Patents

Literature

823results about How to "Avoid friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

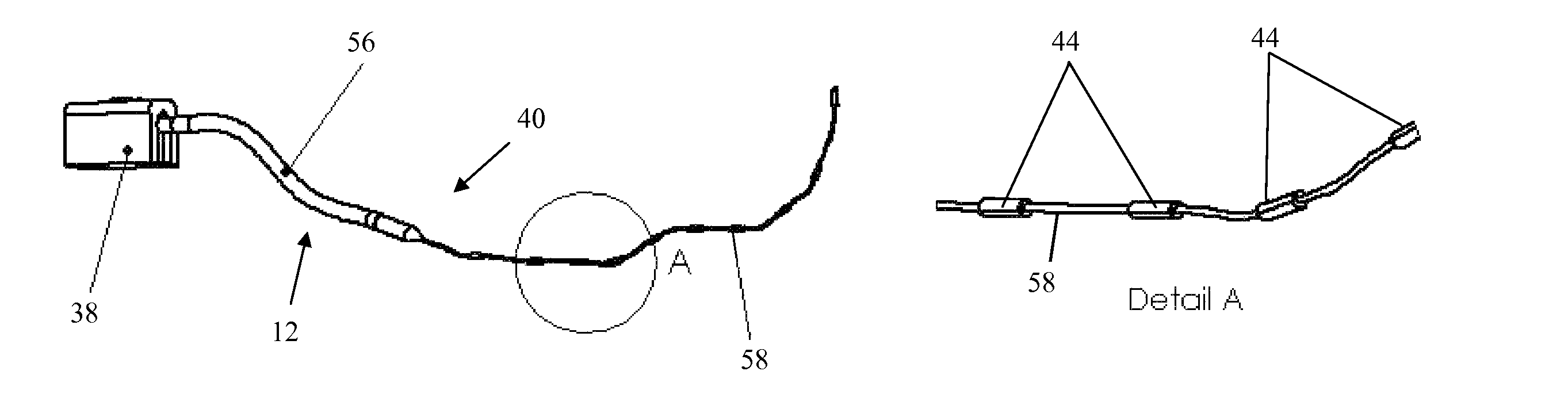

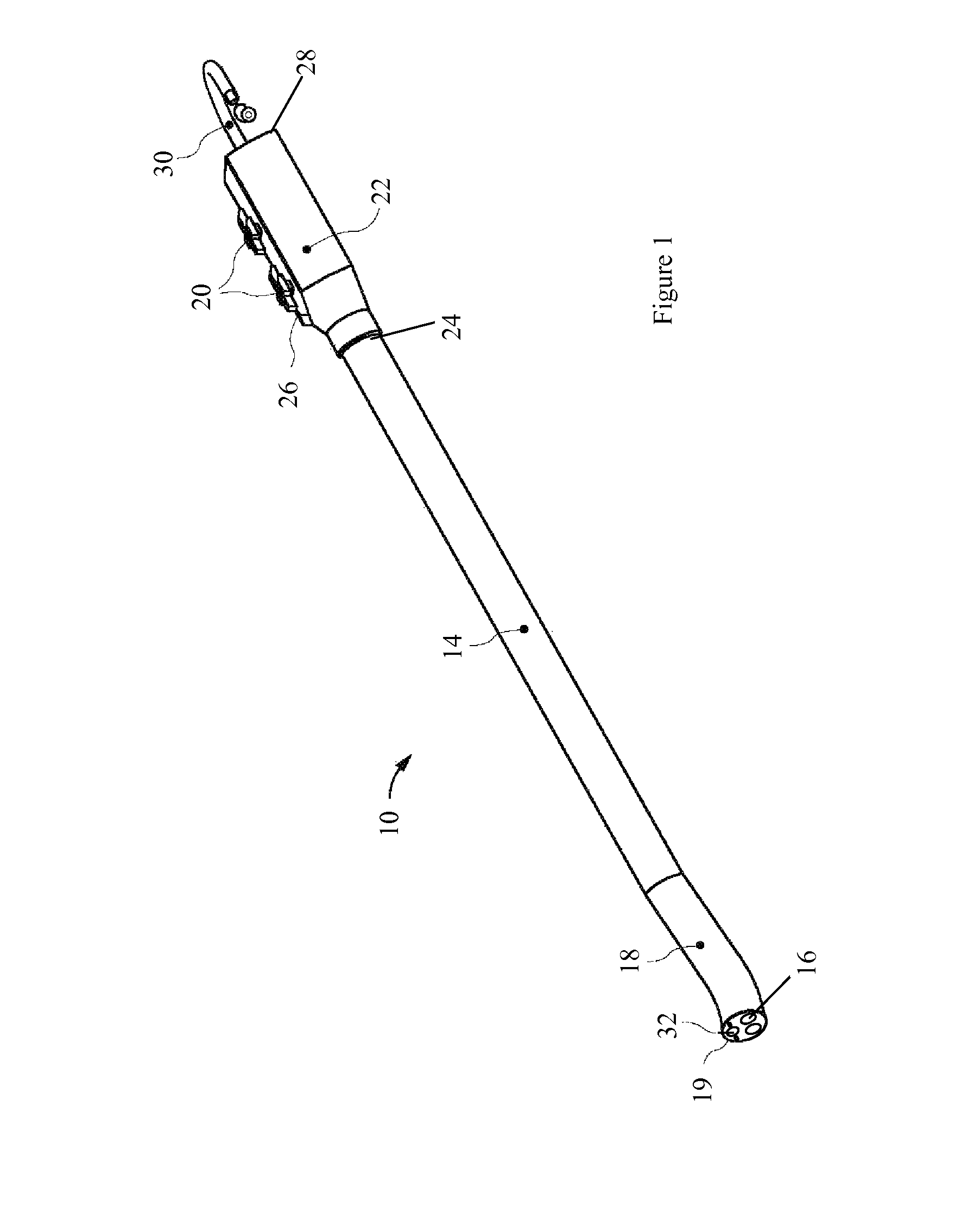

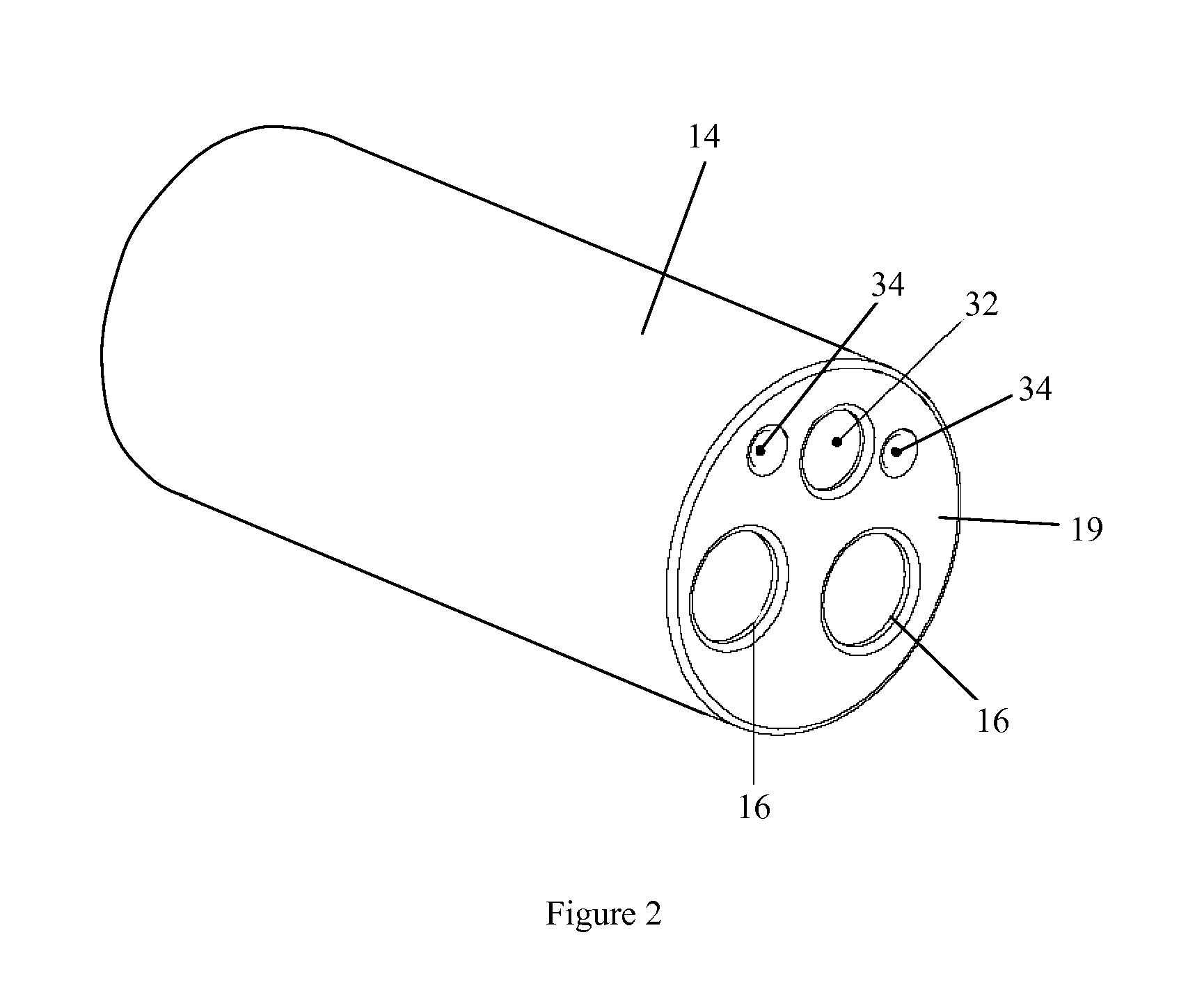

Vibratory device, endoscope having such a device, method for configuring an endoscope, and method of reducing looping of an endoscope

Owner:PSIP LLC

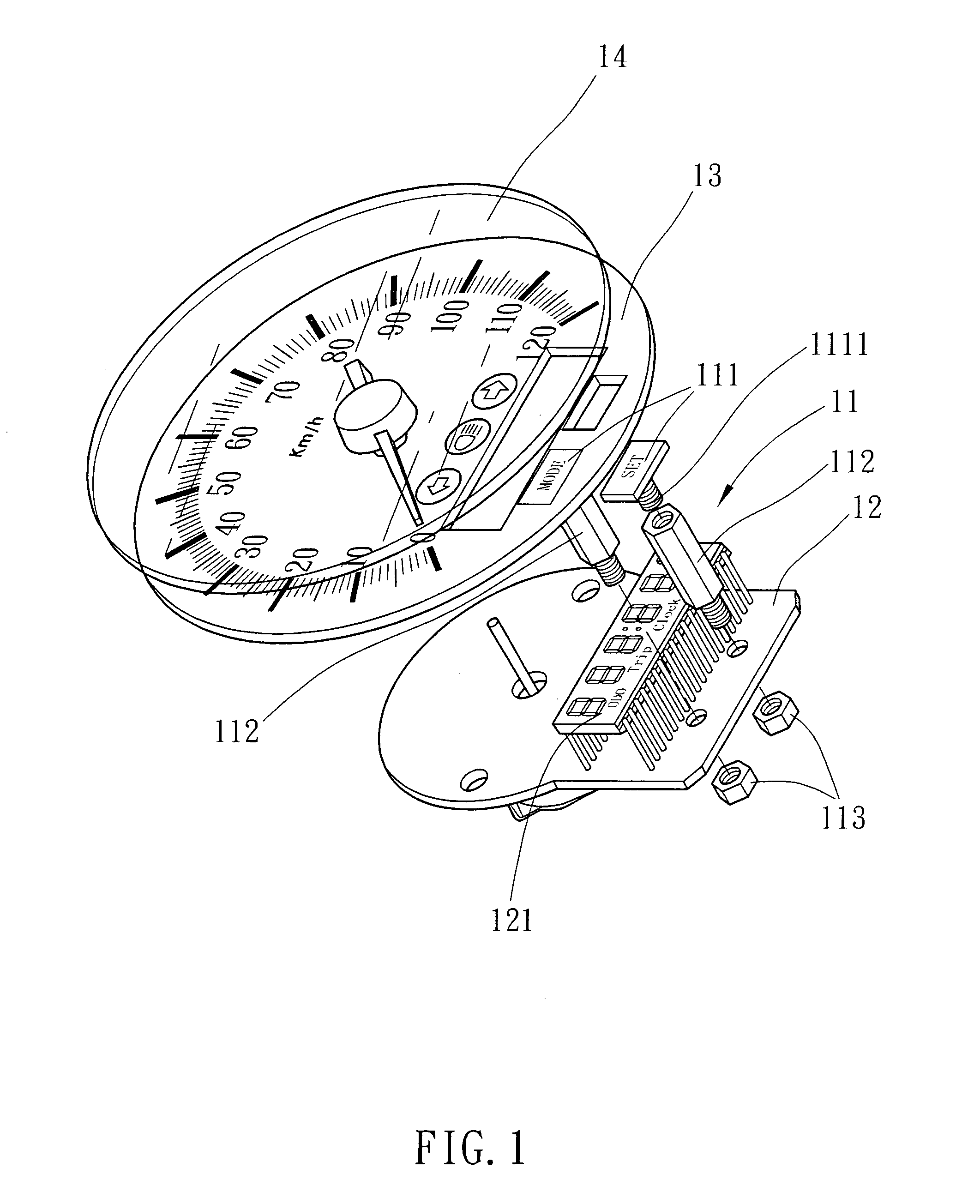

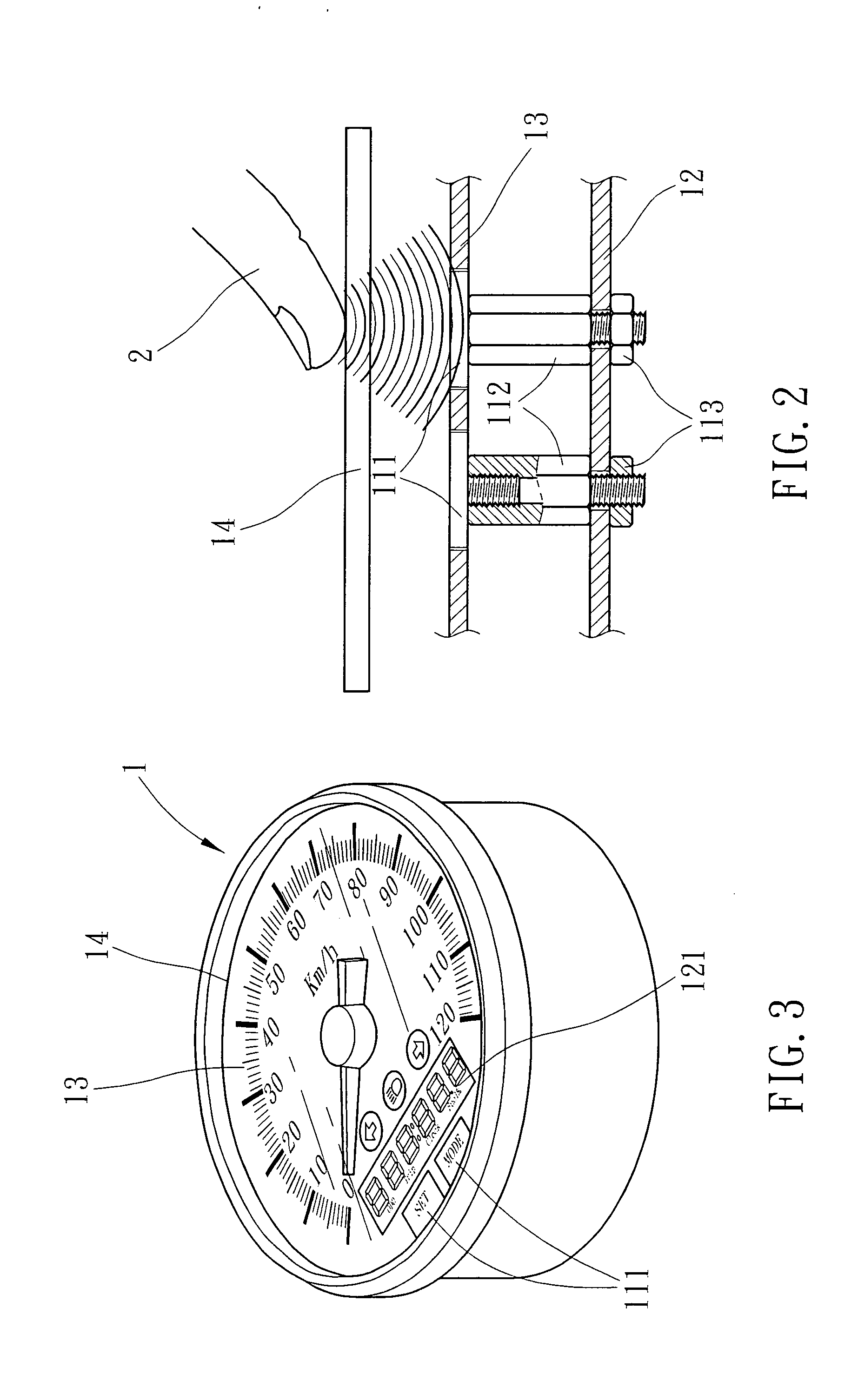

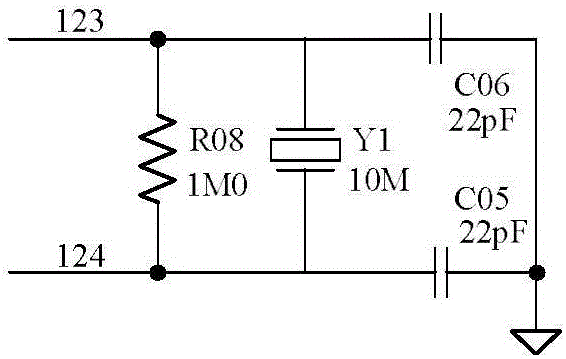

Proximity sensor switch-controlled meter and lamp switch system

InactiveUS20100001974A1Avoid frictionReduce frictionElectronic switchingOptical signallingControl electronicsCar driving

A proximity sensor switch-controlled meter and lamp switch system installed in a motor vehicle that can be a motorcycle or car is disclosed to include a meter having a micro-controller unit (MCU) and an electronic display device, a lamp switch unit installed in one handlebar (or the motorcycle) or steering wheel (of the car), and proximity sensor switches respectively mounted in the meter and the lamp switch unit for controlling the micro-controller unit (MCU) to control the display mode of an electronic display device of the meter or to switch on / off the headlamp or left / right turn signal light of the motor vehicle when the motorcycle rider or car driver touches the meter or the lamp switch unit with a finger.

Owner:SU KUO HSIN +1

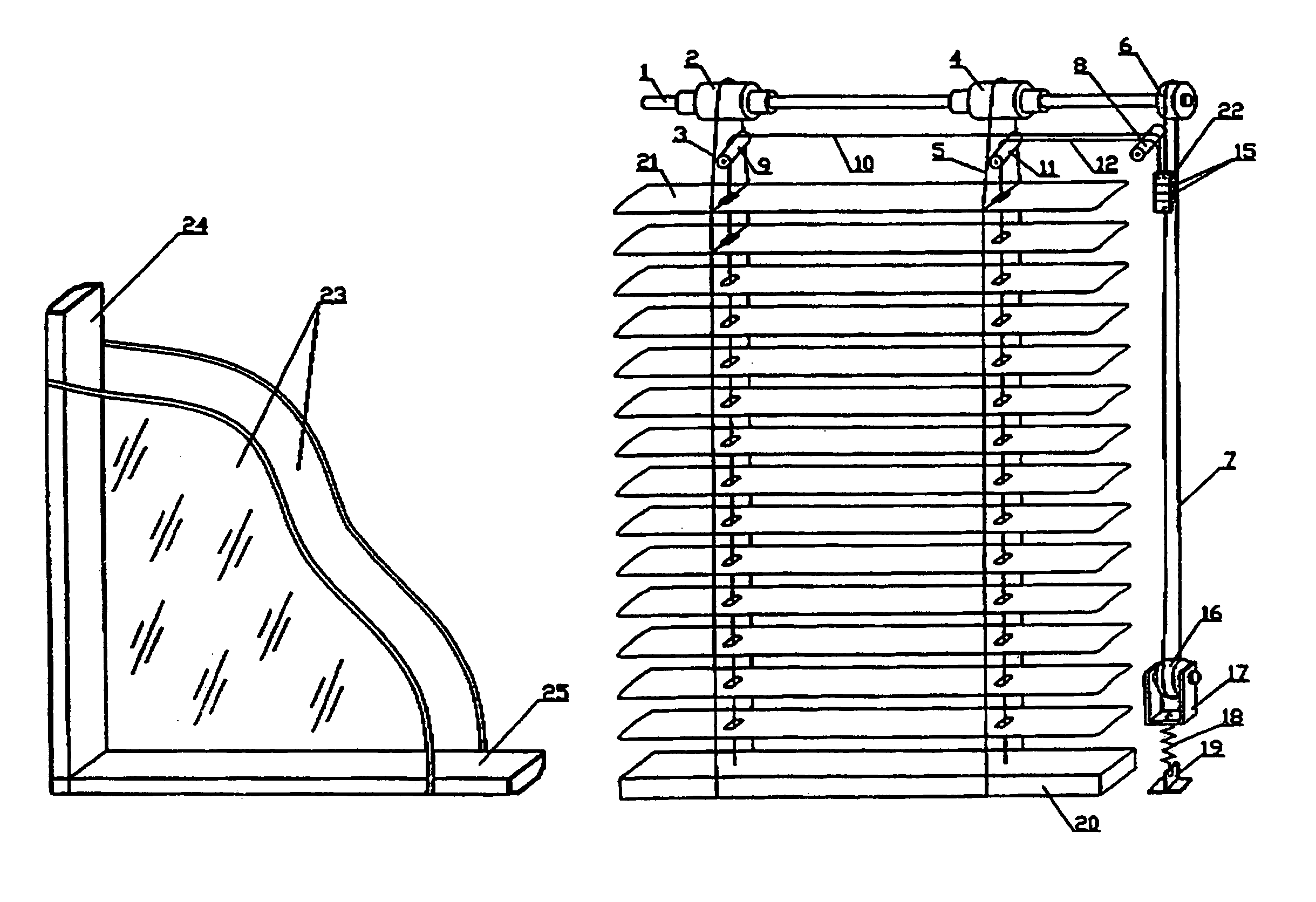

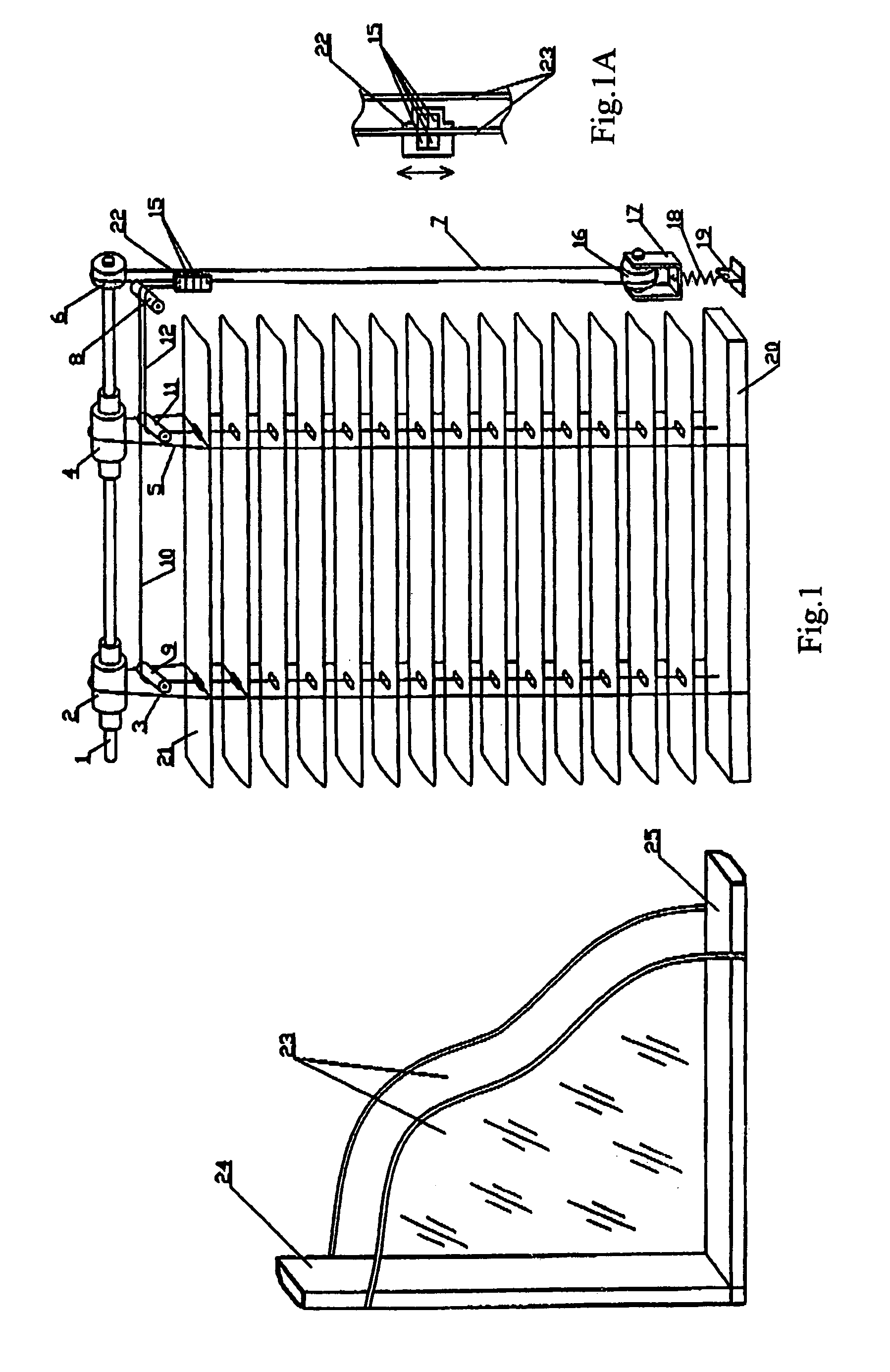

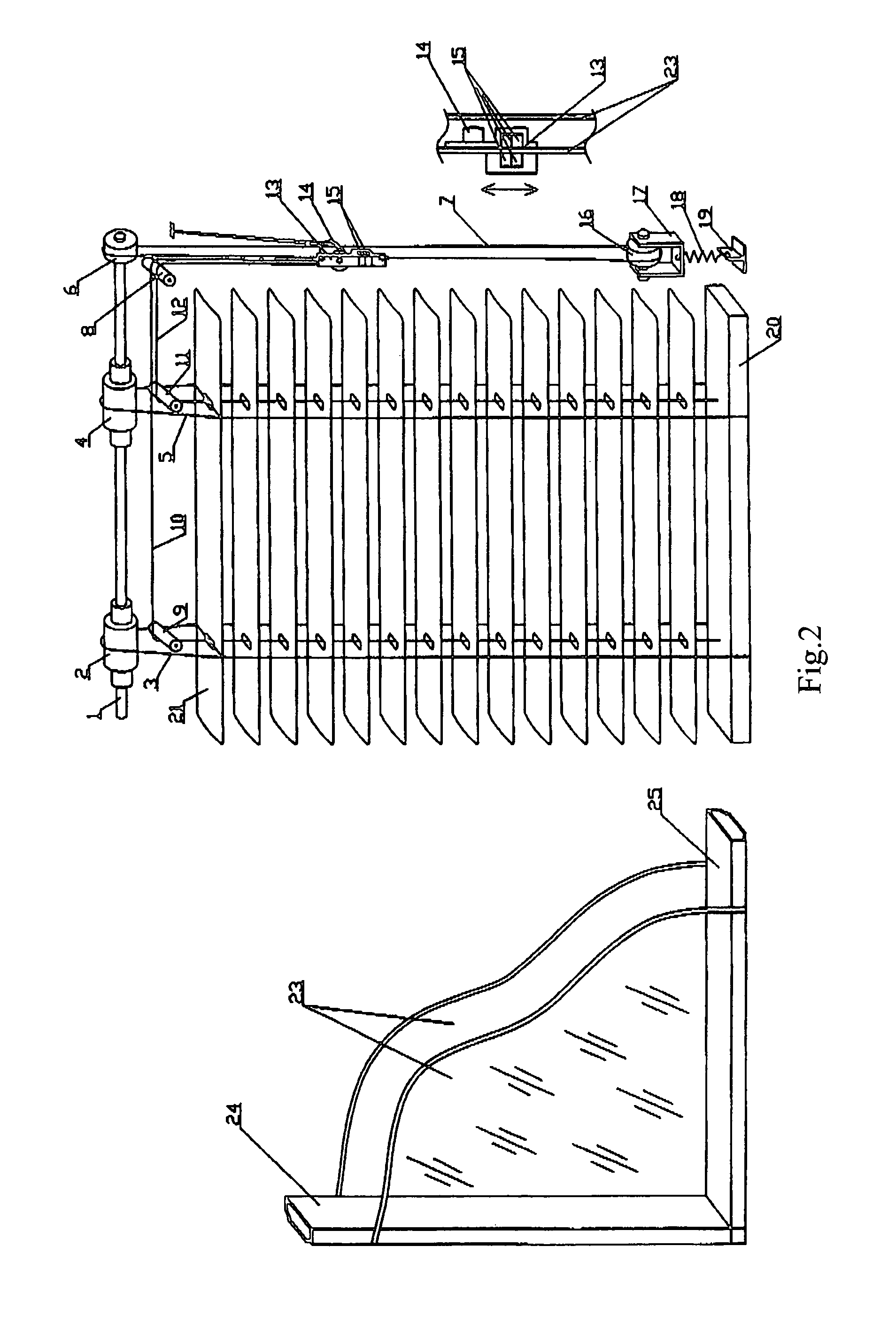

Venetian blind mounted in double glazing unit and a sliding block therefor

ActiveUS7124803B2Simple structureEasy to operateCurtain suspension devicesLight protection screensWindow shutterLong axis

A venetian blind provided in double glazing unit, which is mounted in a space defined by two sheets of glass, side frames, a top frame and a bottom frame, the venetian blind comprising a blind body composed of a counterweight, a long axis and a plurality of leaves, a driving unit, and two magnets, one of which being fixed to said sliding block and the other one being located outside the double glazing unit. The venetian blind could be lifted and deflect by the linear movement or rotation of the two magnets, one of which is inside the double glazing unit and the other one is outside the double glazing unit in the case that the double glazing unit is completely sealed. The venetian blind of the present invention is simple in structure and convenient for operating.

Owner:CHANGSHU HIGH TECH CONSTR ENERGY SAVING TECH +1

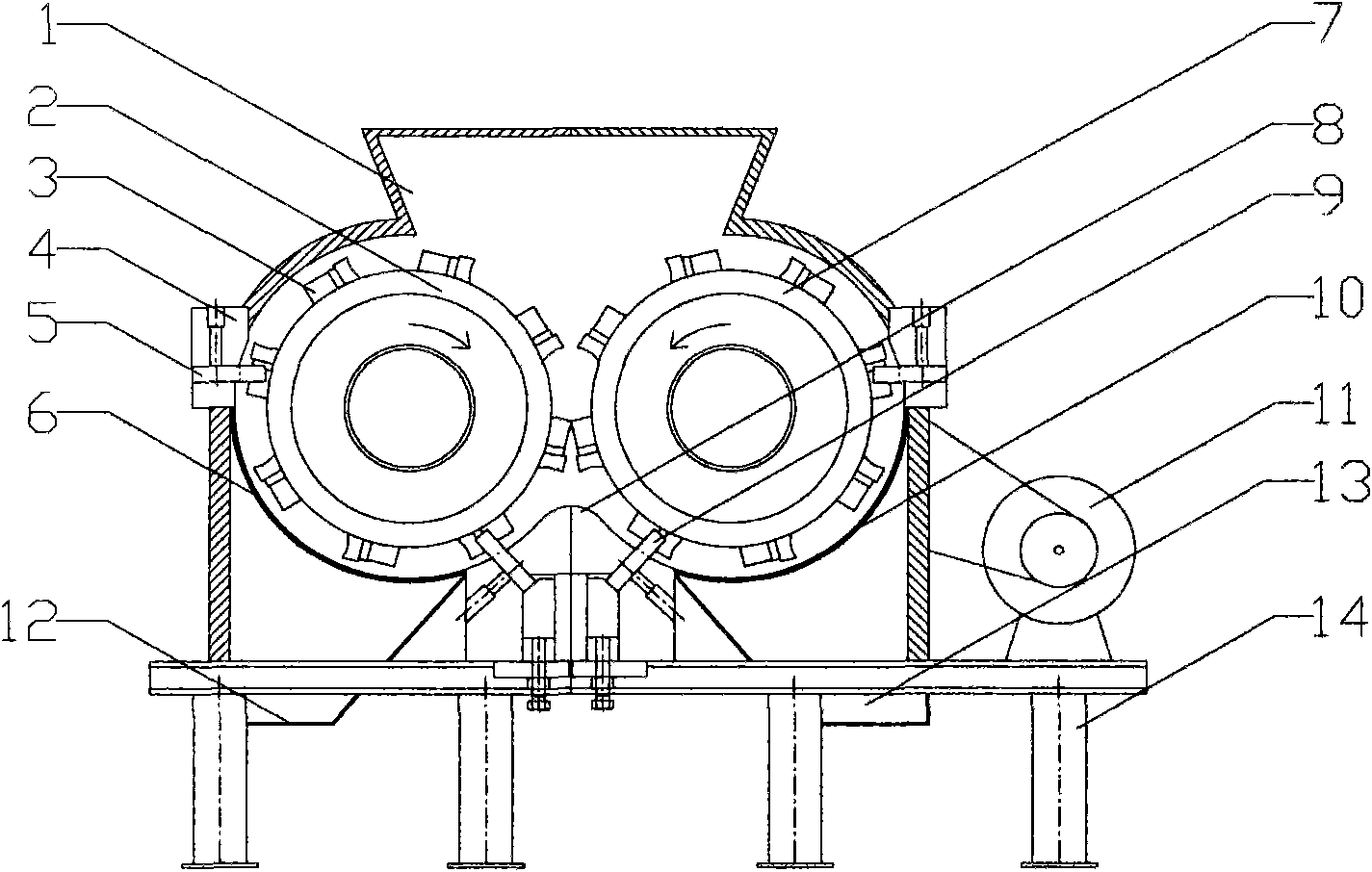

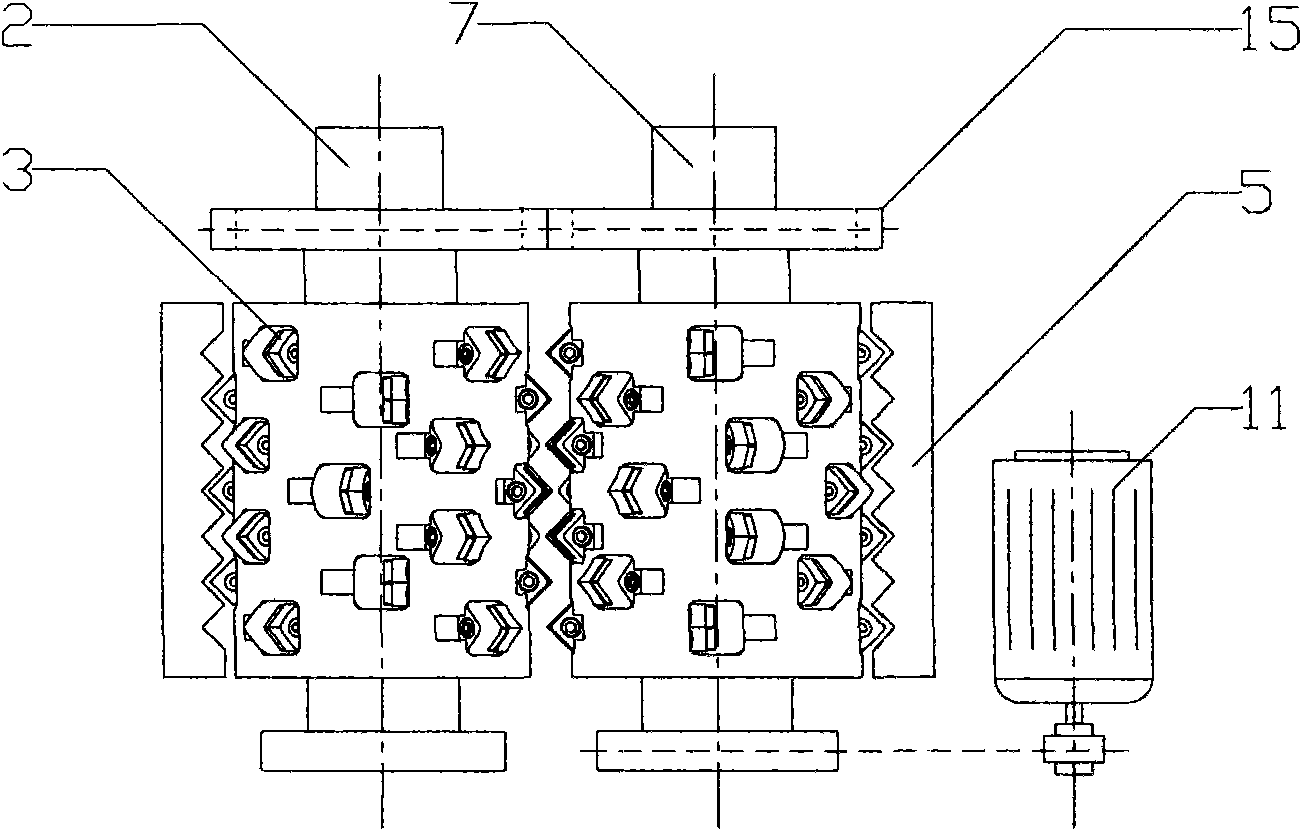

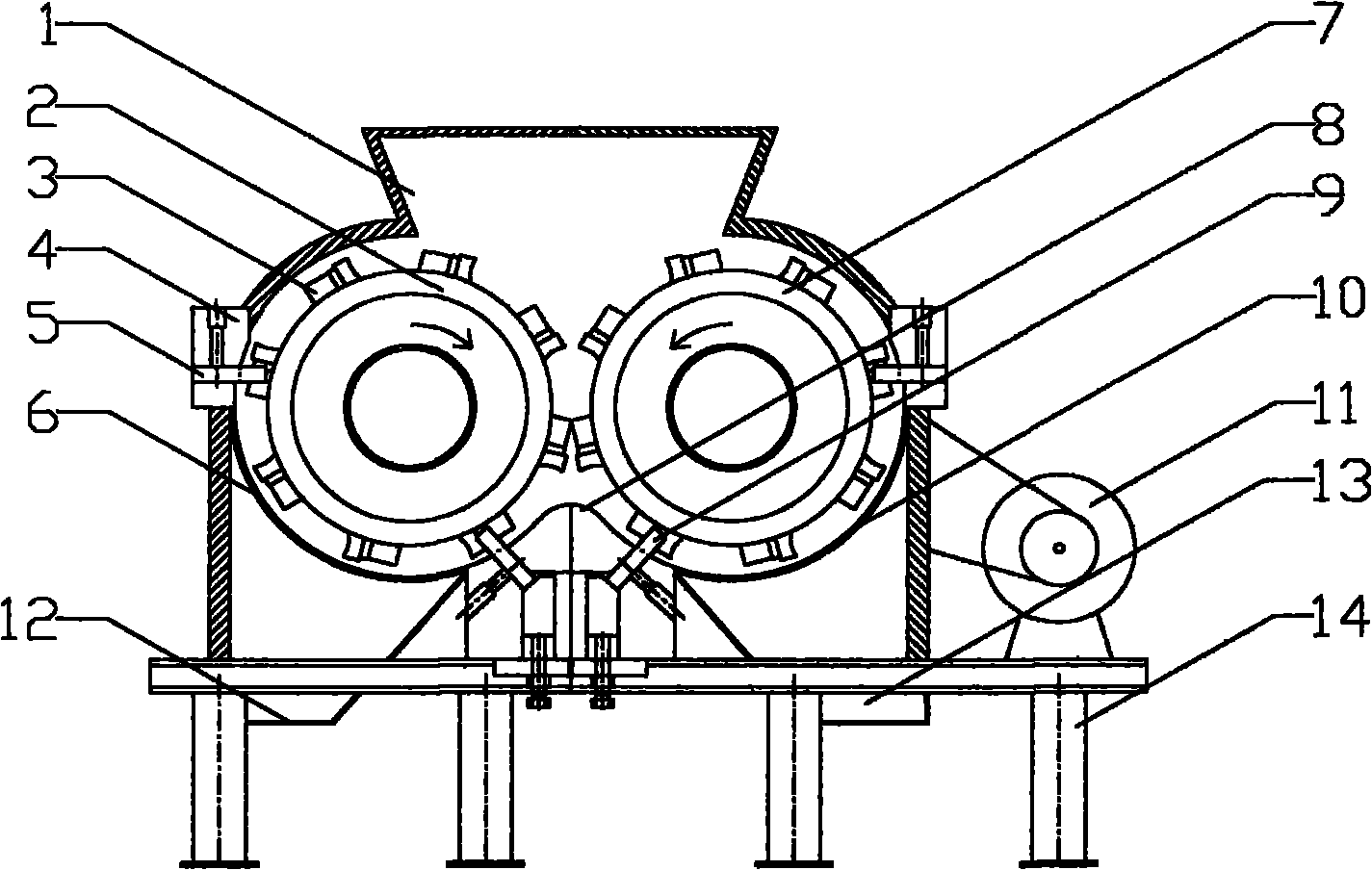

High-efficiency combined type domestic garbage crusher

The invention relates to a high-efficiency combined type domestic garbage crusher, which belongs to the technical field of domestic garbage crushing and comprises a feed hole, a crushing system, a discharge system and a transmission system, wherein the crushing system comprises dual knife rolls, a moving knife group, a static knife group and a knife adjusting device; the discharge system comprises a left screen, a right screen and two discharge holes; and the transmission system comprises a motor and a synchronous gear group, and the synchronous gear group ensures the synchronous running of the dual knife rolls. The left knife roll and the right knife roll are arranged side by side in parallel, a certain gap is reserved between the two knife rolls, and the two knife rolls are connected by the synchronous gear group and run in opposite directions; and the knife rolls are provided with rotating moving knives, the bottoms of the knife rolls are provided with bottom blocks, the bottom blocks are provided with bottom static knives, and simultaneously a frame is provided with a side static knife. Firstly, domestic garbage is crushed in the gap between the two knife rolls, is crushed at the position of the bottom knives after being compressed, then passes through the left screen and the right screen and is respectively discharged from the left discharge hole and the right discharge hole; and the side static knife can crush the garbage with bigger size again. The invention has the advantages of large treatment capacity, high crushing efficiency and low energy consumption.

Owner:SHOUGANG CORPORATION

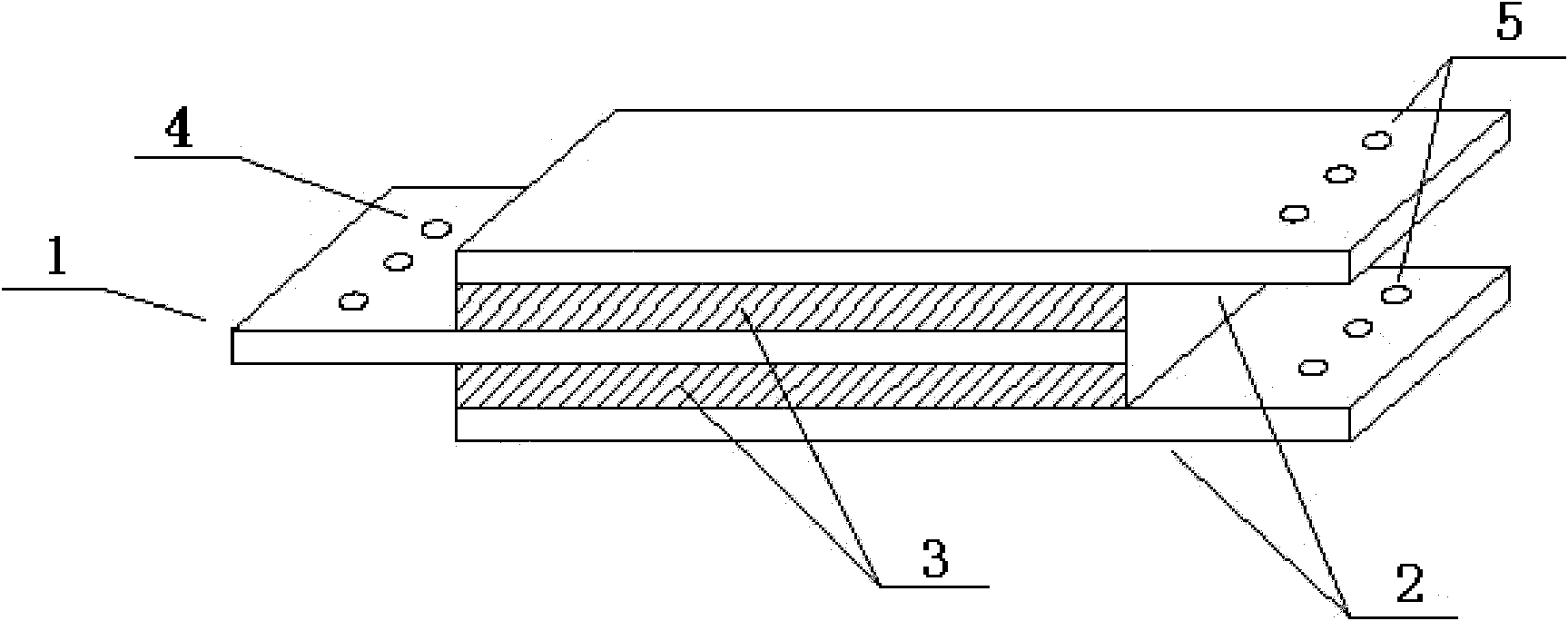

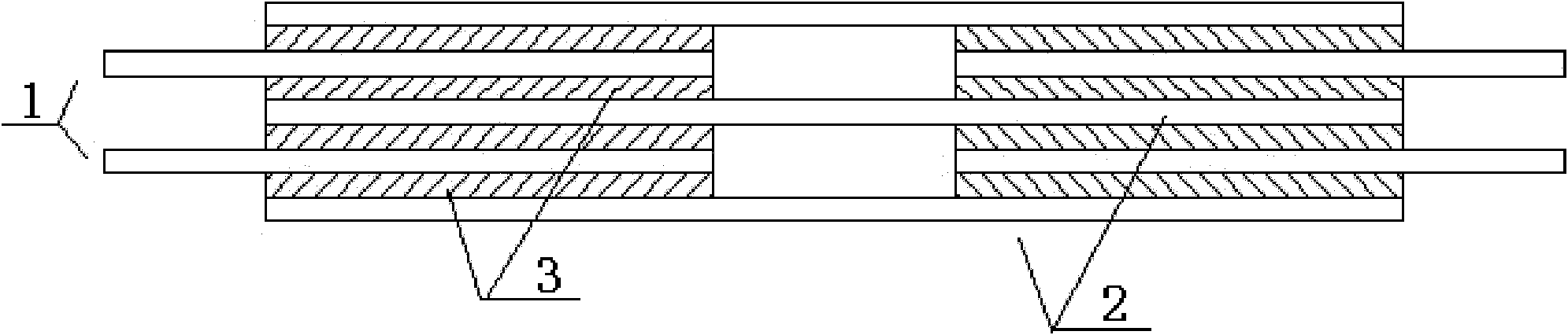

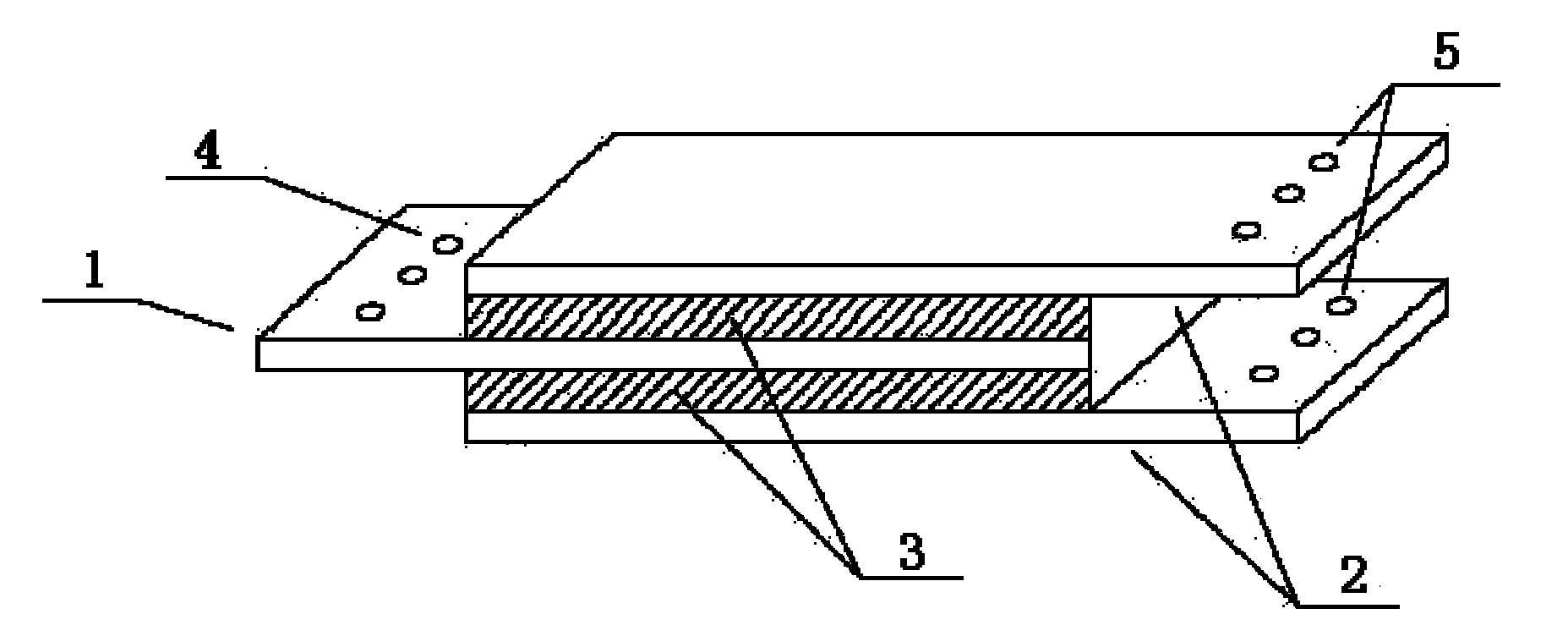

High-damping rubber fluid viscoelastic damper and manufacturing method thereof

ActiveCN102182256AReduce wind vibrationReduced responseBridge structural detailsBridge erection/assemblyHysteresisViscoelastic damping

The invention relates to the technical field of civil engineering, in particular to a damper and a manufacturing method thereof. A high-damping rubber fluid viscoelastic damper comprises a steel plate layer and a fluid viscoelastic material layer, wherein the steel plate layer comprises a middle steel plate and side steel plates arranged at two sides of the middle steel plate, the fluid viscoelastic material layer is arranged between the steel plate layer and the side steel plates, and the fluid viscoelastic material layer is the high-damping rubber fluid viscoelastic material layer made of high-damping rubber fluid viscoelastic material. Due to the adoption of the technical scheme, the invention has the following advantages: the vibration energy can be absorbed effectively by the deformation of the high-damping rubber fluid viscoelastic material, a hysteresis ring is full, and the fatigue resistance is good; and compared with the traditional fluid viscoelastic damper, the energy consumption property has stronger nonlinearity, and the energy consumption property is good under the condition of extremely small displacement and extremely low speed.

Owner:SHANGHAI EAGLE BRIDGE TECH

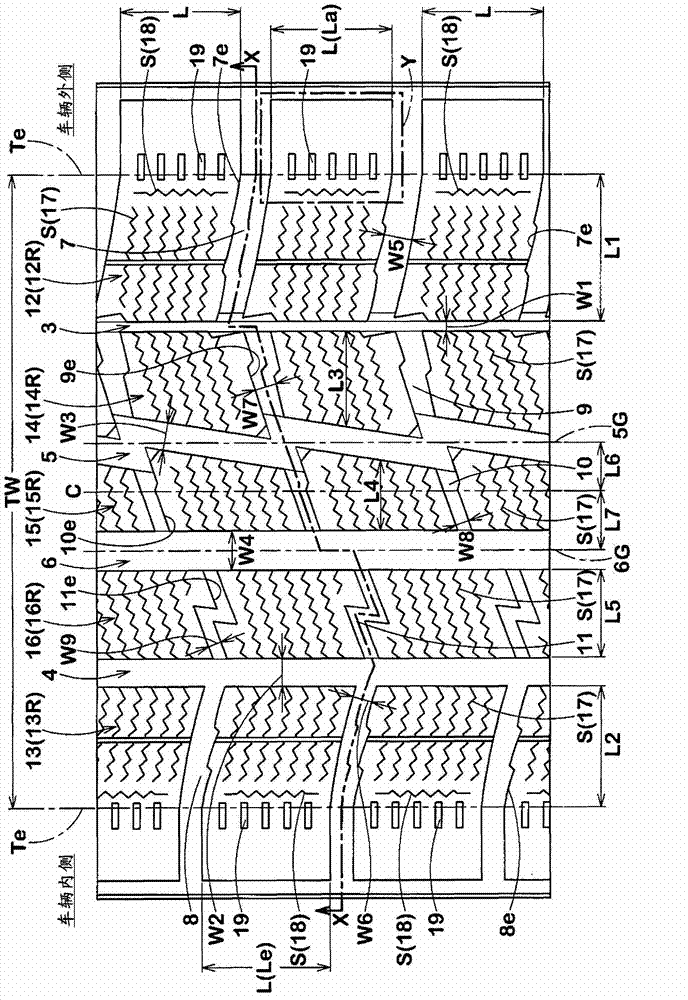

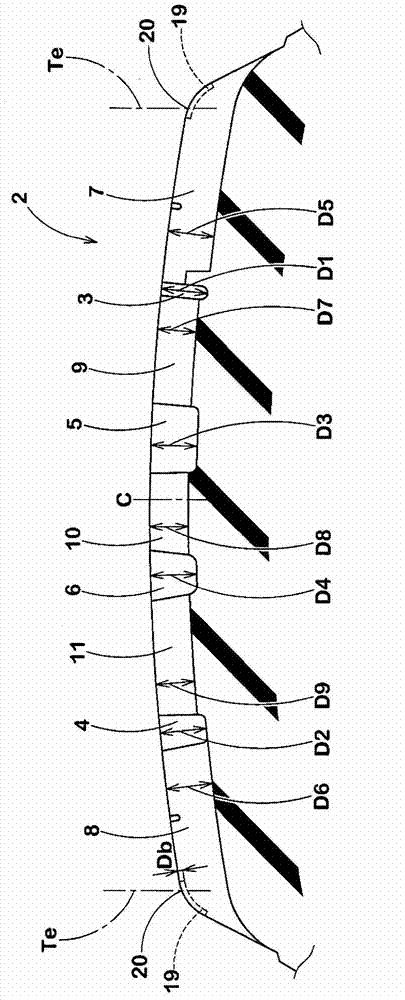

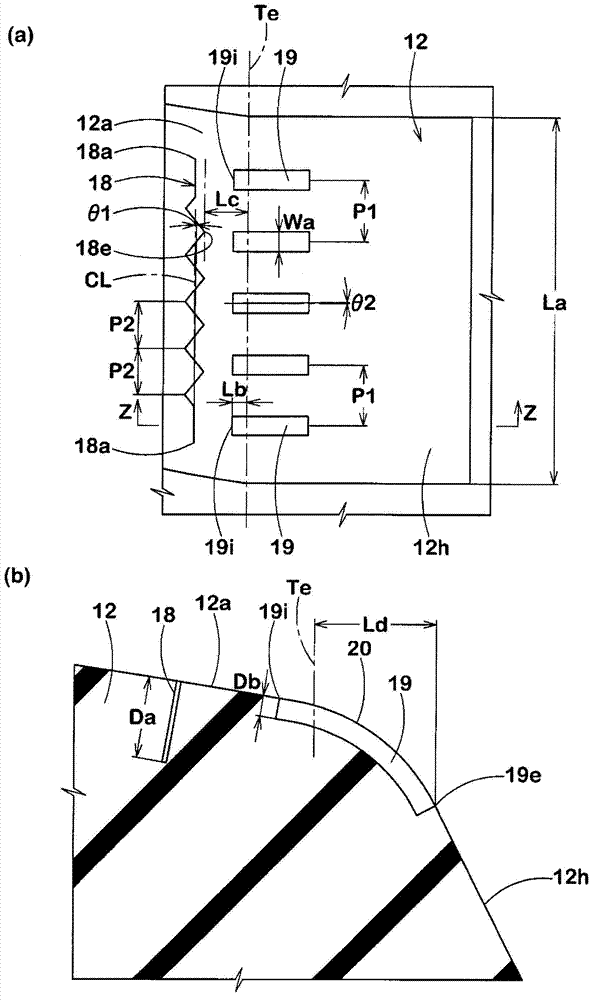

Pneumatic tire

ActiveCN103029526AImprove rigidityImprove cornering performanceTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire capable of evenly improving cornering performance and behavior in critical cornering on snowy / icy roads. The direction of the pneumatic tire to be arranged to a vehicle is specified. Outboard shoulder block (12) and inboard shoulder blocks (13) are formed at a tread portion (2). Both the outboard / inboard shoulder blocks (12, 13) are provided with sipes. The outboard shoulder blocks (12) have an axial width more than the axial width of the inboard shoulder blocks (13). The circumferential sipe (18) of the outboard shoulder blocks (12) extending at an angle of not more than 10 degrees with respect to the tire circumferential direction is arranged at the side of an outboard tread edge (Te) of the vehicle in sipes (17). The outboard shoulder block (12) has an axially outer sidewall (12h) of which surface is provided with a plurality of narrow buttress grooves (19) extending radially inwardly from the outboard tread edge (Te).

Owner:SUMITOMO RUBBER IND LTD

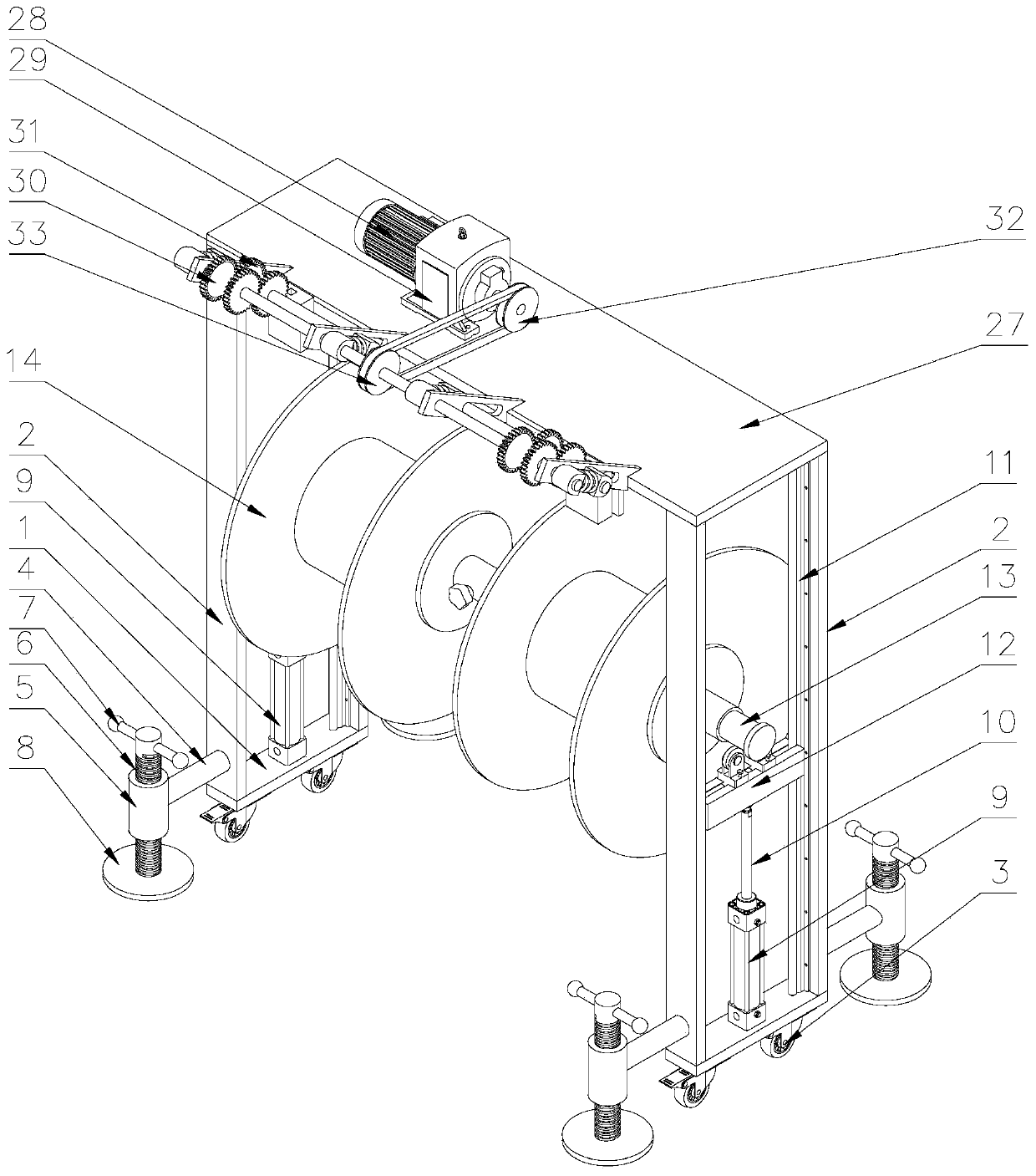

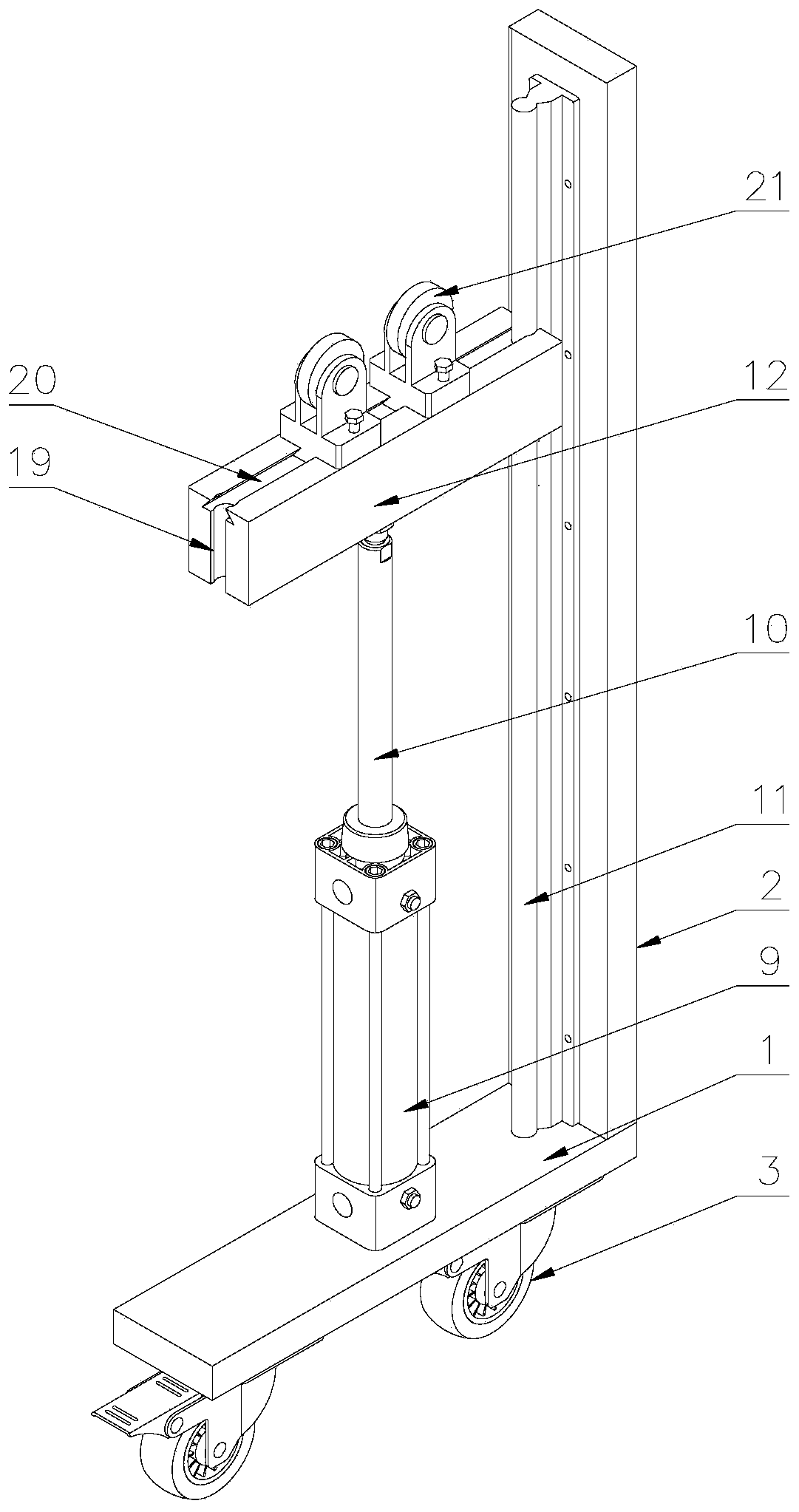

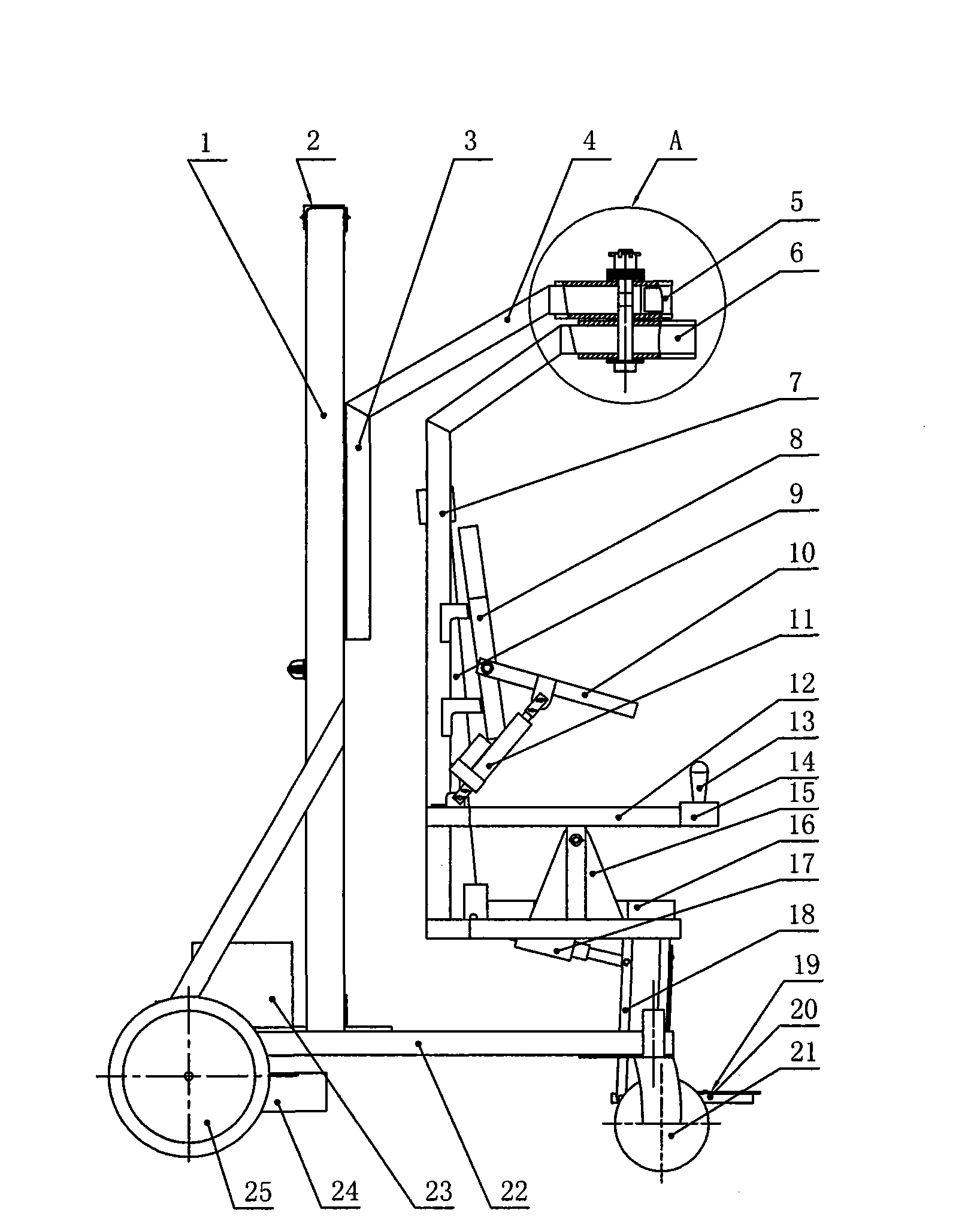

Cable pay-off device for power construction

ActiveCN110061451AReduce difficultyImprove laying efficiencyApparatus for laying cablesEngineeringConductor Coil

The invention discloses a cable pay-off device for power construction. Vertical posts are arranged at two ends of a bottom plate, a guide rail is arranged at one side of each vertical post, an air cylinder is fixedly arranged on the bottom plate, a first sliding block is arranged at an upper end of a piston rod of the air cylinder, upper ends of the vertical posts at two sides are connected by a top plate, two ends of a second connection rod are placed on the first sliding block, a plurality of cable discs are arranged on the second connection rod, a plurality of second supports are arranged at one side f the top plate, a first rotation shaft is arranged on the second supports, a plurality of winding wheels are movably arranged on the first rotation shaft, the numbers of the first windingwheels are equal to the numbers of the cable discs, and the first winding wheel slides among the second supports along an axial direction of the first rotation shaft. The cable disc is jacked up by the air cylinder, the cable disc is prevented from being contacted with ground, so that the friction between the cable disc and the ground is prevented, and the cable pay-off difficulty is reduced; andmoreover, multiple groups of cable discs are arranged on the second connection rod and are used for unwinding, the labor intensity of a worker is reduced, and the cable laying efficiency is greatly improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

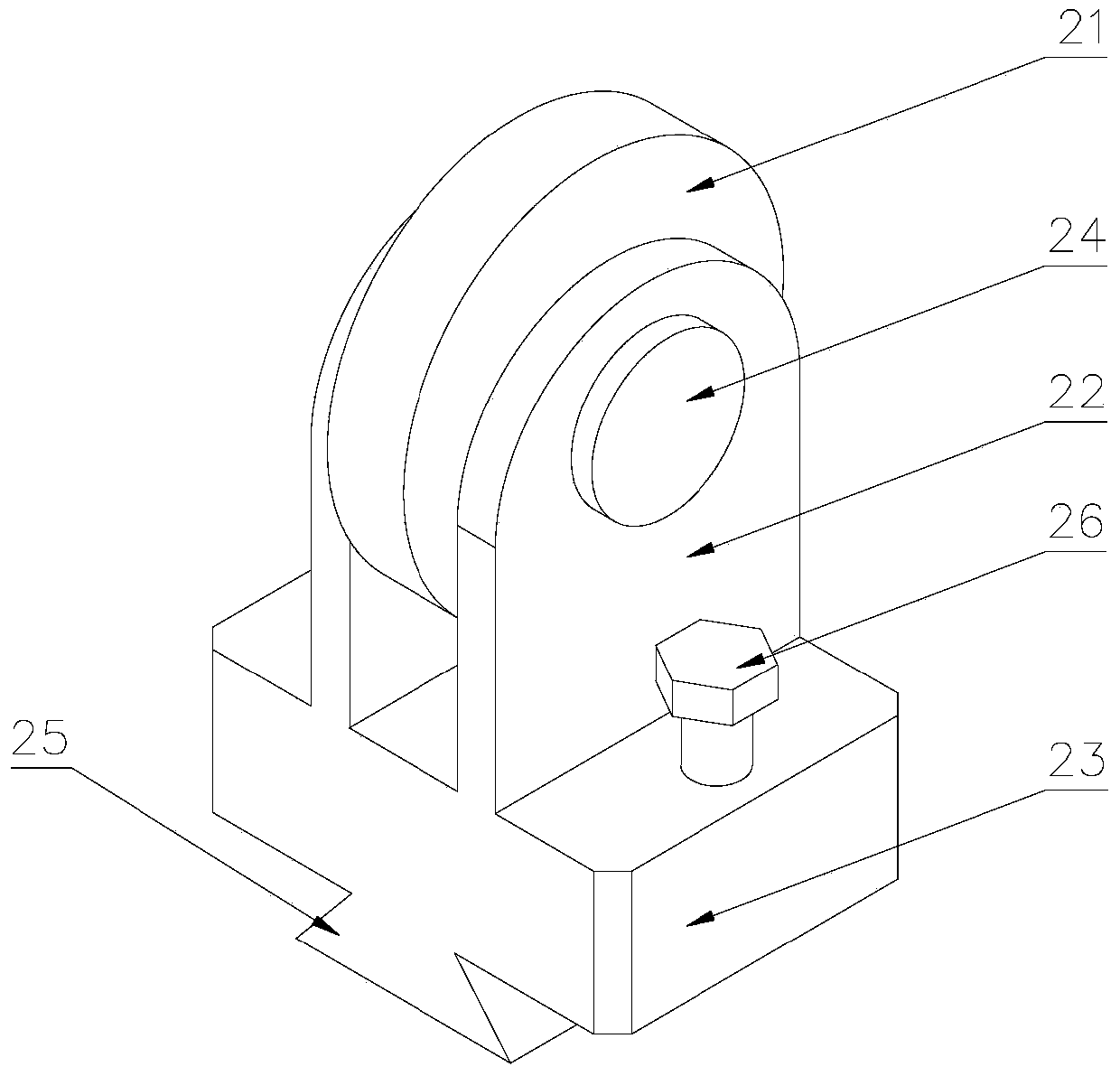

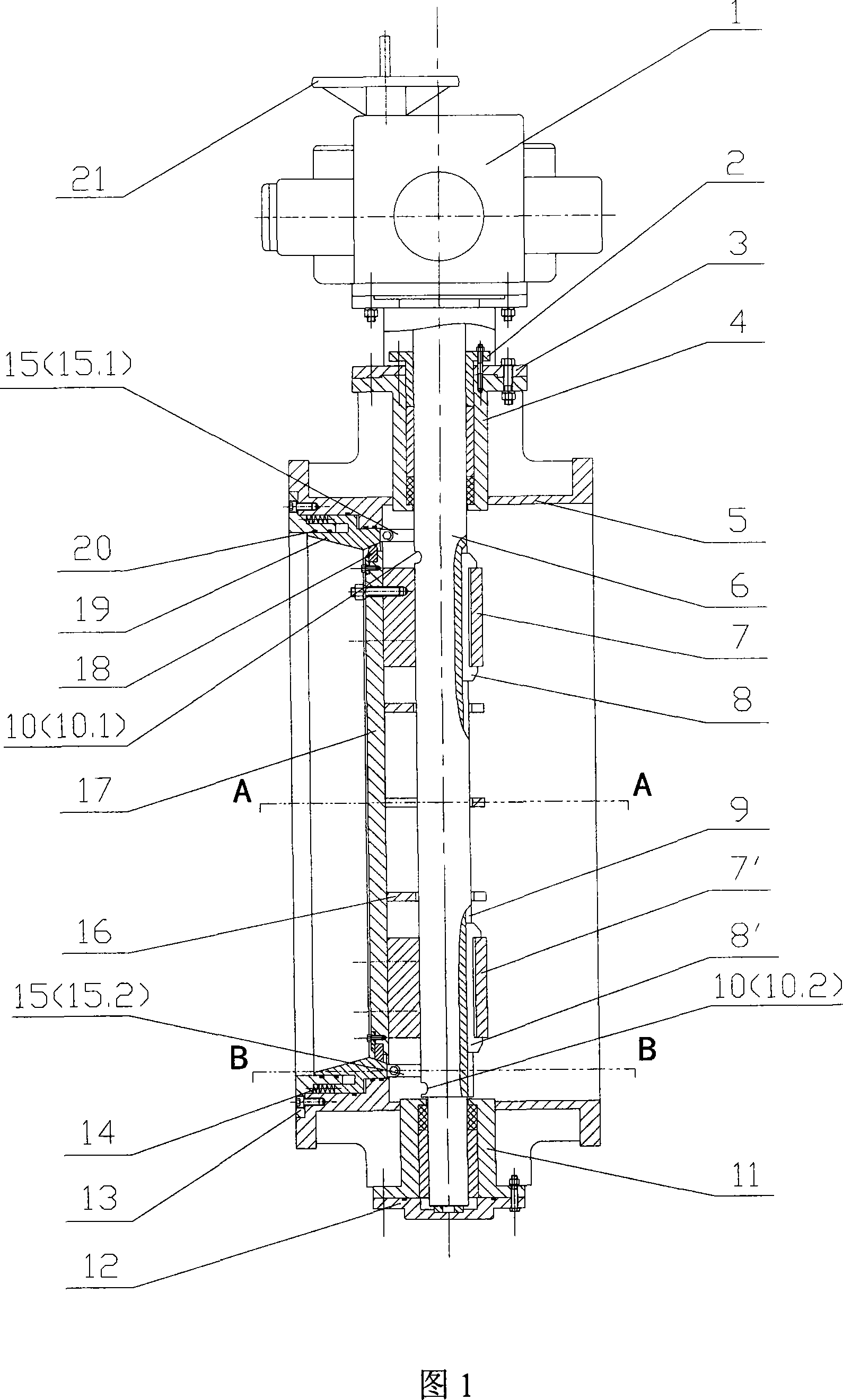

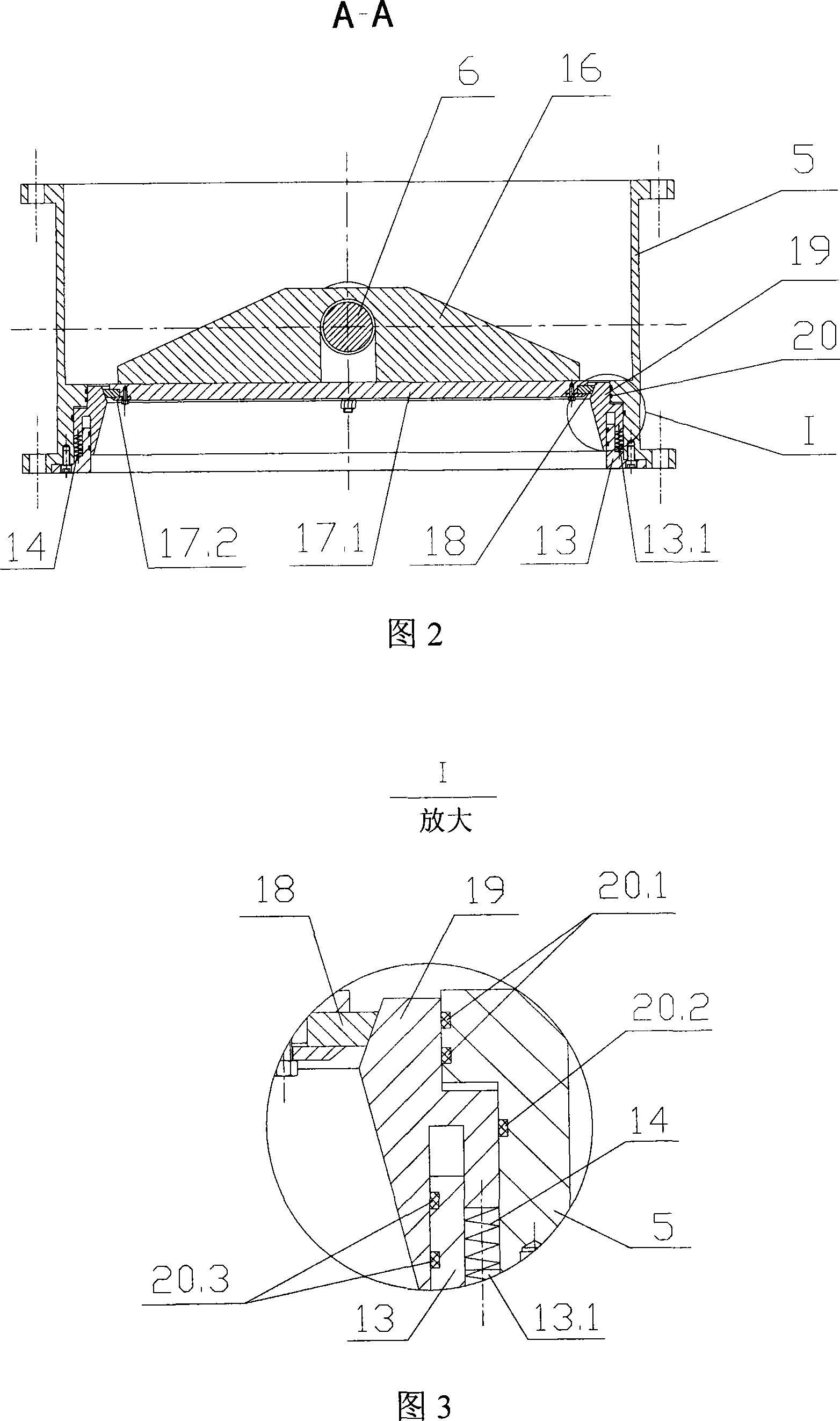

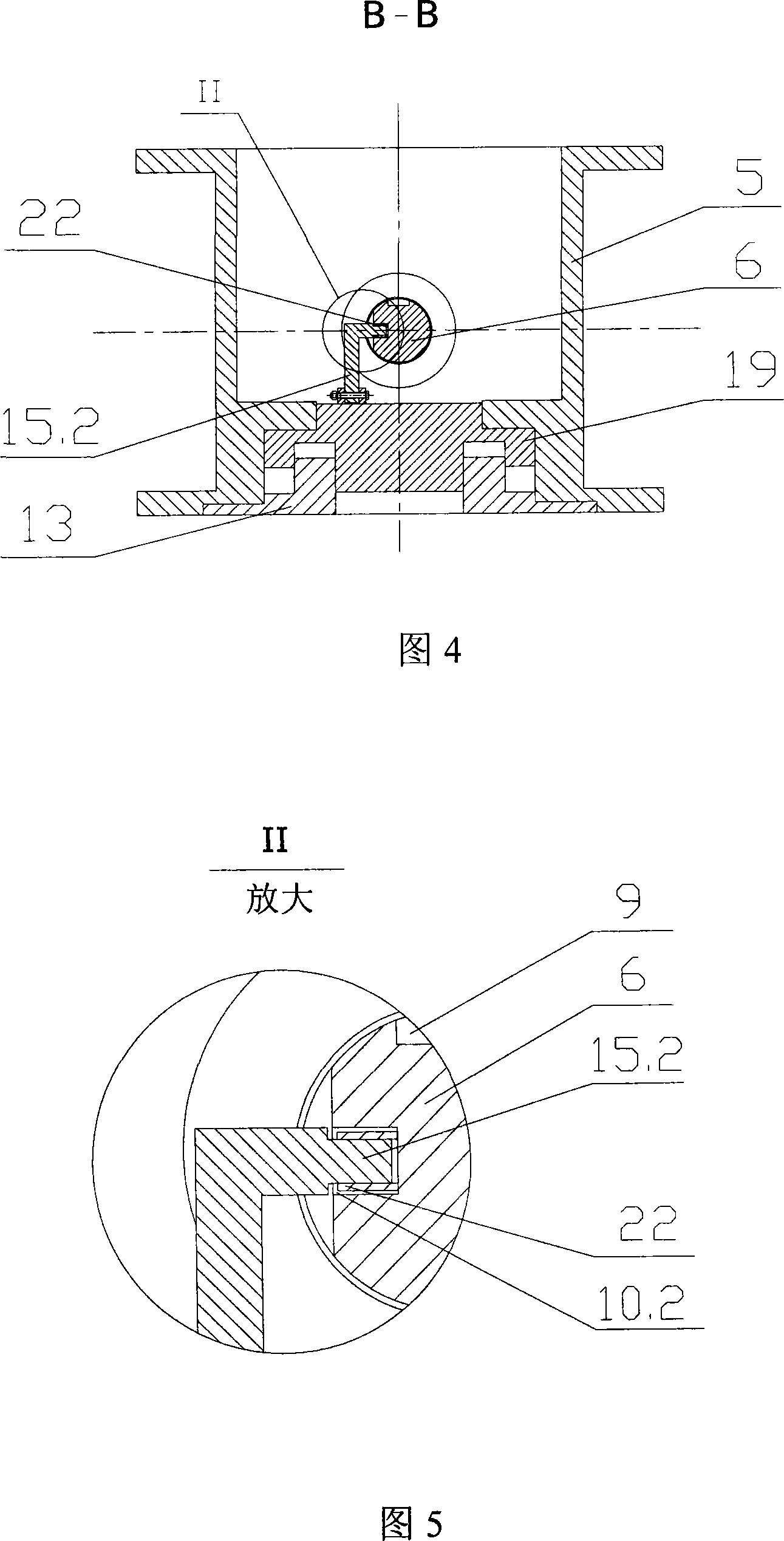

Non-abrasion hard-sealing butterfly valve

The invention relates to a non-loss hard seal butterfly valve which consists of a valve body, a valve rod, a butterfly plate and a valve seat. The invention is characterized in that the valve seat can be a movable valve seat which can axially move along the inner wall of the valve body; one side of the valve body is provided with a lateral body; seal rings are arranged both between the valve seat and the valve body, between the valve seat and the lateral body; a seal component is fixed on a butterfly plate frame; moving fit clearances are reserved between an inner side surface and an outer side surface of the valve seat, between the valve body and the lateral body; a spring is arranged between an outer end surface of the valve seat and the lateral body, an inner end surface of the valve seat is connected with the valve rod through a push rod; an inner end surface of the lateral body is provided with a spring; an upper end and a lower end of the valve rod are respectively provided with a curved slot; an upper curved slot and a lower curved slot are respectively formed by a skewed slot and an arc slot; the middle part of the valve rod is also provided with a long keyway, and an upper sliding key and a lower sliding key which are respectively fixed on an upper connecting seat and a lower connecting seat, and the upper connecting seat and the lower connecting seat are respectively fixed on the butterfly plate; the push rod consists of an upper push rod and a lower push rod, one end of the upper push rod and one end of the lower push rod are both provided with a roller, one end of the lower push rod is embedded in the lower curved slot and capable of sliding, while the other end of the lower push rod is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are symmetrically arranged; a uni-eccentric structure is formed between a butterfly plate rotating axis and a seal pair plane.

Owner:HEBEI UNIV OF TECH

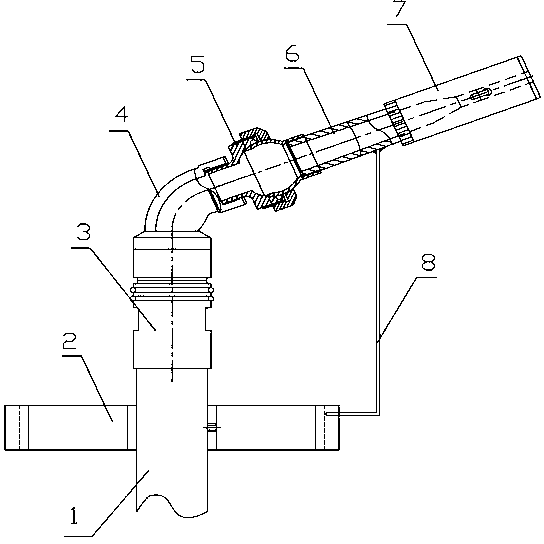

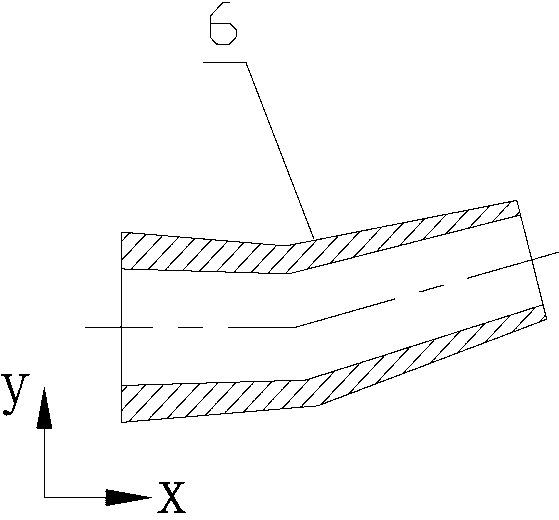

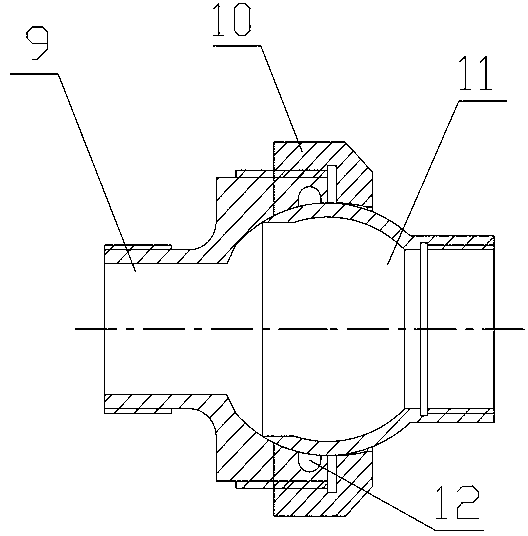

Water jet driving spray-head with elevation angle automatic-adjustment function

ActiveCN103008130ASimple structureEasy to operateMovable spraying apparatusRubber ringElevation angle

The invention relates to a water jet driving spray-head with an elevation angle automatic-adjustment function, belonging to key equipment for a water- saving irrigation and sprinkling irrigation system and being suitable for solving the problem that the jet range automatically changes when the spray-head rotates. The water jet driving spray-head comprises a mounting riser, a guide rail disc, a spray-head rotator, a spray-head elbow, an elevation angle adjusting mechanism, a spray pipe, a jet element body and a guide rod, wherein a rail is arranged at the periphery of the guide rail disc, and the guide rail is set according to the change rule of the jet range; the elevation angle adjusting mechanism consists of an internal spherical surface joint, an outer sleeve, an internal spherical surface joint and a rubber ring; and when the spray head works, the spray pipe rotates to drive the guide rod to rotate together, the guide rod extends into one end of the guide rail and travels along the guide rail, the guide rail moves up and down due to periodic vertical change of the guide rail, the spray pipe moves up and down while horizontally rotating so as to drive the internal spherical surface joint to rotate along the radian of the spherical surface in an up-down angle range, and therefore the elevation angle of the spray-head can be automatically adjusted.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

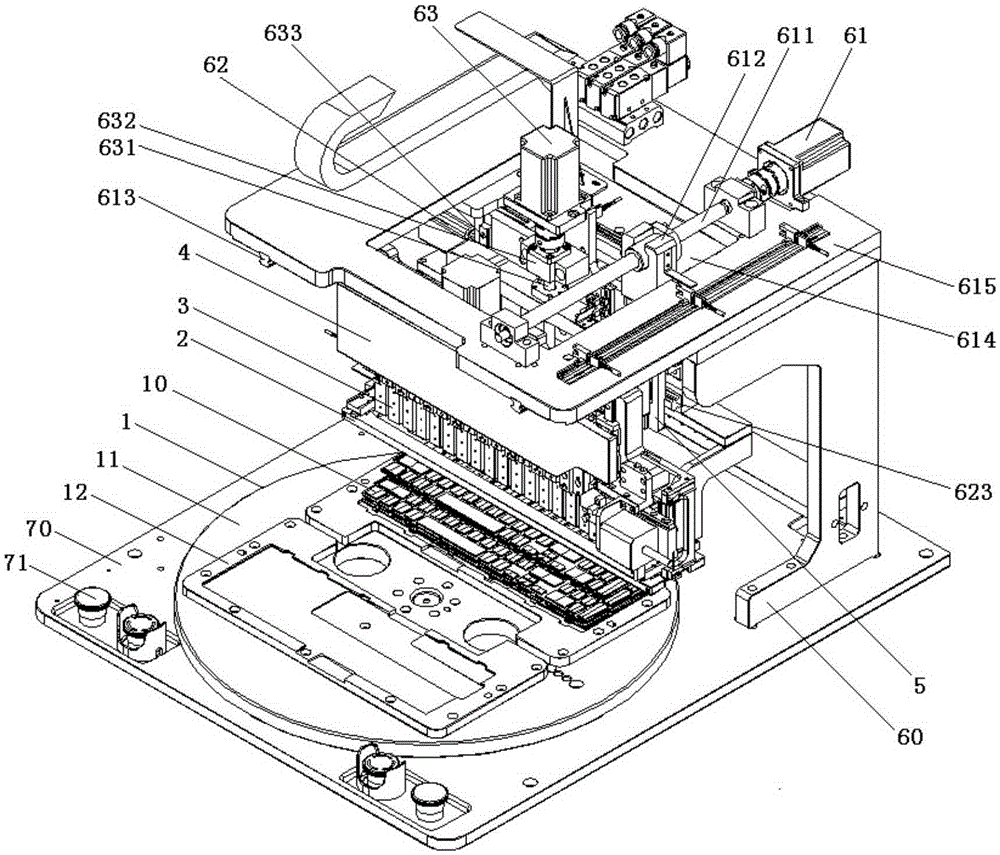

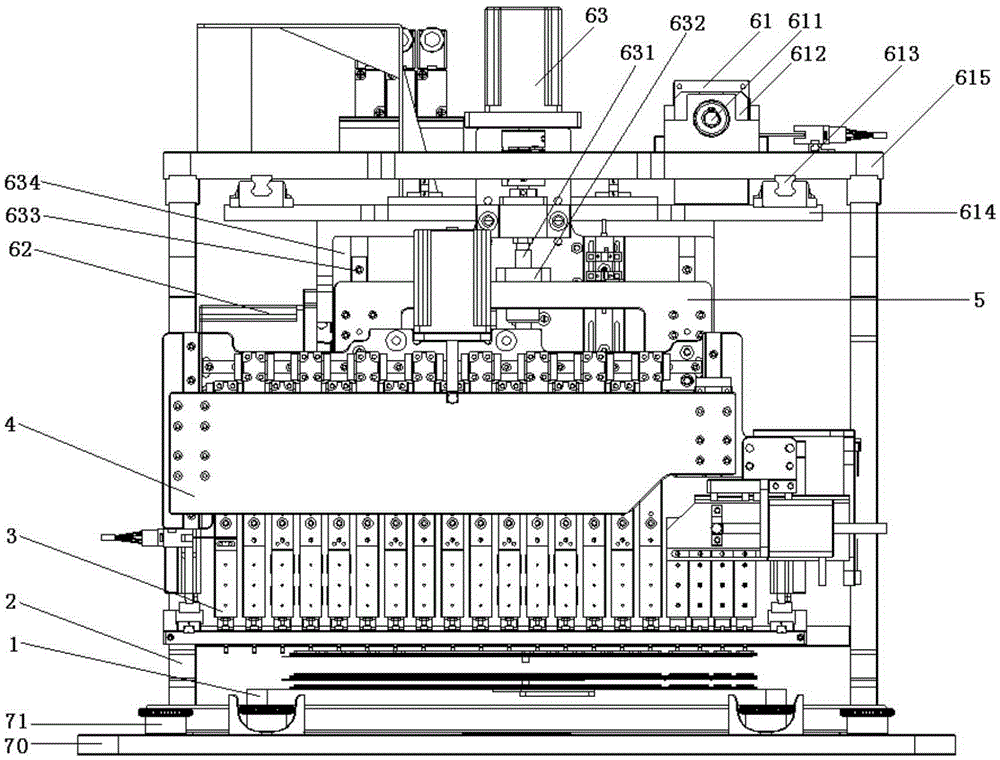

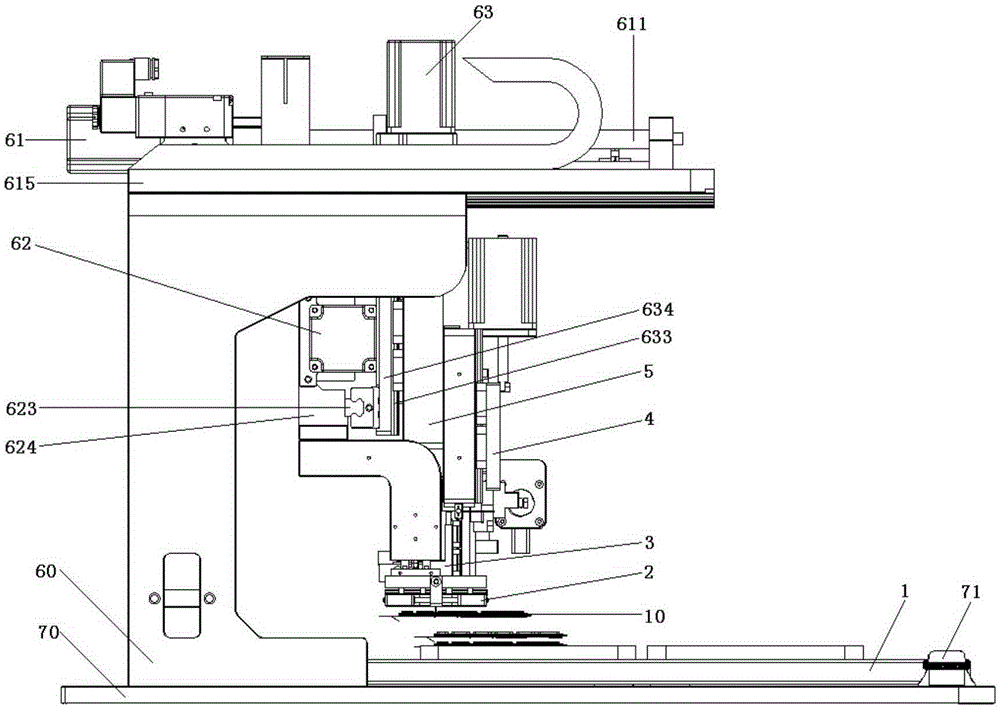

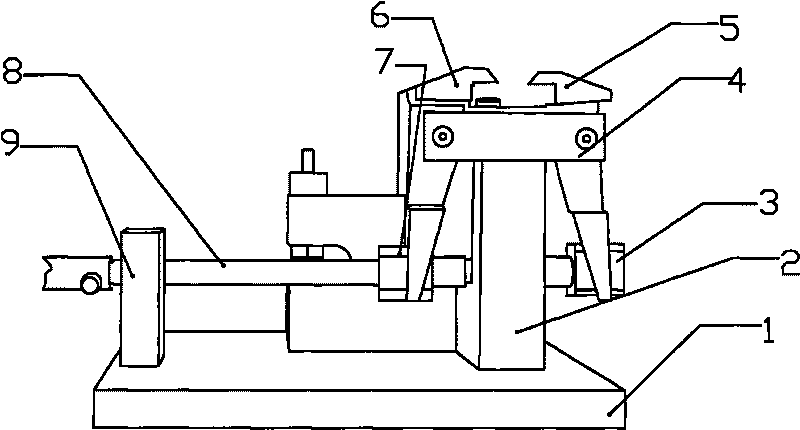

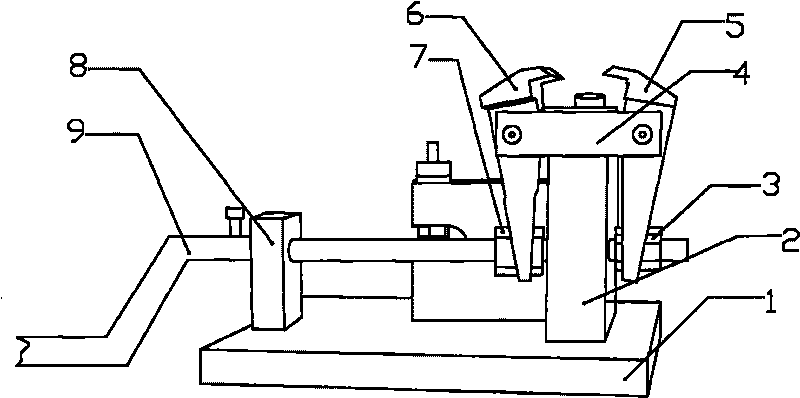

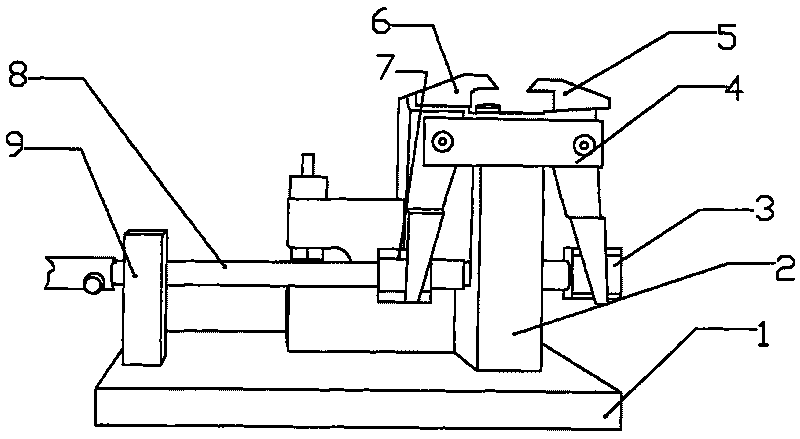

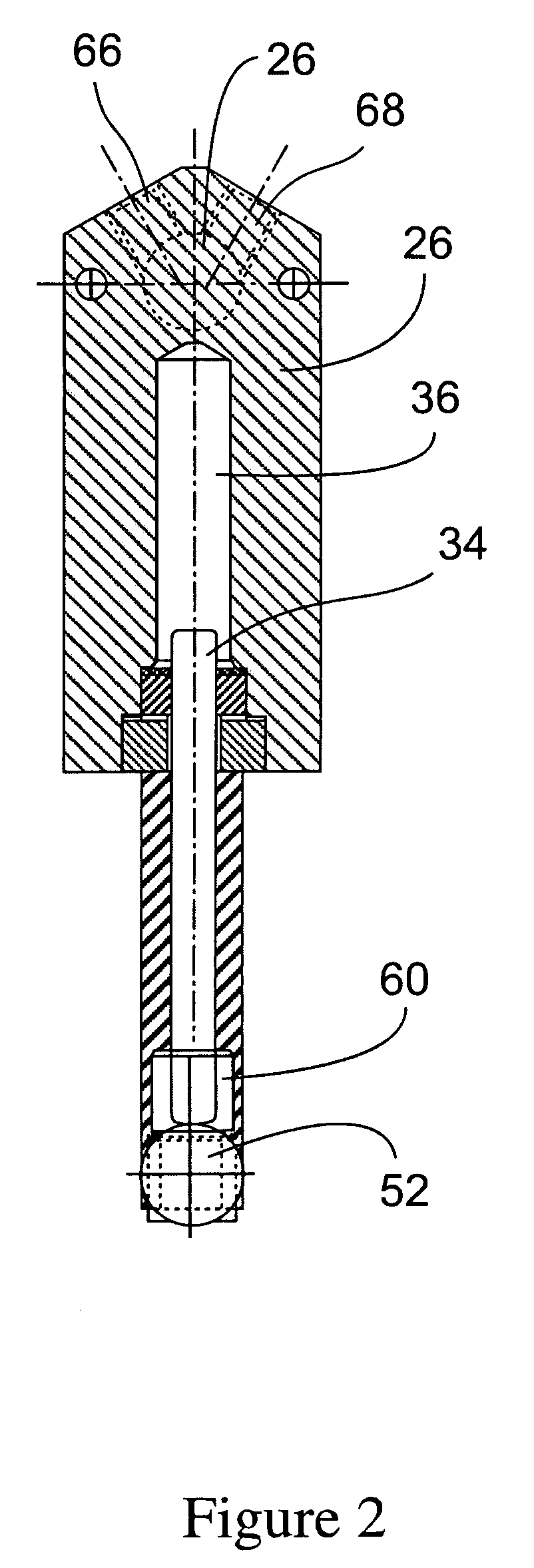

Pressing module for testing drawing force of keycap and test machine for drawing force of keycap

ActiveCN105258834AImprove the pressing effectStrong coordinationApparatus for force/torque/work measurementMechanical engineeringDetection rate

The invention discloses a pressing module for testing drawing force of a keycap and a test machine for the drawing force of the keycap. The pressing module comprises a pressing board, a pressing board cylinder, and a pressing board driver, which are connected in sequence from bottom to top, wherein the pressing board is used for pressing a keyboard; the pressing board cylinder is used for driving the pressing board to move up and down in a vertical direction; and the pressing board driver is used for driving the pressing board cylinder and the pressing board together to move in a Y-axial direction in a keyboard plane. The test machine for the drawing force of the keycap comprises: a keyboard placing device for placing and inputting a to-be-measured keyboard; a pressing module for testing drawing force of the keycap for pressing the keyboard, a drawing force measuring head module for measuring the drawing force of the pressed keycap in the keyboard; a telescoping module for hanging the measuring head module and performing interval adjustment; a substrate for fixing the telescoping module; and a driving device for driving the substrate to move along the X-axial, Y-axial, and Z-axial directions. The test machine is high in detection rate, low in misjudgement rate, good in versatility, and low in detection cost, and doesn't generate damage to a good keycap.

Owner:KUNSHAN HONGZHIXI AUTOMATION EQUIP

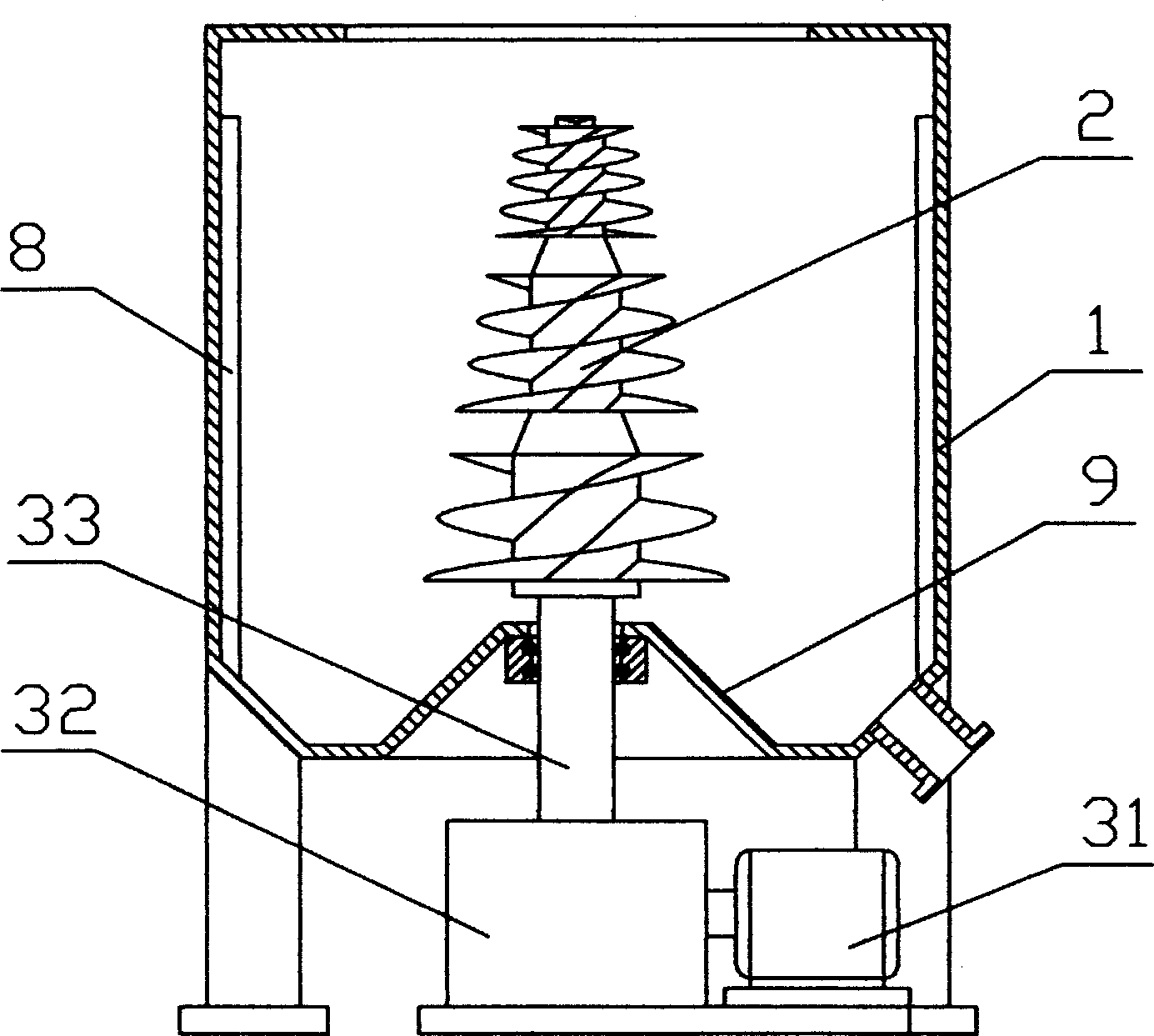

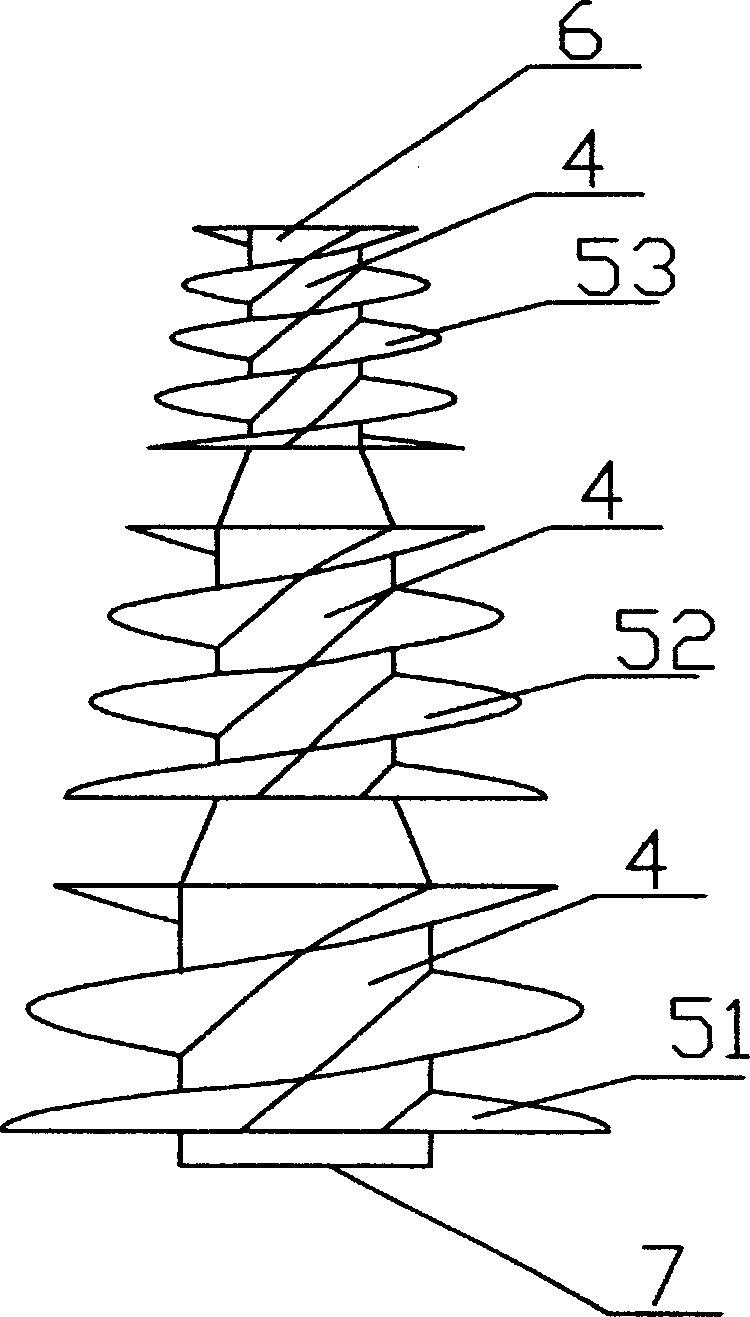

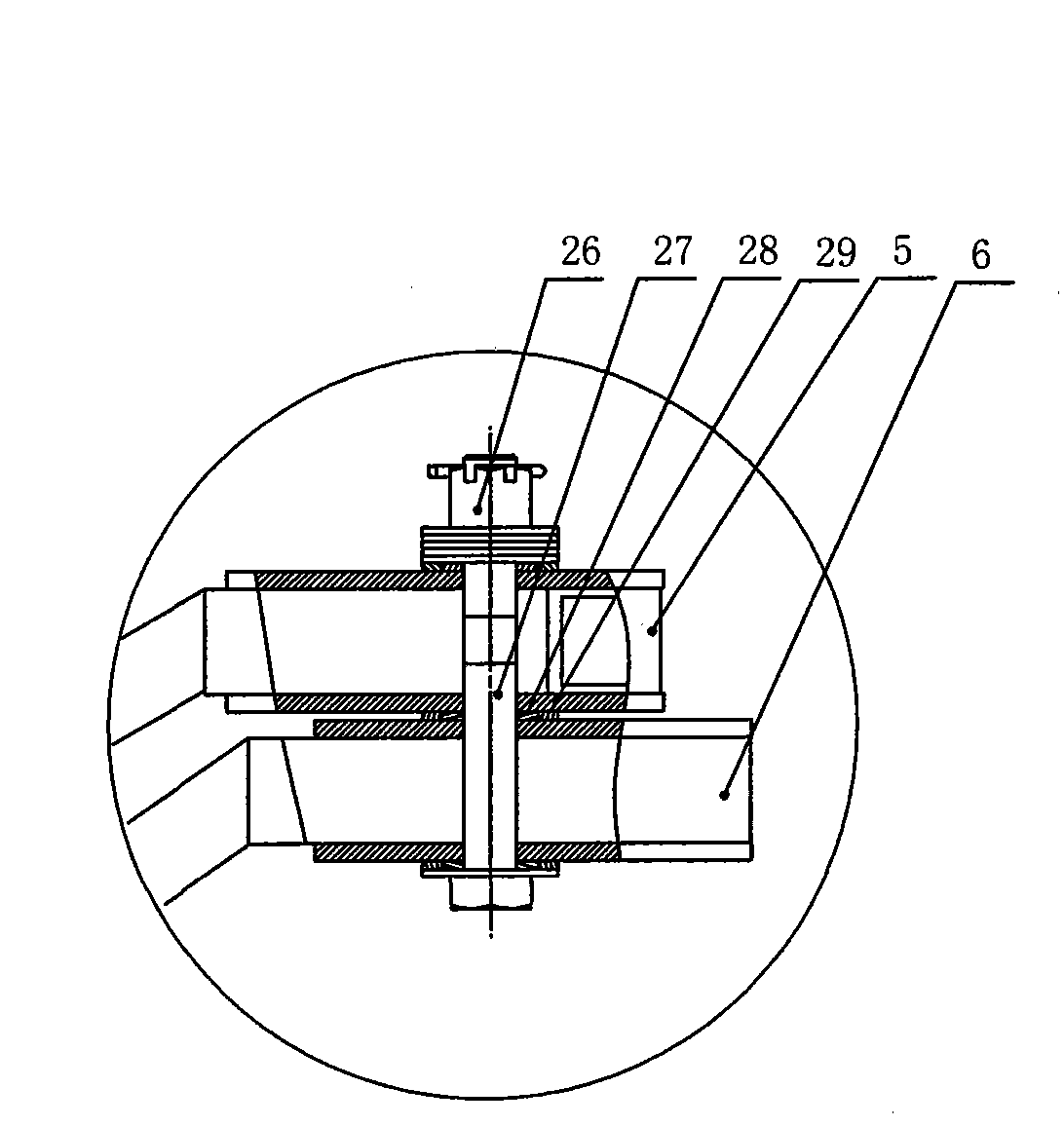

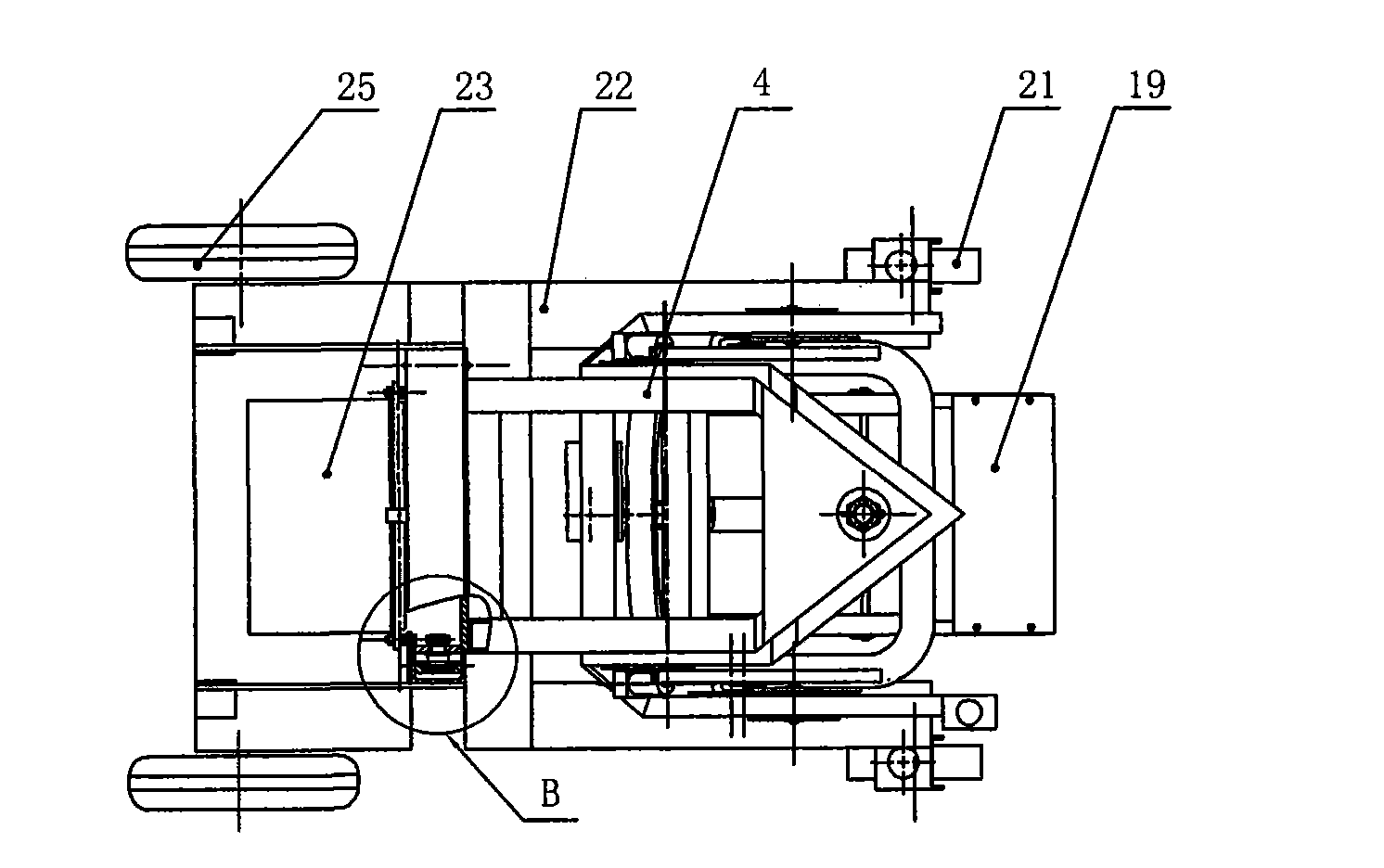

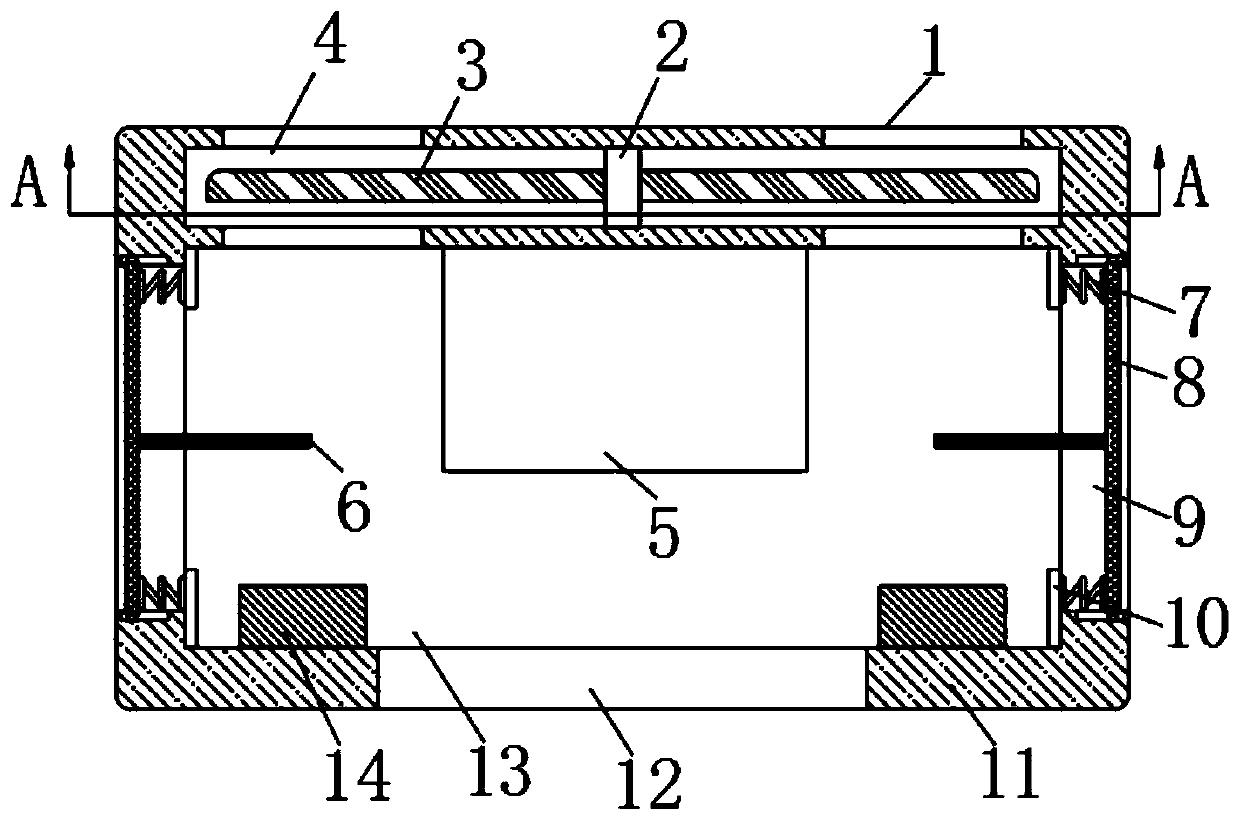

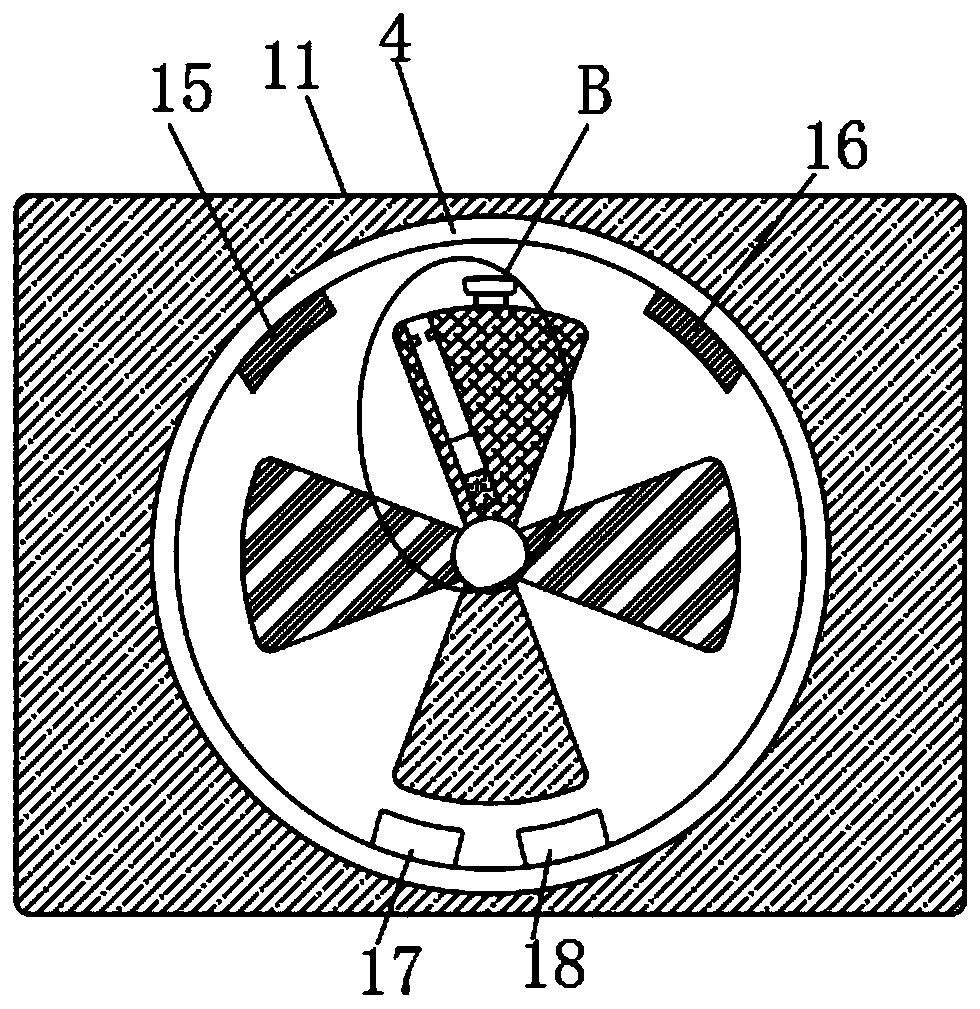

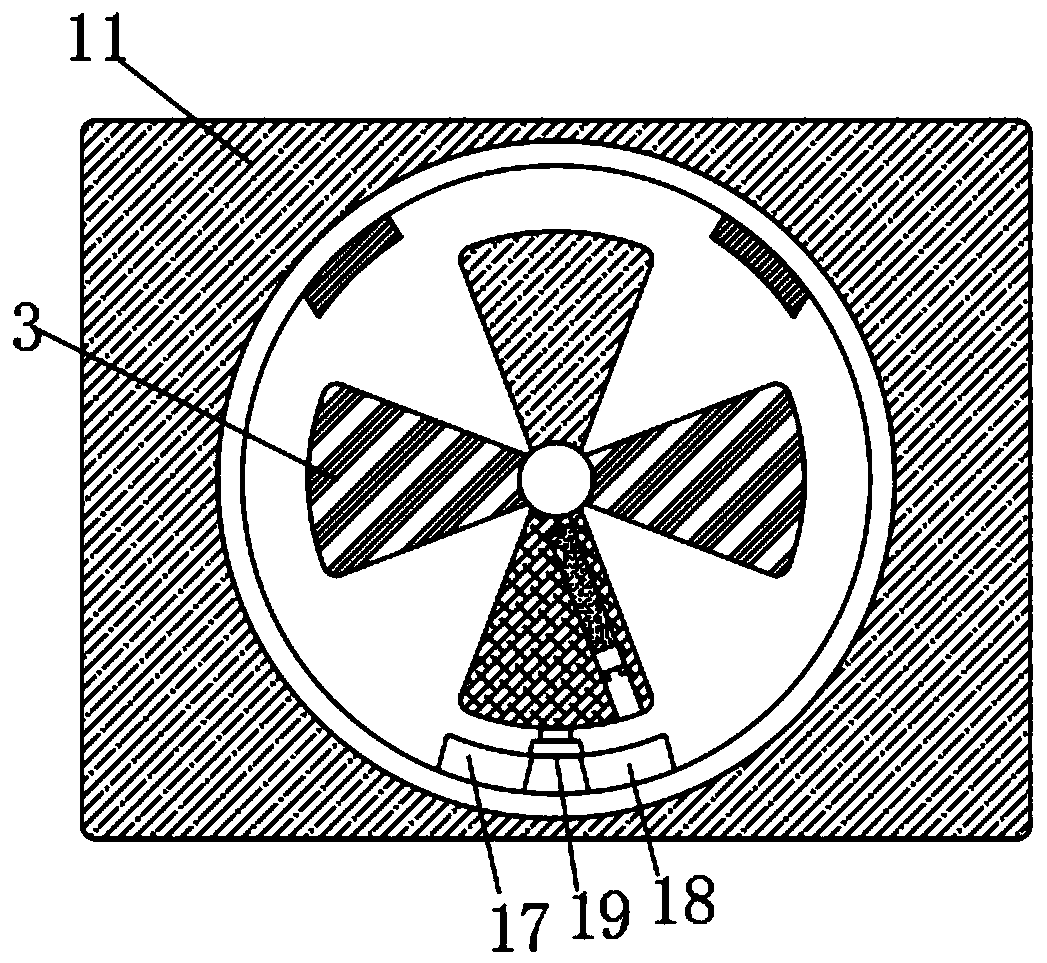

Middle high density hydraulic pulper

InactiveCN1657692AAvoid frictionReduce power consumptionPaper recyclingRaw material divisionEnergy costHigh density

The invention discloses a hydraulic pulp kneader, including the trough solid whose bottom has pulp kneader with corkscrew leaf set vertically, the driving end of pulp kneader is connected to the driving device below the trough solid, and the bottom of trough solid of the pulp kneader driving end is saddlebacked, making the leaf of pulp kneader get away from the bottom of trough solid, avoiding friction between the trough solid and pulp kneader completely, decides the route of whole vorticity circulation and local vorticity circulation formed in the trough solid is lengthed, so that the times of collision is increased and the waste paper is scattered to be the single fiber and it won't be cut off, also, all kinds of nonfiber mixture are kept wholly, it has decreased the energy cost and increased the quality of paper pulp.

Owner:李风宁

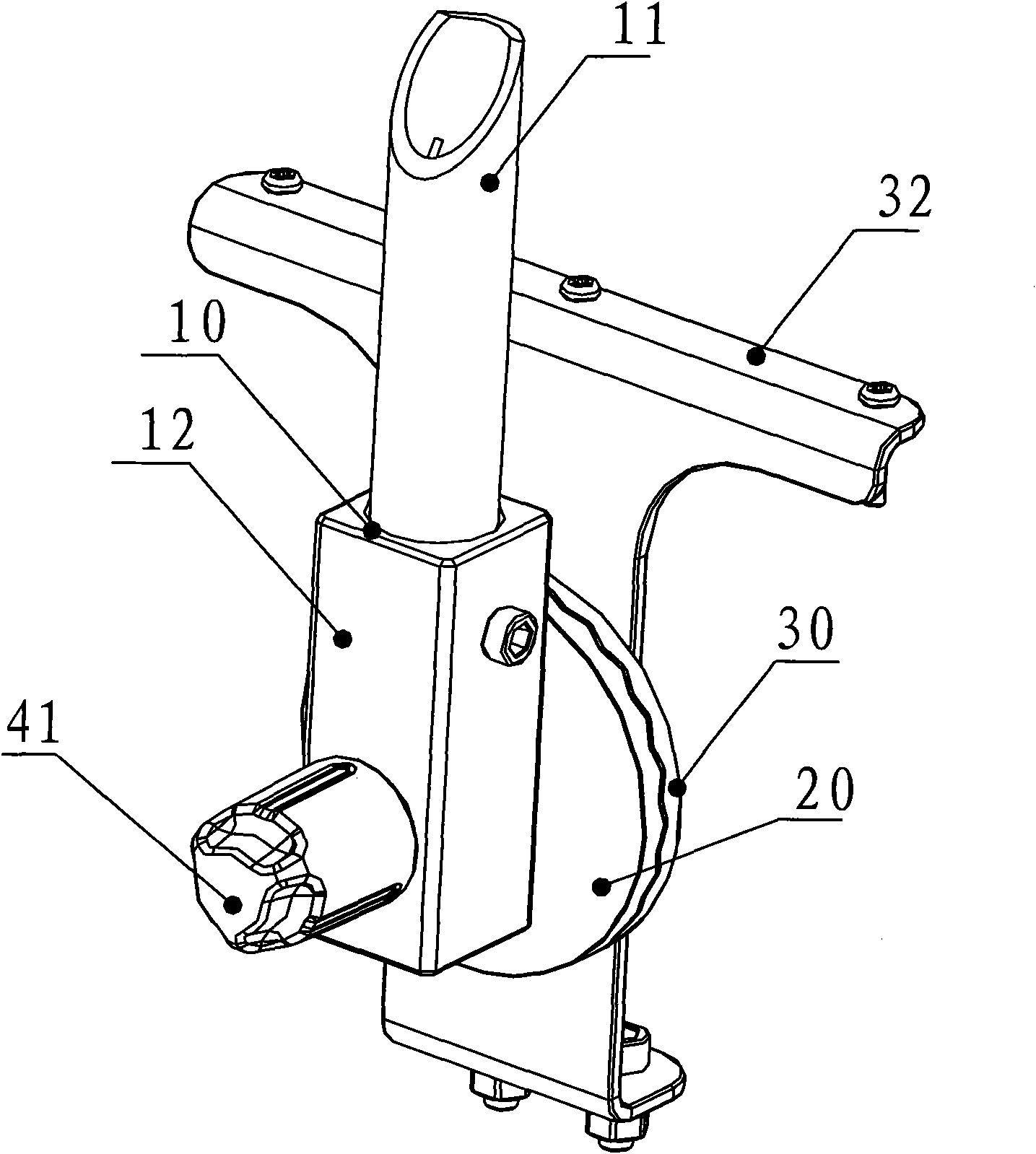

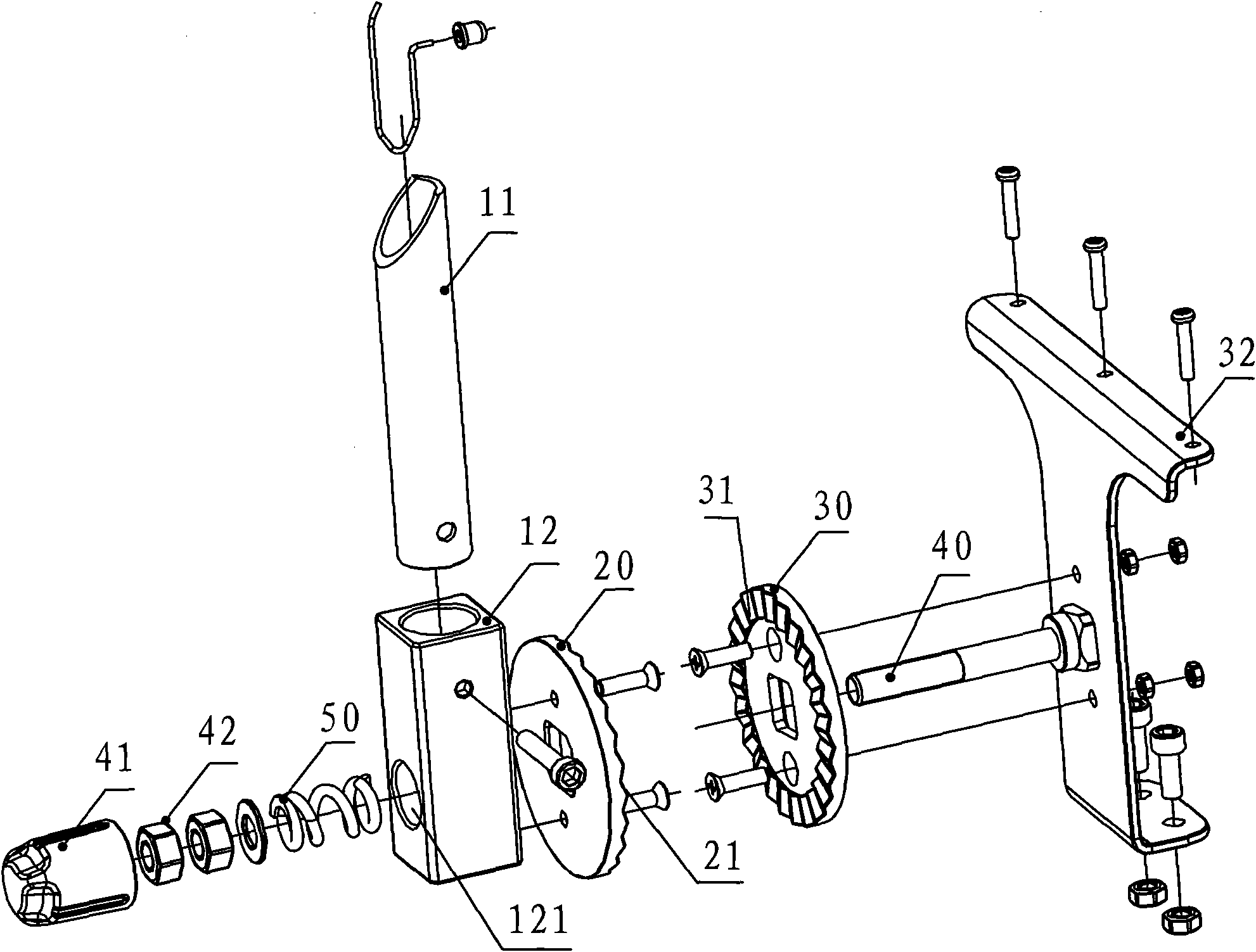

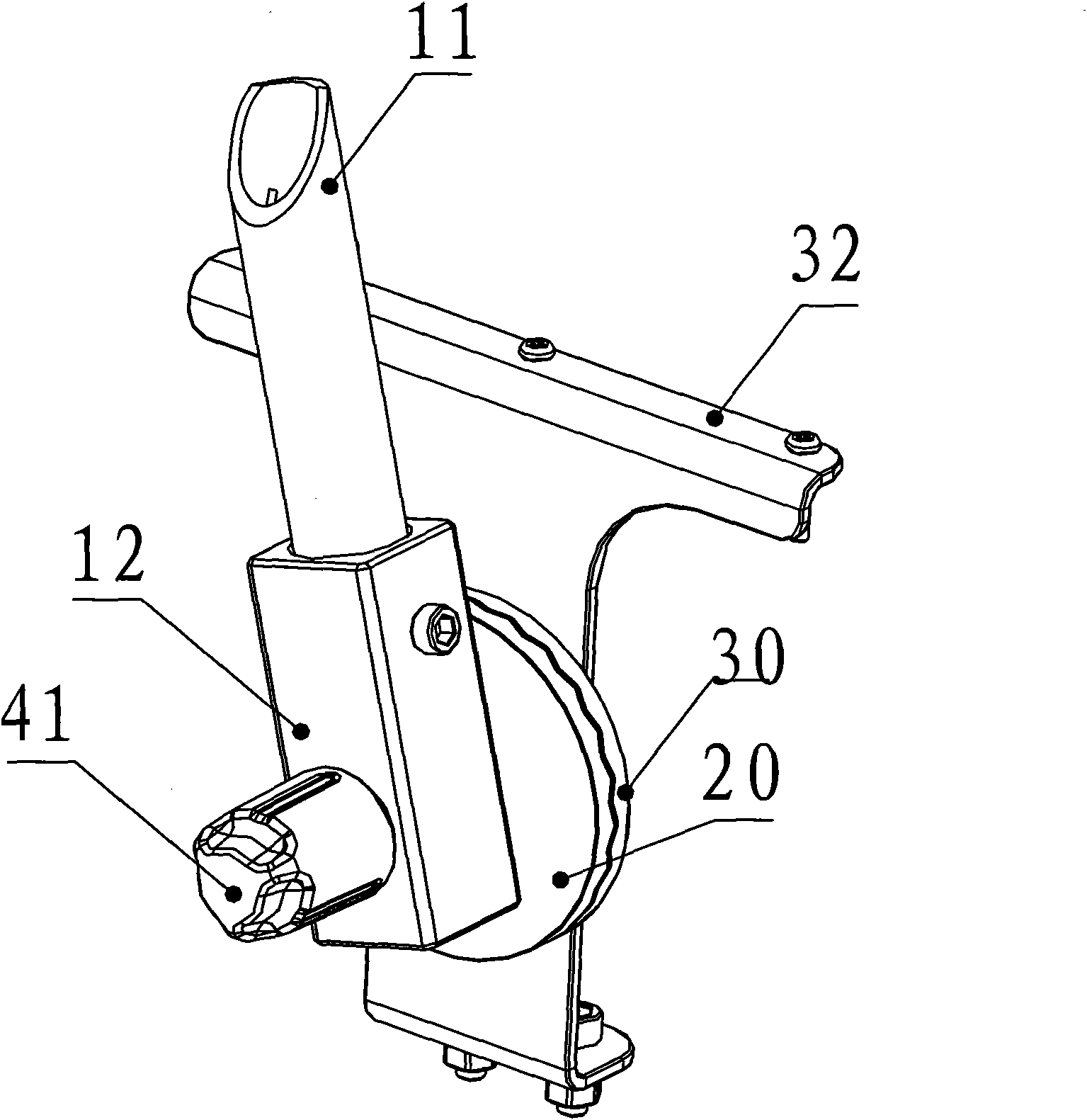

Lamp fixing device capable of adjusting illumination angle and lamp

InactiveCN101832530AIrradiation angle adjustableAvoid frictionLight fasteningsEngineeringMechanical engineering

The invention relates to a lamp fixing device capable of adjusting an illumination angle and a lamp. The lamp fixing device comprises a fixing seat, a first adjusting disc and a second adjusting disc, wherein the fixing seat is used for connecting a lamp holder; the first adjusting disc is arranged on the fixing seat and is provided with a first serrated face; and the second adjusting disc is provided with a second serrated face. Teeth capable of coinciding with one another to lock the lamp at different illumination angles are arranged on the first and second serrated faces; an adjusting bolt sequentially passes through the second adjusting disc, the first adjusting disc and the fixing seat; a nut is arranged at one end of the adjusting bolt, which runs through the fixing seat; a gap is reserved between the nut and the fixing seat; and a spring used for jacking the fixing seat and the first adjusting disc and making the first serrated face fitted with the second serrated face is arranged at the gap. The lamp fixing device can conveniently adjust the illumination angle of the lamp holder with a single hand and also can reliably adjust the illumination angle when the fixing seat is connected with a relatively heavy lamp holder.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Multifunctional wheelchair for handicapped person

InactiveCN101632614AStable and reliable lifting operationAvoid frictionWheelchairs/patient conveyanceVehicle frameWheelchair

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Automatic heat-dissipation type large-power illuminating lamp for factory

ActiveCN110848645AExtended service lifeAvoid frictionDispersed particle filtrationTransportation and packagingThermodynamicsEngineering

The invention discloses an automatic heat-dissipation type large-power illuminating lamp for a factory. The automatic heat-dissipation type large-power illuminating lamp comprises a housing, wherein aheat-dissipation cavity and a mounting cavity are arranged in the housing; an incandescent light bulb is mounted in the heat-dissipation cavity; air inlets for introducing in air are formed in two side walls of the heat-dissipation cavity; filter meshes are connected in the two air inlets in a sliding mode; a shaking mechanism for shaking the two filter meshes left and right is arranged in the heat-dissipation cavity; the shaking mechanism comprises two permanent magnets arranged in the heat-dissipation cavity, multiple connecting plates are arranged in the heat-dissipation cavity; each filter mesh is elastically connected to the corresponding connecting plate through multiple connecting springs separately; and opposite sides of the two filter meshes are fixedly connected with copper frames. The illuminating lamp has relatively good heat dissipation effect, takes a temperature as a trigger condition to realize active heat dissipation, can shake a heat dissipation net during heat dissipation, shakes off the dust on the heat dissipation net, and does not need manual regular clearing.

Owner:江苏光辉照明电气有限公司

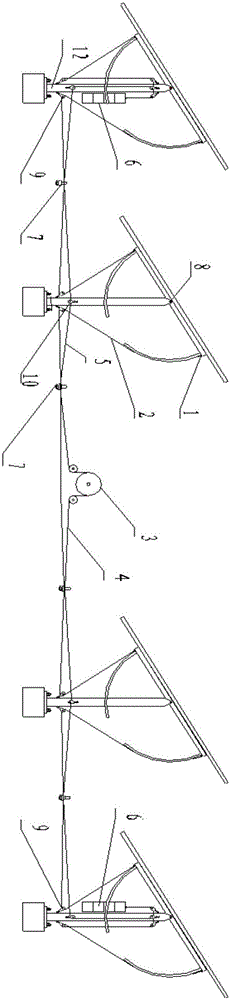

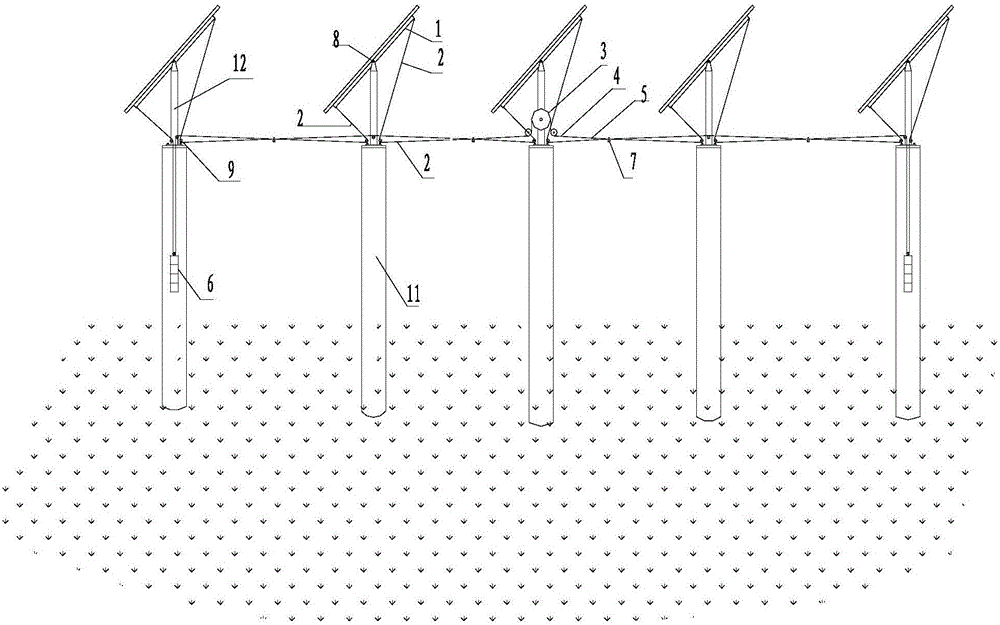

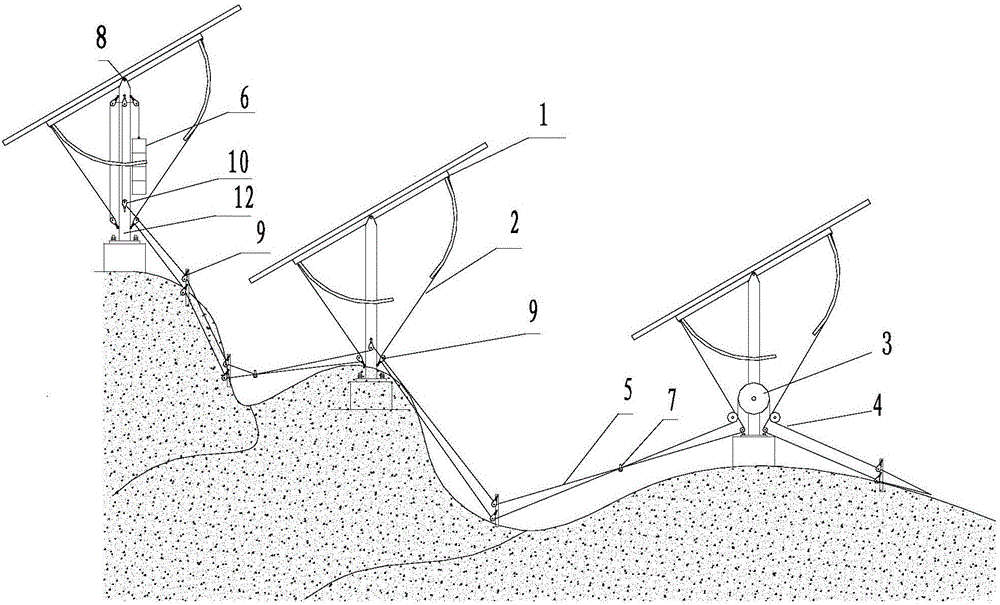

Flexible driving apparatus for all-terrain-matched linkage tracking photovoltaic bracket

ActiveCN105811869AHigh precisionExtended service lifePhotovoltaic supportsPhotovoltaic energy generationLand levelingTerrain

The invention provides a flexible driving apparatus for an all-terrain-matched linkage tracking photovoltaic bracket. The flexible driving apparatus comprises a reduction gear chain wheel, stand columns for supporting and rotating solar cell panels, and main beams moving on the corresponding stand columns, wherein purlines are arranged on the main beams for realizing power transmission for each row of solar cell panel array; the tail end of a former purline is connected with the front end of a next purline through a synchronous cable rope by a pulley A in a guiding connection manner so as to realize the series connection of the heads and the tails of the purlines; the reduction gear chain wheel drives a transmission chain to move in a reciprocating manner; two dragging cable ropes are connected with the two ends of the transmission chain respectively; the other ends of the two dragging cable ropes are connected with the synchronous cable rope through two pulleys B; and each of the two pulleys B is connected with a balance weight part separately for keeping the automatic compensation tensioning force of the transmission chain and the dragging cable ropes. The flexible driving apparatus is simple in structure, easy to mount, and capable of solving the problems of high requirement on land leveling standard and impossibility of being mounted and used in barren mountains and steep slopes with quite severe terrains.

Owner:安徽含羞草智能科技有限公司

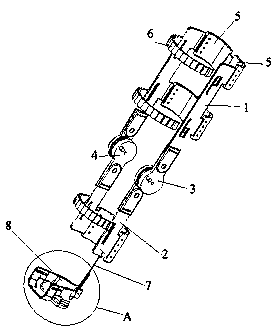

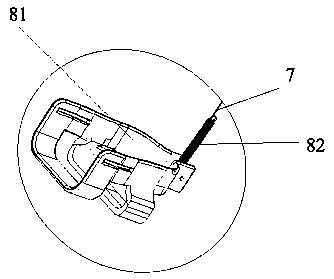

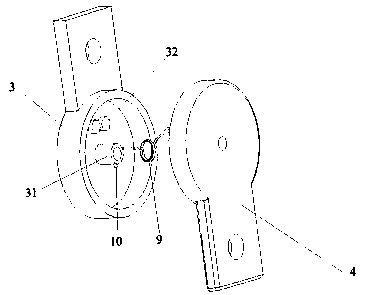

Driven type lower limb motion force assisting exoskeleton device

ActiveCN110744526AAvoid frictionWearableProgramme-controlled manipulatorLower limb exercisesKnee Joint

The invention discloses a driven type lower limb motion force assisting exoskeleton device. A knee joint force assisting mechanism is included and comprises two knee joint force assisting assemblies,knee joint force assisting assembly thigh connecting discs and shank connecting discs. The thigh connecting discs are provided with first protrusions, and the shank connecting discs are provided withsecond protrusions. A plurality of torsional springs are further included and sleeve the first protrusions and (or) the second protrusions. First limiting protrusions and (or) second limiting protrusions are further included. One ends of the torsional springs serve as fixed ends to be fixed to the thigh connecting discs and (or) the shank connecting discs, the other ends serve as movable ends to abut against the first limiting protrusions and (or) the second limiting protrusions when the relative rotation angle of the thigh connecting discs and the shank connecting discs reaches the set value.By means of the driven type lower limb motion force assisting exoskeleton device, the purposes that assisted force is not provided during walking on the level road, and assisted force is only provided during mountain climbing, stair ascending and descending and other large-angle motions are achieved.

Owner:CHONGQING UNIV OF TECH

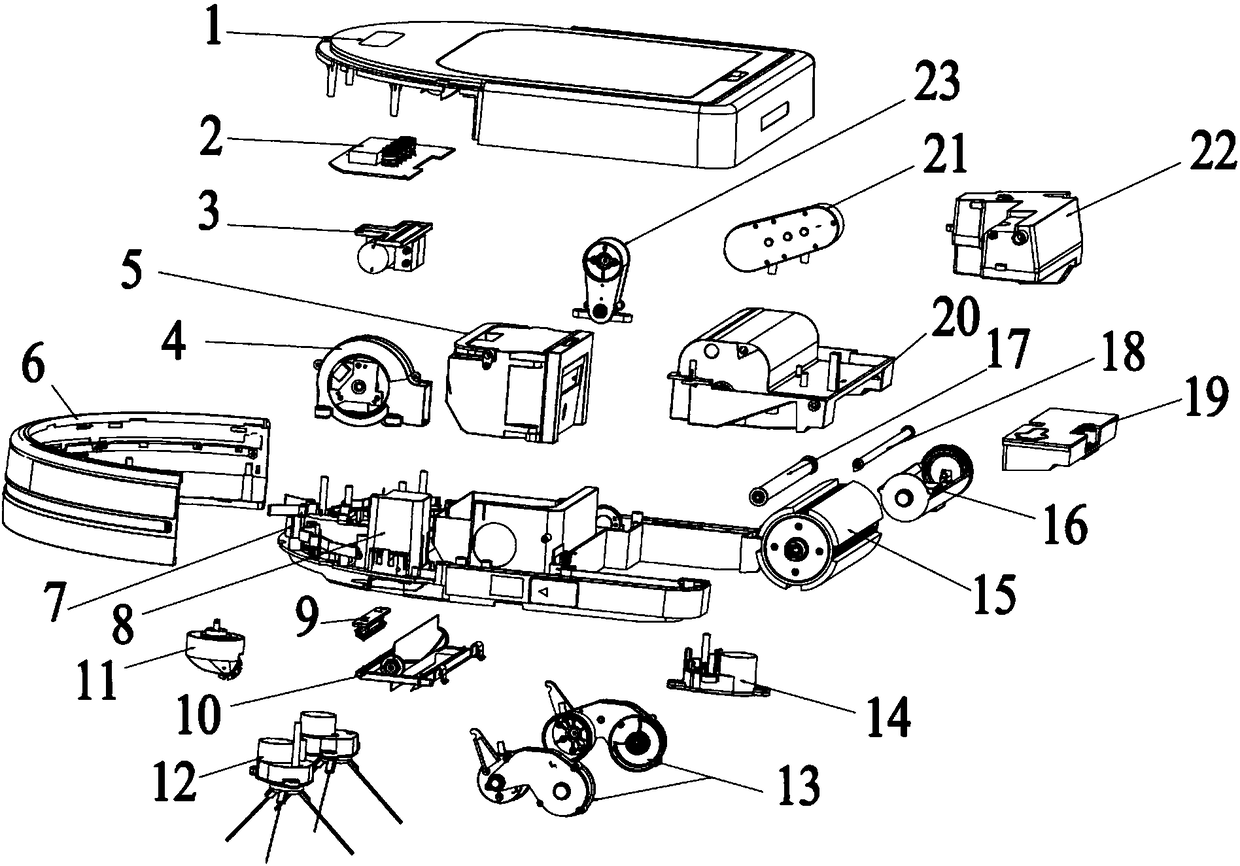

Mopping and sweeping integrated sweeping machine with self-cleaning function and sewage recovery function

PendingCN109316126AAffect performanceEnsure suction effectAutomatic obstacle detectionTravelling automatic controlPulp and paper industrySewage

The invention relates to the technical field of an intelligent sweeping machine, in particular to a mopping and sweeping integrated sweeping machine with a self-cleaning function and a sewage recoveryfunction. Th machine comprises an upper cover, a water pump, a printed circuit board, a display screen, a fan, a dust box, a front touch mechanism, a lower cover base, a battery, a UV lamp assembly,a middle sweep brush assembly, a universal wheel, a side brush, left and right wheel assemblies, a lifting gear box, a roller, a sewage recovery tank, a roller bracket, a roller gear box, a water purifying tank and a medium sweep gear box; the water pump, the fan, the dust box, the battery and the UV lamp assembly are mounted on the base of the lower cover, the universal wheel is installed in front of the lower cover base, the left and right wheel assemblies are respectively mounted on the left and right sides of the lower cover base of the sweeping machine, and the roller is mounted on the roller bracket. The machine solves granular waste, hair, dust and sewage generated by sweeping and mopping the ground at one time, recycles the garbage, the hair, the dust and the sewage into the relevant dust box and a sewage recycle tank, and improves the product practicality.

Owner:勤耕云智能科技(深圳)有限公司

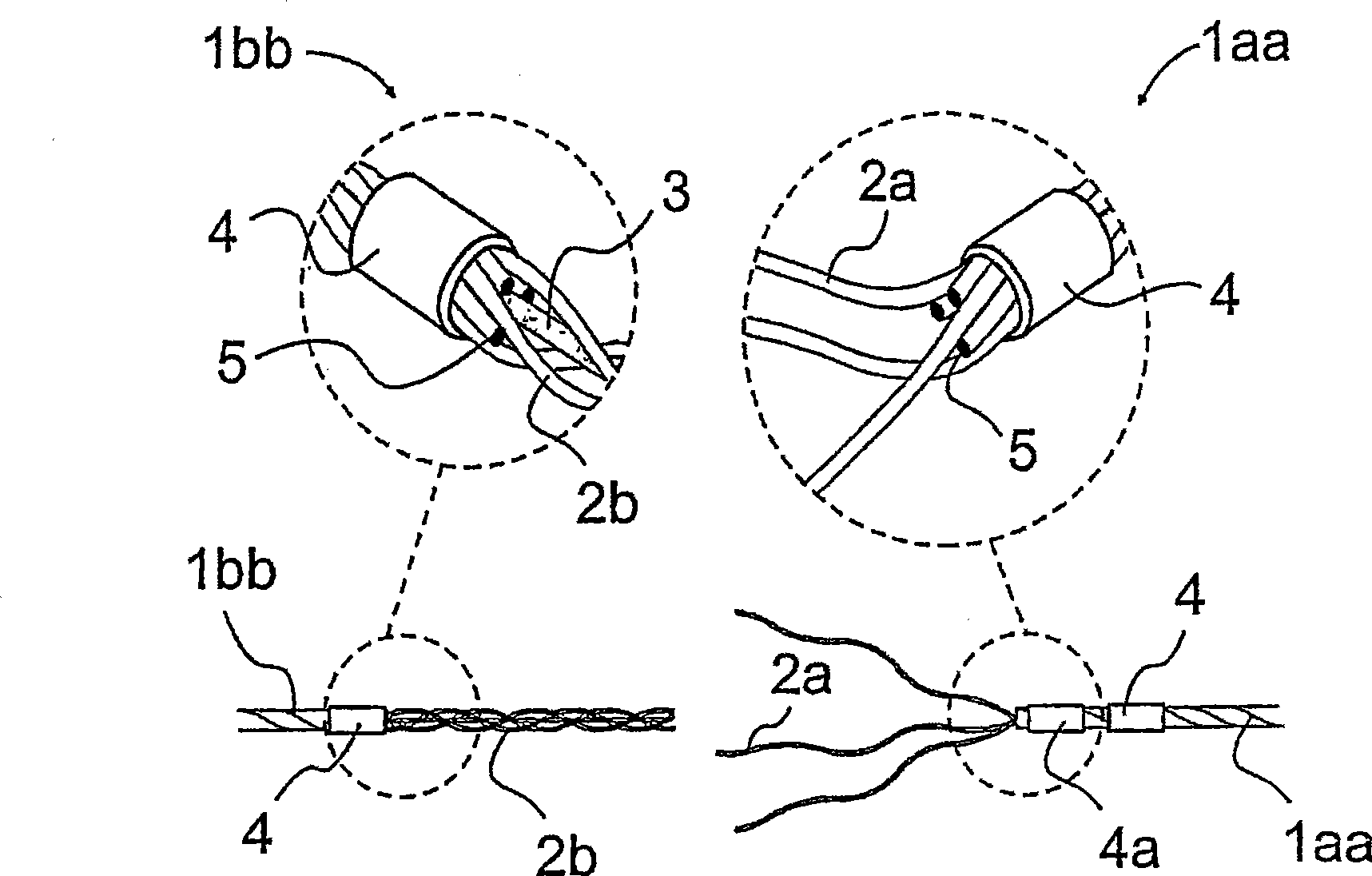

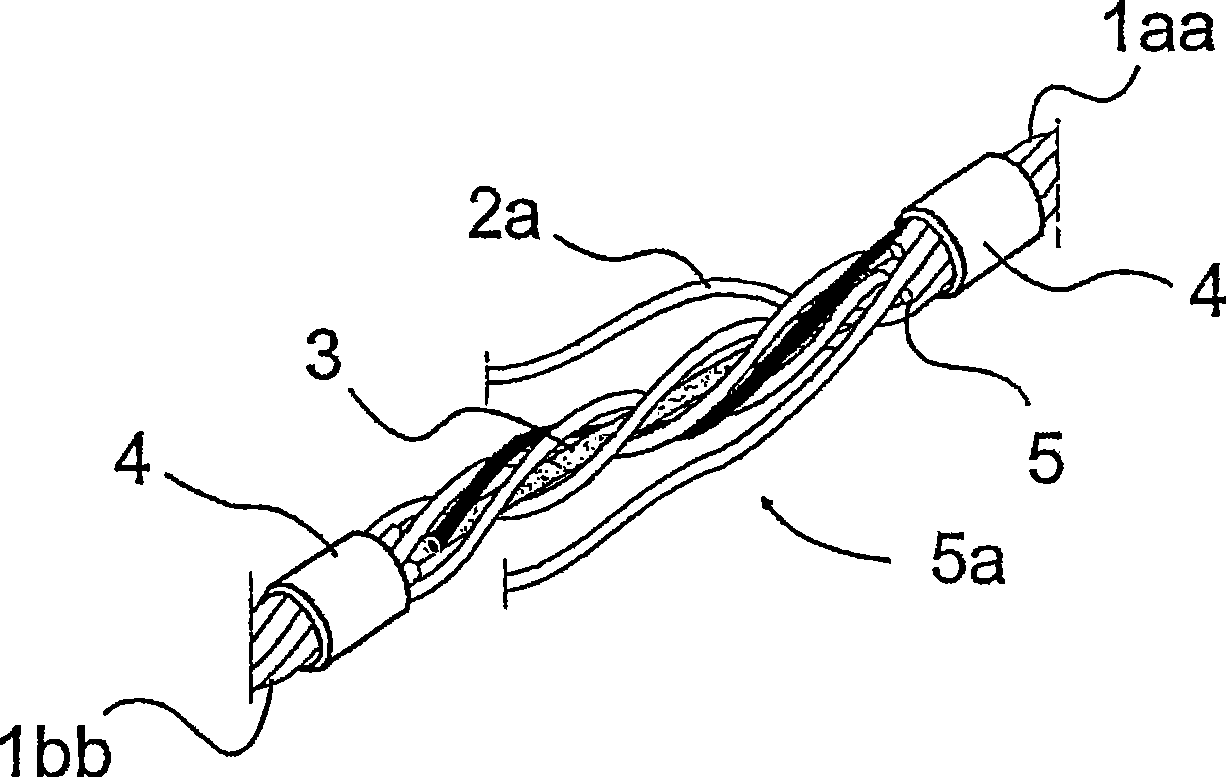

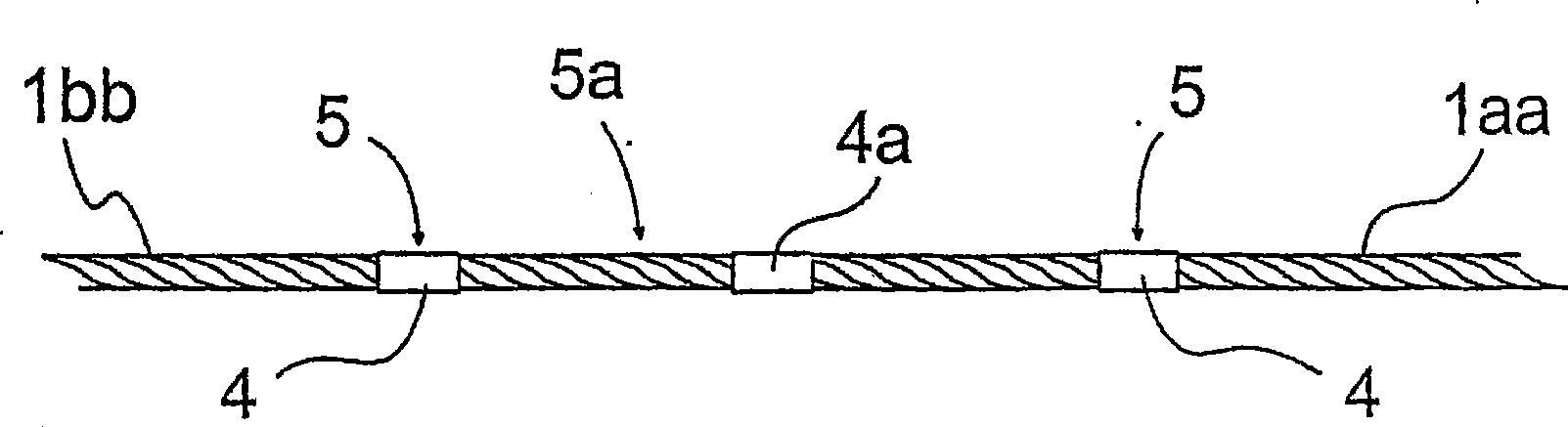

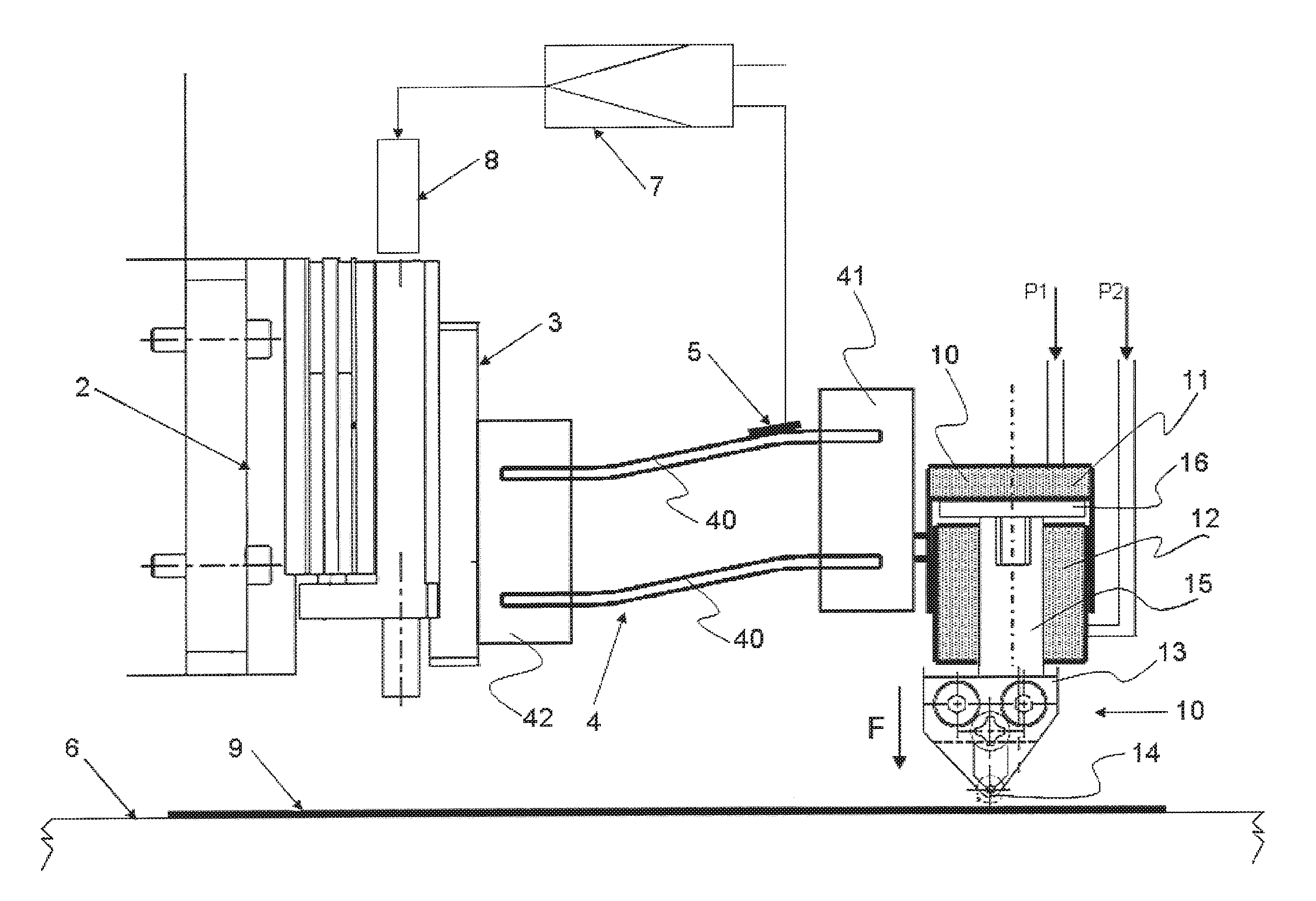

Method for replacing the hoisting roping of an elevator and a traction appliance arrangement used in the replacement

InactiveCN101472827AEffectively and safely replaceQuick changeMechanical apparatusElevatorsEngineering

The present invention relates to a method and a traction appliance arrangement for replacing the hoisting roping of an elevator, which elevator comprises at least guide rails (10) along which an elevator car (7) provided with safety gear (7a) travels in the elevator shaft in an essentially vertical direction, a hoisting machine (8) , a traction sheave (9) and roping (1b) . The ropes (laa) of the new roping (1a) and the ropes (lbb) of the old roping (1b) are joined to each other by splicing the ropes (laa and lbb) together at one of their ends and by strengthening the joint by means of compressive sleeves (4, 4a) , after which the new roping (1a) is pulled into position by means of the old roping (1b) and the hoisting machine (8) of the elevator .

Owner:KONE CORP

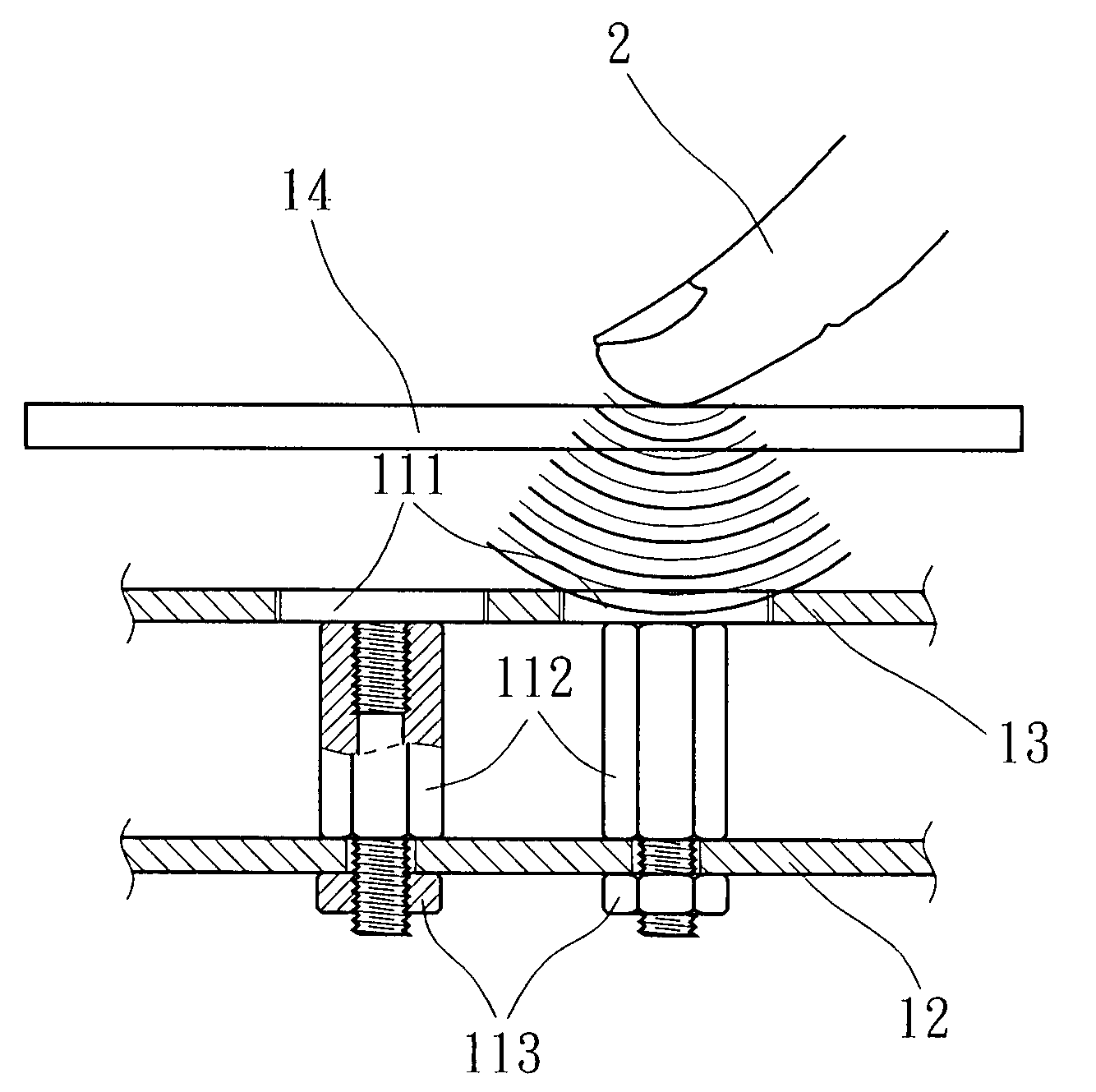

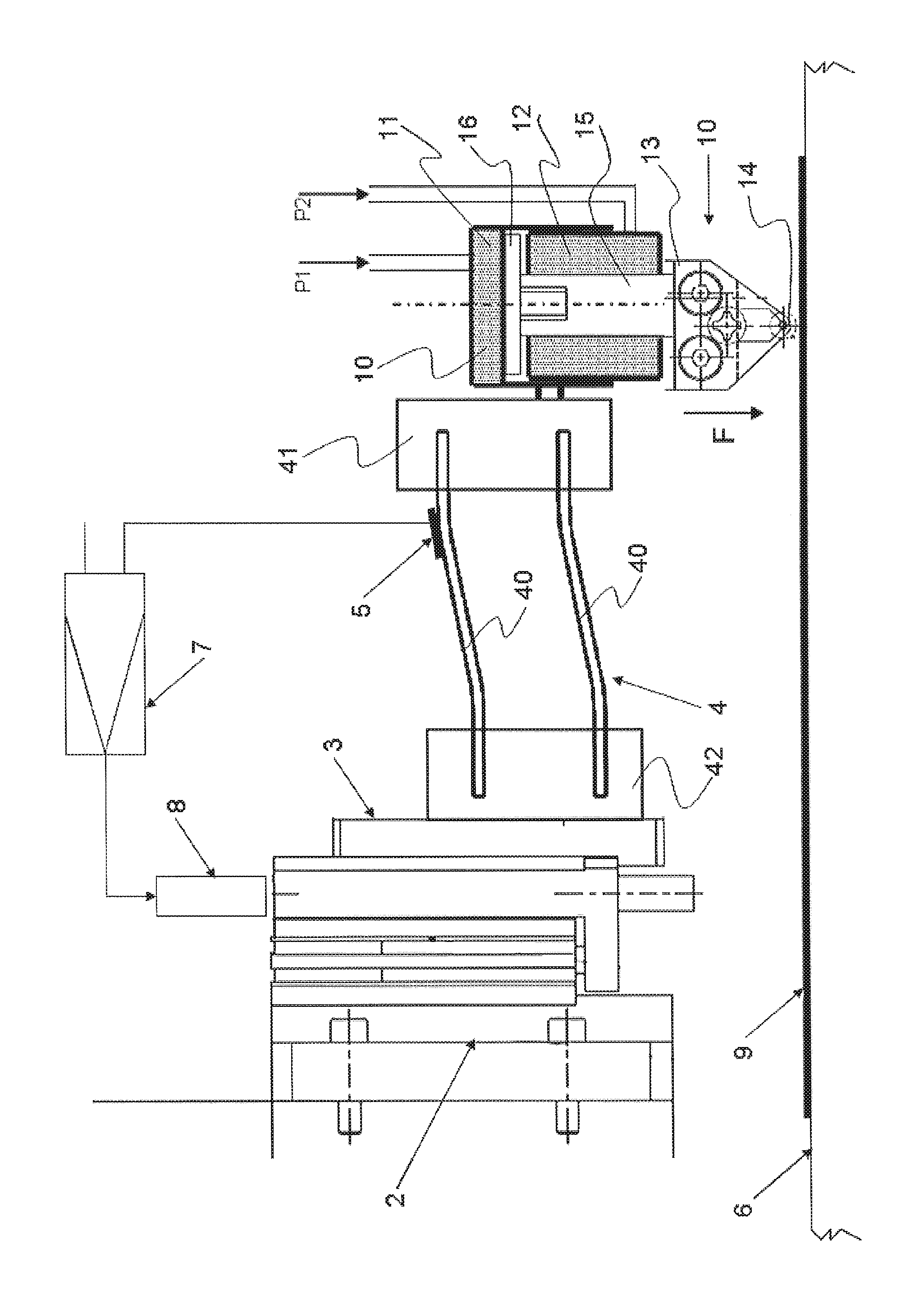

Method and apparatus for scoring thin glass and scored thin glass

ActiveUS20160185647A1Reduce roughnessImprove optical qualityStampsFlexible coversContact pressureHardness

A method and apparatus for scoring thin glass for the purpose of score and break separation as well as an accordingly prepared scored thin glass are provided. The scoring tool is pressed onto the thin glass and drawn along the scoring line with an adjusted scoring contact pressure force as a vertical scoring force component. This permits to production of prescored ultrathin glass of Knoop hardness from 350 to 650 with a score depth from 1 / 20 to ⅘ of the material thickness.

Owner:SCHOTT AG

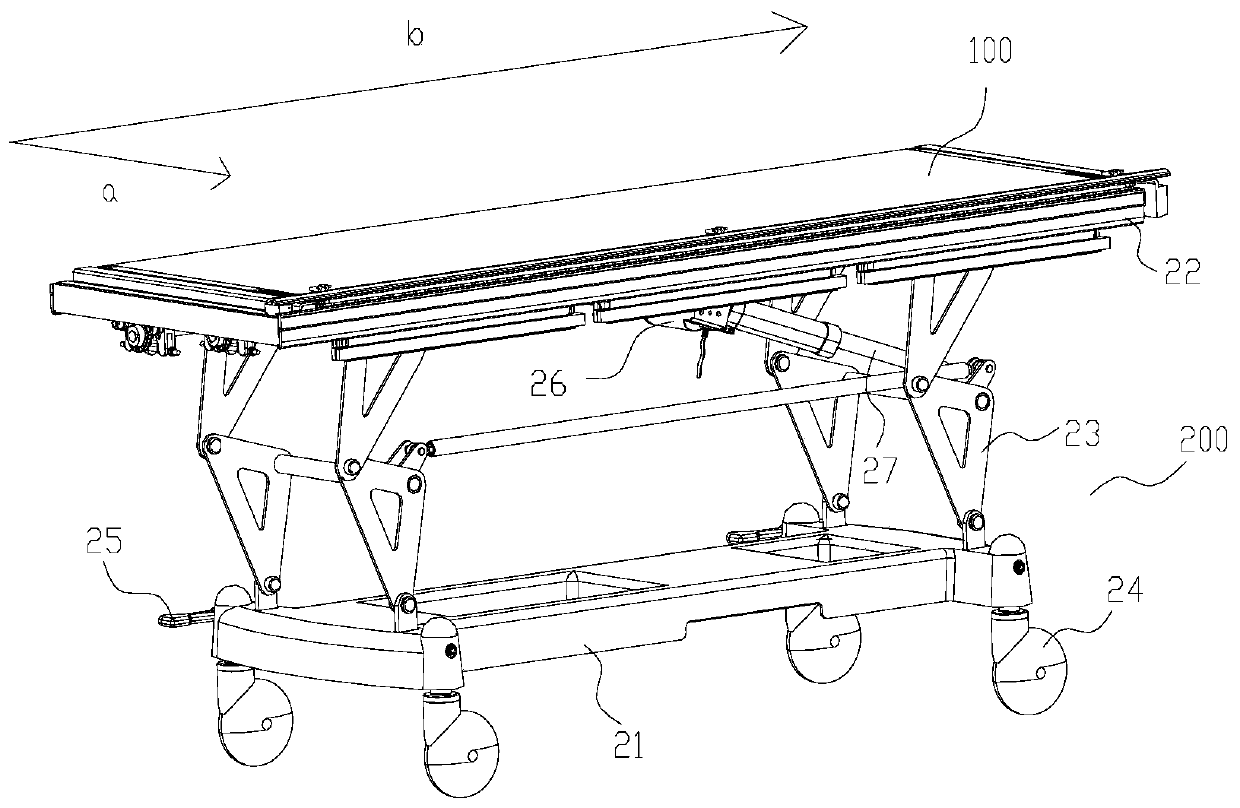

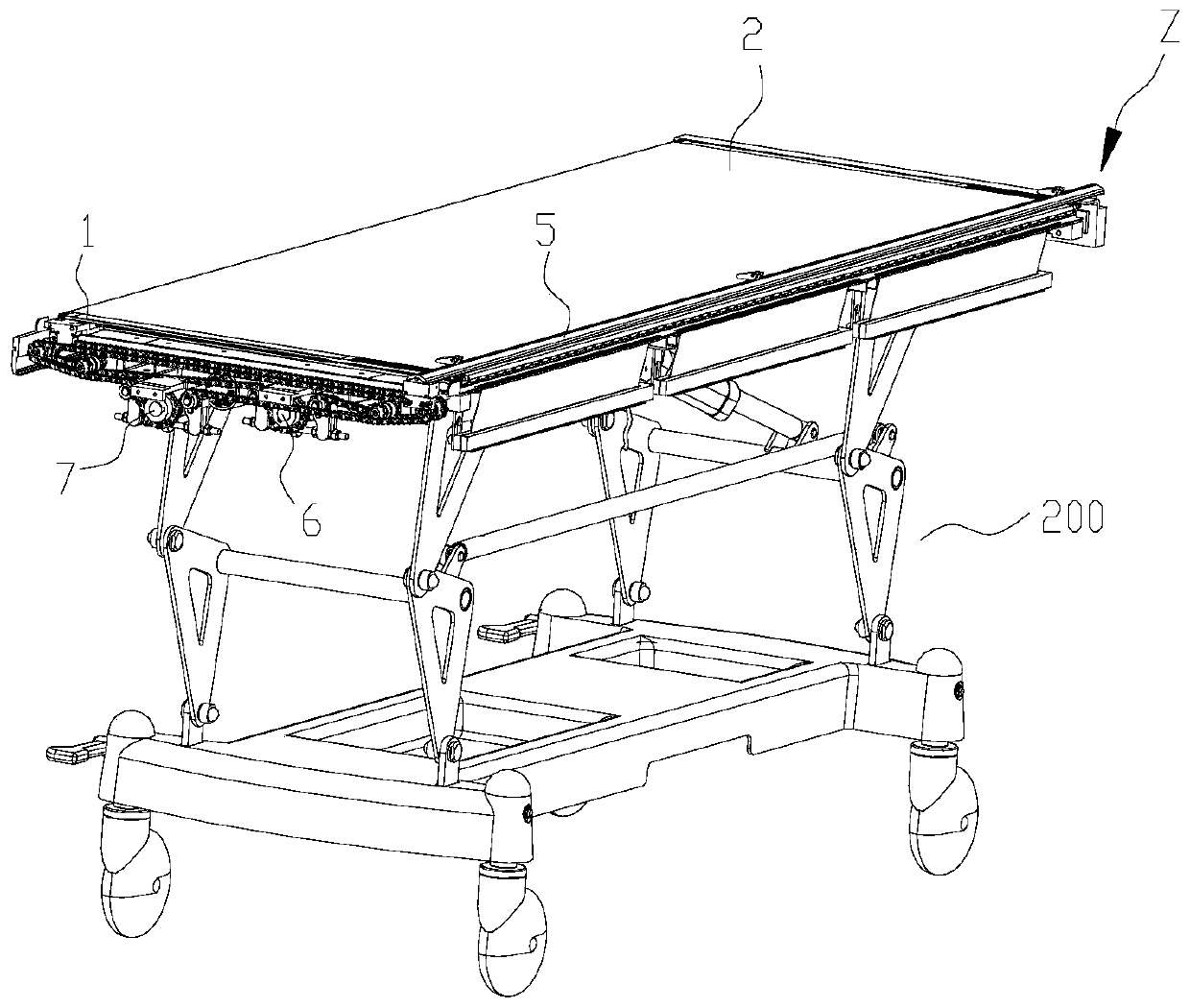

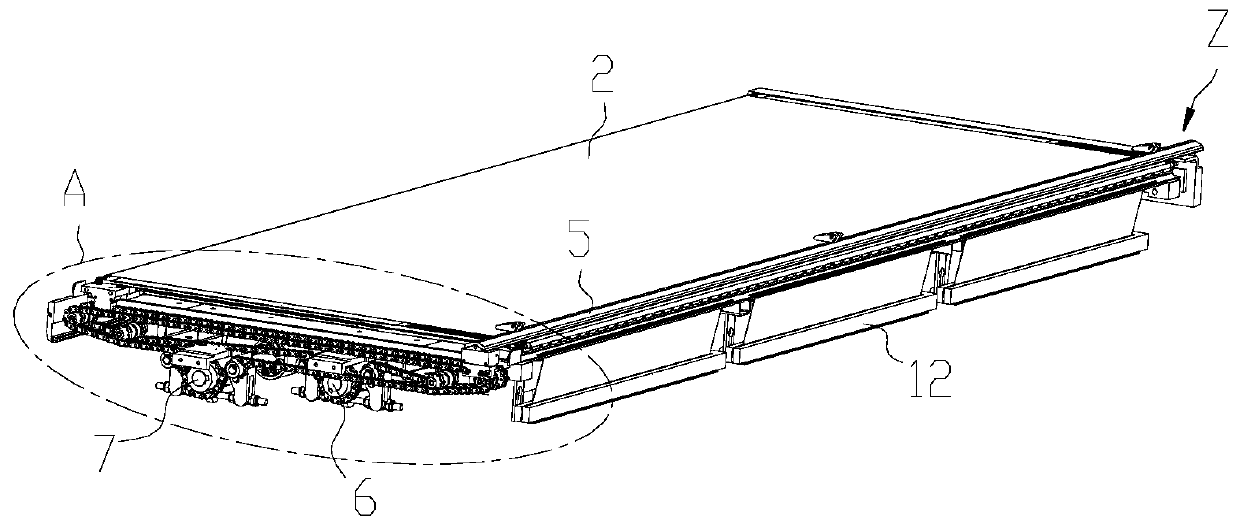

Medical transferring bed

The invention discloses a medical transferring bed. The medical transferring bed comprises a vehicle body, and a moving bed board mechanism, wherein the moving bed board mechanism is mounted on a vehicle frame of the vehicle body; the moving bed board mechanism comprises an upper moving board, an upper moving cloth, a lower moving board, and a lower moving cloth; the lower moving board is arrangedbelow the upper moving board; the upper moving board and the lower moving board are in synchronous lateral movement forward or backward; the upper moving cloth is coated on the periphery of the uppermoving board; a locking strip is longitudinally fixed to the upper moving cloth; the locking strip is locked to the shuttling side of the upper moving cloth, or is moved along with the upper moving cloth after locking is released; the lower moving cloth is coated on the periphery of the lower moving board; two ends of the lower moving cloth are fixed to the vehicle frame of the vehicle body; andthe lower moving cloth is located on the shuttling side of the lower moving board. According to the medical transferring bed disclosed by the invention, the locking strip is arranged, so that a mannerof rotating a transmission cloth through driving rubber rollers in the prior art is replaced; and the structure of the moving bed board mechanism is simplified, no friction coefficient requirement ofmoving cloths is generated, the moving resistance is lower, and the consumed power is lower.

Owner:沛霖医疗技术(广州)有限公司

Patulous self-furling memory alloy lock-release device

ActiveCN101224795AReduce diameter and lengthSmall sizeMechanical control devicesCosmonautic component separationSpacecraftEngineering

The invention discloses a spreading type self-furling memory alloy unlocking device used for a spacecraft, which consists of an arch locking wire subassembly (1), a stop (2), a lock body (3), a compression spring (4), a lifting arm (8), a connecting rod (9) and a releasing device; the arch bottom of the camber locking wire subassembly (1) is fixed at the front end of the lock body (3), the stop (2) is arranged on the arch locking wire subassembly (1), the connecting rod (9) inserts into an inner cavity at the front end of the lock body (3) after being connected with the stop (2); the connecting rod (9) passes through the rear end of the lock body (3) and is connected with the lifting arm (8), the lifting arm (8) tightly presses the compression spring (4) in the lock body (3); the releasing device is clamped at the rear end of the lock body (3) by a connecting part fixed on the lifting arm (8). The memory alloy locking wire provided by the invention adopts an arch spread mode, thus reducing the diameter and the length of the alloy wire, also the size is small and the unlocking time is short; furthermore, the unlocking purpose can be realized after stretching at any side, the reliability is high and the invention can be used for various spacecrafts.

Owner:AEROSPACE DONGFANGHONG SATELLITE

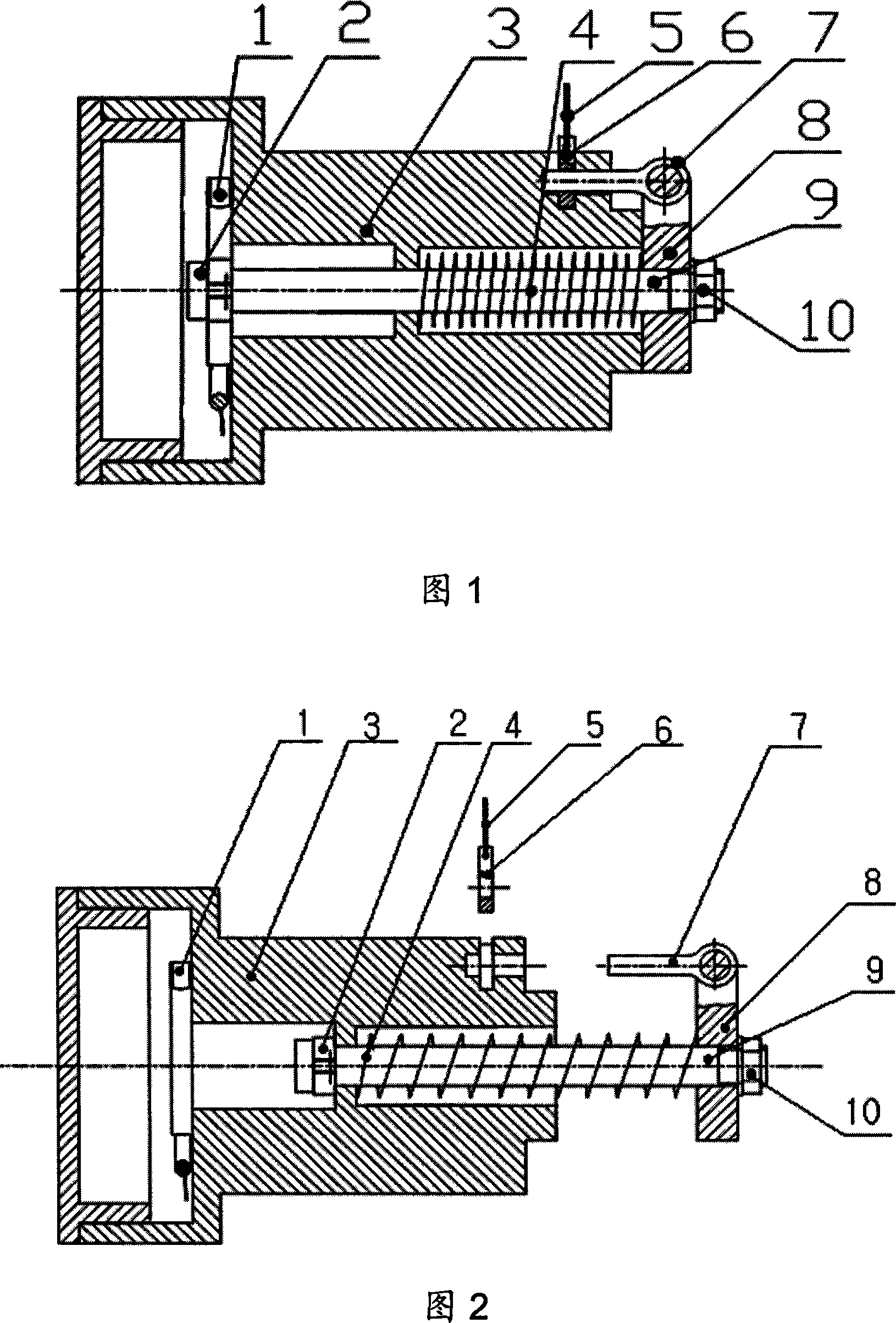

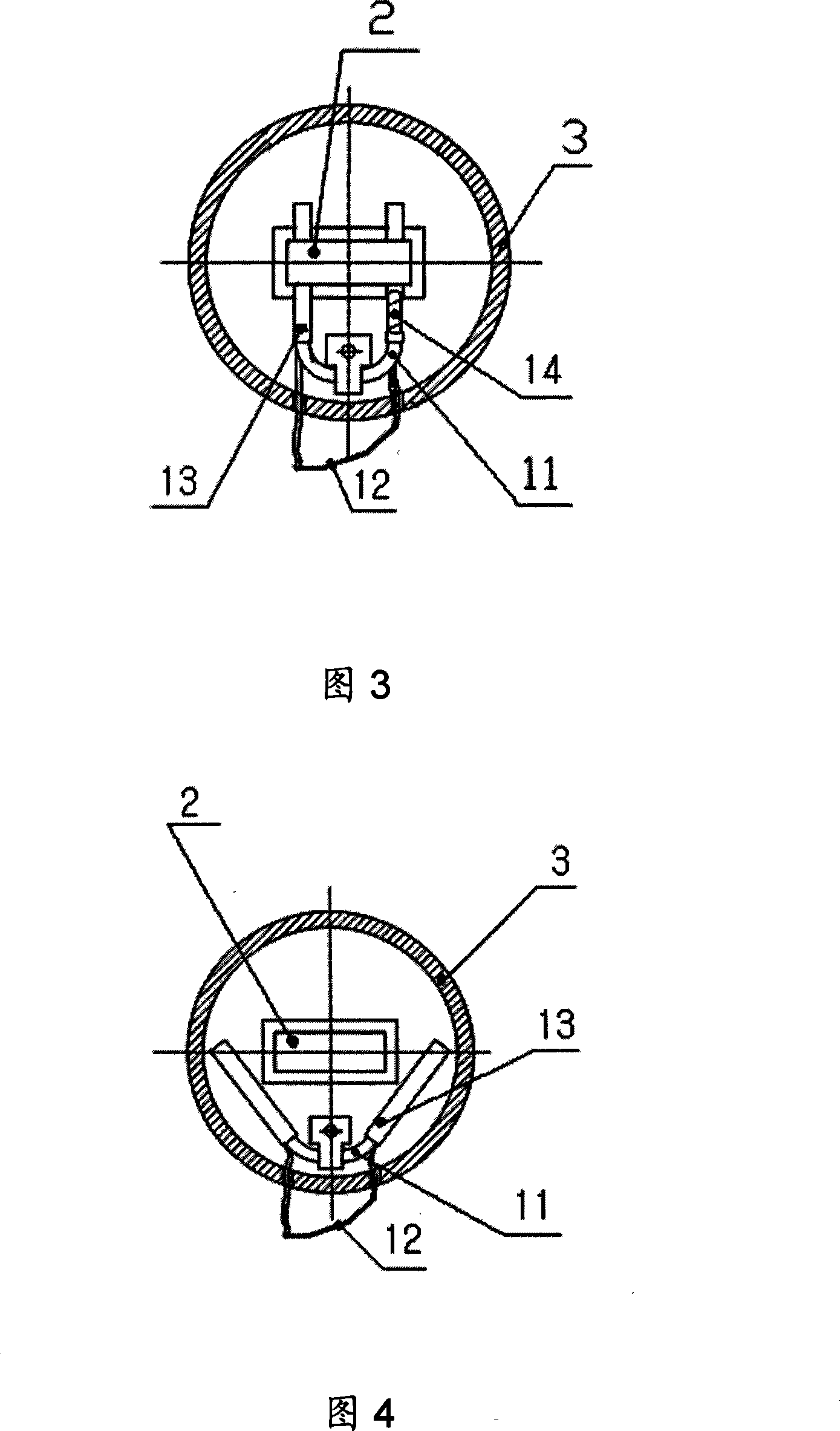

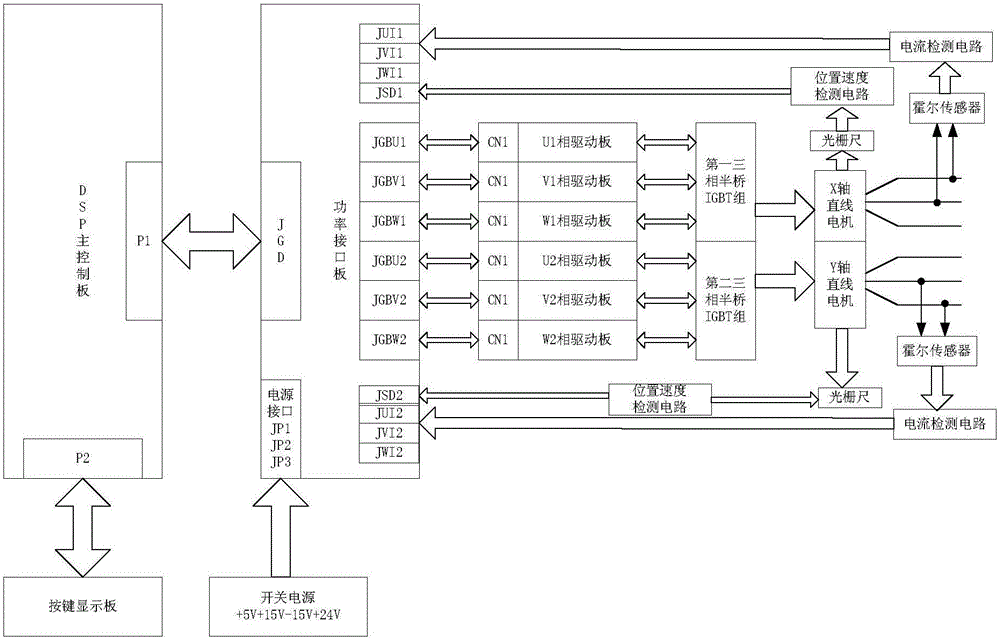

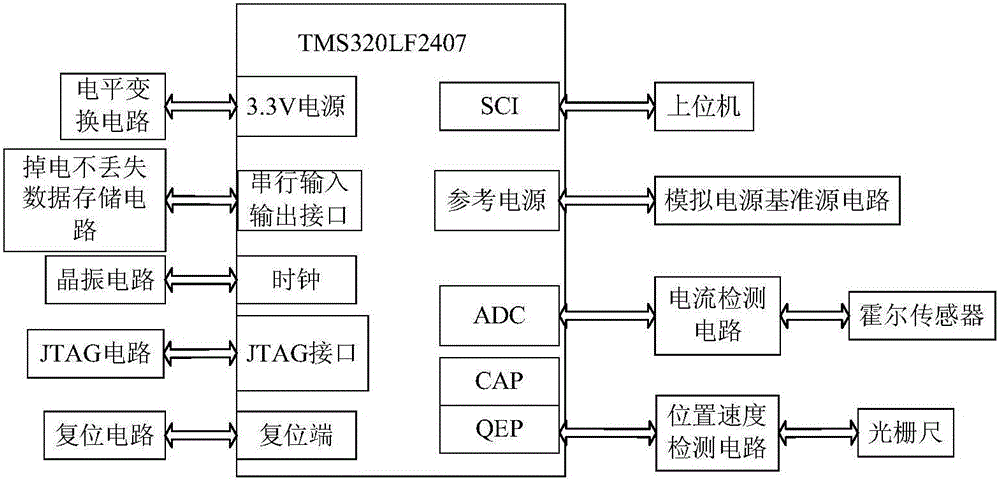

Biaxial motion platform positioning and dynamic locus tracking control device and method

InactiveCN105159227AReduce transient overshootImprove stabilityNumerical controlSelf adaptiveSliding mode control

The invention relates to a biaxial motion platform positioning and dynamic locus tracking control device and method and belongs to the technical field of multi-axis motion control. The method comprises steps of: setting a position coordinate according to a shape of an instruction motion locus and enabling two linear motors to motion when receiving the same instruction signal; determining the actually-measured position and actual speed of each linear motor; computing the position tracking error and the rotating speed deviation of each linear motor; performing variable-speed switching control if a positioning instruction is executed; in a dynamic locus tracking control process executed in real time, preliminarily designing an inversion sliding-mode control law, namely the control current of a permanent-magnetic synchronous linear motor, by selecting a Lyapunov function, correcting the control law in real time in combination with an adaptive method, and feeding the corrected control law, namely the corrected input current, back to the system. The device and the method may achieve smooth platform positioning speed transition, improve platform positioning precision, suppress disturbance existing in the platform system, and achieve precision tracking control of a dynamic locus.

Owner:BOHAI UNIV

Silk pole clamping device

Owner:WUJIANG WANPING XURI SEWING MACHINE PARTS FACTORY

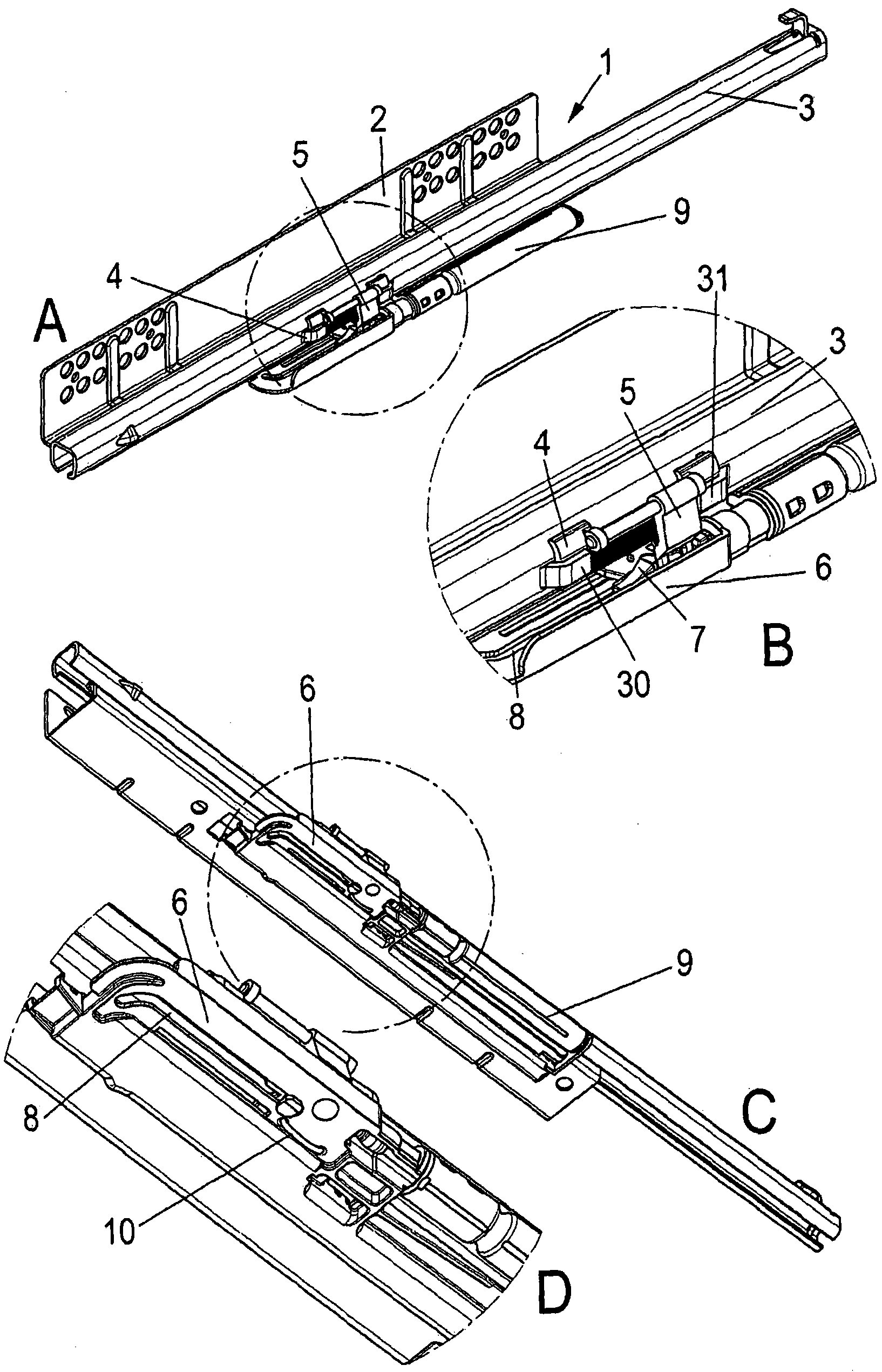

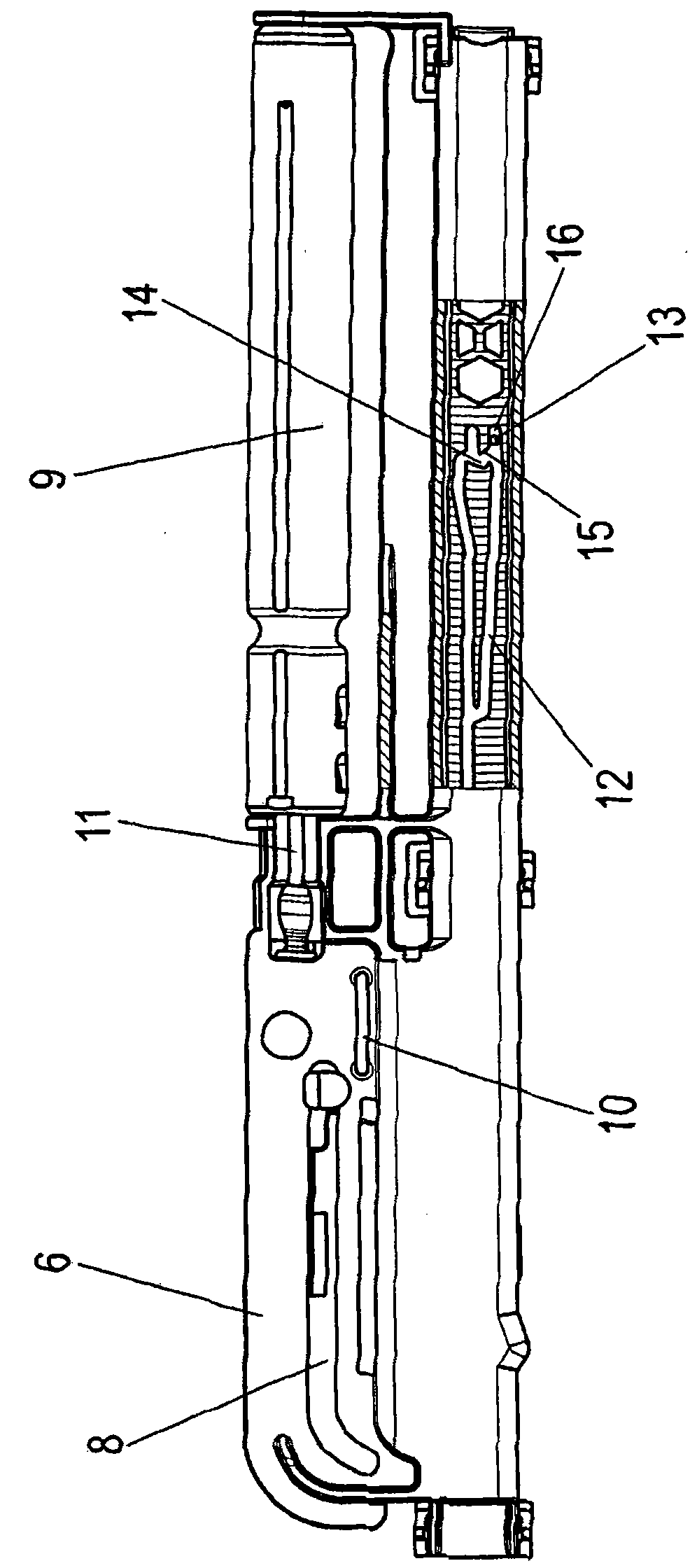

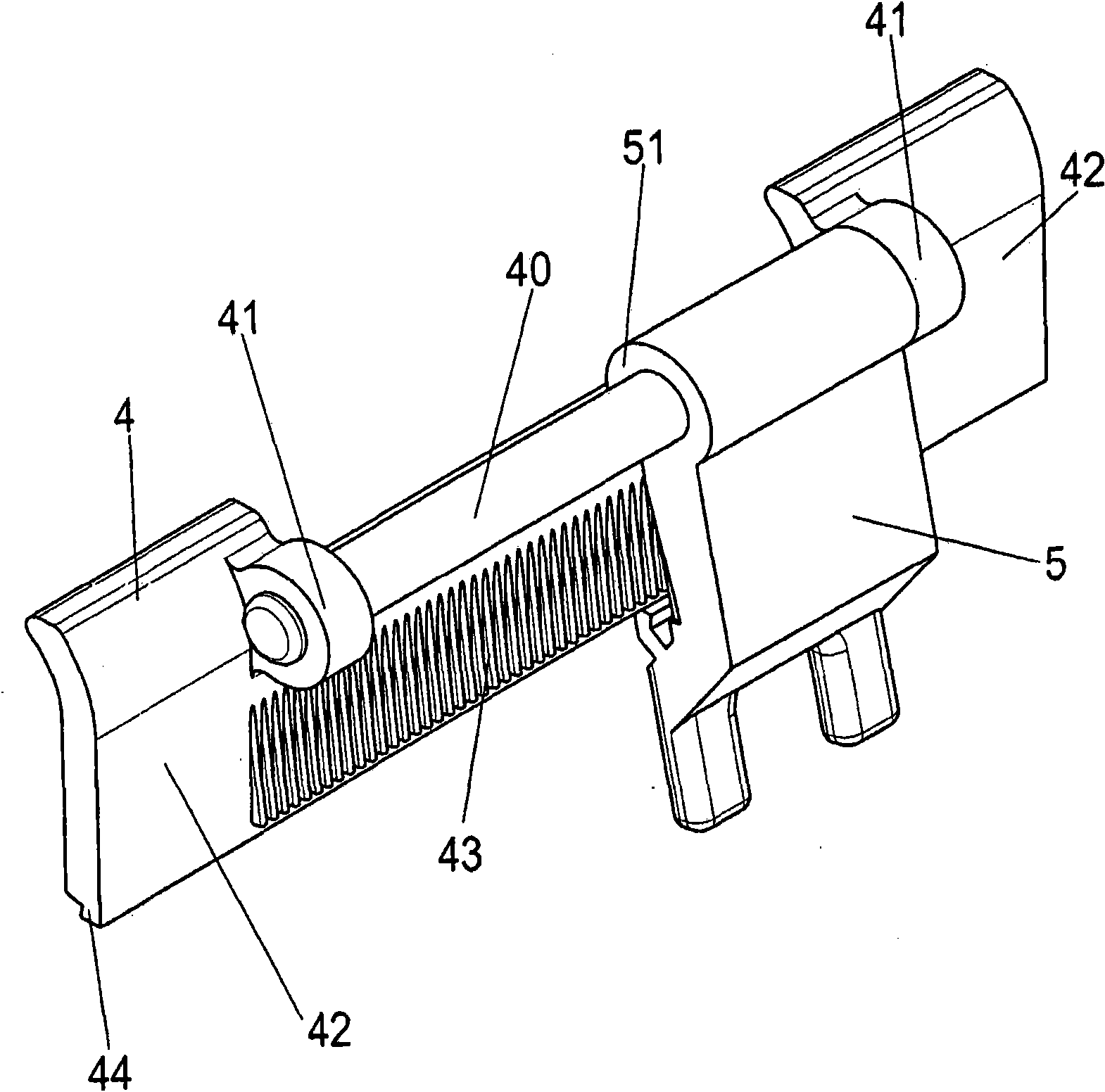

Device for opening and/or closing drawers and method for calibrating the same

The invention relates to a device for opening and / or closing drawers. The device has a pull-out guide (1) including a guide rail (2) fixed at a cabinet body and a displaceably supported sliding rail (3). The sliding rail (3) is fixed with a drawer with a panel and a retaining element (4) with an actuator (5), wherein the actuator (5) is linked with a drawing opening and / or closing mechanism. According to the invention, the actuator (5) is displaceably supported on the retaining element (4) and the retaining element (4) is fixed on different positions in order to adjust the distance between the panel and the cabinet body. In addition, the invention also provides a method for correcting a panel gap by means of such a device so as to adjust the panel gap by a simple method.

Owner:PAUL HETTICH

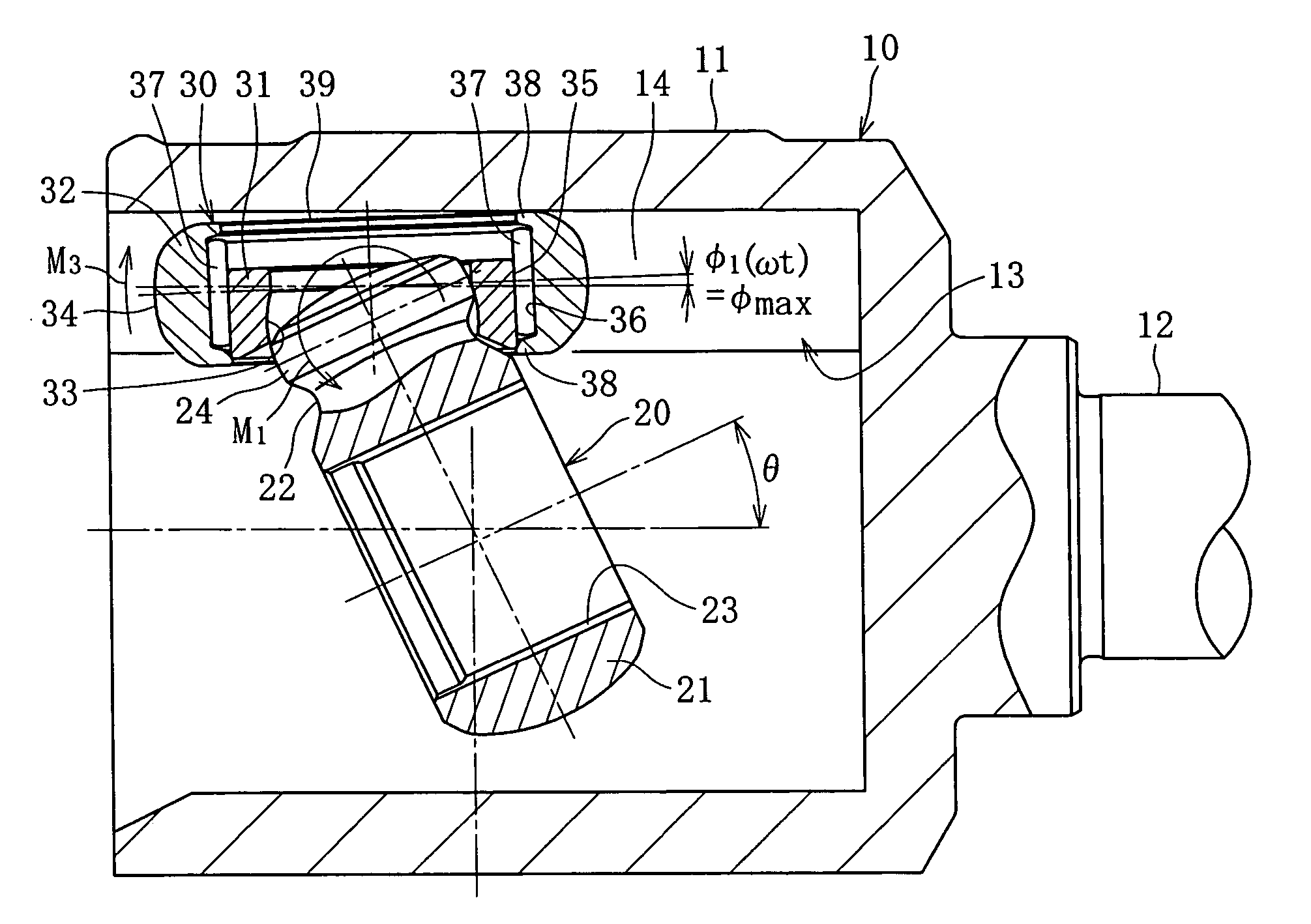

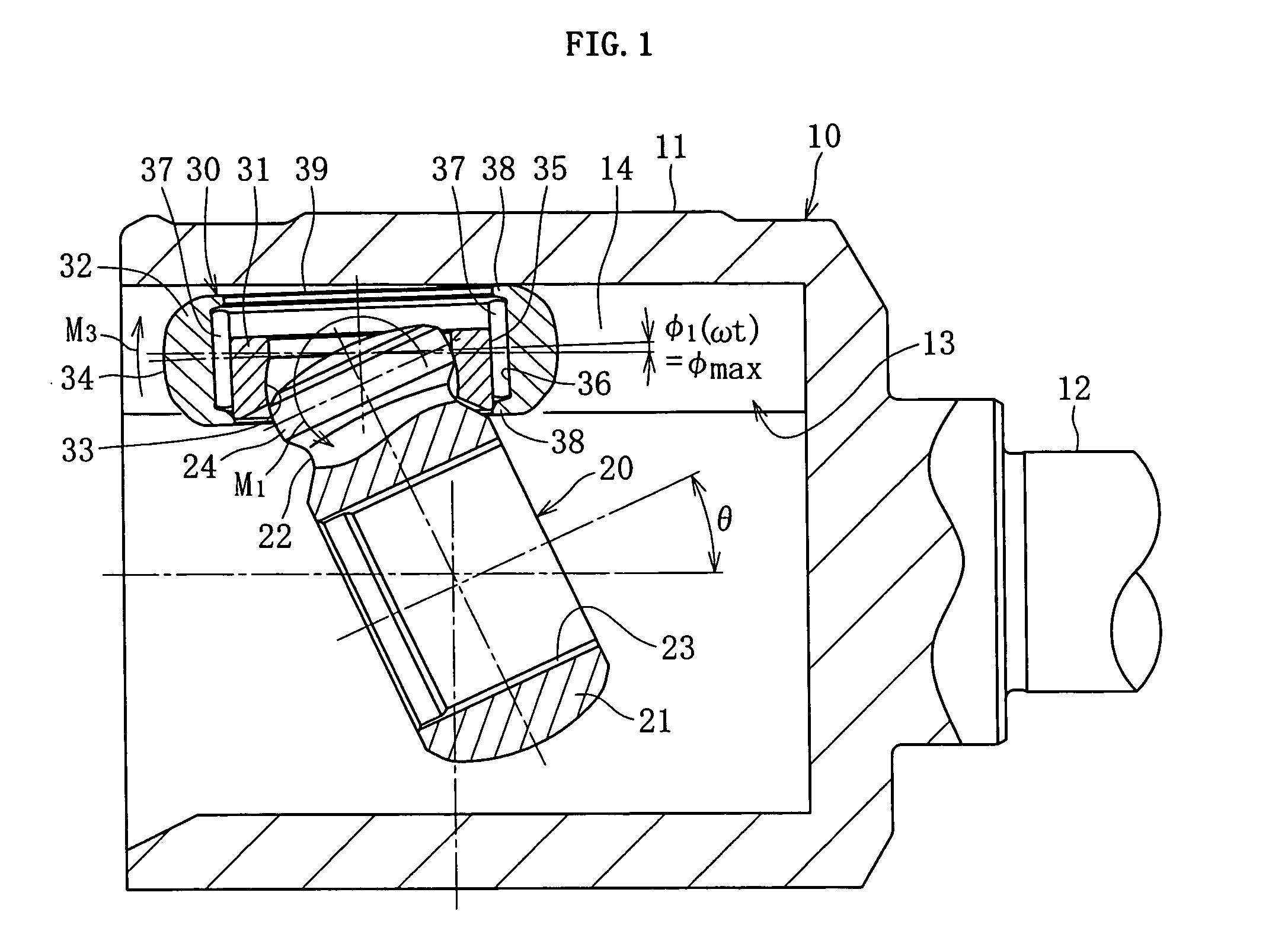

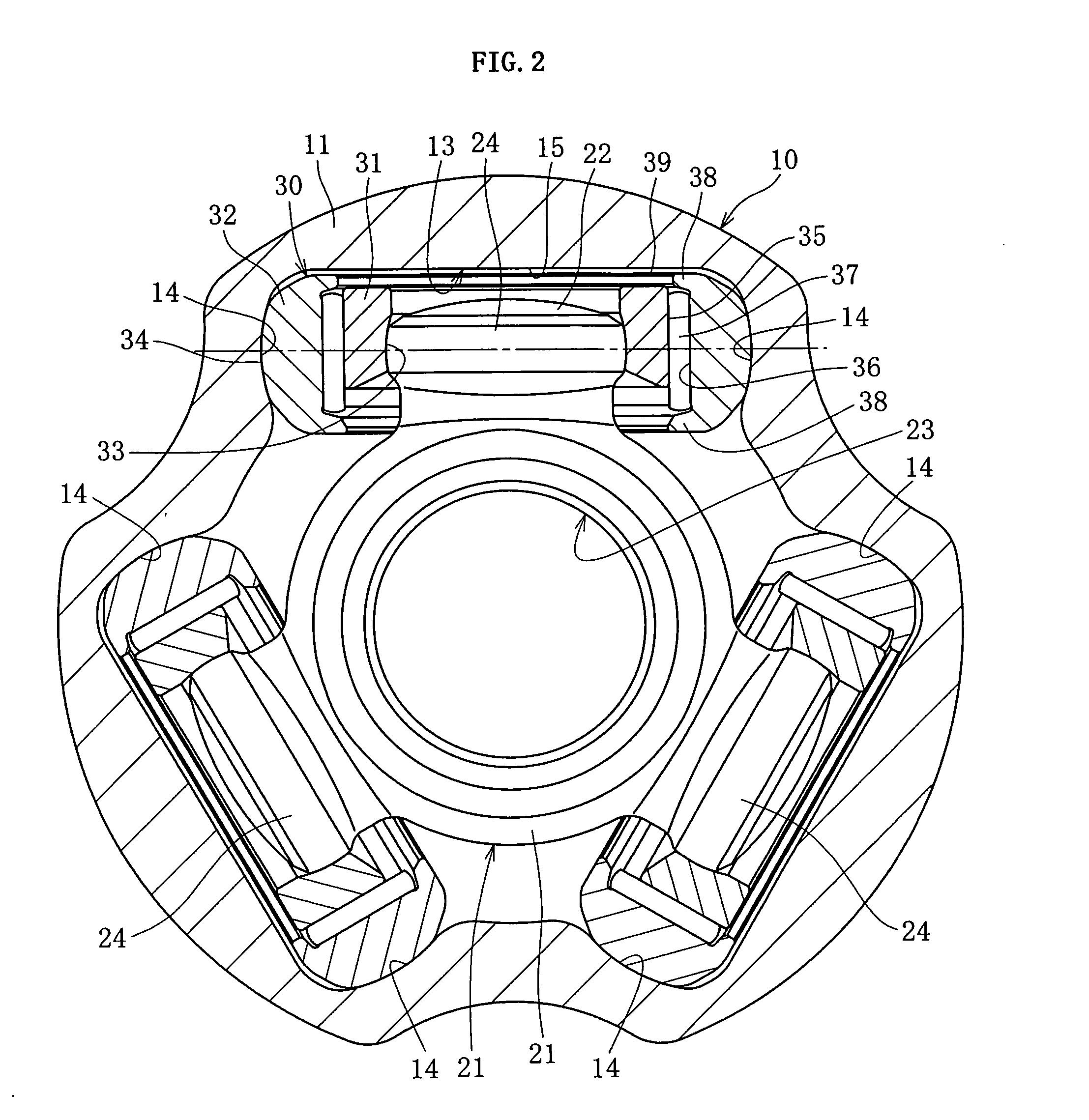

Tripod type constant velocity universal joint

InactiveUS20060030413A1Reduce thicknessImprove retention capabilityYielding couplingRotary machine partsConstant-velocity jointTrunnion

The invention provides a tripod type constant velocity universal joint that can restrain generation of an excessive frictional force inside the joint because of the rotation phase angle of the inner joint member, thereby suppressing vibration and achieving higher rotation durability. The tripod type constant velocity universal joint includes an outer roller rotatably located inside the roller guide section of the outer joint member, and an inner roller spherically fitted to the trunnion of the inner joint member so as to be pivotally rotatable, and to support the outer roller permitting relative rotation and relative axial movement, so that when a torque is applied with the outer joint member and the inner joint member oriented with an operating angle θ, a facet of the outer roller inclined along with the rotation of the inner joint member is sustained by the track groove bottom portion formed in a flat plane.

Owner:NTN CORP

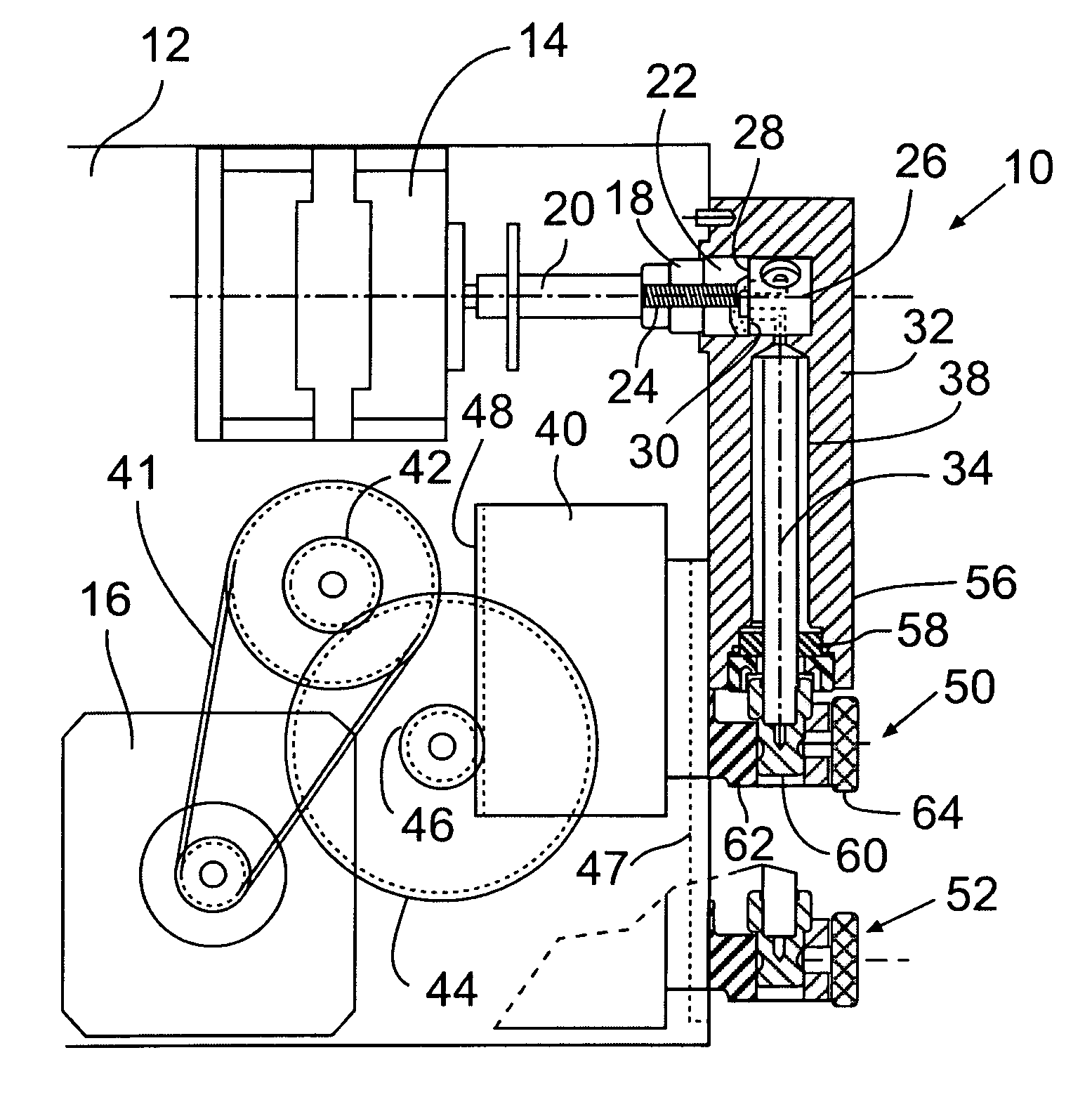

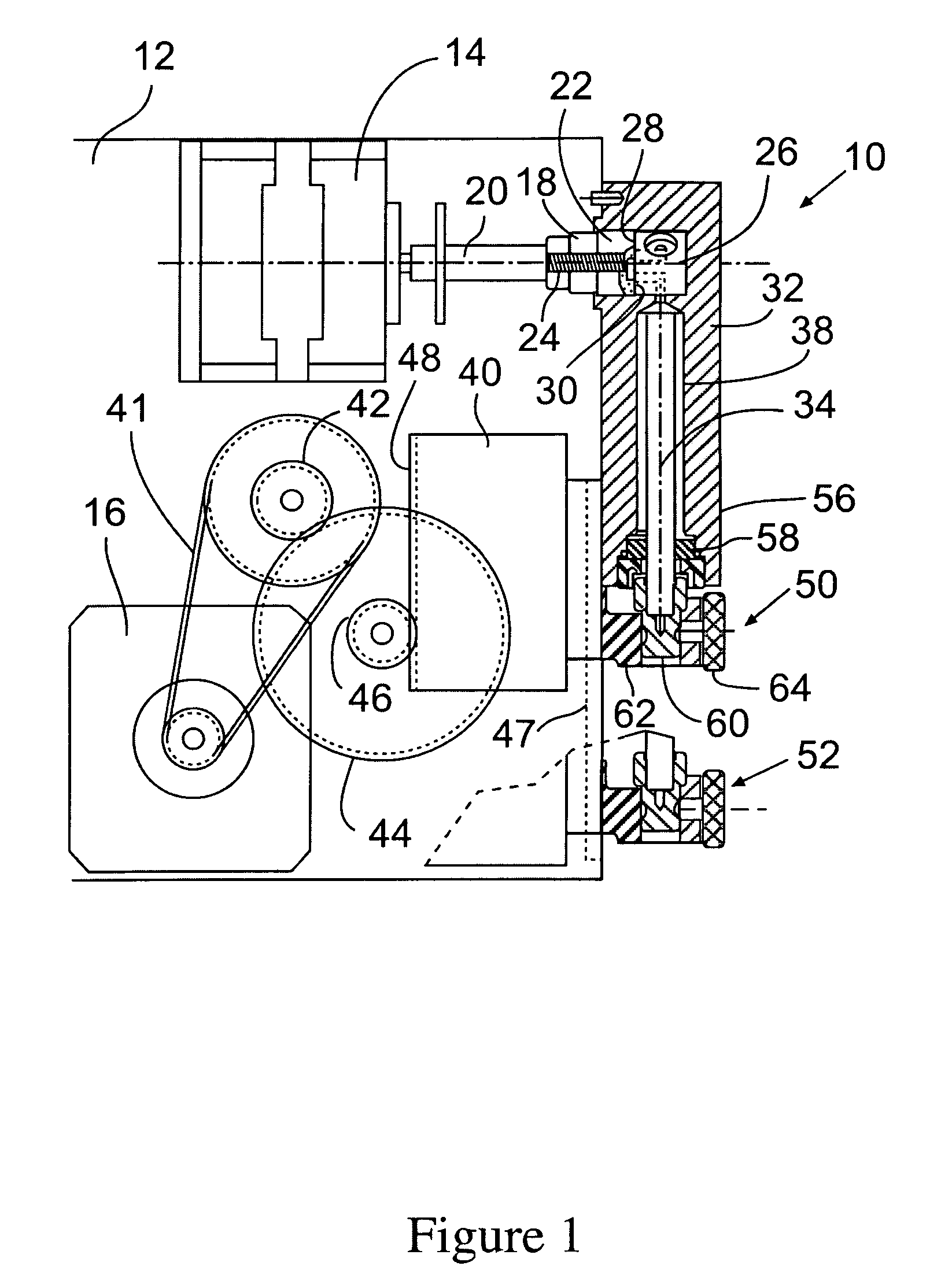

Integrated pump and ceramic valve

ActiveUS7080975B2Avoid frictionHigh pressure sealEngine sealsFluid parameterMechanical engineeringStator

A pump apparatus is provided which comprises a displacement pump and a ceramic valve construction formed of a ceramic rotor and a ceramic stator having flat surfaces which are positioned in sealing relationship. The displacement pump comprises a reciprocating piston within a housing having an interior wall spaced apart from the piston. The position of the piston and the position of the rotor are controlled to effect desired fluid flow through the stator.

Owner:IDEX HEALTH & SCI

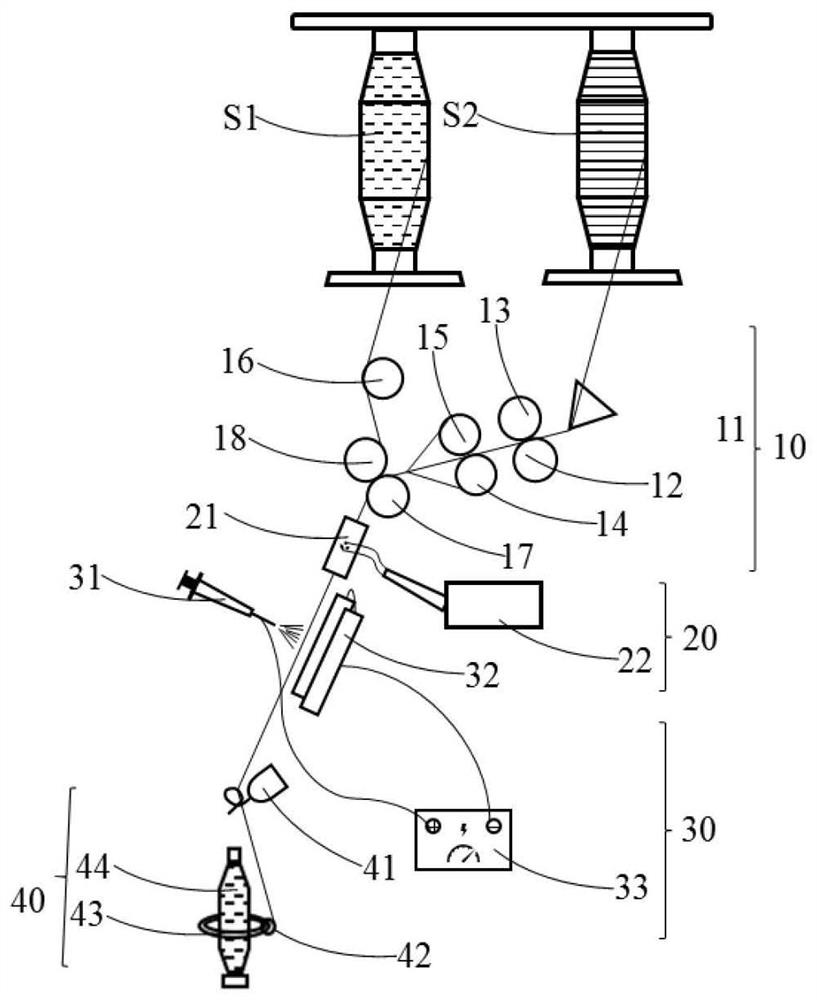

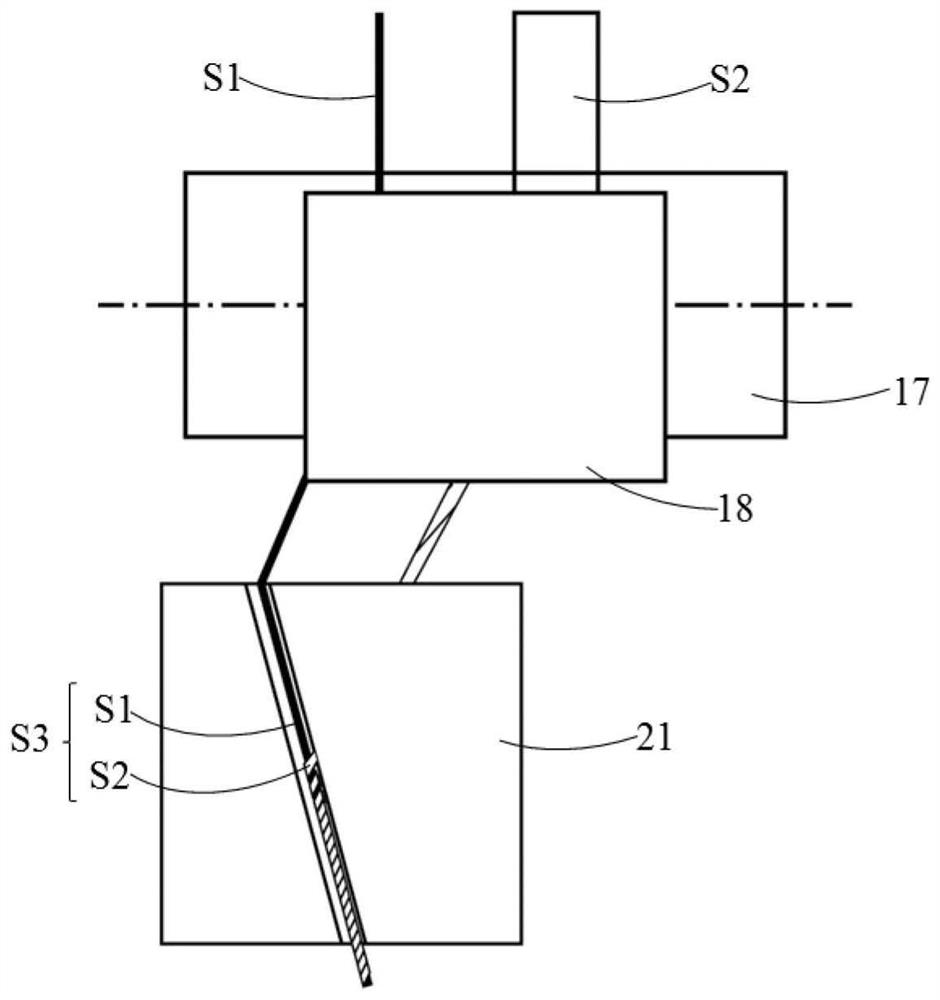

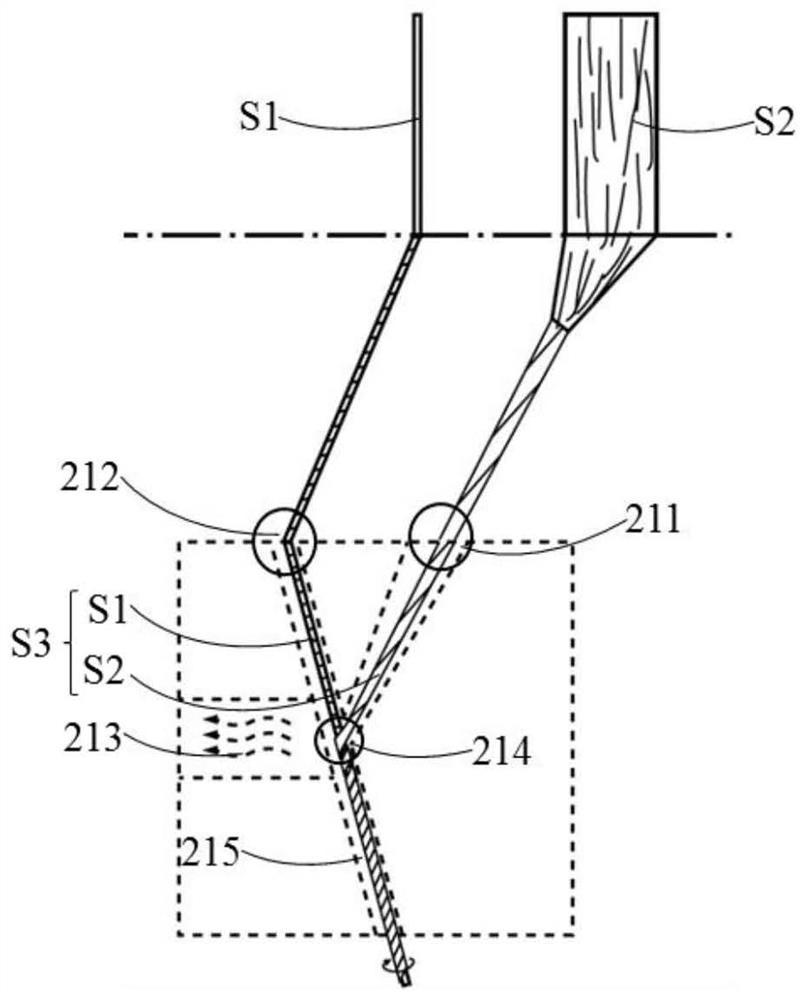

Core spinning device and new-structure core spinning method for full wrapping of macro core

The invention provides a core spinning device and a new-structure core spinning method for full wrapping of a macro core. According to the core spinning device, an auxiliary core wrapping device is additionally arranged between a front roller jaw and a yarn guide hook of a common ring spinning frame; and the auxiliary core wrapping device comprises a first yarn channel used for conveying an outer wrapping material, a second yarn channel used for conveying a core layer material and a wrapping point used for wrapping and converging. In a spinning process, short fiber strands and filaments form a y-shaped twisting structure with the filaments in a straightened state, the filaments are kept in the straightened state at the wrapping point, and the short fiber strands wrap outer layers of the filaments at the wrapping point by means of twisting rotation of the filaments and partial twist of the short fiber strands, so that core spun yarn with a good wrapping effect is formed, and the problem of core exposure of the ring-spun core spun yarn is solved. According to the invention, through coating of nanofibers, the hairiness of resultant yarn is completely eliminated, and the performance of the resultant yarn is comprehensively improved. The operation is convenient, the transformation cost is low, and the performance of the ring-spun core spun yarn is obviously improved.

Owner:WUHAN TEXTILE UNIV

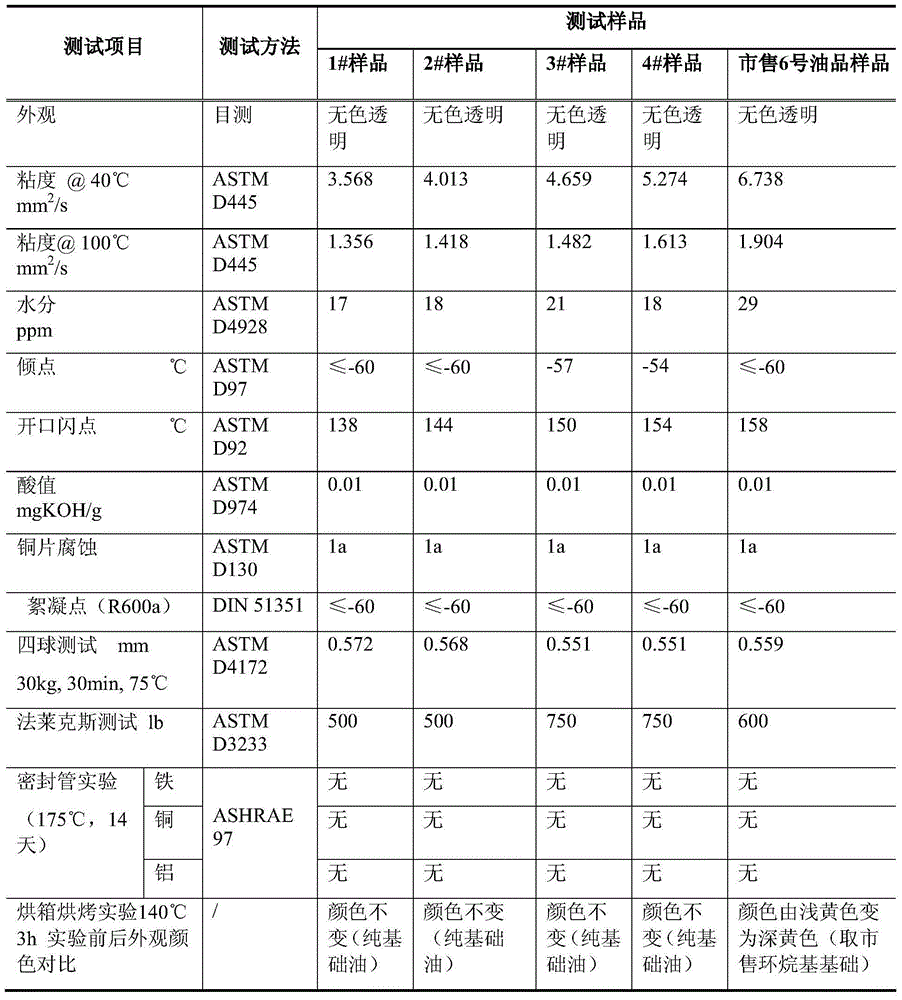

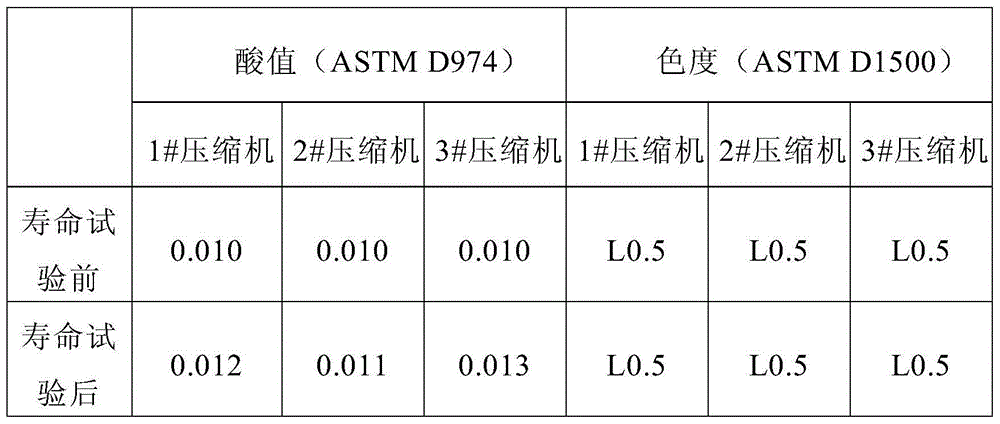

Refrigerating engine oil composition and application thereof

InactiveCN104087388AGood compatibilityImprove high temperature stabilityLubricant compositionRefrigeration compressorAlkane

The invention relates to a refrigerating engine oil composition and an application of the refrigerating engine oil composition. One aim of the invention is to provide a refrigerating engine oil composition which has good compatibility with hydrocarbon refrigerants, is high in flash point and low in viscosity, can be used for furthest increasing the COP (coefficient of performance) value of a compressor, and has excellent thermal stability and relatively low cost. The other aim of the invention is to provide an application of the refrigerating engine oil composition used as a lubricating agent in a refrigeration compressor which uses isobutane, propane or a mixture of isobutane and propane as a refrigerant. The refrigerating engine oil composition consists of the following components in percentage by weight: 96.5-99.5% of base oil and 0.5-3.5% of a lubricating oil additive, wherein by taking the weight of the base oil as 100%, the base oil comprises the following components in percentage by weight: 20-79% of alkylated aromatic hydrocarbon and 21-80% of an alkane mixture; by taking the total weight of the composition as 100%, the lubricating oil additive comprises the following components in percentage by weight: not more than 3% of an extreme pressure anti-wear additive, 0-3% of an antioxidant, 0-3% of the lubricating agent, 0-0.8% of a metal deactivating agent and 0-0.02% of an anti-foaming agent.

Owner:SHRIEVE CHEM SHANGHAI LTD

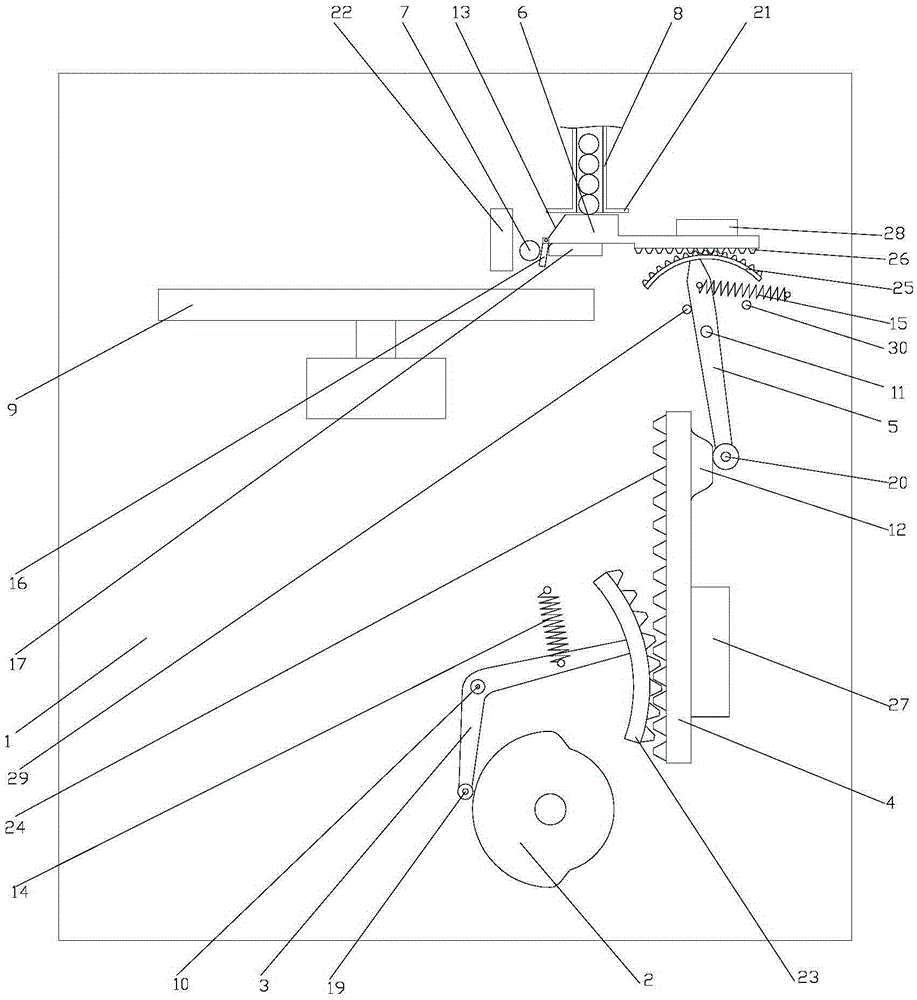

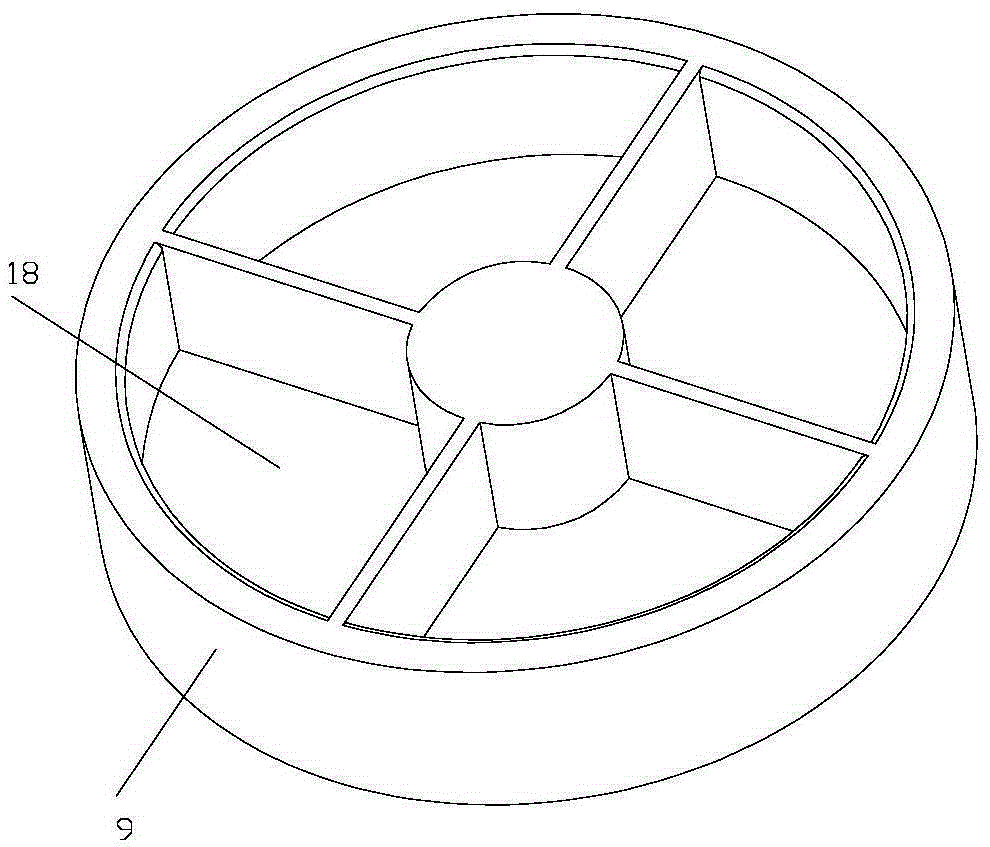

Automatic rolling ball grouping mechanism

InactiveCN105252248AReduce labor intensitySmooth slidingMetal working apparatusElectric machineryCam

The invention discloses an automatic rolling ball grouping mechanism which comprises a base (1), a cam (2), a transmission rod (3), a vertical plate (4), a swing rod (5), a pushing block (6), a material barrel (8) and a rotary plate (9), wherein the cam (2) is rotatably connected on the base (1); a first motor for driving the cam (2) to rotate is arranged on the base (1); the middle part of the transmission rod (3) is rotatably connected on the base (1) through a first hinged point (10); one end of the transmission rod (3) abuts against the external contour of the cam (2); the other end of the transmission rod (3) is provided with a first arc-shaped rack (23); and a first tension spring (14), which is used for tensioning the transmission rod (3) to ensure that one end of the transmission rod (3) always abuts against the external contour of the cam (2), is arranged between the transmission rod (3) and the base (1). The invention provides the automatic rolling ball grouping mechanism, and the mechanism is accurate in checking rolling balls, and small in labor intensity of an operator.

Owner:NEWSUN NINGBO AUTO BEARING MFG

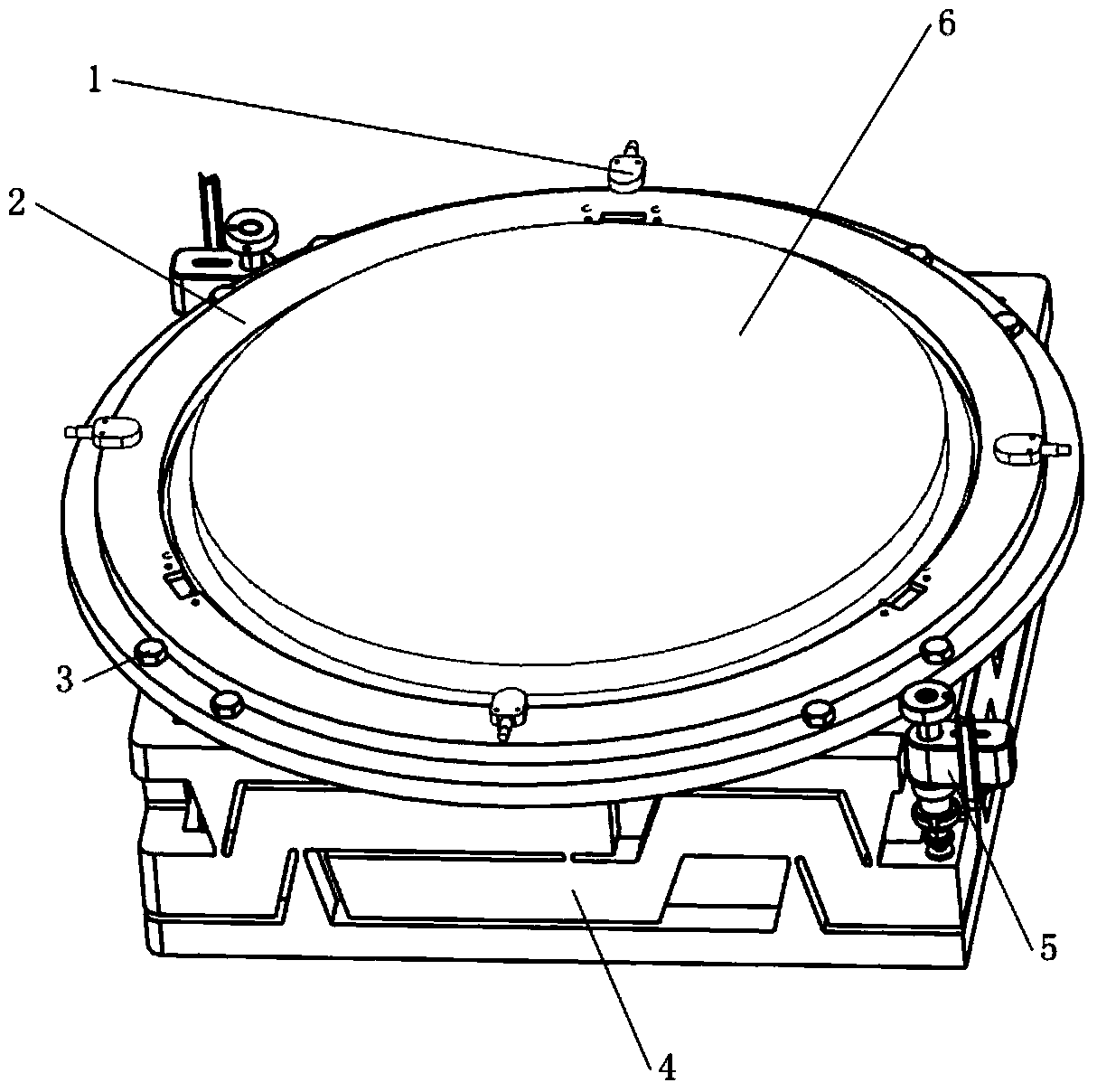

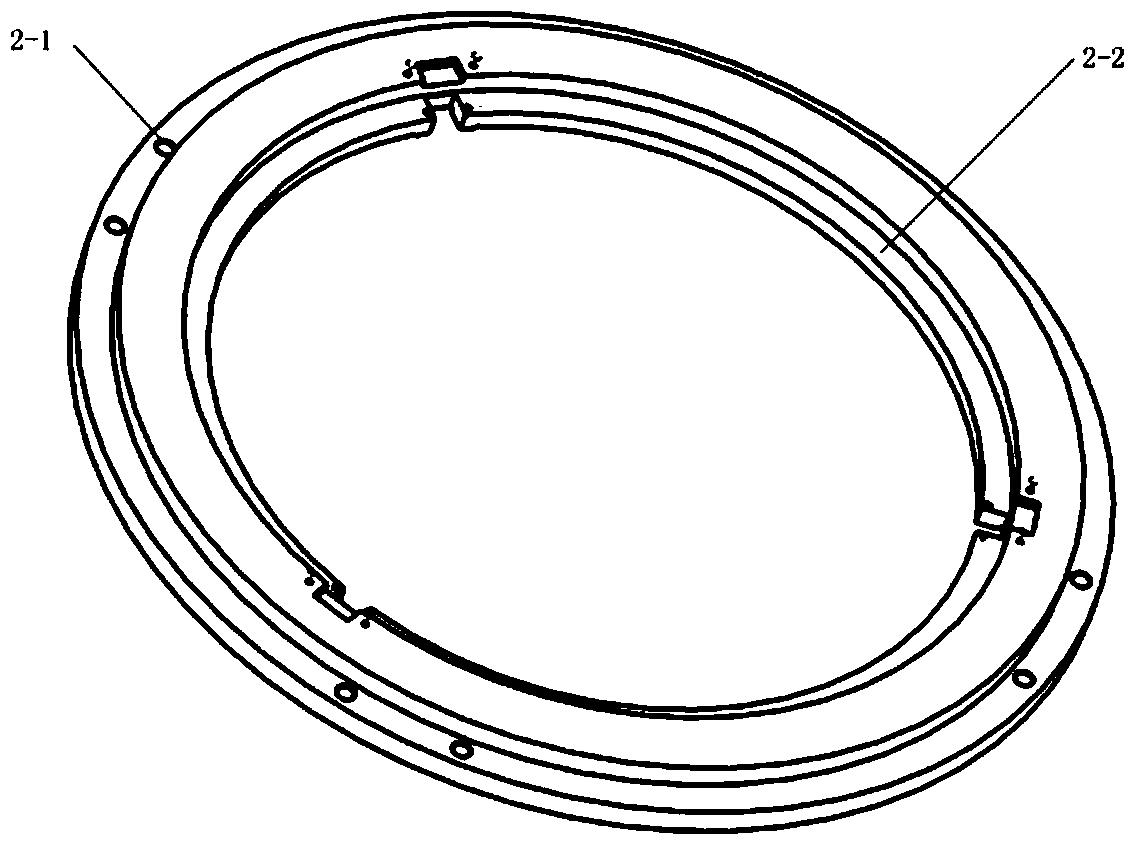

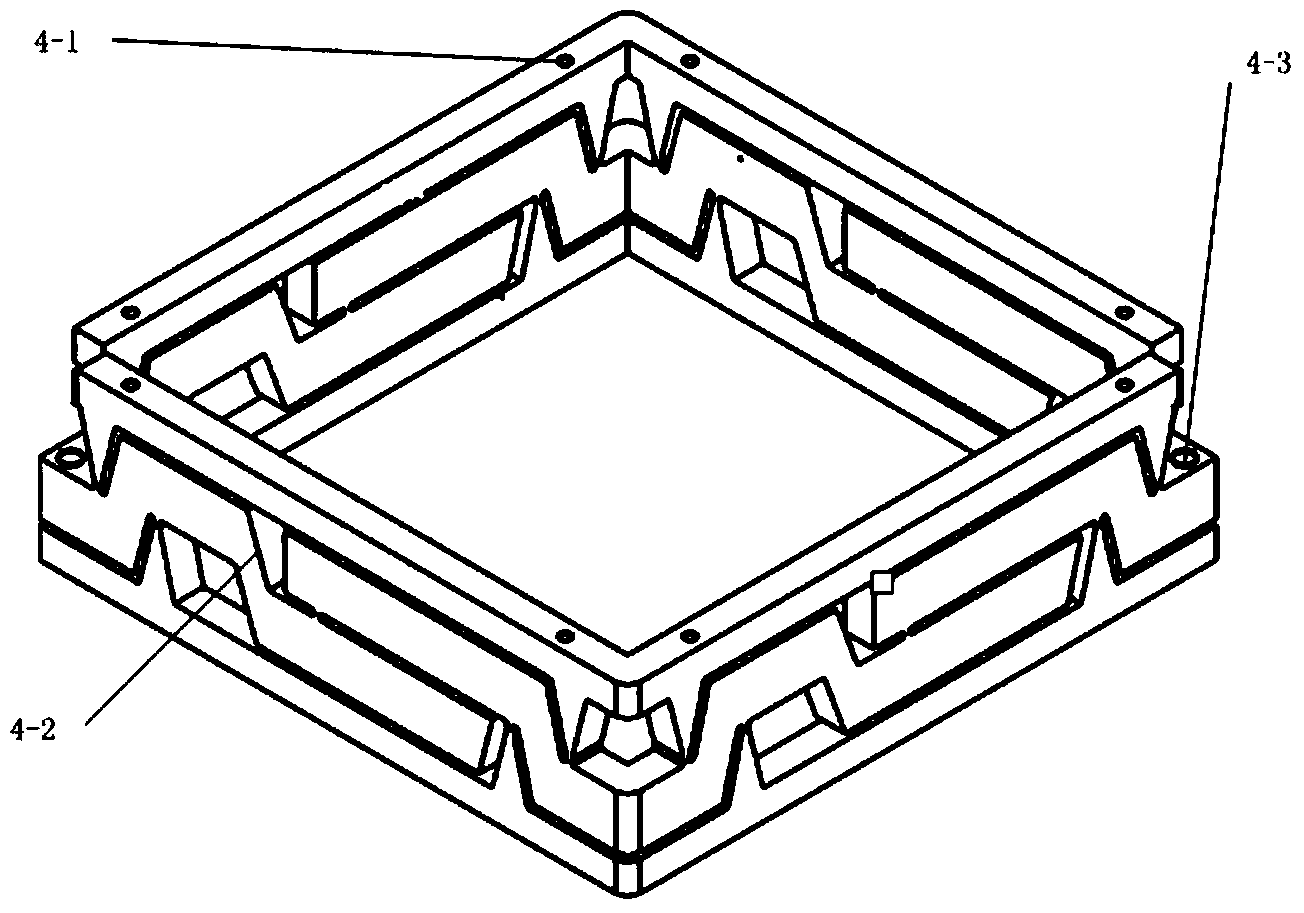

Dual-motor optical element axial adjustment device

InactiveCN103472555AAvoid frictionReduce damagePhotomechanical exposure apparatusMicrolithography exposure apparatusLubricationHinge angle

The invention provides a dual-motor optical element axial adjustment device, relates to the technical field of deep ultraviolet projection photoetching objective lens structural design and adjustment, and aims to solve the problems that an existing optical element aligning device is provided with a large number of actuators and is complex in mechanism and high in processing difficulty. The dual-motor optical element axial adjustment device comprises four capacitive sensors, an optical frame, eight connection screws, a smooth driving block and two piezoelectric actuators. The four capacitive sensors are placed parallel to the upper surface of the optical frame, are evenly distributed along the upper edge of the optical frame, and correspond to the midpoints of all right-angle sides of the smooth driving block. The optical frame and the smooth driving block are fixed through the connection screws. The two piezoelectric actuators are arranged at the diagonal positions of the smooth driving block respectively. An optical element is arranged in the optical frame. By means of the dual-motor optical element axial adjustment device, rapid and precise adjustment is realized, and meanwhile, the problems of friction, lubrication and hysteresis of a mechanical hinge are avoided; the smooth driving block acts on the optical frame so that damage to the surface form of the optical element by adjustment force can be effectively lowered; the structure is simple, a small number of motors are needed, and processing cost is low.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com