Silk pole clamping device

A technology of clamping device and screw rod, which is applied in the direction of clamps, manufacturing tools, etc., and can solve the problems of clamps not being able to clamp, clamping is not firm, and production accuracy is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

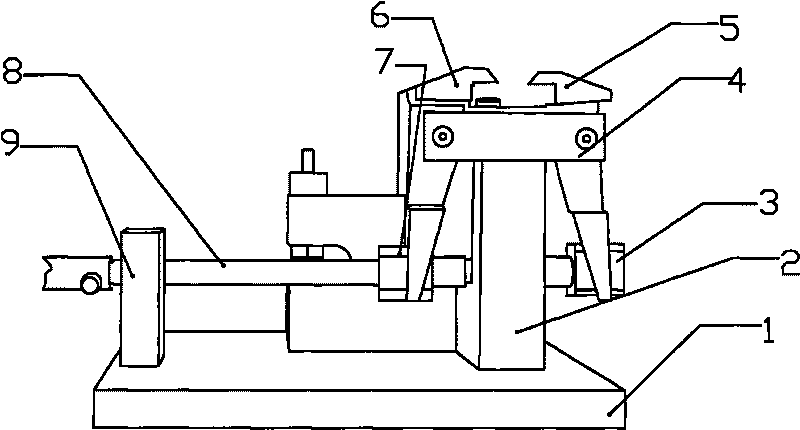

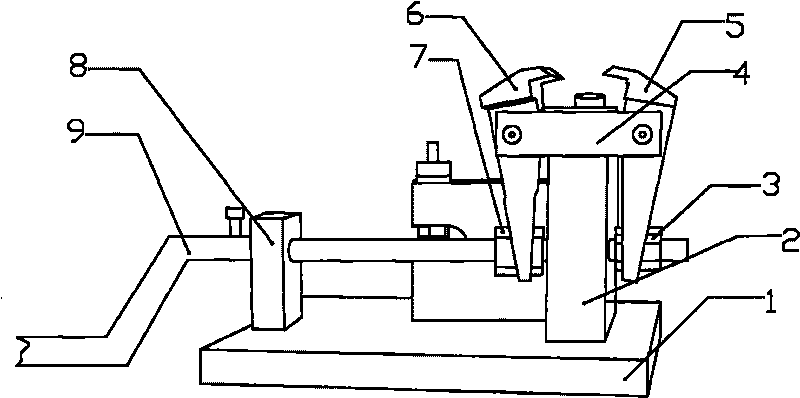

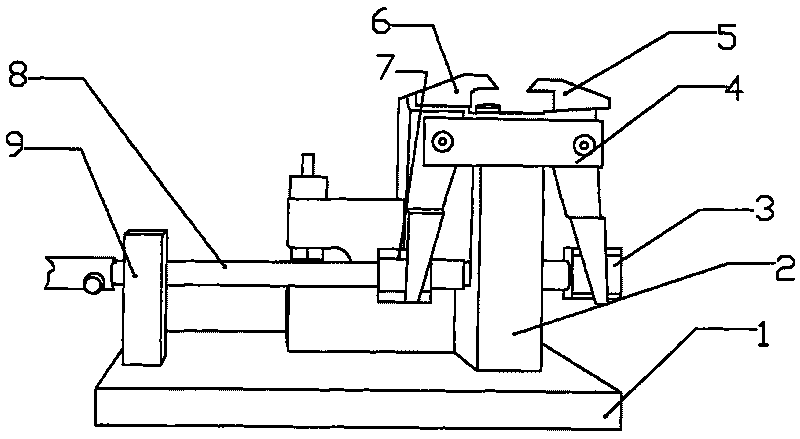

[0008] See attached figure 1 to attach figure 2 , a screw clamping device, comprising a base 1, a support platform 2 located on the upper bottom surface of the base 1 and fixedly connected with the base, a storage platform 4 fixedly connected with the support platform 2, and a storage platform with the storage platform The left clamp 6 and the right clamp 5 that the two ends of 4 are hinged respectively, the left nut 7 and the right nut 3 that are respectively fixedly connected with the ends of the left clamp 6 and the right clamp 5, and the left nut 7 The direction of rotation of the right nut 3 is opposite to that of the left nut 7 and the right nut 3. A threaded screw 9 is connected on the left nut 7 and the right nut 3. The screw 9 is tapped with a left thread and a right thread with opposite directions of rotation. Moreover, the screw rod 9 is rotatably connected to the support table 2 , and the other end of the screw rod 9 is rotatably connected to a fixed support 8 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com