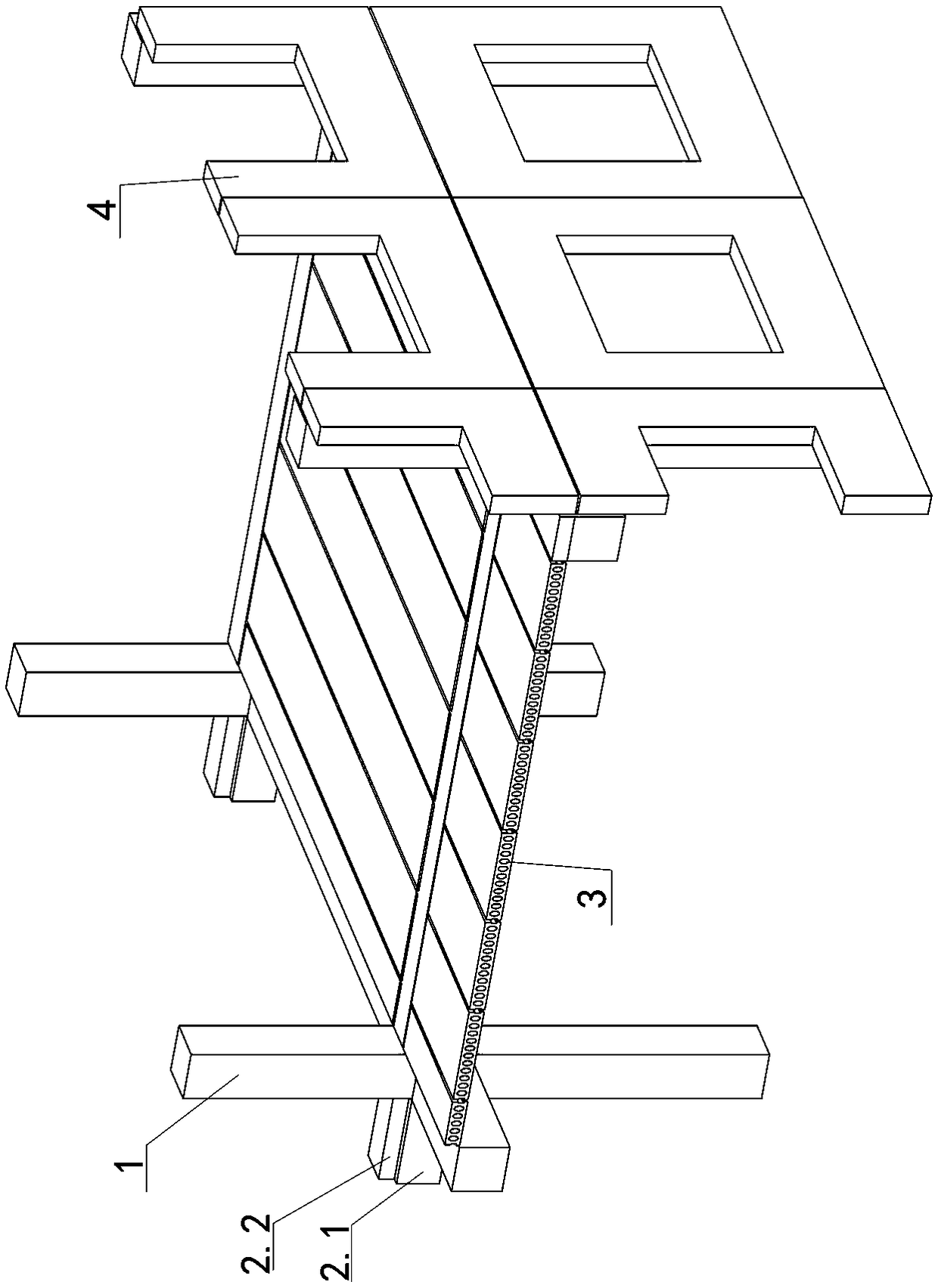

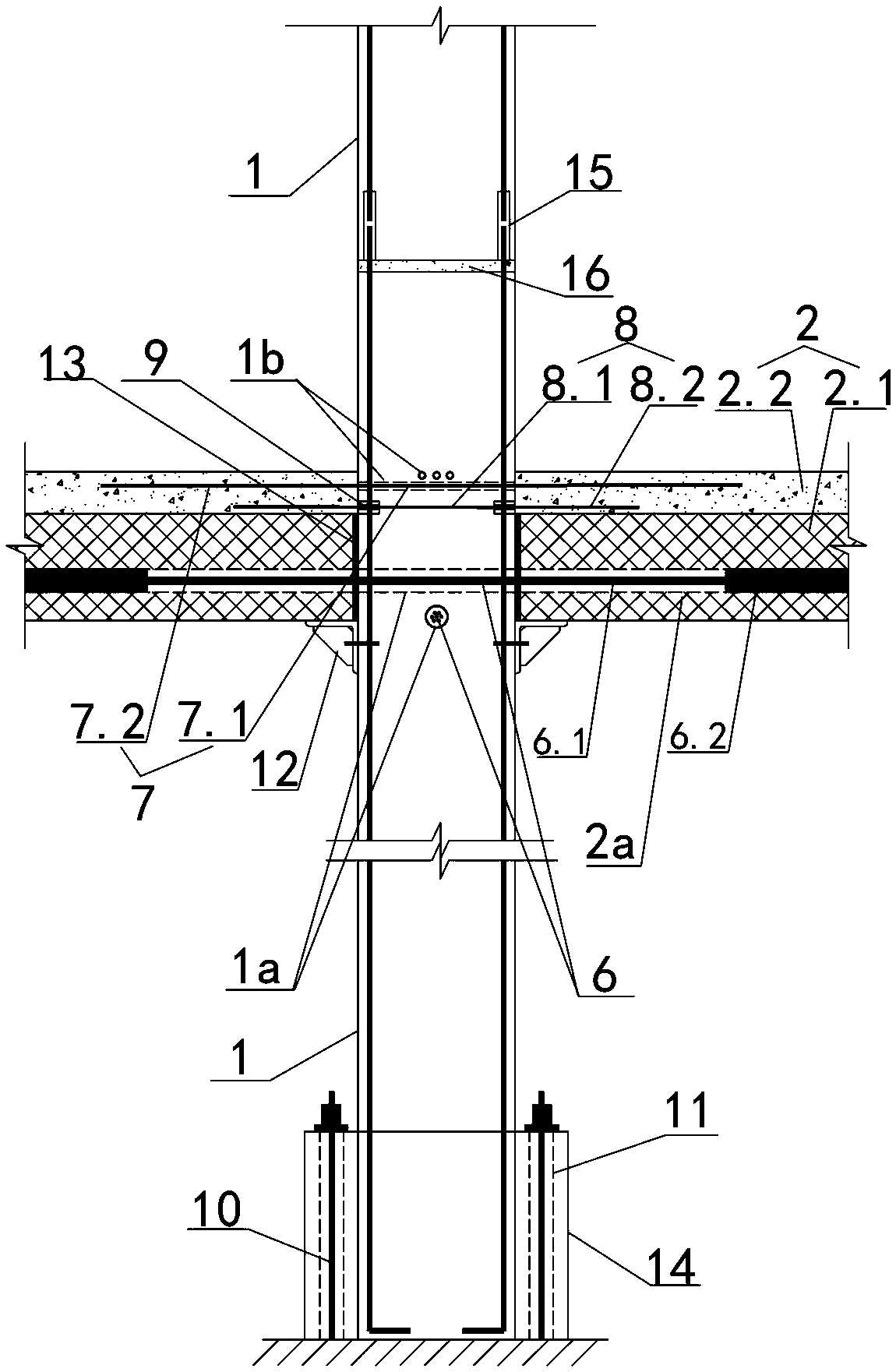

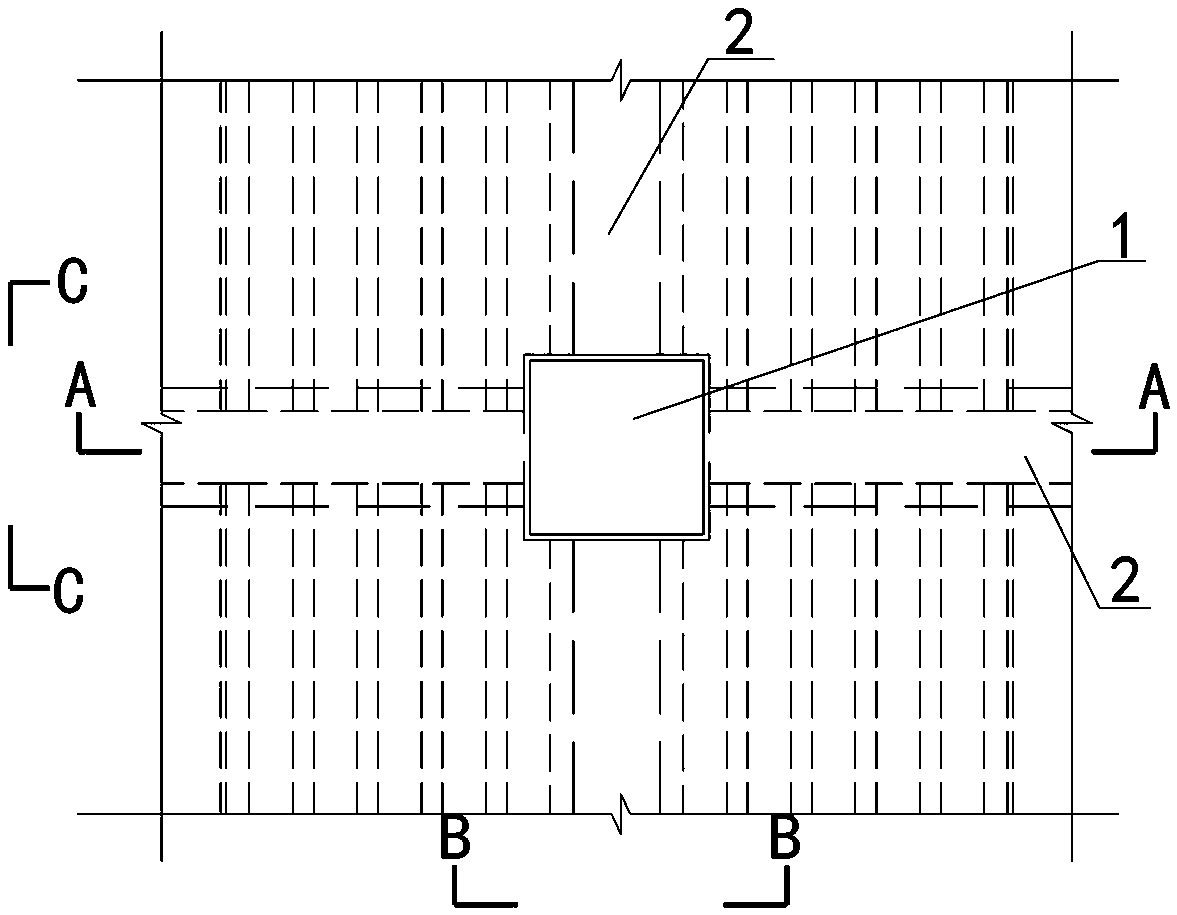

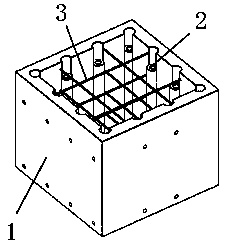

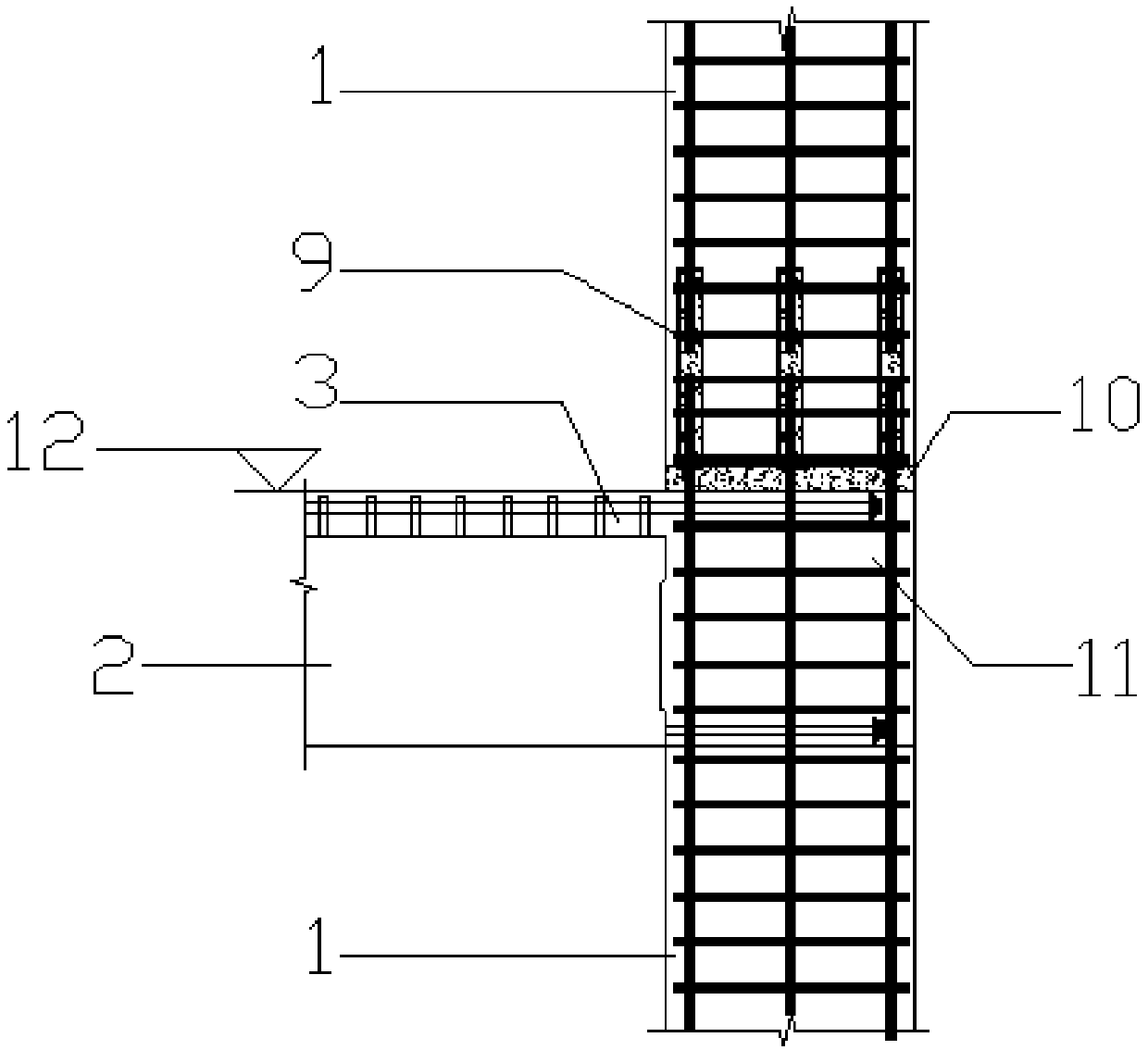

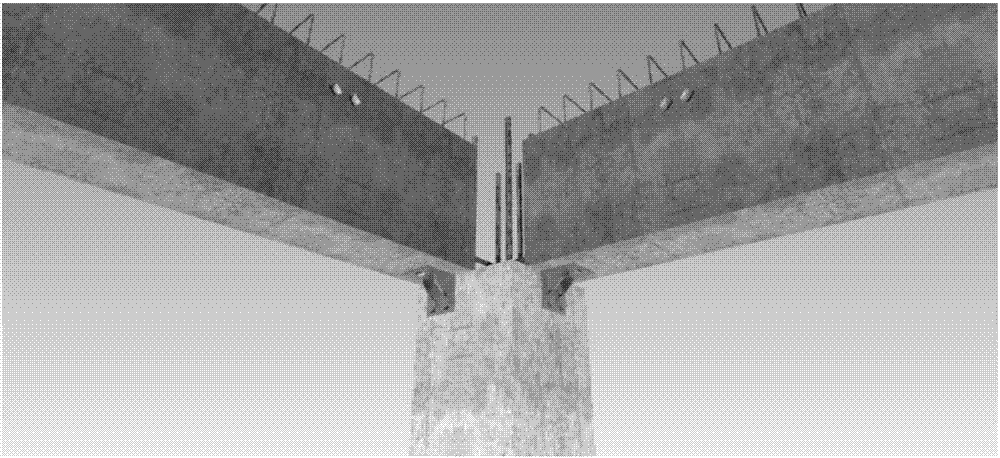

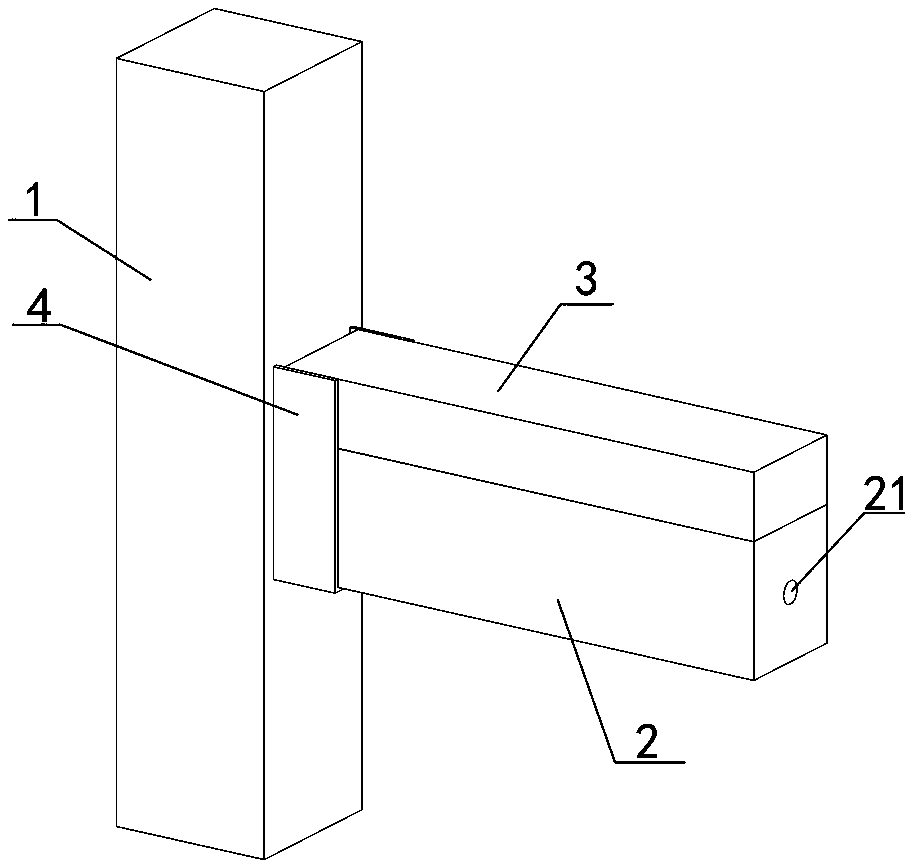

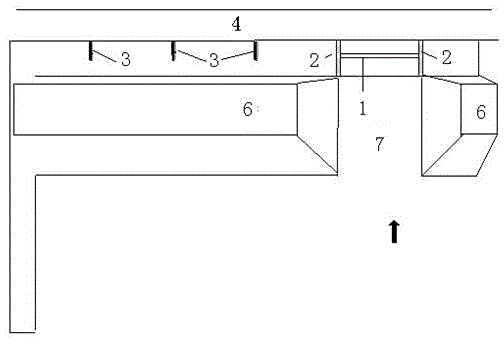

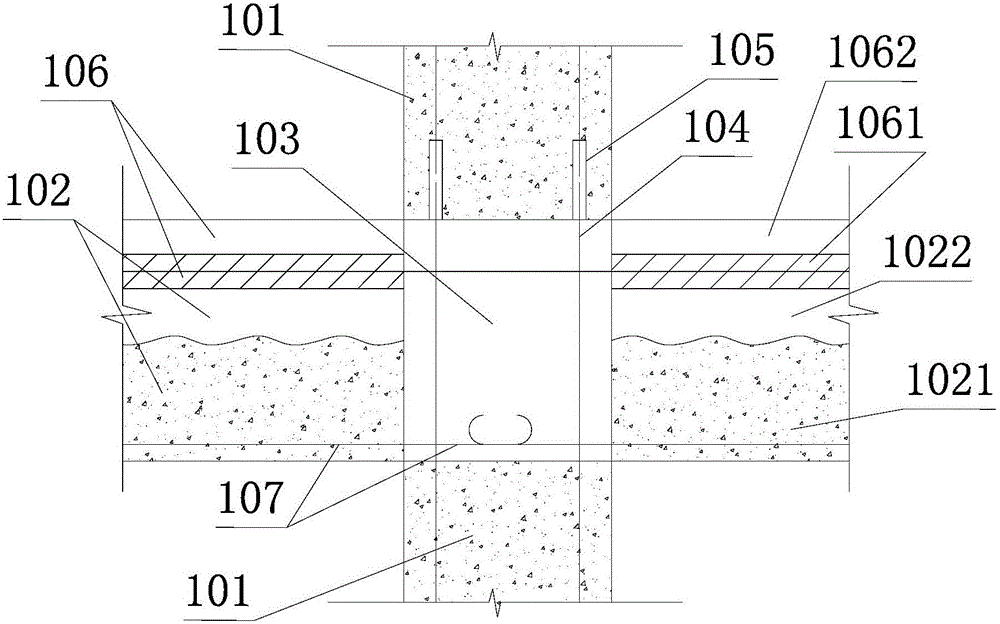

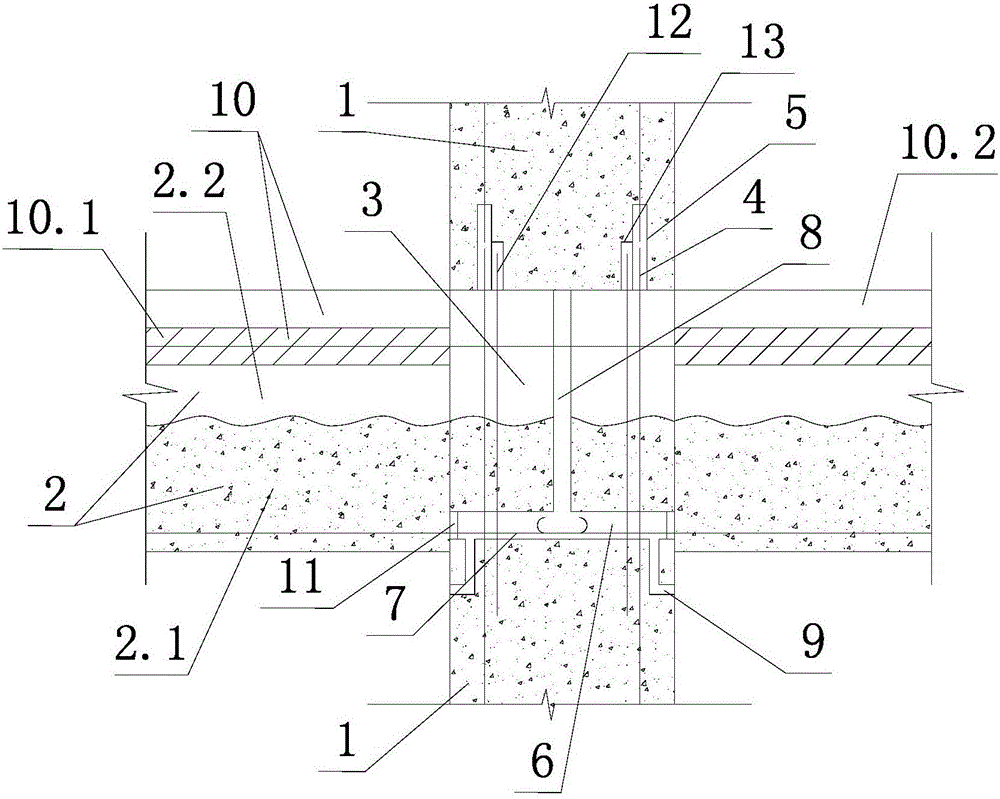

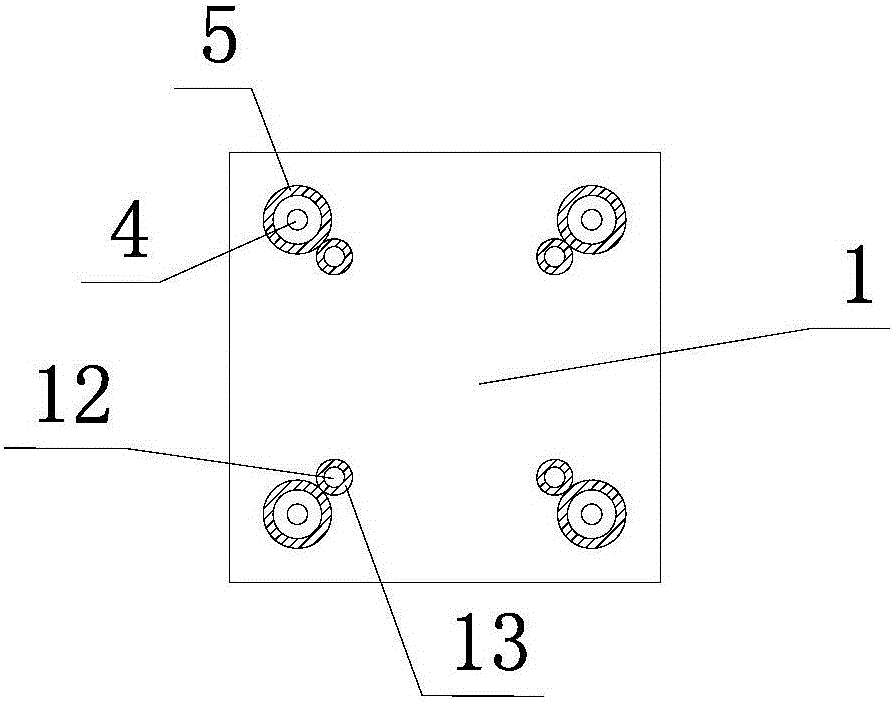

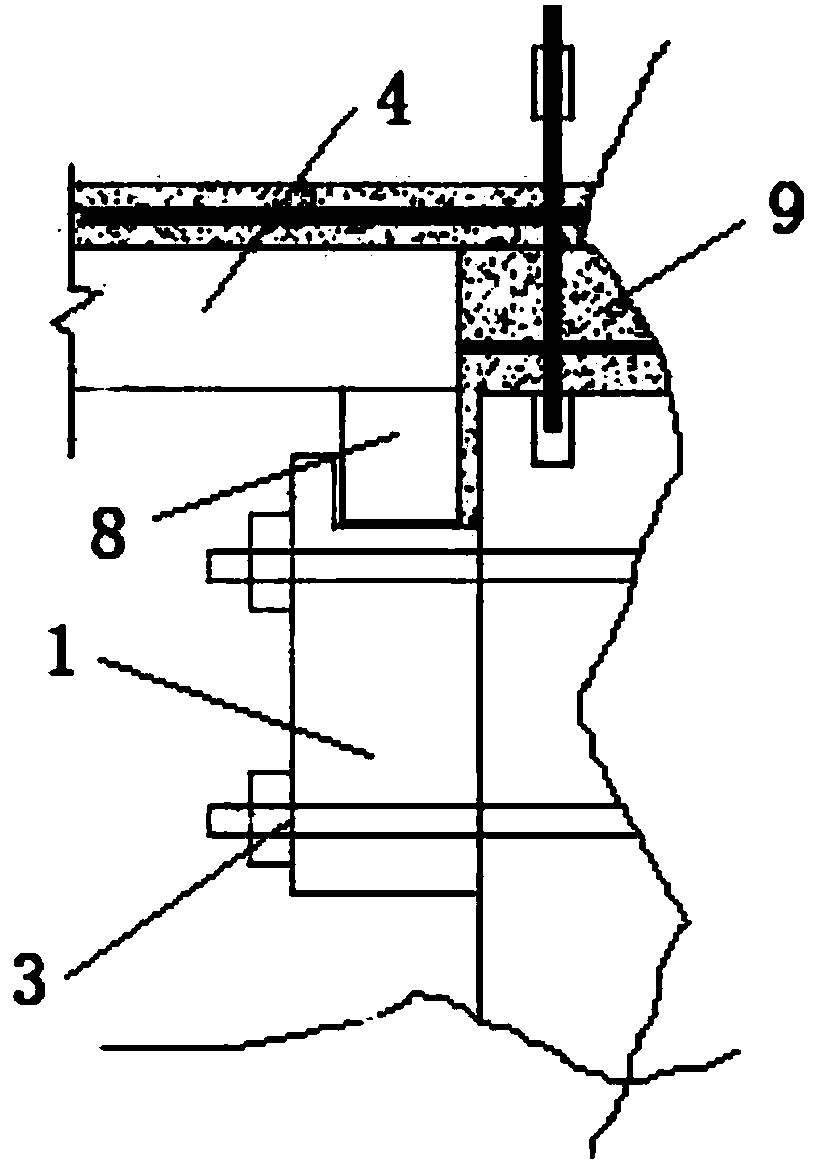

Connecting structure and method for precast column and beam and slab joints of concrete frame structure

ActiveCN106149878APrecise card positioningGuaranteed shear performanceBuilding constructionsGroutLaminated beam

The invention discloses a connecting structure and method for precast column and beam and slab joints of a concrete frame structure. The structure comprises upper and lower precast columns (1), laminated beams (2) on the two sides and a joint area (3). The top of the lower precast column (1) is flush with the laminated faces of precast beams (2.1) of the laminated beams (2) on the two sides, a transverse metal bellows (6) is arranged in the lower precast column (1) in a penetrating mode, and negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into and are anchored in the metal bellows (6). A grout pipe (8) communicated with the metal bellows (6) is anchored in the joint area (3). The method is characterized in that all the negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into the metal bellows (6) of the lower precast column (1) and are anchored. By means of the structure and the method, it can be avoided that operation at joints is difficult due to the narrow space, and the use amount of cast-in-place concrete can be reduced.

Owner:NINGBO PRECA CONSTR TECH CO LTD

Fabricated beam-column connecting joint

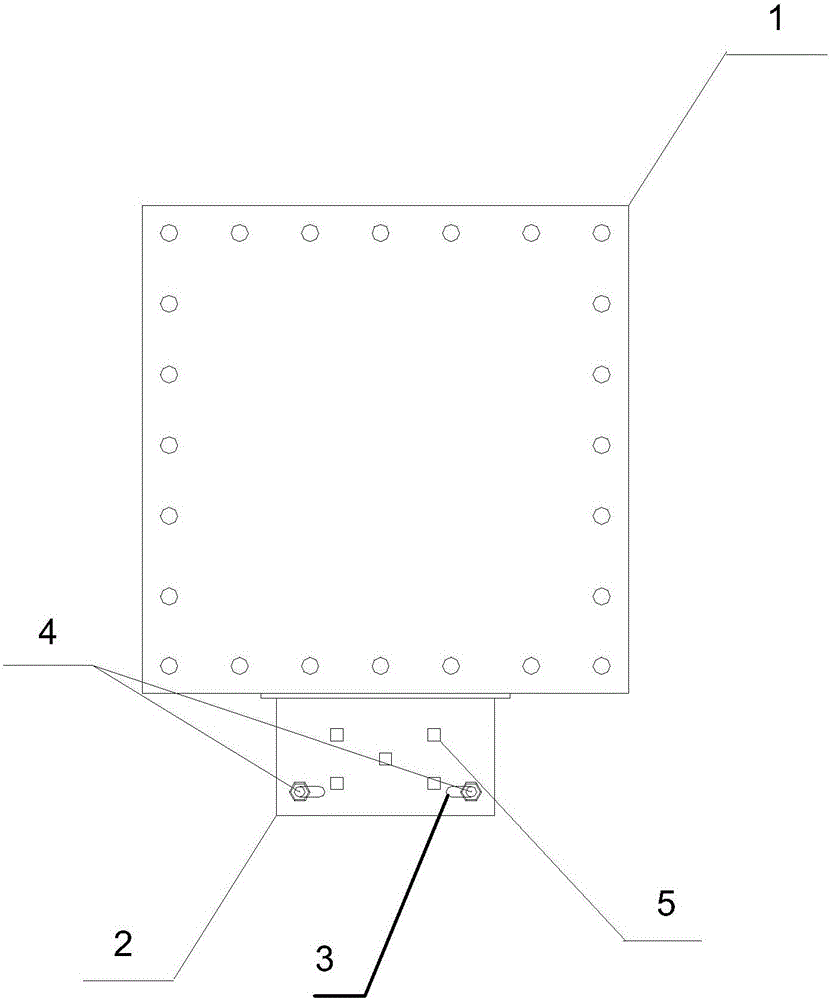

PendingCN108277881AReduce on-site workloadShort construction periodBuilding constructionsReinforced concreteRebar

The invention relates to the technical field of beam-column connecting joints, in particular to a fabricated beam-column connecting joint. The fabricated beam-column connecting joint comprises a U-shaped bracket and a prefabricated laminated beam connecting joint, the periphery of a U-shaped steel skeleton is wrapped with prefabricated concrete; and the prefabricated laminated beam connecting joint comprises a connecting web plate, an upper flange plate and a lower flange plate and is connected with a structural beam, the upper flange plate and a fixing plate are connected and fixed by inserting bolts into second bolt holes and first bolt holes, and web plate studs and bracket studs are arranged in a staggered mode. According to the fabricated beam-column connecting joint, by combining with the steel structure industry with highly-developed industrialization and cooperating with a reinforced concrete combination technology, a system is innovated, the problems of inherent deficiencies of assembling of reinforced concrete connecting joints, environmental pollution of on-site construction, application of green building materials, high production cost, and supply side reform de-capacity are solved, and great significance is achieved.

Owner:BEIJING ZHIHUI YUNJIAN TECH CO LTD

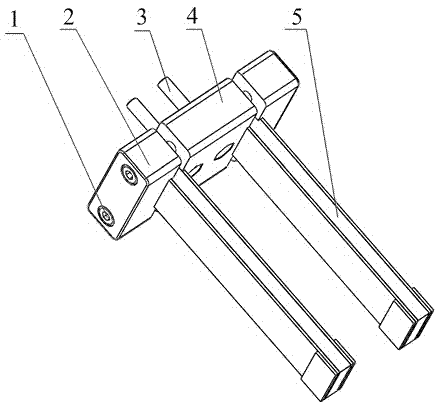

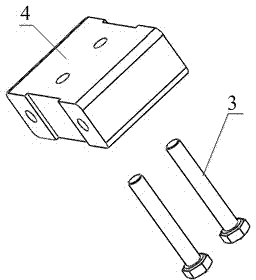

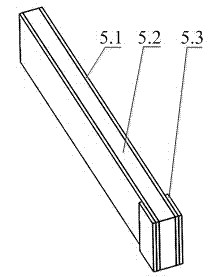

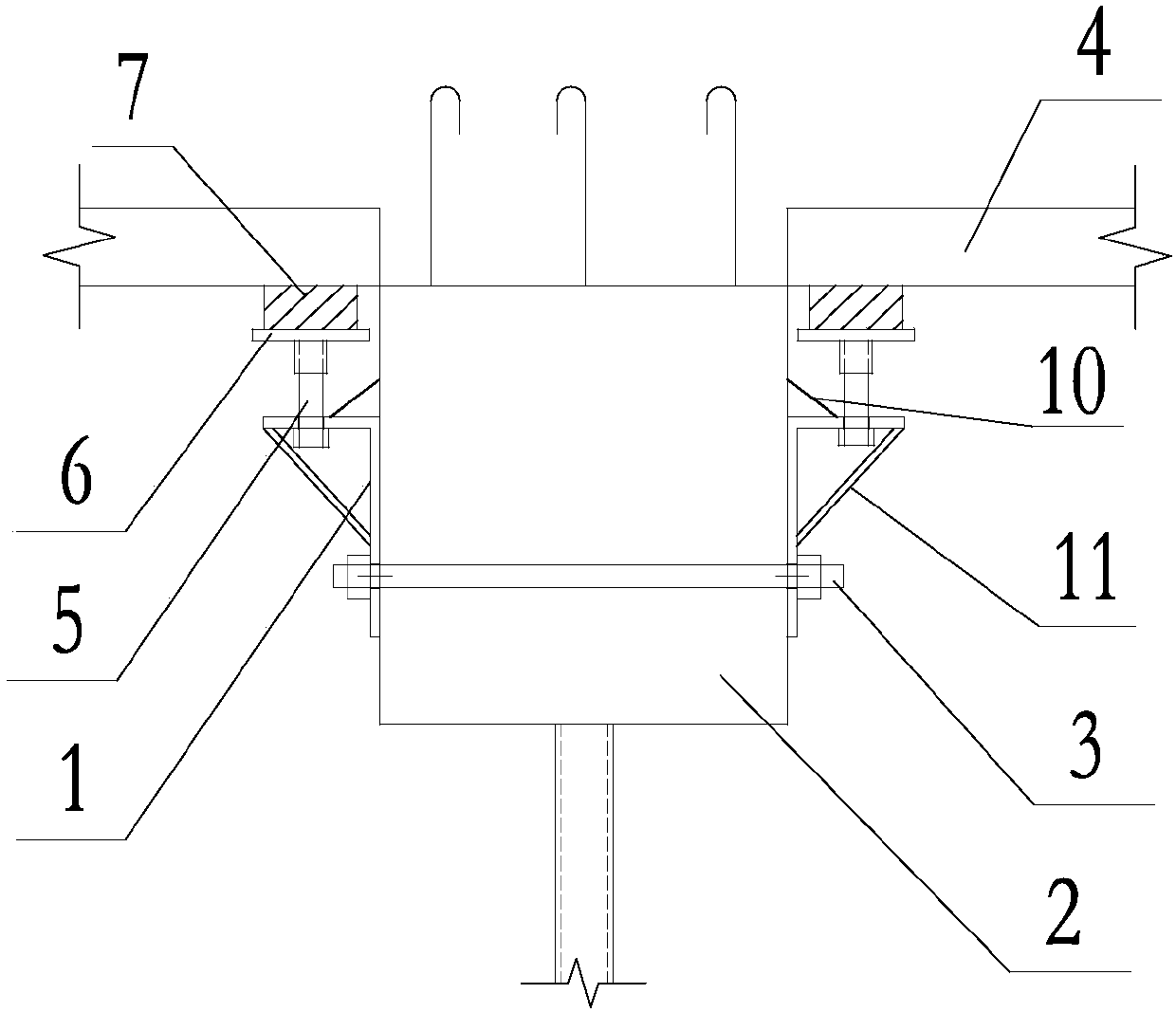

Quick positioning adjusting tool and method for connection of precast laminated beam and precast column

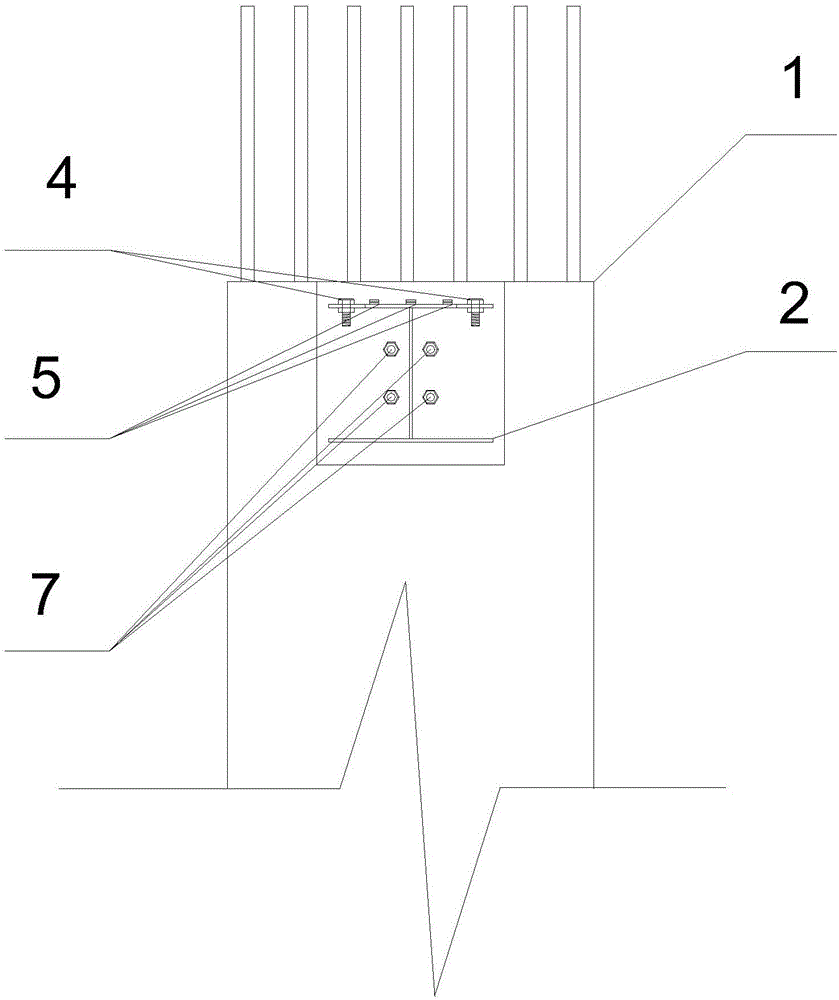

InactiveCN106759880AAvoid repeated setupAvoid duplication of effortBuilding constructionsCorbelLaminated beam

The invention provides a quick positioning adjusting tool and method for a connection of a precast laminated beam and a precast column. According to the quick positioning adjusting tool and method for the connection of the precast laminated beam and the precast column, an original system of installing a temporary support frame under the precast laminated beam is changed to a tooling system of installing adjustable steel corbel on the precast column. The whole tooling system comprises devices such as the adjustable steel corbel, an elevation control shim and a limiting bolt, wherein the elevation control shim is used for adjusting the elevation of the precast laminated beam, the limiting bolt is used for adjusting a horizontal position of the precast laminated bean. The quick positioning adjusting tool and method can accomplish quick temporary fixation, elevation and verticality adjusting functions of the precast laminated beam, achieve quick positioning of precast components, improve efficiency and quality of prefabricated building construction, avoid repeated erection and pulling down of support frames, improve the industrialization degree of construction sites, reduce the labor and shorten the construction period.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

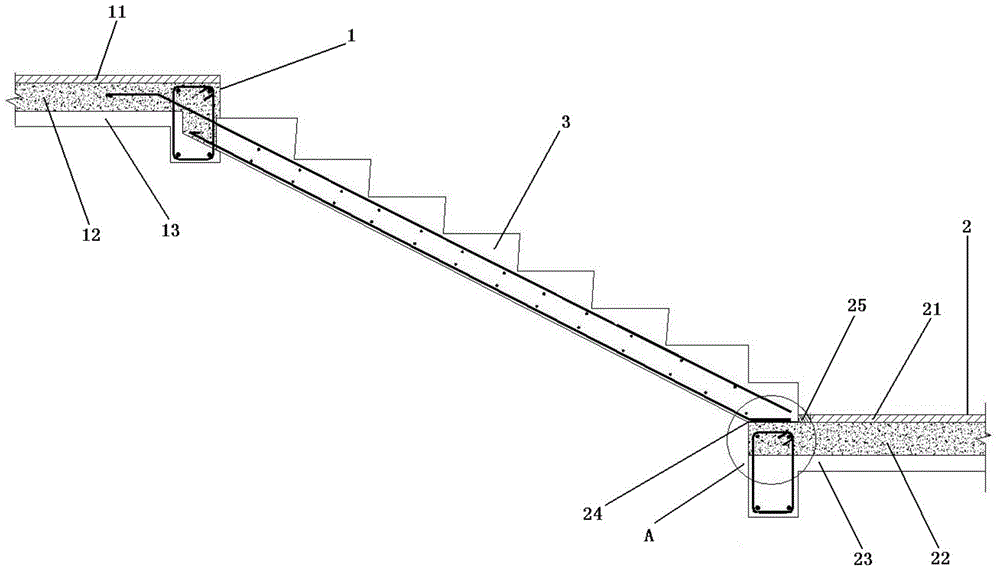

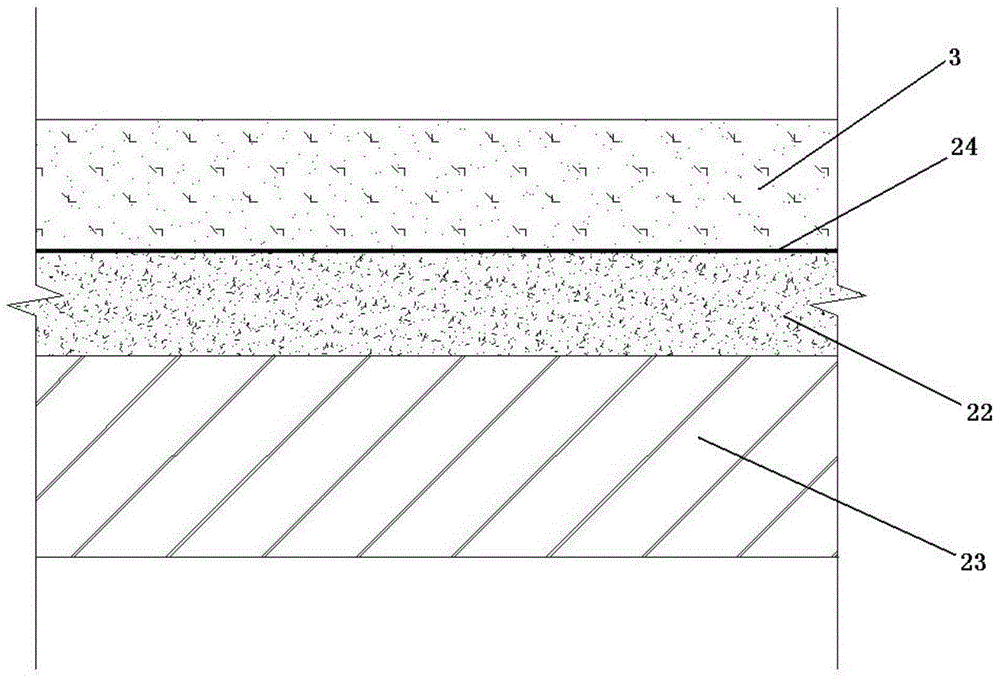

Full precast concrete stair sliding connecting system and construction method thereof

InactiveCN104481090AImprove corrosion resistanceGood weather resistanceStairwaysShock proofingSurface layerLap joint

The invention discloses a full precast concrete stair sliding connecting system. The full precast concrete stair sliding connecting system comprises an upper-layer laminated beam plate, a lower-layer laminated beam plate and a precast stair, wherein the upper-layer laminated beam plate and the lower-layer laminated beam plate serve as rest platforms, and the precast stair serves as steps. The upper-layer laminated beam plate comprises an upper-layer building surface layer, an upper-layer beam plate cast-in-situ layer and an upper-layer beam plate precast layer from top to bottom; the lower-layer laminated beam plate comprises a lower-layer building surface layer, a lower-layer beam plate cast-in-situ layer and a lower-layer beam plate precast layer from top to bottom; the top side end of the precast stair is connected with the upper-layer beam plate precast layer, and is in lap joint with rebars in the upper-layer beam plate cast-in-situ layer; the bottom surface end of the precast stair is placed on a teflon plate which is placed at a placement position on the top surface of the lower-layer beam plate cast-in-situ layer; the space between the bottom side end of the precast stair and the lower-layer building surface layer is filled with a polystyrene plate. Due to the fact that the mode of connection between the stair and a main body structure is changed, the lower section of the stair is completely separated from the overall structure, the mode that one end is hinged, and the other end is stressed in a sliding mode is formed, the rigidity of the stair is effectively reduced, distribution of shearing force of the stair is reduced, and seismic performance is improved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

Overlap beams downstriker movable mould frame bridging machine

InactiveCN101509230BReduce weightImprove carrying capacityBridge erection/assemblyBuilding material handlingStructural engineeringLaminated beam

The invention relates to a bridging device, in particular to a laminated beam descending type movable mold base bridge fabrication machine which belongs to the engineering plant. The bridge fabrication machine essentially consists of a main beam, a guiding beam, a comb shape crossbeam, a pier side bracket, a trolley, a counter weight dolly, a hydraulic system template system, etc. The guiding beam is arranged above the trolley. A hydraulic oil cylinder is arranged between the trolley and the guiding beam. The main beam is arranged in the guiding beam. A combination surface of the guiding beamand the main beam is provided with air cushions which are arranged uniformly. The movable mold base bridge fabrication machine changes the upper structure of the prior bridge fabrication machine and ensures that guiding beam and a bearing main beam form movable laminated beams, and the comb shape crossbeam can move independently when opening a mold, thereby increasing the function of the bridge fabrication machine, improving the safety, the reliability and the working efficiency of the equipment and reducing the weight and the cost of the equipment.

Owner:浙江众磊起重设备制造有限公司

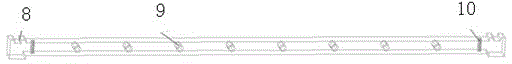

Supporting structure of the end of laminated plate at laminated beam position and high-altitude concrete pouring method

PendingCN107939041AImprove stabilityWill not cause accumulationForms/shuttering/falseworksBuilding material handlingEngineeringLaminated beam

The invention discloses a supporting structure of the end of a laminated plate at the laminated beam position and a high-altitude concrete pouring method. The supporting structure comprises a supporting frame, a detachable-type fixing device used for fixing the supporting frame to a beam, a bolt arranged on the supporting frame and a flat plate sleeve connected to the upper end of the bolt in a sleeving mode and used for supporting the end of the laminated plate. The supporting structure adopts a structure of the bolt and the flat plate sleeve to achieve supporting of the laminated plate, accumulating of concrete between the bolt, the supporting frame and the beam cannot be caused, and stability of supporting of the laminated plate can be improved; and the situation that the concrete flowsinto gaps between the beam and the supporting frame, between the fixing device and the beam as well as between the fixing device and the supporting frame and is solidified can be avoided, disassembling of the whole supporting structure is easy, and installation requirements of the supporting frame are reduced.

Owner:中建科技成都有限公司

Partially laminated beam bridge

InactiveCN110258300AEliminate load effectsImprove deformation resistanceBridge structural detailsBridge materialsPre stressWhole body

The invention discloses a partially laminated beam bridge which is mainly formed by a bridge abutment (1), a pier (2) and a beam body. A pressure zone of the beam body located above the pier (2) is of a concrete structure (3); the other part of the beam body is of a steel structure (4); a rabbet is arranged above the concrete structure (3); an embedded part and a shear connector are welded around the combination part of the concrete structure (3) and the steel structure (4); and in the later period, after the steel structure (4) is placed in place, the steel structure (4) and the embedded part are welded together, and micro-expansion concrete is poured to form a whole body. According to the partially laminated beam bridge provided by the invention, the excellent characteristics of tensile strength and concrete compressive strength of steel can be fully played, so that the material utilization rate is maximized; compared with a prestressed concrete continuous beam bridge, the partially laminated beam bridge is light in weight, so that a spanning capability of the bridge can be remarkably improved; and compared with a full-steel bridge, the partially laminated beam bridge is large in rigidity, less in steel consumption and low in cost.

Owner:广西鸿鹄结构工程技术信息咨询有限公司

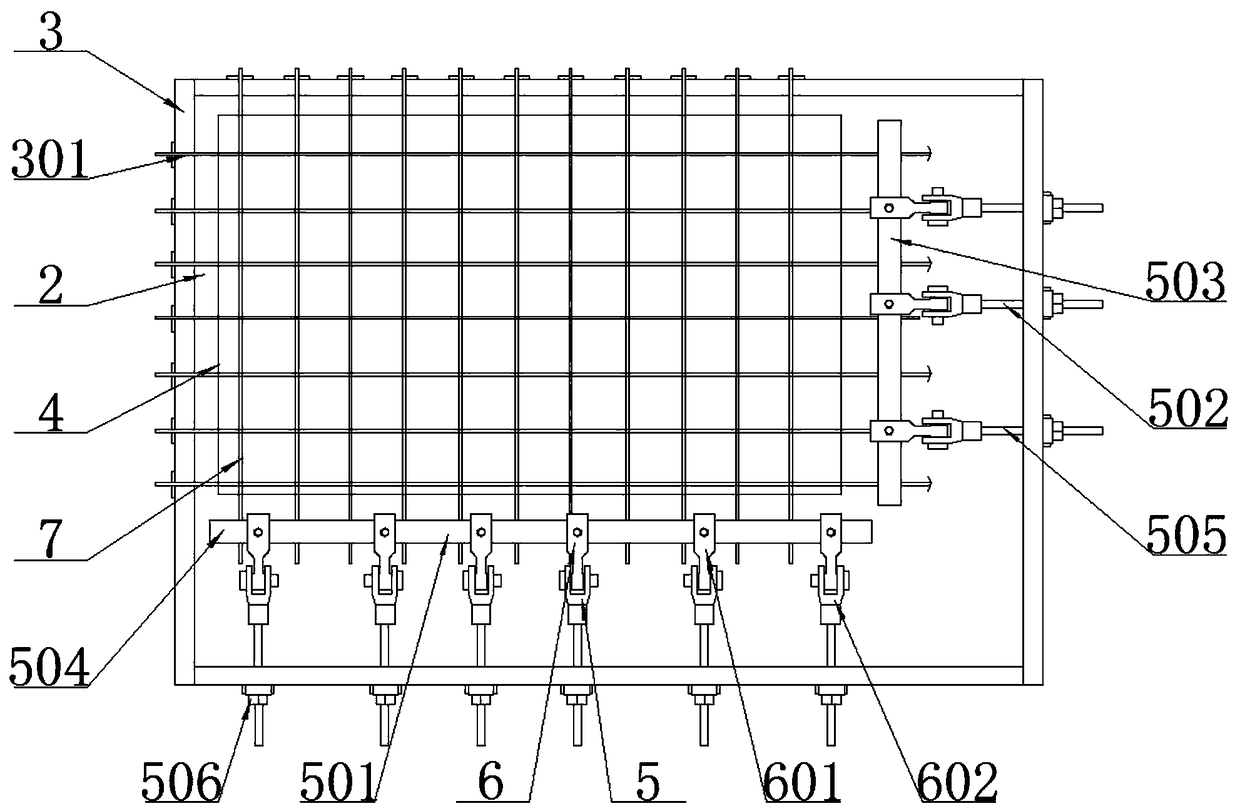

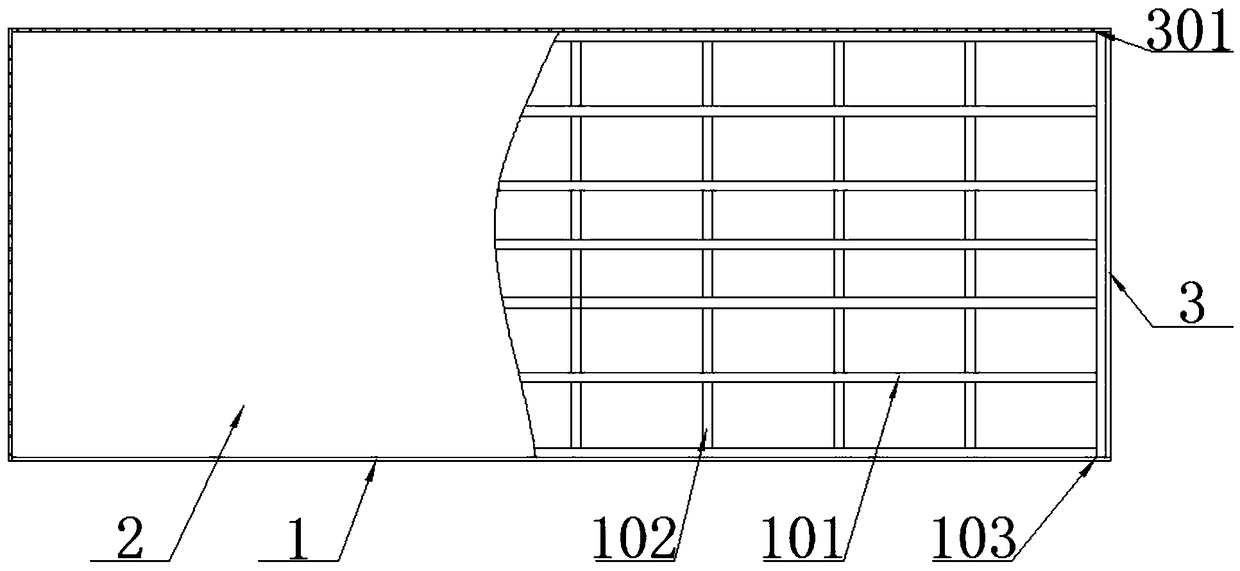

Bidirectional pre-tensioning-method prestressing complete device and production method using the same

InactiveCN109203226APrevent buildupOvercome shortcomingsCeramic shaping apparatusPre stressSteel frame

The invention relates to a bidirectional pre-tensioning-method prestressing complete device and a production method using the same. The bidirectional pre-tensioning-method prestressing complete devicecomprises a steel frame, a horizontal workbench arranged on the steel frame, and vertical tension plates welded to all sides of the steel frame; and open slots are formed in the left tension plate and the rear tension plate. In addition, the complete device includes a frame die; and two horizontal and longitudinal stretching mechanisms are arranged at the inner sides of the tension plates outsidethe frame die. Because of the steel frame, the prestressing requirement is met by the strength of the steel frame structure, so that a problem that the traditional concrete platform can only bear thepressure in a single direction but can not bear the pressure of the other vertical direction is solved. Meanwhile, a phenomenon that the traditional concrete platform is limited by the geomorphic feature of the construction site is avoided; and building of a large underground concrete pier is avoided. During the recovery process of the bidirectional steel strands or steel bars, the solidified concrete is compressed and thus the crack-resistant, bending stiffness, compressive strength and anti-seismic performances of the laminated beams or laminated plates are excellent. The bidirectional pre-tensioning-method prestressing complete device is suitable for the high load field.

Owner:江苏华江祥瑞现代建筑发展有限公司

Connection method for prefabricated shear wall-laminated beams in assembled type RC frame-shear structure

InactiveCN106869331AEasy constructionFirmly connectedBuilding constructionsShear forceLaminated beam

The invention discloses a connection method for prefabricated shear wall-laminated beams in an assembled type RC frame-shear structure. During formal assembling, the shear wall is first assembled for supporting, column nodes of the shear wall are assembled, a wall beam is arranged on the shear wall, longitudinal reinforcements are arranged above the shear wall, and a full grouting sleeve and beam stirrups are arranged on the longitudinal reinforcements at the nodes of the shear wall after the supporting is completed; then, laminated beams provided with upper longitudinal reinforcements are hoisted, the laminated beams are leveled and supported, and the preset full grouting sleeve is screwed, so that the connected longitudinal reinforcements are evenly distributed inside the full grouting sleeve; and after connection is completed, the stirrups are strapped, a rear pouring concrete is poured, and maintenance is carried out. According to the connection method for the prefabricated shear wall-laminated beams in the assembled type RC frame-shear structure, whole construction is simple and convenient, connection is firm, the anti-seismic performance is good, the construction cost is reduced, and the construction period is short.

Owner:成张佳宁

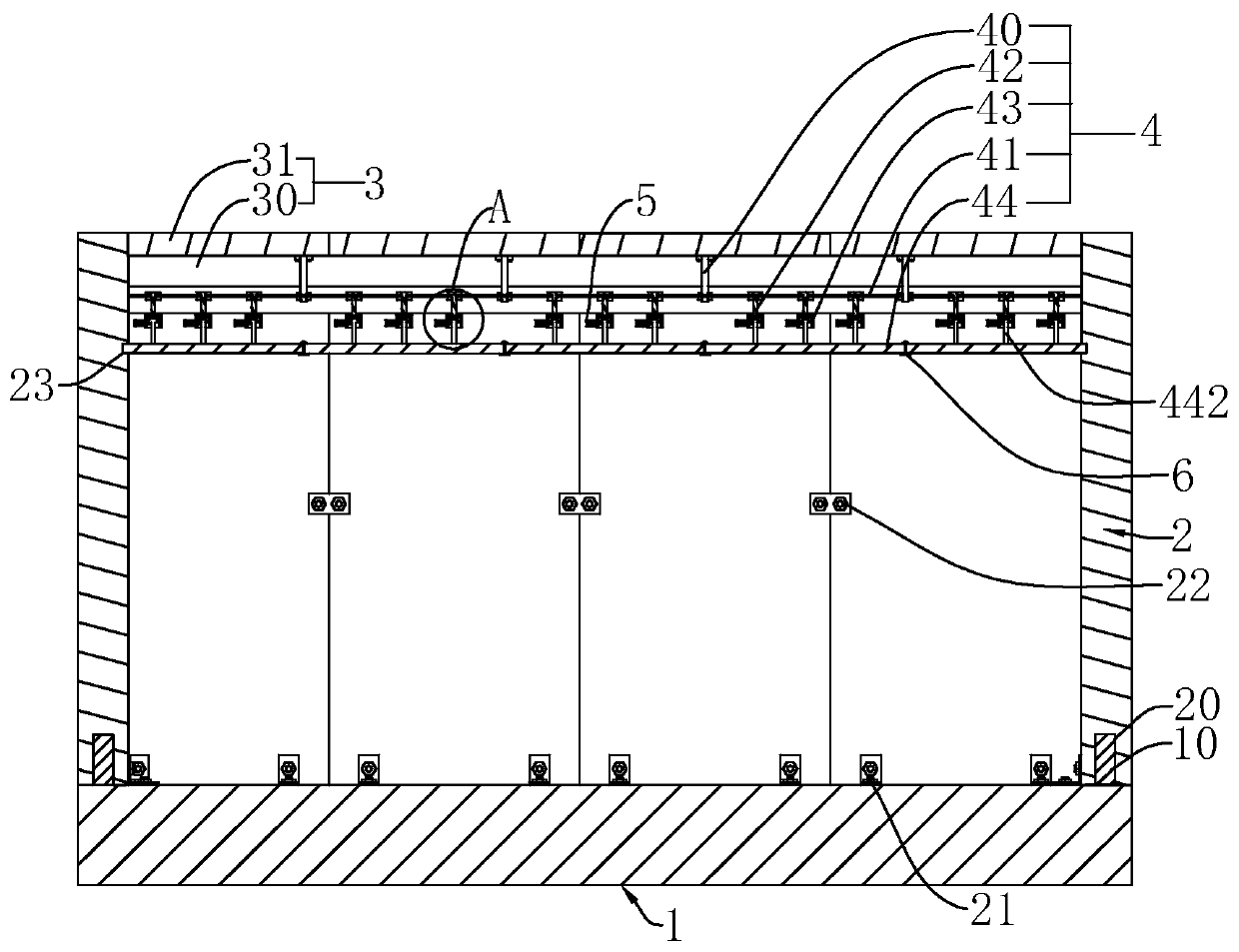

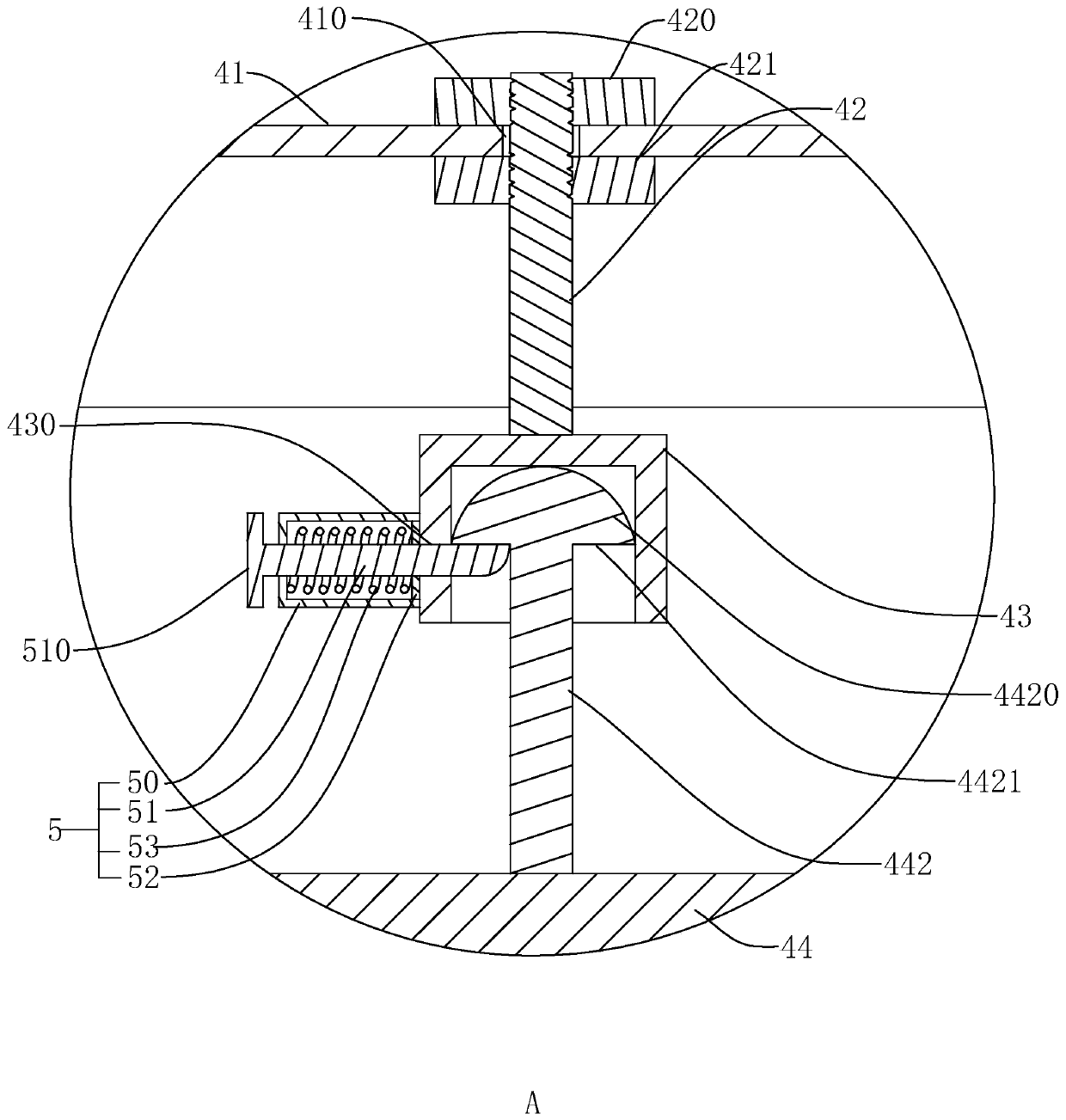

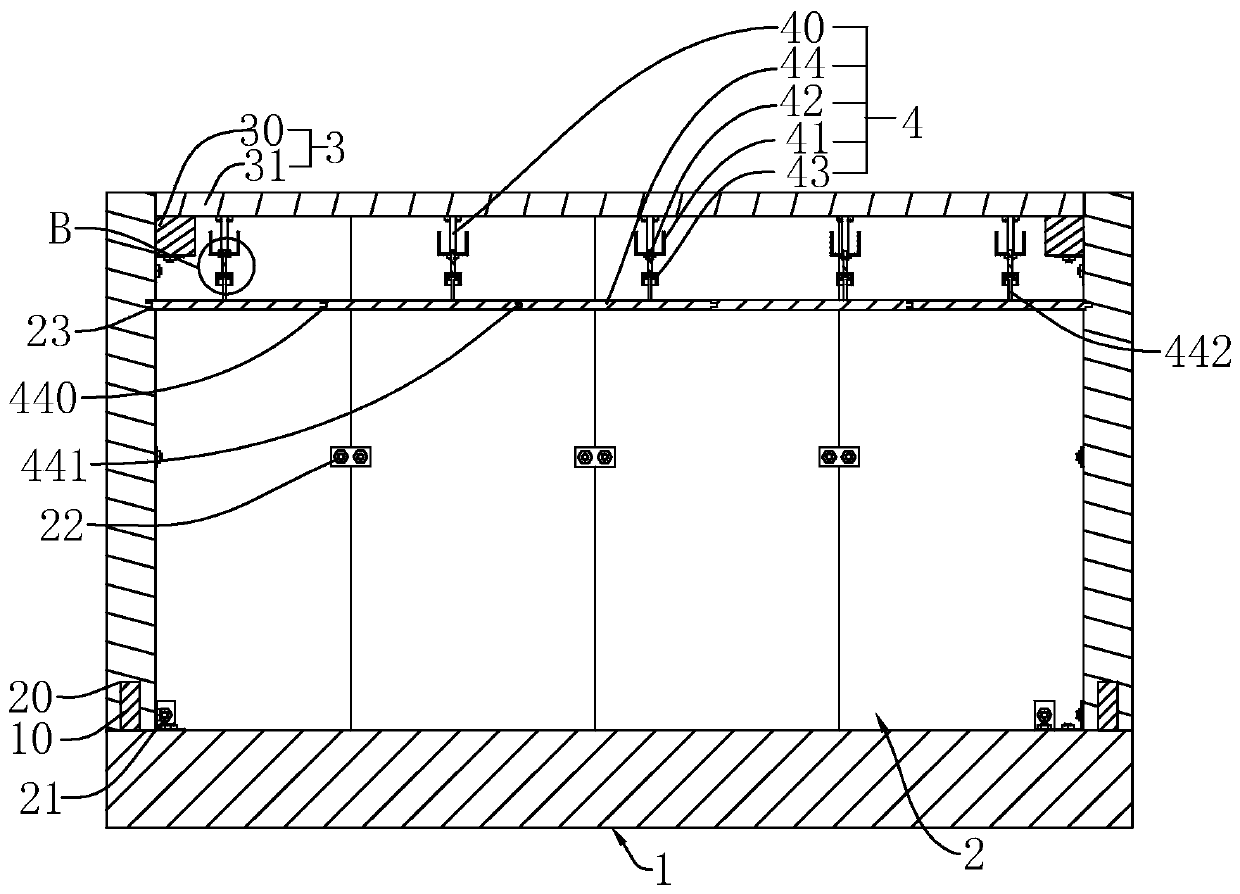

Modular assembled building

A modular assembled building comprises a base, prefabricated wallboards, a beam plate system and a suspended ceiling system; the prefabricated wallboards are installed on the base; the beam plate system comprises laminated beams and laminated floor slabs; the laminated beams are fixed above the prefabricated wallboards; the laminated floor slabs are arranged on the laminated beams; transverse embedding grooves are respectively formed in positions with the same height on a wall body formed by the prefabricated wallboards, and the embedding grooves on two adjacent wall bodies are communicated; the suspended ceiling system comprises suspended ceiling clapboards; the multiple suspended ceiling clapboards are fixedly connected with the laminated floor slabs, the suspended ceiling clapboards arespliced and arranged into a group in the extending direction of the embedding groove at one side, the multiple groups of suspended ceiling clapboards are spliced and arranged below the laminated floor slabs into a whole suspended ceiling plane, and the edges of the suspended ceiling plane is embedded in the embedding grooves; and the suspended ceiling clapboards are each of a plate-shaped structure, a clamping pin is arranged on one side of each suspended ceiling clapboard in a protruding mode, a slot is arranged on the opposite side of each suspended ceiling clapboard, each clamping pin is matched with the corresponding slot, and the clamping pins and the slots on two adjacent suspended ceiling clapboards on each group of the suspended ceiling clapboards are mutually embedded.

Owner:深圳机械院建筑设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com