Dual-motor optical element axial adjustment device

A technology for optical components and adjustment devices, which is applied in the direction of optical components, optics, exposure devices for photolithography, etc., can solve the problems of difficult processing, large number of drivers, complex mechanisms, etc., and achieve low processing costs, compact overall structure, and The effect of a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

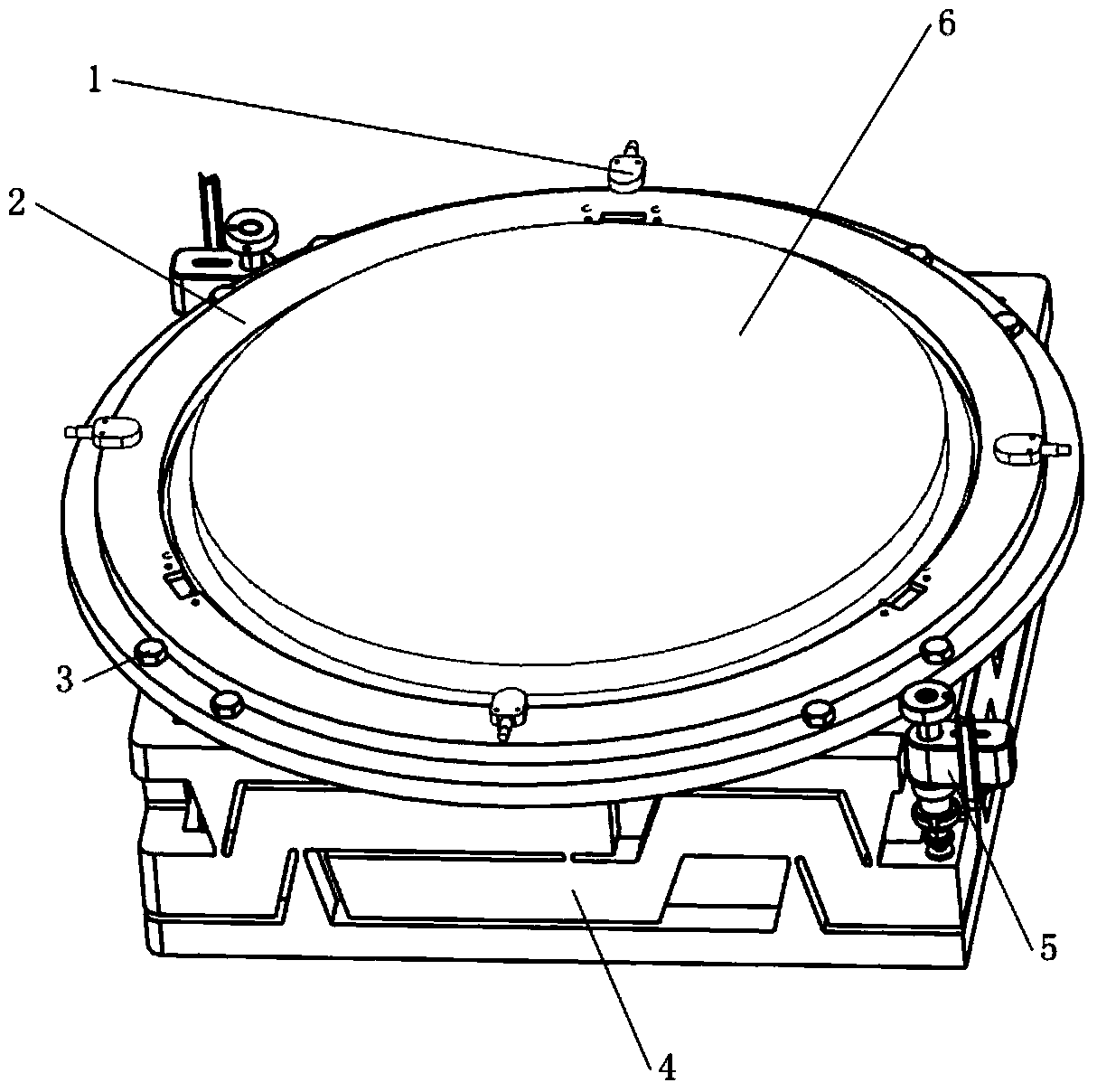

[0015] Such as figure 1 As shown, the dual-motor optical element axial adjustment device includes four capacitive sensors 1 , a mirror frame 2 , eight coupling screws 3 , a compliant drive block 4 and two piezoelectric drivers 5 . The mirror frame 2 and the pliable driving block 4 are fixed by eight coupling screws 3 . The four capacitive sensors 1 are respectively arranged parallel to the upper surface of the mirror frame 2, are evenly distributed along the upper edge of the mirror frame 2, and correspond to the midpoints of each right-angled side of the compliant driving block 4, so as to feedback the magnitude of displacement. Two piezoelectric drivers 5 are respectively arranged at diagonal positions of the compliant driving block 4 . The optical element 6 is fixed in the spectacle frame 2 by bonding after self-alignment.

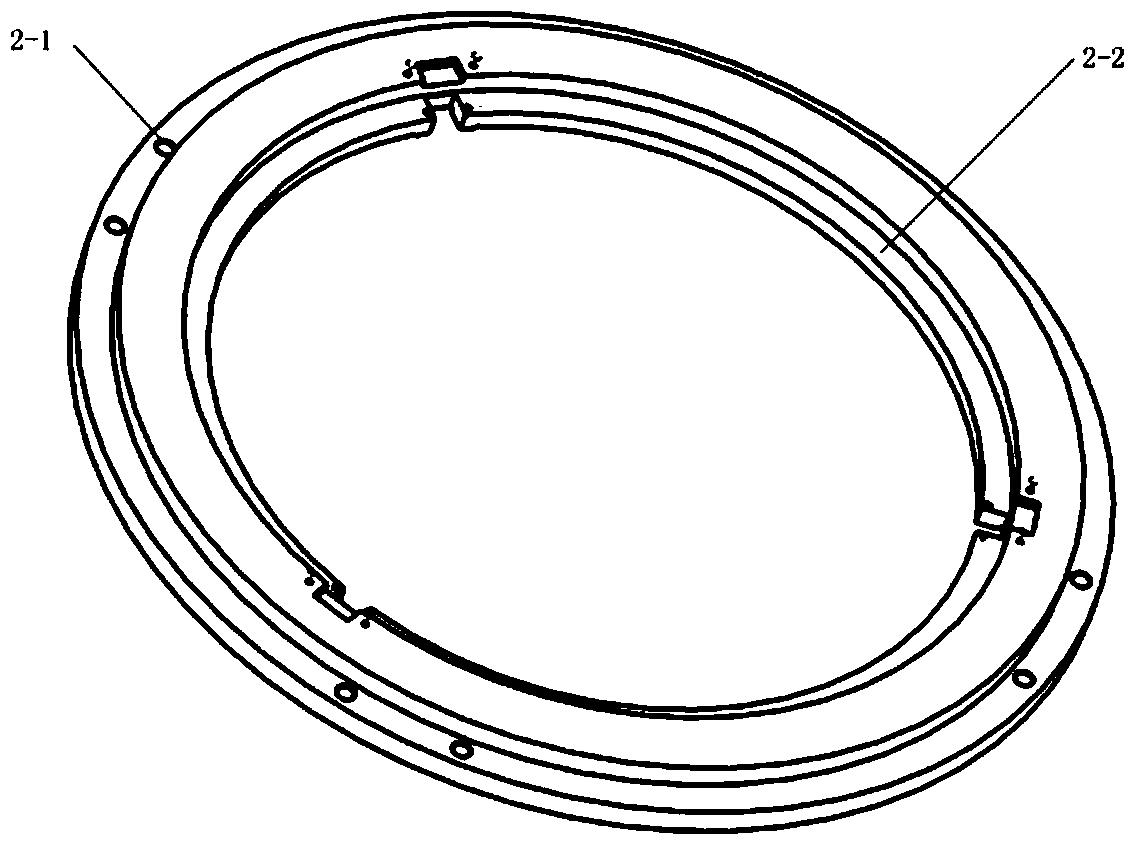

[0016] Such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com