Middle high density hydraulic pulper

A hydraulic pulper and pulper technology, applied in the field of papermaking machinery, can solve the problems of increased power consumption, easy cutting of fibers, and increased production costs, and achieve the effects of reducing power consumption, improving quality, and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

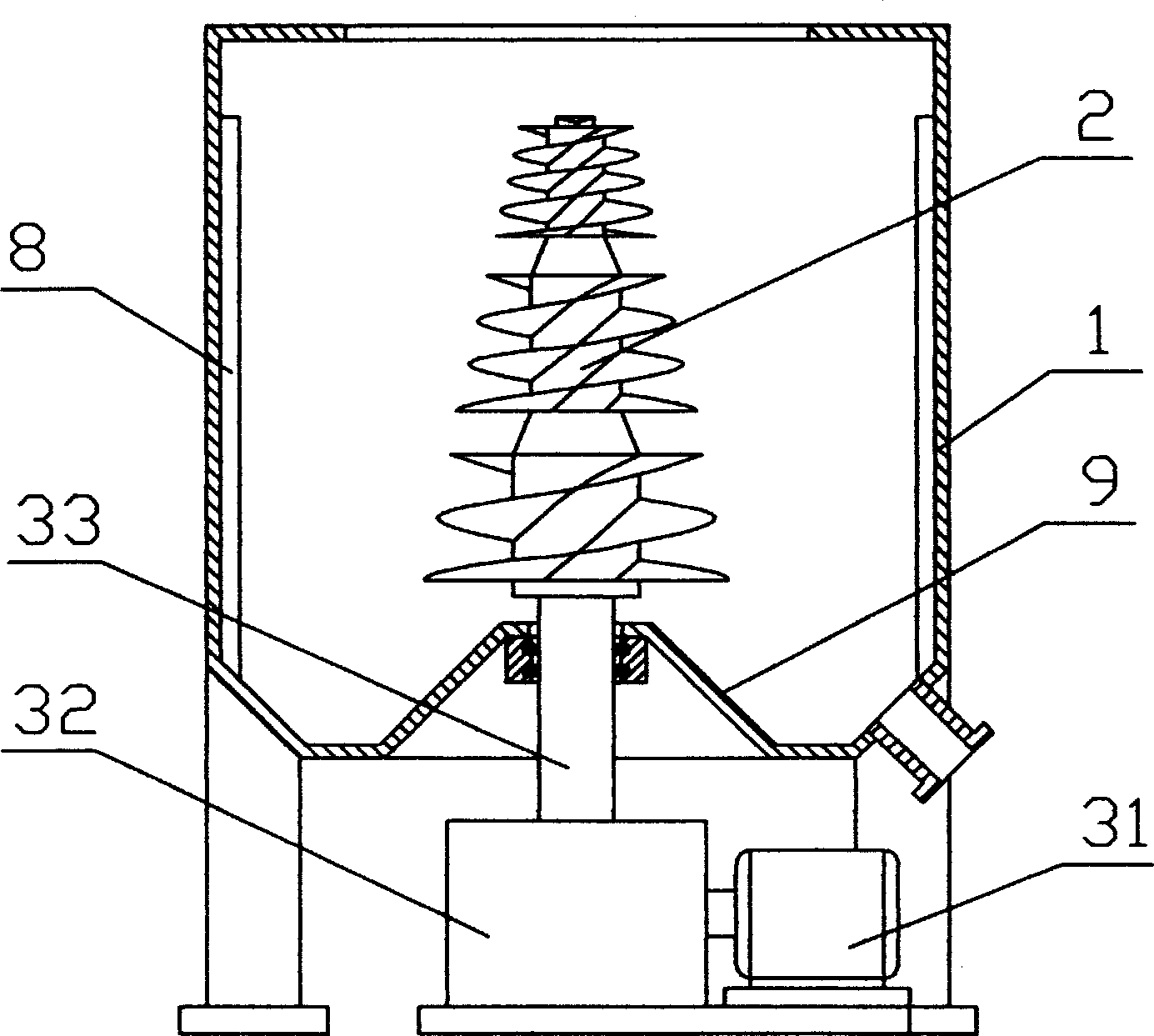

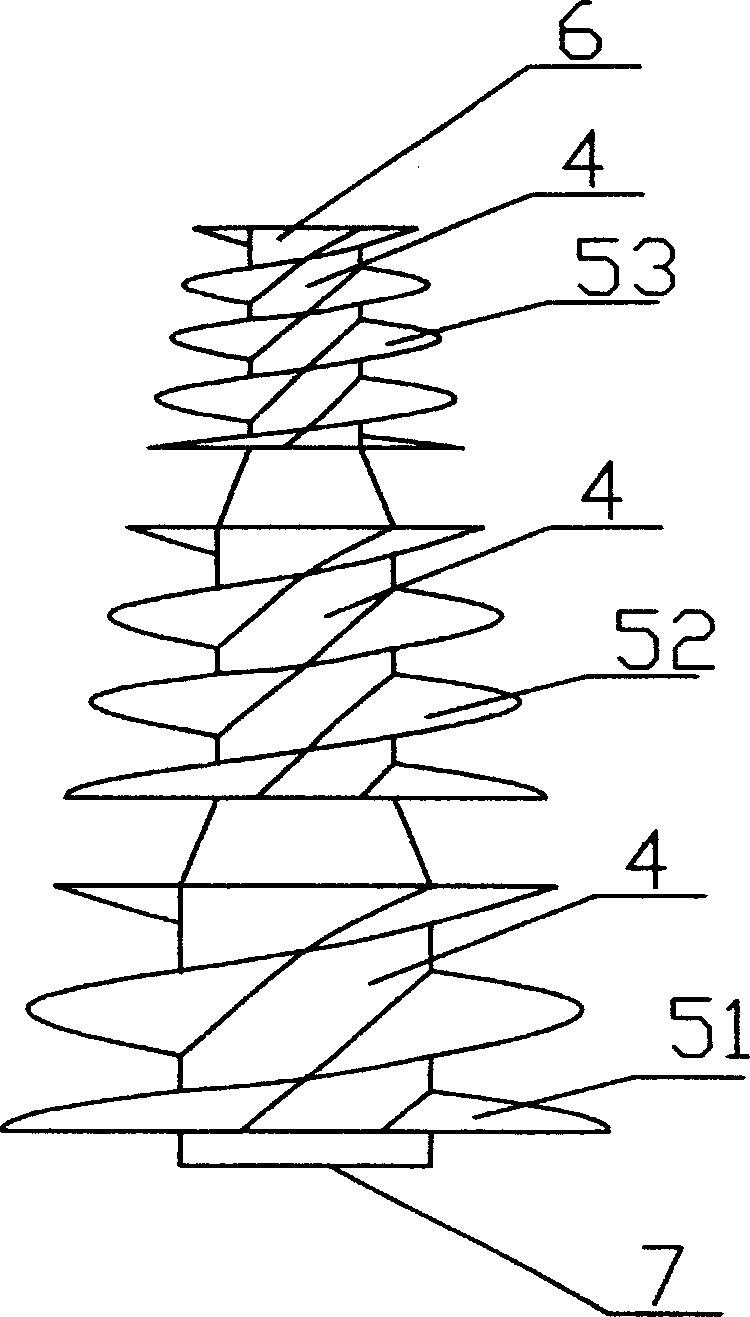

[0012] Such as figure 1 As shown, the medium-high consistency hydraulic pulper includes a pulper tank 1, the bottom of the tank 1 is vertically installed with a pulper rotor 2 with helical blades, and the driving end of the pulper rotor 2 is located in the tank 1. The driving device below is fixedly connected, and the bottom of the tank body 1 corresponding to the driving end of the pulper rotor 2 is an upward boss-like protrusion 9, and the boss-like protrusion is a truncated cone, and of course it can also be a cylinder Shaped or streamlined protrusions, this structural shape is convenient for the vortex circulation of the slurry in the tank to be smooth and unimpeded, avoiding the friction between the rotor and the tank; due to the setting of the boss, the bottom of the tank is formed An annular groove is formed, which is beneficial to the collection of non-fibrous impurities; the inside wall of the pulper tank 1 is provided with a number of loosening fiber protrusions 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com