Bidirectional pre-tensioning-method prestressing complete device and production method using the same

A complete set of device, the technology of pretensioning method, which is applied in the field of movable bidirectional pretensioning method prestressing complete set to produce laminated beams or laminated slabs, can solve the problem of high cost, high production cost and unbearable tolerance of large-diameter concrete piles. problems, to achieve the effect of overcoming the inability to withstand shearing force, easy handling, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

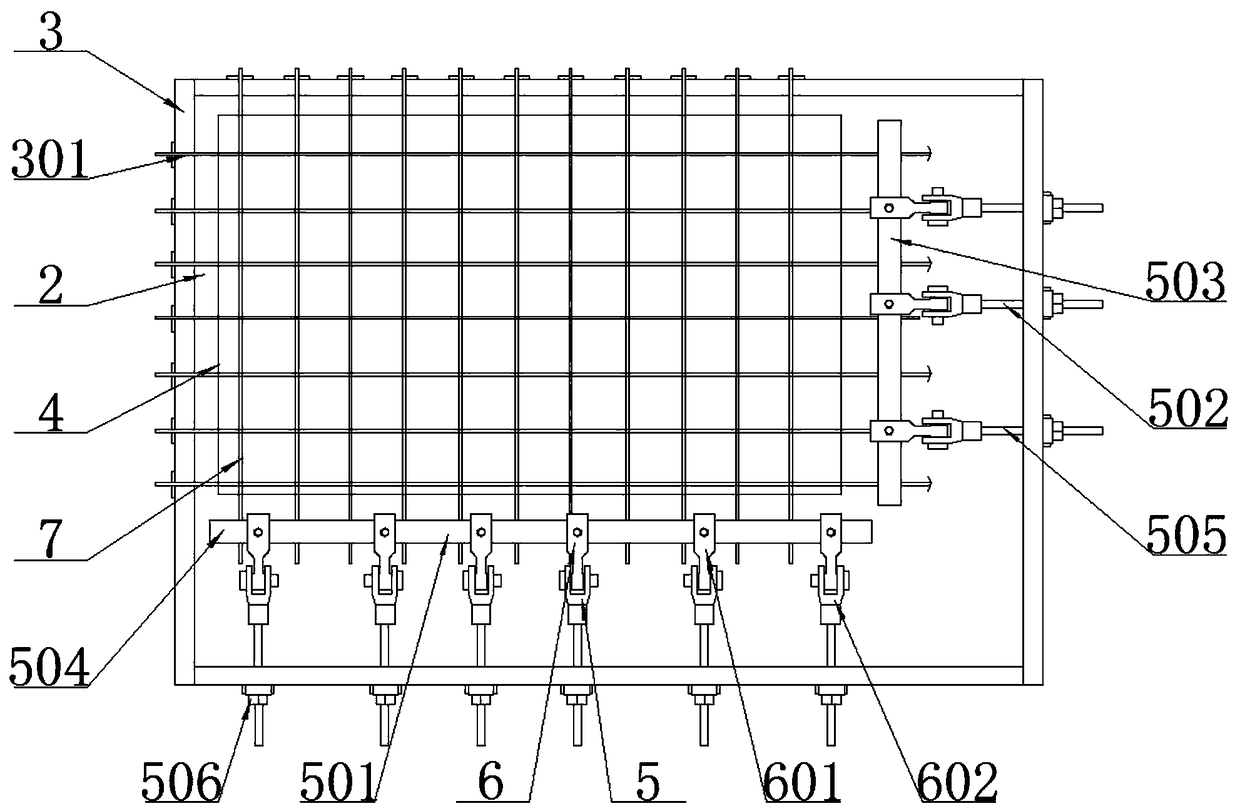

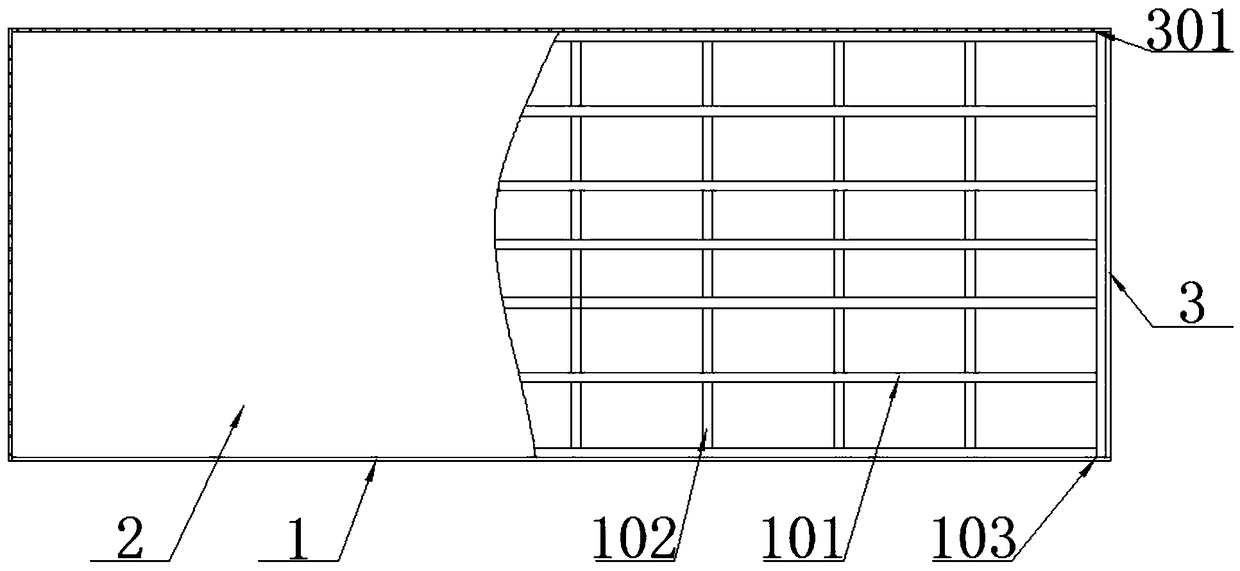

[0026] Such as Figure 1-2As described above, it is a movable two-way pretensioning prestressing complete set for producing laminated beams or laminated slabs, including a squirrel-cage steel frame 1 placed on a horizontal ground, and the steel frame 1 includes several steel structures The cross beam 101, several steel structure longitudinal beams 102 and several steel structure vertical beams 103 are cross-welded. All are welded with vertical tension plates 3, the upper edge of each tension plate 3 extends above the horizontal workbench 2, the upper end surface of the left tension plate 3 and the upper end surface of the rear side tension plate 3 are spaced apart with The opening groove 301 in the thickness direction of the pull plate 3, the cross section of the open groove 301 is a U-shaped hole, and the front side tension plate 3 and the right side tension plate 3 are provided with waist-shaped holes for the insertion of the long screw rod 505. The waist-shaped holes The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com