Medical transferring bed

A transfer bed and mobile bed board technology, applied in medical transportation, hospital beds, medical science, etc., can solve the problems of prone to failure, easy to move left and right on the cloth surface, difficult to clean, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

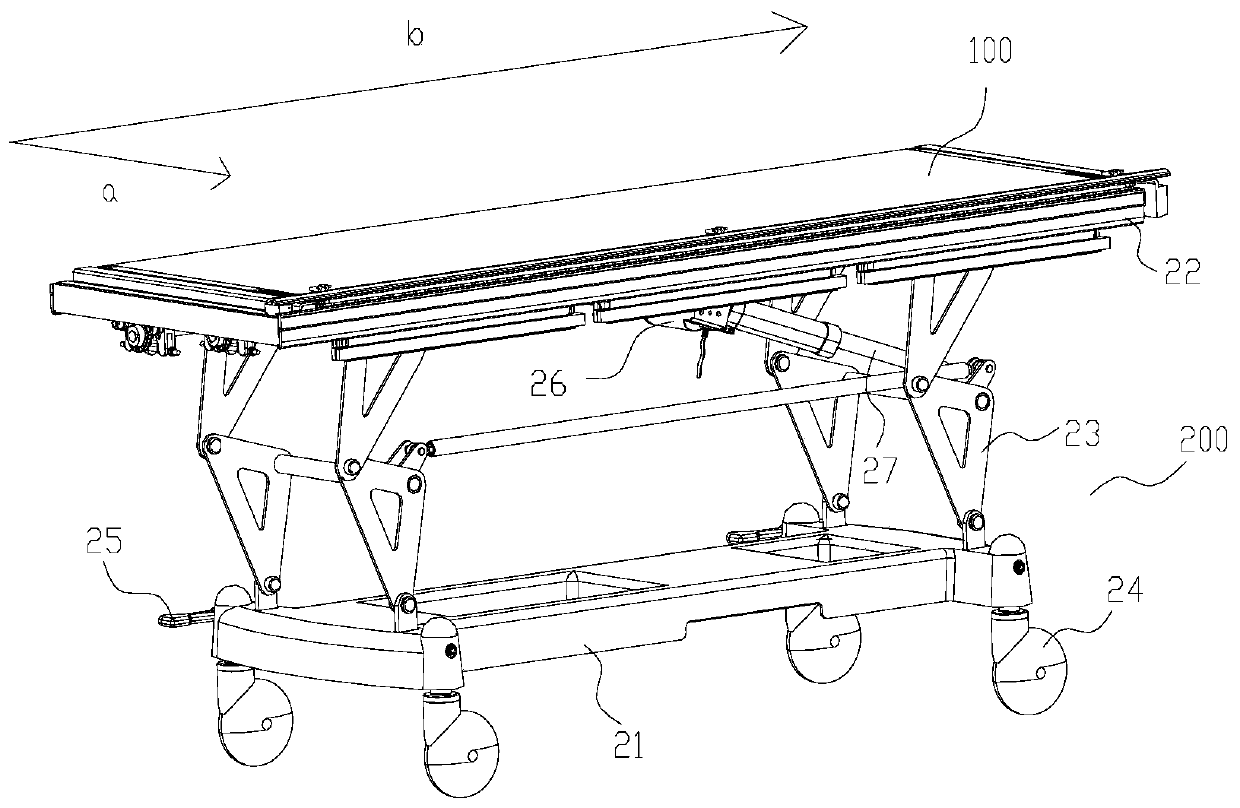

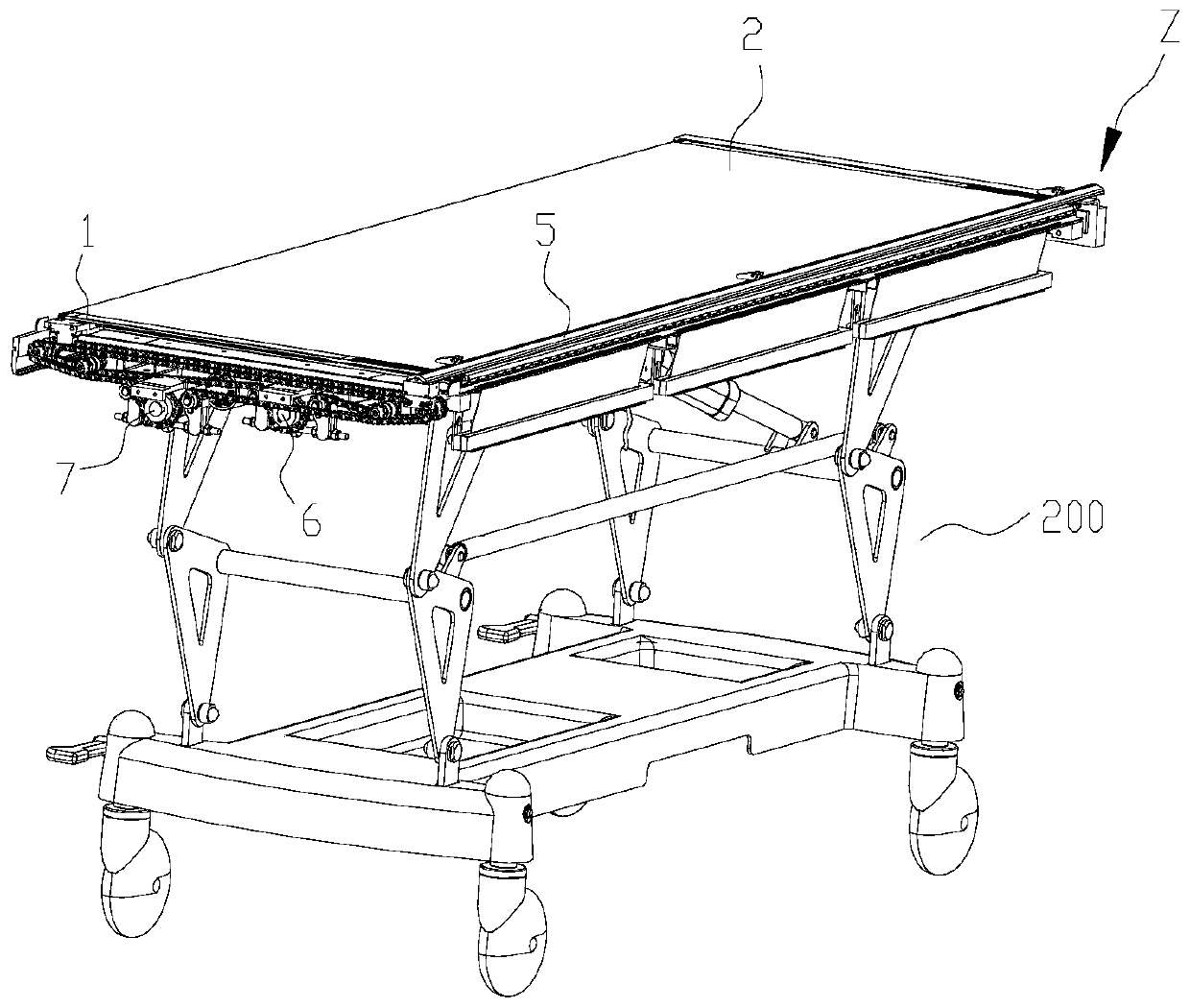

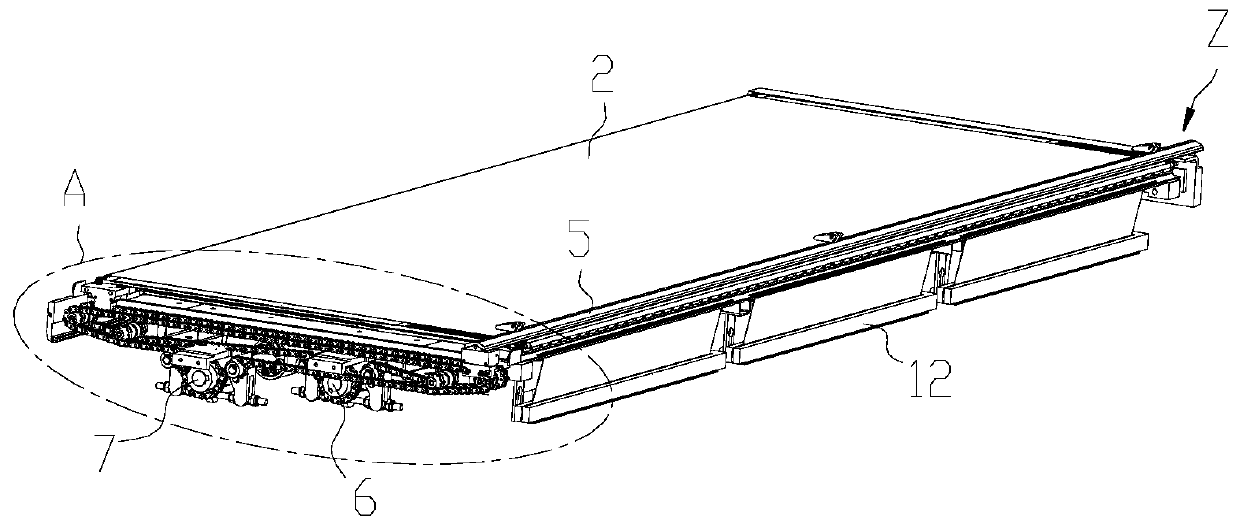

Embodiment 1

[0053] Embodiment 1 is one of preferred embodiments of the present invention, as Figure 1-23 As shown, the medical transfer bed of this embodiment includes a car body 200 with a lifting mechanism and universal casters installed, and a mobile bed board mechanism 100 for laterally moving patients; the mobile bed board mechanism is installed on the vehicle frame of the car body 22 on. In this embodiment, the moving direction of moving the bed board mechanism to stretch back and forth to pick up and drop off the patient is the horizontal direction, such as figure 1 The a direction shown; on the same plane, the vertical direction is the direction perpendicular to each other in the horizontal movement direction, such as figure 1 The b direction shown; figure 1 The mobile bed board mechanism is installed on the car body without telescopic operation, which is the normal state of the medical transfer bed; the mobile bed board mechanism extends forward to be the front, and the mob...

Embodiment 2

[0077] Compared with Example 1, the difference between the medical transfer bed in Example 2 lies in the locking bar driving mechanism. In this embodiment, the locking bar driving mechanism adopts a ratchet, a structure similar to the principle of a ratchet, a brake mechanism, or an electromagnetic device. Wait for a kind of in existing locking mechanism. When locking mechanisms such as ratchets or electromagnetic devices are released (that is, the patient is loaded on the upper moving plate), since the patient is pressed on the upper moving cloth, the friction force between the upper moving cloth and the upper moving plate is large enough to overcome the passive movement of the lower moving cloth. The resulting friction causes the upper moving cloth to remain relatively stationary with the patient and the upper moving plate.

[0078] The working process of the medical transfer bed in the preferred embodiment of the present invention:

[0079] like Figure 22-23 As shown, the ...

Embodiment 3

[0086] In view of the conveying cloth in which the upper and lower moving cloths in the prior art are circularly closed, and once the upper and lower moving cloths are installed, they cannot be disassembled and replaced with new moving cloths, but can only be sterilized by alcohol. Therefore, if the disinfection is not enough, it is easy to cause crossover. Infection, it can be seen that the moving cloth of the existing medical transfer bed cannot be disassembled and cleaned, and it is difficult to achieve the purpose of completely preventing infection. Therefore, this embodiment 3 provides a medical transfer bed that is easy to replace the moving cloth. infection purpose.

[0087] Specifically, compared with Example 1, the difference between the medical transfer bed of Example 3 is that the upper moving cloth is provided with a longitudinal opening; the two sides of the longitudinal opening of the upper moving cloth are respectively connected with rigid limit strips 11; A li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com